Nissan Frontier General Information GI 2000 Owner's Manual

GENERAL INFORMATION

CONTENTS

GI

MA

SECTION GI

EM

LC

EC

PRECAUTIONS AND PREPARATION............................2

Supplemental Restraint System (SRS) ‘‘AIR

BAG’’............................................................................2

General Precautions....................................................3

Precautions for Multiport Fuel Injection System

or Engine Control System ...........................................5

Precautions for Three Way Catalyst............................5

Precautions for Engine Oils.........................................5

Precautions for Fuel ....................................................6

Precautions for Air Conditioning..................................6

HOW TO USE THIS MANUAL........................................7

HOW TO READ WIRING DIAGRAMS............................9

Sample/Wiring Diagram – EXAMPL –.........................9

Description.................................................................11

HOW TO CHECK TERMINAL.......................................17

Connector and Terminal Pin Kit.................................17

How to Probe Connectors .........................................17

How to Check Enlarged Contact Spring of

Terminal .....................................................................18

Waterproof Connector Inspection..............................19

Terminal Lock Inspection...........................................19

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENT ........................................20

Work Flow..................................................................20

Incident Simulation Tests...........................................21

Circuit Inspection .......................................................23

HOW TO FOLLOW TROUBLE DIAGNOSES ..............30

How To Follow Flow Charts in Trouble

Diagnoses..................................................................31

How to Follow Test Groups in Trouble Diagnoses....32

CONSULT CHECKING SYSTEM..................................35

Function and System Application..............................35

Lithium Battery Replacement ....................................35

Checking Equipment..................................................35

Loading Procedure ....................................................36

CONSULT Data Link Connector (DLC) Circuit..........36

IDENTIFICATION INFORMATION.................................37

Model Variation..........................................................37

Identification Number.................................................38

Dimensions................................................................40

Wheels and Tires.......................................................40

LIFTING POINTS AND TOW TRUCK TOWING...........41

Pantograph Jack........................................................41

Garage Jack and Safety Stand.................................42

2-pole Lift...................................................................43

Tow Truck Towing......................................................44

4-WHEEL DRIVE MODELS..................................44

Towing Point ..............................................................45

Vehicle Recovery (Freeing a stuck vehicle) .........45

TIGHTENING TORQUE OF STANDARD BOLTS ........46

SAE J1930 TERMINOLOGY LIST................................47

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL

IDX

PRECAUTIONSANDPREPARATION

Observethefollowingprecautionstoensuresafeandproper

servicing.

SupplementalRestraintSystem(SRS)‘‘AIR

BAG’’

TheSupplementalRestraintSystem‘‘AIRBAG’’,usedalongwith

aseatbelt,helpstoreducetheriskorseverityofinjurytothedriver

andfrontpassengerinafrontalcollision.TheSupplemental

RestraintSystemconsistsofairbagmodules(locatedinthecenterofthesteeringwheelandintheinstrumentpanelonthepassengerside),adiagnosissensorunit,acrashzonesensor(4WD

models),warninglamp,wiringharnessandspiralcable.

SGI646

Thevehicleisequippedwithapassengerairbagdeactivation

switch.Becausenorearseatexistswherearear-facingchild

restraintcanbeplaced,theswitchisdesignedtoturnoffthepassengerairbagsothatarear-facingchildrestraintcanbeusedin

thefrontpassengerseat.Theswitchislocatedinthecenterofthe

instrumentpanel,neartheashtray.Whentheswitchisturnedtothe

ONposition,thepassengerairbagisenabledandcouldinflatein

afrontalcollision.WhentheswitchisturnedtotheOFFposition,

thepassengerairbagisdisabledandwillnotinflateinafrontal

collision.ApassengerairbagOFFindicatorontheinstrument

panellightsupwhenthepassengerairbagisswitchedOFF.The

driverairbagalwaysremainsenabledandisnotaffectedbythe

passengerairbagdeactivationswitch.

Informationnecessarytoservicethesystemsafelyisincludedin

theRSsectionofthisServiceManual.

WARNING:

●

ToavoidrenderingtheSRSinoperative,whichcould

increasetheriskofpersonalinjuryordeathintheevent

ofacollisionwhichwouldresultinairbaginflation,all

maintenanceshouldbeperformedbyanauthorized

NISSANdealer.

●

Impropermaintenance,includingincorrectremovaland

installationoftheSRS,canleadtopersonalinjurycaused

byunintentionalactivationofthesystem.

●

Donotuseelectricaltestequipmentonanycircuitrelated

totheSRSunlessinstructedtointhisServiceManual.

SRSwiringharnessesarecoveredwithyellowinsulation

eitherjustbeforetheharnessconnectorsoronthecompleteharness,foreasyidentification.

●

Thevehicleisequippedwithapassengerairbagdeactivationswitchwhichcanbeoperatedbythecustomer.

WhenthepassengerairbagisswitchedOFF,thepassengerairbagisdisabledandwillnotinflateinafrontalcollision.WhenthepassengerairbagisswitchedON,the

passengerairbagisenabledandcouldinflateinafrontal

collision.AfterSRSmaintenanceorrepair,makesurethe

passengerairbagdeactivationswitchisinthesameposition(ONorOFF)aswhenthevehiclearrivedforservice.

GI-2

PRECAUTIONS AND PREPARATION

SGI285

SGI231

General Precautions

●

Do not operate the engine for an extended period of time

without proper exhaust ventilation.

Keep the workarea well ventilated and free ofany inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refrigerant gas, etc. When working in a pit or other enclosed area,

be sure to properly ventilate the area before working with hazardous materials.

Do not smoke while working on the vehicle.

●

Before jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting before working on the vehicle.

These operations should be done on a level surface.

●

When removing a heavy component such as the engine or

transaxle, be careful not to lose your balance and drop it. Also,

do not allow it to strike adjacent parts, especially the brake

tubes and master cylinder.

●

Before starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

SEF289H

SGI233

●

To prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

●

Before servicing the vehicle:

Protect fenders,upholstery and carpeting withappropriate covers.

Take caution that keys, bucklesor buttons do not scratchpaint.

PD

FA

RA

BR

ST

RS

BT

HA

EL

SGI234

IDX

GI-3

PRECAUTIONSANDPREPARATION

GeneralPrecautions(Cont’d)

●

Cleanalldisassembledpartsinthedesignatedliquidorsolvent

priortoinspectionorassembly.

●

Replaceoilseals,gaskets,packings,O-rings,lockingwashers,

cotterpinsandself-lockingnuts,etc.withnewones.

●

Replaceinnerandouterracesoftaperedrollerbearingsand

needlebearingsasaset.

●

Arrangethedisassembledpartsinsequencewiththeir

assembledlocations.

●

Donottouchtheterminalsofelectricalcomponentswhichuse

microcomputers(suchasECM).

Staticelectricitymaydamageinternalelectroniccomponents.

●

Afterdisconnectingvacuumorairhoses,attachatagtoindicatetheproperconnection.

●

Useonlythefluidsandlubricantsspecifiedinthismanual.

●

Useapprovedbondingagent,sealantsortheirequivalents

whenrequired.

●

Usetoolsandrecommendedspecialtoolswherespecifiedfor

safeandefficientservicerepairs.

●

Whenrepairingthefuel,oil,water,vacuumorexhaust

systems,checkallaffectedlinesforleaks.

●

Disposeofdrainedoilorthesolventusedforcleaningpartsin

anappropriatemanner.

●

Donotattempttotopoffthefueltankafterthefuelpump

nozzleshutsoffautomatically.Continuedrefuelingmaycause

fueloverflow,resultinginfuelsprayandpossiblyafire.

WARNING:

TopreventECMfromstoringthediagnostictroublecodes,do

notcarelesslydisconnecttheharnessconnectorswhichare

relatedtotheenginecontrolsystemandA/Tcontrolsystem.

Theconnectorsshouldbedisconnectedonlywhenworking

accordingtotheWORKFLOWofTROUBLEDIAGNOSESin

ECandATsections.

GI-4

PRECAUTIONS AND PREPARATION

AGI011

Precautions for Multiport Fuel Injection System or Engine Control System

●

Before connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM:

Turn ignition switch to OFF position.

Disconnect negative battery terminal; otherwise, there may be

damage to ECM.

●

Before disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

●

Be careful not to jar components such as ECM and mass air

flow sensor.

Precautions for Three Way Catalyst

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high.To prevent this, follow the

instructions below:

●

Use unleaded gasoline only. Leaded gasoline will seriously

damage the three way catalyst.

●

When checking for ignition spark or measuring engine

compression, make tests quickly and only when necessary.

●

Do not run engine when the fuel tank level is low; otherwise,

the engine may misfire causing damage to the catalyst.

Do not place the vehicle on inflammable material. Keep inflammable material off the exhaust pipe and three way catalyst.

GI

MA

EM

LC

EC

FE

CL

MT

AT

Precautions for Engine Oils

Prolonged and repeated contact with used engine oil may cause

skin cancer. Try to avoid direct skin contact with used oil.

If skin contact is made, wash thoroughly with soap or hand cleaner

as soon as possible.

HEALTH PROTECTION PRECAUTIONS

●

Avoid prolonged and repeated contact with oils, particularly

used engine oils.

●

Wear protective clothing, including oil resistant gloves when

practicable.

●

Do not put oily rags in pockets.

●

Avoid contaminating clothes, particularly underclothing, with

oil.

●

Heavily soiled clothing and oil-impregnated footwear should

not be worn. Overalls must be cleaned regularly.

●

First aid treatment should be obtained immediately for open

cuts and wounds.

●

Use barrier creams, applying them before each work period, to

help the removal of oil from the skin.

●

Wash with soap and water to ensure all oil is removed (skin

cleansers and nail brushes will help). Preparations containing

lanolin replace the natural skin oils which have been removed.

●

Do not use gasoline, kerosene, diesel fuel, gas oil, thinners or

solvents for cleaning skin.

●

If skin disorders develop, obtain medical advice without delay.

●

Where practicable, degrease components prior to handling.

●

Where there is a risk of eye contact, eye protection should be

worn, for example, chemical goggles or face shields. In

addition, an eye wash facility should be provided.

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL

IDX

GI-5

PRECAUTIONSANDPREPARATION

PrecautionsforEngineOils(Cont’d)

ENVIRONMENTALPROTECTIONPRECAUTIONS

Burningusedengineoilinsmallspaceheatersorboilerscanbe

recommendedonlyforunitsofapproveddesign.TheheatingsystemmustmeettherequirementsofHMInspectorateofPollutionfor

smallburnersoflessthan0.4MW.Ifindoubt,checkwiththe

appropriatelocalauthorityand/ormanufactureroftheapproved

appliance.

Disposeofusedoilandusedoilfiltersthroughauthorizedwaste

disposalcontractorstolicensedwastedisposalsites,ortothe

wasteoilreclamationtrade.Ifindoubt,contactthelocalauthority

foradviceondisposalfacilities.

Itisillegaltopourusedoilontheground,downsewers,drains,or

intowatersources.

Theregulationsconcerningpollutionvarybetweenregions.

PrecautionsforFuel

Useunleadedgasolinewithanoctaneratingofatleast87AKI

(Anti-KnockIndex)number(researchoctanenumber91).

CAUTION:

Usingafuelotherthanthatspecifiedcouldadverselyaffect

theemissioncontroldevicesandsystems,andcouldalso

affectthewarrantycoveragevalidity.

Undernocircumstancesshouldaleadedgasolinebeused,

sincethiswilldamagethethreewaycatalyst.

PrecautionsforAirConditioning

Useanapprovedrefrigerantrecoveryunitanytimetheairconditionersystemmustbedischarged.RefertoHAsection[‘‘HFC-134A

(R-134a)ServiceProcedure’’,‘‘SERVICEPROCEDURES’’]for

specificinstructions.

GI-6

HOW TO USE THIS MANUAL

●

AN ALPHABETICAL INDEX is provided at the end of this manual so that you can rapidly find the item

and page you are searching for.

●

A QUICK REFERENCE INDEX, a black tab (e.g., ) is provided on the first page. You can quickly find

the first page of each section by matching it to the section’s black tabs.

●

THE CONTENTS are listed on the first page of each section.

●

THE TITLE is indicated on the upper portion of each page and shows the part or system.

●

THE PAGE NUMBER of each section consists of two letters designating the particular section combined

with a number (e.g., ‘‘BR-5’’).

●

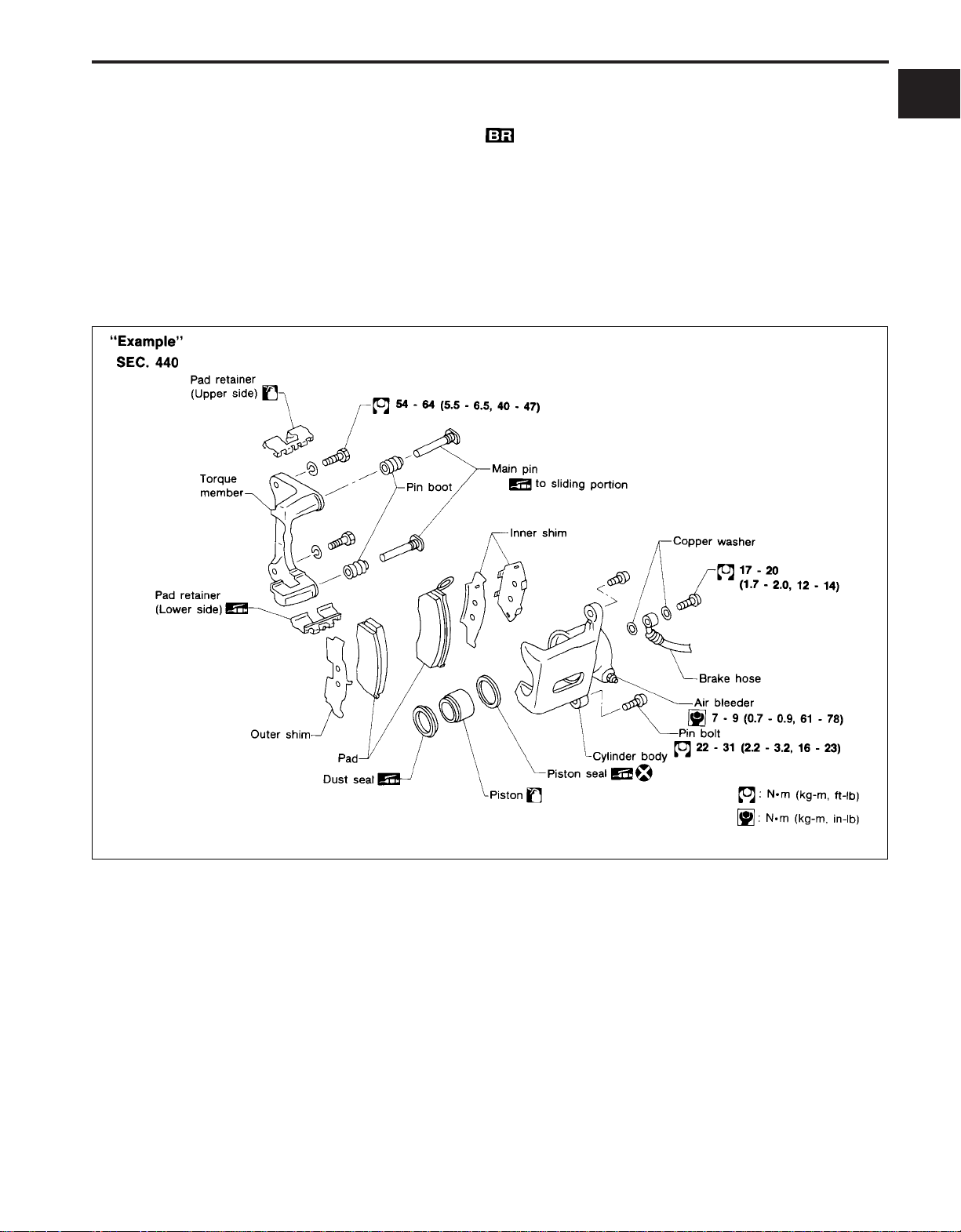

THE LARGE ILLUSTRATIONS are exploded views (see example below). These contain tightening

torques, lubrication points, section number of the PARTS CATALOG (e.g., SEC. 440) and other informa-

tion necessary to perform repairs.

The illustrations should be used in reference to service matters only. When ordering parts, refer to the

appropriate PARTS CATALOG.

GI

MA

EM

LC

EC

FE

CL

MT

AT

●

THE SMALL ILLUSTRATIONS show items not shown in the previous large illustrations. These include

important steps such as inspection points, use of special tools, hidden fasteners and special or unique

procedures.

A step-by-step format for assembly, inspection and adjustment is presented for complicated units such as

the automatic transaxle.

TF

PD

FA

RA

BR

SBR364AC

ST

RS

BT

HA

GI-7

EL

IDX

HOW TO USE THIS MANUAL

●

The following SYMBOLS AND ABBREVIATIONS are used:

, : Tightening torque

: Should be lubricated with grease.

Unless otherwise indicated, use rec-

ommended multi-purpose grease.

: Should be lubricated with oil.

: Sealing point

: Checking point

4WD : 4-Wheel Drive

2WD : 2-Wheel Drive

A/C : Air Conditioner

P/S : Power Steering

Tool : Special Service Tools

SAE : Society of Automotive Engineers,

: Always replace after every disas-

sembly.

P

: Apply petroleum jelly.

s

: Apply ATF.

SDS : Service Data and Specifications

LH, RH : Left-Hand, Right-Hand

FR, RR : Front, Rear

M/T : Manual Transaxle/Transmission

A/T : Automatic Transaxle/Transmission

●

The UNITS given in this manual are primarily expressed as the SI UNIT (International System of Unit),

ATF : Automatic Transmission Fluid

D

1

D

2

D

3

D

4

OD : Overdrive

2

2

2

1

1

2

1

1

,

Inc.

: Drive range 1st gear

: Drive range 2nd gear

: Drive range 3rd gear

: Drive range 4th gear

: 2nd range 2nd gear

: 2nd range 1st gear

: 1st range 2nd gear

: 1st range 1st gear

and alternatively expressed in the metric system and in the yard/pound system.

‘‘Example’’

Tightening torque:

59-78Nzm (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

●

TROUBLE DIAGNOSES are included in sections dealing with complicated components.

●

SERVICE DATA AND SPECIFICATIONS are contained at the end of each section for quick reference of

data.

●

The captions WARNING and CAUTION warn you of steps that must be followed to prevent personal injury

and/or damage to some part of the vehicle.

WARNING indicates the possibility of personal injury if instructions are not followed.

CAUTION indicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTS except WARNING and CAUTION give you helpful information.

GI-8

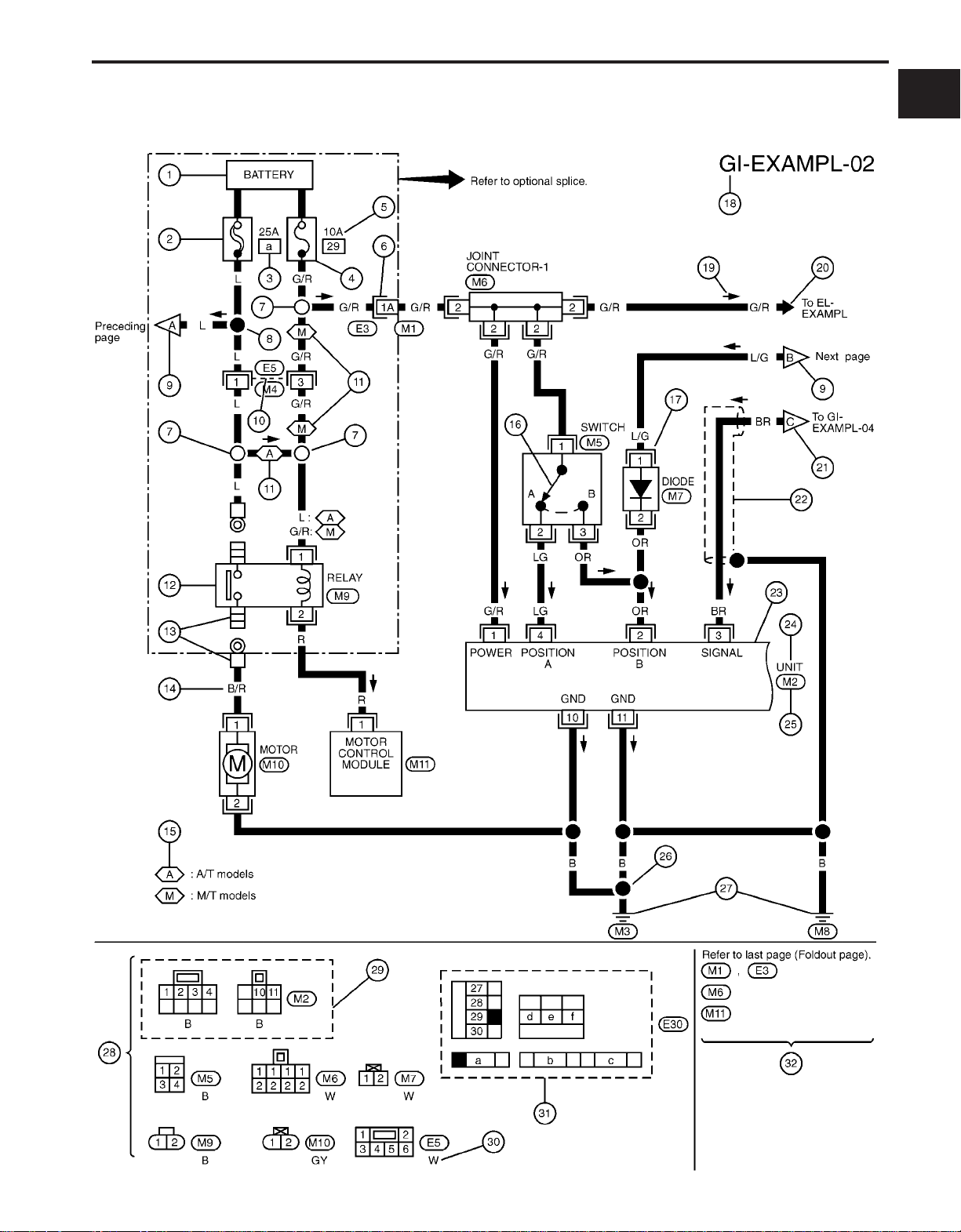

HOW TO READ WIRING DIAGRAMS

●

For Description, refer to GI-11.

Sample/Wiring Diagram – EXAMPL –

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

GI-9

EL

IDX

YGI001

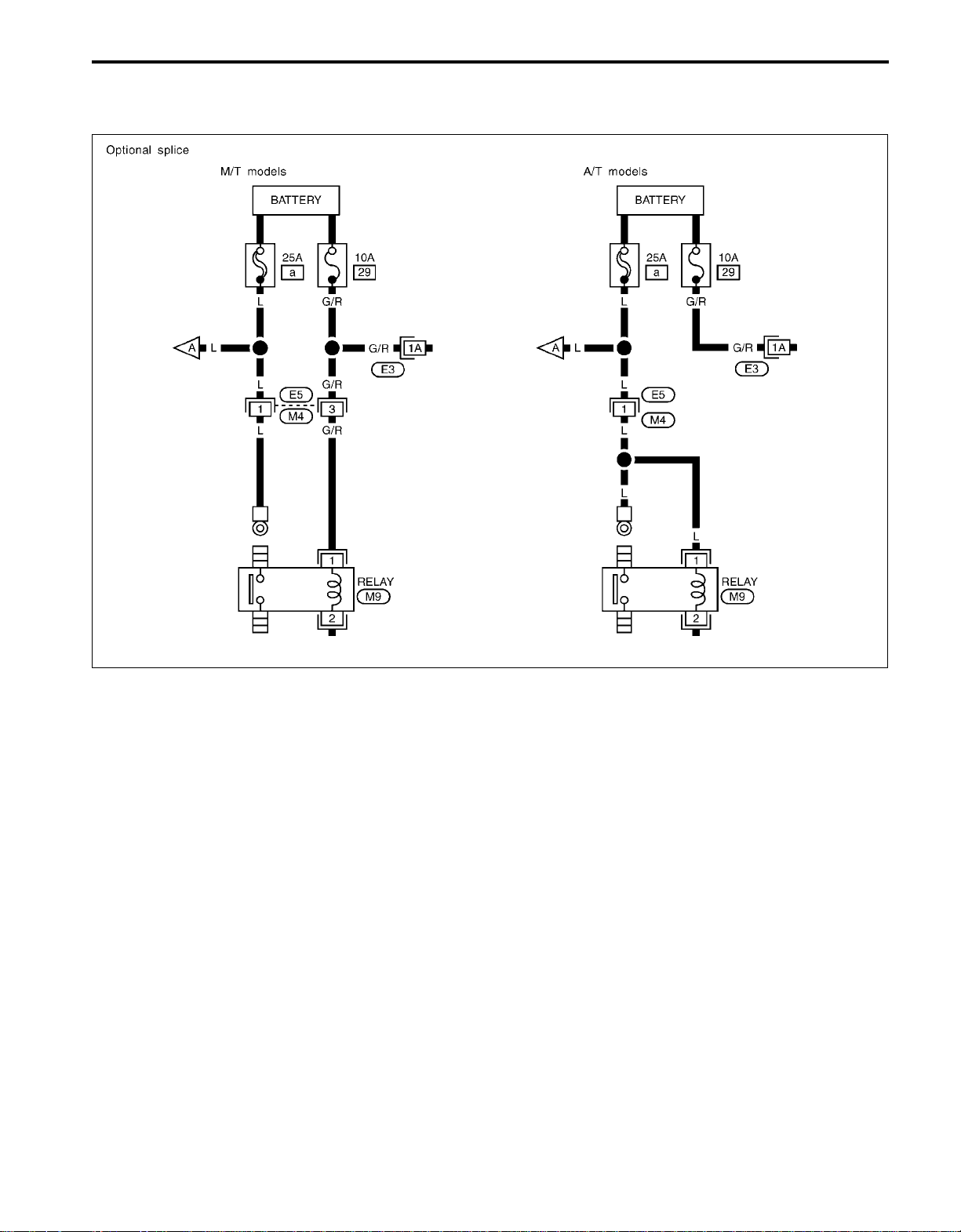

HOW TO READ WIRING DIAGRAMS

Sample/Wiring Diagram – EXAMPL – (Cont’d)

OPTIONAL SPLICE

SGI942

GI-10

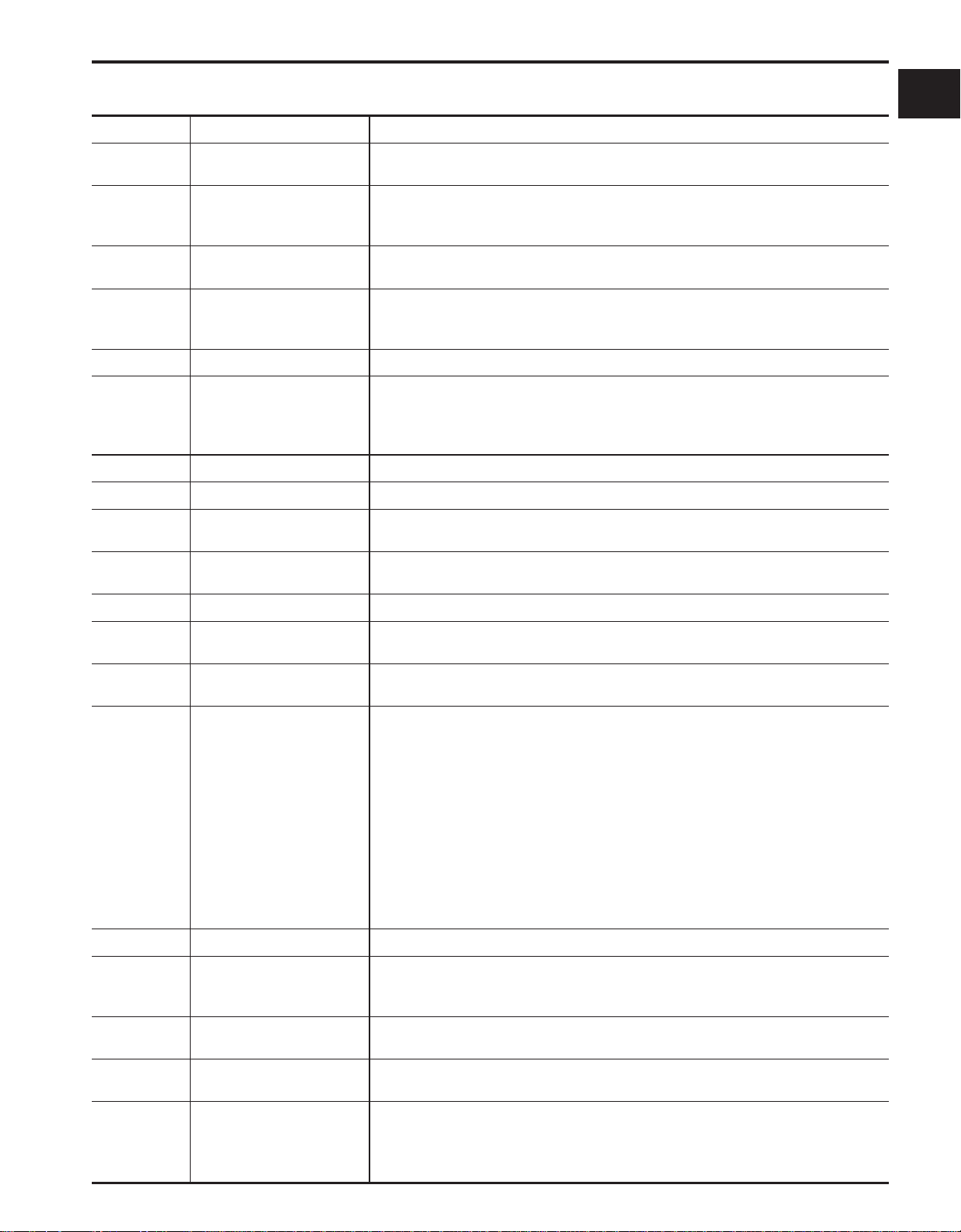

HOW TO READ WIRING DIAGRAMS

Description

Number Item Description

●

1

s

2

s

3

s

4

s

5

s

6

s

7

s

8

s

9

s

10

s

11

s

12

s

13

s

14

s

15

s

16

s

17

s

18

s

19

s

Power condition

Fusible link

Fusible link/fuse location

Fuse

Current rating

Connectors

Optional splice

Splice

Page crossing

Common connector

Option abbreviation

Relay

Connectors

Wire color

Option description

Switch

Assembly parts

Cell code

Current flow arrow

This shows the condition when the system receives battery positive voltage (can

be operated).

●

The double line shows that this is a fusible link.

●

The open circle shows current flow in, and the shaded circle shows current flow

out.

●

This shows the location of the fusible link or fuse in the fusible link or fuse box.

For arrangement, refer to EL section (‘‘POWER SUPPLY ROUTING’’).

●

The single line shows that this is a fuse.

●

The open circle shows current flow in, and the shaded circle shows current flow

out.

●

This shows the current rating of the fusible link or fuse.

●

This shows that connector

●

The G/R wire is located in the 1A terminal of both connectors.

●

Terminal number with an alphabet (1A, 5B, etc.) indicates that the connector is

SMJ connector. Refer to GI-16.

●

The open circle shows that the splice is optional depending on vehicle application.

●

The shaded circle shows that the splice is always on the vehicle.

●

This arrow shows that the circuit continues to an adjacent page.

●

The A will match with the A on the preceding or next page.

●

The dotted lines between terminals show that these terminals are part of the same

connector.

●

This shows that the circuit is optional depending on vehicle application.

●

This shows an internal representation of the relay. For details, refer to EL section

(‘‘STANDARDIZED RELAY’’).

●

This shows that the connector is connected to the body or a terminal with bolt or

nut.

●

This shows a code for the color of the wire.

B = Black BR = Brown

W = White OR = Orange

R = Red P = Pink

G = Green PU = Purple

L = Blue GY = Gray

Y = Yellow SB = Sky Blue

LG = Light Green CH = Dark Brown

When the wire color is striped, the base color is given first, followed by the stripe

color as shown below:

Example: L/W = Blue with White Stripe

●

This shows a description of the option abbreviation used on the page.

●

This shows that continuity exists between terminals

is in the A position. Continuity exists between terminals

switch is in the B position.

●

Connector terminal in component shows that it is a harness incorporated assembly.

●

This identifies each page of the wiring diagram by section, system and wiring diagram page number.

●

Arrow indicates electric current flow, especially where the direction of standard

flow (vertically downward or horizontally from left to right) is difficult to follow.

●

A double arrow ‘‘b—c’’ shows that current can flow in either direction depending

on circuit operation.

E3 is female and connectorsM1 is male.

s

DG = Dark Green

1

s

and

1

s

2

when the switch

s

3

and

s

when the

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL

IDX

GI-11

HOW TO READ WIRING DIAGRAMS

Description (Cont’d)

Number Item Description

●

20

s

21

s

22

s

23

s

24

s

25

s

26

s

27

s

28

s

29

s

30

s

31

s

32

s

System branch

Page crossing

Shielded line

Component box in wave

line

Component name

Connector number

Ground

Ground

Connector views

Common component

Connector color

Fuse and fusible link box

Reference area

This shows that the system branches to another system identified by cell code

(section and system).

●

This arrow shows that the circuit continues to another page identified by cell code.

●

The C will match with the C on another page within the system other than the

next or preceding pages.

●

The line enclosed by broken line circle shows shield wire.

●

This shows that another part of the component is also shown on another page

(indicated by wave line) within the system.

●

This shows the name of a component.

●

This shows the connector number.

●

The letter shows which harness the connector is located in.

Example: M: main harness. For detail and to locate the connector, refer to EL section (‘‘Main Harness’’, ‘‘HARNESS LAYOUT’’). A coordinate grid is included for

complex harnesses to aid in locating connectors.

●

The line spliced and grounded under wire color shows that ground line is spliced

at the grounded connector.

●

This shows the ground connection. For detailed ground distribution information,

refer to ‘‘GROUND DISTRIBUTION’’ in EL section.

●

This area shows the connector faces of the components in the wiring diagram on

the page.

●

Connectors enclosed in broken line show that these connectors belong to the

same component.

●

This shows a code for the color of the connector. For code meaning, refer to wire

color codes, number

●

This shows the arrangement of fusible link(s) and fuse(s), used for connector

views of ‘‘POWER SUPPLY ROUTING’’ in EL section.

The open square shows current flow in, and the shaded square shows current

flow out.

●

This shows that more information on the Super Multiple Junction (SMJ) and Joint

Connectors (J/C) exists on the foldout page. Refer to GI-16 for details.

14

of this chart.

s

GI-12

HOW TO READ WIRING DIAGRAMS

Description (Cont’d)

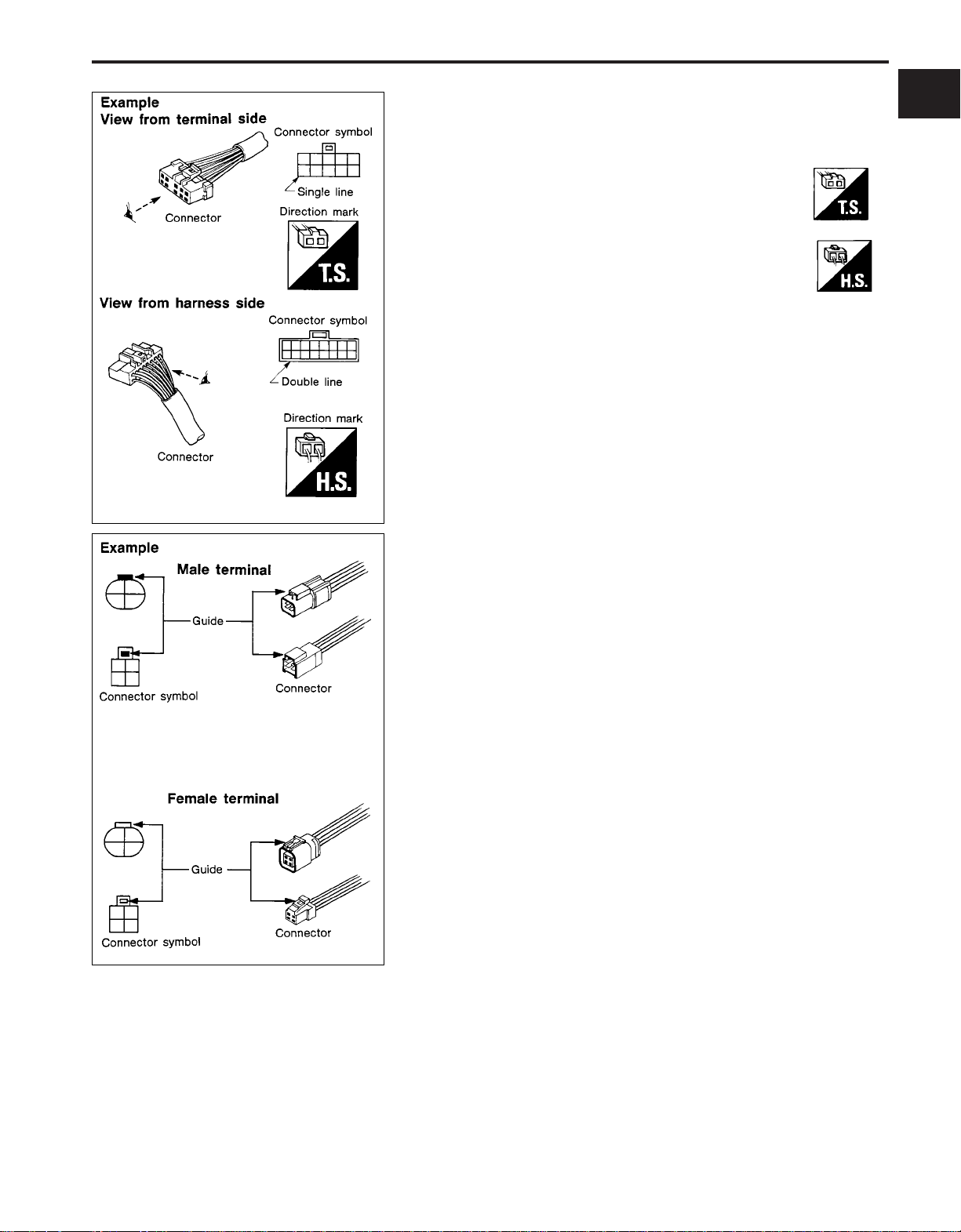

CONNECTOR SYMBOLS

Most connector symbols in wiring diagrams are shown from the

terminal side.

●

Connector symbols shown from the terminal side are enclosed

by a single line and followed by the direction mark

●

Connector symbols shown from the harness side are enclosed

by a double line and followed by the direction mark

●

Certain systems and components, especially those

related to OBD, may use a new style slide-locking type

harness connector. For description and how to

disconnect, refer to EL section, ‘‘Description’’, ‘‘HARNESS

CONNECTOR’’.

GI

MA

.

EM

.

LC

EC

FE

CL

MT

SGI364

SGI363

●

Connector guides for male terminals are shown in black.

●

Connector guides for female terminals are shown in white.

AT

TF

PD

FA

RA

BR

ST

RS

BT

GI-13

HA

EL

IDX

HOW TO READ WIRING DIAGRAMS

Description (Cont’d)

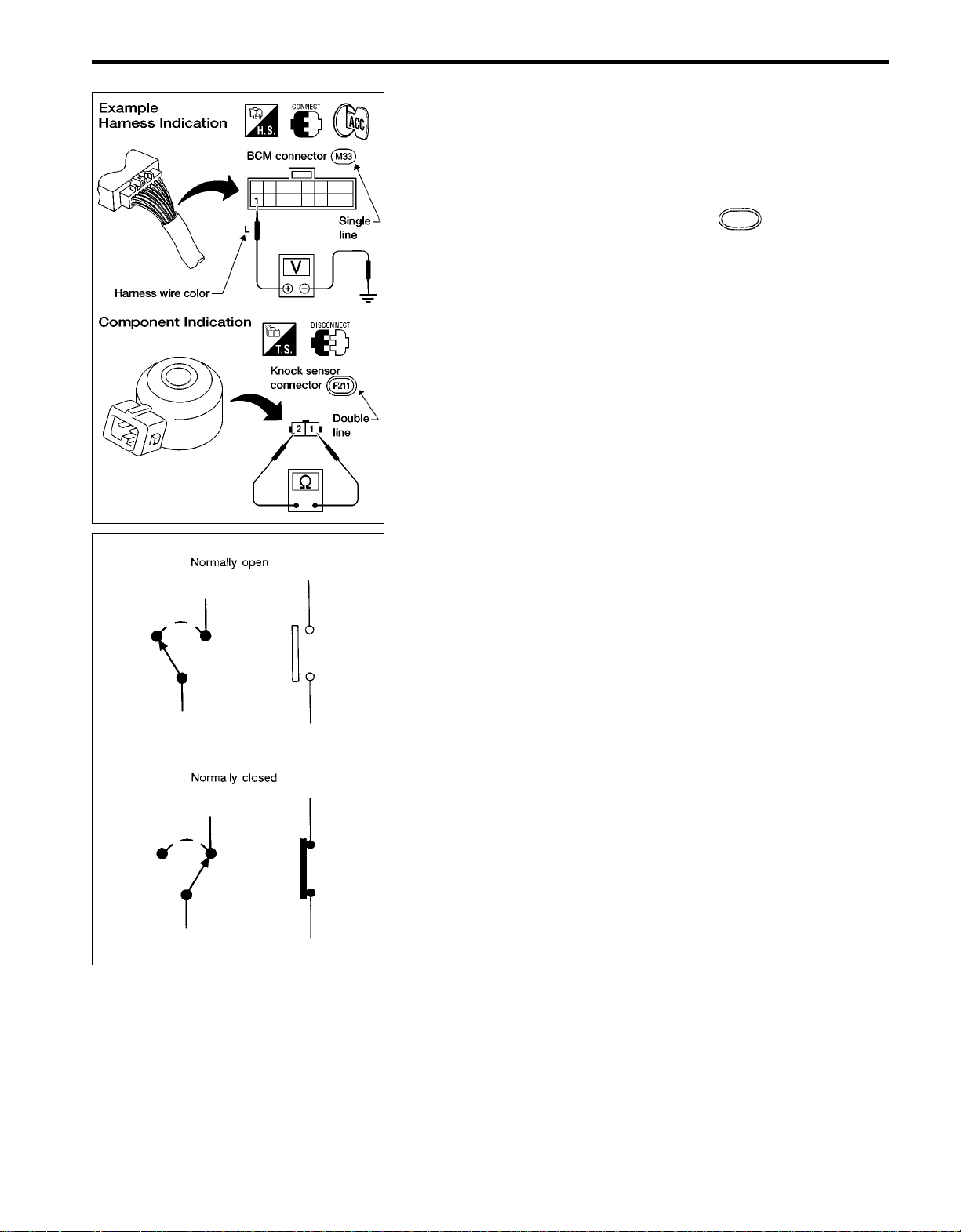

Harness indication

●

Connector numbers in a signal oval (

connectors.

●

Letter designations next to test meter probes indicate harness

(connector) wire colors.

Component indication

●

Connector numbers in a double oval (

nent connectors.

s

M33

) indicate harness

F211

) indicate compo-

AGI070

SGI860

SWITCH POSITIONS

Switches are shown in wiring diagrams as if the vehicle is in the

‘‘normal’’ condition.

A vehicle is in the ‘‘normal’’ condition when:

●

ignition switch is OFF,

●

doors, hood and trunk lid/back door are closed,

●

pedals are not depressed, and

●

parking brake is released.

GI-14

HOW TO READ WIRING DIAGRAMS

Description (Cont’d)

DETECTABLE LINES AND NON-DETECTABLE LINES

In some wiring diagrams, two kinds of lines with different thicknesses are used to represent wires.

●

A line with regular thickness (wider line) represents a ‘‘detectable line for DTC (Diagnostic Trouble Code)’’. A ‘‘detectable

line for DTC’’ is a circuit in which ECM can detect malfunctions

with the on board diagnostic system.

●

A line with less thickness (thinner line) represents a ‘‘non-detectable line for DTC’’. A ‘‘non-detectable line for DTC’’ is a

circuit in which ECM cannot detect malfunctions with the on

board diagnostic system.

GI

MA

EM

LC

EC

FE

CL

MT

AGI086

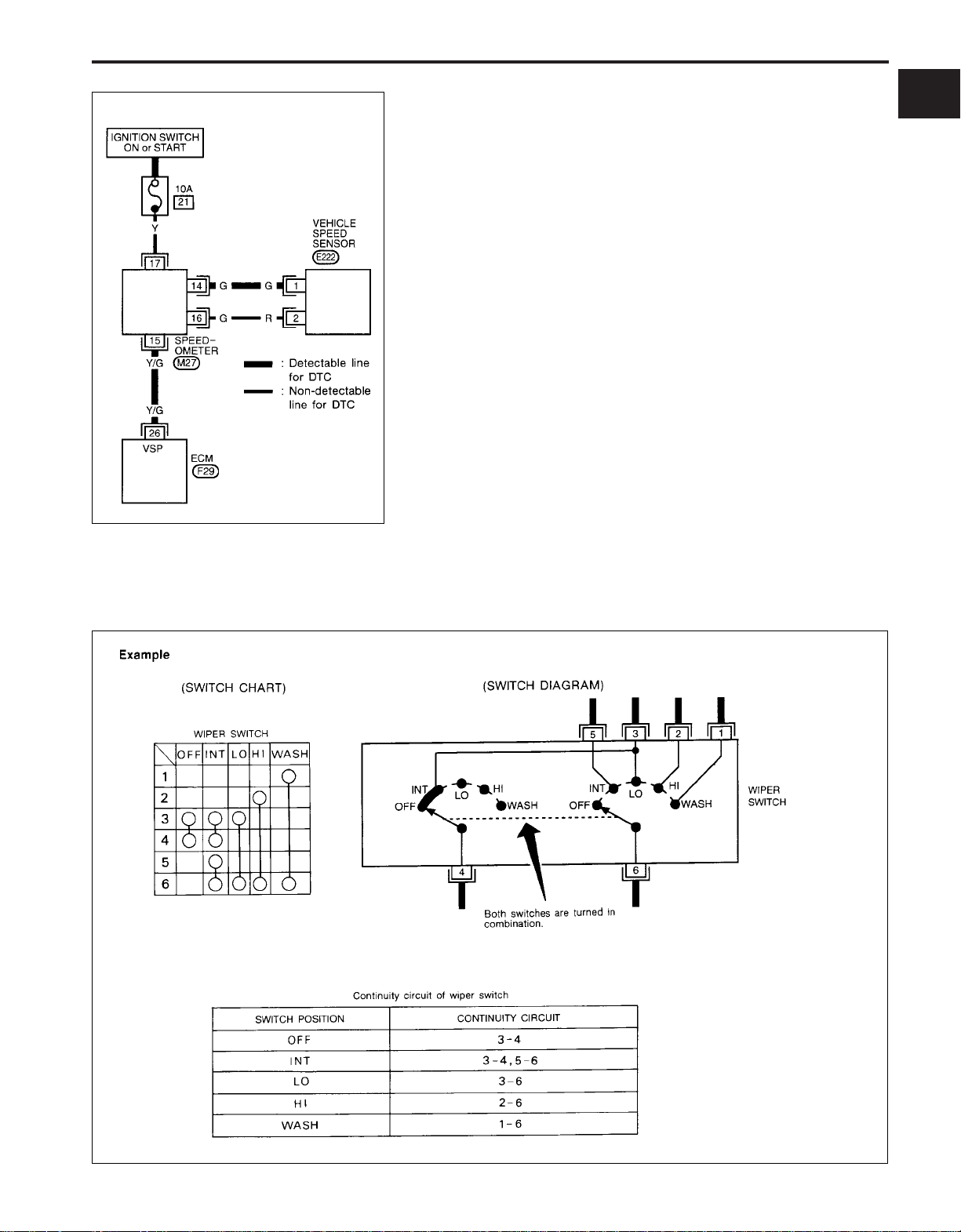

MULTIPLE SWITCH

The continuity of multiple switchis described in two ways as shown

below.

●

The switch chart is used in schematic diagrams.

●

The switch diagram is used in wiring diagrams.

AT

TF

PD

FA

RA

BR

ST

RS

GI-15

AGI033

BT

HA

EL

IDX

Loading...

Loading...