Page 1

Page 2

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

(This page left intentionally blank.)

Page 1–2 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Page 3

RM-84/99

Camera Module Troubleshooting Nokia Customer Care

Table of Contents

Introduction to camera module troubleshooting................................................................................................................1–5

The effect of image taking conditions on image quality...................................................................................................1–6

Image quality analysis ...............................................................................................................................................................1–10

Testing for dust in camera module...................................................................................................................................1–10

Testing camera image sharpness......................................................................................................................................1–11

Dirty camera lens protection window.............................................................................................................................1–12

Image bit errors......................................................................................................................................................................1–13

Camera troubleshooting flowcharts.......................................................................................................................................1–13

Back camera troubleshooting.............................................................................................................................................1–13

Camera hardware failure message troubleshooting............................................................................................1–13

Camera baseband HW troubleshooting.....................................................................................................................1–15

Camera viewfinder troubleshooting...........................................................................................................................1–16

Bad camera image quality troubleshooting............................................................................................................1–17

RM-84 front camera troubleshooting...............................................................................................................................1–18

Front camera hardware failure message troubleshooting.................................................................................1–18

Front camera HW baseband troubleshooting.........................................................................................................1–19

Front camera viewfinder troubleshooting...............................................................................................................1–21

Front camera bad image quality troubleshooting.................................................................................................1–22

Flash LED troubleshooting.........................................................................................................................................................1–23

Introduction to flash LED troubleshooting.....................................................................................................................1–23

Flash LED and image taking conditions...........................................................................................................................1–23

Flash LED construction...........................................................................................................................................................1–27

Analysing image quality.......................................................................................................................................................1–28

Possible faults in image quality...................................................................................................................................1–28

Testing flash module functionality.............................................................................................................................1–28

Testing image colours with flash................................................................................................................................1–29

Testing flash power..........................................................................................................................................................1–29

Flash LED troubleshooting flowcharts..............................................................................................................................1–30

Bad image quality when using flash LED..................................................................................................................1–30

Flash LED indicator mode troubleshooting..............................................................................................................1–30

Flash LED HW baseband troubleshooting.................................................................................................................1–31

List of Figures

Figure 1 Blurred image. Target too close................................................................................................................................1–6

Figure 2 Blurring caused by shaking hands............................................................................................................................1–7

Figure 3 Near objects get skewed when taking images from a moving vehicle........................................................1–7

Figure 4 Noisy image taken in +70 degrees Celsius.............................................................................................................1–8

Figure 5 Image taken against light...........................................................................................................................................1–8

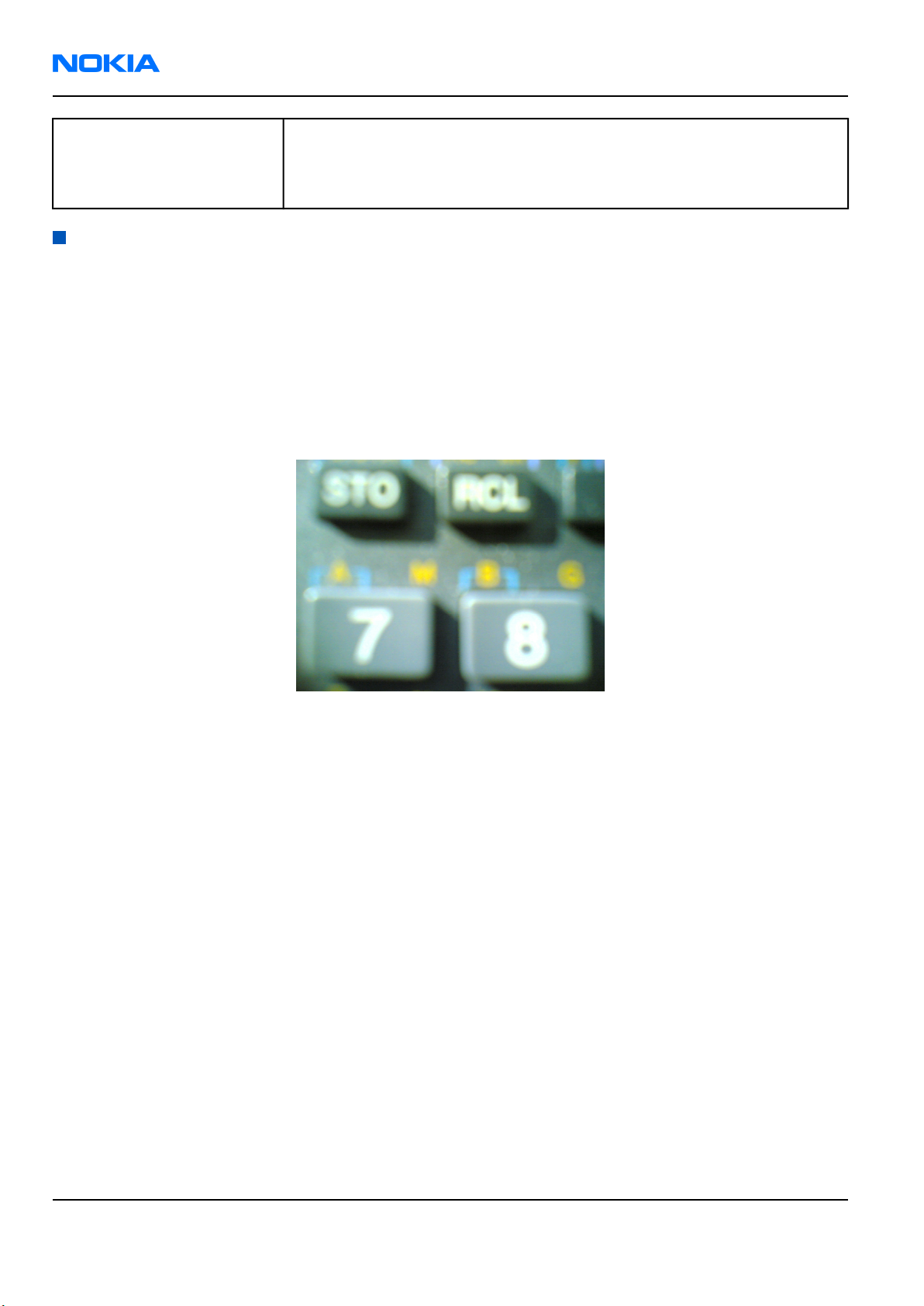

Figure 6 Flicker in an image; object illuminated by strong fluorescent light..............................................................1–9

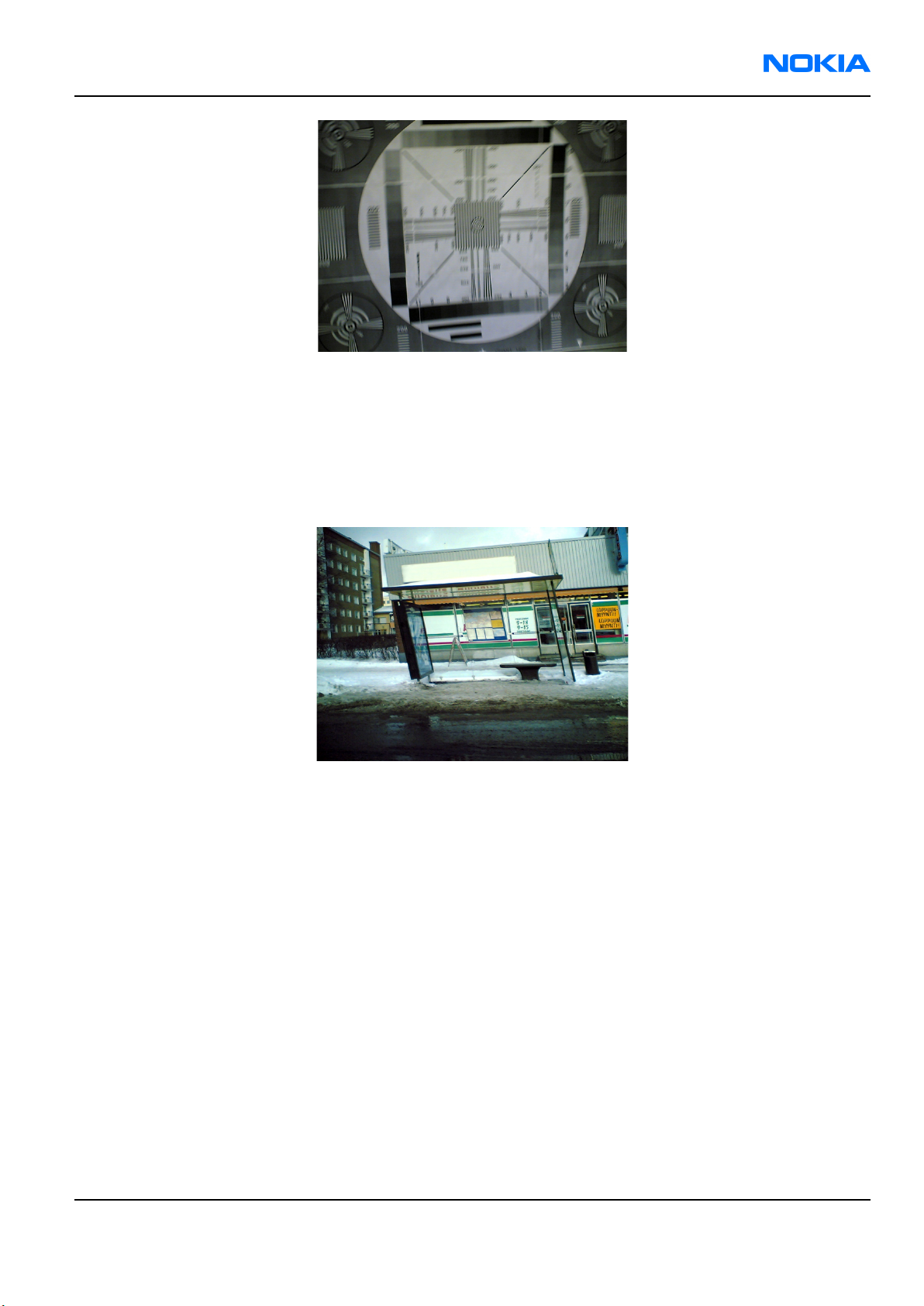

Figure 7 A lens reflection effect caused by sunshine...........................................................................................................1–9

Figure 8 Good image taken indoors.......................................................................................................................................1–10

Figure 9 Good image taken outdoors....................................................................................................................................1–10

Figure 10 Effects of dust on optical path..............................................................................................................................1–11

Figure 11 Image taken with clean protection window....................................................................................................1–13

Figure 12 Image taken with greasy protection window.................................................................................................1–13

Figure 13 Bit errors caused by JPEG compression..............................................................................................................1–13

Figure 14 Example of a good quality image taken with the flash LED........................................................................1–23

Figure 15 overexposed image..................................................................................................................................................1–24

Figure 16 Dark and noisy image..............................................................................................................................................1–25

Issue 1 Company Confidential Page 1–3

Copyright ©2005 Nokia. All Rights Reserved.

Page 4

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

Figure 17 Shaken image.............................................................................................................................................................1–26

Figure 18 Camera white balance failure and overexposure...........................................................................................1–27

Figure 19 Color difference between flash colour limit samples....................................................................................1–27

Figure 20 Mechanical construction of the flash LED module..........................................................................................1–28

Page 1–4 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Page 5

RM-84/99

Camera Module Troubleshooting Nokia Customer Care

Introduction to camera module troubleshooting

Background, tools and terminology

Faults or complaints in camera operation can be roughly categorised into three subgroups:

1 Camera is not functional at all; no image can be taken.

2 Images can be taken but there is nothing recognizable in them.

3 Images can be taken and they are recognizable but for some reason the quality of images is seriously

degraded.

Image quality is very hard to measure quantitatively, and even comparative measurements are difficult

(comparing two images) to do, if the difference is small. Especially if the user is not satisfied with his/her device's

image quality, and tells, for example, that the images are not sharp, it is fairly difficult to accurately test the

device and get an exact figure which would tell whether the device is functioning properly.

Often subjective evaluation has to be used for finding out if a certain property of the camera is acceptable or

not. Some training or experience of a correctly operating reference device may be needed in order to detect

what actually is wrong.

It is easy for the user to take bad images in bad conditions. Therefore the camera operation has to be checked

always in constant conditions (lighting, temperature) or by using a second, known-to-be good device as

reference.

When checking for possible errors in camera functionality, knowing what error is suspected significantly helps

the testing by narrowing down the amount of test cases. The following types of image quality problems may

be expected to appear:

• Dust (black spots)

• Lack of sharpness

• Bit errors

Terms

Dynamic range Camera's ability to capture details in dark and bright areas of the scene

simultaneously.

Exposure time Camera modules use silicon sensor to collect light and for forming an image.

The imaging process roughly corresponds to traditional film photography,

in which exposure time means the time during which the film is exposed to

light coming through optics. Increasing the time will allow for more light

hitting the film and thus results in brighter image. The operation principle

is exactly the same with silicon sensor, but the shutter functionality is

handled electronically i.e. there is no mechanical moving parts like in film

cameras.

Flicker Phenomenon, which is caused by pulsating in scene lighting, typically

appearing as wide horizontal stripes in an image.

Noise Variation of response between pixels with same level of input illumination.

Resolution Usually the amount of pixels in the camera sensor; for example, RM-1 has a

1280 x 960 pixel sensor resolution. In some occasions the term resolution is

used for describing the sharpness of the images.

Sensitivity Camera module's sensitivity to light. In equivalent illumination conditions,

a less sensitive camera needs a longer exposure time to gather enough light

in forming a good image. Analogous to ISO speed in photographic film.

Issue 1 Company Confidential Page 1–5

Copyright ©2005 Nokia. All Rights Reserved.

Page 6

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

Sharpness Good quality images are 'sharp' or 'crisp', meaning that image details are

well visible in the picture. However, certain issues, such as non-idealities in

optics, cause image blurring, making objects in picture to appear 'soft'. Each

camera type typically has its own level of performance.

The effect of image taking conditions on image quality

There are some factors, which may cause poor image quality, if not taken into account by the end user when

shooting images, and thus may result in complaints. The items listed are normal to camera operation and are

not a reason for changing the camera module.

Distance to target

The lens in the module is specified to operate satisfactorily from 40 cm to infinite distance of scene objects. In

practice, the operation is such that close objects may be noticed to get more blurred when distance to them is

shorter than 40 cm. The lack of sharpness is first visible in full resolution images. If observing just the viewfinder,

even very close objects may seem to appear sharp. This is normal; do not change the camera module.

Figure 1 Blurred image. Target too close.

The amount of light available

In dim conditions camera runs out of sensitivity. The exposure time is long (especially in the night mode) and

the risk of getting shaken (= blurred) images increases. In addition, image noise level grows. The maximum

exposure time in the night mode is ¼ seconds. Therefore, images need to be taken with extreme care and by

supporting the phone when the amount of light reflected from the target is low. Because of the longer exposure

time and larger gain value, noise level increases in low light conditions. Sometimes blurring may even occur in

daytime, if the image is taken very carelessly. See the figure below for an example. This is normal; do not change

the camera module.

Page 1–6 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Page 7

RM-84/99

Camera Module Troubleshooting Nokia Customer Care

Figure 2 Blurring caused by shaking hands

Movement in bright light

If an image is taken of moving objects or if the device is used in a moving vehicle, object 'skewing' or 'tilting'

may occur. This phenomenon is fundamental to most CMOS camera types, and usually cannot be avoided. The

movement of camera or object sometimes cause blurring indoors or in dim lighting conditions because of long

exposure time. This is normal; do not change the camera module.

Figure 3 Near objects get skewed when taking images from a moving vehicle

Temperature

High temperatures inside the mobile phone cause more noise to appear in images. For example, in +70 degrees

(Celsius), the noise level may be very high, and it further grows if the conditions are dim. If the phone processor

has been heavily loaded for a long time before taking an image, the phone might have considerably higher

temperature inside than in the surrounding environment. This is also normal to camera operation; do not

change the camera module.

Issue 1 Company Confidential Page 1–7

Copyright ©2005 Nokia. All Rights Reserved.

Page 8

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

Figure 4 Noisy image taken in +70 degrees Celsius

Phone display

If the display contrast is set too dark, the image quality degrades: the images may be very dark depending on

the setting. If the display contrast is set too bright, image contrast appears bad and "faint". This problem is

solved by setting the display contrast correctly. This is normal behaviour; do not change the camera module.

Basic rules of photography (especially shooting against light)

Because of dynamic range limitations, taking images against bright light might cause either saturated image

or the actual target appear too dark. In practice, this means that when taking an image indoors and having, for

example, a window behind the object, the result is usually poor. This is normal behaviour; do not change the

camera module.

Figure 5 Image taken against light

Flicker

In some occasions a bright fluorescent light may cause flicker in the viewfinder and captured image. This

phenomenon may also be a result, if images are taken indoors under the mismatch of 50/60 Hz electricity

network frequency. The electricity frequency used is automatically detected by the camera module. In some

very few countries, both 50 and 60 Hz networks are present and thus probability for the phenomenon increases.

Flickering occurs also under high artificial illumination level. This is normal behaviour; do not change the camera

module.

Page 1–8 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Page 9

RM-84/99

Camera Module Troubleshooting Nokia Customer Care

Figure 6 Flicker in an image; object illuminated by strong fluorescent light

Bright light outside of image view

Especially the sun can cause clearly visible lens glare phenomenon and poor contrast in images. This happens

because of undesired reflections inside the camera optics. Generally this kind of reflections are common in all

optical systems. This is normal behaviour; do not change the camera module.

Figure 7 A lens reflection effect caused by sunshine

Issue 1 Company Confidential Page 1–9

Copyright ©2005 Nokia. All Rights Reserved.

Page 10

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

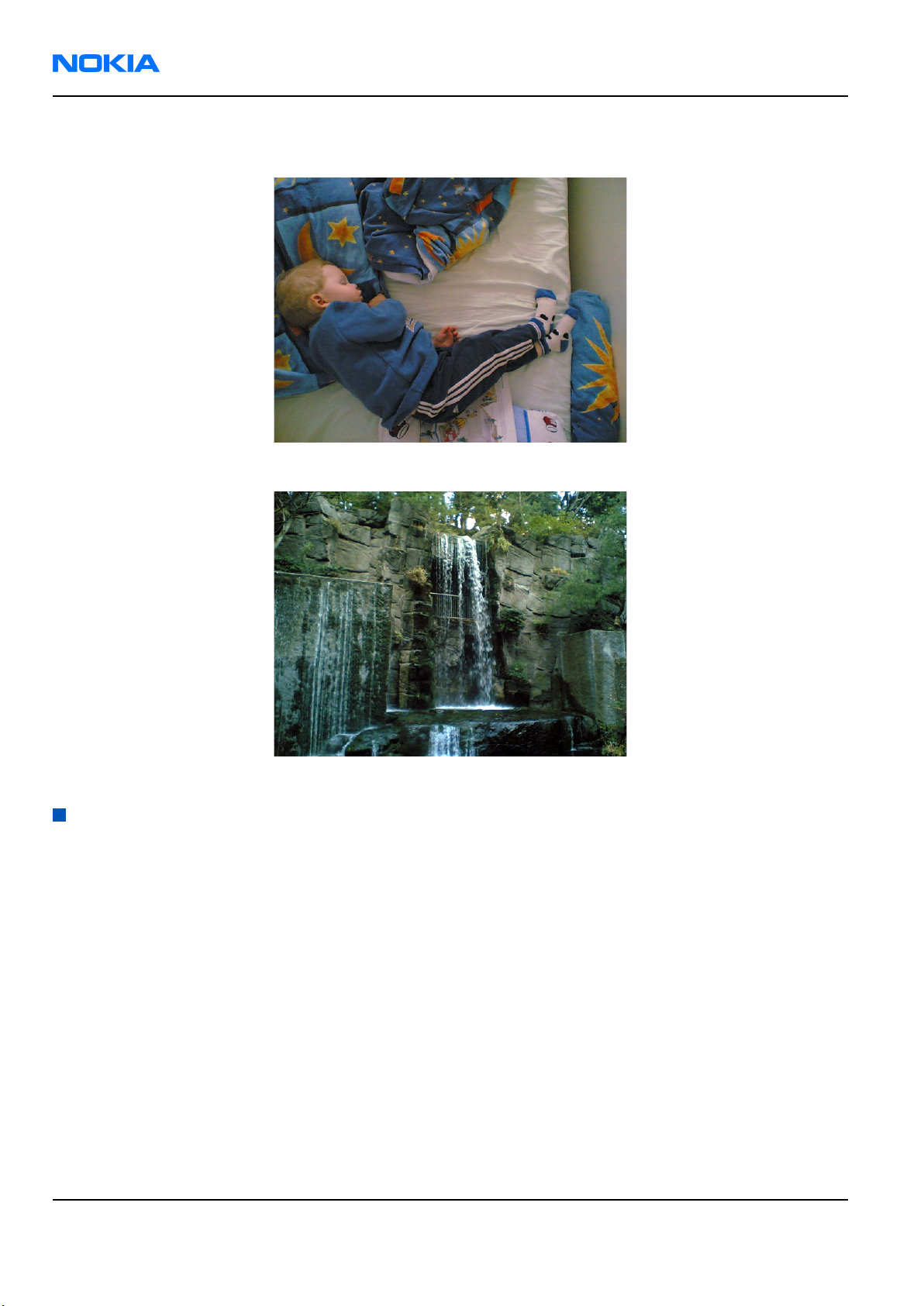

Examples of good quality images

Figure 8 Good image taken indoors

Figure 9 Good image taken outdoors

Image quality analysis

Testing for dust in camera module

Context

For detecting these kinds of problems, take an image of a uniform white surface and analyse it in full resolution.

A good quality PC monitor is preferred for analysis. Search carefully, since finding these defects is not always

easy. Figure "Effects of dust on optical path" is an example image containing easily detectable dust problems.

When taking a white image, use uniformly lightened white paper or white wall. One possibility is to use uniform

light but in this case make sure that the camera image is not flickering when taking the test image. In case

flickering happens, try to reduce illumination level. Use JPEG image format for analysing, and set the image

quality parameter to ‘High Quality’.

Black spots in an image are caused by dirt particles trapped inside the optical system. Clearly visible and sharp

edged black dots in an image are typically dust particles on the image sensor. These spots are searched for in

the manufacturing phase, but it is possible that the camera body cavity contains a particle, which may move

onto the image sensor active surface, for example, when the phone is dropped. Thus it is also possible that the

problem will disappear before the phone is brought to service. The camera should be replaced if the problem

is present when the service technician analyses the phone.

Page 1–10 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Page 11

RM-84/99

Camera Module Troubleshooting Nokia Customer Care

If a dust particle is lying on the infrared filter surface on either side, they are hard to locate because they are

out of focus, and appear in the image as large, grayish and fading-edge 'blobs'. Sometimes they are invisible

to the eye, and thus the user probably does not notice them at all. However, it is possible that a larger particle

disturbs the user, causing need for service.

Figure 10 Effects of dust on optical path

If large dust particles get trapped on top of the lens surface in the cavity between camera window and lens,

they will cause image blurring and poor contrast. The dust gasket between the window and lens should prevent

any particles from getting into the cavity after the manufacturing phase.

If dust particles are found on the sensor, this is classified as a manufacturing error of the module and the camera

should be replaced. Any particles inside the cavity between the protection window and lens have most probably

been trapped there in the assembly phase at a Nokia factory. Unauthorized disassembling of the product can

also be the root of the problem. However, in most cases it should be possible to remove the particle(s) by using

clean compressed air. Never wipe the lens surface before trying compressed air; the possibility of damaging

the lens is substantial. Always check the image sharpness after removing dust.

See Also

• Testing camera image sharpness (Page 1–11)

Testing camera image sharpness

Context

If pictures taken with a device are claimed to be blurry, there are six possible sources for the problem:

1 The protection window is fingerprinted, soiled, dirty, visibly scratched or broken.

2 The photographed object is too close – the camera lens operates with distances from 40 cm to infinity. This

is no cause to replace camera module.

Issue 1 Company Confidential Page 1–11

Copyright ©2005 Nokia. All Rights Reserved.

Page 12

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

3 User has tried to take pictures in too dark conditions, and images are blurred due to handshake or movement.

This is no cause to replace camera module.

4 There is dirt between the protection window and camera lens.

5 The protection window is defective. This can be either a manufacturing failure or caused by the user. The

window should be changed.

6 The camera lens is misfocused because of a manufacturing error.

A quantitative analysis of sharpness is very difficult to conduct in any other environment than optics laboratory.

Therefore, subjective analysis should be used.

If no visible defects (items 1-4) are found, a couple of test images should be taken. Generally, a well-illuminated

typical indoor scene can be used as a target. The main considerations are:

• The protection window has to be clean.

• The amount of light (300 – 600 lux (bright office lighting)) is sufficient.

• The scene should contain, for example, small objects for checking sharpness. Their distance should be 1 – 2

meters.

• If possible, compare the image to another image of the same scene, taken with a different device. Note that

the reference device has to be a similar Nokia phone.

Steps

1. Take several images of small objects in the distance of 1-2 metres.

2. Analyse the images on a PC screen at 100% scaling with the reference images.

Pay attention to the computer display settings: at least 65000 colors (16-bit) have to be used. True colour

(24-bit, 16 million colours) or 32-bit (full colour) setting is recommended.

Next action

If there appears to be a clearly noticeable difference between the reference image and the test images, the

module might have a misfocused lens -> change the module.

Re-check the resolution after changing the camera module.

If the changed module produces the same result, the fault is probably in the camera window. Check the window

by looking carefully through it when replacing the module.

See Also

• Testing for dust in camera module (Page 1–10)

• Dirty camera protection window (Page 1–12)

Dirty camera lens protection window

The following series of images demonstrates the effects of fingerprints on the camera protection window.

It should be noted that the effects of any dirt in images can vary much. It may be difficult to judge whether the

window has been dirty or if something else is wrong. Therefore, the cleanness of the protection window should

always be checked and the window should be wiped clean with a suitable cloth.

Page 1–12 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Page 13

RM-84/99

Camera Module Troubleshooting Nokia Customer Care

Figure 11 Image taken with clean protection

window

Figure 12 Image taken with greasy protection window

Image bit errors

Bit errors are image defects caused by data transmission errors between the camera module and the phone

baseband and/or errors inside the module.

Usually bit errors can be easily detected in images, and they are best visible in full resolution images. A good

practice is to use a uniform white test target when analysing these errors. The errors are clearly visible, colourful

sharp dots or lines in camera images. See the following figure.

Figure 13 Bit errors caused by JPEG compression

One type of bit error is a lack of bit depth. In this case, the image is almost totally black under normal conditions,

and only senses something in very highly illuminated environments. Typically this is a contact problem between

the camera module and the phone main PWB. You should check the camera assembly and connector contacts.

If the fault is in the camera module, bit errors are typically visible only when using some specific image

resolution. For example, in case of a viewfinder fault, the error might exist but is not visible in a full size image.

Camera troubleshooting flowcharts

Back camera troubleshooting

Camera hardware failure message troubleshooting

Context

If you get a hardware failure message when using the camera, follow the next troubleshooting flowchart.

Issue 1 Company Confidential Page 1–13

Copyright ©2005 Nokia. All Rights Reserved.

Page 14

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

Note: Make sure that the phone has the latest software before continuing.

Results

The camera is working properly.

Next action

If there are still problems with the camera, see "Camera baseband hardware troubleshooting".

Page 1–14 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Page 15

RM-84/99

Camera Module Troubleshooting Nokia Customer Care

Camera baseband HW troubleshooting

Issue 1 Company Confidential Page 1–15

Copyright ©2005 Nokia. All Rights Reserved.

Page 16

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

Camera viewfinder troubleshooting

Page 1–16 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Page 17

RM-84/99

Camera Module Troubleshooting Nokia Customer Care

Bad camera image quality troubleshooting

See Also

• Camera hardware failure message troubleshooting (Page 1–13)

Issue 1 Company Confidential Page 1–17

Copyright ©2005 Nokia. All Rights Reserved.

Page 18

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

RM-84 front camera troubleshooting

Front camera hardware failure message troubleshooting

Page 1–18 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Page 19

Page 20

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

Page 1–20 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Page 21

RM-84/99

Camera Module Troubleshooting Nokia Customer Care

Front camera viewfinder troubleshooting

Issue 1 Company Confidential Page 1–21

Copyright ©2005 Nokia. All Rights Reserved.

Page 22

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

Front camera bad image quality troubleshooting

Page 1–22 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Page 23

RM-84/99

Camera Module Troubleshooting Nokia Customer Care

Flash LED troubleshooting

Introduction to flash LED troubleshooting

A fault or complaint associated to LED flash operation can be roughly categorized into two subgroups:

1 Flash is not functional at all (no light output at all).

2 Images can be taken and they are recognizable but for some reason the quality of images is degraded.

The quality of an image is very difficult to measure quantitatively, and even comparative measurements are

difficult (comparing two images), if the difference between reference images is small. If a user is not satisfied

with his/her device's image quality, it is fairly difficult to accurately test the device and get an exact result, which

would tell if the device is working properly.

Often subjective evaluation has to be used for finding out if there is something wrong in the flash. Some training

or experience of a correctly operating reference device may be needed in order to detect possible faults. It is

easy for a user to take low quality images in bad conditions. Therefore, the camera and flash operation has to

be always checked in constant conditions (lighting, temperature) or by using a second, known-to-be good

reference device.

Flash LED and image taking conditions

This section describes some of common factors, which may cause poor image quality if not taken into account

by end users when taking pictures, and may therefore result in complaints. The items described are normal to

the camera and LED flash operation and do not raise a need for servicing the components.

Figure 14 Example of a good quality image taken with the flash LED

Distance to the target (too close)

There is no feedback in the flash system, which means that the light output is constant in every situation. This

causes the images to overexposure, when shot from close distance. The flash LED is designed to work optimally

between distances of 50cm – 1.20m.

This is normal behaviour; do not change the flash module.

Issue 1 Company Confidential Page 1–23

Copyright ©2005 Nokia. All Rights Reserved.

Page 24

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

Figure 15 overexposed image

Distance to the target (too far away):

The power of the white LED flash is still very modest compared to xenon flash technology. Even with the full

power, the maximum distance for an acceptable image quality is roughly 1.2m. If the distance is greater than

1.2m, the images will appear dark and the noise level increases.

This is normal behaviour; do not change the flash module.

Page 1–24 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Page 25

RM-84/99

Camera Module Troubleshooting Nokia Customer Care

Figure 16 Dark and noisy image

Shaken (= blurred) images

The traditional xenon flash has the advantage of stopping the movement. This is a result of an extremely short

and intense light pulse, which makes it possible for a camera to use very short exposure time. Due to the weak

output of the LED flash, the exposure time has to be actually increased in the viewfinder mode in total blackness,

instead of shortening it. This allows the sensor to integrate longer and collect more light but this also easily

creates blurred images if care is not taken.

Issue 1 Company Confidential Page 1–25

Copyright ©2005 Nokia. All Rights Reserved.

Page 26

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

Figure 17 Shaken image

Camera white balance failure and overexposure due to presence of ambient light

Because the spectral output of the flash is known, the white balance and the exposure control of the camera

work in optimal way with the flash in total blackness. This is why some of the pictures may fail, if there is some

ambient light present when the image is taken.

If the flash works correctly in dark conditions, there is no need to change the flash module.

Page 1–26 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Page 27

RM-84/99

Camera Module Troubleshooting Nokia Customer Care

Figure 18 Camera white balance failure and overexposure

Colour difference between different modules

There is some variation in the spectrum of the flash, which derives from the manufacturing process of the white

LEDs. Because of this variation, there may be some variation in the colour of the images as well.

This is normal behaviour; do not change the flash module.

Figure 19 Color difference between flash colour limit samples

Flash LED construction

This section describes the actual construction of the LED flash module for getting a better understanding of the

mechanics of the module.

Issue 1 Company Confidential Page 1–27

Copyright ©2005 Nokia. All Rights Reserved.

Page 28

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

Figure 20 Mechanical construction of the flash LED module

The flash LED module as a component is not a repairable part, i.e. components / parts in the module cannot be

changed. Only cleaning dust from the lens is allowed; use clean compressed air.

The main parts of the module are:

• Housing, which is glued to the PWB

• Lens area (round area on top of the housing with circle patterns)

• LED chip (yellow chip inside the housing), which is soldered to the PWB

• ESD protection diode (black passive component inside the housing), which is soldered to the PWB

• PWB

• Contact pads

• Laser marked serial number

The flash LED is fixed to the phone mechanics with special clips. The contacts to the main PWB are formed by

using spring connectors.

Analysing image quality

Possible faults in image quality

When checking for possible errors in the flash functionality, knowing what error is suspected, significantly helps

the testing by narrowing down the number of possible test cases. The following types of image quality problems

may be expected to appear:

• LED module is not flashing at all

• Image colours are not good

• Flash power is weak

Testing flash module functionality

Context

With the help of this test you can check the flash module's overall functionality.

Always set the flash to FORCED FLASH mode when performing the test. The FORCED FLASH mode enforces the

LED module to flash, even if there is some ambient light present.

Page 1–28 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Page 29

RM-84/99

Camera Module Troubleshooting Nokia Customer Care

Steps

1. Take an image with the flash and monitor at same time whether the LED module flashes.

Results

If the LED flashes normally, the overall functionality of the module is OK.

Testing image colours with flash

Context

With the help of this test you can check if the image colours are normal when using the flash.

Steps

1. Take an image of a target, which contains something white in total blackness from less than 1 m range.

Results

If the white target appears to be white, the flash is working correctly. However, remember that there is some

variation in the flash colour from module to module. For more information, see sectionColor difference between

flash colour limit samples (Page 1–27)in Flash LED and image taking conditions (Page 1–23).

Testing flash power

Context

With the help of this test you can check if the flash is working with adequate power level.

Steps

1. Take an image with the flash in total blackness (ambient light <1 lux) of a target 80 cm - 1 cm away.

Results

If the flash is working normally with adequate power level, the image is correctly exposed from 80cm – 1m

distances.

Remember that the brightness level in the corners is always less than in the center of the image because of

camera and flash optics.

Issue 1 Company Confidential Page 1–29

Copyright ©2005 Nokia. All Rights Reserved.

Page 30

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

Flash LED troubleshooting flowcharts

Bad image quality when using flash LED

Flash LED indicator mode troubleshooting

For checking the indicator mode functionality, force the camera to record a video clip and monitor the flash led

at the same time. The flash LED should work with very low brightness constantly during the video recording.

Page 1–30 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Page 31

RM-84/99

Camera Module Troubleshooting Nokia Customer Care

Flash LED HW baseband troubleshooting

If there are problems in the flash LED driver circuit, the testing procedure is complicated, because the driver

circuit output cannot be reliably measured without the load (LED). Load (LED) is always disconnected from the

output when the phone is disassembled.

Issue 1 Company Confidential Page 1–31

Copyright ©2005 Nokia. All Rights Reserved.

Page 32

RM-84/99

Nokia Customer Care Camera Module Troubleshooting

(This page left intentionally blank.)

Page 1–32 Company Confidential Issue 1

Copyright ©2005 Nokia. All Rights Reserved.

Loading...

Loading...