Page 1

MAINTENANCE

CONTENTS

PRECAUTIONS ...............................................................3

Precautions for Supplemental Restraint System

(SRS) ″AIR BAG″ and ″SEAT BELT

PRE-TENSIONER″......................................................3

PREPARATION ...............................................................4

Special Service Tool....................................................4

PRE-DELIVERY INSPECTION ITEMS............................5

GENERAL MAINTENANCE............................................6

PERIODIC MAINTENANCE (FOR EUROPE).................7

Maintenance Schedule for Petrol Engines

(Annual Mileage < 30,000 km/year)............................7

VQ ENGINE

CHASSIS AND BODY MAINTENANCE

Maintenance Under Severe Driving Conditions

(Annual Driving Distance < 30,000 km/year)..............9

Maintenance Schedule for Petrol Engines

(Annual Mileage > 30,000 km/year)..........................10

VQ ENGINE

CHASSIS AND BODY MAINTENANCE

Maintenance Under Severe Driving Conditions

(Annual Driving Distance > 30,000 km)....................12

RECOMMENDED FLUIDS AND LUBRICANTS...........13

Fluids and Lubricants ................................................13

SAE Viscosity Number ..............................................14

Engine Coolant Mixture Ratio....................................14

ENGINE MAINTENANCE..............................................15

Checking Drive Belts.................................................15

Changing Engine Coolant..........................................16

- DRAINING ENGINE COOLANT -

- REFILLING ENGINE COOLANT -

- FLUSHING COOLING SYSTEM -

Checking Cooling System .........................................19

CHECKING HOSES

CHECKING RADIATOR

CHECKING RADIATOR CAP

CHECKING COOLING SYSTEM FOR LEAKS

Checking Fuel Lines..................................................20

Changing Air Cleaner Filter .......................................20

VISCOUS PAPER TYPE

Changing Engine Oil..................................................21

..............................................................7

........................8

............................................................10

......................11

............................16

...........................17

............................18

.................................................19

............................................19

....................................19

............20

...........................................20

SECTION

Changing Oil Filter.....................................................21

Changing Spark Plugs (Platinum-tipped Type).........22

Checking Positive Crankcase Ventilation (PCV)

System.......................................................................23

CHECKING PCV VALVE

CHECKING VENTILATION HOSES

Checking Vacuum Hose and Connections................23

Checking EVAP Vapor Lines.....................................24

Checking Heated Oxygen Sensor (HO2S)................24

CHECKING PROCEDURE

CHASSIS AND BODY MAINTENANCE.......................25

Checking Exhaust System.........................................25

Checking Clutch Fluid Level and Leaks....................25

Checking Clutch System ...........................................25

Checking M/T Oil.......................................................25

Changing M/T Oil.......................................................26

Checking A/T Fluid ....................................................26

Changing A/T Fluid....................................................27

Balancing Wheels (Bonding Weight Type)................27

REMOVAL

WHEEL BALANCE ADJUSTMENT

Tire Rotation..............................................................29

Checking Brake Fluid Level and Leaks.....................29

Checking Brake Lines and Cables............................29

Changing Brake Fluid................................................29

Checking Brake Booster, Vacuum Hoses,

Connections and Check Valve ..................................30

Checking Disc Brake.................................................30

ROTOR

CALIPER

PAD

Checking Steering Gear and Linkage.......................31

STEERING GEAR

STEERING LINKAGE

Checking Power Steering Fluid and Lines................31

Lubricating Locks, Hinges and Hood Latches...........31

Checking Seat Belts, Buckles, Retractors,

Anchors and Adjusters...............................................32

Checking Body Corrosion..........................................32

...............................................................27

...................................................................30

.................................................................30

........................................................................30

MA

...........................................23

...........................23

........................................24

............................27

....................................................31

...............................................31

Page 2

CONTENTS (Cont’d)

SERVICE DATA AND SPECIFICATIONS (SDS).........33

Engine Maintenance..................................................33

BELT DEFLECTION AND TENSION

..........................33

SPARK PLUG (PLATINUM-TIPPED TYPE)

Chassis and Body Maintenance................................33

WHEEL BALANCE

...................................................33

................33

MA-2

Page 3

PRECAUTIONS

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT

PRE-TENSIONER”

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELTPRE-TENSIONER” used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL A33 is as follows (The composition varies according to the destination and optional equipment.):

+ For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steering wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+ For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring

harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in the RS section of this Service Manual.

WARNING:

+ To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be performed by an authorized NISSAN dealer.

+ Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+ Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

NFMA0001

MA-3

Page 4

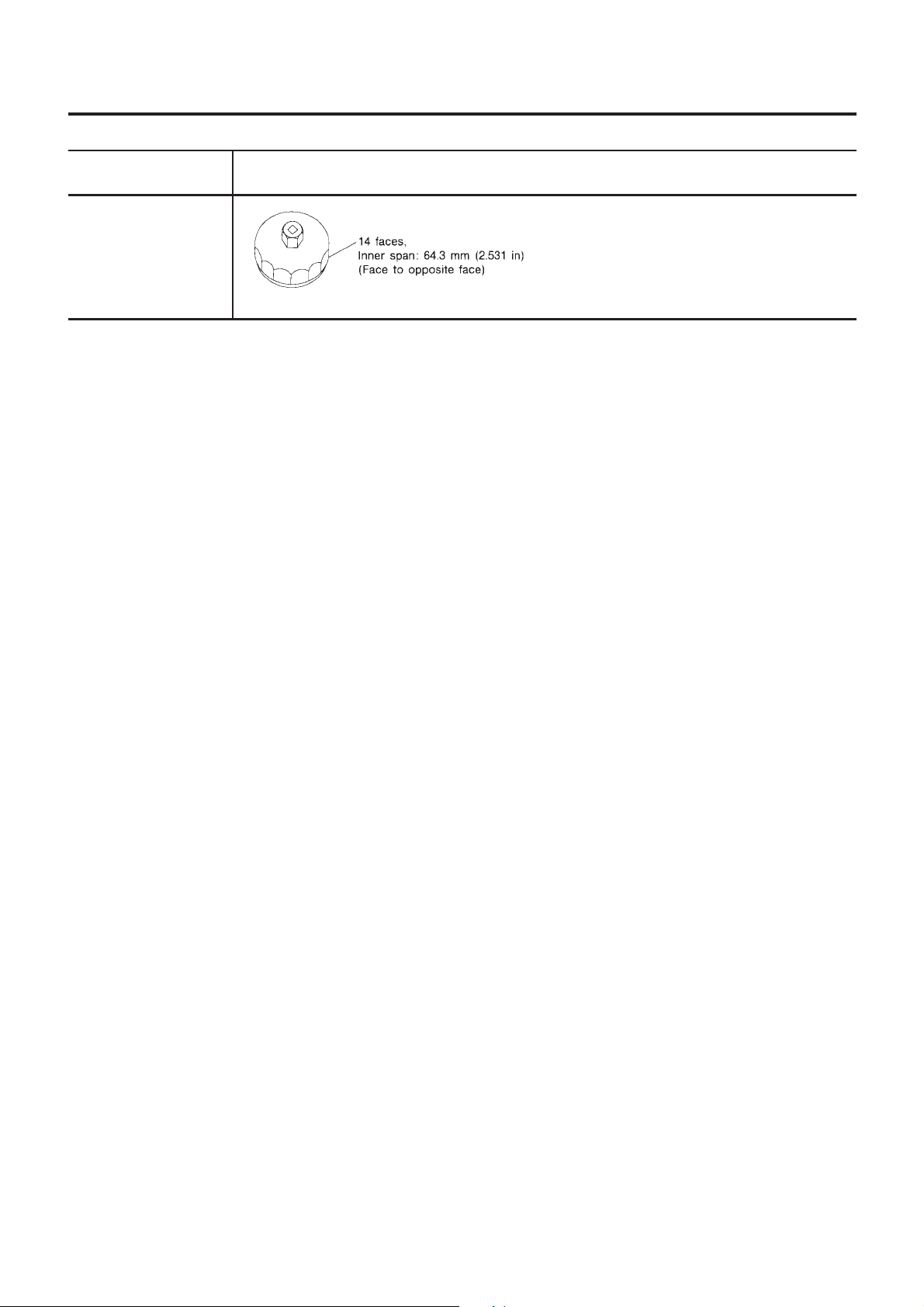

Special Service Tool

PREPARATION

Tool number

Tool name

KV10115801

KV10115800

(Kent-Moore Europe

make)

Oil filter wrench

Description

NT362

Special Service Tool

Removing oil filter

NFMA0002

MA-4

Page 5

NFMA0036

PRE-DELIVERY INSPECTION ITEMS

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD — engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts, and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

MA-5

Page 6

NFMA0004

GENERAL MAINTENANCE

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

Tires Check the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.

—

Windshield wiper

blades

Doors and engine

hood

Tire rotation Tires should be rotated every 10,000 km (6,000 miles). MA-29

Check for cracks or wear if they do not wipe properly. —

Check that all doors, the engine hood, the trunk lid and back door operate

properly.Also ensure that all latches lock securely. Lubricate if necessary.

Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.

MA-31

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

Item Reference page

Lamps Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps,

and other lamps are all operating properly and installed securely. Also check

headlamp aim.

Warning lamps and

chimes

Steering wheel Check for change in the steering conditions, such as excessive free play,

Make sure that all warning lamps and chimes are operating properly. —

hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)

—

—

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.

MA-32

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.

Item Reference page

Windshield washer

fluid

Engine coolant level Check the coolant level when the engine is cold. MA-17

Engine oil level Check the level after parking the vehicle on a level spot and turning off the

Brake and clutch

fluid levels

Battery Check the fluid level in each cell. It should be between the “MAX” and “MIN”

Check that there is adequate fluid in the tank. —

engine.

Make sure that the brake and clutch fluid levels are between the “MAX” and

“MIN” lines on the reservoir.

lines.

MA-21

MA-25, 29

—

MA-6

Page 7

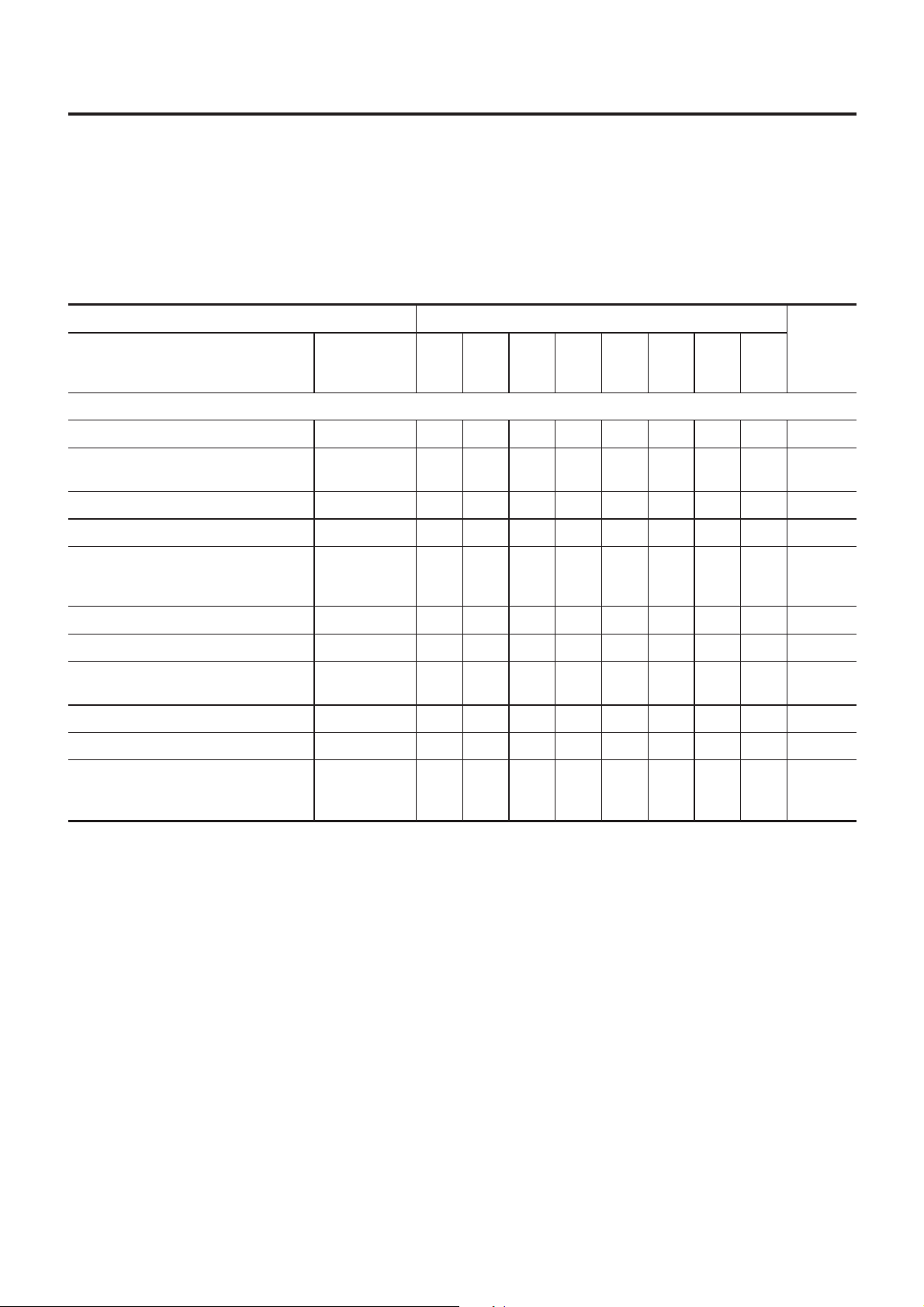

NFMA0043

PERIODICMAINTENANCE(FOREUROPE)

Maintenance Schedule for Petrol Engines (Annual Mileage < 30,000 km/year)

Thefollowingtablesshowthenormalmaintenanceschedule.Dependinguponweatherandatmospheric

conditions,varyingroadsurfaces,individualdrivinghabitsandvehicleusage,additionalormorefrequent

maintenancemayberequired.

Periodicmaintenancebeyondthelastperiodshownonthetablesrequiressimilarmaintenance.

MaintenanceScheduleforPetrolEngines

(AnnualMileage<30,000km/year)

VQENGINE

Abbreviations:R=Replace, I=Inspect:Correctorreplaceifnecessary, E=Checkandcorrecttheenginecoolantmixtureratio,

[ ]=Atthespecifiedmileageonly

NFMA0043S01

NFMA0043S0101

MAINTENANCEOPERATION MAINTENANCEINTERVAL

Performonakilometerbasis,buton

anannualbasiswhendrivinglessthan

15,000km(9,000miles)peryear

Engineoil(Userecommendedoil)★ RRRRRRRRMA-21

Engineoilfilter(UseNISSANgenuine

partorequivalent)★

Drivebelts IIIIIIIIMA-15

Coolingsystem IIIIIIIIMA-19

Engineanti-freezecoolant(Usegenu-

ineNISSANAnti-FreezeCoolant(L2N)

orequivalent)

Aircleanerfilter★ R R MA-20

Intakeandexhaustvalveclearance SeeNOTE(2)

FuelandEVAPvapourlines IIII

Sparkplugs Platinum-tippedtype [R] MA-22

Fuelfilter SeeNOTE(3)

kmx1,000

(milesx1,000)

Months

Enginecompartmentandundervehicle

SeeNOTE(1) E MA-16

15

30

45

60

75

(9)

(18)

(27)

12

24

RRRRRRRRMA-21

36

(36)

48

(45)

60

90

(54)

72

105

(63)

84

120

(72)

Refer-

ence

pages

96

EM-51

MA-20/

MA-24

Heatedoxygensensor(Exhaustgas

sensor)★

NOTE:

(1)Firstreplaceat100,000km(60,000miles)/60months,thenevery60,000km(36,000miles)/48months.

(2)Periodicmaintenanceisnotrequired.However,ifvalvenoiseincreases,checkvalveclearance.

(3)Maintenance-freeitem.Forserviceprocedures,refertoFEsection.

(4)Performonlyaccordingto“MaintenanceUnderSevereDrivingConditions”formodelswithoutEuro-OBDsystem.For

modelswithEuro-OBDsystem,periodicmaintenanceisnotrequired.

★Maintenanceitemswith“★”shouldbeperformedmorefrequentlyaccordingto“MaintenanceUnderSevereDrivingCon-

ditions”.

SeeNOTE(4)

MA-24

MA-7

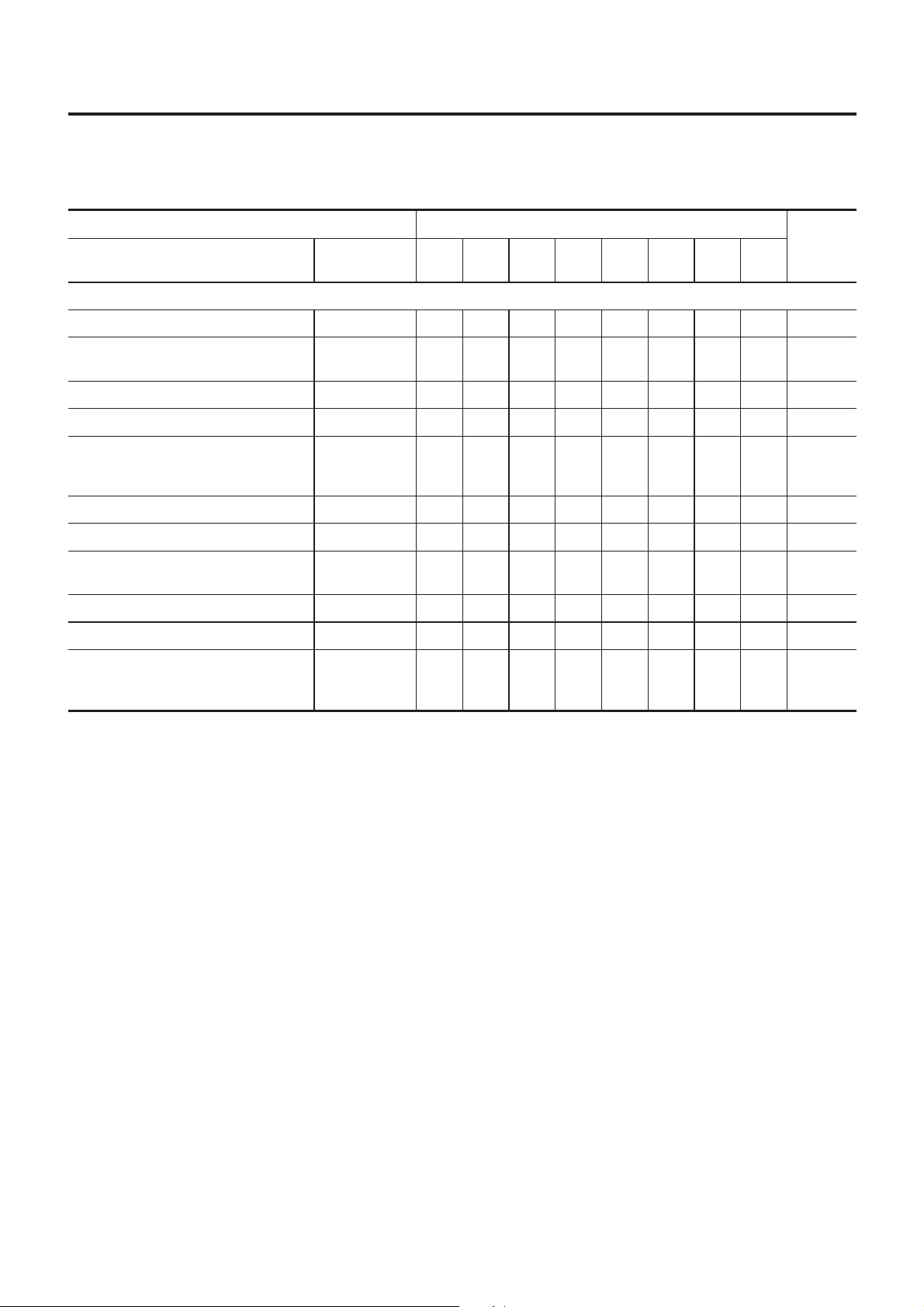

Page 8

PERIODICMAINTENANCE(FOREUROPE)

Maintenance Schedule for Petrol Engines (Annual Mileage < 30,000 km/year) (Cont’d)

CHASSISANDBODYMAINTENANCE

Abbreviations:R=Replace I=Inspect:Correctorreplaceifnecessary

MAINTENANCEOPERATION MAINTENANCEINTERVAL

Performonakilometerbasis,buton

anannualbasiswhendrivinglessthan

15,000km(9,000miles)inayear.

Headlampaiming IIIIIIII

Wheelalignment(ifnecessary,balance

&rotatewheels)

Brakepads,rotors&otherbrakecomponents★

Footbrake,parkingbrake&clutch(for

freeplay,stroke&operation)

Brakeboostervacuumhoses,

connections,checkvalve

Brake&clutch,systemsandfluid(for

levelandleaks)

Brakefluid★ RRRR

kmx1,000

(milesx1,000)

Months

Underhoodandundervehicle

15

30

45

60

75

(9)

(18)

(27)

12

24

IIIIIIII

IIIIIIIIMA-30

IIIIIIII

IIIIMA-30

IIIIIIII

36

(36)

48

(45)

60

90

(54)

72

105

(63)

84

120

(72)

96

=NFMA0043S0102

Refer-

ence

pages

EL-67

SU-6

MA-27

BR-12

BR-39

MA-25/

MA-29

BR-7

MA-29

/

/

,

Powersteeringfluidandlines(forlevel

andleaks)

ASCDvacuumhoses IIIIIIII

Supplementalairbagsystem SeeNOTE(1)

Ventilationairfilter★ RRRR

Manualtransaxlegearoil(checkfor

leakage).

Automatictransaxlefluid(forleveland

leaks)★

Steeringgear&linkage,axle&suspensionparts,driveshafts,exhaust

system★

Bodycorrosion SeeNOTE(2) MA-32

NOTE:

(1)Inspectatthefirst10years,andthenevery2years.

(2)Inspectonceperyear.

★Maintenanceitemswith“★”shouldbeperformedmorefrequentlyaccordingto“MaintenanceUnderSevereDrivingCon-

ditions”.

IIIIIIIIMA-31

EL-237

RS-14

HA-123

IIIIIIIIMA-25

IIIIIIIIMA-26

MA-25/

IIII

SU-6

SU-20

MA-31

/

/

MA-8

Page 9

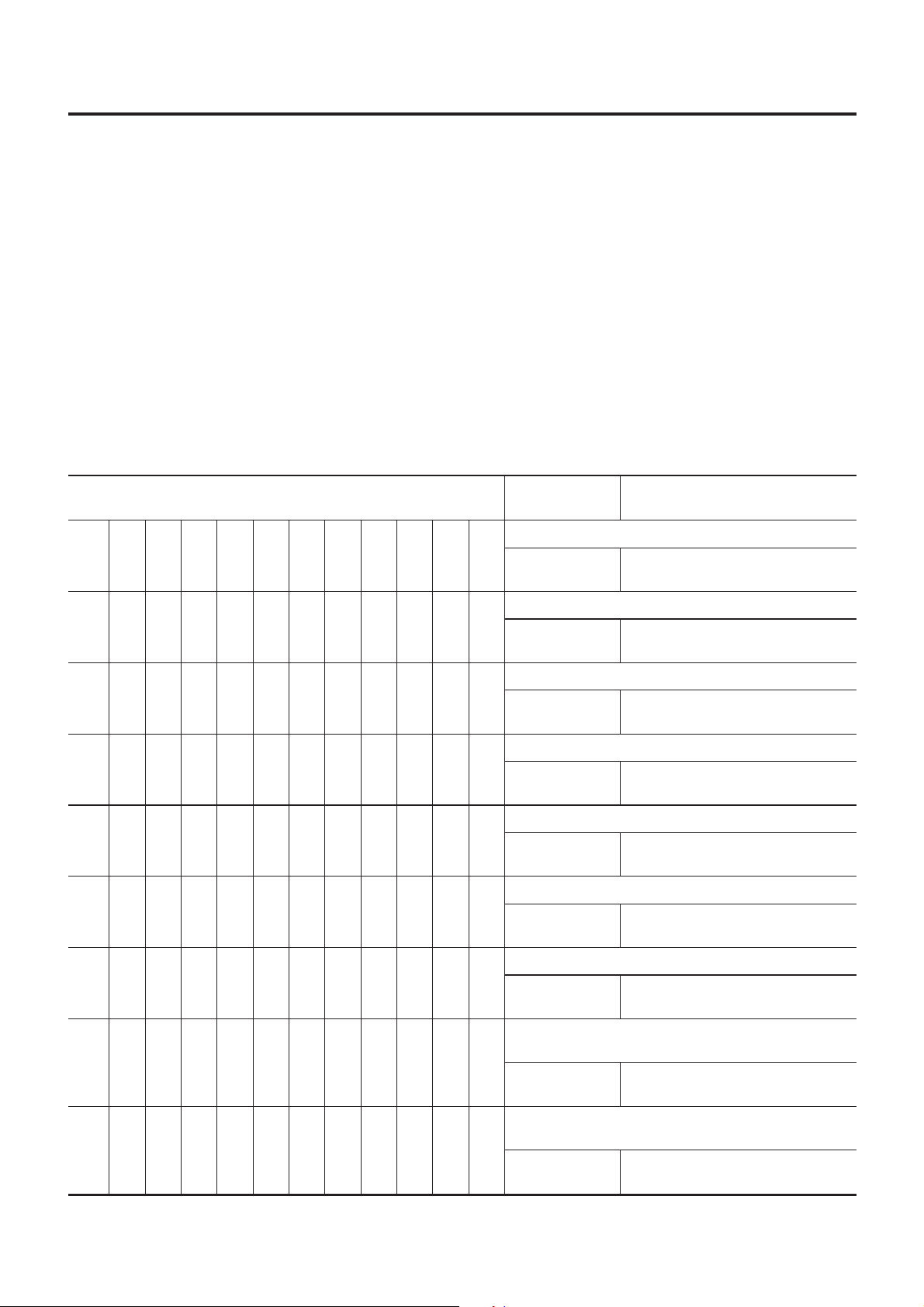

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Under Severe Driving Conditions (Annual Driving Distance < 30,000 km/year)

Maintenance Under Severe Driving Conditions

(Annual Driving Distance < 30,000 km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be performed on the following items as shown in the table.

A — Driving under dusty conditions

B — Driving repeatedly short distances

C — Towing a trailer or caravan

D — Extensive idling

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity areas or in mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

J — Frequent off road use or driving in water

K — Sustained high speed driving

L — For models without Euro-OBD system

=NFMA0043S03

Driving condition

ABCD........

A...........

...........L

...........L

A...........

.....F......

Maintenance

operation

Engine oil & engine oil filter

Replace

Air cleaner filter

Replace

Front Heated Oxygen Sensor

Inspect

Rear Heated Oxygen Sensor

Inspect

Ventilation air filter

Replace

Brake fluid

Replace

Every 7,500 km (4,500 miles) or 6

months

Every 30,000 km (18,000 miles) or

24 months

Every 30,000 km (18,000 miles) or

24 months

Every 30,000 km (18,000 miles) or

24 months

Every 15,000 km (9,000 miles) or 12

months

Every 15,000 km (9,000 miles) or 6

months

Maintenance interval

..C....H....

A.C...GHI...

......GH....

MA-9

Automatic transaxle fluid

Replace

Brake pads, rotors & other brake system components

Inspect

Steering gear & linkage, axle & suspension parts,

drive shafts, exhaust system

Inspect

Every 30,000 km (18,000 miles) or

24 months

Every 7,500 km (4,500 miles) or 6

months

Every 15,000 km (9,000 miles) or 12

months

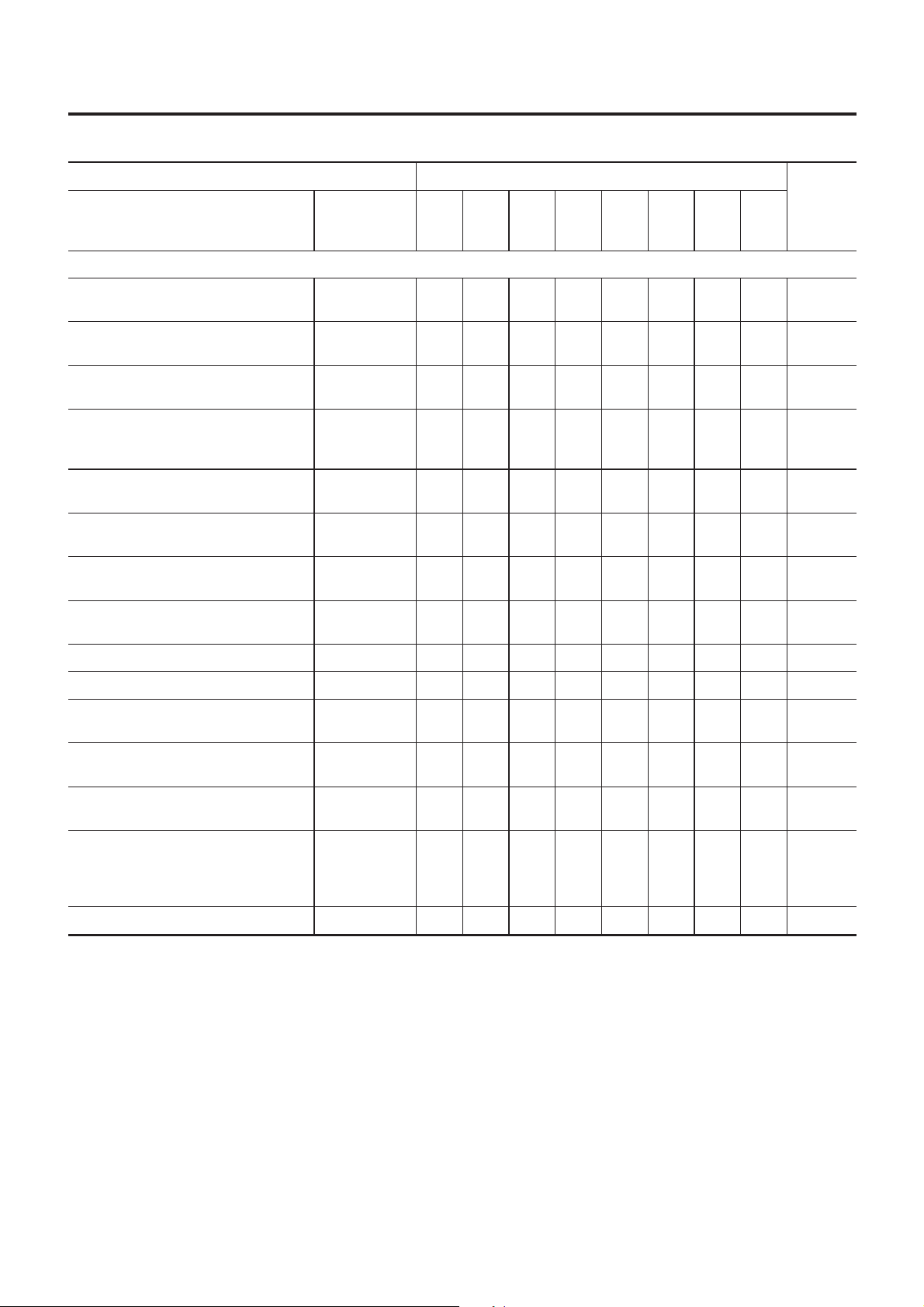

Page 10

PERIODICMAINTENANCE(FOREUROPE)

Maintenance Schedule for Petrol Engines (Annual Mileage > 30,000 km/year)

MaintenanceScheduleforPetrolEngines

(AnnualMileage>30,000km/year)

VQENGINE

Abbreviations:R=Replace, I=Inspect:Correctorreplaceifnecessary, E=Checkandcorrecttheenginecoolantmixtureratio

=NFMA0043S04

NFMA0043S0401

MAINTENANCEOPERATION MAINTENANCEINTERVAL

Performonakilometerbasisonly.

Engineoil(Userecommendedoil)★ RRRRRRRRMA-21

Engineoilfilter(UseNISSANgenuine

partorequivalent)★

Drivebelts IIIIIIIIMA-15

Coolingsystem IIIIMA-19

Engineanti-freezecoolant(Usegenu-

ineNISSANAnti-FreezeCoolant(L2N)

orequivalent)

Aircleanerfilter★ R R MA-20

Intake&exhaustvalveclearance SeeNOTE(2)

FuelandEVAPvaporlines I I

Sparkplugs Platinum-tippedtype R MA-22

Fuelfilter SeeNOTE(3) R

Heatedoxygensensor(Exhaustgas

sensor)★

kmx1,000

(milesx1,000)15(9)30(18)45(27)60(36)75(45)90(54)

Enginecompartmentandundervehicle

RRRRRRRRMA-21

SeeNOTE(1) E MA-16

SeeNOTE(4)

105

(63)

120

(72)

Refer-

ence

pages

EM-52

MA-20/

MA-24

MA-24

NOTE:

(1)Firstreplaceat100,000km(60,000miles),thenevery60,000km(36,000miles).

(2)Periodicmaintenanceisnotrequired.However,ifvalvenoiseincreases,checkvalveclearance.

(3)Maintenance-freeitem.Forserviceprocedures,refertoFEsection.

(4)Performonlyaccordingto“MaintenanceUnderSevereDrivingConditions”formodelswithoutEuro-OBDsystem.For

modelswithEuro-OBDsystem,periodicmaintenanceisnotrequired.

★Maintenanceitemswith“★”shouldbeperformedmorefrequentlyaccordingto“MaintenanceUnderSevereDrivingCon-

ditions”.

MA-10

Page 11

PERIODICMAINTENANCE(FOREUROPE)

Maintenance Schedule for Petrol Engines (Annual Mileage > 30,000 km/year) (Cont’d)

CHASSISANDBODYMAINTENANCE

Abbreviations:R=Replace I=Inspect:Correctorreplaceifnecessary

MAINTENANCEOPERATION MAINTENANCEINTERVAL

Performonakilometerbasisonly.

Headlampaiming IIII

Wheelalignment(ifnecessary,balance

&rotatewheels)

Brakepads,rotors&otherbrakecomponents★

Footbrake,parkingbrake&clutch(for

freeplay,stroke&operation)

Brakeboostervacuumhoses,

connections,checkvalve

Brake&clutch,systemsandfluid(for

levelandleaks)

Brakefluid★ RR

kmx1,000

(milesx1,000)15(9)30(18)45(27)60(36)75(45)90(54)

Underhoodandundervehicle

IIII

IIIIMA-30

IIII

I I MA-30

IIII

105

(63)

120

(72)

=NFMA0043S0402

Refer-

ence

pages

EL-67

SU-6

/

MA-27

BR-12

/

BR-39

/

MA-25/

MA-29

BR-7

,

MA-29

Powersteeringfluidandlines(forlevel

andleaks)

ASCDvacuumhoses IIII

Supplementalairbagsystem SeeNOTE(1)

Ventilationairfilter★ RRRR

Manualtransaxlegearoil(checkfor

leakage).

Automatictransaxlefluid(forleveland

leaks)★

Steeringgearandlinkage,axle&suspensionparts,driveshafts,exhaust

system★

Bodycorrosion SeeNOTE(2) MA-32

NOTE:

(1)Inspectatthefirst10years,andthenevery2years.

(2)Inspectonceperyear.

★Maintenanceitemswith“★”shouldbeperformedmorefrequentlyaccordingto“MaintenanceUnderSevereDrivingCon-

ditions”.

IIIIMA-31

EL-237

RS-14

HA-123

IIIIMA-25

IIIIMA-26

MA-25/

II

SU-6

SU-20

MA-31

/

/

MA-11

Page 12

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Under Severe Driving Conditions (Annual Driving Distance > 30,000 km)

Maintenance Under Severe Driving Conditions

(Annual Driving Distance > 30,000 km)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be performed on the following items as shown in the table.

A — Driving under dusty conditions

B — Driving repeatedly short distances

C — Towing a trailer or caravan

D — Extensive idling

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity areas or in mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

J — Frequent off road use or driving in water

K — Sustained high speed driving

L — For models without Euro-OBD system

=NFMA0043S06

Driving condition

ABCD........

A...........

...........L

...........L

A...........

.....F......

..C....H....

A.C...GHI...

Maintenance

operation

Engine oil & engine oil filter

Replace Every 7,500 km (4,500 miles)

Air cleaner filter

Replace Every 30,000 km (18,000 miles)

Front Heated Oxygen Sensor

Inspect Every 60,000 km (36,000 miles)

Rear Heated Oxygen Sensor

Inspect Every 60,000 km (36,000 miles)

Ventilation air filter

Replace Every 15,000 km (9,000 miles)

Brake fluid

Replace Every 30,000 km (18,000 miles)

Automatic transaxle fluid

Replace Every 60,000 km (36,000 miles)

Brake pads, rotors & other brake system components

Inspect Every 15,000 km (9,000 miles)

Maintenance interval

......GH....

MA-12

Steering gear & linkage, axle & suspension parts,

drive shafts, exhaust system

Inspect Every 30,000 km (18,000 miles)

Page 13

RECOMMENDED FLUIDS AND LUBRICANTS

NFMA0006

Fluids and Lubricants

Fluids and Lubricants

Capacity (Approximate)

Liter Imp qt

Engine oil

(Refill)

With oil filter 4.0 3-1/2 qt

Without oil filter 3.7 3-1/4 qt

LHD 8.5 7-1/2 qt

VQ20

RHD 8.2 7-1/4 qt

LHD 7.7 6-3/4 qt

Cooling

system

With reservoir tank

For Europe

VQ30

RHD 7.4 6-1/2 qt

Reservoir 0.7 (5/8)

7-3/4 -

Manual

transaxle

gear oil

RS5F50A

Oil level L mm (in)

16 - 25 (0.63 - 0.98)

4.5 - 4.8

7-7/8 -

8-1/2 pt*4

RS5F50V 4.25 - 4.55 3-3/4-4qt

Automatic

transaxle

RE4F04B/W 9.4 8-1/4 qt

fluid

Power steering fluid — — Type Dexron

Recommended fluids and lubricants

API SG, SH or SJ*1 for Europe

ILSAC grade GF-I or GF-II*1

Genuine Nissan anti-freeze coolant

(L2N) or equivalent for Europe*3

API GL-4*1

Viscosity SAE 75W-90

Genuine Nissan ATF or equiva-

lent*2

TM

III or equivalent

NFMA0006S01

Brake and clutch fluid — —

DOT 3 or DOT 4 (US FMVSS No.

116)*4

Multi-purpose grease — — NLGI No. 2 (Lithium soap base)

*1: For further details, see “SAE Viscosity Number”.

*2: Contact a Nissandealershipfor more information regarding suitable fluids, including recommended brand(s) ofDexron

TM

III/Mercon

TM

Automatic Transmission Fluid.

*3: Use Genuine Nissan anti-freeze coolant, or equivalent in its quality, in order to avoid possible aluminum corrosion within the engine

cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*4: Never mix different types of fluids (DOT 3 and DOT 4).

MA-13

Page 14

SAE Viscosity Number

RECOMMENDED FLUIDS AND LUBRICANTS

Mixed coolant specific gravity

SMA084D

SMA089D

SAE Viscosity Number

=NFMA0006S02

+ For warm and cold areas: 10W-30 is preferable for ambient

temperature above −20°C (−4°F).

5W-30 will positively improve fuel economy.

+ For hot areas: 20W-40 and 20W-50 are suitable.

Engine Coolant Mixture Ratio

NFMA0006S04

The engine cooling system is filled at the factory with a high-quality,

year-round and extended life engine coolant. The high quality

engine coolant contains the specific solutions effective for the anticorrosion and the anti-freeze function. Therefore, additional cooling system additives are not necessary.

CAUTION:

When adding or replacing coolant, be sure to use only Genuine Nissan Anti-freeze Coolant (L2N) or equivalent. Because

L2N is premixed type coolant.

The use of other types of engine coolant may damage your

cooling system.

+ When checking the engine coolant mixture ratio by the coolant

hydrometer, use the chart below to correct your hydrometer

reading (density) according to coolant temperature.

Unit: specific gravity

Engine coolant mixture

ratio

30% 1.046 - 1.050 1.042 - 1.046 1.038 - 1.042 1.033 - 1.038

50% 1.076 - 1.080 1.070 - 1.076 1.065 - 1.071 1.059 - 1.065

Coolant temperature °C (°F)

15 (59) 25 (77) 35 (95) 45 (113)

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could be caused by high pressure fluid escaping from

the radiator. Wait until the engine and radiator cool down.

MA-14

Page 15

ENGINE MAINTENANCE

Checking Drive Belts

Checking Drive Belts

NFMA0007

1. Inspect belts for cracks, fraying, wear and oil. If necessary,

replace with a new one.

2. Inspect drive belt deflection at a point on the belt midway

between pulleys.

+ Inspect drive belt deflection when engine is cold.

+ Adjust if belt deflection exceeds the limit or it is not within

specifications.

Belt deflection:

Limit After adjustment

With air conditioner compressor

Alternator

Without air conditioner compressor

Power steering oil pump 11 (0.43)

7 (0.28)

10 (0.39) 6.3 - 6.9 (0.248 - 0.272) 5.6 - 6.0 (0.220 - 0.236)

Deflection adjustment mm (in)

Applied pushing force: 98 N (10 kg, 22 lb)

Used belt

4.2 - 4.6

(0.165 - 0.181)

7.3-8

(0.287 - 0.315)

6.5 - 7.2 (0.256 - 0.283)

SMA804CB

New belt

3.7 - 4.1

(0.146 - 0.161)

MA-15

Page 16

Changing Engine Coolant

ENGINE MAINTENANCE

SMA032D

Changing Engine Coolant

NFMA0008

WARNING:

+ To avoid the danger of being scalded, never change the

coolant when the engine is hot.

+ Wrap a thick cloth around cap and carefully remove the

cap. At first, turn the cap a quarter of a turn to release

built-up pressure. Then turn the cap all the way.

— DRAINING ENGINE COOLANT —

NFMA0008S01

1. Set air conditioning system as follows to prevent coolant from

remaining in the system.

a. Turn ignition switch ON and set temperature controller to maxi-

mum hot position.

b. Wait 10 seconds before turning ignition switch OFF.

2. Open radiator drain plug at the bottom of radiator, and remove

radiator filler cap.

3. Remove reservoir tank, drain coolant, then clean reservoir

tank.

+ Be careful not to allow coolant to contact drive belts.

SMA033D

MA-16

Page 17

ENGINE MAINTENANCE

4. Cover the exhaust tube heat shield to prevent from splashing

coolant.

5. Remove drain plugs on both sides of cylinder block and air

relief plug.

6. Check drained coolant for contaminants such as rust, corrosion or discoloration. If contaminated flush engine cooling

system, refer to “FLUSHING COOLING SYSTEM”, MA-18.

7. Blow the coolant around the exhaust tube heat shield.

SMA034D

Changing Engine Coolant (Cont’d)

SMA953CA

SMA083D

— REFILLING ENGINE COOLANT —

NFMA0008S02

1. Install reservoir tank, and radiator drain plug.

2. Close and tighten cylinder block drain plugs securely.

+ Apply sealant to the thread of cylinder block drain plugs.

Left side:

: 60 - 66 N·m (6.1 - 6.7 kg-m, 44 - 48 ft-lb)

Right side:

: 18 - 22 N·m (1.8 - 2.2 kg-m, 13 - 16 ft-lb)

With oil cooler:

: 25 - 29 N·m (2.5 - 3.0 kg-m, 18 - 21 ft-lb)

3. Fill radiator slowly with coolant until coolant spills from the air

relief plug, then install air relief plug.

Air relief plug:

: 6.9 - 7.8 N·m (0.7 - 0.8 kg-m, 61 - 69 in-lb)

+ Use Nissan genuine engine coolant or equivalent.

MA-17

Page 18

Changing Engine Coolant (Cont’d)

ENGINE MAINTENANCE

Refer to “RECOMMENDED FLUIDS AND LUBRICANTS” for

coolant mixture ratio, MA-14.

Unit: ! (Imp qt)

VQ20DE VQ30DE

LHD RHD LHD RHD

Engine coolant capacity

(With reservoir tank)

8.5 (7-1/2) 8.2 (7-1/4) 7.7 (6-3/4) 7.4 (6-1/2)

SMA182B

SMA412B

Reservoir tank

capacity

0.7 (5/8)

+ Pour coolant through coolant filler neck slowly to allow air

in system to escape.

4. Fill radiator and reservoir tank to specified level.

5. Warm up engine to normal operating temperature without

radiator cap installed.

+ If coolant overflows radiator filler hole, install filler cap.

6. Run engine at 2,500 rpm for 10 seconds and return to idle

speed with radiator cap installed.

+ Repeat two or three times.

Watch coolant temperature gauge so as not to overheat the

engine.

7. Stop engine and cool it down.

+ Cool down using a fan to reduce the time.

+ If necessary, refill radiator up to filler neck with coolant.

8. Refill reservoir tank to MAX level line with coolant.

9. Repeat steps 5 through 8 two or more times with radiator cap

installed until coolant level no longer drops.

10. Check cooling system for leaks with engine running.

11. Warm up engine, and check for sound of coolant flow while

running engine from idle up to 3,000 rpm with heater temperature controller set at several positions between COOL and

WARM.

+ Sound may be noticeable at heater water cock.

12. If sound is heard, bleed air from cooling system by repeating

steps 5 through 8 until coolant level no longer drops

+ Clean excess coolant from engine.

13. Check cooling system for leaks. Refer to MA-20.

— FLUSHING COOLING SYSTEM —

NFMA0008S03

1. Open air relief plug with drain plugs installed.

2. Open coolant passage to heater unit. Refer to step 1 of

“DRAINING ENGINE COOLANT”.

3. Fill radiator with water until water spills from the air relief hole,

then close air relief plug. Fill radiator and reservoir tank with

water and reinstall radiator cap.

4. Run engine and warm it up to until lower radiator hose

becomes warm.

5. Rev engine two or three times under no-load.

Watch coolant temperature gauge so as not to overheat

the engine.

6. Stop engine and wait until it cools down.

+ Cool with a fan to save time

7. Drain water.

MA-18

Page 19

ENGINE MAINTENANCE

Checking Cooling System

8. Repeat steps 1 through 7 until clear water begins to drain from

radiator.

Checking Cooling System

NFMA0037

CAUTION:

Do not remove the thermostat especially on engines with the

thermostat in the water inlet side (radiator lower hose side). If

the thermostat is removed, coolant flow to radiator and coolant pressure in upper radiator hose will be reduced. This will

result in engine overheating.

CHECKING HOSES

NFMA0037S01

Check hoses for improper attachment and for leaks, cracks,

damage, loose connections, chafing and deterioration.

CHECKING RADIATOR

NFMA0037S02

Check radiator for mud or clogging. If necessary, clean radiator as

follows.

+ Be careful not to bend or damage the radiator fins.

+ When radiator is cleaned without removal, remove all sur-

rounding parts such as cooling fan, radiator shroud and horns.

Then tape the harness and connectors to prevent water from

entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surfaces once per

minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core vertically downward.

+ Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm

2

,71

psi) and keep distance more than 30 cm (11.8 in).

5. Blow air again into all the radiator core surfaces once per

minute until no water sprays out.

NOTE:

For air conditioner equipped models, do the same on the condenser as the above.

SLC613-A

CHECKING RADIATOR CAP

NFMA0037S03

Apply pressure to radiator cap with cap tester to see if it is satisfactory.

Radiator cap relief pressure:

Standard

78 - 98 kPa (0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2

,11-

14 psi)

Limit

59 - 98 kPa (0.59 - 0.98 bar, 0.6 - 1.0 kg/cm

2

,9-14

psi)

MA-19

Page 20

Checking Cooling System (Cont’d)

ENGINE MAINTENANCE

Pull the negative-pressure valve to open it. Check that it closes

completely when released.

SMA871B

CHECKING COOLING SYSTEM FOR LEAKS

To check for leakage, apply pressure to the cooling system with a

tester.Check that the pressure does not drop for at least 2 minutes.

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

CAUTION:

Higher than the specified pressure may cause radiator damage.

If the pressure drops, check hoses, radiator and water pump

SMA990A

for leaks. If no external leaks are found, check heater core,

cylinder block and cylinder head.

Checking Fuel Lines

Inspect fuel lines and tank for improper attachment, leaks, cracks,

damage, loose connections, chafing or deterioration. If necessary,

repair or replace faulty parts.

2

, 23 psi)

NFMA0037S04

NFMA0009

SMA803A

MMA104A

SMA037D

CAUTION:

Tighten high-pressure rubber hose clamp so that clamp end is

3 mm (0.12 in) from hose end.

Tightening torque specifications are the same for all rubber

hose clamps.

Ensure that screw does not contact adjacent parts.

Changing Air Cleaner Filter

VISCOUS PAPER TYPE

NFMA0011

NFMA0011S01

The viscous paper type filter does not need cleaning.

MA-20

Page 21

ENGINEMAINTENANCE

Changing Engine Oil

SMA038D

ChangingEngineOil

NFMA0012

WARNING:

+ Becarefulnottoburnyourself,astheengineoilishot.

+ Prolongedandrepeatedcontactwithusedengineoilmay

causeskincancer;trytoavoiddirectskincontactwith

usedoil.Ifskincontactismade,washthoroughlywith

soaporhandcleanerassoonaspossible.

1. Warmupengine,andcheckforoilleakagefromenginecomponents.

2. Stopengineandwaitmorethan10minutes.

3. Removedrainplugandoilfillercap.

4. Drainoilandrefillwithnewengineoil.

Oilspecificationandviscosity:

+ Referto“RECOMMENDEDFLUIDSANDLUBRICANTS”,

MA-13.

Oilcapacity(Approximate):

Unit:liter(Impqt)

Withoilfilterchange 4.0(3-1/2)

Drainandrefill

Dryengine(engineoverhaul) 4.2(3-3/4)

Withoutoilfilter

change

3.7(3-1/4)

CAUTION:

+ Besuretocleandrainplugandinstallwithnewwasher.

Oilpandrainplug:

:29-39N·m(3.0-4.0kg-m,22-29ft-lb)

SMA954C

SMA039DA

+ Therefillcapacitydependsontheoiltemperatureand

draintime.Usethesespecificationsforreferenceonly.

Alwaysusethedipsticktodeterminewhentheproper

amountofoilisintheengine.

+ Neverpulloutlevelgaugewhilefillingengineoil.

5. Warmupengineandcheckareaarounddrainplugandoilfilterforoilleakage.

6. Stopengineandwaitmorethan10minutes.

7. Checkoillevel.

ChangingOilFilter

NFMA0013

1. Theoilfilterisasmallfull-flowcartridgetypeandisprovided

withareliefvalve.

LC-6

Referto

, “Oil Filter”.

2. RemoveoilfilterwithToolorsuitabletool.

WARNING:

Becarefulnottoburnyourself,astheengineandtheengine

oilarehot.

MA-21

Page 22

Changing Oil Filter (Cont’d)

ENGINE MAINTENANCE

3. Before installing new oil filter, clean oil filter mounting surface

on cylinder block. Coat rubber seal of new oil filter with engine

oil.

SMA010

4. Screw in the oil filter until a slight resistance is felt, then tighten

additionally 2/3 turn.

5. Add engine oil.

Oil filter:

: 14.7 - 20.5 N·m (1.5 - 2.1 kg-m, 11 - 15 ft-lb)

Refer to “Changing Engine Oil”, MA-21.

SMA229B

SMA040D

SEM294A

Changing Spark Plugs (Platinum-tipped Type)

NFMA0014

1. Remove left side rocker cover ornament.

2. Disconnect ignition coil harness connectors.

3. Loosen ignition coil fixing bolts and pull out coil from intake

manifold connector.

4. Remove spark plugs with suitable spark plug wrench.

Spark plug (Platinum-tipped type):

Make NGK

Standard type PFR5G-11

Hot type PFR4G-11

Cold type PFR6G-11

Use standard type spark plug for normal condition.

The hot type spark plug is suitable when fouling may occur with the

standard type spark plug such as:

+ frequent engine starts

+ low ambient temperatures

The cold type spark plug is suitable when spark knock may occur

with the standard type spark plug such as:

+ extended highway driving

+ frequent high engine revolution

Gap (Nominal): 1.1 mm (0.043 in)

: 20 - 29 N·m (2.0 - 3.0 kg-m, 14 - 22 ft-lb)

MA-22

Page 23

ENGINE MAINTENANCE

+ Do not use a wire brush for cleaning.

+ If plug tip is covered with carbon, spark plug cleaner may

be used.

Cleaner air pressure:

Less than 588 kPa (5.9 bar, 6 kg/cm

Cleaning time:

Less than 20 seconds

SMA773C

+ Checking and adjusting plug gap is not required between

removals.

Changing Spark Plugs (Platinum-tipped Type) (Cont’d)

2

, 85 psi)

SMA806C

SEF244Q

Checking Positive Crankcase Ventilation (PCV) System

CHECKING PCV VALVE

With engine running at idle, remove ventilation hose from PCV

valve; if valve is working properly, a hissing noise will be heard as

air passes through it and a strong vacuum should be felt immediately when a finger is placed over valve inlet.

CHECKING VENTILATION HOSES

1. Check hoses and hose connections for leaks.

2. Disconnect all hoses and clean with compressed air. If any

hose cannot be freed of obstructions, replace.

NFMA0035

NFMA0035S01

NFMA0035S02

Checking Vacuum Hose and Connections

NFMA0038

Check vacuum hoses for improper attachment and for leaks,

cracks, damage, loose connections, chafing and deterioration.

MA-23

Page 24

Checking EVAP Vapor Lines

ENGINEMAINTENANCE

SMA082D

CheckingEVAPVaporLines

NFMA0015

1. VisuallyinspectEVAPvaporlinesforimproperattachmentand

forcracks,damage,looseconnections,chafinganddeterioration.

2. Inspectfueltankfillercapvacuumreliefvalveforclogging,

sticking,etc.

EC-32

Referto

CheckingHeatedOxygenSensor(HO2S)

CHECKINGPROCEDURE

Referto

, “Evaporative Emission System”.

EC-179

, “HEATED OXYGEN SENSOR 1 (FRONT)”.

NFMA0039

NFMA0039S01

MA-24

Page 25

CHASSIS AND BODY MAINTENANCE

Checking Exhaust System

SMA211A

SMA941B

Checking Exhaust System

NFMA0016

Check exhaust pipes, muffler and mounting for improper

attachment, leaks, cracks, damage, chafing or deterioration.

Checking Clutch Fluid Level and Leaks

NFMA0017

If fluid level is extremely low, check clutch system for leaks.

Checking Clutch System

NFMA0040

Check fluid lines and operating cylinder for improper attachment,

cracks, damage, loose connections, chafing and deterioration.

SMA450C

SMA066C

SMT512C

Checking M/T Oil

Check for oil leakage and oil level.

Never start engine while checking oil level.

Filler plug:

: 25 - 34 N·m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

NFMA0018

MA-25

Page 26

Changing M/T Oil

CHASSIS AND BODY MAINTENANCE

SMA067C

SMA053D

SMA051D

Changing M/T Oil

=NFMA0019

1. Drain oil from drain plug and refill with new gear oil.

2. Check oil level.

Oil grade:

API GL-4

Viscosity:

See “RECOMMENDED FLUIDS AND LUBRICANTS”,

MA-13.

Capacity:

See “RECOMMENDED FLUIDS AND LUBRICANTS”,

MA-13.

Drain plug:

: 15 - 20 N·m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

Checking A/T Fluid

NFMA0020

1. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50°C (86 to 122°F) using “COLD” range on A/T fluid

level gauge.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check fluid level with engine idling.

d. Remove A/T fluid level gauge and wipe clean with lint-free

paper.

e. Re-insert A/T fluid level gauge into charging pipe as far as it

will go.

f. Remove A/T fluid level gauge and note reading. If reading is

at low side of range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80°C (122

to 176°F) using “HOT” range on A/T fluid level gauge.

CAUTION:

Firmly fix the A/T fluid level gauge to the A/T fluid charging

pipe using a stopper attached.

MA-26

Page 27

CHASSISANDBODYMAINTENANCE

6. Checkfluidcondition.

+ Iffluidisverydarkorsmellsburned,refertoATsectionfor

checkingoperationofA/T.Flushcoolingsystemafterrepairof

A/T.

+ IfA/Tfluidcontainsfrictionalmaterial(clutches,bands,etc.),

replaceradiatorandflushcoolerlineusingcleaningsolvent

andcompressedairafterrepairofA/T.Referto

tor”.

SMA853B

Checking A/T Fluid (Cont’d)

LC-18

, “Radia-

SMA052D

ChangingA/TFluid

NFMA0021

1. WarmupA/Tfluid.

2. Stopengine.

3. DrainA/TfluidfromdrainplugandrefillwithnewA/Tfluid.

Alwaysrefillsamevolumewithdrainedfluid.

Fluidgrade:

GenuineNissanATForequivalent

Refer to “RECOMMENDED FLUIDS AND

LUBRICANTS”,MA-13.

Fluidcapacity(Withtorqueconverter):

RE4F04B/RE4F04W

9.4!(8-1/4Impqt)

Drainplug:

:29-39N·m(3.0-4.0kg-m,22-29ft-lb)

4. Runengineatidlespeedforfiveminutes.

5. Checkfluidlevelandcondition.Referto“CheckingA/TFluid”.

Iffluidisstilldirty,repeatstep2.through5.

BalancingWheels(BondingWeightType)

REMOVAL

NFMA0022

NFMA0022S01

1. Removeinnerandouterbalanceweightsfromtheroadwheel.

CAUTION:

Becarefulnottoscratchtheroadwheelduringremovalprocedures.

2. Usingreleasingagent,removedouble-facedadhesivetape

fromtheroadwheel.

CAUTION:

+ Becarefulnottoscratchtheroadwheelduringremoval.

+ Afterremovingdouble-facedadhesivetape,wipeclean

tracesofreleasingagentfromtheroadwheel.

WHEELBALANCEADJUSTMENT

NFMA0022S02

+ Ifatirebalancemachinehasadhesionbalanceweightmode

settingsanddrive-inweightmodesetting,selectandadjusta

drive-inweightmodesuitableforroadwheels.

1. Setroadwheelonwheelbalancerusingthecenterholeasa

guide.Startthetirebalancemachine.

2. Wheninnerandouterunbalancevaluesareshownonthe

wheelbalancerindicator,multiplyouterunbalancevalueby1.6

todeterminebalanceweightthatshouldbeused.Selectthe

outerbalanceweightwithavalueclosesttothecalculated

MA-27

Page 28

CHASSIS AND BODY MAINTENANCE

Balancing Wheels (Bonding Weight Type) (Cont’d)

value above and install it to the designated outer position of,

or at the designated angle in relation to the road wheel.

CAUTION:

+ Do not install the inner balance weight before installing

the outer balance weight.

+ Before installing the balance weight, be sure to clean the

mating surface of the road wheel.

Indicated unbalance value × 1.6 = balance weight to be

installed

Calculation example:

23 g (0.81 oz) × 1.6 = 38.33 g (1.35 oz) = 40 g (1.41 oz) balance weight (closer to calculated balance weight value)

Note that balance weight value must be closer to the calculated balance weight value.

Example:

37.4 = 35 g (1.23 oz)

37.5 = 40 g (1.41 oz)

SMA054D

SMA055DA

SMA056D

a. Install balance weight in the position shown in the figure at left.

b. When installing balance weight to road wheels, set it into the

grooved area on the inner wall of the road wheel as shown in

the figure at left so that the balance weight center is aligned

with the wheel balancer indication position (angle).

CAUTION:

+ Always use genuine Nissan adhesion balance weights.

+ Balance weights are unreusable; always replace with new

ones.

+ Do not install more than three sheets of balance weight.

c. If calculated balance weight value exceeds 50 g (1.76 oz),

install two balance weight sheets in line with each other (as

shown in the figure at left).

CAUTION:

Do not install one balance weight sheet on top of another.

3. Start wheel balancer again.

4. Install drive-in balance weight on inner side of road wheel in

the wheel balancer indication position (angle).

CAUTION:

Do not install more than two balance weights.

5. Start wheel balancer. Make sure that inner and outer residual

MA-28

Page 29

CHASSISANDBODYMAINTENANCE

Balancing Wheels (Bonding Weight Type) (Cont’d)

unbalancevaluesare10g(0.35oz)eachorbelow.

+ Ifeitherresidualunbalancevalueexceeds10g(0.35oz),

repeatinstallationprocedures.

Wheelbalance(Maximumallowableunbalance):

SMA829C

Maximumallowable

unbalance

TireRotation

Dynamic(Atrimflange) 10g(0.35oz)(oneside)

Static 20g(0.71oz)

NFMA0023

+ DonotincludetheT-typesparetirewhenrotatingthe

tires.

+ Afterrotatingthetires,adjustthetirepressure.

+ Retightenthewheelnutswhenthevehiclehasbeen

drivenfor1,000km(600miles)(alsoincasesofaflattire,

etc.).

Wheelnuts:

:98-118N·m(10.0-12.0kg-m,72-87ft-lb)

CheckingBrakeFluidLevelandLeaks

NFMA0024

Iffluidlevelisextremelylow,checkbrakesystemforleaks.

SBR451D

SBR389C

SBR404C

CheckingBrakeLinesandCables

NFMA0025

Checkbrakefluidlinesandparkingbrakecablesforimproper

attachment,leaks,chafing,abrasions,deterioration,etc.

ChangingBrakeFluid

NFMA0041

1. Drainbrakefluidfromeachairbleedervalve.

2. Refilluntilnewbrakefluidcomesoutfromeachairbleeder

valve.

Usesameprocedureasinbleedinghydraulicsystemtorefill

brakefluid.

Referto

BR-8

, “Bleeding Brake System”.

+ Refillwithrecommendedbrakefluid.

See“RECOMMENDEDFLUIDSANDLUBRICANTS”.

+ Neverreusedrainedbrakefluid.

+ Becarefulnottosplashbrakefluidonpaintedareas.

MA-29

Page 30

CHASSIS AND BODY MAINTENANCE

Checking Brake Booster, Vacuum Hoses, Connections and Check Valve

Checking Brake Booster, Vacuum Hoses,

Connections and Check Valve

Check vacuum lines, connections and check valve for improper

attachment, air tightness, chafing and deterioration.

NFMA0042

SMA260A

Checking Disc Brake

ROTOR

Check condition and thickness.

Unit: mm (in)

Front Rear

Brake model CLZ25VC CL9HB

Standard thickness 26 (1.02) 9 (0.35)

Maximum runout 0.07 (0.0028) 0.07 (0.0028)

Minimum thickness

(Wear limit)

CALIPER

Check for leakage.

24.0 (0.945) 8.0 (0.315)

NFMA0026

NFMA0026S01

NFMA0026S02

SMA922A

SMA847B

PAD

Check for wear or damage.

Unit: mm (in)

Brake model CLZ25VC CL9HB

Standard thickness 11 (0.43) 10 (0.39)

Minimum thickness

(Wear limit)

2.0 (0.079) 1.5 (0.059)

MA-30

NFMA0026S03

Page 31

CHASSIS AND BODY MAINTENANCE

Checking Steering Gear and Linkage

SMA654C

SST850C

Checking Steering Gear and Linkage

STEERING GEAR

NFMA0027

NFMA0027S01

+ Check gear housing and boots for looseness, damage and

grease leakage.

+ Check connection with steering column for looseness.

STEERING LINKAGE

NFMA0027S02

Check ball joint, dust cover and other component parts for

looseness, wear, damage and grease leakage.

Checking Power Steering Fluid and Lines

NFMA0028

Check fluid level in reservoir tank with engine off.

Use “HOT” range at fluid temperatures of 50 to 80°C(122 to 176°F)

or “COLD” range at fluid temperatures of 0 to 30°C (32 to 86°F).

CAUTION:

+ Do not overfill.

TM

+ Recommended fluid is type Dexron

III or equivalent.

Refer to “RECOMMENDED FLUIDS AND LUBRICANTS”,

MA-13.

+ Check lines for improper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.

+ Check rack boots for accumulation of power steering fluid.

SST851C

Lubricating Locks, Hinges and Hood Latches

NFMA0029

SMA081D

MA-31

Page 32

CHASSIS AND BODY MAINTENANCE

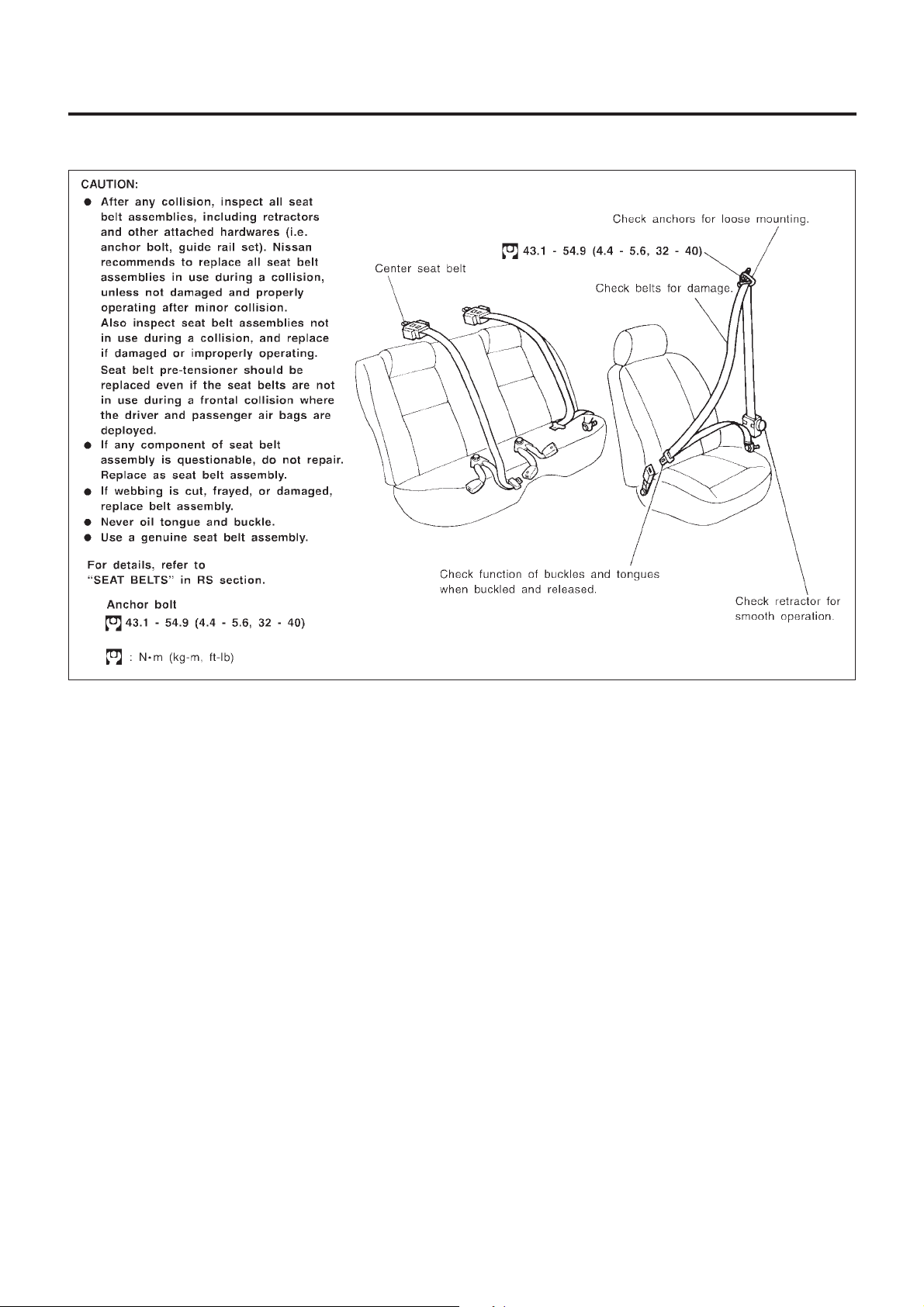

Checking Seat Belts, Buckles, Retractors, Anchors and Adjusters

Checking Seat Belts, Buckles, Retractors,

Anchors and Adjusters

NFMA0030

SMA042DA

Checking Body Corrosion

NFMA0044

Visually check body panels for corrosion, paint damage (scratches,

chipping, rubbing, etc.) or damage to the anti-corrosion materials.

In particular, check the following locations.

Hemmed panels

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear

fender, around strut tower in engine compartment, etc.

Panel edge

Trunk lid opening, sunroof opening, fender wheel-arch flange, fuel

filler lid flange, around holes in panel, etc.

Parts contact

Waist moulding, windshield moulding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping

protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair

Manual.

MA-32

Page 33

SERVICE DATA AND SPECIFICATIONS (SDS)

Engine Maintenance

BELT DEFLECTION AND TENSION

Deflection adjustment

mm (in)

Used belt

Limit After adjustment

With air conditioner compressor 7 (0.28)

Alternator

Power steering oil pump 11 (0.43)

Applied pushing force 98 N (10 kg, 22 lb)

Without air conditioner compressor

10 (0.39)

4.2 - 4.6

(0.165 - 0.181)

6.3 - 6.9

(0.248 - 0.272)

7.3-8

(0.287 - 0.315)

Engine Maintenance

NFMA0031

New belt

3.7 - 4.1

(0.146 - 0.161)

5.6 - 6.0

(0.220 - 0.236)

6.5 - 7.2

(0.256 - 0.283)

SPARK PLUG (PLATINUM-TIPPED TYPE)

Make NGK

Standard PFR5G-11

Hot PFR4G-11

Type

Cold PFR6G-11

Plug gap mm (in) 1.1 (0.043) (Nominal)

Chassis and Body Maintenance

WHEEL BALANCE

Dynamic (At rim flange) 10 g (0.35 oz) (one side)

Maximum allowable unbalance

Static 20 g (0.71 oz)

NFMA0032

NFMA0033

MA-33

Page 34

Note

SERVICE DATA AND SPECIFICATIONS (SDS)

Note

MA-34

Loading...

Loading...