Page 1

CAUTION

Read all precautions and instructions in this manual before using

this equipment. Save this manual

for future reference.

Model No. 831.159770

Serial No.

The serial number is found in the

location shown below. Write the

serial number in the space above.

USER’S MANUAL

QUESTIONS?

As a manufacturer, we are committed to providing complete

customer satisfaction. If you

have questions, or if there are

missing parts, we will guarantee

complete satisfaction through

direct assistance from our factory.

TO AVOID DELAYS, PLEASE

CALL DIRECT TO OUR TOLLFREE CUSTOMER HOT LINE.

The trained technicians on our

customer hot line will provide

immediate assistance, free of

charge.

CUSTOMER HOT LINE:

1-888-825-2588

Mon.–Fri., 6 a.m.–6 p.m. MST

Serial Number Decal

Visit our website at

www.nordictrack.com

new products, prizes,

fitness tips, and much more!

Page 2

2

IMPORTANT PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

BEFORE YOU BEGIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CABLE DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

WEIGHT RESISTANCE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

TROUBLE-SHOOTING AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

EXERCISE GUIDELINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

ORDERING REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

Note: A PART IDENTIFICATION CHART and a PART LIST/EXPLODED DRAWING are attached in the center of

this manual. Remove the PART IDENTIFICATION CHART and PART LIST/EXPLODED DRAWING before beginning assembly.

NordicTrack is a registered trademark of ICON Health & Fitness, Inc.

TABLE OF CONTENTS

Page 3

1. Read all instructions in this manual and in

the accompanying literature before using the

weight system. Use the weight system only

as described in this manual.

2. It is the responsibility of the owner to ensure

that all users of the weight system are adequately informed of all precautions.

3. The weight system is intended for home use

only. Do not use the weight system in a commercial, rental, or institutional setting.

4. Use the weight system only on a level surface. Cover the floor or carpet beneath the

weight system to protect the floor.

5. Make sure all parts are properly tightened

each time you use the weight system.

Replace any worn parts immediately.

6. Keep children under the age of 12 and pets

away from the weight system at all times.

7. The weight system is designed to be used by

only one person at a time. The weight system is designed to support a maximum user

weight of 250 pounds.

8. Always wear athletic shoes for foot protection while exercising.

9. Always disconnect the lat bar from the

weight system when performing an exercise

that does not require it.

10. Make sure the cables remain on the pulleys

at all times. If the cables bind while you are

exercising, stop immediately and make sure

the cables are on all of the pulleys.

11. Always stand on the foot plate when performing an exercise that could cause the

weight system to tip.

12. Never release the press arm, leg lever, lat

bar, leg press, ab strap, or ankle strap while

weights are raised. The weights will fall with

great force.

13. Keep hands and feet away from moving

parts.

14. Insert the weight pin fully into the weight

stack before exercising.

15. If you feel pain or dizziness at any time while

exercising, stop immediately and cool down.

16. The warning decals

shown here have

been placed on the

weight system in the

locations shown on

page 4. Note that

decals number 2 and

3 have been placed

in two locations

each. If a decal is

missing or illegible,

please call our

Customer Service

Department toll-free

at 1-888-825-2588,

Monday through

Friday, 6 a.m. until

6 p.m. Mountain

Time, to order a free

replacement decal.

Place the decal on

the weight system in

the location shown

on page 4.

WARNING: Before beginning this or any exercise program, consult your physician. This

is especially important for persons over the age of 35 or persons with pre-existing health problems.

Read all instructions before using. ICON assumes no responsibility for personal injury or property

damage sustained by or through the use of this product.

3

WARNING: To reduce the risk of serious injury, read the following important precau-

tions before using the weight system.

Warning Decal No. 1

Warning Decal No. 2

• Keep clear of

this area.

IMPORTANT PRECAUTIONS

Keep hands and

fingers clear of

this area.

Warning Decal No. 3

Page 4

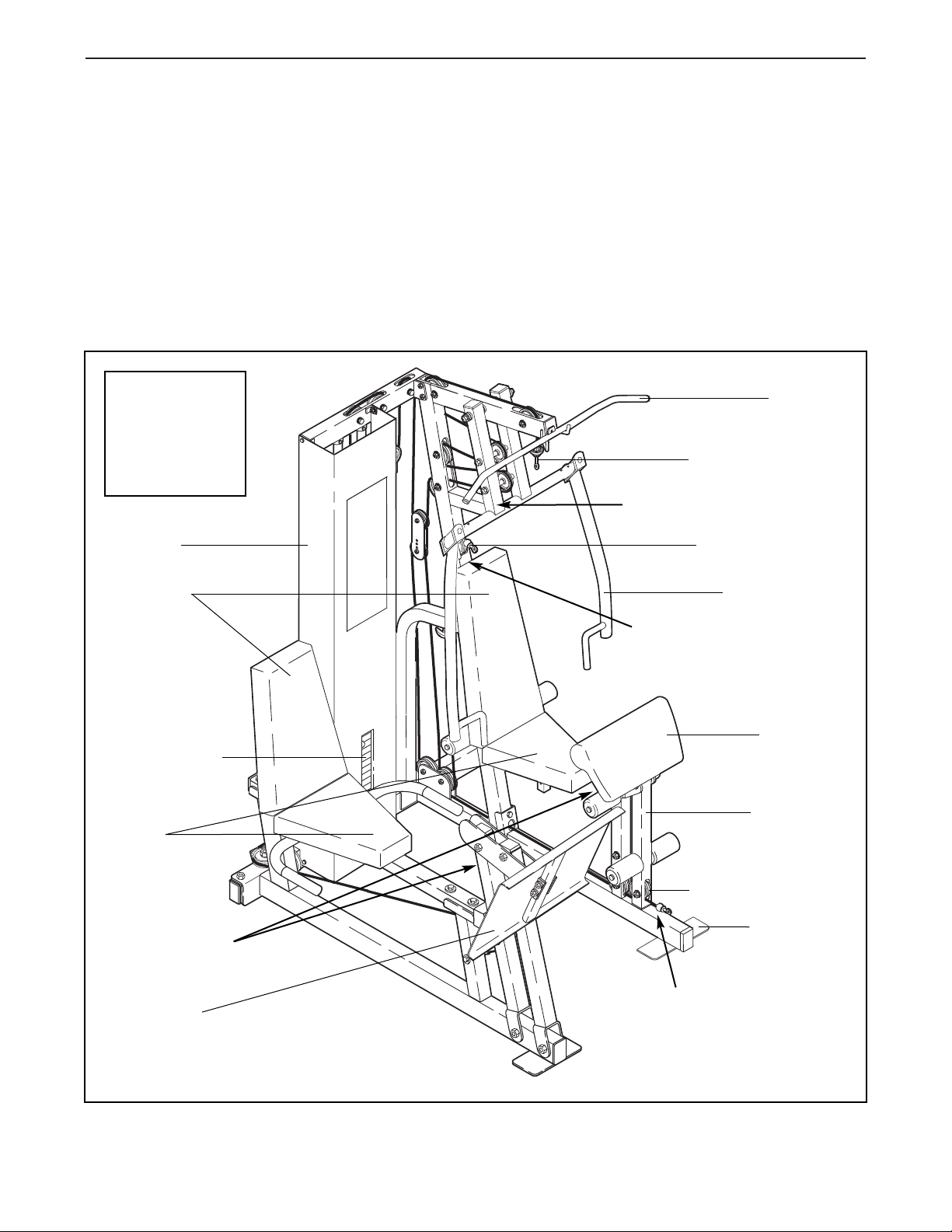

BEFORE YOU BEGIN

4

ASSEMBLED

DIMENSIONS:

Height: 81 in.

Width: 72 in.

Length: 64 in.

Low Pulley Station

Foot Plate

High Pulley Station

Curl Pad

Shroud

Seat

Leg Press

Backrest

Leg Lever

Thank you for selecting the versatile NordicTrack

®

VERTEX 670 weight system. The VERTEX 670 offers

a selection of weight stations designed to develop

every major muscle group of the body. Whether your

goal is to tone your body, build dramatic muscle size

and strength, or improve your cardiovascular system,

the VERTEX 670 will help you to achieve the results

you want.

For your benefit, read this manual carefully before

using the weight system. If you have additional ques-

tions, please call our Customer Service Department

toll-free at 1-888-825-2588, Monday through Friday,

6 a.m. until 6 p.m. Mountain Time (excluding holidays).

To help us assist you, please note the product model

number and serial number before calling. The model

number is 831.159770. The serial number can be

found on a decal attached to the weight system (see

the front cover of this manual).

Before reading further, please review the drawing below

and familiarize yourself with the parts that are labeled.

AB Pulley Station

Press/Fly Arm

Lat Bar

Weight Stack

Warning

Decal

No. 3

Warning

Decal

No. 2

Warning

Decal

No. 2

Warning

Decal

No. 1

Page 5

5

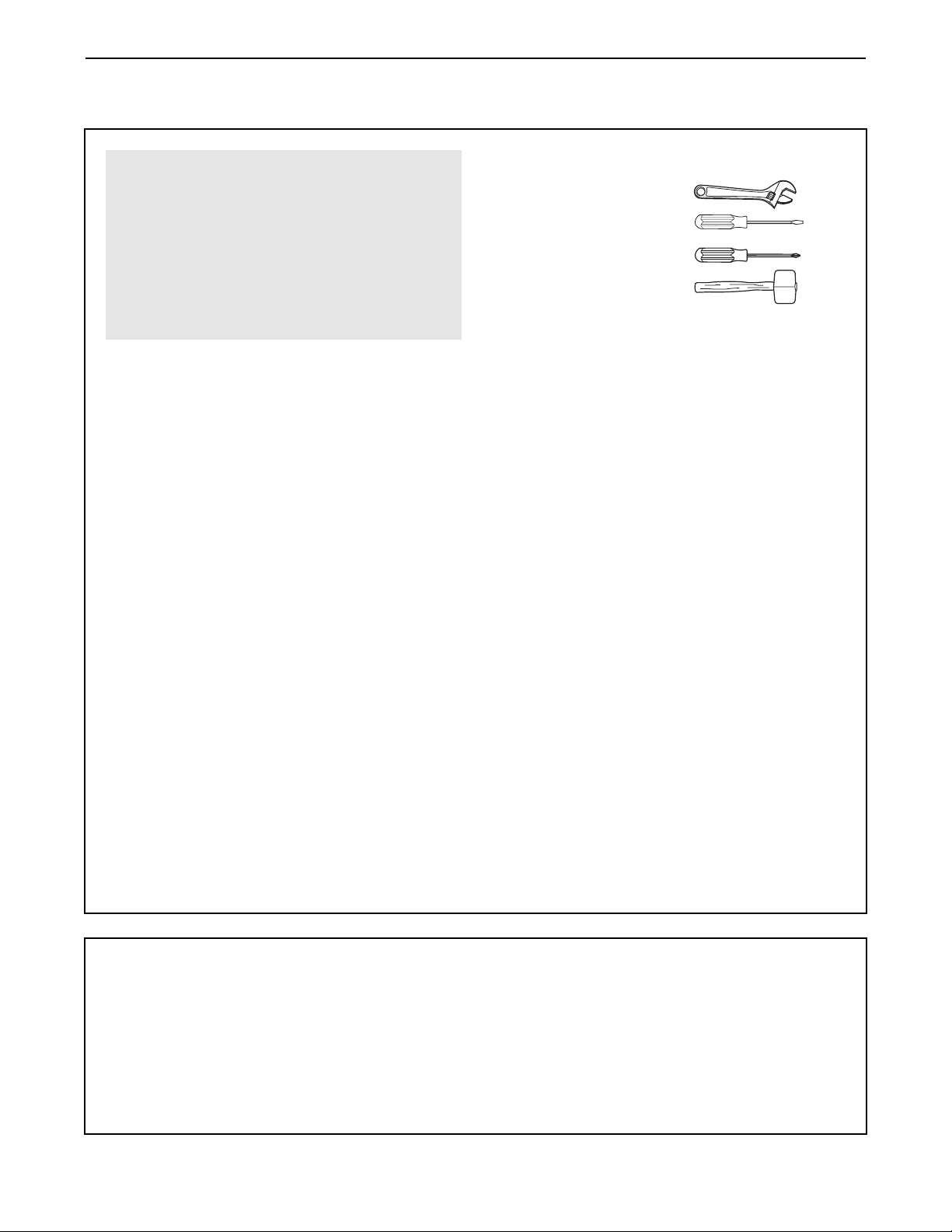

Make sure you have the following tools:

• Two adjustable wrenches

• One standard screwdriver

• One phillips screwdriver

• One rubber mallet

• You will also need grease or petroleum jelly, and a

small amount of soapy water.

Note: Assembly will be more convenient if you have

a socket set, a set of open-end or closed-end

wrenches, or a set of ratchet wrenches.

How to Identify Parts

To help you identify the small parts used in assembly,

we have included a PART IDENTIFICATION CHART

in the center of this manual. Place the chart on the

floor and use it to easily identify parts during each

assembly step. Note: Some small parts may have

been pre-attached. If a part is not in the parts

bag, check to see if it has been pre-attached.

How to Orient Parts

As you assemble the weight system, orient all parts

exactly as shown in the drawings.

Tightening Parts

Tighten all parts as you assemble them, unless

instructed to do otherwise.

Questions?

If you have questions after reading the assembly

instructions, please call our Customer Service

Department toll-free at 1-888-825-2588 Monday

through Friday, 6 a.m. until 6 p.m. Mountain Time.

Assembly Requires Two Persons

For your convenience and safety, assemble the

weight system with the help of another person.

Set Aside Enough Time

Due to the many features of the weight system, the

assembly process will require a few hours. By setting aside plenty of time and by deciding to make

the task enjoyable, assembly will go smoothly. You

may want to assemble the weight system over a

couple of evenings.

Select a Location for the Weight System

Because of its weight and size, the weight system

should be assembled in the location where it will be

used. Make sure that there is enough room to walk

around the weight system as you assemble it.

How to Unpack the Box

To make assembly as easy as possible, we have

divided the assembly process into four stages. The

parts needed for each stage are found in individual

bags. Important: Wait until you begin each stage

to open the parts bag for that stage. Place all

parts of the weight system in a cleared area and

remove the packing materials. Do not dispose of

the packing materials until assembly is completed.

Make Assembly Easier for Yourself

Everything in this manual is designed to

ensure that the weight system can be assembled successfully by anyone. Before begin-

ning assembly, make sure to read the

information on this page; this brief introduction will save you much more time than

it takes to read it.

The Four Stages of the Assembly Process

Frame Assembly—You will begin by assembling

the base and the uprights that serve as the skeleton of the weight system.

Arm Assembly—During this stage you will

assemble the press arm, leg lever, handles, and

leg press.

Cable Assembly—During this stage you will

attach the cables and pulleys that connect the

arms and other parts to the weights.

Seat Assembly—During this stage you will

assemble the seats, the backrests, the curl pad,

the shroud, and other miscellaneous parts.

ASSEMBLY

Page 6

6

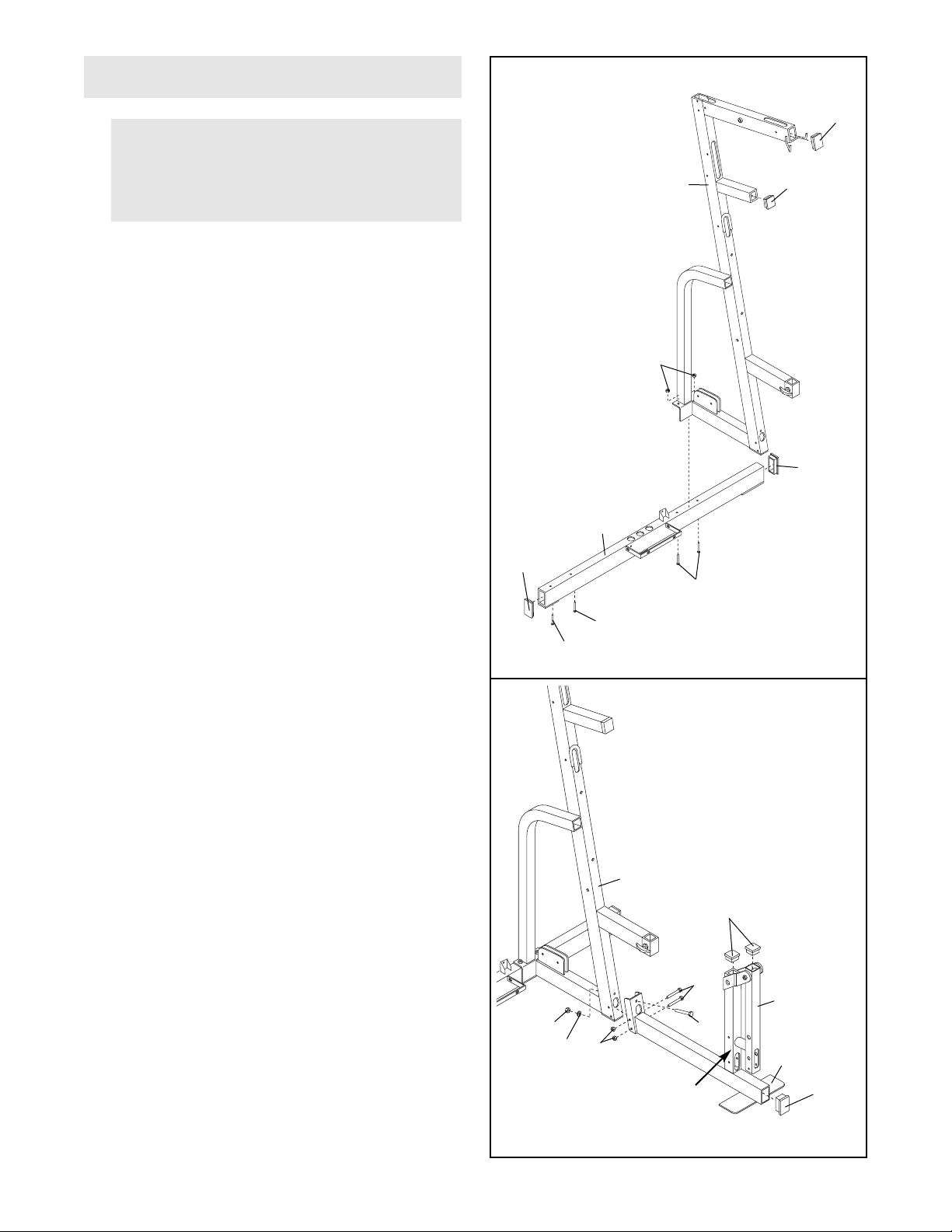

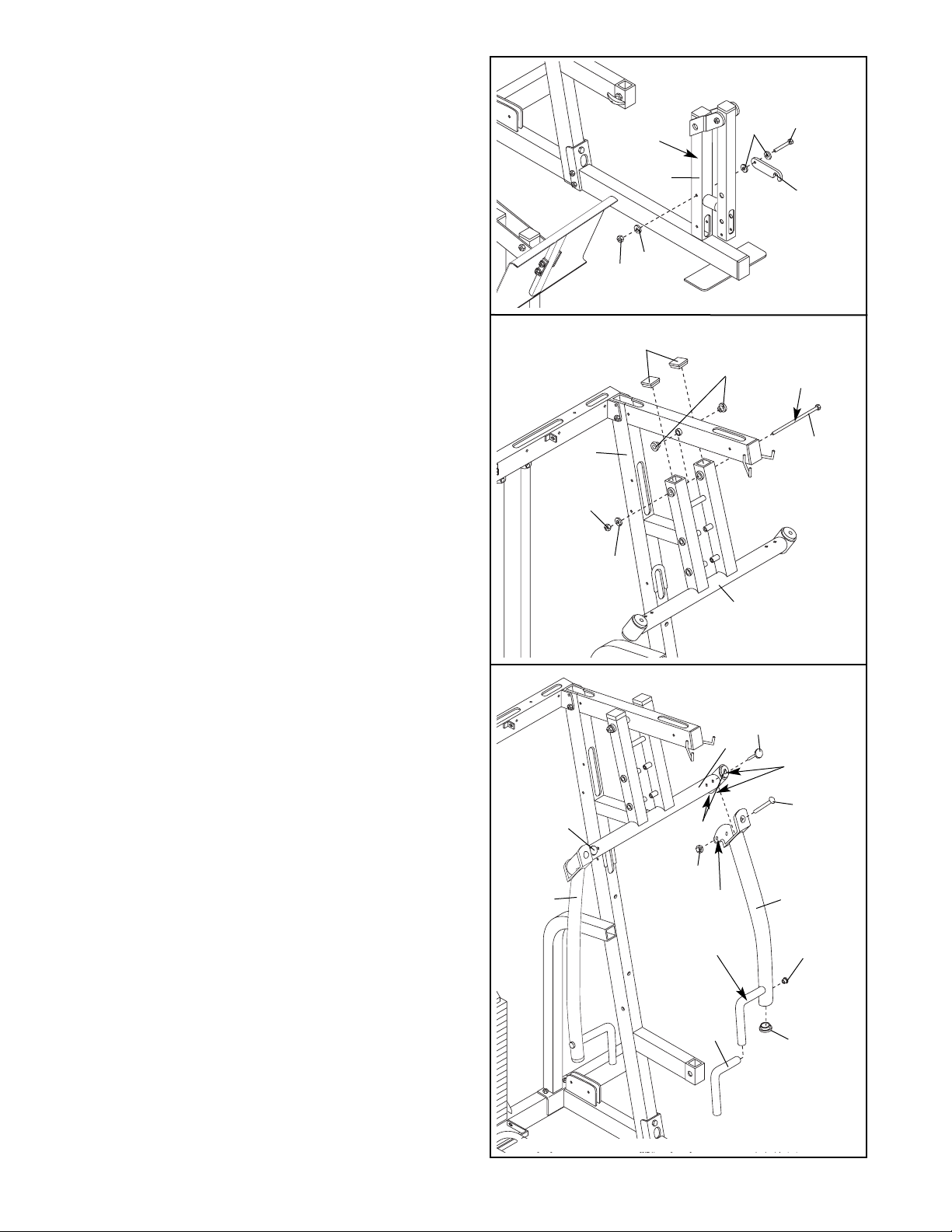

1.

Open the parts bag labeled “FRAME ASSEMBLY.”

Press two 2” x 3” Inner Caps (24) into the ends of

the Stabilizer (5). Press a 2” x 3” Inner Cap and a

2” Square Inner Cap (33) into the Main Upright

(3) in the indicated locations.

Insert three 3/8” x 3 3/4” Carriage Bolts (52) and

a 3/8” x 5” Carriage Bolt (82) into the indicated

holes in the Stabilizer (5).

Attach the Main Upright (3) to the Stabilizer (5)

with the two indicated 3/8” x 3 3/4” Carriage Bolts

(52) and two 3/8” Nylon Locknuts (50). Do not

tighten the Nylon Locknuts yet.

1

24

52

82

52

5

24

81

78

50

33

24

3

33

2. Press a 2” x 3” Inner Cap (24) into the end of the

Base (8). Press two 2” Square Inner Caps (33)

into the Leg Lever (29) and the front leg on the

Base. Note: Do not fully insert the 2” Square

Inner Cap into the Base; it will need to be

removed later to attach the Curl Post (not

shown).

Attach the Base (8) to the Main Upright (3) with a

3/8” x 4” Bolt (65), a 3/8” Washer (55), and a 3/8”

Nylon Locknut (50). The Bolt must be inserted

from the side shown. Do not tighten the Nylon

Locknut yet.

Slide two 5/16” x 3” Bolts (78) through the Base

(8) and the Main Upright (3), and hand tighten

two 5/16” Nylon Locknuts (81) onto the Bolts. Do

not tighten the Nylon Locknuts yet.

Before beginning assembly, make sure you

have read and understood the information

on page 5. This brief introduction will save

you much more time than it takes to read it.

2

65

50

55

24

29

8

Front

Leg

3

Frame Assembly

Page 7

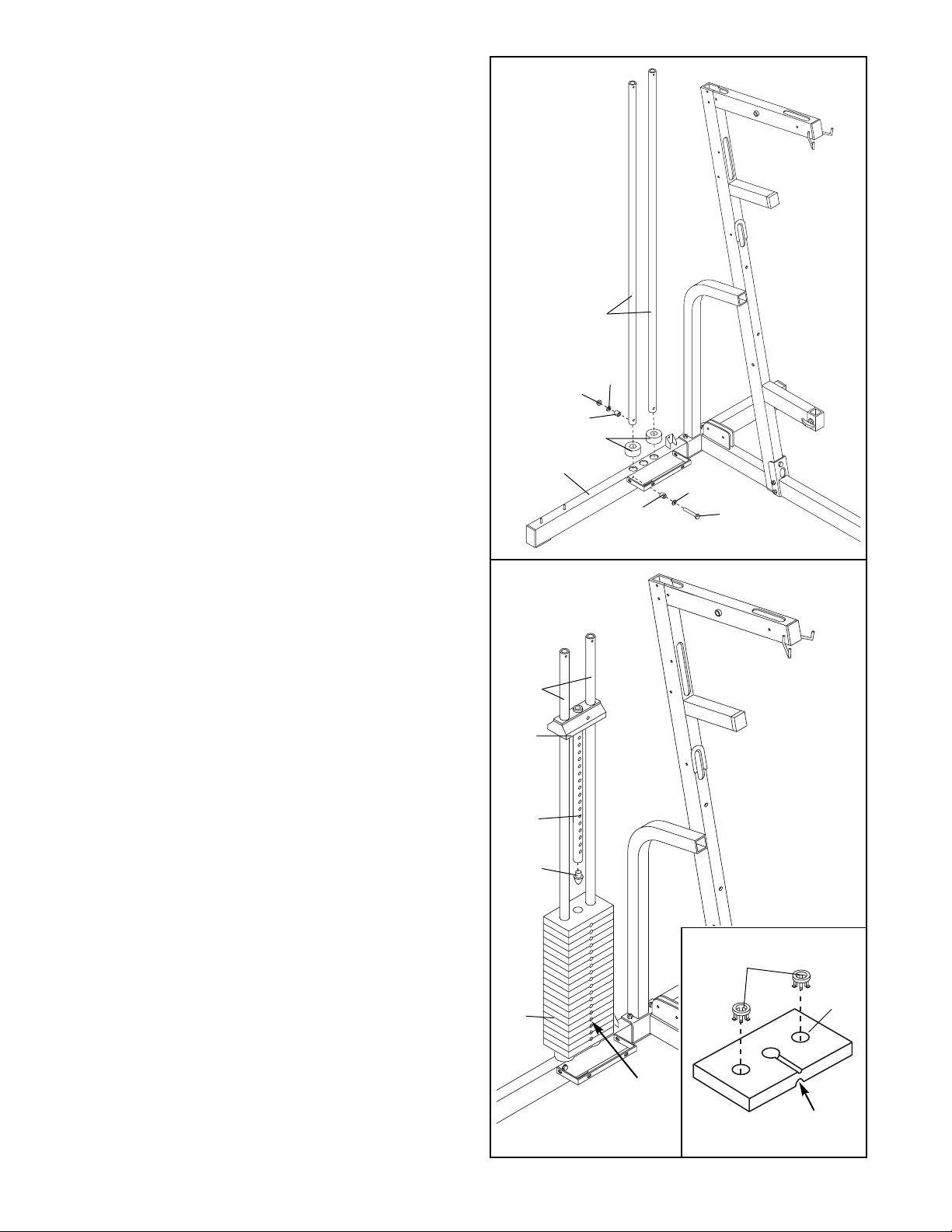

3. Place two Weight Bumpers (19) over the indicated holes in the Stabilizer (5). Insert the two

Weight Guides (23) into the Weight Bumpers and

the Stabilizer.

Attach the indicated Weight Guide (23) to the

Stabilizer (5) with a 3/8” x 2 1/2” Bolt (54), two

5/8” x 1/2” Bushings (42), two 3/8” Washers (55),

and a 3/8” Nylon Jamnut (63).

3

23

55

5

19

63

55

42

42

54

4. Open the parts bag labeled “Weight Inserts.”

See the inset drawing. Press two Weight Inserts

(77) into the indicated holes in each Weight (26).

Make sure the large pin groove is oriented as

shown.

Slide all nineteen Weights (26) onto the Weight

Guides (23). Make sure the Weights are orient-

ed correctly; the pin grooves must be on the

side shown.

Press the Weight Tube Bumper (47) into the bottom of the Weight Tube (36).

Slide the Top Weight (16) onto the Weight Guides

(23). Insert the Weight Tube (36) into the Weights

(26).

4

23

16

36

47

26

Pin

Grooves

77

26

Large Pin

Groove

7

Page 8

8

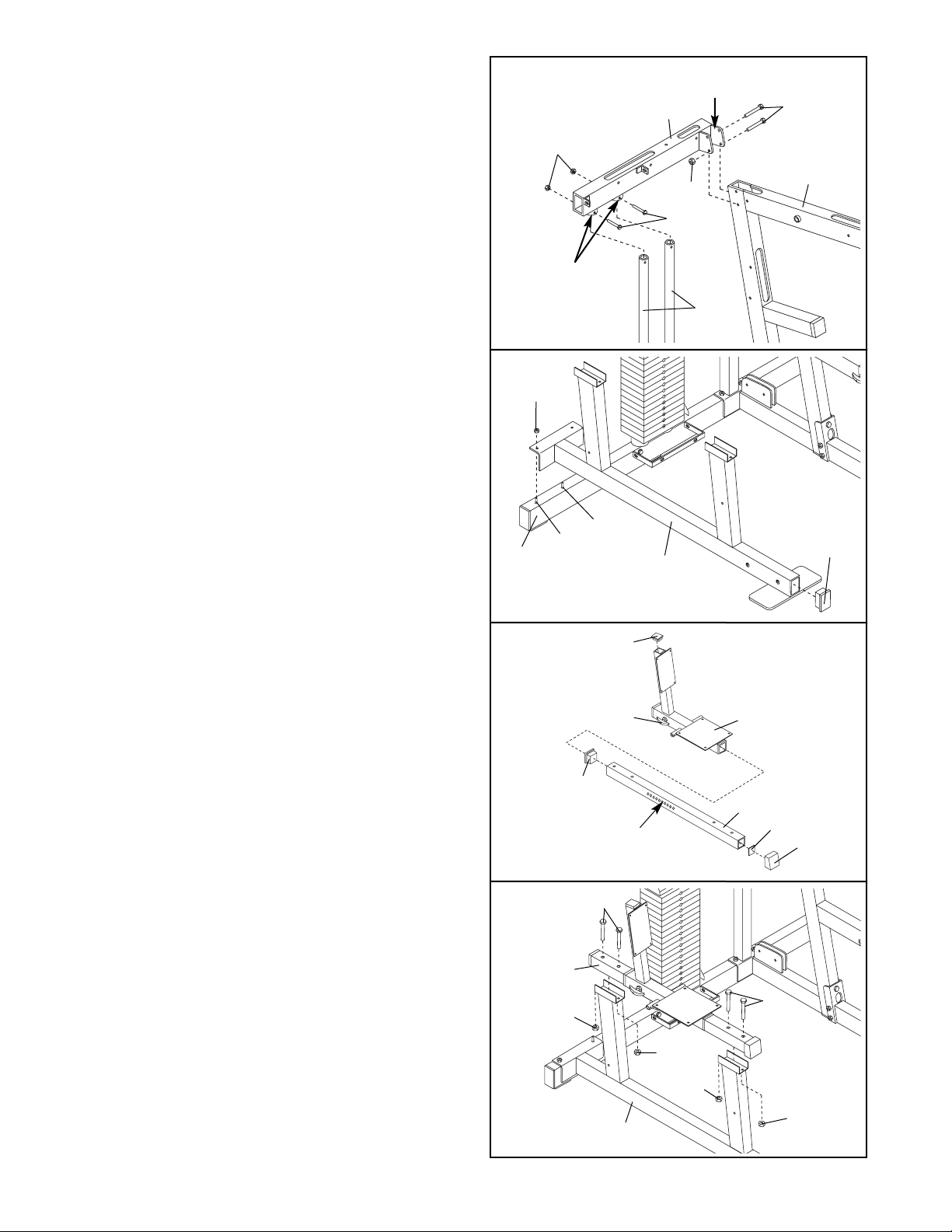

7. Turn the Adjustment Knob (9) on the Sliding Seat

Frame (74) counterclockwise to loosen it. Pull out

the Knob as far as possible and slide the Sliding

Seat Frame onto the Seat Frame Channel (88).

Release the Knob and let it engage one of the

adjustment holes in the Seat Frame Channel.

Tighten the Knob fully.

Press a 2” Square Inner Cap (33) into the top of

the Sliding Seat Frame (74). Press a 2” Square

Inner Cap into the indicated end of the Seat

Frame Channel (88). Press the Angle Cap (99)

and the Flat Plate (4) onto the other end of the

Seat Frame Channel.

7

9

99

4

88

74

33

33

Adjustment

Holes

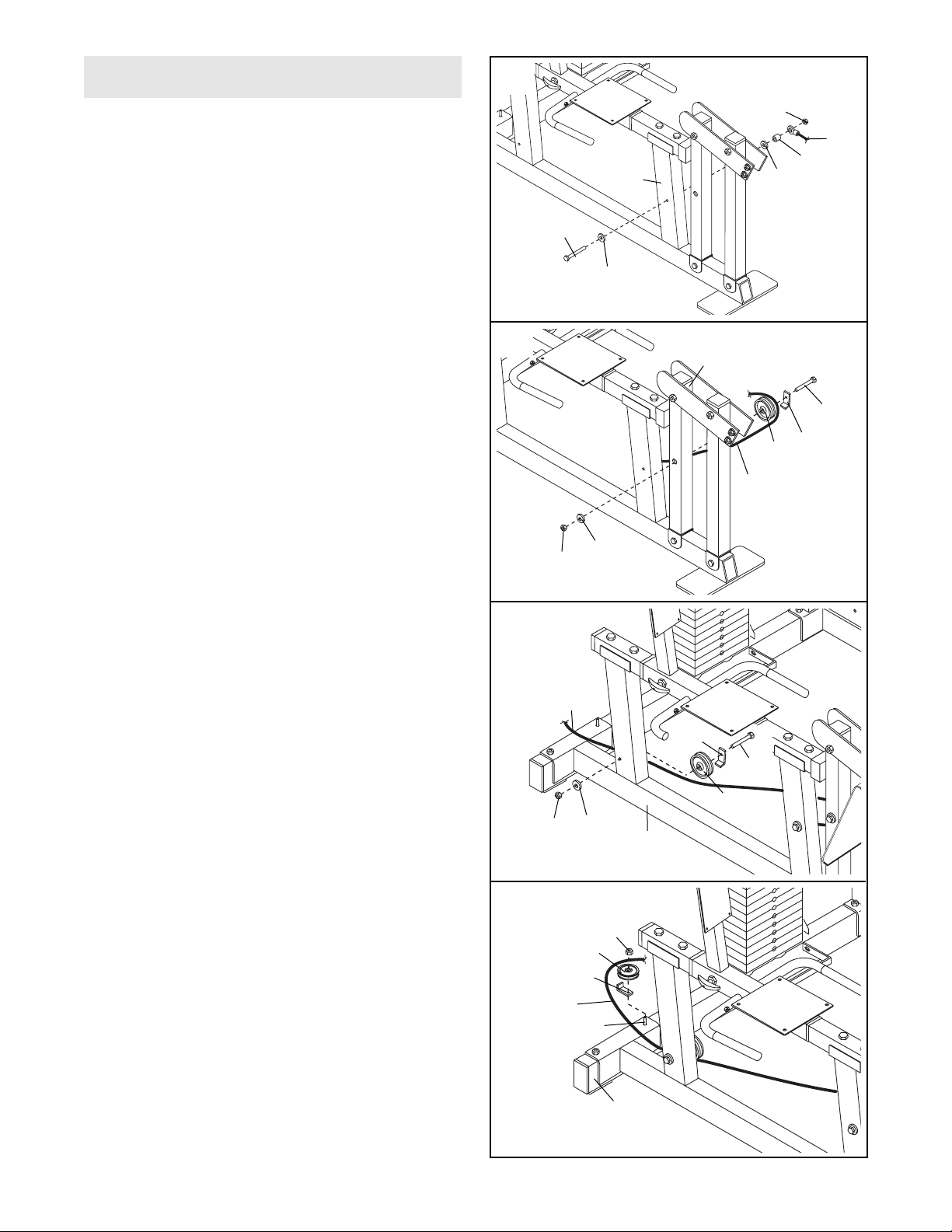

8. Attach the Seat Frame Channel (88) to the Leg

Press Base (84) with four 3/8” x 3” Carriage Bolts

(64) and four 3/8” Nylon Locknuts (50).

Tighten the 3/8” Nylon Locknuts (50) used in

steps 1 and 2.

8

64

50

50

88

84

64

50

50

45

60

1

23

50

5

50

Welded

Tubes

Bracket

3

6. Press a 2” x 3” Inner Cap (24) into the end of the

Leg Press Base (84).

Slide the Leg Press Base (84) onto the 3/8” x

3 3/4” Carriage Bolt (52) and the 3/8” x 5”

Carriage Bolt (82) in the Stabilizer (5). Tighten a

3/8” Nylon Locknut (50) onto the 3/8” x 3 3/4”

Carriage Bolt. Do not place a Nylon Locknut on

the 3/8” x 5” Carriage Bolt yet.

6

84

24

82

52

50

5

5. Slide the welded tubes on the Top Frame (1) over

the upper ends of the Weight Guides (23). Align

the bracket on the Top Frame with the indicated

holes in the Main Upright (3). Insert two 3/8” x 3”

Bolts (45) into the holes. Thread a 3/8” Nylon

Locknut (50) onto the lower Bolt. Do not thread a

Locknut onto the upper Bolt yet.

Attach the Weight Guides (23) to the Top Frame

(1) with two 3/8” x 1 3/4” Bolts (60) and two 3/8”

Nylon Locknuts (50).

Page 9

9

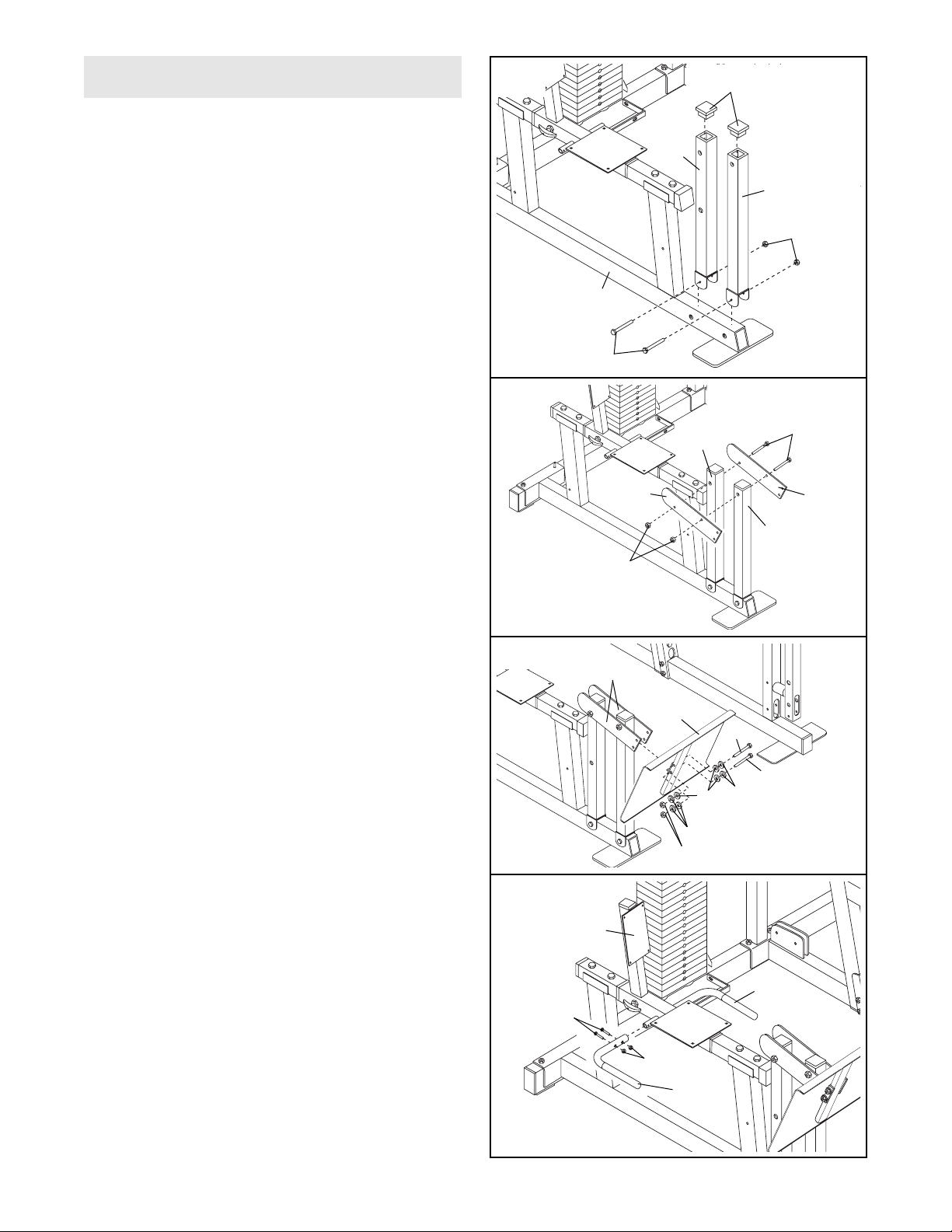

10. Attach the two Leg Press Attachments (100) to

the Rear and Forward Leg Press Uprights (97,

98) with two 3/8” x 3 1/4” Bolts (87) and two 3/8”

Nylon Jamnuts (63).

10

11. Attach the Leg Press Plate (85) to the Leg Press

Attachments (100) with two 3/8” x 3 1/4” Bolts

(87), eight 3/8” Washers (55), and two 3/8” Nylon

Jamnuts (63).

Note: All eight of the 3/8” Washers (55) must

be between the Leg Press Attachments (100)

and the welded tube on the Leg Press Plate

(85).

12. Attach a Handle (95) to the Sliding Seat Frame

(74) with two 1/4” x 1 1/2” Bolts (101) and two 1/4”

Nylon Locknuts (25).

Attach the other Handle (95) in the same manner.

101

95

85

74

11

12

25

95

9

9. Open the parts bags labeled “ARM ASSEM-

BLY.”

Attach the Rear and Forward Leg Press Uprights

(97, 98) to the Leg Press Base (84) with two 3/8”

x 3 1/4” Bolts (87) and two 3/8” Nylon Locknuts

(50). Note: The Rear Leg Press Upright (97)

has an extra hole in it.

Press two 2” Square Inner Caps (33) into the

Rear and Forward Leg Press Uprights (97, 98).

98

97

33

87

84

50

Arm Assembly

87

87

100

87

98

63

97

100

100

55

55

55

63

Page 10

10

80

80

Front

Leg

81

8

78

13. Attach the Leg Lever Lock (11) to the front leg of

the Base (8) with a 5/16” x 3” Bolt (78), three

5/16” Washers (80), and a 5/16” Nylon Locknut

(81). Do not overtighten the Nylon Locknut; the

Leg Lever Lock must pivot easily.

14

15

18

Lubricate

33

12

51

11

50

3

13

14. Press two 2” Square Inner Caps (33) into the top

of the Press Frame (12). Press two 3/4” x 1/2”

Flange Bushings (18) into the Main Upright (3).

Remove the 3/8” x 9” Bolt (51), the Large Washer

(104), and the 3/8” Nylon Locknut (50) from the

Press Frame (12). Lubricate the Bolt. Attach the

Press Frame to the Main Upright (3) with the Bolt,

Washer, and Locknut. Do not overtighten the

Bolt and Locknut; the Press Frame must be

able to pivot easily.

15. Lubricate the flat surfaces of the four Large

Bushings (48).

Attach the Left Press/Fly Arm (49) to the Press

Frame (12) with a 3/8” x 3” Carriage Bolt (64) and

a 3/8” Nylon Jamnut (63). Make sure to attach

the Left Press/Fly Arm on the correct side by

noting the position of the tab.

Press a 2” Round Inner Cap (57) and a 1” Round

Inner Cap (103) into the Left Press/Fly Arm (49).

Wet the handle on the Left Press/Fly Arm (49)

with soapy water. Slide an Arm Grip (58) onto the

handle.

Insert an Adjustment Pin (20) into the Press

Frame (12) and the hole in the tab on the Left

Press/Fly Arm (49).

Repeat this step with the Right Press/Fly Arm

(46).

104

20

Lubricate

Ta b

Handle

48

20

12

57

103

63

64

58

46

49

Page 11

18. Route the Leg Press Cable (76) under a 4” Pulley

(35). Attach the Pulley and a Cable Trap (44) to

the Leg Press Base (84) with a 3/8” x 3 3/4” Bolt

(92), a 3/8” Washer (55), and a 3/8” Nylon

Locknut (50). Be sure that the Cable Trap (44)

is positioned to hold the Cable in the pulley

groove.

19. Wrap the Leg Press Cable (76) around a 4”

Pulley (35). Attach the Pulley and a Cable Trap

(44) to the 3/8” x 5” Carriage Bolt (82) in the

Stabilizer (5) with a 3/8” Nylon Locknut (50).

Be sure that the Leg Press Cable (76) is routed in the direction shown, and that the Cable

Trap (44) is positioned to hold the Cable in the

pulley groove.

17. Wrap the Leg Press Cable (76) up around a 4”

Pulley (35). Attach the Pulley and a Cable Trap

(44) to the Rear Leg Press Upright (97) with a 3/8”

x 3 3/4” Bolt (92), a 3/8” Washer (55), and a 3/8”

Nylon Locknut (50).

Be sure that the Leg Press Cable (76) is routed in the direction shown, and that the Cable

Trap (44) is positioned to hold the Cable in the

pulley groove.

17

55

44

97

35

76

50

18

44

84

76

55

92

50

19

76

50

35

82

5

44

16. Open the parts bags labeled “CABLE ASSEM-

BLY” and “4 PULLEYS.” Refer to the CABLE

DIAGRAM on page 21 to identify the cables

and for correct cable routing.

Locate the Leg Press Cable (76). Attach the Leg

Press Cable to the indicated hole in the Leg

Press Base (84) with a 3/8” x 3” Bolt (45), two

3/8” Washers (55), a 5/8” x 1/4” Bushing (90), and

a 3/8” Nylon Jamnut (63).

16

55

55

76

90

84

63

45

11

92

35

Cable Assembly

Page 12

21. Remove the pre-assembled 4” Pulley (not shown)

from the Pulley Bracket (91).

Attach the end of the Leg Press Cable (76) to the

Pulley Bracket (91) with a 1/4” Washer (71) and a

1/4” Nylon Locknut (25).

Lay the Pulley Bracket (91) and the Leg Press

Cable (76) aside; they will be attached in step

29.

21

71

25

91

76

20. Wrap the Leg Press Cable (76) around a 4”

Pulley (35). Attach the Pulley and a Cable Trap

(44) to the bracket on the Stabilizer (5) with a 3/8”

x 2” Bolt (62) and a 3/8” Nylon Locknut (50).

Be sure that the Cable Trap (44) is positioned

to hold the Cable in the pulley groove.

20

50

62

12

22. Locate the High Cable (73). Feed the bolt end of

the High Cable up through the indicated slot in

the Main Upright (3). Feed almost all of the Cable

through the slot.

Slide a 3/8” Washer (55) and a 5/8” x 1/2” Bushing

(42) onto a 3/8” x 2 1/2” Bolt (54).

Wrap the High Cable (73) around a 4” Pulley (35).

Hold the Pulley inside the indicated slot in the

Main Upright (3). Insert the 3/8” x 2 1/2” Bolt (54)

through the Main Upright and the Pulley.

Slide another 5/8” x 1/2” Bushing (42) and 3/8”

Washer (55) onto the 3/8” x 2 1/2” Bolt (54).

Tighten a 3/8” Nylon Jamnut (63) onto the Bolt.

22

Slot

35

73

55

54

42

55

3

42

63

35

76

5

44

Bracket

Page 13

13

23. Remove the upper 3/8” x 3” Bolt (45) from the

Top Frame (1) and the Main Upright (3).

Route the High Cable (73) around a 4” Pulley

(35) and down through the indicated slot in the

Main Upright (3), as shown. Attach the Pulley

inside the slot with a 3/8” x 2 1/2” Bolt (54), two

3/8” Washers (55), two 5/8” x 1/2” Bushings (42),

and a 3/8” Nylon Jamnut (63).

Re-insert the 3/8” x 3” Bolt (45) and secure it with

a 3/8” Nylon Locknut (50). Note: The High Cable

(73) must be seated in the groove of the 4”

Pulley (35) before the Bolt is inserted.

23

Slot

35

73

55

54

42

55

3

42

63

45

50

1

25. Wrap the High Cable (73) around a 4” Pulley (35).

Attach the Pulley inside the indicated slot in the

Main Upright (3) with a 3/8” x 2 1/2” Bolt (54), two

3/8” Washers (55), two 5/8” x 1/2” Bushings (42),

and a 3/8” Nylon Jamnut (63).

Wrap the High Cable (73) around another 4” Pulley

(35) in the direction shown. Route the High Cable

through the slot in the Main Upright (3). Attach the

Pulley to the Press Frame (12) with a 3/8” x 8 1/2”

Bolt (59) and a 3/8” Nylon Locknut (50).

24

25

73

Welded Tube

50

50

35

59

73

42

42

63

55

55

54

59

3

12

35

12

Slot

35

24. Route the High Cable (73) under the welded tube

on the Press Frame (12) and around a 4” Pulley

(35) as shown. Attach the Pulley to the Press

Frame with a 3/8” x 8 1/2” Bolt (59) and a 3/8”

Nylon Locknut (50).

Page 14

14

26. Wrap the High Cable (73) around a 4” Pulley (35).

Attach the Pulley inside the slot in the Main

Upright (3) with a 3/8” x 2 1/2” Bolt (54), two 3/8”

Washers (55), two 5/8” x 1/2” Bushings (42), and

a 3/8” Nylon Jamnut (63).

26

55

42

63

3

35

42

55

54

73

27. Disassemble the pre-assembled Pulley Plates (31).

Wrap the High Cable (73) around a 4” Pulley (35)

in the direction shown. Attach the Pulley and a

Cable Trap (44) to the top set of holes in the end

of the Pulley Plates (31) with a 3/8” x 1 3/4” Bolt

(60) and a 3/8” Nylon Jamnut (63). Make sure

the Cable is in the groove of the Pulley and

that the Cable Trap is oriented to hold the

Cable in place.

27

73

60

44

35

31

63

28. Route the High Cable (73) up through the indicated slot in the Top Frame (1), over a 4” Pulley

(35), and back down through the Top Frame.

Attach the 4” Pulley (35) inside the slot in the Top

Frame (1) with a 3/8” x 2 1/2” Bolt (54), two 3/8”

Washers (55), two 5/8” x 1/2” Bushings (42), and

a 3/8” Nylon Jamnut (63).

28

1

35

42

55

54

63

42

73

55

Slot

Page 15

15

29. Wrap the High Cable (73) around a 4” Pulley

(35). Attach the Pulley and a Cable Trap (44) to

the top hole in the Pulley Bracket (91) attached to

the Leg Press Cable (76), with a 3/8” x 1 3/4”

Bolt (60) and a 3/8” Nylon Jamnut (63).

30. Route the High Cable (73) up through the next

slot in the Top Frame (1) and wrap the Cable

around a 4” Pulley (35) in the direction shown.

Attach the 4” Pulley (35) to the Top Frame (1)

with a 3/8” x 2 1/2” Bolt (54), two 3/8” Washers

(55), two 5/8” x 1/2” Bushings (42), and a 3/8”

Nylon Jamnut (63).

29

30

44

63

73

73

1

35

63

55

55

42

35

31. Route the High Cable (73) around a 4” Pulley

(35) and down through the indicated slot in the

Top Frame (1).

Attach the 4” Pulley (35) to the Top Frame (1)

with a 3/8” x 2 1/2” Bolt (54), two 3/8” Washers

(55), two 5/8” x 1/2” Bushings (42), and a 3/8”

Nylon Jamnut (63).

Let the High Cable (73) hang over the weight

stack; it will be attached in step 38.

31

42

42

35

54

55

55

63

73

1

60

76

91

32. Locate the Low Cable (72), which has a ball on

each end. Route the Low Cable through the slots

in the Leg Lever (29) and the Base (8).

Attach a 4” Pulley (35) inside the Leg Lever (29)

with a 3/8” x 2 1/2” Bolt (54), two 3/8” Washers

(55), two 5/8” x 1/2” Bushings (42), and a 3/8”

Nylon Jamnut (63).

Attach the 1/2” x 1 3/4” Bushing (94) inside the

bottom of the Leg Lever (29) with a 5/16” x 2 1/2”

Bolt (96), two 5/16” Washers (80), and a 5/16”

Nylon Jamnut (79). Press a 2” Square Inner Cap

(33) into the bottom of the Leg Lever. Note: It

may be easier to attach the 2” Square Inner

Cap if you pivot the Leg Lever upward.

32

55

42

42

72

29

8

63

79

80

94

33

80

96

55

54

35

54

Page 16

16

50

372

8

35

62

Slot

33. Attach a 4” Pulley (35) over the Low Cable (72),

inside the front leg of the Base (8) with a 3/8” x

2 1/2” Bolt (54), two 3/8” Washers (55), two 5/8” x

1/2” Bushings (42), and a 3/8” Nylon Jamnut (63).

34. Route the Low Cable (72) through the indicated

slot in the Main Upright (3) and the Base (8).

Wrap the Low Cable (72) around a 4” Pulley (35)

in the direction shown. Attach the Pulley inside

the bracket on the Main Upright (3) with a 3/8” x

2” Bolt (62) and a 3/8” Nylon Locknut (50).

35. Wrap the Low Cable (72) over a 4” Pulley (35).

Slide the Pulley and a Cable Trap (44) between the

two Pulley Plates (31). Make sure the Cable is in

the groove of the Pulley and that the Cable Trap

is oriented so it will hold the Cable in place.

Attach the 4” Pulley (35) and the Cable Trap (44)

to the third set of holes from the bottom of the

Pulley Plates (31) with a 3/8” x 1 3/4” Bolt (60)

and a 3/8” Nylon Jamnut (63).

34

33

63

54

8

42

42

55

55

72

35

Bracket

31

35

72

35

44

60

63

36. Wrap the Low Cable (72) around a 4” Pulley (35).

Attach the Pulley inside the bracket on the Main

Upright (3) with a 3/8” x 2” Bolt (62) and a 3/8”

Nylon Locknut (50).

36

3

50

72

62

35

Page 17

37. Route the end of the Low Cable (72) through the

indicated slot in the Main Upright (3).

Wrap the Low Cable (72) around a 4” Pulley (35).

Attach the Pulley inside the slot in the Main

Upright (3) with a 3/8” x 2 1/2” Bolt (54), two 3/8”

Washers (55), two 5/8” x 1/2” Bushings (42), and

a 3/8” Nylon Jamnut (63).

37

Slot

63

42

55

35

42

72

3

55

54

17

38. IMPORTANT: Follow the cables from end to

end; make sure that they are in the grooves of

the pulleys and that the cables and pulleys

move smoothly.

Thread the 1/2” Plain Nut (68) part way onto the

bolt at the end of the High Cable (73). Place the

1 1/2” Washer (40) on top of the Weight Tube

(36).

Insert the bolt on the High Cable (73) through the

ring on the Weight Pin (39) and into the threaded

hole in the Weight Tube (36). Tighten the bolt into

the Weight Tube until the Cables (73, 72, 76) are

tight.

Tighten the 1/2” Plain Nut (68) against the 1 1/2”

Washer (40).

38

Bolt

36

76

39

72

40

68

73

9

39. Open the parts bag labeled “ARM AND SEAT

ASSEMBLY.”

Attach a Seat (13) to the Seat Upright (37) with

four 1/4” x 3/4” Bolts (17).

Turn the Adjustment Knob (9) on the Main Upright

(3) counterclockwise to loosen it and pull it out as

far as possible. Slide the Seat Upright (37) into

the Main Upright. Release the Knob and let it

engage one of the adjustment holes in the Seat

Upright. Retighten the Knob.

13

3

17

37

17

39

Seat Assembly

Adjustment

Holes

Page 18

18

40. Insert a 1/4” x 3 3/4” Carriage Bolt (43) into each

Backrest Plate (27). Attach the Backrest Plates to

the Backrest (41) with four 1/4” x 3/4” Bolts (17).

Attach the Backrest (41) to the Main Upright (3)

with the two 1/4” x 3 3/4” Carriage Bolts (43), two

1/4” Washers (71), and two 1/4” Nylon Locknuts

(25). Be sure the Backrest is oriented as

shown.

40

17

43

43

17

41

3

71

71

25

25

41. Attach the other Seat (13) to the Sliding Seat

Frame (74) with four 1/4” x 3/4” Bolts (17).

42. Attach the Leg Press Backrest (70) to the Sliding

Seat Frame (74) with four 1/4” x 3/4” Bolts (17).

41

42

13

74

70

74

17

17

17

43. Press four 3/4” Round Inner Caps (34) into the

ends of two Pad Tubes (28).

Slide a Pad Tube (28) through the hole in the

front leg on the Base (8). Slide two Foam Pads

(30) onto the ends of the Pad Tube.

Slide the other Pad Tube (28) through the hole in

the Leg Lever (29). Slide two Foam Pads (30)

onto the ends of the Pad Tube.

34

8

29

34

30

28

34

30

30

43

Page 19

19

44

45

34

34

56

32

38

38

5

Bracket

32

3

44. Press two 3/4” Round Inner Caps (34) into the

ends of the remaining Pad Tube (28).

Slide the Pad Tube (28) through the hole in the

Main Upright (3). Slide two Foam Pads (30) onto

the ends of the Pad Tube.

45. Slide the two Tinnerman Clips (38) down over the

slots in the bracket on the Stabilizer (5).

Attach the lower end of the Shroud (56) to the

bracket on the Stabilizer (5) with two #8 x 3/4”

Screws (32). The Screws must be inserted

through the square holes in the Shroud and into

the Tinnerman Clips (38).

30

30

28

Page 20

20

48. Make sure that all parts have been properly tightened. The use of the remaining parts will be explained in

ADJUSTMENTS, beginning on page 22 of this manual.

Before using the weight system, pull each cable a few times to make sure that the cables move smoothly

over the pulleys. If one of the cables does not move smoothly, find and correct the problem. IMPORTANT: If

the cables are not properly installed, they may be damaged when heavy weight is used. If there is

any slack in the cables, you will need to remove the slack by tightening the cables. See TROUBLESHOOTING AND MAINTENANCE on page 25.

46. Attach the upper end of the Shroud (56) to the

two “L”-brackets on the Top Frame (1) with two

1/4” x 3/4” Bolts (17), two 1/4” Washers (71), and

two 1/4” Nylon Locknuts (25). Make sure that the

indicated corner of the Shroud is lined up with

the indicated corner of the Top Frame. The

Bolts must be inserted through the square

holes in the Shroud.

46

71

“L”-Brackets

1

25

17

Align

Corners

17

56

71

47. Attach the Curl Pad (21) to the Curl Post (83) with

four 1/4” x 3/4” Bolts (17).

83

17

17

21

47

Page 21

21

The diagram below shows the proper routing of the Low Cable (72), the High Cable (73), and the Leg Press

Cable (76). The numbers show the correct route for each cable. Make sure that the cables are routed cor-

rectly, that the pulleys move smoothly, and that the cable traps do not touch or bind the cables.

Incorrect cable routing can damage the weight system.

High Cable (73)

Large Ball

Low Cable (72)

Leg Press Cable (76)

2

8

10

12

9

1

3

7

6

4

5

11

6

Cable ID Chart

—72

—73

—76

4

2

3

1

1

2

6

5

4

3

5

CABLE DIAGRAM

Page 22

ATTACHING THE ACCESSORIES

The Lat Bar (61), Ankle Strap (10), and Ab Strap (75)

can be attached to the cable at the desired pulley station with a Cable Clip (69). For some exercises, the

Chain (67) should be connected between the attachment and the cable with two Cable Clips. Adjust the

length of the Chain between the accessory and

the cable so the accessory is in the correct starting position for the exercise to be performed.

ADJUSTING THE HEIGHT OF THE SEAT

To adjust the height of the Seat (13), loosen the indicated Adjustment Knob (9). Pull out the Knob as far

as possible and slide the Seat Upright (37) to the

desired position. Release the Knob so that it engages

one of the adjustment holes in the Seat Upright. Fully

tighten the Knob.

USING THE LEG LEVER LOCK

Some exercises can be performed more comfortably

with the Leg Lever (29) locked.

To lock the Leg Lever (29), turn the Leg Lever Lock

(11) until it engages the Pad Tube (28) on the Leg

Lever.

22

13

9

37

The instructions below describe how each part of the weight system can be adjusted. Refer to the exercise

guide accompanying this manual to see how the weight system should be set up for each exercise. IMPOR-

TANT: When attaching the lat bar, ankle strap, or ab strap, make sure that the accessories are in the correct starting position for the exercise to be performed. If there is any slack in the cables or chain as an

exercise is performed, the effectiveness of the exercise will be reduced.

61

69

10

67

69

75

CHANGING THE WEIGHT SETTING

To change the setting of the weight stack, insert the

Weight Pin (39) under the desired Weight (26). Be

sure to insert the Weight Pin until the bent end of the

Weight Pin is touching the Weights, and turn the bent

end downward. The setting of the weight stack can be

changed from 10 pounds to 200 pounds, in increments of 10 pounds. Note: Due to the cables and

pulleys, the amount of resistance at each exercise

station may vary from the weight setting. Use the

WEIGHT RESISTANCE CHART on page 24 of this

manual to find the approximate amount of resistance at each weight station.

26

39

ADJUSTMENTS

11

28

29

Page 23

23

ATTACHING THE CURL PAD

Remove the 2” Square Inner Cap (33) from the front

leg on the Base (8). Slide the Curl Post (83) into the

front leg and secure it with the Curl Knob (89).

8

89

83

33

CONVERTING THE PRESS/FLY ARMS

To use the Press/Fly Arms (46, 49) as fly arms, insert

the Adjustment Pins (20) into the inner holes in the

Press Frame (12) (see inset drawing A).

To use the Press/Fly Arms (46, 49) as press arms,

insert the Adjustment Pins (20) into the outer holes in

the Press Frame (12) and the tabs on the Press/Fly

Arms (see inset drawing B).

Make sure that the Adjustment Pins (20) are fully

inserted into the same holes in both sides of the

Press Frame (12) before performing any exercises.

20

49

46

A

B

12

20

20

20

49

49

Page 24

24

This chart shows the approximate weight resistance at each weight station. “Top” refers to the 10 lb. top weight.

The other numbers refer to the 10 lb. weight plates. Note: The actual resistance at each station may vary due to

differences in individual weight plates as well as friction between the cables, pulleys, and weight guides.

Weight Press Low High AB Leg Leg

Plates Arm Pulley Pulley Pulley Lever Press

(lbs.) (lbs.) (lbs.) (lbs.) (lbs.) (lbs.)

Top 24 11 13 13 11 28

1 35 22 25 24 22 51

2 46 34 36 35 34 74

3 57 46 48 46 46 97

4 68 57 60 57 57 120

5 79 69 72 68 69 143

6 90 80 83 79 80 167

7 102 92 95 90 92 190

8 113 104 107 102 104 213

9 124 115 119 113 115 236

10 135 127 130 124 127 259

11 146 138 142 135 138 282

12 157 150 154 146 150 305

13 168 162 166 157 162 328

14 179 173 177 168 173 351

15 190 185 189 179 185 374

16 201 196 201 190 196 397

17 213 208 213 201 208 420

18 224 219 224 213 219 443

19 235 231 236 224 231 466

WEIGHT RESISTANCE CHART

Page 25

25

TIGHTENING THE CABLES

Woven cable, the type of cable used on the weight

system, can stretch slightly when it is first used. If

there is slack in the cables before resistance is felt,

the cables should be tightened.

To tighten the cables, insert the Weight Pin (39) under

the third Weight (26) from the top. Next, loosen the

1/2” Plain Nut (68) securing the bolt at the end of the

High Cable (73). Tighten the bolt two turns into the

Weight Tube (36) until the cables feel tighter. Tighten

the Plain Nut to prevent the bolt from turning.

Note: For clarity, the drawing shows the shroud

removed; it is not necessary to remove the

shroud.

36

Bolt

73

Additional slack can be removed by moving the indicated 4” Pulley (35) down one set of holes in the

Pulley Plates (31). To do this, remove the 3/8” x 1 3/4”

Bolt (60) and the 3/8” Nylon Jamnut (63) from the

Pulley and the Cable Trap (44). Re-attach the Pulley

and Cable Trap to the lower set of holes with the Bolt

and Nylon Jamnut. Make sure that the High Cable

(73) is in the groove of the Pulley and that the

Cable Trap is turned as shown. The lower pulley

can be moved up to the two higher sets of holes

in the same way.

Slack can also be removed by moving the indicated

4” Pulley (35) to the lower hole in the Pulley Bracket

(91). To do this, remove the 3/8” x 1 3/4” Bolt (60) and

the 3/8” Nylon Jamnut (63) from the Pulley and the

Cable Trap (44). Re-attach the Pulley and Cable Trap

to the lower set of holes with the Bolt and Nylon

Jamnut. Make sure that the High Cable (73) is in

the groove of the Pulley and that the Cable Trap is

turned as shown.

Note: If a cable tends to slip off the pulleys, the

cable may have become twisted. Remove the

cable and re-install it.

If a cable needs to be replaced, refer to the back

cover of this manual.

60

44

Make sure all parts are properly tightened each time you use the weight system. Replace any worn parts immediately. The weight system can be cleaned using a damp cloth and mild non-abrasive detergent. Do not use solvents.

63

35

60

73

91

39

26

63

31

35

73

35

44

68

TROUBLE-SHOOTING AND MAINTENANCE

Page 26

26

EXERCISE GUIDELINES

THE FOUR BASIC TYPES OF WORKOUTS

Muscle Building

To increase the size and strength of your muscles,

push them close to their maximum capacity. Your muscles will continually adapt and grow as you progressively increase the intensity of your exercise. You can

adjust the intensity level of an individual exercise in

two ways:

• by changing the amount of weight used

• by changing the number of repetitions or sets per-

formed. (A “repetition” is one complete cycle of an

exercise, such as one sit-up. A “set” is a series of

repetitions.)

The proper amount of weight for each exercise

depends upon the individual user. You must gauge

your limits and select the amount of weight that is right

for you. Begin with 3 sets of 8 repetitions for each

exercise you perform. Rest for 3 minutes after each

set. When you can complete 3 sets of 12 repetitions

without difficulty, increase the amount of weight.

Toning

You can tone your muscles by pushing them to a moderate percentage of their capacity. Select a moderate

amount of weight and increase the number of repetitions in each set. Complete as many sets of 15 to 20

repetitions as possible without discomfort. Rest for 1

minute after each set. Work your muscles by completing more sets rather than by using high amounts of

weight.

Weight Loss

To lose weight, use a low amount of weight and

increase the number of repetitions in each set.

Exercise for 20 to 30 minutes, resting for a maximum

of 30 seconds between sets.

Cross Training

Cross training is an efficient way to get a complete and

well-balanced fitness program. An example of a balanced program is:

• Plan weight training workouts on Monday,

Wednesday, and Friday.

• Plan 20 to 30 minutes of aerobic exercise, such as

cycling or swimming, on Tuesday and Thursday.

• Rest from both weight training and aerobic exercise

for at least one full day each week to give your body

time to regenerate.

The combination of weight training and aerobic exercise will reshape and strengthen your body, plus develop your heart and lungs.

PERSONALIZING YOUR EXERCISE PROGRAM

Determining the exact length of time for each workout,

as well as the number of repetitions or sets completed,

is an individual matter. It is important to avoid overdoing it during the first few months of your exercise program. You should progress at your own pace and be

sensitive to your body’s signals. If you experience pain

or dizziness at any time while exercising, stop immediately and begin cooling down. Find out what is wrong

before continuing. Remember that adequate rest and a

proper diet are important factors in any exercise program.

WARMING UP

Begin each workout with 5 to 10 minutes of stretching

and light exercise to warm up. Warming up prepares

your body for more strenuous exercise by increasing

circulation, raising your body temperature and delivering more oxygen to your muscles.

WORKING OUT

Each workout should include 6 to 10 different exercises. Select exercises for every major muscle group,

emphasizing areas that you want to develop most. To

give balance and variety to your workouts, vary the

exercises from session to session.

Schedule your workouts for the time of day when your

energy level is the highest. Each workout should be

followed by at least one day of rest. Once you find the

schedule that is right for you, stick with it.

EXERCISE FORM

Maintaining proper form is an essential part of an

effective exercise program. This requires moving

through the full range of motion for each exercise, and

moving only the appropriate parts of the body.

Exercising in an uncontrolled manner will leave you

feeling exhausted. On the exercise guide accompanying this manual you will find photographs showing the

correct form for several exercises, and a list of the

muscles affected. Refer to the muscle chart on page

27 to find the names of the muscles.

The repetitions in each set should be performed

smoothly and without pausing. The exertion stage of

each repetition should last about half as long as the

return stage. Proper breathing is important. Exhale

during the exertion stage of each repetition and inhale

during the return stroke. Never hold your breath.

Page 27

27

Rest for a short period of time after each set. The

ideal resting periods are:

• Rest for three minutes after each set for a muscle

building workout.

• Rest for one minute after each set for a toning work-

out.

• Rest for 30 seconds after each set for a weight loss

workout.

Plan to spend the first couple of weeks familiarizing

yourself with the equipment and learning the proper

form for each exercise.

COOLING DOWN

End each workout with 5 to 10 minutes of stretching.

Include stretches for both your arms and legs. Move

slowly as you stretch and do not bounce. Ease into

each stretch gradually and go only as far as you can

without strain. Stretching at the end of each workout

is an effective way to increase flexibility.

STAYING MOTIVATED

For motivation, keep a record of each workout. List

the date, the exercises performed, the weight used,

and the numbers of sets and repetitions completed.

Record your weight and key body measurements at

the end of every month. Remember, the key to

achieving the greatest results is to make exercise a

regular and enjoyable part of your everyday life.

MUSCLE CHART

A. Sternomastoid (neck)

B. Pectoralis Major (chest)

C. Biceps (front of arm)

D. Obliques (waist)

E. Brachioradials (forearm)

F. Hip Flexors (upper thigh)

G. Abductor (outer thigh)

H. Quadriceps (front of thigh)

I. Sartorius (front of thigh)

J. Tibialis Anterior (front of calf)

K. Soleus (front of calf)

L. Rectus Abdominus (stomach)

M. Adductor (inner thigh)

N. Trapezius (upper back)

O. Rhomboideus (upper back)

P. Deltoid (shoulder)

Q. Triceps (back of arm)

R. Latissimus Dorsi (mid back)

S. Spinae Erectors (lower back)

T. Gluteus Medius (hip)

U. Gluteus Maximus (buttocks)

V. Hamstring (back of leg)

W. Gastrocnemius (back of calf)

A

B

C

D

E

G

H

I

J

K

F

M

L

T

N

O

P

Q

R

S

U

V

W

Page 28

Part No. 182580 R0402A Printed in Canada © 2002 ICON Health & Fitness, Inc.

To order replacement parts, simply call our Customer Service Department toll-free at 1-888-825-2588, Monday

through Friday, 6 a.m. until 6 p.m. Mountain Time (excluding holidays). To help us assist you, please be prepared to give the following information:

1. The MODEL NUMBER of the product (831.159770)

2. The NAME of the product (NordicTrack

®

VERTEX 670 weight system)

3. The SERIAL NUMBER of the product (see the front cover of this manual)

4. The KEY NUMBER and DESCRIPTION of the part(s) (see the PART LIST and EXPLODED DRAWING in the

center of this manual).

ORDERING REPLACEMENT PARTS

LIMITED WARRANTY

WHAT IS COVERED—The entire NordicTrack®VERTEX 670 weight system (“Product”) is warranted to be free of all defects in material and workmanship.

WHO IS COVERED—The original purchaser or any person receiving the Product as a gift from the original purchaser.

HOW LONG IS IT COVERED—ICON Health & Fitness, Inc. (“ICON”), warrants the product for one year after the date of purchase.

Labor is covered for one year.

WHAT WE DO TO CORRECT COVERED DEFECTS—We will ship to you, without charge, any replacement part or component, providing the repairs are authorized by ICON first and are performed by an ICON trained and authorized service provider, or, at our

option, we will replace the Product.

WHAT IS NOT COVERED—Any failures or damage caused by unauthorized service, misuse, accident, negligence, improper

assembly or installation, alterations, modifications without our written authorization or by failure on your part to use, operate, and

maintain as set out in your User’s Manual (“Manual”).

WHAT YOU MUST DO—Always retain proof of purchase, such as your bill of sale; store, operate, and maintain the Product as specified in the Manual; notify our Customer Service Department of any defect within 10 days after discovery of the defect; as instructed, return any defected part for replacement or, if necessary, the entire product, for repair.

USER’S MANUAL—It is VERY IMPORTANT THAT YOU READ THE MANUAL before operating the Product. Remember to do the

periodic maintenance requirements specified in the Manual to assure proper operation and your continued satisfaction.

HOW TO GET PARTS AND SERVICE—Simply call our Customer Service Department at 1-888-825-2588 and tell them your name

and address and the serial number of your Product. They will tell you how to get a part replaced, or if necessary, arrange for service where your Product is located or advise you how to ship the Product for service. Before shipping, always obtain a Return

Authorization Number (RA No.) from our Customer Service Department; securely pack your Product (save the original shipping carton if possible); put the RA No. on the outside of the carton and insure the product. Include a letter explaining the product or problem and a copy of your proof of purchase if you believe the service is covered by warranty.

ICON is not responsible or liable for indirect, special or consequential damages arising out of or in connection with the use or performance of the product or damages with respect to any economic loss, loss of property, loss of revenues or profits, loss of enjoyment or use, costs of removal, installation or other consequential damages of whatsoever nature. Some states do not allow the

exclusion or limitation of incidental or consequential damages. Accordingly, the above limitation may not apply to you.

The warranty extended hereunder is in lieu of any and all other warranties and any implied warranties of merchantability or fitness

for a particular purpose is limited in its scope and duration to the terms set forth herein. Some states do not allow limitations on how

long an implied warranty lasts. Accordingly, the above limitation may not apply to you.

No one is authorized to change, modify or extend the terms of this limited warranty. This warranty gives you specific legal rights and

you may have other rights which vary from state to state.

ICON HEALTH & FITNESS, INC., 1500 S. 1000 W., LOGAN, UT 84321-9813

Page 29

This chart is provided to help you identify the small parts used in assembly. The number in parenthesis below

each part refers to the key number of the part from the PART LIST in the center of this manual. Important:

Some parts may have been pre-assembled for shipping. If you cannot find a part in the parts bags,

check to see if it has been pre-assembled.

Note: Assembly is divided into four stages: 1) frame assembly, 2) arm

assembly, 3) cable assembly, and 4) seat assembly. The hardware for

each stage is packaged separately. Wait until you begin each stage to

open the parts bag for that stage.

Page 30

1/2” x 1 3/4” Bushing (94)

1/2” x 3/4” Long Bushing (93)

5/8” x 1/4” Bushing (90)

5/8” x 1/2” Bushing (42)

2" Square Inner Cap (33)

3/4" Round Inner Cap (34)

1" Round Inner Cap (103)

Cable Clip (69)

2" Round Inner Cap (57)

2" x 3” Inner Cap (24)

3/4” x 1/2” Flange Bushing (18)

Page 31

3/8" x 2 1/2" Bolt (54)

5/16" x 3" Bolt (78)

3/8" x 3" Bolt (45)

3/8" x 3" Carriage Bolt (64)

3/8" x 3 1/4" Bolt (87)

1/2" x 3 1/2" Bolt (22)

3/8" x 3 3/4" Bolt (92)

1/4" x 3 3/4" Carriage Bolt (43)

3/8" x 3 3/4" Carriage Bolt (52)

3/8" x 9" Bolt (51)

3/8" x 8 1/2" Bolt (59)

3/8" x 4" Bolt (65)

3/8" x 5" Carriage Bolt (82)

Page 32

PART IDENTIFICATION CHART—Model No. 831.159770 R0402A

1/4" Nylon Locknut (25)

1/2" Plain Nut (68)

5/16" Nylon Jamnut (79)

5/16" Nylon Locknut (81)

3/8" Nylon Jamnut (63)

3/8" Nylon Locknut (50)

1 1/2" Washer (40)

1/4" Washer (71)

5/16" Washer (80)

Large Washer (104)

3/8" Washer (55)

#8 x 3/4" Screw (32)

1/4" x 3/4" Bolt (17)

#10 x 1" Tap Screw (7)

1/4" x 1 1/2" Bolt (101)

3/8" x 1 1/2" Button Cap Screw (2)

3/8" x 1 3/4" Bolt (60)

3/8" x 2" Bolt (62)

5/16" x 2 1/2" Bolt (96)

Page 33

REMOVE THIS PART LIST/EXPLODED DRAWING

FROM THE MANUAL.

SAVE THIS PART LIST/EXPLODED DRAWING FOR FUTURE REFERENCE

81

Page 34

1 1 Top Frame

2 1 3/8” x 1 1/2” Button Cap Screw

3 1 Main Upright

4 1 Flat Plate

5 1 Stabilizer

6 1 Leg Lever Bumper

7 1 #10 x 1” Tap Screw

8 1 Base

9 2 Adjustment Knob

10 1 Ankle Strap

11 1 Leg Lever Lock

12 1 Press Frame

13 2 Seat

14 2 Plastic Sleeve

15 2 Handgrip

16 1 Top Weight

17 22 1/4” x 3/4” Bolt

18 8 3/4” x 1/2” Flange Bushing

19 2 Weight Bumper

20 2 Adjustment Pin

21 1 Curl Pad

22 1 3/8” x 3 1/2” Bolt

23 2 Weight Guide

24 4 2” x 3” Inner Cap

25 9 1/4” Nylon Locknut

26 19 Weight

27 2 Backrest Plate

28 3 Pad Tube

29 1 Leg Lever

30 6 Foam Pad

31 2 Pulley Plate

32 2 #8 x 3/4” Screw

33 10 2” Square Inner Cap

34 6 3/4” Round Inner Cap

35 21 4” Pulley

36 1 Weight Tube

37 1 Seat Upright

38 2 Tinnerman Clip

39 1 Weight Pin

40 1 1 1/2” Washer

41 1 Backrest

42 22 5/8” x 1/2” Pulley Bushing

43 2 1/4” x 3 3/4” Carriage Bolt

44 7 Cable Trap

45 3 3/8” x 3” Bolt

46 1 Right Press/Fly Arm

47 1 Weight Tube Bumper

48 4 Large Bushing

49 1 Left Press/Fly Arm

50 23 3/8” Nylon Locknut

51 1 3/8” x 9” Bolt

52 3 3/8” x 3 3/4” Carriage Bolt

53 2 Plastic Sleeve Bushing

54 11 3/8” x 2 1/2” Bolt

55 35 3/8” Washer

56 1 Shroud

57 2 2” Round Inner Cap

58 2 Arm Grip

59 2 3/8” x 8 1/2” Bolt

60 5 3/8” x 1 3/4” Bolt

61 1 Lat Bar

62 3 3/8” x 2” Bolt

63 22 3/8” Nylon Jamnut

64 6 3/8” x 3” Carriage Bolt

65 1 3/8” x 4” Bolt

66 1 Weight Cover

67 1 Chain

68 1 1/2” Plain Nut

69 3 Cable Clip

70 1 Leg Press Backrest

71 5 1/4” Washer

72 1 Low Cable

73 1 High Cable

74 1 Sliding Seat Frame

75 1 Ab Strap

76 1 Leg Press Cable

77 38 Weight Insert

78 3 5/16” x 3” Bolt

79 1 5/16” Nylon Jamnut

80 5 5/16” Washer

81 3 5/16” Nylon Locknut

82 1 3/8” x 5” Carriage Bolt

83 1 Curl Post

84 1 Leg Press Base

85 1 Leg Press Plate

86 2 Handgrip

87 6 3/8” x 3 1/4” Bolt

88 1 Seat Frame Channel

89 1 Curl Knob

90 1 5/8” x 1/4” Bushing

91 1 Pulley Bracket

92 2 3/8” x 3 3/4” Bolt

93 1 1/2” x 3/4” Long Bushing

94 1 1/2” x 1 3/4” Bushing

95 2 Handle

96 1 5/16” x 2 1/2” Bolt

97 1 Rear Leg Press Upright

98 1 Forward Leg Press Upright

99 1 Angle Cap

100 2 Leg Press Attachment

101 4 1/4” x 1 1/2” Bolt

102 1 Chart Decal

103 2 1” Round Inner Cap

104 1 Large Washer

# 1 User’s Manual

Key No. Qty. Description Key No. Qty. Description

PART LIST—Model No. 831.159770 R0402A

Note: “#” indicates a non-illustrated part. Specifications are subject to change without notice. See the back cover

of the user’s manual for information about ordering replacement parts.

Page 35

EXPLODED DRAWING—Model No. 831.159770 R0402A

64

20

48

51

59

18

18

33

35

44

18

50

60

63

25

15

61

35

35

42

42

17

71

35

48

12

104

50

48

76

91

71

42

35

54

15

42

42

35

45

42

35

42

1

55

42

63

55

63

55

63

50

77

102

63

64

20

43

27

17

14

54

73

55

55

42

54

55

55

55

63

50

42

54

55

60

77

103

49

63

43

27

17

24

14

42

35

63

42

55

55

63

42

42

35

42

39

26

56

57

58

46

103

41

34

33

54

55

30

72

55

24

3

71

25

25

63

35

5

50

50

44

35

19

62

32

21

57

34

30

28

33

13

17

37

17

62

28

62

71

35

30

60

31

44

35

50

54

52

55

38

42

38

24

83

89

17

17

6

11

78

54

80

80

65

78

8

81

9

55

50

50

50

34

44

35

33

31

63

64

88

64

82

50

33

52

34

96

30

22

18

33

18

42

7

55

55

63

80

81

30

34

87

100

33

92

97

99

4

92

50

44

35

13

54

55

28

29

55

63

30

35

42

24

75

87

55

63

98

50

35

44

55

63

50

90

76

50

44

35

55

50

86

72

42

35

42

80

94

33

80

79

63

34

69

10

67

85

63

55

50

87

24

87

55

55

45

84

25

71

17

40

73

68

23

36

47

55

42

63

32

2

93

16

66

70

74

33

101

17

17

53

95

17

25

9

53

101

17

17

86

25

95

Loading...

Loading...