ENGINE MECHANICAL

GI

MA

CONTENTS

QG18DE

PRECAUTIONS ...............................................................4

Parts Requiring Angular Tightening.............................4

Liquid Gasket Application Procedure ..........................4

PREPARATION ...............................................................5

Special Service Tools ..................................................5

Commercial Service Tools...........................................7

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING...................................................10

NVH Troubleshooting - Engine Noise .......................10

OUTER COMPONENT PARTS.....................................12

Removal and Installation...........................................12

QG18DE (EXCEPT CALIF. CA MODEL)

QG18DE (CALIF. CA MODEL)

MEASUREMENT OF COMPRESSION PRESSURE....16

OIL PAN.........................................................................17

Components...............................................................17

Removal.....................................................................17

Installation..................................................................18

TIMING CHAIN ..............................................................20

Components...............................................................20

Removal.....................................................................21

Inspection...................................................................24

Installation..................................................................24

OIL SEAL.......................................................................29

Replacement..............................................................29

VALVE OIL SEAL

FRONT OIL SEAL

REAR OIL SEAL

CYLINDER HEAD..........................................................31

Components...............................................................31

Removal.....................................................................32

Disassembly...............................................................34

Inspection...................................................................34

CYLINDER HEAD DISTORTION

CAMSHAFT VISUAL CHECK

CAMSHAFT RUNOUT

CAMSHAFT CAM HEIGHT

CAMSHAFT JOURNAL CLEARANCE

.....................................................29

....................................................29

......................................................30

..............................................35

..................................15

....................................35

.......................................35

....................14

...............................34

........................36

SECTION

CAMSHAFT END PLAY

CAMSHAFT SPROCKET RUNOUT

VALVE GUIDE CLEARANCE

VALVE GUIDE REPLACEMENT

VALVE SEATS

REPLACING VALVE SEAT FOR SERVICE PARTS

VALVE DIMENSIONS

VALVE SPRING

VALVE LIFTER AND VALVE SHIM

Assembly ...................................................................41

Installation..................................................................41

Valve Clearance.........................................................45

CHECKING

ADJUSTING

ENGINE ASSEMBLY.....................................................49

Removal and Installation...........................................49

REMOVAL

INSTALLATION

CYLINDER BLOCK.......................................................53

Components...............................................................53

Removal and Installation...........................................54

Disassembly...............................................................54

PISTON AND CRANKSHAFT

Inspection...................................................................55

PISTON AND PISTON PIN CLEARANCE

PISTON RING SIDE CLEARANCE

PISTON RING END GAP

CONNECTING ROD BEND AND TORSION

CYLINDER BLOCK DISTORTION AND WEAR

PISTON-TO-BORE CLEARANCE

CRANKSHAFT

BEARING CLEARANCE

CONNECTING ROD BUSHING CLEARANCE

(SMALL END)

REPLACEMENT OF CONNECTING ROD

BUSHING (SMALL END)

FLYWHEEL/DRIVE PLATE RUNOUT

Assembly ...................................................................62

PISTON

CRANKSHAFT

SERVICE DATA AND SPECIFICATIONS (SDS).........66

.........................................................38

.............................................................45

............................................................46

...............................................................50

........................................................52

.........................................................58

..........................................................61

..................................................................62

.........................................................63

EM

............................................36

...........................37

....................................37

................................37

....39

...............................................40

.......................................................40

............................40

....................................54

..................55

............................55

..........................................56

...............56

...........57

..............................57

...........................................59

..........................................61

........................61

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS (Cont’d)

General Specifications...............................................66

Compression Pressure..............................................66

Cylinder Head............................................................66

Valve ..........................................................................67

....................................................................67

VALVE

VALVE SPRING

VALVE LIFTER

VALVE CLEARANCE

VALVE GUIDE

AVAILABLE SHIMS

VALVE SEAT

VALVE SEAT RESURFACE LIMIT

.......................................................67

........................................................67

................................................67

.........................................................68

..................................................68

...........................................................71

.............................71

Camshaft and Camshaft Bearing..............................72

Cylinder Block............................................................72

Piston, Piston Ring and Piston Pin ...........................73

PISTON

PISTON RING

PISTON PIN

..................................................................73

.........................................................73

............................................................73

Connecting Rod.........................................................74

Crankshaft..................................................................75

Main Bearing..............................................................75

STANDARD

UNDERSIZE

.............................................................75

............................................................76

Connecting Rod Bearing ...........................................76

STANDARD SIZE

UNDERSIZE

....................................................76

............................................................76

Bearing Clearance.....................................................76

Miscellaneous Components.......................................76

SR20DE

PRECAUTIONS .............................................................77

Parts Requiring Angular Tightening...........................77

Liquid Gasket Application Procedure ........................77

PREPARATION .............................................................78

Special Service Tools ................................................78

Commercial Service Tools.........................................80

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING...................................................82

NVH Troubleshooting - Engine Noise .......................83

OUTER COMPONENT PARTS.....................................84

Removal and Installation...........................................84

MEASUREMENT OF COMPRESSION PRESSURE....87

OIL PAN.........................................................................88

Components...............................................................88

Removal.....................................................................88

Installation..................................................................90

TIMING CHAIN ..............................................................93

Components...............................................................93

Removal.....................................................................94

Inspection...................................................................97

Installation..................................................................97

OIL SEAL.....................................................................102

Replacement............................................................102

VALVE OIL SEAL

FRONT OIL SEAL

REAR OIL SEAL

...................................................102

..................................................103

....................................................103

CYLINDER HEAD........................................................105

Components.............................................................105

Removal...................................................................106

Disassembly.............................................................108

Inspection.................................................................110

CYLINDER HEAD DISTORTION

CAMSHAFT VISUAL CHECK

CAMSHAFT RUNOUT

CAMSHAFT CAM HEIGHT

CAMSHAFT JOURNAL CLEARANCE

CAMSHAFT END PLAY

CAMSHAFT SPROCKET RUNOUT

VALVE GUIDE CLEARANCE

VALVE GUIDE REPLACEMENT

VALVE SEATS

REPLACING VALVE SEAT FOR SERVICE PARTS

VALVE DIMENSIONS

VALVE SPRING

HYDRAULIC LASH ADJUSTER

ROCKER ARM, SHIM AND ROCKER ARM GUIDE

............................................111

..........................................112

.......................................................114

.............................................115

.....................................................116

.............................110

..................................111

.....................................111

......................111

.........................112

..................................112

..............................113

..114

..............................116

...117

Assembly .................................................................117

Installation................................................................120

ENGINE ASSEMBLY...................................................127

Removal and Installation.........................................127

REMOVAL

INSTALLATION

.............................................................128

......................................................129

CYLINDER BLOCK.....................................................130

Components.............................................................130

Removal and Installation.........................................131

Disassembly.............................................................131

PISTON AND CRANKSHAFT

..................................131

Inspection.................................................................132

PISTON AND PISTON PIN CLEARANCE

PISTON RING SIDE CLEARANCE

PISTON RING END GAP

CONNECTING ROD BEND AND TORSION

CYLINDER BLOCK DISTORTION AND WEAR

PISTON-TO-BORE CLEARANCE

CRANKSHAFT

BEARING CLEARANCE

CONNECTING ROD BUSHING CLEARANCE

(SMALL END)

REPLACEMENT OF CONNECTING ROD

BUSHING (SMALL END)

REPLACEMENT OF PILOT BUSHING (M/T) OR

PILOT CONVERTER (A/T)

FLYWHEEL/DRIVE PLATE RUNOUT

.......................................................135

........................................................138

........................................133

............................134

.........................................135

........................................138

......................................138

................132

..........................132

.............133

.........133

......................139

Assembly .................................................................139

PISTON

CRANKSHAFT

................................................................139

.......................................................140

SERVICE DATA AND SPECIFICATIONS (SDS).......143

General Specifications.............................................143

EM-2

CONTENTS (Cont’d)

Compression Pressure............................................143

Cylinder Head..........................................................143

Valve ........................................................................144

..................................................................144

VALVE

VALVE SPRING

HYDRAULIC LASH ADJUSTER (HLA)

VALVE GUIDE

VALVE SHIM CLEARANCE ADJUSTMENT

AVAILABLE SHIM

VALVE SEAT

VALVE SEAT RESURFACE LIMIT

Camshaft and Camshaft Bearing............................148

Cylinder Block..........................................................149

Piston, Piston Ring and Piston pin..........................150

PISTON

.....................................................144

.....................144

.......................................................145

..............145

..................................................146

.........................................................147

...........................148

................................................................150

PISTON RING

PISTON PIN

Connecting Rod.......................................................151

Crankshaft................................................................152

Main Bearing............................................................153

STANDARD

UNDERSIZE

Connecting Rod Bearing .........................................153

STANDARD SIZE

UNDERSIZE

Bearing Clearance...................................................153

Miscellaneous Components.....................................153

.......................................................150

..........................................................150

...........................................................153

..........................................................153

..................................................153

..........................................................153

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

EM-3

IDX

Parts Requiring Angular Tightening

PRECAUTIONS

QG18DE

SEM164F

Parts Requiring Angular Tightening

NIEM0041

쐌 Use an angle wrench for the final tightening of the following

engine parts:

a) Cylinder head bolts

b) Main bearing cap bolts

c) Connecting rod cap nuts

쐌 Do not use a torque value for final tightening.

쐌 The torque value for these parts are for a preliminary step.

쐌 Ensure thread and seat surfaces are clean and coated with

engine oil.

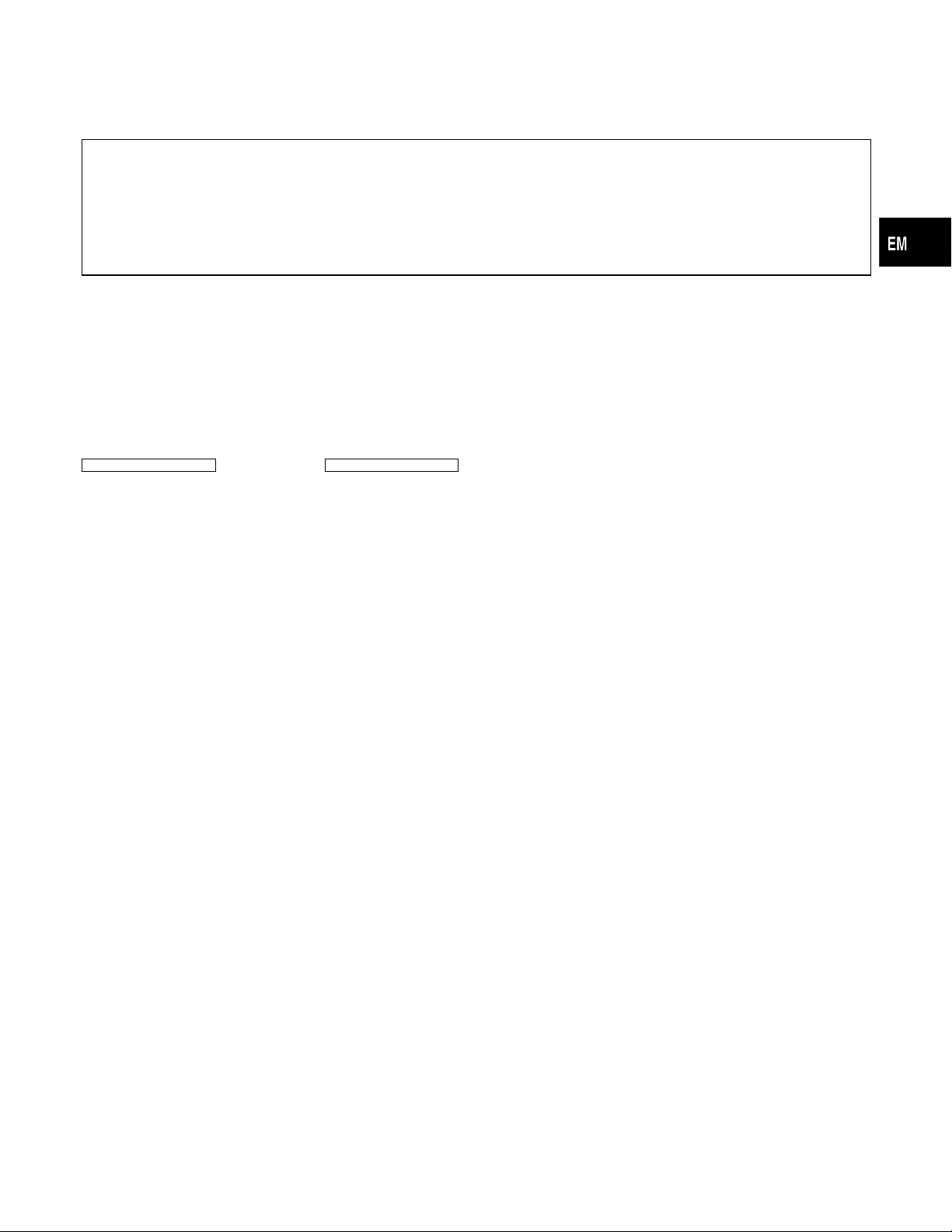

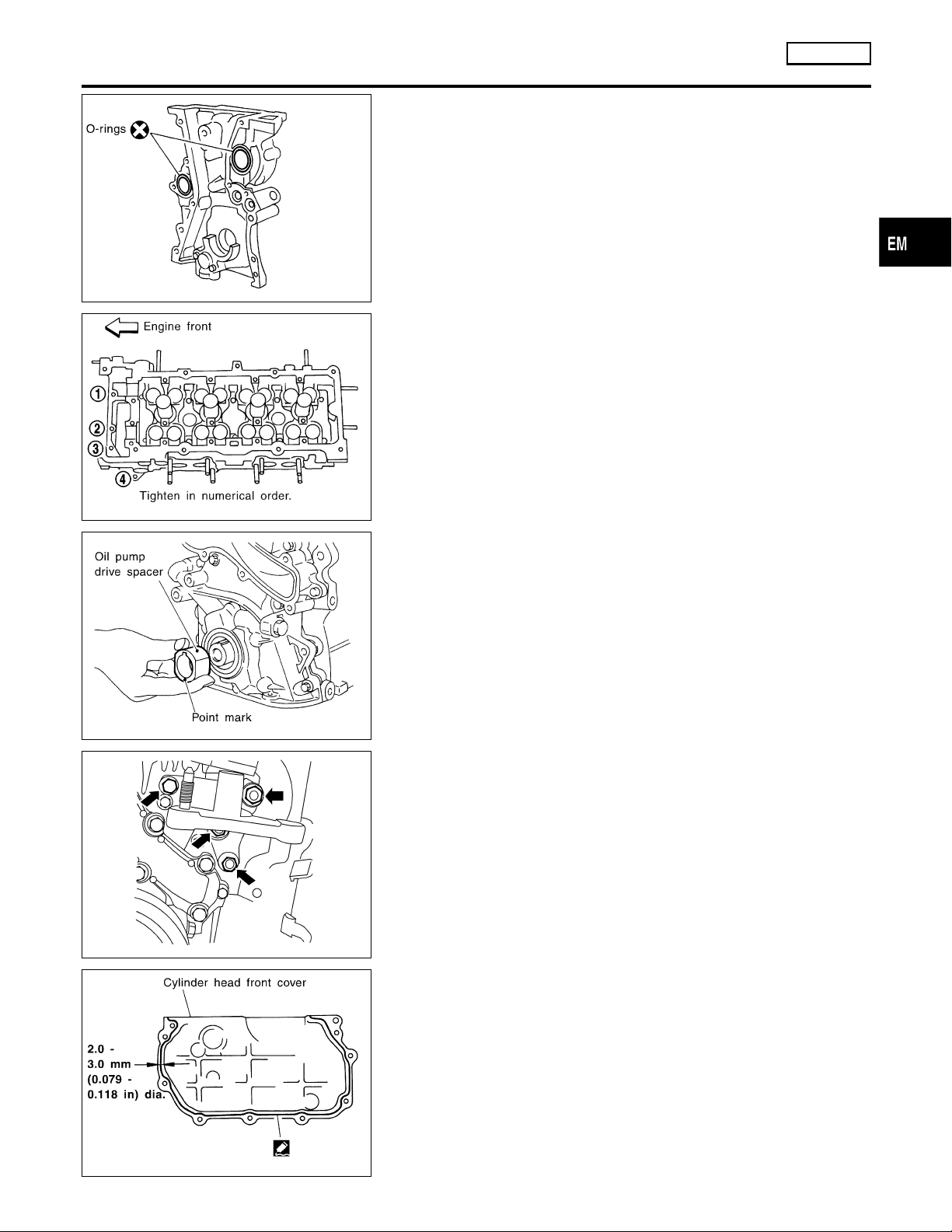

Liquid Gasket Application Procedure

NIEM0042

1. Use a scraper to remove old RTV Silicone Sealant from

mating surfaces and grooves. Also, completely clean any

oil from these areas.

2. Apply a continuous bead of RTV Silicone Sealant to mat-

ing surfaces. (Use Genuine RTV Silicone Sealant Part No.

999MP-A7007 or equivalent.)

쐌 For oil pan, be sure RTV Silicone Sealant diameter is 3.5

to 4.5 mm (0.138 to 0.177 in).

쐌 For areas except oil pan, be sure RTV Silicone Sealant

diameter is 2.0 to 3.0 mm (0.079 to 0.118 in).

3. Apply RTV Silicone Sealant around the inner side of bolt

holes (unless otherwise specified).

4. Assembly should be done within 5 minutes after coating.

5. Wait at least 30 minutes before refilling engine oil and

engine coolant.

AEM080

EM-4

PREPARATION

QG18DE

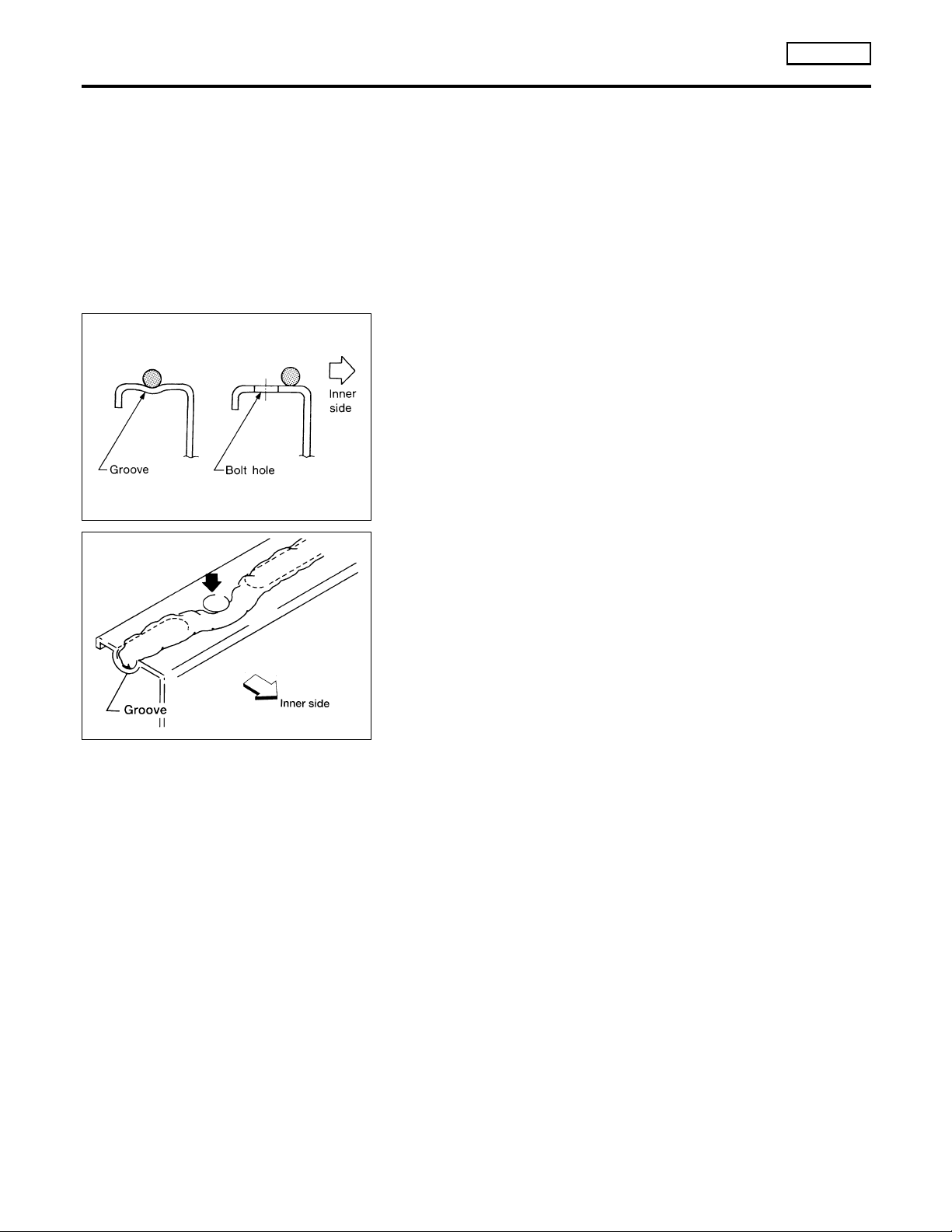

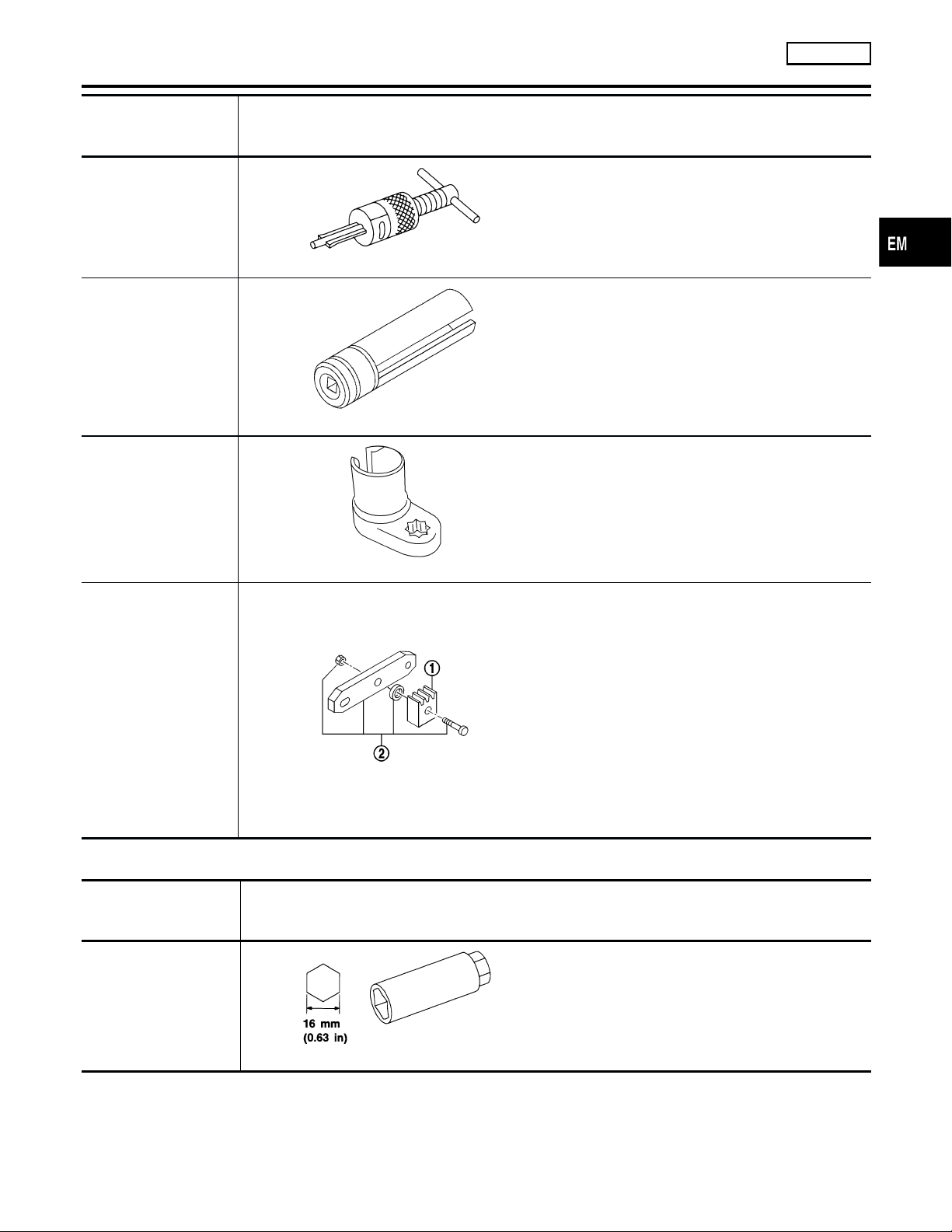

Special Service Tools

Special Service Tools

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

ST0501S000

(—)

Engine stand assembly

1 ST05011000

(—)

Engine stand

2 ST05012000

(—)

Base

Engine attachment

assembly

1 KV10106500

(—)

Engine attachment

2 KV10113300

(—)

Sub-attachment

Description

Disassembling and assembling

NT042

Overhauling engine

NIEM0043

GI

MA

LC

EC

FE

CL

MT

ST10120000

(J24239-O1)

Cylinder head bolt

wrench

KV10116200

(J26336-B)

Valve spring compressor

1 KV10115900

(J26336-20)

Attachment

2 KV10109220

(—)

Adapter

KV10115600

(J38958)

Valve oil seal drift

KV10107902

(J-36467)

Valve oil seal puller

NT029

NT583

WEM044

NT024

Loosening and tightening cylinder head bolt

a: 13 mm (0.51 in) dia.

b: 12 mm (0.47 in)

c: 10 mm (0.39 in)

Disassembling valve mechanism

Installing valve oil seal

Displacement valve lip seal

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

NT011

IDX

EM-5

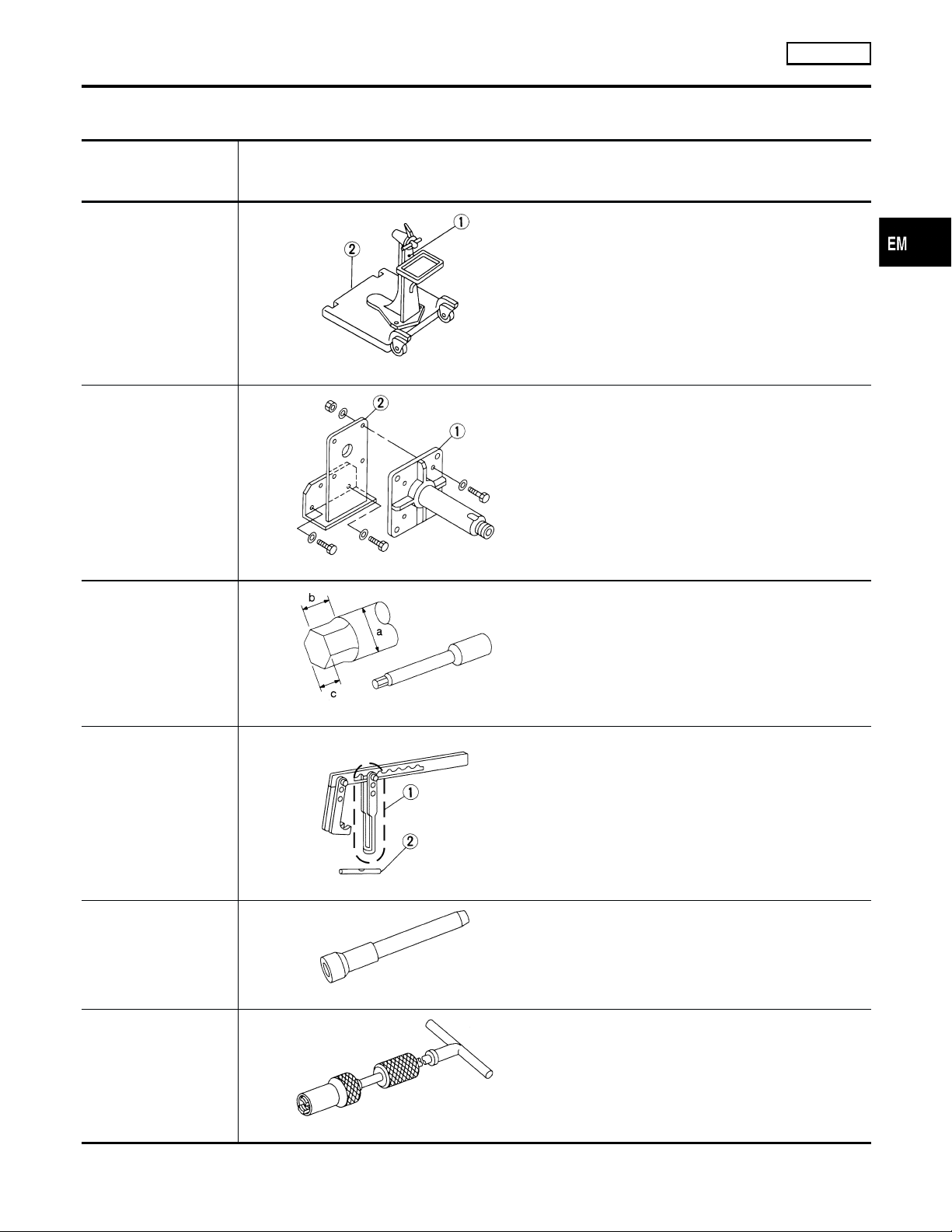

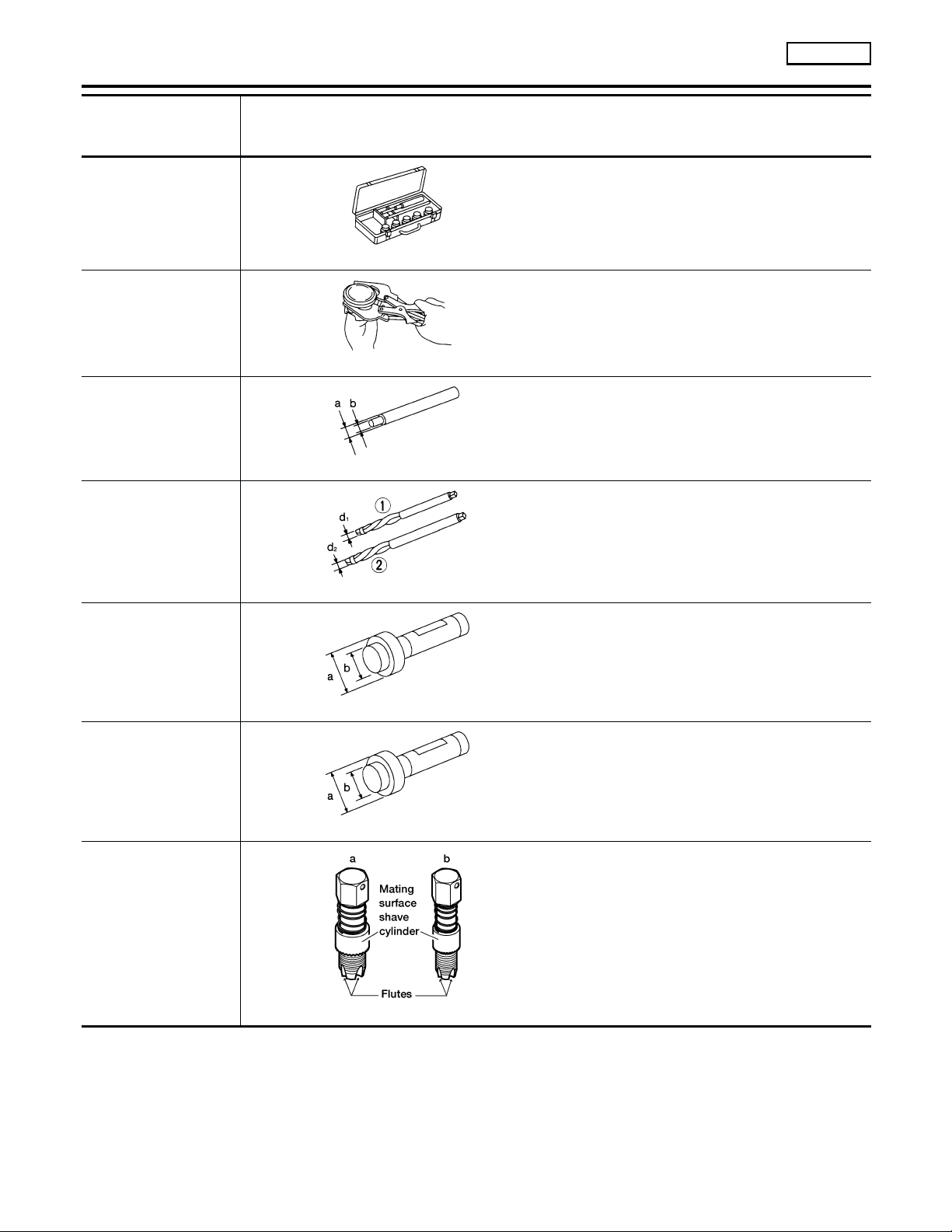

Special Service Tools (Cont’d)

Tool number

(Kent-Moore No.)

Tool name

Description

PREPARATION

QG18DE

KV101151S0

(J38972)

Lifter stopper set

1 KV10115110

Camshaft pliers

2 KV10115120

Lifter stopper

EM03470000

(J8037)

Piston ring compressor

KV10107400

(J26365-12, J26365-A)

Piston pin press stand

1 KV10107310

( — )

Center shaft

2 ST13040020

( — )

Stand

3 ST13040030

( — )

Spring

4 KV10107320

( — )

Cap

5 ST13040050

( — )

Drift

Changing shims

NT041

Installing piston assembly into cylinder bore

NT044

Disassembling and assembling piston pin

NT013

KV10111100

(J37228)

Seal cutter

WS39930000

( — )

Tube presser

KV10112100

(BT-8653-A)

Angle wrench

Removing oil pan

NT046

Pressing the tube of liquid gasket

NT052

Tightening bolts for bearing cap, cylinder head, etc.

NT014

EM-6

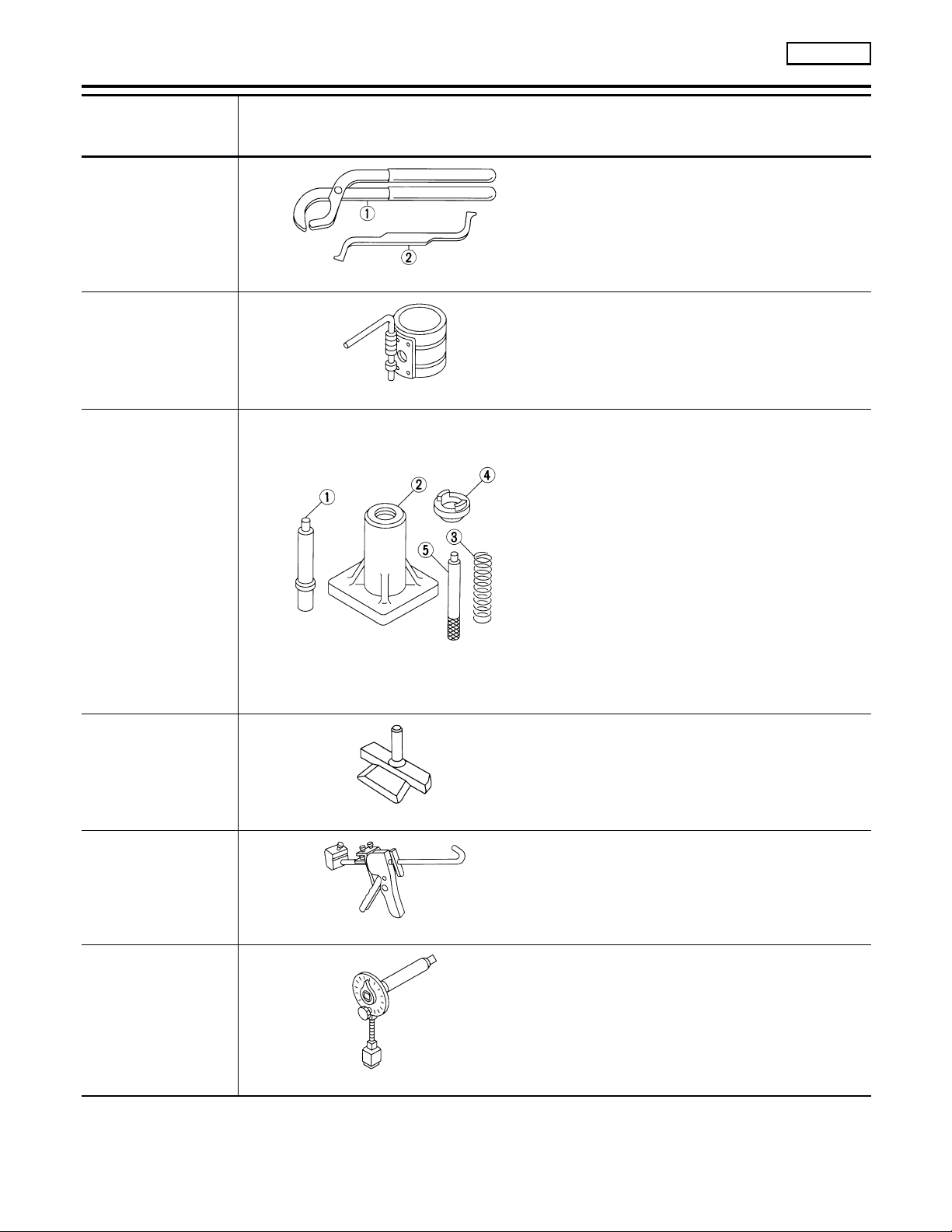

Tool number

(Kent-Moore No.)

Tool name

Description

PREPARATION

QG18DE

Special Service Tools (Cont’d)

GI

ST16610001

(J23907)

Pilot bushing puller

(J36471-A)

Front (heated) oxygen

sensor wrench

(J44626)

Air fuel ratio (A/F) sensor wrench

KV101056S0

( — )

Rear gear stopper

1 KV10105620

( — )

Adapter

2 KV10105610

( — )

Plate assembly

NT045

NT379

LEM054

Removing pilot bushing

Loosening or tightening heated oxygen sensor with

22 m (0.87 in) hexagon nut

Loosening or tightening air fuel ratio (A/F) sensor 1

Preventing crankshaft from rotating

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

Tool number

(Kent-Moore No.)

Tool name

Spark plug wrench

NT773

Description

NT047

Commercial Service Tools

Removing and installing spark plug

EM-7

NIEM0044

ST

RS

BT

HA

SC

EL

IDX

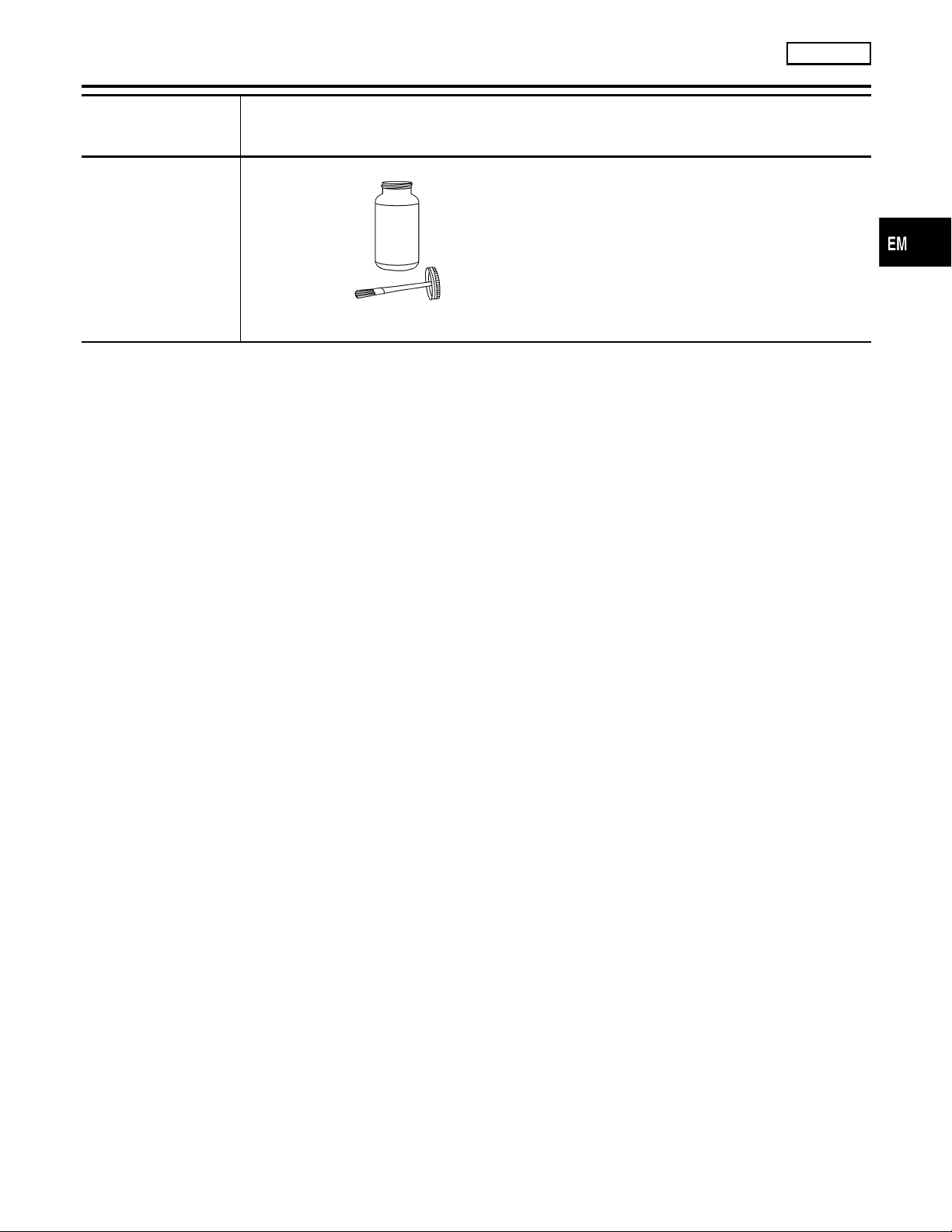

Commercial Service Tools (Cont’d)

Tool number

(Kent-Moore No.)

Description

Tool name

PREPARATION

QG18DE

Valve seat cutter set

Piston ring expander

Valve guide drift

Valve guide reamer

Front oil seal drift

NT048

NT030

NT015

NT016

Finishing valve seat dimensions

Removing and installing piston ring

Removing and installing valve guide

Intake & Exhaust:

a: 9.5 mm (0.374 in) dia.

b: 5.5 mm (0.217 in) dia.

Reaming valve guide 1 or hole for oversize valve

guide 2

Intake & Exhaust:

: 5.5 mm (0.217 in) dia.

d

1

: 9.685 mm (0.3813 in) dia.

d

2

Installing front oil seal

a: 52 mm (2.05 in) dia.

b: 40 mm (1.57 in) dia.

Rear oil seal drift

(J-43897-18)

(J-43897-12)

Oxygen sensor thread

cleaner

NT049

Installing rear oil seal

a: 103 mm (4.06 in) dia.

b: 84 mm (3.31 in) dia.

NT049

Reconditioning the exhaust system threads before

installing a new oxygen sensor (Use with anti-seize

lubricant shown below.)

a: J-43897-18 [18 mm dia.] for zirconia oxygen

sensor

b: J-43897-12 [12 mm dia.] for titania oxygen

sensor

AEM488

EM-8

Tool number

(Kent-Moore No.)

Tool name

Description

PREPARATION

QG18DE

Commercial Service Tools (Cont’d)

GI

Anti-seize lubricant

(Permatex 133AR or

equivalent meeting MIL

specification MIL-A-907)

AEM489

Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

EM-9

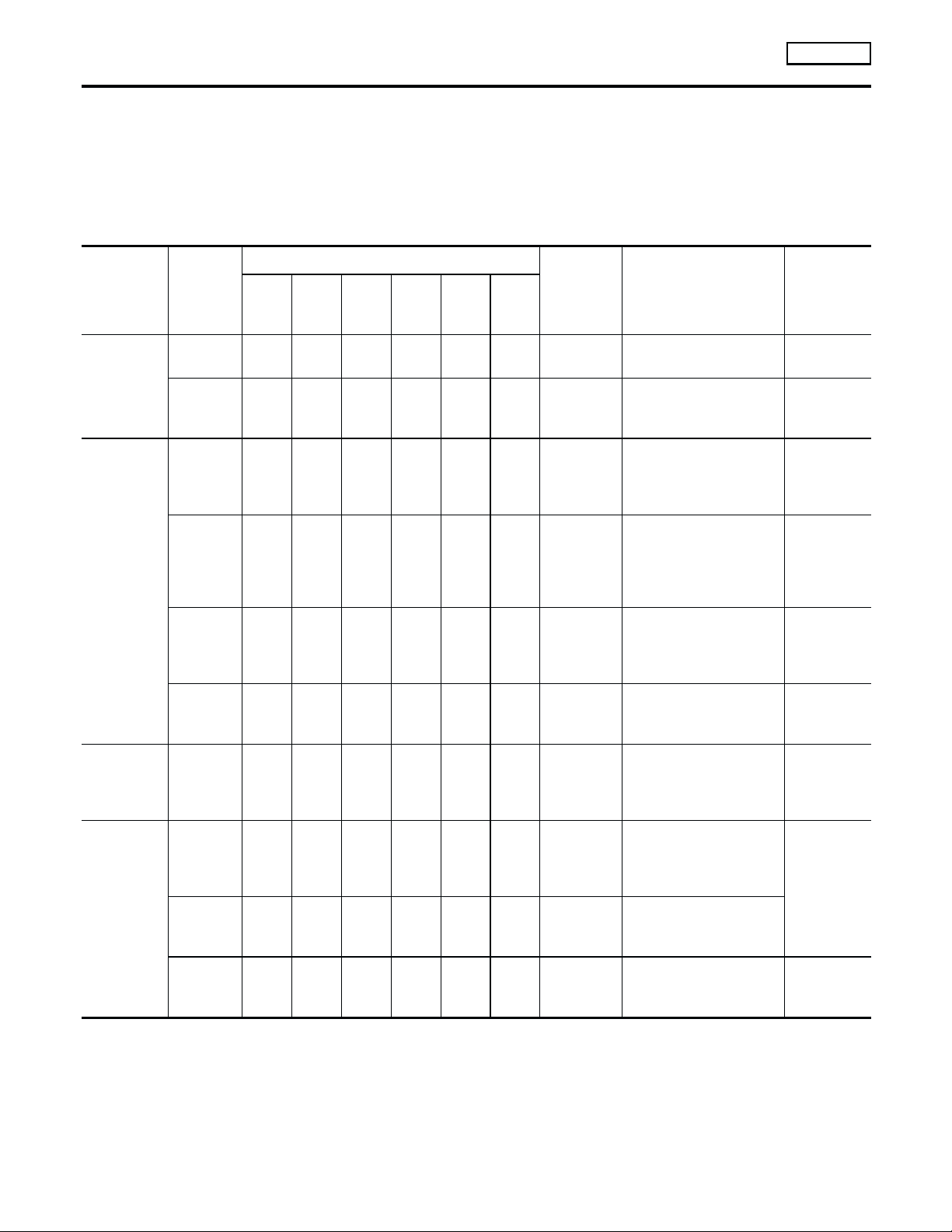

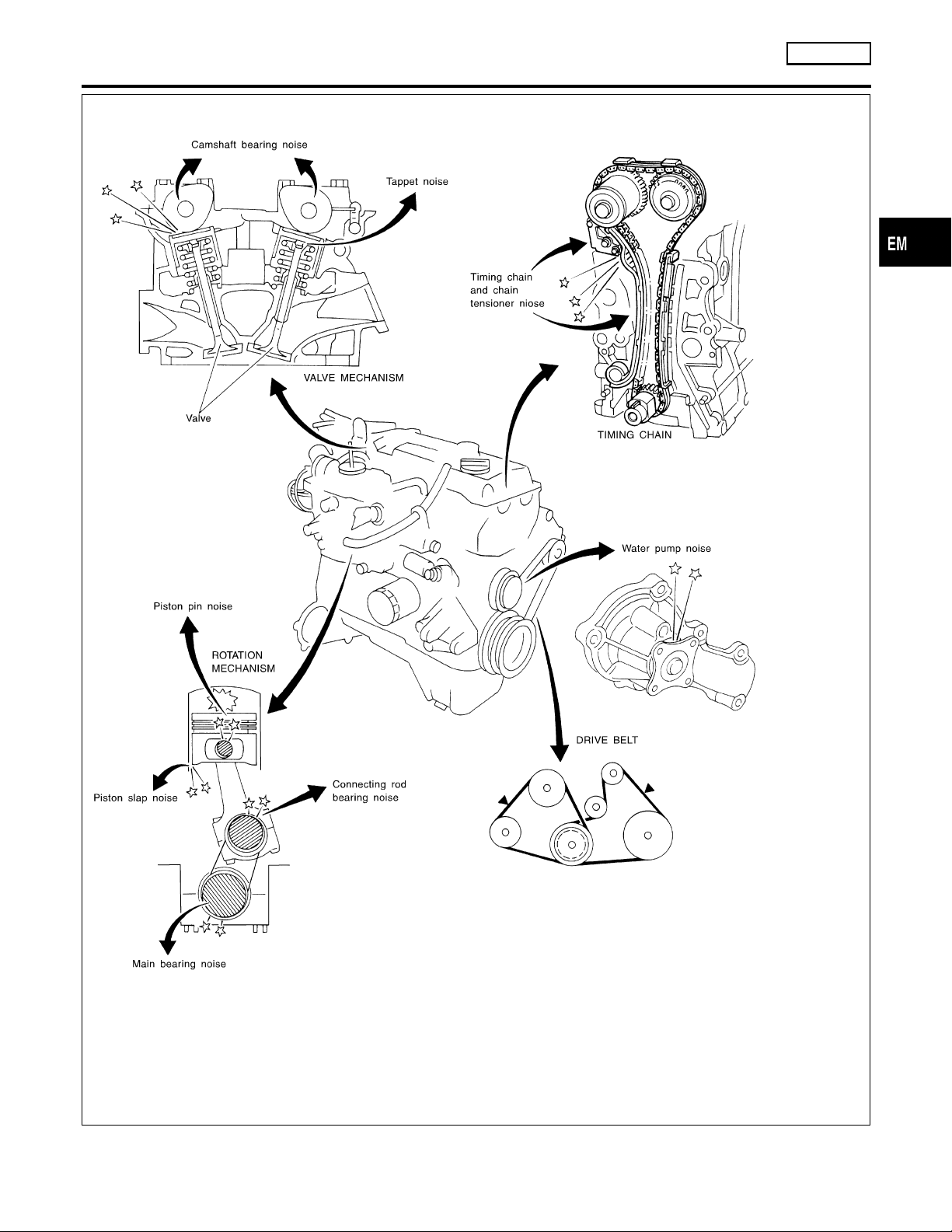

NOISE, VIBRATION AND HARSHNESS (NVH)

NVH Troubleshooting — Engine Noise

TROUBLESHOOTING

NIEM0045

QG18DE

Location of

noise

Top of

Engine

Rocket

Cover Cylinder Head

Crankshaft

Pulley

Cylinder

block (Side

of Engine)

Oil pan

NVH Troubleshooting — Engine Noise

Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Operating condition of engine

Type of

noise

Ticking or

click

Rattle C A — A B C Camshaft

Slap or

knock

Slap or

rap

Before

warm-

CA— AB— Tappet

— A — BB— Piston pin

A ——B B A Piston slap

up

After

warm-

up

When

start-

ing

When

idling

When

racing

While

driving

Source of

noise

noise

bearing

noise

noise

noise

Check item

Valve clearance EM-45

Camshaft journal clearance

Camshaft runout

Piston and piston pin

clearance

Connecting rod bushing

clearance

Piston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend and

torsion

Reference

page

EM-36

EM-55, 61

EM-57, 55,

56, 56

NIEM0045S01

Knock A B C B B B Connecting

Knock A B — A B C Main bear-

Front of

Engine Timing Chain

Cover

Front of

Engine

A: Closely related B: Related C: Sometimes related —: Not related

Tapping or

ticking

Squeak or

fizzing

Creaking ABABABOther drive

Squall or

creak

AA— BBBTiming

AB— B — C Other drive

AB— BABWater pump

rod bearing

noise

ing noise

chain and

chain tensioner noise

belts (sticking or slipping)

belts (slipping)

noise

Connecting rod bearing

clearance (Big end)

Connecting rod bushing

clearance (Small end)

Main bearing oil clearance

Crankshaft runout

Timing chain cracks and

wear

Timing chain tensioner

operation

Drive belts deflection MA-25,

Idler pulley bearing

operation

Water pump operation LC-13,

EM-60, 61

EM-58

EM-24

“Checking

Drive Belts”

“INSPECTION”

EM-10

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING

NVH Troubleshooting — Engine Noise (Cont’d)

QG18DE

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

EM-11

SC

EL

IDX

SEM937F

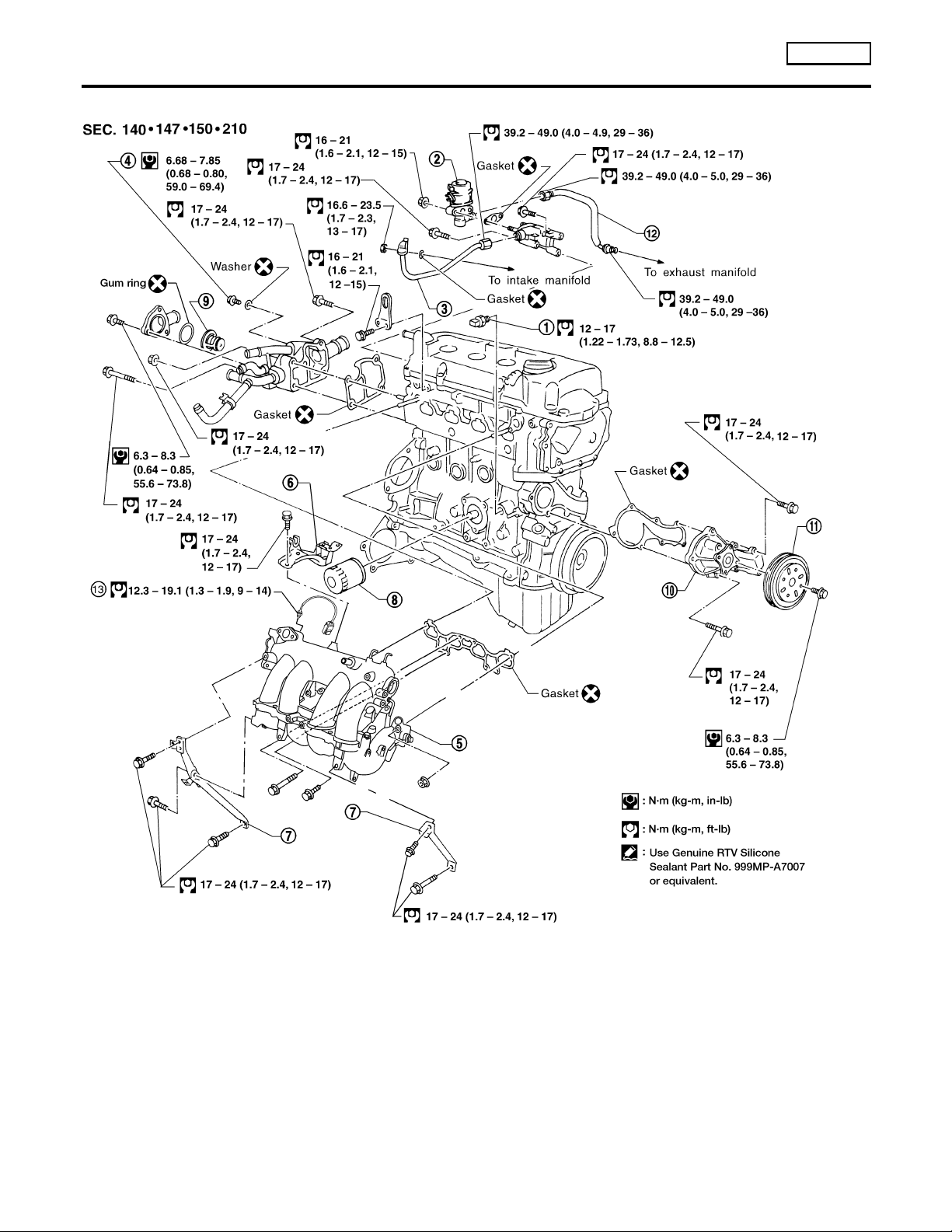

Removal and Installation

OUTER COMPONENT PARTS

QG18DE

Removal and Installation

NIEM0046

1. Oil pressure switch

2. EGR valve

3. EGR guide tube

4. Air relief plug

5. Intake manifold

6. Intake manifold upper support

7. Intake manifold rear supports

8. Oil filter

9. Thermostat

EM-12

WEM015

10. Water pump

11. Water pump pulley

12. EGR tube

13. EGR temperature sensor

OUTER COMPONENT PARTS

QG18DE

Removal and Installation (Cont’d)

GI

MA

LC

EC

FE

CL

1. Throttle position sensor

2. IACV-AAC valve

3. Throttle body

4. Injector

5. Injector tube

6. Pressure regulator

7. Intake manifold

8. Canister purge control valve

MT

AT

AX

SU

BR

ST

RS

BT

WEM016

HA

SC

EM-13

EL

IDX

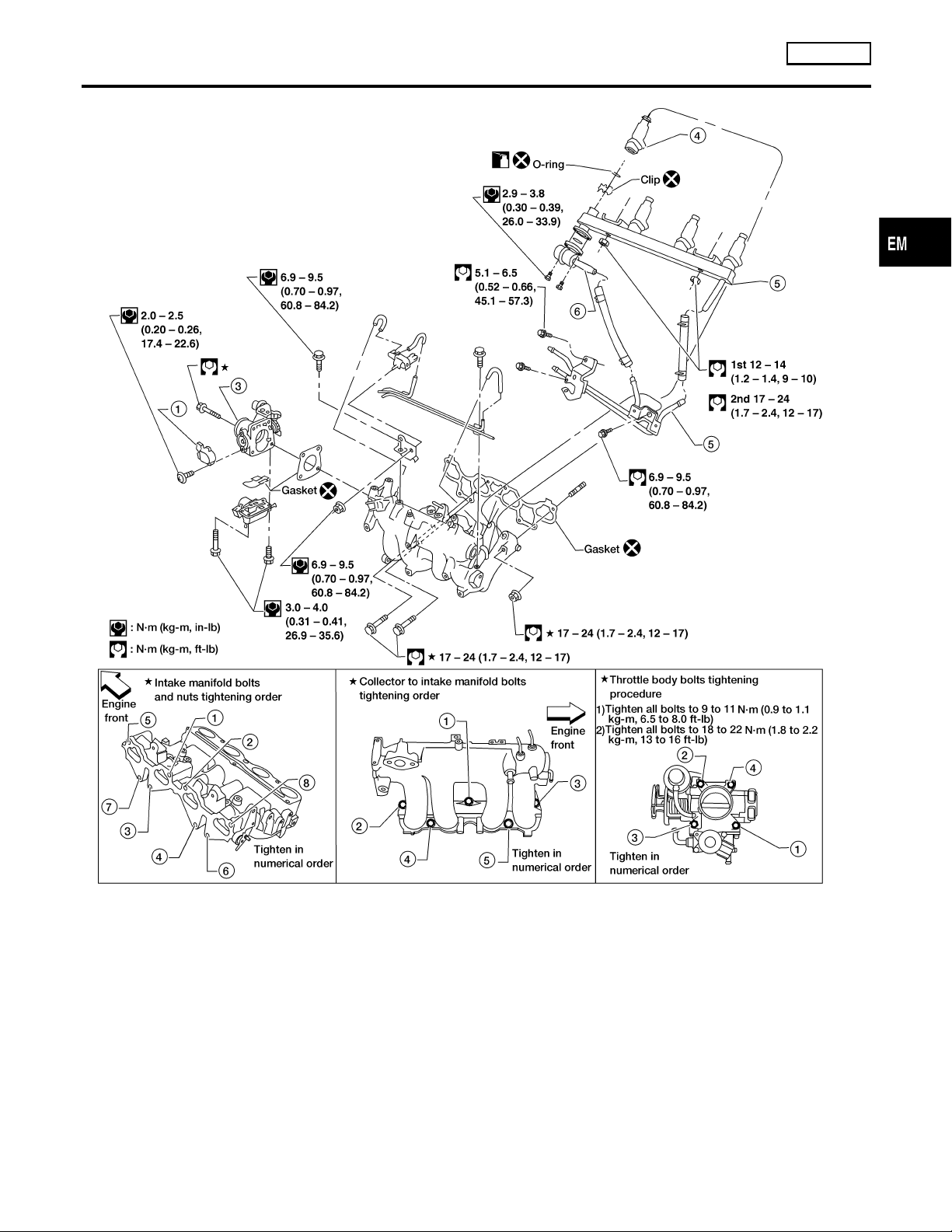

Removal and Installation (Cont’d)

OUTER COMPONENT PARTS

QG18DE

QG18DE (EXCEPT CALIF. CA MODEL)

NIEM0046S02

1. Crankshaft pulley

2. Engine coolant temperature sensor

3. Gasket

4. Exhaust manifold

5. Exhaust manifold cover

6. Thermal transmitter

7. Water drain plug

8. Heated oxygen sensor

EM-14

WEM017

9. Three way catalyst (TWC)

10. Converter cover

11. Ignition coil

12. Spark plug

OUTER COMPONENT PARTS

QG18DE

Removal and Installation (Cont’d)

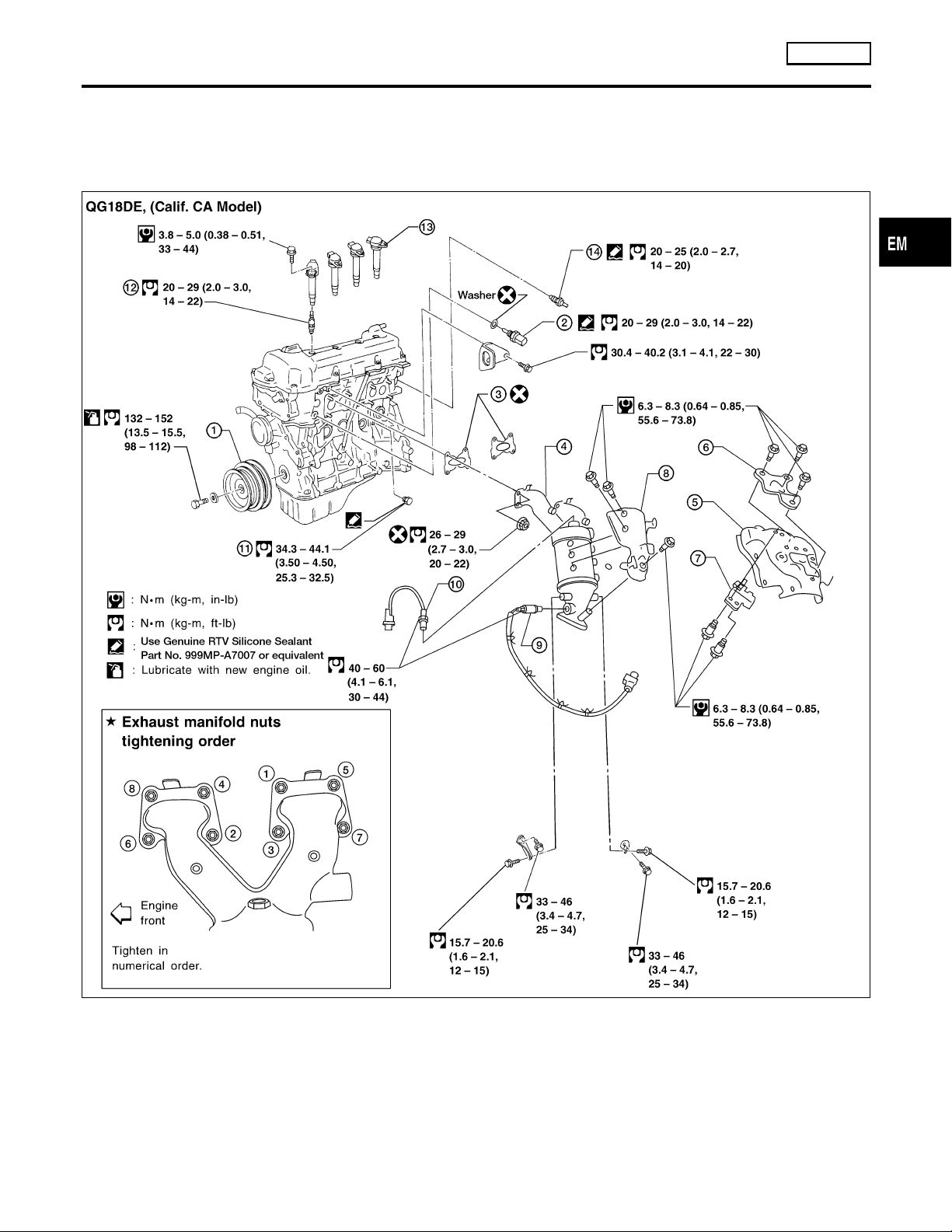

QG18DE (CALIF. CA MODEL)

CAUTION:

If the Calif. CAModel’s TWC (manifold three way catalyst) or ADS-TWC (adsorber pre-catalyst) replacement is necessary, always replace the TWC together with the ADS-TWC. Never replace these catalysts

individually. The TWC and the ADS-TWC are only available together as a kit.

=NIEM0046S03

GI

MA

LC

EC

FE

CL

MT

LEM046

AT

AX

SU

BR

ST

RS

BT

HA

SC

1. Crankshaft pulley

2. Engine coolant temperature sensor

3. Gasket

4. TWC (manifold three way catalyst)

5. TWC manifold cover

6. Air fuel ratio sensor cover

7. Sensor wire bracket

8. TWC cover

9. Heated oxygen sensor 2 (rear)

10. Air fuel ratio (A/F) sensor 1

EM-15

11. Water drain plug

12. Spark plug

13. Ignition coil

14. Thermal transmitter

EL

IDX

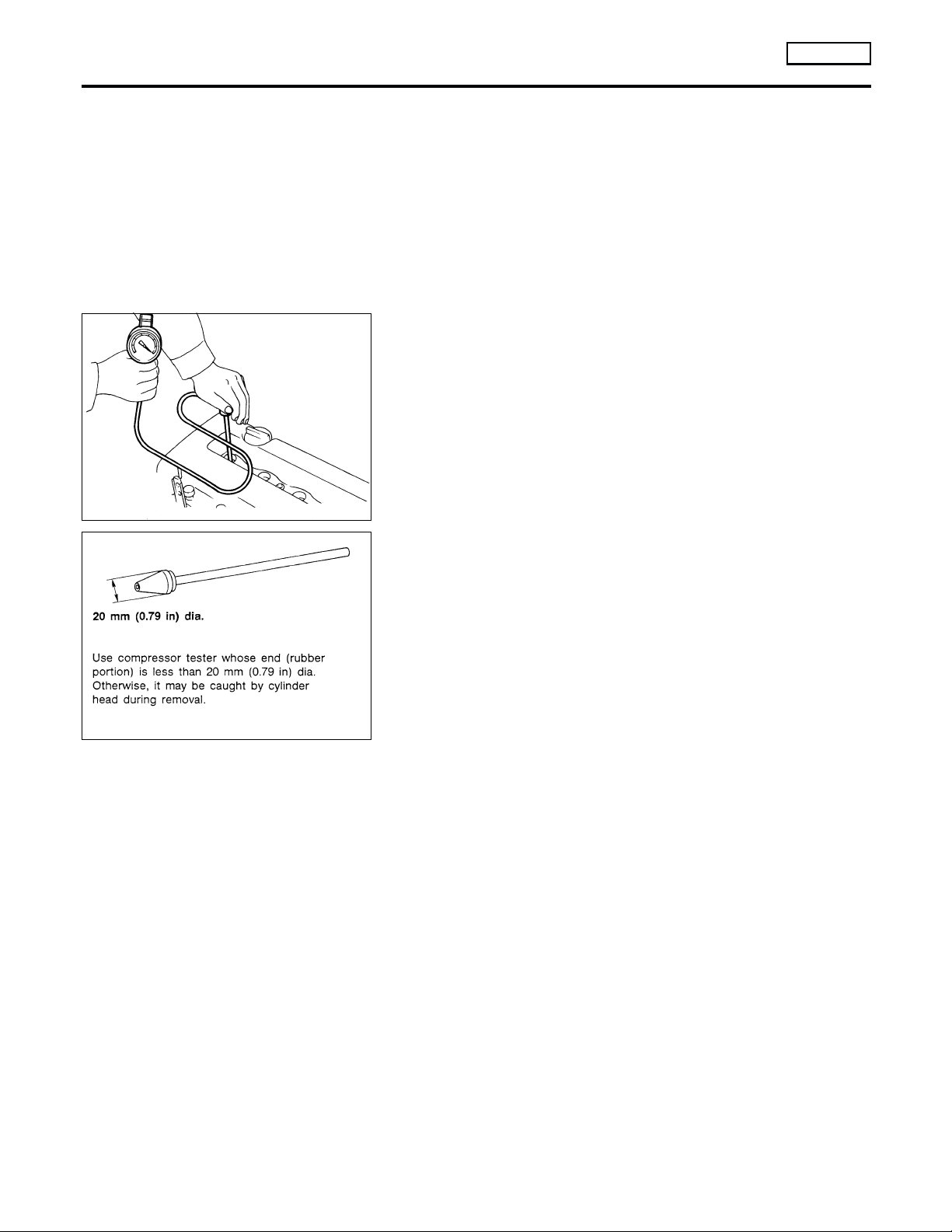

MEASUREMENT OF COMPRESSION PRESSURE

1. Warm up engine.

2. Turn ignition switch OFF.

3. Release fuel pressure.

Refer to EC-67 [QG18DE (except Calif. CA Model)] or EC-744

[QG18DE (Calif. CA Model)], “Fuel Pressure Release”.

4. Remove ignition coils.

5. Remove spark plugs.

쐌 Clean area around plug with compressed air before removing

the spark plug.

6. Attach a compression tester to No. 1 cylinder.

7. Depress accelerator pedal fully to keep throttle valve wide

open.

8. Crank engine and record highest gauge indication.

9. Repeat the measurement on each cylinder as shown above.

쐌 Always use a fully-charged battery to obtain specified

engine speed.

Compression pressure: kPa (bar, kg/cm

Standard

SEM973E

SEM387C

10. If cylinder compression in one or more cylinders is low, pour a

small amount of engine oil into the cylinder through the spark

plug hole and retest compression.

쐌 If adding oil improves cylinder compression, piston rings

may be worn or damaged. If so, replace piston rings after

checking piston.

쐌 If pressure stays low, a valve may be sticking or seating

improperly. Inspect and repair valve and valve seat. Refer

to “VALVE”, EM-67 and “VALVE SEAT”, EM-71. If valve or

valve seat is damaged excessively, replace them.

쐌 If compression in any two adjacent cylinders is low and if add-

ing oil doesnot improve compression,there is leakagepast the

gasket surface. If so, replace cylinder head gasket.

11. Install spark plugs, ignition coils and fuel pump fuse.

12. Erase DTC if any DTC appears. Refer to EC-98 [QG18DE

(exceptCalif.CAModel)]orEC-770[QG18DE(Calif.CAModel)],

“HOW TO ERASE EMISSION-RELATED DIAGNOSTIC

INFORMATION”.

1,324 (13.24, 13.5, 192)/350

Minimum

1,157 (11.57, 11.5, 168)/350

Maximum allowable difference between cylinders

98 (0.98, 1.0, 14)/350

QG18DE

2

, psi)/rpm

NIEM0047

EM-16

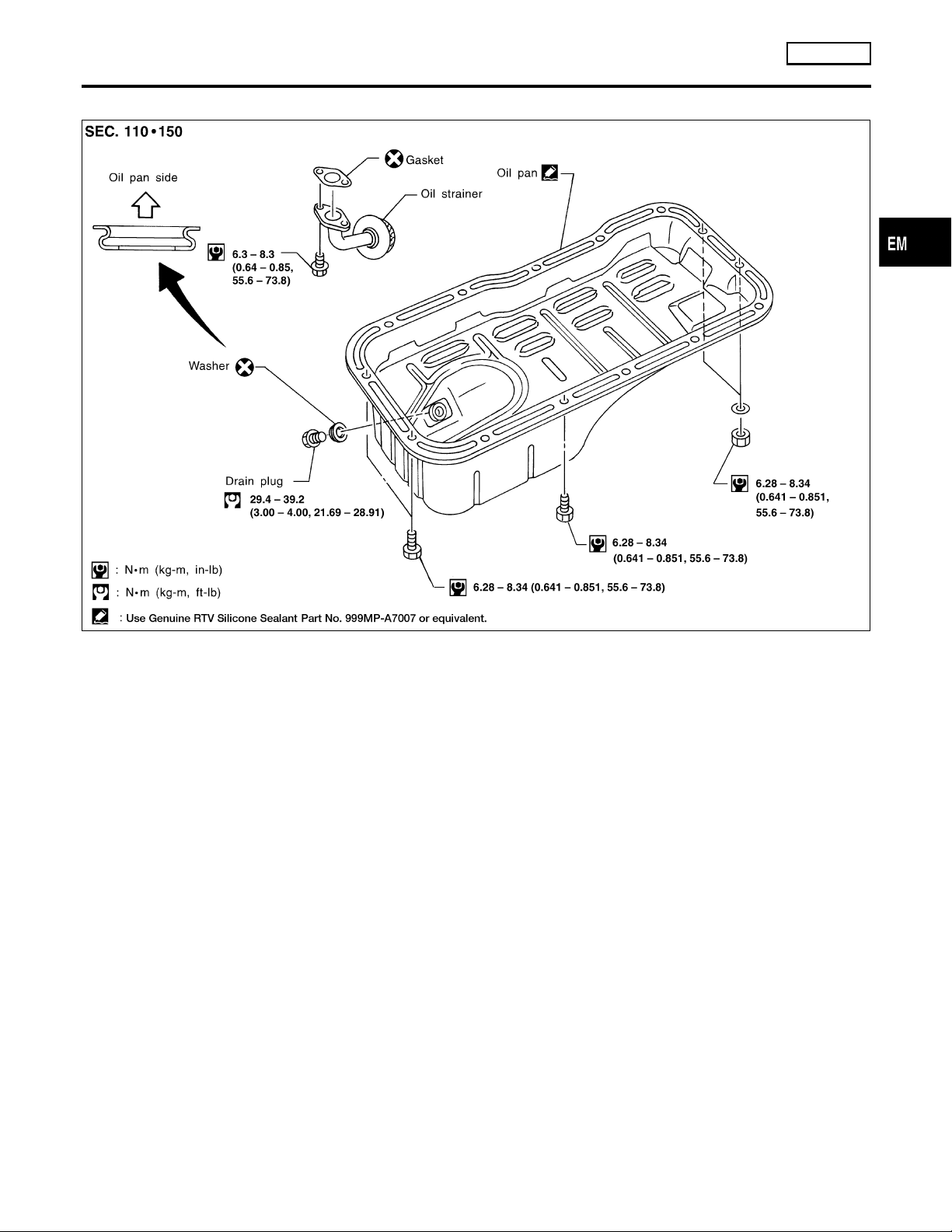

OIL PAN

QG18DE

Components

Components

NIEM0048

GI

MA

LC

EC

FE

CL

MT

Removal

1. Remove engine RH side undercover splash shield.

2. Drain engine oil.

3. Remove front exhaust tube.

Refer to FE-15, “Removal and Installation”.

4. Remove the exhaust manifold support.

WEM021

NIEM0049

AT

AX

SU

BR

ST

RS

BT

HA

SC

EM-17

EL

IDX

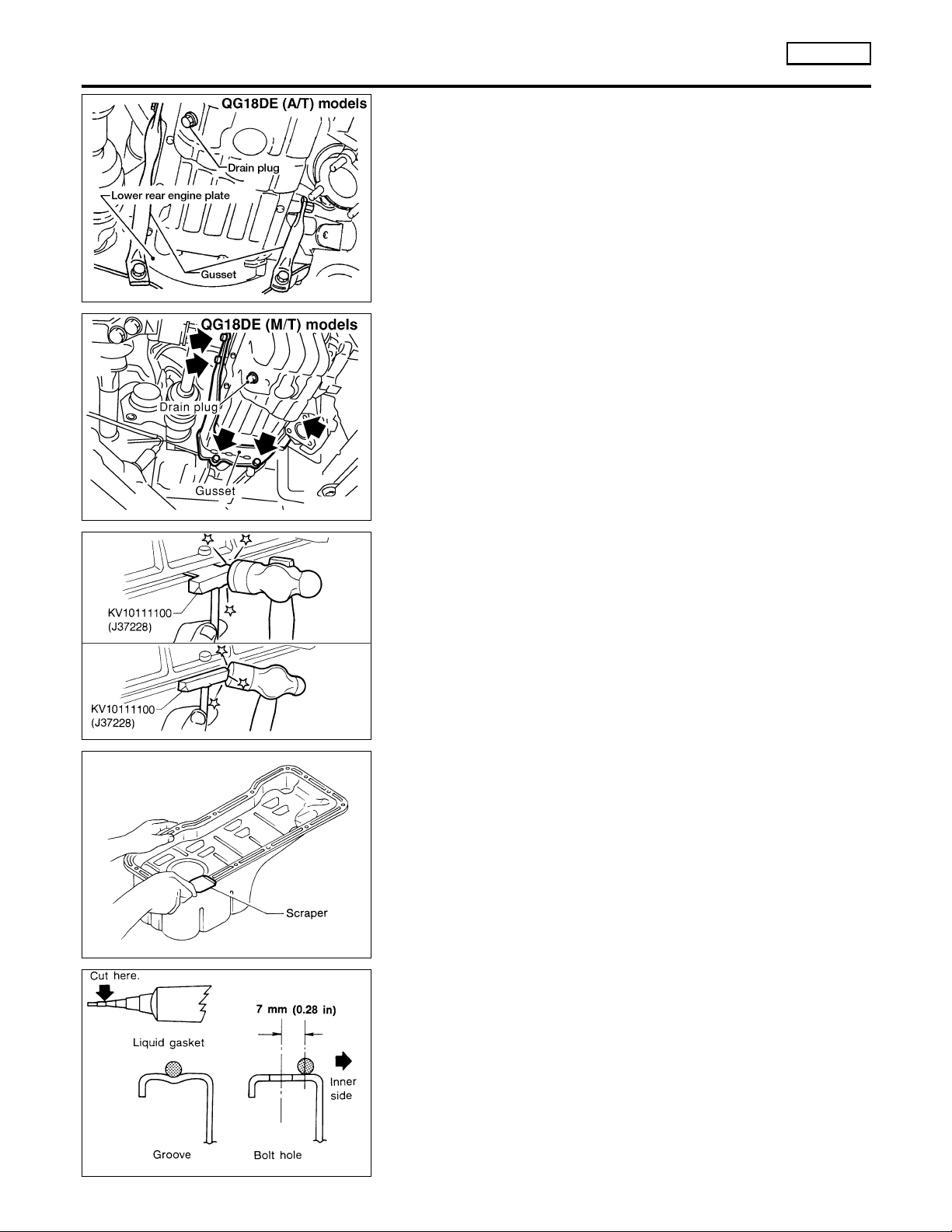

Removal (Cont’d)

WEM049

OIL PAN

5. Remove the engine gusset.

6. Remove rear plate cover (A/T models).

QG18DE

SEM110G

SEM365E

SEM295C

7. Remove oil pan.

a. Insert Tool between cylinder block and oil pan.

쐌 Be careful not to damage aluminum mating face.

Do not insert screwdriver, or oil pan flange will be damaged.

b. Slide Tool by tapping on the side of the Tool with a hammer.

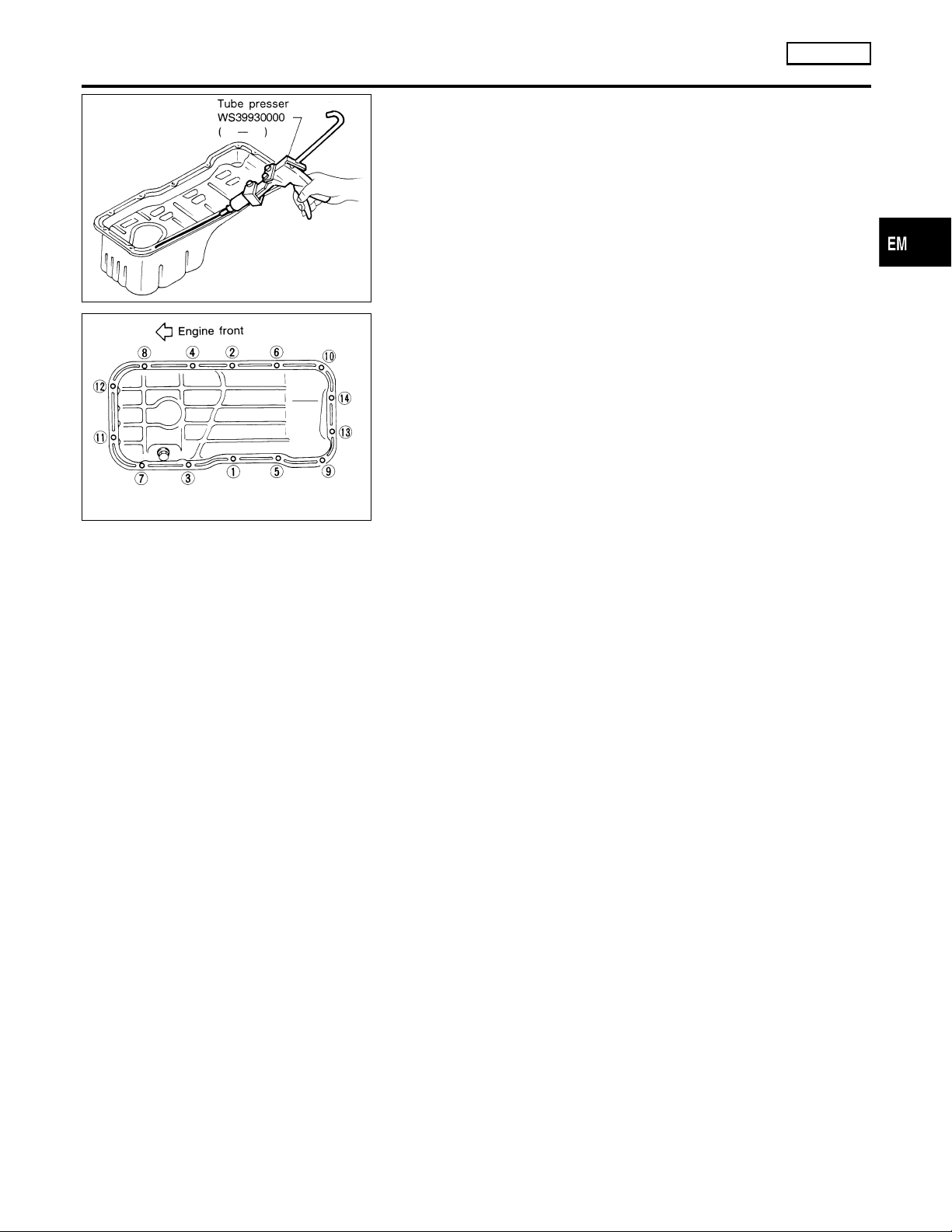

Installation

NIEM0050

1. Use a scraper to remove old RTV Silicone Sealant from mating surface of oil pan.

쐌 Also remove old RTV Silicone Sealant from mating sur-

face of cylinder block.

2. Apply a continuous bead of RTV Silicone Sealant to mating

surface of oil pan.

쐌 Use Genuine RTV Silicone Sealant Part No. 999MP-A7007

or equivalent.

쐌 Apply to groove on mating surface.

쐌 Allow 7 mm (0.28 in) clearance around bolt holes.

SEM015E

EM-18

OIL PAN

쐌 Be sure RTV Silicone Sealant diameter is 3.5 to 4.5 mm

(0.138 to 0.177 in).

쐌 Attaching should be done within 5 minutes after coating.

QG18DE

Installation (Cont’d)

GI

MA

SEM296CA

SEM072F

3. Install oil pan.

쐌 Tighten oil pan nuts and bolts in the numerical order.

쐌 Wait at least 30 minutes before refilling engine oil.

4. Install parts in reverse order of removal.

LC

EC

FE

CL

MT

AT

AX

SU

BR

EM-19

ST

RS

BT

HA

SC

EL

IDX

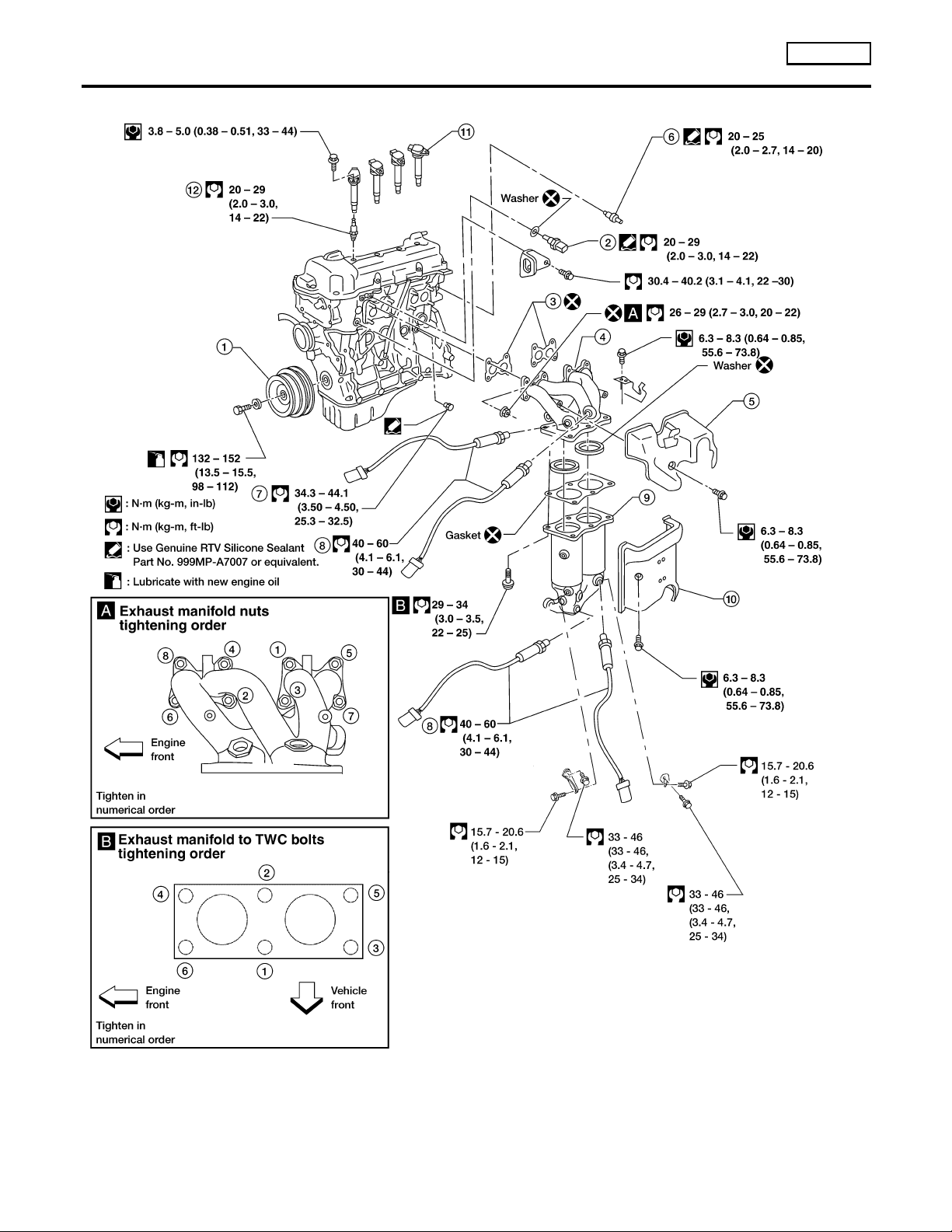

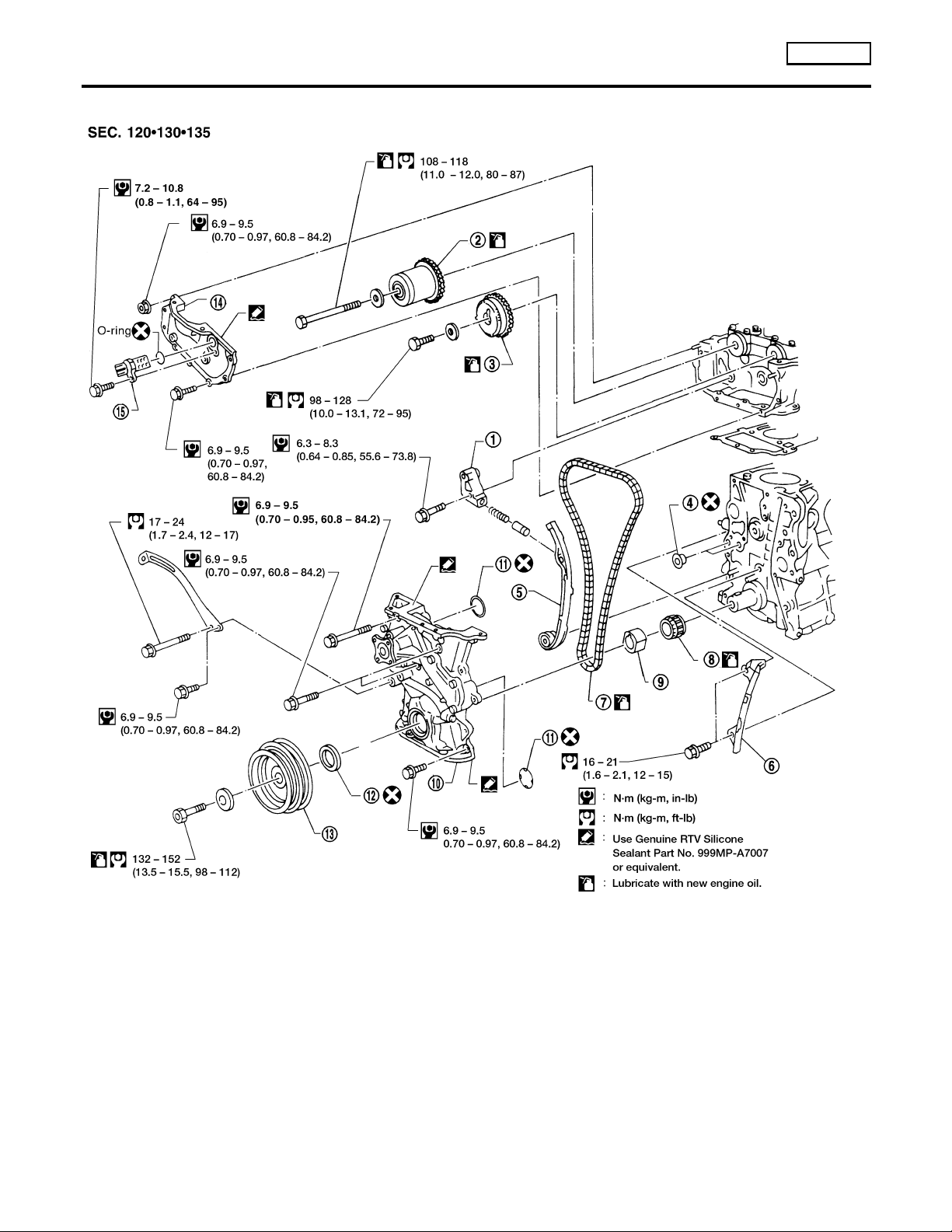

Components

TIMING CHAIN

QG18DE

Components

NIEM0051

1. Chain tensioner

2. Camshaft sprocket (Intake)

3. Camshaft sprocket (Exhaust)

4. O-ring

5. Slack side timing chain guide

6. Timing chain tension guide

7. Timing chain

8. Crankshaft sprocket

9. Oil pump drive spacer

10. Front cover

EM-20

WEM026

11. O-ring

12. Oil seal

13. Crankshaft pulley

14. Cylinder head front cover

15. Camshaft position sensor

(PHASE)

SEM869F

TIMING CHAIN

Components (Cont’d)

CAUTION:

쐌 After removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

쐌 When installing chain tensioner, oil seats, or other sliding

parts, lubricate contacting surfaces with new engine oil.

쐌 Apply new engine oil to bolt threads and seat surfaces

when installing camshaft sprocket and crankshaft pulley.

쐌 When removing oil pump assembly, remove camshaft

position sensor (PHASE), then remove timing chain from

engine.

쐌 Be careful not to damage sensor edges.

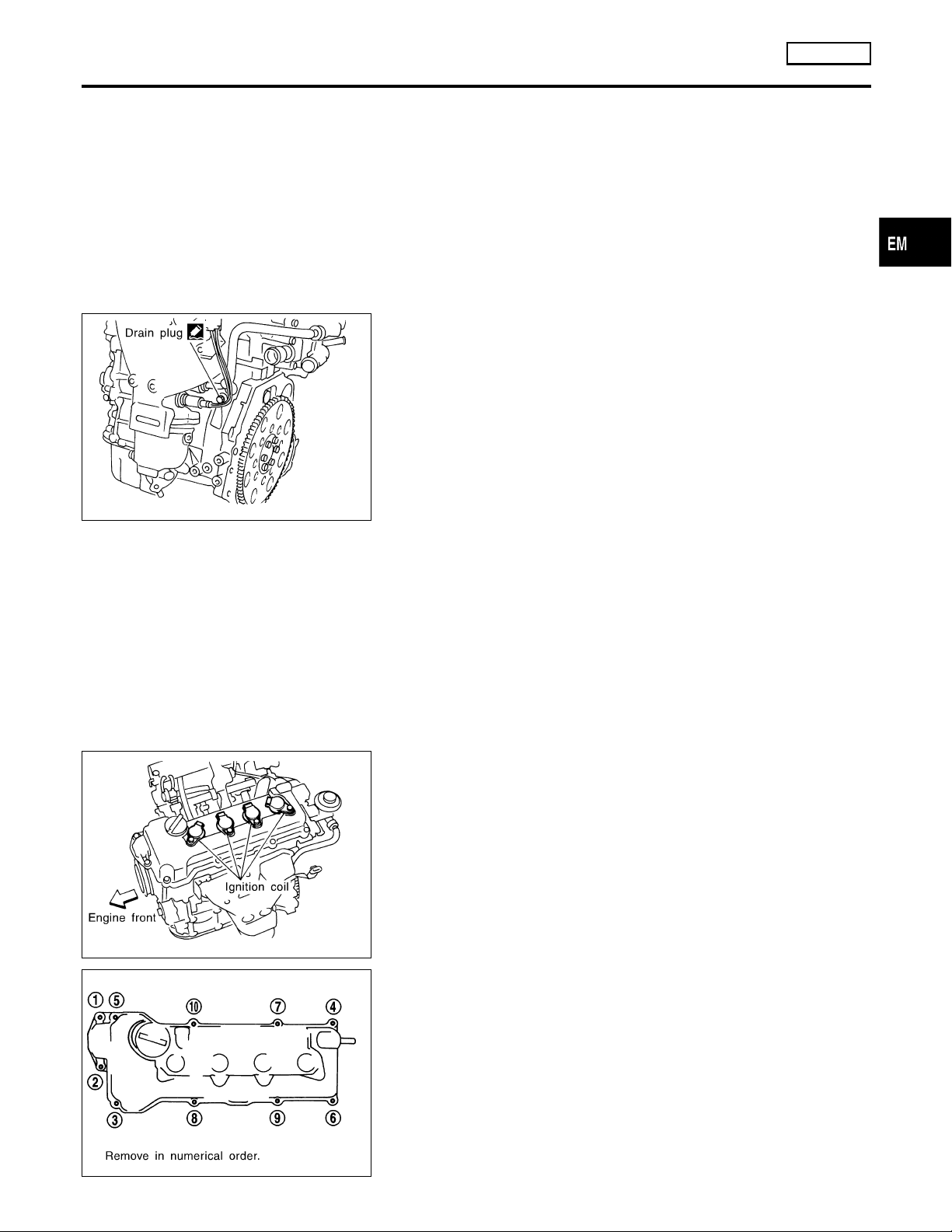

Removal

1. Drain engine coolant from radiator and cylinder block.

Be careful not to spill coolant on drive belts.

2. Remove the following belts.

쐌 Power steering pump drive belt

쐌 Alternator drive belt

3. Remove front RH wheel.

4. Remove front/right-side splash undercover.

5. Remove front exhaust tube.

6. Disconnect vacuum hoses for:

쐌 EVAP canister

쐌 Brake power booster

쐌 Fuel pressure regulator

QG18DE

NIEM0052

GI

MA

LC

EC

FE

CL

MT

AT

SEM870F

7. Remove ignition coils.

8. Remove spark plugs.

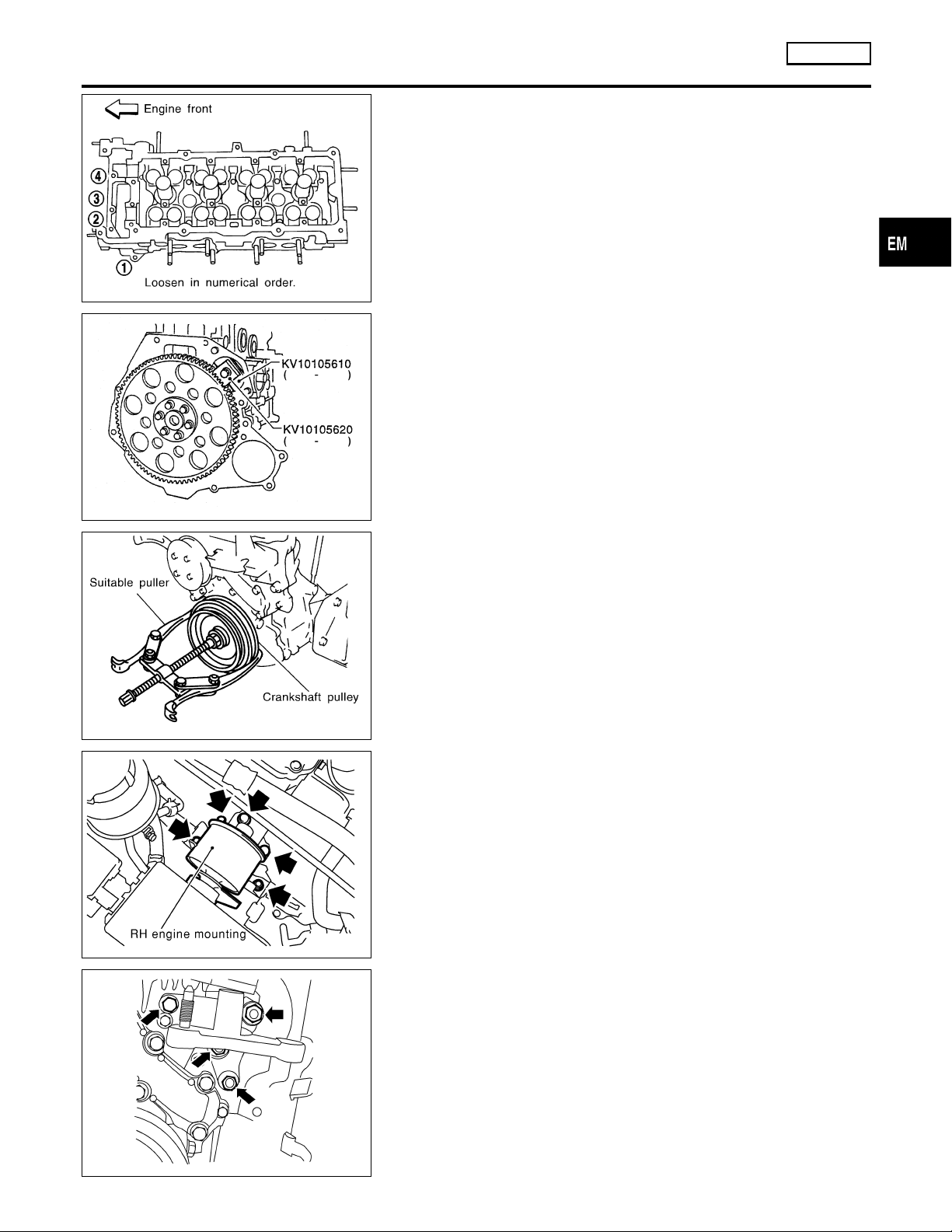

9. Remove rocker cover bolts in numerical order as shown in the

figure.

AX

SU

BR

ST

RS

BT

HA

SC

EL

SEM871F

IDX

EM-21

Removal (Cont’d)

SEM872F

TIMING CHAIN

QG18DE

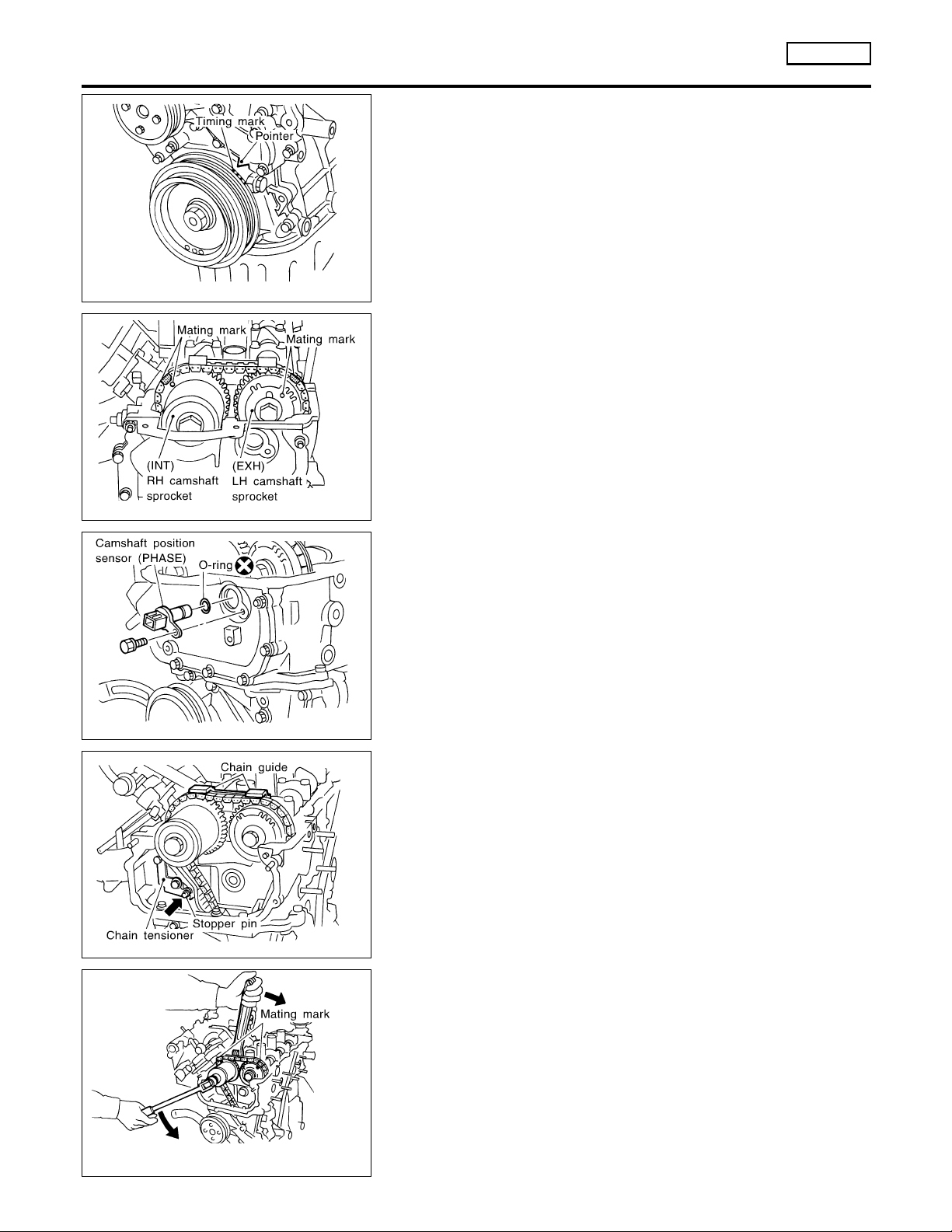

10. Set No. 1 piston at TDC on its compression stroke.

쐌 Rotate crankshaft until mating mark on camshaft sprocket

is set at position indicated in figure at left.

SEM873F

SEM889F

SEM875F

11. Remove camshaft position sensor (PHASE).

쐌 Do not allow any magnetic materials to contact the cam-

shaft position sensor (PHASE).

쐌 Be careful not to damage sensor.

12. Remove cylinder head front cover.

13. Remove timing chain guide from camshaft bracket.

14. Attach a suitable stopper pin to chain tensioner.

15. Remove chain tensioner.

16. Remove camshaft sprocket bolts.

쐌 Apply paint to timing chain and cam sprockets for align-

ment during installation.

17. Remove camshaft sprockets.

SEM876F

EM-22

TIMING CHAIN

18. Remove cylinder head bolts at engine front side as shown.

19. Remove oil pan. Refer to “Removal”, EM-17.

QG18DE

Removal (Cont’d)

GI

MA

SEM008G

WEM031

SEM881F

20. Remove starter motor, and set ring gear stopper using mounting bolt holes.

21. Loosen crankshaft pulley bolt.

22. Remove crankshaft pulley with a suitable puller.

23. Support engine with a suitable hoist or jack.

24. Remove RH engine mounting.

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

SEM103G

WEM019

25. Remove RH engine mounting bracket.

26. Remove idler pulley and bracket.

EM-23

RS

BT

HA

SC

EL

IDX

Removal (Cont’d)

SEM883F

TIMING CHAIN

QG18DE

27. Remove water pump pulley and water pump.

28. Remove front cover bolts and front cover as shown.

★1: Located on water pump

★2: Located on power steering pump adjusting bar, remove

the bar

쐌 Inspect for oil leakage at front oil seal. Replace seal if oil leak

is present.

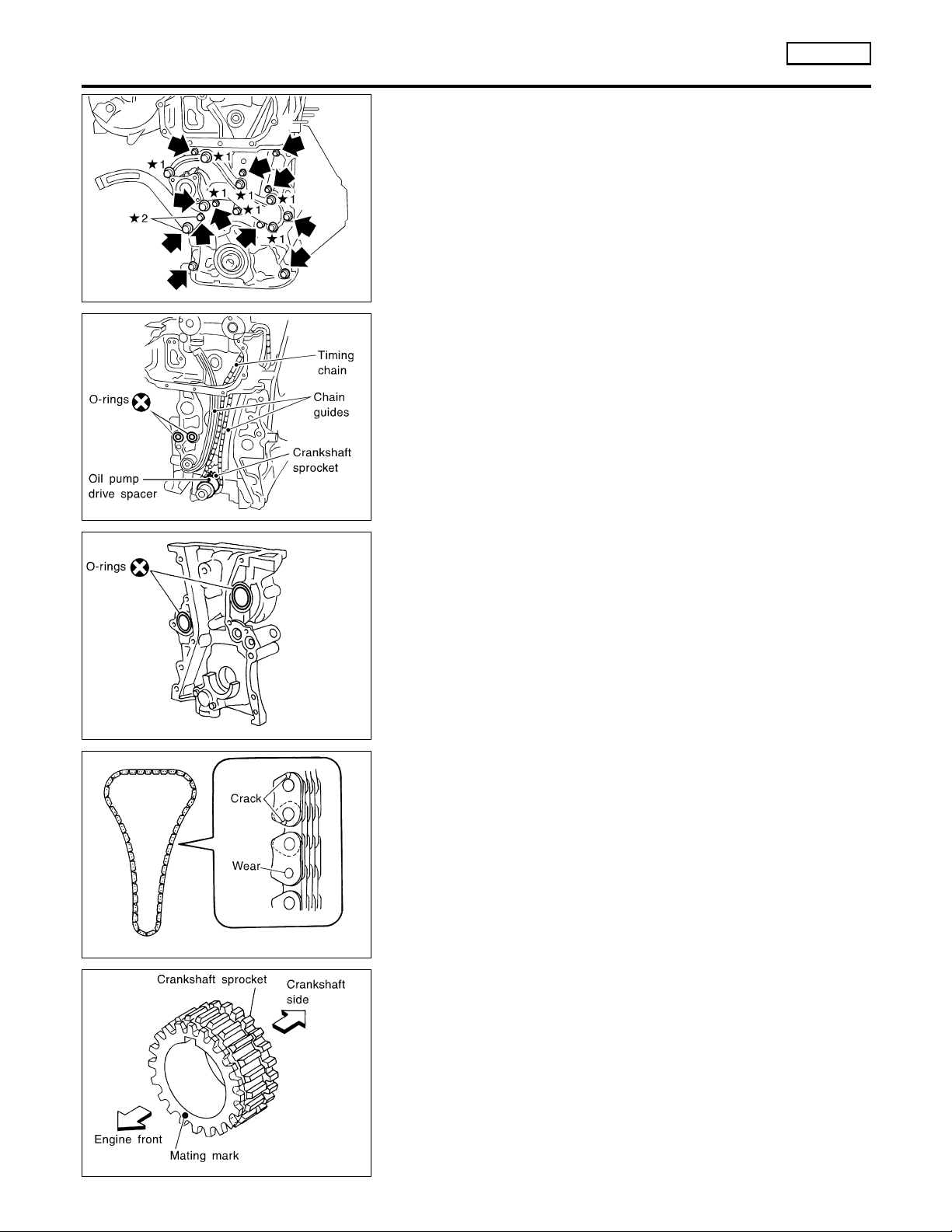

29. Remove timing chain.

30. Remove oil pump drive spacer.

31. Remove chain guides.

32. Remove crankshaft sprocket.

SEM884F

SEM897F

SEM885F

33. Remove O-rings from cylinder block and front cover.

Inspection

NIEM0053

Check for cracks and excessive wear at roller links. Replace

if necessary.

SEM886F

Installation

NIEM0054

1. Install crankshaft sprocket on crankshaft.

쐌 Make sure mating marks on crankshaft sprocket face front

of engine.

EM-24

TIMING CHAIN

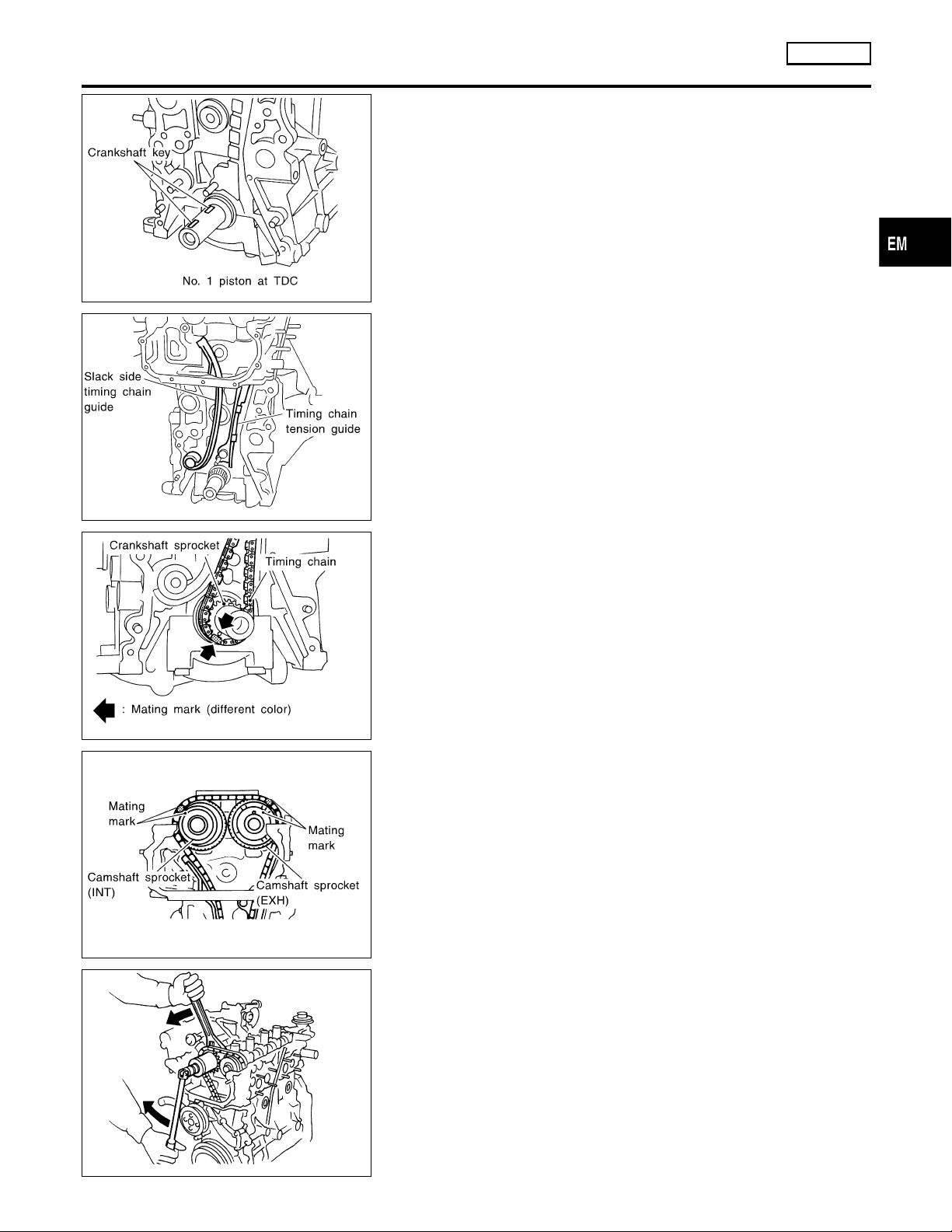

2. Position crankshaft so that No. 1 piston is at TDC and crankshaft key is at 12 o’clock.

QG18DE

Installation (Cont’d)

GI

MA

SEM890F

SEM891F

SEM892F

3. Install slack side timing chain guide and timing chain tension

guide.

4. Install timing chain on crankshaft sprocket.

쐌 Set timing chain by aligning its mating mark with that on

the crankshaft sprocket.

쐌 Make sure sprocket’s mating mark faces engine front.

5. Install camshaft sprockets.

쐌 Set timing chain by aligning mating marks with those of

camshaft sprockets.

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

SEM905F

SEM906F

6. Install camshaft sprocket bolts to correct torque.

쐌 Apply new engine oil to bolt threads and seat surface.

EM-25

BT

HA

SC

EL

IDX

Installation (Cont’d)

SEM907F

TIMING CHAIN

QG18DE

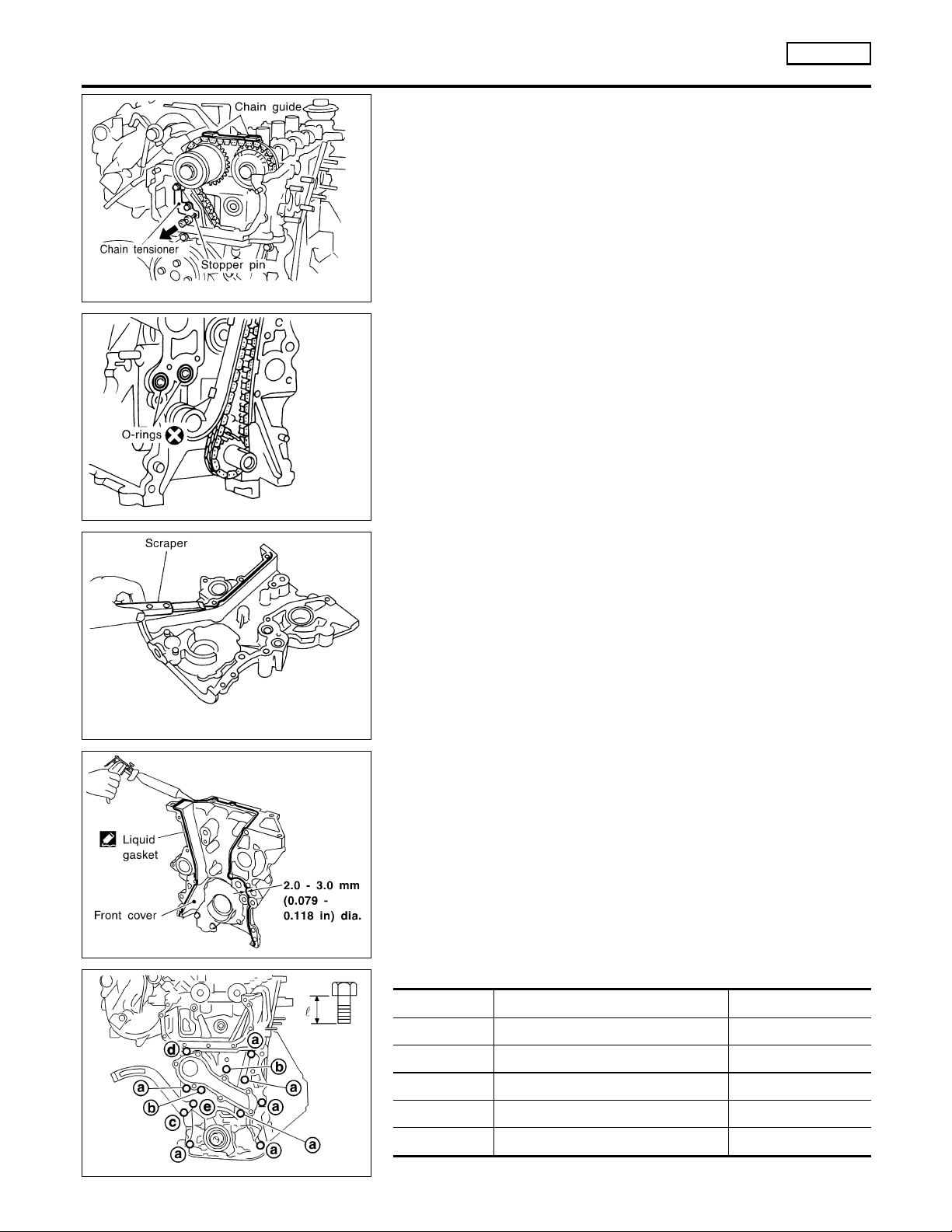

7. Install chain tensioner.

쐌 Before installing chain tensioner, insert a suitable pin into

pin hole of chain tensioner.

쐌 After installing chain tensioner, remove the pin.

8. Install timing chain guide.

9. Install O-rings to cylinder block.

SEM893F

SEM894F

SEM895F

10. Before installing front cover, remove all traces of RTV Silicone

Sealant from mating surface using a scraper.

쐌 Also remove traces of RTV Silicone Sealant from mating sur-

face of cylinder block.

11. Apply a continuous bead of Genuine RTV Silicone Sealant

Part No. 999MP-A7007 or equivalent to mating surface of front

cover.

쐌 Check alignment of mating marks on chain and crankshaft

sprocket.

쐌 Align oil drive spacer with oil pump.

쐌 Place timing chain to the side of chain guide. This pre-

vents the chain from making contact with water seal area

of front cover.

12. Install front cover.

SEM896F

Bolt No. Tightening torque N·m (kg-m, in-lb) “” mm (in)

a. 6.9 - 9.5 (0.70 - 0.97, 61 - 84) 20 (0.79)

b. 6.9 - 9.5 (0.70 - 0.97, 61 - 84) 40 (1.57)

c. 17 - 24 (1.7 - 2.4, 148 - 208*) 70 (2.76)

d. 6.9 - 9.5 (0.70 - 0.97, 61 - 84) 72.8 (2.866)

e. 6.9 - 9.5 (0.70 - 0.97, 61 - 84) 12 (0.47)

*: 12 - 17 ft-lb

EM-26

TIMING CHAIN

쐌 Make sure two O-rings are present.

쐌 Be careful not to damage oil seal when installing front

cover.

QG18DE

Installation (Cont’d)

GI

MA

SEM897F

SEM009G

SEM945F

13. Install cylinder head bolts at engine front side as shown.

쐌 Tightening procedure

Tighten bolts (1 - 4) to 6.3 to 8.3 N·m (0.64 to 0.85 kg-m,

55.8 to 73.5 in-lb).

14. Install oil pump drive spacer.

15. Install water pump and water pump pulley.

Refer to LC-12, “REMOVAL AND INSTALLATION”.

16. Install idler pulley and bracket.

17. Install RH engine mounting bracket.

18. Install RH engine mounting.

19. Install oil pan. Refer to “Installation”, EM-18.

20. Install crankshaft pulley.

21. Remove ring gear stopper.

22. Install starter motor.

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

WEM019

SEM887F

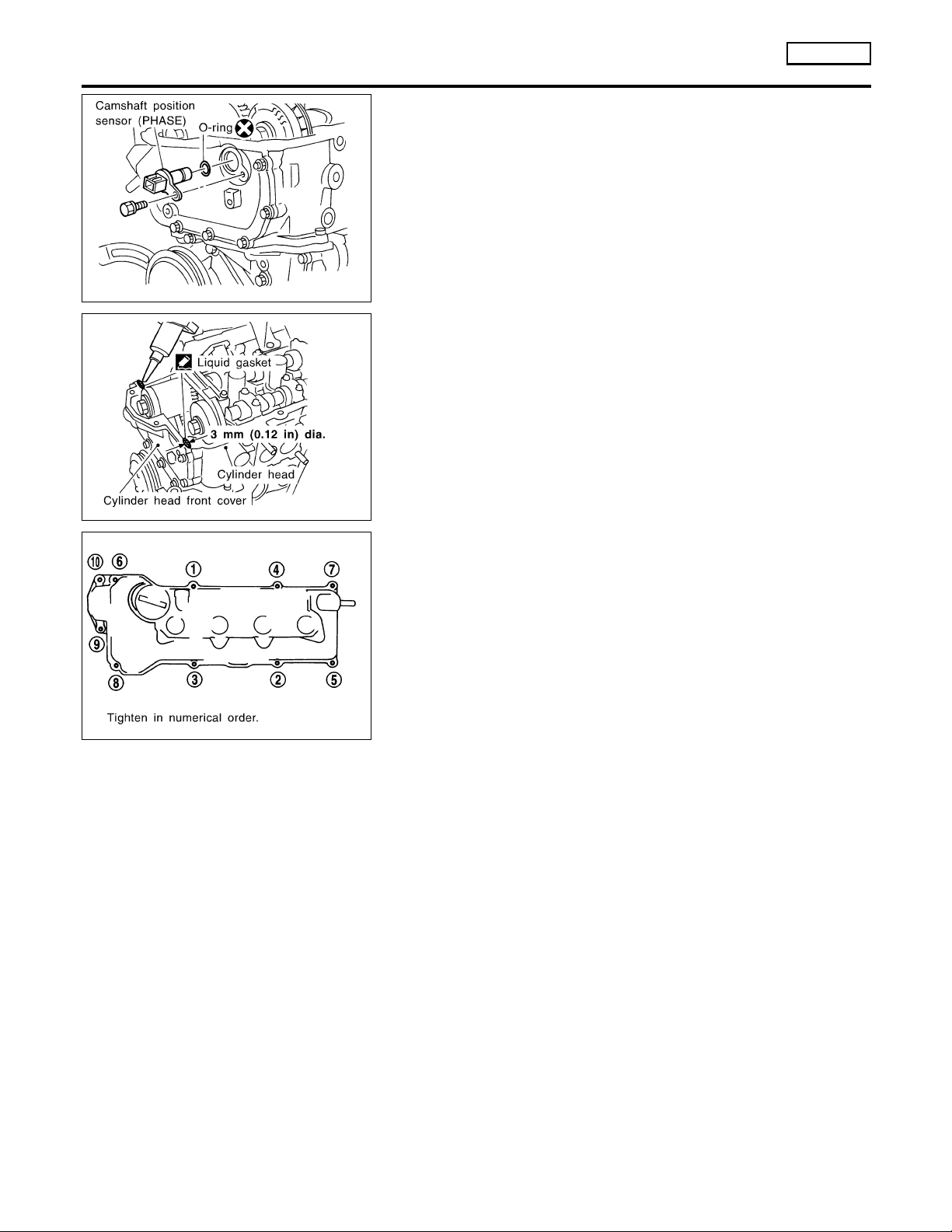

23. Install cylinder head front cover.

쐌 Apply RTV Silicone Sealant to cylinder head front cover.

쐌 Use Genuine RTV Silicone Sealant Part No. 999MP-A7007 or

equivalent.

EM-27

HA

SC

EL

IDX

Installation (Cont’d)

SEM889F

TIMING CHAIN

QG18DE

24. Install camshaft position sensor (PHASE).

25. Before installing rocker cover, apply a bead of Genuine RTV

Silicone Sealant Part No. 999MP-A7007 to mating surface of

cylinder head as shown.

26. Install rocker cover gasket into rocker cover.

SEM888F

SEM908F

27. Install rocker cover and tighten in numerical order as shown in

the figure.

28. Install spark plugs.

29. Install ignition coils.

30. Install front exhaust tube.

31. Install front/right-side splash undercover.

32. Install front RH wheel.

33. Drive belts.

For adjusting drive belt deflection, refer to MA-16, “Checking

Drive Belts”.

34. Reinstall parts in reverse order of removal.

EM-28

OIL SEAL

QG18DE

Replacement

WEM032

WEM033

Replacement

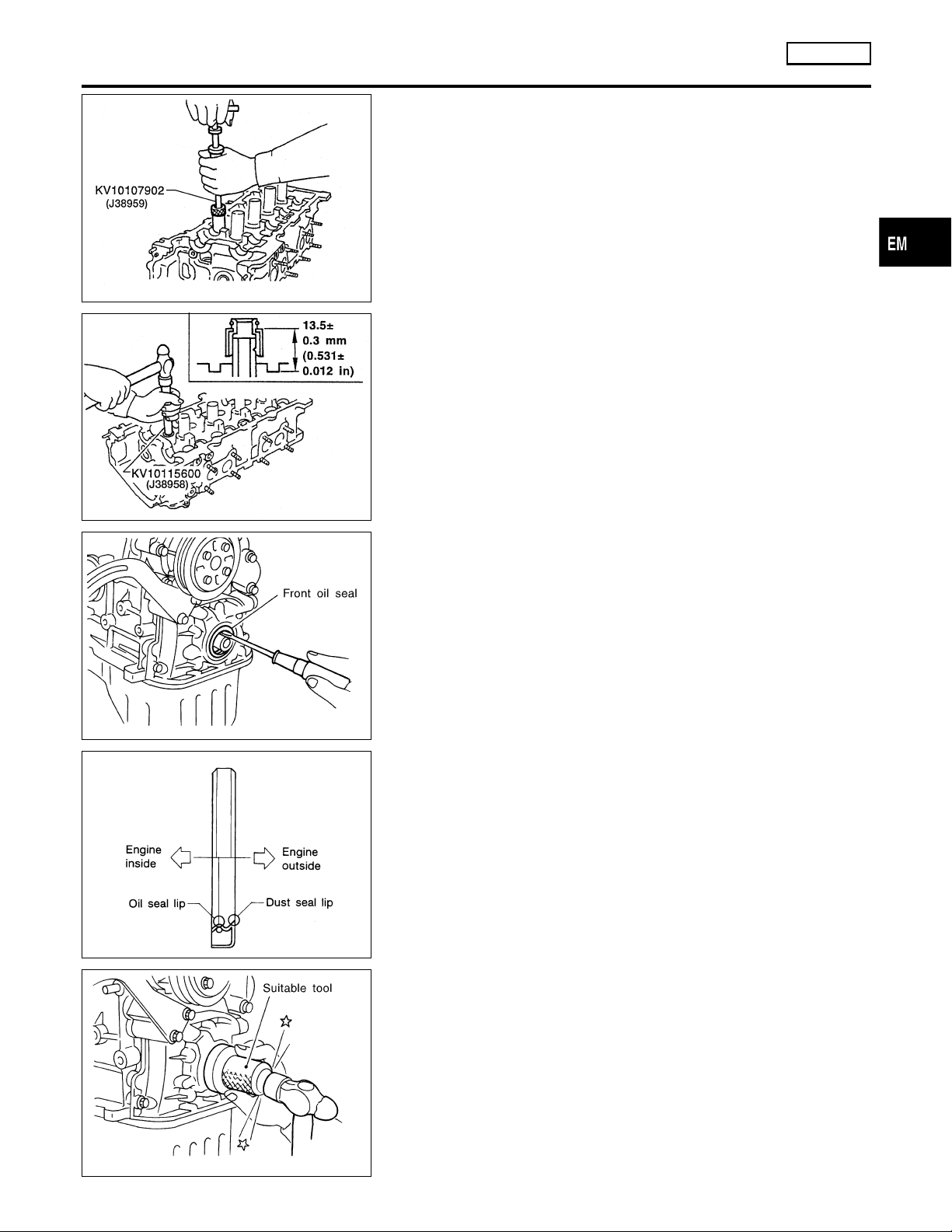

VALVE OIL SEAL

1. Remove rocker cover.

2. Remove camshaft.

3. Remove valve spring. Refer to “Components”, EM-31.

4. Remove valve oil seal with Tool.

Piston concerned should be set at TDC to prevent valve from

falling.

5. Apply new engine oil to new valve oil seal and install it with

Tool.

FRONT OIL SEAL

1. Remove the following parts:

쐌 Engine under cover

쐌 RH engine side cover

쐌 Generator and power steering drive belts

쐌 Crankshaft pulley

2. Remove front oil seal from front cover.

쐌 Be careful not to scratch front cover.

NIEM0055

NIEM0055S01

NIEM0055S02

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

SEM911F

SEM715A

3. Apply new engine oil to new oil seal and install it using a suitable tool.

쐌 Install new oil seal in the direction shown.

BR

ST

RS

BT

HA

SC

EL

IDX

SEM912F

EM-29

Replacement (Cont’d)

OIL SEAL

QG18DE

SEM096F

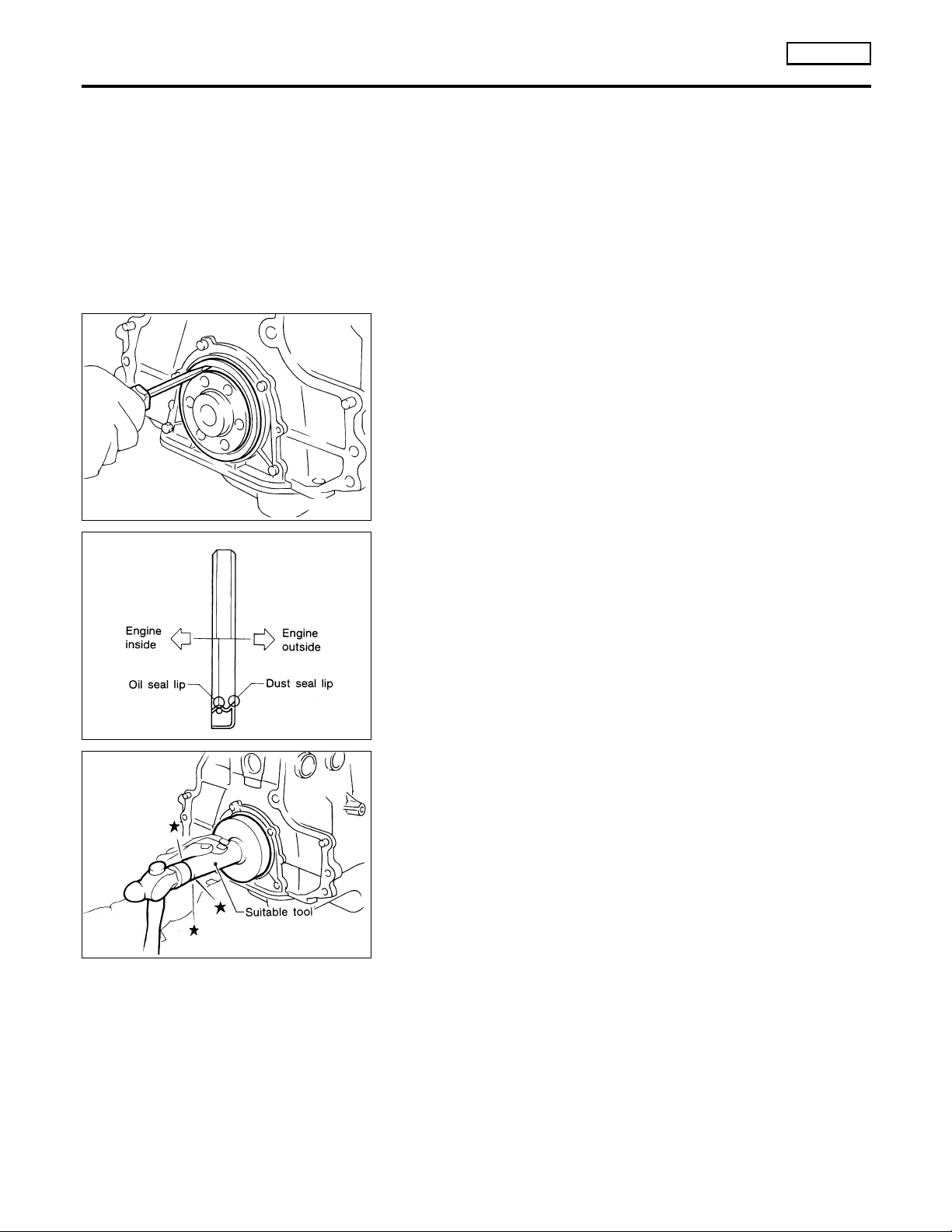

REAR OIL SEAL

=NIEM0055S03

1. Remove transaxle. Refer to MT-12, “Removal” or AT-436,

“Removal”.

2. Remove flywheel or drive plate.

3. Remove rear oil seal.

쐌 Be careful not to scratch rear oil seal retainer.

4. Apply new engine oil to new oil seal and install it using a suitable tool.

쐌 Install new oil seal in the direction shown.

SEM715A

SEM097F

EM-30