Nissan Sunny B110 User Manual

1

j

t

t

mf

j

il

t

DATSUN

MODEL

CHASSIS

Bll0

AND

INISSANI

1200

SERIES

BODY

i

ti

p

l

t

Rov

2

11

PIN

f

99999

1

20019

NIS

AN

MOTOR

TOKYO

JAPAN

CO

LTD

i

r

i

r

J

si

r

r

r

QUICK

fGE

M

Nl

A

l

7

REFERENCE

o

t

tNIFrO

I

r

R

r

M

A I

fl

t

O

N

INDEX

Itr

ti

J

i

cii

J

c

W

I

ls

t

ti

9

S1l

r

ib

S10N

ROiNIJ

S

y

VA1

L1AJION

a

S

USRf

NSON

SPENSION

M

j

C

T

f1Ar

RIA

I

B

iEiNJiN

W

E

i

MtANUAL

o

MOID

Oi

j

O

eOOiO

SIEIR

D

IEIL

m@fIDW

IES

1

J

t

c

i

elE

B

r

JU

7

R1

RO

RAU

lR

I

N

6

r

j

1NSM

IS

i

Xi

f

R

lA1XiirEC

y

E1ARU

8ijR

WHEEL

N D

A

I

c

J

I

Mfiool

fl

W

INI

1M

@il

TOI1O

@

@

JAPAN

U

Q

I

w

Y

ft

I

SHE

fNGINE

f

BODY

BODY

t

RING

CO

M

EXHA1UST

HECTRIC

SERVI

c

E

EQUIPME

c

R

lJl

l

r

f

Un

SYSUIM

NT

r

FE

BF

BE

S

FOREWORD

Thi5

senllce

personnels

DATSUN

Since

proper

by

keeping

The

followings

1

Explanations

hand drive

the

for

PleUje

2

MANUAL

information

3

All

part

and

replacements

4

All

based

approvaL

manual

our

of

1200

model

maintenance

their

should

but

version

refer

for

concerning

name

the

only

information

the

on

di5tributors

BllO

in

can

be

in

this

will

models

to

both

complete

this

in

genuine

illustrations

latest

has

been

and

the

noted

manual

easily

this

the

manual

service

product

and

series

service

best

for

be

details

chassi5

parts

prepared

dealers

are

condition

effective

are

mainly

referred

AlO

and

of

and

conform

listed

and

specifications

information

for

for

most

this

utilization

concerning

also

the

body

to

in

the

effective

essential

manual

the

for

A12

car

because

only

DATSUN

this

parts

available

purpose

service

to

should

this

of

the

left

SERIES

1200

catalog

contained

at

of

and

sati5fy

be read

manual

model

hand drive

ENGINE

this manual

PARTS

should

in

time

the

assi5ting

maintenance

customers

our

BllOU

models

SER

CATALOG

be

manlUll

this

of

publication

serolce

carefully

right

and

VICE

describes

used

for

of

are

5

6

It

is

emphUjized

to

the

issued

Rights

by

for

SER

VICE

the

alteration

that

factory

those

JOURNAL

which

in

specifications

who

carry

and

use

the

this

SER

and

NI55AN

latest

manual

VICE

others

DA

factory

at

MOTOR

TOKYO

revise

TA

AND

approved

time

any

JAPAN

the

CO

contents

SPECIFlCA

servicing

are

reseroed

LTD

acconIing

TIONS

method

j

SECTION

GENERAL

INFORMATION

GI

em

DATSUN

MODEL

CHASSIS

NIS

I

8110

1200

SERIES

BODY

N

I

MODEL

IDENTIFICATION

GENERALVIEWS

IDENTIFICATIONS

NUMBER

GI 3

Gl

GI 5

3

NISSAN

MOTOR

TOKYO

JAPAN

CO

LTD

GENERAL

FINAL

RECOMMENDED

JACKINGUPAND

SPECIFICATlo

TRANSMISSIDN

SPEEDOMETER

LUBRICANTS

PERIDDICAL

TOWING

THE

NS

AND

RATIOS

AND

MAINTENANCE

CAR

GI

GI

GI

GI

9

ll

ll

l1

GENERAL

INFORMATION

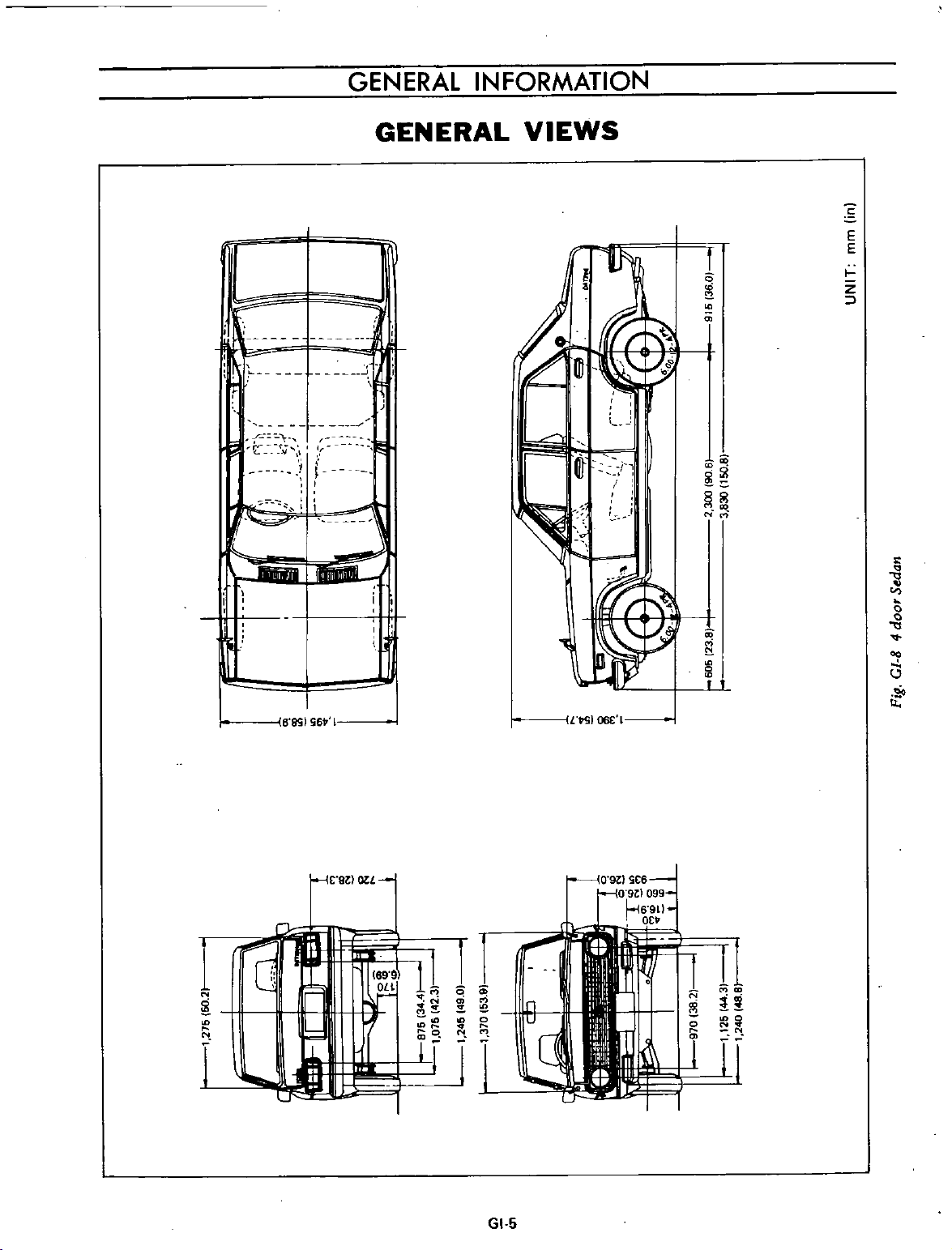

Fig

GIl4

door

Sedan

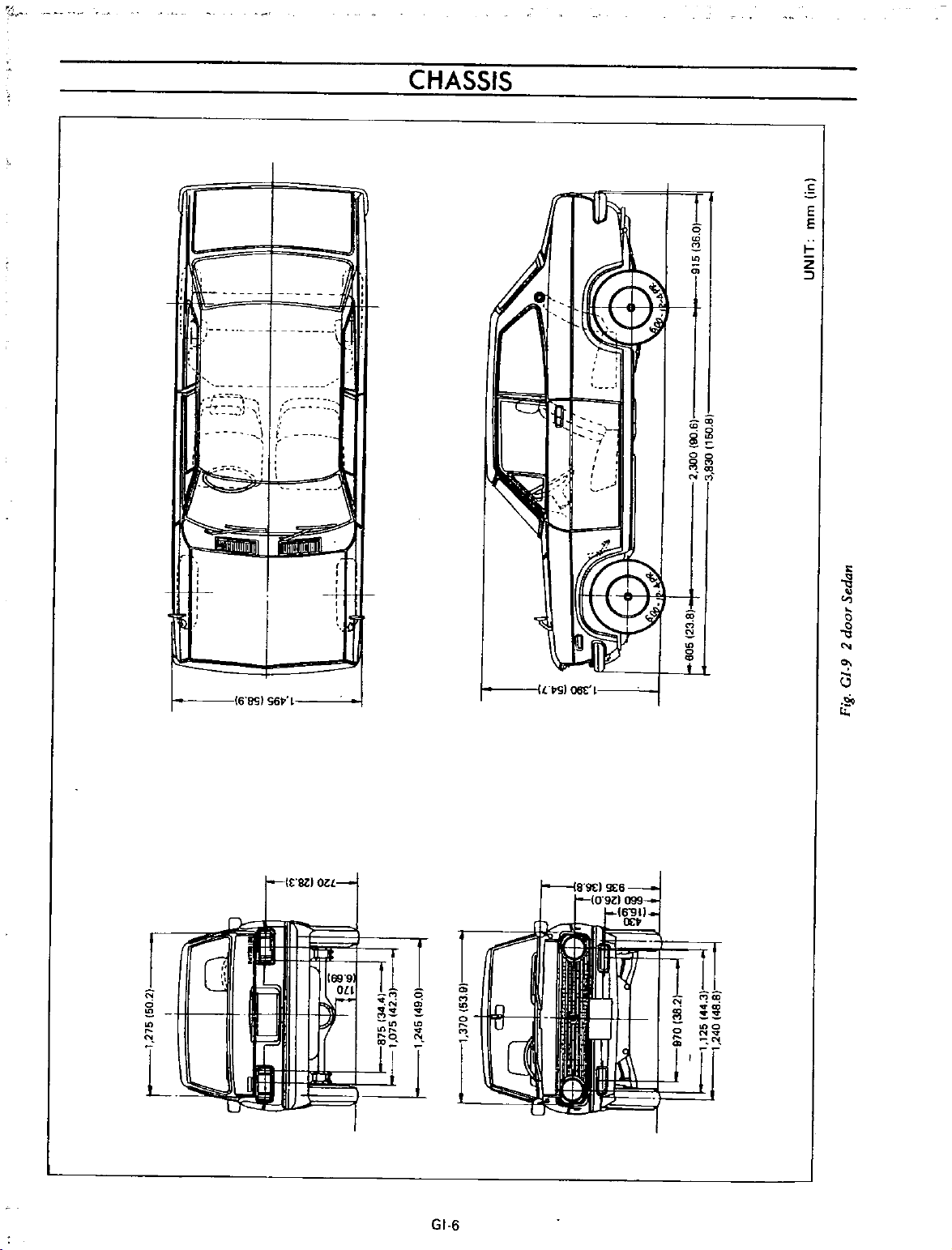

Fig

GI

2 2

door

Sedan

l

GI

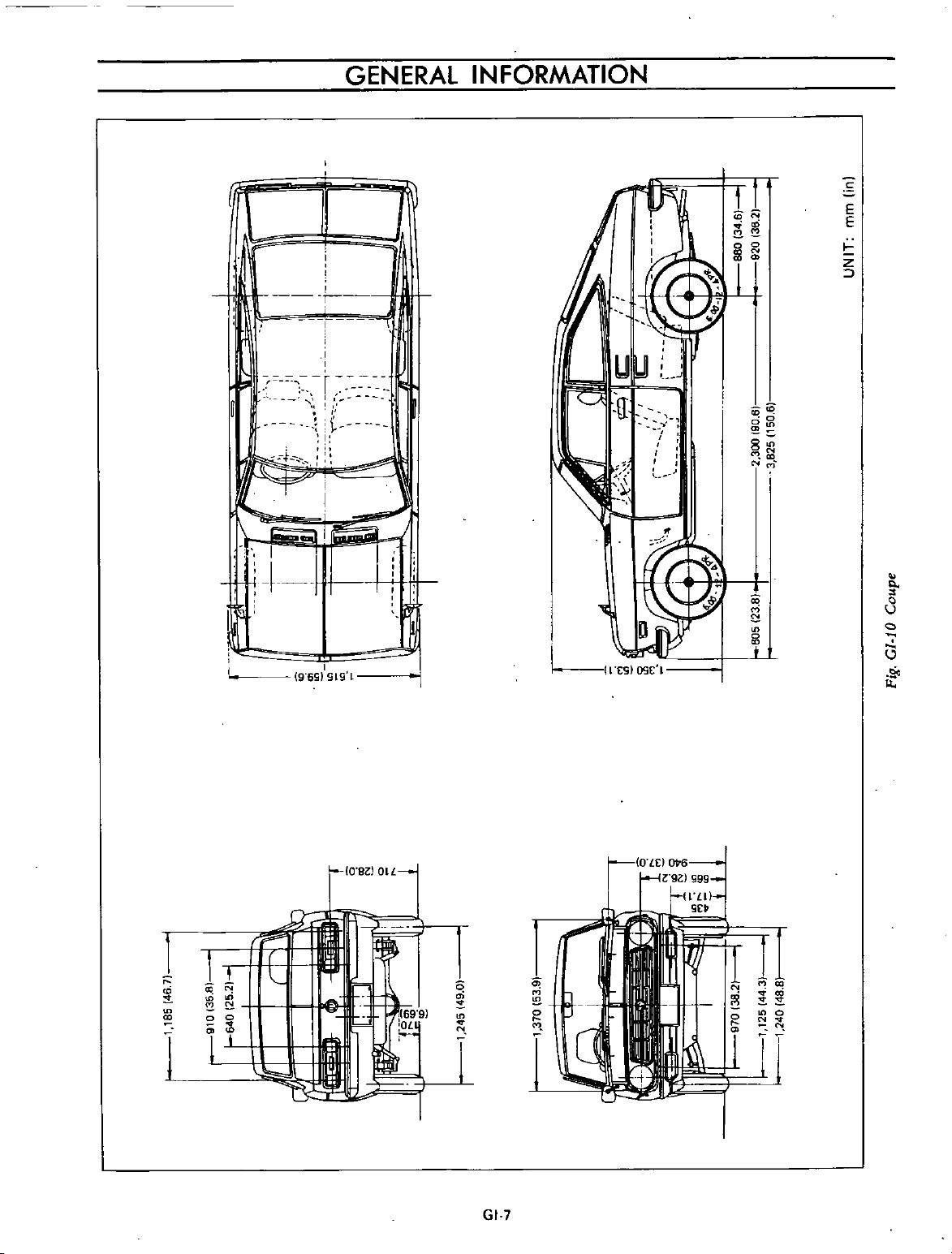

Fig

J

Coupe

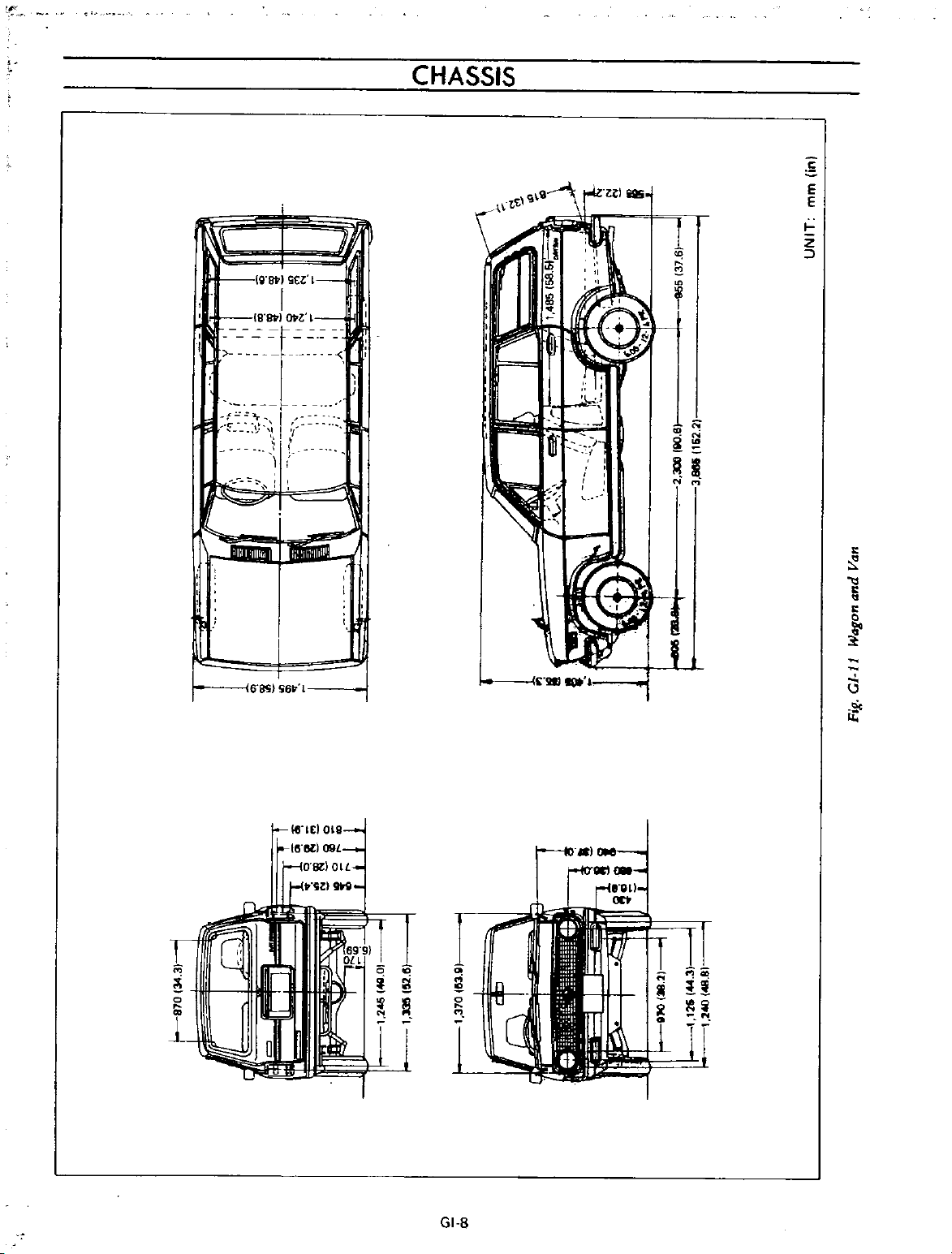

GI

Van

Wagon

4

GI

Fl

Or

2

GI

GENERAL

INFORMATION

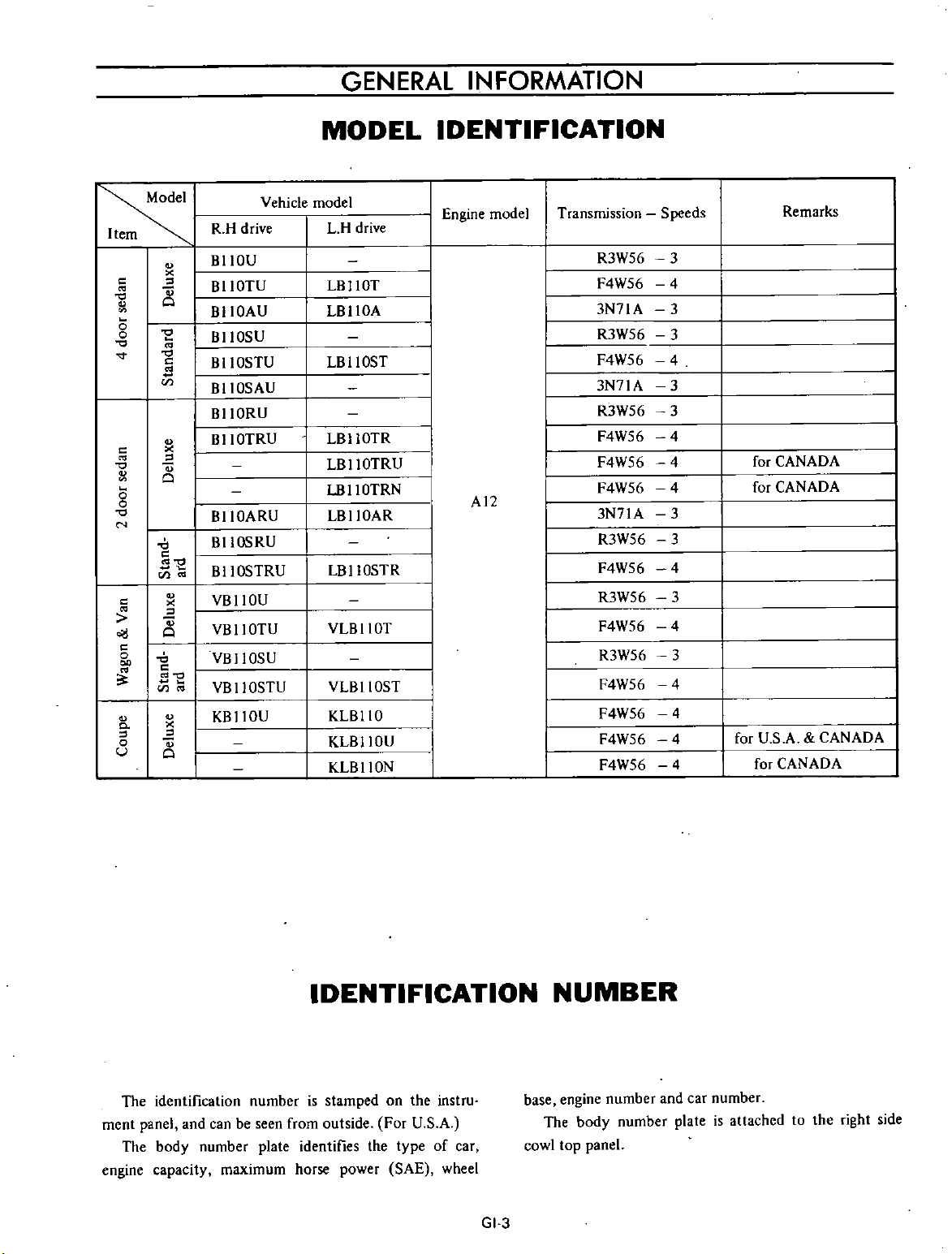

Item

MODEL

Vehicle

H

drive

R

BllOU

BllOTU

Q

BIIOAU

0

E

BllOSU

BllOSTU

J

BIlOSAU

BllORU

BllOTRU

Q

0

0

BllOARU

j

oll

0

j

0

0

u

BI10SRU

SE

BllOSTRU

J

VBIIOU

ll

VBIIOTU

Q

VBIIOSU

J

VBllOSTU VLBIIOST

KBllOU

Q

model

LHdrive

LBIIOT

LBl10A

LBIIOST

LBllOTR

LBllOTRU

LB

LBIlOAR

LBllOSTR

VLBIIOT

KLB

KLBIIOU

KLBIION

llOTRN

110

IDENTIFICATION

Engine

model

Al2

Transmission

R3W56

F4W56

3N71A

R3W56

F4W56

3N7lA

R3W56

F4W56

F4W56

F4W56

3N7lA

R3W56

F4W56

R3W56

F4W56

R3W56

F4W56

F4W56

F4W56

F4W56

Speeds

3

4

3

3

4

3

3

4

4

4

3

3

4

3

4

3

4

4

4

4

for

for

for

USA

for

Remarks

CANADA

CANADA

CANADA

CANADA

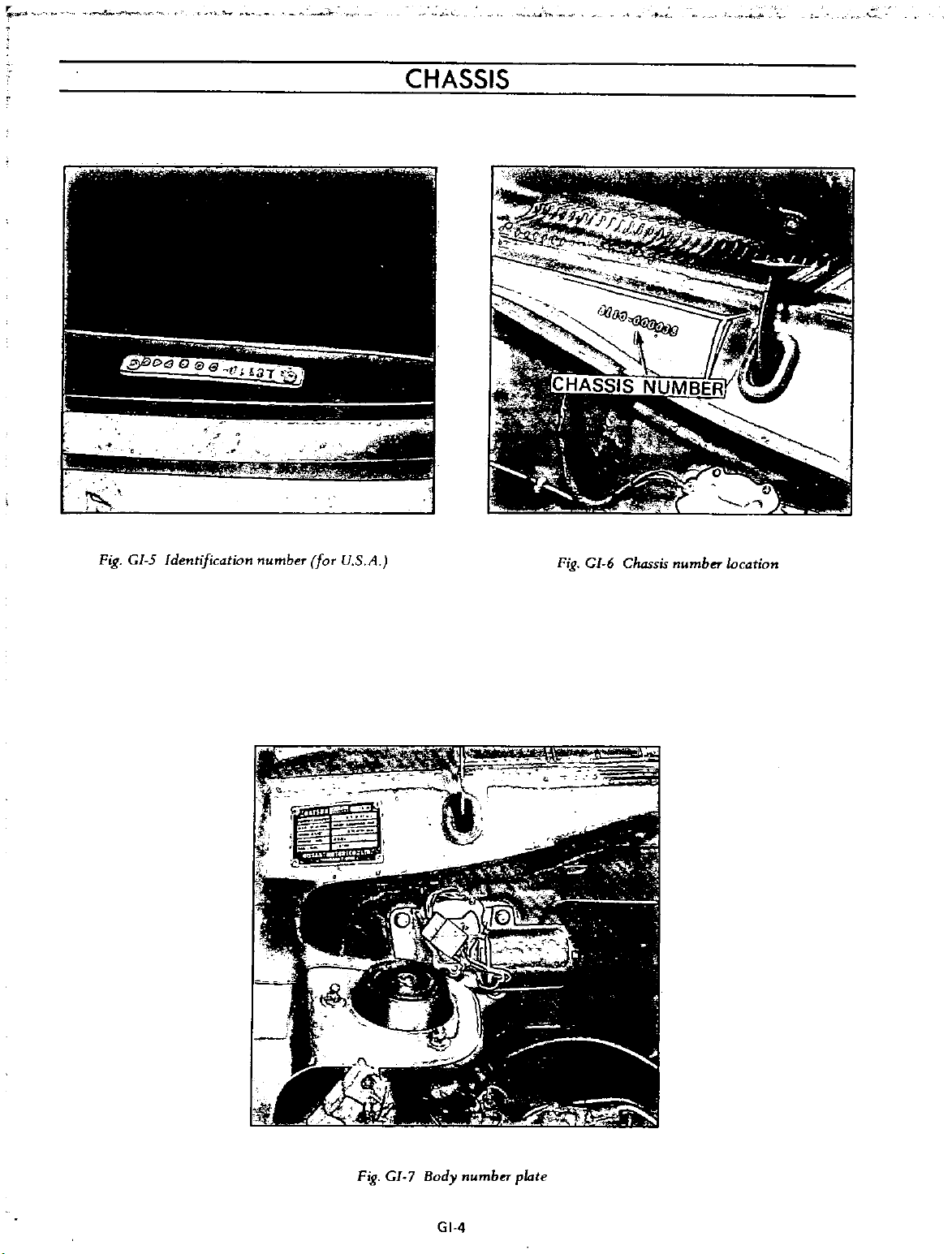

The

ment

The

engine

identification

panel

body

capacity

and

can

number

maximum

be

number

seen

plate

IDENTIFICATION

power

on

ForUS

the

type

SAE

is

from

identifies

horse

stamped

outside

the

instru

A

of

wheel

NUMBER

base

The

car

cowl

GI 3

engine

body

top

number

panel

and

number

car

plate

number

is

attached

to

the

right

side

I

I

CHASSIS

Fig

GI

5

Identification

number

l

1

f

for

Y

fill

C

USA

GI

6

Chassis

Fig

i

J

I

number

location

Fig

GI

7

Body

GI 4

number

plate

GENERAL

INFORMATION

GENERAL

t

c

VIEWS

E

E

I

Z

Sl

I

l

N

i

V

00

ll

l

gg

96v

6

LKIl6

l

G1

5

CHASSIS

s

E

E

f

Z

J

D

j

iil

00

iil

l

ri

il

o

o

gj

Q6t

L

IC

OZL

SZI

169

N

ci

e

N

OLI

l

M

N

t t

a

M

oi

e

0

M

N

20

u

L

il

GI

6

inl

mm

UNIT

61

61

190

300

6251150

2

3

Coupe

IO

GI

7

185146

1

31

44

125

1

8

48

240

1

Fig

F

CHASSIS

E

E

f

Z

la

6

gBl1

BlrIOtrZ

f

l

gCl

I

L

I

I

I

I

J

i

ill

IU

N

N

tO

r

l

S6

nllll

o

1

Q

It

o

GI

B

GENERAL

INFORMATION

Item

c

c

is

Minimum

Vchide

8

Overall

length

Overall

width

Owrallheight

Wheel

base

Length

8

Width

E

8

0

Height

Front

1i

road

wright

Naximwn

km

Naxim

wn

MiniwwrR

clearance

peed

h

grade

turning

lIPH

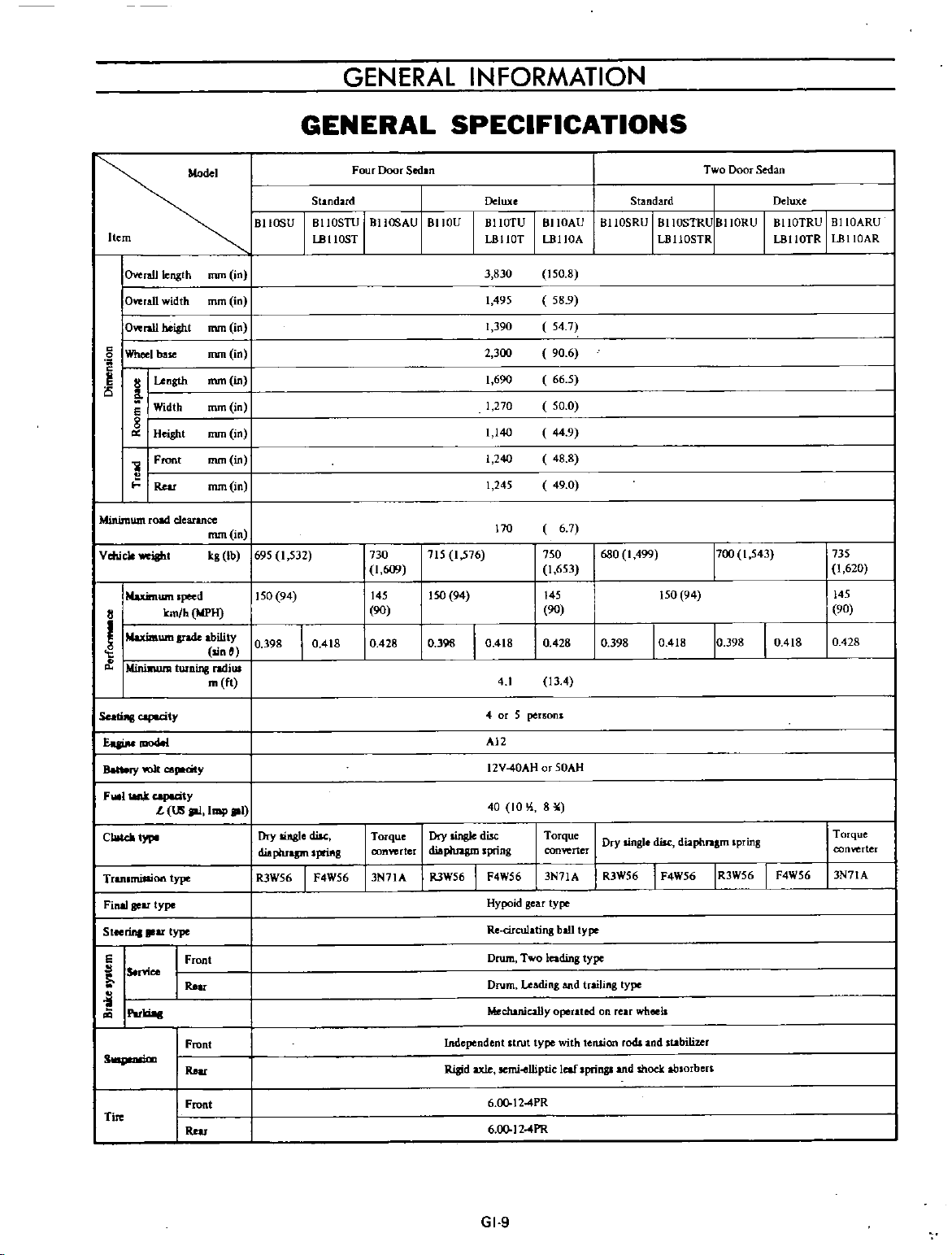

GENERAL

Standard

398

8110STU

LBIlOST

I

94

00418

BIIOSU

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

nun

in

mm

in

mm

in

mm

in

6951532 730 715

kg

lb

150

bili

ty

0

sin

J

radius

m

ft

Four

Door

BIIOSAU

1

609

145

90

0

428

SPECIFICATIONS

Sedln

Deluxe

BIIOU

ISO

0

398

BllOTU BllOAU

LBIlOT

I

3

1

1

2

1

1

1

140

1

1

1

576

94

0

I

830

495

390

300

690

270

240

245

418

70

4

1

Two

Door

Sedan

Standard

BllOSRU

LBllOA

S

l50

58

9

54

7

90

6

66

5

50

0

44

9

48

8

49

0

6

7

428

653

680

0

39g

4

750

1

145

90 90

0

13

IIOSTRU

LBllOSTR

I

1

499

150

10

418

BllORUIBllOTRU

7001543 735

94

0

398

Deluxe

LBllOTR

I

OAI8

BllOARU

LBllOAR

1

620

45

0

428

SeltillB

EqiN

att

Fuel

Clutdr

Tr

n

Final

Steerilllpar

E

Strriee

i

0

S

Tire

capacity

raodoI

1

OIt

ry

t

mil

lion

gear

PIt

al

Ynkcapec

ity

LUJ

type

type

type

aty

pi

Front

Ro

Front

Ro

Front

Imp

pi

lhy

diaphrapn

R3W56

dUe

F4W56

5

4

persons

AI2

12V

40AH

50AH

40

IO

g

Torque

COllWirter

pri

8

3N71A

ingledisc

Dry

diaphngm

R3W56IF4W56

spring

Hypoid

Re

Drum

Mechanically

Independent

axle

Risid

6

6002

circulating

Drlm

strut

124PR

00

gear

Two

Leading

type

semi

elliptic

PR

Torque

converter

3N71A

type

ball

leading

and

operated

with

leaf

type

type

trailiftg

tension

springl

Dry

Jingle

R3W56

type

rearwheeb

rodsndstabilizer

and

shock

disc

F4W56

I

diaphJIlm

absorbers

spring

R3W56IF4W56

Torque

converter

3N7lA

GI

9

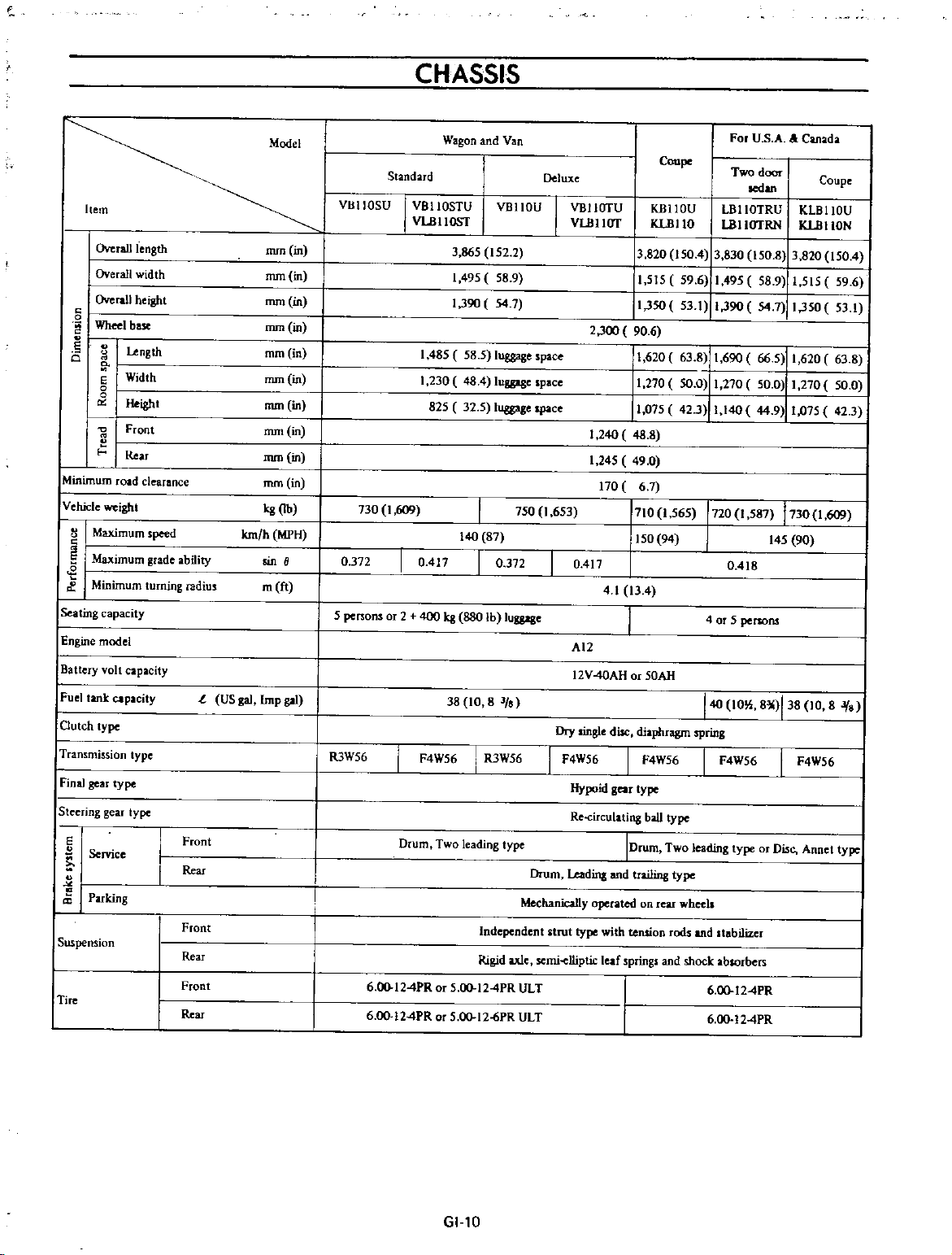

CHASSIS

Item

Overall

Overall

Overall

c

Wheel

c

e

is

Minimum

Vehicle

Maximum

u

c

Maximum

E

Minimum

i

Stating

Engine

Battery

Fuel

tank

Clutch

Transmission

Final

gear

Steering

e

Service

i

Parking

Suspension

Tire

u

E

0

0

weight

apacity

model

volt

type

gear

length

width

height

base

Length

Width

Height

Front

Re

road

clearance

capacity

capacity

type

type

type

speed

grade

turning

ability

radius

Front

Rear

Front

Rear

Front

Re

l

kmhMPH

US

SaI

Model

Standard

VHllOSU

mm

in

mm

in

mm

in 1

mm

in

in

mm

mm

in

mm

in

mm

in

mm

in

mm

in

0

5

persons

7301609

372

or

kgOb

sin

m

Imp

8

ft

gal

R3W56

I

6

6

lJO

BlIOSTU

VlllllOST

I

I

2

I

Drum

I24PR

114PR

1

4SS

1

230

815

0

417

400

F4W56

Wagon

3

86S

1

495

390

140

kg

38108

Two

0

S

or

S

and

SS5

48

4

5

32

880

leading

lJO

I

I

Van

YBllOU

IS1

2

S8

9

54

7

IU88

8e

sp

luggage

l

8PIe

space

7S01653

87

0

372

Ib

luggage

I

R3W56

type

Mechanically

Independent

we

Rigid

124PR ULT

I2

6PR

ULT

Deluxe

pace

Drum

I

ce

I

Dry

I

atrut

YBIIOTU

VlJlIlOT

1

1

0

417

AI2

12V40AH

single

F4W56

Hypoid

Re

circulating

Leading

type

senti

elliptic

2

300

240

245

170

4113

disc

gear

and

operated

with

lear

ForUSA4

Coupe

Two

door

oedan

KBllOU

KLBllO

3

S10

51S

1

I

3SO

90

6

620

1

270

1

075

48

8

49

0

6 7

710

ISO

94

4

or

50AH

diaphragm

I

1

LBllOTRU KLBllOU

IllI

5043

S30

5961

495

53

1

1

39O

6381

690

O1170

SO

4231

140

565

720

4or5

40

spring

HrrRN

1

0

418

lOll

ISOS3

SS9I

547I

6651

SO O 1

44

587

persons

SJO

9

1730

145

F4W56 F4WS6 F4WS6

type

ball

type

Drum

trailing

tension

springs

ear

Two

and

type

rods

leading

wheels

and

shock

6

type

Itabilizer

absorbers

I24PR

600124PR

or

Disc

Can2da

Coupe

KLBllON

810 ISO

SIS

3S0

610

270

I

Q1S423

1

609

90

38108

Annet

4

S9

6

53

1

63

8

50

0

I

type

GI

I0

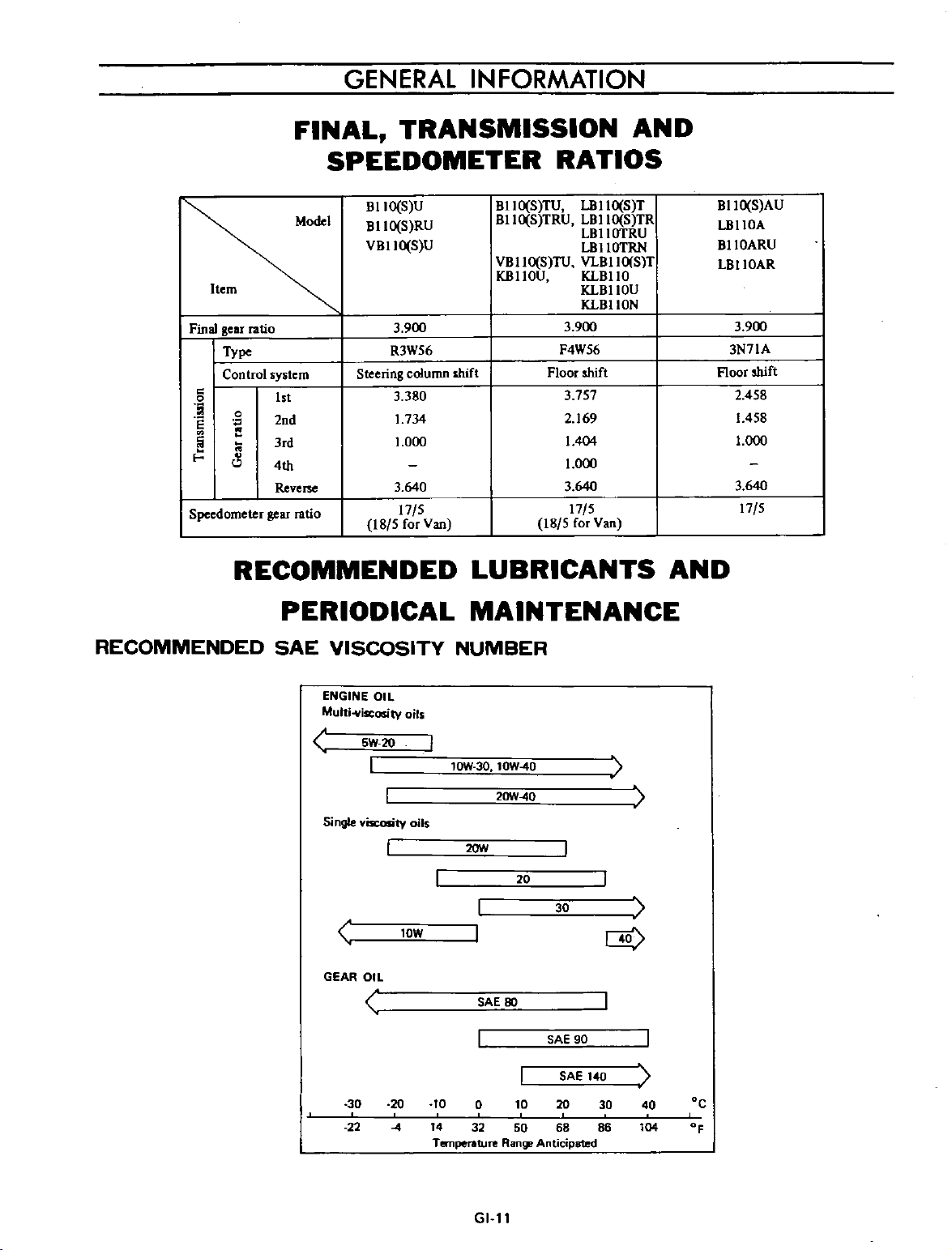

GENERAL

INFORMATION

Item

gear

ratio

Final

Type

Control

system

0

5

E

Speedometer

1st 3

0

2nd

e

3rd

4th

Reverse

gear

RECOMMENDED

FINAL

TRANSMISSION

SPEEDOMETER

S

Model

ratio

BIIO

BIIO

VBIIO

Steering

18

S

900

3

R3W56

column shift

380

1

734

1

000

3

640

17

for

5

AND

RATIOS

U

RU

S

U

5

Van

BllO

BllO

VBllO

KBllOU

S

TU

TRU

S

S

185for

TU

Floor

3

900

F4W56

3

757

2

169

1

404

1

000

3

640

17

LBllO

LBllO

LBllOTRU

LB

llOTRN

VLBllO

KLBllO

KLBllOU

KLBllON

shift

5

Van

S

T

S

TR

ST

BIlO

LBllOA

BllOARU

LB

IIOAR

3

3N71A

Floor

2

1

1

3

17

900

458

458

000

640

S

shift

AU

5

LUBRICANTS AND

PERIODICAL MAINTENANCE

RECOMMENDED SAE

VISCOSITY

Multi

viscosity

5W

viscosity

OIL

30

22

OIL

20

ENGINE

Single

GEAR

oils

oils

lOW

20 10

4

NUMBER

lOW

20W

I

32 50

Temperature

30

SAE

0

80

10W

40

2OW

40

20

30

SAE

90

SAE

140

10 20 30

68

Anticipated

Ran

J

OQ

86

104

Oc

0

OF

GI

ll

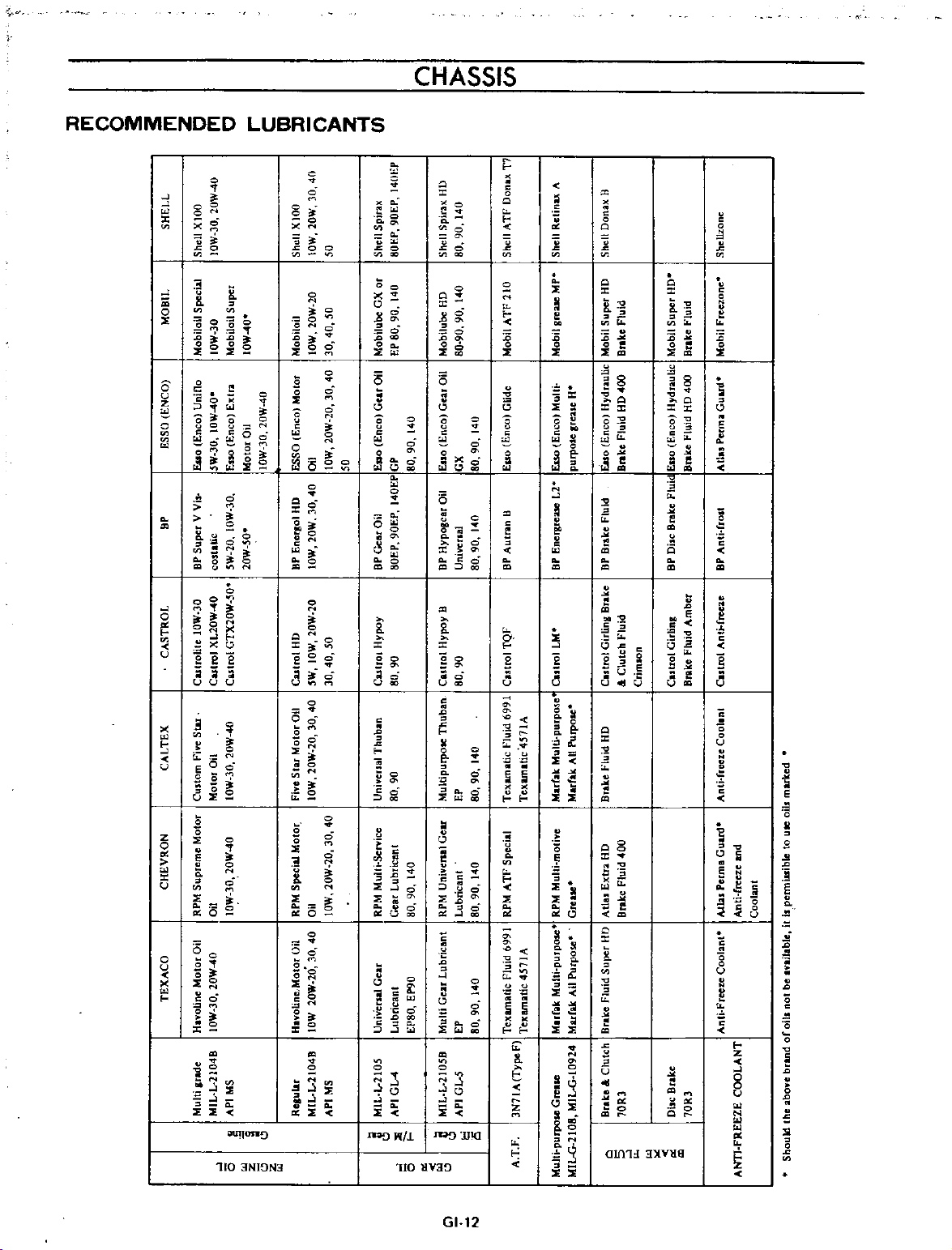

z

Ul

S

Ul

I11oo 11Zo11o

20W

40

100

SHELL

X

30

IOW

Shell

Special

MOBIL

30

IOW

MobiloiJ

Unifio

IOW

ENCO

ESSG

DP

40

Enco

30

Ruo

5W

Vis

V

Super

DP

costalie

r

clDI

Super

IOW

40

Mobiloil

40

Extril

20W

Oil

Enca

3D

Elso

Motor

IOW

3D

lOW

50

20

SW

lOW

o

40

30

IOU

lOW

X

lOW

Shell

50

20

SO

20W

40

lOW

30

Mobiloil

40

30

Molor

lO

Enco

lOW

lOW

Oil

40

3D

lOW

lOW

50

ESSO

0

Enerzel

DP

Ul

7

1

140EP

HD

ShellSplf

l

90EP

Spu

SOH

Shell

140

GX

90

80

Mobilube

EP

Oil

Gear

Enco

Ego

GP

140EP

Oil

90EP

Gear

BP

80EP

AD

Mobilube

Oil

Gear

140

Enco

90

80

Ellu

Oil

HypOgClIl

DP

Don

140

ATF

90

80

Shell

210

140

90

ATF

90

80

Mobil

Glide

140

Eneo

90

80

GX

Euo

140

90

Autnlllll

Unlvcnal

80

DP

j

Don

Retinax

Shell

Shell

MP

Mullt

Eneo

Euo

L2

DP

HD

Mobilgl

CaJe

Super

FlUid

Mobil

Brlke

400

H

Hydraulic

HD

u

gre

Fluid

Eneo

pUrpOle

Easo

Brake

Energre

ue

Fluid

Brake

BP

Shellzone

HO

Super

Mobil

Hydraulic

Eneo

Ellu

Flul

Bralte

Oil

BP

Free

FlUid

Brake

Mobil

400

Guud

HO

Perm

FlUid

Brake

Atlas

frost

Anti

BP

50

3D

XL20W

40

lOW

CASTROL

CALTEX

GTX20W

Culrolite

Culrol

Castrol

40

Star

20W

Five

Oil

3D

lOW

Custom

Motor

Motor

20W40

CHEVRON

Supreme

3D

IOW

RPM

Oil

Oil

20W

40

Motor

TEXACO

3D

oline

IOW

H

048

J

2

srade

L

L

Multi

MI

APIMS

a

0

z

Ul

i

J

20

20W

IOW

CastrolHD

SW

40

Oil

30

lO

Motor

lOW

Star

lOW

Five

Motor

la

SpeCial

RPM

Oil

40

30

lQ

MotolOil

20W

lOW

Hlvolinc

2104B

L

ular

Re

MIL

Ul

Z

50

40

30

40

3D

lOW

lOW

PotS

API

Hypoy

90

Caslnll

80

Thuban

90

Unlvenal

80

Service

140

Multi

Lubrlcanl

10

RPM

Gelll

80

EP90

UmvenalGeac

EP80

Lubncanl

l10S

GL

4

L

API

MIL

3

ll

0

B

Hypoy

Castrol

W

T

90

80

Castrol

LM

llrol

c

Brake

Amber

FlUid

Girting

Clutch

Castrol

l

FlUid

CnmlOn

ClltrolGirling

Brake

frcuc

Anti

Culrol

6991

Thuban

FlUid

140

90

EP

Multipurpole

80

Texamatk

Gear

Special

140

Umvenal

RPM

Lubricant

1I

Ge

Multi

2105B

L

MIL

Ul

ATF

90

Lubneant

80

RPM

6991

FlUid

140

90

EP

80

Texamalic

S

GL

API

Ii

is

purpose

HD

Purpose

4571A

Multi

All

FlUid

Texamatic

Marlak

Marfak

Brake

e

400

HD

mOlll

Multi

RPM

Greue

purpose

4571A

Purpose

All

Multi

Texamatic

Marrak

Marfak

TypeF

3N7IA

F

T

A

I0924

MIL

Q

Grease

2108

purpose

Multi

MIlrG

FlUid

Extu

Brake

Atlu

HI

Super

FlUid

Brake

Clutch

ol

Brake

70R3

Q

5

Brake

Oil

Ul

70R3

Coolanl

free4

Antl

and

freeze

A

tIasPermaGuard

Anti

Coolant

Coolant

e

Freez

Anli

COOLANT

FREEZE

ANTI

marked

oils

ute

to

pernuuiblc

it

available

be

not

oill

of

brand

abol

e

the

Should

G

l

mZmlCr

z

o

lC

z

o

o

11

3

ZI11Zlo

100

95

90

50

45

85

40

80

INTERVAL

35

75

30

70

25

65

MAINTENANCE

60

20

30

27

24

21

18

15

12

Z

60

57

54

51

48

45

42

39

36

oIlo

X

X

X

X

X

X

X

X

X

X

I

tl

X

R

X

X

X

X

X

X

R

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

15

10

5

55

9

33

6

3

X

X

X

X

X

X

X

X

X

X

X

Replacement

1

6

0

X

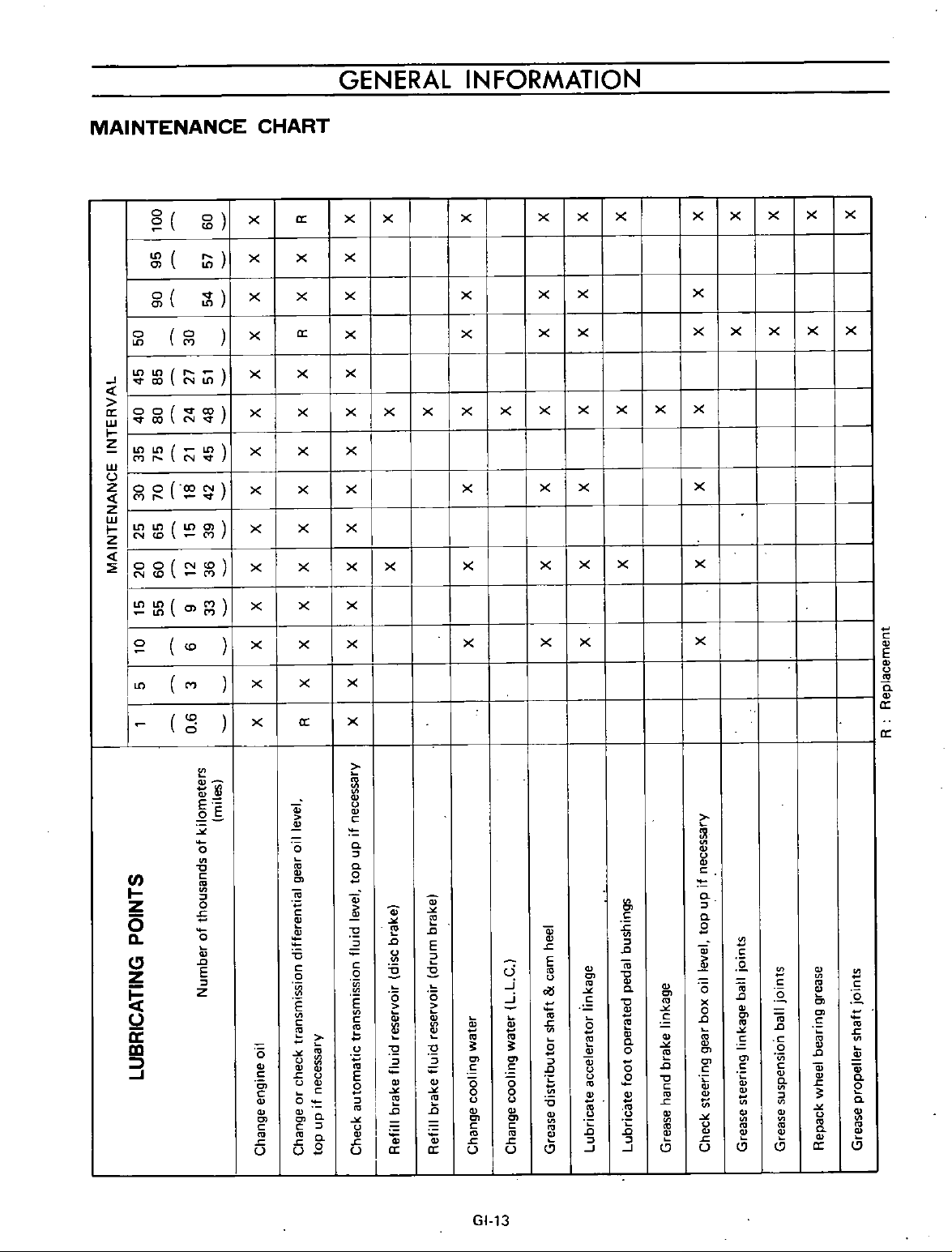

miles

kilometers

of

level

oil

gear

thousands

POINTS

of

differential

Number

transmission

oil

LUBRICATING

check

or

engine

Change

Change

X

R

necessary

if

up

top

level

fluid

transmission

necessary

if

automatic

up

top

Check

brake

brake

disc

drum

reservoir

reservoir

fluid

fluid

brake

brake

Refill

Refill

C

L

L

water

water

cooling

cooling

Change

Change

necessary

if

up

heel

eam

bushings

pedal

iinkage

shaft

operated

accelerator

foot

distributor

Grease

Lubricate

Lubricate

top

level

joints

oil

ball

joints

box

linkage

gear

ball

linkage

brake

hand

Grease

steering

steering

Check

suspension

Grease

Grease

grease

bearing

wheel

Repack

R

joints

shaft

propeller

Grease

Gl

w

g

X

n

X

X

X

J

X

X

X

X

X

M

X

30

X

27

M

X

X

X

X

24

X

INTERVAL

MAINTENANCE

21

18

16

12

d

X

X

g

X

X

9

X

6

X

3

6

0

X

X

X

X

I

I

I

I

X

L

X

X

L

X

X

X

X

X

X

X

X

I

X

X

X

X

I

X

X

X

X

X

X

X

X

X

X

C

X

X

X

I

X

X

X

X

X

X

X

X

X

X

X

X

X

Replacement

R

miles

o

TS

AOAl

p

dCA

A

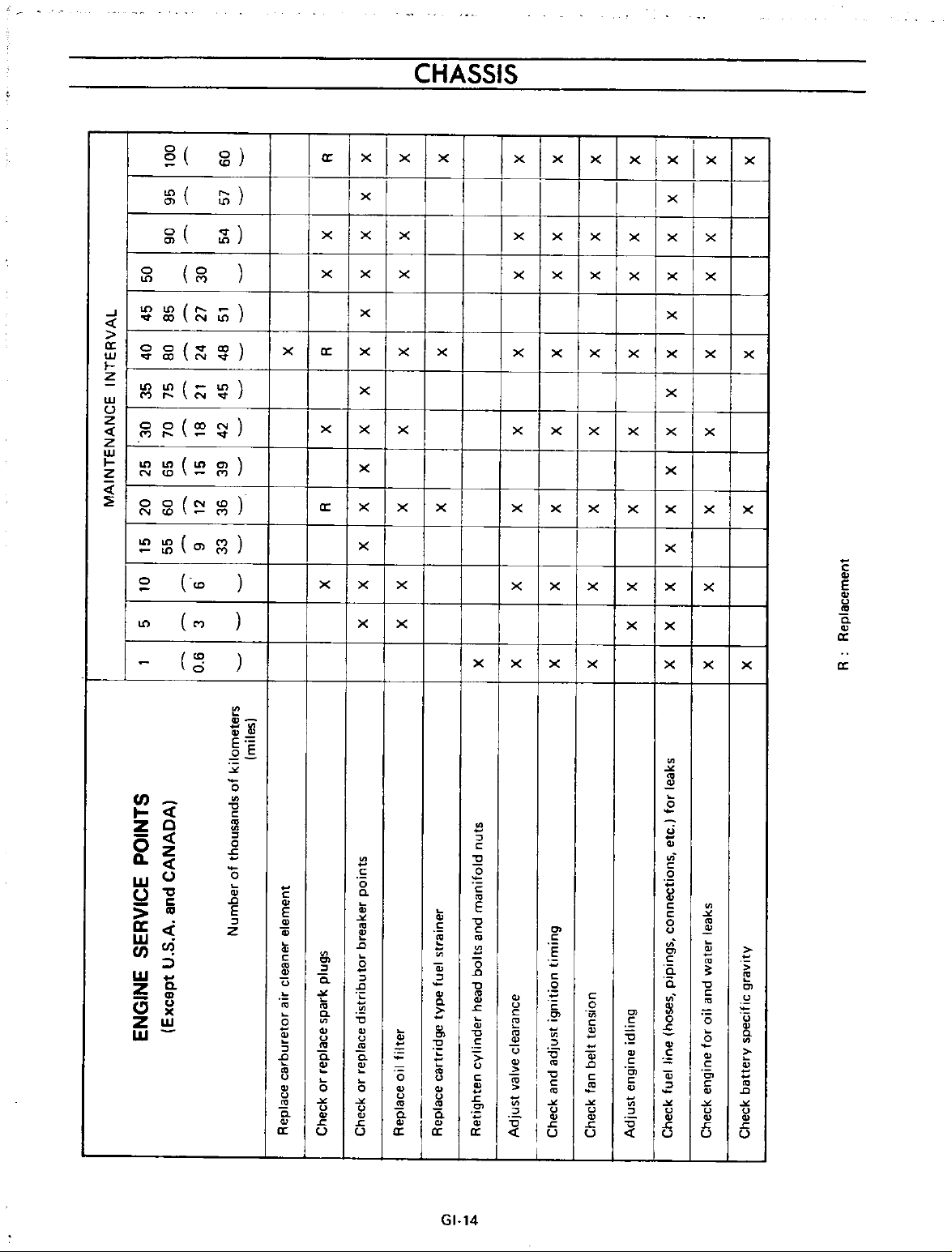

SERVICE

US

o

GIIlE

E

0

w

m

ww

o

o

c

w

M

M

oo

cl

M

A

I

I

I

o

wreN

100

60

mZm

R

R

X

r Z

TI

o

X

X

X

z

o

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

R

X

X

X

R

X

X

X

X

X

X

R

X

X

X

R

X

X

X

X

X

X

X

X

X

X

50

45

40

95

90

B5

BO

30

27

24

57

54

51

48

X

INTERVAL

35

75

21

45

70

65

60

55

18

15

12

9

6

3

0

42

39

36

33

6

30

25

MAINTENANCE

20

15

10

5

1

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Replacement

R

miles

kilometers

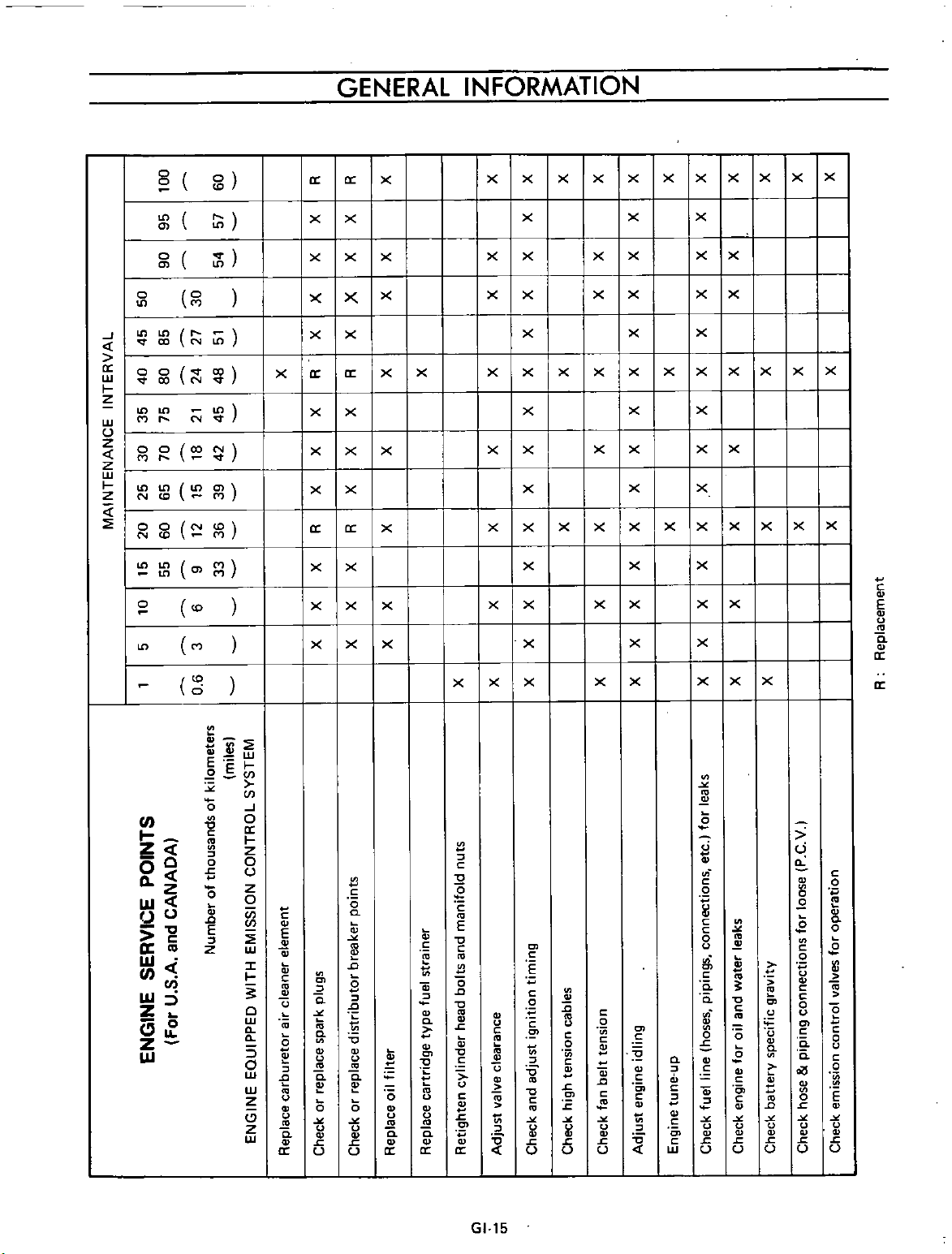

SYSTEM

of

CONTROL

POINTS

SERVICE

thousands

of

CANADA

and

Number

EMISSION

element

A

S

U

For

WITH

cleaner

air

points

breaker

plugs

spark

distributor

nuts

manifold

and

strainer

bolts

fuel

head

type

ENGINE

EQUIPPED

replace

carburetor

or

ENGINE

Replace

Check

filter

replace

oil

or

Replace

Check

cylinder

cartridge

Replace

Retighten

G

leaks

for

etc

connections

leaks

timing

pipings

cables

ignition

tension

clearance

valve

Adjust

tension

adjust

high

and

Check

Check

idling

up

belt

tune

engine

fan

Check

Engine

Adjust

and

oil

hoses

for

line

engine

fuel

Check

Check

I

V

C

P

loose

operation

for

for

water

gravity

specific

battery

Check

valves

connections

control

pipin9

hose

emission

Check

Check

100

95

60

57

x

X

X

X

X

X

X

X

X

fl

fl

X

X

X

X

X

X

X

X

X

1

I

X

X

X

X

50

45

40

90

85

80

30

27

24

54

48

X

I

X

INTERVAL

35

75

21

45

70

65

60

55

18

15

12

9

6

3

6

0

30

25

MAINTENANCE

20

15

10

5

1

42

39

36

33

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

miles

kilometers

of

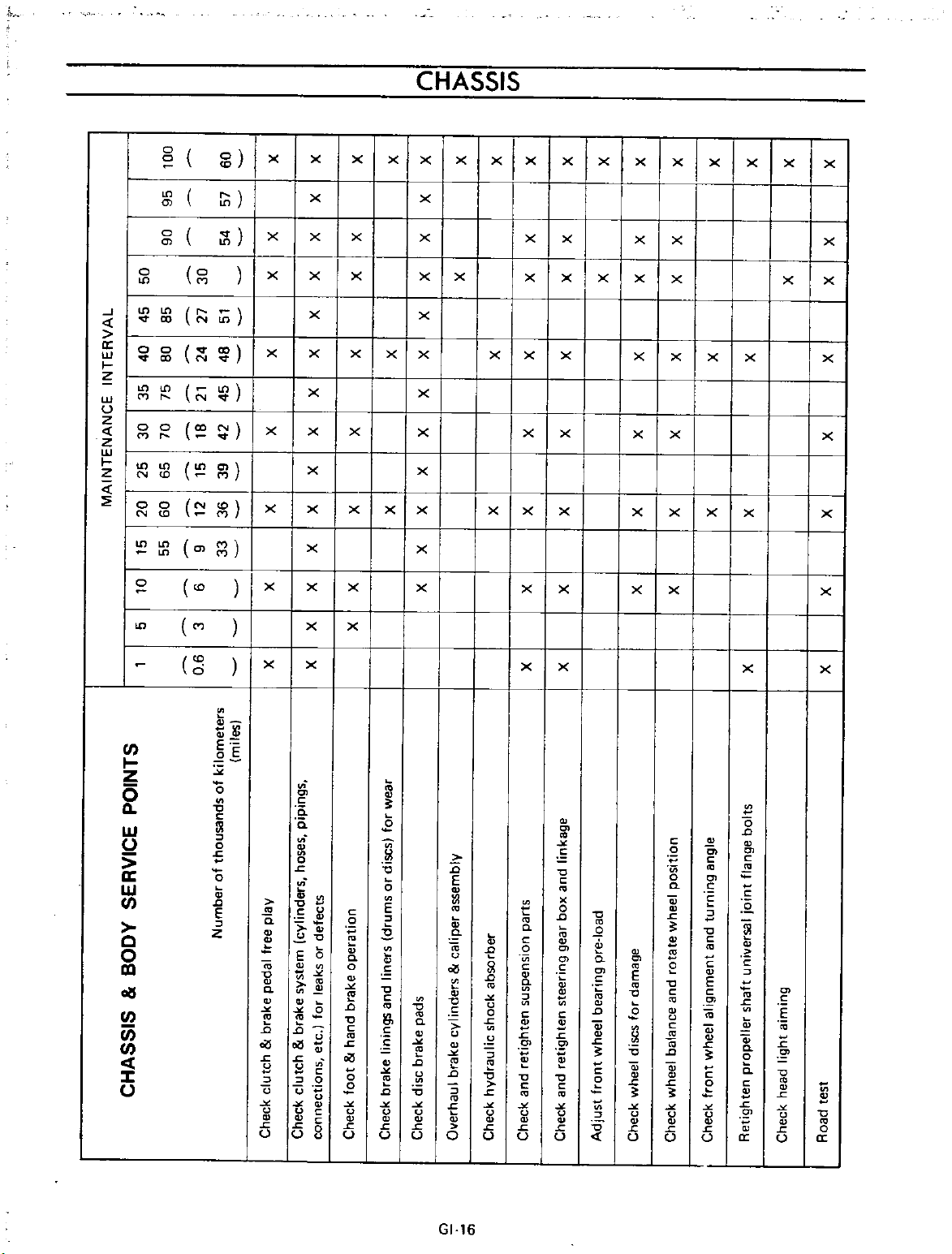

POINTS

thousands

of

pipings

hoses

SERVICE

play

Number

BODY

CHASSIS

cylinders

Iree

pedal

brake

clutch

Check

defects

or

system

leaks

for

braKe

etc

clutch

ChecK

connections

wear

for

discs

or

assembly

drums

operation

liners

and

brake

hand

linings

foot

brake

Check

Check

caliper

pads

cylinders

brake

brake

disc

Check

Overhaul

bolts

linkage

and

box

parts

absorber

suspension

shock

retighten

and

hydraulic

Check

Check

load

gear

pre

steering

retighten

and

Check

damage

bearing

for

discs

wheel

front

wheel

Adiust

Check

angle

position

wheel

rotate

and

balance

flange

joint

turning

and

universal

shaft

alignment

wheel

aiming

light

propeller

front

wheel

Check

Check

head

Retighten

Check

test

Road

C

a

GENERAL

INFORMATION

LUBRICANTS

CAPACITY

Fuel

tank

Cooling

Oil

pan

Oil

filter

Transmission

Differential

Coupe

system

case

Sedan

case

Wagon

with

without

Manual

Automatic

heater

heater

Van

Liter

40

L

38

l

4 9

l

4

2

l

2 7

l

0

54

l

12

l

5 5

l

0

I

75

l

USA

measure

1

10

2

gal

10

47

2

2

5

15

I

gal

53

16

qts

16qts

7

8

qts

1

I

8

pints

2

pints

7

8

quarts

8

pints

8

8

4

3

2

I

2

4

I

Imp

measure

3

3

5

11

3

1

7

3

gal

8

gal

16

qts

16

qts

8

qts

Is

pin

8

pints

8

quarts

8

pints

JACK

UP

Pantograph

Apply

a

j8ck

is

embossed

Do

not

jack

for

identification

up

JACK

Fig

JACKING

jack

to

the

other

UP

POINTS

GI

IZ

indicated

position

of

JQ

king

position

up

point

JACK

UP

where

J

AND

sill

Jange

TOWING

JACKING

SUPPORTED

Jacking

Note

B

jacked

stand

b

use

stand

Front

When

beneath

be

jack

and

jack

the

jack

located

supporting

front

portion

and

up

When

When

a

side

jacking

the

sure

front

coming

behind

the

THE

UP

point

operation

up

s

applying

of

piece

s

up

front

suspension

to

use

suspension

into

the

vehicle

of

the

CAR

AND POINT

WITH

to

be

supported

Carried

s

be

cloth

a

front

sure

the

piece

contact

front

with

to

stand

or

wood between

vehicle

member

of

member

suspension

a

side

member

STAND

support

s

cloth

with

stand

to

apply

or

Be

the

with

out

the

When

wood

careful

steering

apply

TO

stand

with

the

body

the

a

member

the

BE

the vehicle

vehicle

be

sure

body

garage

applying

between

not

to allow

cross

stand

with

to

and

jack

the

the

rod

When

to

17

GI

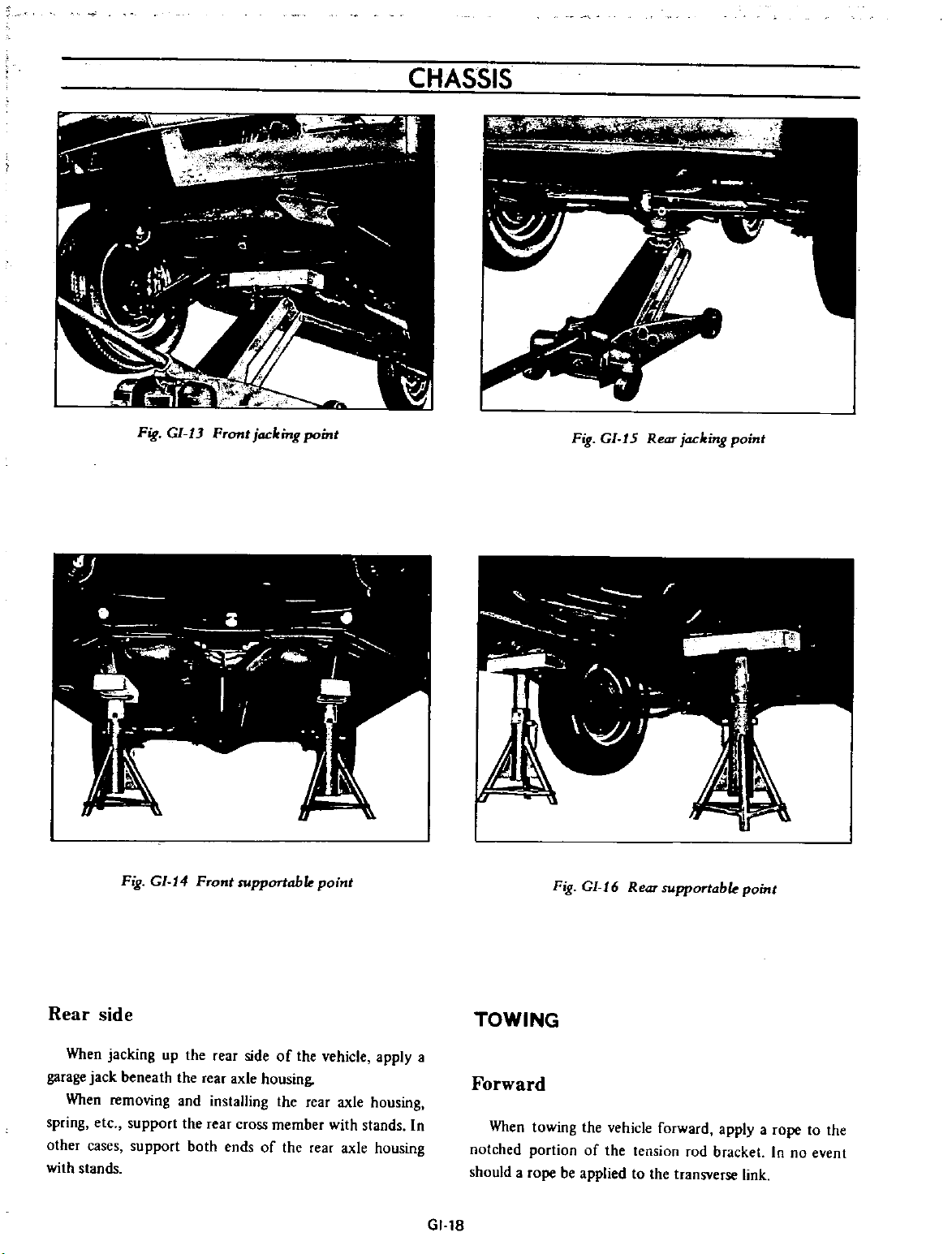

Fig

CHASSIS

GI

I5

Front

GI

tJ

jacking

point

Fig

Rear

jacking

point

Rear

When

garage

When

spring

other

with

side

jack

etc

cases

stands

Fig

jacking

benea

removing

support

support

GI

14

Front

GI

supportable

point

Fig

16

Rear

supportable

point

TOWING

the

rear

rear

rear

ins

side

axle

talling

cross

ends

up

the

th

and

the

both

of

housing

the

member

the

of

the

rear

rear

vehicle

axle

with

axle

stands

apply

housing

housing

a

Forward

tension

to

forward

the

rod

transverse

the

be

vehicle

of

the

applied

In

GI

IB

When

notched

should

portion

a

rope

towing

apply

bracket

link

a

to

rope

In

the

no

event

Rearward

When

rear

shackle

towing

of

Fig

rear

the

GI

spring

17

vehicle

Front

towing

rearward

GENERAL

point

a

apply

rope

INFORMATION

to

the

Fig

GI

18

Rea

towing

point

SERVICE

JOURNAL

BULLETIN

JOURNAL

or

No

PAGE

OR

BULLETIN

NoDATE

REFERENCE

SUBJECT

GI

19

CHASSIS

DATE

SERVICE

JOURNAL

BULLETIN

JOURNAL

or

No

PAGE

No

OR

BULLETIN

REFERENCE

SUBJECT

GI

20

SECTION

ER

DATSUN

MODEL

CHASSIS

8110

1200

SERIES

BODY

ENGINE

INSTAllATION

REMOVAL

a

Nt

SSAN

NISSAN

I

MOTOR

TOKYO

JAPAN

I

CO

LTD

ENGINE

ENGINE

AND

MOUNTING

REMOVAL

INSTALLATION

ER

U4

1

ENGINE

REMOVAL

INSTALLATION

FRONT

Removal

Reinstallation

ENGINE

MOUNTING

ENGINE

MOUNTING

CONTENTS

ER

l

ER

l

ER

2

REAR

Removal

Reinstallation

ENGINE

MOUNTING

CO

ER

ER

ER

2

2

3

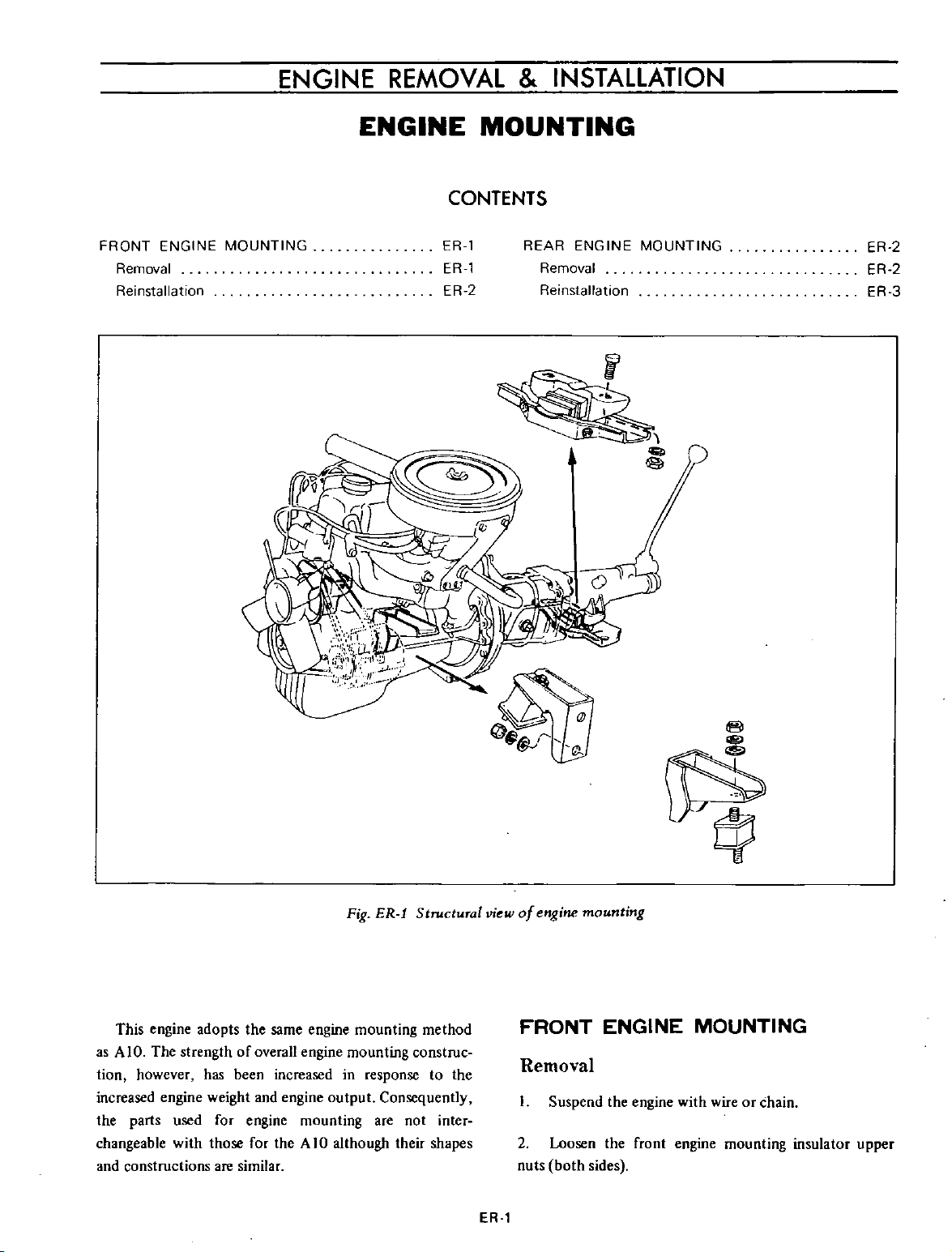

This

engine

as

A

I

O

tion

however

increased

the

parts

changeable

and

constructions

The

engine

adopts

strength

used

with

has

weight

for

those

are

the

of

been

engine

for the

similar

same

overall

and

engine

engine

increased

engine

mounting

A

output

10

Fig

mounting

mounting

in

response

although

ER

1

Structural

method

construe

to

Consequently

not

are

their

shapes

inter

the

@

view

l1J

of

engine

FRONT

Removal

t

Suspend

2

Loosen

both

nuts

mounting

ENGINE MOUNTING

the

the

sides

engine

front

with

engine

wire

s

or

chain

mounting

insulator

upper

ER

l

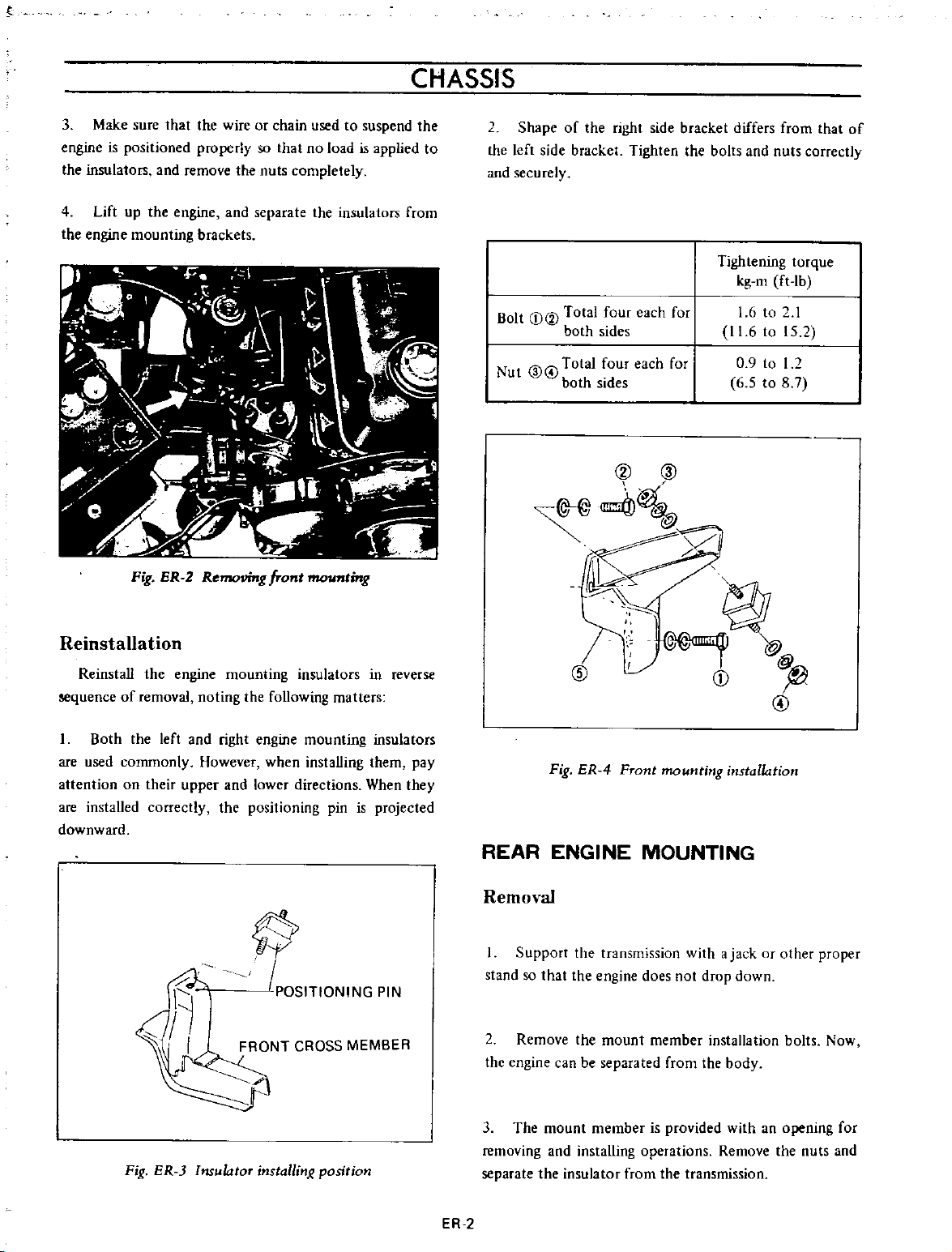

3

Make

sure

that

engineispositioned

the

insulators

and

the

properly

remove

wire

the

or

SO

nuts

chain

that

completely

no

used

load

to

suspend

is

applied

CHASSIS

the

to

2

the

and

Shape

left

side

securely

of

bracket

the

right

side

Tighten

bracket differs

the

bolts

and

nuts

from

that

correctly

of

4

Lift

the

engine

Itl

A

0

7

Reinstallation

Reinstall

sequence

of

the

up

mounting

I

r

r

J

ER

Fig

the

removal

engine

brackets

vf

l

I

l

2

engine

noting

and

J

ii

jl

Removing

mounting

the

separate

o

J

JI

l

front

following

the

IV

1

b

0

I

n

mounting

insulators

insulators

matters

from

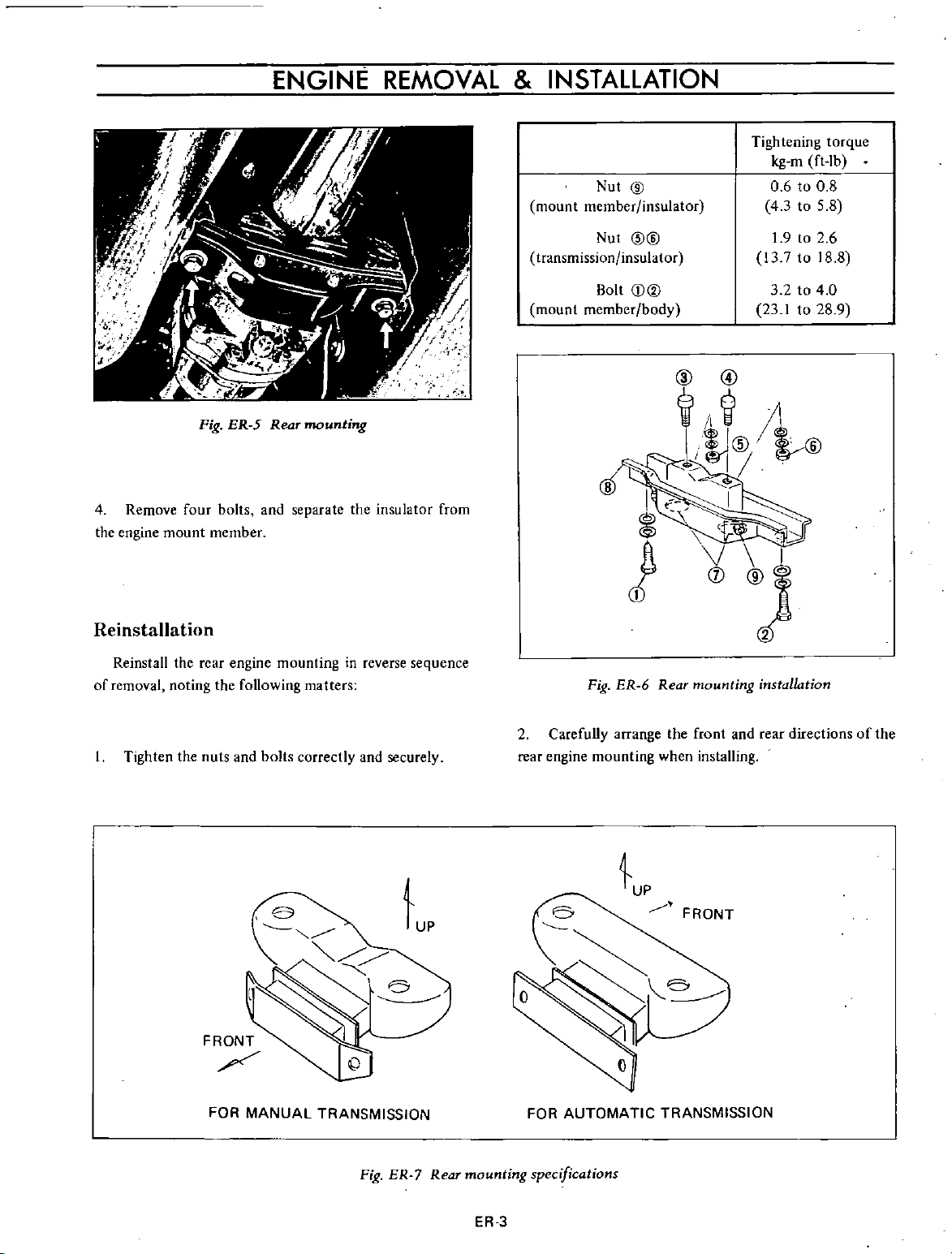

Bolt

Nut

CD@

@@

Total

both

Total

both

foor

sides

four

sides

@

each

each

@

for

for

Tightening

kg

1

11

0

6

m

ft

to

2

6

6to15

9toI 2

5to8

torque

Ib

1

2

7

H

f8J

in

reverse

@@

@

Both

are

used

attention

installed

are

downward

the

left

commonly

on

their

correctly

ER

Fig

and

However

upper

3

InsUlatOT

right

and

the

engine

when

lower

positioning

FRONT

installinR

mounting

installing

directions

pinisprojected

CROSS

position

insulators

them

When

MEMBER

pay

they

REAR

Removal

Support

standsothat

2

Remove

the

engine

3

The

removing

separate

the

Fig

ENGINE

the

can

mount

and

insulator

ER4Front

the

transmission

engine

the

mount

be

separated

member

installing

mounting

MOUNTING

does

member

from

is

provided

operations

from

the

with

a

not

drop

installation bolts

the

Remove

transmission

installation

or

jack

down

body

with

an

other

opening

the

nuts

proper

Now

for

and

ER

2

ENGINE

REMOVAL

INSTALLATION

4

the

Remove

engine

mount

four

Fig

bolts

member

ER5Rear

and

mounting

separate

the

insulator

from

mount

transmission

mount

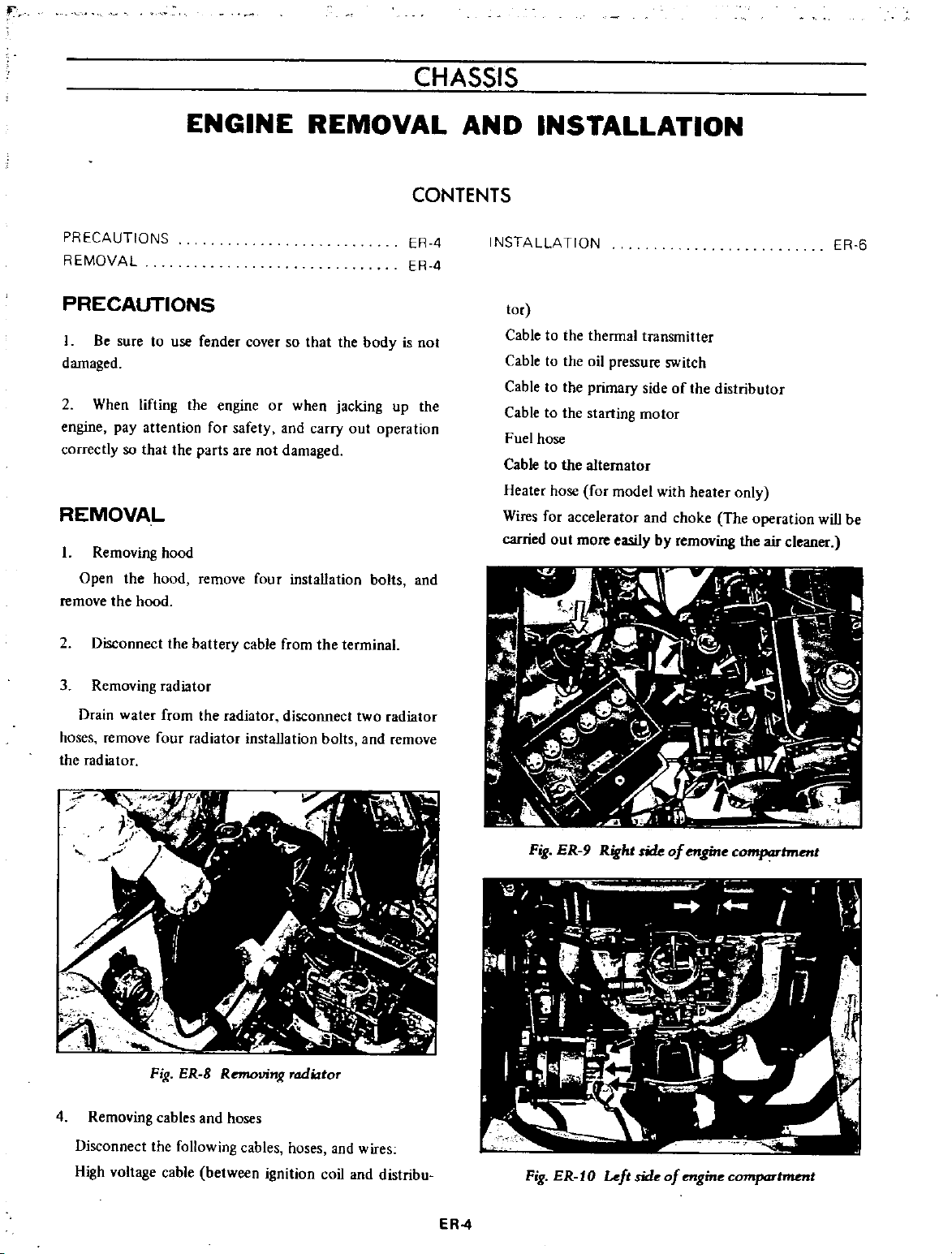

Nut

member

Nut

Bolt

member

@

ID@

insula

j

insulator

tor

@

body

Tightening

m

kg

0

to

6

43

to

1

9to2

7

to

13

3

2to4

23

1

to

ft

0

5

18

28

torque

Ib

8

8

6

8

0

9

Reinstallation

Reinstall

of

removal

I

Tighten

the

noting

the

rear

nuts

FRONT

the

engine

following

and

mounting

bolts

matters

correctly

in

reverse

sequence

and

installation

rear

directions

of

the

and

securely

2

rear

Carefully

engine

ER6Rear

Fig

arrange

mounting

the

when

mounting

front

installing

tp

Lp

FOR

MANUAL

TRANSMISSION

ER7Rear

Fig

mounting

ER

3

FOR

sp

cjfications

AUTOMATIC

TRANSMISSION

f

CHASSIS

PRECAUTIONS

REMOVAL

PRECAUTIONS

Be

L

damaged

2

When

engine

correctly

REMOVAL

I

Removing

Open

remove

2

Disconnect

3

Removing

Drain

hoses

the

radiator

pay

the

remove

sure

so

the

water

to

lifting

attention

that

hood

hood

radiator

four

ENGINE

use

the

the

parts

hood

the

battery

from

radiator

fender

engine

for

safety

are

remove

the radiator

cover

or

not

four

cable

installation

REMOVAL

so

that

when

jacking

and

carry

damaged

installation

from

the

disconnect

bolts

the

out

terminal

two

body

operation

bolts

radiator

and

CONTENTS

ERA

ER

4

is

not

the

up

and

remove

AND

INSTAllATION

t

INSTAllATION

tor

hose

11

f

to

to

to

to

to

for

fI

the

hose

out

the

the

the

the

accelerator

lfti

Cable

Cable

Cable

Cable

Fuel

Cable

Heater

Wires

carried

1

thermal

oil

primary

starting

alternator

for

more

pressure

model

easily

IlO

1

d

CI

0

transmitter

switch

sideofthe

motor

with

and

choke

by

removing

I

P

J

I

D

heater

i

7

distributor

only

The

the

c

Ie

fj

t

k

I1

u

operation

air

cleaner

i

l

t

I

ER

6

will

be

j

r

0

y

1

4

Disconnect

High

Removing

voltage

Fig

cables

the

cable

ER

8

Removing

and

following

between

hoses

cables

rculiator

hoses

ignition

coil

and

and

wires

distribu

ER

4

Fig

Fig

ER

ER tO

9

Right

side

of

engine

compartment

Leftsideofenginecompartment

ENGINE

REMOVAL

INSTALLATION

5

Disconnecting

On

left

the

clutch

Disconnect

withdrawal

6

Remove

hand

slave

lever

drive

the

the

clutch wire

model

cylinder

clutch wire

See

exhaust

the

disconnect

section

front

on

at

covering

tube

right

hand

hydraulic

the

portion

the

drive

clutch

line

model

from

of

the

II

Model

Remove

remove

Sospend

with

the

Fig

pins

ER

automatic

from

shift

the

12

rod

engine

Removing

transmission

both

with

ends

wire

front

of

the

tube

cross

shaft

and

7

Disconnect

8

Disconnect

9

Remove

Remove

and

withdraw

10

Remove

Model

Disconnect

transmission

control

Model

Remove

the

compartment

lever

Fig

with

rod

with

four

the

ER

the

the

the

the

the

remote

the

floor

boot

The

l1

Disconnecting

cabletothe

speedometer

propeller

bolts

propeller

shift

remote

outer

operation

shaft

usedinthe differential

shaft

lever

control

control

lever

lever

shift

withdraw

is

back

cable

shift

and

the

carried

clutch

up

lever

rod at

remove

lock

out

lamp

the

pin

in

wire

the

switch

carrier

portion

the

and

passenger

remote

remove

side

engine

engine

the

remote

mounting

engine

beneath

control

mounting

mounting

the

ER

Fig

12

Remove

of

nuts

13

14

nuts

Remove

When

be

sure

13

the

the

fear

removing

to

applyajack

Removing

front

rod

installation

installation

installation

transmission

nuts

ER

5

Loading...

Loading...