Page 1

Programme’s After Market Services

NME–3 Series Transceivers

Troubleshooting

Issue 1 10/99

Page 2

NME–3

PAMS

Troubleshooting

Technical Documentation

CONTENTS

Introduction 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Radiounit failures 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flashing failures 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone doesn’t Power On 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone doesn’t Power Off 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handset not recognized 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone doesn’t register to network or phone doesn’t make a call 15

Receiver faults 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter faults 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AMC not working 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Car Radio Mute not working 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backlight dimming not working 49. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio failure Handsetmode 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audiofailure Handsfreemode 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Failure in Data interface 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIM–Card not recognized 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handset failures 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Microphone path fault 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Earpiece path fault 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LCD fault 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIM interface fault 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad fault 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BLD fault 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hall sensor fault 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power key fault 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2

Issue 1 10/99

Page 3

PAMS

NME–3

Technical Documentation

Introduction

This document gives a comprehensive guide to NME–3 faultfinding.

NOTE

ules and ensure that:

a) There is no mechanical damages at the units

b) Soldered joints are o.k.

c) check which unit is broken HS or Radiounit

NOTE

umentations. (Power supply connected to the unit, IGNS high, Handset

conneced,...)

The following hints should make it easier to find the cause of the problem

when the product seems to be faulty. This trouble shooting instruction is

divided into the following sections:

: The first thing to do is carry out a through visual check of the mod-

: Make sure that the system is installed as specifided in the AS doc-

Troubleshooting

1. Which Unit is broken

2. RU failures

3. HS failures

Which Unit is broken

To check which unit is broken, the following steps should be performed:

Have a look at the failure describtion, if it doesn’t already indicate which

unit is broken, follow the procedure descibed below:

if there is a handset audio problem, connect the HS to a reference Radiounit and check if the problem is still there.

if the the system is not working at all then follow the steps described below:

– Connect the HS to 8V

– check if the current consumption is O.K.

– check if the Nokia Hands are shown

– If both things are O.K. connect the HS to a reference Radiounit and check if it

works without problems

– In this case it is most likely a Radiounit problem, in all other cases it is most likely

a Handset problem

– Important NOTE: After repair of one unit it allways have to be checked that the

combination of both units is working !!!

Issue 1 10/99

Page 3

Page 4

NME–3

PAMS

Troubleshooting

Radiounit failures

This chapter describes how to find failures in the Radiounit:

Radiounit doesn’t Powerup

Connect the Radiounit to +12V while ignition sense is switched off and

look to see if the Leds are turned ON for a short time

– If they don’t turn on at all,

– check the current consumtion, if it is about 300– 400uA the wakeup

logic should be checked, if it is much less or more there is a Problem

in the powersupply

– Check the status of all voltages

– Check the status of the wakeup logic

– If the Leds stay on,

– Check the digital part

Technical Documentation

– Check powerdown logic

– If the LEDs go off as specifed and current is O.K.:

– Try to wakeup the radiounit by turning Ignition sense ON,

– if the Leds stay on go to the next step

– if they don’t stay on or don’t turn on at all check the Ignition circuit

– Try to wakeup the radiounit by pressing the powerbutton of the HS,

– if the Leds stay on go on, try flashing the unit

– if they don’t stay on or don’t turn on at all check the Powerbutton cir-

cuit

Page 4

Issue 1 10/99

Page 5

PAMS

NME–3

Technical Documentation

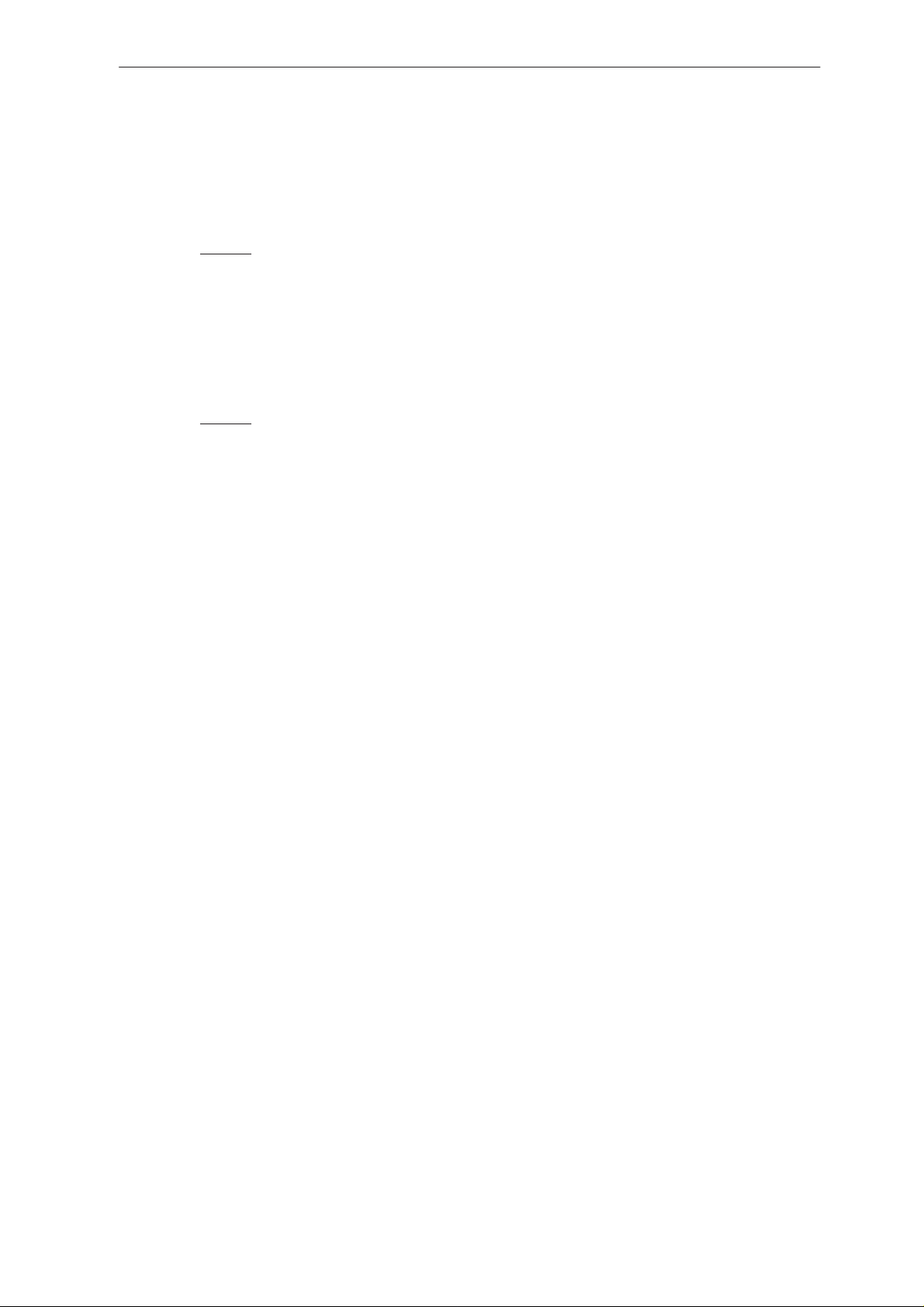

12V at V1

Yes

12V at C437

Yes

3.8V at C426

No

No

No

Check PCB

fuse, and solderjoints on systemconnector

Check L13

Check N402 and V404

Troubleshooting

Yes

12V at C410

Yes

8V at C415

Yes

8V at C404

Yes

No

No

Check

N401

No

PURX high

D701 Pin 9

Yes

voltage at

C403 =0.7V

No

Check N400

No

Yes

Check

Overvoltagecircuit

Check

wakeup

logic

Check

V400,

V403

Powersupply

O.K.

Issue 1 10/99

Figure 1.

Check the voltages and powersupply

Page 5

Page 6

NME–3

PAMS

Troubleshooting

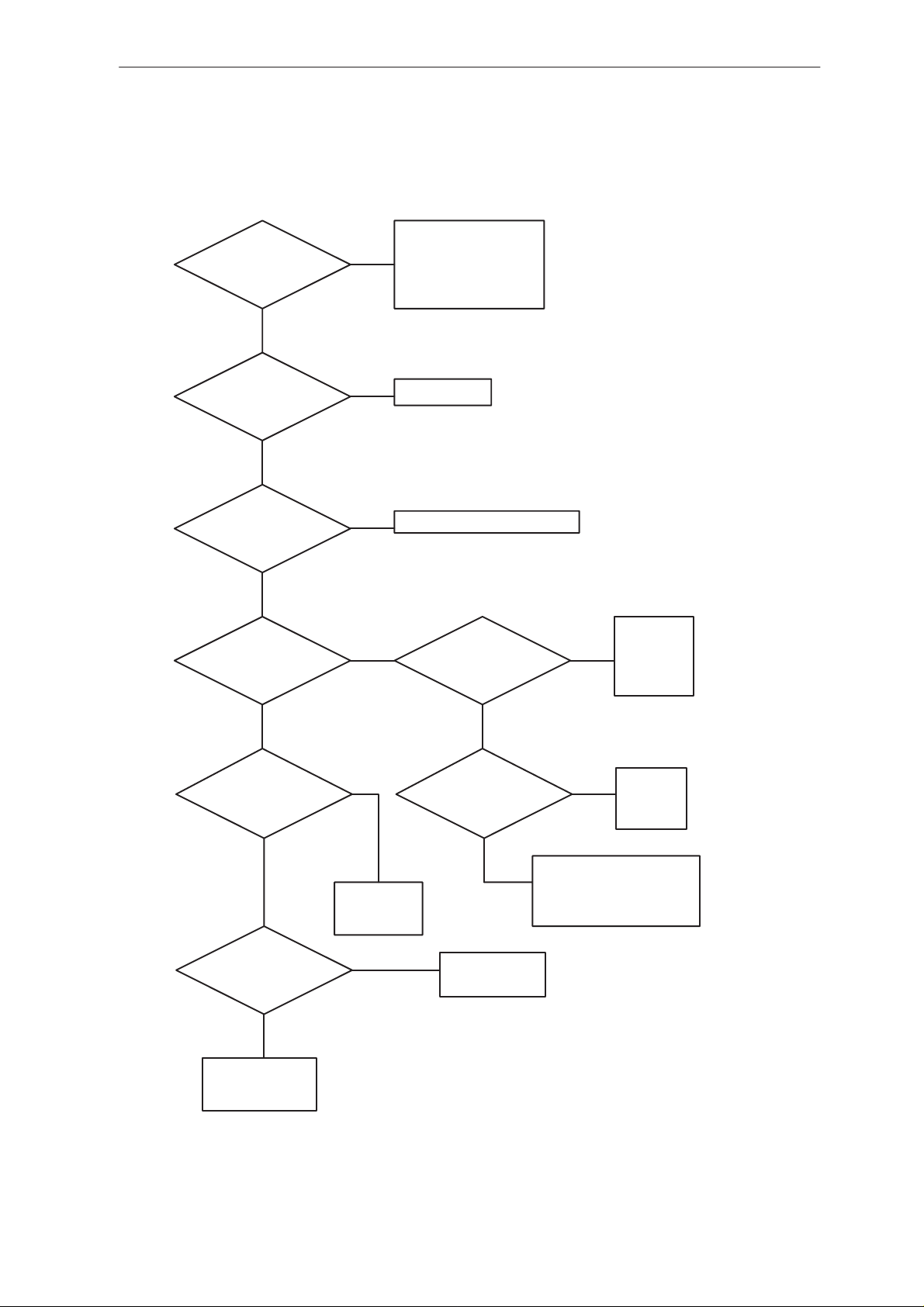

Is Pin 9 of

D702 high

No

Is Pin 13 of

D702 high

Yes

Yes

No

Check circuit on

Pin 13 of D702

Technical Documentation

Disconnect the Powersupply

Connect Probe to Pin 3 of D701

set scope to singletrigger falling edge,

reconnect the powersupply

Scope pic

according

figure 1

Yes

No

Check D701

Check D702

Check that a low pulse is produced

on Pin 10 of D702 when

switching Power On

D701 Pin 9 high

Yes

LEDs on

Yes

No

Check CCONT

No

Check

Powersupply

Check

Digitalpart

Page 6

Figure 2. check wakeup circuit

Issue 1 10/99

Page 7

PAMS

NME–3

Technical Documentation

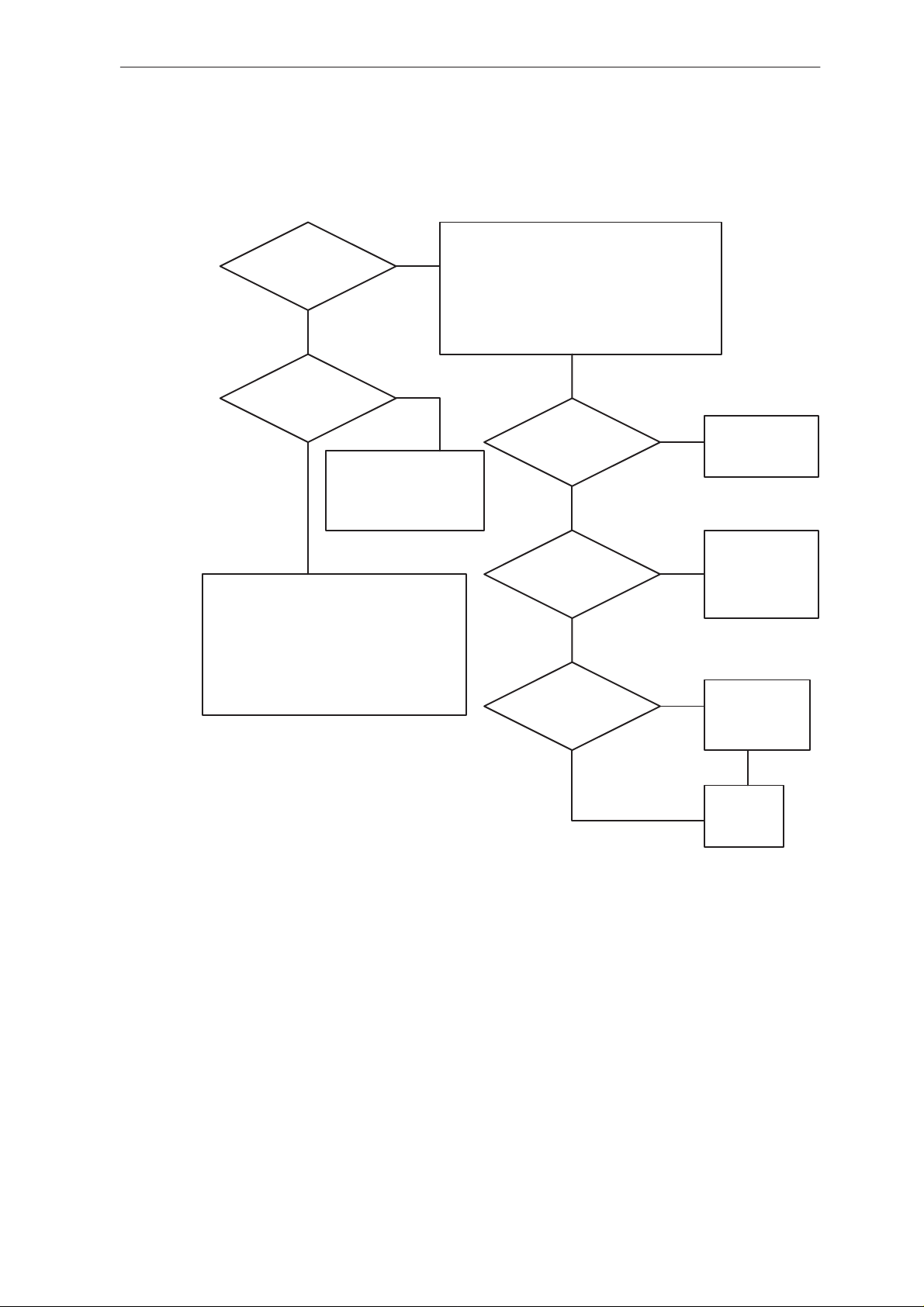

32 Khz

clock on

N700 Pin 48

Yes

13 Mhz

clock on

N700 Pin 48

Yes

No

Check CCONT

and 32Khz oscilator

No

Check VCXO circuit

Troubleshooting

Frequent data from

MAD to CCONT on

CCONT PIN 49–51

No

Check D600.. D603 for

open solder joints

shortcircuits

and broken components

Yes

Try to flash new SW

Issue 1 10/99

Figure 3. check digital part

Page 7

Page 8

NME–3

PAMS

Troubleshooting

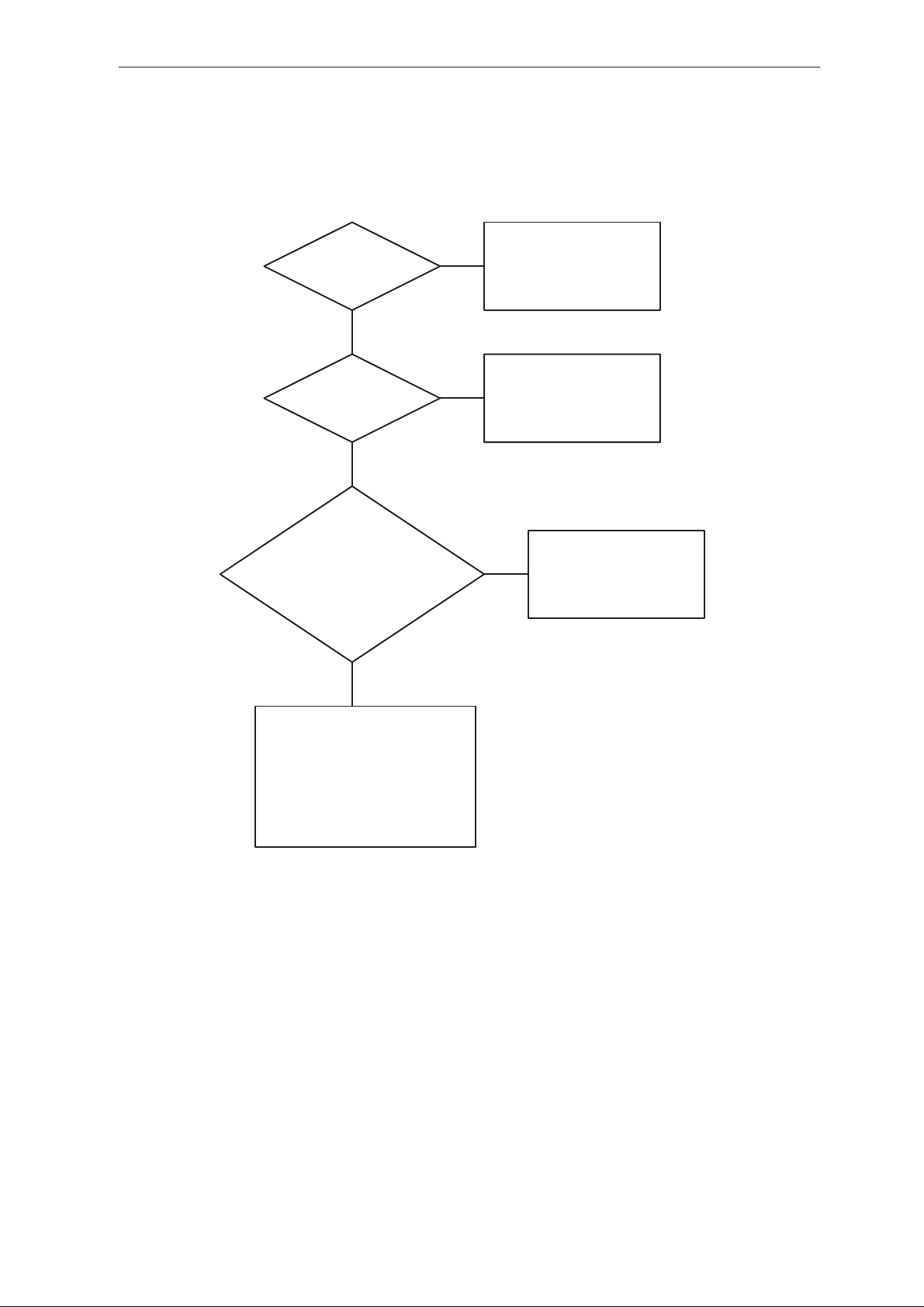

D702 Pin 10

high ??

No

Is SW producing a

Powerdown signal

on R721

Check circuit

arround V707

and D702

Technical Documentation

Yes Check circuit connected

to this pin

No

Signal on

R600 low

Yes

Signal on

R603 low

Yes

No

No

check related

circuit

check related

circuit

Try to Flash new

SW

check digital part

Page 8

Figure 4. Check Powerdownlogic

Issue 1 10/99

Page 9

PAMS

NME–3

Technical Documentation

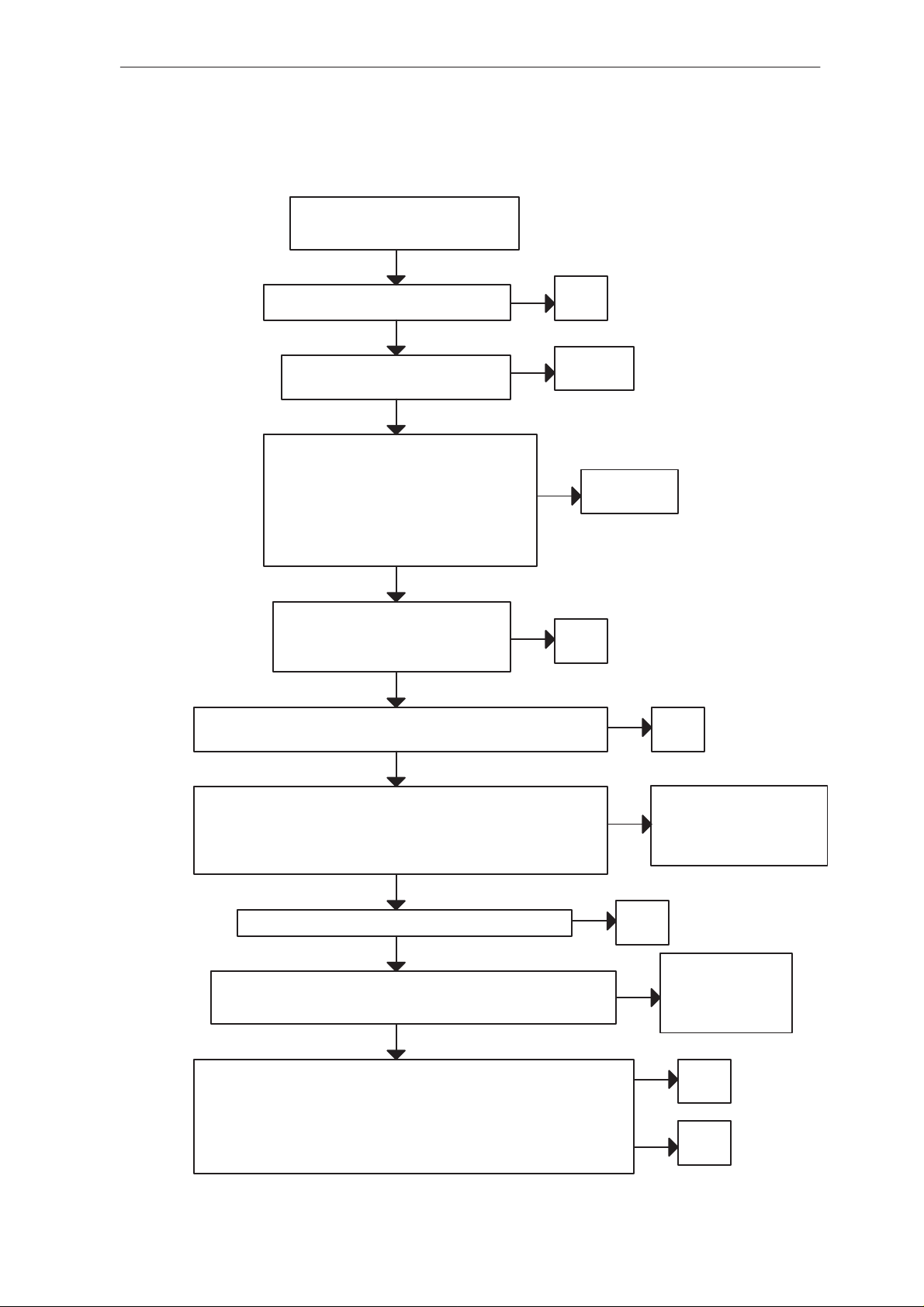

Flashing not possible

The flash programming can be done via system connector X1.

In production, the first programming is done applying 12V flashvoltage to

TP610. In aftersales the Flashvoltage is generated by an on board regulator.

The main differences between production flashing and aftersales flashing

are :

a) FLASH programming voltage is produced in a different way.

b) Signal routings are different.

The fault finding diagrams for production flash programming are shown in

figures 5 and 6.

The fault finding diagrams for aftersales flash programming are shown in

figures 7 and 8.

Troubleshooting

In flash programming error cases the flash prommer can give some information about a fault.

The fault information messages could be:

– MCU doesn’t boot

– Serial clock line failure

– Serial data line failure

– External RAM fault

– Algorithm file or alias ID don’t find

– MCU flash Vpp error

In cases that the flash programming doesn’t succeed there is a possibility

to check short circuits between the memories and the MCU (MAD2).

This test is useful to do, when the fault information is: MCU doesn’t boot,

Serial clock line failure or Serial data line failure.

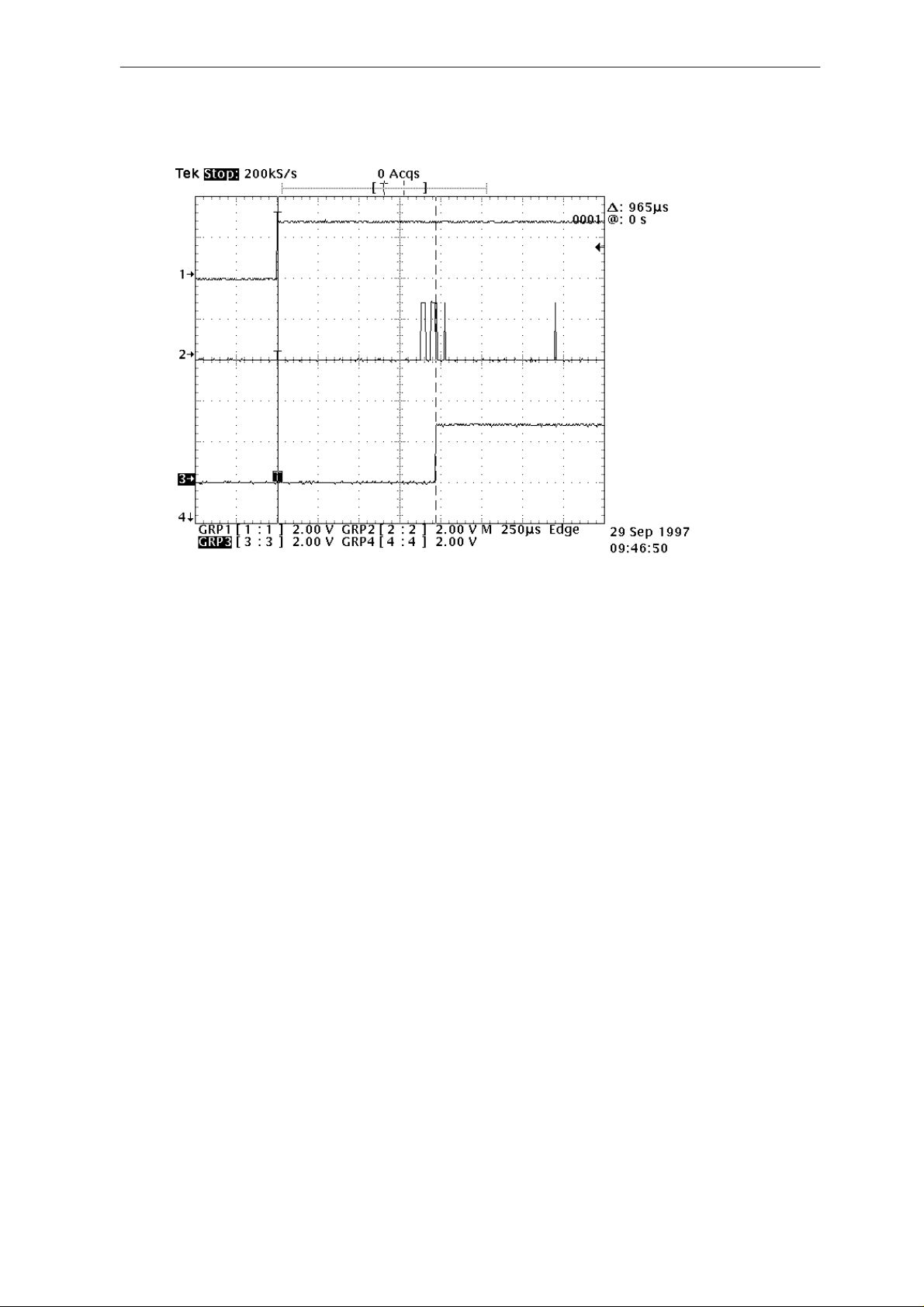

The test procedure is following:

1. Connect the short circuit wire between the test points J229 and J230.

2. Switch power on to start selftest

3. If the voltage level in D600 PIN 134 is 2.8 V (”1”), the interface is OK. If

there is a short circuit, the voltage level in D600 PIN 134 stays low and

32kHz square wave signal can be seen in the lines which are already

tested.

Selftest behaviour can be seen on the next page.

Note this test can be found only short circuits, not open pins.

Also upper data lines (15:8) of flash circuit D602 are not included to this

test.

Issue 1 10/99

Page 9

Page 10

NME–3

PAMS

Troubleshooting

passed

Technical Documentation

CCONT pin 54

MAD pin 38

MAD pin 134

( PURX )

( MCUAD0)

( ExtSysResX))selftest

Page 10

Issue 1 10/99

Page 11

PAMS

NME–3

Technical Documentation

Production Flash Programming Failure (1)

Flash programming doesn’t work

YES

If the fault information from the prommer is:

a) MCU doesn’t boot

b) serial data line failure

c) serial clock line failure

connect:

connect watchdog disable (WDDIS) line (N700 PIN 28) to ground

OK

EEPROM (D601) Pin 8 (VBB) 2.8V

C706 (VXO) 2.8V

YES

NO

Troubleshooting

See section: Phone is totally dead

check C213, R213

YES

R607 (RFC) 13Mhz

800 mV min

NO

check buffer V300 and

VCXO G300

NO TP700 clock(SCLK)

D701 PIN 9 PURX =”1” 2.8V

YES

NO

MAD2 (D600) pin 93 13 Mhz sine wave

clock signal: 500 mVpp min.

YES

Check that following lines are correct:

FCLK (MBUS) line: X1 pin 22 –> D600 pin 112

FTX (fbus_tx) line: X1 pin 6 ––> D600 pin 104

FRX (fbus_rx) line: X1 pin21 .–>D600 pin 109

check also pullup and pulldown resistors: R606,R614,R617

Check D700, no low signal from N650

OK

Enable the selftest function of D200 by connecting

Voltage level rises to ”1” after power on at D600 Pin 134

D600 PIN 17 to GND

Connect an oscilloscope to D600 PIN 134 and

power on

YES

square wave 32 kHz

YES

Faulty circuit N700

or over loaded PurX line

NO

There is a shortcircuit

somewhere in memory control

lines or MCU address lines or

MCU lower (7:0) data lines

check sleep

NO

clock circuitry

(B701,R707,..)

Issue 1 10/99

There could be open pins in circuits D600 (D602, D603)

If not, the PCB or D600 (D602, D603) is faulty

Figure 5.

Page 11

Page 12

NME–3

PAMS

Troubleshooting

Production Flash Programming failure (2)

Flash progrmming doesn’t work

YES

If the fault information from the prommer is:

External RAM fault

YES

Check pins of SRAM (D603)

Check control lines of SRAM:

RAMSelX ...

Flash progrmming doesn’t work

YES

Technical Documentation

If the fault information from the prommer is:

Algorithm file or alias ID don’t find, ID is unknown etc.

YES

Check pins of FLASH (D602)

Check control lines and upper data lines (15:8)

of FLASH: ROM1SelX...

Flash progrmming doesn’t work

YES

If the fault information from the prommer is:

MCU flash Vpp error

YES

Check connection between TP610 ––> D210; 13

Check components C600, R612, N600, V600

OK

Page 12

Faulty component D602

Figure 6.

Issue 1 10/99

Page 13

PAMS

NME–3

Technical Documentation

Aftersales Flash Programming failure (3)

Flash programming doesn’t work

YES

If the fault information from the prommer is:

a) MCU doesn’t boot

b) serial data line failure

c) serial clock line failure

connect:

connect the shortcircuit wire from N700 pin 29 to Ground (watchdog)

OK

EEPROM (D601) pin 8 (VBB)

C706 (VTX) 2.8V

YES

NO

VBAT is correct

3.8 V

Troubleshooting

YES

N700 is faulty

check C213, R213

YES

R607 (RFC) 13Mhz

800 mV min

NO

check buffer V300 and

VCXO G300

NO C728 sleep clock (SCLK)

D701 Pin 9 PURX = ”1” (2.8V)

YES

NO

MAD2 (D600) pin 93 13 Mhz sine wave

clock signal: 500 mVpp min.

YES

Check that following lines are correct:

FCLK (MBUS) line: X1 pin 22 –> D600 pin 112

FTX (fbus_tx) line: X1 pin 6 ––> D600 pin 104

FRX (fbus_rx) line: X1 pin21 .–>D600 pin 109

check also pullup and pulldown resistors: R606,R614,R617

Check D700, no low signal from N650

OK

Enable the selftest function of D200 by connecting

Voltage level rises to ”1” after power on at D600 Pin 134

D600 PIN 17 to GND

Connect an oscilloscope to D600 PIN 134 and

power on

YES

square wave 32 kHz

YES

Faulty circuit N700

or over loaded PurX line

NO

There is a shortcircuit

somewhere in memory control

lines or MCU address lines or

MCU lower (7:0) data lines

NO

clock circuitry

(B 701, R707)

check sleep

Issue 1 10/99

There could be open pins in circuits D600 (D602, D603)

If not, the PCB or D600 (D602, D603) is faulty

Figure 7.

Page 13

Page 14

NME–3

PAMS

Troubleshooting

Aftersales Flash Programming failure (4)

Flash progrmming doesn’t work

YES

If the fault information from the prommer is:

External RAM fault

YES

Check pins of SRAM (D603)

Check control lines of SRAM:

RAMSelX ...

Flash progrmming doesn’t work

YES

Technical Documentation

If the fault information from the prommer is:

Algorithm file or alias ID don’t find, ID is unknown etc.

Check pins of FLASH (D602)

Check control lines and upper data lines (15:8)

of FLASH: ROM1SelX...

Flash progrmming doesn’t work

YES

If the fault information from the prommer is:

MCU flash Vpp error

YES

Vpp > 3 V in D602 pin 13 (or C600)

YES

Check components C600, R612

OK

NO

YES

Vpp > 3 V in testpoint TP610

YES

Check D601 for bad soldering

NO

Check regulator N600

Page 14

Faulty component D601

Figure 8.

Issue 1 10/99

Page 15

PAMS

NME–3

Technical Documentation

Phone doesn’t Power On

This is described in section 2.2.1

Phone doesn’t Power Off

Press Powerbutton, and check if Powerdown pulse is produced on R 721,

if it isn’t check Powerbutton circuit, if it is produced check circuit around

D702 according to Figure 5.

Set Auto power off to 45 seconds, switch Ignition Off, look if a message

Power will switch of if not used comes up after some seconds. If not

check Ignitionsensecircuit

If yes check if the powerdownpulse is produced on R721, if it is check circuit arround D702 according to figure 2.

If no pulse is produced check the connection from R721 to D600 !!

Handset not recognized

Connect a probe to R606, and check if the line is high and carrying HS

signals, if it check the resistor and the MAD D600.

Troubleshooting

If yes follow the M–Bus signal to the connector.

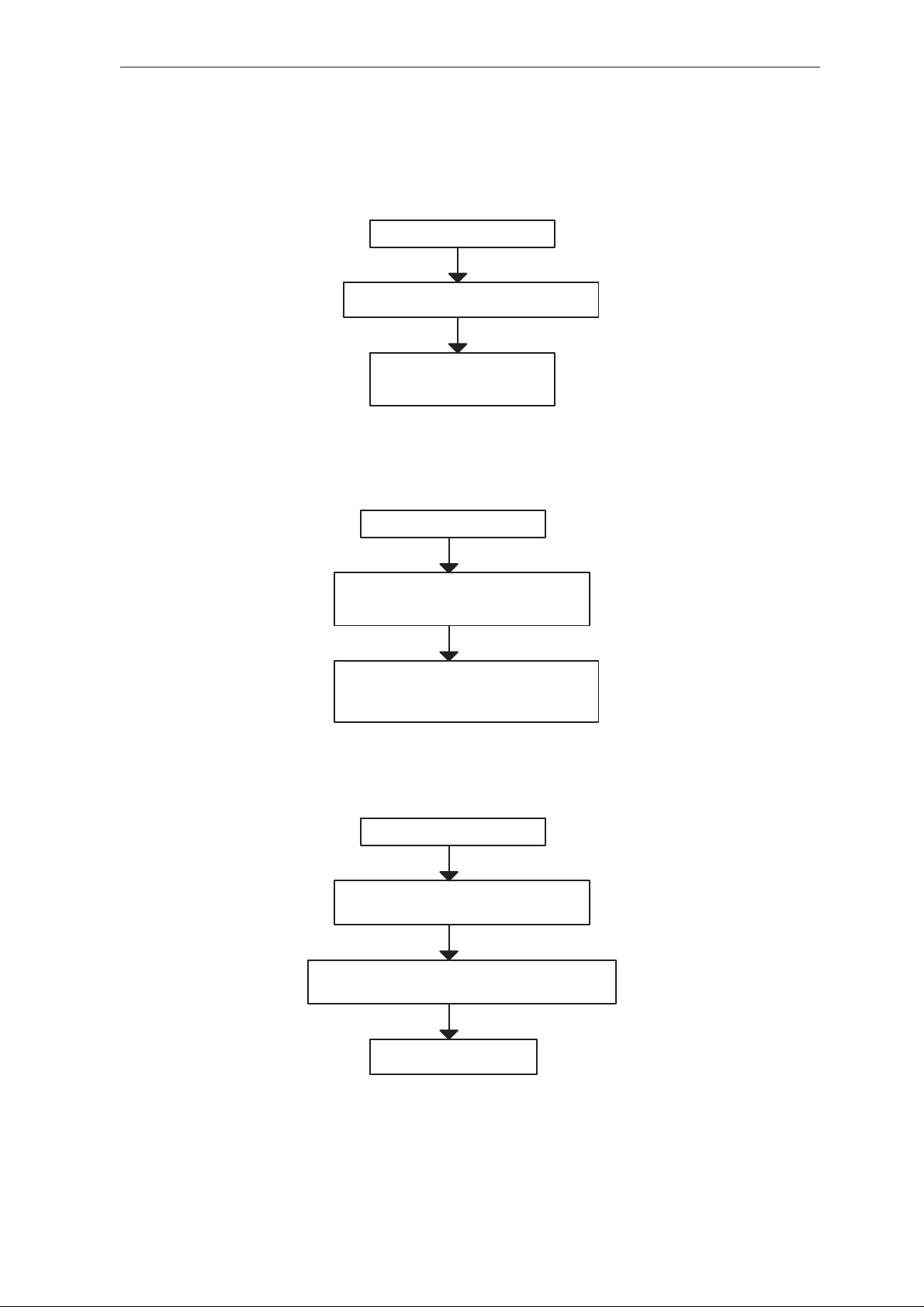

Phone doesn’t register to network or phone doesn’t make a call

If the phone doesn’t register to the network or the phone doesn’t make a

call, the reason could be either the baseband or the RF part.

The phone can be set to wanted mode by WinTesla service software and

determinate if the fault is in RF or in baseband part (RF interface measurements).

The control lines for RF part are supplied by both the System Asic

(MAD2;D600) and the RFI (Cobba; N800). MAD2 handles digital control

lines ( like synthe, TxP etc.) and Cobba handles analog control lines (like

AFC, TxC etc.).

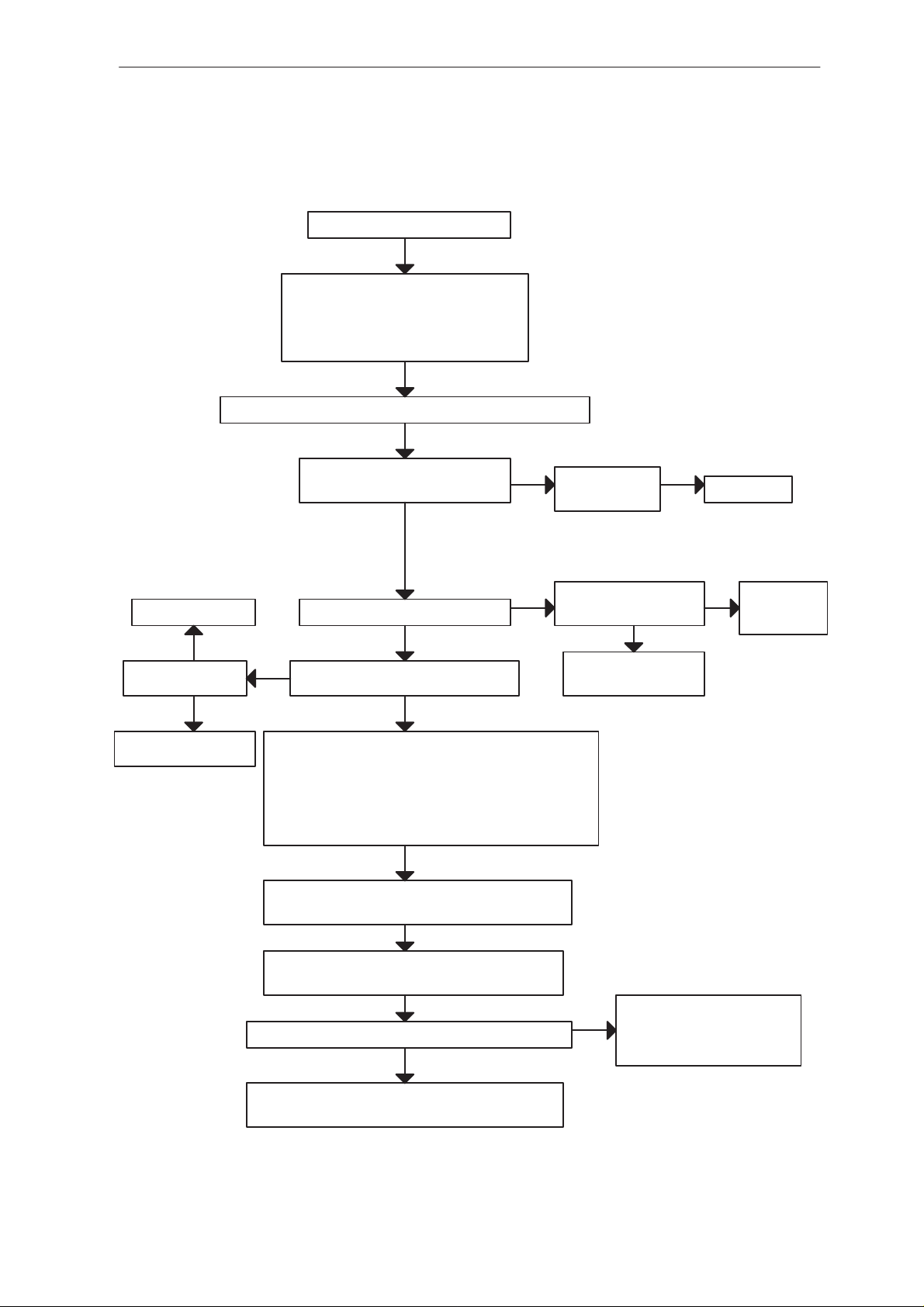

The DSP software is constructed so that operation states of DSP (MAD2)

can be seen in external flag (DSPXF) output pin (D600 pin 91).

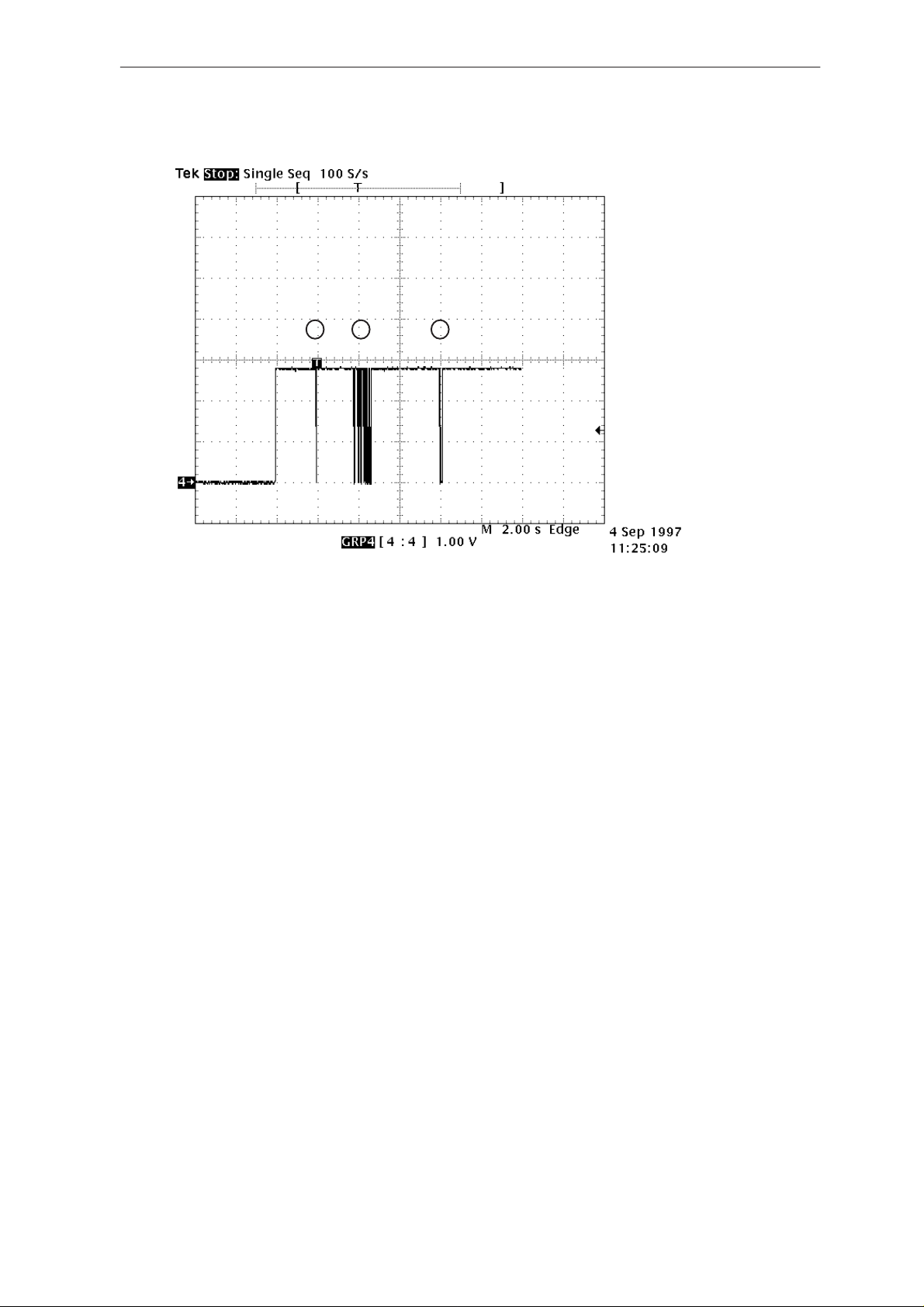

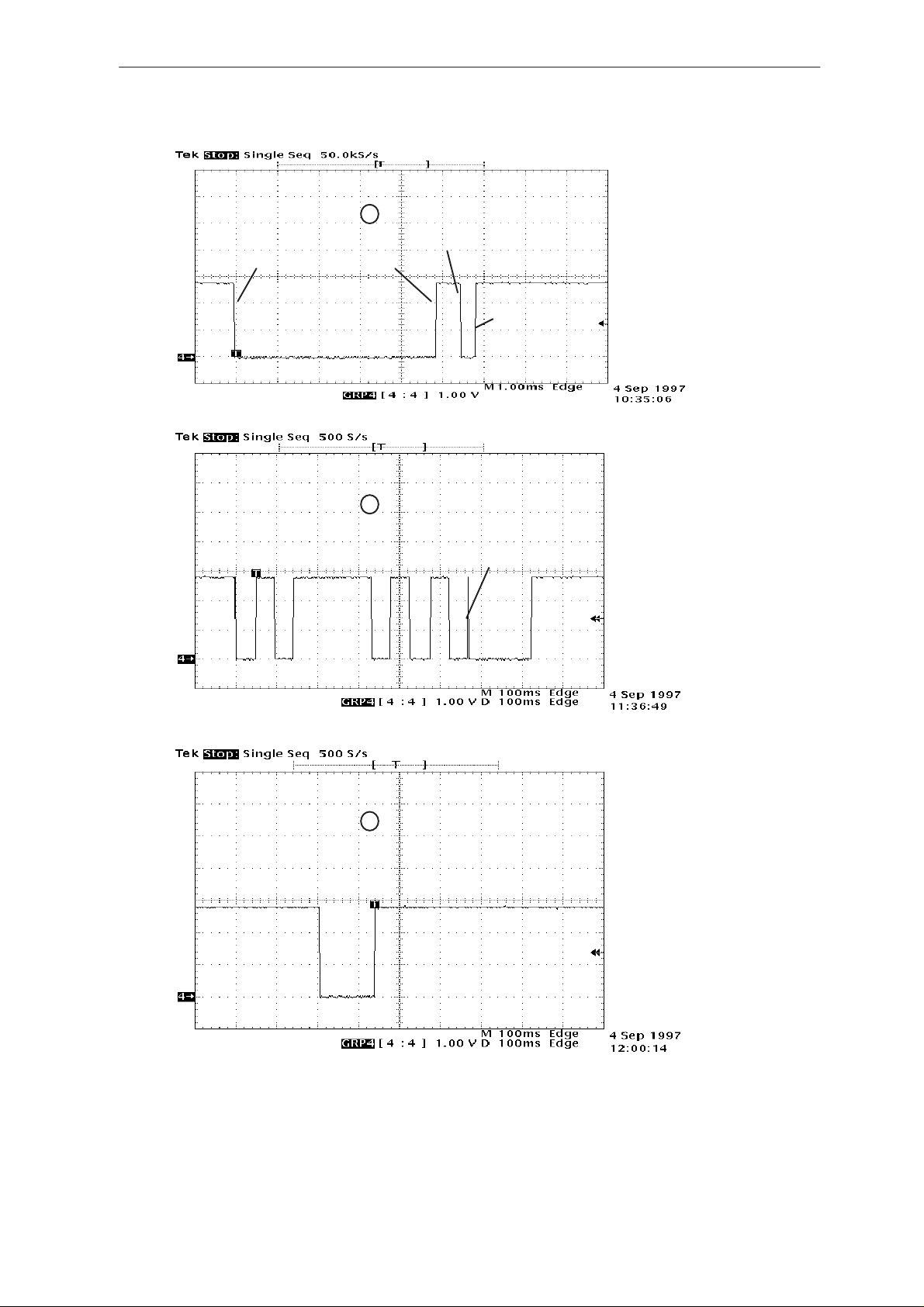

After power up, DSP signals all completed functions by changing the state

of the XF pin (see figure 9 for complete timing and figure10 for detailed

timing).

Issue 1 10/99

Page 15

Page 16

NME–3

PAMS

Troubleshooting

Technical Documentation

1. DSP initialization done

2.Synchronization to network

done

3. Registrarition to network

done.

1 2 3

MAD2 pin 91 (DSPXF)

Figure 9.

Page 16

Issue 1 10/99

Page 17

PAMS

NME–3

Technical Documentation

init

initialize

1

patch code

download

2

dsp

constants

download

initialization

done

Troubleshooting

MAD2 pin 91 (DSPXF)

channel

scan starts

PSW

search last PSW

OK

3

send RACH

RACH OK

go SDCCH

imediate assigment

OK

synchronization

OK

MAD2 pin 91 (DSPXF)

MAD2 pin 91 (DSPXF)

Issue 1 10/99

Figure 10.

Page 17

Page 18

NME–3

PAMS

Troubleshooting

Phone register failure

Phone doesn’t register to the network

Analog supply voltage VCOBBA is >2.7 V

at pin 7,12 ... of Cobba (N800)

Analog reference voltage Vref is 1.5 V

Supply voltage VCP (N700 pin 32) > 4.8 V

Supply voltage VRX (N700 pin 9) > 2.7 V

Supply voltage VSYN_1 (N700 pin 15) > 2.7 V

Supply voltage VSYN_2 (N700 pin 4) > 2.7 V

Supply voltage VTX (N700 pins 11, 20) > 2.7 V

phone doesn,t make a call

or

YES

YES

at pin 9 of Cobba (N800)

YES

during the receiving slot

during the transmitting slot

Check

NO

N700

NO

Check

R800,C800

NO Check

Technical Documentation

N700, D600

YES

Synthesizer lines: SEna (N101 pin 56),

SClk (N101 pin 54)

SData (N101 pin 55)

pulses 0 –> 1 during receiving slot

YES

NO

Check

D600

RF control lines: RxC (N800 pin 18) 0 –> 2.3 Vmax during receiving slot

AFC (N800 pin 19) 0 – 1.2 V typ. during receiving slot

YES

Analog data signal RxIP (N800 pin 22) 0–> 1.5 V DC during receiving slot

Analog data signal RxIN (N800 pin 22) 0–> 1.5 V DC during receiving slot

Used benefit signal is biased to DC and its amplitude is 50 mVpp

nominal and frequency is 13 MHz

YES

NO

DAX signal (N800 pin 48) pulses 1 –> 0 during receiving slot

YES

RF control lines: TxC (N800 pin 17) 0 –> 2.3 Vmax during transmit slot

TxP (D600 pin 176) 0–>1 (2.8 V) during transmit slot

YES

NO

Check

N800

NO

Check

N800 if DC is failed

Check

RF part if benefit signal is failed

Check

N800

Check

NO

N800 if TxC is failed

Check

D600 if TxP is failed

Page 18

Analog data signals: TxIN (N800 pin 13) 0–> 0.8 V DC during transmit slot

TxIP (N800 pin 14) 0 –>0.8 V DC during transmit slot

TxQN (N800 pin 15) 0 –>0.8 V DC during transmit slot

TxQP (N800 pin 16) 0 –>0.8 V DC during transmit slot

Used benefit signal is biased to DC and its amplitude is 300 mVpp

nominal and frequency is 64 kHz

NO

YES

Check

N800

Check

RF part

Issue 1 10/99

Page 19

PAMS

NME–3

Technical Documentation

Receiver faults

This section gives an overview of the strategies used to hunt failures and

defects in the receiver path of the radio unit. Tracking of receiver errors is

best done by following the RX signal path and tracking the signal applied

to the antenna port with a probe and a spectrum analyzer. The following

steps should be done prior to the signal tracking:

– Apply test signal generated by CMD55 to antenna port.

– Set radio unit to local mode with Wintesla.

– Choose RF Controls from Wintesla Testing menu.

– Perform the following settings:

The test signal should then be tracked through the rx signal path by following the procedures given in the figures below.

Troubleshooting

Frequency: 947 MHz

Level: –55dBm

Set RX continuous mode

Set Cont. mode channel 60

Tick front end on.

The RF levels given in the following flow charts were measured with a

Hewlett Packard RF probe. When measuring the levels with a different

probe the resulting levels may be different. The most important thing to

check is wether there is a signal present or not.

Issue 1 10/99

Page 19

Page 20

NME–3

PAMS

Troubleshooting

Receiver Fault (1)

RX

FAULT

Duplexer (Z100)

Ant Pin: –56dBm ?

Yes

Duplexer (Z100)

RX Pin: –59dBm ?

Yes

RX Filter (Z101)

Input: –39dBm ?

Yes

RX Filter (Z101)

Output: –42dBm ?

Yes

No

No

No

No

C135: Check soldering!

If soldering okay:

Change C135!

Z100:Check soldering!

If soldering okay:

Change Z100!

Check Bias of V100!

Vbase = 0.9 V (at R109)

Vcoll = 2.3V (at C115)

Yes

Check soldering of passive

components in LNA

area and change component (V100) if necessary!

Z101: Check soldering!

If soldering is okay

change Z101!

No

Technical Documentation

Check VRX2 (R102):

2.8V

Yes

Check Pdata0 (R100):

2.8V

Yes

Check soldering of passive

components in LNA

area and change component (V100) if necessary!

Check supply of CCONT!

No

No

CCONT (N700)

Check soldering!

MAD (D600):

Check soldering!

Mixer (N100)

RF Input: –44dBm?

1st IF

71MHz

Page 20

Yes

No

C108: Check soldering!

If soldering is okay

change C108!

Issue 1 10/99

Page 21

PAMS

NME–3

Technical Documentation

Receiver Fault (2)

1st IF

71MHz

Mixer (N100)

IF Output: –50dBm

at 71 MHz?

Yes

IF Amp output:

C104

IF signal: –37dBm

at 71 MHz

No

No

Mixer (N100)

RF LO Input:

9dBm at 1018MHz?

Yes

N100: Check soldering!

If soldering is okay

change N100!

Check Bias of V102:

Vbase=0.9V

Vcoll=1.7V

No

No

Troubleshooting

UHF LO

Check soldering of passive

components in IF–AMP

area and change compo-

nents if necessary!

Yes

IF Filter (Z102):

Input: –18 dB

Yes

IF Filter (Z102):

Output: –29 dB

Yes

Plussa (N101):

Pin 51,52: –29 dB

(Single ended)

No

No

No

Yes

C108, C104:

Check soldering!

If soldering is okay

change components!

L101,L102,C109:

Check soldering!

If soldering okay,check for-

short circuits and change

brocken components!

Z102: Check soldering!

If soldering is okay

change Z102!

L104,L105,L107,C110,C111,C1 12,R106:

Check soldering! If soldering okay, check for

short circuits and change brocken components!

Also check Plussa (N101) soldering!

2nd IF

13MHz

Issue 1 10/99

Yes

Page 21

Page 22

NME–3

PAMS

Troubleshooting

Receiver Fault (3)

2nd IF

13MHz

Plussa (N101):

Pin 8: 0dBm at 232

Mhz?

Yes

Plussa (N101):

Pin 44: –3dBm at

13 Mhz?

Yes

No

No No

VHFLO

Plussa (N101):

Pin 47: 2.8V?

Yes

Plussa (N101):

Pin 53: 1.2V?

No

Technical Documentation

Check VRX1 supply volt-

age at CCONT!

Check RXC control voltage

from COBBA (N800)

Pin 18!

Filter (Z103) Input:

–7dBm at 13 MHz?

Yes

Filter (Z103) Output:

–10dBm at 13 MHz?

Yes

Plussa (N101):

Pin 34: –20dBm

Pin35: –16dBm at 13 MHz?

Yes

A

No

No

No

Yes

Change Plussa (N101)!

R116: Check soldering!

If soldering okay, change

component!

Z103: Check soldering!

If soldering okay, change

component!

Plussa (N101):

Pin 34,35: 1.4V DC?

Yes

R114,R112:

Check soldering!

If soldering okay, change

component!

No

Change Plussa (N101)!

Page 22

Issue 1 10/99

Page 23

PAMS

NME–3

Technical Documentation

Receiver Fault (3a)

A

Plussa (N101):

Pin 29,30:

–2dBm at 13 MHz?

Yes

Cobba (N800):

Pin 22,23:

–2dBm at 13 MHz?

No

No

Plussa (N101):

Pin 29,30: 1.2V DC?

Yes

Plussa (N101):

Check soldering!

If soldering okay, change

component!

Check connections

between

Plussa (N101),

Cobba (N800)!

Troubleshooting

Change Plussa (N101)!

No

Yes

COBBA

Issue 1 10/99

Page 23

Page 24

NME–3

PAMS

Troubleshooting

Receiver Fault (4)

COBBA

Cobba (N800):

Pin 7,12,21,25,63: 2.8V

DC?

Yes

Cobba (N800):

Pin 27,53: 2.8V DC?

Yes

No

No

Technical Documentation

Check Cobba voltage!

CCONT Pin 22

Check VBB voltage!

CCONT Pin 55

Cobba (N800):

Pin 9: 1.5V DC?

Yes

Cobba (N800):

Pin 10: 100k load?

Yes

Cobba (N800):

Pin 45:13MHz clock OK?

Yes

Cobba (N800):

Pin 28: “High”?

Yes

Check data and adress lines be-

tween MAD and Cobba(N800)!

If OK, change Cobba (N800)!

No

No

No

No

Check Vref voltage!

CCONT Pin 13

through R253

R800: Check soldering!

If soldering okay,

change component!

Check COBBACLK line

from MAD (D600) Pin144!

Check COBBRSTX line

from MAD (D600) Pin163!

Page 24

Issue 1 10/99

Page 25

PAMS

NME–3

Technical Documentation

Receiver Fault (5)

UHFLO

UHFLO (G301):

Output: –10dBm at

1018 MHz

Yes

No

UHFLO (G301):

Vcc pin: 2.8V DC?

Yes

UHF LO (G301):

VC Voltage (R313)

2.2V at Mid CH?

Yes Yes

Change G301!

No

Check VVCO and R305!

No

Also check Plussa (N101)

Troubleshooting

UHFLO (G301):

Check soldering!

connections!

B

Check bias of V303

Vbase= 0.73V

Vcoll= 7.3V

Yes

Check passive components

in supply and signal path for

soldering and short circuits!

Change defective compo-

nents!

No

Check V8PA (R306):

8V DC?

Yes

Check soldering of V303!

If soldering is OK, change

component!

Check 8V regulator for

No

V8PA!

Issue 1 10/99

Page 25

Page 26

NME–3

PAMS

Troubleshooting

Receiver Fault (5a)

B

UHFLO (G301)

oscillates at any

frequency?

Yes

Plussa (N101):

Pin 21: 13 MHz?

Yes

No

No

Technical Documentation

Change G301!

Check C304

and soldering at Plussa

(N101)!

Plussa (N101):

Pin 9,22,25: 2.8V DC?

Yes

Plussa (N101):

Pin 17,28: 5.0V DC?

Yes

Plussa (N101):

Pin 59: 15k load?

Yes

SCLK, SDATA, SENA

signalling okay?

No

No

No

No

Check VSYN from

CCONT (N700) and

CNTVR3 control from

MAD (D600)!

Check VCP voltage

from CCONT (N700)

Pin 32!

Check soldering at

N101 and R125!

If OK, change R125!

Check SCLK, SDATA,

SENA line from MAD

(D600)!

Change Plussa N101!

Page 26

Yes

Issue 1 10/99

Page 27

PAMS

NME–3

Technical Documentation

Receiver Fault (6)

VHFLO

Plussa (N101):

Pin 18: 2.0V?

Yes

Check soldering of compo-

nents and change defect

components if necessary!

Plussa (N101):

Pin 9,22,25: 2.8V DC?

No

No

Does the VCO oscillate

at any frequency?

Yes

Check VVCO

supply voltage!

No

V301 collector:

2.6V DC?

V301 base:

1.7V DC?

Yes

Yes

Troubleshooting

Check VVCO

No

No

supply voltage!

R311,R319:

Check soldering!

If soldering OK,

change component!

Yes

Plussa (N101):

Pin 17, 25 5V DC?

Yes

Change Plussa (N101)!

No

Check VCP

supply voltage!

V301 emitter:

1.2V DC

Yes

Check V301 and passive

components for soldering

and short circuits!

Change defective

components!

Load at emitter: 330 Ohm

No

If OK, change V301!

V301:

Issue 1 10/99

Page 27

Page 28

NME–3

PAMS

Troubleshooting

Receiver Fault (7)

AFC

RSSI tuning OK?

Yes

Cobba (N800):

Pin 19

between 0.5 ... 2.3V?

Yes

Set Spectrum Analyzer!

Frequency: 13MHz

Span: 10kHz

RESBW:3kHz

No

No

RX Fault

Cobba (N800):

Load at Pin 19:

>1M Ohm?

Change Cobba

Yes

(N800)!

No

Technical Documentation

Check AFC line

for short circuits!

If OK, change Cobba

(N800)!

VCTCXO (G300):

Output frequency

exactly 13MHz?

No

Use Wintesla to set

AFC to MAX!

VCTCXO (G300):

AFC voltage: 2.3V?

Yes

VCTCXO (G300)

Main clock > 13MHz

No

No

Check R302,C305!

If OK, change Cobba

(N800)!

Change VCTCXO

(G300)!

Page 28

Issue 1 10/99

Page 29

PAMS

NME–3

Technical Documentation

Transmitter faults

The following chapter gives an overview of the principles helpful to hunt

errors in the transmit path of the radio unit. The best possibility to look for

the root cause of a transmitter malfunction is to track the transmit signal

through the transmitter path starting at the RF–BB interface to the antenna port.

The following settings should be done using Wintesla prior to the examination of the transmitter path:

– Set radio unit to local mode.

– Choose RF Controls from Wintesla menu.

– Set TX level to TEST.

– Set TX continuos mode.

– Set cont. mode channel 60.

The test signal can now be tracked from the TX–IQ inputs of the Plussa to

the antenna connector.

Note The transmitter should under no circumstances be operated in continuos mode on

any other then the TEST level. If a higher power level is needed for error hunting the

transmitter has to be switched to burst mode.

Troubleshooting

Issue 1 10/99

Page 29

Page 30

NME–3

PAMS

Troubleshooting

Transmitter Fault (1)

TX

FAULT

Plussa (N101) Pin 8:

–2dBm at 232MHz

Yes

Plussa (N101):

Pin 61,62:

–10dBm at 116 MHz

Yes

TXLEV: Test

No

No

Technical Documentation

VHFLO

C

CRFU1A (N200):

Pin 2.3:

–13dBm at 116 MHz

Yes

CRFU1A (N200):

Pin 13:

–10dBm at 1018MHz?

Yes

D

CRFU1A (N200);

No No

Check soldering of R201, R202, L203,

If OK, change defective components!

Load at pin 2,3,

> 1MOhm?

Yes

L203, L201, L202, C203!

UHFLO

No

Check CRFU1A (N200)

pin 2,3 for short circuits!

If OK, change N200!

Page 30

Issue 1 10/99

Page 31

PAMS

NME–3

Technical Documentation

Transmitter Fault (1a)

C

Plussa (N101):

TXQP,TXQN,TXIP,TXIN

okay?

Yes

Plussa (N101):

TXP pulse at Pin 1 OK?

Yes

No

No

Check TXQP,TXQN,TXIP,TXIN

lines from Cobba (N800, pin

13...16) and soldering at Plussa

(N101) and Cobba (N800)!

If OK, change Cobba (N800)!

Check TXP line from MAD (D600)!

Troubleshooting

Note:

For the steps described on this

page the transmitter should be

switched to burst mode!

Power level should be 2!

Plussa (N101):

Pin 63:

VTX pulse OK?

Yes

Plussa (N101):

Pin 11:

TXC pulse OK?

Yes

Plussa (N101):

Pin 58:

VREF: 1.5V DC?

Yes

Plussa (N101):

Pin 59:

load = 15 kOhm?

No

No

No

No

Check VTX supply voltage from

CCONT (N700)!

Check TXC line

from COBBA (N800)!

Check VREF line from

CCONT (N700)!

R125:Check soldering!

If soldering OK,

change component!

Plussa (N101):

Pin 61,62:

0.8V DC?

Issue 1 10/99

Yes

Change Plussa (N800)!

No

Page 31

Page 32

NME–3

PAMS

Troubleshooting

Transmitter Fault (1b)

D

CRFU1A (N200):

Pin 30:

–10dBm at 902 MHz

Yes

TX Fault 1

No

CRFU1A (N200):

Pin 1,29:

2.8V DC?

Yes

CRFU1A (N200):

Pin 16:

1.5V DC?

Technical Documentation

For the steps described on this

page the transmitter should be

switched back to continuos mode!

No

No

Note:

Check VTX supply voltage

from CCONT (N700)!

Check VREF

from CCONT (N700)!

Yes

CRFU1A (N200):

Pin 20:

load = 10kOhm?

Yes

Change CRFU1A (N200)!

No

R205: Check soldering!

If OK, change component!

Page 32

Issue 1 10/99

Page 33

PAMS

NME–3

Technical Documentation

Transmitter Fault (2)

TX Fault 1

TX Filter (Z250):

Input: 6 dBm?

Yes

No

V8PA supply

at C624 OK?

Yes

Check bias of V254:

Vbase =0.75V

Vcollector =5V

For the steps described on this

page the transmitter should be

switched to burst mode!

TX power level should be 2!

No

No

Note:

Check V8PA regulator (N400)

and switching circuit (V253,

S251) for soldering and defective

components!

Check passive components for sol-

dering and defective components!

Troubleshooting

PA (N254):

Input: 4 dBm?

Yes

PA (N254)

Output: 40 dBm?

Yes

E

No

No

Yes

V254: Check soldering!

If soldering okay, change

component!

TX FIlter (Z250):

Check for soldering

and short circuits!

If OK change TX Filter (Z254)!

PA (N254)

Pin 3: 12V DC?

Yes

PA (N254)

Pin 2: TXC Pulse?

Yes

Change P A module (N245)!

No

No

Check VPA connection!

Check C272, C273, C274, C275

for short circuits!

Change defective components!

Power

control

Issue 1 10/99

Page 33

Page 34

NME–3

PAMS

Troubleshooting

Transmitter Fault (2b)

E

Duplexer (Z100)

Output: 39 dBm?

Yes

Antenna port (X240)

Output: 39 dBm?

Yes

Ant connector (X240):

Check for soldering and short circuits!

If okay, change connector (X240)!

No

No

Technical Documentation

Check duplexer (Z100) for solder-

ing and short circuits!

If OK, change duplexer (Z100)!

(C135): Check soldering!

If OK, change component!

Page 34

Issue 1 10/99

Page 35

PAMS

NME–3

Technical Documentation

Transmitter Fault (3)

Power

control

Transmitter OK?

Yes

Plussa (N101):

Pin 11:

TXC pulse OK?

Yes

No

No No

TX Fault

Cobba (N800):

Pin 17

TXC pulse OK?

Yes

R110, R11 1:

Check for soldering

and short circuits!

If OK change defective components!

Troubleshooting

Note:

For the steps described on this

page the transmitter should be

switched to burst mode!

TX power level should be 2!

Check Cobba (N800)

for soldering and short circuits!

If OK, change Cobba (N800)!

Plussa (N101):

Pin 15:

TXC pulse OK?

Yes

OpAmp (N250):

Pin 5:

TXC pulse OK?

Yes

OpAmp (N250):

Pin 10:

LOOP = 2.8V?

Yes

OpAmp (N250):

Pin 8:

LOOP = 8V?

Yes

F

No

No

No

No

Plussa (N101):

Check for soldering

and short circuits!

If OK change Plussa (N101)!

R268, R270, R266, C259:

Check for soldering

If OK change defective component!

Check LOOP signal from

and short circuits!

MAD (D600) Pin 168!

OpAmp (N250):

Pin 9:

1.4V DC?

Yes

Check N250 and supply

(8V at pin 4) for soldering

and short circuits!

If OK, change N250!

No

Check R258, R252, C257, C256

for soldering and short circuits and

change defective components!

Issue 1 10/99

Page 35

Page 36

NME–3

PAMS

Troubleshooting

Transmitter Fault (4)

F

OpAmp (N250):

Pin 6: Picture 12?

Yes

No

Switch (N250):

Pin 1:

Picture 12?

Yes

OpAmp (N250):

Pin 6:

Picture 12?

Yes

Check N250 and supply

(8V at pin 4) for soldering

and short circuits!

If OK, change N250!

No

No

Technical Documentation

Check S250

for soldering and short circuits!

Change components if soldering is

okay!

Check R260, R256, R257, R250,

R255, C 254

for soldering and short circuits and

change defective components!

OpAmp (N250):

Pin 7: Picture 13?

Yes

OpAmp (N250):

Pin 3: Picture 14?

Yes

OpAmp (N250):

Pin 2: Picture 15?

Yes

OpAmp (N250):

Pin 1: Picture 16?

Yes

Check N250 and supply

(8V at pin 4) for soldering

and short circuits!

If OK, change N250!

No

No

No

No

Check N250 and supply

(8V at pin 4) for soldering

and short circuits!

If OK, change N250!

Check R263, R255

for soldering and short circuits and

change defective components!

Detector-

Fault

Check R261, C255

for soldering and short circuits and

change defective components!

Page 36

Issue 1 10/99

Page 37

PAMS

NME–3

Technical Documentation

Transmitter Fault (5)

Detector-

Fault

Diode (V252):

Pin 3: Picture 17?

Yes

Transistor (V251):

Base: Picture 18?

No

No

Transistor (V251)::

Emitter: 8V DC?

Yes

Check R272, R271, C261, R269

for short circuits and soldering!

Change defective components!

PA Module (N254):

Pin 2: 12V DC?

No

Troubleshooting

Check V8PA supply!

No

Check VPA supply!

Yes

Transistor (V251):

Collector: Fig 19?

Yes

Check V250, R253, R254

for short circuits and soldering!

Change defective components!

No

Yes

Check R264, R267, C260, R265,

R262, V252, R259, V261

for short circuits and soldering!

Change defective components!

Check V251

for short circuits and soldering!

Change defective components!

Issue 1 10/99

Page 37

Page 38

NME–3

PAMS

Troubleshooting

Clock Signals

Technical Documentation

Picture 1. COBBACLK – signal

Picture 2. 13 MHz Main clock – signal

Page 38

Issue 1 10/99

Page 39

PAMS

NME–3

Technical Documentation

Synthesizer Signals

Picture 3. SCLK – signal

Troubleshooting

Picture 4. SDATA – signal

Picture 5. SENA1 – signal

Issue 1 10/99

Page 39

Page 40

NME–3

PAMS

Troubleshooting

Transmitter Signals

Technical Documentation

Picture 6. TXQP, TXQN, TXIP and TXIN – signal

Picture 7. TXQP, TXQN, TXIP and TXIN – signal (single burst)

Page 40

Issue 1 10/99

Page 41

PAMS

NME–3

Technical Documentation

Troubleshooting

Picture 8. TXC – signal at Plussa Pin 5, Pin 15

Picture 9. VTX – signal

Issue 1 10/99

Page 41

Page 42

NME–3

PAMS

Troubleshooting

Technical Documentation

Picture 10. Vapc – signal (TXLEV2)

Picture 11. OPAMP (N250) Pin 5

Page 42

Issue 1 10/99

Page 43

PAMS

NME–3

Technical Documentation

Troubleshooting

Picture 12. OPAMP (N250) Pin 6

Picture 13. OPAMP (N250) Pin 7

Issue 1 10/99

Page 43

Page 44

NME–3

PAMS

Troubleshooting

Technical Documentation

Picture 14. OPAMP (N250) Pin 3

Picture 15. OPAMP (N250) Pin 2

Page 44

Issue 1 10/99

Page 45

PAMS

NME–3

Technical Documentation

Troubleshooting

Picture 16. OPAMP (N250) Pin 1

Picture 17. Signal at detector diode input

Issue 1 10/99

Page 45

Page 46

NME–3

PAMS

Troubleshooting

Technical Documentation

Picture 18. Signal V251 base

Picture 19. Signal V251 emitter

Page 46

Issue 1 10/99

Page 47

PAMS

NME–3

Technical Documentation

AMC not working

Switch on the phone, with no

load on the AMC ouput

AMC output

high ?

Yes

Add 150 Ohm Load

to AMC output

AMC output

high ?

No

Ask load from

Yes

costumer

check cableing

highlevel

on R458

Yes

Troubleshooting

No

Check D600

for shortcicuits or

open Joints

No

Check

C451, R455

R459 V453

Follow Levels in

AMC circuit

Figure 11. AMC not working

Issue 1 10/99

Page 47

Page 48

NME–3

PAMS

Troubleshooting

Car Radio Mute not working

Switch on the phone, make a call

with no load

on the CRM ouput

CRM output

low ?

Yes

Add 150 Ohm Load

to CRM output and 12V

CRM output

low ?

No

Ask load from

Yes

costumer

check cableing

highlevel

on R453

Yes

Technical Documentation

No

Check D600

for shortcicuits or

open Joints

No

Check

C450, R451

R454 V45

Follow Levels in

CRM circuit

Figure 12. CRM not working

Page 48

Issue 1 10/99

Page 49

PAMS

NME–3

Technical Documentation

Backlight dimming not working

Apply different Dutycycles

to BLD input

Inverted BLD

at R712 ?

DC Level at C729

follows dutycycle

Check circuit

No

before R712

No

Troubleshooting

Check BLD

circuit

Yes

Check N700 for

bad solderpoints

shortcircuits, or

change CCONT

Figure 13. Backlight dimming not working

Audio failure Handsetmode

Setup a call to a GSM–Tester

If uplink is broken use testbox to feed a audiosignal into the circuit, and

follow the signal to the COBBA.

If it is O.K. till here, check the PCM interface on PIN 49..52 of N800.

Check N800,D600 for broken solderjoints shortcircuits, or change compo-

nents

If downlink is broken send a testsignal from the GSM–Tester to phone

and follow the signal from COBBA till the Connector.

If no signal comes out of N800 check PCM interface and act as decribed

above.

Issue 1 10/99

Page 49

Page 50

NME–3

PAMS

Troubleshooting

If both links are broken, start the investigation on the N800 side as described

Audiofailure Handsfreemode

First steps:

Check that 8V DC are on the HF–Micinput, when no load is connected.

Check that a 4V DC Offset voltage is at the outputs are on N502

PIN 7, PIN8

If not check the Offset voltage generation (R522, N502 )

Check that a 4V DC Offset voltage is at the outputs of N501PIN 1, Pin 7

If not check the Offset voltage generation (R522, N502 )

If these checks are passed make a call to the CMD 55.

Technical Documentation

If there is an uplink failure, feed a signal into the HF–Microphone input,

and follow the signal to N800.

If it is O.k. check N800, D600 and the PCM interface

If there is a downlink failure, send a audio signal from the tester to the

phone, and follow the signal from the Cobba to the outputs for Lineout

and HF speaker.

If no signal comes out of N800 check N800, D600 and the PCM interface

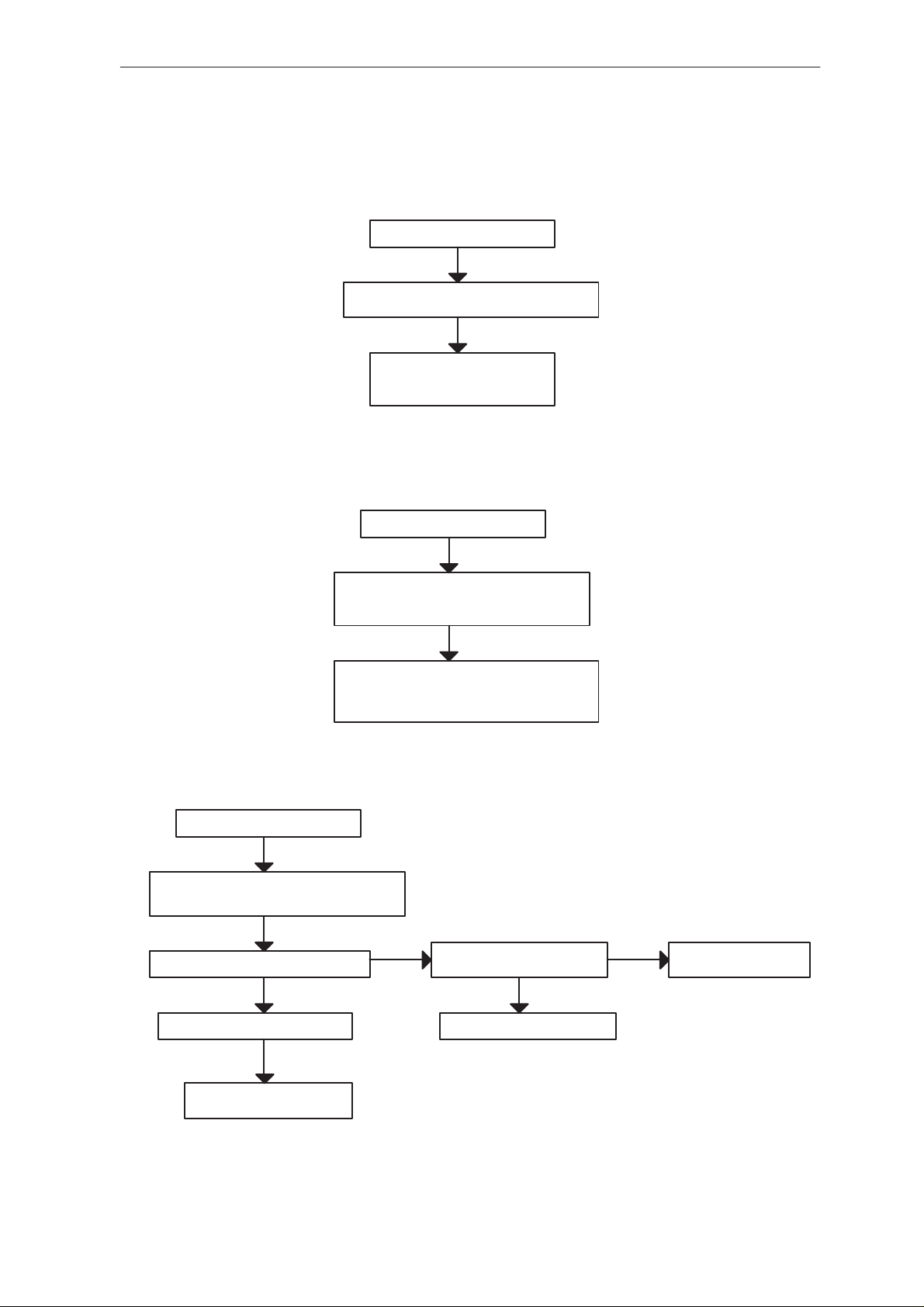

Failure in Data interface

Put the data loopback adapter to the D9 connector and use Win–tesla to

control the RS232 outputpins and read the RS232–Inputs.

Page 50

Issue 1 10/99

Page 51

PAMS

NME–3

Technical Documentation

Pin 26 N650

2.8V ?

Yes

Pin 4 N650

–5V ?

Yes

Pin 27 N650

+5V ?

Troubleshooting

No

Check Z650

No

Check Chargepump

C650..C653, N650

No

Yes

Use Wintesla and Loopbackadapter to set the status of every loop

On and Off. Follow every signal

from the Madoutput to the connector and back from the connector to

the MADinput

Figure 14. Failure in RS232 interface

Issue 1 10/99

Page 51

Page 52

NME–3

PAMS

Troubleshooting

SIM–Card not recognized

Disconnect SIM from

phone, connect probe to

C750

2.8V at

No

C750

Yes

Press SIM.

switch

Yes

0V at

C750

Technical Documentation

Check R751, check C750 and

X750 for Shortcircuits

Check contact of

No

SIM–Reader check

switch

Yes

Put Simcard on Simreader

using Simadapter

SIM

No

recognized ?

Yes

Follow instructions

described in Figure 10

Figure 15.

Put insulated wire to C750,

assemble Bottomenclossure, repeat test using big

SIM–Card to close switch

Page 52

Issue 1 10/99

Page 53

PAMS

NME–3

Technical Documentation

The hardware of the SIM interface from MAD2 (D600) to the SIM connector (X750) can be tested without the SIM card.

You have to close the SIM–Switch by using the SIMCard adapter with a

SIM–Card. When the power is switched on, the Sim interface is started

once at 3V and once at 5V. Check with a storage osciloscope, that

VSIM,RSTand DATA rise up to 3V and 5V for some short time, and that

there is 3V/5V Clocksignal on the Clock Pin. To Trace the signals you

should switch the phone on and off several times.

Thus ”Insert SIM card” faults can be found without SIM card.

The fault information ”Card rejected” means that ATR message (the first

message is always sent from card to phone) is sent from card to phone

but the message is somehow corrupted, data signal levels are wrong etc.

or factory set values (stored to the EEPROM) are not correct.

Troubleshooting

Issue 1 10/99

Page 53

Page 54

NME–3

PAMS

Troubleshooting

SIM Card failure

VSIM(36), DATAO(43),SIMRSTO(42) and SIMCLKO(38) lines

rises up to 3/5 V after power on at pins of N100 (CCONT)

SIMPWR(30), DATAA(44), SIMRST A(40), SIMCLK(41) and SIMIOC(39) lines

Insert SIM card fault

YES

Voltage level < 1.5 V

NO

at pin 95 of D600 when

YES

VSIM, DATA, RESET and CLOCK lines

rises up to 3/5 V after power on at pins

Check

R751,C750,X750

YES

of SIM card

NO

YES

NO

rises up to 2.8 V after power on at pins of N700 (CCONT)

NO

Technical Documentation

Check

SIM card and SIM reader

connectors

Check

X750, R709, R710, C730

C731, V703

YES

faulty circuit

N700 (CCONT)

SIMCardPwr(129), SIMCardData(120), SIMCardRstX(127), SIMCardClk(126) and SIMCardIOC(128) lines

rises up to 2.8 V after power on at pins of D600 (MAD2)

NO

Check again that voltage level at pin 95 (SIMCardDetX) of D600 is lower than 1.5V

If it is, change D600

Card Rejected fault

YES

VSIM is according the specification

VSIM = 2.8 V min (with 3 V SIM card)

NO

faulty circuit

N700 (CCONT)

VSIM = 4.5 V min (with 5 V SIM card)

YES

The ATR data can be seen at pin 43

(CCONT, N700)

YES

The ATR data can be seen at pin 120

(MAD2, D600)

YES

SIMIOControl line (N700 pin 36) is ”1”

during the ATR message

NO

NO

NO

Check

X750, R710

Check

N700

Check

D600

YES

faulty PCB

Page 54

YES

Check D600

Issue 1 10/99

Page 55

PAMS

NME–3

Technical Documentation

2 Handset failures

This section describes faults by active components and trace defects,

serial resistances, interconnections etc..

When you get a defective HS then first connect the HS to 8V and check if

the Nokia hands are shown in the display. In this case you can be sure

that main parts of the HS are running (MCU and oscillator, 5V and 3V

power supply, reset circuit, LCD circuit), if not go to section 3.1.

If no further information is shown on the LCD when connected to the reference RU, then there is a problem with the HS MBUS circuit, goto section 3.2.

When there is some further information on the LCD when connected to

the reference RU you can be sure that the MBUS circuit is working and

you can go to other failures like

1. Audio failure

2. LCD failure

Troubleshooting

3. Sim Interface failure

4. Keypad failure

5. Backlight dimming failure

6. Hall sensor failure

7. Power key failure

These are described separately at the end of the section

Issue 1 10/99

Page 55

Page 56

NME–3

PAMS

Troubleshooting

HS general fault

HS general

fault

8V supply ok?

Limits 7.5V – 8.0V

C106

Yes

5V supply ok?

Limits 4.8–5.2V

C113

Yes

No

No

Check Curly–Cord

Check V100

Yes

Check N100

Technical Documentation

No

Change V100

No

Change N100

3V supply ok?

Limits 2.8–3.2V

C124

Yes

Measure Pin 3 /

N101 if High

Limits 4.5–5.0V

Yes

Measure Pin 4 /

N102 if High

Limits 4.8–5.0V

No

No

No

Change N103

Measure Pin 2 /

N101 if Low

Limits 0–0.5V

Yes

Change N101

Change N102

No

Change V101

Next Page

Page 56

Issue 1 10/99

Page 57

PAMS

NME–3

Technical Documentation

Continue

Yes

Check oscillator

Pin 77 / D300

Scope 14.6–14.8 MHz

Yes

Check RAM D301

connections to MCU

Yes

Troubleshooting

No

Change crystal B300

No

Change RAM D301

Change MCU D300

Issue 1 10/99

Page 57

Page 58

NME–3

PAMS

Troubleshooting

MBUS fault

Connect the Handset to a Radiounit and switch on the equipment. Between the MBUS messages are times without datatransfer consider these

measurements.

MBUS fault

Yes

Check MBUS communicatiom

at R302

Yes

Check MBUS communication

at R307

No

No

Change Curly–Cord

Change V300

Technical Documentation

Receive–Path and

Transmit–Path

Receive–Path

Yes

Check MBUS communication

Check MBUS communication

at R305

Yes

at R305 and R302

parallel

Yes

Change MCU D300

No

No

Change MCU D300

Change V301

Transmit–Path

Transmit–Path

Page 58

Issue 1 10/99

Page 59

PAMS

NME–3

Technical Documentation

Audio fault

1 Microphone path fault

For checking the microphone path connect the handset to an radiounit

and connect this equipment to an power supply and an CMD55. Set the

CMD55 for audio in the echomode and make a speech test.

With a microphone path fault the first step is to check the microphone,

therefore change the complete microphone and boot and then check the

microphone path again.

If it doesn‘t work check the complete microphone amplifier stage.

Micamp fault

Yes

Check 2.5V supply

at L202

Limits 2.3–2.7V

No

Troubleshooting

Change N201

Yes

Sinus at the

input T207/208

uin=30mVRMS

Check signal at C235/253

u=21mVRMS

+/–3dB

Yes

Sinus at the

input T207/208

Check signal at R218/R229

u=790mVRMS

+/–3dB

Yes

Sinus at the

input T207/208

Check signal at Pin 8/9 X1

u=790mVRMS

+/–3dB

Yes

Change Curly–Cord

No

Check the input path

No

Change OP N202

No

Check the output path

Issue 1 10/99

Page 59

Page 60

NME–3

PAMS

Troubleshooting

Earpiece path fault

For checking the earpiece path connect the handset to an radiounit and

connect this equipment to an powersupply and an CMD55. Set the

CMD55 for audio in the echomode and make a speech test.

With an earpiece path fault the first step is to check the earpiece resistance is between 26 and 36 ohms. If not then change the complete B–cover with earpiece. Then check the earpiece path again.

Earamp fault

Yes

Sinus at the

Wetern–Plug Pin 5/6

Check Pin 5/6 X1

uin=500mVRMS

Yes

Technical Documentation

No

Change Curly–Cord

Sinus at the

Wetern–Plug Pin 5/6

Check signal at C201/C220

u=500mVRMS

+/–2dB

Yes

Sinus at the

Wetern–Plug Pin 5/6

Check signal at Pin 5/8 N200

u=2000mVRMS

+/–2dB

Yes

Sinus at the

Wetern–Plug Pin 5/6

Check signal at X200

u=500mVRMS

+/–2dB

No

Check the input path

No

Change N200

No

Check the output path

Page 60

Issue 1 10/99

Page 61

PAMS

NME–3

Technical Documentation

LCD fault

If there is an LCD fault first check what kind of failure it is. If there are

missing lines or rows, missing pixels or permanently on pixels you have to

change the LCD module, because these failures are related to the module itself.

When you connect the HS to 8V power supply and there are no Nokia

Hands on the display you have to perform the following steps.

LCD fault

Troubleshooting

Nokia Hands ok?

SIM interface fault

For testing of the SIM interface use the Wintesla and also the HCI functions of the Handset. You can use these functions to switch on the 3V and

5V power supply for the SIM interface and to set the SIM_CLK and

SIM_data line to low and high level.

If you don‘t have the possibility to set the HCI functions (R&D software)

you can only test the functionality of the SIM–door switch by WinTesla

and the general power supply for the SIM card.

No

Check SCLK at pin 2 and

SDIN at pin 4 of D401

Yes

Check SCLK at pin 18 and

SDIN at pin 16 of D401

No

No

Change MCU (D300)

Change D401

When you get a Handset with SIM failure first connect it to an RU and put

in a Test–SIM, to check if SIM switch is working. If SIM card is not recognized the failure is related to the SIM switch, otherwise to the rest of the

SIM interface.

Before error hunting also check the mechanics of the SIM reader and the

SIM door for damage or dirt on the contacts. After this goto the following

procedure.

Issue 1 10/99

Page 61

Page 62

NME–3

PAMS

Troubleshooting

SIM fault

Check 3V power

supply at C401 (lim-

its 2.8V to 3.2V)

Yes

No

Check 3V power supply at

C400 (limits 2.8V to 3.2V)

Yes

Check voltage of gate V401

limits 0V to 0.5V

Yes

No

No

Technical Documentation

Check voltage at basis of

V400 (limits 0V to 0.5V)

for 3V

Yes

Change V400

Change MCU D300

Check 5V power

supply at C400 (lim-

its 4.8V to 5.2V)

Yes

Change D400

By no reaction

Change MCU D300

No

Change V401

Check voltage at basis of

V400 (limits 0V to 0.5V)

for 5V

Yes

Change V400

No

Change MCU D300

Page 62

Issue 1 10/99

Page 63

PAMS

NME–3

Technical Documentation

Keypad fault

First check with WINTESLA which keys are not working. Then change

keymat and repeat test. If anything is ok keymat was defective otherwise

check connections from MCU to keypad matrix.

If all connections are ok check diodes and pullup resistors for keypress

interrupt. If ok change the MCU (D300).

BLD fault

First check which kind of failure you have, is complete keypad and/or

LCD illumination not working or only a part of the illumination not working.

If complete keypad illumination is not working measure voltage at base

(Pin2/V422). If voltage is approximately 4.4V then change V422, if not

change MCU D300.

If complete LCD illumination is not working measure voltage at base

(Pin2/V423). If voltage is approximately 4.4V then change V423, if not

change MCU D300.

Troubleshooting

If only one part of the keypad or LCD illumination is not working check the

3 diodes of the common part.

Hall sensor fault

For checking the hall sensor connect the handset to an radiounit and connect this equipment to an powersupply and an CMD55. Setup a call. Then

check the handset and the handsfree mode via the cradle. If the audio

switch handset/handsfree is working then change the cradle.Also check

the level at the hallsensor output N400 is low when the handset is in the

cradle. If not change the hallsensor. Is the hallsensor working then

change the MCU D300.

Power key fault

When the power key is not working first check the curly cord. If curly cord

is ok change power key button else check the passive hardware circuit.

Issue 1 10/99

Page 63

Loading...

Loading...