Page 1

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

1

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

SERVICE MANUAL

Level 1&2

Nokia X7-00

(RM-707)

Nokia X7-00.1

(RM-659)

Transceiver characteristics

Band

EGSM 850/900/1800/1900 MHz

RM-707:

WCDMA 850/900/1700/1900/2100 MHz

RM-659:

WCDMA 850/1900/2100 MHz

Display

4” AMOLED, up to 16.7 million colors, 16:9

widescreen aspect ratio, 640x360 pixel

resolution

Camera

8Mpix EDOF camera with dual LED flash,

1280x720 25 fps HD video recording

Operating System

Symbian for Nokia devices

Connections:

Micro USB 2.0 with OTG support, Bluetooth

3.0, WLAN 802.11 b/g/n

Transceiver with BL-5K battery pack

Talk time

Standby

GSM:

Up to 6 hours

WCDMA:

Up to 4.5 hours

GSM:

Up to 450 hours

WCDMA:

Up to 450 hours

Note:

Talk times are dependent on network

parameters

and phone settings

Page 2

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

2

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

Table of contents

1. COPYRIGHT .......................................................................................................................................................................... 4

2. WARNINGS AND CAUTIONS ............................................................................................................................................. 5

2.1 WARNINGS................................................................................................................................................................. 5

2.2 CAUTIONS ................................................................................................................................................................... 5

3. ESD PROTECTION ............................................................................................................................................................... 6

4. CARE AND MAINTENANCE ................................................................................................................................................ 7

5. BATTERY INFORMATION ................................................................................................................................................... 8

6. EXLPODED VIEW ................................................................................................................................................................. 9

7. SERVICE DEVICES ................................................................................................................................................................ 10

8. SOFTWARE UPDATE ........................................................................................................................................................... 11

9. DISASSEMBLY INSTRUCTIONS ......................................................................................................................................... 12

10. ASSEMBLY INSTRUCTIONS ............................................................................................................................................... 22

11. ASSEMBLY WITH THE SS-252 JIG INSTRUCTIONS ....................................................................................................... 34

12. RESETTING A SHORT-CIRCUITED X7-00 ........................................................................................................................ 47

13. SOLDER COMPONENTS ...................................................................................................................................................... 48

Page 3

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

3

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

Status

Version No.

Date

Comments

Approved

1.0

12.04.2011

CHANGE HISTORY

The purpose of this document is to help NOKIA service levels 1 and 2 workshop technicians to

carry out service to NOKIA products. This Service Manual is to be used only by authorized NOKIA

service suppliers, and the content of it is confidential. Please note that NOKIA provides also other

guidance documents (e.g. Service Bulletins) for service suppliers, follow these regularly and

comply with the given instructions.

While every endeavor has been made to ensure the accuracy of this document, some errors may

exist. If you find any errors or if you have further suggestions, please notify NOKIA using the

address below:

Nokia Care Academy

service.manuals@nokia.com

Please keep in mind also that this documentation is continuously being updated and modified,

so watch always out for the newest version.

Page 4

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

4

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

1. COPYRIGHT

Copyright © 2011 Nokia. All rights reserved.

Reproduction, transfer, distribution or storage of part or all of the contents in this document in

any form without the prior written permission of Nokia is prohibited.

Nokia, Nokia Connecting People, and Nokia X and Y are trademarks or registered trademarks of

Nokia Corporation. Other product and company names mentioned herein may be trademarks or

tradenames of their respective owners.

Nokia operates a policy of continuous development. Nokia reserves the right to make changes

and improvements to any of the products described in this document without prior notice.

Under no circumstances shall Nokia be responsible for any loss of data or income or any special,

incidental, consequential or indirect damages howsoever caused.

The contents of this document are provided “as is”. Except as required by applicable law, no

warranties of any kind, either express or implied, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose, are made in relation to the

accuracy, reliability or contents of this document. Nokia reserves the right to revise this

document or withdraw it at any time without prior notice.

The availability of particular products may vary by region.

IMPORTANT

This document is intended for use by qualified service personnel only.

Page 5

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

5

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

2. WARNINGS AND CAUTIONS

Please refer to the phone’s user guide for instructions relating to operation, care and

maintenance including important safety information. Note also the following:

2.1 Warnings

1. CARE MUST BE TAKEN ON INSTALLATION IN VEHICLES FITTED WITH ELECTRONIC ENGINE

MANAGEMENT SYSTEMS AND ANTI–SKID BRAKING SYSTEMS. UNDER CERTAIN FAULT CONDITIONS,

EMITTED RF ENERGY CAN AFFECT THEIR OPERATION. IF NECESSARY, CONSULT THE VEHICLE

DEALER/MANUFACTURER TO DETERMINE THE IMMUNITY OF VEHICLE ELECTRONIC SYSTEMS TO RF

ENERGY.

2. THE HANDPORTABLE TELEPHONE MUST NOT BE OPERATED IN AREAS LIKELY TO CONTAIN

POTENTIALLY EXPLOSIVE ATMOSPHERES, EG PETROL STATIONS (SERVICE STATIONS), BLASTING

AREAS ETC.

3. OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT, INCLUDING CELLULAR TELEPHONES, MAY

INTERFERE WITH THE FUNCTIONALITY OF INADEQUATELY PROTECTED MEDICAL DEVICES. CONSULT

A PHYSICIAN OR THE MANUFACTURER OF THE MEDICAL DEVICE IF YOU HAVE ANY QUESTIONS.

OTHER ELECTRONIC EQUIPMENT MAY ALSO BE SUBJECT TO INTERFERENCE.

2.2 Cautions

1. Servicing and alignment must be undertaken by qualified personnel only.

2. Ensure all work is carried out at an anti–static workstation and that an anti–static wrist

3. Use only approved components as specified in the parts list.

4. Ensure all components, modules screws and insulators are correctly re–fitted after servicing

5. Ensure all cables and wires are repositioned correctly

strap is worn.

and alignment.

Page 6

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

6

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

Nokia requires that service points have sufficient ESD protection (against static

electricity) when servicing the phone.

Any product of which the covers are removed must be handled with ESD

protection. The SIM card can be replaced without ESD protection if the product

is otherwise ready for use.

To replace the covers ESD protection must be applied.

All electronic parts of the product are susceptible to ESD. Resistors, too, can be

damaged by static electricity discharge.

All ESD sensitive parts must be packed in metallized protective bags during

shipping and handling outside any ESD Protected Area (EPA).

Every repair action involving opening the product or handling the product

components must be done under ESD protection.

ESD protected spare part packages MUST NOT be opened/closed out of an ESD

Protected Area.

For more information and local requirements about ESD protection and ESD

Protected Area, contact your local Nokia After Market Services representative.

3. ESD PROTECTION

Page 7

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

7

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

4. CARE AND MAINTENANCE

This product is of superior design and craftsmanship and should be treated with care. The

suggestions below will help you to fulfil any warranty obligations and to enjoy this product for

many years.

Keep the phone and all its parts and accessories out of the reach of small

children.

Keep the phone dry. Precipitation, humidity and all types of liquids or

moisture can contain minerals that will corrode electronic circuits.

Do not use or store the phone in dusty, dirty areas. Its moving parts can be

damaged.

Do not store the phone in hot areas. High temperatures can shorten the life

of electronic devices, damage batteries, and warp or melt certain plastics.

Do not store the phone in cold areas. When it warms up (to its normal

temperature), moisture can form inside, which may damage electronic circuit

boards.

Do not drop, knock or shake the phone. Rough handling can break internal

circuit boards.

Do not use harsh chemicals, cleaning solvents, or strong detergents to clean

the phone.

Do not paint the phone. Paint can clog the moving parts and prevent proper

operation.

Use only the supplied or an approved replacement antenna. Unauthorised

antennas, modifications or attachments could damage the phone and may

violate regulations governing radio devices.

All of the above suggestions apply equally to the product, battery, charger or any accessory.

Page 8

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

8

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

5. BATTERY INFORMATION

Note: A new battery’s full performance is achieved only after two or three complete charge and

discharge cycles! The battery can be charged and discharged hundreds of times but it will

eventually wear out.

When the operating time (talk-time and standby time) is noticeably shorter than normal, it is

time to buy a new battery. Use only batteries approved by the phone manufacturer and

recharge the battery only with the chargers approved by the manufacturer.

Unplug the charger when not in use. Do not leave the battery connected to a charger for longer

than a week, since overcharging may shorten its lifetime.

If left unused a fully charged battery will discharge itself over time Temperature extremes can

affect the ability of your battery to charge.

For good operation times with Ni-Cd/NiMh batteries, discharge the battery from time to time by

leaving the product switched on until it turns itself off (or by using the battery discharge facility

of any approved accessory available for the product).

Do not attempt to discharge the battery by any other means Use the battery only for its

intended purpose.

Never use any charger or battery which is damaged.

Do not short-circuit the battery. Accidental short-circuiting can occur when a metallic object

(coin, clip or pen) causes direct connection of the + and - terminals of the battery (metal strips

on the battery) for example when you carry a spare battery in your pocket or purse.

Shortcircuiting the terminals may damage the battery or the connecting object.

Leaving the battery in hot or cold places, such as in a closed car in summer or winter conditions,

will reduce the capacity and lifetime of the battery. Always try to keep the battery between 15°C

and 25°C (59°F and 77°F).

A phone with a hot or cold battery may temporarily not work, even when the battery is fully

charged. Batteries’ performance is particularly limited in temperatures well below freezing.

Do not dispose batteries in a fire! Dispose of batteries according to local regulations (e.g.

recycling).

Do not dispose as household waste.

Page 9

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

9

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

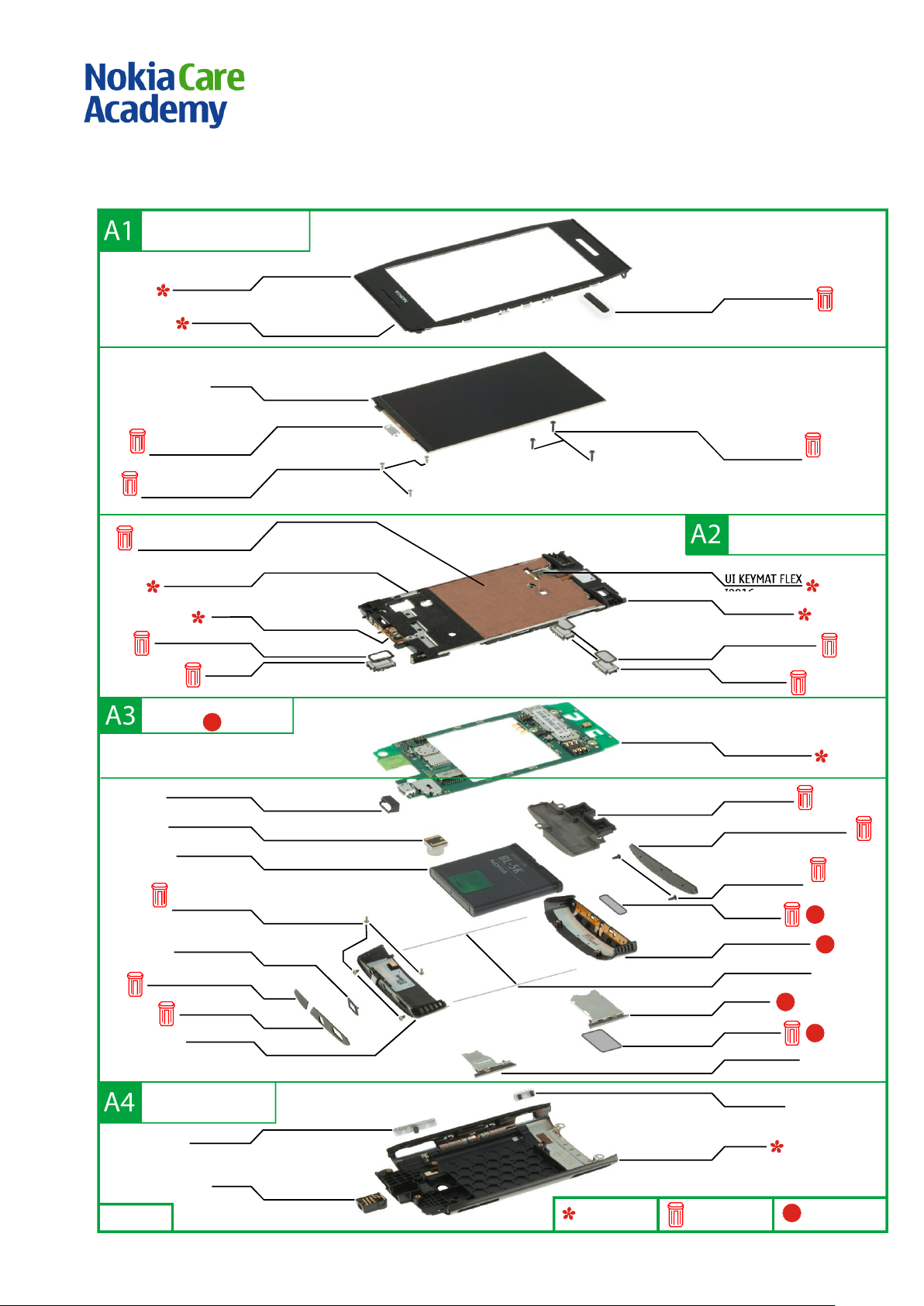

NOKIA X7-00/X7-00.1

RM-707/RM-659

EXPLODED VIEW

LOCK KEY FACE PLATE

I0001

AV FACE PLATE

I0002

MENU / HOME KEY

I0009

A-COVER FRAME

I0008

TOUCH FLEX

I0007

DISPLAY

I0010

DISPLAY CONNECTOR

RETENTION CLIP

I0011

EARPIECE

I0018

MICRO USB BOOT

I0023

EARPIECE ADHESIVE

I0019

MAIN CHASSIS

I0022

DISPLAY

CONDUCTIVE ADHESIVE

I0014

AV JACK

I0031

MICRO SD TRAY

I0034

SIM TRAY

I0035

BOTTOM END FACE PLATE

I0038

BOTTOM END CAP

I0037

SIDE LOCKING PIN

I0006

IHF BB SHIELD

I0033

CAMERA KEY

I0029

VOLUME KEY

I0030

B-COVER

I0032

CAMERA MODULE

I0027

UI KEYMAT FLEX

I0016

AV FRONT SEAL

I0003

AV FLEX

I0015

VOLUME KEY FLEX

I0017

SCREW TORX+

SIZE 4 M1.4x5.0

I0013

BL-5K BATTERY

I0028

IHF SPEAKER

I0020

TYPE LABEL

I0026

TYPE LABEL

I0026

LIGHT SWAP PWB

I0025

IHF SPEAKER MESH

I0021

SCREW CAMERA CROSS

M1.4X2.8

I0012

TOP END CAP

I0005

SCREW TORX+

SIZE 4 M1.4X3.7

I0036

SCREW TORX+

SIZE 4 M1.4X2.5

I0004

Ver. 1.0

Only available

as assembly

Not reuseable

after removal

Repair/swap

only in level 3

L3

L3

L3

L3

L3

L3

A-COVER TOUCH ASSEMBLY

(I0007 - I0009)

MAIN CHASSIS ASSEMB LY

(I0014 - I0022)

LIGHT SWAP PACKAGE

(I0025)

B-COVER ASSEMBLY

(I0029 - I0032)

6. EXLPODED VIEW

Page 10

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

10

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

CA-101 Service Cable

AC-10 Travel Charger

BL-5K Battery

SS-252 Assembly Jig

Nokia Standard Toolkit (v2)

For more information, refer to the

Service Bulletin (SB-011) on Nokia

Online. Supplier or manufacturer

contacts for tool re-order can be

found in “Recommended service

equipment” document on Nokia

Online.

7. SERVICE DEVICES

Page 11

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

11

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

8. SOFTWARE UPDATE

Flash concept (Point of Sale)

To use the FLS-5 Flash Dongle, follow the user guide inside the sales package. Please check

always for the latest version of flash software, which is available on Nokia Online.

Page 12

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

12

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

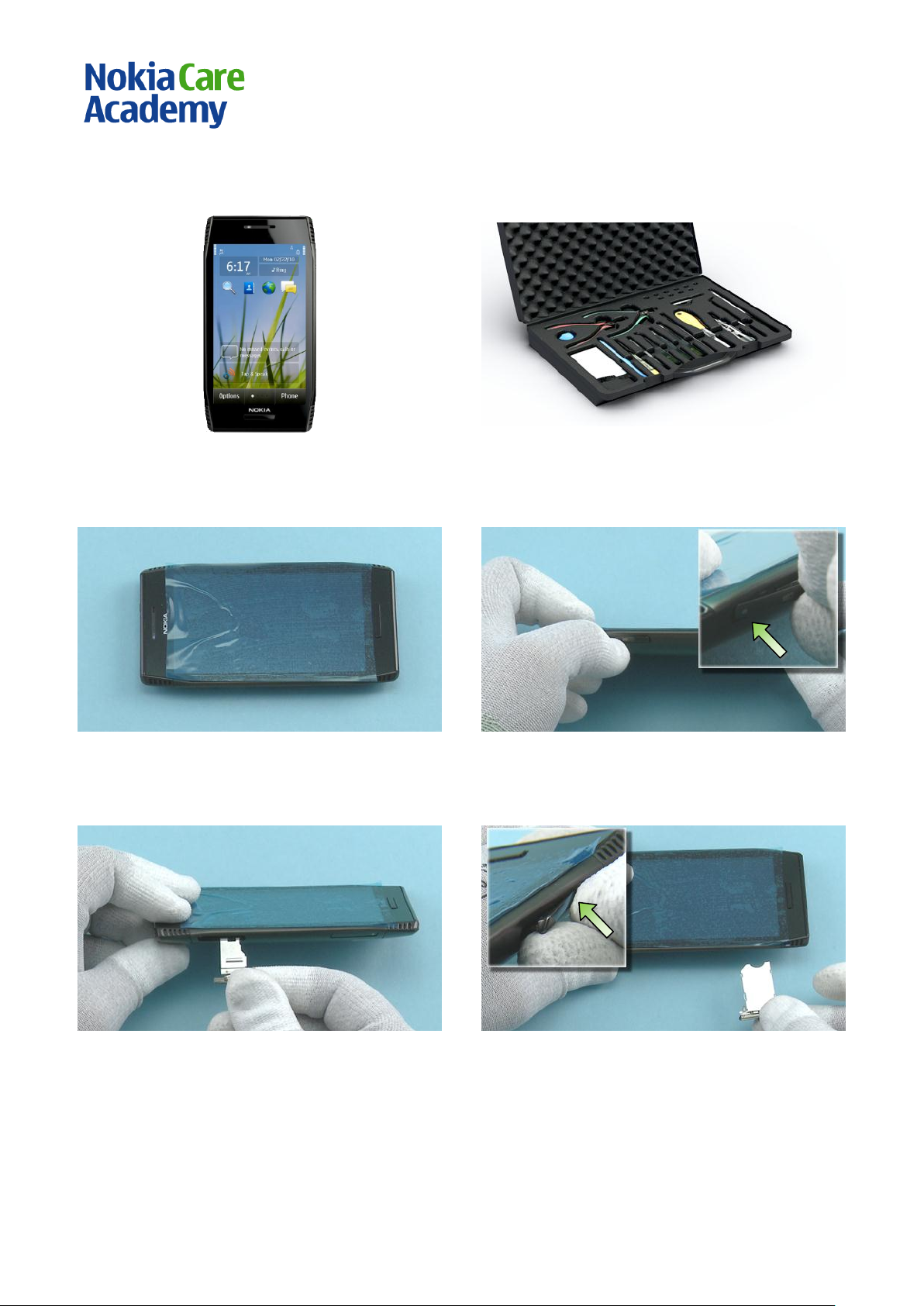

1) Nokia X7-00 disassembly.

2) You must use the Nokia Standard Toolkit version

2.

3) Protect the A-COVER TOUCH ASSEMBLY with

protective film.

4) Push from the shown place to open the MICRO SD

TRAY.

5) Pull out and remove the MICRO SD TRAY.

6) Push from the shown place to open the SIM TRAY.

Pull out and remove the SIM TRAY.

9. DISASSEMBLY INSTRUCTIONS

Page 13

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

13

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

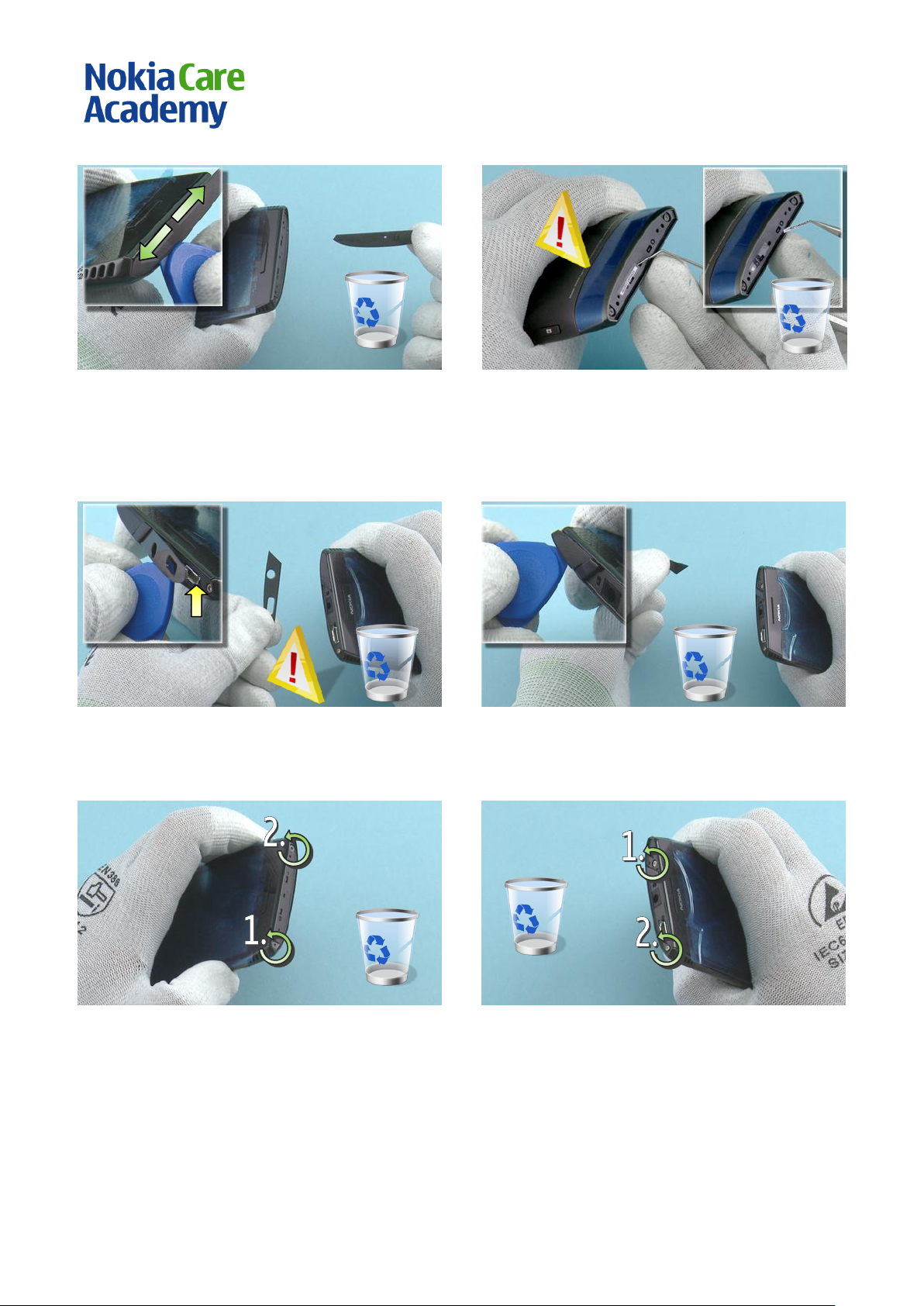

7) Slide the SRT-6 to directions shown to release the

BOTTOM END FACE PLATE. Do not use it again. Discard

it.

8) Note that this step is for Level 3 only! In case the

BOTTOM END CAP or the ENGINE BOARD is to be

replaced, use the dental tool to release the second

TYPE LABEL. Remove it with tweezers. Discard it. Be

careful not to injure yourself with the sharp end of

the dental tool.

9) Release the AV FACE PLATE with the SRT-6. Be

careful not to damage the MICRO USB connector. Do

not use the AV FACE PLATE again. Discard it.

10) Release the LOCK KEY FACE PLATE with the SRT-6.

Do not use it again. Discard it.

Unscrew the two Torx+ size 4 screws in the order

shown. Do not use them again. Discard them.

11) Unscrew the two Torx+ size 4 screws in the order

shown. Do not use them again. Discard them.

Page 14

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

14

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

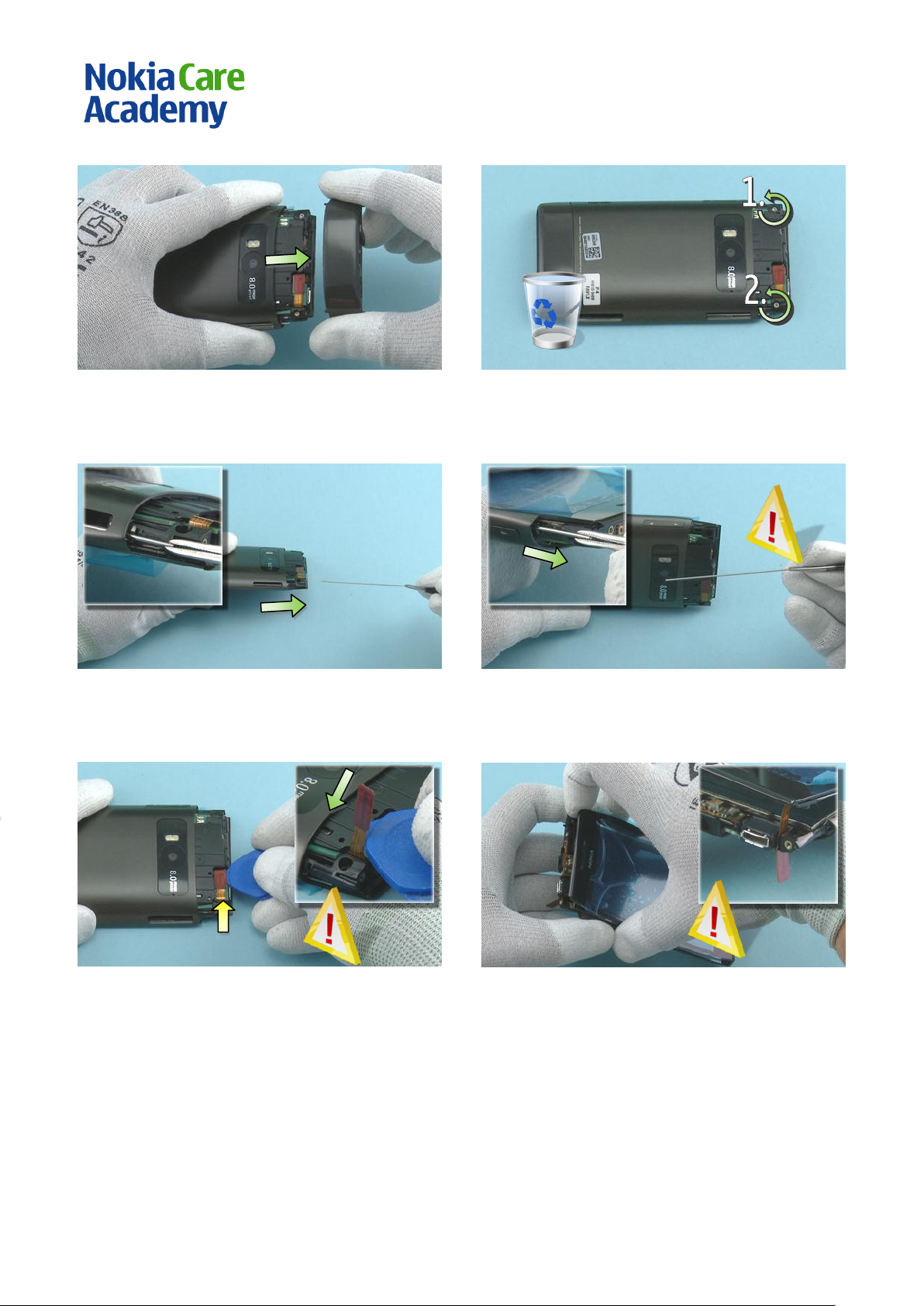

12) Pull the TOP END CAP to the direction shown and

remove it.

13) Unscrew the two Torx+ size 4 screws in the order

shown. Do not use them again. Discard them.

14) Remove the SIDE LOCKING PIN on the left side

with the serrated nose tweezers. Be careful not to

damage the A-COVER TOUCH ASSEMBLY while

removing the SIDE LOCKING PIN.

15) Remove the SIDE LOCKING PIN on the right side

with the serrated nose tweezers. Be careful not to

damage the A-COVER TOUCH ASSEMBLY while

removing the SIDE LOCKING PIN.

16) Open and turn aside the TOUCH FLEX connector

with the SRT-6. Be careful not to damage the

connector.

17) Lift slightly up the top end of the A-COVER TOUCH

ASSEMBLY. Be careful not to damage the TOUCH FLEX

connector.

Page 15

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

15

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

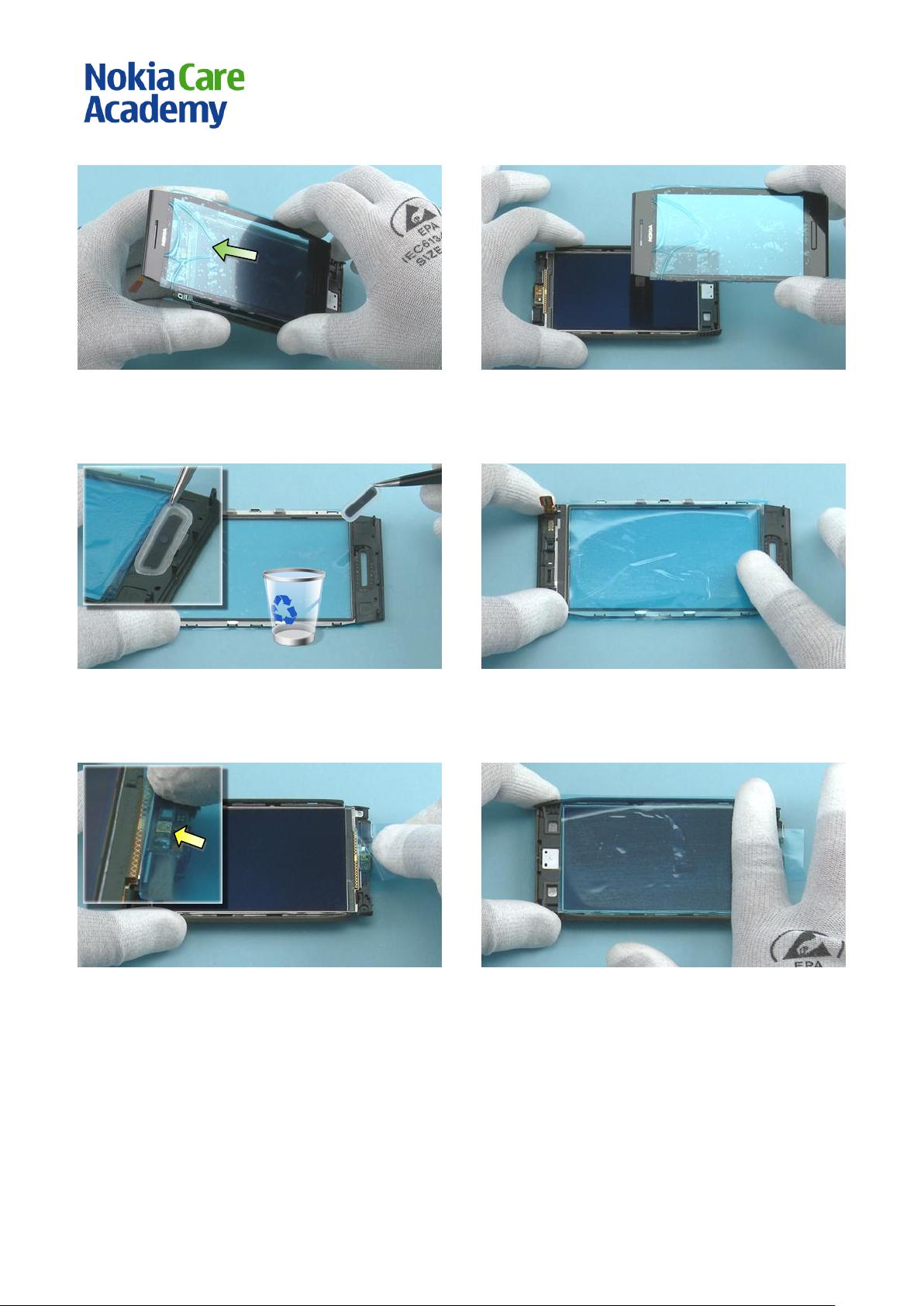

18) Lift up the sides and the bottom end of the ACOVER TOUCH ASSEMBLY. Push the A-COVER TOUCH

ASSEMBLY to direction shown to safely remove the

TOUCH FLEX connector from its place.

19) Separate the A-COVER TOUCH ASSEMBLY.

20) Remove the MENU / HOME KEY with the tweezers.

Do not use it again. Discard it.

21) Protect the inner side of the A-COVER TOUCH

ASSEMBLY with the protective film.

22) Protect the DIPRO LED with the protective film to

avoid short circuit.

23) Protect the DISPLAY with the protective film.

Page 16

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

16

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

24) Lift up the DISPLAY with the SRT-6 tool carefully

from the shown place. Be careful not to bend the

DISPLAY.

25) Push the SS-93 carefully under the DISPLAY to

loosen the DISPLAY CONDUCTIVE ADHESIVE. Be careful

not to bend the DISPLAY.

26) Turn the DISPLAY over. Be careful not to damage

the DISPLAY connector.

27) Remove the DISPLAY CONDUCTIVE ADHESIVE with

the tweezers. Do not use it again. Discard it.

28) Release the DISPLAY CONNECTOR RETENTION CLIP

with the dental tool from the shown place.

29) Remove the DISPLAY CONNECTOR RETENTION CLIP

with the tweezers. Do not use it again. Discard it.

Page 17

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

17

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

30) Open the DISPLAY connector with the SRT-6 as

shown. Be careful not to damage the DISPLAY

connector.

31) Remove the DISPLAY.

32) Unscrew the three Torx+ size 4 screws in the

order shown. Do not use them again. Discard them.

33)Unscrew the three camera cross screws in the

order shown. Do not use them again. Discard them.

34) Protect the VOLUME KEY with the protective film.

35) Protect the CAMERA KEY with the protective film.

Page 18

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

18

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

36) Remove the BOTTOM END CAP by pushing from

the back side to release the shown clip.

37) Remove the BOTTOM END CAP.

38) Use the SRT-6 to release the B-COVER from the

shown place.

39) Turn the device over and remove the B-COVER.

40) Remove the BATTERY.

41) Remove the IHF BB SHIELD. Do not use it again.

Discard it.

Page 19

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

19

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

42) Release the AV FLEX connector with the SS-93. Be

careful not to damage the connector or any nearby

components.

43) Carefully lift up the ENGINE BOARD and pull it to

the direction shown. Be careful not to damage the

connector or any nearby components.

44) Use the dental tool to release the IHF SPEAKER.

45) Remove the IHF SPEAKER with the tweezers. Do

not use it again. Discard it.

46) Release the IHF SPEAKER MESH with the dental

tool and remove it with the tweezers. Do not use it

again. Discard it.

47) Use the dental tool to release the second IHF

SPEAKER and remove it with the tweezers. Do not use

it again. Discard it.

Page 20

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

20

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

48) Release also the second IHF SPEAKER MESH with

the dental tool and remove it with the tweezers. Do

not use it again. Discard it.

49) Use the sharp end of the SS-93 to release the

EARPIECE.

50) Remove the EARPIECE with the tweezers. Do not

use it again. Discard it.

51) Remove the EARPIECE ADHESIVE with dental tool.

Do not use it again. Discard it.

52) Remove the MICRO USB BOOT.

53) Remove the CAMERA KEY with the tweezers.

Page 21

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

21

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

54) Remove the VOLUME KEY with the tweezers.

55) Remove the AV JACK.

56) The Nokia X7-00 disassembly is now complete.

-END OF DISASSEMBLY-

Page 22

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

22

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

1) Nokia X7-00 assembly.

2) For assembling you need the Nokia Toolkit version

2.

3) Protect the DIPRO LED with the protective film to

avoid short circuit.

4) Remove the EARPIECE ADHESIVE protective films.

5) Place the EARPIECE ADHESIVE with the tweezers.

Press it gently with the SS-93 to active the adhesive.

6) Place the EARPIECE with the tweezers. Note the

alignment of the EARPIECE.

10. ASSEMBLY INSTRUCTIONS

Page 23

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

23

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

7) Push the EARPIECE with the SS-93 to its place as

shown. Be careful not to touch the highlighted area!

8) Remove the IHF SPEAKER MESH protective films.

9) Place the first IHF SPEAKER MESH with the

tweezers. Press it gently with the SS-93 to activate

the adhesive.

10) Then place the first IHF SPEAKER with the

tweezers. Note the alignment of the IHF SPEAKER.

Push the IHF SPEAKER with the SS-93 to its place as

shown. Be careful not to touch the highlighted area!

11) Use the same procedure as described earlier to

place the second IHF SPEAKER MESH and second the

IHF SPEAKER. Be careful not to touch the highlighted

area!

12) Peel off the DISPLAY CONDUCTIVE ADHESIVE

protective film.

Page 24

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

24

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

13) Place the DISPLAY CONDUCTIVE ADHESIVE on the

MAIN CHASSIS. To place the DISPLAY CONDUCTIVE

ADHESIVE correctly, use the shown places as guides.

14) Press the DISPLAY CONDUCTIVE ADHESIVE to

activate the adhesive.

15) Use the tweezers to place the AV JACK. Press

gently the AV JACK with the SS-93 to lock it into its

place.

16) Use the tweezers to place the CAMERA KEY and

the VOLUME KEY.

17) To ensure that the VOLUME KEY and the CAMERA

KEY stays in place, be sure to use the protective film

as shown.

18) Remove the CAMERA opening protective film with

the tweezers.

Page 25

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

25

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

19) Place the CAMERA MODULE with the tweezers.

Check that the guiding pin is aligned correctly. Press

the CAMERA MODULE with the SS-93, so that the

camera retaining pins are locked.

20) Place the MICRO USB BOOT as shown.

21) Before placing the ENGINE BOARD, move the HSJ

FLEX connector out of the way carefully. Carefully

place the ENGINE BOARD by using the two shown

guiding pins.

22) Connect the HSJ FLEX connector with the SS-93.

Be careful not to damage the HSJ FLEX connector.

23) Place the IHF BB SHIELD and align it using the

three shown holes.

24) Place the BATTERY.

Page 26

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

26

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

25) Place the CAMERA KEY and the VOLUME KEY side of

the B-COVER first.

26) Then lower down the opposite side of the BCOVER. Press the B-COVER down until it snaps into

place.

27) Tighten these three camera cross screws to the

torque of 10 Ncm in the order shown.

28) Place the BOTTOM END CAP, by first sliding it in

partially. Push it from the back side to lock the

shown clip into its place. Be careful not to damage

the clip. Press the BOTTOM END CAP to its place by

pressing from the shown sides, and from the back of

it.

29) Tighten the shown TORX+ size 4 screw to the

torque of 25 Ncm.

30) Hold the device as shown while fastening the

next two screws to minimize the gap between the

BOTTOM END CAP and the MAIN CHASSIS ASSEMBLY.

Tighten the two shown TORX+ size 4 screws to the

torque of 25 Ncm in the order shown.

Page 27

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

27

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

31) Check the shown gaps for defects in installation.

Please refer to the gap specification document for

accurate values.

32) Use the SS-93 to connect the DISPLAY CONNECTOR.

Be careful not to damage the connector.

33) Use the tweezers to place the DISPLAY

CONNECTOR RETENTION CLIP as shown. Press the

DISPLAY CONNECTOR RETENTION CLIP with the SS-93

to fasten it correctly.

34) Remove the DISPLAY CONDUCTIVE ADHESIVE

protective film.

35) Turn the DISPLAY over on to the MAIN CHASSIS.

36) Activate the adhesive by gently pressing the

DISPLAY for 5 seconds from the top, middle and

bottom as shown. Be careful not to damage the

DISPLAY.

Page 28

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

28

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

37) Remove the DIPRO LED protective film.

38) Remove the DISPLAY protective film.

39) Remove the adhesive protective film from the

MENU / HOME KEY. Hold the MENU / HOME KEY as

shown with tweezers to avoid scratches. If possible

use plastic tweezers or tweezers with rubber tips.

40) Place the MENU / HOME KEY to the A-COVER TOUCH

ASSEMBLY as shown. Press the MENU / HOME KEY very

gently so that the adhesive does not activate

completely.

41) Check that the MENU / HOME KEY is aligned

correctly in to the A-COVER TOUCH ASSEMBLY. The

MENU / HOME KEY should be located on the center.

Press the MENU / HOME KEY for 3 seconds to activate

the adhesive.

42) Remove the inner A-COVER TOUCH ASSEMBLY

protective film.

Page 29

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

29

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

43) Guide the TOUCH FLEX to its gap as shown. Be

careful not to damage the flex! Start placing the ACOVER TOUCH ASSEMBLY to its place from the shown

side. Note that the A-COVER TOUCH ASSEMBLY has to

be assembled in a slight angle.

44) Lower down the other side of the A-COVER TOUCH

ASSEMBLY. Be careful not to damage the B-COVER

water seal with the A-COVER TOUCH ASSEMBLY hooks.

Press the side and the bottom end of the A-COVER

TOUCH ASSEMBLY into place.

45) Connect the TOUCH FLEX connector with the SS-

93. Be careful not to damage the connector.

46) Hold tightly from the side of the device and push

the SIDE LOCKING PIN in as shown.

47) Use the same procedure and push in also the

second SIDE LOCKING PIN.

48) Tighten these two TORX+ size 4 screws to the

torque of 10 Ncm in the order shown. Press the BCOVER down while tightening these screws.

Page 30

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

30

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

49) Place the AV FRONT SEAL to the AV JACK as shown.

Then press the AV FRONT SEAL to its place with finger

and make sure it is aligned correctly.

50) Place the TOP END CAP and push it from the top

side and from the back side to lock it in its place.

51) Test that the device can be powered up properly.

If the device does not power up, this may be caused

by the Dipro LED short circuit. In this case please

follow the instructions how to reset a short-circuited

Nokia X7-00 on page 47.

52) Push the TOP END CAP with finger as shown

while fastening the next two screws. Tighten these

two TORX+ size 4 screws to the torque of 10 Ncm in

the order shown.

53) Check the shown gaps for defects in installation.

Please refer to the gap specification document for

accurate values.

54) Push the BOTTOM END CAP with finger as shown

while fastening the next two screws. Tighten these

two TORX+ size 4 screws to the torque of 10 Ncm in

the order shown.

Page 31

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

31

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

55) Check the shown gaps for defects in installation.

Please refer to the gap specification document for

accurate values.

56) Check the shown gaps for defects in installation.

Please refer to the gap specification document for

accurate values.

57) Note that this step is for Level 3 only! Take the

second TYPE LABEL and attach it to the BOTTOM END

CAP in the shown place.

58) Peel out the BOTTOM END FACE PLATE adhesive

protective film.

59) Place the BOTTOM END FACE PLATE to the BOTTOM

END CAP and press it gently for 5 seconds to activate

the adhesive.

60) Peel out the AV FACE PLATE adhesive protective

film.

Page 32

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

32

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

61) Place the AV FACE PLATE to the TOP END CAP and

press it gently for 5 seconds to activate the adhesive.

62) Peel out the LOCK KEY FACE PLATE adhesive

protective film.

63) Place the LOCK KEY FACE PLATE to the TOP END CAP

and press it gently for 5 seconds to activate the

adhesive.

64) Insert the SIM TRAY and the MICRO SD TRAY.

65) Remove the BOTTOM END CAP and the CAMERA

KEY protective films.

66) Remove the VOLUME KEY and the TOP END CAP

protective films.

Page 33

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

33

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

67) Remove the B-COVER and the CAMERA protective

films.

68) Now the Nokia X7-00 assembly procedure is

complete.

Page 34

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

34

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

1) Nokia X7-00 assembly with the SS-252 jig.

2) For assembling you need the Nokia Toolkit version

2. You will also need the SS-252 jig. Note that the SS252 jig is optional and it is targeted only for high

volume repair usage.

3) Protect the DIPRO LED with the protective film to

avoid short circuit.

4) Remove the EARPIECE ADHESIVE protective films.

5) Place the EARPIECE ADHESIVE with the tweezers.

Press it gently with the SS-93 to active the adhesive.

6) Place the EARPIECE with the tweezers. Note the

alignment of the EARPIECE.

11. ASSEMBLY WITH THE SS-252 JIG INSTRUCTIONS

Page 35

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

35

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

7) Push the EARPIECE with the SS-93 to its place as

shown. Be careful not to touch the highlighted area!

8) Remove the IHF SPEAKER MESH protective films.

9) Place the first IHF SPEAKER MESH with the

tweezers. Press it gently with the SS-93 to activate

the adhesive.

10) Then place the first IHF SPEAKER with the

tweezers. Note the alignment of the IHF SPEAKER.

Push the IHF SPEAKER with the SS-93 to its place as

shown. Be careful not to touch the highlighted area!

11) Use the same procedure as described earlier to

place the second IHF SPEAKER MESH and second the

IHF SPEAKER. Be careful not to touch the highlighted

area!

12) Peel off the DISPLAY CONDUCTIVE ADHESIVE

protective film.

Page 36

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

36

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

13) Place the DISPLAY CONDUCTIVE ADHESIVE on the

MAIN CHASSIS. To place the DISPLAY CONDUCTIVE

ADHESIVE correctly, use the shown places as guides.

14) Press the DISPLAY CONDUCTIVE ADHESIVE to

activate the adhesive.

15) Use the tweezers to place the AV JACK. Press

gently the AV JACK with the SS-93 to lock it into its

place.

16) Use the tweezers to place the CAMERA KEY and

the VOLUME KEY.

17) To ensure that the VOLUME KEY and the CAMERA

KEY stays in place, be sure to use the protective film

as shown.

18) Remove the CAMERA opening protective film with

the tweezers.

Page 37

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

37

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

19) Place the CAMERA MODULE with the tweezers.

Check that the guiding pin is aligned correctly. Press

the CAMERA MODULE with the SS-93, so that the

camera retaining pins are locked.

20) Place the MICRO USB BOOT as shown.

21) Place the MAIN CHASSIS on the SS-252 jig by

using the two shown guiding pins. Before placing

the ENGINE BOARD, move the HSJ FLEX connector out

of the way carefully with the SS-93.

22) Place the ENGINE BOARD by using the same

guiding pins as in previous step. Be careful not to

damage the HSJ FLEX connector.

23) Connect the HSJ FLEX connector with the SS-93.

Be careful not to damage the connector.

24) Place the IHF BB SHIELD and align it using the

three shown holes.

Page 38

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

38

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

25) Place the BATTERY.

26) Place the CAMERA KEY and the VOLUME KEY side of

the B-COVER first. Then lower down the opposite side

of the B-COVER. Press the B-COVER down until it snaps

into place.

27) Remove the device from the jig.

28) Open the jig as shown. Be sure to open also the

shown end of the jig.

29) Place the device in the jig by using the two

shown guiding pins.

30) Lock the bottom end of the jig.

Page 39

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

39

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

31) Place the screw guide plate.

32) Tighten the three shown TORX+ size 4 screws to

the torque of 25 Ncm in the order shown.

33) Tighten these three camera cross screws to the

torque of 10 Ncm in the order shown.

34) Remove the screw guide plate.

35) Adjust the top part of the jig as shown.

36) Use the SS-93 to connect the DISPLAY CONNECTOR.

Be careful not to damage the connector.

Page 40

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

40

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

37) Use the tweezers to place the DISPLAY

CONNECTOR RETENTION CLIP as shown. Press the

DISPLAY CONNECTOR RETENTION CLIP with the SS-93

to fasten it correctly.

38) Remove the DISPLAY CONDUCTIVE ADHESIVE

protective film.

39) Turn the DISPLAY over on to the MAIN CHASSIS.

Check that the shown side of the press plate is on

top.

40) Close the jig as shown. Lock the jig and keep it

locked down for 5 seconds to activate the DISPLAY

CONDUCTIVE ADHESIVE.

41) Unlock and open the jig and remove the device

from it. Check the shown gaps for defects in

installation. Please refer to the gap specification

document for accurate values.

42) Remove the DIPRO LED protective film.

Page 41

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

41

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

43) Remove the DISPLAY protective film.

44) Remove the adhesive protective film from the

MENU / HOME KEY. Hold the MENU / HOME KEY as

shown with tweezers to avoid scratches. If possible

use plastic tweezers or tweezers with rubber tips.

45) Place the MENU / HOME KEY to the A-COVER TOUCH

ASSEMBLY as shown. Press the MENU / HOME KEY very

gently so that the adhesive does not activate

completely.

46) Check that the MENU / HOME KEY is aligned

correctly in to the A-COVER TOUCH ASSEMBLY. The

MENU / HOME KEY should be located on the center.

Press the MENU / HOME KEY for 3 seconds to activate

the adhesive.

47) Remove the inner A-COVER TOUCH ASSEMBLY

protective film.

48) Guide the TOUCH FLEX to its gap as shown. Be

careful not to damage the flex! Start placing the ACOVER TOUCH ASSEMBLY to its place from the shown

side. Note that the A-COVER TOUCH ASSEMBLY has to

be assembled in a slight angle.

Page 42

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

42

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

49) Lower down the other side of the A-COVER TOUCH

ASSEMBLY. Be careful not to damage the B-COVER

water seal with the A-COVER TOUCH ASSEMBLY hooks.

Press the side and the bottom end of the A-COVER

TOUCH ASSEMBLY into place.

50) Connect the TOUCH FLEX connector with the SS-

93. Be careful not to damage the connector.

51) Hold tightly from the side of the device and push

the SIDE LOCKING PIN in as shown.

52) Use the same procedure and push in also the

second SIDE LOCKING PIN.

53) Tighten these two TORX+ size 4 screws to the

torque of 10 Ncm in the order shown. Press the BCOVER down while tightening these screws.

54) Place the AV FRONT SEAL to the AV JACK as shown.

Then press the AV FRONT SEAL to its place with finger

and make sure it is aligned correctly.

Page 43

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

43

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

55) Place the TOP END CAP and push it from the top

side and from the back side to lock it in its place.

56) Test that the device can be powered up properly.

If the device does not power up, this may be caused

by the Dipro LED short circuit. In this case please

follow the instructions how to reset a short-circuited

Nokia X7-00 on page 47.

57) Remove the pin guide from the jig.

58) Turn over the press plate so that rubber bumps

are on top.

59) Place the device in the jig as shown and lock the

bottom end of the jig. Then close the top part of the

jig and lock it.

60) Turn the jig so that the bottom end is facing

upwards. Tighten these two TORX+ size 4 screws to

the torque of 10 Ncm in the order shown.

Page 44

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

44

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

61) Turn around the jig. Tighten these two TORX+

size 4 screws to the torque of 10 Ncm in the order

shown.

62) Open the jig and remove the device from it.

Check the shown gaps for defects in installation.

Please refer to the gap specification document for

accurate values.

63) Check the shown gaps for defects in installation.

Please refer to the gap specification document for

accurate values.

64) Note that this step is for Level 3 only! Take the

second TYPE LABEL and attach it to the BOTTOM END

CAP in the shown place.

65) Peel out the BOTTOM END FACE PLATE adhesive

protective film.

66) Place the BOTTOM END FACE PLATE to the BOTTOM

END CAP and press it gently for 5 seconds to activate

the adhesive.

Page 45

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

45

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

67) Peel out the AV FACE PLATE adhesive protective

film.

68) Place the AV FACE PLATE to the TOP END CAP and

press it gently for 5 seconds to activate the adhesive.

69) Peel out the LOCK KEY FACE PLATE adhesive

protective film.

70) Place the LOCK KEY FACE PLATE to the TOP END CAP

and press it gently for 5 seconds to activate the

adhesive.

71) Insert the SIM TRAY and the MICRO SD TRAY.

72) Remove the BOTTOM END CAP and the CAMERA

KEY protective films.

Page 46

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

46

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

73) Remove the VOLUME KEY and the TOP END CAP

protective films.

74) Remove the B-COVER and the CAMERA protective

films.

75) Now the Nokia X7-00 assembly procedure is

complete.

Page 47

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

47

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

Negative side of power supply connected to micro USB casing

(black probe) and positive side of power supply is connected to

VBAT test pad (red probe).

12. RESETTING A SHORT-CIRCUITED X7-00

Nokia X7-00 is susceptible to shorting of the VBAT line during display assembly due to exposed

VBAT at the Dipro IR LED. This results in the battery protection circuit opening. The following

instructions will close the battery protection circuit.

1. In order to get access to VBAT test pad, remove the top end cap as described in disassembly

instructions.

2. Set the power supply to 3.8VDC with current limited to 500mA. Put the negative side of

power supply to micro USB connector casing and positive side of power supply to VBAT test

pad (J2070). The power supply should show the current draw when battery protection

circuit closes. Phone should then power up provided VBAT level is high enough for SW to

start up. If phone does not power on, at this point a charger can be connected into the

phone and it should start charging and when VBAT reaches the proper level it should power

on.

Page 48

Nokia X7-00 / X7-00.1

RM-707 / RM-659

Service Manual Level 1&2

48

Confidential | Copyright © 2011 Nokia | All rights reserved

Version 1.0

X2064

X2702

X2707

X2701

X2704

X2703 X2700X2063

X1502 X1500

X2100

X6301

X6302

X2502

F3300

S2700

X1650

X6310

X2065X2402 X2401 X2066

Ver. 1.0

NOKIA X7-00.1/X7-00

RM-659/RM-707

Solder components

TOP

BOTTOM

13. SOLDER COMPONENTS

Loading...

Loading...