Nordyne M3RL 060A AW, M3RL 080A BW, M3RL 060A BW, M3RL 060A BWT, M3RL 080A BWT Installation Instructions Manual

...

Direct Vent (Sealed Combustion) Forced Air Gas Furnaces

M3RL Series 90+ Downflow Condensing Furnace

For installation in:

1. Manufactured Homes

2. Park Models and Manufactured Buildings

3. Modular Homes/Buildings

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could

result in serious injury, death or property

damage.

- Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

-WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Leave the building immediately.

• Immediately callyourgas supplierfrom a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

-Installation and service must be performed by a

qualified installer, service agency, or the gas

supplier

BW Models

J

BWT Models

J

ADVERTISSEMENT:

RISQUE D'INCENDIE OU D'EXPLOSION

Le non=respect des avertissements de securite

pourrait entrainer des blessures graves, la

mort ou des dommages materiels.

- Ne pas entreposer ni utiliser de I'essence ni

d'autres vapeurs ou liquides inflammables dans le

voisinage de cet appareil, ni de tout autre appareil.

-QUE FAIRE S'ILYA UNE ODEUR DE GAZ

• Ne pas tenter d'allumer aucun appareil.

• Ne toucher a aucun interrupteur electrique;

n'utiliser aucun t61ephone dans le b_timent.

• €:vacuer I'immeuble immediatement.

•Appeler immediatement le fournisseur de gaz en

employant le tel6phone d'un voisin. Respecter

la lettre les instructions du fournisseur de gaz.

• Si personne ne repond, appeler le service des

incendies.

-L'installation et I'entretien doivent Ctre effectues

par un installateur qualifie, un organisme de

service ou le fournisseur de gaz.

LEAVE THESE INSTRUCTIONS WITH THE HOMEOWNER.

WARNING:

Should overheating occur, or the

gas supply fail to shut off, shut

off the manual gas valve to the

appliance before shutting off the

electrical supply.

Improper installation, adjust-

ment, alteration, service or

maintenance can cause injury

or property damage. Refer to

this manual. For assistance or

additional information consult

a qualified installer, service

agency or the gas supplier.

2

TABLE OF CONTENTS

General ...................................................... 4

Unit Dimensions .................................. 4

Shipping Weights ................................ 4

Furnace Specification ........................ 4

Air Flow Data ..................................... 4

Owner's information ................................ 5

installation Requirements ...................... 6

Location .............................................. 8

Clearance ........................................... 8

Circulating Air Supply .......................... 10

Return Air Provisions ............................ 10

Air Distribution Systems ...................... 11

Duct Connector Selection .................... 11

Duct installation .................................... 12

Venting and Combustion

Air Requirements .......................... 14

Venting Requirements .......................... 14

Vent Table ........................................ 15

Vent Pipe Material ............................ 16

Vent Pipe Length and Diameter ....... 16

Vent Pipe installation ........................ 16

Pipe Routing & Support .................... 16

Location of Outdoor Termination ..... 18

Horizontal Venting ............................ 18

Vertical Venting ................................ 19

Vent Freezing Protection ................. 19

Concentric Vent Termination ........... 20

Drainage of Condensate

From Furnace ................................ 20

Gas Supply and Piping ......................... 21

Leak Check ...................................... 22

High Altitude Derate ......................... 22

Pressure Switch ............................... 22

Conversion ............................................. 22

Lighting and Adjustment

of the Appliance ............................ 24

Electrical Wiring ..................................... 24

Line Voltage Wiring .......................... 25

Low Voltage Wiring .......................... 26

Ventilation ............................................... 26

Start-up and Adjustment ..................... 26

Start-Up Procedure ......................... 26

Shut Down Procedure ..................... 27

Verifying and Adjusting Firing Rate. 27

Temperature Rise ............................ 27

Verifying and Adjusting

Verifying Burner Operation .............. 28

Verifying Operation of the

Supply Air Limit Switch ................. 28

Description of Components ................ 29

Furnace Accessories ............................. 29

Maintenance ........................................... 29

Combustion Air and Vent System .... 29

Air Filter(s) ....................................... 29

Lubrication ........................................ 30

Condensate Drain Assembly ........... 30

Blower Compartment ....................... 30

Heat Exchanger and Burner

Maintenance .................................. 30

System Operation Information ............. 30

Sequence of Operation .................... 30

Furnace Fails to Operate ................. 31

Component Location ............................ 32

Wiring Diagram ....................................... 33

Installation/Performance

Checklist ......................................... 35

M3RL-060A-A W

Application

M-Manufactured Home

Furnace Series

Comfort Model

RL - Condensing Downflow

Heating Capacity

input, BTUH (000')

Table 1. Model Identification

LReturn Air Configuration

Blank- Front

L

T - Top

Door Color

W - White

G - Gray

Cabinet Dimensions

A - 56"x 19-3/4" x 23-3/4"

B - w/Coil Cavity,

76" x 19-3/4" x 23-3/4"

Electrical Code

A - 1PH, 60 Hz, 120 VAC

3

GENERAL

Top Return Knockouts

7/3243. I12

27-25/32

"B" Cabinet

-- 19-7/8 --

16

--3-17/32

COMBUSTION AIR INTAKE

--1-11/16

EXHAUST

VENT

Figure 1. Furnace Dimensions

--3-17/32

COMBUSTION AIR INTAKE

--1-11/16

EXHAUST

VENT

"A" Cabinet

"\ /

SIDE RETURN

KNOCKOUTS

/\

L--- ......_

_ 21-15/16--

m

_ _ 12.000

1,000

I

:

21.000

Y

Top View Top Returrl Opening

(AW and BW Models) (BWT Models)

Furnace Specifications / Airflow Data

Furnace Furnace Temp. External Static Pressure ( Inches Water Column)

Furnace Input Output

rVlodel No. Btuh Btuh

M3 RL-060 60,000 54,000

M3 RL-080 80,000 72,000

Rise @ Motor Motor 0.1 0.2 0.3 0.4

.3"WC °F HP Speed CFM CFM CFM CFM

35 - 65 1/2

35 - 65 1/2 Med-High 1512 1467 1416 1363

High* 1660 1599 1544 1474

Med-High 1512 1467 1416 1363

Med-Low 1340 1304 1261 1217

Low** 1176 1142 1108 1025

High* 1660 1599 1544 1474

Med-Low** 1340 1304 1261 1217

Low** 1176 1142 1108 1025

(

Shipping

Furnace Model Weight

(Ibs)

M3RL 060A AW 150

M3RL 060A BW* 170

M3RL 080A AW 155

M3RL 080A BW* 175

* May include suffix - T

Table 2. Shipping Weight

Recommended

0.5 A/C

CFM Ton

1410 4

1304 3

1158 2.-1/2

966 2

1410 4

1304 3

1158 2.-1/2

966 2

Note: Data is for Operation with Filter. * Factory Wired Cooling Tap

Table 3. Furnace Specifications/Airflow Data

4

•* Factory Wired Heating Tap

/ WARNING:

Do not use this appliance if any part

has been submerged underwater, im-

mediately call a qualified service tech-

nician to inspect the appliance and to

replace any part of the control system

and any gas control that has been

submerged underwater,

NOTICE TO INSTALLER

Installer is advised to follow carefully all instruc-

tions and warnings in this manual to insure

maximum performance, safety, and operating

efficiency ofthese appliances. Improper installa-

tion may create hazardous conditions, and will

void the appliance warranty.

GENERAL

General Description

The M3 series gas furnaces are listed direct

vent (sealed combustion) forced air furnaces

for use with both natural and propane gases.

The M3 series is a Category IV and type FSP

furnace. The M3 furnace series has been

certified to the ANSI Z21.47/CSA2.3-2001 for

use in the United States and Canada and to the

UL307B --1995 for use in the United States.

5. Never test for gas leaks with an open

flame. Use a commercially available soap

solution made specifically for the detection

of leak to check all connections.

6. Always install furnace to operate within the

furnace's intended temperature rise range

with a duct system that has an external

static pressure within the allowable range,

as specified in page 4 of these instruc-

tions. See Table 3 and the furnace rat-

ing plate.

7. When a furnace is installed so that supply

ducts carry air circulated by the furnace to

areas outside the space containing the

furnace, the return air shall also be handled

by duct(s) sealed to the furnace casing

and terminating outside the space contain-

ing the furnace. Note: This section only

applies to furnaces installed with side or

top return air.

8. A gas4ired furnace for installation in a

residential garage must be installed as

specified in page 9 of these instructions.

9. The furnace is not to be used for tempo-

rary heat of buildings or structures under

construction.

M3 series furnaces are air conditioning ready

as shipped. The furnace cooling capacities of

the blower motor speed taps are shown in

Table 3. Table 2 lists the shipping weights for

the M3 series furnaces.

These furnaces may be installed in:

1. Manufactured Homes.

2. Park Models and Manufactured buildings

3. Modular Homes/Buildings

The following are safety guidelines with refer-

ences to their specific sections or pages in the

manual.

1. Use only type of gas approved for this

furnace. Refer to the furnace rating plate.

2. Install this furnace only in location and

position as specified in pages 8 - 14 of

these instructions.

3. Provide adequate combustion and ventila-

tion air to the furnace space as specified in

pages 13 - 20 of these instructions.

4. Combustion products must be discharged

outdoors, connect this furnace to an ap-

proved vent system only, as specified in

pages 14-20 of these instructions.

OWNER INFORMATION

NORDYNE has been involved in the design of

products for the manufactured home industry

since the first manufactured home or trailer

was built.

NORDYNE originated the sealed combustion

system, which separates the furnace com=

bustion system from the living area of the

home, now a standard for the manufactured

home industry.

NORDYNE engineers developed the first cen-

tral heating system and the first central air

conditioner for manufactured homes.

NORDYNE is dedicated to bringing to its cus=

tomers the finest heating and cooling comfort

possible. NORDYNE constantly seeks to fur=

ther refine its products to continuously provide

exceptional comfort.

Followtheinstructionsinthisbookletcarefully

andthisappliancewillprovidemanyyearsof

superiorperformance.

If youwishto coolyour homeautomatically

witha centralairconditioningsysteminvesti-

gatetheexcellentNORDYNEcoolingsystems

availablefromyourheatingandcoolingcon-

tractor.Thesesystemsaredesignedto work

bestwithyourNORDYNEfurnaceand have

beencarefullyengineeredto deliveroptimum

performancewhen matedwith NORDYNE

manufacturedhomefurnaces.

NORDYNEalsoofferswaterheaters,fireplaces

and ventilatingsystemsspecificallydesigned

for manufacturedhousingapplications.Check

with your manufacturedhomeretailer,your

heating and cooling contractor or your

distributorfor information.Writedirectlyto the

factory8000PhoenixParkway,O'Fallon,MO

63368ifyouarenotabletolocateasourcefor

NORDYNEmanufacturedhousingproductsin

yourarea.

MANUFACTURER WARRANTY, OWNER'S

RESPONSIBILITIES

It is the sole responsibility of the homeowner to

make certain the gas furnace has been correctly

set up and converted to the proper fuel (L.P. gas

or Natural gas) and adjusted to operate prop-

erly. All gas furnaces are manufactured for

Natural gas and must be field converted when

using LP. gas.

A warranty certificate with full details is included

with these instructions. However, NORDYNE

will not be responsible for any costs found nec-

essary to correct problems due to improper

setup, improper installation, furnace adjustments,

improper operating procedure on the part of the

user, etc.

Some specific examples of service calls which

cannot be included in warranty payments are:

1. Converting the furnace to use another type

of gas.

2. Repairing ductwork in the home found to be

faulty.

3. Correcting wiring problems in the electrical

circuit supplying the furnace.

4. Resetting circuit breakers, blown fuses or

other switches.

5. Correcting problems due to improper gas

supply pressure to the furnace.

6. Providing instructional training on how to

light and operate the furnace.

7. Furnace problems caused by installation of

an air conditioner, heat pump or other air

comfort devices.

8. Revising installation of the furnace flue

assembly.

9. Adjusting or calibrating of thermostat.

10. Any construction debris which falls into

the flue system.

Carefully review these responsibilities with your

manufactured housing dealer, service company

or gas supplier so there will be no misunder-

standing at a later time.

CAUTION:

• Never attempt to alter or modify this

furnace or any of its components.

• Never attempt to repair damaged or

inoperable components. Such action

could cause unsafe operation, ex-

plosion, fire and/or asphyxiation.

• If a malfunction has occurred, or if

you feel that the furnace is not oper-

ating as it should, contact a qualified

service agency or gas utility for as-

sistance.

INSTALLATION STANDARDS

Installer shall be familiarwith and complywith all

codes and regulations applicable to the installa-

tion of these heating appliances and related

equipment. In lieu of local codes, the installation

shall be in accordance with the current provi-

sions of one or more of the following standards.

a. Federal Manufactured Home Constructions

& Safety Standard (H.U.D. Title 24, Part

3280.707[a][2])

b. The Standard for Manufactured Home Instal-

lations (Manufactured Home Sites, Commu-

nities, and Set-Ups) ANSI A225.1 and/or

CAN/CSA-2240 MH Series).

c. American National Standard (ANS1=119.2/

NFPA=501C) for all recreational vehicle in-

stallations.

d. American National Standard (ANSI=Z223.1/

NFPA-54) and/or CAN/CGA B149 for all gas-

fired furnace models.

e. American National Standard (ANSI=C1/NFPA-

70) and/or CSA 22.1 Canadian Electric Code

Part 1 for all electrical field wiring.

6

CE g6nerateurd'air chauddoitCtreinstalle

conformementauxinstructionsdufabricantet

auxcodesIocaux.EnI'absencedecodelocal,

respecterlanormeANSIZ223.,1,instituleNa-

tionalFuelGasCodeoulescodesd'installation

CAN/GCA-B149.

the side wall horizontal vented gas fueled

equipment. It shall be the responsibility of the

property owner to secure the services of

qualified licensed professionals for the

installation of hard wired carbon monoxide

detectors.

The National Fuel Gas Code is available by

writing:

American National Standards Institute, Inc.

1430 Broadway

New York, NY 10018

NFPA publications are available by writing:

National Fire Protection Association

Batterymarch Park

Quincy, ME 02269

IMPORTANT NOTE

INSTALLATION REQUIREMENTS =

COMMONWEALTH OF

MASSACHUSETTS

The Commonwealth of Massachusetts

requires compliance with regulation 248 CMR

5.00 for installation of the side wall horizontal

venting. The following requirements shall be

satisfied.

INSTALLATION OF CARBON

MONOXIDE DETECTORS

At the time of installation of the side wall

horizontal vented gas fuel equipment, the

installing plumber or gasfitter shall observe

that a hard wired carbon monoxide detector

with an alarm and battery back-up is installed

on the floor level where the gas equipment is

to be installed. In addition, the installing plumber

or gasfitter shall observe that a battery operated

or hard wired carbon monoxide detector with

an alarm is installed on each additional level of

the dwelling, building or structure served by

ALL MODELS

Front

Back

Sides

Vent

Top

Duct (Plenum)

w/Coil Box

w/o Coil Box

(within 3 feet)

*Note: For 1" clearance, use a fully Iouvered door with at least

400 square inches of free airflow area.

CLOSET

Inches

1/4

Table 4. Minimum Clearances

ALC OVE

Inches

1"

0

0

0

6

0

1"

0

0

0

6

0

1/4

In the event that the side wall horizontally

vented gas fueled equipment is installed in a

crawl space or an attic, the hard wired carbon

monoxide detector with alarm and battery

back-up may be installed on the next adjacent

floor level.

In the event that the requirements of this

subdivision can not met at the time of completion

of installation, the owner shall have a period of

thirty (30) days to comply with the above

requirements; provided, however, that during

said thirty (30) day period, a battery operated

carbon monoxide detector with an alarm shall

be installed.

APPROVED CARBON MONOXIDE

DETECTORS

Each carbon monoxide detector as required in

accordance with the above provisions shall

comply with NFPA 720 and be ANSI/UL 2034

listed and IAS certified.

SIGNAGE

A metal or plastic identification plate shall be

permanently mounted to the exterior of the

building at minimum height of eight feet above

grade directly in line with the exhaust vent

terminal for the horizontally vented gas fueled

heating appliance or equipment. The sign shall

read, in print size no less than one-half (1/2)

inch in size, "GAS VENT DIRECTLY BELOW.

KEEP CLEAR OF ALL OBSTRUCTIONS."

INSPECTION

The state or local gas inspector of the side wall

horizontally vented gas fueled equipment shall

not approve the installation unless, upon

inspection, inspector observes carbon

monoxide detectors and signage installed in

accordance with the provisions of 248 CNR

5.08(2)(a) 1 through 4.

Exemptions: The following equipment is

exempt frolTl 248 CMR 5.08(2)(a) 1 through 4:

Product approved side wall horizontally vented

f_eled equipment installed in room or structure

separated from the dwelling, building or

structure used in whole or in part for residential

purposes.

MANUFACTURERREQUIREMENTS-

GASEQUIPMENTVENTINGSYSTEM

NOT PROVIDED.

When the manufacturer of a Product Approved

side wall horizontally vented gas fueled

equipment does not provide the parts for

venting the flue gases, but identifies" special

venting systems", the following requirements

shall be satisfied by the manufacturer:

1. The reference "special venting

system" instructions shall be

included with the appliance or

equipment instructions; and

2. The "special venting systems" shall

be Product Approved by the board,

and the instructions for that system

shall include a part list and detailed

installation instructions.

A copy of all installation instructions for all

Product Approved side wall horizontally vented

gas fueled equipment, all venting instructions,

all parts lists for venting instructions, and/or all

venting design instructions shall remain with

the appliance or equipment at the completion

of the installation.

LOCATION

The furnace must be installed on a level sur-

face, and as close to the center of the air

distribution system as possible. See Figure 1

for overall dimensions to determine the required

clearances in hallways, doorways, stairs, etc.

to allow the furnace to be moved to the instal=

lation point. The furnace must be installed so

that all electrical components are protected

from water.

Minimum clearances to combustible materials

are listed in Table 4. Access for positioning and

servicing must be considered when locating the

unit.

This furnace is certified for use on wood floor=

ing. The furnace must be installed on a solid

surface and must be level front-to-back and

Top View

of Duct

Connector

A Single trunk duct

, D

_" Dual trunk duct

B w/crossover connector

I

Transition duct

C [p w/branches [']____[1_

Figure 2. Non-Platinum

7

II II II

Supply Duct System

FLOOR CAVITY

(depth equal to "X" in Table 5)

I I

Figure 4. Connector Dimensions

Use Duct Connector

If "X" (Floor Cavity)is: Model Part Number:

English Metric (mm) Finger Tab ScrewDowr

7/8" 22 901987 904008

2" 51 901988 904009

4 1/4" 108 901989 904010

6 1/4" 150 901990 904011

8 1/4" 210 901991 904012

10 1/4" 260 901992 904013

12 1/4" 311 901993 904014

Table 5. Duct Connector Sizes

8

Figure 3. Floor Cavity

REDUCER _\

FELT-SEAL

SPACERS

(1) FINGER TAB DUCT CONNECTOR ONLY

(2) SCREW DOWN DUCT CONNECTOR ONLY

Figure 5. Duct Connector

side=to=side. This furnace must not be installed

directly on carpeting, tile, or any combustible

material other than wood flooring. The furnace

may be installed on combustible flooring when

installed on a Nordyne duct connector (see

Table 5).

The ductwork within 3 feet of the furnaces

without the A/C coil box must be installed such

that surfaces are at least 1/4" from combustible

materials.

,&

X SEE

TABLE 5

( )OPENING TO DUCT

(1) WITH PLATE (C) REMOVED

OPENING BECOMES

13-1/4" x 13-1/4"

(2) WITH PLATE (C) REMOVED

OPENING BECOMES

13"X 13". WITH REDUCER

IT IS 13"X 10-1/8",

When installed in a residential garage, the fur=

nace must be positioned so the burners and the

source of the ignition are located no less than

18 inches above the floor and protected from

physical damage by vehicles.

F I 142-_/2 _ 2-3/4'_

_/////_.REAR WALL OF CLOSET bR_,_co_E_

2-1/4

F F LRODOuRc_UT-oONUNTECT i O N S

14-1/2

3-1/4

-3/4

fl ....

' 1-1/4 / I _ 12-7/8

ALT FUEL LINE / !. _ !__q,_

24

ENTRY /' / ..... I

_,, _ 15-1/2 _

i I

I

_- FLOOR CUT-OUT

FOR OPTIONAL

COOLING COIL

FOR NON-PLATINUM

SERIES UNITS

lO"

FLo2

23-1/4"

HOLE \\\\\

Figure 6. Closet or Alcove

g

17-29/32

u_

-- 3-19/32

-- 1-3/4

_- VENT

COMBUSTION AIR INTAKE

J

_-- FUEL LINE ENTRY

2

_ 1-3/4

FURNACE

OUTER DOOR

21-7/16

Figure 7. Floor Cut-Out Dimensions

9

CIRCULATING AiR SUPPLY

z WARNING:

Products of combustion must not be

allowed to enter the return air openings

of the furnace or the circulating air

supply, Failure to prevent products of

combustion from being circulated into

the living space can create potentially

hazardous conditions including carbon

monoxide poisoning that could result in

personal injury or death,

The floor or platform on which the furnace

ismounted must provide sound physical

support of the furnace with no gaps,

cracks, or sagging between the furnace

and the floor or platform,

The circulating air ductwork must not be

connected to any other heat producing

device such as a fireplace insert, stove,

etc,

GENERAL

Plenums and air ducts must be installed in

accordance with the Standard for the Installa-

tion of Air Conditioning and Ventilating Systems

(NFPA No. 90A) or the Standard for the Instal-

lation of Warm Air Heating and Air Conditioning

Systems (NFPA No. 90B).

RETURN AIR PROVISIONS

U.S.A. home manufacturers shall comply with

all of the following conditions to have accept-

able return air systems for closet installed

forced air heating appliances:

a. Regardless of the location, the return air

opening into the closet shall not be less than

specified in the appliance's listing.

b. Means shall be provided to prevent inadvert-

ent closure by a flat object placed over the

return air opening when it islocated in the floor

of the closet (versus the vertical front or side

wall).

c. Closet installations must use a Iouvered door

having a minimum free area of 235 sq. in.

when located 6" from furnace. For clearance

between 1" and 6" from furnace, require-

ments are a Iouvered door with minimum of

235 sq. in. free area, with the openings in

closet door directly inline with the Iouvered

openings in the furnace door. For 1" clear-

ance from furnace, use a fully Iouvered door

with at least 400 sq. in. of free airflow area.

d. The cross-sectional area of the return duct

system leading into the closet, when located

in the floor or ceiling shall notbe less than 235

square inches.

e. The total free area of openings in the floor or

ceiling registers serving the return air duct

system must be at least 352 sq. in. At least

one register should be located where it is not

likely to be covered by carpeting, boxes and

other objects.

f. Materials located in the return duct system

must have a flame spread classification of

200 or less. This includes a closet door if the

furnace is in a closet.

g. Noncombustible pans having 1" upturned

flanges are located beneath openings in a

floor duct system.

h. Wiring materials located in the return duct

system shall conform to Articles 300-22 of

the National Electrical Code (ANSI Cl/

NFPA-70).

i. Gas piping is not run in or through the return

duct system.

j. Test the negative pressure in the closet with

the air-circulating fan operating at high speed

and the closet closed. The negative

pressure is to be no more negative than

minus 0.05 inch water column.

k. For floor return systems, the manufactured

home manufacturer shall affix a prominent

marking on or near the appliance where itcan

be easily read when the closet door is open.

The marking shall read:

CAUTION:

HAZARD OF ASPHYXIATION: Do not

cover or restrict return air opening,

I. Air conditioning systems may require more

duct register and open louver area to ob-

tain necessary airflow. Use NORDYNE's

certiduct program to determine proper duct

size for A/C.

10

DUCTEDRETURNAIR

M3furnaceswithmodelnumbersendinginAW

orBWarefactoryconfiguredfor thereturnair

to flowthroughthefrontIouvereddoor.The

returnairmayalsobeattachedtoeithersideor

the top of the furnacecabinetusinga field

installedkit.RefertoTable10fortheNORDYNE

ductedreturnkitP/Nnumber.Thelocationand

sizeof thesideandtopreturnairconnections

areshowninFigure1.Thefiltersizefortheside

returnairis20"x20"x1".Fortopreturnthefilter

sizeis24"x 16"x 1".

M3furnaceswithmodelnumbersendingin

BWTarefactoryconfiguredforthereturnairto

enterthetopofthefurnace.

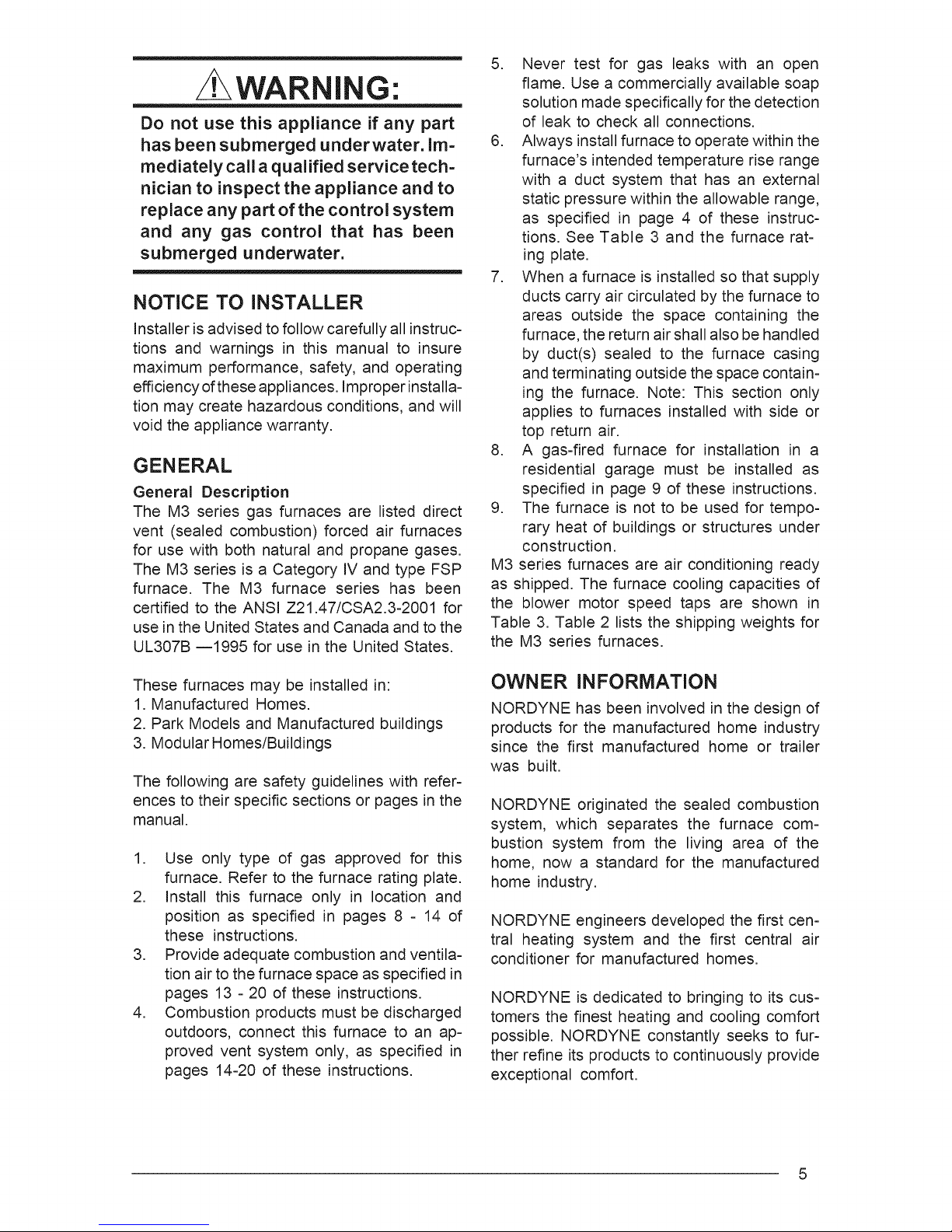

AIR DISTRIBUTION SYSTEMS

For proper air distribution, the supply duct

system must be designed so that the static

pressure measured external to the furnace

does not exceed the listed static pressure

rating shown on the furnace rating plate.

Three typical distribution systems are illus-

trated in Figure 2. Location, size, and number

of registers should be selected on the basis of

best air distribution and floor plan of the home.

DUCT CONNECTOR SELECTION

PLATINUM SERIES

a. For Platinum ready construction use

the 14" round plenum, p/n: 903896.

NON=PLATINUM SERIES

a.

Determine depth of floor cavity from

surface of floor to top of supply air duct

(See Figure 3).

b.

Select appropriate model from Table 5

which matches X-dimension of the floor

cavity. To maximize air delivery, re-

move reducer "C" (see Figure 5) to

obtain the largest open area that will fit

the duct/floor construction.

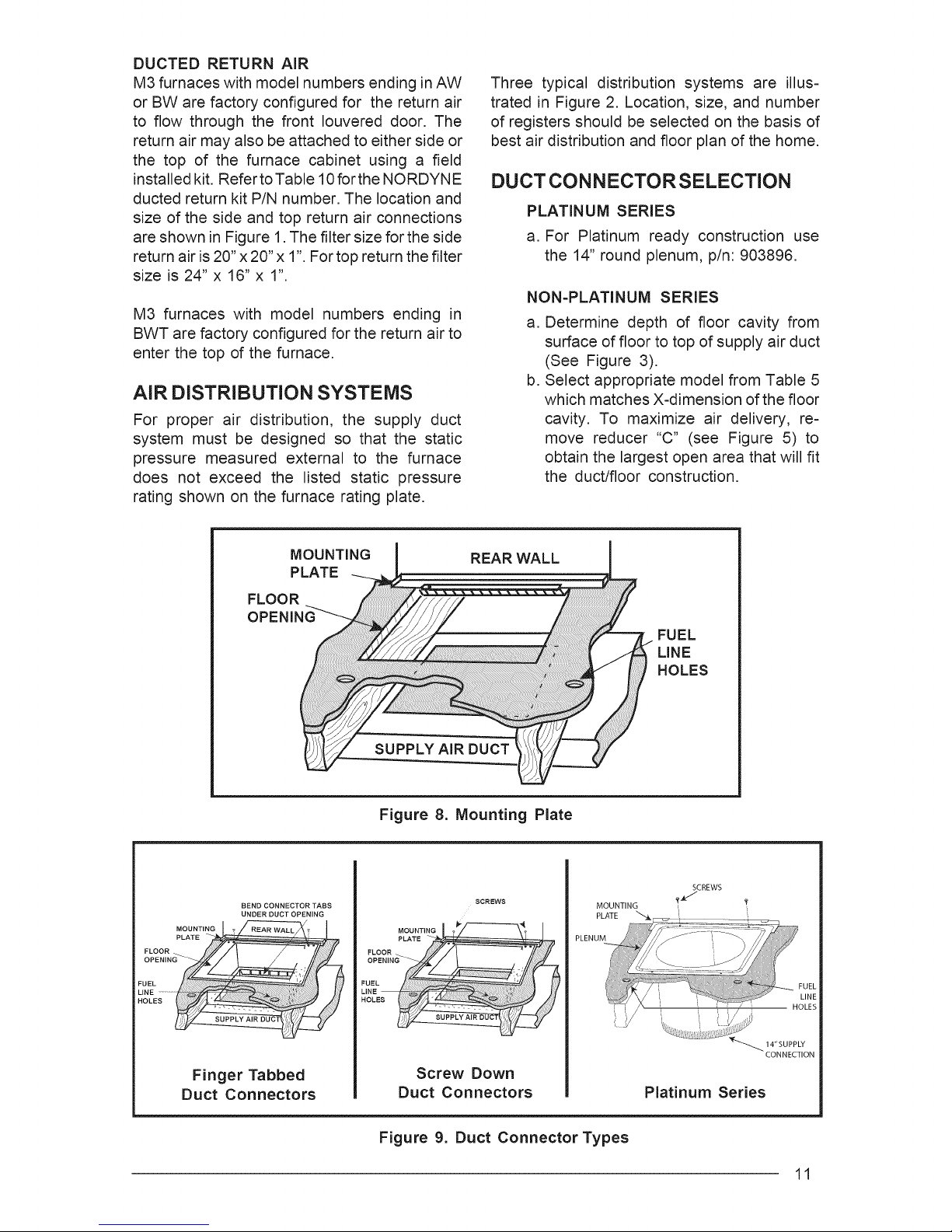

MOUNTING

PLATE

FLOOR

OPENING

BEND CONNECTOR TABS

UNDER DUCT OPENING

REAR WALL

SUPPLY AIR DUCT

Figure 8. Mounting Plate

MOUNTING

PLATE

FUEL

LINE

HOLES

SCREWS

Finger Tabbed

Duct Connectors

Screw Down

Duct Connectors

Figure 9. Duct Connector Types

CONNECTION

Platinum Series

11

Loading...

Loading...