Page 1

Proven Performance

OWNER’S MANUAL

MO DEL 6500 DPG, I TEM # 165961

Diesel Port a bl e G enerator

M165961B

Call Customer Service at 1-800-270-0810

Hours: Monday - Friday 7:00 AM to 5:00 PM CST

Saturday 7:30 AM to 11:30 AM CST

Page 2

THANK YOU

Thank you for purchasing a NorthStar Diesel Series Generator. Your machi ne is desi gned for

long life, dependability, and the top performance you demand. Please take time now to read

through this manual so you can better understand the machine’s operation, maintenance and

safety precautions. Everyone who operates this generator must read and understand this m anual.

T he time you t ake now will p rolong you r gene rato r’s l ife a nd prep are yo u fo r i ts saf e ope ration .

Enj oy the exceptional perform ance of your NorthStar Diesel Series Generator.

IMPORTANT

Make certain the operator:

- Reads and understands the manuals pertai ning to this machine.

- Is instructed in safe and proper operation of this m achine.

NOTICE

K-BAR Industries Incorporated reserves the right to make improvements in design and/or

changes in specifications at any time without incurring any obligation to install them on units

previousl y sold.

TABL E OF CONT ENTS

Thank you 1

Specifications 2

Machine component identification 3

Gener ator f eature s 4-5

Introduction 5

A NSI safety definitions 5

Rules for safe operation 5-6

Installation 6

Load applic ation 6-8

Pre- star t up prepar ation 8

Electric E ngine St ar ting 8-9

Manual Engine Star ting 8-9

Engine Shutdown 9

Engine care 9

Gener ator car e 9

Engine Fuel Line Bleeding 9

Tr oubleshooting 10-11

1

Page 3

SPECIFICATIONS

Item Nu mb er 165961

Maxi mum O utpu t 6500 Watts (W )

Continuous Output 5500 Watts (W )

Voltage 120 / 240 Volt (V)

Phase Single pha s e ( 4- wire)

Frequency 56.5 - 63.3 Hert z (Hz)

Power Fact or 1.0 p.f.

Engine 10 HP HATZ 1B 40

Engine Speed 3390 - 3798 RPM

Fuel Type Diesel

Fuel Capacity 6.5 gallons (24. 6 L)

Oil Capacity 1.76 US quar ts (1. 65 L)

St ar ting Method Electric / Recoil

120V Recept ac le 20 Amp (A) Duplex G FCI (NEMA 5-20R)

30 Amp (A) Loc k ing ( NEMA L5- 30R)

120/240V Recept ac le 30 Amp (A) Loc k ing ( NE MA L14- 30R)

Circuit Breakers 30 Amp (A) M agnetic, Qty. 1

20 Amp (A), Thermal type, Qty. 2

Gr ounding Sc r ew Receives 10 Ga. Fork Terminal

Battery 12-Volt battery with an amper e- hour r ating

of at least 36 AH

Dimensions

Length 34.00” ( 86.4 cm)

Width 23.25” ( 59.1 cm)

Height 22.25” ( 56.5 cm)

Dry W eight 118 lb. ( 54 k g)

Gr os s Weight 310 lb. ( 141 kg)

2

Page 4

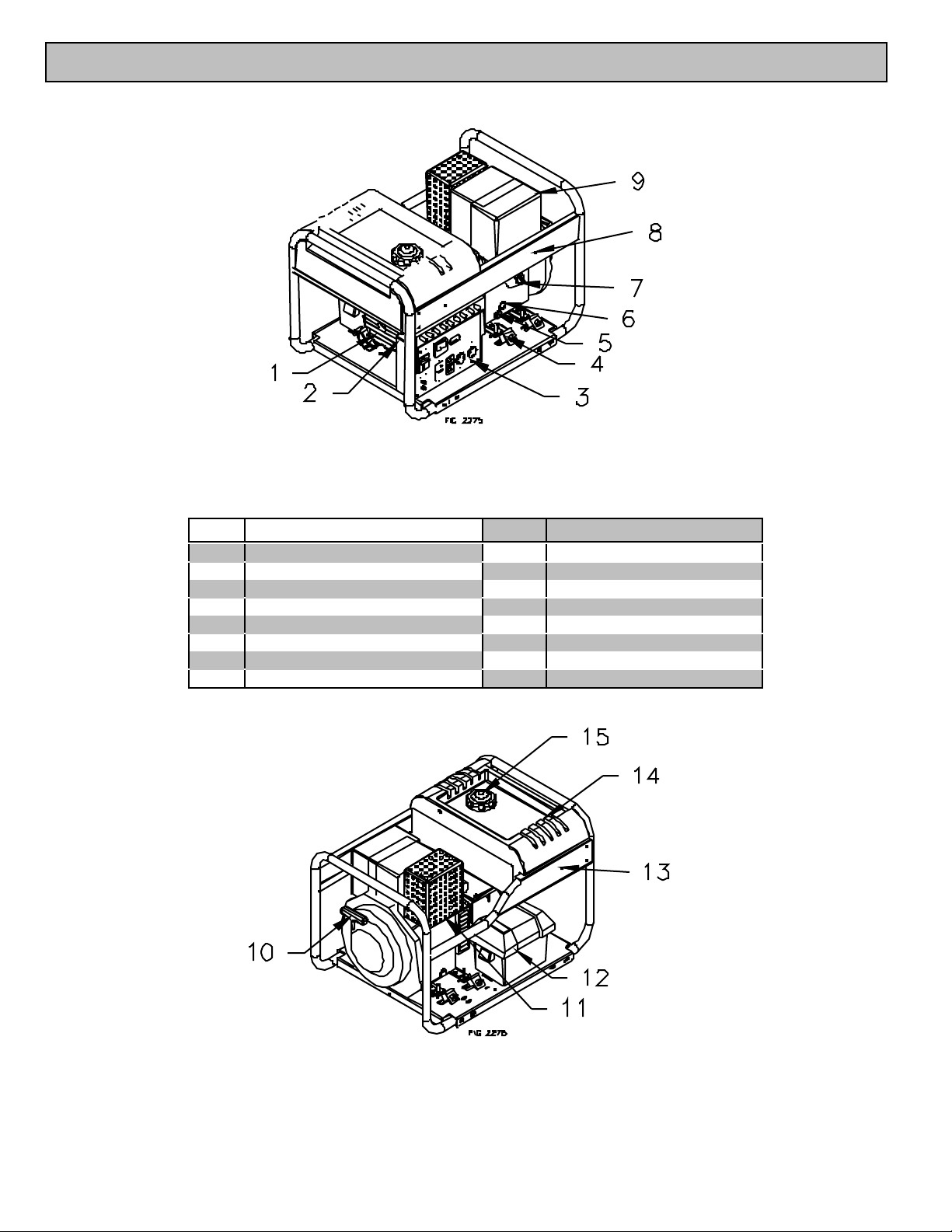

MACHI NE COMPO NENT IDENTIF ICATIO N

Figure 1 (Ref. 1-9)

2275

Ref. Description Ref. Description

1 Generator 9 Air Cl eaner Housing

2 Grounding Screw 10 Rec oil Hand le

3 Control Panel 11 Muffler

4 Isolation Mounts 12 Battery Box

5 Oil Drain Plug 13 Warning Decals

6 Oil Filt er A c cess Cover 14 6.5 Ga l lon Fue l Tank

7 Oil Fill and Dip Stick 15 Fuel Cap with Gauge

8 Oper ati on Instr uc ti ons

Figure 2 (Ref. 10-15) 2276

3

Page 5

GENERATOR FE ATURES

POWER ED BY

Reference 1 – Generator. The generator is

equipped with a high quality brushless generator. T he

genera tor is maint enanc e free and will pro vi de yea rs of

dependable service. The neutral i s bonded to ground.

Reference 2 - Grounding Screw. Ground the

generator via the grounding screw, to a copper pipe or

r od th at is driven i nto m ois t s oi l.

Refe rence 3 - Control Pa nel. See Figure 3 for

details.

Reference 14 - 6.5 Gallon Fuel Tank. Large

tank allows for extended run capabilities. Always

allow room for fuel expansion by not filling the tank

compl etely fu l l.

Refe rence 15 - Fue l Ca p w ith Gauge . The fuel

cap is extra lar ge, c r eating a lar ge hole fo r refill ing and

a comfortable grip. You can always moni tor the fuel

l e vel wi th out rem o vin g t h e ca p b y u si n g t he fu el le vel

indicator buil t in to the fuel cap.

WARNING Contact a licensed electrician to

wire electri cal pl ugs and/or cord-sets. Improper wiring

could result in a fire or electri cal shock.

Refe rence 4 - Vibr ation I solation M ounts. The

engine and generator are mounted on rubber mounts

that absorb most of the engine vibration. T his feature

eliminates the tendency of the m achi ne to “walk” whi ch

is common with engine powered equipment. If the

mounts appear damaged, replace with factory

approved parts.

Reference 5 - Oil Drain Plug. Removal of plug

allows drainage of oil from the engine. Consult your

Hatz engine manual for further detai ls.

Reference 6 - Oil Filter Access Cover. Your

Hatz engine is equipped with a reusable oil filter. T he

fil ter should be every 1000 hours of use. Consult your

Hatz engine manual for further detai ls.

Reference 7 - Oil Fill and Dip Stick. Consult

your Hatz engine owner’s manual for details

concerning oil change intervals.

Reference 8 - Warning Decal. Nev er operate the

generator or engine until all warning labels are fully

understood. If warning label s are missi ng contact our

customer service department at 1-800-270-0810.

Refe r ence 9 - Air Cleaner Housing. Refer to the

Hatz engi ne manual for air cleaner care.

Reference 10 - Recoil Handle. Consult your

owner’s m anual for engine starting or refer to page 8

of this manual.

Reference 11 - Muffler. Never operate the

generator without the deflector i nstalled in the upright

position.

Re ference 12 - - Batter y Box. Warning: Always

wear safety glasses w hen w orking on or near the

battery. The battery box provides protection for the

battery and will accept a standard lawn tractor size

battery (Group U1-7). The engine requires a 12 volt

battery, with a minimum rating of 36 Ah (Amp-hour).

When installing the battery, always connect the red

colored (“positive” or “+”) cable first. When

disconnecting the battery, always remove the black

colored (“nega tive” or “-”) cable first.

WARNING Sulfuric acid is a corrosive

poison. Avoid contact with skin, eyes or clothing.

Always wear safety gl a sses.

Reference 13 - Decal. Decal describes product

features.

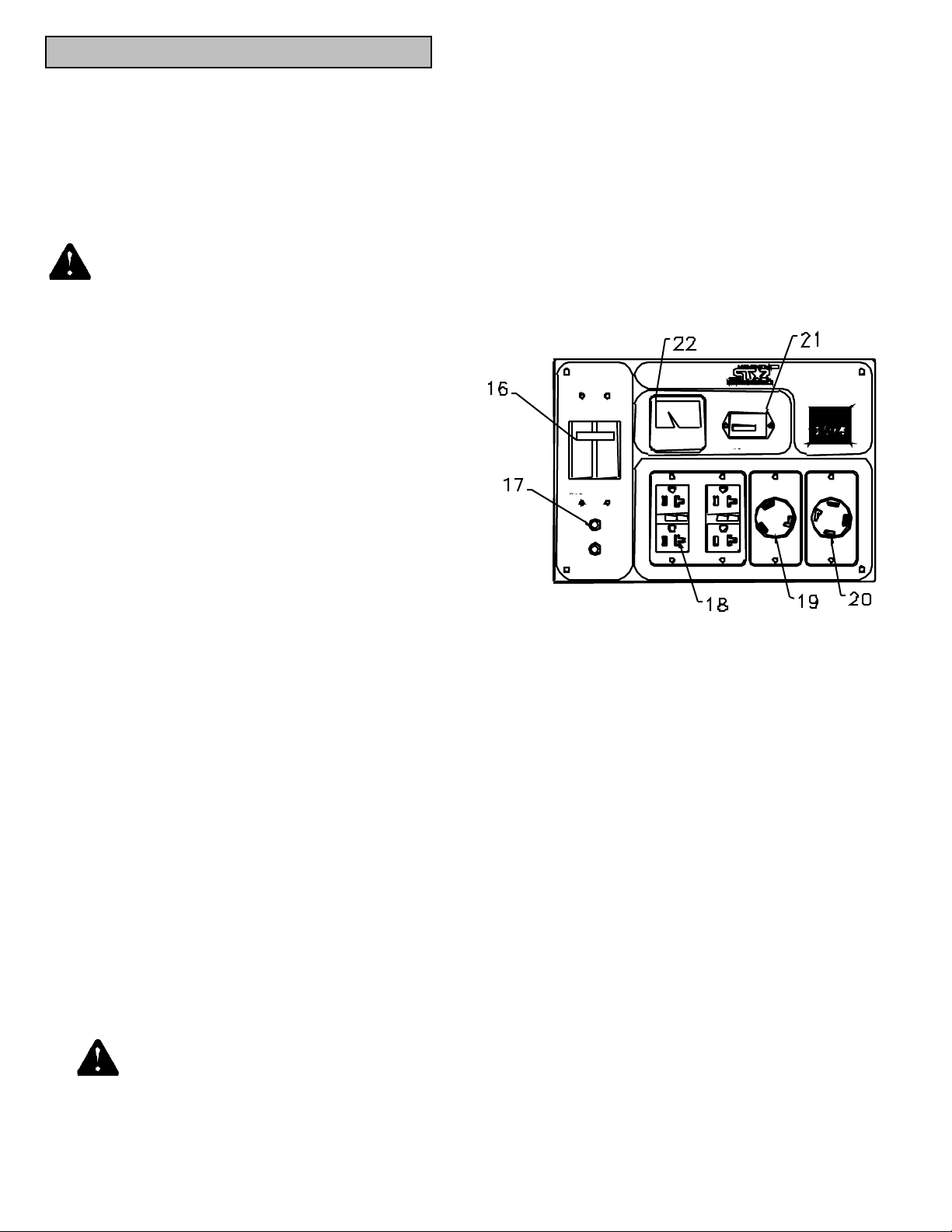

Figure 3 (Ref . 18-26)

Ref er ence 16 - Main Line Br eaker. The main line

breaker is a two-pole thermo-magnetic circui t breaker.

The circuit breaker will protect the generator from

overload and short circuit conditions. To reset the

circuit breaker move the toggle to the OFF position,

then back to the ON position. When this circuit

bre aker i s in the OFF p ositi on , a ll re cepta cl e s will be

off.

Reference 17 - Thermal Circuit Breakers. The

control panel has two thermal circuit breakers. If the

ci rcui t b rea ke r trip s, a bl ac k p ost will e xtend f rom the

circui t breake r, push the bl ack post to reset the ci rcuit

breaker. If the ci rcuit brea ker will not re set, wait two

minutes and try again.

Reference 18 – 120 Volt-20 Amp GFCI Duplex

Receptacle. T he control panel i s equipped with four

1 2 0 Vol t -20 Amp g rou nd f aul t ci rc ui t i nt e rru pt (GF CI )

receptacles (NEMA 5-20R). The receptacles will

accept either NEMA 5-15P or NEMA 5-20P plugs. In

the center of each duplex receptacle there is both a

test/reset button and indicator lamp. If there is a faul t

condition with a load connected to a duplex receptacle,

the indicator lamp will glow and the reset button will

extend. To test the GFCI press the test button and the

reset button should extend. The reset button m ust be

pus hed t o reset the rec e ptacle .

4

Page 6

Reference 19 - 120 Volt-30 Amp Locking

Receptacle. T he control panel i s equipped with one

NEMA L5-30R receptacle. This receptacle accepts

on ly N E MA L5- 3 0P pl ugs.

Reference 20 -120/240 Volt-30 Amp Locking

Receptacle. T he control panel i s equipped with one

NEMA L14-30R receptacl e. Thi s receptacle accepts

onl y NEMA L14-30P plugs. This receptacl e is popular

for connection to a transfer switch for home standby

pow er. See i tem #164 12 in th e N ORTHERN catalog.

Reference 21 - Hour Meter. The hour meter

allows for monitoring of engine maintenance

schedules.

Re fer ence 22 - V ol tme te r. The vol t mete r al lo ws

for monitoring of the generator. The needl e should be

in th e green ar ea for al l load co nd itions.

GENE RATOR FE ATURES NO T SHOWN

Fuel Shut Off Va lv e. The fuel tank is equipped

with a fuel shut off valve. Always turn the fuel val ve to

the off position when the generator is not in use. The

valve i s loca ted under neath the f uel tank.

moderate injury. It may also be used to alert against

uns af e pr actices.

RULES FOR SAFE OPERATIONS

Safety precautions are essential when operating

this generator. Respectful and cauti ous operation will

considerably lessen the possibilities of a personal

inju ry . Thi s manual will warn of specific pe rsonal inju ry

pote nti al, and these will be de si gnated by the symbol:

WARNING This generator is equipped

with a grounding screw located on the rear of the

generator. Always complete the grounding path from

the generator to a copper pipe/rod that i s driven into

moist earth, to prevent electrical shock.

ALWAYS use electrical cords that are in good

condition. Worn, bare, frayed or otherwise damaged

cords can cause electri c shock.

I NTRODUCTION

Before starting your generator, thoroughly study

the instructions and cautions in this manual to assure

you are fully acquainted with the operation of all

components of this generator. Proper preparation,

operation and maintenance will result in operator

s af ety , b est per forma nce and lon g l ife of t he g enerator.

For detailed engine operation and maintenance always

refer to the Hatz engine owner’s manual furnished with

the ge ner ator .

NorthStar is constantly improving its products.

The specifications outlined herein are subject to

change without prior notice or obligation. The

purchaser and/or user assumes liability of any

m od if i cati on an d /o r al te ra ti on s on th i s equi pm en t fr om

original design and m anufacture.

Before using, the user shall determine the

suitability of this product for its intended use and

assumes liability therein.

ANSI SAFETY DEFINITIONS

DANGER indicates an imminently hazardous

sit uati on whic h, if no t a v oide d, will result in dea th o r

serious injury. This signal word is to be limited to the

most extreme situations.

NEVER operate the generator, or handle any

electrical equipment while standing in water, while

barefoot, while hands are wet or while in the rain or

snow. Electric shock may resul t.

ALWAYS use a ground fault circuit interrupter

(GFCI) in damp or highly electrical conductive areas

and on construction job-sites to prevent electric shock.

ALWAYS disconnect the battery before working

on the engine or generator. Disconnect the negative

cable first then the posi tive cable. The key should be

in the OFF posi tion when disconnecting or connecting

battery cables.

ALWAYS provide adequate ventilation. Do not

operate generator in any enclosed or narrow space.

Engi nes consume oxygen and give off deadl y carbon

monoxide poisonous gas. Improper ventilation will

cause damage to generator and possible injury to

people.

NEVER touch hot mu ffler, hot exhaust m anifold or

engine cooling fins.

ALWAYS remove all oil or fuel deposits and

accumul ated dirt from generator and i mmediate area.

Keep ge nerato r and engine cl ean.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in a

dea th or seri ous i nj ury.

CAUTION indicates a potentially hazardous

s ituatio n, wh ic h if not av o id ed , may r es ul t in min or or

NEVER operate the generator under the following

conditions:

A. Excessive change in engine speed, slow or

fa st.

B. Overheating of load connecting devices.

C. Sparking or arcs from generator.

D. Loss of electrical output.

E. Dam aged receptacles.

5

Page 7

F. En gine misfi re.

G. Excessive vib ratio n.

H. Enclosed compartments, or confined areas.

I. Flame or smoke.

J. Rain, snow or wet conditions.

K. Operator non-attendance.

WARNING Check fuel system on a

regular basis. Look for signs of leaks, deterioration,

chafed or spongy fuel hose, loose or missing fuel hose

clamps, damaged fuel tank or a defective fuel shut-off

valve. Correct any defects before operation.

WARNING Keep the fire extinguisher

close by your generator, and be familiar on how to use

it. Consult your local fire department for correct

extingui sher type.

INSTALLATION

OUTDOORS: Choose locations where the

ge nera tor will not b e exp osed to rain , sno w or dire ct

sunlight. Position the generator on secure, level

ground so it will not tip or sl ide down a hill. Place the

generator so that the exhaust fumes will not be

directed towards people.

The installation site must be free from water,

mo is tur e, or dus t. All e lect rica l c om pon ents s hould be

protected from excessive moisture or the insulation

system will deteriorate and result in grounding or

shorting out the generating system.

Foreign matters, such as dust, dirt, sand, lint, or

abrasive materi als can cause damage to the generator

head and engine if allowed into its cooling system.

NEVER install your generator inside confined

areas. Inside installation can cause heal th hazards or

death.

DANGER Remember, exhaust fumes are

deadly carbon monoxide gas, and must be vented to

the outside where there are no people. Cooling air of

sufficient amounts must be brought in and exhausted

out to ensure proper cooling of the engine and

generator head.

LOAD APPLICATION

It is i mportant to determine the total electrical load

bef or e it is conn ec t ed to t he ge ner ator . The tw o ma jor

factors in determining the life of a generator head are:

heat build-up, caused by overloading the generator

and corrosive contaminants that attack the wiring

insulation. If the generator is overloaded, the wires

become excessively hot and cause the insulation to

break down, reducing its ability to resist corrosive

contaminants. Over time the effectiveness of the

insulation is elim inated and a dead short can result.

Always compare the generator nameplate data

with that of the equipment to be used to ensure that

watts, volts, amperage, and frequency requirements

are suitable for operating equipment. The wattage

listed on the equipment namepl ate i s its rated output.

However, some equi pment may requi re three to ten

tim es more wattage than its rating on the nameplate,

as the wattage is influenced by the equipment

efficiency, power factor and starting system. NOTE: If

wattage is not given on equipment nameplate,

approximate wattage may be determined by

multiplying nameplate voltage by nameplate

amperage.

VOLTS X AMPS = WATTS

Example: 120V X 5A = 600W

When connecting a resistive load such as

incandescent lights, heaters or common el ectric power

tools, a capacity of up to the generator full rated

wattage output can be used.

When connecting a resistive-inductive load such

as a fluorescent or mercury light, transformers or

inductive coils, a capacity of up to 0.6 times the

generators full rated output can be used.

Always allow the generator to reach operating

speed before a load is applied.

STARTI NG EL ECT RIC MOTORS

El ect ri c mot ors req ui re mu ch m ore curre nt (a mp s)

to sta rt tha n to run. Some motors, particularly low cost

spli t-phase m otors, are very hard to start and require 5

to 7 times m ore current to start than to run. Capaci tor

motors are easier to start and usually requi re 2 to 4

tim es as much current to start than to run. Repulsi on

Induction motors are the easi est to start and require

1.5 to 2.5 times as much to start than to run.

Most fractional motors take about the same

amount of current to run them whether they are of

Repulsion-Induction (RI), Capacitor (Cap), or Split-

Phase (SP) type. The following chart shows the

approximate current required to start and run various

types and sizes of 120 volt 60 cycle electric motors

under various conditions.

120 V, 60 Hz Mo t o rs

Hp motor Running

Watts

1/6 525 7-11 9-18 16-22

1/4 700 9-15 12-23 22-32

1/3 875 11-18 14-29 26-35

1/2 1175 15-25 20-40 NA

1 1925 24-40 32-64 NA

1 1/2 2400 30-50 40-80 NA

2 2900 36-60 48-96 NA

3 4075 51-85 68-136 NA

5 6750 84-140 112-224 NA

The figures given above are for an average load

such as a blower or fan. If the electric motor is

6

RI type Cap type SP type

Starting Am ps

Page 8

connected to a hard starting load such as an air

co mpressor, it will requi re more sta rting c urrent. If i t is

connected to a light load or no l oad such as a power

saw, it will require less starting current. The exact

req uirem ent will al so vary with th e bra nd o r d esign of

the mo tor .

Generators respond to severe overloading

differentl y than the power line. When overloaded, the

engine i s not able to supply enough power to bring the

electric motor up to operating speed. T he generator

responds to the high initial starting current, but the

engine speed drops sharply. The overload may stall

the engine. If allowed to operate at very low speeds,

the electric motor starting winding will burn out in a

short tim e. The generator head wi nding might also be

damaged.

Running the generator under these conditions may

r es ult in da ma ge to t he ge ner a t or s tat or as wel l as th e

motor windi ngs. Because the heavy surge of current

is req uired for only an insta nt , the gene rator will not b e

dam aged if it can bring the m otor up to speed in a few

seconds. If difficulties in starting a motor are

experienced, turn off all other electrical loads and if

possibl e reduce the load on the electric motor.

EXTENSION CORDS

When electri c power is to be provided to various

loads at some distance from the generator, extensi on

cords can be used. T hese cords should be si zed to

allow for distance in length and amperage so that the

voltage drop between the set and poi nt of use i s held

t o a minimum.

Current/ Power Maximum Extension Cord Le ngth

Amps

at

240V

10 2400 250’ 150’ 100’ 75’

20 4800 125’ 75’ 50’ 25’

30 7200 60’ 35’ 25’ 10’

40 9600 30’ 15’ 10’ *

50 12000 15’ * * *

low voltage caused by using an extension cord with a

smal l wire size.

generator.

Device Running Watts

Air Conditi oner (12,000 Btu) 1700 (a)

Battery Charger (20 Amp) 500

Belt Sand er (3”) 1000

Chain Saw 1200

Circ ul ar Saw (6-1/2”) 900

Coffee Maker 1000

Co mpressor (1 HP) 2000 (a)

Co mpressor (3/4 HP) 1 800 (a)

Co mpressor (1/2 HP) 1400 (a)

Load

(wa tts)

*Not recommended

CAUTION: Equipment damage can resul t from the

Use this chart to estimate the total load on your

For Determining Generator Load Requirements

#10

Ga.

Cord

#12

Ga.

Cord

#14

Ga.

Cord

#16

Ga.

Cord

Curling Iron 700

Dishwas her 1200

Edg e Tri m mer 500

Electric Nail Gun 1200

Electric Range (one element) 1500

Elec tr ic Sk ill et 1250

Furnace Fan (1/3 HP) 1200 (a)

Freezer 800 (b)

Hair Drye r 1200

Hand Drill (1”) 1100

Hand Drill (1/2”) 875

Hand Drill (3/8”) 500

Hand Drill (1/4”) 250

Hedge Tri mm er 450

Home Computer 150

Impact Wrench 500

Jet Pump 800 (a)

Lawn Mower 1200

Light Bulb 100

Microw ave O ve n 700

Milk Cooler 1100 (a)

Oil Burner on Furnace 300

Oil Fired Space Htr (140,000 Btu) 400

Oil Fired Space Htr (85,000 Btu) 225

Load Requireme nts, continued

Oil Fired Space Htr (30,000 Btu) 150

Oven 4500

Pain t Sp raye r, Airless (1/3 HP) 6 00 (a)

Pai nt Sprayer, Airless (handheld) 150

Radio 200

Refrigerator 600 (b)

Slow Cooker 200

Submersible Pump ( 1-1/2 H P) 2800 (a)

Submersible Pump (1 HP) 2000 (a)

Submersible Pump ( 1/2 H P) 1500 (a)

Sump Pum p 600 (a)

Table Saw (1 0” ) 2000 (a)

Television 500

Toaster 1000

Vacuum cleaner 250

VCR 70

Water Heater 3000

W eed Tri m mer 500

(a ) Hard -sta rt in g mo to rs re q uire 3 to 5 t im es the

rated running watts.

(b) These loads m ay require up to 15 minutes to

restart due to its normal build up of compressor head

pressure.

NOT E: For extremel y hard to start loads such as

air conditioners and air compressors, consult the

equipment deal er to determine the maximum wattage.

PRE-START PREPARATIONS

Your generator has been thoroughl y tested prior to

shipment from the factory. A factory test report has

been included with this manual. However, damage

can occur during shipping, so be sure to check for

dam aged parts, loose or missing nuts and bolts. If the

a fo rem en ti on ed p rob lem s o c cu r, cal l cu stom e r se rvi c e

at 1-800-270-0810.

7

Page 9

GRO UNDING - All units m ust be grounded. Dr ive

a 3/4” or 1” copper pipe or rod into the ground close to

the generator. The pipe/rod must penetrate moist

earth. Connect an approved ground clamp to the pi pe.

Run a 10-gauge wire from the cl amp to the generator

grounding screw located at the rear of the generator.

Do not connect to a water pipe or a ground used by a

radio system.

CAUTION: The engine has been shipped without

oil. Fill the crankcase wi th oil before tryin g to start.

OPERAT ING SPEE D

The generator must be run at the correct speed in

order to produce the proper electrical voltage and

frequency. The speed of the engine was carefully

adj usted at the factory so that the generator produces

the proper voltage and frequency.

The output vol tage should be checked to ensure

the generator is working properly before connecting a

load to the generator. Failure to do so could result in

damage to equipment plugged into the unit and

possibl e injury to the indi vidual.

All engines have a tendency to sl ow down when a

load is applied. When the electrical l oad is connected

to the generator, the engine is more heavily loaded,

and as a result the speed drops sli ghtly. This slight

decrease in speed, together with the voltage drop

within the generator itself, results in a slightly lower

voltage when the generator is loaded to its full capacity

than when it is running with no load. The slight

variation has no appreciable effect in the operation of

motors, lights and most appliances. Electronic

equipment and clocks will be affected if correct RPM is

not maintained. See Load vs. Output chart.

Load Output

Percent of

Genera to r

Output

0 % 3780 63.0 129V

50 % 3600 60.0 120V

100 % 3480 58.0 112V

Output voltage should be periodically checked to

ensure continued and proper operation of the

generator. T he voltage can be checked with a portable

voltmeter. Frequency can be checked by using a

electric clock, with a sweep second hand. Timed

against a wristwatch or stopwatch. T he clock should

be correct within +/- 2 seconds per minute. A qualified

technician should accomplish engine speed

adj ustments.

Speed

(RPM)

Frequency

(Hz)

Genera to r

Vo lta ge at 120V

Receptacle

BEFORE STARTING

1. Make sure the generator is posi tioned on a firm

level surface.

2. Check the crankcase for oil and m aintained at a

pr oper lev e l.

3. Check fuel level and fill tank 7/8 full with diesel

fuel. Never fill fuel tank compl e tely to the top.

Always wipe up and rem ove any spilled diesel

fuel.

4. Make sure that the exhaust fumes are directed

away from people.

ELEC TRIC START OF ENGINE

1. Disconnect all loads to generator.

2. T urn gas line valve to ON positi on.

3. T urn the ignition key to the START position.

4. If the engi ne does not start after 10 seconds,

wait 15 seconds before attempting to start agai n.

5. If the engine will not start consult the trouble

shooting table (page 10).

MANUAL START OF ENGINE

1. Disconnect all loads to generator.

2. T urn fuel line valve to ON posi tion.

3. Turn the ign ition key to th e RUN po si tion.

4. Grasp the recoi l handle and pull until a strong

resistance is felt.

5. Le t the rec oil ha nd le return to the initial po si tio n.

6. Push down the decompressi on lever. T he lever

is located on top of the engine and is color ed

RED.

7. Pull out the recoil handle briskl y with both

hands.

8. If the engine will not start consult the trouble-

shooting table (page 10).

CAUTION A battery must always be

connected to the battery cables, or engine damage

could result.

ENGINE SHUTDOWN

1. Disconnect all loads from generator.

2. T urn the ignition key to the OFF position.

3. T urn the fuel valve to the OFF posi tion.

ENGINE CAR E

Refer to you r Hatz Owner’s Manual fo r prope r care

and maintenance.

Refer to you r Hatz Owners manual fo r fuel an d oil

information.

IMPORTANT: It is possible that the fuel line will

need to be bled the first time the fuel tank is filled.

8

Page 10

NOTE: When changi ng t he oil on a hot engine, the

oil might overshoot the oil drain hole on the generator

base. Use a deflector (piece of cardboard or paper) to

direct the oil down the hole.

GENERATOR CARE

The generator is a two pole, 3600 RPM, 60 Hz,

brushless, revol ving field, and synchronous type with

one sealed radial roll er bearing. The generator rotor is

directly connected to the engine crankshaft and the

sta t o r i s ri gi dl y co up le d to t he en gi ne ca sti n g via the

generator adapter casting.

Exercising the Generator - The generator

shoul d be ope ra ted eve ry four w ee ks . Warm the

generator by starting the engine and letti ng it run for

10 to 15 minutes. This will dry out any moisture that

has accumulate d in the windings. If left, this moisture

can cause corrosion in the winding. Frequent

operation of the engine/generator will also ensure that

the set is operating properly should it be needed in an

emergency.

Ge ne ra tor Ma inte na nce - The generator head i s

brushless and maintenance free. Major generator

service including the installation or replacement of

parts, should be performed only by qualified electrical

service technici ans. USE ONLY FACTORY

APPROVED REPAIR PARTS. Obtain factory parts

from Customer Service at 1-800-270-0810.

A. Bearing - The bearing used in the generators is

a heavy duty sealed roller bearing, requires no

maintenance or lubrication.

B. Receptacles - Quality receptacles have been

utilized. If a receptacle should become cracked or

otherwise damaged, replace it. Using cracked or

damaged receptacles can be both dangerous to the

operator and destructive to the equipment.

WA RNING, Stan d-by Op erat ion

If your generator is to be used as a standby

electric power source i n case of uti lity failure, it must

be installed by a registered and licensed electrician

and in compliance with all applicable state and local

electrical codes. Also, local Fire Departm ents m ust be

consulted concerning proper and safe handling

procedures for gasoline. NEVER connect any

generator to any exi sting electrical system without an

isolating, UL approved transfer switch, installed by a

licensed electrician.

ENG INE FU EL LINE BLEEDING

If the engine i s having difficulty in starting and the

fuel and oil levels are acceptable, the problem can

usually be traced to air bubbles trapped in the fuel line.

To bleed air from the fuel line:

1 : Allow engi ne to cool down.

2: Turn the fuel valve to the OFF posi tion.

3: Loosen the hose clamp on the fuel line.

4 : Pull the fuel inlet line off of the fuel pump.

5: Turn the fuel valve to the ON position

6: Allow one half cup of fuel to drain from the

f uel line into a sm all container.

7 . Reattach the fuel line to the fuel injector.

9

Page 11

TROUBLESHOOTING

Proble m Possible Causes Possible Remedies

Engi ne wi ll not start. a) Low oil level.

b) Air in th e li ne.

c) Ou t of fuel.

d) Battery is defective.

e) Fuel Filter clogged.

f) Fuel shut off valve is in the OFF position.

Voltage too low. a) Engine speed too slow.

b) Ge nerator is overl o aded .

Circuit b reake r trips. a ) Defective load connected to generator.

b) Defective receptacle.

c) Generator overloaded.

Voltage too high. a) Engine speed too hi gh. a) B r ing gener at or t o a qualified

Gen er ator ov er h eatin g. a) Gen er ator is overloa de d.

b) In sufficient ventilatio n.

No output voltage. a) Defective lo ad connected to generator.

b) Broken or l oose wi re.

c) Defective recept acle.

d) Defective stator.

e) Defective rotor.

f) Defective capacitor.

Engine lacks power. a) Generator is overloaded.

b ) Dirty air fil ter.

Engi ne shuts down

dur ing oper at io n.

a) Ou t of fuel.

b) Low oil level.

a) Fill crankcase to proper oi l level.

b) Bleed the air from the fuel line.

(see page 9)

c) Fi ll fuel tank.

d) Charge or replace battery.

e) Replace fuel filter.

f) Tu rn the valve to the ON position.

a) B r ing gener at or t o a qualified

te chni cian for adjustment.

b) Reduce the l oad. (See Load

Ap plication section of this manual .)

a) Disconnect load.

b) Replace receptacl e.

c) Reduce the load. (See Load

Application section of thi s manual.)

te chni cian for adjustment.

a) Reduce the l oad. (See Load

Application section of thi s manual.)

b) Make sure there is at least 3 feet of

clearance on all sides of generator.

a) Disconnect load.

b) B r ing gener at or t o a qualified

te chni cian for rep air.

c) Replace receptacle.

d) B r ing gener at or t o a qualified

te chni cian for rep air.

e) B r ing gener at or t o a qualified

te chni cian for rep air.

f ) Bring generator t o a qualified

te chni cian for rep air.

a) Reduce the l oad. (See Load

Application section of thi s manual.)

b) Clean or replace air filter.

a) Fill fuel tan k.

b) Fill crankcase to proper oi l level.

10

Page 12

Part s Breakdow n – Expl oded View 165961 Rev. B

11

Page 13

Component List 165961 Re v. B

Diag.# Part # Description Qty.

1 33321 Fuel Cap 1

2 38761 Fuel Tank Assembly 1

3 38217 Decal 1

4 35369 Cradle 1

5 30754 Leather Washer 4

6 777108 Battery Cable, Black 1

7 16707 Battery Cable, Red 1

8 777352 Battery Box with Ho ld Down Strap 1

9 32551 Battery Warning Decal 1

10 E777303 Generator Assembly 1

11 778123 Generator Mount 1

12 36138 Relay 1

13 32844 Lower Bracket 6

14 778118 Base 1

15 38770 Control Panel Weldment 1

16 82067 Clip Nut, 10-32 4

17 778120 Control Panel Assembly 1

18 32769 Nameplate, 6500 DPG 1

19 34172 Isomount 6

20 306459 Engine Ground Wire 1

21 32848 Upper Bracket 6

22 778057 HATZ Diesel En gine 1

23 38321 Decal 1

24 777345 Fuel Line 19”

25 30755 Fuel Filter 1

26 777345 Fuel Line 10.0”

27 171410 Clamp 6

28 777345 Fuel Line 17.0”

29 305564 Wire Harness 1

30 778121 Engine Bracket 2

12

Page 14

Wiring Diagram 778120

#1

#2

#4 #3

#6

#5

13

Loading...

Loading...