Page 1

Nokia Customer Care

Service Manual

RH-128 (Nokia 1506 ; L3&4)

Mobile Terminal

Part No: (Issue 1)

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 2

Amendment Record Sheet

Amendment No Date Inserted by Comments

Issue 1 December, 2009 Lijun Gu

RH-128

Amendment Record Sheet

ii

COMPANY CONFIDENTIAL

Issue 1

Copyright © 2009 Nokia. All rights reserved.

Page 3

RH-128

Copyright

Copyright

Copyright© 2009 Nokia. All rights reserved.

Reproduction, transfer, distribution or storage of part or all of the contents in this document in any form without

the prior written permission of Nokia is prohibited.

Nokia, Nokia Connecting People, X and Y are trademarks or registered trademarks of Nokia Corporation. Other

product and company names mentioned herein may be trademarks or tradenames of their respective owners.

Nokia operates a policy of continuous development. Nokia reserves the right to make changes and

improvements to any of the products described in this document without prior notice.

Under no circumstances shall Nokia be responsible for any loss of data or income or any special, incidental,

consequential or indirect damages howsoever caused.

The contents of this document are provided "as is". Except as required by applicable law, no warranties of any

kind, either express or implied, including, but not limited to, the implied warranties of merchantability and fitness

for a particular purpose, are made in relation to the accuracy, reliability or contents of this document. Nokia

reserves the right to revise this document or withdraw it at any time without prior notice.

The availability of particular products may vary by region.

IMPORTANT

This document is intended for use by qualified service personnel only.

Issue 1

Copyright © 2009 Nokia. All rights reserved.

COMPANY CONFIDENTIAL

iii

Page 4

RH-128

Warnings and cautions

Warnings and cautions

Please refer to the phone’s user guide for instructions relating to operation, care and maintenance including

important safety information. Note also the following:

WARNINGS

z CARE MUST BE TAKEN ON INSTALLATION IN VEHICLES FITTED WITH ELECTRONIC ENGINE

MANAGEMENT SYSTEMS AND ANTI–SKID BRAKING SYSTEMS. UNDER CERTAIN FAULT

CONDITIONS, EMITTED RF ENERGY CAN AFFECT THEIR OPERATION. IF NECESSARY, CONSULT

THE VEHICLE DEALER/MANUFACTURER TO DETERMINE THE IMMUNITY OF VEHICLE

ELECTRONIC SYSTEMS TO RF ENERGY.

z THE HANDPORTABLE TELEPHONE MUST NOT BE OPERATED IN AREAS LIKELY TO CONTAIN

POTENTIALLY EXPLOSIVE ATMOSPHERES, EG PETROL STATIONS (SERVICE STATIONS),

BLASTING AREAS ETC.

z OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT, INCLUDING CELLULAR TELEPHONES,

MAY INTERFERE WITH THE FUNCTIONALITY OF INADEQUATELY PROTECTED MEDICAL DEVICES.

CONSULT A PHYSICIAN OR THE MANUFACTURER OF THE MEDICAL DEVICE IF YOU HAVE ANY

QUESTIONS. OTHER ELECTRONIC EQUIPMENT MAY ALSO BE SUBJECT TO INTERFERENCE.

CAUTIONS

z Servicing and alignment must be undertaken by qualified personnel only.

z Ensure that all work is carried out at in anti–static workstation and that an anti–static wrist strap is worn.

z Use only approved components as specified in the parts list.

z Ensure that all components, modules screws and insulators are correctly re–fitted after servicing and

alignment.

z Ensure that all cables and wires are correctly repositioned.

iv

COMPANY CONFIDENTIAL

Issue 1

Copyright © 2009 Nokia. All rights reserved.

Page 5

RH-128

For your safety

For your safety

QUALIFIED SERVICE

Only qualified personnel may install or repair mobile terminal equipment.

ACCESSORIES AND BATTERIES

Use only approved accessories and batteries. Do not connect incompatible products.

CONNECTING TO OTHER DEVICES

When connecting to any other device, read its user’s guide for detailed safety instructions. Do not connect

incompatible products.

Issue 1

COMPANY CONFIDENTIAL

v

Copyright © 2009 Nokia. All rights reserved.

Page 6

ESD protection

RH-128

ESD protection

Nokia requires that product service points have sufficient ESD protection (against

static electricity) when servicing products.

Any product of which the covers are removed must be handled with ESD protection.

The SIM card can be replaced without ESD protection if the product is otherwise

ready for use.

To replace the covers ESD protection must be applied.

All electronic parts of the product are susceptible to ESD. Resistors, too, can be

damaged by static electricity discharge.

All ESD sensitive parts must be packed in metallized protective bags during

shipping and handling outside any ESD Protected Area (EPA).

Every repair action involving opening the product or handling the product

components must be done under ESD protection.

ESD protected spare part packages MUST NOT be opened/closed out of an ESD

Protected Area.

For more information and local requirements about ESD protection and ESD

Protected Area, contact your local Nokia After Market Services representative.

vi

Copyright © 2009 Nokia. All rights reserved.

COMPANY CONFIDENTIAL

Issue 1

Page 7

RH-128

Care and maintenance

Care and maintenance

This product is of superior design and craftsmanship and should be treated with care. The suggestions

below will help you to fulfill any warranty obligations and to enjoy this product for many years.

Keep the phone and all its parts and accessories out of the reach of small children.

Keep the phone dry. Precipitation, humidity and all types of liquids or moisture can contain minerals that will

corrode electronic circuits.

Do not use or store the phone in dusty, dirty areas. Its moving parts can be damaged.

Do not store the phone in hot areas. High temperatures can shorten the life of electronic devices, damage

batteries, and warp or melt certain plastics.

Do not store the phone in cold areas. When it warms up (to its normal temperature), moisture can form

inside, which may damage electronic circuit boards.

Do not drop, knock or shake the phone. Rough handling can break internal circuit boards.

Do not use harsh chemicals, cleaning solvents, or strong detergents to clean the phone.

Do not paint the phone. Paint can clog the moving parts and prevent proper operation.

Use only the supplied or an approved replacement antenna. Unauthorized antennas, modifications or

attachments could damage the phone and may violate regulations governing radio devices.

All of the above suggestions apply equally to the product, battery, charger or any accessory.

Issue 1

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

vii

Page 8

RH-128

Company policy

Company policy

Our policy is of continuous development; details of all technical modifications will be included with service

bulletins.

While every endeavor has been made to ensure the accuracy of this document, some errors may exist. If

any errors are found by the reader, NOKIA MOBILE PHONES Business Group should be notified in writing.

Please state:

Title of the Document + Issue Number/Date of publication

Latest Amendment Number (if applicable)

Page(s) and/or Figure(s) in error

Please send to:

NOKIA CORPORATION

Nokia Mobile Phones Business Group

Nokia Customer Care

PO Box 86

FIN-24101 SALO

Finland

viii

Copyright © 2009 Nokia. All rights reserved.

COMPANY CONFIDENTIAL

Issue 1

Page 9

RH-128

Battery information

Battery information

Note that a new battery's full performance is achieved only after two or three complete charge and

discharge cycles!

The battery can be charged and discharged hundreds of times but it will eventually wear out. When the

operating time (talk-time and standby time) is noticeably shorter than normal, it is time to buy a new battery.

Use only batteries approved by the phone manufacturer and recharge the battery only with the chargers

approved by the manufacturer. Unplug the charger when not in use. Do not leave the battery connected to a

charger for longer than a week, since overcharging may shorten its lifetime. If left unused a fully charged

battery will discharge itself over time.

Temperature extremes can affect the ability of your battery to charge.

For good operation times with Ni-Cd/NiMh batteries, discharge the battery from time to time by leaving the

product switched on until it turns itself off (or by using the battery discharge facility of any approved

accessory available for the product). Do not attempt to discharge the battery by any other means.

Use the battery only for its intended purpose.

Never use any charger or battery that is damaged.

Do not short-circuit the battery. Accidental short-circuiting can occur when a metallic object (coin, clip or pen)

causes direct connection of the + and – terminals of the battery (metal strips on the battery) for example

when you carry a spare battery in your pocket or purse. Short-circuiting the terminals may damage the

battery or the connecting object.

Leaving the battery in hot or cold places, such as in a closed car in summer or winter conditions, will reduce

the capacity and lifetime of the battery. Always try to keep the battery between 15°C and 25°C (59°F and

77°F). A phone with a hot or cold battery may temporarily not work, even when the battery is fully charged.

Batteries' performance is particularly limited in temperatures well below freezing.

Do not dispose of batteries in a fire!

Dispose of batteries according to local regulations (e.g. recycling). Do not dispose as household waste.

Issue 1

COMPANY CONFIDENTIAL

ix

Copyright © 2009 Nokia. All rights reserved.

Page 10

RH-128

Battery information

(This page left intentionally blank.)

x

COMPANY CONFIDENTIAL

Issue 1

Copyright © 2009 Nokia. All rights reserved.

Page 11

RH-128

Nokia 1506; L3&4 Service Manual Structure

Nokia 1506; L3&4 Service Manual Structure

1- General Information

2- Service Software Instruction

3- Service Tools

4- Antenna Description and Troubleshooting

5- Baseband Description and Troubleshooting

6- RF Description and Troubleshooting

7- Schematics

Glossary

Issue 1

COMPANY CO NFIDENTIA L

xi

Copyright © 2009 Nokia. All rights reserved.

Page 12

RH-128

Nokia 1506; L3&4 Service Manual Structure

(This page left intentionally blank.)

xii

COMPANY CO NFIDENTIA L

Issue 1

Copyright © 2009 Nokia. All rights reserved.

Page 13

Nokia Customer Care

1- General Information

Issue 1

Copyright © 2009 Nokia. All rights reserved.

COMPANY CONFIDENTIAL

Page 1-1

Page 14

RH-128

General Information

(This page left intentionally blank.)

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 1-2

Page 15

RH-128

General Information

Table of Contents

Product selection....................................................................................................................page 1-5

RH-128 PCI overview...............................................................................................................page 1-6

Phone features and sales package..........................................................................................page 1-7

Accessories............................................................................................................................page 1-8

Technical Specifications..........................................................................................................page 1-8

General specifications.....................................................................................................page 1-8

Battery endurance...........................................................................................................page 1-9

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 1-3 Issue 1

Page 16

RH-128

General Information

(This page left intentionally blank.)

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 1-4

Page 17

RH-128

General Information

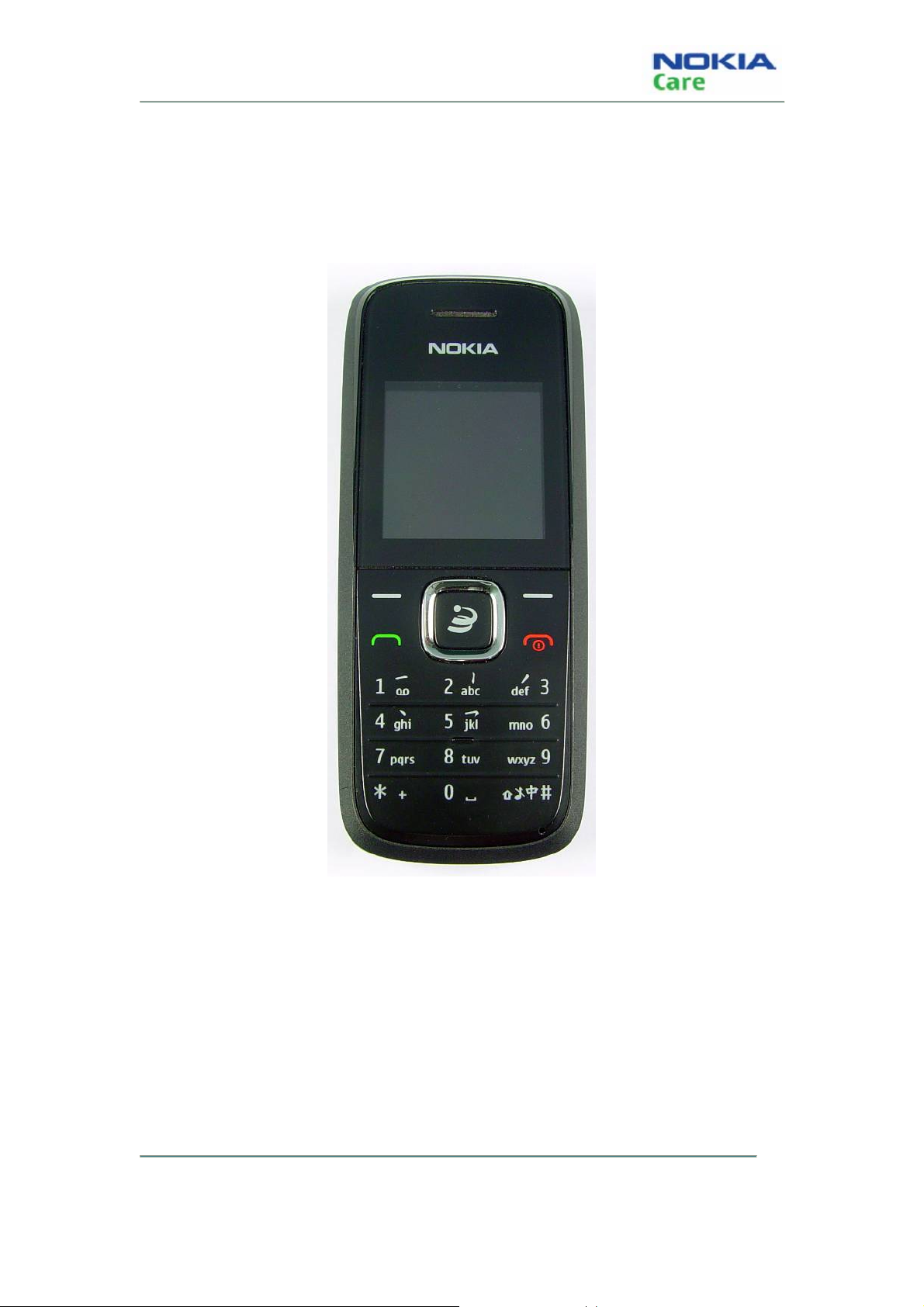

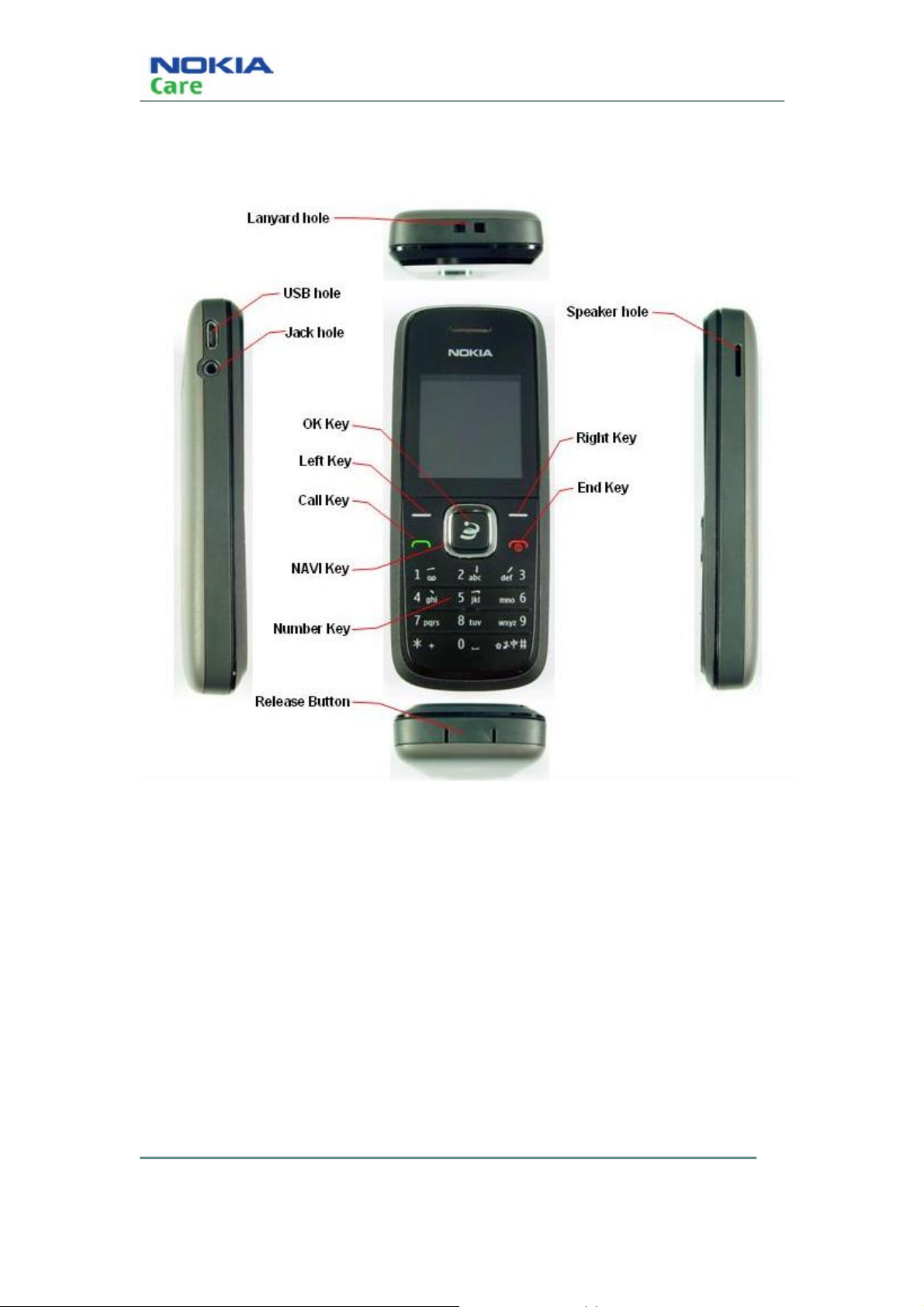

Product selection

RH-128 (Nokia 1506) mobile terminal offers a CDMA single band engine.

Figure 1: View of RH-128

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 1-5 Issue 1

Page 18

RH-128 PCI overview

RH-128

General Information

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 1-6

Page 19

RH-128

General Information

Phone features and sales package

Hardware & Mechanics

z 800MHz, CDMA2000 1xRTT

z 1.47” 128*128 CSTN, 65k Main display

z 4-way Navigation Keys

z Internal antenna

z IHF speaker

z Battery (860mAh, BL-4C)

z RUIM

z 4-pin 2.5mm audio jack required for UHJ support

z Micro-USB 2.0

z White Backlighting

z Lanyard notch/ hole

SW

z Long SMS just for China telecom version

z SMS with predictive text

z Calling Restrictions

z 32midi ring tone

z Minimum 500 contacts with 5 phone entries per name

z Access to Voice Mail

z Alarm Clock, Calculator, Calendar, Timer, World Clock

z Voice Memo recording (at least 90 seconds)

z MSL/SPC supported

z OTAPA/OTASP supported

z Airplane Mode supported

z OMSI Interface supported

z Support for GIF, JPG, PNG image formats and BMP image formats

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 1-7 Issue 1

Page 20

z 5 pre-loaded alarm tones and 20 Ring tones pre-installed

Sales package contents

z Transceiver: RH-128

z Standard Battery (860 mAh Li-on): BL-4C

z AC-6C/AC-8C

z User Guide

Accessories

Supported accessories

Type Name

RH-128

General Information

DC-6 Car Charger

AC-6C Travel Charger

DT-28 Charging Deskstand

WH-101 Stereo Headset

WH-100 2.5mm Mono headset

CA-101 Micro USB Cable

Technical Specifications

General specifications

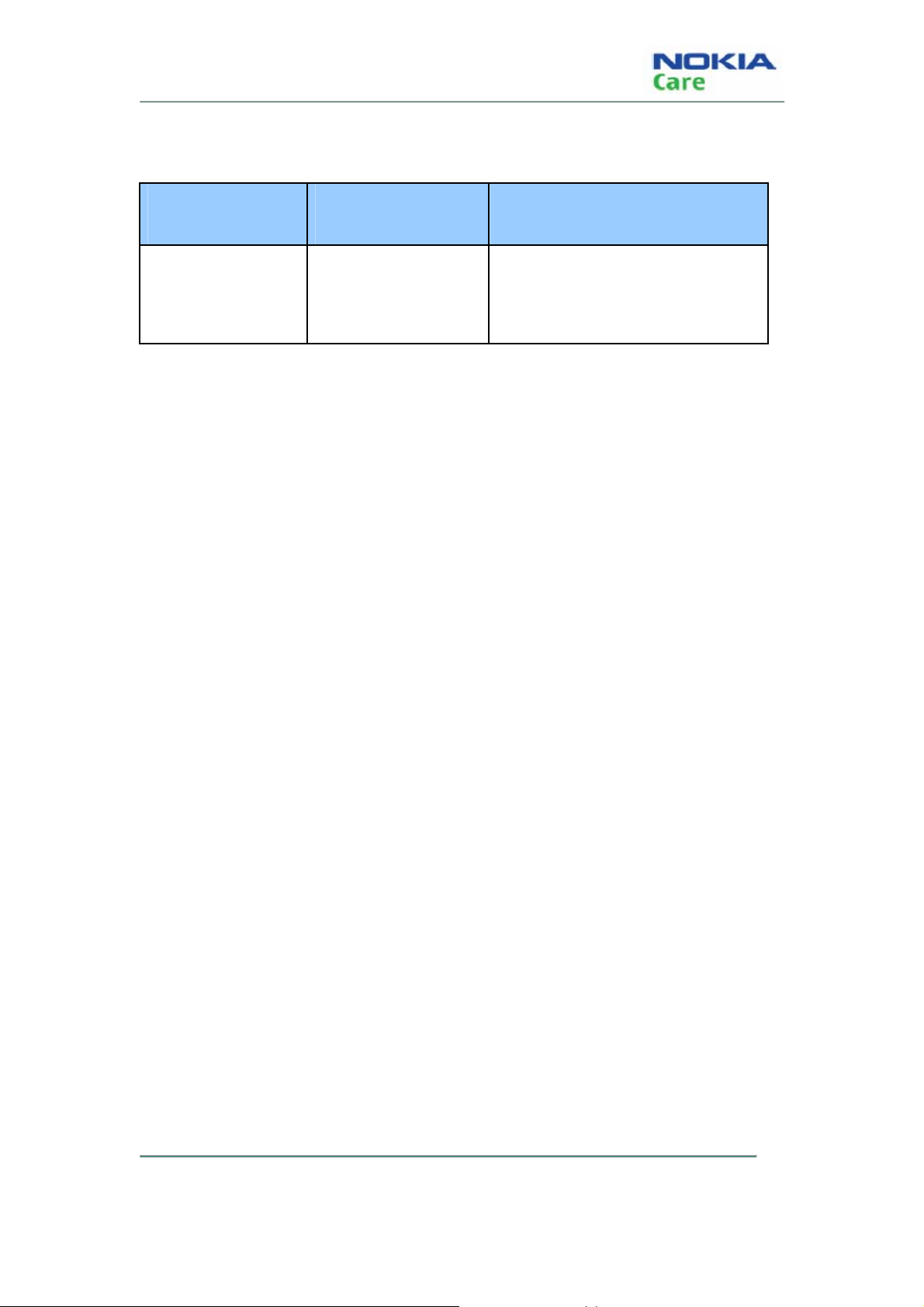

Unit Dimension (mm) Weight (g) Volume (cc)

Transceiver with

103.8*43*15.4 70 56

BL-4C; 860 mAh Li-Ion

battery pack

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 1-8

Page 21

RH-128

General Information

Battery endurance

Battery Talk Time Standby Time

BL-4C 860 mAh Li-ion 3.25 hours China 2 to 10 days

SEAP/MEA/LTA 4 to 10 days

COMPANY CONFIDENTIAL

Page 1-9 Issue 1

Copyright © 2009 Nokia. All rights reserved.

Page 22

RH-128

General Information

(This page left intentionally blank.)

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 1-10

Page 23

Nokia Customer Care

2- Service Software Instructions

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 2-1 Issue 1

Page 24

RH-128

Service Software Instruction

(This page left intentionally blank.)

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-2

Page 25

RH-128

Service Software Instruction

Table of Contents

Software summary..............................................................................................................................page 2-5

Hardware, Operating system and environment request.........................................................page 2-5

Software utilization....................................................................................................................page 2-5

Installation..................................................................................................................................page 2-5

Use of AMS..........................................................................................................................................page 2-8

Download Mode........................................................................................................................page 2-11

General Mode ...........................................................................................................................page 2-16

Issue 1 Page 2-3

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 26

RH-128

Service Software Instruction

(This page left intentionally blank.)

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-4

Page 27

RH-128

Service Software Instruction

Software summary

In order to understand the requests of operating device and driver for the software, the user should read

this chapter carefully before using Nokia 1508 AMS tool. Users can setup the PC according to their own

needs, in order to get the most out of the service software.

Hardware, Operating system and environment request

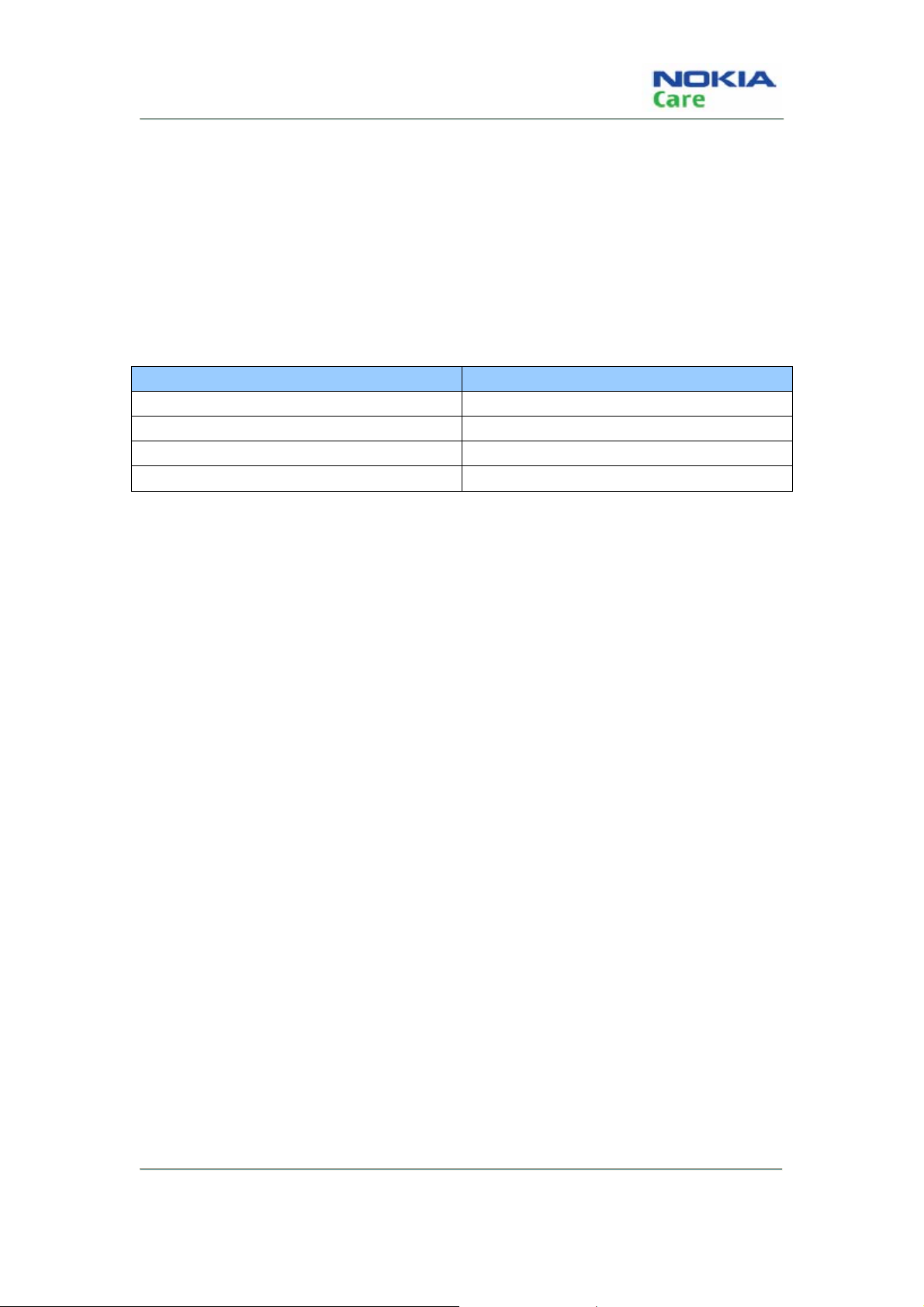

Table.1 shows the lowest request for Hardware configuration.

Operating system: Windows 2000, Windows XP

PC Minimum Requirement

Processor 700MHz

RAM 256MB

Required Disk space 100MB

Interface ports USB

Table.1 Lowest request for Hardware configuration

Software utilization

Insert Dongle.

AMS has two function modes: Download mode and General mode. When in download mode, the

handset must be working in this mode. When in general mode, the handset must be working in power

up mode. AMS tool will report Warning message if the two modes are used incorrectly.

Download mode comprises of one type: Emergency Download. General mode includes six types:

Phone Information, Display Capture, Label Print, Critical Data Backup, RF Calibration and RF Tool.

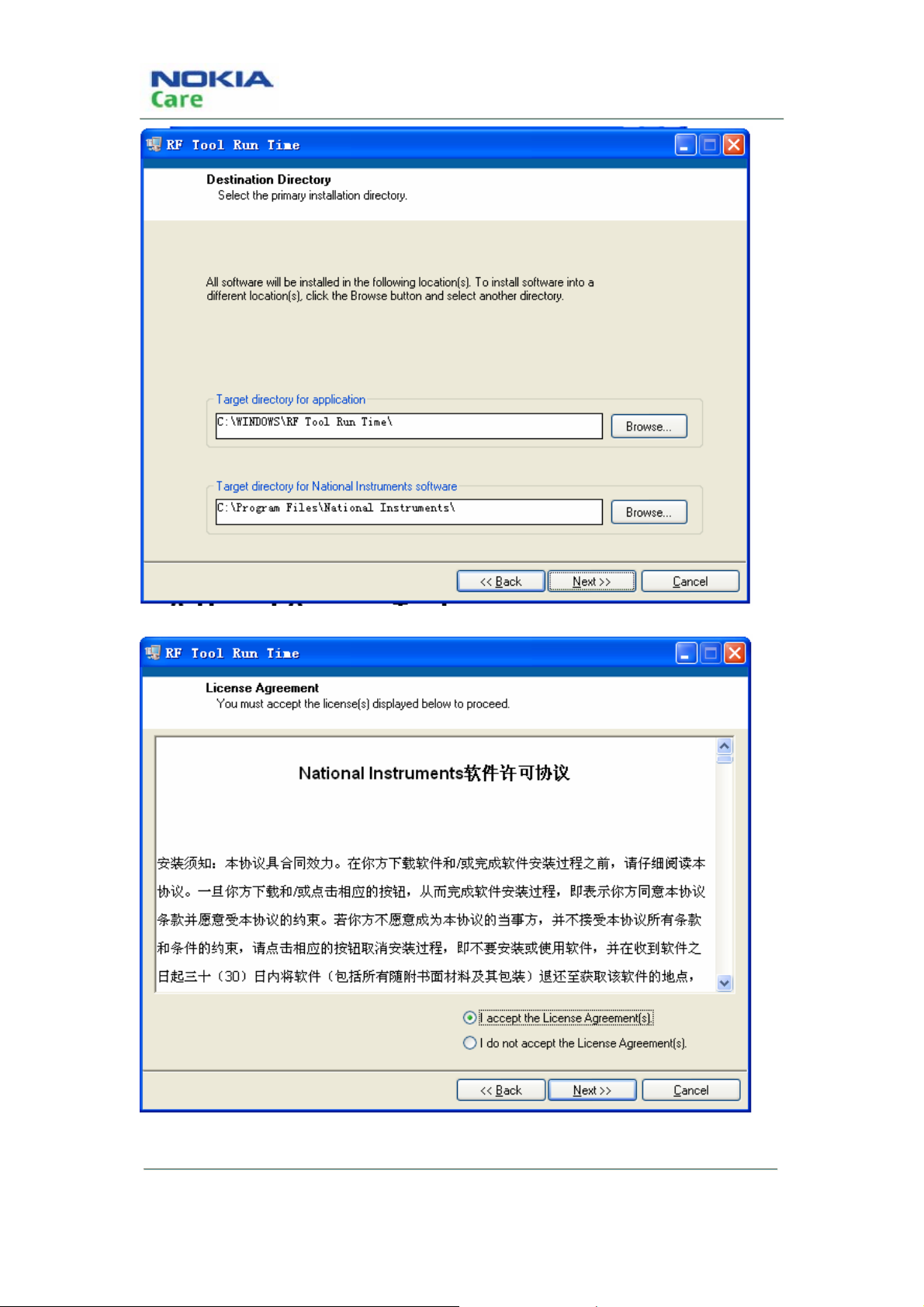

Installation

Please install the Nokia 1506 AMS tool as follows. It generally has three parts, where driver and RF Tool

Run Time must be installed separately. You can install the AMS software directly if the driver and RF

Tool Run Time are already installed.

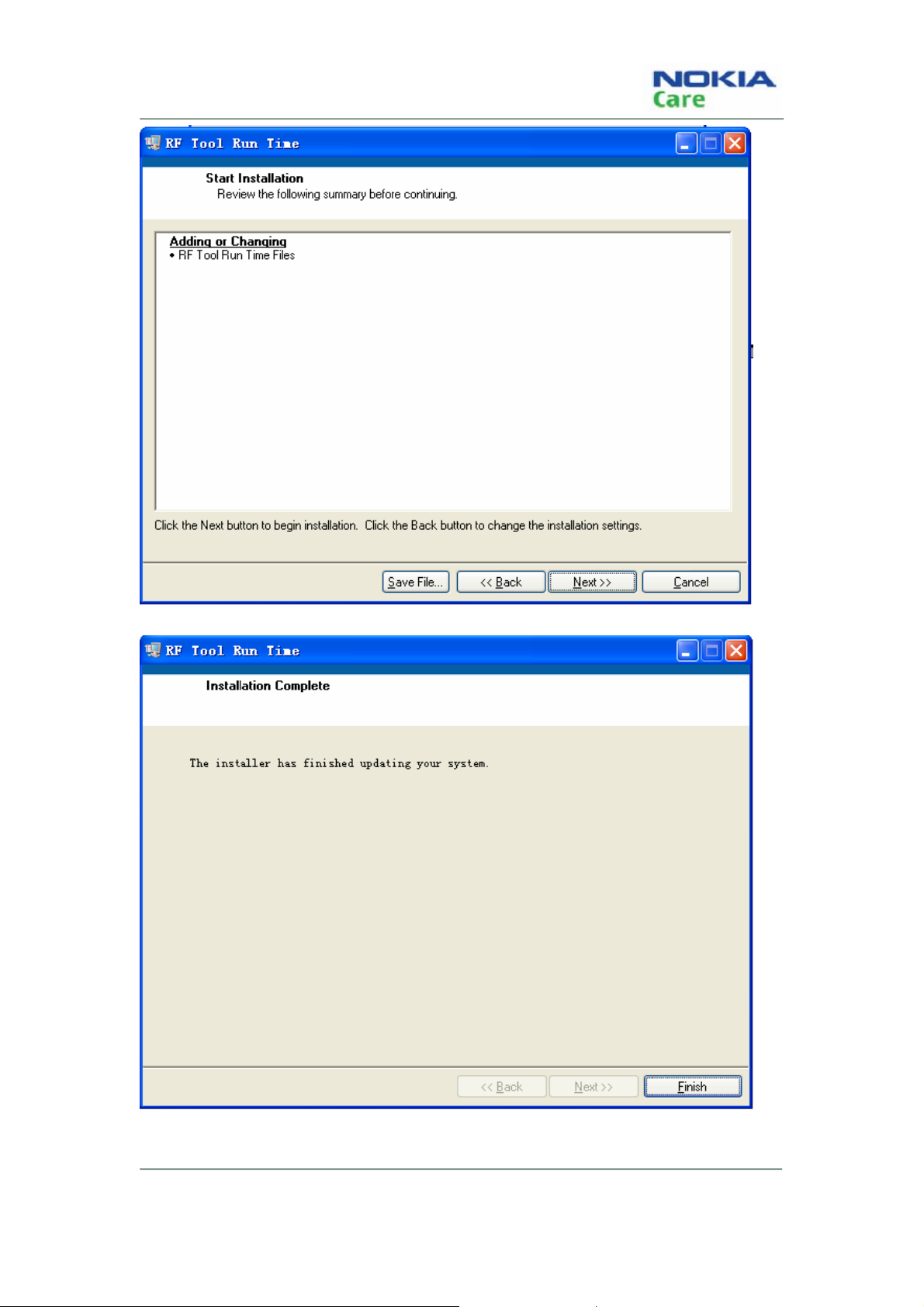

Steps for installing RF Tool Run Time:

1. Double click the setup.exe,

2. It will remind you to select the installation path. Click “next” to continue with the following steps.

Issue 1 Page 2-5

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 28

RH-128

Service Software Instruction

3. Select “I accept the License Agreement(s)”. Then click “Next”.

4. Click “Next”.

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-6

Page 29

RH-128

Service Software Instruction

5. Click “Finish” button to complete the installation.

Issue 1 Page 2-7

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 30

RH-128

Service Software Instruction

Use of AMS

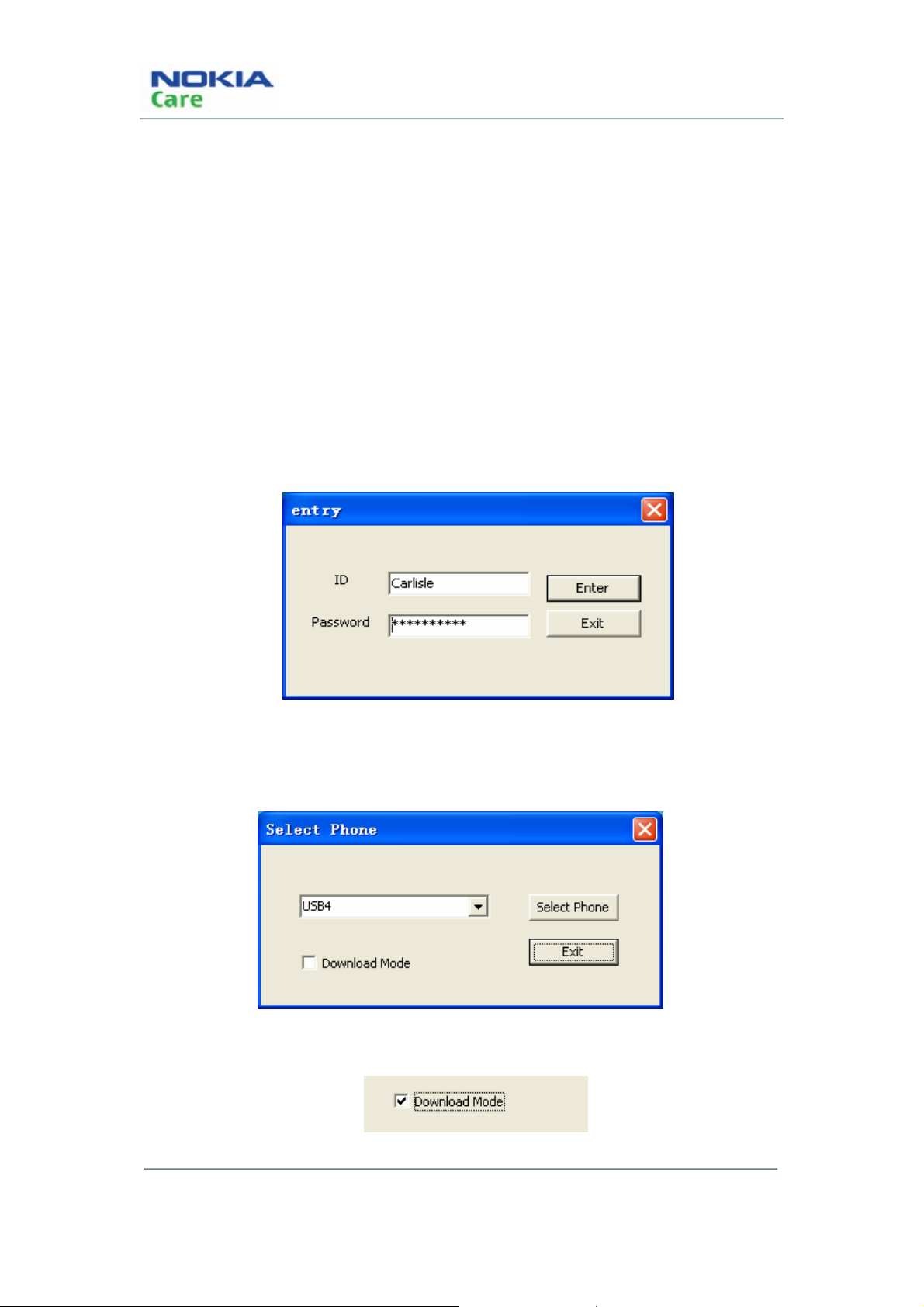

There are three steps to use AMS tool: Firstly, choose Handset and Use mode; secondly, choose the

appropriate function; finally, do related operation with the help of manual.

Select phone and use mode:

Note: When using the download functions, please set the mobile phone in download mode. The

following are steps of entering download mode:

1. Resume power supply after the mobile phone is powered off.

2. Connect your phone with PC, run AMS

3. Input ID and Password and then press the button “Enter” to enter “Select Phone” panel.

ID: Carlisle

Password: 1234@btcsz

After the above actions are completed, you can use the download functions of AMS.

1. Run AMS and pop up “Select Phone” dialogue box:

2. Select “Download Mode” to enter download mode.

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-8

Page 31

RH-128

Service Software Instruction

3. Deselect this option if you just want to use general mode.

4. Click “Select Phone” button. The general mode is shown as below.

Download mode is shown as below.

Issue 1 Page 2-9

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 32

RH-128

Service Software Instruction

Select Phone: Activate “Select Phone” in the panel

When the dialogue box is closed, and if you want to use AMS tool, you can re-open the dialogue box in

the panel.

1. In the main menu, select “Phone”.

2. Select the submenu “New” to open a new dialogue box

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-10

Page 33

RH-128

Service Software Instruction

Download Mode

Download mode provides only one function, “Emergency Download”.

Emergency Download

Before using “Emergency Download”, you must install some packages in the local PC to support the

software download. This package contains all BIN files requested by mobile phone. The file name is

composed of 5 parts.

For example: RH128_MNV_CL_1500B00_N800

Mode Type

Version info

1900 or 800: RF parameter

Carrier

N: Non-RUIM

R: RUIM

Steps for installing package:

1. Double-click the package you want to install. It displays as below:

2. Click the button “Next >”.

3. Click the button “Install” to start the installation.

Issue 1 Page 2-11

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 34

4. Wait until the installation is finished.

RH-128

Service Software Instruction

5. Click the button “Finish” to exit the installation.

In “Emergency Download”, it is possible to search and display all suitable version files according to the

CPC code input by user. These version files are used for software download.

1. Click the tab to switch to “Emergency Download”

2. It displays as below:

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-12

Page 35

RH-128

Service Software Instruction

3. Input CPC code.

4. Click the button “OK”. A list of related version files is displayed.

Issue 1 Page 2-13

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 36

RH-128

Service Software Instruction

NOTE: If the warning dialog pops up, the reason might be one of the following:

1. You have input an incorrect CPC number.

2. You have not installed the appropriate

3. You have not

registered the msxmil4.dll file.

package.

There are four steps to register the msxmil4.dll file.

1. Install MSXML 4.0SP2_cn.msi.

2. Copy msxml4.dll and regist_msxml4_object.bat to the PC path where AMS is installed.

3. Run regist_msxml4_object.bat by double click.

4. If it is registered successfully, restart AMS.

Select the version file you want to download.

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-14

Page 37

RH-128

Service Software Instruction

5. The option “Flash Erase” is selected by default. If you don’t need to erase FSM data, you can

deselect this option (it is not recommended to modify the default setup, except for software

developers).

6. Click the button “Download” to start the download.

Issue 1 Page 2-15

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 38

RH-128

Service Software Instruction

7. Wait until the download is finished.

8. Download is finished.

General Mode

The General Mode provides five different functions, including “Phone Information”, “Display Capture”,

“Label Printing”, “Critical Data Backup” and “RF Calibration”. Before using this mode, the handset must

be in Power Up status.

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-16

Page 39

RH-128

Service Software Instruction

Phone Information

When getting into General mode, the default is Phone Information which can read out nine parameters

from the handset and display them on the screen.

The nine parameters are Module Number, PSN, ESN, MEID, HWID, Application Code, Language Pack,

Warranty Data and CPC.

1. Switch to “Phone Information”

2. It displays as below:

3. Click button “Refresh” to refresh the current data parameters.

4. Refresh is finished.

Issue 1 Page 2-17

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 40

RH-128

Service Software Instruction

Display Capture

Display Capture is used to capture the screen of the handset and then choose the path to save. The file

can be saved as BMP, JPG and PNG formats.

1. Switch to Display Capture.

2. It displays as below:

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-18

Page 41

RH-128

Service Software Instruction

3. Click the button “Begin To Capture” and a box “SnapShot” appears as below:

4. Click the button “Connect”.

5. It displays a connection successful message in dialogue box.

Issue 1 Page 2-19

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 42

6. Click the button “GetImage” to capture the current screen.

7. Click “Option”.

RH-128

Service Software Instruction

8. In “Option”, modify the directory to save the image.

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-20

Page 43

RH-128

Service Software Instruction

9. Click “Browse”.

10. Choose the save directory.

11. Click the button “OK” (the left button) to confirm, the save directory is modified and saved.

12. Switch back to “Main”.

Issue 1 Page 2-21

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 44

13. Choose image format.

14. Click the button “SaveImage” to save the image.

RH-128

Service Software Instruction

Notice: When Display Capture is in use, the other AMS functions are disabled.

Label Printing

Label Printing is used to print out the product label. Read out the data from the handset and transfer into

printing file to print it out.

Note: Please make sure you have installed RF Tool Run Time before you using label printing.

Set up the printer before label printing.

Select Start->Control panel->Printer and fax on your PC.

COMPANY CONFIDENTIAL

Issue 1 Page 2-22

Copyright © 2009 Nokia. All rights reserved.

Page 45

RH-128

Service Software Instruction

Click right button to set Zebra 110XiIII Plus (600dpi) printer as the default printer.

Right click the icon, select Properties, choose Port sheet, select Lpt1 port

Click “OK” button, finish the configuration.

It means OK

1. Switch to “Label Printing”.

2. It displays as below:

Issue 1 Page 2-23

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 46

RH-128

Service Software Instruction

3. Click “Refresh”.

4. Read out the data and transfer into printing file.

5. Before printing, you can adjust X, Y offset for proper label print if needed, the default coordinate of

label’s top-left corner is set as (0,0), The latest X, Y offset adjusted by you will be reserved when you

open the tool next time.

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-24

Page 47

RH-128

Service Software Instruction

6. Click “print” to start printing.

Critical Data Backup

Critical Data Backup is used to backup the data, i.e. RF parameters.

1. Switch to RF Backup.

2. It displays as below:

3. Click Critical Data Backup to start the backup. The button is disabled.

Issue 1 Page 2-25

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 48

RH-128

Service Software Instruction

4. Five seconds later, the backup is finished. The button is enabled again.

RF Calibration

RF calibration is a tool for automatic tuning of the RF values of target, and automatic testing of the RF

performance.

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-26

Page 49

RH-128

Service Software Instruction

1. Click on the RF Calibration tab.

2. RF Calibration screen:

2.1. Log Display Frame

Log Display: calibration information.

2.2. Control Setting Frame

Issue 1 Page 2-27

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 50

RH-128

Service Software Instruction

● Text Window: Show test result.

● Band Select: Switch band.

● Select Action: Calibration or Test.

● Select Function: Enable save Log, Enable Detail UI information and enable Mo call mode.

● Test Set info: Show test set which program auto detected.

3. Program Setting

Config>>Setting

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-28

Page 51

RH-128

Service Software Instruction

● GPIB setting: Set GPIB card Number, Callbox Address, and Power Supply Address.

● Phone: Set communicate type.

● Cable Loss: Set cable loss of testing band.

4. Call Config

Config>>Call Config

Configure the parameter when establishing a call, and test.

5. Start Test

Click on the Start button to Setup calibration or test.

Final result will be shown on Text Window.

Click on the Stop button to stop calibration or test on current step.

6. Battery Calibration

In battery Calibration, select Config>>Power supply Control, and set Communicate port as serial

port. Otherwise the battery Calibration value will write default value.

Program support power supply Type:

Agilent E3631, Agilent 66319, Agilent 66309, Agilent 66311, Agilent 66312, Kethley 2306, Kethley

2304, Kethley 2303, Kethley 2302.

Issue 1 Page 2-29

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 52

Service Software Instruction

7. RF Calibration & Performance test

Program support Callbox Type:

Agilent 8960, R&S CMU200.

8. Error Code

Use Error Translate tool to help explain the cause of a failed test.

Enter the Error code in Error Code String window, click on OK button. The detailed error

information will show Text window. For example, Error code: 17815, can Translate as shown

below:

RH-128

DebugTool

DebugTool overview

The DebugTool is used for online debugging and repair analysis.

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-30

Page 53

RH-128

Service Software Instruction

There are several function areas in the main screen. There are 3 buttons, including an error code

translate tool button, a configure setting button and a quit program button. A text message box shows

the command sent out and received.

Config and Error code Translate

Config

Config setting panel can set com port type (USB or Serial), com port number, and baud rate.

Error code Translate

Enter the error code in Error Code text box, then click on OK button. Error code will be Translated in the

message window.

Issue 1 Page 2-31

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 54

RH-128

Service Software Instruction

Log

Debugtool creates a log file after the Via hub Setup. All operations on the main panel will be recorded in

this log. The log is stored in the folder in local dir of program.

A sample log is shown as below. This file is named by create time.

Text Info

All operations are displayed in this window.

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-32

Page 55

RH-128

Service Software Instruction

Setup communication

Setup Hub for communication. All the buttons are dimmed when the program is open. To activate the

buttons and setup soft hub, first click on the Setup Hub button.

Then wait for all buttons to be activated.

Issue 1 Page 2-33

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 56

RH-128

Service Software Instruction

Release hub will disconnect the communication. Then all the buttons are deactivated.

Enter calibration mode

All BB and RF calibration must be done in calibration mode. This mode can be entered when the phone

is switched on and in boot waiting time (only 1.5s). This mode can also be entered when the power is

already on.

In this chapter, use the Initial frame.

Enter when phone on.

A. Start with power supply power down.

B. Click on the Boot To Loader button.

C. Power on. Wait for phone to stop on boot.

D. Click on the Enter Cal Mode button.

E. Click on the Jump Loader button. Then wait for 3s to 5s, the phone is in the calibration mode.

Enter after phone on.

A. Start with power supply power on until the phone is fully on.

B. Click on the Jump Loader button.

D. Click on the Enter Cal Mode button.

E. Click on the Jump Loader button. Then wait for 3s to 5s, the phone is in the calibration mode.

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-34

Page 57

RH-128

Service Software Instruction

PSN SFC read and writing

PSN is the product serial number. SFC is the keyword for MES.

In this chapter, use the Process frame.

CDMA Battery Measurement Calibration

Calibration method

Select some groups of voltage value, switch them to corresponding Aux ADC values and write them into

memory. Calibration steps: Select 5 groups of voltage value, switch them to 5 groups of Aux ADC

numerical value via AD.

Calibration Procedure

A. Start with reset system (PS power down, reset).

B. Set the power supply to the desired value.

C. Get the Aux ADC Value from the Debug Tool. The battery AUX ADC detect channel is 1, the on/off

status is on. Click on the Get Result button to get ADC value.

D. Try more than 5 times. Get the average value. Store the power supply voltage point versus the Aux

ADC value.

E. Iterate steps B - D once for another power supply voltage.

Issue 1 Page 2-35

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 58

RH-128

Service Software Instruction

CDMA RxAGC Calibration

Supported receiver calibration items are the following:

CP DB HWD PCS RxAGC

CP DB HWD PCS RxAGC Freq Chan Adj

Note: Before starting the RxAGC Calibration, the Rx date must be set empty. Otherwise the calibration

value may not be correct.

CDMA RxAGC Baseline

CDMA RxAGC Baseline overview

The basic mechanism for calibration is to provide a signal of known power at the antenna, allow the

RxAGC to settle, and make note of the resulting RxAGC PDM value. In this way, the “settled” value of

the PDM for a given Rx power is known.

Calibration Procedure

A. Start with reset system (PS power down, reset).

B. Click on CP Enable/Disable and CP Power Down/Up. Let the CP disable and power down.

C. Set the channel. Set the control mode to Manual, and the band to the target band.

D. Set the test set frequency channel to the test frequency. For the first data point, enter the channel

used to calibrate the Rx AGC. Then set the test set transmission power to a desired power which is in

the Rx highest gain. The Reference Level is -99dB.

E. Initialize the calibration RxAGC gain state by clicking on DSPM Rfc Dagc. Set gain state to highest

gain.

F. Click on DSPM Spy Enable/Disable.

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-36

Page 59

RH-128

Service Software Instruction

The Spy windows become active, and display the current Tx and Rx status.

G. Get the RxDAgc Value Bitsel and the RxDAgc Value Gain. Write those calibration parameters

together with Reference Level to the non-volatile area of flash memory. To confirm the new calibration,

first update the Flash by either power cycling the UUT or by using the CalMode Select with the NVRAM

option.

H. Calibrate the Gain offset. Set the test set transmission power to the desired power which is

between the switch point of each gain level. Calibrate the gain level from the high gain to low gain. Set

the calibration RxAGC gain state by clicking on DSPM Rfc Dagc.

I. Get the received power form the Spy window. For example, if the BS power is -85dBm, and the gain

state is 3, we get -96dBm from spy window. The offset of gain 4 to gain 3 is -85 – (-96) = 11dBm. Write

the calibration parameters to the non-volatile area of flash memory. Confirm the new calibration result.

J. Iterate steps H - I for all desired calibration points.

CDMA RxAGC Frequency Channel Adjustment

About CDMA RxAGC Frequency Channel Adjustment

This procedure is performed at only one power setting. This procedure assumes that the baseline

RxAGC calibration table has been loaded into NVRAM. However, if the calibration application (running

on a PC) stores the RxAGC tables from Section 7.2.1 in PC memory, then the PC Application can

interpolate dBm power values from the PDM value returned by Debugtool. More details are provided

below in the steps below.

CDMA RxAGC Frequency Channel Adjustment Procedure

Issue 1 Page 2-37

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 60

RH-128

Service Software Instruction

A. Perform the procedure at “nominal” or room temperature.

B. The baseline RxAGC calibration must have already been completed.

C. The RxAGC frequency channel adjustment, and temperature adjustment tables must be zeroed.

D. Connect the antenna to CDMA test set.

E. Reset the UUT, start Debugtool, and do not press the Power key on the Virt MMI (i.e., PS should

be off and LID reset). Send the message CP Enable, with Disable option.

F. Set the test set Transmission Power to a desired power point (-100 dBm is a suggested value). This

is normally a point that is calibrated during Rx AGC calibration.

G. Set the test set frequency channel to the test frequency. For the first data point, enter the channel

used to calibrate the RX AGC.

H. Set the frequency channel to the calibration frequency using the CP PLL Channel Config. For the

first data point, enter the channel used to calibrate the RX AGC. Set the Control mode as Manual, the

band to target band.

I. Allow for 25 ms (or more) of settle time.

J. Get the RxAGC Antenna Power (dBm) value using the DSPM Rx AGC Get Parms. As show in the

picture, we get received power -101.1dBm.

K. Calculate Error Power = Transmission Power – Antenna Power, where the Transmission Power

was set in step F and the Antenna Power was obtained in step J. Store the Error Power (dB) versus the

frequency channel point in the non-volatile area of flash memory.

L. Iterate steps G - K for all desired calibration points.

CDMA TxAGC Calibration

There are multiple tables for calibration of the transmitter. All curves must be generated for all band

classes and for all Tx hysteresis states that are utilized.

Supported Transmitter calibration items are the following:

● CP DB HWD PCS TxAGC

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-38

Page 61

RH-128

Service Software Instruction

● CP DB HWD PCS TxAGC Freq Chan Adj

● CP DB HWD PCS Tx Limit Freq Chan Adj

● CP DB HWD PCS Tx Power Detect

● CP DB HWD PCS Tx Power Detect Freq Chan Adj

CDMA TxAGC Baseline

CDMA TxAGC Baseline overview

The basic mechanism of the calibration is to transmit a signal at the antenna port with a certain PDM

setting, the power of which is measured by a power meter, spectrum analyzer, or CDMA test set. The

PDM setting and resulting power are then recorded. Care should be taken to provide enough calibration

points near maximum power to ensure accurate transmission power at this level.

CDMA TxAGC Baseline Procedure

A. Perform the procedure at “nominal” or room temperature.

B. The baseline RxAGC calibration must have already been completed.

C. The RxAGC frequency channel adjustment, and temperature adjustment tables must be zeroed.

D. Connect the antenna to CDMA test set.

E. Reset the UUT, start Debugtool, and do not press the Power key on the Virt MMI (i.e., PS should

be off and LID reset). Send the message CP Enable, with Disable option.

F. Set the frequency channel to the calibration frequency using the PLL Channel Config. This is the

baseline frequency, since the frequency compensation table is not active. Set the Control mode as

Manual, the band to target band.

G. Initialize the TxAGC PDM (HW Val in the box below) with a suitably low known value, to prevent a

potential surge of Tx power when the transmitter is turned on in the next step. Use the DSPM Tx AGC

Config. Set the Mode as Manual, the Method as HW_Value, the Hyst as current state.

Issue 1 Page 2-39

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 62

RH-128

Service Software Instruction

H. Turn on the transmitter using the Tx Rate. Set the Rate is Tr Full Rate.

I. Set up the spectrum analyzer or test set to measure the channel power on the same channel

selected in step F.

J. Vary the HW Val until the reported power is within +/-1 dB of the desired power level using DSPM

Tx AGC Config.

K. Store the reported test set channel power (dBm) versus PDM value point in the non-volatile area of

flash memory.

L. Iterate steps G to K for all desired calibration points and Write to store the values.

M. Repeat steps G – L for all desired gain points.

CDMA TxAGC Frequency Channel Adjustment

CDMA TxAGC Frequency Channel Adjustment overview

To perform this calibration, the baseline Tx AGC calibration should have already been performed. This is

performed for all gain states.

CDMA TxAGC Frequency Channel Adjustment Procedure

A. Perform the procedure at “nominal” or room temperature.

B. The baseline RxAGC calibration must have already been completed.

C. The RxAGC frequency channel adjustment, and temperature adjustment tables must be zeroed.

D. Connect the antenna to CDMA test set.

E. Reset the UUT, start Debugtool, and do not press the Power key on the Virt MMI (i.e., PS should

be off and LID reset). Send the message CP Enable, with Disable option.

F. Turn off the transmitter test using the Tx Rate Test with the rate set to Tr Full Rate.

G. Set the frequency channel to the channel used for calibrating the TX AGC using the PLL Channel

Config. CP PLL Channel Config Settings, Ctrl Mode: Manual, Band: Band being calibrated, Channel:

Channel being calibrated.

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-40

Page 63

RH-128

Service Software Instruction

H. Set the measurement equipment to the frequency channel used for calibrating the TX AGC (see

step F).

I. Turn on the transmitter test using the Tx Rate Test with the rate set to Tr Full Rate.

J. Set the Tx power by direct control of the dBm setting using TxAGC Config. DSPM Tx AGC Config

Settings, Ctrl Mode: Manual, Method: dB Gain, HW Val: N/A, Hyst State: N/A, Power (dBm): Middle of

band being calibrated (This is the Target Tx Power).

K. Get the Measured Tx Power from the CDMA test set or other measuring device and calculate:

Antenna Power Error = Target Tx Power - Measured Tx Power

L. Store the Antenna Power Error (dB) versus frequency channel point in the non-volatile area of flash

memory.

M. Iterate steps F to L for all desired calibration points and Write to store the values.

N. Repeat steps F – M for all desired gain points.

CDMA TxAGC Max Power Limit Frequency Adjustment

CDMA TxAGC Max Power Limit Frequency Adjustment overview

In order to perform this calibration, the other Tx AGC calibrations should have already been performed.

This procedure is performed for only one gain state, the highest gain stage, since this table only applies

to max power.

CDMA TxAGC Max Power Limit Frequency Adjustment procedure

A. Baseline TxAGC calibration tables must be loaded.

B. The Tx Limit Freq Chan Adj table must be cleared (write zeros in the DBM template).

C. This procedure is identical to the procedure described in above section, but must be performed at

the Max Power Level.

D. Write calibration parameters to the non-volatile area of flash memory.

Issue 1 Page 2-41

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 64

RH-128

Service Software Instruction

CDMA TxAGC Closed Loop RF Power

CDMA TxAGC Closed Loop RF Power overview

The procedure for baseline, temperature adjustment and frequency channel adjustment is the same as

that for calibration of the dBm to PDM value tables as described in above Sections, except that the Tx

power detection ADC should be read using Aux ADC Get.

CDMA TxAGC Closed Loop RF Power Procedure.

A. Perform the procedure at “nominal” or room temperature.

B. The baseline RxAGC calibration must have already been completed.

C. The RxAGC frequency channel adjustment, and temperature adjustment tables must be zeroed.

D. Connect the antenna to CDMA test set.

E. Reset the UUT, start Debugtool, and do not press the Power key on the Virt MMI (i.e., PS should

be off and LID reset). Send the message CP Enable, with Disable option.

F. Set the measurement equipment to the frequency channel used for calibrating the TX AGC

G. Turn off the transmitter test using the Tx Rate Test with the rate set to Tr Full Rate.

H. Set the frequency channel to the channel used for calibrating the TX AGC using the PLL Channel

Config. CP PLL Channel Config Settings, Ctrl Mode: Manual ,Band: Band being calibrated , Channel:

Channel being calibrated. (see step F).

I. Turn on the transmitter test using the Tx Rate with the rate set to Tr Full Rate.

J. Set the Tx power by direct control of the dBm setting using DSPM TxAGC Config. Vary the HW Val

until the reported power is within +/-1 dB of the desired power level using DSPM Tx AGC Config. DSPM

Tx AGC Config Settings, Ctrl Mode: Manual, Method: dB Gain ,HW Val: N/A, Hyst State: N/A, Power

(dBm): Some starting value

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-42

Page 65

RH-128

Service Software Instruction

K. Send the Aux ADC Get, a number of times (10 is good) and take the average. CP AUX ADC Get

Settings, AUX ADC Channel: Design specific, Tx PCG Sync: On.

L. Iterate steps J to K for all desired calibration points and Write to store the values.

CDMA TxAGC Closed Loop Frequency Channel Adjustment

CDMA TxAGC Closed Loop Frequency Channel Adjustment overview

In order to perform this calibration, the baseline Tx AGC calibration should have already been

performed. This is performed for only one gain state.

CDMA TxAGC Closed Loop Frequency Channel Adjustment Procedure

A. Perform the procedure at “nominal” or room temperature.

B. The baseline RxAGC calibration must have already been completed.

C. The RxAGC frequency channel adjustment, and temperature adjustment tables must be zeroed.

D. Connect the antenna to CDMA test set.

E. Reset the UUT, start Debugtool, and do not press the Power key on the Virt MMI (i.e., PS should

be off and LID reset). Send the message CP Enable, with Disable option.

F. Turn off the transmitter test using the Tx Rate Test with the rate set to Tr Full Rate.

G. Set the frequency channel to the calibration frequency using PLL Channel Config. This is the

baseline frequency, since the frequency compensation table is not active.

H. Set the frequency channel to the channel used for calibrating the TX AGC using the PLL Channel

Config. CP PLL Channel Config Settings, Ctrl Mode: Manual ,Band: Band being calibrated , Channel:

Channel being calibrated.

Issue 1 Page 2-43

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 66

RH-128

Service Software Instruction

I. Turn on the transmitter test using the Tx Rate with the rate set to Tr Full Rate.

J. Set the Target Tx Power by direct control of the dBm setting using DSPM TxAGC Config. Vary the

HW Val until the reported power is within +/-1 dB of the desired power level using DSPM Tx AGC Config.

DSPM Tx AGC Config Settings, Ctrl Mode: Manual, Method: dB Gain ,HW Val: N/A, Hyst State: N/A,

Power (dBm): Some starting value

K. Set the measurement equipment to the measurement frequency channel.

L. Get the Measured Tx Power (over the 1.25 MHz bandwidth) from the CDMA test set (or other

measuring device) and get the Closed Loop Tx Power from the Current Tx Power.

The true power calculate: Read Power / 64 = True Power (dB)

M. Calculate Power Error = Measured Tx Power - Closed Loop Tx Power .

N. Store the Power Error (dB) versus frequency channel point.

O. Iterate steps 7, 10-12 for all desired calibration points.

P. Write calibration parameters to the non-volatile area of flash memory

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-44

Page 67

RH-128

Service Software Instruction

Error Code

Three class error code

Use Error Translate tool to help explain the cause of a failed test.

Enter the Error code in Error Code Stringwindow, click on OK button. The detail error information will

show in the Textwindow shown below. For example, Error code: 17815, can Translate as shown.

Error Message Table

[Error_Class_3]

1000 INIT_SetUp_ETSCOMPort_ERROR

3000 INIT_ModeSetting_ERROR

2000 Check_CPSWHWVersion_Compare_ERROR

4000 Check_CheckProcessBit_ERROR

Process control Error

5000 Check_BandSelect_ERROR

6000 Check_EndProcess_ERROR

7000 Cal_InitValue_ERROR

23000 Process_CheckBit_ERROR

8000 Cal_TxAGCBaseCal_ERROR Calibration Error

Issue 1 Page 2-45

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 68

9000 Cal_RxAGCBaseCal_ERROR

10000 Cal_TxAGCFREQCHAN_ERROR

11000 Cal_RxAGCFREQCHAN_ERROR

12000 Cal_TxAGCLIMFREQCHAN_ERROR

13000 Cal_TxAGCCLOSEDRFPWR_ERROR

14000 Cal_TxAGCCLOSEDFREQCHAN_ERROR

15000 Cal_WriteTemperatureDB_ERROR

16000 Cal_WriteBatteryDB_ERROR

17000 Cal_HWDBatteryCal_ERROR

18000 PTest_SetupCall_ERROR

19000 PTest_CallInitial_ERROR

20000 PTest_CallBandInitial_ERROR

21000 PTest_CallConnectFunction_ERROR

22000 PTest_QuickPerformanceTest_ERROR

39000 Loopback_Call_ERROR

[Error_Class_2]

390 INSTR_INSTRUMENTNULL_ERROR

400 INSTR_SETUP8960_ERROR

410 INSTR_SETCABLELOSS_ERROR

420 INSTR_WRITESECAPWR_ERROR

430 INSTR_SETONOFFSECAPER_ERROR

440 INSTR_WRITERFCHANNEL_ERROR

450 INSTR_SETUPTESTSET_ERROR

460 INSTR_RFPORTSET_ERROR

470 INSTR_SETIM2_ERROR

480 INSTR_SETOPERATINGMODE_ERROR

490 INSTR_SETITC_ERROR

500 INSTR_GETCURRPER_ERROR

510 INSTR_SETTXDYNAMIC_ERROR

520 INSTR_SETTXDYNAMICINIT_ERROR

530 INSTR_RESTORETXDYNAMIC_ERROR

540 INSTR_MEASTXDYNAMIC_ERROR

550 INSTR_RESETTESTSET_ERROR

560 INSTR_QUERYFSTATUS_ERROR

570 INSTR_PRINTFFATATUS_ERROR

580 INSTR_SETMEASSPEED_ERROR

590 INSTR_SWITCHPOWER_ERROR

600 INSTR_SETVOLTAGECURRENT_ERROR

610 INSTR_READCURRENT_ERROR

620 INSTR_SINGLECHIPCOMMUNICATE_ERROR

810 INSTR_Callbox_Initial_ERROR

RH-128

Service Software Instruction

Performance Test Error

Instrument Communicate

Error

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 2-46

Page 69

RH-128

Service Software Instruction

820 INSTR_PowerSupply_Initial_ERROR

830 INSTR_GPIBCard_ERROR

20 ETSCommand_Get_BootToLoader_ERROR

30 ETSCommand_EnterCalbrationMode_ERROR

40 ETSCommand_JumoToLoader_ERROR

50 ETSCommand_Loopback_ERROR

60 ETSCommand_CPOff_ERROR

70 ETSCommand_PowerDown_ERROR

80 ETSCommand_SNReadWrite_ERROR

90 ETSCommand_ProcessBit_RW_ERROR

100 ETSCommand_TestSWVersion_RW_ERROR

110 ETSCommand_CPSWHWVersionRead_ERROR

120 ETSCommand_DBFlush_ERROR

130 ETSCommand_RFBackup_ERROR

140 ETSCommand_DBClear_ERROR

150 ETSCommand_InitialNVRAM_ERROR

160 ETSCommand_AFCData_WriteDB_ERROR

170 ETSCommand_BandGapData_WriteDB_ERROR

180 ETSCommand_Battery_AUXValGet_ERROR

190 ETSCommand_Battery_WriteDB_ERROR

200 ETSCommand_TransmitOnOff_ERROR

210 ETSCommand_SetPLLConfig_ERROR

220 ETSCommand_TxRateSet_ERROR

230 ETSCommand_DSPMTxAGCConfig_ERROR

240 ETSCommand_RF_WriteDB_ERROR

250 ETSCommand_HWResultDetect_OverRange_ERROR

260 ETSCommand_ModesEnableSlotted_ERROR

270 ETSCommand_ReceiverOnOff_ERROR

280 ETSCommand_DSPMRfcDagcSetGain_ERROR

290 ETSCommand_DSPMSpyEnable_ERROR

300 ETSCommand_DSPMSpyGet_ERROR

310 ETSCommand_DSPMSpyGet_Empty_ERROR

320 ETSCommand_BitselGain_Detect_ERROR

330 ETSCommand_DSPMRxAgcGet_ERROR

340 ETSCommand_PowerDetect_AUXValGet_ERROR

350 ETSCommand_ReadCurrentTxPower_ERROR

360 ETSCommand_CallInitiate_ERROR

670 RFPT_OffCurrent_ERROR

680 RFPT_PowerOnCurrent_ERROR

690 RFPT_CallCurrent_ERROR

700 RFPT_RxSensitivity_ERROR

Phone Communicate

Command Error

Performance Test Error

Issue 1 Page 2-47

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 70

Service Software Instruction

710 RFPT_MaxPower_ERROR

720 RFPT_TxSpuriousTest_ERROR

730 RFPT_MinPower_ERROR

740 RFPT_WaveformCodeDomain_ERROR

750 RFPT_TimeRspVsOpenloop_ERROR

760 RFPT_GetedPower_ERROR

780 XMLMsg_Response_Null_ERROR

790 XMLMsg_Response_Corresponding_ERROR

MES Communicate Error

800 XMLMsg_Response_Java_ERROR

840 XML_SFC_ReadWrite_ERROR

980 Result_OverRange_ERROR Test Result Error

990 Error_Max_Other

[Error_Class_1]

8 Result_OverRange_Low_ERROR

Test Result Error

9 Result_OverRange_High_ERROR

2 CMD_SETTING_ERROR

3 CMD_COMMANDSEND_ERROR

4 CMD_FINDRESPONSE_ERROR

Phone Communicate Error

5 CMD_RSPCORRESPOND_ERROR

6 CMD_VIACMD_ERROR

7 CMD_RESPONSENULL_ERROR

RH-128

COMPANY CONFIDENTIAL

Issue 1 Page 2-48

Copyright © 2009 Nokia. All rights reserved.

Page 71

Nokia Customer Care

3- Service Tools

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 3-1 Issue 1

Page 72

RH-128

Service Tools

(This page left intentionally blank.)

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 3-2

Page 73

RH-128

Service Tools

Table of Contents

Introduction......................................................................................................................................... page3-5

Service configuration......................................................................................................................... page3-5

Service tools............................................................................................................................... page3-5

Service configuration.................................................................................................................page3-6

MJ-200 handling instructions............................................................................................................ page3-6

External connections & switch instructions............................................................................page3-6

MJ-200 PWB pin definition........................................................................................................page3-8

Handling instruction.................................................................................................................. page3-8

Power on sequence.......................................................................................................................... page3-10

Issue 1

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 3-3

Page 74

RH-128

Service Tools

(This page left intentionally blank.)

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 3-4

Page 75

RH-128

Service Tools

Introduction

This document explains relevant service software, service tools and handling instructions for RH-128.

Service configuration

Service tools

The table below gives an overview of service tools with Module jig that would be used in service testing,

tuning and error analysis.

CA-101 Data Service Cable

This cable provides a connection from the USB port of the personal

computer or notebook to the micro USB connector of the phone and

allows Point of Sale (POS) locations to flash the mobile terminal.

MJ-200 Module Jig

This jig allows PWB-level service and troubleshooting. It supports

regulated and unregulated DC input voltages, a headset jack for audio

tests and a RUIM card reader. It also supports simultaneous RF

connections to the CDMA engine.

AK05G-0650400W2 AC power adapter

This AC power adapter (with 5.50mm power cord connector) is used to

provide DC power to the mobile phone and service tools (e.g. Module

Jig) from power supply for CDMA tuning (packaged with the module jig).

CA-128RS RF Service Cable

This test cable is used for RF engine testing and tuning. It snaps directly

on the mobile terminal’s RF connector and converts the output to a

Issue 1

surface mounting assembly connector.

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 3-5

Page 76

PK-86 AMS SW Protection Key

This hardware dongle connected to the USB port of the service

computer, enables the use of the service software. It is not possible to

use the service software without the dongle.

Service configuration

The following diagram illustrates service setup with Module Jig.

RH-128

Service Tools

MJ-200 handling instructions

External connections & switch instructions

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 3-6

Page 77

RH-128

Service Tools

1- Micro USB connector

2- S101 Power Key (turn power “on” when starting )

3- U52 banana connectors for current meter (0~1A)

4- S1 switch for current measurement

5- U51 banana connectors for back up power supply DC 3.7V~4.2V

6- Serial Port (connect 9 pin serial cable with PC for battery calibration and RF calibration )

7- CN101 AC Power Supply connector (for AC adapter or power service cable 6.5V~7.5V. 1A)

8- S102 for main power and back up power switch

9- S2 Download/Test mode switch (Turn “off” when using the module jig, enter download mode by

pressing and holding up key on keypad)

10- UIM slot

Issue 1

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 3-7

Page 78

MJ-200 PWB pin definition

RH-128

Service Tools

Handling instruction

1. Put PWB onto the module jig.

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 3-8

Page 79

RH-128

Service Tools

2. Close the module jig up.

Issue 1

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 3-9

Page 80

3. Connection with PC

RH-128

Service Tools

1) RF calibration

RF Cable provides a connection from RF connector on the jig to RF connector on CMU200 or

Agilent8960 and executes RF calibration function in AMS.

2) SW update / flashing

USB Cable CA-101 provides a connection from the USB port of the personal computer or notebook to

the micro USB connector on Module jig for SW update/flashing.

3) Full Phone functionality

Press #0000# , select CIT test >Manual test to perform the phone functionality check.

Power on sequence

1. S

@ VCC1 (Power Supply 1 :AC adapter or power service cable

102

:6.5V-7.5V,I

V

cc1

max

=1A); S

@ VCC2(Power Supply 2)

102

2. S1@ on(power on )

3. S

@ On(main current ); S

101

@ Off (adding a current meter between two red banana

101

connectors U52 for current measurement)

4. S2 @off (test mode)

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 3-10

Page 81

Nokia Customer Care

4- Antenna Description

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 4-1 Issue 1

Page 82

RH-128

Antenna Description and Troubleshooting

(This page left intentionally blank.)

Page 4-2 Issue 1

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 83

RH-128

Antenna Description and Troubleshooting

Table of Contents

Introduction...................................................................................................................................................... page 4-5

Visual quality requirements................................................................................................................... page 4-5

Failures and corrective measures.................................................................................................................. page 4-5

Damaged RF feed point pin....................................................................................................................page 4-6

Obstructed RF feed point pad........................................................................................................................ page 4-7

RF connector failure........................................................................................................................................ page 4-8

Issue 1

COMPANY CONFIDENTIAL

Page 4-3

Copyright © 2009 Nokia. All rights reserved.

Page 84

RH-128

Antenna Description and Troubleshooting

(This page left intentionally blank.)

Page 4-4 Issue 1

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 85

RH-128

Antenna Description and Troubleshooting

Introduction

The mobile terminal includes an internal antenna. This antenna arrangement is used for Cellular frequency

bands. The internal antenna assembly adopts Monopole Antenna structure used for the cellular engine.

Visual quality requirements

Below are the minimum acceptable visual quality requirements of the internal antenna assembly:

z Wear gloves to assemble the antenna. Don’t touch the antenna radiator with bare hands.

z No visual cracks or mechanical defects.

z No oil, dirt or particles attached on the parts.

z Radiator must be flat without warping and aligned with the plastic housing.

z The length of all pins must be identical and the pins align.

Failures and corrective measures

The two antennas are assembled into B Cover as shown in Figure 1. If no internal antenna is installed, the

antenna gain is degraded by more than 20 dB.

z If the internal antenna is missing, install antenna-asm Module.

z If the radiator is damaged, replace it with a new antenna-asm Module.

Figure 1: B Cover Assembly

Issue 1

Page 4-5

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 86

RH-128

Antenna Description and Troubleshooting

Damaged RF feed point pin

The pin (spring clip) of the antenna must be properly connected to the PWB.

z If the main antenna’s RF feed point pin does not touch the PWB, the antenna gain degrades by more

than 17 dB.

z If the RF feed pin is broken or bent, replace the antenna-asm Module.

z If the RF feed pin spring turns out damaged, replace the antenna-asm Module.

Figure 2: Back view of internal antennas

Page 4-6 Issue 1

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 87

RH-128

Antenna Description and Troubleshooting

Obstructed RF feed point pad

If the RF feed point pad is obstructed, removed or covered, the antenna pin does not touch the PWB and

the antenna performance degrades.

z If there is any corrosion or the pad is missing, replace the PWB.

z If a pad is obstructed or covered by something, clean the pad.

z If any component of antenna match circuit is missing, replace the related component.

Figure 3: PWB layout of RF feed point and antenna match circuit

Issue 1

Page 4-7

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 88

RH-128

Antenna Description and Troubleshooting

RF connector failure

The RF connector fails when it does not properly connect RF input terminal to RF output terminal during

SMT. If this happens the antenna gain degrades by 25 dB. Check this failure by measuring the resistance

value between the input and output of RF connector, if the value is close to zero, replace the RF connector.

Note:

Do not insert RF cable to RF connector when testing the resistance value. Because the RF connector

is also a switch, when RF cable is inserted, RF output is disconnected from RF input.

z RF input terminal – connect to duplexer.

z RF output terminal – connect to the antenna pad through antenna match circuit.

z RF connector terminal – connect to RF coaxial cable.

Figure 4: RF input / output terminal

Page 4-8 Issue 1

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 89

Nokia Customer Care

5- Baseband Description and

Troubleshooting

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 5-1 Issue 1

Page 90

RH-128

Baseband Description and Troubleshooting

(This page left intentionally blank.)

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 5-2

Page 91

RH-128

Baseband Description and Troubleshooting

Table of Contents

Key components overview................................................................................................................ page 5-5

System block diagram.......................................................................................................................page 5-6

Platform Introduction.........................................................................................................................page 5-6

CBP 5.0....................................................................................................................................... page 5-6

Power Up.................................................................................................................................... page 5-9

Power Off................................................................................................................................... page 5-9

Clock Distribution..................................................................................................................... page 5-9

Power Distribution.................................................................................................................. page 5-10

VC-TCXO.................................................................................................................................. page 5-11

Battery...................................................................................................................................... page 5-11

Display and Keypad.........................................................................................................................page 5-12

Troubleshooting............................................................................................................................... page 5-13

Power Does Not Stay ON.................................................................................................................page 5-13

Power Does Not Stay ON Troubleshooting...........................................................................page 5-14

Audio Faults..................................................................................................................................... page 5-15

No Sound in Earpiece & Microphone (refer to Audio PA Circuit design)...........................page 5-15

Audio Faults Troubleshooting............................................................................................... page 5-16

Audio PA Circuitry...................................................................................................................page 5-18

Display Faults................................................................................................................................... page 5-18

Display Faults Troubleshooting............................................................................................. page 5-18

Keypad Faults ..................................................................................................................................page 5-20

Keypad Faults Troubleshooting.............................................................................................page 5-20

Vibrator Faults (reference to the Vibrator Circuit Design)........................................................... page 5-21

No Vibration T roubleshooting................................................................................................ page 5-21

Vibrator Circuit........................................................................................................................ page 5-22

USB Interface Faults........................................................................................................................page 5-23

USB Interface Disabled Troubleshooting..............................................................................page 5-23

USB Circuitry...........................................................................................................................page 5-24

UIM Card Unreadable troubleshooting.......................................................................................... page 5-24

Charging Faults Troubleshooting...................................................................................................page 5-25

Issue 1

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 5-3

Page 92

RH-128

Baseband Description and Troubleshooting

(This page left intentionally blank.)

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 5-4

Page 93

RH-128

Baseband Description and Troubleshooting

Key components overview

Component Model Number Supplier

Baseband processor CBP 5.0 VIA

PMU ACT5805 Active

Memory TV00560002EDGB TOSHIBA

LCD BM4531J BYD

Issue 1

Figure 1 Component layout

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Page 5-5

Page 94

System block diagram

RH-128

Baseband Description and Troubleshooting

Platform Introduction

CBP 5.0

VIA Telecom’s CBP 5.0 single-chip CDMA Base Band Processors provide a complete 3G CDMA2000®

1X (Release 0) solution. They are designed to meet or exceed the specifications of mobile stations for

worldwide 3G CDMA systems as specified by CDMA2000® 1X (Release 0) standards and are

backward-compatible to IS -95.

CBP 5.0 integrates three processor subsystems

ARM7TDMI® Control Processor (CP) supports the protocol stack, user interface, and hardware

interface processing. Two TeakLite® Digital Signal Processors (DSPs): one DSP supports CDMA

modem processing, the second DSP supports CDMA voice processing.

The main features of the CBP 5.0

z Supports CDMA2000® 1X (Release 0)

z Backward compatible to IS-95 standards

z Supports IS-2000 Quick Paging Channel for improved standby time

COMPANY CONFIDENTIAL

Copyright © 2009 Nokia. All rights reserved.

Issue 1 Page 5-6

Page 95

RH-128

Baseband Description and Troubleshooting

z Support for multiple CDMA band classes (Band Class 0/US-Cellular, Band Class 1/US-PCS, Band

Class 3/JTACS, Band Class 4/Korean-PCS); support for additional band classes which can be

added upon customer request

z Special purpose logic provides signal processing, modulation, demodulation, hardware

accelerators and interfaces for keypad and display

z Mixed signal circuitry for the Rx analog-to-digital converter (ADC), Rx filter, Tx digital-to-analog

converter (DAC), Tx filter, internal PLLs, voice codec, auxiliary ADCs, auxiliary DACs, RF control

and 32.768 kHz oscillator

z Dual supply voltage (1.8 V digital core, 3.0 V analog and 3.0 V digital I/O)

z 3.0 V or 1.8 V external memory interface

z USB support (12 Mbps)

z Removable User Identity Module (R-UIM) compliant with IS-820

z 32-voice polyphonic ringer

The interface of the CBP 5.0 is described in the following diagram. Receive and transmit interfaces for

CBP 5.0 provides analog I and Q signals and support super-heterodyne radio and direct conversion

radio design. The CP external-memory interface supports 3.0V or 1.8V, the address bus supports 16-bit

address which can support three to six external devices via chip selects. CBP 5.0 includes 48 GPIOs

and interrupts, some of which are multiplexed with other functions. All GPIO pins are in input state by

default and use a large pull-up or pull-down resistor value to minimize the current drain. The USB port

supports data rates of up to 12Mbps, the USB analog drivers and 48.00MHz PLL are integrated into

CBP 5.0, the control processor manages the USB function. Two independent serial-peripheral interfaces

are provided on CBP 5.0: one is for RF control and the other is for general-purpose use. The R-UIM

interface supports 3V UIM cards and consists of five pins, these pins are multiplexed with another

function. The CP manages the R-UIM function.

Five independent PDM DACs are supplied on the CBP 5.0 chip.

Three of the outputs are dedicated to radio-control signals for Rx automatic gain control (AGC), Tx AGC,

and automatic frequency control (AFC). The fourth and fifth PDM outputs are spares. The PDMs are

12-bit DACs and have a guaranteed output range of 0.2 V to 2.5 V.

The 12-bit auxiliary ADC supports eight independent external channels on pins AUXADC [7:0]. There

are also eight internal channels used to measure internal analog voltages. The input voltage range is

0.2 V to 2.7 V. The conversion time is 156 µsec. The typical uses of the external auxiliary ADC channels

include: Tx RF power measurement, battery voltage, and temperature sensors.