Page 1

PAMS T echnical Documentation

NSB-8 Series Transceivers

T roubleshooting Instructions

Issue 1 01/02 ãNokia Corporation

Page 2

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Table of Contents

Page No

Transceiver Troubleshooting ......................................................................................... 5

Baseband Troubleshooting ..........................................................................................5

PWB Points (and Measurement Points).................................................................... 5

Troubleshooting steps ................................................................................................34

General instructions................................................................................................. 35

RF Troubleshooting ...................................................................................................55

Phone Settings for TX Troubleshooting.................................................................. 55

Phone Settings for RX Troubleshhoting ................................................................. 55

NO TX GSM 1900.................................................................................................. 56

NO RX GSM 1900.................................................................................................. 56

Measurements points for AMS and production repair ..............................................57

TX Troubleshooting points ..................................................................................... 57

RX Troubleshooting points..................................................................................... 63

RF Tuning and Calibration Instructions....................................................................... 67

TX tunings .................................................................................................................67

TX Output power tuning ............................................................................................67

TX IQ tuning ..............................................................................................................70

RX tunings .................................................................................................................72

Channel select filter calibration .................................................................................73

RX tuning GSM1900 .................................................................................................74

AM suppression tuning ..............................................................................................76

RF Service Tools.......................................................................................................... 78

MJS-46 Module Jig ....................................................................................................78

JVB-1 Docking Station, MJF-6 Adapter and coupler CPL-6 ....................................78

Coupler attenuation calibration ..................................................................................78

Functionality Testing Limits .....................................................................................78

JXS-1 Shield Box ......................................................................................................79

Page 2 ãNokia Corporation Issue 1 01/02

Page 3

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

List of Figures

Page No

Fig 1 Picture of top testpoints..............................................................................................5

Fig 2 Picture of bottom testpoints........................................................................................6

Fig 3 Top testpoints .............................................................................................................7

Fig 4 Bottom testpoints........................................................................................................8

Fig 5 C660: RFCLK (26 MHz), VCTCXO (G660 pin 3) -> HAGAR (N600 pin H1).......14

Fig 6 J1: RESET, UPP (D400 pin D12) -> HAGAR (N600 pin E3) ..................................14

Fig 7 J2: RFBUSDA, UPP (D400 pin F12) -> HAGAR (N600 pin E1).............................15

Fig 8 J3: RFBUSCLK, UPP (D400 pin G11) -> HAGAR (N600 pin E2)..........................15

Fig 9 J3: RFBUSCLK (closer look), UPP (D400 pin G11) -> HAGAR (N600 pin E2).....16

Fig 10 J4: RFBUSEN1, UPP (D400 pin G13) -> HAGAR (N600 pin D1) ........................16

Fig 11 J386: SIMDATA, UEM (D200 pin B2) <-> SIM CARD READER (X386 pin 4...17

Fig 12 J387: SIMRST, UEM (D200 pin A2) <-> SIM CARD READER (X386 pin 2).....17

Fig 13 J388: SIMCLK, UEM (D200 pin B3) <-> SIM CARD READER (X386 pin 3) ....18

Fig 14 J396 PAD 2: FBUSTX (during flashing), UEM (D200 pin N5) -> SERVICE INTER-

FACE (J396 PAD 2)..............................................................................................................18

Fig 15 J396 PAD 3 FBUSRX (during flashing), SERVICE INTERFACE (J396 PAD 3) ->

UEM (D200 pin P5)...............................................................................................................19

Fig 16 J396 PAD 7: MBUS (during flashing), UEM (D200 pin M6) <-> SERVICE INTER-

FACE (J396 PAD 7)..............................................................................................................19

Fig 17 J402: PURX, UEM (D200 pin C10) -> UPP (D400 pin K2)...................................20

Fig 18 J403: SLEEPX, UEM (D200 pin B11) -> UPP (D400 pin L1)................................20

Fig 19 J404: SLEEPCLK, UEM (D200 pin D9) -> UPP (D400 pin H3)............................21

Fig 20 J405: UEMINT, UEM (D200 pin A10) -> UPP (D400 pin J2) ...............................21

Fig 21 J406: CBUSCLK, UEM (D200 pin A8) -> UPP (D400 pin G1).............................22

Fig 22 J407: CBUSDA, UEM (D200 pin B7) <-> UPP (D400 pin G2) .............................22

Fig 23 J408: CBUSENX, UEM (D200 pin C8) -> UPP (D400 pin F3)..............................23

Fig 24 J409: MBUSTX (during flashing), UPP (D400 pin E3) -> UEM (D200 pin C6)....23

Fig 25 J410: MBUSRX (during flashing), UEM (D200 pin D6) -> UPP (D400 pin D3)...24

Fig 26 J411: FBUSTX (during flashing), UPP (D400 pin F1) -> UEM (D200 pin A7).....24

Fig 27 J412: FBUSRX (during flashing), UEM (D200 pin C7) -> UPP (D400 pin E4).....25

Fig 28 J413: DBUSCLK, UEM (D200 pin D10) -> UPP (D400 pin K3)...........................25

Fig 29 J414: DBUSDA, UEM (D200 pin A11) <-> UPP (D400 pin L3) ...........................26

Fig 30 J415: DBUSENX1, UEM (D200 pin B10) -> UPP (D400 pin J3)..........................26

Fig 31 J416: EXTWRX (during flashing), UPP (D400 pin N9) -> FLASH (D450 pin A6)27

Fig 32 J417: EXTRDX, UPP (D400 pin L7) -> FLASH (D450 pin C10)..........................27

Fig 33 J419: FLSCLK, UPP (D400 pin N12) -> FLASH (D450 pin A4)...........................28

Fig 34 J420: FLSCSX, UPP (D400 pin N6) -> FLASH (D450 pin B9) .............................28

Fig 35 J700: TXP, UPP (D400 pin D11) -> HAGAR (N600 pin D5).................................29

Fig 36 R301: PWRONX, POWER BUTTON (S300) -> UEM (D200 pin P7)...................29

Fig 37 R305: KLIGHT, UEM (D200 pin F3) -> BACKLIGHT CIRCUITRY (V300 pins 2,3,5

and V301 pins 2,5,6) .............................................................................................................30

Fig 38 R420: RFCLK (13 MHz), HAGAR (N600 pin E4) -> UPP (D400 pin M5)...........30

Fig 39 X100 PIN 9: VIBRA, UEM (D200 pin G3) -> SYSTEM CONNECTOR (X100 pin 9)

31

Fig 40 X300 PIN 1: XRES (startup), UPP (D400 pin A7) -> LCD CONNECTOR (X300 pin

1)............................................................................................................................................31

Issue 1 01/02 ãNokia Corporation Page 3

Page 4

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Fig 41 X300 PIN 2: XCS, UPP (D400 pin C7) -> LCD CONNECTOR (X300 pin 2).......32

Fig 42 X300 PIN 4: SDA, UPP (D400 pin B6) -> LCD CONNECTOR (X300 pin 4) ......32

Fig 43 X300 PIN 5: SCLK, UPP (D400 pin C6) -> LCD CONNECTOR (X300 pin 5)....33

Fig 44 X300 PIN 8: VOUT, LCD CONNECTOR (X300 PIN 8) -> C301 and C302 ........33

Fig 45 X303 PIN 2: KEYB_LIGHT, BACKLIGHT CIRCUITRY (V300 pin 6) -> UI CON-

NECTOR (X303 pin 2)..........................................................................................................34

Fig 46 Troubleshooting: Top...............................................................................................36

Fig 47 Phone is dead............................................................................................................38

Fig 48 Flash Faults...............................................................................................................39

Fig 49 Phone is jammed.......................................................................................................41

Fig 50 Charging Faults ........................................................................................................43

Fig 51 SIM Card ..................................................................................................................44

Fig 52 Audio Faults ............................................................................................................45

Fig 53 Display faults............................................................................................................49

Fig 54 Keypad Faults...........................................................................................................52

Fig 55 TP 20 ........................................................................................................................57

Fig 56 TP 21 ........................................................................................................................57

Fig 57 TP 22 ........................................................................................................................58

Fig 58 TP 51, 52, 53 ............................................................................................................58

Fig 59 TP 23, 24 ..................................................................................................................59

Fig 60 TP 40 ........................................................................................................................59

Fig 61 TP 25, 28 ..................................................................................................................60

Fig 62 TP 26, 27 ..................................................................................................................60

Fig 63 TP 30 ........................................................................................................................61

Fig 64 TP 29 ........................................................................................................................61

Fig 65 TP 20 ........................................................................................................................62

Fig 66 TP 20 ........................................................................................................................63

Fig 67 TP 31, 32 ..................................................................................................................63

Fig 68 TP 33 ........................................................................................................................64

Fig 69 TP 36 ........................................................................................................................64

Fig 70 TP 37 (RX continuous mode)...................................................................................65

Fig 71 TP 37 (RX burst mode) ...........................................................................................65

Fig 72 TP 51, 52, 53 ............................................................................................................66

Fig 73 TP 40 ........................................................................................................................66

Fig 74 Power 30 dBm..........................................................................................................80

Fig 75 Phase error RMS.......................................................................................................80

Fig 76 Signal Strength Reading...........................................................................................81

Fig 77 BER(-102 dBm)........................................................................................................81

Page 4 ãNokia Corporation Issue 1 01/02

Page 5

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Transceiver T roubleshooting

Baseband Troubleshooting

PWB Points (and Measurement Points)

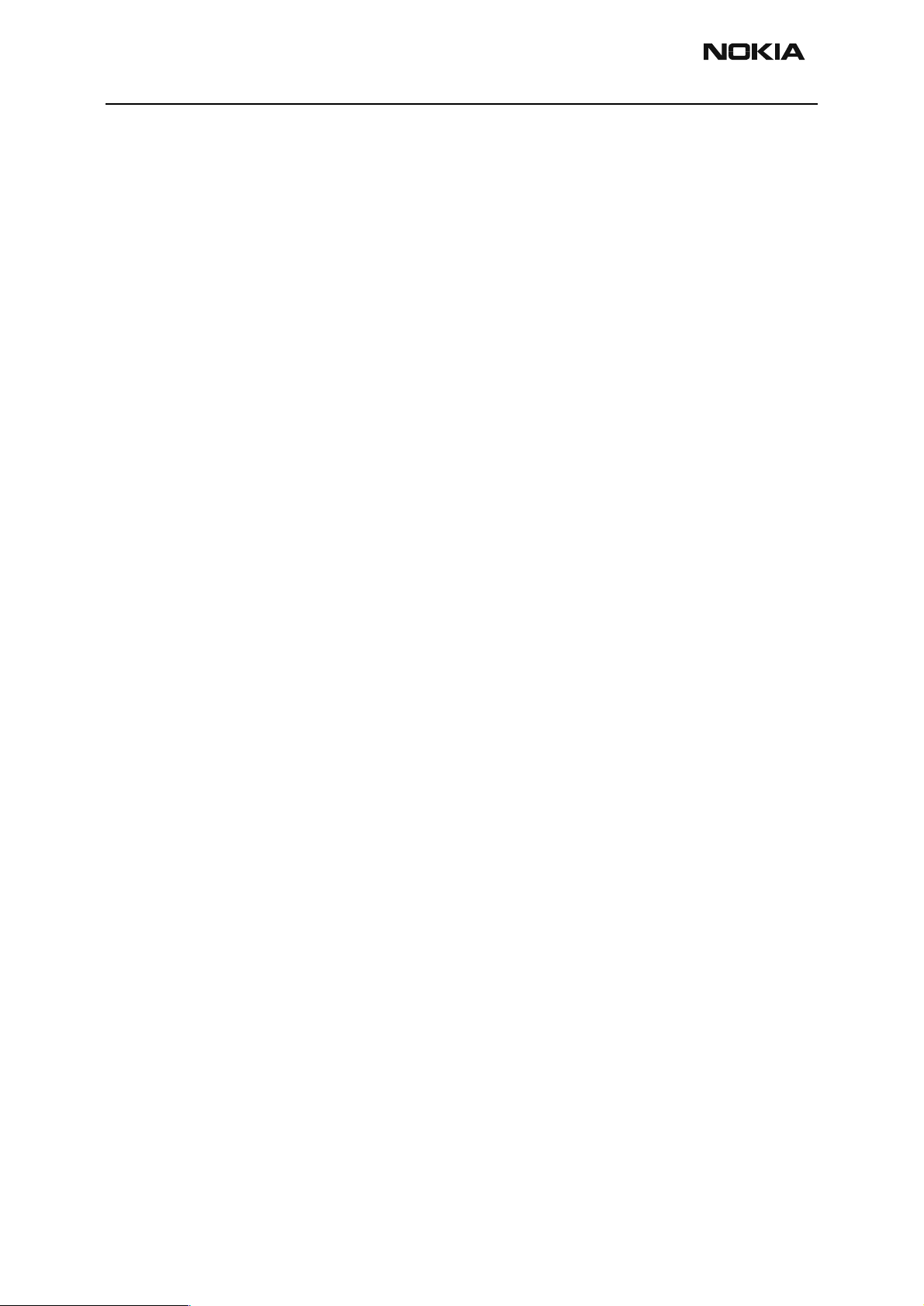

The following figures are the most needed testpoints in the NSB-8 transceiver.

Figure 1: Picture of top testpoints

Issue 1 01/02 ãNokia Corporation Page 5

Page 6

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

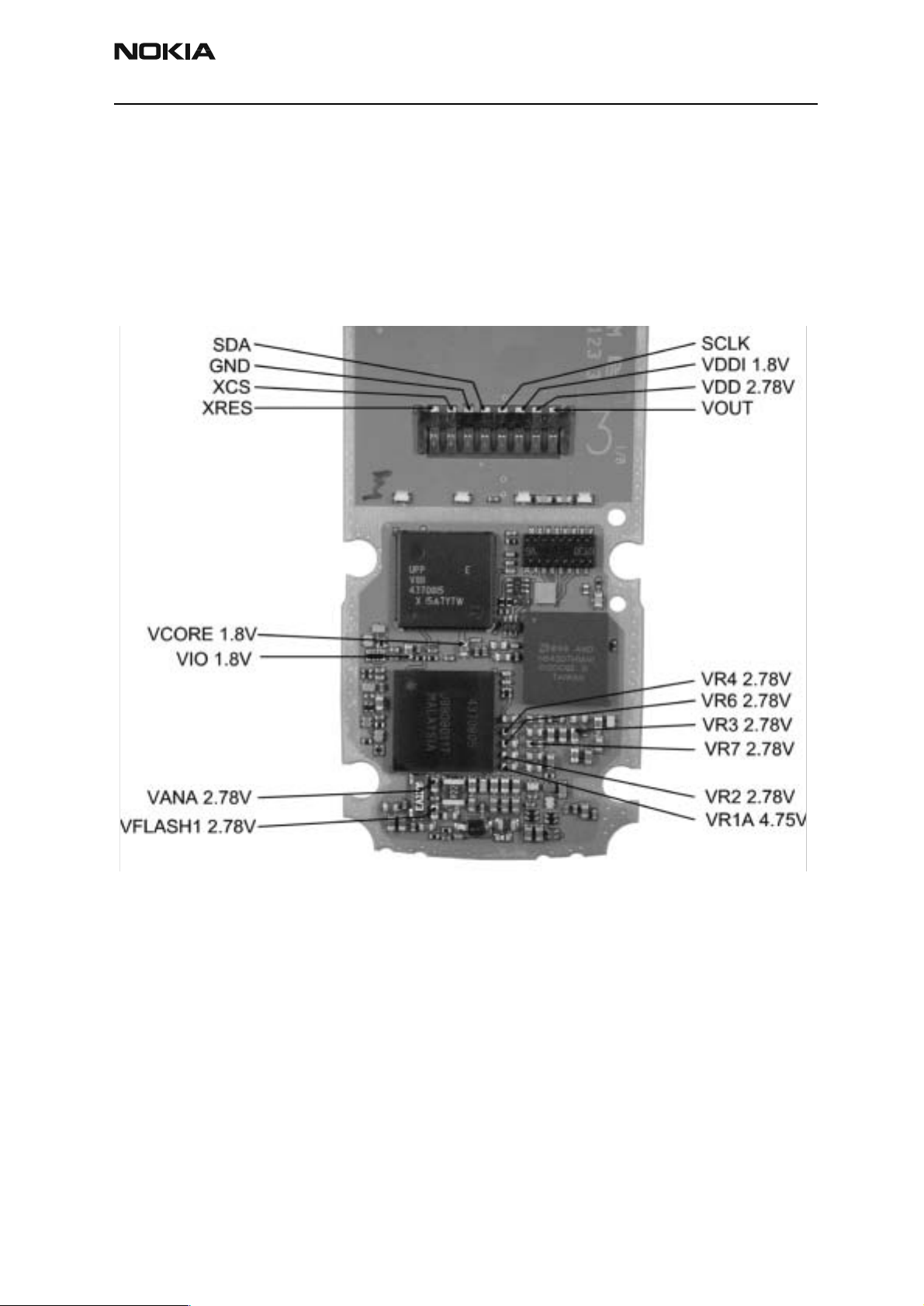

Figure 2: Picture of bottom testpoints

Page 6 ãNokia Corporation Issue 1 01/02

Page 7

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

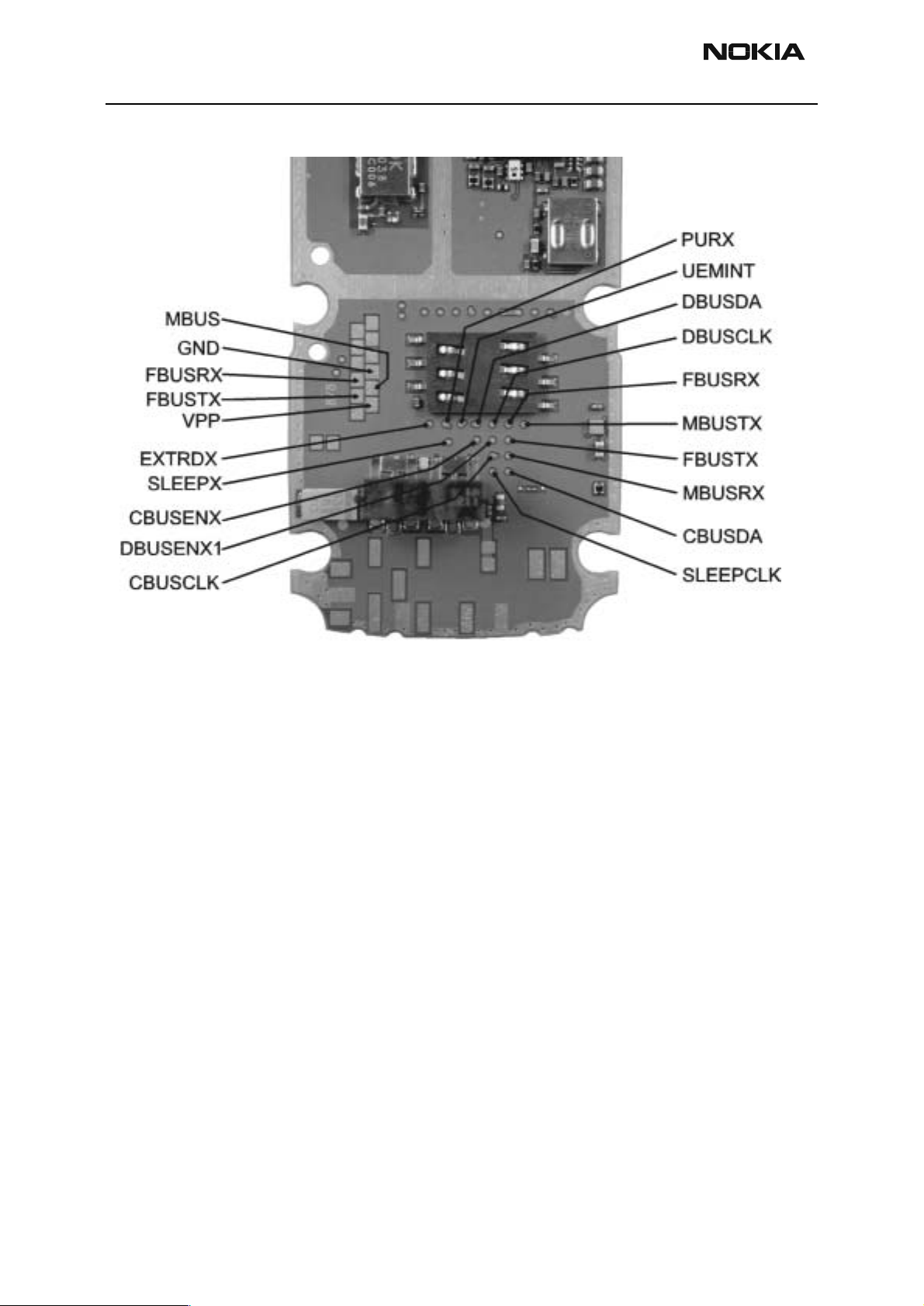

Figure 3: Top testpoints

Issue 1 01/02 ãNokia Corporation Page 7

Page 8

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

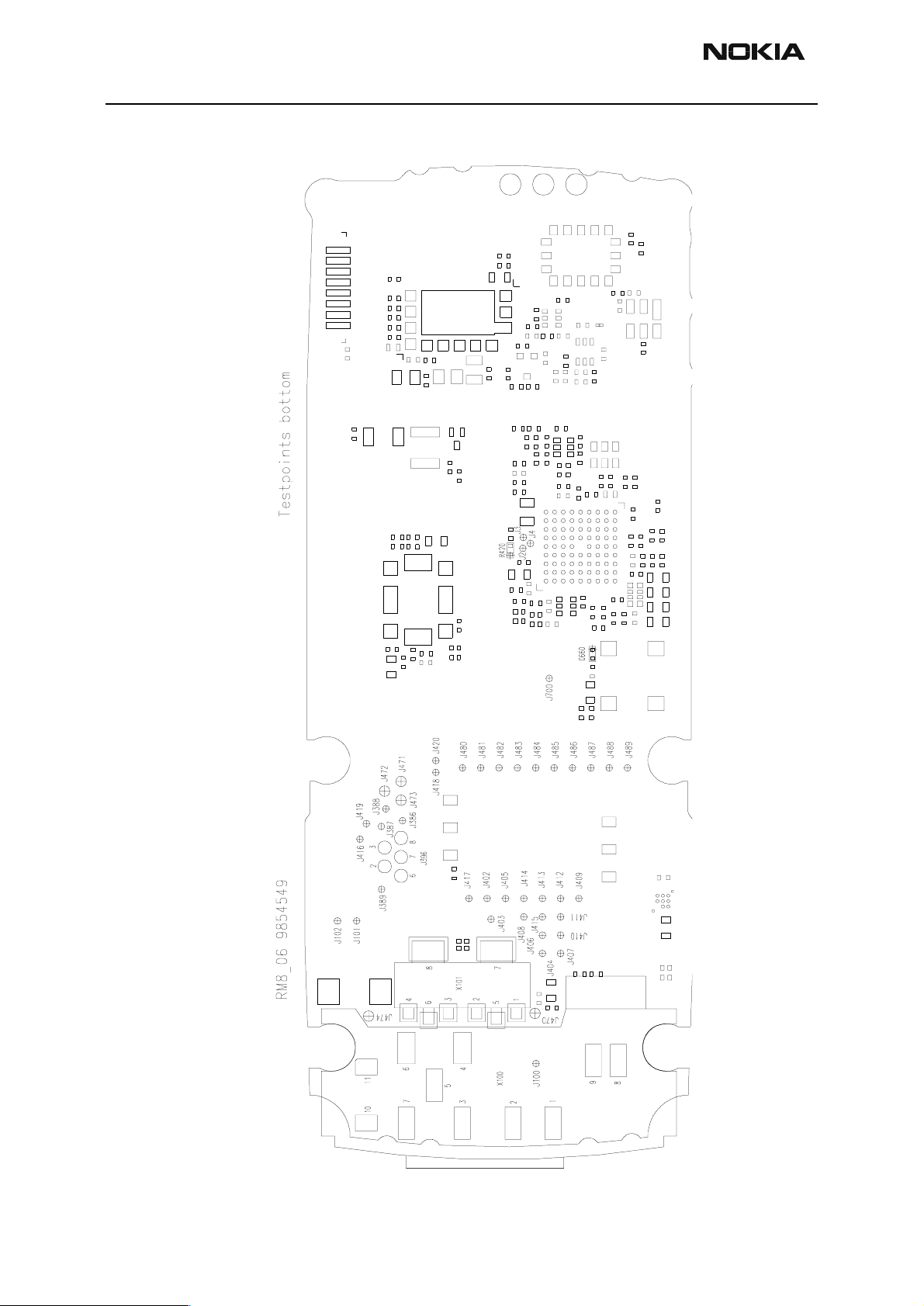

Figure 4: Bottom testpoints

Page 8 ãNokia Corporation Issue 1 01/02

Page 9

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

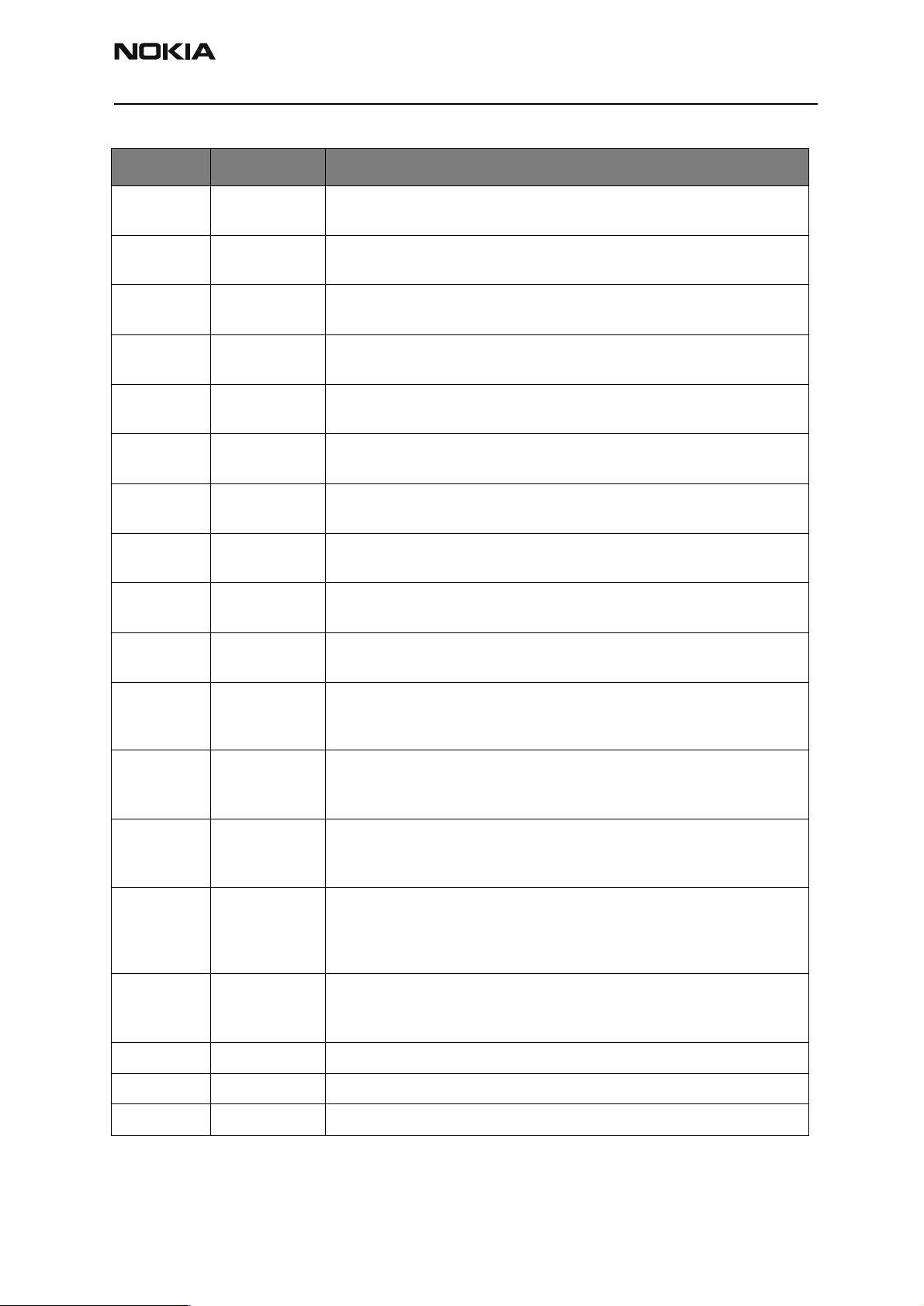

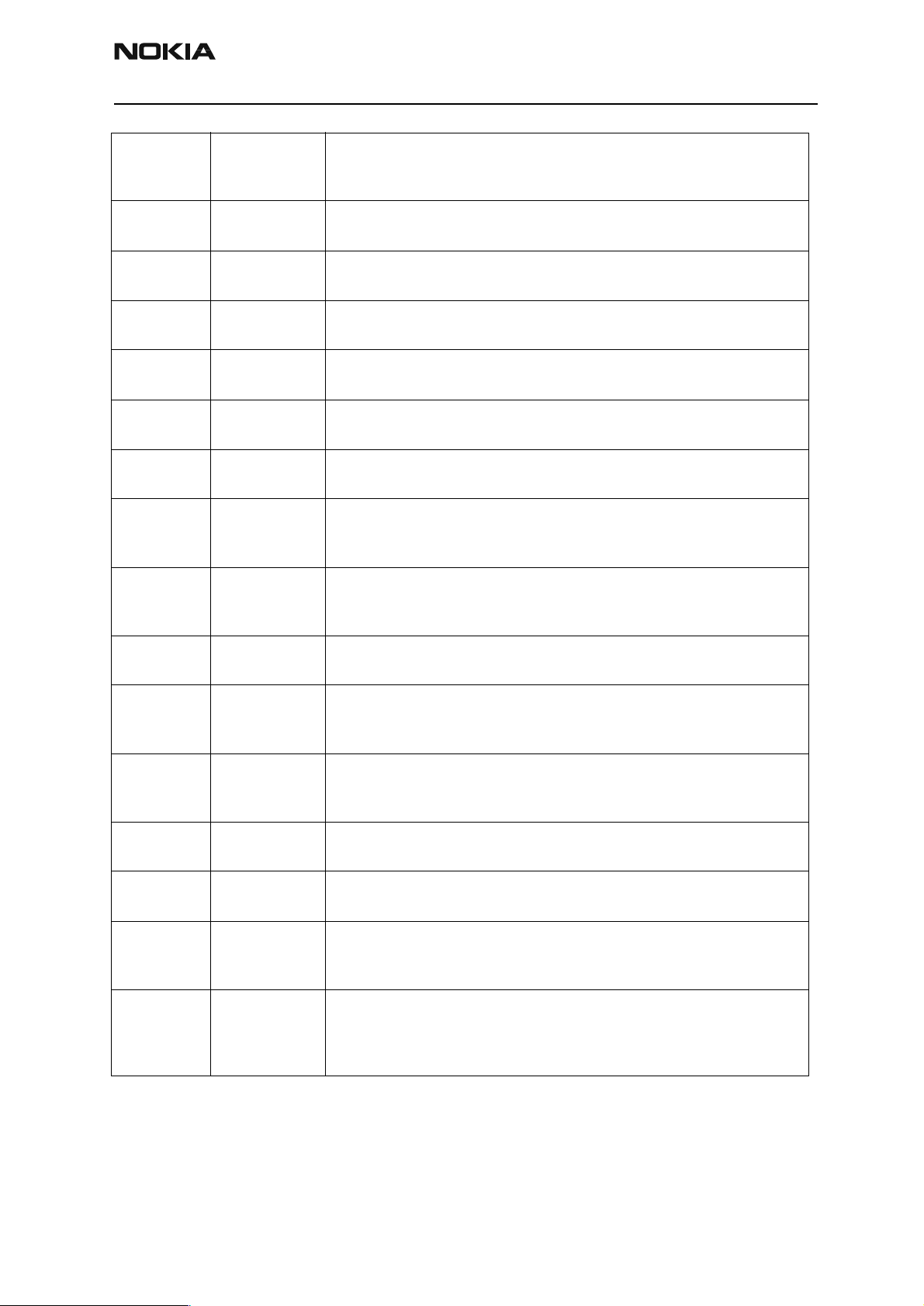

Table 1: Testpoints

REFERENCE SIGNAL NOTE

C205 VFLASH1 2.78 V regulator output

UEM (D200) -> external FLASH memory

C206 VANA 2.78 V regulator output

UEM (D200) -> internal and external analog circuitry

C207 VIO 1.8 V regulator output

UEM (D200) -> internal and external logic circuitry

C208 VCORE 1.8 V programmable regulator output

UEM (D200) -> UPP (D400)

C221 VR1A 4.75 V RF regulator output

UEM (D200) -> HAGAR (N600)

C222 VR4 2.78 V regulator output

UEM (D200) -> HAGAR (N600)

C223 VR6 2.78 V regulator output

UEM (D200) -> HAGAR (N600)

C224 VR7 2.78 V regulator output

UEM (D200) -> VCO (G650)

C225 VR2 2.78 V regulator output

UEM (D200) -> transf balun (T700)

C227 VR3 2.78 V regulator output

UEM (D200) -> HAGAR (N600) and VCTCXO (G660)

C660 RFCLK (26MHz) Main clock oscillator 26 MHz, see Figure 5, “C660: RFCLK (26 MHz ),

VCTCXO (G660 pin 3) -> HAGAR (N600 pin H1),” on page 14

VCTCXO (G660) -> HAGAR (N600)

J1 RESET Reset signal, see Fi gure 6, “J1: RESET, UPP (D400 pin D12) -> HAGAR

(N600 pin E3),” on pa ge 14

UPP (D400) -> HAGAR (N600)

J2 RFBUSDA RFBUS data, see Figure 7, “J2: RFBUSDA, UPP (D400 pin F12) -> HAGAR

(N600 pin E1),” on pa ge 15

UPP (D400) -> HAGAR (N600)

J3 RFBUSCLK RFBUS clock, see Figure 8, “J3: RFBUSCLK, UPP (D4 00 p in G 11) ->

HAGAR (N600 pin E2),” on page 15 and Figure 9, “J3: RFBUSCLK (closer

look), UPP (D400 pi n G 11) -> HAGAR (N600 pin E2),” on page 16

UPP (D400) -> HAGAR (N600)

J4 RFBUSEN1 RFBUS enable, see Figure 10, “J4: RFBUSEN1, UPP (D400 pin G13) ->

HAGAR (N600 pin D1 ), ” on page 16

UPP (D400) -> HAGAR (N600)

J100 VBAT Battery voltage pad for jig

J101 BSI Battery size indicator for jig

J102 BTEMP Battery temperature for jig

Issue 1 01/02 ãNokia Corporation Page 9

Page 10

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

J386 SIMDATA SIM data, see Figure 11, “J386: SIMDAT A, UEM (D200 pin B2) <-> SIM CARD

READER (X386 pin 4,” on page 17

UEM (D200) <-> SIM CARD READER (X386)

J387 SIMRST SIM reset, see Figure 12, “J387: SIMRST, UEM (D200 pin A2) <-> SIM

CARD READER (X386 pin 2) ,” on page 17

UEM (D200) -> SIM CARD READER (X386)

J388 SIMCLK SIM clock, see Figure 13, “J388: SIMCLK, UEM (D200 pin B3) <-> SIM

CARD READER (X386 pin 3) ,” on page 18

UEM (D200) -> SIM CARD READER (X386)

J389 VSIM SIM voltage 3 V or 1.8 V

UEM (D200) -> SIM CARD READER (X386)

J396 PAD 2 FBUSTX FBUS transmitted data, see Figure 14, “J396 PAD 2: FBUSTX (during

flashing), UEM (D200 pin N5 ) -> SERV ICE INTERFACE (J396 PAD 2),”

on page 18 (during flashing)

UEM (D200) -> SERVICE INTERFACE

J396 PAD 3 FBUSRX FBUS received data, s ee Figure 15, “J396 PAD 3 FBUSRX (duri ng f lash-

ing), SERVICE INTERFACE (J396 PAD 3) -> UEM (D200 pin P5),” on

page 19 (during flashing)

SERVICE INTERFACE -> UEM (D200)

J396 PAD 6 VPP Flash programming voltage

UEM (D200), SERVICE INTERFACE -> FLASH (D450)

J396 PAD 7 MBUS One wire bidirectional serial bus, see Figure 16, “J396 PAD 7: MBUS (dur-

ing flashing), UEM (D200 pin M6) <-> SERV ICE INTERFACE (J396 PAD

7),” on page 19 (dur i ng fl ashing)

UEM (D200) <-> SERVICE INTERFACE

J396 PAD 8 GND Ground p oint for s ervice interface

J402 PURX Power Up Reset, see Fi gure 17, “J402: PURX, UEM (D200 pin C10) ->

UPP (D400 pin K2),” on page 20

UEM (D200) -> UPP (D400)

J403 SLEEPX Sleep enable, see Figure 18, “J403: SLEEPX, UEM (D200 pin B11) -> UPP

(D400 pin L1),” on pa ge 20

UEM (D200) -> UPP (D400)

J404 SLEEPCLK Sleep clock, see Figure 19, “J404: SLEEPCLK, UEM (D200 pin D9) -> UPP

(D400 pin H3),” on page 21

UEM (D200) -> UPP (D400)

J405 UEMINT UEM interrupt, see Figure 20, “J405: UEMINT, UEM (D200 pin A10) ->

UPP (D400 pin J2),” on page 21

UEM (D200) -> UPP (D400)

J406 CBUSCLK CBUS clock, see Figure 21, “J406: CBUSCLK, UEM (D200 pin A8) -> UPP

(D400 pin G1),” on page 22

UEM (D200) -> UPP (D400)

J407 CBUSDA CBUS data, see Figure 22, “J407: CBUSDA, UEM (D200 pin B7) <-> UPP

(D400 pin G2),” on page 22

UEM (D200) <-> UPP (D400)

Page 10 ãNokia Corporation Issue 1 01/02

Page 11

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

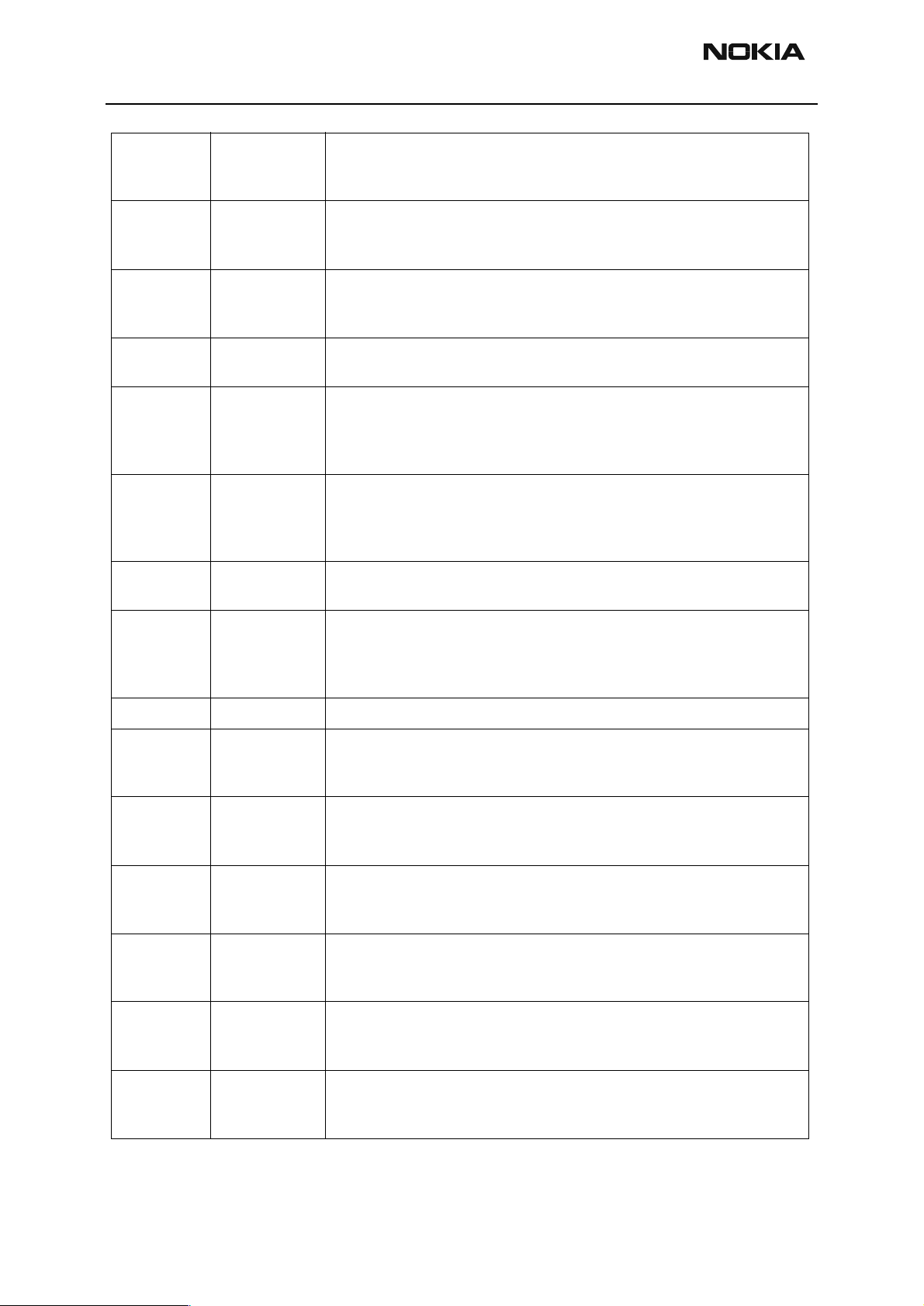

J408 CBUSENX CBUS enable, see Figure 23, “J408: CBUSENX, UEM (D200 pin C8) ->

UPP (D400 pin F3),” on page 23

UEM (D200) -> UPP (D400)

J409 MBUSTX MBUS transmitted data, see Figure 24, “J409: MBUSTX (during flashing),

UPP (D400 pin E3) -> UEM (D20 0 pi n C6) ,” o n page 23 (during flashing)

UPP (D400) -> UEM (D200)

J410 MBUSRX MBUS received data, see Figure 25, “J410: MBUSRX (during flashing),

UEM (D200 pin D6) -> UPP (D400 pin D3),” on page 24 (during flashing)

UEM (D200) -> UPP (D400)

J411 FBUSTX FBUS transmitted data, see Figure 26, “J411: FBUSTX (during flashing),

UPP (D400 pin F1) -> UEM (D200 pin A7),” on pag e 24 (during flashing)

UPP (D400) -> UEM (D200)

J412 FBUSRX FBUS received data, see Figure 27, “J412: FBUSRX (during flashing), UEM

(D200 pin C7) -> UPP (D400 pin E4),” on page 25 (during flashing)

UEM (D200) -> UPP (D400)

J413 DBUSCLK DBUS clock, see Figure 28, “J413: DBUSCLK, UEM (D200 pin D10) ->

UPP (D400 pin K3),” on page 25

UEM (D200) -> UPP (D400)

J414 DBUSDA DBUS data, see Figure 29, “J414: DBUSDA, UEM (D200 pin A11) <->

UPP (D400 pin L3),” on page 26

UEM (D200) <-> UPP (D400)

J415 DBUSENX1 DBUS enable, see Figure 30, “J41 5: DBUSENX1, UEM (D200 pin B10 ) ->

UPP (D400 pin J3),” on page 26

UEM (D200) -> UPP (D400)

J416 EXTWRX FLASH write enable, see Figure 31, “J416: EXTWRX (during flashing), UPP

(D400 pin N9) -> FLASH (D450 pin A6),” on page 27 (during flashing)

UPP (D400) -> FLASH (D450)

J417 EXTRDX FLAS H re ad e na b le , see Figure 32, “J417: EXTRDX, UPP (D400 pin L7) ->

FLASH (D450 pin C10),” on page 27

UPP (D400) -> FLASH (D450)

J418 FLS2CSX UPP (D400) -> TESTPOINT

J419 FLSCLK FLASH clock, see Figure 33, “J419: FLSCLK, UPP (D4 00 pin N12) ->

FLASH (D450 pin A4),” on page 28

UPP (D400) -> FLASH (D450)

J420 FLSCSX FLASH chip enable, see Figure 34, “J420: FLSCSX, UPP (D400 pin N6) ->

FLASH (D450 pin B9),” on pag e 28

UPP (D400) -> FLASH (D450)

J470 VBAT Battery voltage

J471 GENTEST0/

STITxD

J472 GENTEST1/

STISClk

J473 STIRxD OSTRICH received data

OSTRICH transmitted data

UPP (D400) -> TESTPOINT

OSTRICH clock

UPP (D400) -> TESTPOINT

UPP (D400) -> TESTPOINT

Issue 1 01/02 ãNokia Corporation Page 11

Page 12

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

J474 GND Ground poin t

J480 JTMS UPP (D400) -> TESTPOINT

J481 JTRst UPP (D400) -> TESTPOINT

J482 JTDI UPP (D400) -> TESTPOINT

J483 VCC Supply voltage from 1.8 V VIO regulator

J484 JTDO UPP (D400) -> TESTPOINT

J485 JTClk_ret UPP (D400) -> TESTPOINT

J486 JTClk UPP (D400) -> TESTPOINT

J487 EMU0 UPP (D400) -> TESTPOINT

J488 EMU1 UPP (D400) -> TESTPOINT

J489 GND Ground poin t

J700 TXP T r ansmitted power control, see Figure 35, “J700: TXP, UPP (D400 pin

D11) -> HAGAR (N600 pin D5),” on page 29 (during call)

UPP (D400) -> HAGAR (N600)

R301 PWRONX Power on button, see Figure 36, “R301: PWRONX, POWER BUTTON

(S300) -> UEM (D200 pin P7),” on page 29

POWER BUTTON -> UEM (D200)

R305 KLIGHT Backlight enable, s ee Figure 37, “R305: KLIGHT, UEM (D200 pin F3) ->

BACKLIGHT CIRCUITRY (V30 0 pi ns 2,3,5 and V301 pins 2,5,6),” on

page 30

UEM (D200) -> BACKLIGHT CIRCUIT RY (V300 and V301)

R420 RFCLK (13MHz) Main clock 13 MHz, see Figure 38, “R420: RFCLK (13 MHz), HAGAR

(N600 pin E4) -> UPP (D400 pin M5),” on page 30

HAGAR (N600) -> UPP (D400)

X100 PIN 1 GND Ground poin t

X100 PIN 2 VCHAR Charger voltage

SYSTEM CONNECTOR (X100) -> UEM (D200)

X100 PIN 3 XMICN External mic (-)

SYSTEM CONNECTOR (X100) -> UEM (D200)

X100 PIN 4 XEARN External earpiece (-)

SYSTEM CONNECTOR (X100) -> UEM (D200)

X100 PIN 5 XMICP External mic (+)

SYSTEM CONNECTOR (X100) -> UEM (D200)

X100 PIN 6 HEADINT Headset interrupt

SYSTEM CONNECTOR (X100) -> UEM (D200)

X100 PIN 7 XEARP External earpiece (+)

SYSTEM CONNECTOR (X100) -> UEM (D200)

X100 PIN 8 VBAT (VIBRA) Vibra supply voltage

VBAT -> SYSTEM CONNECTOR (X100)

Page 12 ãNokia Corporation Issue 1 01/02

Page 13

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

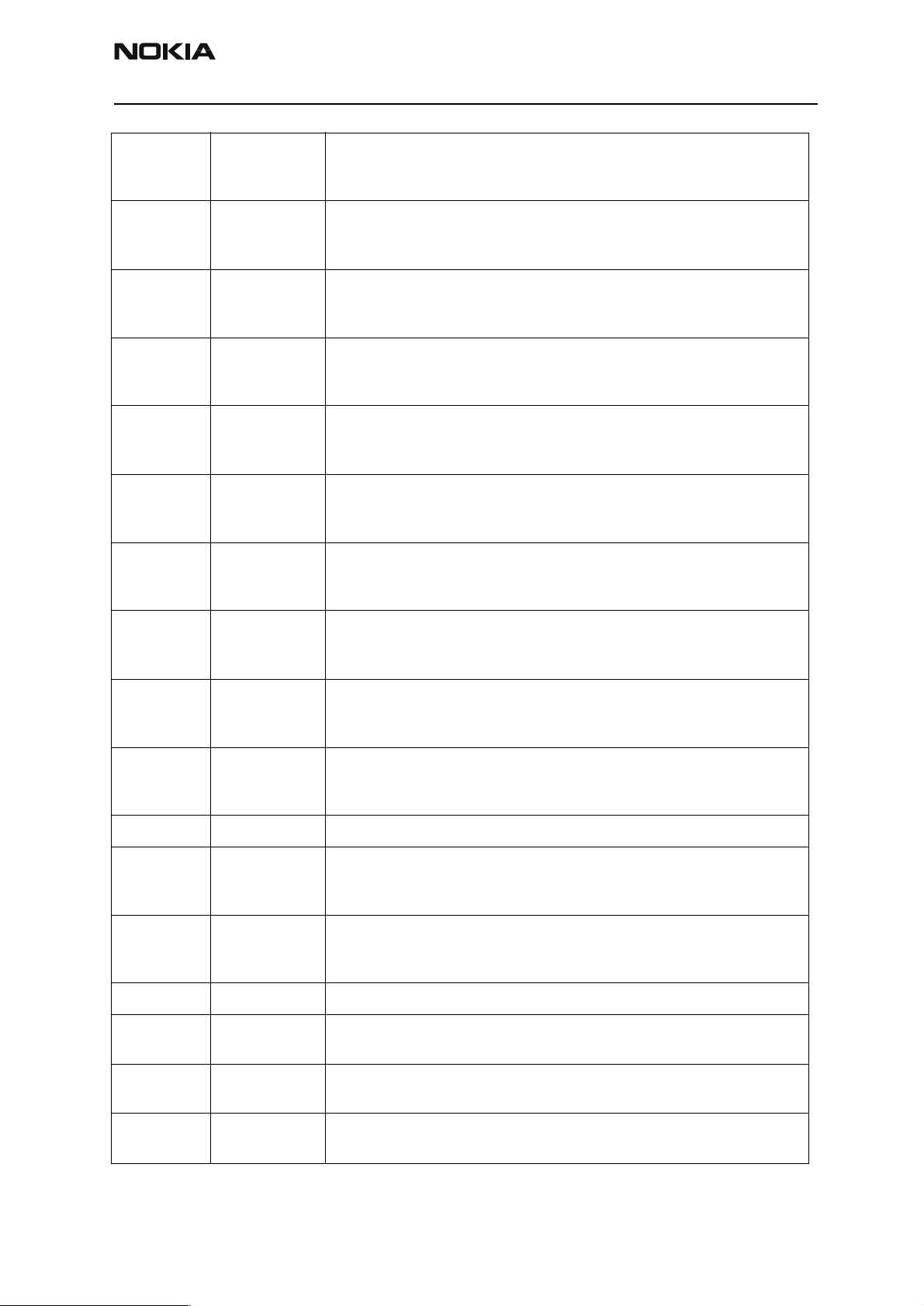

X100 PIN 9 VIBRA Vibra control, see Figure 39, “X100 PIN 9: VIBRA, UEM (D200 pin G3) ->

SYSTEM CONNECTOR (X100 pin 9),” on page 31

UEM (D200) -> SYSTEM CONNECTOR (X100)

X100 PIN 10 MIC (-) Internal mi c (- )

SYSTEM CONNECTOR (X100) -> UEM (D200)

X100 PIN 11 MIC (+) In t e rn al mic (+)

SYSTEM CONNECTOR (X100) -> UEM (D200)

X10 1 PIN 1 VBAT Battery voltage

BATTERY CONNECTOR (X101) -> VBAT

X10 1 PIN 2 BTEMP Battery temperature

BATTERY CONNECTOR (X101) -> UEM (D200)

X10 1 PIN 3 BSI Battery size indicator

BATTERY CONNECTOR (X101) -> UEM (D200)

X10 1 PIN 4 GND Battery ground

BATTERY CONNECTOR (X 101) -> PHONE GRO UND

X300 PIN 1 XRES LCD reset, see Figure 40, “X300 PIN 1: XRES (startup), UPP (D400 pin

A7) -> LCD CONNECTOR (X300 pin 1),” on page 31

UPP (D400) -> LCD CONECTOR (X300)

X300 PIN 2 XCS LCD chip select, see Figure 41, “X300 PIN 2: XCS, UPP (D400 pin C7) ->

LCD CONNECTOR (X300 pin 2),” on pag e 32

UPP (D400) -> LCD CONECTOR (X300)

X300 PIN 3 VSS LCD ground

LCD CONECTOR (X300) -> PHONE GROUND

X300 PIN 4 SDA LCD data, see Figure 42, “X300 PIN 4: SDA, UPP (D400 pin B6) -> LCD

CONNECTOR (X300 pin 4),” on page 32

UPP (D400) -> LCD CONECTOR (X300)

X300 PIN 5 SCLK LCD clock, see Figure 43, “X300 PIN 5: SCLK, UPP (D400 pin C6) -> LCD

CONNECTOR (X300 pin 5),” on page 33

UPP (D400) -> LCD CONECTOR (X300)

X300 PIN 6 VDDI LCD logic voltage supply 1.8 V

VIO 1.8 V -> LCD CONECTOR (X300)

X300 PIN 7 VDD LCD voltage supply

VFLASH1 2.78 V -> LCD CONECTOR (X300)

X300 PIN 8 VOUT Booster output, see Figure 44, “X300 PIN 8: VOUT, LCD CONNECTOR

(X300 PIN 8) -> C301 and C302,” on page 33

LCD CONNECTOR (X300) -> C301 and C302

X303 PIN 2 KEYB_LIGHT Keyboard backlight current, see Figure 45, “X303 PIN 2: K E YB _LIGHT,

BACKLIGHT CIRCUITRY (V300 pi n 6) -> UI CONNECTOR (X303 pin 2),”

on page 34

BACKLIGHT CIRCUITRY (V300) -> UI CONNECTOR (X303)

Issue 1 01/02 ãNokia Corporation Page 13

Page 14

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 5: C660: RFCLK (26 MHz), VCTCXO (G660 pin 3) -> HAGAR (N600 pin H1)

Figure 6: J1: RESET, UPP (D400 pin D12) -> HAGAR (N600 pin E3)

Page 14 ãNokia Corporation Issue 1 01/02

Page 15

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Figure 7: J2: RFBUSDA, UPP (D400 pin F12) -> HAGAR (N600 pin E1)

Figure 8: J3: RFBUSCLK, UPP (D400 pin G11) -> HAGAR (N600 pin E2)

Issue 1 01/02 ãNokia Corporation Page 15

Page 16

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 9: J3: RFBUSCLK (closer look), UPP (D400 pin G11) -> HAGAR (N600 pin E2)

Figure 10: J4: RFBUSEN1, UPP (D400 pin G13) -> HAGAR (N600 pin D1)

Page 16 ãNokia Corporation Issue 1 01/02

Page 17

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Figure 11: J386: SIMDATA, UEM (D200 pin B2) <-> SIM CARD READER (X386 pin 4

Figure 12: J387: SIMRST, UEM (D200 pin A2) <-> SIM CARD READER (X386 pin 2)

Issue 1 01/02 ãNokia Corporation Page 17

Page 18

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 13: J388: SIMCLK, UEM (D200 pin B3) <-> SIM CARD READER (X386 pin 3)

Figure 14: J396 PAD 2: FBUSTX (during flashing), UEM (D200 pin N5) -> SERVICE INTERFACE (J396 PAD 2)

Page 18 ãNokia Corporation Issue 1 01/02

Page 19

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Figure 15: J396 PAD 3 FBUSRX (during flashing), SERVICE INTERFACE (J396 PAD 3) -> UEM (D200 pin P5)

Figure 16: J396 PAD 7: MBUS (during flashing), UEM (D200 pin M6) <-> SERVICE INTERFACE (J396 PAD 7)

Issue 1 01/02 ãNokia Corporation Page 19

Page 20

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 17: J402: PURX, UEM (D200 pin C10) -> UPP (D400 pin K2)

Figure 18: J403: SLEEPX, UEM (D200 pin B11) -> UPP (D400 pin L1)

Page 20 ãNokia Corporation Issue 1 01/02

Page 21

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Figure 19: J404: SLEEPCLK, UEM (D200 pin D9) -> UPP (D400 pin H3)

Figure 20: J405: UEMINT, UEM (D200 pin A10) -> UPP (D400 pin J2)

Issue 1 01/02 ãNokia Corporation Page 21

Page 22

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 21: J406: CBUSCLK, UEM (D200 pin A8) -> UPP (D400 pin G1)

Figure 22: J407: CBUSDA, UEM (D200 pin B7) <-> UPP (D400 pin G2)

Page 22 ãNokia Corporation Issue 1 01/02

Page 23

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Figure 23: J408: CBUSENX, UEM (D200 pin C8) -> UPP (D400 pin F3)

Figure 24: J409: MBUSTX (during flashing), UPP (D400 pin E3) -> UEM (D200 pin C6)

Issue 1 01/02 ãNokia Corporation Page 23

Page 24

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 25: J410: MBUSRX (during flashing), UEM (D200 pin D6) -> UPP (D400 pin D3)

Figure 26: J411: FBUSTX (during flashing), UPP (D400 pin F1) -> UEM (D200 pin A7)

Page 24 ãNokia Corporation Issue 1 01/02

Page 25

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Figure 27: J412: FBUSRX (during flashing), UEM (D200 pin C7) -> UPP (D400 pin E4)

Figure 28: J413: DBUSCLK, UEM (D200 pin D10) -> UPP (D400 pin K3)

Issue 1 01/02 ãNokia Corporation Page 25

Page 26

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 29: J414: DBUSDA, UEM (D200 pin A11) <-> UPP (D400 pin L3)

Figure 30: J415: DBUSENX1, UEM (D200 pin B10) -> UPP (D400 pin J3)

Page 26 ãNokia Corporation Issue 1 01/02

Page 27

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Figure 31: J416: EXTWRX (during flashing), UPP (D400 pin N9) -> FLASH (D450 pin A6)

Figure 32: J417: EXTRDX, UPP (D400 pin L7) -> FLASH (D450 pin C10)

Issue 1 01/02 ãNokia Corporation Page 27

Page 28

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 33: J419: FLSCLK, UPP (D400 pin N12) -> FLASH (D450 pin A4)

Figure 34: J420: FLSCSX, UPP (D400 pin N6) -> FLASH (D450 pin B9)

Page 28 ãNokia Corporation Issue 1 01/02

Page 29

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Figure 35: J700: TXP, UPP (D400 pin D11) -> HAGAR (N600 pin D5)

Figure 36: R301: PWRONX, POWER BUTTON (S300) -> UEM (D200 pin P7)

Issue 1 01/02 ãNokia Corporation Page 29

Page 30

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 37: R305: KLIGHT, UEM (D200 pin F3) -> BACKLIGHT CIRCUITRY (V300 pins 2,3,5 and V301 pins

2,5,6)

Figure 38: R420: RFCLK (13 MHz), HAGAR (N600 pin E4) -> UPP (D400 pin M5)

Page 30 ãNokia Corporation Issue 1 01/02

Page 31

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Figure 39: X100 PIN 9: VIBRA, UEM (D200 pin G3) -> SYSTEM CONNECTOR (X100 pin 9)

Figure 40: X300 PIN 1: XRES (startup), UPP (D400 pin A7) -> LCD CONNECTOR (X300 pin 1)

Issue 1 01/02 ãNokia Corporation Page 31

Page 32

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 41: X300 PIN 2: XCS, UPP (D400 pin C7) -> LCD CONNECTOR (X300 pin 2)

Figure 42: X300 PIN 4: SDA, UPP (D400 pin B6) -> LCD CONNECTOR (X300 pin 4)

Page 32 ãNokia Corporation Issue 1 01/02

Page 33

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Figure 43: X300 PIN 5: SCLK, UPP (D400 pin C6) -> LCD CONNECTOR (X300 pin 5)

Figure 44: X300 PIN 8: VOUT, LCD CONNECTOR (X300 PIN 8) -> C301 and C302

Issue 1 01/02 ãNokia Corporation Page 33

Page 34

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 45: X303 PIN 2: KEYB_LIGHT, BACKLIGHT CIRCUITRY (V300 pin 6) -> UI CONNECTOR (X303 pin 2)

Troubleshooting steps

The following hints should help to find the cause of the problem when the circuitry

seems to be faulty. This trouble shooting instruction is divided into sections.

1 Phone is totally dead

2 Power does not stay on or the phone is jammed

3 Flash programming does not work

4 Display is not working

5 Plug in SIM card is out of order (insert SIM card).

6 Audio fault

7 Charging fault

The first thing to do is carry out a through visual check of the module. Ensure in particular that:

a) there are no mechanical damages

b) soldered joints are OK.

Page 34 ãNokia Corporation Issue 1 01/02

Page 35

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

General instructions

Most semiconductors are static discharge sensitive! ESD p rotection must be taken care

of during repair (ground straps and ESD soldering irons). HAGAR, PA, UEM, UPP, and Flash

are moisture sensitive and must be pre-baked prior to soldering, if they have been out of

their vacuum package longer t han the specified time.

• Connect test jig to computer with DAU-9S cable or to FPS-8 Flash Prommer with

AXS-4 serial cable.

• Make sure that you have PKD-1 dongle connected to computer’s parallel port.

• Connect DC power supply to module test jig with FLC-2 cable.

• Set the DC supply voltage to 3.9 V and set the module test jig (MJS-46) jumper

connector to ”bypass” position. VBAT must not exceed 5.15 V to avoid damaging

the power amplifier (PA), if PA is active.

• MJS-46’s current consumption is ~ 9 mA. Note that MJS-46 is not protected against reverse voltage and there is a 2 A fuse which may blow if the

phone is shortcircuited.

• When doing BB energy management (EM) calibrations use JBV-1 jig and DC supply voltage 12 – 15 V.

• JBV-1’s current consumption is ~ 40 mA with 3.9 V supply voltage and ~ 80

mA with 15 V supply voltage.

• Set the phone module to test jig and start Phoenix service software. Initialize

connection to phone (use FBUS driver when using DAU-9S and COMBOX driver

when using FPS-8).

Issue 1 01/02 ãNokia Corporation Page 35

Page 36

NSB-8

jammed

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 46: Troubleshooting: Top

TOP

Phone totally

dead

No

Flash programming

doesn´t work

No

Phone

doesn´t start up or

the phone is jammed

Yes

Yes

Yes

Phone is

dead

Flash

faults

Phone is

No

Charging

doesn´t work

No

TOP 2

Yes

Charger

Page 36 ãNokia Corporation Issue 1 01/02

Page 37

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

TOP 2

Phone doesn´t read

SIM card

No

Audio faults

No

Display or LEDs

don´t work

Yes

Yes

Yes

SIM

card

Audio

faults

Display

faults

No

Keypad

doesn´t work

No

Yes

Keypad

faults

END

Issue 1 01/02 ãNokia Corporation Page 37

Page 38

NSB-8

No

No

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 47: Phone is dead

Phone

is dead

Phone current

is zero?

No

Phone current is

< 50 mA?

No

Phone current is

~ 54 mA?

Yes

Yes

No

Is phone flash

programming OK?

Yes

Check X101

solder and

VBAT lines.

Phone is

jammed

Flash

faults

Yes

Check BSI

Is phone in

LOCAL mode?

Yes

OK,

retest

No

line, X101, C241,

R203, C109, and

R202. Are they

OK?

Yes

Change

UEM

Repair

Page 38 ãNokia Corporation Issue 1 01/02

Page 39

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Figure 48: Flash Faults

Flash

faults

The phone

does not set

Flashbus TXD line

high after the

No

startup?

The phone

does not set

Flashbus TXD line low

after the line has

been high?

Yes

Yes

Measure BSI

pulse during Flash

programming.

Is it OK?

Measure

FBUSTX line during

Flash programming from

testpoint J411. Is it

high (1.8 V)?

Yes

Yes

No

No

Check BSI line

X101, C241,

R203, C109,

and R202.

Check R102

If OK ->

change UEM.

Change

UPP

Change

UPP

No

Flash faults

page 2

Issue 1 01/02 ãNokia Corporation Page 39

Page 40

NSB-8

jammed

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Flash faults

page 2

Wrong

manufacturer ID and

device ID?

Is the phone

totally dead?

No

Yes

Yes

Change

Flash

Phone is

dead

No

Phone

doesn´t start up

or the phone is

No

jammed?

Retest

Yes

Phone is

Page 40 ãNokia Corporation Issue 1 01/02

Page 41

NSB-8

No

jammed

PAMS Technical Documentation Troubleshooting Instructions

Figure 49: Phone is jammed

Phone is

Check

VBATT1-6, VIO,

VCORE, FLASH1,

Measure

VIO, VCORE,

FLASH1, VANA, and

VR3 voltages. Are

they OK?

Measure

32.768 kHz SLEEPCLK

from testpoint J404.

Is it OK?

Yes

Yes

No

No

VANA, and VR3

lines. Are they

OK?

Yes

Measure

32.768 kHz SLEEPCLK

from B200.

Is it OK?

Yes

No

No

Check

L260 - L265,

C260 - C265,

BSI / BTEMP,

and VBATT1-6

lines.

Check BSI /

BTEMP lines.

If OK ->

UEM regulators

are not working.

Change UEM

Check B200,

C209, and

C210

Change UEM

Measure

13 MHz RFCLK

from R420. Is it

OK?

Yes

Measure PURX

signal from testpoint J402

Is it high (1.8 V)?

Yes

Jammed

Page 2

No

No

Measure

26 MHz RFCLK

from C660. Is it

OK?

Yes

Check R661,

C661, R660,

C660. If OK ->

change G660.

Check R420 and

C420. If OK ->

change N600.

Change UEM

Issue 1 01/02 ãNokia Corporation Page 41

Page 42

NSB-8

Is it OK?

Troub l esh oot ing Instructions PAMS Technical Document a t ion

No

Yes

Yes

No

Measure watchdog

signal CBUSDA from

testpoint J414.

Is it OK?

No

Change UPP

Jammed

Page 2

Phone shuts down

after 30 s?

Measure DBUSCLK

1 MHz signal

from testpoint J413

Is it OK?

Read phone

information with Phoenix.

Yes

Retest.

No

Is it OK?

Change RM8

module

No

FBUSRX signal during

phone info reading from

Measure

testpoint J412.

Is it OK?

Measure

FBUSTX signal du ring

phone info read from

testpoint J411.

Is it OK?

Yes

Yes

No

Change UEM

No

Change UPP

Change UEM

Page 42 ãNokia Corporation Issue 1 01/02

Page 43

NSB-8

V100, C103,

PAMS Technical Documentation Troubleshooting Instructions

Figure 50: Charging Faults

Charger

Connect

(ACP-7)

charger.

Battery bars

don`t work (scroll)?

Yes

Measure

voltage over V100

(TVS). Is it

> 3.0 Vdc?

No

No

Retest

Check X100,

C100, F100,

L100, and

line.

Yes

Read

BTEMP value.

Compare it to

ambient temperature.

Is it ~ 25ْC

(0319)?

Yes

Remove

F100 (fuse) and

measure current. Is it

~ 350...390

mA?

Yes

No

No

Check

X101,C109

R202, C240,

R203, and line.

Change UEM

Retest

Issue 1 01/02 ãNokia Corporation Page 43

Page 44

NSB-8

,

.

.

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 51: SIM Card

SIM card

Check BSI line,

Insert SIM card

faults?

Yes

Set phone

in LOCAL mode.

Is it OK?

No

X101, C241,

R203, C109,

and R202.

If OK ->

change UEM.

No

Yes

Check X386

Measure VSIM voltage

from X386

Is it 3 V?

Yes

Check SIM

power UP sequence.

Is it OK?

No

No

Check VSIM line, X386

C203, and C389.

If OK -> change R388.

If still wrong VSIM

voltage -> change UEM

Check SIM lines.

If OK -> change R388.

If still fail -> change UEM

Yes

Change

END

UPP

Page 44 ãNokia Corporation Issue 1 01/02

Page 45

NSB-8

,

R161, C163, R166,

PAMS Technical Documentation Troubleshooting Instructions

Figure 52: Audio Faults

Audio

faults

Is earpiece working?

Yes

No

Set EXT IN, HP OUT, LOOP ON.

Change earpiece.

Is it working now?

No

Set phone in LOCAL mode.

Use Phoenix Audio Test.

Measure DC

offset voltage

from earpiece pads.

Is it ~ 1.38 V?

Yes

Yes

No

Retest

Check L151, C160,

R164, and line.

If OK ->

change UEM.

Issue 1 01/02 ãNokia Corporation Page 45

Audio

faults 2

Measure MICB2

voltage from XMICP

pads (L106).

Is it ~ 2.2 V?

Yes

Earpiece 2

No

Check L106, C112

C165, R167,

and line.

If OK ->

change UEM.

Page 46

NSB-8

Check R156, C153,

,

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Earpiece 2

Connect EXT audio signal 1 kHz

(sine) (200 mVp-p) to XMICP pads

and ground to XMICN.

Measure sine signal

from earpiece pads.

Is it ~ 880 mVp-p?

Yes

No

Retest

Measure sine signal

from UEM (R156).

Is it ~ 130 mVp-p?

No

Yes

Change

UEM

C155, R166, R167

C163, R161, and

line.

Page 46 ãNokia Corporation Issue 1 01/02

Page 47

NSB-8

No

.

PAMS Technical Documentation Troubleshooting Instructions

Audio

faults 2

Is microphone working?

Yes

Set HP IN, EXT OUT, LOOP ON.

Try change bottom

connector X100.

Is it working now?

No

Set phone in LOCAL mode.

Use Phoenix Audio Test.

Measure MICB1

voltage from MICP pads.

Is it ~ 2.1 V?

Yes

No

Retest

Check L105,

C105, C152,

C156, R152,

C168, C166,

C215, and line

If OK ->

change UEM.

Yes

Check C151,

R157, C105,

C154, and line.

If OK ->

change UEM.

Audio

faults 3

Issue 1 01/02 ãNokia Corporation Page 47

Page 48

NSB-8

frequency 3100 Hz and strength e.g. 5.

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Audio

faults 3

Is buzzer

(B301) working?

No

Yes

Set phone in LOCAL mode. Use

Phoenix Audio Test. Set buzzer

Measure VBAT

voltage from B301.

Is it OK?

Yes

Then set volume on.

Measure

buzzer control

signal from (C307).

Is it 3.1 kHz

pulses?

No

Yes

Check VBAT

line.

Change

buzzer

(B301).

No

Check C306,

C307, C308,

and line.

If OK ->

change UEM.

END

Page 48 ãNokia Corporation Issue 1 01/02

Page 49

NSB-8

Are the UI

No

V300, V329,

PAMS Technical Documentation Troubleshooting Instructions

Figure 53: Display faults

Display

faults

Set phone into LOCAL mode .

Start Display Test with Phoenix.

LEDs turned on?

-module

Yes

Change UI-module

Is it working now?

No

Check X303

No

Retest

Yes

Measure

signal from V300 pin

or R306. Is it LOW?

No

Check R306 if OK.

Measure V BAT

from V300 pin 4.

Is it OK?

Measure

LEDs’ control signal

KLIGHT from R305

(UEM side).

Is it LOW?

Yes

Yes

No

Check X303

Check R304

and VBAT

line.

Check control

signal line. If OK

-> change UEM.

Check R305,

and line.

Display

faults 2

Yes

Issue 1 01/02 ãNokia Corporation Page 49

Page 50

NSB-8

l

>

.

V301, V329,

No

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Display

faults 2

Are the display

LEDs turned on?

Yes

No

Measure signal

from V301 pin 3.

Is it LOW?

No

Measure VBAT

from V301 pin 4.

Is it OK?

Yes

Measure

LEDs’ control signal

KLIGHT from R305

(UEM side).

Is it LOW?

Yes

No

Check LEDs

Check contro

change UEM

Check R305,

and line.

Check R307

and VBAT

line.

signal line.

If OK -

and line.

Yes

Display

faults 3

Page 50 ãNokia Corporation Issue 1 01/02

Page 51

NSB-8

VDD (2.78 V) and

VDDI (1.8 V).

VOUT voltage.

X300, and lines.

PAMS Technical Documentation Troubleshooting Instructions

Display

faults 3

No

Does the display start?

Yes

Measure

Are they OK?

Yes

Change UI module.

Is it working now?

Check X300

No

No

Yes

Retest

Check C303

and lines.

If OK ->

change UEM.

Measure

Is it ~ 8.1 V?

Yes

Measure

XRES and XCS.

Are they ~ 1.8 V?

Yes

END

No

No

Check C302,

Check X300

and lines.

If OK ->

change UPP.

Issue 1 01/02 ãNokia Corporation Page 51

Page 52

NSB-8

0

jammed

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 54: Keypad Faults

faults

Check R301,

No

Measure voltage

from S300.

Is it high?

No

C312, S300,

and line.

If OK ->

change UEM.

Keypad

Is the power key (S300)

working?

Yes

Measure

voltage from S300

when it is pressed.

Is it high?

Yes

Yes

Check S300.

Is it OK?

Yes

Phone is

dead

Keypad

faults 2

No

No

Change S30

Phone is

Page 52 ãNokia Corporation Issue 1 01/02

Page 53

NSB-8

> change

> change UPP.

> change UPP.

PAMS Technical Documentation Troubleshooting Instructions

Keypad

faults 2

Are UI-module keys

working?

Yes

No

Change UI-module.

Are the keys working

now?

No

Check X303

Measure

ROW0, ROW1,

ROW2, ROW3, and

ROW4 lines from

X303. Are they

~ 1.8 V?

Yes

Yes

No

Retest

Check ROW0-4

lines and X303.

If OK -

Z301. If still fail

-

Keypad

faults 3

Measure

SLEEPX signal

from J403 when key

is pressed. Is it

~ 1.8 V?

Yes

When any

UI-module key is

pressed, are the LEDs

turned on?

Yes

No

No

Check ROW0-4

lines and X303.

If OK -> change

Z301. If still fail

-> change UPP.

Check ROW0-4

lines and X303.

If OK -> change

Z301. If still fail

-

Display

faults

Issue 1 01/02 ãNokia Corporation Page 53

Page 54

NSB-8

working?

No

change Z301.

.

change Z301.

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Yes

Check S301,

No

Measure ROW0

line from S301.

Is it ~ 1.8 V?

Yes

Measure

COL1 from S301

when S301 is pressed.

Is there a 50 us

pulse?

No

S302, and lines.

If OK ->

change Z301.

If stil l fail ->

change UPP.

Check S301

and COL1 line.

If OK ->

If still fail ->

change UPP.

Keypad

faults 3

Is volume UP key

working?

Is volume DOWN key

Yes

END

Yes

Change UPP

Check S301,

No

Measure ROW0

line from S302.

Is it ~ 1.8 V?

Yes

Measure

COL4 from S302

when S302 is pressed.

Is there a 50 us

pulse?

Yes

No

No

S302, and lines.

change Z301.

If still fail ->

change UPP.

If OK ->

Change UPP

Check S302

and COL4 line

If OK ->

If still fail ->

change UPP.

Page 54 ãNokia Corporation Issue 1 01/02

Page 55

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

RF Troubleshooting

Phone Settings for TX Troubleshooting

TX – burst mode

Channel 661

PCL 10

Phone Settings for RX Troubleshhoting

RX – continous mode

Traffic channel 661

AGC value 5

+ signal generator feeds –55 dBm to antenna pad

Issue 1 01/02 ãNokia Corporation Page 55

Page 56

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

NO TX GSM 1900

8 Check 26MHz VCTCXO G660 at (test point) TP20. (frequency deviation <100Hz)

Check also TP3 2.8VDC.

9 Check TX IQ signals at TP21. If not OK change UEM.

10 Check 1880MHz CH661 at TP22 if OK go to 8.

11 Check supply voltages for HAGAR at TP 4, 5, 6, 8: 2.8VDC; TP10 1.35VDC and TP1

4.8VDC if not OK change UEM.

12 Check SDATA at TP51, SCLK TP53, SLE TP52.

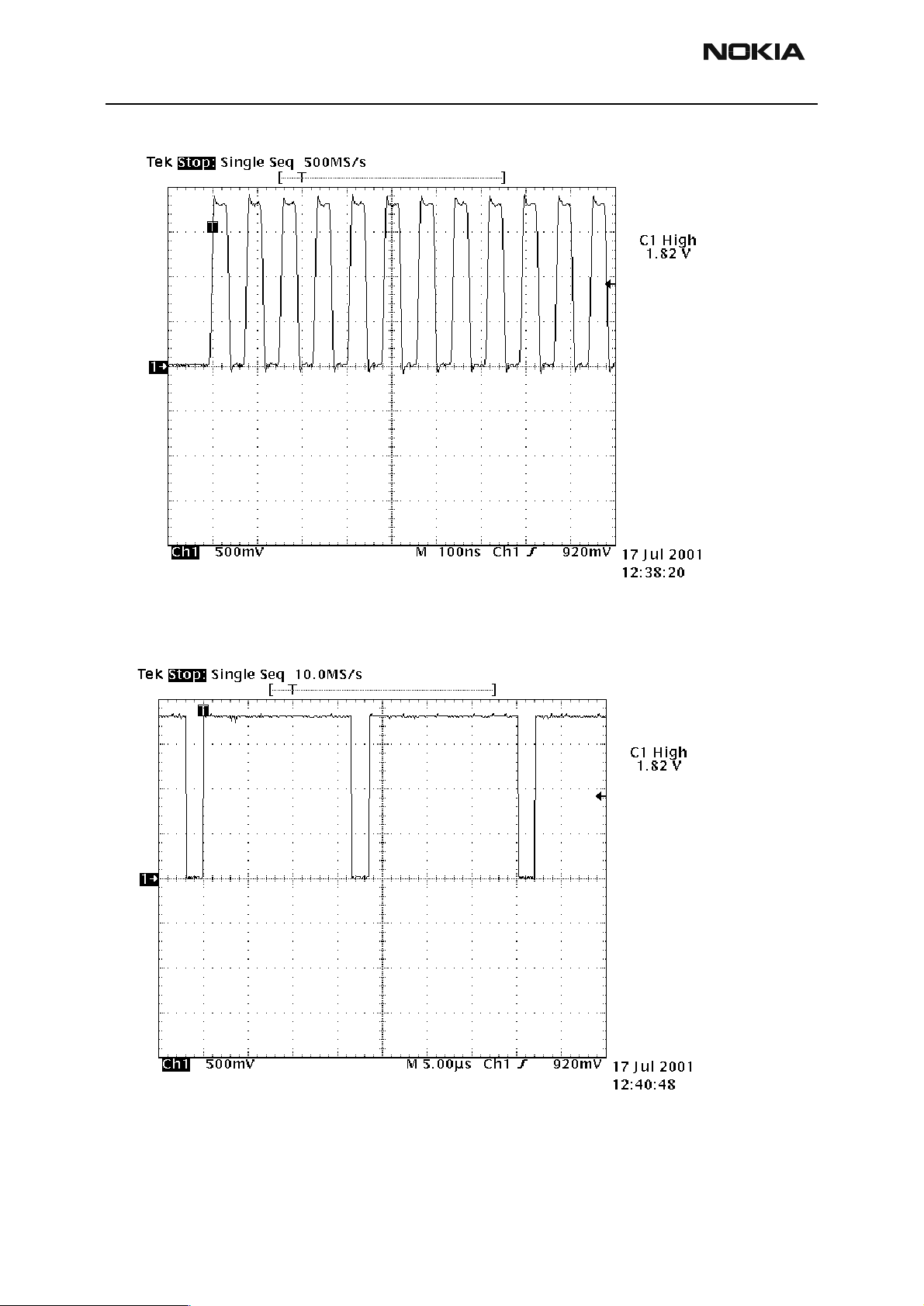

13 Check TXC at TP23 and TXP at TP24

14 Check frequency of VCO G650 at TP40 (3760MHz/CH661, TX-mode). If not OK

check TP7 2.8VDC and TP41 ~1.6VDC. If TP41 is 4.8VDC, the VCO doesn’t work in

all probability. If all HAGAR signals are OK probably HAGAR is broken -> change

HAGAR N600.

15 Check 1880MHz at TP25 if not OK check Vbatt at TP9 3.9VDC, also check TP26

and TP27. Change PA if necessary.

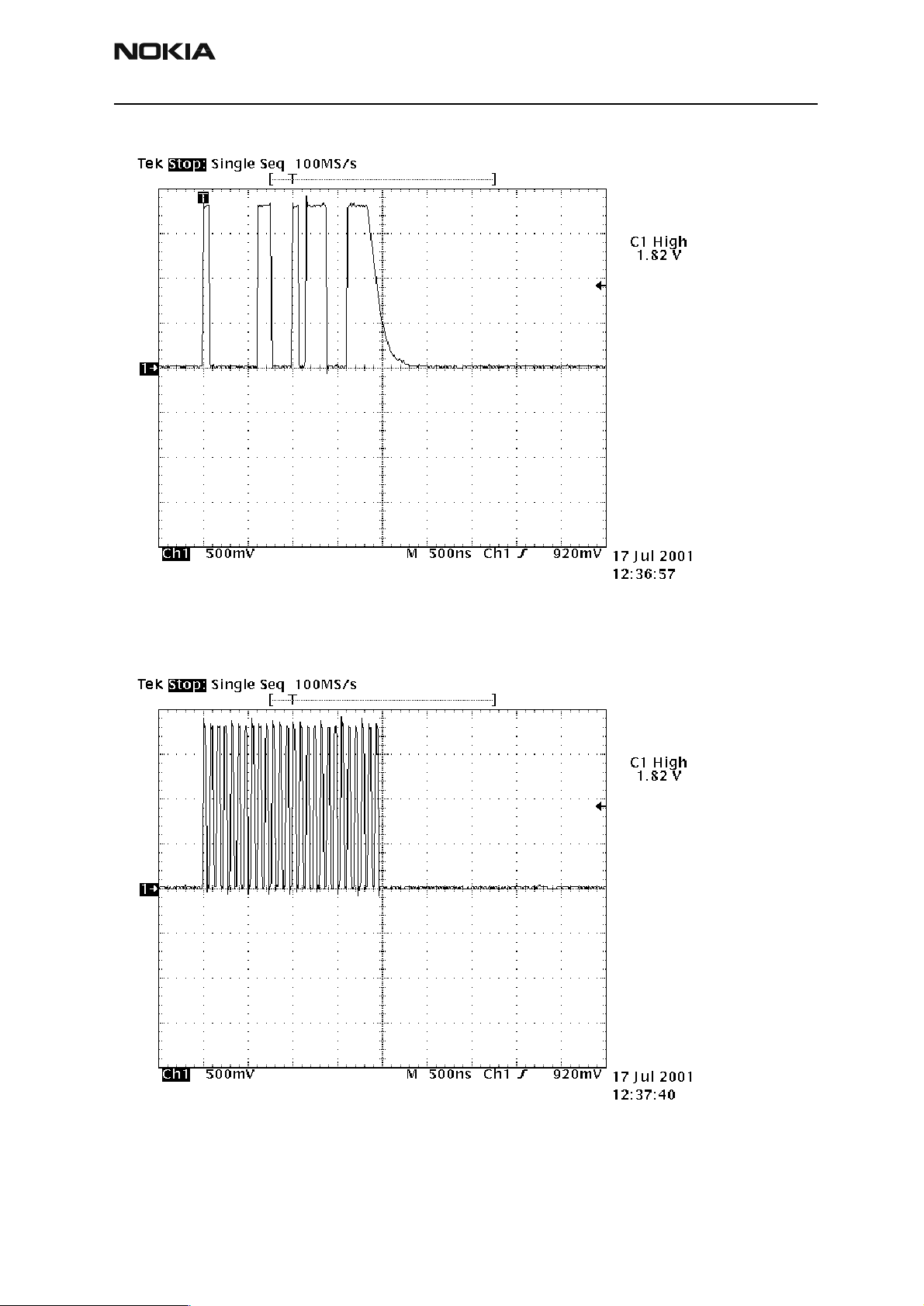

16 Check 1880MHz at TP30 if not OK, check TP28. Also check TP29 squarewave

2.8Vpp at burst mode. If TP28 and TP29 OK change Z500 (Antenna switch).

NO RX GSM 1900

1 Check 26MHz VCTCXO G660 at (test point) TP20. (frequency deviation <100Hz)

Check also TP3 2.8VDC.

2 Check RX signal level 1960MHz at TP31 if not OK change Z500.

3 Check RX signal level at TP32 in not OK change Z520

4 Check RX signal level at TP33 if not OK check voltages at TP33 2.7VDC , TP34

2.7VDC , TP35 0VDC. If TP33 not OK check L550 and R550. If components are OK

change V550. If that doesn’t help change HAGAR N600.

5 Check RX signal level at TP36 If not OK change Z551.

6 Check RX IQ signals at TP37 (also in burst-mode). If not OK check HAGAR supply

voltages at TP4, 5, 6, 8: 2.8VDC; TP10 1.35VDC and TP1 4.8VDC if not OK

change UEM.

7 Check SDATA at TP51, SCLK TP53, SLE TP52.

8 Check frequency of VCO G650 at TP40 (3920MHz/CH661, RX cont.-mode). If not

OK check TP7 2.8VDC and TP41 ~2.9VDC. If TP4 1 is 4.8VDC, the VCO doesn’t work

in all probability. If all HAGAR signals are OK probably HAGAR is broken ->

change HAGAR N600.

9 If all signal and voltage levels are OK change UEM.

Please note that you ca n view the RF testpoint dia gram and RF testpoint

PWB layout in the Schematics section of this document.

Page 56 ãNokia Corporation Issue 1 01/02

Page 57

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Measurements points for AMS and production repair

TX Troubleshooting points

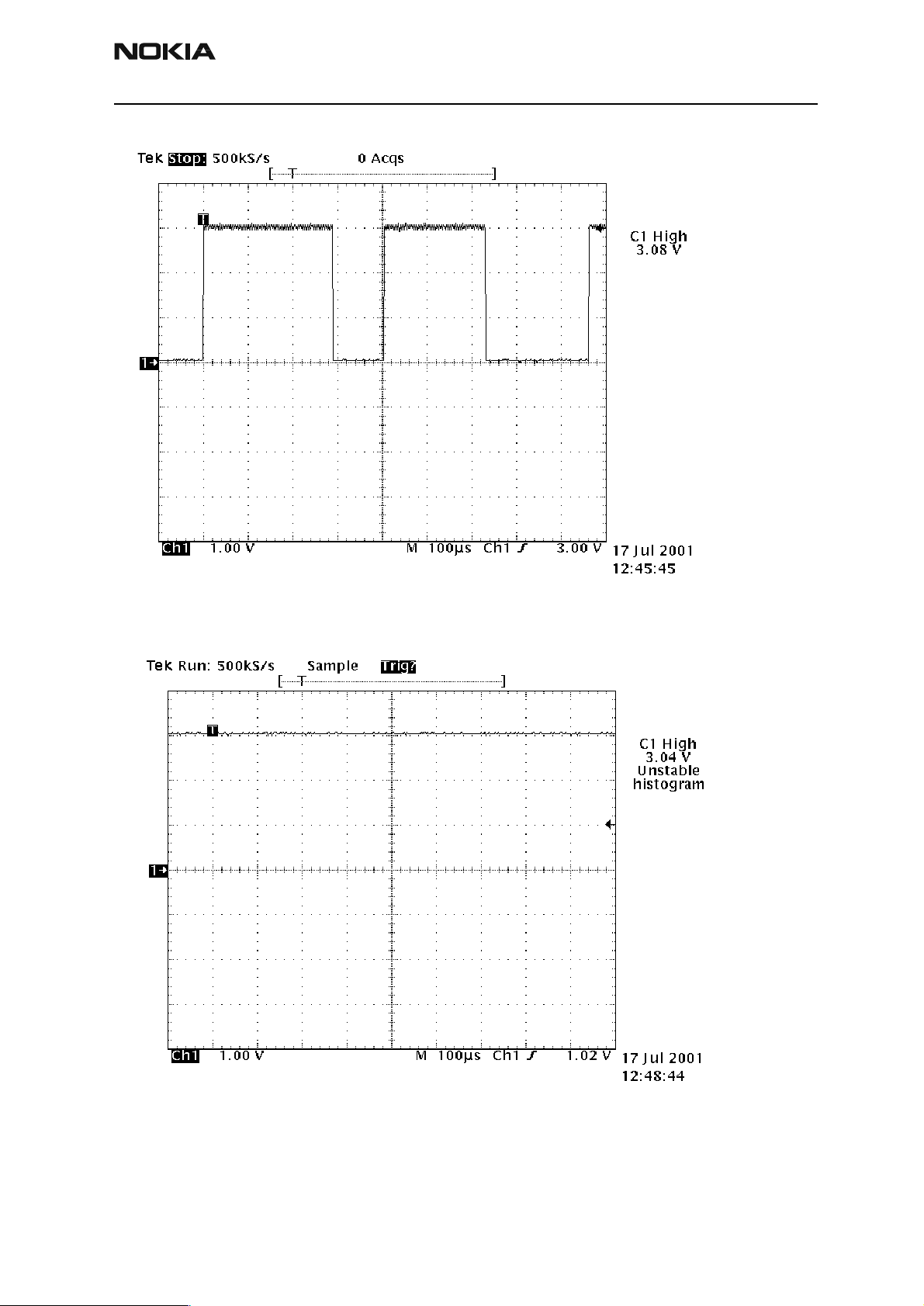

Figure 55: TP 20

Figure 56: TP 21

Issue 1 01/02 ãNokia Corporation Page 57

Page 58

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

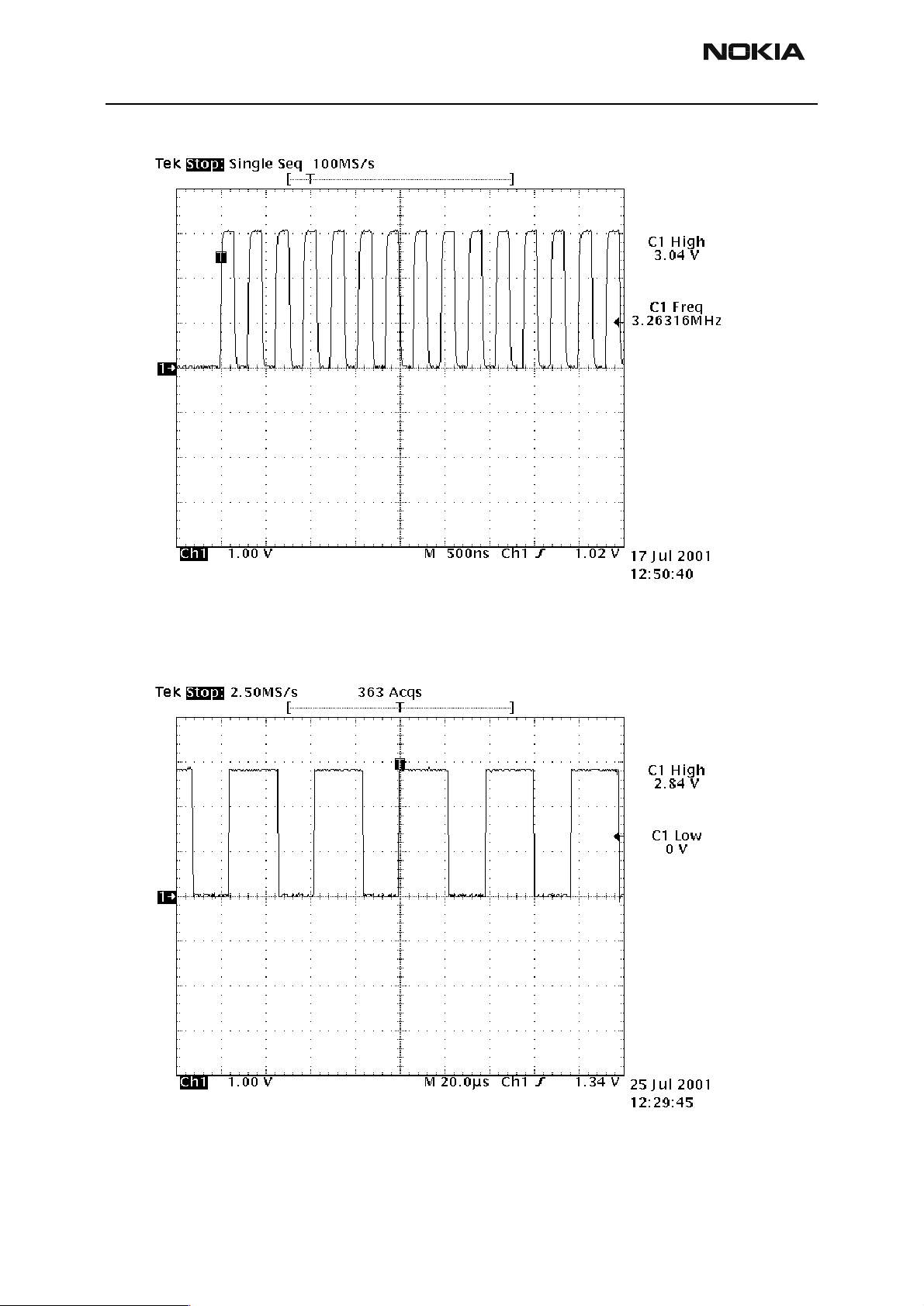

Figure 57: TP 22

Figure 58: TP 51, 52, 53

Page 58 ãNokia Corporation Issue 1 01/02

Page 59

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Figure 59: TP 23, 24

Figure 60: TP 40

Issue 1 01/02 ãNokia Corporation Page 59

Page 60

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

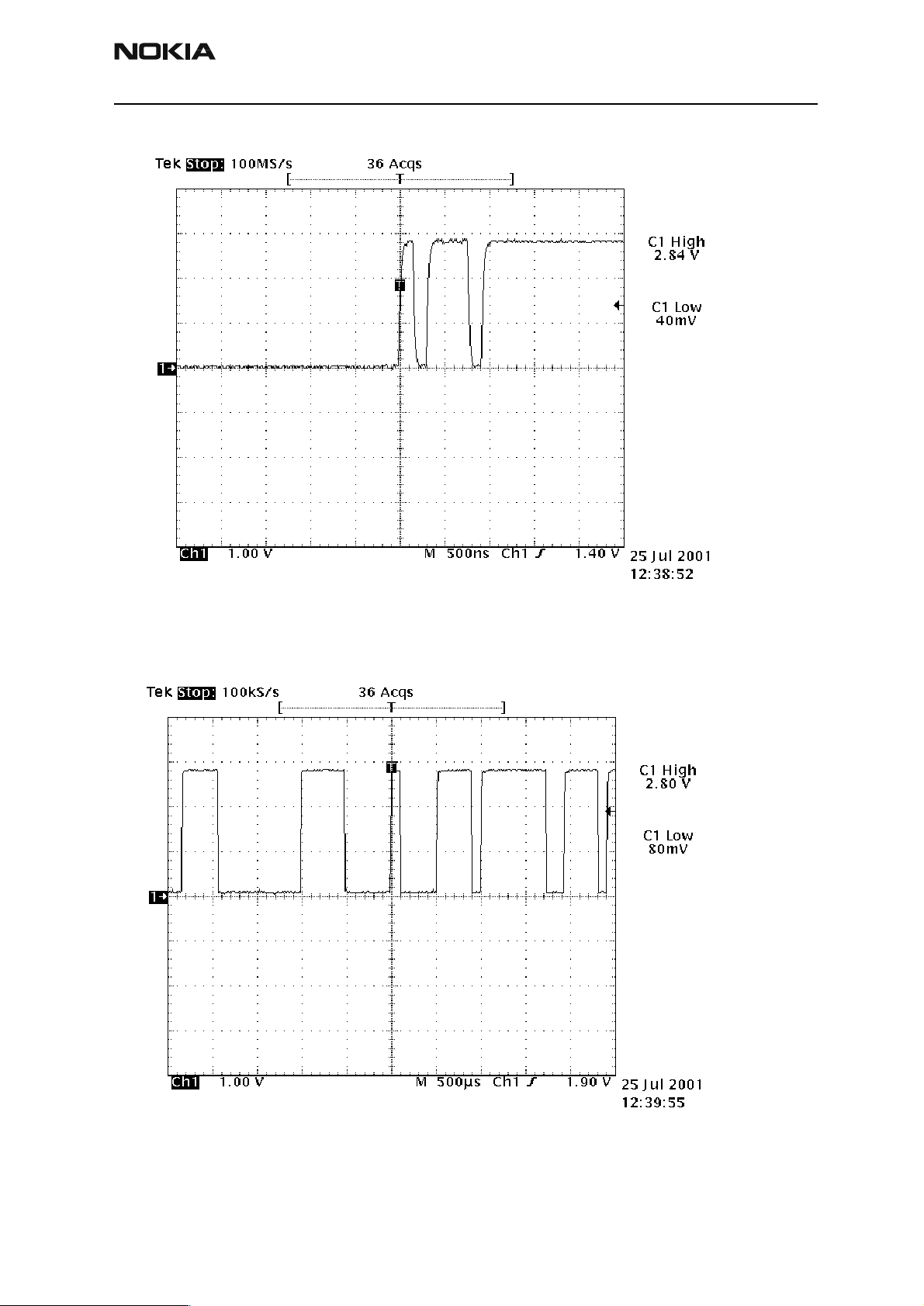

Figure 61: TP 25, 28

Figure 62: TP 26, 27

Page 60 ãNokia Corporation Issue 1 01/02

Page 61

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Figure 63: TP 30

Figure 64: TP 29

Issue 1 01/02 ãNokia Corporation Page 61

Page 62

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 65: TP 20

Page 62 ãNokia Corporation Issue 1 01/02

Page 63

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

RX Troubleshooting points

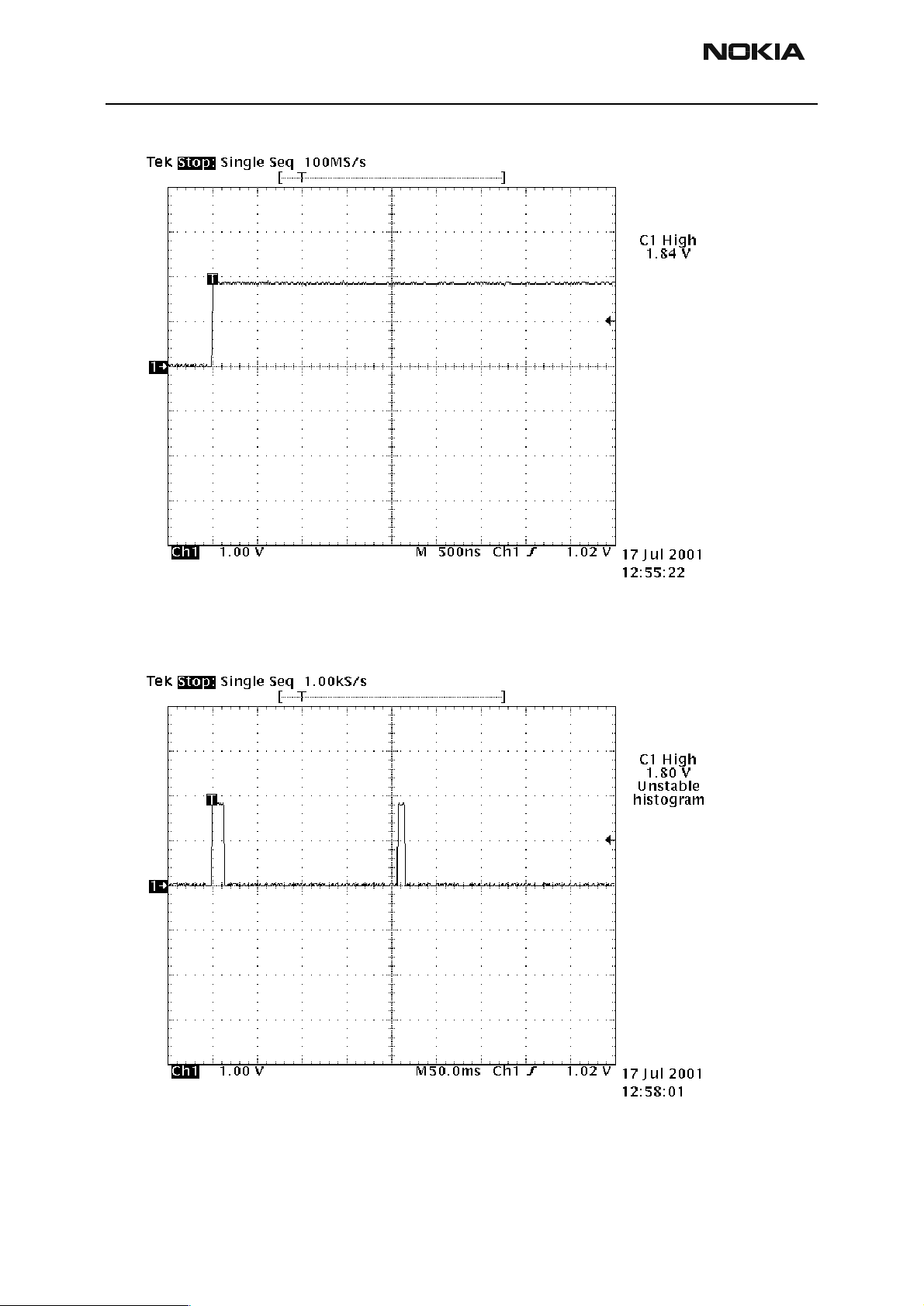

Figure 66: TP 20

Figure 67: TP 31, 32

Issue 1 01/02 ãNokia Corporation Page 63

Page 64

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 68: TP 33

Figure 69: TP 36

Page 64 ãNokia Corporation Issue 1 01/02

Page 65

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

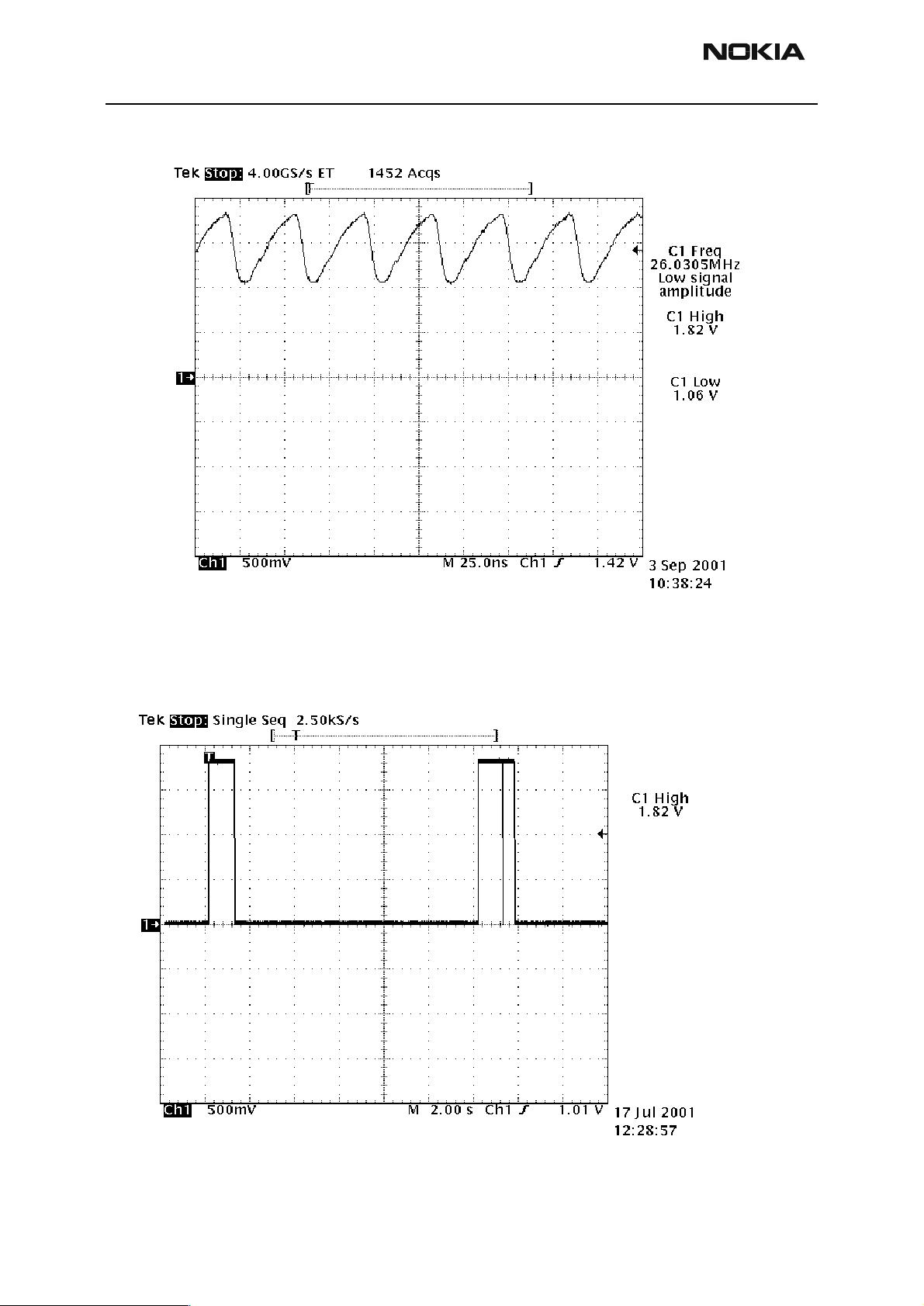

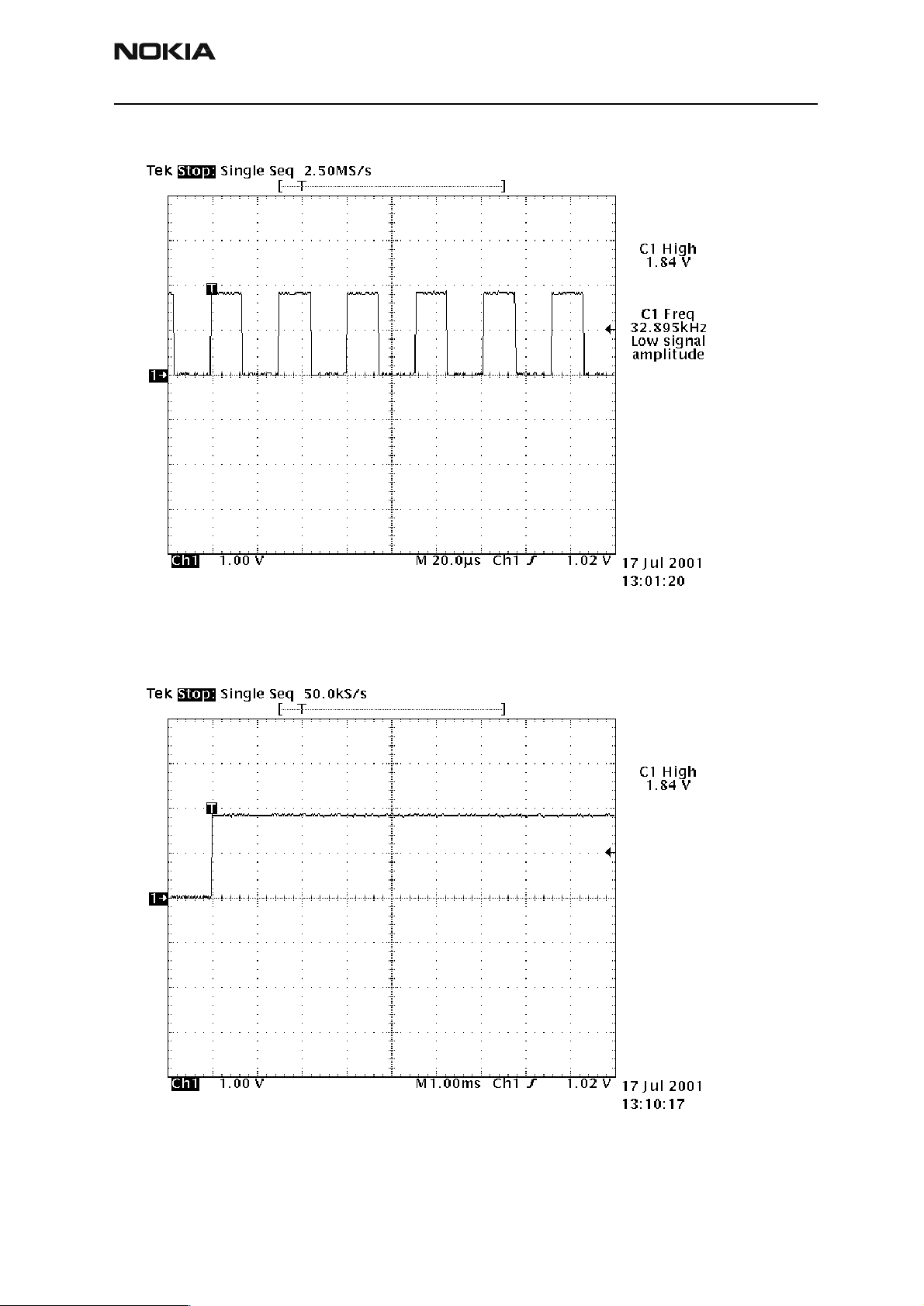

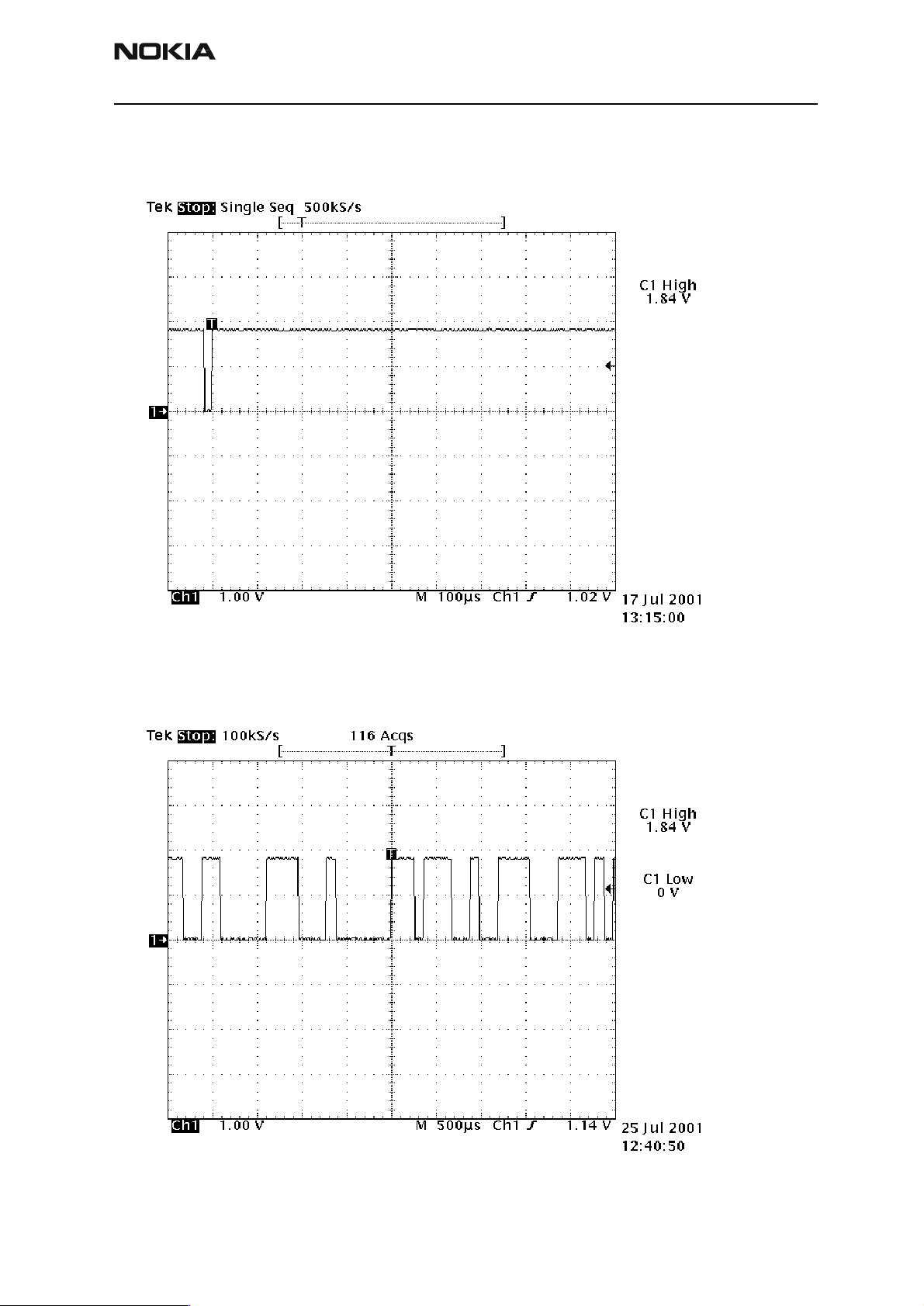

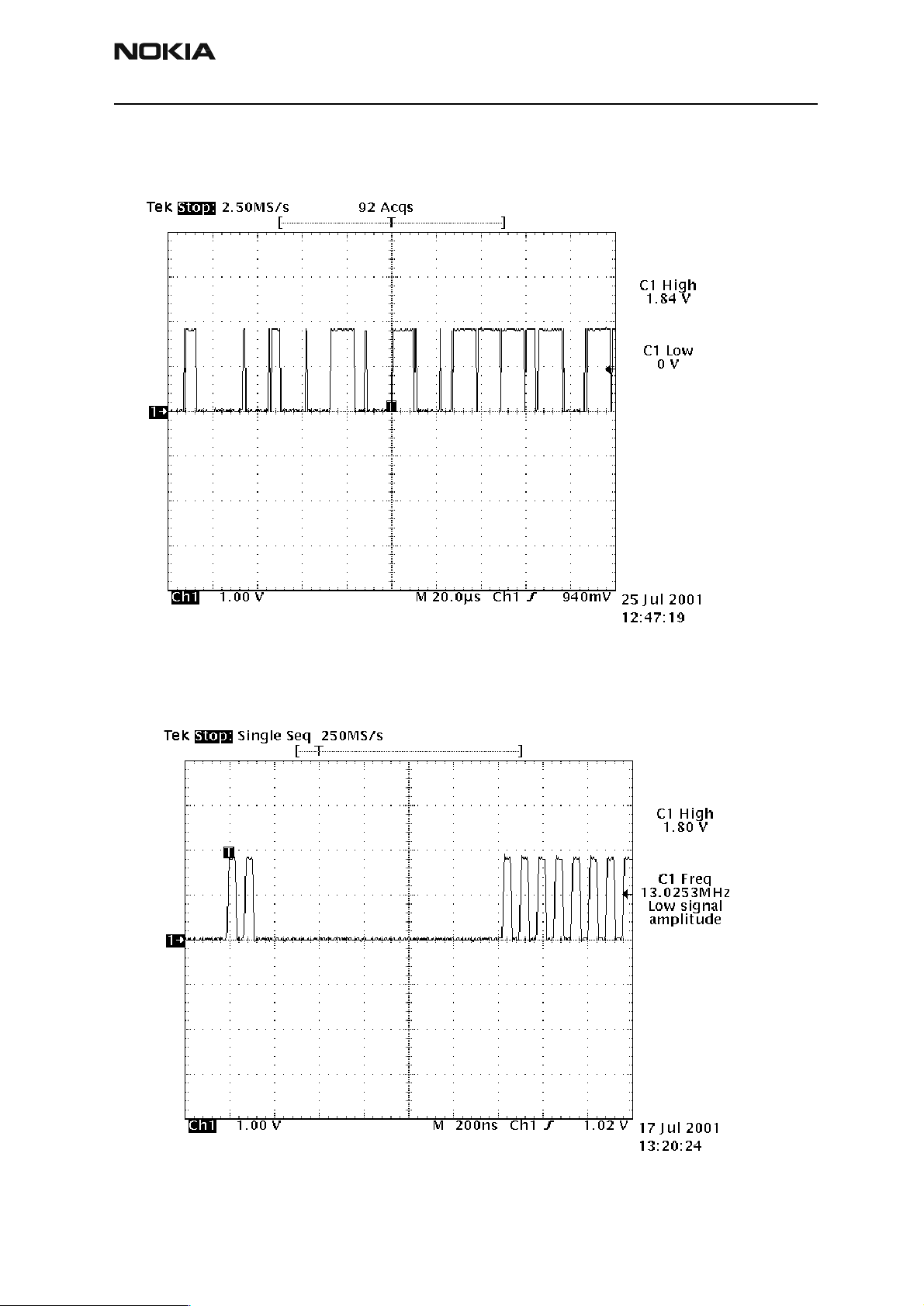

Figure 70: TP 37 (RX continuous mode)

Figure 71: TP 37 (RX burst mode)

Issue 1 01/02 ãNokia Corporation Page 65

Page 66

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

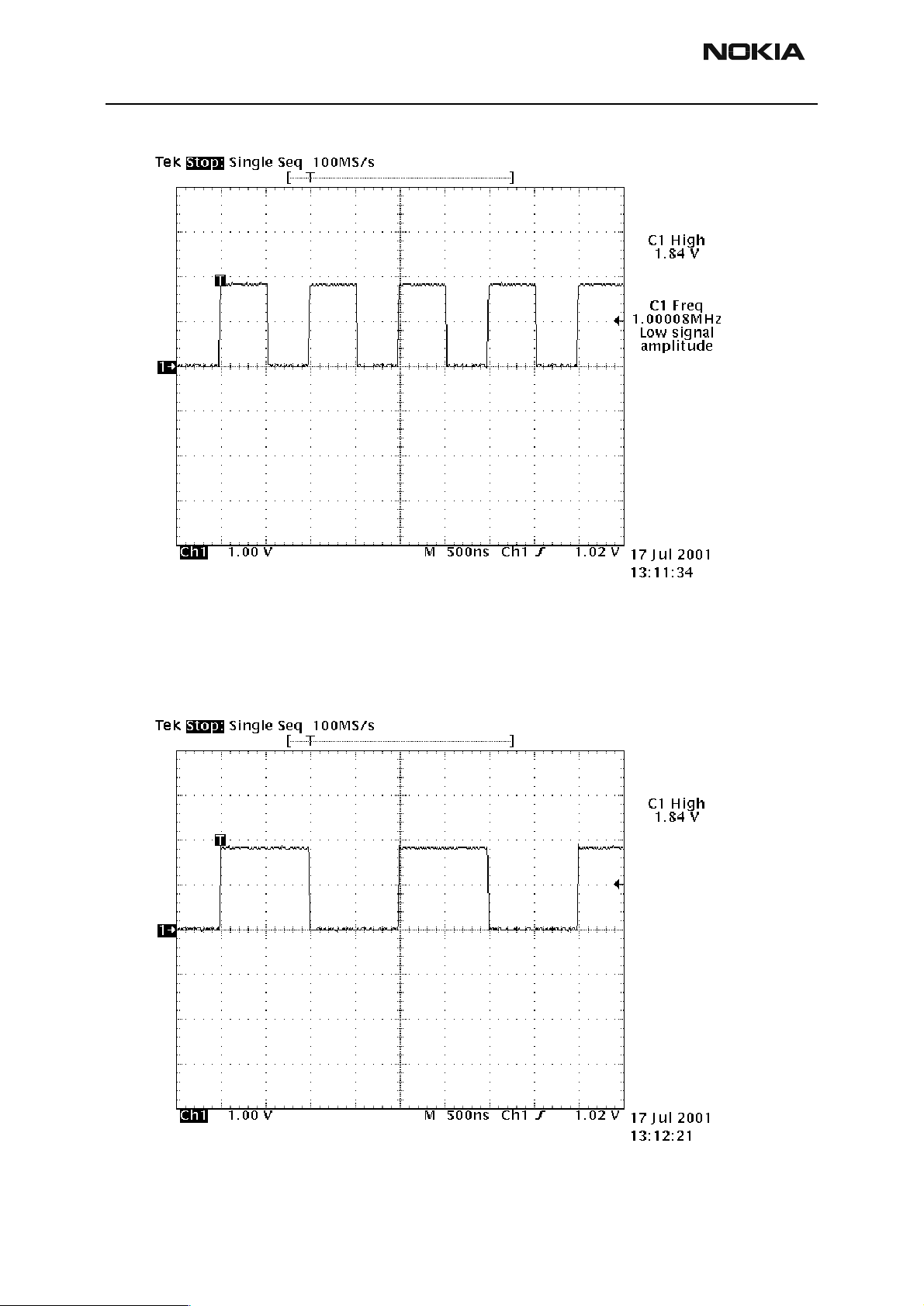

Figure 72: TP 51, 52, 53

Figure 73: TP 40

Page 66 ãNokia Corporation Issue 1 01/02

Page 67

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

RF Tuning and Calibration Instructions

Phoenix is used to control the phone.

TX tunings

When changing any TX components, all TX tunings need to be done.

Equipment’s needed for TX tuning:

• Spectrum analyzer

• Computer with Phoenix -software

TX Output power tuning

Spectrum analyzer setting for TX output power tuning

• Frequency: 1880MHz

• Span: 0Hz

• RBW/VBW: 3MHz

• SweepTime: 5ms

• RefLevel: +30dBm

Note: Cable and test fixture attenuation. Tuning is easier to do when using VIDEOtrigger on spectrum analyzer.

1 Start the Phoenix service software

2 Scan product (Ctrl + R) Software should automatically detect NSB-8. If product

is not found, choose product manually.

Phoenix should initialize connection automatica lly. If it does not, initialize the connec-

Issue 1 01/02 ãNokia Corporation Page 67

Page 68

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

tion from FILE - Manage Connections -menu.

3 Then change the operating mode to Local.

4Select Tuning from Maintenance –menu and choose TX powe r level tuning.

Page 68 ãNokia Corporation Issue 1 01/02

Page 69

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

5 Press Start and load tuning values from Permanent memory.

6 Adjust tuning values.

Note: It is only necessary to adjust Base (-30dBm), PCL 15, 11 and 0. After that it is

possible to use Calculate coefficients –function to linearize other values.

Tuning target of 29.5 dBm, for PCL 0, is aimed for phone without mechanics when tuning

in service jig. Mechanics are increasing TX power level about 0.5 dBm.

TX Power target of PCL 0 is 30 dBm for phone with mechanics.

Issue 1 01/02 ãNokia Corporation Page 69

Page 70

NSB-8

29 .5 d B m

+0 .2 … -0.5 d B

Troub l esh oot ing Instructions PAMS Technical Document a t ion

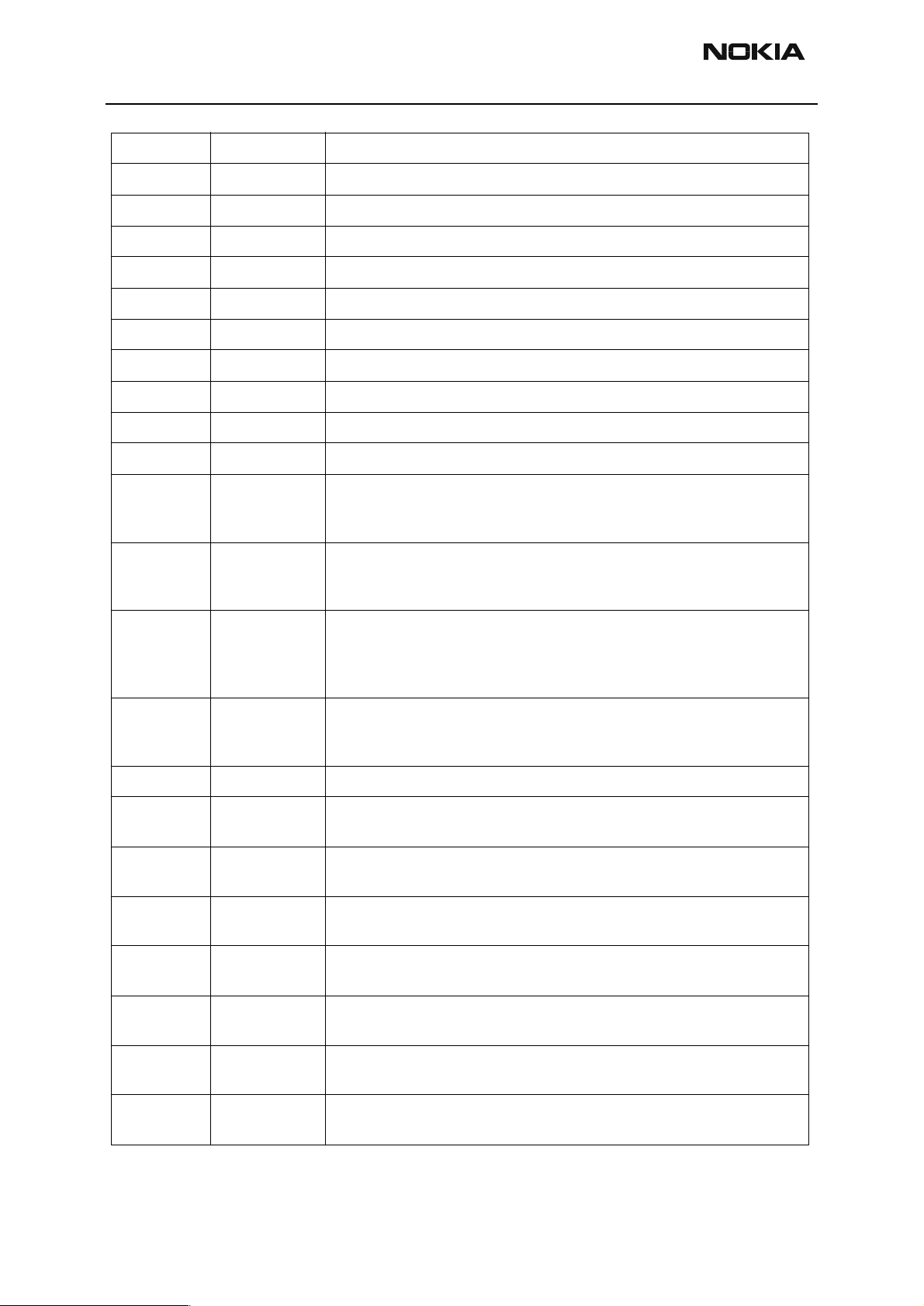

TX Power Tuning targets and limits:

Power

level

Base -30 dBm +/- 1.0 dBm +/-2.0 dB

Test

RF Power at

antenna pad

0

1 28.0 dBm +/- 0.5 dBm +/-1 dB

2 26.0 dBm +/- 0.5 dBm +/-1 dB

3 24.0 dBm +/- 0.5 dBm +/-1 dB

4 22.0 dBm +/- 0.5 dBm +/-1 dB

5 20.0 dBm +/- 0.5 dBm +/-1 dB

6 18.0 dBm +/- 0.5 dBm +/-1 dB

7 16.0 dBm +/- 0.5 dBm +/-1 dB

8 14.0 dBm +/- 0.5 dBm +/-1 dB

9 12.0 dBm +/- 0.5 dBm +/-1.5 dB

10 10.0 dBm +/- 0.5 dBm +/-1.5 dB

11 8.0 dBm +/- 0.5 dBm +/-1.5 dB

12 6.5 dBm +/- 0.5 dBm +/-1.5 dB

13 5.0 dBm +/- 0.5 dBm +/-1.5 dB

14 3.5 dBm +/- 1.0 dBm +/-2.0 dB

15 2.0 dBm +/- 1.0 dBm +/-2.0 dB

Tuning target

tolerance Testing limits

+/- 0.1 dBm

29 .7 … 29 .0 d B m

7 When tuning values are correct; save them to Phone Permanent Memory

New tuning values will be in use immediately.

--> Close TX Power Level Tuning window

TX IQ tuning

Spectrum analyzer setting for TX IQ tuning:

• Frequency: 1880MHz

• Span: 200kHz

• RBW/VBW: 10kHz

• SweepTime: 2s

• RefLevel: +20dBm

Page 70 ãNokia Corporation Issue 1 01/02

Page 71

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

1Select Tuning from Maintenance –menu bar and choose TX IQ Tuning.

2 Load tuning values from Product and Start –tuning.

Adjust tuning values so that IQ spectrum is balanced (see example picture below, data ‘

Issue 1 01/02 ãNokia Corporation Page 71

Page 72

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

All 1’).

3Choose Save to Product and Stop tuning.

--> Close Tx IQ Tuning window.

RX tunings

When changing any RX components, all RX tunings need to be done.

1 Channel select filter

2 RX tuning GSM1900 (gain step A1 … A9 tuning)

3 AM suppression GSM1900 (to minimize AM signal disturbance)

Equipment needed for RX tuning:

Page 72 ãNokia Corporation Issue 1 01/02

Page 73

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

• Signal generator with AM-Modulation

• Computer with Phoenix -software

Channel select filter calibration

1 Choose product and initialize connection as in TX output power tuning procedure

(Steps 1 and 2)

2Select Tuning from Maintenance –menu bar and choose RX Channel Select fil-

ter Calibration.

3 Load tuning values from phone.

4Use Auto Tune to calibrate Channel Select filter.

Issue 1 01/02 ãNokia Corporation Page 73

Page 74

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

After tuning, select Stop and save the values onto the phone.

5Close the Rx Channel Select Filter Calibration window.

RX tuning GSM1900

1Select Tuning from Maintenance –menu bar and choose RX Calibration.

2Start Manual tuning with PM Setting.

Page 74 ãNokia Corporation Issue 1 01/02

Page 75

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

3Choose Calibrate and adjust signal generator accordingly.

4 Stop and Save new calibration values to phone.

--> Close Rx Calibration window.

RX Calibration limits:

Issue 1 01/02 ãNokia Corporation Page 75

Page 76

NSB-8

RSSI 0 60 70

Troub l esh oot ing Instructions PAMS Technical Document a t ion

RSSI 2 70 80

RSSI 3 80 90

RSSI 4 90 100

RSSI 4 100 110

RSSI 5 110 120

RSSI 6 120 130

RSSI 7 130 140

RSSI 8 140 150

Check AFC_slope 0 1000

Check AFC_value -500 500

AM suppression tuning

1Select Tuning from Maintenance –menu bar and choose RX Am Suppression.

2 Start tuning with PM settings.

Page 76 ãNokia Corporation Issue 1 01/02

Page 77

NSB-8

LOP_I 0 1023

PAMS Technical Documentation Troubleshooting Instructions

3 Adjust signal generator accordingly and Tune.

4 Stop and save values to phone.

--> Close Rx Am Suppression window.

Rx Am Suppression limits:

LOM_I 0 1023

LOP_Q 0 1023

LOM_Q 0 1023

RSSI -120 -92

Issue 1 01/02 ãNokia Corporation Page 77

Page 78

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

RF Service Tools

MJS-46 Module Jig

All RF tunings should be performed in MJS-46 Jig. When using Test Jig MJS-46, the reference level attenuation is 0.1 dB + cable loss.

JVB-1 Docking Station, MJF-6 Adapter and coupler CPL-6

The reference level attenuation for Docking Station JBV-1 + MJF-6 adapter with antenna

coupler CPL-6 is approximately 4 dB +cable loss.There can be minor differences between

CPL-6 antenna couplers, but maximum distribution is +-0.3dBm. Attenuation can varie

between antenna couplers. There is differe n ces in attenuations between low and high

channel, but those can be ignored.

Coupler attenuation calibration

When Docking Station with MJF-6 and CPL-6 inside the shield box JSX-1 is used, then

calibration procedure is following:

• Measure one known phone in MJS-46 Module Jig in Ch 661, the output power

(P1) should be 29.5dBm +- 0.2dB. Remember the jig loss 0.1dB and cable loss.

• Assemble the measured phone in to mechanics

• Put the phone in to the JBV-1 Docking Station, without JXS-1 Shield Box

• Measure the output power (P2) in Ch 661

• The attenuation (A1) of the antenna coupler is: A1=(P1+0.5dBm)-P2

•(Note! Mechanics will increase output power 0.5dB)

Typical coupler (CPL-6) attenuation is 4.0dB. If measurements are done without JXS-1

Shield Box, the same value can be used in TX and RX.

If using shielded box JSX-1, additional loss is needed separately for LO, MID and HI

Channels. Typical loss values are: LO= 5.7dB, MID=2.3dB and HI=0.5dB

Functionality Testing Limits

When checking the phone’s functionality in the JBV-1 docking station with a coupler,

the TX power may vary to some degree. TX power levels 14 and 15 should be ignored, as

the coupler’s response is not reliable. The following table lists the TX output power tolerances, when CPL-6 is used for measuring:

Page 78 ãNokia Corporation Issue 1 01/02

Page 79

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Table 2: TX Output Power Tolerances

PCL Target (dBm) Tolerance (dBm)

029.5 +/-3

128 +/-3

226 +/-3

324 +/-3

422 +/-3

520 +/-3

618 +/-3

716 +/-3

814 +/-4

912 +/-4

10 10 +/-4

11 8 +/-4

12 6.5 +/-4

13 5 +/-4

14 3.5 +/-5

15 2 +/-5

JXS-1 Shield Box

Metal shielded box, mentioned to avoid disturbing RF signals, has a great effect to TX

output power, Bit error and Signal Strength reporting results, since the surface of

shielded box is reflecting RF-waves and therefore changing RF performance.

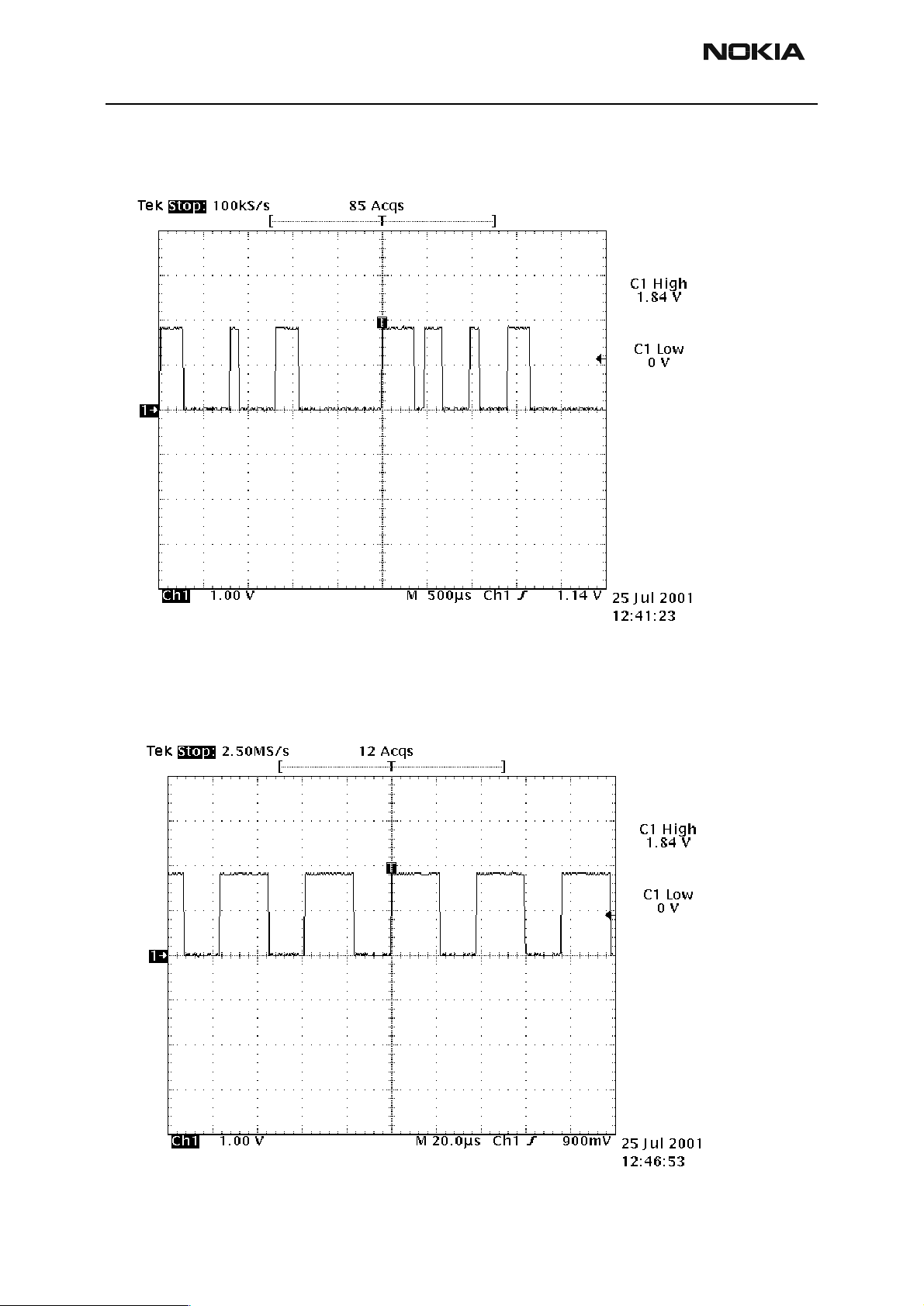

In following pictures the behavior of JVB-1 Docking Station with MJF-6 adapter is presented in JXS-1 Shield Box and without the box (coupler).

The measurements are done in the following conditions:

• Temperature +25 °C (77 °F)

• NOKIA 8390 Cellular Phone

• NOKIA JXS-1 Shield Box

• NOKIA JBV-1 Docking station with antenna coupler (1900 MHz)

• RF-Attenuation for MJF-6 and cable is 4.5dB

Issue 1 01/02 ãNokia Corporation Page 79

Page 80

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

Figure 74: Power 30 dBm

Power 30 dBm

31

30

29

28

27

Power(dBm)

26

25

24

512 562 6 12 662 712 762 8 12

Channel

AMS-Box Coupler

Figure 75: Phase error RMS

Phase error RMS

5

4

Phase error(deg)

3

2

512 562 612 662 712 762

Channel

Box Coupler

Page 80 ãNokia Corporation Issue 1 01/02

Page 81

NSB-8

PAMS Technical Documentation Troubleshooting Instructions

Figure 76: Signal Strength Reading

-82

512 562 612 662 712 762 812

-82,5

-83

-83,5

-84

Reading (dBm)

-84,5

-85

-85,5

-86

Channel

AMS-Box Coupler

Figure 77: BER(-102 dBm)

BER(-102dBm)

1

0,8

0,6

BER%

0,4

0,2

0

512 562 612 662 712 762

Channnel

Box Coupler

When using JXS-1 shield box different RF attenuations have to be used. It is recommended that in the shield box all measurement ar e perfor med o nly on channel 661 and

additional 2.5 dBm loss in added to Reference leve l offset, so that total RF att enuation

caused by JXS-1 shield box and CPL-6 Adapter is 6.5 dBm+ cable loss.

Issue 1 01/02 ãNokia Corporation Page 81

Page 82

NSB-8

Troub l esh oot ing Instructions PAMS Technical Document a t ion

This page intentionally left blank.

Page 82 ãNokia Corporation Issue 1 01/02

Loading...

Loading...