Page 1

Nokia Customer Care

6(b) - RF Troubleshooting

Instructions

Issue 1 03/2005 COMPANY CONFIDENTIAL

Copyright © 2005 Nokia. All Rights Reserved.

Page 2

RM-31

Nokia Customer Care 6(b) - RF Troubleshooting Instructions

This page has been intentionally left blank.

2 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 3

RM-31

6(b) RF Troubleshooting Nokia Customer Care

Table of Contents

Page No

General Information on RF Troubleshooting ................................................... 5

Test environment ............................................................................................... 5

Test conditions................................................................................................... 5

Receiver Verification and Troubleshooting...................................................... 7

General instructions for RX troubleshooting ...................................................... 7

Measuring RX I/Q signals using RSSI reading .................................................. 7

Measuring RX performance using SNR measurement .................................... 8

Measuring front-end power levels using spectrum analyzer .......................... 10

Measuring analogue RX I/Q signals using oscilloscope ................................ 10

Fault finding chart of the receiver..................................................................... 11

Transmitter ........................................................................................................ 18

General instructions for TX troubleshooting..................................................... 18

GSM850 transmitter......................................................................................... 18

General instructions for GSM850 TX troubleshooting ................................... 18

Fault finding chart for GSM850 transmitter .................................................... 20

GSM1800 transmitter....................................................................................... 22

General instructions for GSM1800 TX troubleshooting ................................. 22

Fault finding chart for GSM1800 transmitter .................................................. 24

GSM1900 transmitter....................................................................................... 26

General instructions for GSM1900 TX troubleshooting ................................. 26

Fault finding chart for GSM1900 transmitter .................................................. 28

Synthesizer ........................................................................................................ 31

General instructions for synthesizer troubleshooting ....................................... 31

Checking synthesizer operation....................................................................... 31

Fault finding chart for PLL synthesizer............................................................. 34

Frequency tables ............................................................................................. 36

GSM850 ......................................................................................................... 36

GSM1800 ....................................................................................................... 37

GSM1900 ....................................................................................................... 38

DC Supply Voltage Check ................................................................................ 39

Receiver test points ......................................................................................... 42

Transmitter test points ..................................................................................... 44

Synthesizer test points..................................................................................... 47

Issue 1 03/2005 COMPANY CONFIDENTIAL 3

Copyright © 2005 Nokia. All Rights Reserved.

Page 4

RM-31

Nokia Customer Care 6(b) RF Troubleshooting

This page has been intentionally left blank.

4 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 5

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

General Information on RF Troubleshooting

Notes:

Several bills of material (BOM): There are two different kinds of VCOs, VCTXOs, RF-PAs, SAWfilters and Antenna Switches (ASM) assembled. They may only be replaced with the same type

as the original component (from the same manufacturer).

Phoenix version: In this document there are example measurements being depicted with pictures of AMS-Phoenix, version A 2004.06.1.69. In later versions pictures of menus and windows

may look differently.

Layout version: The drawings of test points and component placement in this version of the document are taken from build B4.0 layout (1gqa_41a). If you use the document for newer layout

versions, make sure to use the corresponding assembly and test point drawings.

■ Test environment

It is assumed, that the phones are disassembled and tested with a repair jig MJ-22R.

The following measurements have to be done for repairing the phone boards:

• RF measurements shall be done using a spectrum analyzer together with a highfrequency probe. Note that the signal will be significantly attenuated. Correct attenuation can be checked using a “good” phone board for example.

• LF (low frequency) and DC measurements shall be carried out with an oscillo-

scope together with a 10:1 probe.

• For receiver measurements, a signal generator specified for frequencies up to

2000 MHz is required. The signal generator is connected to the antenna port of the

repair jig.

Most of the radio communication testers, like CMU200, can be used as a signal generator, but make sure to have a continuous (CW) signal without modulation for alignment purposes.

• Transmitter output level measurements shall be done with a power meter

which is connected to the antenna port of the repair jig.

Always make sure that the measurement set-up is calibrated when measuring RF parameters

at the antenna port. Remember to put the correct losses of the module repair jig and the connecting cable in Phoenix or in the set-up programs of the RF generators when realigning the

phone.

Apart from key-components described in this document, there are a lot of discrete components

(resistors, inductors and capacitors) for which troubleshooting has to be done by checking its

proper soldering and complete assembly on the PWB. Capacitors and resistors can be

checked by means of an ohm-meter, but be aware in-circuit measurements should be evaluated carefully.

■ Test conditions

Rx tuning of the 26 MHz reference oscillator (VCTCXO) is temperature sensitive because

of the estimations of <AFC_value> and <AFC_slope>. According to the Production Test Specification DCS02294-EN-0.5, the ambient temperature has to be within a temperature range of

22°C to 28°C.

Issue 1 03/2005 COMPANY CONFIDENTIAL 5

Copyright © 2005 Nokia. All Rights Reserved.

Page 6

RM-31

Nokia Customer Care 6(b) - RF Troubleshooting

Most RF semiconductors are static discharge sensitive. ESD protection must be taken into

account during repair (ground straps and ESD soldering irons).

The RF ASIC Helgo is moisture sensitive. Therefore, the ASIC must be pre-baked prior to

soldering.

6 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 7

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

Receiver Verification and Troubleshooting

■ General instructions for RX troubleshooting

Connect the phone to a PC, which has Phoenix Service Software and a dongle installed, using

either

• repair jig and DAU-9S (RS232) cable or

• repair jig and XCS-4 cable via FPS-8 Flash Box or

• DAU-9T cable (RS232).

Connect the phone to a power supply (DC voltage: 3.6V, max. current: 3A) and an RF signal

generator. Switch the phone on.

Start Phoenix Service Software and open FBUS connection.

Select Scan Product Ctrl-R

and wait until the phone information (RM-31) is shown in the lower right corner of the screen.

Follow the instructions below.

■ Measuring RX I/Q signals using RSSI reading

Start Phoenix Service Software and open FBUS connection.

Select Scan Product Ctrl-R

Wait until the phone information is shown in the lower right corner of the screen.

Set the operating mode to local mode

Select Testing T

RF Controls F

Select Band GSM850 or GSM1800 or GSM1900

Active unit RX

Operation mode Burst

RX/TX Channel 190 or 700 or 661

Select Testing T

RSSI reading

In the RSSI Reading window, the <measuring mode> shall be set on Sum vector and the

<reading mode> on Continuous.

The set up should now look like this:

Issue 1 03/2005 COMPANY CONFIDENTIAL 7

Copyright © 2005 Nokia. All Rights Reserved.

R

Page 8

RM-31

Nokia Customer Care 6(b) - RF Troubleshooting

(The example below shows a screen shot in GSM900!)

Make the following settings on your signal generator:

Frequencies:

• GSM850: 881.66771 MHz (channel 190 + 67.710 kHz offset)

• GSM1800: 842.86771 MHz (channel 700 + 67.710 kHz offset)

• GSM1900: 1960.06771 MHz (channel 661+ 67.710 kHz offset)

RF power level:

• – 80 dBm @ the antenna connector of the phone/ test jig

(remembering to compensate for the cable and jig attenuation).

Click on <Read now> in RSSI reading.

The resulting RSSI level shall be – 80 dBm +/– 0.5 dB in each band.

Measuring RX performance using SNR measurement

Start Phoenix Service Software and open FBUS connection.

Select Scan Product Ctrl-R

Wait until the phone information is shown in the lower right corner of the screen.

Set operating mode to <local mode>.

Select Testing T

RF Controls F

Select Band GSM850 or GSM1800 or GSM1900

Active unit RX

8 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 9

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

Operation mode Burst

RX/TX Channel 190 or 700 or 661

Select Testing T

SNR Measurement M

Select Measuring mode Fast SNR (Radio Button)

Press Start

The window <Signal Measurement> pops up informing on frequency and power level of the

signal generator to be set. Follow the command <Turn ON the RF generator>.

Press <ok> and the window will close.

Read the SNR result from the window SNR Measurement. The value shall exceed:

• GSM850: > 20 dB

• GSM1800: > 18 dB

• GSM1900: > 18 dB

The set up should now look like this:

(The example below shows a screen shot in GSM900!)

Choose the remaining GSM bands and measure accordingly the procedure described above.

Issue 1 03/2005 COMPANY CONFIDENTIAL 9

Copyright © 2005 Nokia. All Rights Reserved.

Page 10

RM-31

Nokia Customer Care 6(b) - RF Troubleshooting

Measuring front-end power levels using spectrum analyzer

Spectrum analyzer (SA) level values depend on the probe type and shall be verified by a properly working phone sample. The levels that are given in this document are measured with a resistive probe (50 Ohm semi-rigid cable).

Start Phoenix Service Software and open FBUS connection.

Select Scan Product Ctrl-R

Wait until the phone information is shown in the lower right corner of the screen.

Set <operating mode> to <local mode>.

Select Testing T

RF Controls F

Select Band GSM850 or GSM1800 or GSM1900

Active unit RX

Operation mode Continuous

RX/TX Channel 190 or 700 or 661

Please refer to the fault finding chart and Appendix for proper levels at different test points.

Measuring analogue RX I/Q signals using oscilloscope

Measuring with an oscilloscope RX I and RX Q signals on the test points <RXI> respectively

<RXQ> is recommended only if the RSSI reading does not provide enough information. Input

level = -60dBm.

Start Phoenix Service Software and open FBUS connection.

Select Scan Product Ctrl-R

Wait until phone information is shown in the lower right corner of the screen.

Set operating mode to <local mode>.

Select Testing T

RF Controls F

Wait until the RF Controls

window pops up.

Select Band GSM850 or GSM1800 or GSM1900

Active unit RX

Operation mode Continuous

RX/TX Channel 190 or 700 or 661

AGC 10

10 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 11

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

The following picture should be displayed on an oscilloscope's screen if the receiver is working

properly:

Signal amplitude 1.40Vpp

DC offset ª 1.28V as the offset is floating, switch to the operating mode

<Burst> in Phoenix and read the DC offset

Frequency 67kHz

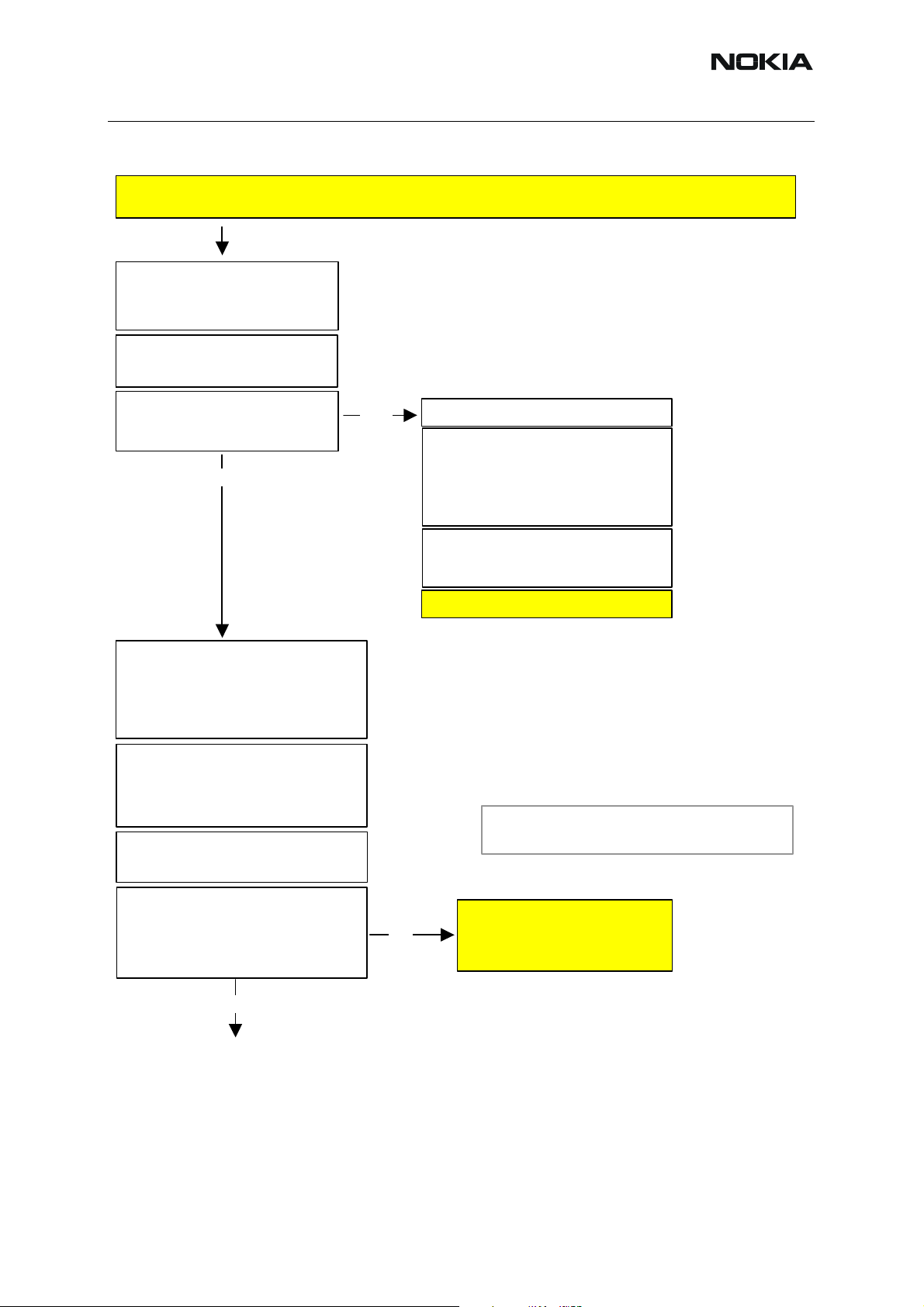

■ Fault finding chart of the receiver

During fault finding, the calibration procedure is used to find out, whether all bands are affected

(error in common part of the Rx chain) or only one band (error in a Rx part of the failed band).

Take care not to save calibration values to the phone memory, which are out of limits.

Find the error first and repair it.

When a defective phone has been calibrated, a possible error in RX front-end might be

masked. In that case, one can get a reasonable RSSI reading, although the front-end shows

excessive losses. If it is not sure that incorrect re-calibration has been made, following steps

shall be carried out:

• Check if AGC calibration is within limits.

• Check if SNR reading is o.k.

Use an oscilloscope to check levels of “RXI” and “RXQ”.

The RF ASIC generates only single ended I and Q signals (RXI, RXQ). As the A/D converter

in UEM requires two differential signals, an artificial mid voltage is generated from VrefRF02.

The phone layout has dedicated test points for the analogue RX I and Q signals (J512, J513).

Issue 1 03/2005 COMPANY CONFIDENTIAL 11

Copyright © 2005 Nokia. All Rights Reserved.

Page 12

RM-31

Nokia Customer Care 6(b) - RF Troubleshooting

The BB part is used to measure those signals by means of RSSI reading. This works only if

correct calibration has been carried out in production.

RSSIreading [dBm] = 20log(U

BB/ULSB

) - AGC

calibrated

In order to check the levels and frequencies of RF signals, the following probe can be used

(note that only the core lead contacts the test point, the shielding of the coaxial cable does not

contact GND during the measurement):

Connect this probe via a coaxial cable and a DC block to a spectrum analyzer. The DC block

is important to protect the spectrum analyzer from DC levels, which superpose the RF signal

at several test points.

If both RX and TX path seem to be faulty, it has to be checked if the synthesizer is working.

12 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 13

RM-31

A

A

A

6(b) - RF Troubleshooting Nokia Customer Care

Phoenix:

Phone: local mode

Open

Signal Generator:

Phoenix:

Open

Check RSSI Level = -80dBm

Execute Rx Calibration in selected

band, refer to chapter 9.2.1

re calibration results within limits?

Make sure that

Synthesizer is working

Yes

All 3 bands

RF Controls

Active Unit: Rx

Op. Mode: Burst

Rx/Tx channel: default (mid)

Level: –80dBm

Frequency: calculated from

Phoenix + 67.71kHz

RSSI reading

No

:

see

No

Yes next bandNo

Synthesizer Fault

Finding Tree

Yes

Selected band is working and

calibrated.

re all 3 bands measured?

Yes

Rx chain is functional

and calibrated

Receiver

Fault Finding Tree

part 1

= To be done in all

three bands.

No

re all 3 bands measured?

Yes

Are all 3 bands defective?

Yes

Oscilloscope:

Check supply voltages of RF ASIC:

VR4 = 2.8V ? (TP: VR4)

Yes

Oscilloscope:

Check supply voltages of RF ASIC:

VR6 = 2.8V ? (TP:VR6)

Yes

No

No

Continue with single

band fault finding.

No

No

Check supply filter

components (C2233,

C7519, C7520) and UEM

Check supply filter

components (C2231,

C7521) and UEM

Receiver

Fault Finding Tree

part 2

Receiver

Fault Finding Tree

part 3

Issue 1 03/2005 COMPANY CONFIDENTIAL 13

Copyright © 2005 Nokia. All Rights Reserved.

Page 14

RM-31

r

Nokia Customer Care 6(b) - RF Troubleshooting

Oscilloscope:

Check reference voltages of RF part:

VrefRF01 = 1.35V ?

(TP: VrefRF01*)

Yes

No

Check supply filter

components (R7511,

C7524) and UEM

Receiver

Fault Finding Tree

part 4

Oscilloscope:

Check reference voltages of RF part:

VrefRF02 = 1.35V ?

(TPs: VrefRF02* and VrefRF02**)

Yes

Phoenix:

Phone: local mode

RF Controls

Active Unit: Rx

Op. Mode:

Rx/Tx channel: default (mid)

AGC: 14

:

Continuous

Signal Generator:

To be tuned that input power at spectrum

analyzer: –60dBm

(power at probe:

Frequency: calculated from Phoenix

offset: 67.71kHz

= approx. -63 dBm)

Pref

Spectrum Analyzer: 1)

Check Rx/Tx Switch (Diplexer)

Depending on selected band, check level at TPs:

850

GSM900 output Rx1 Pref -1.5dB ?

GSM1800 output Rx2 Pref -2.0dB ?

GSM1900 output Rx3 Pref -2.5dB

Yes

Check supply filter

No

components (R2900,

R2901, C2900, C2901)

and UEM

Receive

Fault Finding Tree

part 5

No

?

Change Z7800

Note 1):

RF levels are dependent on RF probe and have to be validated

with a known good sample.

Oscilloscope:

RX IQ levels ok (TPs: RXI, RXQ) ?

Yes

Oscilloscope:

RF-BB serial interface ok?

(TPs: RFBusData, RFBusClk, RFBusEna1)

No

No

Yes

Change RF

ASIC (Helgo)

BB error:

Check UPP

Change RF

ASIC (Helgo)

Receiver

Fault Finding Tree

part 6

14 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 15

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

Select faulty band in Phoenix and continue measurements on dedicated Rx part.

Phoenix:

SNR Measurement

open

Meas. Mode: Fast SNR

Measure

Press

Signal Generator:

Level: –92dBm

Frequency: calculated from Phoenix

Phoenix:

SNR measurement ok?

(SNR > 18.37dB)?

Phoenix:

Phone: local mode

RF Controls

Active Unit: Rx

Op. Mode:

Rx/Tx channel: default (mid)

AGC: 14

.

No

:

Continuous

Single band fault finding

Receiver

Fault Finding Tree

part 7

Yes

Front end is ok.

Phoenix:

Phone: local mode

RF Controls

Active Unit: Rx

Op. Mode:

Rx/Tx channel: default (mid)

AGC: 10

:

Continuous

Signal Generator:

Level: –60dBm

Frequency: calculated from Phoenix

offset: 67.71kHz

Continue with Rx Fault Finding part 6.

Receiver

Fault Finding Tree

part 8

Signal Generator:

To be tuned that input power at spectrum

analyser: –60dBm

power at probe:

Frequency: calculated from Phoenix

offset: 67.71kHz

=approx. -63dBm)

Pref

Spectrum Analyzer: 1)

Center Freq: calculated from Phoenix

RBW 20kHz

Check Rx SAW filter and matching

network of selected band:

GSM900 TPs: INM_G_RX / INP_G_RX

GSM850

both output levels > Pref -3.5dB ?

GSM1800 TPs: INM_D_RX / INP_D_RX

both output levels > Pref -6dB ?

Yes

No

Note 1):

RF levels are dependent on RF probe and have to be validated

with a known good sample.

Change Rx SAW filters (Z7802,

Z7803) or component(s) of

matching network depending on

selected band

Issue 1 03/2005 COMPANY CONFIDENTIAL 15

Copyright © 2005 Nokia. All Rights Reserved.

Page 16

RM-31

g

1)

Nokia Customer Care 6(b) - RF Troubleshooting

If selected band = GSM1900

Spectrum Analyzer:

Check SAW filter Z7801:

TP: OUT-Z7801

Output signal > Pref - 3.5dB

No

Spectrum Analyzer:

Check external LNA V7800:

TP: OUT-V7800

Output signal > Pref +14dB

Spectrum Analyzer:

Check balun T7800 and matching network:

TPs: INM_P_RX / INP_P_RX

Both output signals > Pref +12dB

RF ASIC N7500 seems to be

defective. Exchange N7500.

Yes

Yes

Yes

Yes

No

Yes

1)

No

1)

Oscilloscope:

Check voltages for V7800:

No

Voltage at C7802 = 2.5V ?

e at C7800 = 0V ?

Volta

Receiver

Fault Finding Tree

part 9

Change Z7801

Check supply

No

around V7800

filter components

and RF ASIC

Yes

No

Note 1):

RF levels are dependent on RF probe and have to be validated

with a known good sample.

Change T7800

16 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 17

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

Make sure that Synthesizer is

working and supply voltages of

RF ASIC are ok

Phoenix:

Phone: local mode

RF Controls

Active Unit: Rx

Op. Mode:

Rx/Tx channel: default (mid)

AGC: 14

:

Burst

Continue measurement only when channel select filter calibration failed

Channel select filter fault finding

Receiver

Fault Finding Tree

part 10

Signal Generator:

Level: –60dBm

Frequency: 942.4MHz

Offset: 67.71kHz

Oscilloscope:

RF-BB filter signals ok?

TPs: CM_F_Q & CM_F_I

CM_DTOS_Q & CM_DTOS_I

Yes

Repair finished

No

Re-solder capacitor array C7523

Re-calibrate

Channel Select Filter

Calibration ok ?

NoYes

Change RF

ASIC (Helgo)

Make following tunings/calibrations

Tx power l evel tuning

x

Tx IQ tuning

x

x Rx calibration

Rx Band Filter Response Calib.

x

Issue 1 03/2005 COMPANY CONFIDENTIAL 17

Copyright © 2005 Nokia. All Rights Reserved.

Page 18

RM-31

Nokia Customer Care 6(b) - RF Troubleshooting

Transmitter

■ General instructions for TX troubleshooting

Connect the phone to a PC, which has Phoenix Service Software and a dongle installed, using

either

• repair jig and DAU-9S (RS232) cable or

• repair jig and XCS-4 cable via FPS-8 Flash Box or

• DAU-9T cable (RS232)

Connect the phone to a power supply (DC voltage of 3.6V) and switch the phone on. The value

of the DC voltage of 3.6V at the phone battery connector is crucial.

Connect an RF cable between the test jig and the measurement equipment (GSM test equipment, power meter, spectrum analyzer, or similar).

Make use of an adequate attenuator at the input of your measurement equipment (10dB to

20dB are recommended for a spectrum analyzer or a power meter). Additionally, a DC block is

recommended. Assure not to overload or destroy the equipment.

It is strongly recommended to use TXP as external trigger for all TX tunings. External triggering

gives the following advantages:

• trigger for spectrum analyzer (gated sweep)

• trigger for oscilloscope

• trigger for power meter (avoid exchanging of attenuator and getting better accuracy in power measurements)

Start Phoenix Service Software and open FBUS connection:

Select Scan Product Ctrl-R

and wait until the phone information is shown in the lower right corner of the screen.

Follow the instructions in the chapters below.

■ GSM850 transmitter

The GSM850 chapters apply only for RM-31 (US variant).

General instructions for GSM850 TX troubleshooting

Start the preparations as described in chapter “General instructions for TX troubleshooting”.

GMSK

Set operating mode to local mode.

Select Testing RF Controls

Wait until the RF Controls window pops up

Select Band GSM850

18 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 19

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

Active unit TX

Operation mode Burst

RX/TX Channel 190

TX Power Level 10

TX Data Type Random

Edge Off

The setup should now look like this:

Now the measurement equipment should detect the following output signal of the phone:

P

= +23dBm @ 836.6 MHz

out

If this is not the case, go to the GMSK fault finding chart for the GSM850 transmitter.

EDGE

Set operating mode to local mode.

Select Testing RF Controls

Wait until the RF Controls window pops up.

Select Band GSM850

Active unit TX

Operation mode Burst

RX/TX Channel 190

Issue 1 03/2005 COMPANY CONFIDENTIAL 19

Copyright © 2005 Nokia. All Rights Reserved.

Page 20

RM-31

Nokia Customer Care 6(b) - RF Troubleshooting

TX Power Level 10

TX Data Type All1

Edge On

The setup should now look like this:

Now the measurement equipment should detect the following output signal of the phone:

= +24.5 dBm @ 836.6 MHz

P

out

If this is not the case, go to the EDGE fault finding chart for GSM850 transmitter.

Fault finding chart for GSM850 transmitter

In the following, it is assumed that the TXP signal is used as trigger signal. For that, a TXP test

point is provided.

20 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 21

RM-31

836.6Mh

836.6Mh

6(b) - RF Troubleshooting Nokia Customer Care

GMSK

Use Phoenix to select

TX_Data Type: Random

TX Power Level: 10

Ch190

Ch37

Ensure Vbatt=3.6 V

Yes

Oscilloscope

C7711

R7511

C7512

TXP testpoint

C7517

R7516

Yes

Oscilloscope

C7529

C7529

C7530

C7530

Yes

Oscilloscope

C7701

VC1

VC2

VC3

R7713

Yes

Spectrum analyzer No Check

Z7700 out, R7704 in RFin_850/

Compare with good

Yes Synthesizer

Mode

VREF01

VR2

TXP

VR5

VR3

TXIOUTP

Vdc = 1.35 Volt Check

Vdc = 2.78 Volt No Baseband

V = 1.8 Volt

Vdc = 2.78 Volt

Vdc = 2.78 Volt

V = 0 Volt

67kHz

No Check

Vac = 0.45 Vpp, Vdc =

1.2 V

TXIOUTN

67kHz

Baseband

Vac = 0.45 Vpp, Vdc =

1.2 V

TXQOUTP

67kHz

Vac = 0.45 Vpp, Vdc =

1.2 V

TXQOUTN

67kHz

Vac = 0.45 Vpp, Vdc =

1.2 V

VTXB_900

CONT1

CONT2

CONT3

VPCTRL_90

0

V = 2.78 Volt No Check:

V = 0 Volt Helgo Serial Interface

V = 0 Volt Helgo

V = 2.7 Volt

V = 1.17 Volt

P>= 2 dBm, 897.4MHz EGSM TX SAW Filter

900

Helgo

sample

Spectrum analyzer Check PA N7700

Z7800 TX1 (PA N7700

RFOut_850/900)

Power = +24.3 dBm,

897.4 MHz

z

No Check Power Loop

(TXC, Vpctrl900, DET)

Yes

Spectrum analyzer Check

RF@Test-Jig No

Pout

= +23 dBm, 897.4 MHz

z

Antenna Switch (Z7800)

Yes

GSM850

GSM900 TX

OK

Issue 1 03/2005 COMPANY CONFIDENTIAL 21

Copyright © 2005 Nokia. All Rights Reserved.

Page 22

RM-31

GSM850

Nokia Customer Care 6(b) - RF Troubleshooting

EDGE

Ensure that GMSK is ok.

Use Phoenix to select

TX_Data Type: All 1

EDGE: On

TX Power Level: 10

Ch190

Ch37

Ensure Vbatt=3.6 V

Yes

Oscilloscope

C7702

C7711

VPCTRL_900

Yes

Spectrum analyzer Check PA N7700

RF@Test-Jig No Check Power Loop

Pout

= +24.5 dBm, 897.4MHz

GSM900 TX

836.6MHz

Yes

OK

IREF01

Mode

R7713

(TXC,Rfin 900, DET)

V ~ 1.77 Volt Check

V = 1.8 Volt No Baseband

V= 2.7 V

■ GSM1800 transmitter

General instructions for GSM1800 TX troubleshooting

Start the preparations as described in chapter “General instructions for TX troubleshooting”.

GMSK

Set operating mode to local mode.

Select Testing RF Controls

Wait until the RF Controls window pops up

Select Band GSM1800

Active unit TX

Operation mode Burst

RX/TX Channel 700

TX Power Level 5

TX Data Type Random

Edge Off

22 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 23

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

The setup should now look like this:

Now the measurement equipment should detect the following output signal of the phone:

P

= +23dBm @ 1747.8 MHz

out

If this is not the case, then go to the GMSK fault finding chart for GSM1800 transmitter.

EDGE

Set operating mode to local mode.

Select Testing RF Controls

Wait until the RF controls window pops up.

Select Band GSM1800

Active unit TX

Operation mode Burst

RX/TX Channel 700

TX Power Level 5

TX Data Type All 1

Edge On

Issue 1 03/2005 COMPANY CONFIDENTIAL 23

Copyright © 2005 Nokia. All Rights Reserved.

Page 24

RM-31

Nokia Customer Care 6(b) - RF Troubleshooting

The setup should now look like this:

Now the measurement equipment should detect the following output signal of the phone:

= +21.5 dBm @ 1747.8 MHz

P

out

If this is not the case, then go to the EDGE fault finding chart for GSM1800 transmitter.

Fault finding chart for GSM1800 transmitter

In the following, it is assumed that the TXP signal is used as trigger signal. For that, a TXP

test point is provided.

24 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 25

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

GMSK

TX_Data Type: Random

TX Power Level: 5

Ch700

Ensure Vbatt=3.6 V

Yes

Oscilloscope

C7711

R7511

C7512

TXP testpoint

C7517

R7516

Yes

Oscilloscope

C7529

C7529

C7530

C7530

Yes

Oscilloscope

C7709

VC1

VC2

VC3

R7715

Yes

Spectrum analyzer No Check

T7700 out, R7709 in RFin_180

Compare with good

Yes Synthesizer

Spectrum analyzer Check PA N7700

Z7800 TX2 (PA N7700

RFOut_1800/1900)

Power = +21.6 dBm,

1747.8 MHz

Yes

Spectrum analyzer Check

RF@Test-Jig No

Pout

= +20 dBm, 1747.8 MHz

Yes

GSM 1800 TX

OK

Mode

VREF01

VR2

TXP

VR5

VR3

TXIOUTP

Vdc = 1.35 Volt Check

Vdc = 2.78 Volt No Baseband

V = 1.8 Volt

Vdc = 2.78 Volt

Vdc = 2.78 Volt

Vac = 0.4 Vpp, Vdc =

V = 0 Volt

No Check

1.2 V

TXIOUTN

Vac = 0.4 Vpp, Vdc =

Baseband

1.2 V

TXQOUTP

Vac = 0.4 Vpp, Vdc =

1.2 V

TXQOUTN

Vac = 0.4 Vpp, Vdc =

1.2 V

VTXB_1800

_1900

CONT1

CONT2

CONT3

VPCTRL_18

00_1900

V = 2.7 Volt No Check

V = 2.7 Volt Helgo Serial Interface

V = 2.7 Volt Helgo

V = 0 Volt

V > 1.14 Volt

P> 2 dBm, 1747.8MHz T7700 Balun

0/1900

Helgo

sample

No Check Power Loop

(TXC, Vpctrl 1800 1900,

DET)

Antenna Switch (Z7800)

Issue 1 03/2005 COMPANY CONFIDENTIAL 25

Copyright © 2005 Nokia. All Rights Reserved.

Page 26

RM-31

Nokia Customer Care 6(b) - RF Troubleshooting

EDGE

Ensure that GMSK is ok.

Use Phoenix to select

TX_Data Type: All 1

EDGE: On

TX Power Level: 5

Ch700

Ensure Vbatt=3.6 V

Yes

Oscilloscope

C7702

C7711

VPCTRL_900

Yes

Spectrum analyzer Check PA N7700

RF@Test-Jig No Check Power Loop

Pout

= +21.5 dBm, 1747.8

MHz

Yes

GSM 1800 TX

OK

IREF_900

Mode

R7715

(TXC, RFin 1800 1900,

V = 1.83 Volt Check

V = 1.8 Volt No Baseband

Vdc= 2.7 V

DET)

■ GSM1900 transmitter

General instructions for GSM1900 TX troubleshooting

Start the preparations as described in chapter “General instructions for TX troubleshooting”.

GMSK

Set operating mode to local mode.

Select Testing RF Controls

Wait until the RF Controls window pops up.

Select Band GSM1900

Active unit TX

Operation mode Burst

RX/TX Channel 661

TX Power Level 5

TX Data Type Random

Edge Off

26 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 27

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

The setup should now look like this:

Now the measurement equipment should detect the following output signal of the phone:

= +23dBm @ 1880 MHz

P

out

If this is not the case, then go to the GMSK fault finding chart for GSM1900 transmitter.

EDGE

Set operating mode to local mode.

Select Testing RF Controls

Wait until the RF Controls window pops up.

Select Band GSM1900

Active unit TX

Operation mode Burst

RX/TX Channel 661

TX Power Level 5

TX Data Type All1

Edge On

Issue 1 03/2005 COMPANY CONFIDENTIAL 27

Copyright © 2005 Nokia. All Rights Reserved.

Page 28

RM-31

Nokia Customer Care 6(b) - RF Troubleshooting

The setup should now look like this:

Now the measurement equipment should detect the following output signal of the phone:

P

= +21.5 dBm @ 1880 MHz

out

If this is not the case, then go to the EDGE fault finding chart for GSM1900 transmitter.

Fault finding chart for GSM1900 transmitter

In the following, it is assumed that the TXP signal is used as trigger signal. For that, a TXP

test point is provided.

28 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 29

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

GMSK

Use Phoenix to select

TX_Data Type: Random

TX Power Level: 5

Ch661

Ensure Vbatt=3.6 V

Yes

Oscilloscope

C7711

R7511

C7512

TXP testpoint

C7517

R7516

Yes

Oscilloscope

C7529

C7529

C7530

C7530

Yes

Oscilloscope

C7709

VC1

VC2

VC3

R7715

Yes

Spectrum analyzer No Check

T7700 out, R7709 in RFin_180

Compare with good

Yes Synthesizer

Spectrum analyzer Check PA N7700

Z7800 TX2 (PA N7700

RFOut_1800/1900)

Power = +21.6 dBm, 1880

MHz

Yes

Spectrum analyzer Check

RF@Test-Jig No

Pout

= +20 dBm, 1880 MHz

Yes

GSM 1900 TX

OK

Mode

VREF01

VR2

TXP

VR5

VR3

TXIOUTP

Vdc = 1.35 Volt Check

Vdc = 2.78 Volt No Baseband

V = 1.8 Volt

Vdc = 2.78 Volt

Vdc = 2.78 Volt

Vac = 0.4 Vpp, Vdc =

Vdc = 0 Volt

No Check

1.2 V

TXIOUTN

Vac = 0.4 Vpp, Vdc =

Baseband

1.2 V

TXQOUTP

Vac = 0.4 Vpp, Vdc =

1.2 V

TXQOUTN

Vac = 0.4 Vpp, Vdc =

1.2 V

VTXB_1800

_1900

CONT1

CONT2

CONT3

VPCTRL_18

00_1900

V = 2.78 Volt No Check

V = 2.7 Volt Helgo Serial Interface

V = 2.7 Volt Helgo

V = 0 Volt

V = 1.12 Volt

P> 2 dBm, 1880 MHz T7700 Balun

0/1900

Helgo

sample

No Check Power Loop

(TXC Vpctrl 1800 1900,

DET)

Antenna Switch (Z7800)

Issue 1 03/2005 COMPANY CONFIDENTIAL 29

Copyright © 2005 Nokia. All Rights Reserved.

Page 30

RM-31

Nokia Customer Care 6(b) - RF Troubleshooting

EDGE

Ensure that GMSK is ok.

Use Phoenix to select

TX_Data Type: All 1

EDGE: On

TX Power Level: 5

Ch661

Ensure Vbatt=3.6 V

Yes

Oscilloscope

C7702

C7711

VPCTRL_1800 1900

Yes

Spectrum analyzer Check PA N7700

RF@Test-Jig No Check Power Loop

Pout

= +21.5 dBm, 1880 MHz

Yes

GSM 1900 TX

OK

IREF_900

Mode

R7715

(TXC, RFin 1800 1900,

V = 1.83 Volt Check

V = 2.78 Volt No Baseband

V= 2.7 V

DET)

30 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 31

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

Synthesizer

■ General instructions for synthesizer troubleshooting

Connect the phone to a PC, which has Phoenix Service Software and a dongle installed, using

either

• repair jig and DAU-9S (RS232) cable or

• repair jig and XCS-4 cable via FPS-8 Flash Box or

• DAU-9T cable (RS232).

Connect the phone to a power supply (DC voltage of 3.6V) and switch the phone on.

Follow the instructions in the chapters below.

■ Checking synthesizer operation

Start Phoenix Service Software and open FBUS connection.

Select “Scan Product” (Ctrl-R or in menu File - Scan Product).

Wait until phone information is shown in the lower right corner of the screen.

Set <operating mode> to <Local>.

Open window “RF Controls” (menu Testing - RF Controls)

Set the synthesizer to the following mode:

Select Band GSM1800

Active unit RX

Operation mode Continuous

RX/TX Channel 700

The setup should now look like this:

Issue 1 03/2005 COMPANY CONFIDENTIAL 31

Copyright © 2005 Nokia. All Rights Reserved.

Page 32

RM-31

Nokia Customer Care 6(b) - RF Troubleshooting

The VCO chamber has a fixed shielding lid, which can only be opened by destroying it. To enable measurements with a closed lid, holes are located at positions where the supply voltage

VR7, the tuning voltage Vc and the output frequency f

Figure 1:Test holes in the VCO chamber

can be measured.

VCO

The VCO frequency has to be measured with a special probe, which fits into the holes of the

shielding lid. A thin coax cable can be used for this purpose, where the outer conductor is removed for 2mm. The isolation and the inner conductor must fit into the hole of the shielding lid

and provide a capacitive coupling to the attenuator R7503 at the VCO output. A spectrum analyzer is used to display the frequency.

Figure 2:VCO probe

The VCO frequency is twice the Rx frequency in the GSM1800 band:

= 2 * fRX = 2 * 1842.8 MHz = 3685.6 MHz

f

VCO

The tuning voltage can be easily measured at the Vc input of the VCO. The corresponding hole

in the shielding lid enables the voltage measurement at C7503, which shows the same DC voltage as Vc.

The tuning voltage should be 2.1V

.. 2.6VDC at f

DC

= 3685.6MHz.

VCO

The tuning sensitivity of the VCO is typically 250MHz/V. The typical relation of VCO frequency

and tuning voltage is shown in the following diagram:

32 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 33

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

Figure 3:Typical frequency tuning curve for the FDK VCO

Temperature: +25°C

4500

4000

Frequency [MHz]

3500

3000

00.511.522.533.544.555.56

VCTRL [V]

2.55V @ 24.4 .. 25.4°C 2.7V @ 24.4 .. 25.4°C 2.85V @ 24.4 .. 25.4°C

High limit Low limit

Even if the PLL is not working properly (Vc outside the valid range), a frequency at the output

of the VCO can be detected between 3GHz and 4.4 GHz (if the VCO itself is ok and the supply

voltage VR7 = 2.78V is applied).

If the frequency or the tuning voltage have other values than given above, see the fault finding

chart for PLL syntesizer below.

Issue 1 03/2005 COMPANY CONFIDENTIAL 33

Copyright © 2005 Nokia. All Rights Reserved.

Page 34

RM-31

A

Nokia Customer Care 6(b) - RF Troubleshooting

■ Fault finding chart for PLL synthesizer

Figure 4:PLL Fault Finding Tree

Phoenix:

Phone is responding to Phoenix commands. For example,

Ctrl-R reads the right phone information.

No

Yes

Baseband part is not working,

possible reason: 26MHz missing.

Oscilloscope

VCTCXO output at G7501

26MHz,app.0.8Vpp

No

Oscilloscope:

Check VCTCXO supply

(VR3=2.78V, this can be checked after

power on for a time of about

fter that time the voltage is going

down.)

Yes

Oscilloscope

REFCLK output of N7500:

Signal VCTCXO=RFCLK_I

at C2902, R2902.

26MHz,app.0.8Vpp

.

32sec

Yes

No

Yes

No

Synthesizer

Fault Finding Tree

part 1

Check Baseband part for errors

Check supply filter components:

R7519, C7522, VDIG at N7500

Check C2902, R2902 and N7500.

Check UEM and Software.

VCTCXO G7501 defective or

short circuit to GND.

Check supply filter components :

C2235, R7516, C7526.

Check UEM and base band part.

34 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 35

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

Setup with Phoenix:

Band: GSM 1800

Mode: RX Continuous

Channel: 700

Spectrum analyzer

VCO out (G7500)

f

= 3685.6 MHz

VCO

Vc of VCO = 2.1..2.6V

Spectrum analyzer

VCO out (G7500)

Some signal 3 - 4.4 GHz

Yes

Oscilloscope

VCO tuning voltage

Vc of VCO = 0V

No

Yes

PLL Block is functional

No

Oscilloscope

VCO supply

(VR7 = 2.78V)

Yes

No

Synthesizer

Fault Finding Tree

part 2

Check R7503 and T7500.

Change VCO G7500

Check supply filter components:

C2203, R7500, C7500, C7501

Check UEM.

Yes

Oscilloscope

PLL supply

(VR1=4.7V, VR5=2.78V)

No

Oscilloscope

Check RFBus signals

RFBusClk, RFBusData,

RFBusEn1 ok?

Yes

No

Yes

No

Change RF ASIC N7500

Check baseband part.

Check loop filter components:

C7502, C7503, C7504, R7501, R7502

Short circuit to ground?

RF ASIC N7500 could be defective.

Check supply filter components:

C2232, C299, C7516, C7517, C7518

Check UEM.

It is important to note that the power supply VR3 of the VCTCXO is only switched off in the so

called ‘Deep Sleep Mode’ and the power supply VR7 of the VCO (G7500) is switched off in so

called ‘Sleep Mode’.

Issue 1 03/2005 COMPANY CONFIDENTIAL 35

Copyright © 2005 Nokia. All Rights Reserved.

Page 36

RM-31

V

V

Nokia Customer Care 6(b) - RF Troubleshooting

■ Frequency tables

GSM850

CH TX RX

128 824.2 869.2 3296.8 3476.8 190 836.6 881.6 3346.4 3526.4

129 824.4 869.4 3297.6 3477.6 191 836.8 881.8 3347.2 3527.2

130 824.6 869.6 3298.4 3478.4 192 837.0 882.0 3348.0 3528.0

131 824.8 869.8 3299.2 3479.2 193 837.2 882.2 3348.8 3528.8

132 825.0 870.0 3300.0 3480.0 194 837.4 882.4 3349.6 3529.6

133 825.2 870.2 3300.8 3480.8 195 837.6 882.6 3350.4 3530.4

134 825.4 870.4 3301.6 3481.6 196 837.8 882.8 3351.2 3531.2

135 825.6 870.6 3302.4 3482.4 197 838.0 883.0 3352.0 3532.0

136 825.8 870.8 3303.2 3483.2 198 838.2 883.2 3352.8 3532.8

137 826.0 871.0 3304.0 3484.0 199 838.4 883.4 3353.6 3533.6

138 826.2 871.2 3304.8 3484.8 200 838.6 883.6 3354.4 3534.4

139 826.4 871.4 3305.6 3485.6 201 838.8 883.8 3355.2 3535.2

140 826.6 871.6 3306.4 3486.4 202 839.0 884.0 3356.0 3536.0

141 826.8 871.8 3307.2 3487.2 203 839.2 884.2 3356.8 3536.8

142 827.0 872.0 3308.0 3488.0 204 839.4 884.4 3357.6 3537.6

143 827.2 872.2 3308.8 3488.8 205 839.6 884.6 3358.4 3538.4

144 827.4 872.4 3309.6 3489.6 206 839.8 884.8 3359.2 3539.2

145 827.6 872.6 3310.4 3490.4 207 840.0 885.0 3360.0 3540.0

146 827.8 872.8 3311.2 3491.2 208 840.2 885.2 3360.8 3540.8

147 828.0 873.0 3312.0 3492.0 209 840.4 885.4 3361.6 3541.6

148 828.2 873.2 3312.8 3492.8 210 840.6 885.6 3362.4 3542.4

149 828.4 873.4 3313.6 3493.6 211 840.8 885.8 3363.2 3543.2

150 828.6 873.6 3314.4 3494.4 212 841.0 886.0 3364.0 3544.0

151 828.8 873.8 3315.2 3495.2 213 841.2 886.2 3364.8 3544.8

152 829.0 874.0 3316.0 3496.0 214 841.4 886.4 3365.6 3545.6

153 829.2 874.2 3316.8 3496.8 215 841.6 886.6 3366.4 3546.4

154 829.4 874.4 3317.6 3497.6 216 841.8 886.8 3367.2 3547.2

155 829.6 874.6 3318.4 3498.4 217 842.0 887.0 3368.0 3548.0

156 829.8 874.8 3319.2 3499.2 218 842.2 887.2 3368.8 3548.8

157 830.0 875.0 3320.0 3500.0 219 842.4 887.4 3369.6 3549.6

158 830.2 875.2 3320.8 3500.8 220 842.6 887.6 3370.4 3550.4

159 830.4 875.4 3321.6 3501.6 221 842.8 887.8 3371.2 3551.2

160 830.6 875.6 3322.4 3502.4 222 843.0 888.0 3372.0 3552.0

161 830.8 875.8 3323.2 3503.2 223 843.2 888.2 3372.8 3552.8

162 831.0 876.0 3324.0 3504.0 224 843.4 888.4 3373.6 3553.6

163 831.2 876.2 3324.8 3504.8 225 843.6 888.6 3374.4 3554.4

164 831.4 876.4 3325.6 3505.6 226 843.8 888.8 3375.2 3555.2

165 831.6 876.6 3326.4 3506.4 227 844.0 889.0 3376.0 3556.0

166 831.8 876.8 3327.2 3507.2 228 844.2 889.2 3376.8 3556.8

167 832.0 877.0 3328.0 3508.0 229 844.4 889.4 3377.6 3557.6

168 832.2 877.2 3328.8 3508.8 230 844.6 889.6 3378.4 3558.4

169 832.4 877.4 3329.6 3509.6 231 844.8 889.8 3379.2 3559.2

170 832.6 877.6 3330.4 3510.4 232 845.0 890.0 3380.0 3560.0

171 832.8 877.8 3331.2 3511.2 233 845.2 890.2 3380.8 3560.8

172 833.0 878.0 3332.0 3512.0 234 845.4 890.4 3381.6 3561.6

173 833.2 878.2 3332.8 3512.8 235 845.6 890.6 3382.4 3562.4

174 833.4 878.4 3333.6 3513.6 236 845.8 890.8 3383.2 3563.2

175 833.6 878.6 3334.4 3514.4 237 846.0 891.0 3384.0 3564.0

176 833.8 878.8 3335.2 3515.2 238 846.2 891.2 3384.8 3564.8

177 834.0 879.0 3336.0 3516.0 239 846.4 891.4 3385.6 3565.6

178 834.2 879.2 3336.8 3516.8 240 846.6 891.6 3386.4 3566.4

179 834.4 879.4 3337.6 3517.6 241 846.8 891.8 3387.2 3567.2

180 834.6 879.6 3338.4 3518.4 242 847.0 892.0 3388.0 3568.0

181 834.8 879.8 3339.2 3519.2 243 847.2 892.2 3388.8 3568.8

182 835.0 880.0 3340.0 3520.0 244 847.4 892.4 3389.6 3569.6

183 835.2 880.2 3340.8 3520.8 245 847.6 892.6 3390.4 3570.4

184 835.4 880.4 3341.6 3521.6 246 847.8 892.8 3391.2 3571.2

185 835.6 880.6 3342.4 3522.4 247 848.0 893.0 3392.0 3572.0

186 835.8 880.8 3343.2 3523.2 248 848.2 893.2 3392.8 3572.8

187 836.0 881.0 3344.0 3524.0 249 848.4 893.4 3393.6 3573.6

188 836.2 881.2 3344.8 3524.8 250 848.6 893.6 3394.4 3574.4

189 836.4 881.4 3345.6 3525.6 251 848.8 893.8 3395.2 3575.2

CO TX VCO RX CH TX RX

Frequency list GSM850

CO TX VCO RX

36 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 37

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

GSM1800

Issue 1 03/2005 COMPANY CONFIDENTIAL 37

Copyright © 2005 Nokia. All Rights Reserved.

Page 38

RM-31

Nokia Customer Care 6(b) - RF Troubleshooting

GSM1900

38 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 39

RM-31

6(b) - RF Troubleshooting Nokia Customer Care

DC Supply Voltage Check

For a quick check of DC power supplies, refer to the diagram below. The RF power supplies

are generated in the UEM and can be measured either in the Small Signal Chamber or in the

Base Band Chamber.

The UEM output voltages can be measured at the respective resistors' / capacitors' pads

marked below in brackets, e.g. < C1234 >.

UEM

< C7516 >

< C7510 >

< R7516 >

< C7519 >

< C7517 >

VR1

VR2

VR3

VR4

VR5

4.75 V [ 4.6V ... 4.9V ]

charge pump (VCP)

2.78 V [ 2.70V ... 2.86V ]

Tx modulator (Vcc_ModOut)

TX buffer & EDGE ALCs (VRF_TX)

2.78 V [ 2.70V ... 2.86V ]

VCTCXO (+VCC)

digital interface (VDIG)

2.78 V [ 2.70V ... 2.86V ]

Rx Front End (VRF_RX)

Bias & Rx CH filters (VF_RX)

RF controls (VPAB_VLNA)

2.78 V [ 2.70V ... 2.86V ]

PLL prescaler (VPRE)

phasing dividers of Rx (VLO)

< C7521 >

< C7500 >

< R7511/C7516 >

< R2901/C2901 >

AND

VR6

VR7

V

refRF01

V

refRF02

2.78 V [ 2.70V ... 2.86V ]

2.78 V [ 2.70V ... 2.86V ]

16 mA [max. 20 mA]

1.35 V [ 1.32V ... 1.38V ]

100 uA

1.35 V [ 1.32V ... 1.38V ]

100 uA

BB buffer (VDIG)

VCO (VCC_VCO)

bias reference (VB_EXT)

bias reference

(RXIINN, RXQINN)

< R2900/C2900 >

VBAT

Issue 1 03/2005 COMPANY CONFIDENTIAL 39

Copyright © 2005 Nokia. All Rights Reserved.

2.7 V [ 2.95V ... 4.7V ]

Triple band PA

Page 40

RM-31

Nokia Customer Care 6(b) - RF Troubleshooting

This page has been intentionally left blank.

40 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 41

Nokia Customer Care

Appendix 6A: Test Points

Issue 1 03/2005 2005 Nokia Corporation. Page 41

Company Confidential

Page 42

RM-31

GSM

190

Nokia Customer Care Appendix 6A: Test Points

■ Receiver test points, layout 1gqa-41

2 ) V r e f R F 0 2 * *

GSM850

B a n d G S M 9 0 0

A c t i v e U n i t R X

B u r s t

C o n t i n u o u s o r

190

O p e r a t i o n M o d e

R X / T X C h a n n e l 3 7

D C L e v e l 1 . 3 5 V

1 ) V r e f R F 0 2 *

T e s t p o i n t s

O U T - Z 7 8 0 1

T e s t p o i n t

B a n d G S M 1 9 0 0

A c t i v e U n i t R X

O p e r a t i o n M o d e C o n t i n u o u s

R X / T X C h a n n e l 6 6 1

O U T - V 7 8 0 0

T e s t p o i n t

B a n d G S M 1 9 0 0

A c t i v e U n i t R X

O p e r a t i o n M o d e C o n t i n u o u s

R X / T X C h a n n e l 6 6 1

V r e f R F 0 2 *

R 2 9 0 1 / C 2 9 0 1

V r e f R F 0 2 * *

R 2 9 0 0 / C 2 9 0 0

1 ) I N P _ P _ R X

2 ) I N M _ P _ R X

P r e f - 3 . 5 d B

A G C 1 4

I n p u t P o w e r 6 0 d B m

I n p u t F r e q u e n c y 1 9 6 0 . 0 6 7 7 1 M H z

P r o b e d P o w e r

P r e f + 1 4 d B

A G C 1 4

I n p u t P o w e r 6 0 d B m

I n p u t F r e q u e n c y 1 9 6 0 . 0 6 7 7 1 M H z

P r o b e d P o w e r

P r e f - 6 . 5 d B

V R 6

T e s t p o i n t

V R 4

T e s t p o i n t

850

B a n d G S M 9 0 0

A c t i v e U n i t R X

GSM850

B a n d G S M 9 0 0

A c t i v e U n i t R X

R x 3

B u r s t

C o n t i n u o u s

o r

L N A B _ P *

190

O p e r a t i o n M o d e

R X / T X C h a n n e l 3 7

D C L e v e l 2 . 8 V

T e s t p o i n t

B a n d G S M 1 9 0 0

A c t i v e U n i t R X

O p e r a t i o n M o d e C o n t i n u o u s

R X / T X C h a n n e l 6 6 1

B u r s t

C o n t i n u o u s

O p e r a t i o n M o d e

L N A _ P *

o r

190

T e s t p o i n t

B a n d G S M 1 9 0 0

A c t i v e U n i t R X

O p e r a t i o n M o d e C o n t i n u o u s

R X / T X C h a n n e l 3 7

D C L e v e l 2 . 8 V

R X / T X C h a n n e l 6 6 1

2 . 5 d B

P r e f

T y p .

2 . 5 V

A G C : 1 4

D C L e v e l

T y p .

1 . 8 V

0 V

A G C : 4

D C L e v e l

A G C : 5

D C L e v e l

V r e f R F 0 1 *

T e s t p o i n t

GSM850

B a n d G S M 9 0 0

A c t i v e U n i t R X

B u r s t

C o n t i n u o u s o r

190

O p e r a t i o n M o d e

R X / T X C h a n n e l 3 7

D C L e v e l 1 . 3 5 V

T e s t p o i n t

B a n d G S M 1 9 0 0

A c t i v e U n i t R X

O p e r a t i o n M o d e C o n t i n u o u s

R X / T X C h a n n e l 6 6 1

A G C 1 4

I n p u t P o w e r 6 0 d B m

I n p u t F r e q u e n c y 1 9 6 0 . 0 6 7 7 1 M H z

P r o b e d P o w e r

2 . 0 d B

R x 2

T e s t p o i n t

B a n d G S M 1 8 0 0

A c t i v e U n i t R X

O p e r a t i o n M o d e C o n t i n u o u s

R X / T X C h a n n e l 7 0 0

R x 1

GSM850

190

T e s t p o i n t

B a n d G S M 8 5 0 / 9 0 0

A c t i v e U n i t R X

O p e r a t i o n M o d e C o n t i n u o u s

R X / T X C h a n n e l 3 7

P r e f

A G C 1 4

I n p u t P o w e r 6 0 d B m

I n p u t F r e q u e n c y 1 8 4 2 . 8 6 7 7 1 M H z

P r o b e d P o w e r

1 . 5 . 0 d B

P r e f

881.66771MHz

A G C 1 4

I n p u t P o w e r 6 0 d B m

I n p u t F r e q u e n c y 9 4 2 . 4 6 7 7 1 M H z

P r o b e d P o w e r

L a y o u t : 1 c n a _ 4 1 ( B u i l d 4 . 0 )

t y p . 6 3 d B m

P r e f ( d B m )

t y p . 6 3 d B m

P r e f ( d B m )

GSM850

A N T ( A n t e n n a F e e d )

R e c e i v e r T e s t P o i n t s ( 1 / 2 )

T e s t p o i n t

B a n d G S M 9 0 0 G S M 1 8 0 0 G S M 1 9 0 0

A c t i v e U n i t R X

O p e r a t i o n M o d e C o n t i n u o u s

R X / T X C h a n n e l 3 7 7 0 0 6 6 1

A G C 1 4

t y p . 6 3 d B m

P r e f ( d B m )

881.66771MHz

w i t h

I n p u t P o w e r 6 0 d B m 6 0 d B m 6 0 d B m

I n p u t F r e q u e n c y 9 4 2 . 4 6 7 7 1 M H z 1 8 4 2 . 8 6 7 7 1 M H z 1 9 6 0 . 0 6 7 7 1 M H z

P r o b e d P o w e r

( e . g . m e a s u r e d

r e s i s t i v e p r o b e , r e f . t o

L 7 8 0 7 / C 7 8 0 6

I N M _ P _ R X

L 7 8 0 7 / C 7 8 0 5

I N P _ P _ R X

L 7 8 0 3

I N P _ D _ R X

L 7 8 0 2

I N M _ D _ R X

L 7 8 0 5

L N A B _ P *

R 7 8 0 1 / C 7 8 0 3

V C 3

V A N T _ 1

V C 1

V A N T _ 2

V C 2

V A N T _ 3

I N M _ G _ R X

L 7 8 0 4

I N P _ G _ R X

L 7 8 0 0 / C 7 8 0 1

O U T - Z 7 8 0 1

V R 6

V R 4

c h a p t e r 5 . 2 )

C 7 5 2 1

C 7 5 1 9

V r e f R F 0 1 *

R 7 5 1 1 / C 7 5 2 4

O U T - V 7 8 0 0

L 7 8 0 1 / C 7 8 0 4 / R 7 8 0 2

R x 3

GSM850

B a n d G S M 9 0 0

A c t i v e U n i t R X [ T X ]

R x 2

( G S M 1 9 0 0 )

( G S M 1 8 0 0 )

V A N T _ 3

190

V A N T _ 2

V A N T _ 1

O p e r a t i o n M o d e C o n t i n u o u s

R X / T X C h a n n e l 3 7

T e s t p o i n t s

L N A _ P *

R 7 8 0 0 / C 7 8 0 0

V A N T _ 1 , 2 , 3

T e s t p o i n t

A N T

R x 1

( G S M 8 5 0 / 9 0 0 )

( V C 3 )

( V C 1 )

V A N T _ 1 , 2 , 3

( V C 3 )

T e s t p o i n t

B a n d G S M 1 8 0 0

D C L e v e l 0 V [ 2 . 6 V ] 0 V [ 0 V ] 0 V [ 2 . 6 V ]

A c t i v e U n i t R X [ T X ]

T e s t p o i n t s

B a n d G S M 1 9 0 0

A c t i v e U n i t R X

O p e r a t i o n M o d e C o n t i n u o u s

R X / T X C h a n n e l 6 6 1

A G C 1 4

I n p u t P o w e r 6 0 d B m

I n p u t F r e q u e n c y 1 9 6 0 . 0 6 7 7 1 M H z

P r o b e d P o w e r

D C L e v e l 1 . 6 V

1 ) I N P _ D _ R X

2 ) I N M _ D _ R X

T e s t p o i n t s

B a n d G S M 1 8 0 0

A c t i v e U n i t R X

O p e r a t i o n M o d e C o n t i n u o u s

R X / T X C h a n n e l 7 0 0

G N D

a n d p i n s

( G R O U N D )

m e t a l s h i e l d i n g

2 ) I N M _ G _ R X

D C L e v e l 0 V [ 0 V ] 0 V [ 2 . 6 V ] 0 V [ 2 . 6 V ]

GSM850

B a n d G S M 9 0 0

A c t i v e U n i t R X

190

O p e r a t i o n M o d e C o n t i n u o u s

R X / T X C h a n n e l 3 7

V A N T _ 1 , 2 , 3

T e s t p o i n t

B a n d G S M 1 9 0 0

1 ) I N P _ G _ R X

T e s t p o i n t s

( V C 3 )

V A N T _ 3

( V C 1 )

V A N T _ 2

( V C 3 )

V A N T _ 1

O p e r a t i o n M o d e C o n t i n u o u s

R X / T X C h a n n e l 7 0 0

T e s t p o i n t s

P r e f 6 d B

A G C 1 4

I n p u t P o w e r 6 0 d B m

I n p u t F r e q u e n c y 1 8 4 2 . 8 6 7 7 1 M H z

P r o b e d P o w e r

D C L e v e l T y p . 1 . 6 V

881.66771MHz

P r e f 3 . 5 d B

A G C 1 4

I n p u t P o w e r 6 0 d B m

I n p u t F r e q u e n c y 9 4 2 . 4 6 7 7 1 M H z

P r o b e d P o w e r

D C L e v e l T y p . 1 . 6 V

( V C 3 )

V A N T _ 3

( V C 1 )

V A N T _ 2

( V C 3 )

V A N T _ 1

A c t i v e U n i t R X [ T X ]

O p e r a t i o n M o d e C o n t i n u o u s

R X / T X C h a n n e l 6 6 1

T e s t p o i n t s

D C L e v e l 0 V [ 0 V ] 0 V [ 2 . 6 V ] 2 . 6 V [ 2 . 6 V ]

42 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 43

RM-31

R

i

T

P

i

( 2 / 2 )

Appendix 6A: Test Points Nokia Customer Care

R X I

J 1 0 0 5

R X Q

J 1 0 0 4

881.66771, 1842.86771 or 1990.0677MHz

190 or 700 or 661

GSM850 or GSM1800 or GSM1900

1 ) R X I

2 ) R X Q

T e s t p o i n t s

B a n d G S M 9 0 0 o r G S M 1 8 0 0 o r G S M 1 9 0 0

A c t i v e U n i t R X

O p e r a t i o n M o d e C o n t i n u o u s

R X / T X C h a n n e l 3 7 o r 7 0 0 o r 6 6 1

C 7 5 2 3

C M _ D T O S _ I

1 . 4 V p p

A G C 1 0

I n p u t P o w e r 6 0 d B m

I n p u t F r e q u e n c y 9 4 2 . 4 6 7 7 1 , 1 8 4 2 . 8 6 7 7 1 o r 1 9 6 0 . 0 6 7 7 1 M H z

S i g n a l

A m p l i t u d e

D C O f f s e t 1 . 2 8 V d c

F r e q u e n c y 6 7 k H z

G r a p h

( t y p i c a l f o r a l l

T P s a n d b a n d s )

C 7 5 2 3

C M _ D T O S _ Q

C 7 5 2 3

C M _ F _ I

C 7 5 2 3

C M _ F _ Q

881.66771, 1842.86771 or 1990.0677MHz

1 ) C M _ F _ I

2 ) C M _ F _ Q

GSM850 or GSM1800 or GSM1900

190 or 700 or 661

T e s t p o i n t s

B a n d G S M 9 0 0 o r G S M 1 8 0 0 o r G S M 1 9 0 0

A c t i v e U n i t R X

O p e r a t i o n M o d e B u r s t

R X / T X C h a n n e l 3 7 o r 7 0 0 o r 6 6 1

A N T

A p p r o x . 1 . 7 5 V p p

A G C 1 0

I n p u t P o w e r 6 0 d B m

I n p u t F r e q u e n c y 9 4 2 . 4 6 7 7 1 , 1 8 4 2 . 8 6 7 7 1 o r 1 9 6 0 . 0 6 7 7 1 M H z

S i g n a l

A m p l i t u d e

G r a p h

( t y p i c a l f o r b o t h

T P s a n d a l l

b a n d s )

n t s

o

881.66771, 1842.86771 or 1990.0677MHz

1 ) C M _ D T O S _ I

e s t

v e r

e c e

2 ) C M _ D T O S _ Q

T e s t p o i n t s

GSM850 or GSM1800 or GSM1900

B a n d G S M 9 0 0 o r G S M 1 8 0 0 o r G S M 1 9 0 0

A c t i v e U n i t R X

190 or 700 or 661

O p e r a t i o n M o d e B u r s t

R X / T X C h a n n e l 3 7 o r 7 0 0 o r 6 6 1

A p p r o x . 2 V p p

A G C 1 4

I n p u t P o w e r 6 0 d B m

I n p u t F r e q u e n c y 9 4 2 . 4 6 7 7 1 , 1 8 4 2 . 8 6 7 7 1 o r 1 9 6 0 . 0 6 7 7 1 M H z

S i g n a l

A m p l i t u d e

G r a p h

( t y p i c a l f o r b o t h

T P s a n d a l l

b a n d s )

Issue 1 03/2005 COMPANY CONFIDENTIAL 43

Copyright © 2005 Nokia. All Rights Reserved.

Page 44

RM-31

GSM850

1800

1900

GSM850

1800

1900

GS

GS

190

700

661

GS

/

/

Nokia Customer Care Appendix 6A: Test Points

■ Transmitter test points, layout:1gqa-41

or

or

or

M850

VR3

Testpoint

190

Band GSM900

Active Unit TX

Operation Mode Burst

RX/TX Channel 37

DC Level 2.8V

or

GMSK ( EDGE = OFF ) 8-PSK ( EDGE = ON )

Burst Burst

Modulation

Band GSM 850 or 900 or 1800 or 1900 GSM 850 or 900 o r 1800 or 1900

Active Unit TX TX

Operation

Mode

Test point TXC TXC

Graph

e.g.

GSM900 PL10

GSM850

or

or

TXIP (R713/1)

TXIM (R713/3)

TXIP (R713/7)

TXQM (R713/5))

GSM850 or GSM1800 or GSM1900

Testpoints

Band GSM 850 or 900 or GSM1800 or GSM1900

Active Unit TX

Operation Mode Burst

RX/TX Channel 190 or 37 or 700 o r 661

Tx Data Type Random

Tx Power Level any

Tx2

Tx1

Rx3

Transmitter Test Points (1/3)

Rx2

Rx1

_1

VANT

Test points: RFout_900 and RFout_1800/1900

Matrix Antenna Switch Module Z7800

_3

VANT

_2

VANT

RFout

RFout

520mVpp

Signal

Amplitude

/1900

_1800

_900

VC3

VC2

VC1

[Volt]

M850

Test point VTXB_900 VTXB_900

Graph e.g.

GSM900 PL10

GSM850

Test point VPctrl_900 VPctrl_900

Graph

e.g.

GSM850

GSM900 PL10

Test point VDET

VREF01

Testpoint

Band GSM900

Active Unit TX

Operation Mode Burst

190

RX/TX Channel 37

DC Level 1.35V

Layout: 1cna_41 (Build 4.0)

TXA

VPCTRL_1800_1900

VBAT

DC Offset 1. 2Vdc

Graph

(typical for all

TPs and bands)

Tx

1800

GSM

/1900

Tx

850

/900

GSM

Rx

1900

GSM

X

X

Rx

1800

GSM

Rx

850

/900

GSM

[Volt]

[Volt]

0 0 0 X

0 0 0

0 2.6 2.6

1900

1800

VR2 (C7512)

GSM850

X

X

Testpoint

Band GSM900/1800/1900

M850

VBAT

0 2.6 0

2.6 2.6 0

Testpoint

Band GSM900

Active Unit TX

190

Active Unit TX

Operation Mode Burst

RX/TX Channel 37

DC Level 2.8V

190

Operation Mode Burst

RX/TX Channel 37

DC Level Typ. 3.6V

RFin_1800_1900

VTXB_1800_1900

VTXB_900

VR3

RFin_900 P

RFin_1800_1900 P

TXC

RFin_900 M

RFin_1800_1900 M

VR2

TXQP

TXQM

(C7530)

TXIP

TXIM

(C7529)

VrefRF01*

VPCTRL_900

RFin_900

MODE

Iref_900

Iref_1800_1900 DETRFout_900

RFout_1800_1900

ANT

44 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 45

RM-31

Appendix 6A: Test Points Nokia Customer Care

+ d B m

+ 2 d B m

+ d B m

1 . R F i n _ 9 0 0 P

2 . R F i n _ 9 0 0 M

T e s t p o i n t

B a n d G S M 8 5 0 o r 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n G M S K ( E d g e = o f f )

R X / T X C h a n n e l 1 9 0 o r 3 7

T x P o w e r L e v e l 1 0

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

+ 2 d B m

+ d B m

R F i n _ 9 0 0

1 . R F i n _ 1 8 0 0 _ 1 9 0 0 P

2 . R F i n _ 1 8 0 0 _ 1 9 0 0 M

T e s t p o i n t

B a n d G S M 1 8 0 0 o r 1 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n G M S K ( E d g e = o f f )

R F i n _ 1 8 0 0 _ 1 9 0 0

L a y o u t : 1 c n a _ 4 1 ( B u i l d 4 . 0 )

V P C T R L _ 1 8 0 0 _ 1 9 0 0

T X A

T e s t p o i n t

B a n d G S M 8 5 0 o r 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n G M S K ( E d g e = o f f )

R X / T X C h a n n e l 1 9 0 o r 3 7

T x P o w e r L e v e l 1 0

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

V B A T

T e s t p o i n t

B a n d G S M 1 8 0 0 o r 1 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n G M S K ( E d g e = o f f )

V P C T R L _ 9 0 0

+ 0 d B m

R X / T X C h a n n e l 7 0 0 o r 6 6 1

T x P o w e r L e v e l 5

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

+ 2 d B m

+ d B m

R X / T X C h a n n e l 7 0 0 o r 6 6 1

T x P o w e r L e v e l 5

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

R F i n _ 1 8 0 0 _ 1 9 0 0

+ d B m

R F o u t _ 9 0 0

+ 2 4 . 3 d B m

R F i n _ 9 0 0

R F o u t _ 1 8 0 0 _ 1 9 0 0

M O D E

I r e f _ 9 0 0

+ d B m

+ 2 1 . 6 d B m

V T X B _ 1 8 0 0 _ 1 9 0 0

T e s t p o i n t

B a n d G S M 8 5 0 o r 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n G M S K ( E d g e = o f f )

R X / T X C h a n n e l 1 9 0 o r 3 7

T x P o w e r L e v e l 1 0

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

V T X B _ 9 0 0

T X C

T e s t p o i n t

B a n d G S M 1 8 0 0 o r 1 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n G M S K ( E d g e = o f f )

R X / T X C h a n n e l 7 0 0 o r 6 6 1

T x P o w e r L e v e l 5

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

I r e f _ 1 8 0 0 _ 1 9 0 0 D E TR F o u t _ 9 0 0

V R 3

+ 2 0 d B m

+ 2 3 d B m

+ d B m

R F i n _ 9 0 0 P

A N T

R F i n _ 9 0 0 M

A N T

+ d B m

R F o u t _ 1 8 0 0 _ 1 9 0 0

T e s t p o i n t

B a n d G S M 8 5 0 o r 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n G M S K ( E d g e = o f f )

R X / T X C h a n n e l 1 9 0 o r 3 7

T x P o w e r L e v e l 1 0

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

V R 2

T X Q P

T X Q M

R F i n _ 1 8 0 0 _ 1 9 0 0 P

R F i n _ 1 8 0 0 _ 1 9 0 0 M

( C 7 5 3 0 )

T X I P

T X I M

( C 7 5 2 9 )

V r e f R F 0 1 *

A N T

T e s t p o i n t

B a n d G S M 1 8 0 0 o r 1 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n G M S K ( E d g e = o f f )

R X / T X C h a n n e l 7 0 0 o r 6 6 1

T x P o w e r L e v e l 5

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

R F @ T e s t - J i g

T e s t p o i n t

B a n d G S M 8 5 0 o r 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

m e a s u r e m e n t w i t h t h e 5 0 O h m s p o w e r m e a s u r e m e n t .

P o w e r m e a s u r e m e n t s a t t h e t e s t p o i n t s b y m e a n s o f a p r o b e w i t h 4 7 0 ( ! ) O h m s a t t h e p e a k o n l y . G a i n s o r l o s s e s o f t h e k e y c o m p o n e n t s d e t e c t e d w i t h t h e p r o b e s h a l l b e c o m p a r a b l e t o t h e

M o d u l a t i o n G M S K ( E d g e = o f f )

T y p . + 2 3 d B m

R X / T X C h a n n e l 1 9 0 o r 3 7

T x P o w e r L e v e l 1 0

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m

L o s s e s o f j i g c o m p e n s a t e d

R F @ T e s t - J i g

T e s t p o i n t

B a n d G S M 1 8 0 0 o r 1 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n G M S K ( E d g e = o f f )

T y p . + 2 0 d B m

R X / T X C h a n n e l 7 0 0 o r 6 6 1

T x P o w e r L e v e l 5

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

L o s s e s o f j i g c o m p e n s a t e d

Issue 1 03/2005 COMPANY CONFIDENTIAL 45

Copyright © 2005 Nokia. All Rights Reserved.

Page 46

RM-31

Nokia Customer Care Appendix 6A: Test Points

- 1 5 - 8 d B m

1 . R F i n _ 9 0 0 P

2 . R F i n _ 9 0 0 M

T e s t p o i n t

B a n d G S M 8 5 0 o r 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n 8 - P S K ( E d g e = o n )

R X / T X C h a n n e l 1 9 0 o r 3 7

R F i n _ 9 0 0

d B m

1 . R F i n _ 1 8 0 0 _ 1 9 0 0 P

B O M 1 , B O M 2 , B O M 2 b

I r e f _ 9 0 0

T x P o w e r L e v e l 1 0

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

d B m

- 1 5 - 8 d B m

G S M 8 5 0 o r 9 0 0

T e s t p o i n t

B a n d

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n 8 - P S K ( E d g e = o n )

R X / T X C h a n n e l 1 9 0 o r 3 7

T x P o w e r L e v e l 1 0

T x D a t a T y p e A l l 1

U s e s a m e t e s t p o i n t

I r e f _ 9 0 0 f o r h i g h e r G S M

I r e f _ 1 8 0 0 _ 1 9 0 0 ( B O M 1 )

I r e f _ 9 0 0 ( B O M 2 , B O M 2 b )

b a n d s i n c a s e o f B O M 2

a n d B O M 2 b !

G S M 1 8 0 0 o r 1 9 0 0

V o l t a g e 1 . 9 2 V ( B u r s t )

T e s t p o i n t

R E M A R K

B a n d

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n 8 - P S K ( E d g e = o n )

R X / T X C h a n n e l 7 0 0 o r 6 6 1

T x P o w e r L e v e l 1 0

T x D a t a T y p e A l l 1

V o l t a g e 2 . 0 V ( B u r s t )

2 . R F i n _ 1 8 0 0 _ 1 9 0 0 M

T e s t p o i n t

B a n d G S M 1 8 0 0 o r 1 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n 8 - P S K ( E d g e = o n )

R X / T X C h a n n e l 7 0 0 o r 6 6 1

R F i n _ 1 8 0 0 _ 1 9 0 0

L a y o u t : 1 c n a _ 4 1 ( B u i l d 4 . 0 )

V P C T R L _ 1 8 0 0 _ 1 9 0 0

T e s t p o i n t

B a n d G S M 8 5 0 o r 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n 8 - P S K ( E d g e = o n )

R X / T X C h a n n e l 1 9 0 o r 3 7

T x P o w e r L e v e l 1 0

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

T X A

T e s t p o i n t

B a n d G S M 1 8 0 0 o r 1 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n 8 - P S K ( E d g e = o n )

R X / T X C h a n n e l 7 0 0 o r 6 6 1

d B m

- 1 8 - 1 0 d B m

T x P o w e r L e v e l 5

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

- 1 6 - 8 d B m

d B m

T x P o w e r L e v e l 5

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

V B A T

V P C T R L _ 9 0 0

+ 2 5 . 8 d B m

R F o u t _ 9 0 0

T e s t p o i n t

B a n d G S M 8 5 0 o r 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n 8 - P S K ( E d g e = o n )

R X / T X C h a n n e l 1 9 0 o r 3 7

+ d B m

T x P o w e r L e v e l 1 0

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

R F i n _ 1 8 0 0 _ 1 9 0 0

V T X B _ 1 8 0 0 _ 1 9 0 0

V T X B _ 9 0 0

T X C

V R 3

+ 2 4 . 5 d B m

A N T

T e s t p o i n t

B a n d G S M 8 5 0 o r 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n 8 - P S K ( E d g e = o n )

R X / T X C h a n n e l 1 9 0 o r 3 7

+ d B m

R F i n _ 9 0 0 P

T x P o w e r L e v e l 1 0

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

R F i n _ 9 0 0 M

V R 2

T X Q P

T X Q M

R F i n _ 1 8 0 0 _ 1 9 0 0 P

R F i n _ 1 8 0 0 _ 1 9 0 0 M

( C 7 5 3 0 )

T X I P

T X I M

( C 7 5 2 9 )

V r e f R F 0 1 *

R F i n _ 9 0 0

+ 2 3 . 1 d B m

R F o u t _ 1 8 0 0 _ 1 9 0 0

M O D E

I r e f _ 9 0 0

T e s t p o i n t

B a n d G S M 1 8 0 0 o r 1 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n 8 - P S K ( E d g e = o n )

R X / T X C h a n n e l 7 0 0 o r 6 6 1

+ d B m

T x P o w e r L e v e l 5

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

I r e f _ 1 8 0 0 _ 1 9 0 0 D E TR F o u t _ 9 0 0

+ d B m

A N T

R F o u t _ 1 8 0 0 _ 1 9 0 0

T e s t p o i n t

B a n d G S M 1 8 0 0 o r 1 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n 8 - P S K ( E d g e = o n )

+ 2 1 . 5 d B m

R X / T X C h a n n e l 7 0 0 o r 6 6 1

T x P o w e r L e v e l 5

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

P o w e r @ p r o b e

A N T

R F @ T e s t - J i g

T e s t p o i n t

B a n d G S M 8 5 0 o r 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

m e a s u r e m e n t w i t h t h e 5 0 O h m s p o w e r m e a s u r e m e n t .

P o w e r m e a s u r e m e n t s a t t h e t e s t p o i n t s b y m e a n s o f a p r o b e w i t h 4 7 0 ( ! ) O h m s a t t h e p e a k o n l y . G a i n s o r l o s s e s o f t h e k e y c o m p o n e n t s d e t e c t e d w i t h t h e p r o b e s h a l l b e c o m p a r a b l e t o t h e

M o d u l a t i o n 8 - P S K ( E d g e = o n )

T y p . + 2 4 . 5 d B m

M O D E

GSM850/1800/1900

R X / T X C h a n n e l 1 9 0 o r 3 7

T x P o w e r L e v e l 1 0

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

L o s s e s o f j ig c o m p e n s a t e d

T e s t p o i n t

B a n d G S M 8 5 0 / 9 0 0 / 1 8 0 0 / 1 9 0 0

190 or 700 or 661

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n 8 - P S K ( E d g e = o n )

R X / T X C h a n n e l 1 9 0 o r 3 7 o r 7 0 0 o r 6 6 1

T x P o w e r L e v e l 1 0

T x D a t a T y p e A l l 1

V o l t a g e 1 . 9 6 V ( B u r s t )

R F @ T e s t - J i g

T e s t p o i n t

B a n d G S M 1 8 0 0 o r 1 9 0 0

A c t i v e U n i t T X

O p e r a t i o n M o d e B u r s t

M o d u l a t i o n 8 - P S K ( E d g e = o n )

+ 2 1 . 5 d B m

R X / T X C h a n n e l 7 0 0 o r 6 6 1

T x P o w e r L e v e l 5

T x D a t a T y p e A l l 1

P o w e r @ 5 0 O h m s

L o s s e s o f j ig c o m p e n s a t e d

46 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 47

RM-31

(GS

)

(GSM