Nordyne M4RC Upflow, M4RL Downflow, M4RC, M4RL, M4RC054D-24B Installation Instructions Manual

...

GAS FURNACES

Installation Instructions

Single Stage Condensing Gas Furnaces

92.1% AFUE

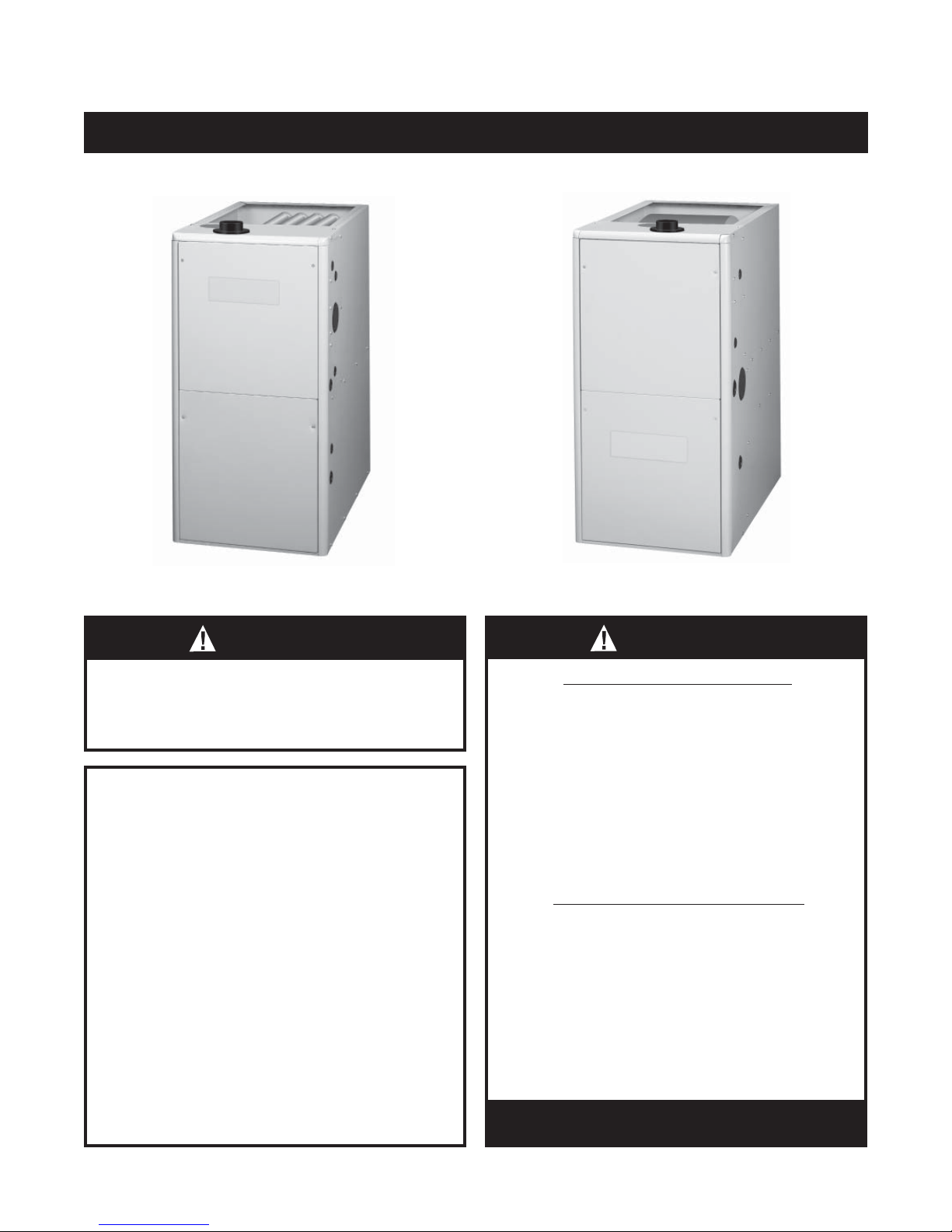

M4RC Upfl ow Furnace

WARNING:

PROPOSITION 65 WARNING: This product

contains chemicals known to the state of

California to cause cancer, birth defects or

other reproductive harm.

ATTENTION INSTALLERS:

It is your responsibility to know this product better than your

customer. This includes being able to install the product

according to strict safety guidelines and instructing the

customer on how to operate and maintain the equipment for

the life of the product. Safety should always be the deciding

factor when installing this product and using common sense

plays an important role as well. Pay attention to all safety

warnings and any other special notes highlighted in the

manual. Improper installation of the furnace or failure to

follow safety warnings could result in serious injury, death,

or property damage.

These instructions are primarily intended to assist qualifi ed

individuals experienced in the proper installation of this

appliance. Some local codes require licensed installation/

service personnel for this type of equipment. Please read all

instructions carefully before starting the installation. Return

these instructions to the customer’s package for future

reference

.

M4RL Downfl ow Furnace

WARNING:

FIRE OR EXPLOSION HAZARD

• Failure to follow safety warnings exactly

could result in serious injury or property

damage.

• Installation and service must be performed

by a qualifi ed installer, service agency or

the gas supplier.

• Do not store or use gasoline or other

fl ammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier from a

neighbors phone. Follow the gas suppliers

instructions.

• If you cannot reach your gas supplier, call

the fi re department.

DO NOT DESTROY.

KEEP IN A SAFE PLACE FOR FUTURE REFERENCE.

TABLE OF CONTENTS

SAFETY INFORMATION .............................................3

REQUIREMENTS AND CODES ..................................4

GENERAL INSTRUCTIONS ........................................5

Manufacturer Warranty ............................................5

Combustion Air Quality ............................................5

Installation in a Garage ............................................ 5

Heating Load ...........................................................6

Clearances to Combustible Materials ......................6

COMBUSTION AIR REQUIREMENTS ........................6

General Information ................................................. 6

Installation in Confi ned Spaces ............................... 7

Air From Inside .................................................... 7

Outdoor Air from a Crawl Space or

Vented Attic .........................................................7

Outdoor Air Using Vertical Ducts ........................ 7

Outdoor Air Using Horizontal Ducts .................... 7

Air Directly Through an Exterior Wall .................8

Alternate Method of Providing air from

Outside ............................................................... 8

Installation in Unconfi ned Spaces ........................... 8

VENTING REQUIREMENTS ......................................10

Vent Pipe Length and Diameter ............................. 10

Vent Pipe Material ................................................. 11

Vent Pipe Installation ............................................. 11

Outdoor Terminations - Horizontal Venting ............ 11

Outdoor Terminations - Vertical Venting ................. 12

Vent Freezing Protection ....................................... 12

Condensate Disposal ............................................ 13

Concentric Vent Termination .................................. 13

Existing Installations .............................................. 13

CIRCULATING AIR REQUIREMENTS ...................... 14

Plenums and Air Ducts .......................................... 14

Return Air Connections .........................................14

Supply Air Connections ......................................... 15

Acoustical Treatments............................................ 15

FURNACE INSTALLATION ....................................... 15

General Requirements .......................................... 15

Requirements and Codes .....................................15

Upfl ow Furnace Installation .................................. 16

Downfl ow Furnace Installation .............................. 16

Alternate Attachment Method ........................... 18

Bottom Panel Removal .......................................... 19

Alternate Bottom Panel Removal ...................... 19

Pressure Switch Relocation .................................. 19

Inducer Assembly Rotation ...................................20

2

Direct Vent (2 - Pipe) Applications ......................... 20

Vent and Inducer Assembly Options ..................... 20

Accessories ..........................................................21

Finish Flange ....................................................21

Rubber Grommets ............................................21

Inline Drain Assembly .......................................21

PVC TEE, Reducer, and Hose Barbs ...............21

Condensate Drain Lines ...................................22

Filter Retainer Brackets ....................................22

Ventilaire™ Bracket...........................................22

Vent Couplings ..................................................23

Upfl ow Furnaces ...........................................23

Downfl ow Furnaces .......................................23

Alternate Vent Pipe Installation .............................23

GAS SUPPLY AND PIPING .......................................24

Leak Check ..........................................................24

High-Altitude Application .......................................24

Conversion to LP/Propane ....................................25

ELECTRICAL WIRING ...............................................29

Low Voltage Wiring ................................................29

Line Voltage Wiring................................................29

Grounding .............................................................29

Twinning ................................................................30

START-UP & ADJUSTMENTS ...................................31

Pre-Start Checklist ................................................31

Start-Up Procedures .............................................31

Verifying and Adjusting Input Rate ........................31

Verifying and Adjusting Temperature Rise ............31

Verifying Burner Operation ....................................31

Verifying Operation of the supply Air

Limit Switch ...........................................................32

OPERATING SEQUENCE .........................................32

Heating Cycle ........................................................32

Cooling Cycle ........................................................32

Fan Mode ..............................................................32

MAINTENANCE .........................................................32

Air Filters ...............................................................33

Blower Compartment ............................................33

Cleaning of Burners ..............................................33

Heat Exchanger and Burner Maintenance ............33

Lubrication ............................................................33

Vent System ..........................................................33

DESCRIPTION OF COMPONENTS ..........................34

TROUBLESHOOTING ...............................................34

FRENCH TRANSLATIONS ........................................35

FIGURES AND TABLES ............................................37

Figure 40 - Furnace Dimensions .......................37

Table 8 - Blower Performance Chart

Electrical Information ..............................................39

Figure 41 - Wiring Diagram ................................39

Gas Information ......................................................40

Table 9 Table 10 Table 11 - High Altitude Deration Chart for

Table 12 - Natural

Table 13 - High Altitude Deration Chart for

Table 14 - High Altitude Deration Chart for

Venting Information .................................................43

Table 15 -

Figure 42 - Horizontal and Vertical Venting ........44

Figure 43 - Upfl ow Options .................................45

Figure 44 - Downfl ow Options ............................46

Location of Furnace Components ..........................47

Figure 45 - Upfl ow/Horizontal Gas Furnace

Components.....................................47

Figure 46 -

Components ....................................47

INSTALLATION/PERFORMANCE CHECKLIST ........48

Gas Flow Rates ...................................40

Gas Pipe Capacities ..........................40

Propane Gas .....................................41

Gas Heating Values ..............41

Nat. Gas - High Heating Values .........42

Nat. Gas - Low Heating Values ..........42

Vent Termination Clearances .............43

Downfl ow Gas Furnace

..................38

SAFETY INFORMATION

Safety markings are used frequently throughout this

manual to designate a degree or level of seriousness and

should not be ignored. WARNING indicates a potentially

hazardous situation that if not avoided, could result in

personal injury or death. CAUTION indicates a potentially

hazardous situation that if not avoided, may result in minor

or moderate injury or property damage.

WARNING:

The safety information listed below must be

followed during the installation, service, and

operation of this furnace. Failure to follow safety

recommendations could result in possible

damage to the equipment, serious per

injury or death

• Use only with type of gas approved for this furnace.

Refer to the furnace rating plate.

• Install this furnace in accordance to the minimum

clearances to combustible materials listed in Table 1

(page 9).

• Provide adequate combustion and ventilation air to the

furnace space as specifi ed on pages 6 - 9.

• Provide adequate clearances around the vent air intake

terminal as specifi ed in Figures 6 - 9 (pages 12 - 13).

• Combustion products must be discharged outdoors.

Connect this furnace to an approved vent system only,

as specifi ed on Pages 10 - 13.

• Never test for gas leaks with an open fl ame. Use a

commercially available soap solution to check all

connections (page 24).

• This furnace is designed to operate with a maximum

external pressure rise of 0.5 inches of water column.

Consult Table 8 (page 38), and the rating plate for the

proper circulating air fl ow and temperature rise.

NOTE: It is important that the duct system be designed

to handle the desired fl ow rate and external pressure

rise. An improperly designed duct system can result

in nuisance shutdowns, and comfort or noise issues.

• When supply ducts carry air circulated by the furnace

to areas outside the space containing the furnace, the

return air shall also be handled by duct(s) sealed to

the furnace casing and terminating outside the space

containing the furnace. See page 14.

• This furnace may not be used for temporary heating

of buildings or structures under construction.

.

sonal

3

REQUIREMENTS and CODES

This furnace must be installed in accordance with

these instructions, all applicable local building codes

and the current revision of the National Fuel Gas Code

(NFPA54/ANSI Z223.1) or the Natural Gas and Propane

Installation Code, CAN/CGA B149.1.

CE générateur d'air chaud doit être installé conformément

aux instructions du fabricant et aux codes locaux. En

l'absence de code local, respecter la norme ANSI Z223.,1,

institulé National Fuel Gas Code ou les codes d'installation

CAN/GCA-B149.

The Commonwealth of Massachusetts requires

compliance with regulation 248 CMR 4.00 and 5.00 for

installation of through – the – wall vented gas appliances

as follows:

1. For direct-vent appliances, mechanical-vent heating

appliances or domestic hot water equipment, where

the bottom of the vent terminal and the air intake is

installed below four feet above grade the following

requirements must be satisfi ed:

a.) A carbon monoxide (CO) detector and alarm shall be

placed on each fl oor level where there are bedrooms.

The detector shall comply with NFPA 720 (2005

Edition) and be mounted in the living area outside

the bedroom(s).

b.) A (CO) detector shall be located in the room that

houses the appliance or equipment and shall:

• Be powered by the same electrical circuit as

the appliance or equipment. Only one service

switch shall power the appliance and the (CO)

detector;

• Have battery back-up power;

• Meet ANSI/UL 2034 Standards and comply with

NFPA 720 (2005 Edition); and Approved and listed

by a Nationally Recognized Testing Laboratory as

recognized under 527 CMR.

c.) A Product-approved vent terminal must be used,

and if applicable, a product-approved air intake must

be used. Installation shall be in strict compliance

with the manufacturer’s instructions. A copy of

the installation instructions shall remain with the

appliance or equipment at the completion of the

installation.

d.) A metal or plastic identifi cation plate shall be mounted

at the exterior of the building, four feet directly above

the location of vent terminal. The plate shall be of

suffi cient size, easily read from a distance of eight

feet away, and read “Gas Vent Directly Below”.

2. For direct-vent appliances, mechanical-vent heating

appliances or domestic hot water equipment where

the bottom of the vent terminal and the air intake is

installed above four feet above grade the following

requirements must be satisfi ed:

a.) A (CO) detector and alarm shall be placed on

each fl oor level where there are bedrooms. The

detector shall comply with NFPA 720 (2005 Edition)

and be mounted in the living area outside the

bedroom(s).

b.) The (CO) detector shall:

• Be located in the room that houses the appliance

or equipment;

• Be hard-wired or battery powered or both.

• Shall comply with NFPA 720 (2005 Edition).

c.) A product-approved vent terminal must be used,

and if applicable, a product-approved air intake must

be used. Installation shall be in strict compliance

with the manufacturer’s instructions. A copy of

the installation instructions shall remain with the

appliance or equipment at the completion of the

installation.

Additional information listed below is for reference

purposes only and does not necessarily have jurisdiction

over local or state codes. Always consult with local

authorities before installing any gas appliance.

Combustion and Ventilation Air

• US: National Fuel Gas Code (NFGC), Air for Combustion

and Ventilation

• CANADA: Natural Gas and Propane Installation Codes

(NSCNGPIC), Venting Systems and Air Supply for

Appliances

Duct Systems

• US and CANADA: Air Conditioning Contractors

Association (ACCA) Manual D, Sheet Metal and

Air Conditioning Contractors National Association

(SMACNA), or American Society of Heating,

Refrigeration, and Air Conditioning Engineers

(ASHRAE) Fundamentals Handbook

Electrical Connections

• US: National Electrical Code (NEC) ANSI/NFPA 70

• CANADA: Canadian Electrical Code CSA C22.1

Gas Piping and Gas Pipe Pressure Testing

• US: NFGC and National Plumbing Codes

• CANADA: NSCNGPIC

General Installation

• US: Current edition of the NFGC and the NFPA 90B. For

copies, contact the National Fire Protection Association

Inc., Batterymarch Park, Quincy, MA 02269; or American

Gas Association, 400 N. Capitol, N.W., Washington DC

20001 or www.NFPA.org

• CANADA: NSCNGPIC. For a copy, contact Standard

Sales, CSA International, 178 Rexdale Boulevard,

Etobicoke (Toronto), Ontario, M9W 1R3 Canada

4

Safety

• US: (NFGC) NFPA 54–1999/ANSI Z223.1 and the

Installation Standards, Warm Air Heating and Air

Conditioning Systems ANSI/NFPA 90B.

• Federal Manufactured Home Constructions & Safety

Standard (H.U.D. Title 24, Part 3280.707[a][2])

• The Standard for Manufactured Home Installations

(Manufactured Home Sites, Communities, and Set-Ups)

ANSI A225.1 and/or CAN/CSA-2240 MH Series).

• Amer ican National Standard (ANSI-119.2/NFPA-501C)

for all recreational vehicle installations.

• CANADA: CAN/CGA-B149.1 and .2–M00 National

Standard of Canada. (NSCNGPIC)

GENERAL INSTRUCTIONS

Manufacturer Warranty, Owner’s Responsibilities

It is the sole responsibility of the homeowner to make

certain the gas furnace has been correctly installed in

the home, converted to the proper fuel (LP gas or Natural

gas), and adjusted for proper operation.

A warranty certifi cate with full details is included with this

furnace. However, NORDYNE will not be responsible for any

costs found necessary to correct problems due to improper

setup, improper installation, furnace adjustments, improper

operating procedure on the part of the user, etc.

Combustion Air Quality

CAUTION:

Combustion air must not be drawn from a

corrosive atmosphere.

To maximize heat exchanger life, the combustion air

must be free of chemicals that can form corrosive acidic

compounds in the combustion gases. The recommended

source of combustion air is to use outdoor air. However,

the use of indoor air in most applications is acceptable

except as listed:

• If the furnace is a single pipe installation and installed

in a confi ned space, it is required that the necessary

combustion air come from the outdoors by way of attic,

crawl space, air duct, or direct opening. See pages 6 - 9

for combustion air requirements.

• Installations in these locations may require outdoor air

for combustion, due to chemical exposures:

Commercial buildings

Buildings with indoor pools

Furnaces installed in laundry rooms

Furnaces installed in hobby or craft rooms

Furnaces installed near chemical storage areas

Some specifi c examples of service calls which cannot be

included in warranty payments are:

• Converting the furnace to use another type of gas.

• Repairing duct work in the home found to be faulty.

• Correcting wiring problems in the electrical circuit

supplying the furnace.

• Resetting circuit breakers, blown fuses or other

switches.

• Correcting problems due to improper gas supply

pressure to the furnace.

• Providing instructional training on how to light and

operate the furnace.

• Correcting any problems caused by installation of an air

conditioner, heat pump or other air comfort devices.

• Revising installation of the furnace fl ue assembly.

• Adjusting or calibrating of thermostat.

• Removing any construction debris which has fallen into

fl ue system.

Carefully review these responsibilities with your

manufactured housing dealer, service company, or gas

supplier, so that there will be no misunderstanding at a

later time.

• Exposure to the following substances in the combustion

air supply may require outdoor air for combustion:

Permanent wave solutions

Chlorinated waxes and cleaners

Chlorine based swimming pool chemicals

Water softening chemicals

De-icing salts or chemicals

Carbon Tetrachloride

Halogen type refrigerants

Cleaning solvents (perchloroethylene)

Printing inks, paint removers, varnishes, etc.

Hydrochloric Acid

Cements and glues

Antistatic fabric softeners

Masonry acid washing materials

Installation in a Garage

WARNING:

Do not place combustible material on or against

the furnace cabinet or within 6 inches of the

vent pipe. Do not place combustible materials,

including gasoline or any other fl ammable

vapors and liquids, in the vicinity of the furnace.

5

This Gas-fi red furnace may be installed in a residential

garage with the provision that the burners and igniter

are located no less than 18 inches (457mm) above the

fl oor. The furnace must be located or protected to prevent

physical damage by vehicles.

Heating Load

This furnace should be sized to provide the design heating

load requirement. Heating load estimates can be made

using approved methods available from Air Conditioning

Contractors of America (Manual J); American Society of

Heating, Refrigerating, and Air Conditioning Engineers;

or other approved engineering methods. Excessive

oversizing of the furnace could cause the furnace

and/or vent to fail prematurely. In addition, the ductwork

should be appropriately sized to the capacity of the

furnace to ensure its proper airfl ow rating. For installations

above 2,000 ft., the furnace should have a sea level input

rating large enough that it will meet the heating load after

deration for altitude.

Clearances to Combustible Materials

This furnace is Design Certifi ed in the U.S. and Canada

by CSA International for the minimum clearances to

combustible material listed in Table 1 (page 9). To obtain

model number and specifi c clearance information, refer

to the furnace rating plate, located inside of the furnace

cabinet.

Access for positioning and servicing the unit must be

considered when locating unit. The need to provide

clearance for access to panels or doors may require

clearance distances over and above the requirements.

Allow 30 inches minimum clearance from the front

of the unit for servicing and positioning. However, 36

inches is strongly recommended.

COMBUSTION AIR REQUIREMENTS

General Information

Provisions must be made during the installation of

this furnace that provide an adequate supply of air for

combustion. NORDYNE condensing furnaces must be

installed with outdoor combustion air piped directly to

the furnace.

WARNING:

Furnace installation using methods other than

those described in the following sections must

comply with the National Fuel Gas Code (NFGC)

and all applicable local codes.

• Requirements in Canada (B149.1) are structured

differently. Consult with B149.1 and local code offi cials

for Canadian installations.

• The M4 series gas furnace has been certifi ed for use

in manufactured homes in the United States to the UL

307B standard and to ANSI Z21.47 CAN/CGA-2.3 in

Canada and the United States. These furnaces may

be installed in:

Manufactured Homes

Recreational Vehicles, Park Models

Manufactured Buildings

Modular Homes / Buildings

• The M4 furnace is listed as a Direct Vent (2-pipe) forced

air furnace (type FSP) for use with both natural and

propane (LP) gases. NOTE: Direct vent appliances

draw combustion air from the outdoors and vent

combustion products back outside, isolating the entire

system from the indoor space. It is important to make

sure that the whole system is sealed and clearances

to combustibles are maintained regardless of the

installation being in a confi ned or unconfi ned space.

• The combustion air from the outside needs to be clear

of chemicals that can cause corrosion. The inlet pipe

should not be placed near corrosive chemicals such

as those listed on page 5.

severe corrosion in the furnace combustion system.

• Air openings on top of the furnace and in closet doors

or walls must never be restricted. If the furnace is

operated without adequate combustion air, the fl ame

roll-out switch will open and turn off the gas supply

to the burners. This safety device is a manually

reset switch. DO NOT install jumper wires across

these switches to defeat their function or reset a

switch without identifying and correcting the fault

condition. If a switch must be replaced, use only the

correct sized part specifi ed in the Replacement Parts

List provided online.

These chemicals can cause

CAUTION:

Exhaust fans, clothes dryers, fi replaces and

other appliances that force air from the house

to the outdoors can create a negative pressure

inside the house, resulting in improper furnace

operation or unsafe conditions such as fl ame roll

out. It is imperative that suffi cient air exchange

with the outdoors is provided to prevent

depressurization. Additional information about

how to test for negative pressure problems can

be found in the NFGC.

• Instructions for determining the adequacy of an

installation can be found in the current revision of the

NFGC (ANSI Z223.1 / NFPA54). Consult local codes

for special requirements. These requirements are for

US installations as found in the NFGC.

6

Installation in Confi ned Spaces

A confi ned space is an area with volume less than 50

cubic feet per 1,000 Btuh of the combined input rates of

all appliances drawing combustion air from that space.

Furnace closets, small equipment rooms and garages are

confi ned spaces. Furnaces installed in a confi ned space

which supply heated air to areas outside the space must

draw return air from outside the space and must have the

return air ducts tightly sealed to the furnace.

The required sizing of these openings is determined by

whether inside or outside air is used to support combustion,

the method by which the air is brought to the space, and

by the total input rate of all appliances in the space. In

all cases, the minimum dimension of any combustion air

opening is 3 inches.

Furnace

Alternate

Air Inlet

Vent or

Chimney

Ventilation Louvers

(each end of attic)

Water

Heater

Inlet Air

---------

---------

NOTE: Air openings shall

each have a free area of

not less than one square

inch per 4,000 Btuh of the

total input rating of all

equipment in the enclosure.

---------

Outlet

Air

---------

Air From Inside

If combustion air is taken from the heated space, the two

openings must each have a free area of at least one square

inch per 1,000 Btuh of total input of all appliances in the

confi ned space, but not less than 100 square inches of

free area. See Example and Figure 1.

Example:

If the combined input rate of all appliances is less than

or equal to 100,000 Btuh, each opening must have a

free area of at least 100 square inches. If the combined

input rate of all appliances is 120,000 Btuh, each opening

must have a free area of at least 120 square inches.

Vent or

Chimney

NOTES:

Each opening must be

at least 100 sq. in. or

1 sq. in. per 1,000 Btuh

of total input rating,

whichever is greater.

Openings must start at

no more than 12 inches

from the top and bottom

of the enclosure.

Total Input Rating

(Btuh)

40,000 100 sq. In 12 inches

60,000 100 sq. In 12 inches

80,000 100 sq. In 12 inches

100,000 100 sq. In 12 inches

120,000 120 sq. In 13 inches

140,000 140 sq. In 14 inches

160,000 160 sq. In 15 inches

Water

Heater

Minimum Free Area

(Each Opening)

12” Max.

Furnace

See

Notes

See

Notes

12” Max.

Round Duct

Diameter

Figure 1. Combustion Air Drawn from Inside

Outdoor Air from a Crawl Space or Vented Attic

When the openings can freely exchange air with the

outdoors, each opening shall have a minimum free area

of 1 square inch per 4,000 Btuh of total appliance input.

The openings shall exchange directly, or by ducts, with

the outdoor spaces (crawl or attic) that freely exchange

with the outdoors. See Figure 2.

Ventilation Louvers For

Unheated Crawl Space

Figure 2. Combustion Air Drawn from a Crawl

Space or Vented Attic

Outdoor Air Using Vertical Ducts

If combustion air is taken from outdoors through vertical

ducts, the openings and ducts must have a minimum free

area of one square inch per 4,000 Btuh of total appliance

input. Attics or crawl spaces must connect freely with the

outdoors if they are the source of air for combustion and

ventilation. See Figure 3.

Ventilation Louvers

at each end of attic

Vent or

Chimney

Total Input Rating

(Btuh)

40,000 10 sq. In 4 inches

60,000 15 sq. In 5 inches

80,000 20 sq. In 5 inches

100,000 25 sq. In 6 inches

120,000 30 sq. In 6 inches

140,000 35 sq. In 7 inches

160,000 40 sq. In 8 inches

Attic

Insulation

Water

Heater

Furnace

Minimum Free Area

(Each Opening)

Air Duct must be

at least 1 sq. in.

per 4,000 Btuh of

total input rating.

Ducts must

extend above

attic insulation.

Air Duct must be

at least 1 sq. in.

per 4,000 Btuh of

total input rating.

12" Max

Round Duct

Diameter

Figure 3. Combustion Air Drawn from Outside

Through Vertical Ducts

Outdoor Air Using Horizontal Ducts

If combustion air is taken from outdoors through horizontal

ducts, the openings and ducts must have a minimum free

area of one square inch per 2,000 Btuh of total appliance

input. Ducts must have cross - sectional area at least as

large as the free area of their respective openings to the

furnace space. See Figure 4 (page 8).

7

Vent or

Chimney

Water

Heater

Air Duct

Furnace

Air Ducts must be

at least 1 sq. in.

per 2,000 Btuh of

total input rating.

Air Duct

Total Input Rating

(Btuh)

40,000 20 sq. In 5 inches

60,000 30 sq. In 6 inches

80,000 40 sq. In 7 inches

100,000 50 sq. In 8 inches

120,000 60 sq. In 9 inches

140,000 70 sq. In 10 inches

160,000 80 sq. In 10 inches

Minimum Free Area

(Each Opening)

Round Duct

Diameter

Alternate Method of Providing Air from Outside:

If acceptable under local Codes, it is permitted to provide

outside air using one opening (See NFGC).

Generally, confi ned spaces must have two openings in

the space for combustion air. One opening must be within

12 inches of the ceiling, and the other must be within

12 inches of the fl oor. However, an alternative method

recently adopted by the NFGC uses one opening within

12 inches of the top of the space. This method may be

used if it is acceptable to the local codes.

The following conditions must be met:

1. The opening must start within 12” of the top of the

structure and connect with the out of doors through

vertical or horizontal ducts or be ducted to a crawl

or attic space that connects with the out of doors.

2. The opening must have a minimum free area of 1 sq.

in. per 3,000 Btu per hour of the total input rating of

all equipment located in the enclosure.

Figure 4. Combustion Air Drawn from Outside

Through Horizontal Ducts

Air Directly Through An Exterior Wall

If combustion air is provided directly through an exterior

wall, the two openings must each have free area of at

least one square inch per 4,000 Btuh of total appliance

input. See Figure 5.

Vent or

Chimney

-

-

-

-

-

See

-

-

-

-

See

Note

-

-

-

-

-

-

-

-

-

12"

Max

Water

Heater

Minimum Free Area

(Each Opening)

Note

12" Max.

Total Input Rating

(Btuh)

40,000 10 sq. In 4 inches

60,000 15 sq. In 5 inches

80,000 20 sq. In 5 inches

100,000 25 sq. In 6 inches

120,000 30 sq. In 6 inches

140,000 35 sq. In 7 inches

160,000 40 sq. In 8 inches

NOTE: Each opening to outside

must be at least 1 sq. in. per

4,000 Btuh of total input rating.

Furnace

Round Duct

Diameter

3. The free area must not be less than the sum of all the

areas of the vent connectors in the enclosure.

Installation in Unconfi ned Spaces

An unconfi ned space is an area including all rooms not

separated by doors with a volume greater than 50 cubic

feet per 1,000 Btuh of the combined input rates of all

appliances which draw combustion air from that space.

In general, a furnace installed in an unconfi ned space will

not require outside air for combustion. However, in homes

built for energy effi ciency (low air change rates), it may

be necessary to provide outside air to ensure adequate

combustion and venting, even though the furnace is located

in an unconfi ned space. See example.

Example:

A space with a water heater rated at 45,000 Btuh

input and a furnace rated at 75,000 Btuh requires a

volume of 6,000 cubic feet [50 x (45 + 75) = 6,000] to

be considered unconfi ned. If the space has an 8 foot

ceiling, the fl oor area of the space must be 750 square

feet (6,000 / 8 = 750).

Figure 5. Combustion Air Drawn from Outside

Through an Exterior Wall

8

INSTALLATION CLEARANCES to COMBUSTIBLE MATERIALS

For UPFLOW, HORIZONTAL & DOWNFLOW FURNACES

Left Side ...................................0 Inches Vent ............................................. 1 Inch Top ...........................................1 Inches

Right Side ................................0 Inches Back .........................................0 Inches Front.......................................4 Inches

UPFLOW APPLICATION

TOP

DOWNFLOW APPLICATION

TOP

†

LEFT SIDE

BOTTOM

†

Allow 30 in. minimum clearance for servicing. Recommended clearance is 36 in.

NOTE: The furnace is listed for installation on combustible or non-combustible fl ooring. However, wood is the only combustible

fl ooring allowed for installation.

Table 1. Minimum Clearances to Combustible Materials

RIGHT SIDE

WARNING:

LEFT SIDE

BOTTOM

RIGHT SIDE

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance connected to the venting system being

placed into operation could result in carbon monoxide poisoning or death. The following steps

shall be followed with each individual appliance connected to the venting system being placed

in operation, while all other appliances connected to the venting system are not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal pitch, as required in the National

Fuel Gas Code, ANSI Z223. 1/NFPA 54 or the CSA B149.1, Natural Gas and Propane Installation

Codes and these instructions. Determine that there is no blockage or restriction, leakage,

corrosion and other defi ciencies which could cause an unsafe condition.

3. As far as practical, close all building doors and windows and all doors between the space

in which the appliance(s) connected to the venting system are located and other spaces

of the building.

4. Close fi replace dampers.

5. Turn on clothes dryers and any appliance not connected to the venting system. Turn on

any exhaust fans, such as range hoods and bathroom exhausts, so they are operating at

maximum speed. Do not operate a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance being inspected into operation. Adjust

the thermostat so appliance is operating continuously.

7. Test for spillage from draft hood equipped appliances at the draft hood relief opening after

5 minutes of main burner operation. Use the fl ame of a match or candle.

8. If improper venting is observed during any of the above tests, the venting system must

be corrected in accordance with the National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or

CSA B149.1, Natural Gas and Propane Installation Codes.

9. After it has been determined that each appliance connected to the venting system properly

vents when tested as outlined above, return doors, windows, exhaust fans, fi replace

dampers and any other gas-fi red burning appliance to their previous conditions of use.

9

VENTING REQUIREMENTS

WARNING:

This furnace must not be vented with other

appliances, even if that appliance is of the

condensing type. Common venting can result

in severe corrosion of other appliances or their

venting and can allow combustion gases to

escape through such appliances or vents. Do

not vent the furnace to a fi replace chimney or

building chase.

Upon completion of the furnace installation,

carefully inspect the entire fl ue system both

inside and outside the furnace to assure it is

properly sealed. Leaks in the fl ue system can

result in serious personal injury or death due

to exposure of fl ue products, including carbon

monoxide.

• This furnace must be vented in compliance with

the current revision of the National Fuel Gas Code

(ANSI-Z223.1/NFPA54) and the instructions

provided below. Consult local codes for special

requirements.

• In Canada, venting shall conform to the requirements of

the current (CAN/CGA B149.1 or .2) installation codes.

Consult local codes for special requirements.

This furnace is classifi ed as a “Category IV” appliance,

which requires special venting materials and installation

procedures. This type of appliance operates with positive

vent pressure and therefore requires the furnace to be

vented to the outdoors and thoroughly sealed. They also

produce liquid condensate, which is slightly acidic and

can cause severe corrosion of ordinary venting materials.

Furnace operation can be adversely affected by restrictive

vent and combustion air piping.

Vent Pipe Length and Diameter

In order for the furnace to operate properly, the combustion

air and vent piping must not be excessively restrictive.

• The venting system should be designed to have the

minimum number of elbows or turns.

• All horizontal runs must slope upwards from the furnace

at 1/4 inch minimum per running foot of vent.

• Transition to the fi nal vent diameter should be done as

close to the furnace outlet as practical.

• Always use the same size or a larger pipe for

combustion air that is used for the exhaust vent.

Table 2 specifi es the maximum allowable pipe length

for vent and combustion air for a furnace of known input

rate, when installed with piping of selected diameter and

number of elbows. To use the table, the furnace input rate,

the centerline length and the number of elbows on each

pipe must be known.

When estimating the length of vent runs, consideration

must be made to the effect of elbows and other fi ttings.

This is conveniently handled using the idea of “equivalent

length”. This means the fi ttings are assigned a linear

length that accounts for the pressure drop they will cause.

For example: a 2” diameter, long radius elbow is worth

the equivalent of 2.5 feet of linear run. A 90 degree tee

is worth 7 ft.

The equivalent lengths of tees and various elbows are

listed in Table 2. Measure the linear length of your vent

run and then add in the equivalent length of each fi tting.

The total length, including the equivalent fi tting lengths,

must be less than the maximum length in the table.

Furnace

(BTU)

54,000 Upfl ow 90 90

72,000 Upfl ow 90 90

90,000

108,000 Upfl ow 90 90

1. The length of 2” pipe needed between the inducer and the exit hole (top of cabinet) is 8 3/4” for upfl ow models and 16” for downfl ow models.

2. Subtract 2.5 ft. for each additional 2 inch long radius elbow, 5 ft. for each additional 2 inch short radius elbow, 3.5 ft. for each additional 3

inch long radius elbow, and 7 ft. for each additional 3 inch short radius elbow. Subtract 8ft for each 3” tee.

3. Two 45 degree elbows are equivalent to one 90 degree elbow.

4. This table applies for elevations from sea level to 2,000 ft. For higher elevations, decrease pipe lengths by 8% per 1,000 ft of altitude.

10

FURNACE

INSTALLATION

Upfl ow 90 90

Downfl ow 90 90

SINGLE PIPE LENGTH (FT.)

with 1 long radius elbow

(See Notes)

OUTLET

3” Diameter

NOTES:

Table 2. Vent Pipe Lengths

DUAL VENT PIPE LENGTH (FT.)

with 1 long radius elbow on each pipe (See

Notes)

INLET/OUTLET

3” Diameter

Condensing furnace combustion products have very little

buoyancy, so Table 2 is to be used without consideration

of any vertical rise in the piping.

Vent Pipe Material

Vent and combustion air pipe and fi ttings must be one of

the following materials in the list and must conform to the

indicated ANSI/ASTM standards. Cement must conform

to ASTM Standard D2564 for PVC and Standard D2235

for ABS. PVC Primer must meet standard ASTM F656.

When joining PVC piping to ABS, use PVC solvent cement.

(See procedure specifi ed in ASTM Standard D3138).

Material ...............................................Standard

Schedule 40PVC ....................................D1785

PVC-DWV ...............................................D2665

SDR-21 & SDR-26 ..................................D2241

ABS-DWV ...............................................D2661

Schedule 40 ABS ....................................F628

Foam/Cellular Core PVC ........................F891

In Canada, all plastic vent pipes and fi ttings including

any cement, cleaners, or primers must be certifi ed as a

system to ULC S636. However, this requirement does not

apply to the fi nish fl anges or piping internal to the furnace.

Vent Pipe Installation

CAUTION:

Combustion air must not be drawn from a

corrosive atmosphere.

This furnace has been certifi ed for installation with zero

clearance between vent piping and combustible surfaces.

However, it is good practice to allow space for convenience

in installation and service.

• The quality of outdoor air must also be considered. Be

sure that the combustion air intake is not located near a

source of solvent fumes or other chemicals which can

cause corrosion of the furnace combustion system.

See list of substances on page 5.

• Route piping as direct as possible between the furnace

and the outdoors. Longer vent runs require larger

diameters. Vent piping must be sloped upwards 1/4” per

foot in the direction from the furnace to the terminal.

This is to ensure that any condensate fl ows back to the

condensate disposal system.

• The combustion air intake and the vent exhaust must

be located in the same atmospheric pressure zone.

This means both pipes must exit the building through

the same portion of exterior wall or roof as shown in

Figures 6 - 9 (page 12 - 13) and Figure 41 (page 44).

• Piping must be mechanically supported so that its

weight does not bear on the furnace. Supports must

be at intervals no greater than 5 ft. Supports may be

at shorter intervals if necessary to ensure that there

are no sagging sections that can trap condensate.

Outdoor Terminations - Horizontal Venting

Vent and combustion air intake terminations shall be

installed as depicted in Figures 6 - 7 (page 12) and in

accordance with these instructions:

• Vent termination clearances must be consistent with the

NFGC, ANSI 2223.1/NFPA 54 and/or the CSA B149.1,

Natural Gas and Propane Installation Code.

• All minimum clearances must be maintained to protect

building materials from degradation by fl ue gases as

shown in Figure 7.

• Vent and combustion air intake terminations must

be located to ensure proper furnace operation and

conformance to applicable codes. The minimum

distance from any door, open window, or air gravity inlet

is 1ft. below, 1ft. horizontally, or 1ft. above. In Canada,

CSA B149.1 takes precedence over these instructions.

Table 15 (page 43) lists the necessary distances from

the vent termination to windows and building air intakes.

• The vent termination shall be located at least 4 ft.

horizontally from any electric meter, gas meter,

regulator and any relief equipment. These distances

apply ONLY to U.S. installations. In Canada, the

Canadian Fuel Gas Code takes precedence over these

instructions.

• Do not install the vent terminal such that exhaust is

directed into window wells, stairwells, under decks

or into alcoves or similar recessed areas, and do not

terminate above any public walkways.

• If venting horizontally, a side wall vent kit is available

according to the pipe diameter size of the installation.

For 2 inch pipe use side wall vent kit #904617, and

for 3 inch pipe use kit #904349. Please follow the

instructions provided with the kit.

• When the vent pipe must exit an exterior wall close to

the grade or expected snow level where it is not possible

to obtain clearances shown in Figure 6, a riser may be

provided as shown in Figure 8 (page 12). Insulation is

required to prevent freezing of this section of pipe. For

vent freezing protection, see page 13.

WARNING:

The combustion air vent and exhaust vent

must be confi gured as shown in Figure 9.

Improper vent terminations can cause the

recirculation of fl ue gases which may result in

furnace vibration. In severe cases, the furnace

will cycle, due to the intermittent contact

between the fl ame and the fl ame sensor.

If you notice these oscillations occurring,

check the vent confi guration to make sure

the exhaust vent does not have a 90 degree

termination.

11

l

Mounting Kit

Faceplate Secured

to Wall with Screws

Typical Both Pipes

Combustion

Air Inlet

Exhaust Vent

Left Side Option

Exhaust

Inlet

12" Min. to Maximum

Expected Snow Level

Typical Both Pipes

90°

Elbow

Figure 6. Exhaust and Combustion Air

Pipe Clearances

9 in.

Note 3

4 ft.

4ft.

Notes

2 & 5

Notes

2 & 3

NOTES:

1. All dimensions shown are minimum requirements.

2. Exterior vent terminations must be located at

least 12” above the maximum expected snow level.

3. Mechanical draft vent terminal

4. Direct vent terminal - more than 50,000 Btuh.

5. Direct vent terminal - less than 50,000 Btuh.

12 in.

12 in.

Notes

2 & 4

Less

than

8" min.

36" max.

Both Sides

Exhaust Vent

Right Side Option

10 ft.

Note 3

3 ft.

Forced

Air Inlet

• For optimal performance, vent the furnace through a wall

that experiences the least exposure to winter winds.

• Termination kits consist of two face plates and an

insulating gasket to seal the exterior surface.

• The hole in the wall must be sized closely to the

diameter of the pipe.

• The pipe that penetrates the wall should be long

enough that it can be held in place by standard close

fi tting couplings.

• Face plates are secured to both sides of the wall by

the couplings, and the gasket is retained against the

wall by the exterior face plate.

• Face plates must be fastened to the wall. Exterior face

plates must be fl ashed to prevent water infi ltration.

If termination kits are not used, these requirements

must be followed:

• The hole size cut through the exterior wall is smaller

than the outside diameter of the couplings.

• The vent pipe extends through the wall approximately

1" and the gap between the wall and pipe is sealed.

• Couplings are applied to the vent pipe on the interior

and exterior sides of the wall. NOTE: This insures the

pipe can not be pushed or pulled through the wall.

• The combustion air inlet pipe must have a 90 degree

termination elbow, and pointed downwards as shown

in Figure 6 & Figure 9 (page 13).

Outdoor Terminations - Vertical Venting

Termination spacing requirements from the roof and from

each other are shown in Figure 9.

• The roof penetration must be properly fl ashed and

waterproofed with a plumbing roof boot or equivalent

fl ashing.

• The combustion air intake must be provided with an

elbow opening downward.

Vent and combustion air piping may be installed in an

existing chimney which is not in use provided that:

Figure 7. Vent Locations

Vent Configuration to

Provide 12" Minimum

height above

Snow Level.

Outside

Wall

Figure 8. Alternate Horizontal Vent Installation

12

12" Min.

19" Max.

Support

1/2"

Armaflex

Insulation or

Equivalent

(if required)

12" Above

Maximum

Expected

Snow Leve

• Both the exhaust vent and air intake run the length of

the chimney.

• The top of the chimney is sealed and weatherproofed.

• The termination clearances shown in Figure 9 are

maintained.

• No other gas fi red or fuel-burning equipment is vented

through the chimney.

Vent Freezing Protection

• When the vent pipe is exposed to temperatures below

freezing (i.e., when it passes through unheated spaces,

chimneys, etc.) the pipe must be insulated with 1/2

inch thick sponge rubber insulation, Armafl ex-type

insulation or equivalent. Insulating pipe is important

to avoid condensate icing.

• Table 3 (page 13) lists the maximum length of fl ue pipe

that can travel through an unconditioned space or an

exterior space. The total vent length must not exceed

the lengths noted in Table 2 (page 10). For Canadian

installations please refer to the Canadian Installation

Code (CAN/CGA-B149.1 or 2) and/or local codes.

• For extremely cold climates or conditions of short furnace

cycles (i.e. set back thermostat conditions), the last 18

inches of vent pipe can be reduced from 3” to 2-1/2”,

3” to 2” or 2” to 1-1/1” if the total vent length is at least

15 feet in length and the vent is sized in accordance

with Table 2. The length of the 2 inch pipe must not

be longer than 18 inches. Smaller vent pipes are less

susceptible to freezing, but must not be excessively

restrictive.

• To prevent debris or creatures from entering the

combustion system, a protective screen may be

installed over the combustion air intake opening. The

screens hole size must be large enough to prevent air

restriction

90° Elbow

12” Above Maximum

Expected Snow Level

(Typ. Both pipes)

Exhaust Vent

Combustion Air

8" Min.

36" Max.

Plumbing Vent

Roof Boot

(Typ. Both Pipes)

Figure 9. Vertical Vent Termination

Maximum Flue Pipe Length

Winter Design

Temperature

20 45 70

02070

-20 10 60

* = Insulation thickness greater than 3/8 inch, based on an

R value of 3.5 (ft x F x hr) / (BTU x in.)

Without Insulation

in Unconditioned and

Exterior Spaces

With Insulation

(feet)

(feet)*

After the condensate lines are J-trapped, they may be

combined together when routed to the drain. Avoid areas

where condensate drainage may cause problems by

dropping onto planters, patios, etc.

NOTE: Industry research studies indicate that when

condensate is routed to an active drain, household

detergents, etc., buffer its acidity. If the drain is not actively

used or if codes require, obtain a neutralizer kit (usually

contains limestone). Proper drains and connections to the

condensate tubing are required as NORDYNE cannot be

held responsible for water leakage which occurs due to

loose hose connections or improperly sealed drain line

pipes.

Concentric Vent Termination

A concentric vent termination is approved for use with

these furnaces. Please follow the installation instructions

provided with the kit for proper installation.

Existing Installations

When an existing furnace is removed from a vent system

serving other appliances, the existing vent system may

not be sized properly to vent the remaining appliances

(Example: water heater). An improperly sized venting

system can result in the formation of condensate, leakage,

or spillage. The existing vent system should be checked to

make sure it is in compliance with NFGC, ANSI Z223.1,

or CAN/CGA B149 and must be brought into compliance

before installing the furnace.

NOTE: If replacing an existing furnace, it is possible you will

encounter an existing plastic venting system that is subject

to a Consumer Product Safety Commission recall. The

pipes involved in the recall are High Temperature Plastic

Vent (HTPV). If your venting system contains these

pipes DO NOT reuse this venting system! This recall

does not apply to other plastic vent pipes, such as white

PVC or CPVC. Check for details on the CPSC website or

call their toll-free number (800) 758-3688.

Table 3. Vent Protection

Condensate Disposal

The method for disposing of condensate varies according

to local codes. Consult your local code or authority having

jurisdiction. Neutralizer kit P/N 902377 is available for

use with this furnace. Please follow the instructions

provided with the kit.

This furnace has multiple options for positioning the vent

pipe as described in the Vent and Inducer Assembly

Options section (page 20). Each of the condensate drain

lines must be J-trapped using fi eld supplied parts.

13

CIRCULATING AIR REQUIREMENTS

WARNING:

Do not allow combustion products to enter the

circulating air supply. Failure to prevent the

circulation of combustion products into the

living space can create potentially hazardous

conditions including carbon monoxide

poisoning that could result in personal injury

or death.

All return ductwork must be secured to

the furnace with sheet metal screws. For

installations in confi ned spaces, all return

ductwork must be adequately sealed. When

return air is provided through the bottom of the

furnace, the joint between the furnace and the

return air plenum must be air tight.

The surface that the furnace is mounted on must

provide sound physical support of the furnace

with no gaps, cracks or sagging between the

furnace and the fl oor or platform.

Return air and circulating air ductwork must

not be connected to any other heat producing

device such as a fi replace insert, stove, etc.

This may result in fi re, explosion, carbon

monoxide poisoning, personal injury, or

property damage.

Plenums and Air Ducts

• Plenums and air ducts must be installed in accordance

with the Standard for the Installation of Air Conditioning

and Ventilating Systems (NFPA No. 90A) or the

Standard for the Installation of Warm Air Heating and

Air Conditioning Systems (NFPA No. 90B).

• Table 8 (page 38) contains the maximum airfl ow and

temperature rise data for each furnace input rate.

NOTE: If the maximum airfl ow is 1,600 CFM or more,

it is recommended that two openings be used for return

air on upfl ow furnaces. Downfl ow furnaces can only

use one return opening.

• It is recommended that the outlet duct contain a

removable access panel. The opening should be

accessible when the furnace is installed in service and

shall be of a size that smoke or refelcted light may be

observed inside the casing to indicate the presence of

leaks in the heat exchanger. The cover for the opening

shall be attached in such a manner as to prevent leaks.

• If outside air is used as return air to the furnace for

ventilation or to improve indoor air quality, the system

must be designed so that the return air is not less than

60° F (15° C) during operation. If a combination of

indoor and outdoor air is used, the ducts and damper

system must be designed so that the return air supply

14

to the furnace is equal to the return air supply under

normal, indoor return air applications.

• When a cooling system is installed which uses the

furnace blower to provide airfl ow over the indoor coil,

the coil must be installed downstream (on the outlet

side) of the furnace or in parallel with the furnace.

• If a cooling system is installed in parallel with the

furnace, a damper must be installed to prevent chilled

air from entering the furnace and condensing on the

heat exchanger. If a manually operated damper is

installed, it must be designed so that the furnace will

not operate when the damper is in the cooling position

or when in heating position, the cooling system is

inoperable.

• It is good practice to seal all connections and joints

with industrial grade sealing tape or liquid sealant.

Requirements for sealing ductwork vary from region

to region. Consult with local codes for requirements

specifi c to your area.

Return Air Connections

In applications where the supply ducts carry heated air

to areas outside the space where the furnace is installed,

the return air must be delivered to the furnace by duct(s)

secured to the furnace casing, running full size and without

interruption.

• Upfl ow furnaces draw the return air from the base of

the furnace. A stand or return air duct must be supplied

to the furnace to provide the required return air.

• Downfl ow models draw the return air from the top of

the furnace. The minimum required clearance to the top

of the furnace is detailed on the furnace rating plate.

Additional clearance may be required depending upon

fi lter accessibility.

For each U.S.A. application, the home manufacturer

shall comply with all of the following conditions to have

acceptable return air systems for closet installed forced

air heating appliances:

• Regardless of the location, the return air opening

into the closet shall not be less than specifi ed in the

appliance’s listing.

• Means shall be provided to prevent inadvertent closure

by a fl at object placed over the return air opening when

it is located in the fl oor of the closet (versus the vertical

front or side wall).

• The cross-sectional area of the return duct system

leading into the closet shall not be less than 390 square

inches.

• The total free area of openings in the fl oor or ceiling

registers serving the return air duct system must be at

least 352 sq. in. At least one register should be located

where it is not likely to be covered by carpeting, boxes

and other objects.

• Materials located in the return duct system must have a

fl ame spread classifi cation of 200 or less. This includes

a closet door if the furnace is in a closet.

• Noncombustible pans having 1" upturned fl anges are

A Single trunk duct

B

Dual trunk duct

w/crossover connector

C

Transition duct

w/branches

located beneath openings in a fl oor duct system.

• Wiring materials located in the return duct system shall

conform to Articles 300-22 of the National Electrical

Code (ANSI C1/NFPA-70).

• Gas piping is not run in or through the return duct

system.

• Test the negative pressure in the closet with the aircirculating fan operating at high speed and the closet

closed. The negative pressure is to be no more negative

than minus 0.05 inch water column.

• Air conditioning systems may require more duct, register

and open louver area to obtain necessary airfl ow. Use

NORDYNE’s certiduct program to determine proper

duct size for A/C.

• For floor return systems, the manufactured home

manufacturer shall affi x a prominent marking on or

near the appliance where it can be easily read when

the closet door is open. The marking shall read:

CAUTION:

HAZARD OF ASPHYXIATION: Do not cover

or restrict return air opening.

Supply Air Connections

For proper air distribution, the supply duct system must be

designed so that the static pressure measured external

to the furnace does not exceed the listed static pressure

rating shown on the furnace rating plate. The supply

air must be delivered to the heated space by duct(s)

secured to the furnace casing, running full size and

without interruption.

Three typical distribution systems are shown in Figure 10.

The location, size, and number of registers should be

selected on the basis of best air distribution and fl oor

plan of the home.

noise eminating from the furnace. These treatments can

produce a quieter installation, particularly in the heated

space. However, they can increase the pressure drop in

the duct system. Care must be taken to maintain the proper

maximum pressure rise across the furnace, temperature

rise and fl ow rate. This may mean increasing the duct size

and/or reducing the blower speed. These treatments must

be constructed and installed in accordance with NFPA and

SMACNA construction standards. Consult with local codes

for special requirements. For best sound performance,

install all the needed gaskets and grommets around

penetrations into the furnace, such as for electrical wiring.

FURNACE INSTALLATION

*RC series gas furnaces are shipped ready for installation

in the upfl ow position with upfl ow return air. *RL series

gas furnaces may only be used for downfl ow operation.

See Table 1 (page 9) for the required clearances needed

to move the furnace to its installation point (hallways,

doorways, stairs, etc).

General Requirements

• The furnace must be leveled at installation and attached

to a properly installed duct system. Do not use the

back of the furnace for return air. See page 14 for

circulating requirements.

• The furnace must be installed so that all electrical

components are protected from water.

• The dimensions of the room or alcove must be able to

accommodate the overall size of the furnace and the

installation clearances listed in Table 1.

• The furnace must be installed upstream from a

refrigeration system.

• The plenum attached to the A/C coil box and ductwork

within 3 ft. of the furnace must be installed so that

surfaces are at least 1/4” from combustible construction.

• The cabinet plug must always be used to close the hole

in the side of the furnace when rotating the inducer.

• Upfl ow and downfl ow models must be installed with

the Nordyne A/C coil box which are listed according to

the cabinet size of the furnace: “B” cabinet - 920169,

“C” cabinet - 920171, and “D” cabinet - 920172.

Figure 10. Typical Supply Duct System

Acoustical Treatments

Damping ducts, fl exible vibration isolators, or pleated

media-style fi lters on the return air inlet of the furnace

may be used to reduce the transmission of equipment

Requirements and Codes

The installer must be familiar with and comply with all

local codes and regulations applicable to the installation of

heating appliances and related equipment. In the absence

of local codes, the installation must conform with these

instructions and the current provisions of one or more of

the following standards:

• Federal Manufactured Home Constructions & Safety

Standard (H.U.D. Title 24, Part 3280.707[a][2])

• The Standard for Manufactured Home Installations

(Manufactured Home Sites, Communities, and SetUps) ANSI A225.1 and/or CAN/CSA-2240 MH Series).

• American National Standard (ANSI-119.2/NFPA-501C)

for all recreational vehicle installations.

15

Loading...

Loading...