Page 1

PAMS Technical Documentation

NSE–1 Series Transceivers

Disassembly &

Troubleshooting

Instructions

Original 03/98

Page 2

NSE–1

PAMS

Disassembly & Troubleshooting Instructions

Technical Documentation

CONTENTS

Disassembly 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trouble Shooting 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone is totally dead 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash programming doesn’t work 6. . . . . . . . . . . . . . . . . . . . . . .

Flash Programming failure (1) 8. . . . . . . . . . . . . . . . . . . . . . .

Flash Programming failure (2) 9. . . . . . . . . . . . . . . . . . . . . . .

Power doesn’t stay on, or phone is jammed 10. . . . . . . . . . . . . .

Display Information: Contact Service 11. . . . . . . . . . . . . . . . . . . .

The phone doesn’t register to the network or phone doesn’t make a call 11

Phone register failure 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIM card is out of order 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIM Card failure 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio failure (1) 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio failure (2) 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charger failure 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Fault (1) 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Fault (2) 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Fault (3) 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Fault (4) 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Fault (5) 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Fault (6) 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Fault (7) 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Fault (1) 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Fault (2) 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Fault (3) 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page No

Page 2

Original 03/98

Page 3

PAMS

NSE–1

Technical Documentation

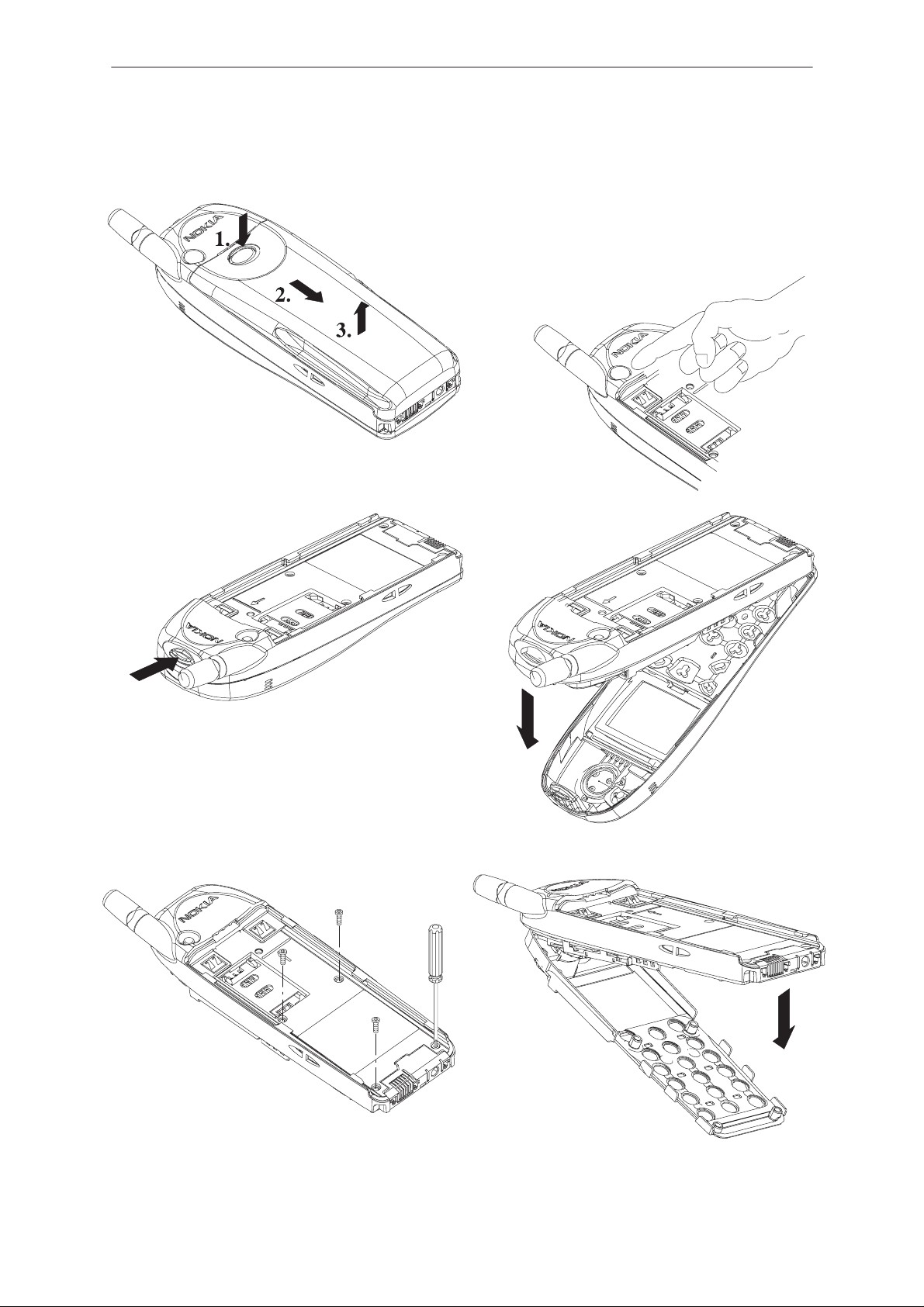

Disassembly

Press strongly towards

arrow direction

Disassembly & Troubleshooting Instructions

Remove battery

Remove dust cap by fingernail

Remove back cover

screws (4 pcs)

Carefully remove A–cover

Note snap fixings !

Remove C–cover

Original 03/98

Page 3

Page 4

NSE–1

PAMS

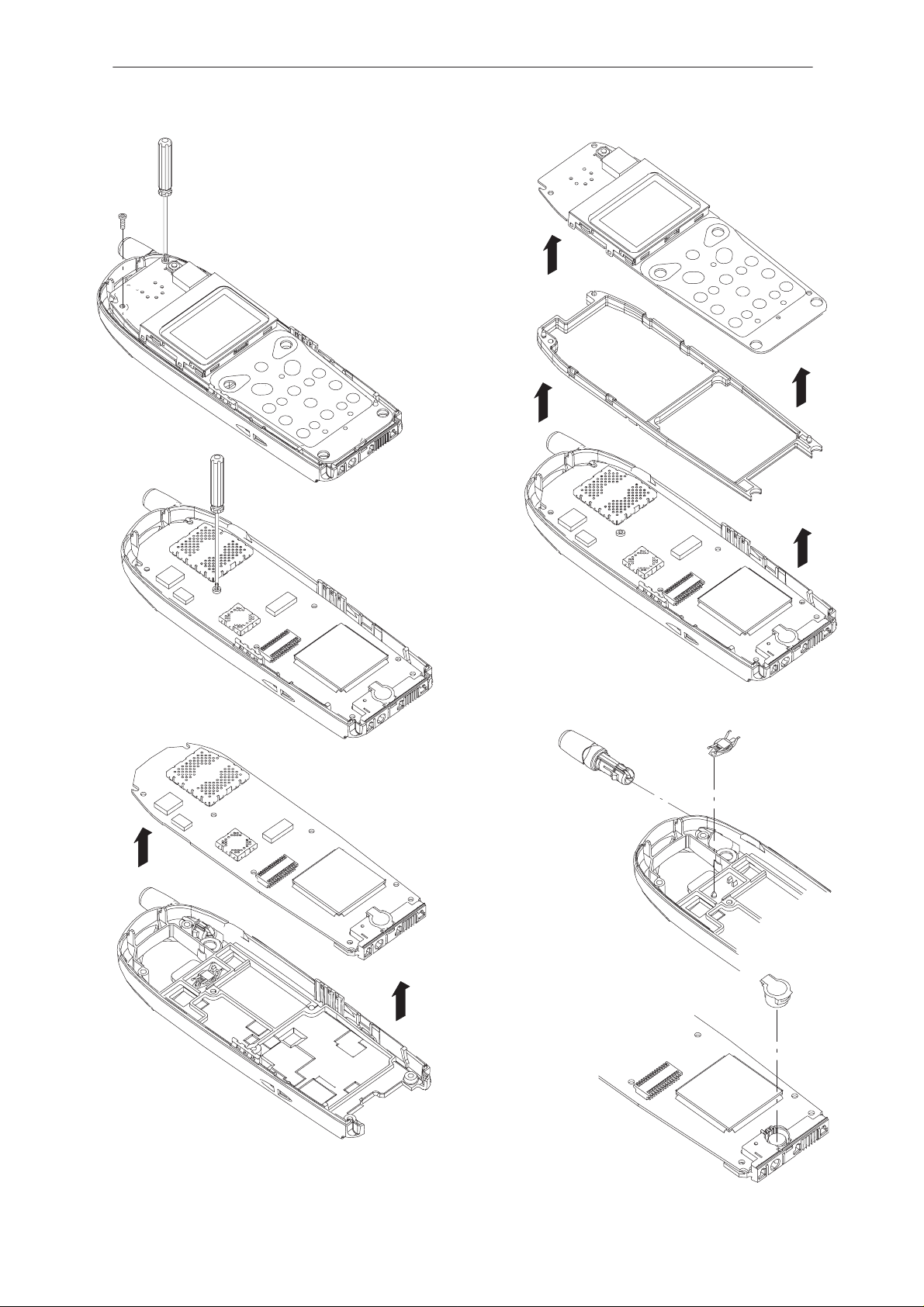

Disassembly & Troubleshooting Instructions

Remove UI–module

screws (2 pcs)

Remove UI–module

and frame

Remove engine

module screw (1 pc)

Technical Documentation

Remove engine module

Remove RTC–battery

Remove antenna by

pulling it straight out

Remove microphone

Page 4

Original 03/98

Page 5

PAMS

NSE–1

Technical Documentation

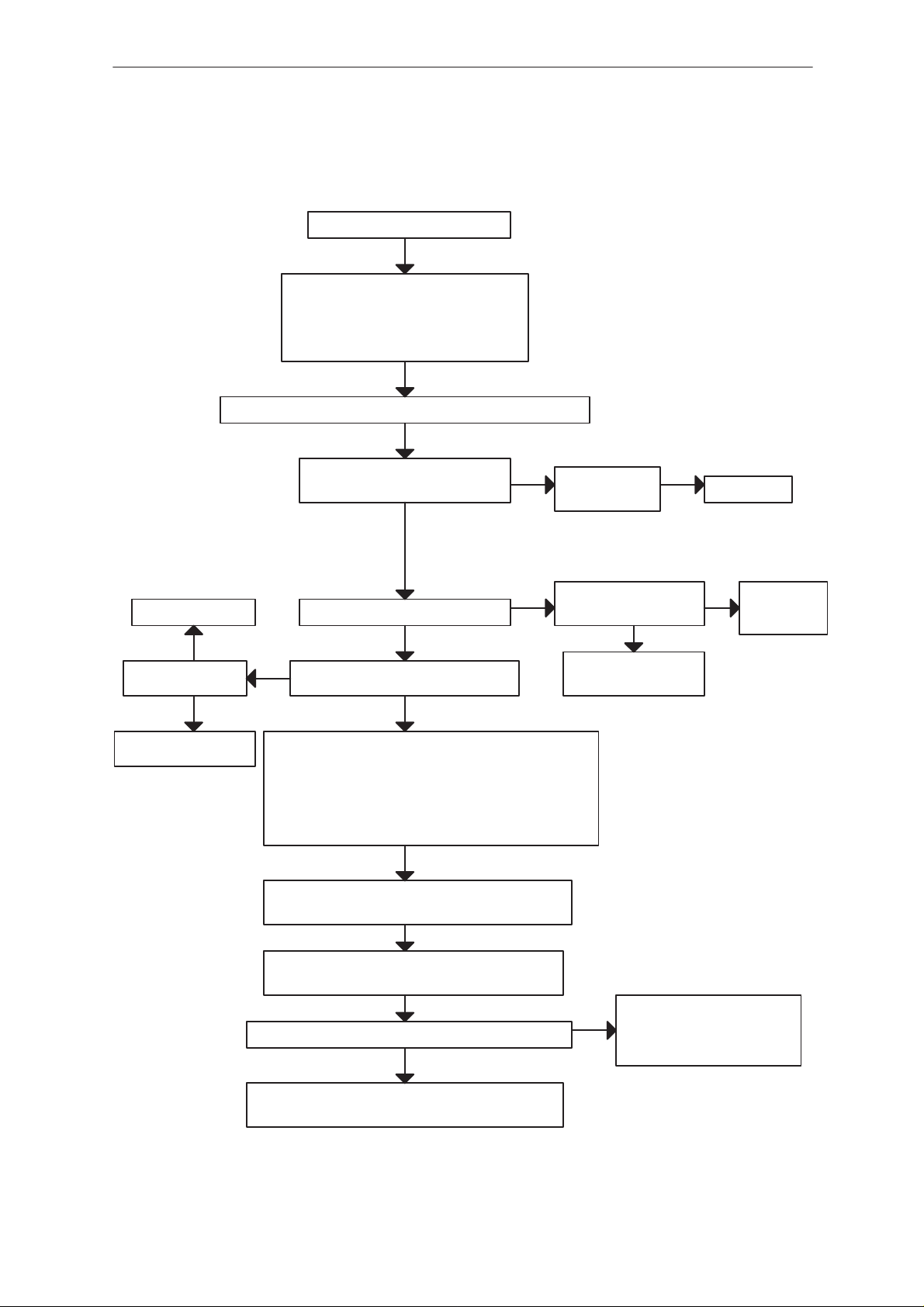

Trouble Shooting

The following hints should facility finding the cause of the problem when

the circuitry seems to be faulty. This trouble shooting instruction is divided following section.

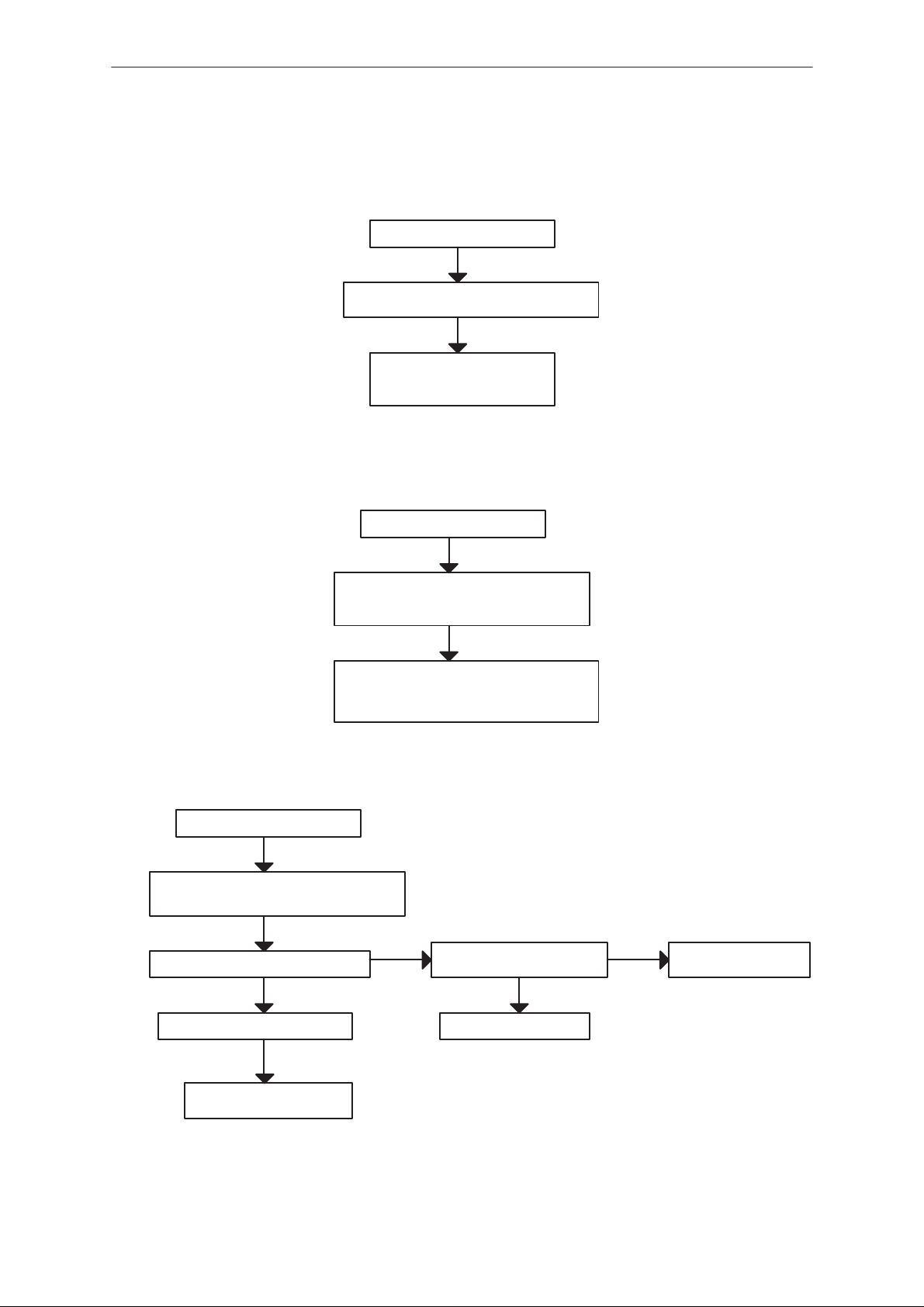

1. Phone is totally dead

2. Flash programming doesn‘t work

3. Power doesn‘t stay on or the phone is jammed

4. Display information: Contact Service

5. Phone doesn‘t register to the network or phone doesn‘t make a call.

6. Plug in SIM card is out of order ( insert SIM card or card rejected).

7. Audio fault.

8. Charging fault

The first thing to do is carry out a through visual check of the module. En-

sure in particular that:

a) there are not any mechanical damages

b) soldered joints are OK

Disassembly & Troubleshooting Instructions

Original 03/98

Page 5

Page 6

NSE–1

PAMS

Disassembly & Troubleshooting Instructions

Phone is totally dead

This means that phone doesn’t take current at all when the power switch

is pressed or when the watchdog disable pin (N100 pin 29) is grounded.

Used battery voltage must be higher than 3.0 V. Otherwise the hardware

of CCONT (N100) prevents totally to switch power on.

Phone is totally dead

YES

J232

VBAT is 3.6 V

YES

Voltage at pin 29 of CCONT (N100)

is 3.6 V

YES

NO Failure in VBAT line

Check X101, X102, L103

NO

Faulty circuit N100

Technical Documentation

N100 pin 55 (VBB) 2.8 V

N100 pin 25 (VXO) 2.8 V

when PWR switch is pressed

or watchdog disable pin is grounded

YES

See section: Power Doesn’t Stay On

NO

CCONT (N100) pin 29 0V

when PWR switch is pressed

Faulty circuit N100

Flash programming doesn’t work

In service places flash programming can be done via system connector

X100.

In flash programming error cases the flash prommer can give some information about a fault.

The fault information messages could be:

– MCU doesn’t boot

– Serial clock line failure

– Serial data line failure

– External RAM fault

– Algorithm file or alias ID don’t find

– MCU flash Vpp error

YES

NO

Check R118, X300

Check UI module

Page 6

In cases that the flash programming doesn’t succeed there is a possibility

to check short circuits between the memories and the MCU (MAD2).

This test is useful to do, when the fault information is: MCU doesn’t boot,

Serial clock line failure or Serial data line failure.

Original 03/98

Page 7

PAMS

NSE–1

Technical Documentation

The test procedure is following:

1. Connect the short circuit wire between the test points J229 and J230.

2. Switch power on

3. If the voltage level in testpoint J225 is 2.8 V (”1”), the interface is OK. If

there is a short circuit, the voltage level in testpoint J225 stays low and

32kHz square wave signal can be seen in the lines which are already tested.

One must be noticed that this test can be found only short circuits, not

open pins.

Also upper data lines (15:8) of flash circuit D210 are not included to this

test.

Disassembly & Troubleshooting Instructions

CCONT pin 54

( PURX )

passed

MAD pin 38

MAD pin 134

J225

( MCUAD0)

( ExtSysResX))selftest

Original 03/98

Page 7

Page 8

NSE–1

PAMS

Disassembly & Troubleshooting Instructions

Flash Programming failure (1)

Flash programming doesn’t work

YES

If the fault information from the prommer is:

a) MCU doesn’t boot

b) serial data line failure

c) serial clock line failure

connect:

connect the shortcircuit fire from N100 pin 29 to ground (watchdog)

OK

EEPROM (D240) pin 8 (VBB) 2.8 V

J522 (VXO) 2.8 V

YES

NO

Technical Documentation

VBAT is correct

3.6 V

YES

N100 is faulty

check C213, R213

YES

J506 (RFC) 13 MHz

800 mV min

NO

check buffer V705 and

VCXO G600

NO J228 sleep clock(SCLK)

J227 master reset (Purx) = ”1” (2.8 V)

YES

NO

MAD2 (D200) pin 93: 13 MHz sine wave

clock signal: 500 mVpp min.

YES

or over loaded PurX line

Check that following lines are correct:

FCLK (MBUS) line: X100 pin 11 –> D200 pin 112

FTX (fbus_tx) line: X100 pin 13 –> D200 pin 104

FRX (fbus_rx) line: X100 pin 12 –> D200 pin 109

check also pullup and pulldown resistors: R203, R201, R215

GND : X100 pin 14 –> GND

OK

Enable the selftest function of D200 by connecting

shortcircuit between testpoints J229 and J230

Connect an oscilloscope to testpoint J225 and switch

power on

Voltage level rises to ”1” after power on at testpoint J225

YES

square wave 32 kHz

YES

Faulty circuit N100

NO

There is a shortcircuit

somewhere in memory control

lines or MCU address lines or

MCU lower (7:0) data lines

check sleep

NO

clock circuitry

(B100, R154...)

Page 8

There could be open pins in circuits D200 (D211, D240)

If not, the PCB or D200 (D211, D240) is faulty

Original 03/98

Page 9

PAMS

NSE–1

Technical Documentation

Flash Programming failure (2)

Flash progrmming doesn’t work

If the fault information from the prommer is:

External RAM fault

Check pins of SRAM (D220)

Check control lines of SRAM:

RAMSelX ...

Flash progrmming doesn’t work

Disassembly & Troubleshooting Instructions

YES

YES

YES

If the fault information from the prommer is:

Algorithm file or alias ID don’t find, ID is unknown etc.

Check pins of FLASH (D210)

Check control lines and upper data lines (15:8)

of FLASH: ROM1SelX...

Flash progrmming doesn’t work

YES

If the fault information from the prommer is:

MCU flash Vpp error

YES

Vpp = 3 V in D210 pin 13 (or C212)

YES

Check components C212, R211

OK

NO

YES

Vpp > 4.5 V in testpoint J234

YES

Check UI regulator N201

NO

Check regulator N100

C132, V116, C131

Faulty component D210

Original 03/98

Page 9

Page 10

NSE–1

PAMS

Disassembly & Troubleshooting Instructions

Technical Documentation

Power doesn’t stay on, or phone is jammed

If this kind of fault has come after flash programming, there are most

probably open pins in ICs.

The soldered joints of ICs: D200 (MAD2), D210 (FLASH), N100

(CCONT), D221 (SRAM) are useful to check at first.

Normally the power will be switched of by CCONT (N100) after 30 seconds, if the watchdog of the CCONT can not be served by software.

The watchdog updating can be seen by oscilloscope at pin 50 (DataselX)

of CCONT.

In normal case there is a short pulse from ”1” –> 0 every 8 seconds.

The power off function of CCONT can be prevented by connecting a short

circuit wire from CCONT pin 29 to ground.

Power doesn’t stay on or phone is jammed

YES

CCONT watchdog is served?

(pin 50 pulses 1 –> 0)

NO

YES

software is able to run

check UI module

If power is switched off

after few seconds, check

BSI and BTEM lines

connect the shortcircuit fire from N100 pin 29 to ground (watchdog)

check C213, R213

YES

J506 (RFC) 13 MHz

800 mV min

NO

check buffer V705 and

VCXO G600

OK

EEPROM (D240) pin 8 (VBB) 2.8 V

J522 (VXO) 2.8 V

YES

J227 master reset (Purx) = ”1” (2.8 V)

YES

NO

MAD2 (D200) pin 93: 13 MHz sine wave

clock signal: 500 mVpp min.

YES

Open pins or faulty circuit:

D200, D210, D221, N100

R215

NO

VBAT is correct

3.6 V

NO J228 sleep clock(SCLK)

square wave 32 kHz

Faulty circuit N100

or over loaded PurX line

YES

YES

N100 is faulty

check sleep

NO

clock circuitry

(B100, R154...)

Page 10

Original 03/98

Page 11

PAMS

NSE–1

Technical Documentation

Disassembly & Troubleshooting Instructions

Display Information: Contact Service

This fault means that software is able to run and thus the watchog of

CCONT (N100) can be served.

Selftest functions are run when power is switched on and software is

started to excute from flash.

If any of selftests is failed, contact service information will be shown on

display.

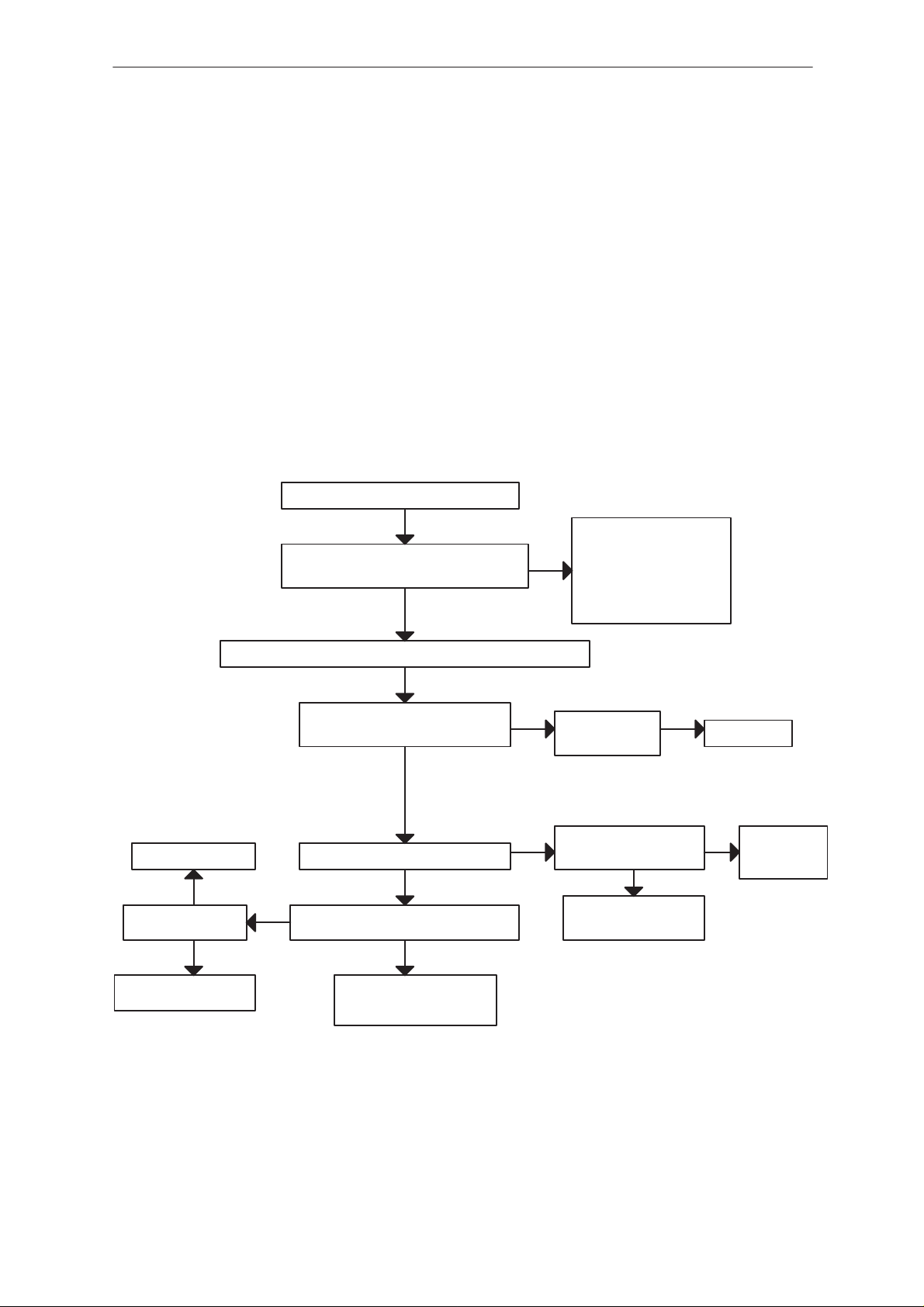

The phone doesn’t register to the network or phone

doesn’t make a call

If the phone doesn’t register to the network or the phone doesn’t make a

call, the reason could be either the baseband or the RF part.

The phone can be set to wanted mode by WinTesla service software and

determinate if the fault is in RF or in baseband part (RF interface measurements).

The control lines for RF part are supplied both the System Asic

(MAD2;D200) and the RFI (Cobba; N250). MAD2 handles digital control

lines ( like synthe, TxP etc.) and Cobba handles analog control lines (like

AFC, TxC etc.).

The DSP software is constructed so that operation states of DSP (MAD2)

can be seen in external flag (DSPXF) output pin (D200 pin 91).

After power up, DSP signals all completed functions by changing the state

of the XF pin (see figures 39 and 40).

1. DSP initialization done

2.Synchronization to network

done

3. Registrarition to network

done.

1 2 3

Original 03/98

MAD2 pin 91 (DSPXF)

J222

Page 11

Page 12

NSE–1

PAMS

Disassembly & Troubleshooting Instructions

init

initialize

1

patch code

download

2

dsp

constants

download

initialization

done

Technical Documentation

MAD2 pin 91 (DSPXF)

J222

channel

scan starts

PSW

search last PSW

OK

3

send RACH

RACH OK

go SDCCH

imediate assigment

OK

synchronization

OK

MAD2 pin 91 (DSPXF)

J222

MAD2 pin 91 (DSPXF)

J222

Page 12

Original 03/98

Page 13

PAMS

NSE–1

Technical Documentation

Phone register failure

Phone doesn’t register to the network

Analog supply voltage VCOBBA is >2.7 V

at pin 7,12 ... of Cobba (N250)

Analog reference voltage Vref is 1.5 V

Supply voltage VCP (N100 pin 32) > 4.8 V

Supply voltage VRX (N100 pin 9) > 2.7 V

Supply voltage VSYN_1 (N100 pin 15) > 2.7 V

Supply voltage VSYN_2 (N100 pin 4) > 2.7 V

Supply voltage VTX (N100 pins 11, 20) > 2.7 V

Disassembly & Troubleshooting Instructions

or

phone doesn,t make a call

YES

YES

at pin 9 of Cobba (N250)

YES

during the receiving slot

during the transmitting slot

Check

NO

N100

NO

Check

R270, R271

NO Check

N100, D200

YES

Synthesizer lines: SEna (N620 pin 56),

SClk (N620 pin 54)

SData (N620 pin 55)

pulses 0 –> 1 during receiving slot

YES

NO

Check

D200

RF control lines: RxC (N250 pin 18) 0 –> 2.3 Vmax during receiving slot

AFC (N250 pin 19) 0 – 1.2 V typ. during receiving slot

YES

Analog data signal RxIP (N250 pin 22) 0–> 1.5 V DC during receiving slot

Analog data signal RxIN (N250 pin 22) 0–> 1.5 V DC during receiving slot

Used benefit signal is biased to DC and its amplitude is 50 mVpp

nominal and frequency is 13 MHz

YES

NO

DAX signal (N250 pin 48) pulses 1 –> 0 during receiving slot

YES

RF control lines: TxC (N250 pin 17) 0 –> 2.3 Vmax during transmit slot

TxP (D200 pin 176) 0–>1 (2.8 V) during transmit slot

YES

NO

Check

N250

NO

Check

N250 if DC is failed

Check

RF part if benefit signal is failed

Check

N250

Check

NO

N250 if TxC is failed

Check

D200 if TxP is failed

Analog data signals: TxIN (N250 pin 13) 0–> 0.8 V DC during transmit slot

Original 03/98

TxIP (N250 pin 14) 0 –>0.8 V DC during transmit slot

TxQN (N250 pin 15) 0 –>0.8 V DC during transmit slot

TxQP (N250 pin 16) 0 –>0.8 V DC during transmit slot

Used benefit signal is biased to DC and its amplitude is 300 mVpp

nominal and frequency is 67 kHz

NO

YES

Check

N250

Check

RF part

Page 13

Page 14

NSE–1

PAMS

Disassembly & Troubleshooting Instructions

SIM card is out of order

The hardware of the SIM interface from MAD2 (D200) to the SIM connector (X302) can be tested without SIM card.

When the power is switched on and if the BSI line (X101;1) is grounded

by resistor, all the used lines (VSIM, RST, CLK, DATA) rises up to 5 V four

times. Thus ”Insert SIM card” faults can be found without SIM card.

The fault information ”Card rejected” means that ATR message (the first

message is always sent from card to phone) is sent from card to phone

but the message is somehow corrupted, data signal levels are wrong etc.

or factory set values (stored to the EEPROM) are not correct.

Technical Documentation

Page 14

Original 03/98

Page 15

PAMS

NSE–1

Technical Documentation

SIM Card failure

VSIM(36), DATAO(43),SIMRSTO(42) and SIMCLKO(38) lines

rises up to 5 V after power on at pins of N100 (CCONT)

SIMPWR(30), DATAA(44), SIMRSTA(40), SIMCLK(41) and SIMIOC(39) lines

rises up to 2.8 V after power on at pins of N100 (CCONT)

Disassembly & Troubleshooting Instructions

Insert SIM card fault

YES

Voltage level < 1.5 V

at pin 95 of D200 when

BSI resistor is connected

YES

VSIM, DATA, RESET and CLOCK lines

rises up to 5 V after power on at pins

of SIM card

NO

NO

NO

NO

Check

R120, R122, X101

C120, C160

YES

Check

SIM card and SIM reader

connectors

YES

Check

X302, R124, R125, R128

YES

faulty circuit

N100 (CCONT)

SIMCardPwr(129), SIMCardData(120), SIMCardRstX(127), SIMCardClk(126) and SIMCardIOC(128) lines

rises up to 2.8 V after power on at pins of D200 (MAD2)

NO

Check again that voltage level at pin 95 (SIMCardDetX) of D200 is lower than 1.5V

If it is, change D200

Card Rejected fault

YES

VSIM is according the specification

VSIM = 2.8 V min (with 3 V SIM card)

NO

faulty circuit

N100 (CCONT)

VSIM = 4.5 V min (with 5 V SIM card)

YES

The ATR data can be seen at pin 43

(CCONT, N100)

YES

The ATR data can be seen at pin 120

(MAD2, D200)

YES

SIMIOControl line (N100 pin 36) is ”1”

during the ATR message

NO

NO

NO

Check

X302, R124

Check

N100

Check

D200

YES

faulty PCB

Original 03/98

YES

Check D200

Page 15

Page 16

NSE–1

PAMS

Disassembly & Troubleshooting Instructions

Audio failure (1)

Uplink (microphone) and downlink (earphone) are broken

YES

Voltage at pin 107 of MAD2 (D200)

is 2.8 V (without external audio devices) HOOKDET

YES

Voltage at pin 108 of MAD2 (D200)

is 2.8 V (without external audio devices) HEADDET

YES

Frequency at pin 138 of MAD2 (D200)

is 1 MHz, square wave 2.8 Vpp

YES

Technical Documentation

NO

Check

R259, R260

NO

NO

Check

R257, R256, R261

Check

N250 (Cobba)

Frequency at pin 139 of MAD2 (D200)

NO

is 8 kHz, square wave pulses 2.8 Vpp

Uplink (microphone) is broken

YES

Voltage at pin 6 of X100 is 1.8 V

NO

Voltage at pin 7 of X100 is 0.3 V

during a call

YES

DC voltage at pins 59 and 60 of

NO Check

N250 is 1.4 V during a call

YES

Analog audio signal (few millivolts) at pins 59 and 60

of N250 during a call

YES

Digital PCM data at pin 137 of MAD2 (D200)

during a call

Check

N250 (Cobba)

Check

microphone, X100 and micbias

components V250...

If OK, check that micbias control line

is (D200 pin1 ) 2.8 V during a call

N250 (Cobba)

NO

Check

C262, C263 and PCB

routings

NO

Check

N250 (Cobba)

Page 16

Original 03/98

Page 17

PAMS

NSE–1

Technical Documentation

Audio failure (2)

Digital PCM data at pin 52 of Cobba (N250)

during a call

Analog audio signal (some ten millivolts) at pins 5 and

6 of N250 during a call

Disassembly & Troubleshooting Instructions

Downlink (earphone) is broken

YES

YES

DC voltage at pins 5 and 6 of

N250 is 1.4 V during a call

YES

NO

NO

N250 (Cobba)

Check

D200 (MAD2)

Check

NO

Check

N250 (Cobba)

Original 03/98

Page 17

Page 18

NSE–1

PAMS

Disassembly & Troubleshooting Instructions

Charger failure

Nothing happens when charger is connected

YES

Voltage level at pin 60 of CCONT (N100)

is higher than 0.4 V when charger is connected

YES

Check N100

Display Information: Not charging

YES

Voltage level at pin 62 of CCONT (N100)

is about 0.8 V when power is connected

BSI resistor value should be 39 k

YES

Technical Documentation

NO

Check

X100, F100, L104

R104, R103

NO Check

X101, R120, R122

Voltage level at pin 63 of CCONT (N100)

is about 0.5 V when power is connected

BTEMP resistor value should be 47 k

YES

32 Hz square wave frequency at pin 7 of CHAPS (N101)

YES

Voltage levels at pins 5 and 12 of CHAPS (N101)

are same as VB

YES

Voltage levels at pins 5 and 12 of CHAPS (N101)

rises when charger is connected

NO

X101, R120, R122

NO

NO

NO

Check

Check

N100

Check

R131, N101

Check

N101

Page 18

Original 03/98

Page 19

PAMS

NSE–1

Technical Documentation

Receiver Fault (1)

Change X540

NO

Ω

YES

and 2 ~ 0

Check soldered joints of X540

Loading between X540 pin 1

NO

and Z550, check also that X540

Change Z550

is assembled correct, if OK

Disassembly & Troubleshooting Instructions

NO

Ω

YES

if OK change Z500

Check soldered joints,

NO

Ω

YES

if OK change it

Z500 input, loading > 1 M

Check C500 soldered joints,

NO

if OK cange Z500

Check C518, C504,

NO

Ω

YES

Z500 output,

Change Z500

loading > 1 M

NO

loading 50

N500 pin 7 and 8,

C520 check

internal coils

Check soldered joints of C516,

NO

Change N500

change N500

Rise up N500

pin 7,8. If level

back to normal

YES

YES

Fault

Receiver

N500 pin 25, SL: –61 dBm

Duplexer ant–pin, SL: –58 dBm

NO

Ω

YES

N500 pin 25,

loading > 1 M

Duplexer Rx–pin, SL: –61 dBm

NO

NO

YES

N500 pin 23, SL: –38 dBmN500 pin 26 is ”HIGH”

NO

YES

NO

YES

Ω

YES

Z500 input, SL: –44 dBm

Z500 output, SL: –47 dBm

N500 pin 17 and 19, 2.8V

NO

YES

YES

N500 pin 16, 1.5V

NO

YES

1st IF

N500 pin 7 and 8, SL: –57 dBm

Ω

YES

N500 pin 20, loading 10 k

NO

Ω

YES

N500 pin 23, loading 10 k

NO

71 MHz

Original 03/98

change N500

Check C506, if OK

Change duplexer

N500 pin 26,

loading > 1 M

NO

Check PDATA0–line

for short circuits

Check PDATA0–line

D200 pin 171

VSYN_1(J516) lines

Check VRX(J510) and

from CCONT

Check VREF_2(J518)

voltage line

Check soldered joints of N500

and R504, if OK change R504

of pin 23, if OK change N500

Check components in line out

Page 19

Page 20

NSE–1

PAMS

Disassembly & Troubleshooting Instructions

Receiver Fault (2)

Z621

OK change

short circiuts, if

UHFLO

NO

YES

SL: –28 dBm

G530 Out, 1018 MHz

to N500 pin 12

Check connections from G530

Check input for

NO

Ω

loading > 1 M

Z621 input 1 and 2,

for short

Check output

NO

YES

line to Z621

Check components in input

Z621 ouput 1 and 2,

Technical Documentation

change Z621

circiuts, if OK

Ω

YES

loading > 1 M

change Z621

joints at N620, if OK

Check components in

output line. Check soldered

1st IF

71 MHz

NO

YES

N500 pin 12,

1018 MHz SL: –28 dBm

YES

SL: –28

N500 pin 9 and 10,

NO

YES

N500 pin 15,

N500 pin 6, 2.8V

NO

NO

NO

YES

SL: –30

Z621 input 1 and 2,

Ω

YES

loading 10 k

N500 pin 9 and 10,

NO

Ω

YES

loading 10 k

NO

SL: –43

Z621 output,

Change N500

YES

N620 pin 51(J530) and

NO

N620 pin 47, 2.8V

NO

YES

52(J532), SL: –43

YES

YES

DC–level ~1.7V

N620 pin 51 and 52,

NO

Ω

2nd IF

13 MHz

Change N620

Page 20

soldered joints

Check VRX(J510) and

Check R504

OK at pads change N500

Rise up 9 and 10, if loading

YES

of N620

Check soldered joints

loading 5 k

N620 pin 51 and 52,

NO

Original 03/98

52 for short circuit

Check N620 pin 51 and

Page 21

PAMS

NSE–1

Technical Documentation

Receiver Fault (3)

VHFLO

Check VRX supply voltage

NO

~2.8V

N620 pin 47(J510),

Check RXC control voltage

NO

YES

N620 pin 53(J554),

from COBBA pin 18

~1.2V

Disassembly & Troubleshooting Instructions

Change N620

NO

YES

Change N620

YES

DC–level ~1V

N620 pin 29 and 30,

2nd IF

13 MHz

NO

N620 pin 8(J542),

NO

YES

SL: – 28 dBm

YES

N620 pin 44,

SL: – 19 dBm

YES

SL: –26 dBm

Z620 input(J540),

NO

joints

Check R626 and soldered

YES

SL: –28 dBm

Z620 output(J538),

NO

change Z620

Check soldered joints, if OK

NO

YES

and pin 35, SL: –33 dBm

N620 pin 34, SL: –36 dBm

NO

YES

DC–level, ~1.4V

N620 pin 34 and 35,

YES

SL: – 29 dBm

N620 pin 29 and 30,

Check R628 and R629

Check soldered joints at N620

and N250, if OK change N620

YES

SL: –29 dBm

N250 pin 22 and 23,

NO

N620 and N250

Check connections between

COBBA

Original 03/98

NO

N620

Change

Page 21

Page 22

NSE–1

PAMS

Disassembly & Troubleshooting Instructions

Receiver Fault (4)

COBBA

N250 pin 7,12,21,25 and 63,

~2.8V

YES

N250 pin 27 and 53,

~2.8V

YES

N250 pin 9,

~1.5V

YES

N250 pin 10,

loading 100 k

YES

N250 pin 45,

13 MHz clock OK

YES

Ω

NO

NO

NO

NO

NO

Check VCOBBA–voltage from

Check VBB–voltage from

Check VREF–voltage from

CCONT pin 13 through R253

Check soldered joints and

Check COBBACLK–line from

Technical Documentation

CCONT pin 22

CCONT pin 55

R253

MAD pin 144

N250 pin 28,

is ”HIGH”

YES

Check data and adress lines

between D200 and N250, if

OK change N250

COBBACLK – signal:

Oscilloscope picture in Appendix A

NO

Check COBBARSTX–line

from MAD pin 163

Page 22

Original 03/98

Page 23

PAMS

NSE–1

Technical Documentation

Receiver Fault (5)

UHFLO

G530 VCC–pin voltage, 2.8V

YES

G530 VC(J500) voltage

~2.25V (Mid CH)

YES

Change G530

Disassembly & Troubleshooting Instructions

NO

Check VSYN_1–line and R530

NO

Check soldered joints

at G530, N620 and components

N620 pin 21, 13 MHz clock

in VC–line

Does G530 oscillate at

any frequency

N620 pin 9,22 and 25,

N620 17 and 28,

2.8V

5V

YES

YES

YES

YES

YES

NO

NO

NO

NO

Change G530

Check C633 and

soldering joints at

Check VSYN_2(J508)

from CCONT and

CNTVR3–control from MAD

Check VCP–voltage

from CCONT pin 32

N620

N620 pin 58,

1.5V

N620 pin 59,

loading 15 k

working OK

SCLK, SDATA, SENA1

Change N620

13 MHz clock oscilloscope picture in Appendix A

SCLK, SDATA, SENA1 oscilloscope pictures in Appendix B

YES

YES

YES

NO

NO

Ω

NO

Check VREF_1–line

Check soldering joints

at N620 and R635, if

OK change R635

Check SCLK, SDATA,

SENA1–lines from

MAD

Original 03/98

Page 23

Page 24

Page 24

VHFLO

Receiver Fault (6)

Disassembly & Troubleshooting Instructions

NSE–1

N620 9,22 and 25, ~2.8V

Original 03/98

N620 pin 18, ~2.3V

YES

N620 17 and 28, ~5V

YES

Change N620

NO

NO

NO

Does the VCO oscillate at any

frequency ?

YES

Check VSYN_2(J508)

supply voltage

Check VCP voltage line

NO

V581 collector,

~2.6V

YES

V581 base, ~1.7V

YES

V581 emitter, ~1V

YES

Check V580, L581, C582,

C583

NO

NO

NO

Check VSYN_1(J516) supply

voltage line to V581

Check R581, R585 and

soldered joints

V581 emitter loading ~330

Ω

if OK change V581

,

Technical Documentation

PAMS

Page 25

Original 03/98

AFC

Receiver Fault (7)

Technical Documentation

PAMS

RSSI tuning working OK ?

YES

N250 pin 19,

voltage between 0.5 – 2.3V

YES

Set SpectrumAnalyzer

Frequency: 13 MHz

Span: 10 kHz

RESBW: 3 kHz

13 MHz in midst,

(Test point J 506)

NO

NO

Use sevice software to set AFC

NO

Receiver

Fault

N250 pin 19,

loading > 1 M

YES

Change N620

to MAX

Ω

NO

Check AFC–line(J520) for

short circuits, if OK change

Disassembly & Troubleshooting Instructions

Page 25

NOTE !

properly, supply voltages stays

down.

If DSP in MAD does not work

AFC–voltage(J520),

~2.3V

YES

Main clock(J506),

> 13 MHz

NO

NO

Check R600 and C602, if

OK change N250

NSE–1

Change G600

Page 26

NSE–1

PAMS

Disassembly & Troubleshooting Instructions

Transmitter Fault (1)

& J560)

from CCONT

Check TXP–line from MAD

Check VTX supply voltage

NO

YES

N620 pin 1,

TXP–pulse OK?

OK ?

N620 pin 63(J514), VTX–pulse

VHFLO

Check TXQP, TXIP, TXQN, TXIN

lines from COBBA pin 13...16 and

soldered joints at N620 and N250,

if OK change N250(Test pins J558

NO

N620: TXQP, TXQN, TXIP

NO

YES

and TXIN, OK ?

Check VREF_1 – line

Check TXC–line from COBBA

NO

YES

NO

YES

N620 pin 58, ~1.5V

N620 pin 11, TXC–pulse OK?

Technical Documentation

joints

Change N620

Check R635 and soldered

NO

YES

NO

Ω

YES

N620 pin 59,

loading 15 k

N620 pin 61 and 62, ~0.8V

TXQP, TXIP, TXIN, TXQN, TXP and VTX:

Oscilloscope pictures in Appendix C

Fault

TXLEV 5

Transmitter

NO

N620 pin 8(J542)

NO

YES

N620 pin 61 and 62,

232 MHz SL: –28 dBm

116 MHz SL: –40 dBm

YES

YES

N500 pin2(J552) and pin3

(J550) 116 MHz SL: –32 dBm

NO

Ω

YES

loading > 1M

N500 pin 2 and 3,

NO

YES

SL: –28 dBm

N500 pin 12(RX–Continous),

NO

UHFLO

change N500

Check C652, C653, C655,

L623, L624, R623, R625, if OK

YES

SL: –18 dBm

N500 pin 30,

NO

YES

~2.8V

N500 pin 16,

N500 pin 1 and 29,

NO

NO

~1.5V

YES

N500 pin 20,

NO

1

Transmitter

Ω

YES

loading 10 k

Change N500

Page 26

OK change N500

3 for short circuits, if

Check N500 pin 2 and

from CCONT

Check VTX supply voltage

Check VREF_2 – line(J518)

joints

Check R504 and soldered

Original 03/98

Page 27

Original 03/98

Transmitter

1

TXLEV5

Transmitter Fault (2)

Technical Documentation

PAMS

Page 27

Check Z505 output for short

circuits, if OK change Z505

Check VBATT–connections to

N550

Check soldered joints

at N550

Check soldered joints at N550

and N620, if OK change N620

VTX and power contol pulse(TXC):

Oscilloscope pictures in Appendix D

NO

Z505 output,

loading > 1 M

YES

Change Z505

NO

N550 pin 2,4,6,12,13 and 14

NO

NO

C564,C505,C566,C572,C555,C

567,L552, if OK change N550

~3.6V

YES

N550 pin 1 and 16,

VTX–pulse

YES

N550 pin 9,

power control pulse

YES

Check

Z505 input,

SL: – 23 dBm

YES

NO

Ω

NO

Z505 output,

SL: –29 dBm

YES

N550 pin 8,

SL: –29 dBm

YES

N550 pin 13,

SL: –2 dBm

YES

Duplexer TX–pin,

SL: 6 dBm

YES

RF–connector X540 pin 1,

SL: 5 dBm

NO

NO

NO

NO

Z505 input,

loading > 1 M

Check C700

Check V640 limiter circuit

DC–levels(VTX–voltage),

Base: ~0.6V

Collector: ~0.6V

Emitter: ~0.3V

Check components in line

from N550 to Z550. Also

check for short circuits, if OK

change Z550

Check X540, if OK change

Ω

YES

Z550

NO

Check Z505 input for short

circuits, if OK change Z505

Check R668, R662, R664,

R666, R670, C660, C662

and C562, If OK change

V640

Disassembly & Troubleshooting Instructions

NSE–1

Page 28

NSE–1

PAMS

Disassembly & Troubleshooting Instructions

Transmitter Fault (3)

Power

Control

TXLEV5

Transmitter working OK

YES

N250 pin 11,

TXC – pulse OK

NO

NO

Check TXC – line from N250

Transmitter

pin 17, if OK change N250

Technical Documentation

Fault

YES

N620 pin 11 and 12 pulses

are about the same

NO

R554, if OK change V550

V550 anode,

DC–voltage ~0.8V

YES

N620 pin 12,

loading ~4 k

YES

Check C554, R553 and

Ω

NO

NO

Check VSYN_1 voltage

through R550, R551 and R552

Check C632, if OK

change N620

TXC – pulse:

Oscilloscope picture in Appendix D

Page 28

Original 03/98

Page 29

PAMS

NSE–1

Technical Documentation

Appendix A

Disassembly & Troubleshooting Instructions

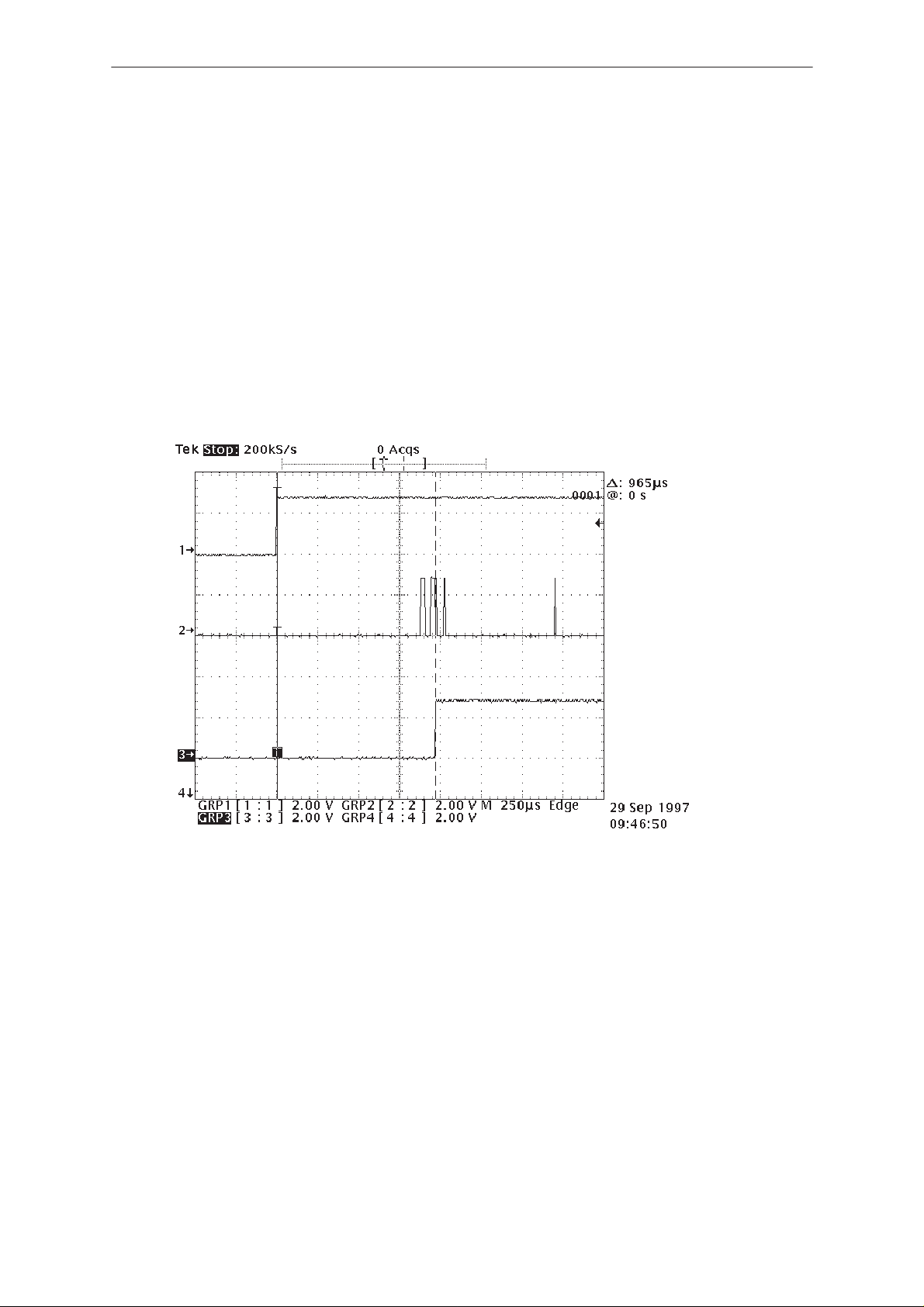

Picture 1. COBBACLK – signal

Picture 2. 13 MHz Main clock – signal

Original 03/98

Page 29

Page 30

NSE–1

PAMS

Disassembly & Troubleshooting Instructions

Appendix B

Picture 3. SCLK – signal

Technical Documentation

Picture 4. SDATA – signal

Picture 5. SENA1 – signal

Page 30

Original 03/98

Page 31

PAMS

NSE–1

Technical Documentation

Disassembly & Troubleshooting Instructions

Appendix C

Picture 6. TXQP, TXQN, TXIP and TXIN – signal

Picture 7. TXP – signal

Picture 8. VTX – signal

Original 03/98

Page 31

Page 32

NSE–1

PAMS

Disassembly & Troubleshooting Instructions

Appendix D

Technical Documentation

Picture 9. TXC – signal (TXLEV5)

Picture 10. DET – signal(N620 pin 12) TXLEV5

Page 32

Original 03/98

Loading...

Loading...