Page 1

PAMS Technical Documentation

NSM–1 Series Transceivers

Tuning Instructions

Original 10/98

Page 2

NSM–1

PAMS

Tuning Instructions

CONTENTS

Tuning Instructions 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Equipment 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Setup 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Setup for Tuning a Phone without Removing Covers 5. . . . . . .

Flash Concept for NSM–1 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Tuning With Covers Off – Using Test–frame JBS–19 7. . . .

Tuning With Covers Off – using Light Jig JBT–1 8. . . . . . . .

Warranty Transfer 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tuning Steps 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. RX Calibration (AGC + AFC) 10. . . . . . . . . . . . . . . . . . . . . .

2. Alignment of Transmitter Power Levels 12. . . . . . . . . . . . .

3. I/Q Modulator Alignments 14. . . . . . . . . . . . . . . . . . . . . . . . .

4. Energy Management Calibration 16. . . . . . . . . . . . . . . . . . .

Technical Documentation

Page 2

Original 10/98

Page 3

PAMS

NSM–1

Technical Documentation

Tuning Instructions

General

All tuning operations of the NSM–1 are carried out using the service software. The service software turns the phone into the locals mode, in which

the phone can be outwardly controlled via the MBUS interface.

Tuning is based on the software communicating with the D/A and A/D

converters of the phone. In some instances the phone processor will also

calculate the required correction parameter.

The tuning values of the phone reside on the EEPROM. The contents of

the EEPROM can be read by the service software and saved as a file.

This is advisable when there is need to retain that information, e.g. in

view of replacement of the circuit. The program also enables writing the

default parameters on the EEPROM, in which case all tuning steps should

be carried out.

Tuning Instructions

During tuning, proceed as follows:

– Take care not to damage sensitive measuring instruments with exces-

sive RF power.

– Carry out all tuning steps in the shortest possible time to avoid exces-

sive heating of RF units.

– Perform all tuning steps in the order presented.

– Never try to mask a fault by tuning it out!

Original 10/98

Page 3

Page 4

NSM–1

PAMS

Tuning Instructions

Required Equipment

– PC with service software; see separate section for instructions on

installation and use.

– Service accessories; see equipment setup pictures.

– Multimeter or DVM.

– GSM radio telephone test station or separate measuring equipment as

follows:

– RF generator

– pulse power meter

– spectrum analyzer

– attenuator and branching unit

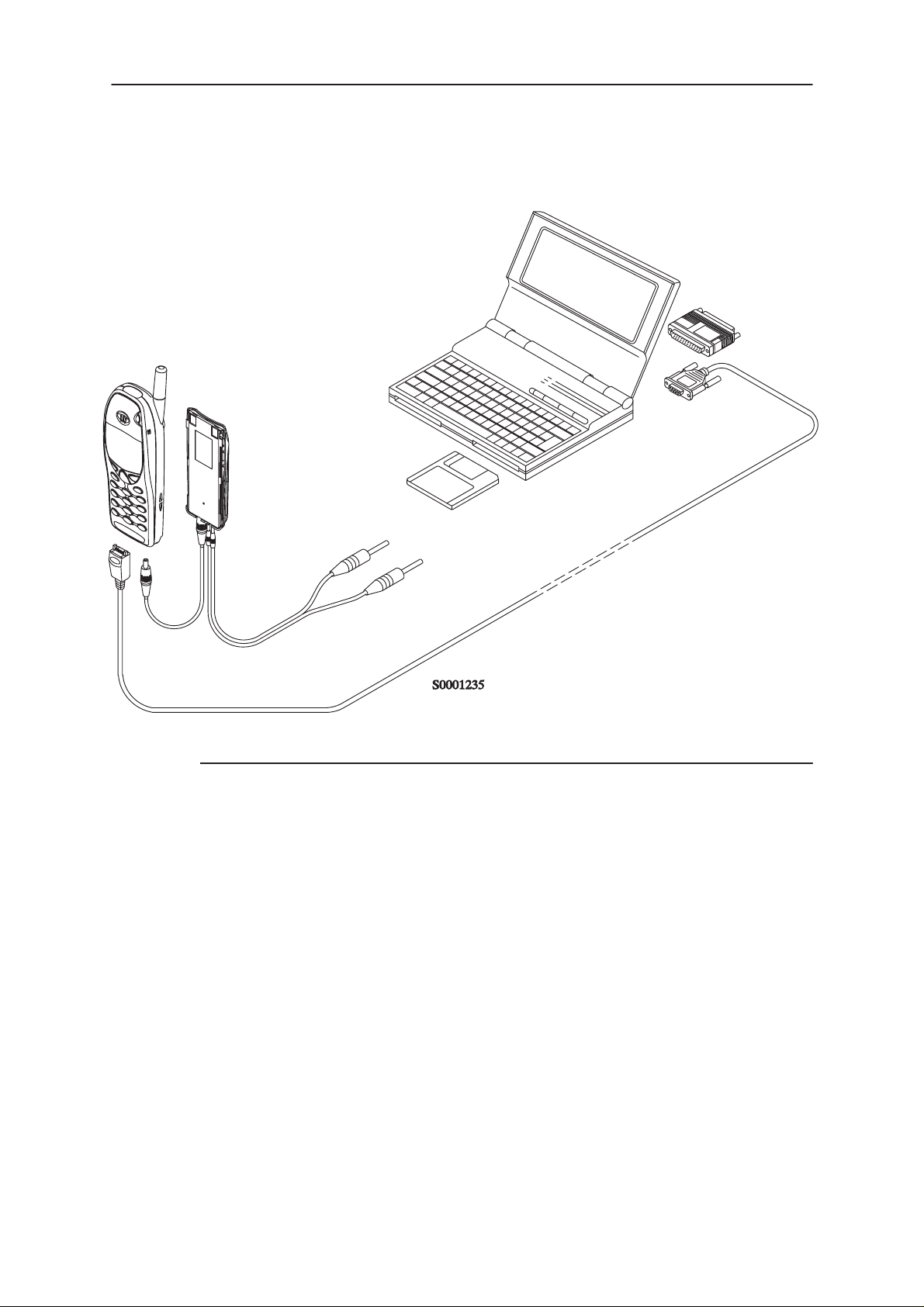

Equipment Setup

Technical Documentation

Caution: Make sure that you have switched off the PC and the printer

before making connections !

Caution: Do not connect the PKD–1 key to the serial port. You may

damage your PKD–1 !

Attach the protection key PKD–1 to parallel port one (25–pin female

D–connector) of the PC. When connecting the PKD–1 to the parallel port

be sure that you insert the PC end of the PKD–1 to the PC (male side). If

you use a printer on parallel port one, place the PKD–1 between the PC

and your printer cable.

Next connect the M2BUS service cable, DAU–9P, to the serial port

(RS–232) of the computer. Attach one end of the service cable to the PC

serial port and the other end to the service box, JBA–4. For servicing the

phone with the covers in place the service box should always be used.

When the phone covers are removed the jigs should be used.

For audio measurements connect the audio cable, ADS–1, as follows:

– EAR line to AF INPUT of test equipment

– MIC line to MOD GEN OUTPUT of test equipment

Page 4

Original 10/98

Page 5

PAMS

NSM–1

Technical Documentation

Tuning Instructions

Equipment Setup for Tuning a Phone without Removing Covers

4.

1.

5.

2.

3.

Item: Service accessory: Product code:

1 Service Battery BBD–3 0775071

2 DC Cable SCB–3 0730114

3 Service MBUS Cable DAU–9P 0730109

4 Software protection key PKD–1 0750018

5 Service SW diskette 3.5” for WinTesla 0774046

6 Service SW diskette 3.5” for NSM–1 0774080

Original 10/98

Page 5

Page 6

NSM–1

PAMS

Tuning Instructions

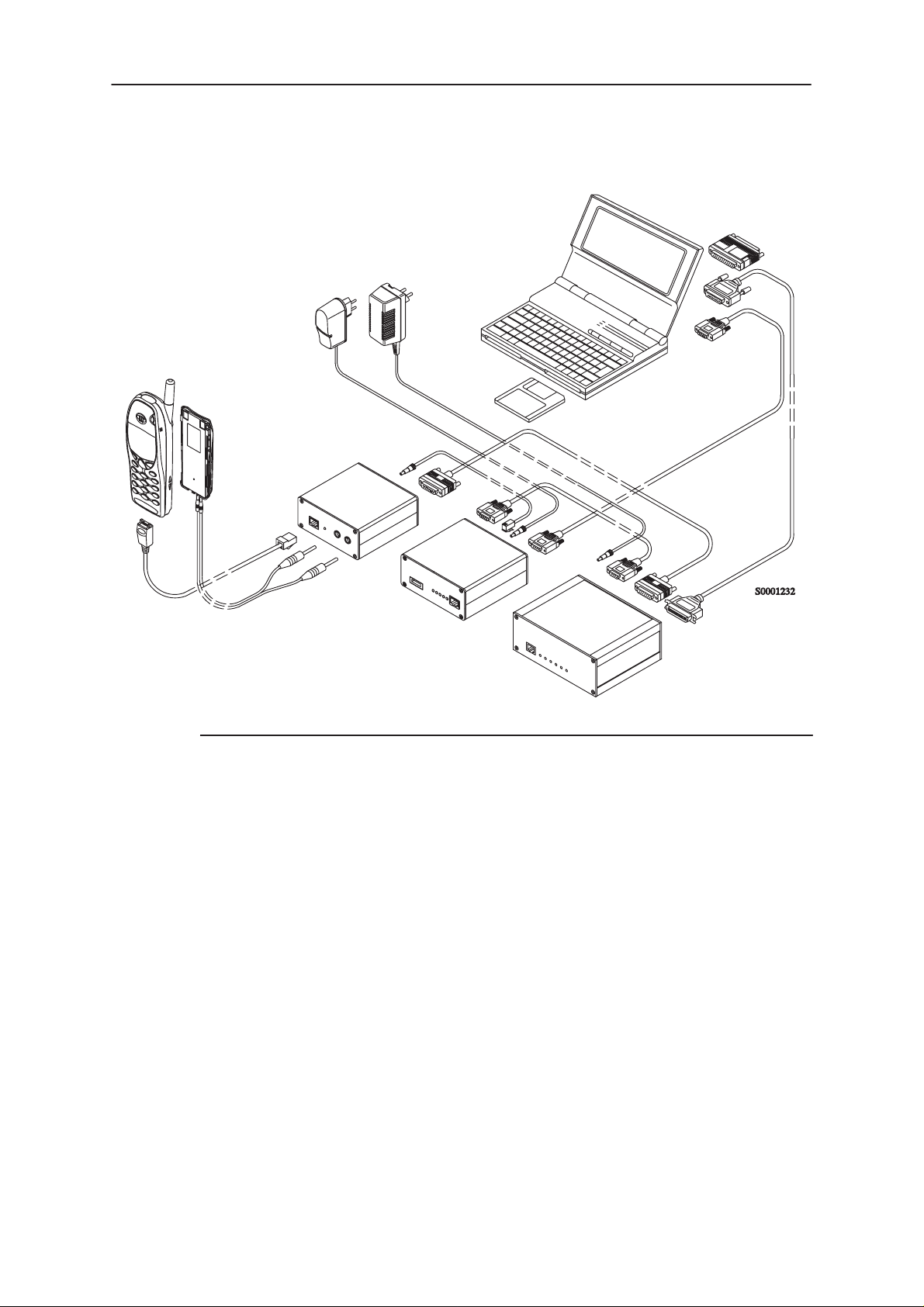

Flash Concept for NSM–1

12.

4.

5.

1.

6.

Technical Documentation

10.

13.

11.

9A.

7.

9B. 8.

2.

3.

Item: Service accessory: Product code:

1 Flash Loading Adapter FLA–5 0080178

2 Flash Security Box TDF–4 0770106

3 Prommer FPS–4S 0085095

4 Service Battery BBD–3 0775071

5 Service Cable SCH–5 0730098

6 DC Cable PCC–1B 0730053

7 D15 – D15 Cable AXS–5 0730091

(Included in FLA–5 sales pack)

8 Printer Cable (Included in FPS–4 sales pack) 0730029

9A D9 – D9 Cable AXS–4 0730090

(Included in FPS–4 sales pack)

9B D9 – D9 Cable AXS–4 0730090

10 Software protection key PKD–1 0750018

11 Service SW diskette 3.5” for NSM–1 0774080

Service SW diskette 3.5” for WinTesla 0774046

12 Travel Charger ACH–6E (Euro) 0270381

Travel Charger ACH–6U (USA/Japan) 0270382

Travel Charger ACH–6X (UK) 0270380

13 AC Charger ACL–3E 0680015

(Included in FPS–4 sales pack)

Page 6

Original 10/98

Page 7

PAMS

NSM–1

Technical Documentation

Tuning With Covers Off – Using Test–frame JBS–19

3.

4.

9.

6.

1.

Tuning Instructions

8.

7.

5.

2.

Item: Service accessory: Product code:

1 Module Jig JBS–19 * 0770098

SIM–Card Holder CAH–1 0770112

2 Service Audio Box JBA–4 ** 0770094

3 DC Cable PCS–1 0730012

4 External Antenna Cable XRC–1B 0730128

5 Service Cable SCH–5 ** 0730098

6 Service MBUS Cable DAU–9S ** 0730108

7 Audio Cable ADS–1 0730011

8 Software Protection Key PKD–1 0750018

9 Service SW diskette 3.5” for WinTesla 0774046

*) The nominal operating voltage for JBS–19 is 3.6 V.

**) SCH–5, JBA–4, and DAU–9S can be replaced with DAU–9P

Original 10/98

Service SW diskette 3.5” for NSM–1 0774080

The supply voltage for JBS–19 must never exceed 5.0 V

Page 7

Page 8

NSM–1

PAMS

Tuning Instructions

Tuning With Covers Off – using Light Jig JBT–1

3.

4.

1.

9.

7.

Technical Documentation

8.

6.

5.

2.

Item: Service accessory: Product code:

1 Light Module Jig JBT–1 * 0770109

2 Service Audio Box JBA–4 ** 0770094

3 DC Cable PCS–1 0730012

4 External Antenna Cable XRC–1B 0730128

5 Service Cable SCH–5 ** 0730098

6 Audio Cable ADS–1 0730011

7 Service MBUS Cable DAU–9S ** 0730108

8 Software Protection Key PKD–1 0750018

9 Service SW diskette 3.5” for WinTesla 0774046

Page 8

Service SW diskette 3.5” for NSM–1 0774080

*) The nominal operating voltage for JBT–1 is 3.6 V.

The supply voltage for JBT–1 must never exceed 5.0 V

**) SCH–5, JBA–4, and DAU–9S can be replaced with DAU–9P

Original 10/98

Page 9

PAMS

NSM–1

Technical Documentation

Warranty Transfer

Tuning Instructions

1.

Item: Service accessory: Product code:

1 Warranty Cable SCH–6 0730099

Original 10/98

Page 9

Page 10

NSM–1

PAMS

Tuning Instructions

Tuning Steps

1. RX Calibration (AGC + AFC)

Procedure

Follow the steps described in chapter ”Service Software Instructions” section ”RX calibration... command”.

Software reports the following:

AFC init value

AFC slope

PSW slope

AGC DAC values and the corresponding voltages for each gain step (0 57 dB)

Technical Documentation

Limits for the reported values

If everything went well the reported values should approximately be the

following:

Parameter Low limit High limit

AFC init value –80 80

AFC slope 130 230

PSW slope 250 350

AGC 0 dB 400 640

AGC 57 dB 100 300

Difference between the two neighbour

AGC steps

10 20

Troubleshooting

If the calibration does not succeed the software normally reports ”Unable

to read data from phone” or ”Failed to set high reference” or ”Failed to set

low reference”.

In this case check first the basic functionality of the receiver chain: RF

generator frequency set as in the calibration and level for example to the

high reference value.

Page 10

Then go to the RSSI reading menu (under RF controls). If the reading is

very low there is something broken in the receiver and must be found by

measuring voltages and signal levels at different places (information of

these can be found elsewhere in this manual).

If the RSSI reading seems to be within 5 - 10 dB the same as the RF input level check that the VCTCXO (G650) frequency is close enough the

Original 10/98

Page 11

PAMS

NSM–1

Technical Documentation

wanted frequency. This is most easiest done by measuring the UHF VCO

(G550) frequency because the absolute value of the deviation is biggest

there. In the GSM mid channel the UHF–VCO frequency should be

2040.0 MHz. If the deviation is bigger than about +/–20 kHz it is probable

that the VCTCXO is not operating correctly.

If both of these (RSSI reading and the frequency) seem to be correct and

calibration still fails the most probable reason is that there is a little lack of

gain somewhere or the AGC gain control slope in N600 is out of the limits.

This can be verified by changing the generator reference levels from the

demanded ones in the calibration procedure in 1 dB steps up and down. If

the calibration goes through with some reference levels the corrective action is most probably changing N500 or N600.

Tuning Instructions

Original 10/98

Page 11

Page 12

NSM–1

Á

Á

Á

Á

Á

Á

Á

Á

PAMS

Tuning Instructions

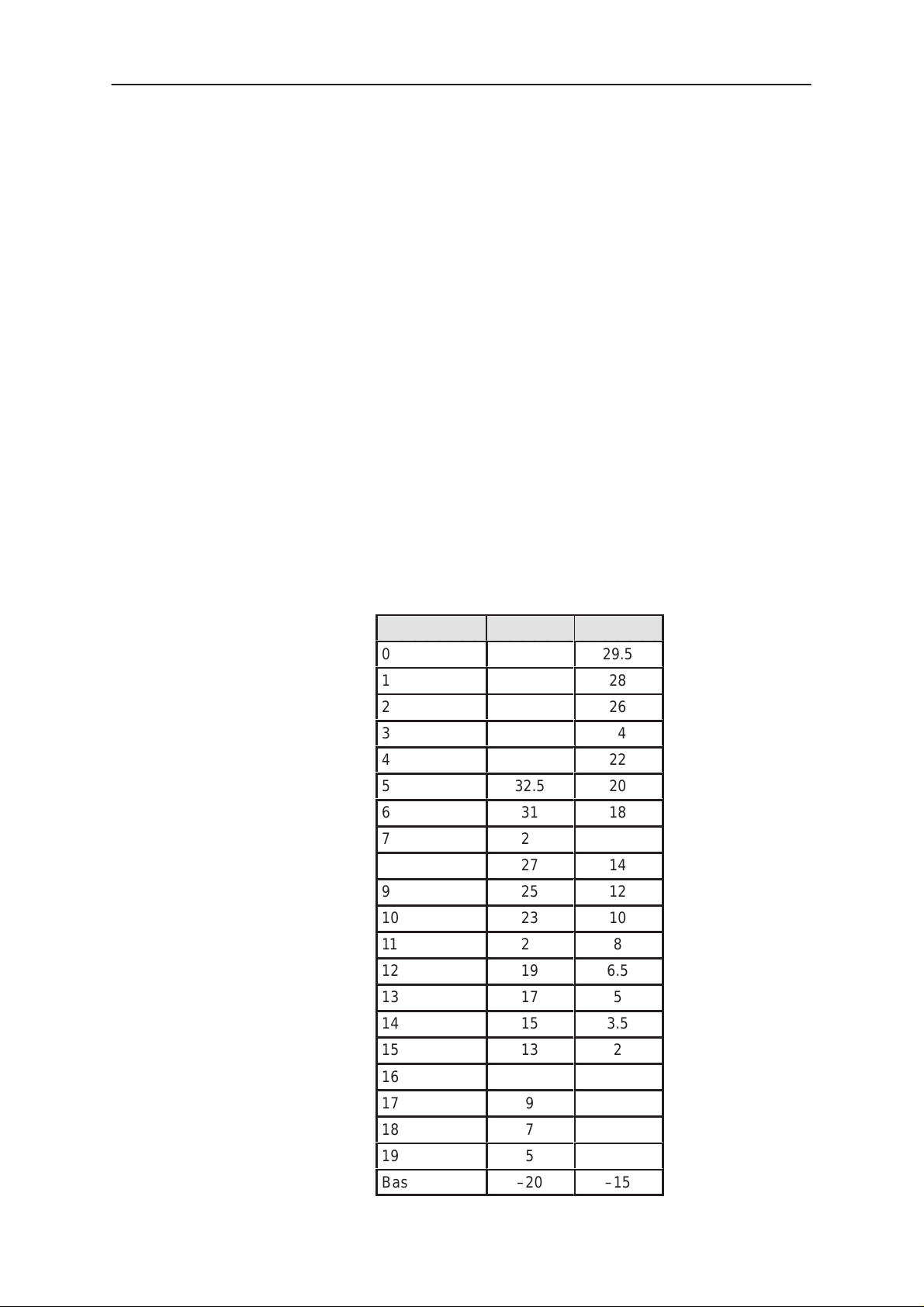

2. Alignment of Transmitter Power Levels

Equipment:

Pulsed power meter or spectrum analyzer and 10 dB attenuator.

Voltage source set to 3.6 V.

The following settings for the spectrum analyzer are recommended when

aligning the power levels: zero span, resolution and video bandwidths 1

MHz, input attenuation 40 dB, sweep time 1 ms, video triggering.

NOTE! If spectrum analyzer is used in power level alignment the

reading needs to be calibrated with a power meter after every power

up.

Procedure:

Follow the instructions given in chapter ”Service Software Instructions”

section ”TX power... command”.

For GSM the alignment channel is 60 (902 MHz) and for PCN 700

(1747.8 MHz). The side channels for GSM are 1 (890.2 MHz) and 124

(914.8 MHz) and for PCN 512 (1710.2 MHz) and 885 (1784.8 MHz).

Technical Documentation

Targets in dBm:

Power level GSM PCN

0

1

ÁÁÁÁ

2

3

4

5

6

7

8

9

10

ÁÁÁÁ

11

12

13

14

15

ÁÁÁÁÁÁ

32.5

31

29

27

25

23

ÁÁÁ

21

19

17

15

13

29.5

28

26

24

22

20

18

16

14

12

10

ÁÁ

6.5

3.5

8

5

2

Page 12

16

17

18

19

ÁÁÁÁ

Base

11

9

7

5

ÁÁÁ

–20

ÁÁ

–15

Original 10/98

Page 13

PAMS

NSM–1

Technical Documentation

It is recommended that all the power levels are separately aligned although there is a possibility to align only three and calculate the rest. This

is due to the fact that the calculation is not accurate enough, especially

for PCN lowest power levels where the targets are NSM–1 specific.

NOTE! Base level must be adjusted manually because the calculation

most often fails.

Tuning Instructions

Original 10/98

Page 13

Page 14

NSM–1

PAMS

Tuning Instructions

3. I/Q Modulator Alignments

I/Q modulator alignments are performed in PCN band. If GSM band has

been selected and I/Q alignment is started, the service software asks to

change to PCN band. If the user wants to continue in GSM, the adjusted

values can only be saved to PC memory, not to phone’s EEPROM. After

changing to PCN band values from PC memory are available, and if the

modulator adjustment is good, also the values can be saved to phone’s

EEPROM. See chapter ”Service Software Instructions” and section ”TX

I/Q... command” for further information.

Procedure:

Connect the spectrum analyzer to the phone antenna connector. The recommended spectrum analyzer settings are: span 200 kHz, resolution BW

10 kHz, video BW 1 kHz, sweep 500 ms, input attenuation 30 dB.

– From

– Go to

(1747.8 MHz).

RF controls

TX I/Q tuning

menu make sure that TX data type is 1.

menu. The alignment channel for PCN is 700

Technical Documentation

– Select the ”TX I DC offset” option and adjust the level of the centre fre-

quency (CHF) to minimum.

– Select the ”TX Q DC offset” option and adjust the level of the CHF

again to minimum.

– After finding both minima change ”TX I DC offset” by step or two from

the current value to both directions to see, whether better minimum

can be found for CHF.

– Select the ”Amplitude Difference” option and adjust the level of the un-

wanted sideband CHF + 67.71 kHz to minimum.

– Select the ”Phase Difference” option and dajust the level of CHF +

67.71 kHz again to minimum.

– After all the minima have been found press ”Save” button to store the

values to phone EEPROM.

Targets:

The level of the centre frequency CHF should be at least 30 dB down to

the wanted sideband CHF - 67.71 kHz.

The level of the unwanted sideband CHF + 67.71 kHz should be at least

35 dB down to the wanted sideband CHF - 67.71 kHz.

Page 14

Alignment verification in GSM band:

– Go to

a SW reset for the phone. Which in turn is needed to get the aligned

I/Q values in use.

– Go to

– Go to

level 10, TX data type 1.

Product ––> Initialize ––> Normal mode

Product ––> Band ––> GSM

RF controls

menu and start transmission on channel 60, power

. This is needed to give

Original 10/98

Page 15

PAMS

NSM–1

Technical Documentation

– Check the levels of CHF and CHF + 67.71 kHz. Both the levels

should be at least 30 dB down to the wanted sideband CHF - 67.71

kHz. If both or either of the specifications is not met adjust the the re-

quired values (I and Q DC offsets for CHF and amplitude and phase

for CHF + 67.71kHz) to meet the specifications.

–67.71 kHz +67.71 kHz

D.C. offset

tunings:

Set this value

to minimum

CHF

> 30 dB

> 35 dB

Tuning Instructions

Amplitude &

phase difference:

Set this value

to minimum

– Store the results in PC memory.

– Go to

Product ––> Band ––> PCN

and then to

TX I/Q Tuning

to check

the alignment with the values which are in PC memory. If the specifications are not met in PCN the solution is to find compromise values

which are not optimum for either bands but still meet the specifications.

– If the PCN band alignment is good with the values from PC memory,

the TX I/Q tuning procedure can be stopped by pressing the ”Save”

button.

Original 10/98

Page 15

Page 16

NSM–1

PAMS

Tuning Instructions

4. Energy Management Calibration

See chapter ”Service Software Instructions” and section ”Tuning – Energy

Management Calibration... command” for further information.

Technical Documentation

Page 16

Original 10/98

Loading...

Loading...