Page 1

Installation Instructions

Split System Heat Pump

The iQ Drive heat pump operates as part of a larger intercommunicating system which provides temperature, air fl ow, and

humidity control for a residence or other similarly sized building. This system includes this outdoor unit, the dedicated iQ

controller (thermostat), and an iQ system-compatible indoor unit, typically an air handler with electric strip heat or a gas

furnace. The system will function only if these components are matched and intended f or use within this system. A complete

list of compatible equipment by model and serial number is available in NORDYNE document 709031, iQ Field Wiring

Installation Instruction. Accessory equipment which may be used with this system includes humidifi ers, electric or electronic

air cleaners, and U/V (ultraviolet) sterilizing lamps.

Refer to the System Operation section below for a complete description of how to use the various features of the system.

In addition to providing the means for operation, the controller also serves as the means for initial system confi guration and

setup, and it provides a considerable amount of information for troubleshooting the system and diagnosing problems.

OTHER REFERENCE DOCUMENTS

• Installation instruction documents for indoor equipment (furnace or air handler, optional humidifi er, etc.)

• iQ Field Wiring Installation Instruction, document 709031, provided in the iQ thermostat/controller kit

• iQ Thermostat/Controller User’s Manual, document 709063, provided in the iQ thermostat/controller kit

• local wiring and building codes

• Nordyne Application Guideline for Refrigerant Lines Over 75 Feet document 044B-0600

• iQ Zone System Zone Thermostat User’s Manual

• iQ Zone System Installation Instructions

Page 2

TABLE OF CONTENTS

PREP ARATION ....................................................................................................................................................3

Slab Mounting ..................................................................................................................................................3

Roof Mounting ..................................................................................................................................................3

ELECTRICAL CONNECTIONS ...........................................................................................................................3

Electrical Power Wiring ....................................................................................................................................3

Control Circuit Wiring .......................................................................................................................................4

iQ Zone Control Wiring ....................................................................................................................................4

Recheck Wiring ................................................................................................................................................4

REFRIGERANT LINE CONNECTIONS ...............................................................................................................4

Line Design and Routing ..................................................................................................................................4

Brazing .............................................................................................................................................................5

System Evacuation ..........................................................................................................................................5

Refrigerant Charging ........................................................................................................................................5

Alternate Procedure for Charging a Heat Pump in Cooling Mode ...................................................................6

Alternate Procedure for Charging a Heat Pump in Heating Mode ...................................................................6

SYSTEM SETUP USING THE IQ CONTROLLER ...............................................................................................6

General ............................................................................................................................................................6

Screen Navigation ............................................................................................................................................6

The Main Screen ..............................................................................................................................................6

Installer Settings ..............................................................................................................................................7

System Confi guration ..................................................................................................................................7

Accessories .................................................................................................................................................8

Defrost Confi guration ..................................................................................................................................8

Dealer Information .......................................................................................................................................8

Heat Off Delay .............................................................................................................................................9

Altitude Adjust .............................................................................................................................................9

Service T ests ...............................................................................................................................................9

SERVICE INFORMATION Screens ................................................................................................................... 10

Other Confi guration Entries ........................................................................................................................... 11

Minimum Heat Pump Operating Temp ......................................................................................................11

Auto Changeover Time .............................................................................................................................. 12

Date and Time ........................................................................................................................................... 12

Program Schedule vs. Nonprogrammable .................................................................................................12

Dehumidifi cation ........................................................................................................................................12

Humidity Settings ......................................................................................................................................12

Smart Recovery ........................................................................................................................................13

Zone Control ..............................................................................................................................................13

System Operation: Quick Start.......................................................................................................................14

System Startup, Checkout, & Troubleshooting ............................................................................................... 15

SYSTEM DIAGNOSIS & TROUBLESHOOTING ...............................................................................................16

Controller .......................................................................................................................................................16

Outdoor Unit Inverter .....................................................................................................................................16

Outdoor Unit Interface Board (right side small circuit board) ......................................................................... 16

Outdoor Unit EXV Board (left side small circuit board) .................................................................................. 17

Indoor Unit Interface Board (in G6 iQ furnace kit or air handler) ...................................................................17

Indoor Unit EXV Board ...................................................................................................................................17

Indoor Unit Constant CFM Motor Control Board ............................................................................................ 17

Indoor Unit One or Two-Stage G7 Furnace Board .........................................................................................

17

Indoor Unit iQ Modulating Gas Furnace Board .............................................................................................. 17

Airzone Control Board ....................................................................................................................................17

iQ Zone System Confi guration .......................................................................................................................18

Common Troubleshooting Issues ...................................................................................................................18

MAINTENANCE .................................................................................................................................................19

FIGURES & DIAGRAMS .................................................................................................................................... 19

2

Page 3

PREPARATION

Before proceeding with installation of iQ heat pump equipment,

consult with the distributor and homeowner to confi rm that the

equipment listed on the order is what was ordered, and that

it matches labeling on the equipment packaging.

Next determine (including consultation with the homeowner) the

intended/preferred location for placement of the compressor/

outdoor coil unit. Unit envelope dimensions are shown in

Figure 1.

This heat pump is designed for outdoor installation only.

Unit placement must take into consideration the following

clearances: (a) A minimum of 18 inches must be provided

between each of the four sides and any solid barrier or wall

which might block free inlet air fl ow into the coil. A minimum

clearance of 36 inches is required between multiple units.

(b) The corner of the unit covered by the control access

cover must be clear enough to allow comfortable access by

a serviceperson. (c) The top of the unit must be open and

unobstructed to prevent recirculation of outdoor f an discharge

air, particularly for air conditioning usage. A minimum distance

of 4 feet ov erhead clearance is recommended. Do not locate

the unit in a pit with high walls on all sides.

• Refrigerant lines should NOT be buried. (in concrete or

otherwise)

• Refer to Nordyne Application Guideline for Refrigerant Lines

Over 75 Feet document 044B-0600, for piping details

Once the above inf ormation has been confi rmed and potential

questions regarding location, refrigerant line routing, and

wire routing have been resolv ed, proceed with unpacking the

equipment. It is strongly recommended that inspection of the

hardware be performed prior to bringing it to the installation

site. Inspect for cosmetic as well as functional damage (such

as obvious holes or gaps in tubes and joints, cut or pinched

wires or wire insulation).

V erify that the iQ Drive

®

heat pump unit package includes the

following:

• Coil/compressor/control unit.

• Packet containing installation instructions and one fi lter-drier.

NOTE: The thermostat/controller which is required for

system operation is part of a separately purchased kit.

ELECTRICAL CONNECTIONS

Locate the unit away from o verhangs which would allow water

runoff or ice to fall directly onto the heat pump. Avoid placing

the unit near sidewalks or walkways to avoid possible icing

from defrost cycles. In low temperature climates, place the

unit where it is not directly in prevailing winds. Avoid placing

the heat pump near sleeping quarters or windows. As the unit

goes through defrost cycles, a change in sound will occur.

Slab Mounting

The preferred unit mounting is on an outdoor slab (concrete

or plastic), on the ground, in an area with good drainage

unlikely to be affected b y heavy runoff, ground settling, or deep

snowdrift accumulation. The support slab should be level. If

the area is subject to heavy snowfall or drift accumulation, the

use of a snow stand is recommended as well. Make sure that

the drain holes in the bottom of the unit are not obstructed.

Roof Mounting

The method used for roof mounting should be designed so

as not to overload roof structures nor transmit noise to the

interior of the structure. Refrigerant and electrical lines should

be routed through suitably waterproofed openings to prev ent

leaking into the structure. Make sure that the roof structure

can adequately support the weight of the equipment. Consult

local building codes for rooftop installations.

After a location has tentatively been selected, trace routing

of new (or pre-existing) refrigerant lines (two), and po wer and

control wiring. See further discussion below.

• Maximum recommended length for refrigerant lines: 100 ft.

• Maximum elevation diff erence, compressor base to indoor

coil base (compressor higher): 50 feet NOTE: An oil trap

is required for elevations exceeding 50 feet.

• Maximum elevation diff erence, compressor base to indoor

coil base (compressor lower): 50 feet NOTE: An oil trap is

required for elevations exceeding 50 feet.

W ARNING:

ELECTRIC SHOCK HAZARD

Disconnect all electrical power at main circuit bo x

before wiring electrical power to the outdoor unit.

Failure to follow these instructions may result in

electric shock or death.

Electrical Power Wiring

Electrical power wiring shall comply with the current

provisions of the National Electrical Code (ANSI/NFP A 70) as

supplemented by applicable local building codes . The installer

should become familiar with the wiring diagram before making

electrical connections to the outdoor unit. An equipment

wiring diagram is included in this instruction and inside the

unit control panel cover . Refer to the unit rating label located

on the exterior of the control box cover for operating voltage,

minimum circuit ampacity , and maximum fuse size. See Table

I for wire sizing.

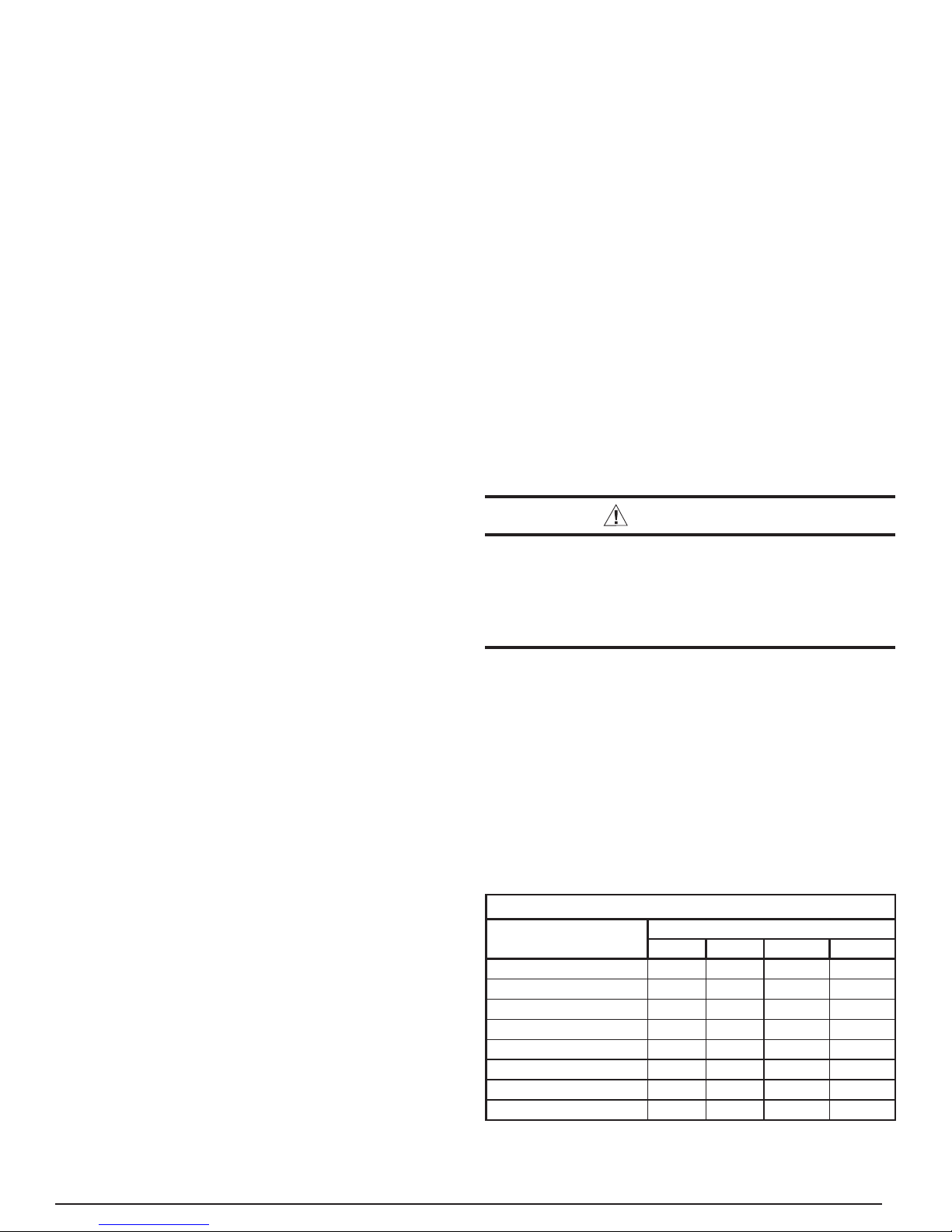

COPPER WIRE SIZE - AWG (1% Voltage Drop)

Supply Circuit Ampacity

15 14 10 8 6

20 12 8 6 4

25 10 8 6 4

30 10 6 4 4

35 8 6 4 3

40 8 6 4 3

45 6 4 3 2

50 6 4 3 2

Wire Sized based on N.E.C. for 60°C type copper conductors

up to 50 51 - 100 101 - 150 151 - 200

Table 1. Copper Wire Ampacity Tables

Supply Wire Length - Ft

3

Page 4

• A properly siz ed branch circuit and disconnect switch must

be installed where it is easily accessible and within line of

sight of the outdoor unit.

• Remove the control panel cover . Route the power and ground

wires (3 wires, including earth ground) from the disconnect

box to the unit. Use of outdoor shielded conduit (metal

lined Sealtite

®

) is required. The electrical conduit opening

is located on the lower left corner of the control box.

• Connect the power wires to L1 and L2 box lugs of the

contactor, and the ground wire to the grounding lug to the

left of the contactor. See Figures 2 and 3. Only copper wires

should be used.

• Replace the control panel cover before applying power.

Control Circuit Wiring

The heat pump is designed to operate with a 24 VAC Class

II control circuit. Control circuit wiring must comply with the

latest version of the National Electrical Code (ANSI/NFPA

70) as supplemented by local building codes.

In general, 24 VAC control power and communication bus

wiring must be run to interconnect the thermostat/controller,

the indoor unit, and the outdoor unit. The “hub” of this network

and source of the 24 VAC is located within the indoor unit (air

handler or furnace). Refer to iQ Drive System Field Wiring

Instructions, NORDYNE document 709031 shipped with the

controller, for connection of control wires to the indoor unit

and for description of other indoor fi eld wiring, including to

the controller.

Five (5) wires must be run between the indoor unit and the

outdoor unit (2 for 24 VAC pow er and 3 f or communications).

Use one shielded cable (3 or more conductors) for

communications only, and a separate cable or pair of wires

for control power . Refer to wiring diagram Figure 4 and Table

II.

1. Pass the 5 control wires into the hole in the lower right side

of the control panel of the outdoor unit, into the separate

low voltage wiring compartment. See Figures 5 and 6.

2. Locate the 5 corresponding factory-wired leads with

stripped ends. Assure that each of these 5 wires (on the

factory wiring side of the wire connections) loops around

and through the “donut” (toroidal choke). Refer to Figure

7 which shows one wire making a single loop.

3. Connect each of the 5 fi eld-run wires to its factory-wired

counterpar t using a wire nut, as indicated in Figures 4, 5

and 6.

4. Replace the control panel cover before applying power.

IMPORTANT

It is critical that the wires meant to connect to 24

vac control power (RED & GRA Y) are not mistakenly

connected to the communication bus wires (YEL,

WHT , GRN). 24 volts applied to the communication

bus will damage the equipment.

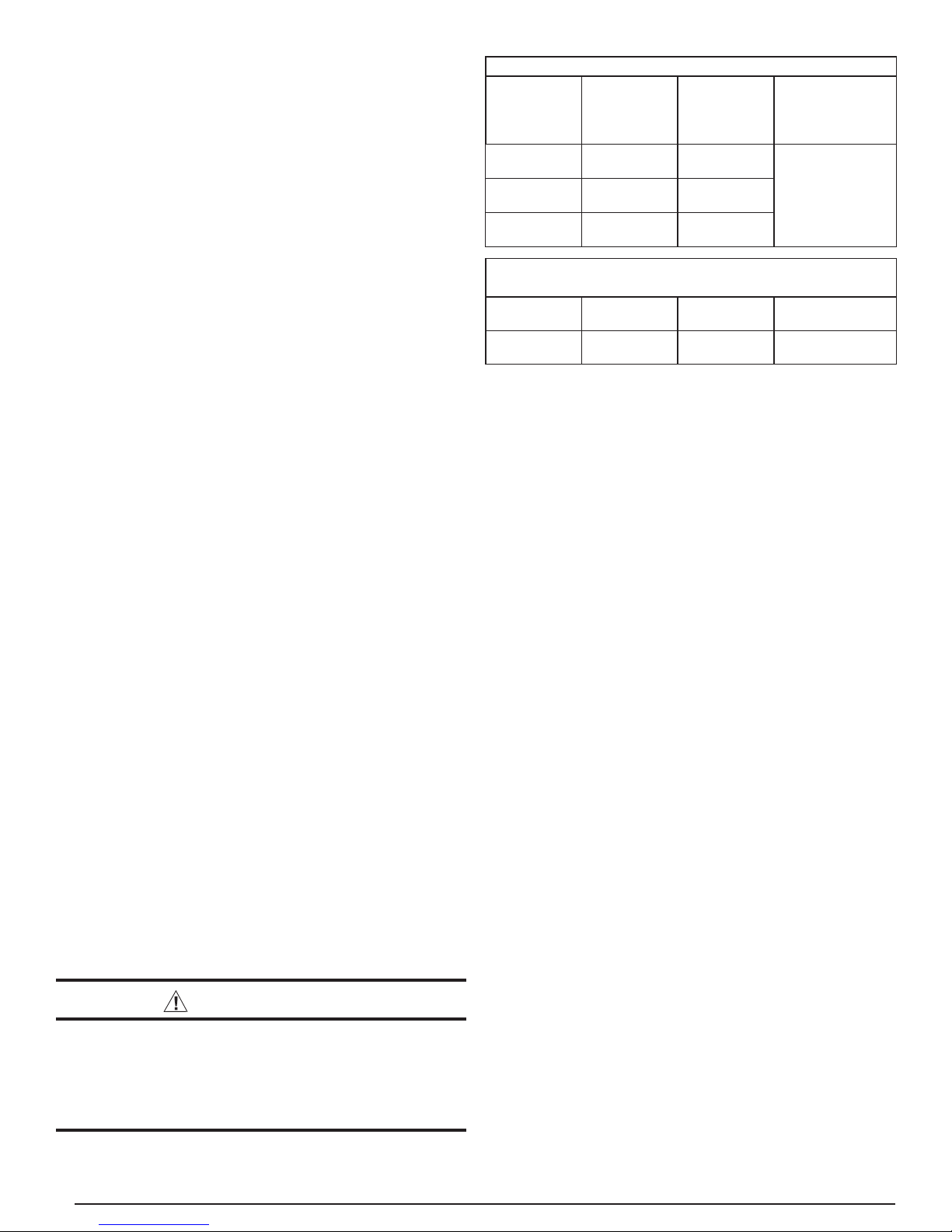

Communication Wiring

Indoor

Interface

Board

Terminal

DX+ YEL YEL

DX- WHT WHT

GND GRN GRN

R (screw)

C (screw)

Indoor

Interface

Board plug

wire color

Control Power Wiring

[no factory

wire]

[no factory

wire]

Outdoor unit

wire color

Outdoor Interface

Board Terminal

(RHS circuit

board)

3 pin 3 wire white

connector plug at

RHS circuit board

terminal

“INDOOR”

RED “R” terminal screw

GRY

(contactor coil,

RHS)

Table 2. Control Wiring to Outdoor iQ Heat Pump Unit

iQ Zone Control Wiring

For iQ Zone systems, fi eld wiring is required to connect the

Airzone control board to the iQ communication bus and to

provide a ground connection for the separate zoning control

and communication network. Refer to the iQ Field Wiring

Instruction document provided in the iQ controller kit for more

details. A 3-wire cable must be run from a splice point in the

iQ communication bus to the one 3-pin connector on the

Airzone control board.

Recheck Wiring

Check that wire routing is correct and connections are secure

for all power and control wiring.

REFRIGERANT LINE CONNECTIONS

Line Design and Routing

Refrigerant lines must be connected by a licensed EPA

certifi ed technician following sound established installation

practice. Once the heat pump location has been determined

and the unit set in place the refrigerant lines should be routed

and connected.

• Refrigerant lines should f ollow a direct path from the indoor

coil to the outdoor unit avoiding sharp bends. When lines

pass through walls, make sure to properly seal and support

them so that vibration is not transmitted to the structure.

• Refrigerant tubing should be supported in a manner which

assures that the tubing will not vibrate or wear as a result

of contact with sharp materials or edges during system

operation.

• Lines must be clean refrigeration-grade copper.

• A void removing caps and plugs from the heat pump or lines

until they are ready to be connected.

• Insulate the vapor line with refrigerant line insulation ¼” wall

thickness or greater.

Proper system performance and oil management depend on

properly selecting the liquid and vapor line sizes. Refer to T able

III for the proper size of fi eld supplied lines. The maximum

allowable refrigerant line length is 100 ft.

4

Page 5

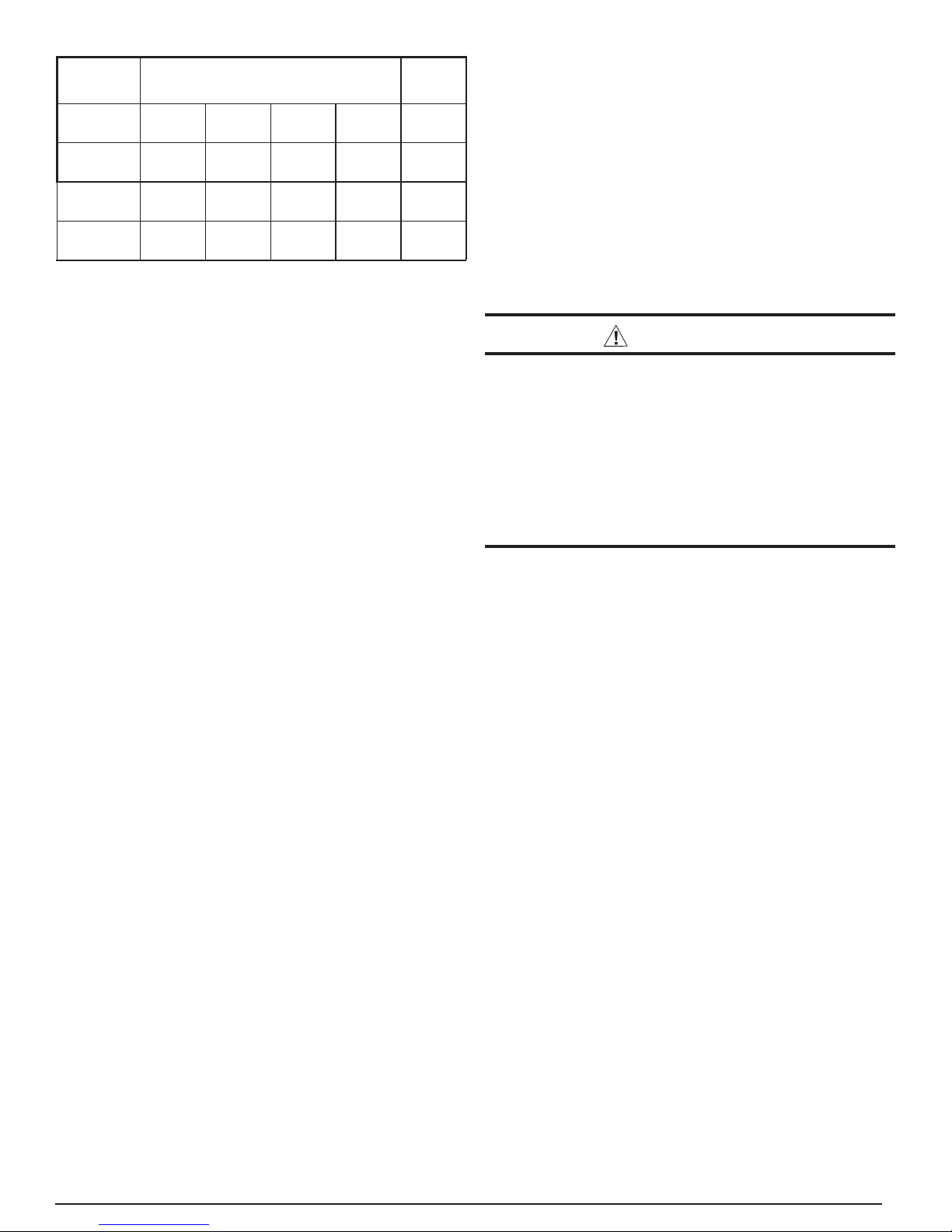

Liquid

Line

up to 100

ft.

3/8 in.

(10 mm)

3/8 in.

(10 mm)

3/8 in.

(10 mm)

Line Set

Length

-024K Units

-036K Units

-048K Units

Vapor Line

up to 24 ft. 25 to 39 ft. 40 to 75 ft.

3/4 in.

(19 mm)

7/8 in.

(22 mm)

7/8 in.

(22 mm)

3/4 in.

(19 mm)

7/8 in.

(22 mm)

1 1/8 in.

(29 mm)

7/8 in.

(22 mm)

1 1/8 in.

(29 mm)

1 1/8 in.

(29 mm)

75 to 100

ft.

1 1/8 in.

(29 mm)

1 1/8 in.

(29 mm)

1 1/8 in.

(29 mm)

Table 3. Permissible Refrigerant Line Sizes

The maximum vertical elevation between the heat pump and

indoor coil is 50 ft. Systems that require more elevation will

need to have an oil trap installed in the vapor line. Refer to

Nordyne Application Guideline for Refrigerant Lines Over 75

Feet (document 044B-0600) for piping details.

A fi lter drier is supplied with the heat pump. It is required and

recommended that it be installed near the indoor coil.

It is recommended to replace existing refrigerant lines that

were previously used f or an R-22 system. If the lines are not

replaced, they must be properly fl ushed by a licensed EPA

certifi ed technician in accordance with the manufacturer’s

instructions and established procedures.

valves and stop the vacuum pump to look for a rapid loss

of vacuum. Loss of vacuum indicates that there is a leak

in the system. Repeat the leak test if required.

3. Evacuate the system to at least 500 microns to remove

non-condensables and water vapor. Close the manifold

valves and remove the vacuum pump.

4. Connect the refrigerant tank to the center manifold port of

the gauge set. Pressurize the system enough to break the

vacuum.

5. Open both service valves by tur ning the valve stems ¼

turn counterclockwise. The stem will be in line with the

tubes. Replace the stem caps and tighten. Proceed with

Refrigerant Charging section.

W ARNING:

The heat pump system contains liquid and

gaseous refrigerant under pressure. Adjustment

of refrigerant charge should only be done by a

qualifi ed, EPA certifi ed technician thoroughly

familiar with this type of equipment. Under no

circumstances should the homeowner attempt to

install and/or service this equipment. Failure to

comply with this warning could result in equipment

damage, personal injury, or death.

Brazing

Use the appropriate safety equipment while brazing. Items

such as gloves, safety glasses, proper ventilation, and a fi re

extinguisher should be used.

1. Route the refrigerant lines from the indoor coil to the service

valves on the heat pump. Avoid sharp radius bends and

turns.

2. Make sure that the vapor line is properly insulated for the

entire length of the run for maximum system effi ciency.

Improper insulation may also create condensation and result

in water damage to the equipment and building structure.

3. Remove the valv e cores from the heat pump service v alves.

Wrap the valves completely with wet rags to protect them

from overheating during the brazing operation.

4. Connect both the vapor and liquid lines. Tubes should be

round, de-burred and free of debris. Use a phosphorous

and copper or silver brazing alloy f or the joints. Do not use

soft solder with a low melting point.

5. Connect the indoor lines according to the indoor unit

instructions. The indoor coil will require the same alloys

and wet rags to protect the sensors from excessive heat

on the refrigerant lines.

6. Allow the service valves to cool and replace the valve cores .

7. Leak test the connections using low pressure dry nitrogen.

System Evacuation

1. Connect the refr igerant gauge manifold to both the vapor

and liquid service valves. See Figure 8. Connect the center

port to the vacuum pump.

2. Open both manifold valves and start the vacuum pump.

After a short time, it is recommended to close the manifold

Refrigerant Charging

NOTE: The unit must be charged at a fi xed speed setting.

or this purpose the thermostat/controller needs to be wired

and powered prior to charging. Using the thermostat, go

to CHARGE MODE under SERVICE TESTS from the

INSTALLER SETTINGS menu, described later in this

document. Select CHARGE MODE to add or verify system

charge. In the CHARGE MODE screen, HEATING or

COOLING mode may be selected, depending upon which

mode of operation is more appropriate or convenient at the

time of charging.

NOTES:

• The heat pump is factory charged for fi eld installed lines 15

ft. in length with the matching indoor equipment. Adjustments

to the refrigerant charge will be required for other length

and tube sizes. For lines longer than 15 ft with a 3/8” OD

liquid line, add 0.52 oz. per ft.

• Small variations in the temperatures and pressures are

normal due to differences in the installation.

• Large variations in the temperatures and pressures

could indicate incorrect charge or another problem with a

component in the system.

The preferred method of charging is by weighing in the

additional refrigerant required. If a charging scale is not

available, the next preferred charging method would be to

use the sub-cooling method in cooling mode.

5

Page 6

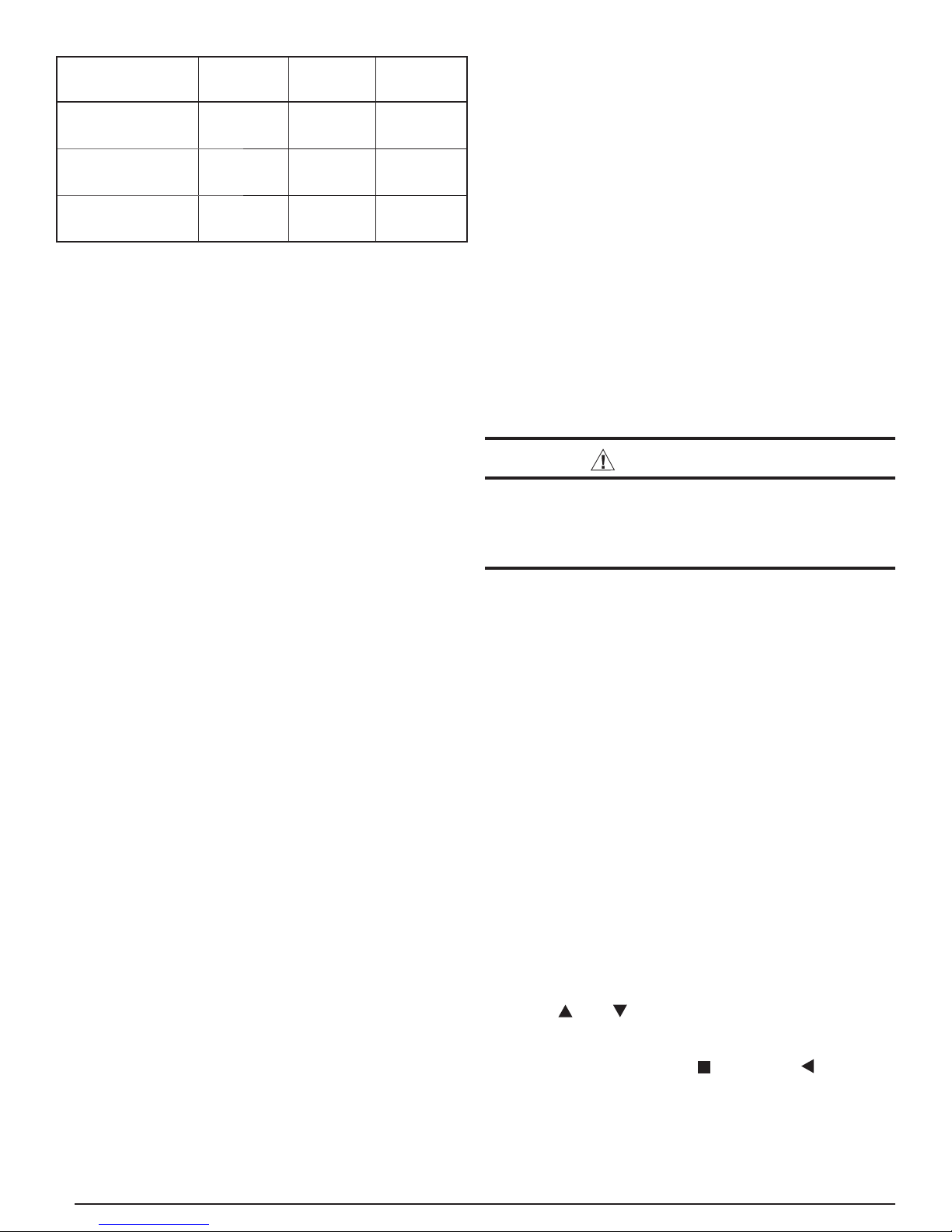

MODEL:

Factory Charge

(for 15 ft. line set)

Additional Charge

for 50 ft. line set

Additional Charge

for 100 ft. line set

2 TON

(-024K)

10.0 lbs

(160 oz)

+ 1.1 lbs

(18 oz)

+ 2.8 lbs

(44 oz)

3 TON

(-036K)

10.5 lbs

(168 oz)

+ 1.1 lbs

(18 oz)

+ 2.8 lbs

(44 oz)

4 TON

(-048K)

11.8 lbs

(188 oz)

+ 1.1 lbs

(18 oz)

+ 2.8 lbs

(44 oz)

Table 4. Refrigerant Charge Quantities

Alternate Procedure for Charging Heat Pump in

Cooling Mode (with outdoor temperatures above

60 °F) Based on Subcooling:

While charging based on weight is preferred, this method is

acceptable. Use this method when the outdoor temperature

is 60°F or higher to verify the correct charge in cooling mode.

The indoor temperature should be between 70°F and 80°F.

1. Connect the gauge manifold to the liquid and vapor service

valves (Figure 8).

2. Start the system in CHARGE MODE, COOLING. Allow

the system to run 15 minutes to stabilize.

3. Record the liquid refrigerant pressure in psig at the service

valve.

4. Record the liquid refrigerant temperature in °F at the service

valve.

5. Using the temperature value recorded, determine the

corresponding liquid refrigerant pressure from the upper

curve (for cooling) in the charging chart (Figure 9).

6. If the pressure measured in step 3 is less than the required

liquid refrigerant pressure determined in step 5, then

refrigerant needs to be added.

7. If the pressure measured in step 3 is greater than the

required liquid refrigerant pressure determined in step 5,

then the system is over-charged.

8. Add or remove charge from the system depending on the

measurements recorded. Allo w the system to stabilize f or

15 minutes before taking the next readings.

2. Start the system in CHARGE MODE, HEA TING. Allow the

system to run 15 minutes to stabilize.

3. Record the liquid refrigerant pressure in psig at the service

valve.

4. Record the liquid refrigerant temperature in °F at the service

valve.

5. Using the temperature value recorded, determine the

corresponding liquid refrigerant pressure from the lower

curve (for heating) in the charging chart (Figure 9).

6. If the pressure measured in step 3 is less than the required

liquid refrigerant pressure determined in step 5, then

refrigerant needs to be added.

7. If the pressure measured in step 3 is greater than the

required liquid refrigerant pressure determined in step 5,

then the system is over-charged.

8. Add or remove charge from the system depending on the

measurements recorded. Allo w the system to stabilize f or

15 minutes before taking the next readings.

SYSTEM SETUP USING THE IQ CONTROLLER

IMPORTANT:

It essential that the wires meant to provide 24 v olts

to the outdoor unit are not mistakenly connected to

the communication terminals. Chec k again before

you apply power!

General

Pow er up the entire system with the iQ controller (thermostat)

installed in its base. The controller will be of use to the installer

for the following general purposes:

• Confi guring the system using INSTALLER SETTINGS

screens (required)

• Running system service tests (recommended)

• Using service information screens to examine and diagnose

system operation (very helpful, if needed)

• Setting options and features which are not typically used

or understood by the homeowner (recommended)

• Setting options and features with the homeowner’ s oversight

in an effort to train him/her (suggested)

Alternate Procedure for Charging Heat Pump in

Heating Mode (with outdoor temperatures below

60 °F) Based on Subcooling:

Use this method when the outdoor temperature is 60°F or

lower to estimate the correct charge in heating mode. The

indoor temperature should be between 65° F and 75° F.

The preferred method of charging is by weighing in the

additional refrigerant required. If a charging scale is not

available , the correct charge can be estimated by this method.

Refrigerant can be stored in the receiver and accumulators

and result in an over-charged system. If it is necessary to

use this method, follow up service should be scheduled when

the temperature is above 60°F, and then charge should be

verifi ed in cooling mode.

1. Connect the gauge manifold to the liquid service valve and

suction service por t located at the left side of the access

panel above the liquid service valve. See Figure 8.

6

The following descriptions of the controller apply specifi cally

to software Version 5.0. A summary of the controller menu

structure is provided in Figures 10 & 11. NOTE: This guideline

is not intended to be a comprehensive substitute for proper

iQ Drive system training (required).

Screen Navigation

Moving between option categories on menu screens or

moving between possible values for any one option is done

using the and keys. The line or value with a dark

background behind the characters is considered “selected”.

In order to change a selected option in most screens, or to

save a changed v alue , use the

key. Use the key to back

up into the previous screen in the menu/screen structure.

The Main Screen

The Main Screen is the normal display viewed on the

controller. It prominently shows room temperature and

Page 7

operating mode (e.g., COOL or HEAT) in large numerals and

letters. Across the bottom line of the display are fi ve words

or abbreviations (normally RH TEMP MODE FAN MENU)

which represent selectable entry points into the menus. The

user can always return to the main screen from any other

screen by repeatedly pressing the

3/13/09

OUTDOOR

70

key.

12:18 PM

FAN AUTO

NOTE: It is important that any settings or service tests which

are appropriate be made at the time of system installation.

System Confi guration

Any time “CONFIGURATION NEEDED” appears at the top of

the Main Screen, the user must proceed through the SYSTEM

CONFIGURATION screens, even if no changes to values or

options are necessary. This will occur when installing a new

thermostat or moving a thermostat to a different type of iQ

system. The outdoor unit should be powered up when

confi rming or entering system confi guration.

76°

HUMIDITY

36

TEMP

MODERH

HEAT

HEAT 62

COOL 85

MENU

FAN

For iQ Zone systems with zone control enabled, the Main

Screen will appear slightly different, as shown below . The local

temperature reading is absent, and ZONE CNTL appears

under the operating mode.

1/19/09

OUTDOOR

46

10:00 AM

FAN AUTO

COOL

HUMIDITY

36

RH TEMP

ZONE CNTL

MODE MENU

FAN

With the fi rst line SYSTEM CONFIGURATION selected,

press the

key to proceed through the system confi guration

screens. The next screen, titled SYSTEM CONFIGURATION,

provides a read-only summary of the confi guration (as

detected, and otherwise showing either defaults or pre viously

confi gured information).

SYSTEM CONFIGURATION

OUTDOOR SYSTEM

2 TON

HEAT PUMP - IQ

WITH

1 STG GAS FURNACE

BLOWER TYPE B

COMMUNICATION

INDOOR UNIT - OK

OUTDOOR UNIT - OK

The words under OUTDOOR SYSTEM and WITH describe

the system components as automatically detected by the

controller. Both entries under COMMUNICATION should

show “OK”. If “CHECK” appears , it is an indication that either

communication wiring is incomplete or incorrect, or the

outdoor unit is not powered up. Proceed through subsequent

screens by using either the

or key (indicated by “NEXT”).

Installer Settings

Using procedures explained in iQ Drive training, go to the

INSTALLER SETTINGS menu screen.

INSTALLER SETTINGS

SYSTEM CONFIGURATION

ACCESSORIES

DEALER INFORMATION

SERVICE TESTS

RESTORE DEFAULTS

DEFROST CONFIG

HEAT OFF DELAY

ALTITUDE ADJUST

IQ DRIVE REV 5.0

Other than in the splash screen displayed when power is

fi rst applied to the controller, this is the only screen which

displays the controller software version number.

The following table indicates the information that may be

or needs to be manually confi gured or confi rmed by the

installer. (Information not listed is automatically determined.)

If necessary, check the ratings of the indoor unit before

proceeding.

Indoor Unit

Electric Heat

G6 gas furnace

G7 single stage gas

furnace

G7 two stage gas

furnace

Modulating MQ gas

furnace

Items Requiring Manual Confi guration

Heat type, number of stages, staging

differentials, kW

Heat type, number of stages, 1

differential, furnace input rate, furnace rise. If

2-stage: 2nd stage differential

st

stage start differential, furnace rise

1

st

stage start differential, 2nd stage differential,

1

furnace rise

Furnace rise

(or Confi rmation)

st

stage start

Table 5. System Confi guration Entry Summary

7

Page 8

For MQ modulating iQ gas furnaces only, an additional

screen titled “OUTDOOR SYSTEM” will appear after the

SYSTEM CONFIGURATION summary screen. “HEAT

PUMP-IQ” should appear on the second line; no other option

may be selected in this screen. Press the

OUTDOOR SYSTEM

HEAT PUMP - IQ

CAPACITY (TONS)

-

STAGES

-

2ND STG DIFFERENTIAL

-

AIR FLOW, CFM PER TON

-

key to proceed.

Proceed through the subsequent confi guration screens

either accepting or changing entries, until the INSTALLER

SETTINGS menu is displayed again. This is an indication

that confi guration has been completed.

Accessories

Use the or keys to select ACCESSORIES. Press the

key to enter the accessories submenus and screens. This

set of screens allows the installer to trigger alerts (reminders)

when periodic maintenance is recommended for any of the

following accessories:

• Air fi lter

• Humidifi er

• U/V lamp

• Air cleaner

Dealer Information

Use the or keys to select DEALER INFORMA TION. Press

the key to enter the dealer information summary screen,

and submenus and screens. This set of screens allows the

installer to enter text information which will be display ed on a

SERVICE NEEDED displa y screen if a persistent fault occurs.

The following items may be entered:

• Brand name (Maytag, Frigidaire, NuTone, Broan, Tappan,

Westinghouse, or custom)

• Model Number

• Contractor Name

• Contractor Phone Number

DEALER INFORMATION

BRAND NAME

MAYTAG

MODEL NUMBER

FT4BI - 048K

CONTRACTOR NAME

JOE’S HVAC

CONTRACTOR PHONE

911 - 393 - 7777

The entered dealer information summary screen accessible

here will be available for future reference by a serviceperson

(under INSTALLER SETTINGS > DEALER INFORMATION).

Entry of this information is optional.

Defrost Confi guration

Use the or keys to select DEFROST CONFIG. Press the

key to enter the screen which allows changes to:

If desired, set the maintenance alert timing for any of these

based on either hours of operation or calendar time. When

triggered by the passing of the selected time or operating

hours, the maintenance reminder message string will be

displayed on the top of the Main Screen. In addition, at the

base of the Main Screen “CANCEL ALERT” will appear. When

this is selected and the

key is pressed, the maintenance

reminder message will be removed.

ACCESSORIES

AIR FILTER

HUMIDIFIER

UV LAMP

AIR CLEANER

Making changes or entries under ACCESSORIES is optional.

• DEFROST TERMINATION TEMPERATURE. This is the

outdoor coil temperature value which, when reached during

the defrost sequence, will signal the end of the defrost phase

during which the system heats up the outdoor coil to melt

accumulated frost. (Default value is 75°F.)

• COIL DEFROST DELTA T. During heat pump heating

operation a defrost sequence will be triggered when

the outdoor coil temperature falls this amount below the

temperature it would operate at with a clear , unfrosted coil.

(Default value is 6°F.)

DEFROST CONFIG

DEFR TERMINATION TEMP

75 DEG F

COIL DEFROST DELTA T

6 DEG F

8

Page 9

Under normal circumstances it is not necessary or advisable

to change these from their default values.

Heat Off Delay

If the system includes a G6 gas furnace, you may use the

or

keys to select HEAT OFF DELAY. Press the key to

enter the screen which allows changes to the length of time

that the blower (indoor fan) will remain on after the fur nace

fl ame is extinguished. Under normal circumstances it is not

necessary or advisable to change this from its default value

of 120 seconds.

Altitude Adjust

If the system includes an iQ modulating gas furnace, you

may use the or keys to select ALTITUDE ADJUST.

Press the key to enter the screen which allows changes to

the installation altitude (feet above sea level). This entry is

advisable for the modulating gas furnace. Refer also to the

furnace Installation Instructions.

Service T ests

You may use the or keys to select SERVICE TESTS.

Press the key to enter the screen which allows access to

a list of service tests. These tests provide an easy way for

the service person to operate the system in various modes

for operational confi rmation and diagnostic troubleshooting

during installation startup. The following fi ve options are

available in the submenu.

SERVICE TESTS

CHARGE MODE

FURNACE TESTS

AIR COND RUN TESTS

HEAT PUMP RUN TESTS

DISCRETE OUTPUTS

CHARGE MODE – Runs the system at the proper speed for

checking and adjusting refrigerant charge. Select the mode as

HEATING or COOLING, then change RUN from OFF to ON.

The screen backlight will blink red. The user may navigate

to other screens (e.g., SERVICE INFORMATION) during the

process until ON in the CHARGE MODE screen is changed

back to OFF and saved. The red b linking backlight serves as

a reminder that the unit is operating in an abnormal (service)

mode. Select OFF (from the list that includes ON and OFF)

and SAVE (

) when fi nished.

FURNACE TESTS – Runs the system at the selected fi re

level to allow confi rmation of proper operation. The screen

backlight will blink red. A short list of instructions (reminders)

is provided. Select STAR T to run a single stage furnace . Select

LO FIRE or HI FIRE to run a two stage furnace. The user may

navigate to other screens (e.g., SERVICE INFORMATION)

during the process. The red blinking backlight serves as a

reminder that the unit is operating in an abnormal (service)

mode. Select DONE (from the list that includes LO FIRE, HI

FIRE, ST ART , STOP) and SA VE (

) when the test is complete,

before leaving the screen for the last time.

AIR COND RUN TESTS and HEAT PUMP RUN TESTS – In

these screens the unit can be made to run at a fi xed speed

regardless of room temperature. RUN can be changed

between OFF, MAX (speed), INTERMED(iate speed), and

MIN (speed). MAX speed is the same as that used in charge

mode. The screen backlight will blink red when anything but

OFF is selected and saved. The user may navigate to other

screens (e.g., SERVICE INFORMATION) during the process

until RUN in this screen is changed back to OFF and saved.

The red blinking backlight serves as a reminder that the unit

is operating in an abnormal (service) mode. This screen is

primarily intended for test agency usage. Heat pump run

tests apply only to heat pump units. Select OFF and SAVE

(

) when fi nished.

NOTE: While running the system from Service Tests is

convenient for some startup operations, much of the nor mal

fault handling and diagnostic message functionality is disabled.

Within each test screen there may be more than one entry which

can be changed. Select the desired entry to be modifi ed using

the

and keys. The line or v alue with a dark background

behind the characters is considered “selected”. Press the

key to allow changing the selected item (its dark backg round

will then blink). Set the desired value for the item using the

and keys, then press the key to save it.

The following is a brief description of the SERVICE TEST

categories. NOTE: With iQ Zone systems there may be a delay

before the test begins, as all zone dampers open.

For iQ heat pumps the capability to force a defrost is a vailable.

As indicated on the HEAT PUMP RUN TESTS screen, this

feature may only be used when MAX speed has been selected.

To perform a sample defrost while a MAX speed heating run

test is running, press the

key to select DEFROST NO W, then

press the ( ) key to begin the defrost. The defrost sequence

will proceed, including use of auxiliary heat while heating the

coil and the 8 minute post-defrost coil temperature calibration.

Only use this feature if the outdoor conditions are typical

heating conditions. Do not force a defrost before the system

has operated in heating for several minutes fi rst.

DISCRETE OUTPUTS – When the unit is off, this screen

allows the user to operate certain relay-driven outputs in the

system for diagnostic purposes: humidifi er (on the indoor

interface board or blower control board), reversing valve (on

the outdoor interface board), indoor coil EXV (on the indoor

interface board or blow er control board), outdoor coil EXV (on

the outdoor interface board), and crankcase heater (on the

outdoor interface board). More than one of these can be set

to ON at the same time. Lea ving the DISCRETE OUTPUTS

screen will shut all of the listed outputs off.

9

Page 10

SERVICE INFORMATION SCREENS

T ypically, when any of these service tests is being perf ormed,

the serviceperson should check operation visually , with special

instrumentation (if available), and vie w operational data on the

SERVICE INFORMATION screens. Refer to iQ Driv e training

information for how to view these screens.

SERVICE INFORMATION

FAULT STATUS

COMPRESSOR STATUS

OUTDOOR FAN STATUS

INDOOR FAN STATUS

FURNACE STATUS

TEMPERATURE STATUS

CLEAR FAULT HISTORY

CALIBRATION DATA

COMMUNICATION DATA

DEFROST STATUS

ZONING DATA

CAPACITY CONTROL

SELECT OPTION

PREVIOUS

Most of the items on the SERVICE INFORMATION menu are

self-explanatory by title. Some k ey f eatures are the f ollowing

(by item name):

FAULT STATUS – The top entry is ACTIVE FAULT. This

should show NO FAULT unless the last fault detected has

not cleared after its 5 minute lockout period, or the fault

condition still exists. The remainder of the screen shows a

history of previous faults or conditions detected, with military

time and date stamps for each. (Ha ving the correct time and

date confi gured is important in making this list useful.) Use

the

key to view the remainder of the last (most recent) 10

faults logged. Generally , fault logging is not functional during

Service T ests.

FAULT STATUS

ACTIVE FAULT

LOW PRESSURE SWITCH

FAULT HISTORY

1

LOW PRESSURE SWITCH

FLT 23:59 11/14/09

2

OD UNIT COMM FLT

#20 23:59 10/31/09

3

NO FAULT

OUTDOOR F AN ST ATUS – Any FAN ERR OR CODE number

(normally 0) will be logged in the FAULT STATUS screen in

more easily understood wording.

INDOOR FAN STATUS – The contents of this screen varies

depending on which type of blower motor is in the equipment

and whether or not iQ Zone is in use. Much of the information

is not useful to the installer.

TEMPERA TURE ST A TUS – This screen lists all temperatures

measured by the iQ system. TEMP AT TSTAT is the local

temperature used for control (when zoning is not enabled),

and it displays one decimal place without showing the decimal

point (e.g., 704 = 70.4°). In iQ Zone systems, a supply duct

temperature sensor is required, and its reading is displayed

here.

CLEAR F A UL T HIST OR Y – It is recommended that any faults

that appeared during and as a consequence of installation be

cleared out before leaving.

CALIBRA TION DA T A – A Panasonic blower can be recalibrated

any time from this screen by pressing the

key. This ma y be

done if a signifi cant change has been made to blower discharge

ducting or damper usage. This screen is not normally useful to

an installer. Data is not displayed for type “B” blower motors.

COMMUNICA TION DA T A – This important screen indicates the

status of communication with all elements on the iQ bus. All

should show OK. If not, investigate and resolve communication

wiring issues. In iQ Zone systems only, the entry ZONE BOARD

will be displayed, representing the main Airzone control board.

COMMUNICATION DATA

BLOWER

OUTDOOR

ID INTERFACE BD

OD INTERFACE BD

OK

BAD

OK

BAD

COMPRESSOR STATUS – This screen should confi rm the

confi gured size as MODEL NUMBER (20 = 2 tons, 30 = 3

tons, etc.) With correct confi guration only 20, 30, or 40 should

appear here. LOW PRESSURE SW shows the state of the

low pressure switch. Any COMPR ERROR CODE number

(normally 0) will be logged in the FAULT STATUS screen in

more easily understood wording. The displayed information

is read from the outdoor unit.

10

Page 11

DEFROST STATUS – This screen confi rms that a heat pump

is in defrost and provides detailed information helpful to

understand (a) the status of an in-progress defrost cycle and

(b) conditions which may trigger the next defrost cycle. It also

indicates the state of the reversing valve (ON for cooling or

during defrost heating). (Refer to training.)

DEFROST STATUS

DEFROST ON

DEFR STG

TARGET STEP

TIMERS:

COMP 210

OUTDOOR TEMP

OD COIL TEMP

ID COIL TEMP

CLEAR COIL DT

DEFROST COIL T

RV ON

7

9

DEFR 210

33

72

66

3

24

F

F

F

F

F

CAPACITY CONTROL

HEAT PUMP HEATING

ROOM TEMP

SP 700

USED DEMAND

STEP

COMP RPM

OD FAN RPM

ID FAN RPM

OVERRIDE ACTIVE?

MODSP

704 F

698 F

-6 F

ACT

TARG

8

2636

2640

1042 1050

910 90 0

NO

8

Other Confi guration Entries

The following settings in the controller fall into the following

categories:

ZONING DATA – This screen and its sub-screen ZONE

MODULE STATUS (accessible by pressing the key when

in the ZONING DATA screen) provide impor tant information

to help confi rm proper installation and setup of an iQ Zone

system. Among other things , the ZONING DA T A screen shows

the numbers of the zones which are active (open and in use)

and the weighting assigned to each zone.

Press the

key to view ZONE MODULE ST A TUS. During zone

system setup this screen will indicate which zone modules are

detected in the zone system communication network, which

zone each module is associated with, and any damper motor

issues. After installation of an iQ Zone system, this screen is

essential to confi rm that all module assignments have been

made and detected correctly.

ZONING DATA

ZONES ACTIVE

AZF

HEAT DEMAND

COOL DEMAND

MODE

ZONE FLAGS

ZONE WEIGHTS

ZONE 1 40

ZONE 2 25

ZONE 3 15

ZONE 4 10

OUTPUT

PREVIOUS

00100001

12345678

65

-90

400

COOL

10000001

ZONE 5 10

ZONE 6 0

ZONE 7 0

ZONE 8 0

NF

DETAILS

CAPACITY CONTROL – This screen contains information

primarily relating to the status of the outdoor iQ unit. Target

and actual speeds are shown for the compressor , outdoor fan,

and indoor blower. The line above “ROOM TEMP” displays

helpful system status messages, including whether or not the

system is dehumidifying during cooling.

• options and features which are not typically used or

understood by the homeowner, and should be examined

and considered for adjustment if desired by the installer,

including:

- minimum heat pump operating temperature

- autochangeover time

• settings which are recommended to be done by the installer,

including:

- setting date and time

• options and features which are recommended to be set with

the homeowner’s oversight, including

- selection of programmable schedule versus nonprogrammable

- usage of dehumidifi cation (enabled by default)

- humidity settings

- usage of Smart Recovery (disabled by default)

• further features which the installer may demonstrate to

the homeowner, including

- schedule, including setback temperature settings

- usage of holds

- fan options

- temperature units (°F or °C)

- USA clock or military time (12 or 24 hour)

• settings and features which are unique to the iQ Zone system

(if installed) which should be explained to the homeowner,

including

- how to disable or re-enable zone control

- ventilation (fan) options

- settings typically made at the iQ controller which do not

apply with an iQ Zone system (with zone control enabled)

- settings associated with an iQ Zone system (with

zone control enabled) which are entered at local zone

thermostats, not from the iQ controller

The above settings are described below:

Minimum Heat Pump Operating Temperature

This is the outdoor temperature (measured beneath the outdoor

unit control panel) below which, when heating is called for , the

heat pump will not operate and backup heat means (electric

heat or gas furnace) will take over. The ideal temperature

setting is the “balance point” below which it would be more

11

Page 12

economical to run the backup heat rather than the heat pump.

The default and minimum value f or this parameter is 12°F . Once

the outdoor temperature rises above this setpoint, the heat

pump will be permitted to operate again after the demand has

been satisfi ed and backup heat has shut off. (Determination

of the balance point is not simple and depends on a variety of

local factors, including the price of electricity and gas at any

particular time.)

1. From the Main Screen, press the

To modify the value, perform the following:

or key to select

MENU at the bottom of the screen, then press the key

to see the Main Menu.

2. Use the or key to select SETTINGS, then press the

key to enter the Settings menu.

3. Use the

or key to select OPTIONS, then press the

key to enter the Options screen.

PROGRAM SCHED USAGE

DEHUMIDIFICATION

AUTO CHANGEOVER TIME

SMART RECOVERY

HEAT PUMP USAGE LIMIT

OPTIONS

4 SCHED EVENTS/DAY

ON

60

OFF

NOT BELOW

MINUTES

14F

4. Use the or key to select the value under HEAT PUMP

USAGE LIMIT, then press the key to allow changing the

setting.

5. Use the or key to change the value (2°F increments),

then press the

key to save the setting.

6. Press the key multiple times to return to the Main Screen.

Auto Changeover Time

This adjustment enables AUTO mode, which allows the system

to automatically switch between heating and cooling without

having to touch the controller. Autochangeov er time is the delay

(minimum time) between the end of cooling operation and

the beginning of heating operation (or the reverse). DISABLE

removes A UTO as an available mode . Otherwise, the time may

be selected from 15 to 120 minutes (default 60 minutes).To

modify the value, perform the following:

1. From the Main Screen, press the

MENU at the bottom of the screen, then press the key

to see the Main Menu.

2. Use the or key to select SETTINGS, then press the

key to enter the Settings menu.

3. Use the or key to select OPTIONS, then press the

key to enter the Options screen.

4. Use the or key to select the value under AUTO

CHANGEOVER TIME, then press the key to allow

changing the setting.

5. Use the

or key to change the value , then press the

key to save the setting.

6. Press the

key multiple times to return to the Main Screen.

or key to select

Date and Time

Setting date and time early in the installation process not only

saves the homeowner from having to do it, but provides an

accurate time and date stamp for any faults logged (during

installation checkout, for example) in FAULT HISTORY. By

default, the clock is in 12 hour format. This ma y be changed

on the OPTIONS menu screen (see either of the above two

items). Da ylight Saving Time is automatically taken into account

but may be disabled from the SET DATE AND TIME menu

screen.

To set date and time, perform the following:

1. From the Main Screen, press the or key to select

MENU at the bottom of the screen, then press the key

to see the Main Menu.

2. SET DATE AND TIME will be selected. Press the

key

two times.

3. Enter the year, month, day (date), hour, and minute on

consecutive screens. Use the

or key to change any

value, and press the key to advance to the next. After

setting the minutes value, press the key to save the

complete setting.

4. Press the key multiple times to return to the Main Screen.

Program Schedule versus Nonprogrammable.

While using “setback” program schedules are advisable to

take advantage of potential economic and energy savings,

some homeowners still prefer to perf orm setpoint adjustment

by exclusiv ely using the

and keys. The f ollowing setting

provides the nonprogrammable option or the option f or different

numbers of events per da y (2 or 4) on the prog ram schedule.

To set the program schedule option, perform the following:

1. From the Main Screen, press the

or key to select

MENU at the bottom of the screen, then press the key

to see the Main Menu.

2. Use the

or key to select SETTINGS, then press the

key to enter the Settings menu.

3. Use the or key to select OPTIONS, then press the

key to enter the Options screen.

4. The value under PROGRAM SCHED USAGE will be

selected. Press the

key to allow changing the setting.

5. Use the or key to change the value between “NON

PROGRAMMABLE”, “4 SCHED EVENTS/D AY”, “2 SCHED

EVENTS/DA Y”, and “2 EVENTS/D BUSINESS”. Then press

the

key to save the setting. (The difference between “2

EVENTS/D BUSINESS” and “2 SCHED EVENTS/DAY”

is only the name given to the time blocks within a daily

schedule.)

6. Press the

key multiple times to return to the Main Screen.

Dehumidifi cation

When dehumidifi cation is enabled (as it is by default),

the system will (depending upon the conditions) suspend

responding to room temperature and lower blower speed to

enhance removal of moisture from the air circulating through

the indoor coil. When operating in this manner, the unit will

run cycles of 10 minutes dehumidifying, 5 minutes normal

cooling (adjusting capacity). See also setting the humidity

setpoints in (6) below . To change the dehumidifi cation option,

perform the following:

12

Page 13

1. From the Main Screen, press the or key to select

MENU at the bottom of the screen, then press the key

to see the Main Menu.

2. Use the or key to select SETTINGS, then press the

key to enter the Settings menu.

3. Use the

or key to select OPTIONS, then press the

key to enter the Options screen.

4. Use the or key to select the value under

DEHUMIDIFICATION, then press the key to allow

changing the setting.

5. Use the

(the default) and “OFF”, then press the

or key to change the value between “ON”

key to save the

setting.

6. Press the key multiple times to return to the Main Screen.

Humidity Settings

Separate setpoints for humidifi cation and dehumidifi cation are

available in units of percent RH (relativ e humidity). The humidify

setpoint only is relevant if optional humidifi er equipment has

been installed and connected to the system (the 24 vac

“H” output – See the Field Wiring Installation Instr uctions).

The installer should clarify for the homeowner that priority

is given to cooling over dehumidifying, so the ability of the

system to satisfy the RH setpoint(s) depends on a variety of

conditions. For example if the cooling load causes the unit

to run at an intermediate speed or higher, the effectiveness

of dehumidifi cation is increased.

Humidifi cation can operate when the system is heating

or the fan is set to Manual (ON) with the compressor off.

Dehumidifi cation can operate only when the system is

cooling mode, the dehumidifi cation option is enabled, and

room temperature is close to the setpoint.

To set the humidity

setpoint(s), perform the following:

1. F rom the Main Screen, press the

or key to select RH

at the bottom of the screen, then press the key to see

the Humidity screen. The current setpoints are displayed.

2. As indicated at the bottom of the screen, press the key

to enter the Humidity Settings screen.

HUMIDITY SETTINGS

HUMIDIFY

45%

DEHUMIDIFY

50%

HUMIDIFY and DEHUMIDIFY are different, and changing

one may push the other so that a minimum of 5% is

maintained between the settings. The humidify setpoint

can be set in the range 30 to 45% in increments of 5%. The

dehumidify setpoint can be set in the range 35 to 70% in

increments of 5%. Press the

key to save any changes

5. Press the key multiple times to return to the Main Screen.

Smart Recovery

When Smart Recovery is enabled, the system will start

changing the cooling or heating setpoint in advance of a

schedule change so that the room temperature is at or near

the setpoint of the subsequent schedule time block when that

time block begins. It only applies if the subsequent cooling

setpoint is lower or heating setpoint in higher. Also, if PROGRAM

SCHED USAGE is set to NON PROGRAMMABLE, this option

does not apply . T o change the smart recovery option, perform

the following:

1. From the Main Screen, press the

or key to select

MENU at the bottom of the screen, then press the key

to see the Main Menu.

2. Use the

or key to select SETTINGS, then press the

key to enter the Settings menu.

3. Use the or key to select OPTIONS, then press the

key to enter the Options screen.

4. Use the

or key to select the value under SMART

RECOVERY, then press the key to allow changing the

setting.

5. Use the or key to change the value between “OFF”

(the default) and “ON”, then press the

key to save the

setting.

6. Press the key multiple times to return to the Main Screen.

Zone Control

The installer should provide to the homeowner(s) a document

or diagram which lists or shows (a) the rooms assigned to

each zone number , (b) the weighting assigned to each z one,

(c) the zone module number associated with each supply vent.

Current date and time must be set in the iQ thermostat/controller

since they will be transmitted to, and continually updated in

the local zone thermostats. The Security Lockout feature will

not prevent changing settings in local z one thermostats in an

iQ Zone system.

Temperature units (Fahrenheit or Celsius) can be changed

as follows: Locate the set of eight microswitches on the iQ

Zone main circuit board. Disconnect control power from the

circuit board. Set micros witch #6 up (on) f or °F, down (off) for

°C. Reconnect control power.

It is recommended for the installer to instruct the homeowner(s)

on the following:

3. Use the or key to select the RH setting to change,

then press the

key to allow changes.

4. Use the or key to change the RH setting then press

the key to save the setting. The confi gurable ranges f or

For zoning operation, Operating Mode (COOL, HEAT,

AUTO, E-HEAT, or OFF) must be selected from the iQ Drive

thermostat/controller as with non-zoning systems. Ho w e v er,

the temperature setpoints that will be used are entered and

stored at the local zone thermostats. With iQ Zone systems,

13

Page 14

all settings made in the iQ thermostat/controller dealing

with temperature setpoint (temporary hold, vacation hold,

permanent hold, time schedule, smart recovery) do not apply

unless zone control is disabled. Similar f eatures are provided

and controlled at each zone independently, from the local

zone thermostats. For example, Manual Setpoint Control

replaces T emporary Hold, Automatic Setpoint Control replaces

time schedules, and Sleep Mode replaces Smart Recovery.

See the iQ Zone System Zone Thermostat User’ s Manual f or

information on these alternative features. With the iQ Zone

system a single setpoint is used for both heating and cooling,

as opposed to the standard non-zoning system, which uses

a different setpoint for each.

Zone Control is enabled by def ault if the system is equipped

with and wired for iQ Zone (the normal operating situation).

However, zone control operation can be disabled by choice,

or it may be automatically disabled if there is a problem

detected with it.

T o manually disable zone control when zoning

is already enabled:

ZONE CONTROL

ZONE CONTROL

ENABLE

MODIFY

PREVIOUS

SAVE

1. From the Main Screen select MENU using the

or button.

2. Press the

button.

3. Select SETTINGS using the or button.

4. Press the button.

5. Select ZONE CONTROL using the or button.

6. Press the button.

7. Press the

or button to change ENABLE to DISABLE.

8. Press the button to save the setting.

T o restore zone control (when the zoning system components

are functioning properly), follow the above sequence, but in

step 7 change DISABLE to ENABLE.

iQ Zone offers two types of ventilation that can be turned on

when the cooling or heating systems are not running:

• To deliver air to some but not all zones when not heating

or cooling, use the zone ventilation f eature that is set up at

the individual zone thermostats. See the iQ Zone System

Zone Thermostat User’s Manual for information on how to

set up zone-by-zone v entilation. From the F AN MENU, enter

the VENTILATION SPEED screen in the iQ thermostat/

controller to select or modify the relative speed to be used

when this type of ventilation is operating.

• To use the fan to deliver air to all zones when not heating

or cooling, set the Fan Mode to ON. The Intermittent Fan

feature described earlier will also operate, serving all zones.

Refer to the iQ Drive User’s Manual for other details relating

to zone control operation.

System Operation: Quick Start

The following is a summary of the sequence for typical operation

of the system.

1. Set the date and time (if not already set).

2. Check the program schedule for desired “setback”, and

modify if desired.

3. From the main screen, check/set the Fan operating mode:

• AUTO oper ates the fan (indoor b lower) when the unit is

cooling or heating. This is the “normal” setting.

• ON operates the fan at the selected speed at all times.

The selected speed may change when the compressor ,

electric heat, or furnace is operating.

• PROGRAMMED FAN operates the fan in A UTO or ON

as specifi ed in the program schedule.

4. From the main screen, check/set the Mode:

• COOL runs the heat pump as an air conditioner using

the cooling setpoint. (With iQ Zone, zone control enabled,

there is a single setpoint for both heating and cooling.)

• HEA T attempts to run the heat pump to provide heat using

the heating setpoint. If (a) the outdoor temperature is

below the Heat Pump Usage Limit, or (b) the heat pump

cannot satisfy the load, or (c) the heat pump is disabled

due to a fault, auxiliary (backup) heat will operate. If

backup heat is electric strip heat, it may operate along

with and supplementing the heat pump. If backup heat

is a gas furnace, the furnace and heat pump will not

operate at the same time (except during defrost). (With

iQ Zone, zone control enabled, there is a single setpoint

for both heating and cooling.)

If the outdoor coil temperature is below 35°F, demand

defrost is enabled. Under these conditions, a fi rst time

defrost will occur after approximately one half hour of

compressor operation. Subsequent defrost cycles ma y

be triggered by a drop in outdoor coil temperature or by

a maximum time between defrosts of 6 hours. Refer to

training material for details.

• E HEAT will run the auxiliary heat (electric strip heat or

gas furnace) using the heating setpoint and disable the

heat pump.

• OFF terminates any of the above.

NOTE: Equipment may not shut off immediately after

switching to OFF due to various system limitations.

Once put into the OFF mode, wait until the furnace or

compressor has shut off before selecting another mode.

14

Page 15

5. For systems without iQ Zone, adjust the operating setpoint

if desired using a temporary hold (pressing the or key

when the Main Screen is displayed). With iQ Zone, zone

control enabled, adjust the operating setpoint for each z one

individually by touching the

System Zone Thermostat User’s Manual for details.)

or icon. (Ref er to iQ Zone

System Startup Checkout & Troubleshooting

The following is a summary of the sequence for typical fi rst

operation to check out the system. Reference is made to

INSTALLER SETTINGS and SERVICE INFORMATION

described above.

1. Install system hardware as described in the individual

component installation instructions.

2. Install power and control wiring to all system components,

including the controller, in accordance with the iQ Field

Wiring Installation Instructions.

3. Perf orm pre-charge evacuation of fi eld-installed refrigerant

lines as described in preceding sections.

4. For iQ Zone systems, fi rst apply 12 volt dc power to the

zone control board with the provided AC/DC converter. Apply

electrical power to the system (including the heat pump).

The controller screen display backlight should come on,

and the “iQ” splash screen should appear. If it does not,

trace the 24 vac control power to the “R” terminal on the

thermostat. CONFIGURATION NEEDED should appear

on the top line of the Main Screen (unless the thermostat

had been previously used on a similar iQ system).

5. Proceed with System Confi guration from the INSTALLER

SETTINGS menu (described above). On the SYSTEM

CONFIGURA TION screen v erify that the using size (2 ton,

3 ton, or 4 ton) is correct as indicated. If the wrong value

is shown, the inverter may require re-initialization. Contact

the service representative of the distributor in this case.

On the same screen, the entries under COMMUNICA TION

should be followed by “OK”. If “CHECK” appears for a

communication item, go to the COMMUNICA TION ST A TUS

screen (in the SERVICE INFORMATION menu, described

above), and view which elements are not comm unicating.

T race and check the three communication wires throughout

the system. If isolating a comm unication problem proves to

be diffi cult, it may be useful to disconnect all communication

wires except those which link the thermostat and the noncommunicating element.

6. If COMMUNICA TION ST ATUS was not checked during the

previous step, check it at this time. All listed items should

show a status of “OK”. If any show “BAD”, determine the

source of the problem as indicated in the previous step,

and resolve.

7. For iQ Zone systems only, the main screen should appear

with no temperature reading, and “ZONE CTRL” should

appear below “OFF”. If this is not the case, go to the ZONE

CONTROL screen from the SETTINGS menu, and change

the zone control option to ENABLE. If ZONE CONTROL

does not show up on that menu, the iQ controller has nev er

communicated with the zone control board, and power and

communication wiring to the zone control board need to be

checked. If the main screen reverts to back to the zoningdisabled screen (showing room temperature), power and

communication wiring to the zone control board need to

be checked.

8. Set date and time as described above. This will provide a

“time stamp” for any fault which may arise during system

checkout.

9. If the installation includes a new gas furnace, check out

its operation fi rst. This may be best accomplished from

FURNACE TESTS under SERVICE TESTS from the

INSTALLER SETTINGS menu (see above). Follow steps

instructions provided in the furnace’s installation instructions.

Be sure to verify blower operation during the test.

10. If the outdoor temperature is abo ve 60°F (14°C), test the

refrigerant system running in cooling mode fi rst. If the

outdoor temperature is between 12° and 60°F (-11 and

14°C), test the refrigerant system running in heating mode

fi rst. This may best be accomplished from CHARGE MODE

under SERVICE TESTS from the INST ALLER SETTINGS

menu. Follow the refrigerant charge adjustment procedure

explained above. Note that if a fault is determined in the

outdoor equipment, the backup heating means (electric

strip heat or gas furnace) will start instead.

11. When charge adjustment is completed (if required), run

the heat pump in both cooling and heating modes. This

may also be done using SER VICE TESTS although some

diagnostic messages are disabled in that method.

12. Check the FAULT STATUS screen (described above)

for any faults logged during the startup process. Any

message listed as “ACTIVE FAULT” refers to a condition

which either still exists or occurred within the preceding 5

minutes. Every fault or notifi cation should appear in the

FAULT HISTORY log which star ts on the same screen.

The last 10 faults to have occurred are retained in this

list. Each new item pushes other logged faults down in

the list. The second line associated with each of the 10

entries includes the time and date of detection. While

the wording of fault messages is intended to provide a

reasonable indication as to the responsible condition, the

information conveyed by the abbreviated wording is limited.

Consequently the installer should refer to training literature

for further information in understanding fault messages.

13. If needed, make use of inf ormation provided below under

Troubleshooting: What to Expect with Normal Operation.

14. Independently confi rm operation of any accessories

installed with the heat pump system following instructions

provided with that equipment.

15. Complete the remainder of confi guration settings and

entries as specifi ed above under Installer Settings and

Other Confi guration Entries.

16. For iQ Zone systems, confi rm the zone system setup by

checking information on the ZONING DATA and ZONE

MODULE ST A TUS screens, accessed from the SER VICE

INFORMATION menu. (See SYSTEM DIAGNOSIS AND

TROUBLESHOOTING below.).

15

Page 16

SYSTEM DIAGNOSIS & TROUBLESHOOTING

The following is a summary of normal and abnormal operation

for typical startup to check out the system. Reference is made

to INSTALLER SETTINGS and SERVICE INFORMATION

screens described above. Refer to tr aining literature for more

details.

Diagnostic information for the heat pump can be obtained

from all of the following sources:

• Controller displays. Refer to training materials for

interpretation of fault messages which appear on the Main,

Fault Status, and Service Needed screens.