Nokia 8550 Service manual

Programs After Market Services (PAMS)

Technical Documentation

[Issue 3: NMP Part No.0275426 ]

[Issue 4: NMP Part No.0275571]

NSM–3/3D

SERIES CELLULAR

PHONES

NSM–3 issue 4: 02/2002

Copyright 2000, 2002. Nokia Corporation. All Rights Reserved.

NSM–3/3D

Foreword

PAMS Technical Documentation

AMENDMENT RECORD SHEET

Amendment Date Inserted By Comments

Issue 1 12/1999 Jouni Rantala

Issue 2 07/2000 Jouni Rantala General Information

HHS–12 Swivel Mount added.

ACP–7P charger removed.

System Module

Parts List and Schematic Diagrams for

layout 16 added.

UI Module

IR Module text edited.

Product Variants

Exploded View and Item numbering

edited.

Service Software Instructions

Edited to correspond with changes

made in Service Software.

Issue 3 11/2000 Jouni Rantala

Issue 4 12/2001 O Juntunen

Non Serviceable Accessories

HHS–12 Swivel Mount added.

ACP–7P charger removed.

NSM–3DX phone added.

NSM–3 layout 18

Schematic Diagrams for layout version

16 can be used with layout 18 (top

and bottom layout pictures added for

version 18).

Note: Issue 3 replaces

issues 1 and 2.

Foreword pp.1 to 4 replaced

System Module

TOC updated

Parts List for NSM–3 layouts 19 and

21 added,

NSM 3D layout 05 added,

HW list added.

Schematic Diagrams for NSM–3

layout 19, 20, 21 added

Schematic Diagrams for NSM–3D

layout 05 added. Document

repaginated.

Page 2

2002. Nokia Corporation.

Issue 4 02/2002

PAMS Technical Documentation

NSM–3/3D

Foreword

Product Variants

Exploded View and Item numbering

updated

Replace pp 1 & 2, 5 to 8

Service Software Instructions

Edited to correspond with changes

made in Service Software. Tuning

Instructions pp. 83–100 to removed to

dedicated section.

Replaced pages: pp.1 to 6, 10, 14, 16,

27, 32, 39, 45, 48, 51 to 58, 64, 68, 71

to 82.

Tuning Instructions

Removed from Service SW section.

28 pages.

Service Tools

pp 1 to 3, p.11, p.25, p.27 edited.

p.13 JBA–6 replaced by BBF–1

p.14 ADS–3 removed

p.26 Modular Cable Jack removed

p.28 FLS–4s updated.

Issue 4 02/2002

Nokia Mobile Phones Ltd.

Page 3

NSM–3/3D

Foreword

PAMS Technical Documentation

NSM–3/3D

SERIES CELLULAR PHONES

SERVICE MANUAL

CONTENTS:

1. Foreword

2. General Information

3. System Module

4. UI Module

5. Product Variants

NSM–3NX

NSM–3DX

6. Service Software Instructions

6. Tuning Instructions

8. Service Tools

9. Disassembly/Troubleshooting Instructions

10. Non–serviceable Accessories

Page 4

2002. Nokia Corporation.

Issue 4 02/2002

PAMS Technical Documentation

This document is intended for use by qualified service personnel only.

Company Policy

Our policy is of continuous development; details of all technical modifications will

be included with service bulletins.

While every endeavour has been made to ensure the accuracy of this document,

some errors may exist. If any errors are found by the reader, NOKIA MOBILE

PHONES Ltd should be notified in writing.

Please state:

Title of the Document + Issue Number/Date of publication

Latest Amendment Number (if applicable)

Page(s) and/or Figure(s) in error

NSM–3/3D

Foreword

IMPORTANT

Please send to: Nokia Mobile Phones Ltd

PAMS Technical Documentation

PO Box 86

24101 SALO

Finland

Issue 4 02/2002

Nokia Mobile Phones Ltd.

Page 5

NSM–3/3D

Foreword

Warnings and Cautions

Please refer to the phone’s user guide for instructions relating to operation,

care and maintenance including important safety information. Note also the

following:

Warnings:

1. CARE MUST BE TAKEN ON INSTALLATION IN VEHICLES

FITTED WITH ELECTRONIC ENGINE MANAGEMENT

SYSTEMS AND ANTI–SKID BRAKING SYSTEMS. UNDER

CERTAIN FAULT CONDITIONS, EMITTED RF ENERGY CAN

AFFECT THEIR OPERATION. IF NECESSARY, CONSULT THE

VEHICLE DEALER/MANUFACTURER TO DETERMINE THE

IMMUNITY OF VEHICLE ELECTRONIC SYSTEMS TO RF

ENERGY.

2. THE HANDPORTABLE TELEPHONE MUST NOT BE OPERATED

IN AREAS LIKELY TO CONTAIN POTENTIALLY EXPLOSIVE

ATMOSPHERES EG PETROL STATIONS (SERVICE STATIONS),

BLASTING AREAS ETC.

PAMS Technical Documentation

3. OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT,

4. CLASS 1 LASER PRODUCT. See IEC60825–1 specification:

Cautions:

1. Servicing and alignment must be undertaken by qualified

2. Ensure all work is carried out at an anti–static workstation and that

3. Ensure solder, wire, or foreign matter does not enter the telephone

4. Use only approved components as specified in the parts list.

5. Ensure all components, modules screws and insulators are

INCLUDING CELLULAR TELEPHONES, MAY INTERFERE WITH

THE FUNCTIONALITY OF INADEQUATELY PROTECTED

MEDICAL DEVICES. CONSULT A PHYSICIAN OR THE

MANUFACTURER OF THE MEDICAL DEVICE IF YOU HAVE

ANY QUESTIONS. OTHER ELECTRONIC EQUIPMENT MAY

ALSO BE SUBJECT TO INTERFERENCE.

825–1; 5: Labelling, 5.1: General, 5.2: Class 1

personnel only.

an anti–static wrist strap is worn.

as damage may result.

correctly re–fitted after servicing and alignment. Ensure all cables

and wires are repositioned correctly.

6. All PC’s used with NMP Service Software for this produce must be

bios and operating system ”Year 2000 Compliant”.

Page 6

2002. Nokia Corporation.

Issue 4 02/2002

PAMS Technical Documentation

NSM–3/3D Series Transceivers

General Information

Issue 3 11/2000 Nokia Mobile Phones Ltd.

NSM–3/3D

General Information

PAMS Technical Documentation

CONTENTS

Product Selection 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handportables 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Desktop Option 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product and Module List 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Specifications 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications of Transceiver NSM–3/3D 6. . . . . . . . .

Page 2

Nokia Mobile Phones Ltd.

Issue 3 11/2000

PAMS Technical Documentation

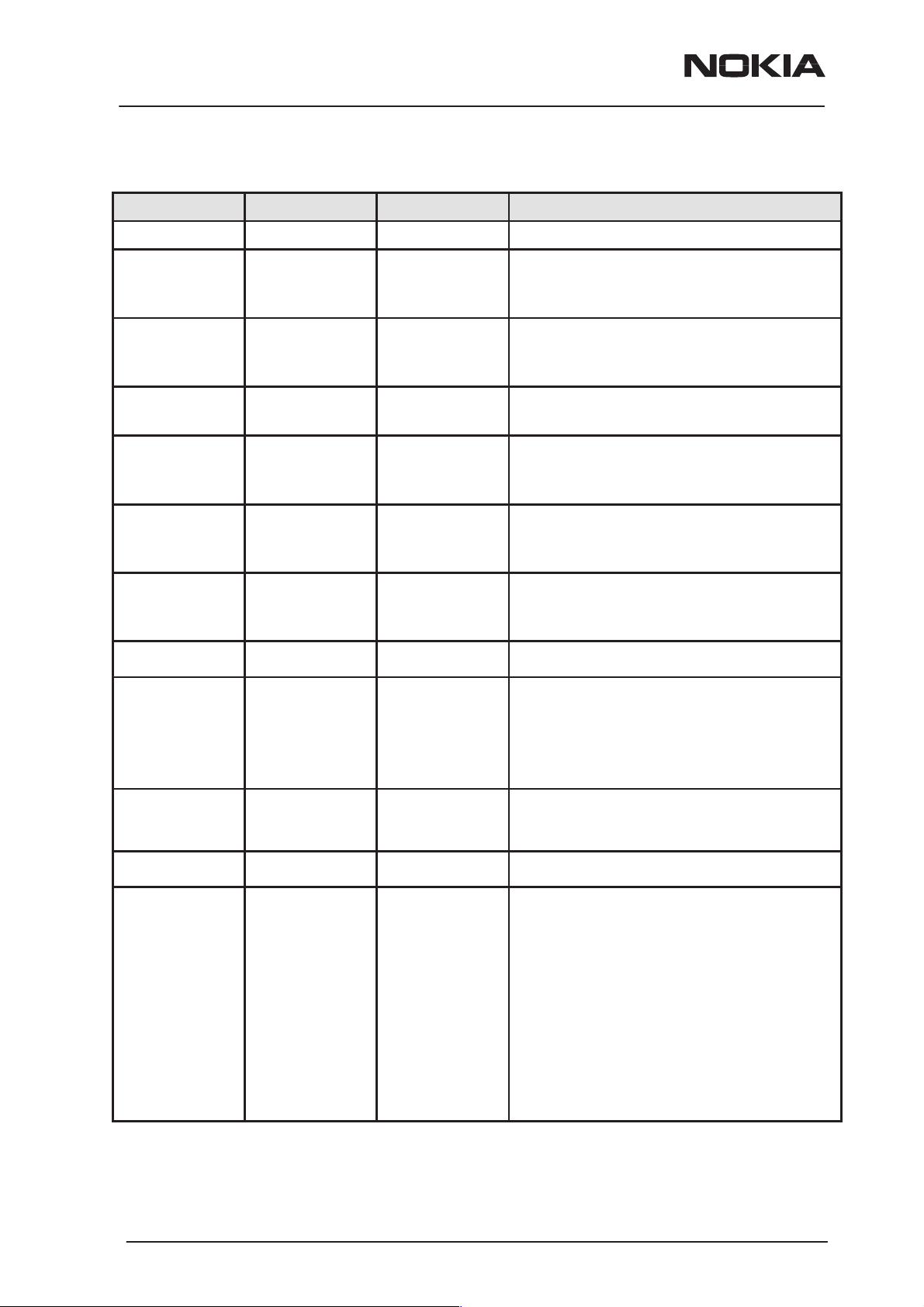

Product Selection

Handportables

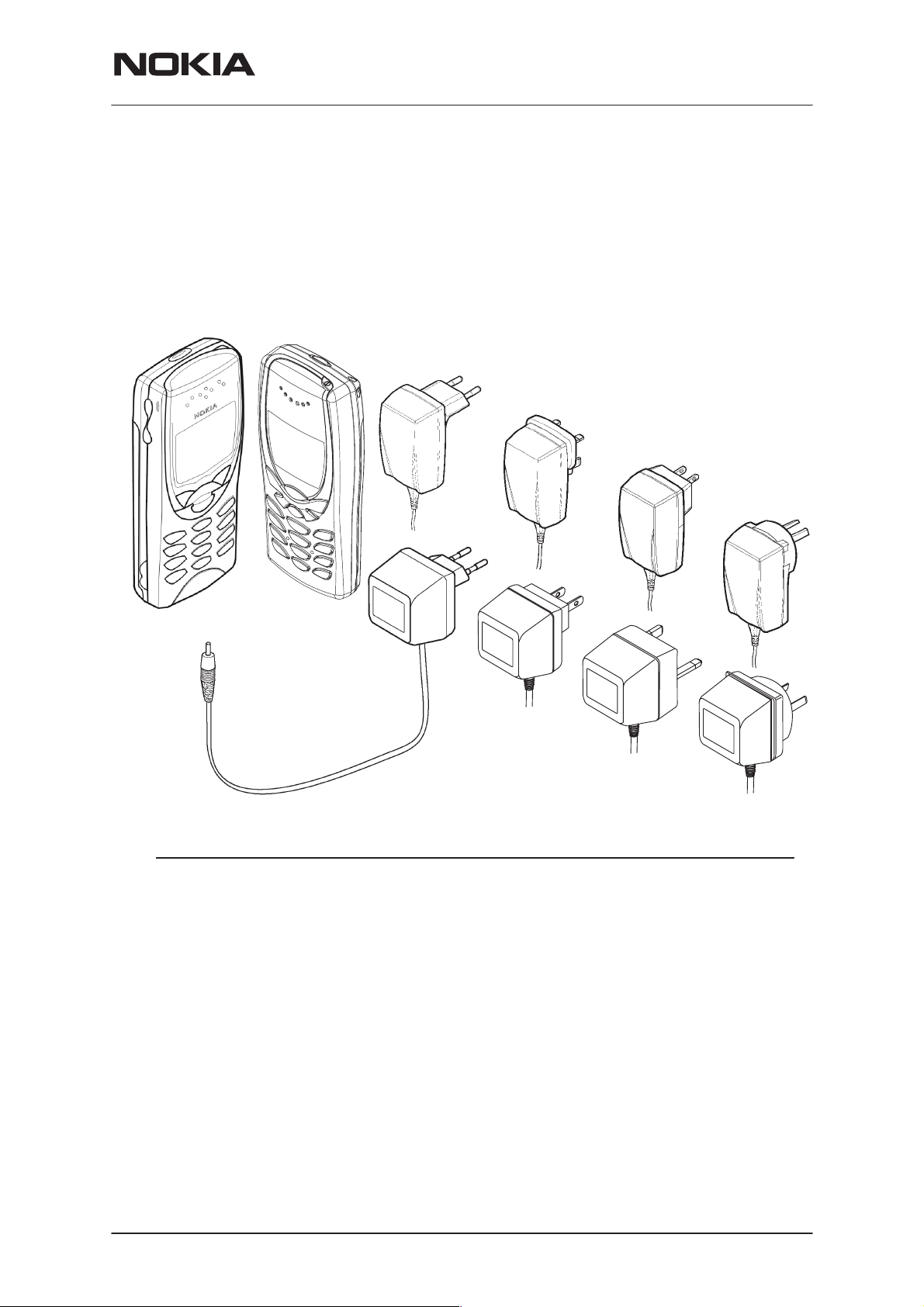

The NSM–3 and NSM–3D are dual band handportable mobile telephones for the E–GSM 900 and GSM1800 networks.

NSM–3/3D

General Information

2.

NSM–3NX

1.

NSM–3DX

2.

3.

ACP–7E

7.

ACP–8E

ACP–8K

ACP–7C

ACP–7U

4.

8.

ACP–8X

5.

ACP–7H

ACP–7X

ACP–8U

ACP–8C

9.

ACP–8A

10.

6.

ACP–7A

Item Name: Type code: Material code:

1. Transceiver See Product Variants

2. Standard battery (Li–ion 650 mAh) BLB–2 0670246

3. AC Travel Charger (Euro plug) 207–253 Vac ACP–7E 0675144

4. AC Travel Charger (US plug) 108–132 Vac ACP–7U 0675143

AC Travel Charger

5. AC Travel Charger

(US plug) 198–242 Vac ACP–7C 0675158

(UK plug) 207–253 Vac ACP–7X 0675145

AC Travel Charger (UK plug) 180–220 Vac ACP–7H 0675146

6. AC Travel Charger (Australia) 216–264 Vac ACP–7A 0675148

7. Performance Travel Charger Euro plug 90–264 Vac ACP–8E 0675195

Performance Travel Charger

Korea plug 90–264 Vac ACP–8K 0675199

8. Performance Travel Charger UK plug 90–264 Vac ACP–8X 0675197

9. Performance Travel Charger US plug 90–264 Vac ACP–8U 0675196

Performance Travel Charger China plug 90–264 Vac ACP–8C 0675211

10. Performance Travel Charger

Issue 3 11/2000

Nokia Mobile Phones Ltd.

Australia plug 90–264 V ac ACP–8A 0675214

Page 3

NSM–3/3D

General Information

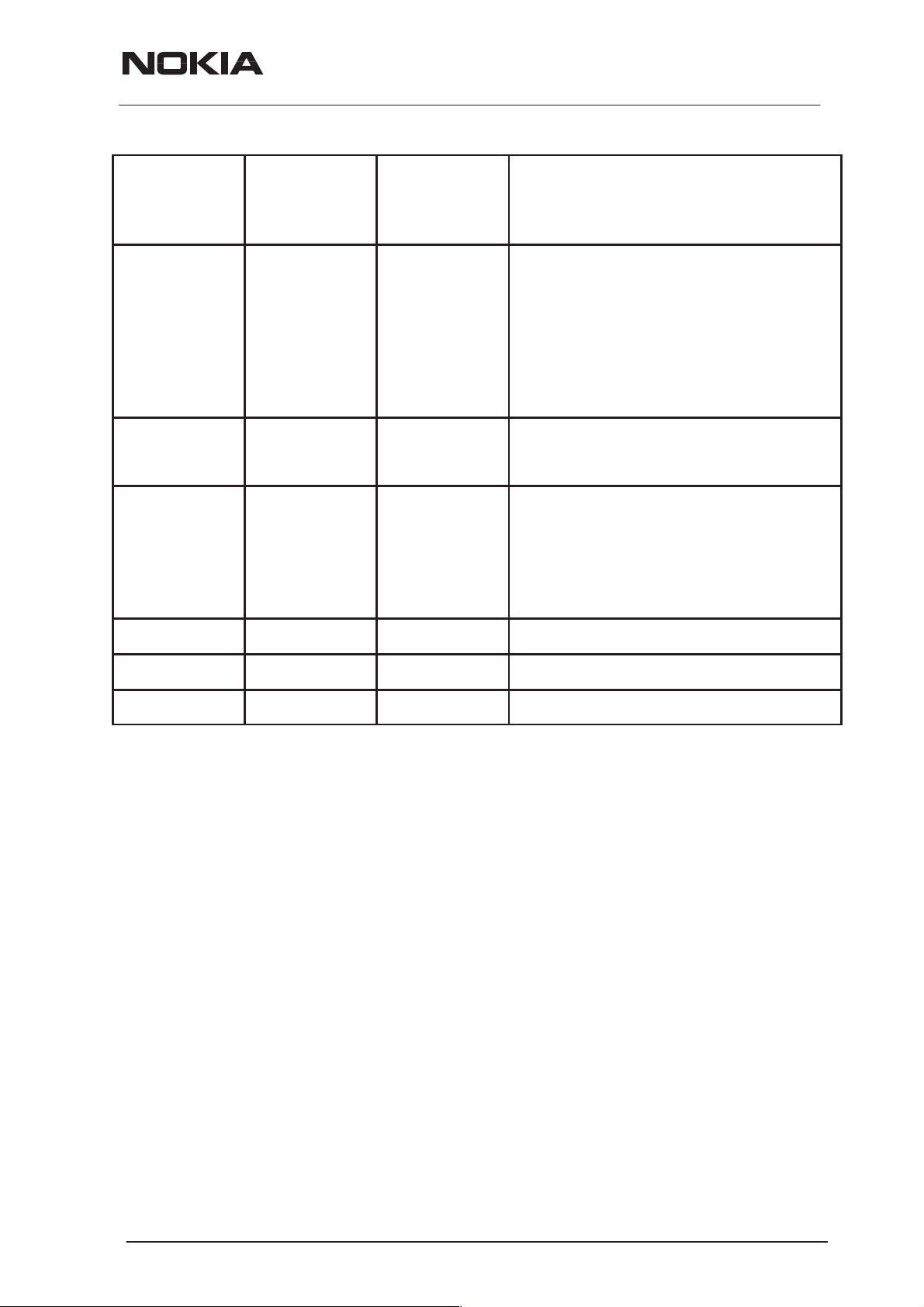

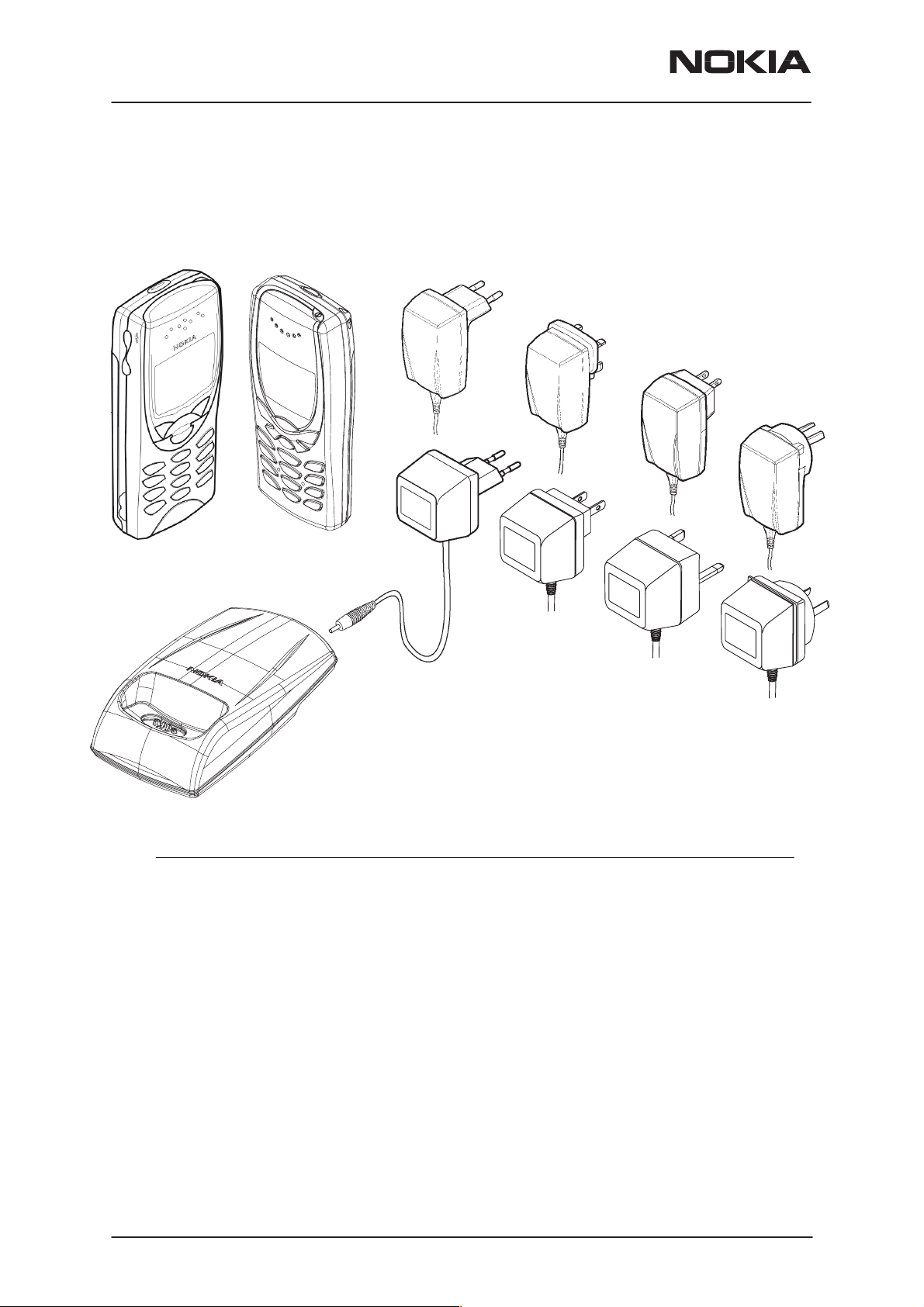

Desktop Option

The desktop option allows the user to charge the phone from the mains.

1.

7.

ACP–8E

ACP–8K

SUKO PINS

PAMS Technical Documentation

ACP–8X

8.

ACP–8U

ACP–8C

9.

ACP–8A

10.

2.

2.

NSM–3NX

NSM–3DX

3.

ACP–7E

4.

ACP–7C

ACP–7U

5.

ACP–7H

ACP–7X

6.

ACP–7A

2.

Item Name: Type code: Material code:

1. Transceiver See Product Variants

2. Desk Stand DVC–1B 0675220

3. AC Travel Charger (Euro plug) 207–253 Vac ACP–7E 0675144

4. AC Travel Charger (US plug) 108–132 Vac ACP–7U 0675143

AC Travel Charger

5. AC Travel Charger

(US plug) 198–242 Vac ACP–7C 0675158

(UK plug) 207–253 Vac ACP–7X 0675145

AC Travel Charger (UK plug) 180–220 Vac ACP–7H 0675146

6. AC Travel Charger (Australia) 216–264 Vac ACP–7A 0675148

7. Performance Travel Charger Euro plug 90–264 Vac ACP–8E 0675195

Performance Travel Charger

Korea plug 90–264 Vac ACP–8K 0675199

8. Performance Travel Charger UK plug 90–264 Vac ACP–8X 0675197

9. Performance Travel Charger US plug 90–264 Vac ACP–8U 0675196

Performance Travel Charger China plug 90–264 Vac ACP–8C 0675211

10. Performance Travel Charger

Australia plug 90–264 V ac ACP–8A 0675214

Page 4

Nokia Mobile Phones Ltd.

Issue 3 11/2000

PAMS Technical Documentation

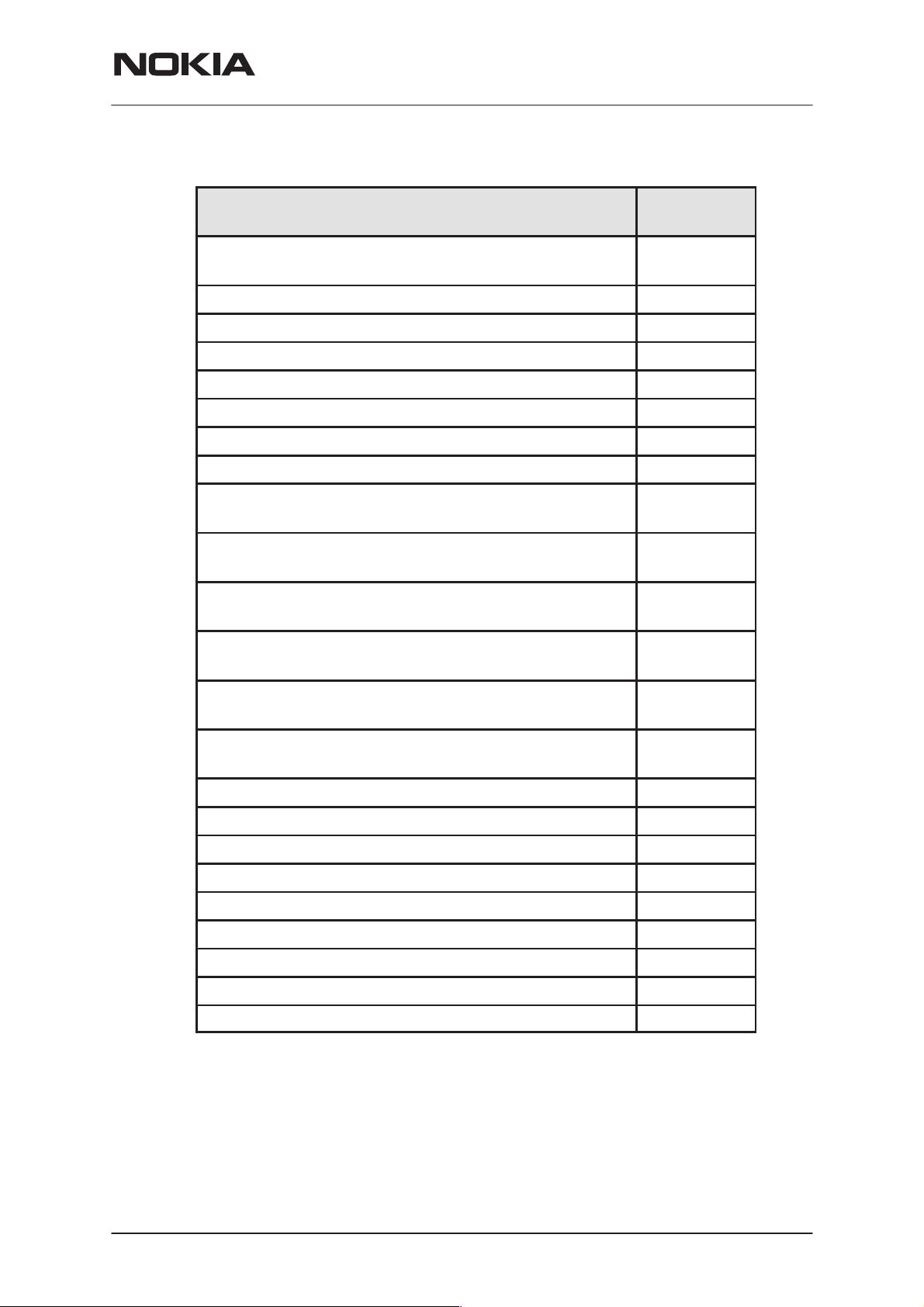

Product and Module List

Unit/type: Product

Transceiver NSM–3/3D See Product

Standard Battery BLB–2 650 mAh Li–ion 0670246

AC Travel Charger ACP–7E (EUR) 207–253 Vac 0675144

AC Travel Charger ACP–7U (US) 108–132 Vac 0675143

AC Travel Charger ACP–7C (US) 198–242 Vac 0675158

AC Travel Charger ACP–7X (UK) 207–253 Vac 0675145

AC Travel Charger ACP–7H (UK) 180–220 Vac 0675146

AC Travel Charger ACP–7A (AUS) 216–264 Vac 0675148

NSM–3/3D

General Information

code:

Variants

Performance Travel Charger ACP–8E (EUR)

90–264 Vac

Performance Travel Charger ACP–8K (Korea)

90–264 Vac

Performance Travel Charger ACP–8X (UK)

90–264 Vac

Performance Travel Charger ACP–8U (US)

90–264 Vac

Performance Travel Charger ACP–8C (China)

90–264 Vac

Performance Travel Charger ACP–8A (Australia)

90–264 Vac

Headset HDC–5 0694059

Loopset LPS–3 0630244

Pocket Clip SKB–2 0720218

Swivel Mount HHS–12 0620054

Desk Stand DCV–1B 0675220

HF Microphone HFM–8 0690016

0675195

0675199

0675197

0675196

0675211

0675214

Plug&Play HF Cigarette Lighter Charger PPH–1 0675182

Cigarette Lighter Charger LCH–8 0675231

Cigarette Lighter Charger LCH–9 0675120

Issue 3 11/2000

Nokia Mobile Phones Ltd.

Page 5

NSM–3/3D

General Information

PAMS Technical Documentation

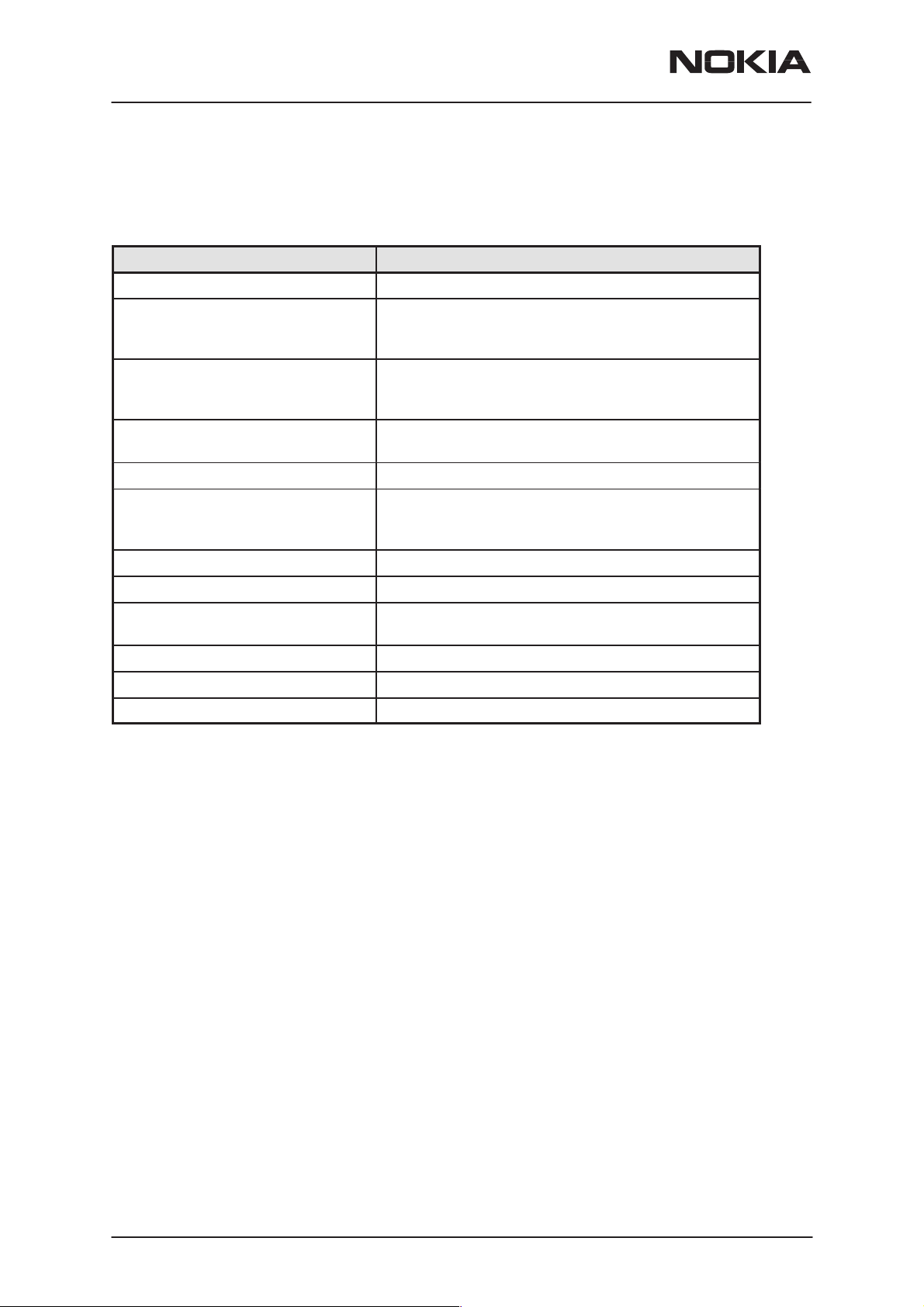

Technical Specifications

General Specifications of Transceiver NSM–3/3D

Parameter Unit

Cellular system GSM900 and GSM1800

RX frequency band EGSM: 925 ... 935 MHz

GSM900 935 ... 960 MHz

GSM1800 1805 ... 1880 MHz

TX frequency band EGSM 880 ... 890 MHz

GSM900 890 ... 915 MHz

GSM1800 1710 ... 1785 MHz

Output power GSM900 * +5 ...+33 dBm / 3.2 mW ... 2 W

GSM1800 +0 ...+30 dBm / 1.0 mW ... 1 W

Duplex spacing GSM900 * 45 MHzGSM1800 95 MHz

Number of RF channels EGSM 50

GSM900 124

GSM1800 374

Channel spacing 200 kHz

Number of TX power levels GSM900 * 15 GSM1800 16

Sensitivity, static channel GSM900: –102 dBm

GSM1800: –100 dBm

Frequency error, static channel < 0.1 ppm

RMS phase error < 5.0

Peak phase error < 20.0

*) applies also to EGSM

o

o

Page 6

Nokia Mobile Phones Ltd.

Issue 3 11/2000

PAMS Technical Documentation

NSM–3/3D Series Transceivers

System Module

Issue 4 02/2002 Nokia Corporation.

NSM–3/3D

System Module

PAMS Technical Documentation

CONTENTS

Transceiver NSM–3/3D 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differences between NSM–3 and NSM–3D 7. . . . . . . . . . . . . .

Introduction NSM–3 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction NSM–3D 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation Modes 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interconnection Diagram 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Module 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Baseband Module 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Diagram 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Summary 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External and Internal Signals and Connections 12. . . . . . . . .

DC (charger) connector 12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service connector 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery connector 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIM card connector 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RTC backup battery 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Distribution 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery charging 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup Charging 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Overvoltage Protection 15. . . . . . . . . . . . . . . . . . . .

Battery Removal During Charging 17. . . . . . . . . . . . . . . . . .

PWM 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Identification 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Temperature 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply Voltage Regulators 20. . . . . . . . . . . . . . . . . . . . . . . .

Switched Mode Supply VSIM 21. . . . . . . . . . . . . . . . . . . . . .

Power Up and Power Down 21. . . . . . . . . . . . . . . . . . . . . . . . .

Power up with a charger 21. . . . . . . . . . . . . . . . . . . . . . . . . .

Power Up With The Power Switch (PWRONX) 22. . . . . . .

Power Up by RTC 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Up by IBI 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Down 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modes of Operation 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acting Dead 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Active Mode 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sleep Mode 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Watchdog 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio control 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM serial interface 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Control 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAD2 WD1 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memories 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAD memory configuration 35. . . . . . . . . . . . . . . . . . . . . . .

Page 2

Nokia Corporation

Issue 4 02/2002

PAMS Technical Documentation

Memory 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program and Data Memory 35. . . . . . . . . . . . . . . . . . . . . . .

Work Memory 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MCU Memory Requirements 35. . . . . . . . . . . . . . . . . . . . . .

MCU Memory Map 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash Programming 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COBBA GJP 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Real Time Clock 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RTC backup battery charging 38. . . . . . . . . . . . . . . . . . . . . .

RF Module 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Ratings 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Characteristics 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Frequency Plan 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC characteristics 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regulators 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Distribution Diagram 41. . . . . . . . . . . . . . . . . . . . . . . . . .

RF Functional Description 42. . . . . . . . . . . . . . . . . . . . . . . . . . .

Frequency synthesizer 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AGC strategy 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AFC function 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC–compensation 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver characteristics 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter characteristics 47. . . . . . . . . . . . . . . . . . . . . . . . . . .

NSM–3/3D

System Module

Parts list of RM7L (EDMS Issue 6.0) Layout 11 Code: 0201386 48

Parts list of RM7L (EDMS Issue 10.1) Layout 16 Code: 0201386 56. . . . . . . . .

Parts list of RM7L (EDMS Issue 11.2) Layout 18 Code: 0201386 64. . . . . . . . .

Parts list of RM7L (EDMS Issue 12.5) Layout 19 Code: 0201386 72. . . . . . . . .

Parts list of RM7L (EDMS Issue 13.5) Layout 21 Code: 0201386 80. . . . . . . . . .

Parts list of RM7LD (EDMS Issue 2.1) Layout 03 Code: 0201682 88. . . . . . . . .

Parts list of RM7LD (EDMS Issue 2.4) Layout 03 Code: 0201682 96. . . . . . . .

Parts list of RM7LD (EDMS Issue 3.2) Layout 05 Code: 0201682 104. . . . . . . .

Parts list of RM7LD (EDMS Issue 3.3) Layout 05 Code: 0201682 112. . . . . . . .

Hardware ID chart for NSM–3/3D System module 120. . . . . . . . . . .

Issue 4 02/2002

Nokia Corporation

Page 3

NSM–3/3D

System Module

Schematic Diagrams: RM7L layout 11 HW 1120(at the back of the binder)

Connection between RF and BB modules (Version 1110 Ed. 16) layout 11 A–1

Baseband Block Interconnections (Version 1110 Edition 11) for layout 11 A–2

Circuit Diagram of Power Supply (Version 1110 Edition 17) for layout 11 A–3

Circuit Diagram of CPU Block (Version 1110 Edition 12) for layout 11 A–4

Circuit Diagram of RF Block (Version 1110 Edition 28) for layout 11 A–5

Circuit Diagram of Audio and RFI (Version 1110 Edition 15) for layout 11 A–6

Circuit Diagram of IR Module (Version 1110 Edition 10) for layout 11 A–7

Circuit Diagram of UI (Version 1110 Edition 12) for layout version 11 A–8

Layout Diagram of RM7L – Top (Version 11) A–9. . . . . . . . . . . . . . . .

Layout Diagram of RM7L – Bottom (Version 11) A–9. . . . . . . . . . . . .

Testpoints of RM7L – Bottom (Version 11) A–10. . . . . . . . . . . . . . . . . .

PAMS Technical Documentation

Schematic Diagrams: RM7L layout 16 HW 1210–1621(at the back of the binder)

Connection between RF and BB modules (Version 1410 Ed. 20) layout 16 A–11

Baseband Block Interconnections (Version 1410 Edition 18) for layout 16 A–12

Circuit Diagram of Power Supply (Version 1510 Edition 26) for layout 16 A–13

Circuit Diagram of CPU Block (Version 1410 Edition 16) for layout 16 A–14

Circuit Diagram of RF Block (Version 1410 Edition 37) for layout 16 A–15

Circuit Diagram of Audio and RFI (Version 1410 Edition 20) for layout 16 A–16

Circuit Diagram of IR Module (Version 1410 Edition 13) for layout 16 A–17

Circuit Diagram of UI (Version 1410 Edition 14) for layout version 16 A–18

Layout Diagram of RM7L – Top (Version 16) A–19. . . . . . . . . . . . . . . .

Layout Diagram of RM7L – Bottom (Version 16) A–19. . . . . . . . . . . .

Testpoints of RM7L – Bottom (Version 16) A–20. . . . . . . . . . . . . . . . . .

Schematic Diagrams: RM7L layout 18 HW1800 (at the back of the binder)

Layout Diagram of RM7L – Top (Version 18) A–21. . . . . . . . . . . . . . . .

Layout Diagram of RM7L – Bottom (Version 18) A–21. . . . . . . . . . . .

Testpoints of RM7L – Bottom (Version 18) A–22. . . . . . . . . . . . . . . . . .

Schematic Diagrams: RM7L layout 19 HW1903–2000 (at the back of the binder)

Connection between RF and Baseband (HW1910 Edit 4) layout 19 A–23

Baseband Block Interconnections (HW1910 Edit 4) layout 19 A–24

Circuit Diagram of Power Supply (HW1910 Edit 4) layout 19 A–25.

Page 4

Nokia Corporation

Issue 4 02/2002

NSM–3/3D

PAMS Technical Documentation

Circuit Diagram of CPU Block (HW 1910 Edit 5) for layout 19 A–26

Circuit Diagram of RF Block (HW 1910 Edit 4) for layout 19 A–27. .

Circuit Diagram of Audio and RFI (HW1910 Edit 4) layout 19 A–28

Circuit Diagram of IR Module (HW 1910 Edit 4) for layout 19 A–29.

Circuit Diagram of UI (HW 1910 Edit 4) for layout version 19 A–30

Layout Diagram of RM7L – Top (Version 19) A–31. . . . . . . . . . . . . . . .

Layout Diagram of RM7L – Bottom (Version 19) A–31. . . . . . . . . . . .

Testpoints of RM7L – Bottom (Version 19) A–32. . . . . . . . . . . . . . . . . .

Schematic Diagrams: RM7L layout 21 HW2100–2103 (at the back of the binder)

Connection between RF and Baseband (HW2103 Ed2) layout 21 A–33. . . . . . .

Baseband Block Interconnections (HW2103 Edit 3) for layout 21 A–34. . . . . . .

Circuit Diagram of Power Supply (HW2103 Edit 5) for layout 21 A–35

System Module

Circuit Diagram of CPU Block (HW2103 Edit 3) for layout 21 A–36.

Circuit Diagram of RF Block (HW2103 Edit 5) for layout 21 A–37. . .

Circuit Diagram of Audio and RFI (HW2103 Edit 20) layout 21 A–38

Circuit Diagram of IR Module (HW2103 Edit 17) for layout 21 A–39

Circuit Diagram of UI (HW2103 Edit 3) for layout version 21 A–40.

Layout Diagram of RM7L – Top (Version 21) A–41. . . . . . . . . . . . . . . .

Layout Diagram of RM7L – Bottom (Version 21) A–41. . . . . . . . . . . .

Testpoints of RM7L (Version 21) A–42. . . . . . . . . . . . . . . . . . . . . . . . . .

Schematic Diagrams: RM7LD layout 03 HW3.01–3.02 (at the back of the binder)

Connection between RF and BB modules (Version 1410 Ed. 4) layout 03 A–D1

Baseband Block Interconnections (Version 1410 Edition 4) for layout 03 A–D2

Circuit Diagram of Power Supply (Version 1510 Edition 7) for layout 03 A–D3

Circuit Diagram of CPU Block (Version 1410 Edition 04) for layout 03 A–D4

Circuit Diagram of RF Block (Version 1410 Edition 3) for layout 03 A–D5

Circuit Diagram of Audio and RFI (Version 1410 Edition 4) for layout 03 A–D6

Circuit Diagram of IR Module (Version 1410 Edition 2) for layout 03 A–D7

Circuit Diagram of UI (Version 1410 Edition 4) for layout version 03 A–D8

Layout Diagram of RM7LD – Top (Version 03) A–D9. . . . . . . . . . . . . .

Layout Diagram of RM7LD – Bottom (Version 03) A–D9. . . . . . . . . . .

Testpoints of RM7LD – Bottom (Version 03) A–D10. . . . . . . . . . . . . . . .

Issue 4 02/2002

Nokia Corporation

Page 5

NSM–3/3D

System Module

Schematic Diagrams: RM7LD layout 05 HW5.01 (at the back of the binder) . . .

Connection between RF and BB (Version 1410 Edit 7) layout 05 A–D11. . . . . . .

Baseband Block Interconnections (Version 1410 Edit 6) layout 05 A–D12. . . .

Circuit Diagram of Power Supply (Version 1510 Edit 8) layout 05 A–D13. . . . . .

Circuit Diagram of CPU Block (Version 1410 Edit 7) layout 05 A–D14

Circuit Diagram of RF Block (Version 1410 Edit 13) layout 05 A–D15.

Circuit Diagram of Audio and RFI (Version 1410 Edit 4) layout 05 A–D16. . . . .

Circuit Diagram of IR Module (Version 1410 Edit 2) layout 05 A–D17

Circuit Diagram of UI (Version 1410 Edit 5) for layout 05 A–D18. . . .

Layout Diagram of RM7LD – Bottom (Version 05) A–D19. . . . . . . . . . .

Layout Diagram of RM7LD – Top (Version 05) A–D19. . . . . . . . . . . . . .

Testpoints of RM7LD (Version 05) A–D20. . . . . . . . . . . . . . . . . . . . . . . .

PAMS Technical Documentation

Schematic Diagrams: RM7LD layout 05 HW5.02 (at the back of the binder) . . .

Connection between RF and Baseband modules (Version 5.02 Edit 8) for layout

version 05 A–D21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Baseband Block Interconnections (Version 5.02 Edit 7) layout 05 A–D22. . . . . .

Circuit Diagram of Power Supply (Version 5.02 Edit 9) layout 05 A–D23. . . . .

Circuit Diagram of CPU Block (Version 5.02 Edit 8) layout 05 A–D24. . . . . . . .

Circuit Diagram of RF Block (Version 5.02 Edit 14) layout 05 A–D25.

Circuit Diagram of Audio and RFI (Version 5.02 Edit 6) layout 05 A–D26. . . . . .

Circuit Diagram of IR Module (Version 5.02 Edit 3) layout 05 A–D27.

Circuit Diagram of UI (Version 5.02 Edit 6) layout 05 A–D28. . . . . . . .

Layout Diagram of RM7LD – Bottom (Version 05) A–D29. . . . . . . . . . .

Layout Diagram of RM7LD – Top (Version 05) A–D29. . . . . . . . . . . . . .

Testpoints of RM7LD (Version 05) A–D30. . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Nokia Corporation

Issue 4 02/2002

PAMS Technical Documentation

Transceiver NSM–3/3D

Differences between NSM–3 and NSM–3D

The main differences are in A–cover and display module. NSM–3 and

NSM–3D share the same accessories. Other differences between the

phones are stated in the text. See also Product Variants –section in this

manual.

Introduction NSM–3

The NSM–3 is a dual band transceiver unit designed for the GSM900 (in-

cluding EGSM) and GSM1800 networks. It is both GSM900 phase 2 power

class 4 transceiver (2W) and GSM1800 power class 1 (1W) transceiver.

The transceiver consists of System/RF module (RM7L), Display module

(UX7) and assembly parts.

NSM–3/3D

System Module

The transceiver has a full graphic display and the user interface is based

on a Jack style UI with two soft keys.

An internal antenna is used, there is no connection to an external anten-

na.

The transceiver has a low leakage tolerant earpiece and an omnidirec-

tional microphone located in B–cover, providing an excellent audio quality.

The transceiver supports a full rate, an enhanced full rate and a half rate

speech decoding.

An integrated IR link provides a connection between two NSM–3 trans-

ceivers or a transceiver and a PC (internal data), or a transceiver and a

printer.

The small SIM ( Subscriber Identity Module ) card is located below the

back cover of the phone.

Introduction NSM–3D

The NSM–3DX is a dualband radio transceiver unit for the E–GSM900 and

GSM1800 networks. GSM power class is 4 and PCN power class is 1. It is

a true 3 V transceiver, with user changeable A–cover and internal vibra.

The transceiver consists of System/RF module (RM7LD), Display module

(UX7V) and assembly parts.

The transceiver has full graphic display and the user interface is based on

Jack style UI with two soft keys.

NSM–3D phone is equipped with an internal antenna and there isn’t any

external antenna connector.

The transceiver has leakage tolerant earpiece and omnidirectional micro-

phone, providing excellent audio quality. Transceiver supports full rate,

enhanced full rate and half rate speech decoding.

Issue 4 02/2002

Nokia Corporation

Page 7

NSM–3/3D

System Module

Integrated IR link provides for connection between two NSM–3DX trans-

ceivers or a transceiver and a PC (internal data), or a transceiver and a

printer.

The small SIM ( Subscriber Identity Module ) card is located below the

back cover of the phone.

Operation Modes

There are five different operation modes:

– power off mode

– idle mode

– active mode

– charge mode

– local mode

In the power off mode only the circuits needed for power up are supplied.

PAMS Technical Documentation

In the idle mode circuits are powered down and only sleep clock is run-

ning.

In the active mode all the circuits are supplied with power although some

parts might be in the idle state part of the time.

The charge mode is effective in parallel with all previous modes. The

charge mode itself consists of two different states, i.e. the fast charge and

the maintenance mode.

The local mode is used for alignment and testing.

Page 8

Nokia Corporation

Issue 4 02/2002

PAMS Technical Documentation

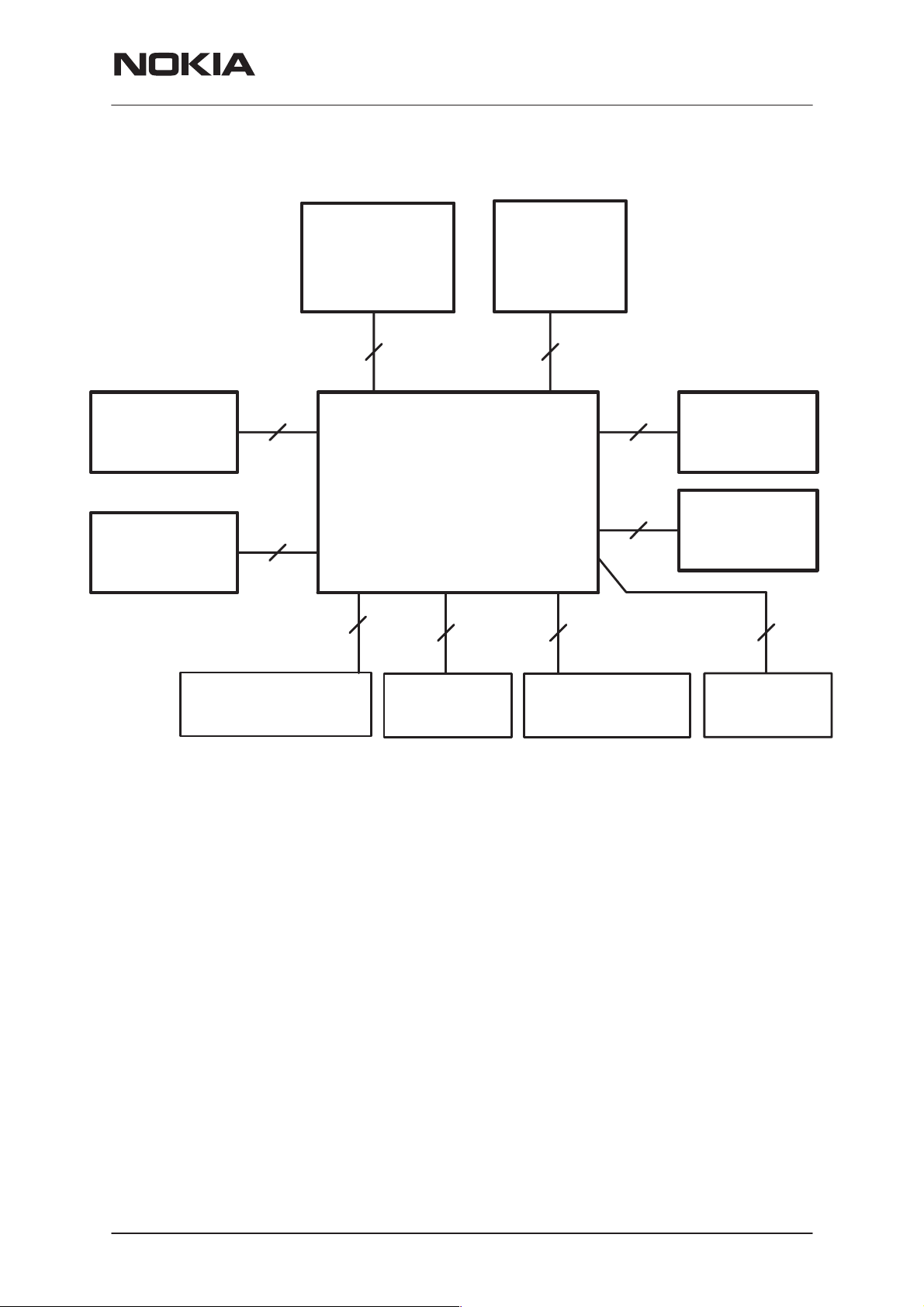

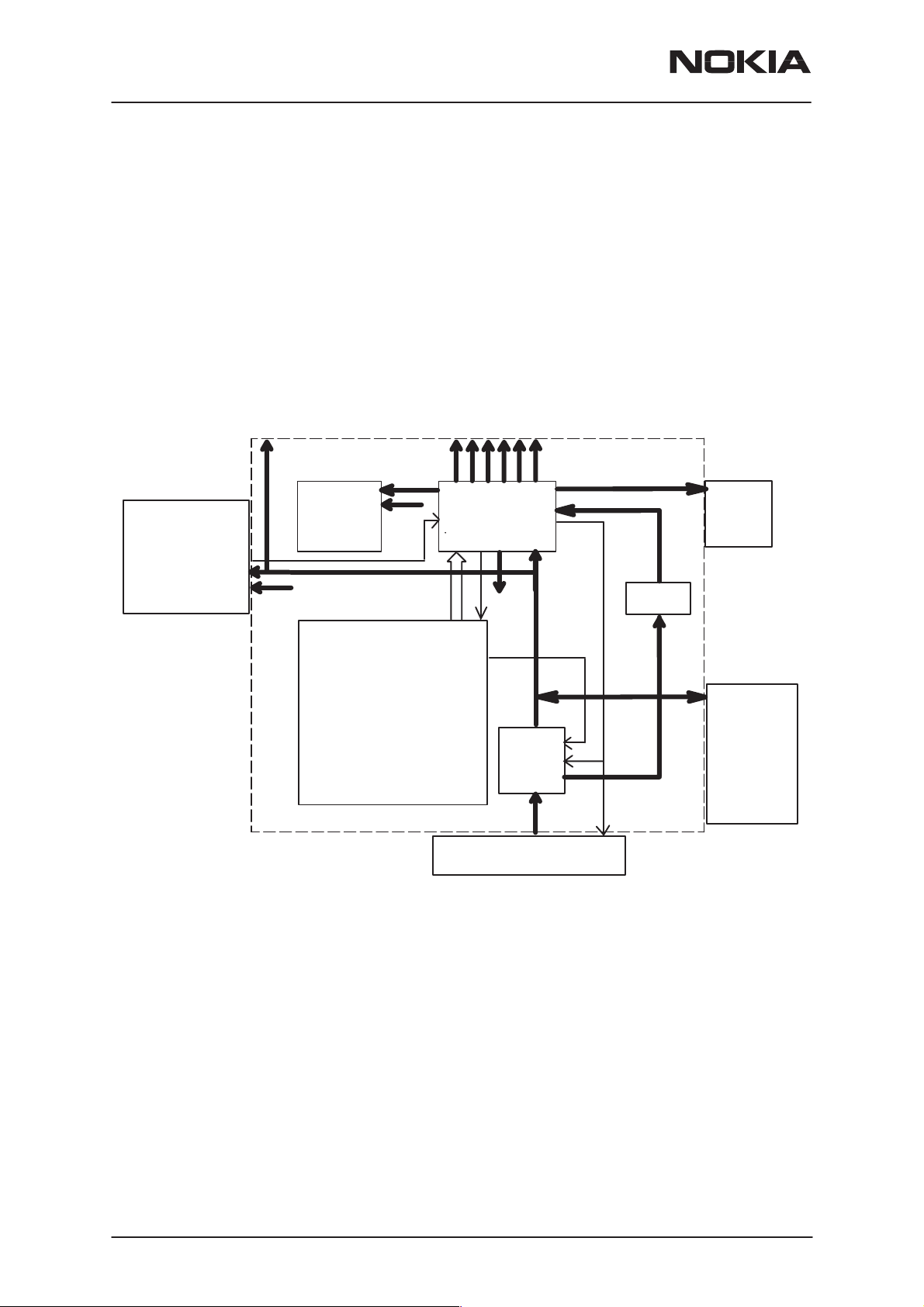

Interconnection Diagram

NSM–3/3D

System Module

Keyboard

module

14

LCD

module

9

64

SIM Battery

Radio

Module

2+2

2

RM7L, RM7LD

Charger

Antenna

2

8

2

4

Mic

IR Link

Earpiece

HF/HS

Issue 4 02/2002

Nokia Corporation

Page 9

NSM–3/3D

System Module

System Module

Baseband Module

The baseband architecture supports a power saving function called ”sleep

mode”. This sleep mode shuts off the VCTCXO, which is used as system

clock source for both RF and baseband. During the sleep mode the sys-

tem runs from a 32 kHz crystal. The phone is waken up by a timer run-

ning from this 32 kHz clock supply. The sleeping time is determined by

some network parameters. The sleep mode is entered when both the

MCU and the DSP are in standby mode and the normal VCTCXO clock

has been switched off.

The battery charging is controlled by a PWM signal from the CCONT. The

PWM duty cycle is determined by a charging software and is fed to the

CHAPS charging switch.

PAMS Technical Documentation

Standard chargers (two wires) provide coarse supply power, which is

switched by the CHAPS for suitable charging voltage and current. Ad-

vanced chargers (three wires) are equipped with a control input. Three

wire chargers are treated like two wire ones.

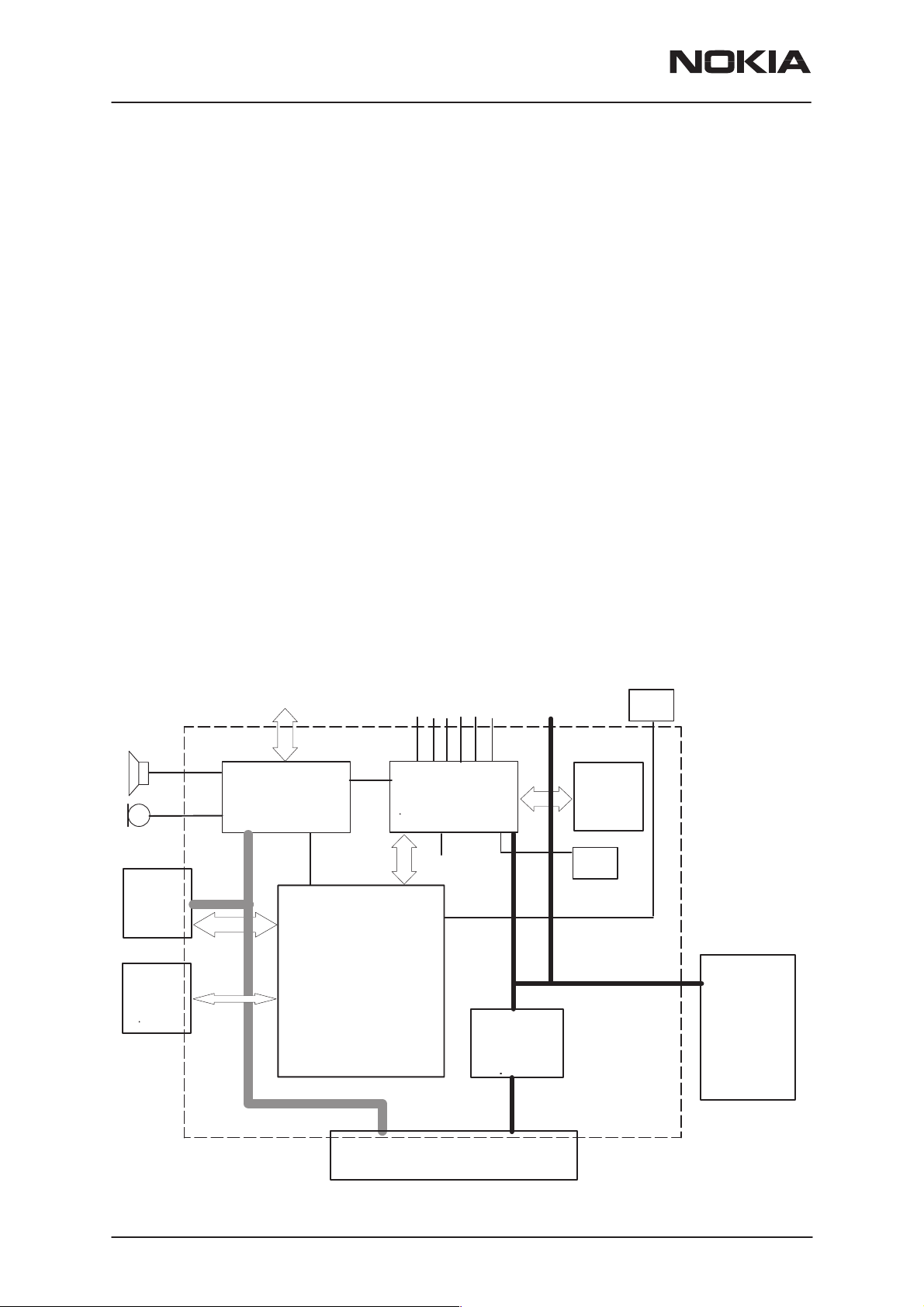

Block Diagram

TX/RX SIGNALS

UI

IR

COBBA SUPPLY

COBBA

MAD

+

MEMORIES

RF SUPPLIES

CCONT

BB SUPPLY

CHAPS

PA SUPPL Y

32kHz

CLK

SLEEP CLOCK

SIM

VBAT

13MHz

CLK

SYSTEM CLOCK

BATTERY

Page 10

BASEBAND

EXT. AUDIO

HS–connector

Nokia Corporation

Charger

connector

Issue 4 02/2002

PAMS Technical Documentation

Technical Summary

The baseband module consists four ASICs; CHAPS, CCONT, COBBA–

GJP and MAD2WD1, which take care of the baseband functions of the

engine.

The baseband is running from a 2.8V power rail, which is supplied by a

power controlling ASIC CCONT. In the CCONT there are 6 individually

controlled regulator outputs for RF–section and two outputs for the base-

band. In addition there is one +5V power supply output (V5V). The

CCONT contains also a SIM interface, which supports both 3V and 5V

SIM–cards. A real time clock function is integrated into the CCONT, which

utilizes the same 32kHz clock supply as the sleep clock. A backup power

supply is provided for the RTC, which keeps the real time clock running

when the main battery is removed. The backup power supply is a re-

chargable battery. The backup time with the battery is ten minutes mini-

mum.

The interface between the baseband and the RF section is mainly han-

dled by a COBBA ASIC. COBBA provides A/D and D/A conversion of the

in–phase and quadrature receive and transmit signal paths and also A/D

and D/A conversions of received and transmitted audio signals to and

from the user interface. The COBBA supplies the analog TXC and AFC

signals to RF section according to the MAD DSP digital control. Data

transmission between the COBBA and the MAD is implemented using se-

rial bus for high speed signalling and for PCM coded audio signals. Digital

speech processing is handled by the MAD ASIC. COBBA is a dual volt-

age circuit, the digital parts are running from the baseband supply VBB

and the analog parts are running from the analog supply VCOBBA.

NSM–3/3D

System Module

The baseband supports both internal and external microphone inputs and

speaker outputs. Input and output signal source selection and gain control

is done by the COBBA according to control messages from the MAD.

Keypad tones, DTMF, and other audio tones are generated and encoded

by the MAD and transmitted to the COBBA for decoding. A buzzer and an

external vibra alert control signals are generated by the MAD with sepa-

rate PWM outputs.

EMC shieding is implemented using a metallized plastic frame. On the

other side the engine is shielded with PCB grounding. Heat generated by

the circuitry will be conducted out via the PCB ground planes.

Issue 4 02/2002

Nokia Corporation

Page 11

NSM–3/3D

System Module

PAMS Technical Documentation

External and Internal Signals and Connections

This section describes the external electrical connection and interface lev-

els on the baseband. The electrical interface specifications are collected

into tables that covers a connector or a defined interface.

DC (charger) connector

DC (charger) connector is physically integrated in the same component

with the accessory interface connector. DC connector has both jack and

contact pads for desk stand.

Service connector

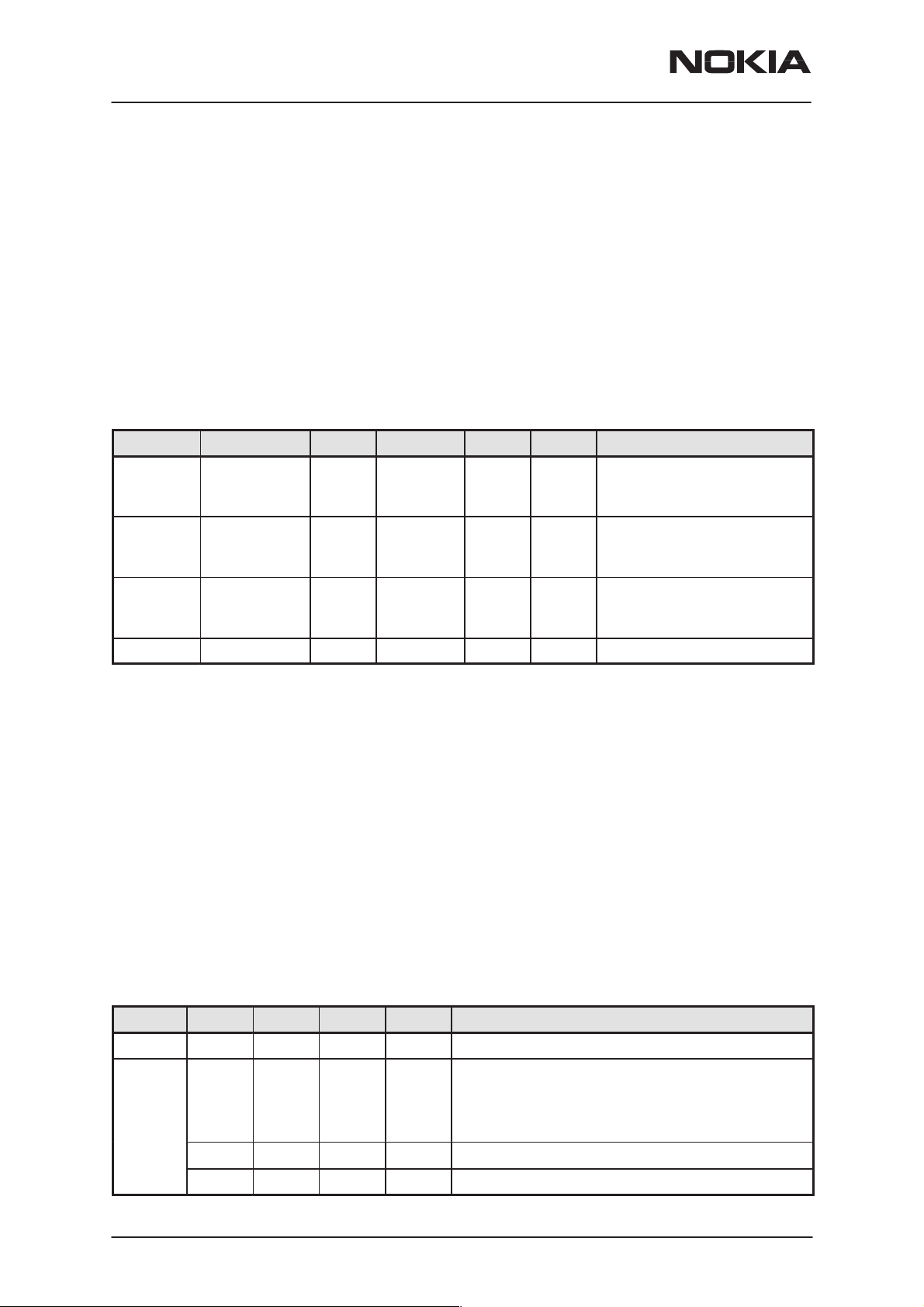

Name Parameter Min Typ Max Unit Remark

MBUS Serial clock

from the

Prommer

FBUS_RX Serial data

from the

Prommer

FBUS_TX Data ac-

knowledge to

the Prommer

GND GND 0 0 V Ground

0

2.0

0

2.0

0

2.0

logic low

logic low

logic low

logic high

logic low

logic high

0.8

2.85

0.8

2.85

0.5

2.85

V Prommer detection and Seri-

al Clock for synchronous

communication

V Receive Data from

Prommer to Baseband

V Transmit Data from Base-

band to Prommer

The service connector is used as a flash programming interface for updating (i.e. re–programming) the flash program memory and an electrical

access for services to the engine.

When the flash prommer is connected to the phone supply power is provided through the battery contacts and the phone is powered up with a

pulse given to the BTEMP line.

Battery connector

The BSI contact on the battery connector is used to detect when the battery is to be removed to be able to shut down the operations of the SIM

card before the power is lost if the battery is removed with power on. The

BSI contact disconnects earlier than the supply power contacts to give

enough time for the SIM and LCD shut down.

Name Min Typ Max Unit Notes

VBATT 3.0 3.9 4.2 V Battery voltage

BSI

Page 12

0 2.85 V Battery size indication

Phone has 100kohm pull up resistor.

SIM Card removal detection

(Treshold is 2.4V@VBB=2.8V)

67 68 69 kohm Battery indication resistor (BLB–2)

0 0 1 kohm Battery indication resistor (service battery)

Nokia Corporation

Issue 4 02/2002

PAMS Technical Documentation

NSM–3/3D

System Module

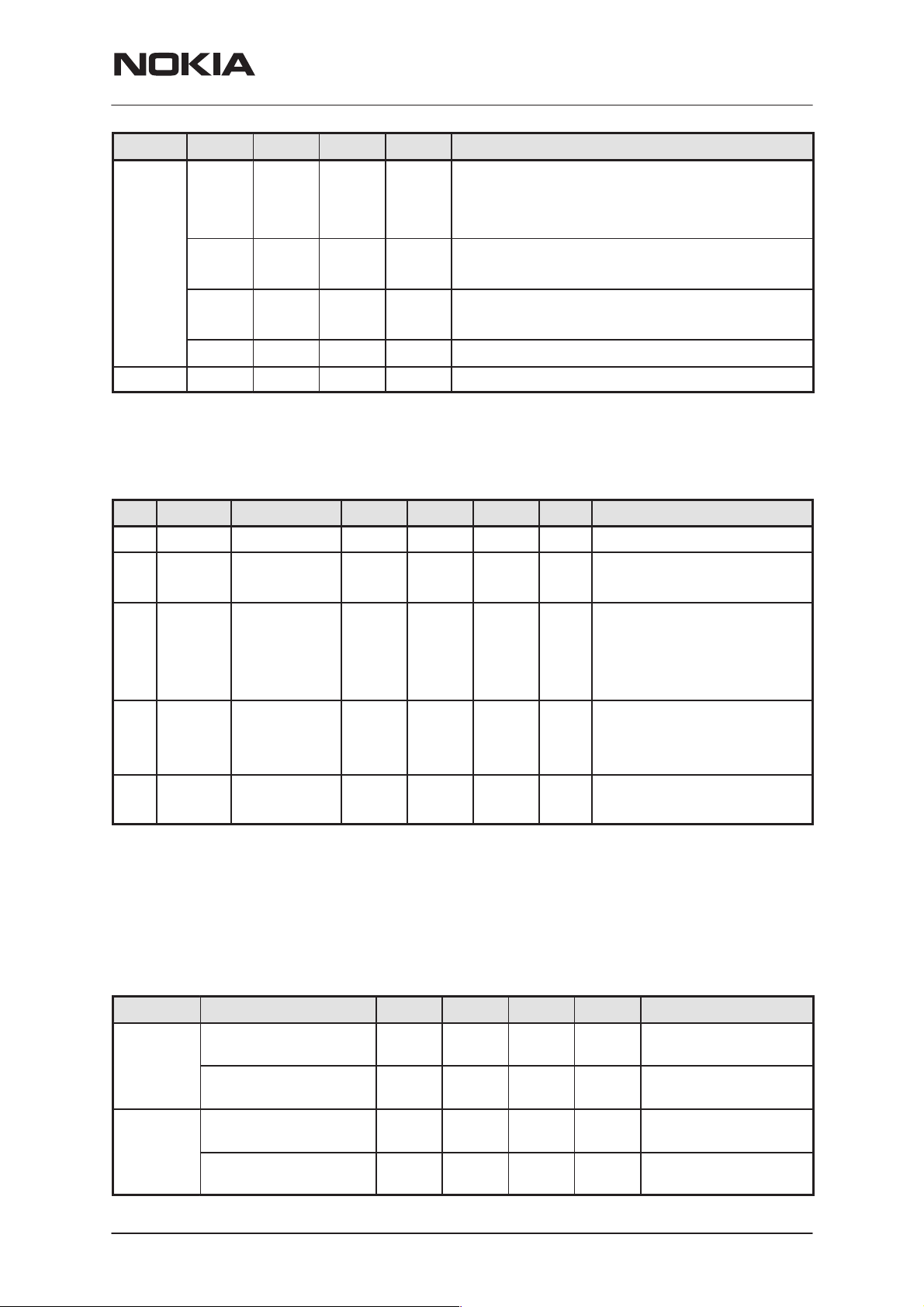

NotesUnitMaxTypMinName

BTEMP

BGND 0 0 V Battery ground

0 1.4 V Battery temperature indication

Phone has a 100k (+–5%) pullup resistor,

Battery package has a NTC pulldown resistor:

47k+–5%@+25C , B=4050+–3%

2.1

5 10

1.9

90 100

0 1 kohm Local mode initialization (in production)

3

20

2.85

200

V

ms

V

ms

Phone power up by battery (input)

Power up pulse width

Battery power up by phone (output)

Power up pulse width

SIM card connector

The SIM card connector is located on the engine board beside the battery

pack.

Pin Name Parameter Min Typ Max Unit Notes

4 GND GND 0 0 V Ground

3, 5 VSIM 5V SIM Card

3V SIM Card

6 DATA 5V Vin/Vout

3V Vin/Vout

2 SIMRST 5V SIM Card

3V SIM Card

4.8

2.8

4.0

0

2.8

0

4.0

2.8

5.0

3.0

”1”

”0”

”1”

”0”

”1”

”1”

5.2

3.2

VSIM

0.5

VSIM

0.5

VSIM

VSIM

V Supply voltage

V SIM data

Trise/Tfall max 1us

V SIM reset

1 SIMCLK Frequency

Trise/Tfall

3.25

25

MHz

ns

SIM clock

RTC backup battery

The RTC block in CCONT needs a power backup to keep the clock running when the phone battery is disconnected. The backup power is supplied from a rechargable polyacene battery that can keep the clock running ten minutes minimum. The backup battery is charged from the main

battery through CHAPS.

Signal Parameter Min Typ Max Unit Notes

VBACK

VBACK

Backup battery charging from CHAPS

Backup battery charging from CHAPS

Backup battery supply

to CCONT

Backup battery supply

to CCONT

3.02 3.15 3.28 V

100 200 500 uA Vout@VBAT–0.2V

2 3.28 V

80 uA

Issue 4 02/2002

Nokia Corporation

Page 13

NSM–3/3D

System Module

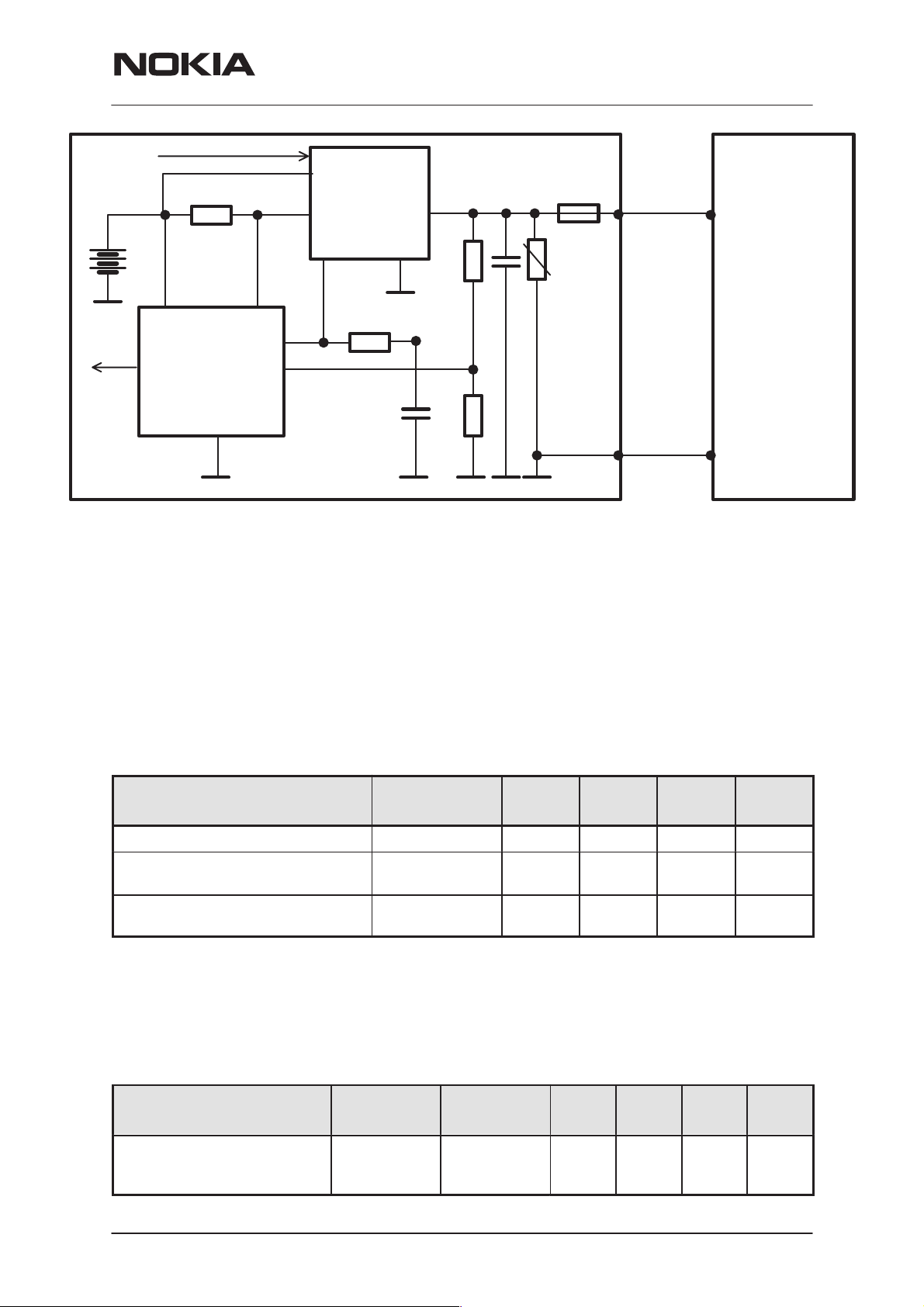

Power Distribution

In normal operation the baseband is powered from the phone‘s battery.

The battery consists of one Lithium–Ion cell. An external charger can be

used for recharging the battery and supplying power to the phone.

The baseband contains parts that control power distribution to whole

phone excluding those parts that use continuous battery supply. The battery feeds power directly to the CCONT and UI (buzzer and display and

keyboard lights).

The power management circuit CHAPS provides protection against overvoltages, charger failures and pirate chargers etc. that would otherwise

cause damage to the phone.

PAMS Technical Documentation

PA SUPPL Y

VCOBBA

COBBA

UI

VBAT

VBB

BASEBAND

VBB

MAD

+

MEMORIES

RF SUPPLIES

CCONT

PWRONX

CNTVR

CHARGER CONNECTOR

PWM

VBB

PURX

LIM

CHAPS

VIN

VSIM

SIM

RTC

BACKUP

VBAT

BATTERY

Battery charging

The electrical specifications give the idle voltages produced by the acceptable chargers at the DC connector input. The absolute maximum input voltage is 30V due to the transient suppressor that is protecting the

charger input. At phone end there is no difference between a plug–in

charger or a desktop charger. The DC–jack pins and bottom connector

charging pads are connected together inside the phone.

Page 14

Nokia Corporation

Issue 4 02/2002

PAMS Technical Documentation

NSM–3/3D

System Module

MAD

VBAT

MAD

CCONTINT

CCONT

Startup Charging

LIM

0R22

PWM_OUT

GND

ICHAR

VCHAR

VOUT

CHAPS

RSENSE

PWM

22k

VCH

GND

1n

TRANSCEIVER

1u

100k

10k

30V

2A

VIN

L_GND

CHARGER

When a charger is connected, the CHAPS is supplying a startup current

minimum of 130mA to the phone. The startup current provides initial

charging to a phone with an empty battery. Startup circuit charges the

battery until the battery voltage level is reaches 3.0V (+/– 0.1V) and the

CCONT releases the PURX reset signal and program execution starts.

Charging mode is changed from startup charging to PWM charging that is

controlled by the MCU software. If the battery voltage reaches 3.55V

(3.75V maximum) before the program has taken control over the charging, the startup current is switched off. The startup current is switched on

again when the battery voltage is sunken 100mV (nominal).

Parameter Symbol Min Typ Max Unit

VOUT Start– up mode cutoff limit Vstart 3.45 3.55 3.75 V

VOUT Start– up mode hysteresis

NOTE: Cout = 4.7 uF

Start–up regulator output current

VOUT = 0V ... Vstart

Vstarthys 80 100 200 mV

Istart 130 165 200 mA

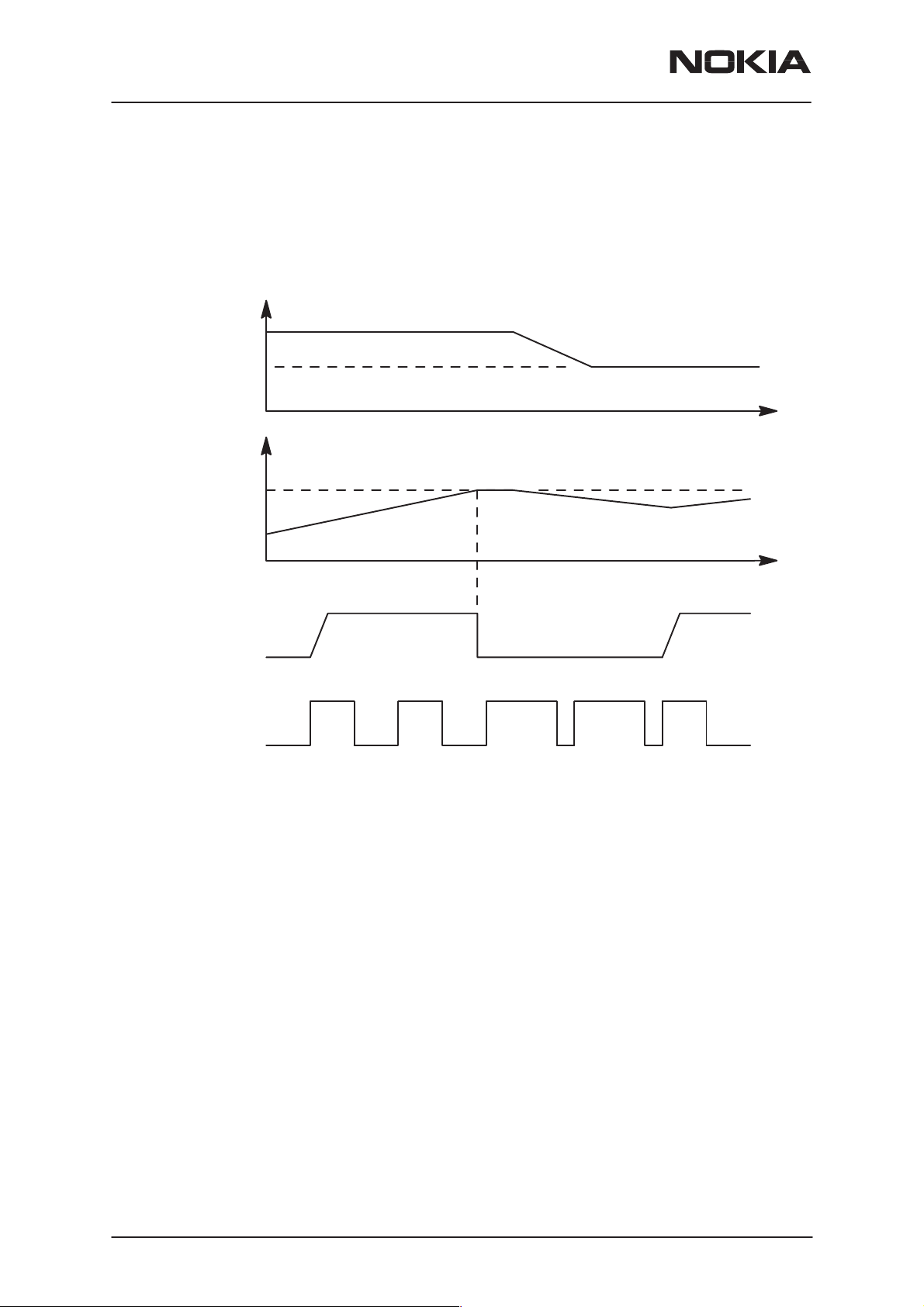

Battery Overvoltage Protection

Output overvoltage protection is used to protect phone from damage.

This function is also used to define the protection cutoff voltage for different battery types (Li or Ni). The power switch is immediately turned OFF if

the voltage in VOUT rises above the selected limit VLIM1 or VLIM2.

Parameter Symbol LIM input Min Typ Max Unit

Output voltage cutoff limit

(during transmission or Li–

battery)

VLIM LOW 4.4 4.6 4.8 V

Issue 4 02/2002

Nokia Corporation

Page 15

NSM–3/3D

System Module

The voltage limit (VLIM1 or VLIM2) is selected by logic LOW or logic

HIGH on the CHAPS (N101) VLIM input pin. In NSM–3 phones VLIM is

fixed low in HW.

When the switch in output overvoltage situation has once turned OFF, it

stays OFF until the the battery voltage falls below VLIM and PWM = LOW

is detected. The switch can be turned on again by setting PWM = HIGH.

VCH

VCH<VOUT

VOUT

PAMS Technical Documentation

t

VLIM

SWITCH

PWM (1 Hz)

ON OFF

t

ON

Page 16

Nokia Corporation

Issue 4 02/2002

PAMS Technical Documentation

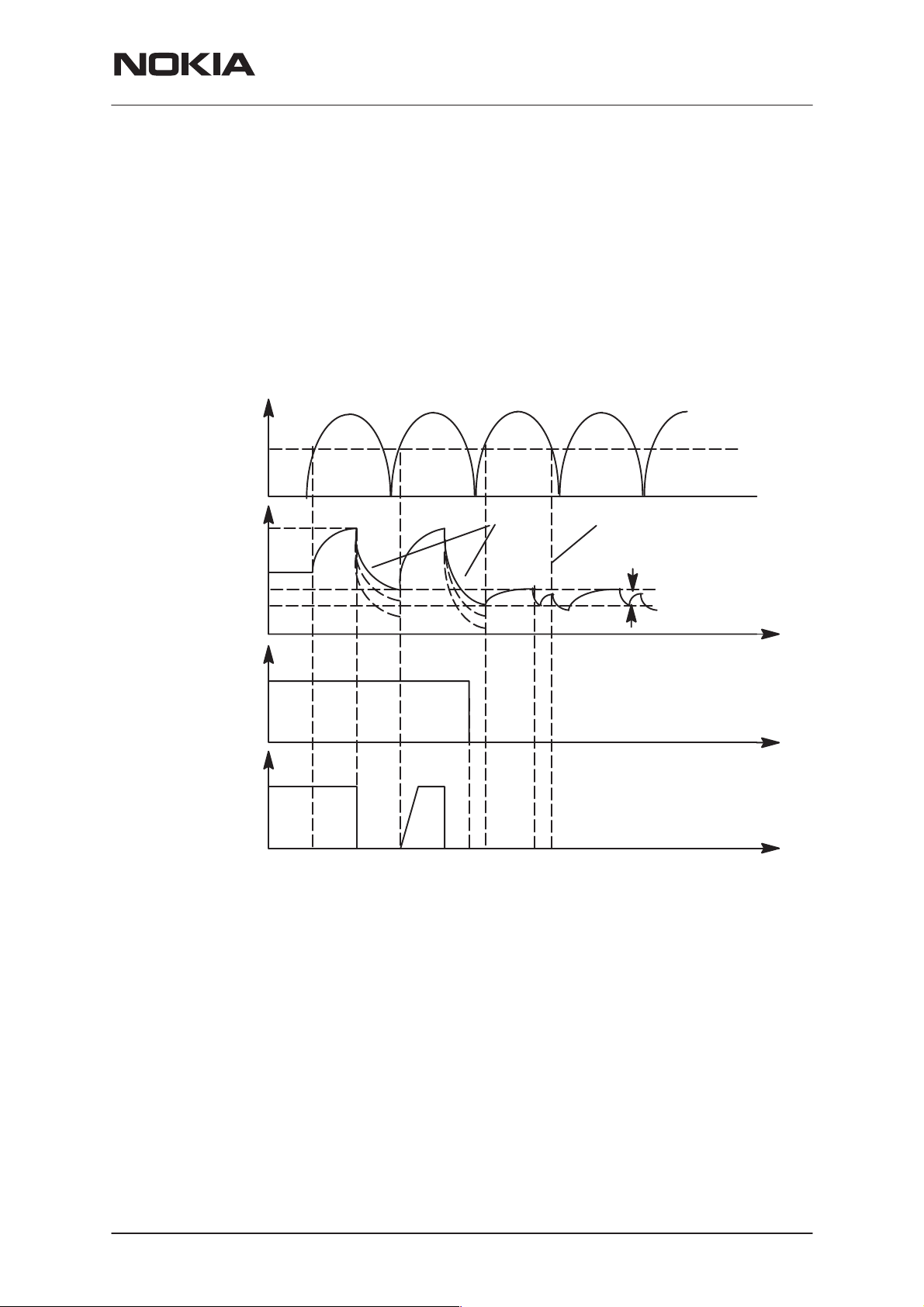

Battery Removal During Charging

Output overvoltage protection is also needed in case the main battery is

removed when charger connected or charger is connected before the battery is connected to the phone.

With a charger connected, if VOUT exceeds VLIM, CHAPS turns switch

OFF until the charger input has sunken below Vpor (nominal 3.0V, maximum 3.4V). MCU software will stop the charging (turn off PWM) when it

detects that battery has been removed. The CHAPS remains in protection

state as long as PWM stays HIGH after the output overvoltage situation

has occured.

NSM–3/3D

System Module

VCH

(Standard

Charger)

VOUT

PWM

SWITCH

Vpor

VLIM

4V

Vstart

”1”

”0”

ON

OFF

Droop depends on load

& C in phone

2

5

4

6

7

Istart off due to VCH<Vpor

Vstarthys

t

t

t

1.1Battery removed, (standard) charger connected, VOUT rises (follows charger voltage)

2. VOUT exceeds limit VLIM(X), switch is turned immediately OFF

3.3VOUT falls (because no battery) , also VCH<Vpor (standard chargers full–rectified

output). When VCH > Vpor and VOUT < VLIM(X) –> switch turned on again (also PWM

is still HIGH) and VOUT again exceeds VLIM(X).

4. Software sets PWM = LOW –> CHAPS does not enter PWM mode

5. PWM low –> Startup mode, startup current flows until Vstart limit reached

6. VOUT exceeds limit Vstart, Istart is turned off

7. VCH falls below Vpor

Issue 4 02/2002

Nokia Corporation

Page 17

NSM–3/3D

System Module

PAMS Technical Documentation

PWM

When a charger is used, the power switch is turned ON and OFF by the

PWM input. PWM rate is 1Hz. When PWM is HIGH, the switch is ON and

the output current Iout = charger current – CHAPS supply current. When

PWM is LOW, the switch is OFF and the output current Iout = 0. To prevent the switching transients inducing noise in audio circuitry of the phone

soft switching is used.

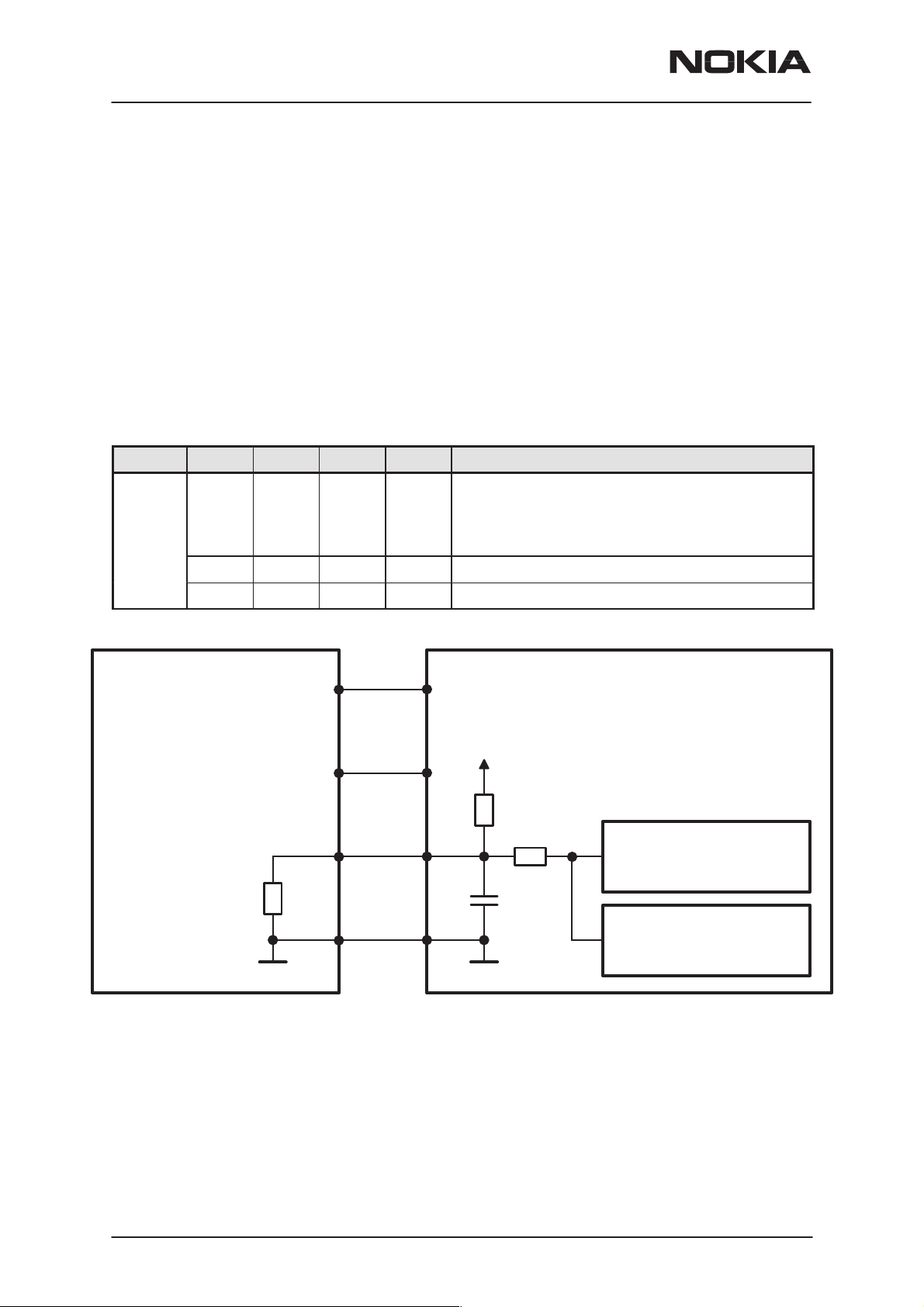

Battery Identification

Different battery types are identified by a pulldown resistor inside the battery pack. The BSI line inside transceiver has a 100k pullup to VBB. The

MCU can identify the battery by reading the BSI line DC–voltage level

with a CCONT (N100) A/D–converter.

Name Min Typ Max Unit Notes

BSI

0 2.8 V Battery size indication

100k pullup resistor to VBB in phone

SIM Card removal detection

(Treshold is 2.4V@VBB=2.8V)

67 68 69 kohm Indication of a BLB–2 battery (650 mAh Li–Ion)

0 1 kohm Indication resistor for a service battery

VBATT

BATTERY

BTEMP

BSI

R

s

BGND

2.8V

100k

10n

10k

TRANSCEIVER

BSI

SIMCardDetX

CCONT

MAD

Page 18

The battery identification line is used also for battery removal detection.

The BSI line is connected to a SIMCardDetX line of MAD2. SIMCardDetX

is a threshold detector with a nominal input switching level 0.85xVcc for a

rising edge and 0.55xVcc for a falling edge. The battery removal detection

is used as a trigger to power down the SIM card before the power is lost.

The BSI contact in the battery contact disconnects before the other contacts so that there is a delay between battery removal detection and supply power off.

Nokia Corporation

Issue 4 02/2002

Loading...

Loading...