ELECTRICAL SYSTEM

SECTION EL

When you read wiring diagrams:

●

Read GI section, ‘‘HOW TO READ WIRING DIAGRAMS’’.

When you perform trouble diagnoses, read GI section, ‘‘HOW TO FOLLOW FLOW

CHART IN TROUBLE DIAGNOSES’’ and ‘‘HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT’’.

●

Check for any service bulletins before servicing the vehicle.

CONTENTS

GI

MA

EM

LC

EC

FE

CL

PRECAUTIONS AND PREPARATION............................4

Supplemental Restraint System (SRS)

‘‘AIR BAG’’...................................................................4

HARNESS CONNECTOR................................................5

Description...................................................................5

STANDARDIZED RELAY ................................................7

Description...................................................................7

POWER SUPPLY ROUTING...........................................9

Schematic....................................................................9

Wiring Diagram — POWER —..................................11

Fuse...........................................................................16

Fusible Link................................................................16

Circuit Breaker Inspection .........................................16

GROUND DISTRIBUTION.............................................17

Main Harness.............................................................17

Engine Room Harness ..............................................19

Engine Control Harness ............................................21

Generator Harness ....................................................23

BATTERY.......................................................................24

How to Handle Battery ..............................................24

Service Data and Specifications (SDS).....................27

STARTING SYSTEM .....................................................28

System Description....................................................28

Wiring Diagram — START —....................................30

Construction...............................................................32

Removal and Installation...........................................33

Pinion/Clutch Check ..................................................33

Service Data and Specifications (SDS).....................33

CHARGING SYSTEM....................................................34

System Description....................................................34

Wiring Diagram — CHARGE —................................35

Trouble Diagnoses.....................................................36

Construction...............................................................37

Removal and Installation...........................................38

Service Data and Specifications (SDS).....................38

COMBINATION SWITCH...............................................39

Check.........................................................................39

Replacement..............................................................40

STEERING SWITCH......................................................41

Check.........................................................................41

HEADLAMP...................................................................42

System Description (For USA) ..................................42

Wiring Diagram (For USA) — H/LAMP — ................43

Trouble Diagnoses.....................................................44

Bulb Replacement .....................................................45

Aiming Adjustment.....................................................45

HEADLAMP — Daytime Light System — ..................47

System Description (For Canada).............................47

Operation (For Canada) ............................................48

Schematic (For Canada) ...........................................49

Wiring Diagram (For Canada) — DTRL —...............50

Trouble Diagnoses (For Canada)..............................53

Bulb Replacement .....................................................54

Aiming Adjustment.....................................................54

PARKING, LICENSE AND TAIL LAMPS......................55

Wiring Diagram — TAIL/L —.....................................55

STOP LAMP ..................................................................57

Wiring Diagram — STOP/L —...................................57

BACK-UP LAMP............................................................58

Wiring Diagram — BACK/L —...................................58

FRONT FOG LAMP.......................................................59

System Description....................................................59

Wiring Diagram — F/FOG —....................................60

Aiming Adjustment.....................................................61

Removal and Installation...........................................62

Bulb and Lens Replacement .....................................62

TURN SIGNAL AND HAZARD WARNING LAMPS.....63

System Description....................................................63

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL

IDX

CONTENTS (Cont’d.)

Wiring Diagram — TURN — .....................................65

Trouble Diagnoses.....................................................67

Electrical Components Inspection.............................67

ILLUMINATION..............................................................68

System Description....................................................68

Wiring Diagram — ILL — ..........................................69

INTERIOR ROOM LAMP...............................................70

Component Parts and Harness Connector

Location .....................................................................70

System Description....................................................71

Wiring Diagram — ROOM/L —.................................73

Trouble Diagnoses (For models with power door

locks)..........................................................................76

SPOT LAMP ..................................................................77

Wiring Diagram — INT/L —.......................................77

METER AND GAUGES .................................................78

Component Parts and Harness Connector

Location .....................................................................78

System Description....................................................79

Unified Control Meter............................................79

How To Change The Display For Odo/Trip

Meter.....................................................................79

Combination Meter ....................................................81

With Tachometer ...................................................81

Without Tachometer ..............................................82

Wiring Diagram — METER —...................................83

Meter/gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode..........................84

Diagnosis Function................................................84

How To Alternate Diagnosis Mode........................84

Flexible Print Circuit (FPC)........................................85

Disconnect.............................................................85

Connect.................................................................85

Trouble Diagnoses.....................................................86

Preliminary Check.................................................86

Symptom Chart 1 (Malfunction is indicated in

diagnosis mode)....................................................87

Symptom Chart 2 (No malfunction is indicated

in diagnosis mode)................................................87

Power Supply And Ground Circuit Check.............88

Inspection/Vehicle Speed Sensor.........................89

Inspection/Engine Revolution Signal (Models

with tachometer)....................................................89

Inspection/Fuel Tank Gauge .................................90

Inspection/Thermal Transmitter.............................90

Electrical Components Inspection.............................91

Meter/Gauge Resistance Check...........................91

Fuel Tank Gauge Unit Check................................91

Thermal Transmitter Check...................................92

Vehicle Speed Sensor Signal Check....................92

WARNING LAMPS ........................................................93

System Description....................................................93

Schematic..................................................................95

Wiring Diagram — WARN — ....................................96

Electrical Components Inspection...........................101

A/T INDICATOR...........................................................102

Wiring Diagram — AT/IND —..................................102

WARNING CHIME .......................................................103

Component Parts and Harness Connector

Location ...................................................................103

System Description..................................................104

Wiring Diagram — CHIME —..................................106

Trouble Diagnoses...................................................108

Electrical Components Inspection...........................114

FRONT WIPER AND WASHER..................................115

System Description..................................................115

Wiring Diagram — WIPER — .................................117

Trouble Diagnoses (With intermittent wipers) .........119

Removal and Installation.........................................121

Washer Nozzle Adjustment .....................................122

Washer Tube Layout ...............................................122

HORN...........................................................................123

Wiring Diagram — HORN —...................................123

CIGARETTE LIGHTER................................................124

Wiring Diagram — CIGAR —..................................124

AUDIO..........................................................................125

System Description..................................................125

Base Audio System.............................................125

Premium Audio System.......................................125

Wiring Diagram — AUDIO —..................................126

Trouble Diagnoses...................................................129

Inspection.................................................................130

AUDIO ANTENNA .......................................................132

Fixed Antenna Rod Replacement............................132

Removal..............................................................132

Installation...........................................................132

POWER DOOR MIRROR............................................133

Wiring Diagram — MIRROR —...............................133

AUTOMATIC SPEED CONTROL DEVICE (ASCD)....134

Component Parts and Harness Connector

Location ...................................................................134

System Description..................................................135

Schematic................................................................137

Wiring Diagram — ASCD — ...................................138

Fail-Safe System Description..................................142

Fail-Safe System Check..........................................143

Trouble Diagnoses...................................................144

ASCD Wire Adjustment ...........................................152

Electrical Components Inspection...........................153

POWER WINDOW.......................................................154

System Description..................................................154

Wiring Diagram — WINDOW — .............................156

Trouble Diagnoses...................................................158

POWER DOOR LOCK.................................................159

EL-2

CONTENTS (Cont’d.)

GI

Component Parts and Harness Connector

Location ...................................................................159

System Description..................................................160

Schematic................................................................162

Wiring Diagram — D/LOCK —................................163

Trouble Diagnoses...................................................166

MULTI-REMOTE CONTROL SYSTEM .......................174

Component Parts and Harness Connector

Location ...................................................................174

System Description..................................................175

Schematic................................................................177

Wiring Diagram — MULTI —...................................178

Trouble Diagnoses...................................................181

Electrical Components Inspection...........................187

ID Code Entry Procedure ........................................188

THEFT WARNING SYSTEM .......................................189

Component Parts and Harness Connector

Location ...................................................................189

System Description..................................................191

Schematic................................................................194

Wiring Diagram — THEFT —..................................195

Trouble Diagnoses...................................................198

SMART ENTRANCE CONTROL UNIT.......................209

Description...............................................................209

Input/Output Operation Signal.................................210

Schematic................................................................211

LOCATION OF ELECTRICAL UNITS.........................213

Engine Compartment...............................................213

Passenger Compartment.........................................214

HARNESS LAYOUT....................................................216

Outline......................................................................216

How to Read Harness Layout.................................217

Main Harness...........................................................218

Engine Room Harness ............................................220

Engine Control Harness ..........................................223

Engine No. 2 Harness .............................................225

Chassis and Tail Harness........................................226

Room Lamp Harness...............................................227

Door Harness...........................................................228

Air Bag Harness ......................................................229

BULB SPECIFICATIONS ............................................230

Headlamps...............................................................230

Exterior Lamps.........................................................230

Interior Lamps..........................................................230

WIRING DIAGRAM CODES (CELL CODES).............231

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL

EL-3

IDX

PRECAUTIONS AND PREPARATION

Supplemental Restraint System (SRS) ‘‘AIR BAG’’

The Supplemental Restraint System ‘‘AIR BAG’’, used along with a seat belt, helps to reduce the risk or

severity of injury to the driver and front passenger in a frontal collision. The Supplemental Restraint System

consists of air bag modules (located in the center of the steering wheel and in the instrument panel on the

passenger side), a diagnosis sensor unit, a crash zone sensor, warning lamp, wiring harness and spiral cable.

The vehicle is equipped with a passenger air bag deactivation switch. Because no rear seat exists where a

rear-facing child restraint can be placed, the switch is designed to turn off the passenger air bag so that a

rear-facing child restraint can be used in the front passenger seat. The switch is located in the center of the

instrument panel, near the ashtray. When the switch is turned to the ON position, the passenger air bag is

enabled and could inflate in a frontal collision. When the switch is turned to the OFF position, the passenger

air bag is disabled and will not inflate in a frontal collision. A passenger air bag OFF indicator on the instrument panel lights up when the passenger air bag is switched OFF.The driver air bag always remains enabled

and is not affected by the passenger air bag deactivation switch.

Information necessary to service the system is included in the RS section of this Service Manual.

WARNING:

●

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be performed by an authorized NISSAN dealer.

●

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal injury caused by unintentional activation of the system.

●

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses are covered with yellow insulation either just before the

harness connectors or on the complete harness, for easy identification.

●

The vehicle is equipped with a passenger air bag deactivation switch which can be operated by

the customer. When the passenger air bag is switched OFF, the passenger air bag is disabled and

will not inflate in a frontal collision. When the passenger air bag is switched ON, the passenger air

bag is enabled and could inflate in a frontal collision. After SRS maintenance or repair, make sure

the passenger air bag deactivation switch is in the same position (ON or OFF) as when the vehicle

arrived for service.

EL-4

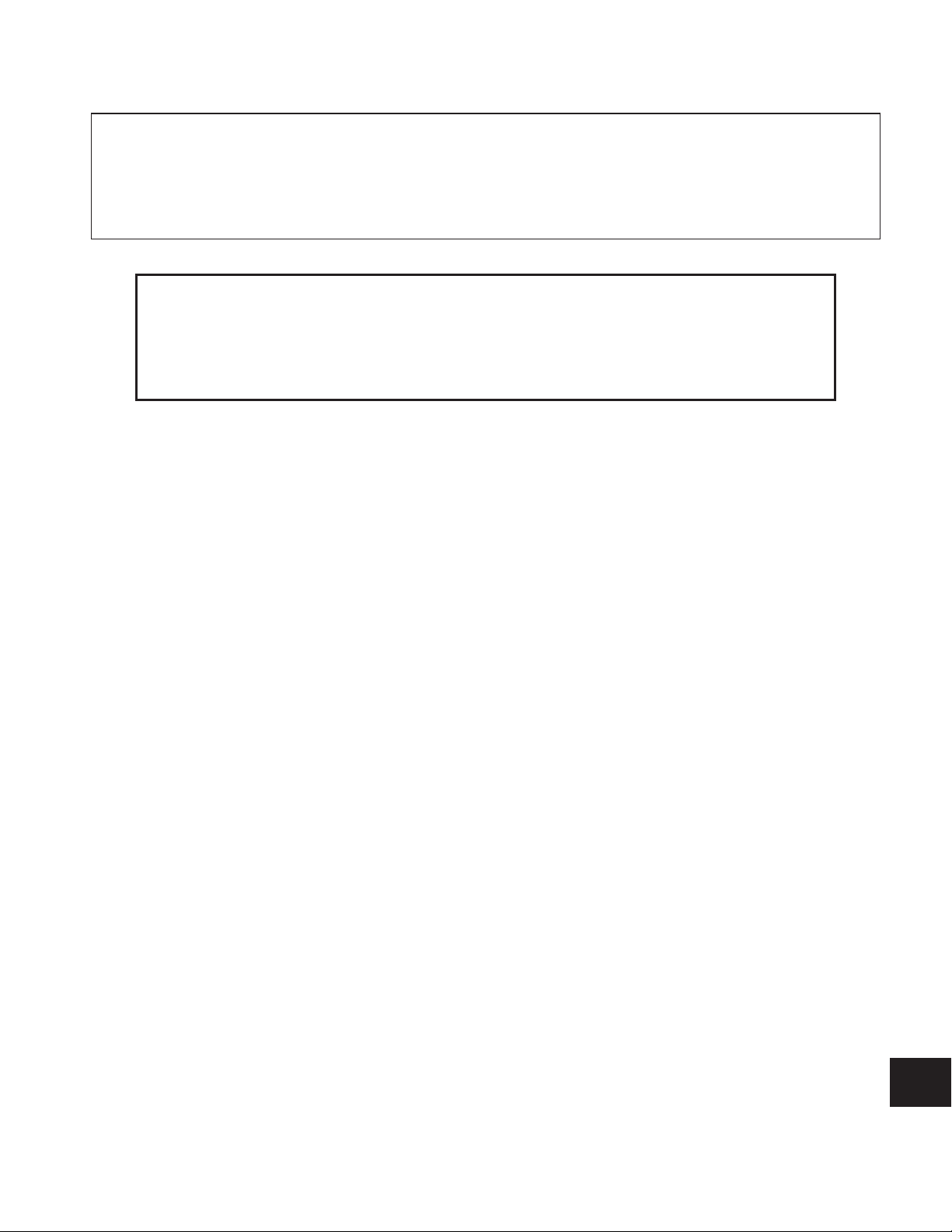

HARNESS CONNECTOR

Description

HARNESS CONNECTOR (TAB-LOCKING TYPE)

●

The tab-locking type connectors help prevent accidental looseness or disconnection.

●

The tab-locking type connectors are disconnected by pushing or lifting the locking tab(s). Refer to illustration below.

Refer to EL-6 for description of the slide-locking type connector.

CAUTION:

Do not pull the harness when disconnecting the connector.

[Example]

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-5

EL

SEL769DA

IDX

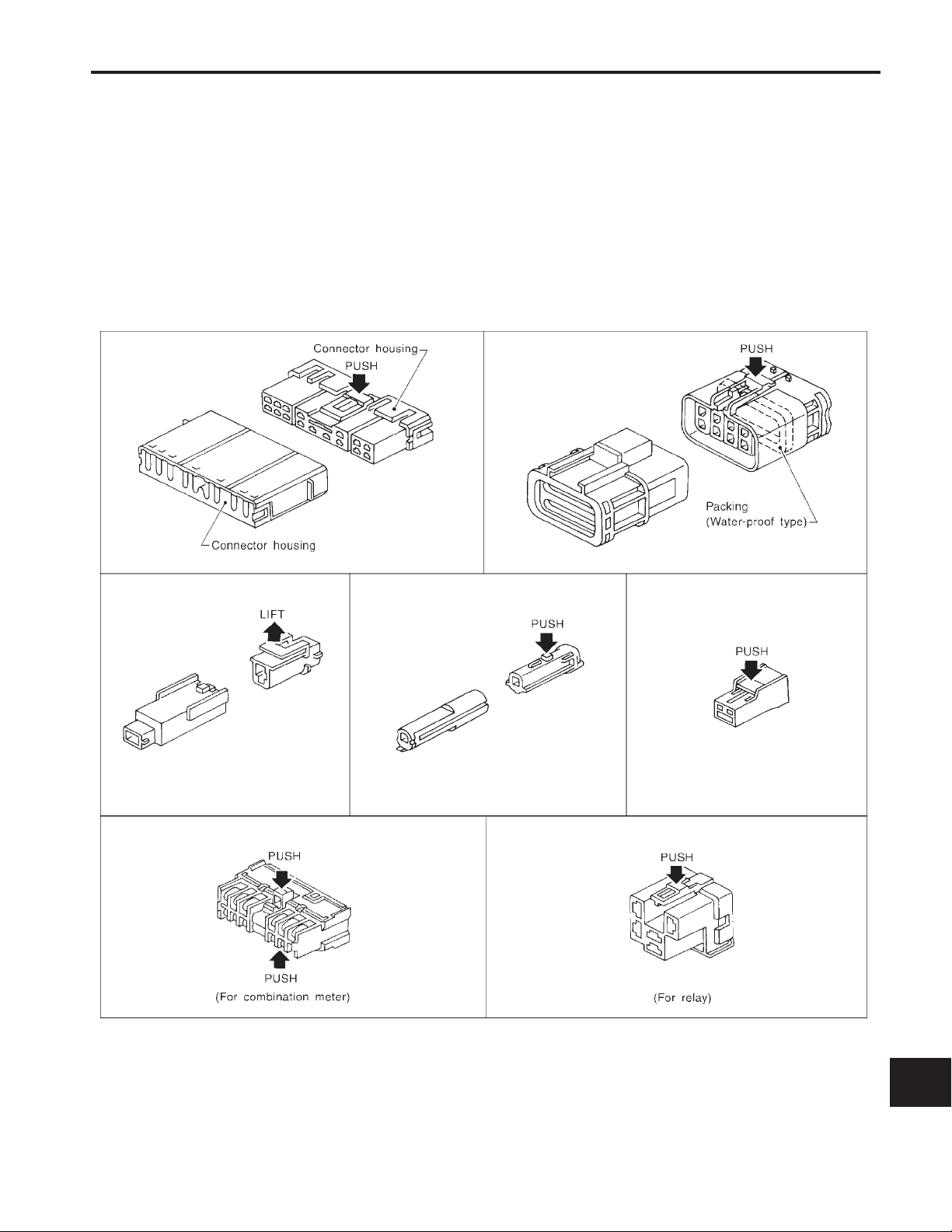

HARNESS CONNECTOR

Description (Cont’d)

HARNESS CONNECTOR (SLIDE-LOCKING TYPE)

●

A new style slide-locking connector is used on certain systems and components, especially those related

to OBD.

●

The slide-locking type connectors help pervent incomplete locking and accidental looseness or disconnection.

●

The slide-locking type connectors are disconnected by pushing or pulling the slider. Refer to illustration

below.

CAUTION:

●

Do not pull the harness or wires when disconnecting the connector.

●

Be careful not to damage the connector support bracket when disconnecting the connector.

[Example]

EL-6

AEL299C

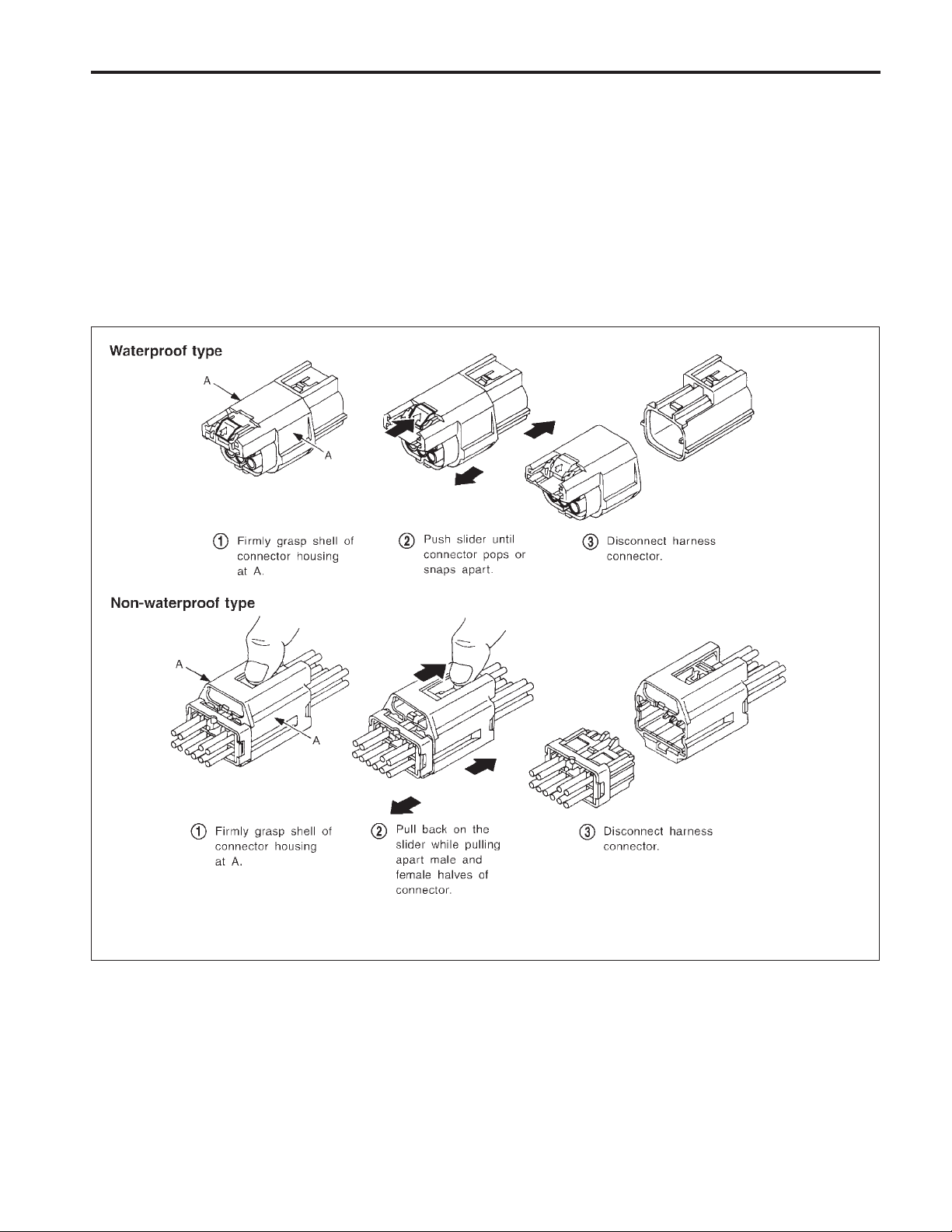

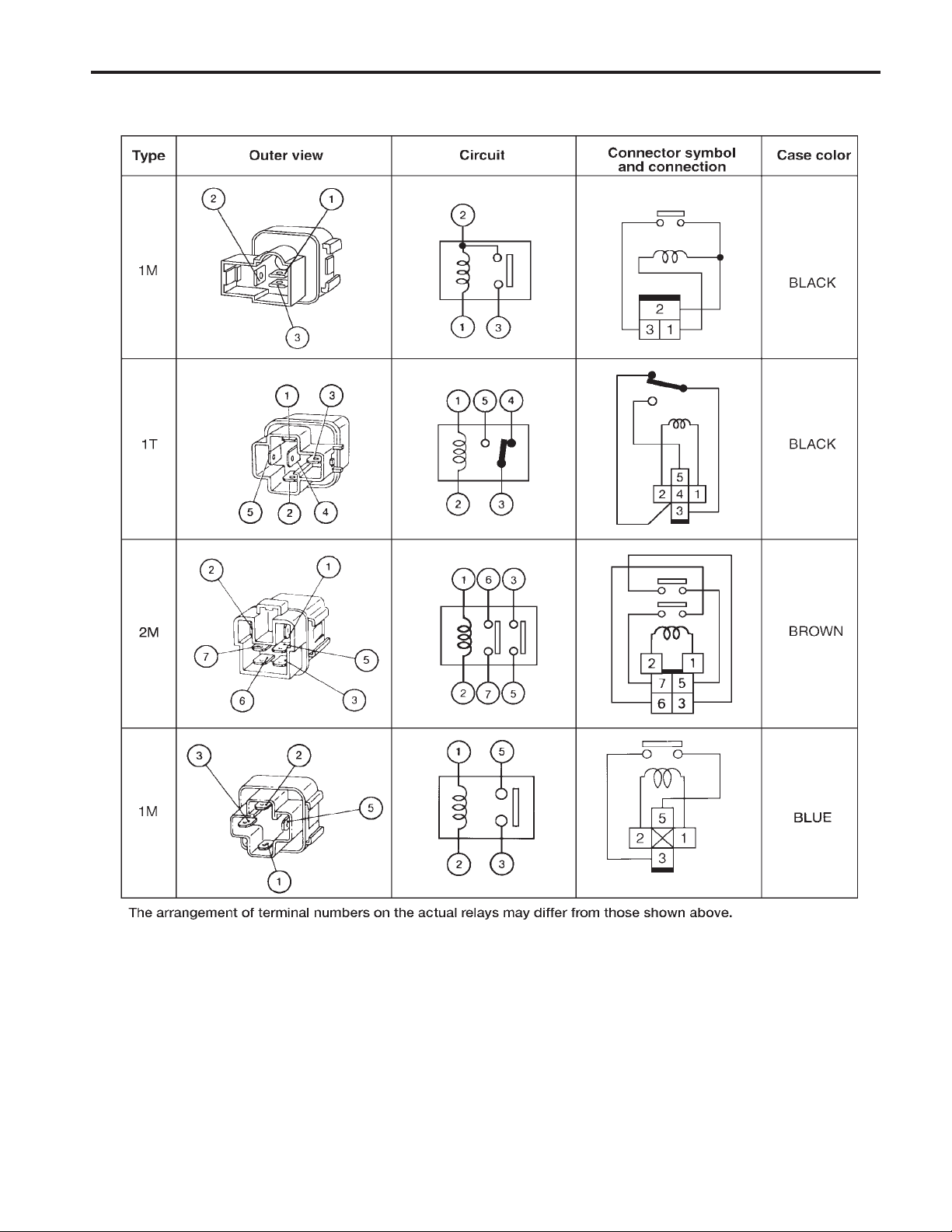

STANDARDIZED RELAY

Description

NORMAL OPEN, NORMAL CLOSED AND MIXED TYPE RELAYS

Relays can be divided into three main types: normal open, normal closed and mixed type relays.

GI

MA

EM

LC

EC

FE

CL

MT

AT

SEL881H

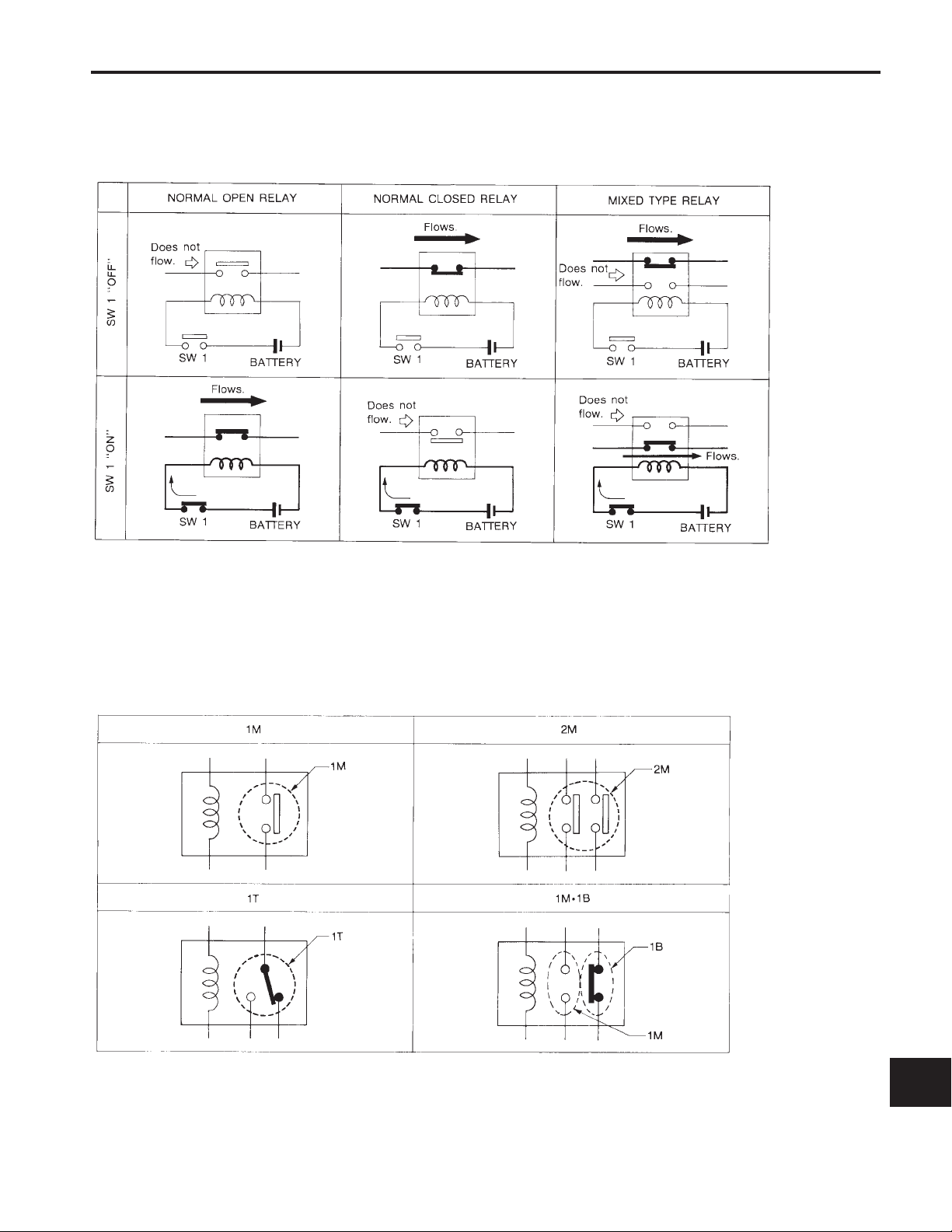

TYPES OF STANDARDIZED RELAYS

1M .................... 1 Make 2M .................... 2 Make

1T .................... 1 Transfer 1Mz1B .................... 1 Make 1 Break

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-7

SEL882H

EL

IDX

STANDARDIZED RELAY

Description (Cont’d)

EL-8

AEL672B

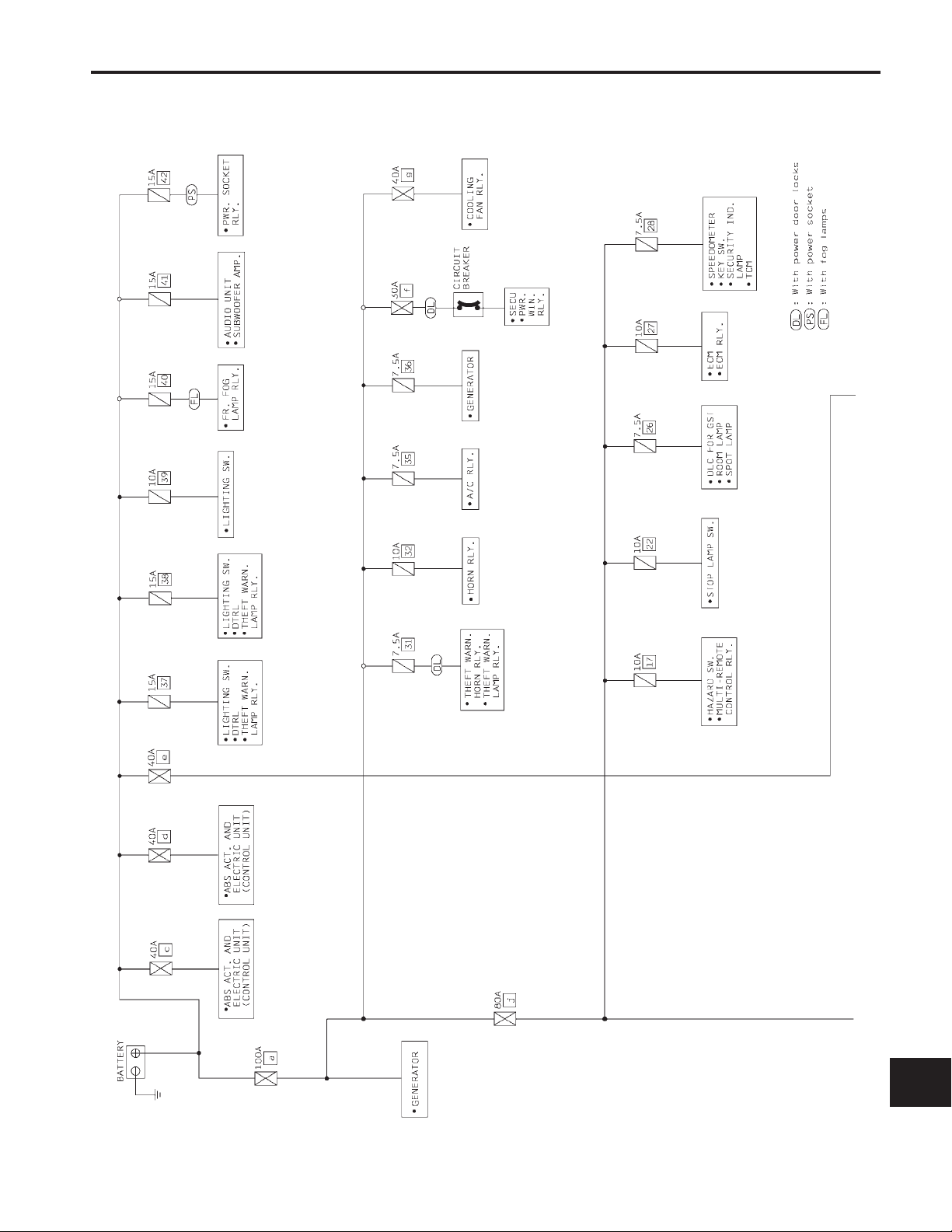

POWER SUPPLY ROUTING

Schematic

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-9

EL

IDX

AEL580C

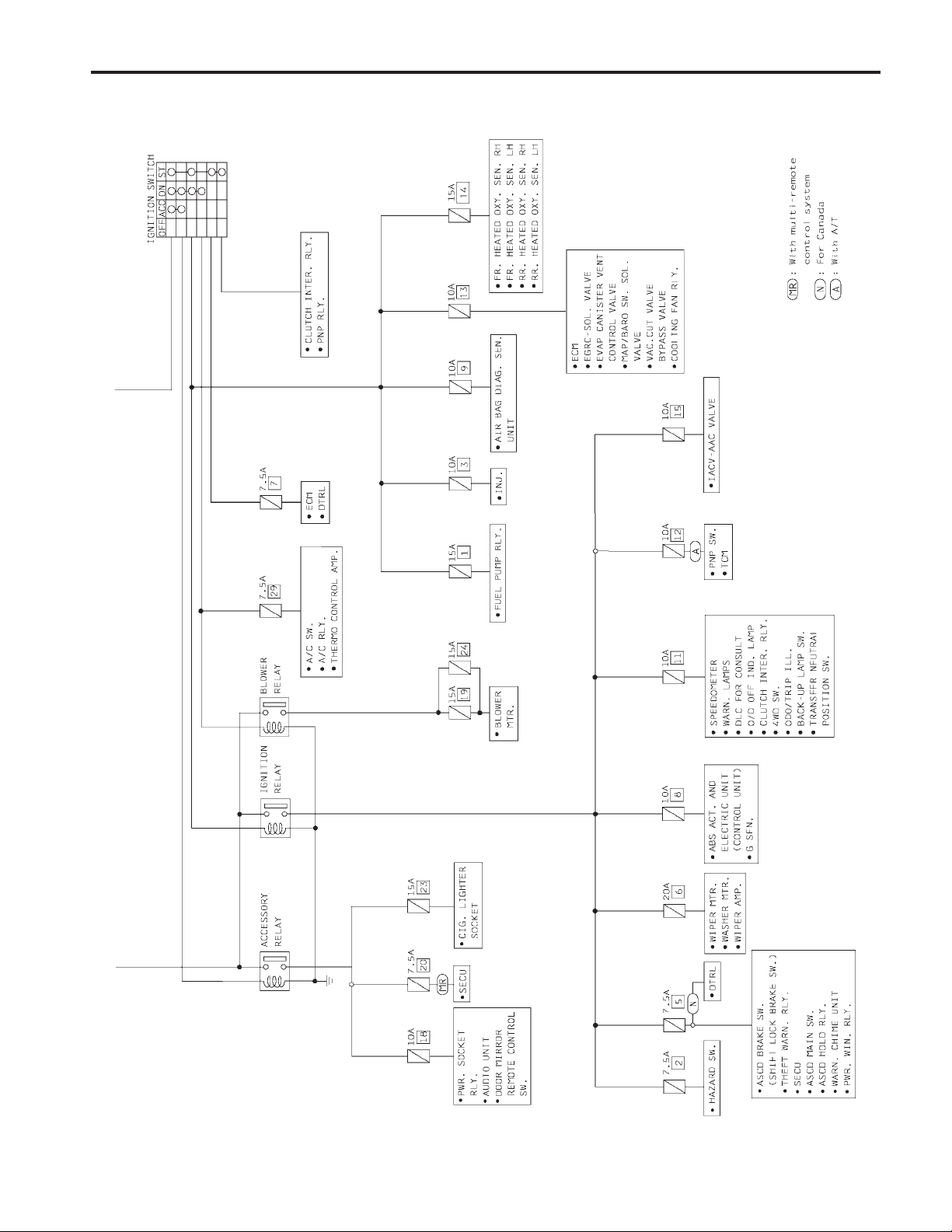

POWER SUPPLY ROUTING

Schematic (Cont’d)

EL-10

AEL581C

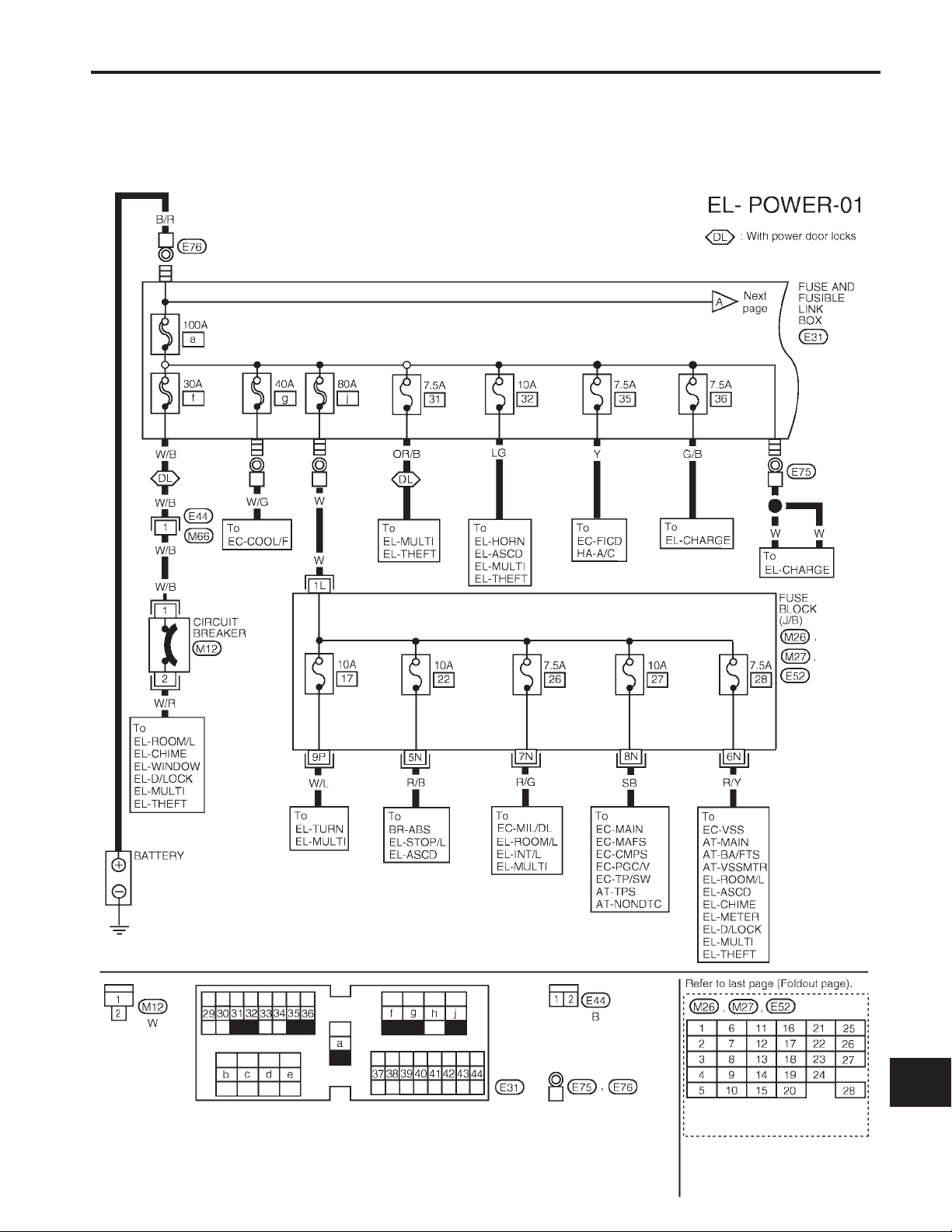

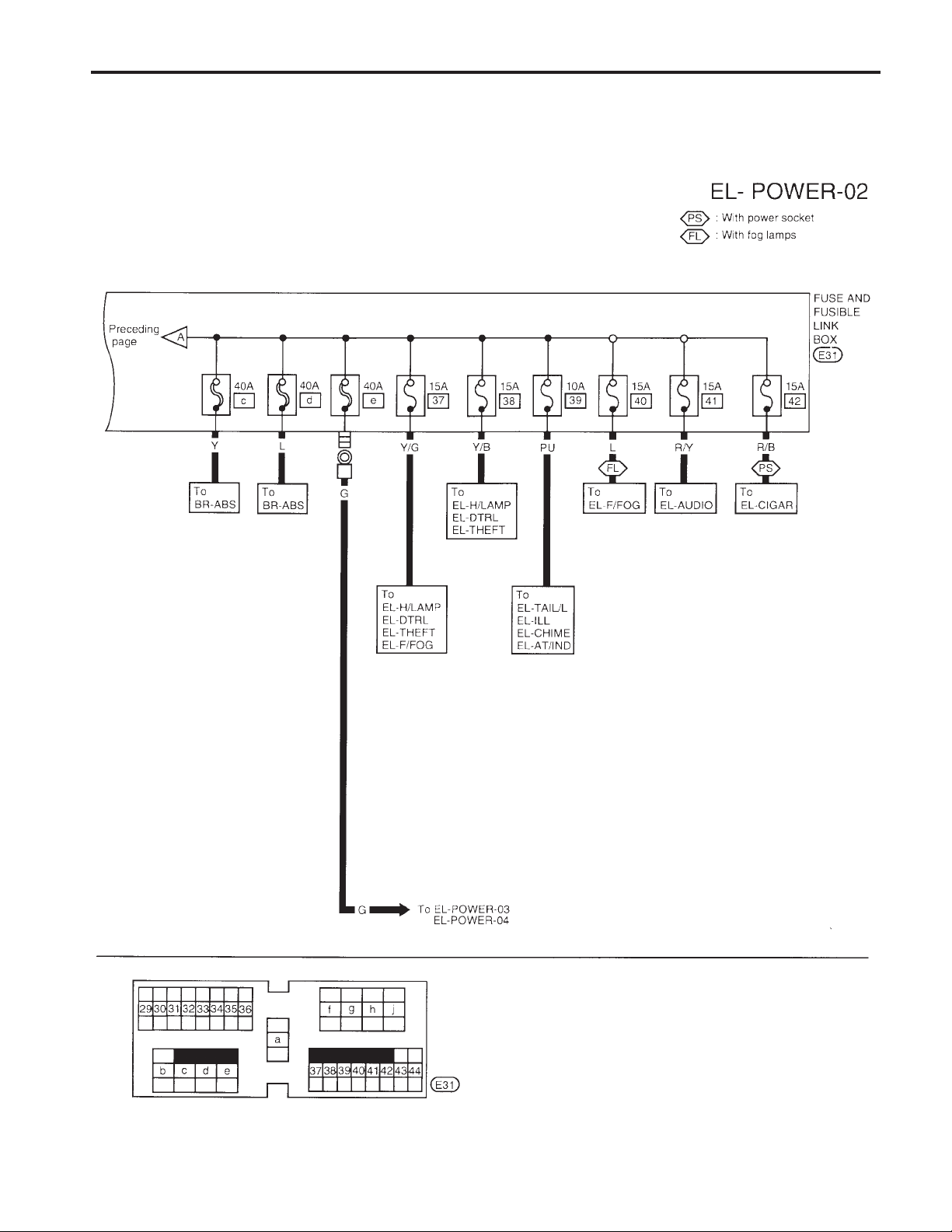

POWER SUPPLY ROUTING

Wiring Diagram — POWER —

BATTERY POWER SUPPLY – IGNITION SW IN ANY POSITION

NOTE: For detailed ground distribution information, refer to ‘‘GROUND DISTRIBUTION’’, EL-17.

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-11

EL

IDX

AEL582C

POWER SUPPLY ROUTING

Wiring Diagram — POWER — (Cont’d)

EL-12

AEL264C

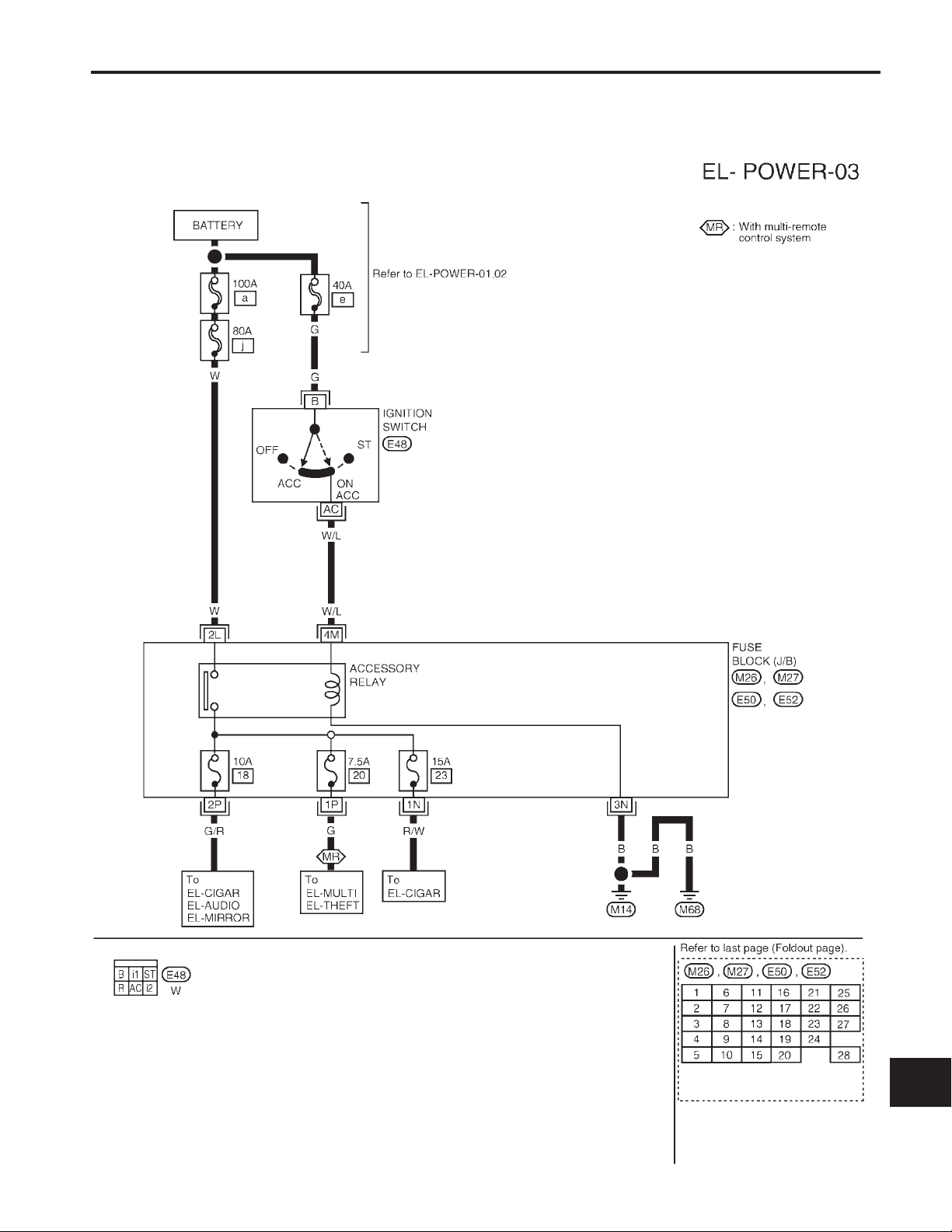

POWER SUPPLY ROUTING

Wiring Diagram — POWER — (Cont’d)

ACCESSORY POWER SUPPLY — IGNITION SW IN ‘‘ACC’’ OR ‘‘ON’’

NOTE: For detailed ground distribution information, refer to ‘‘GROUND DISTRIBUTION’’, EL-17.

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

EL-13

HA

EL

IDX

AEL265C

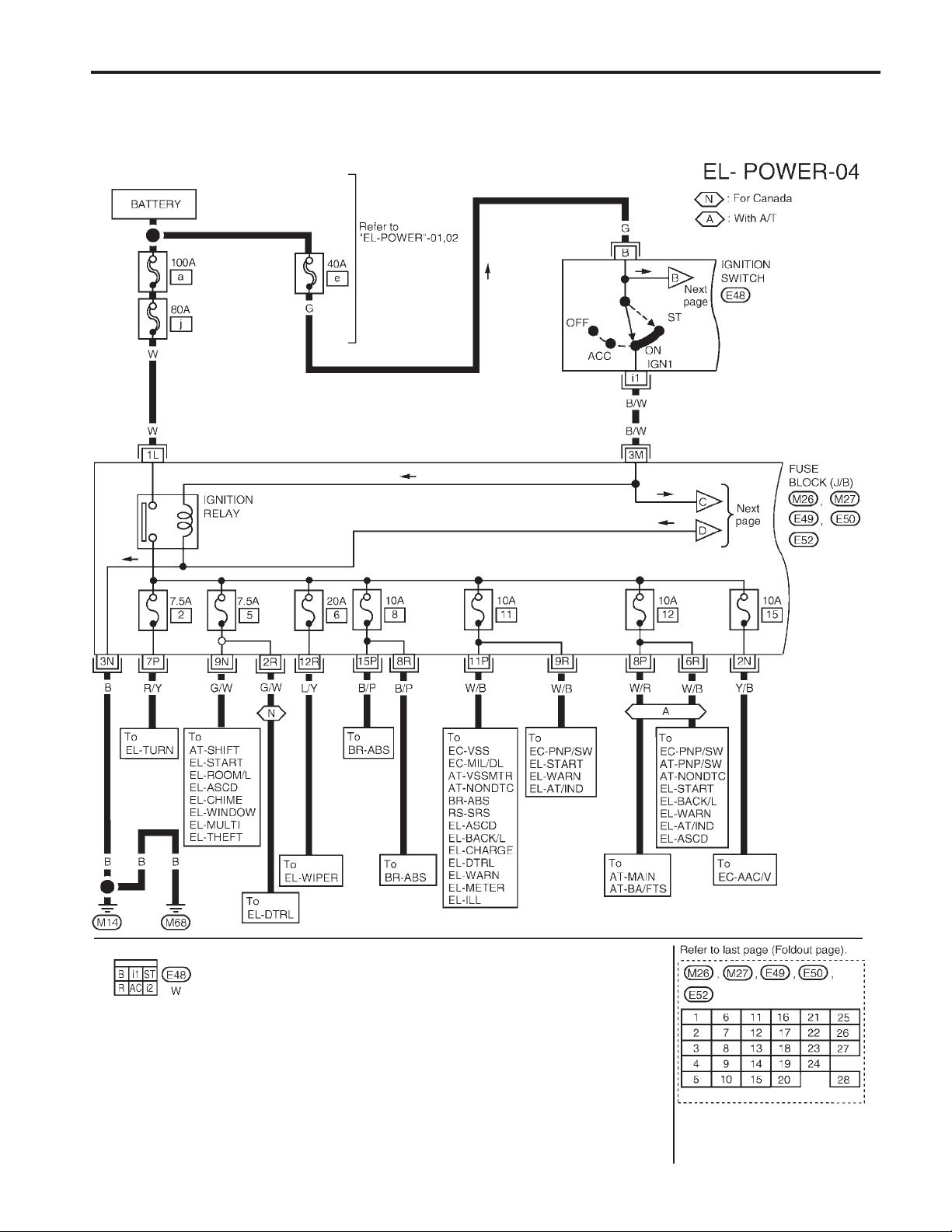

POWER SUPPLY ROUTING

Wiring Diagram — POWER — (Cont’d)

IGNITION POWER SUPPLY – IGNITION SW IN ‘‘ON’’AND/OR ‘‘START’’

NOTE: For detailed ground distribution information, refer to ‘‘GROUND DISTRIBUTION’’, EL-17.

EL-14

AEL266C

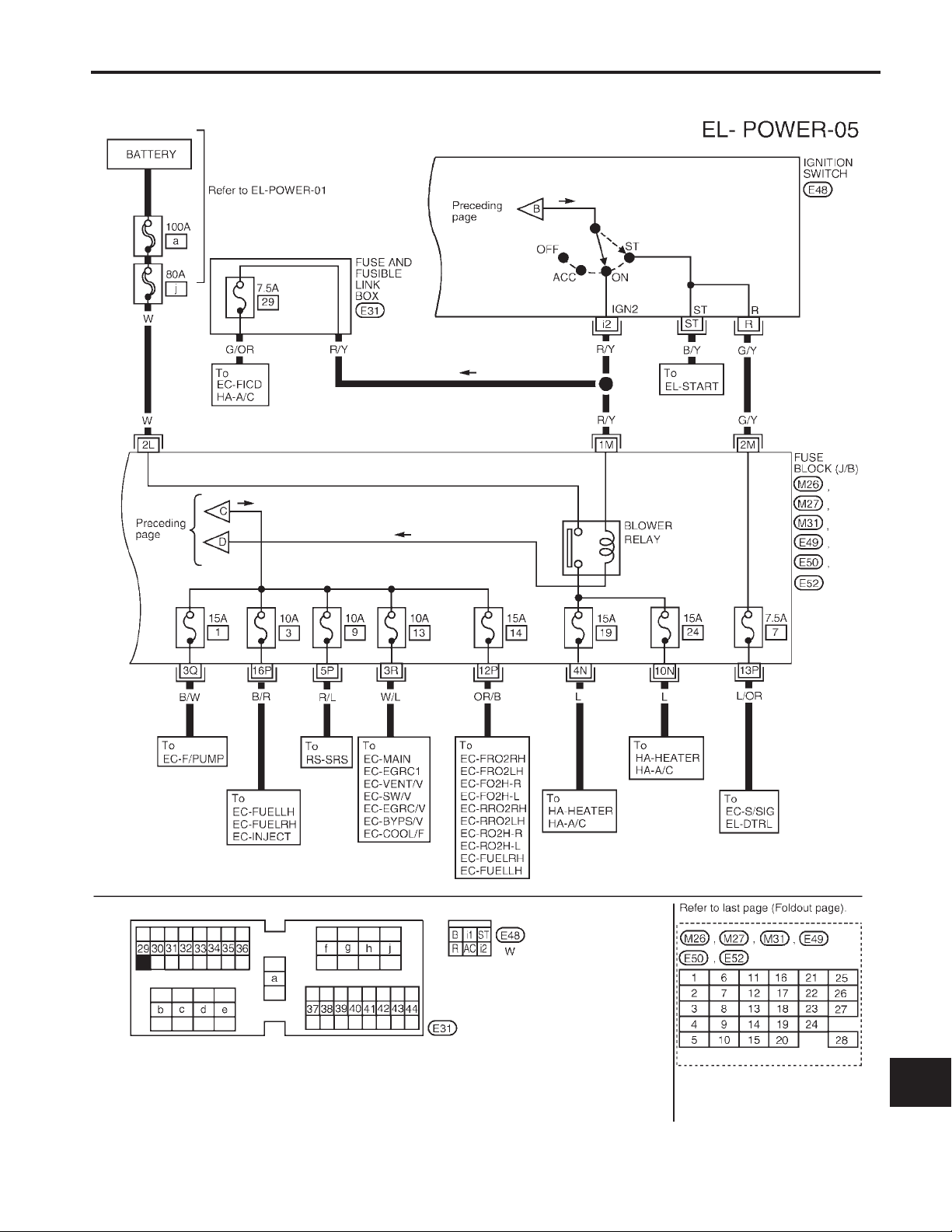

POWER SUPPLY ROUTING

Wiring Diagram — POWER — (Cont’d)

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

EL-15

HA

EL

IDX

AEL267C

POWER SUPPLY ROUTING

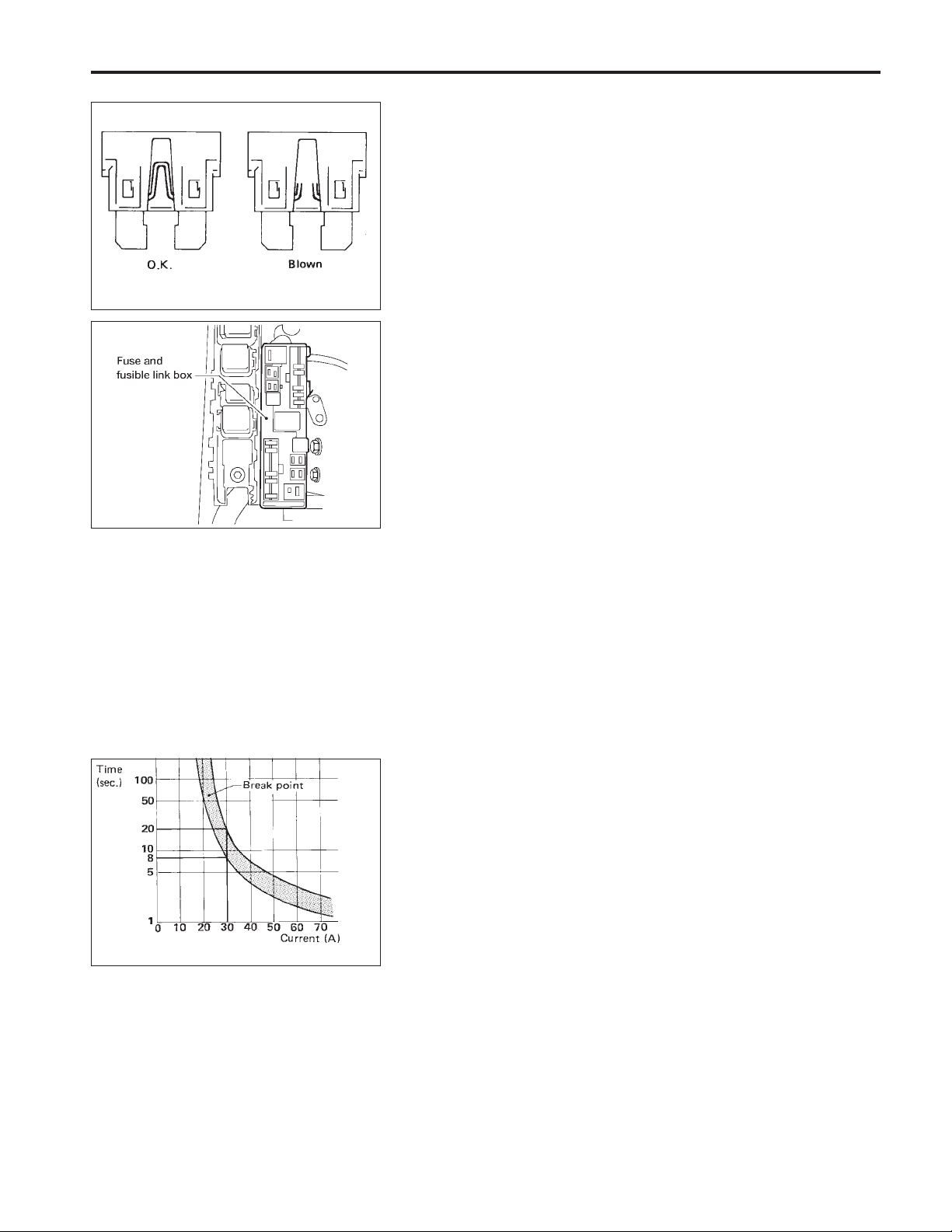

Fuse

a. If fuse is blown, be sure to eliminate cause of problem

before installing new fuse.

b. Use fuse of specified rating. Never use fuse of more than

specified rating.

c. Do not partially install fuse; always insert it into fuse

holder properly.

d. Remove fuse for ‘‘ELECTRICAL PARTS (BAT)’’ if vehicle is

not used for a long period of time.

SEL954J

Fusible Link

A melted fusible link can be detected either by visual inspection or

by feeling with finger tip. If its condition is questionable, use circuit

tester or test lamp.

CAUTION:

●

If fusible link should melt, it is possible that critical circuit

(power supply or large current carrying circuit) is shorted.

In such a case, carefully check and eliminate cause of

problem.

●

Never wrap outside of fusible link with vinyl tape. Impor-

AEL600B

tant: Never let fusible link touch any other wiring harness,

vinyl or rubber parts.

SBF284E

Circuit Breaker Inspection

For example, when current is 30A, the circuit is broken within 8 to

20 seconds.

EL-16

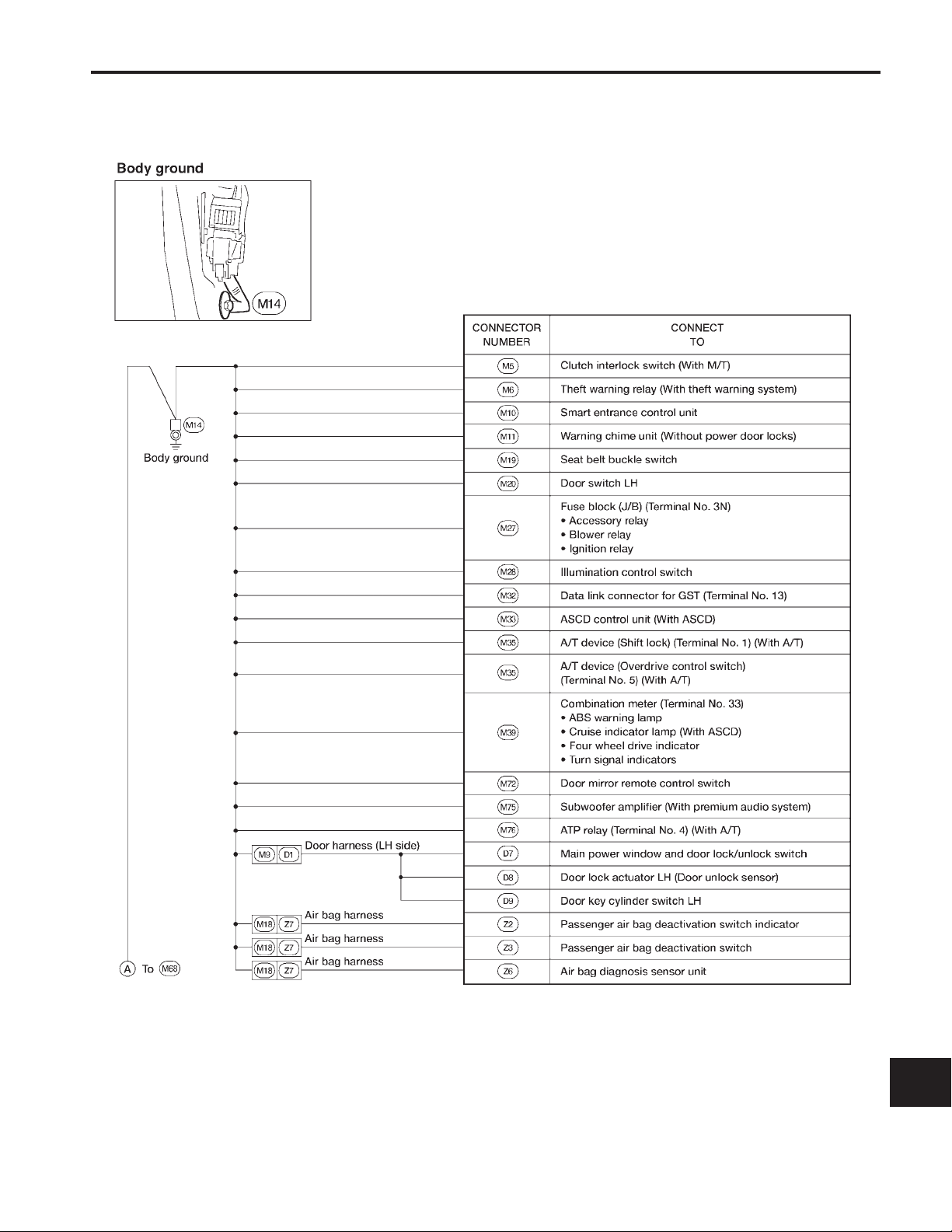

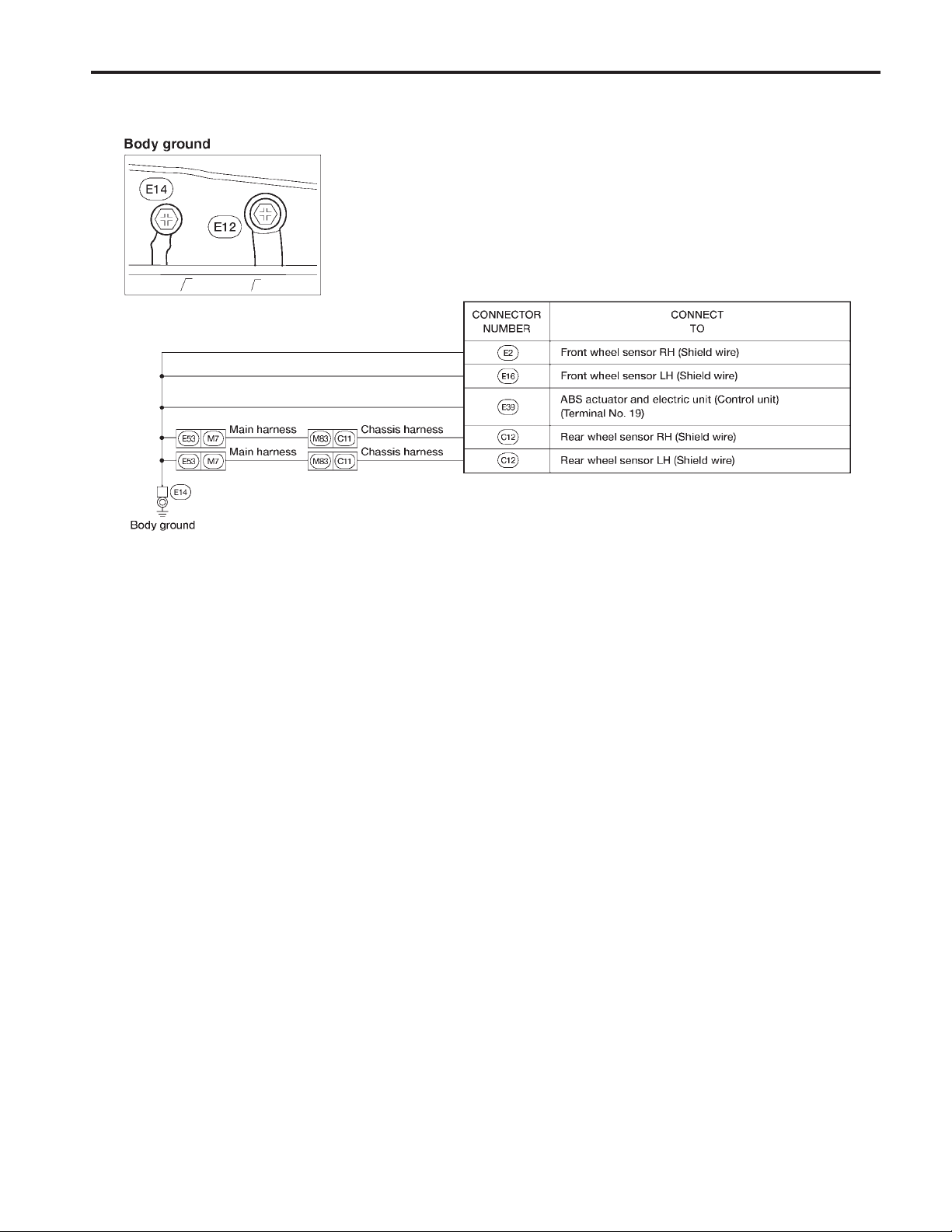

GROUND DISTRIBUTION

Main Harness

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-17

EL

IDX

AEL300C

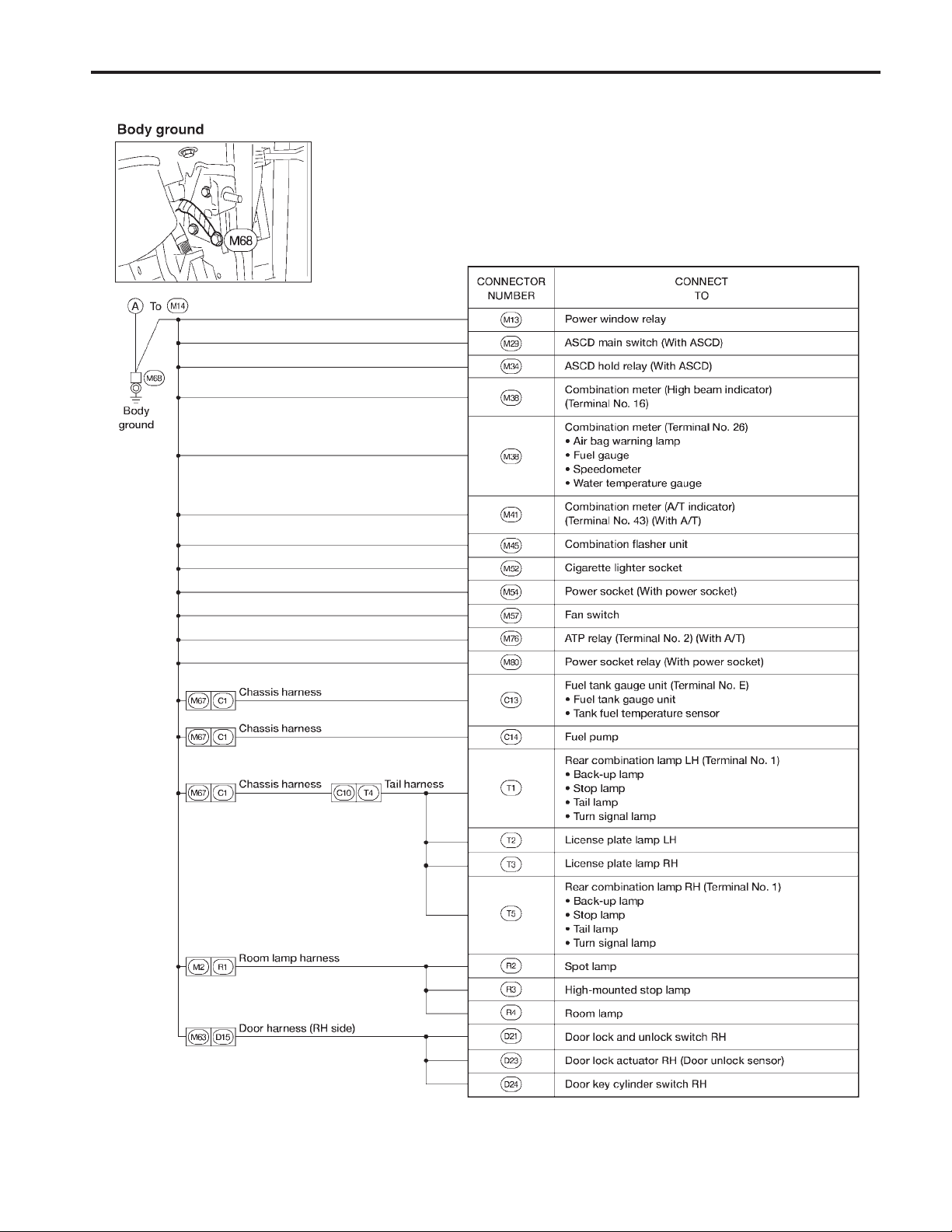

GROUND DISTRIBUTION

Main Harness (Cont’d)

EL-18

AEL301C

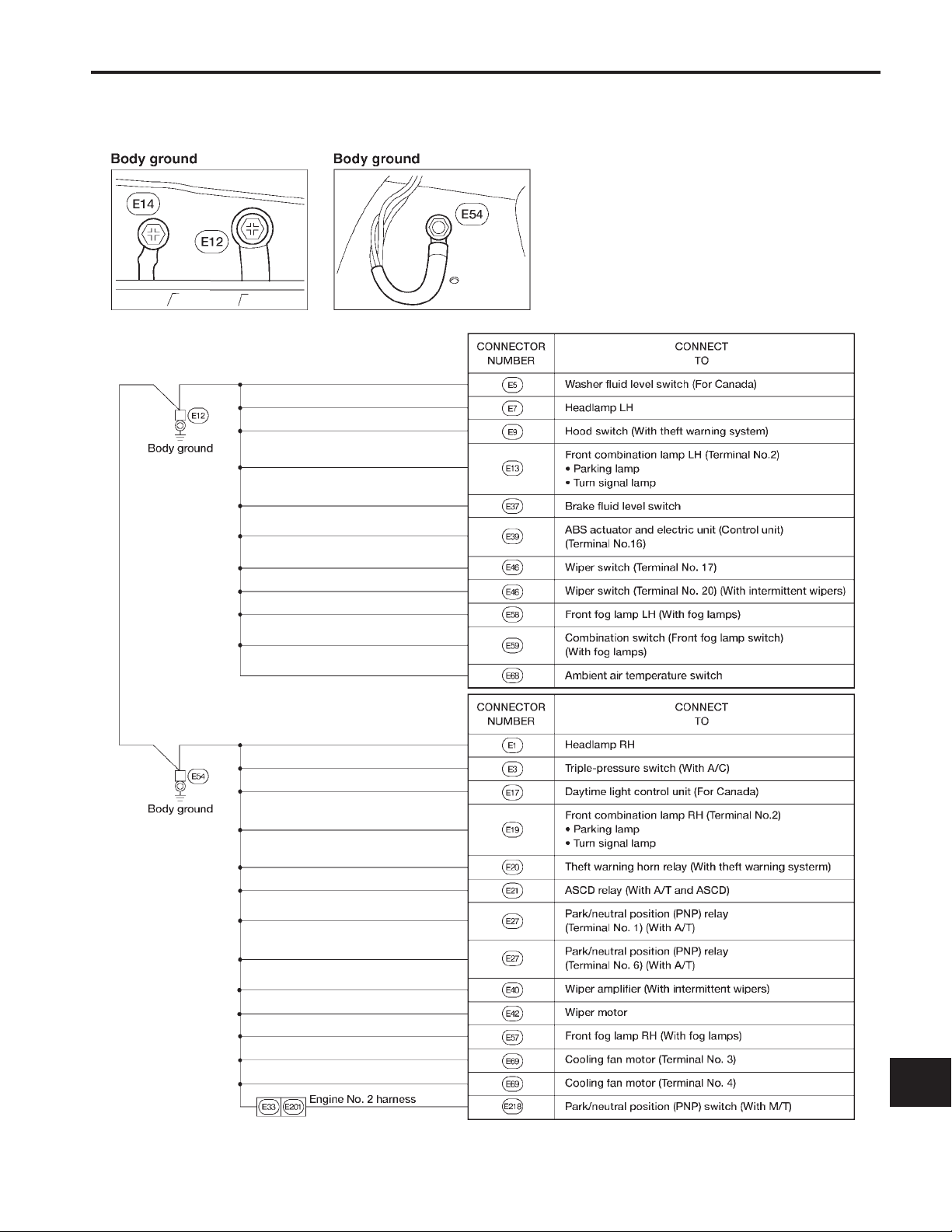

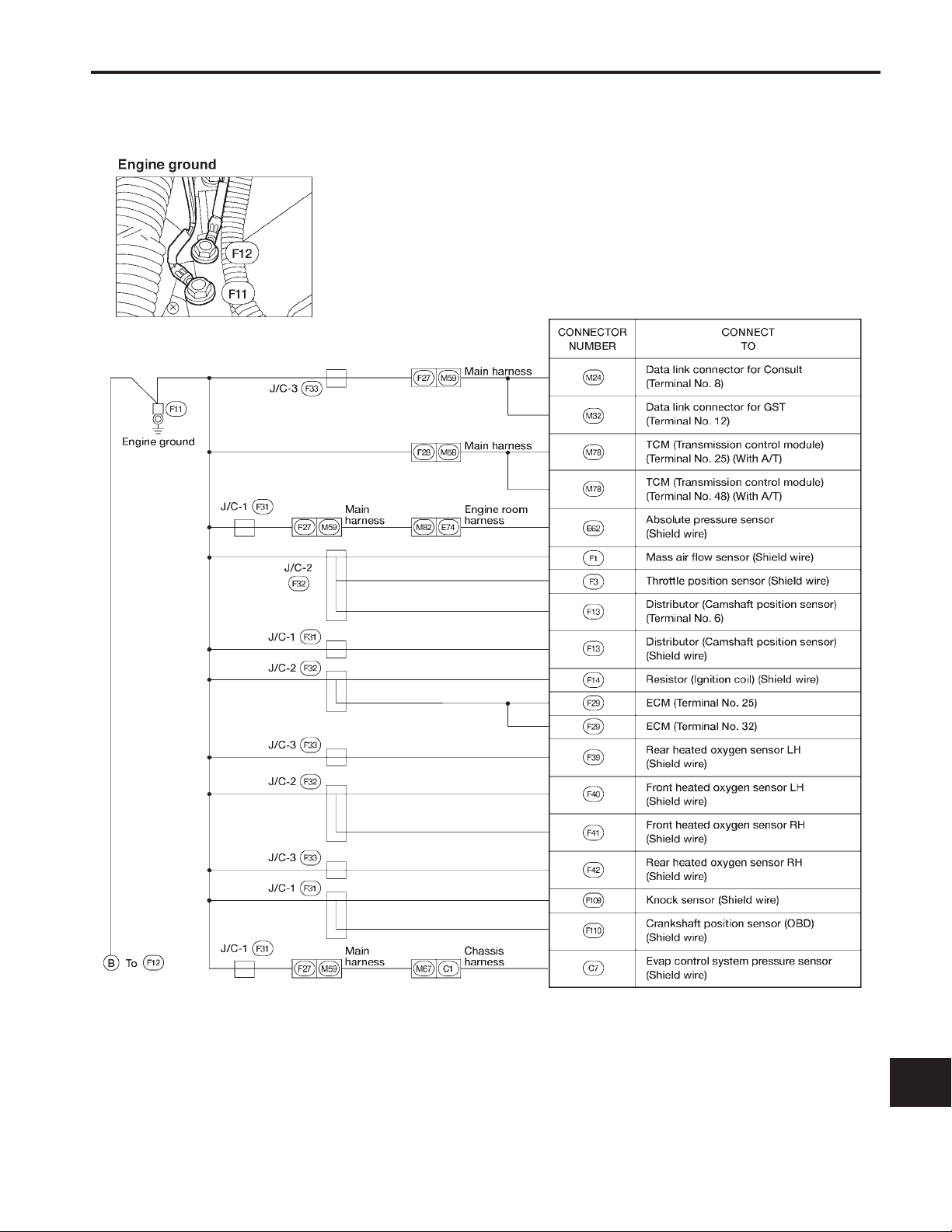

GROUND DISTRIBUTION

Engine Room Harness

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-19

EL

IDX

AEL302C

GROUND DISTRIBUTION

Engine Room Harness (Cont’d)

EL-20

AEL303C

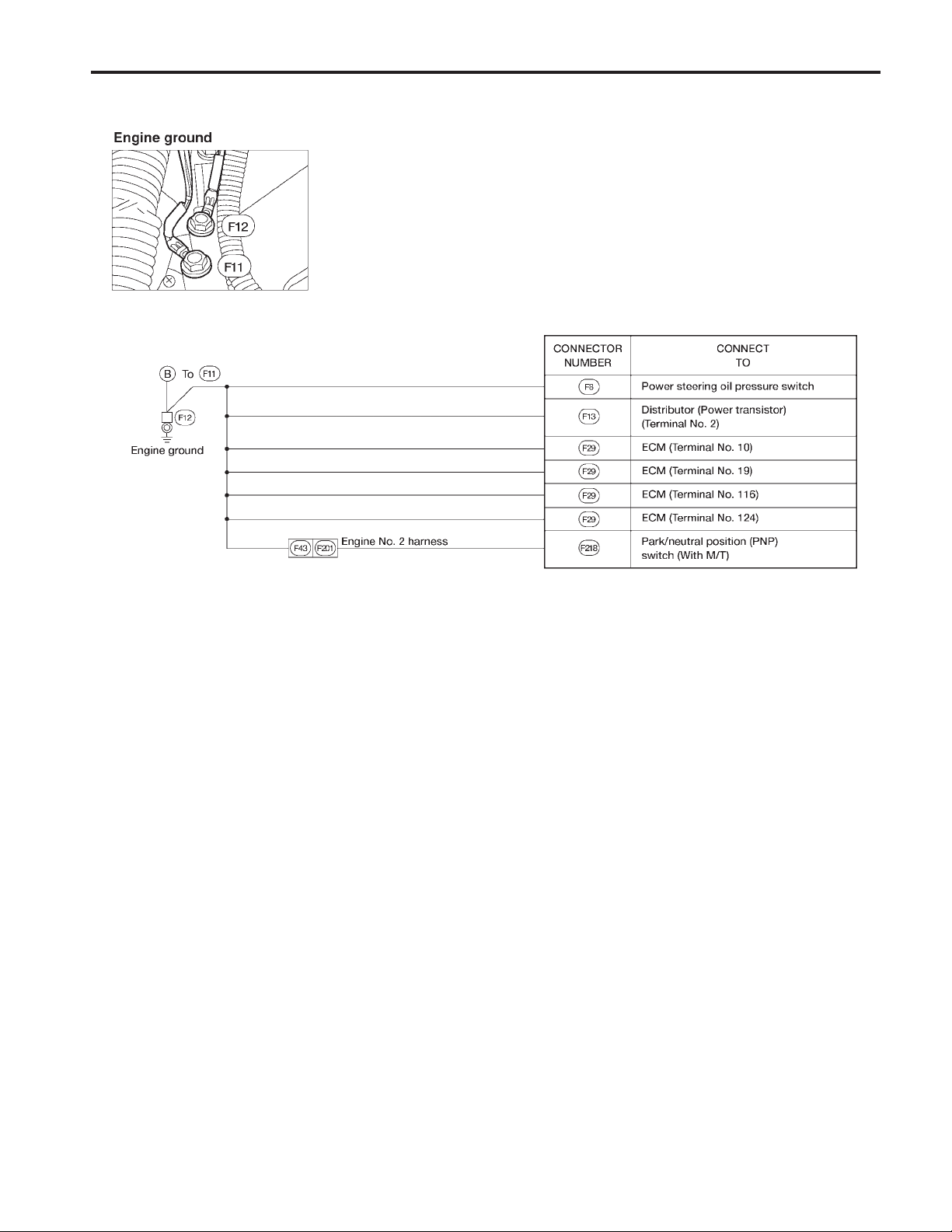

GROUND DISTRIBUTION

Engine Control Harness

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-21

EL

IDX

AEL304C

GROUND DISTRIBUTION

Engine Control Harness (Cont’d)

EL-22

AEL305C

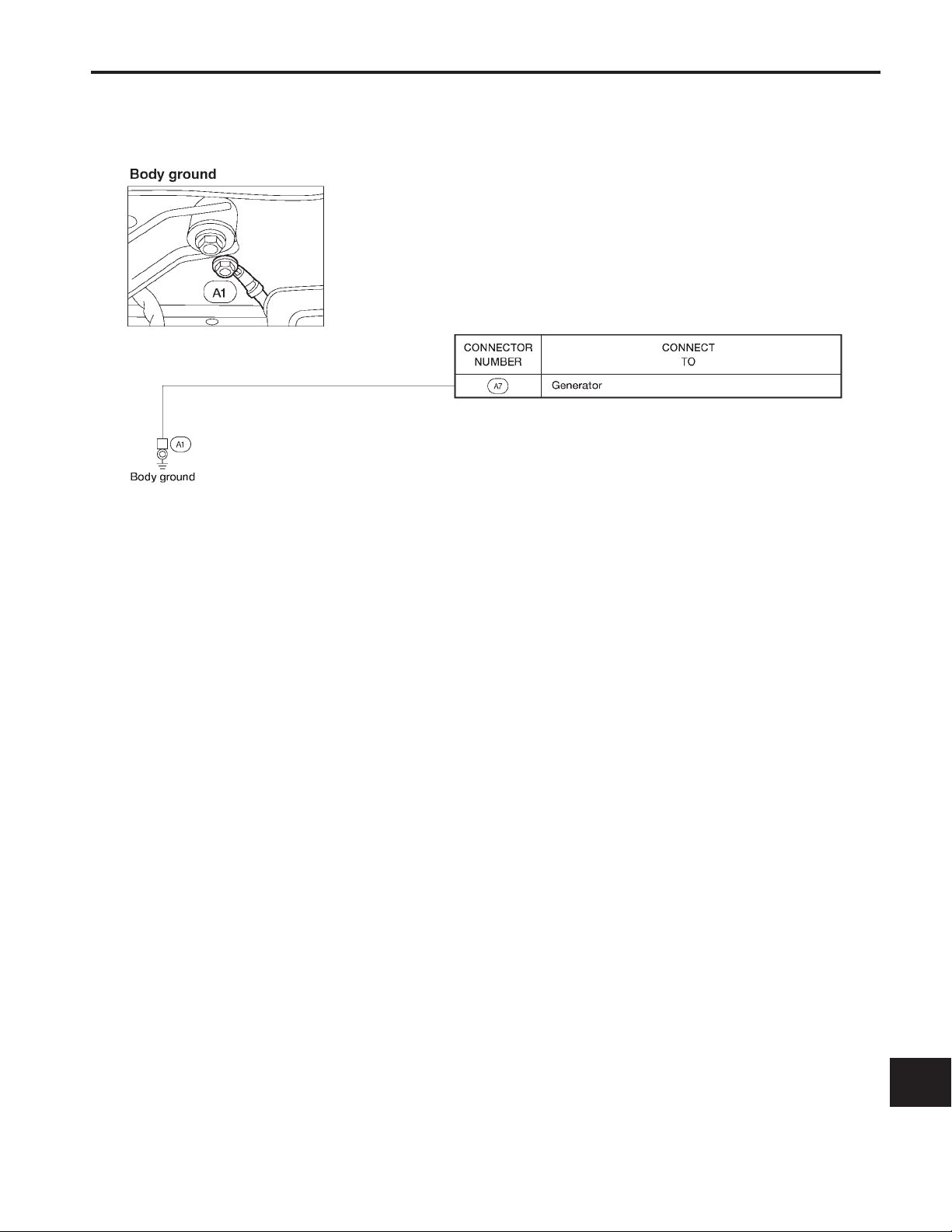

GROUND DISTRIBUTION

Generator Harness

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-23

EL

IDX

AEL306C

BATTERY

CAUTION:

If it becomes necessary to start the engine with a booster

battery and jumper cables:

●

Use a 12-volt booster battery.

●

After connecting battery cables, ensure that they are

tightly clamped to battery terminals for good contact.

●

Never add distilled water through the hole used to check

specific gravity.

How to Handle Battery

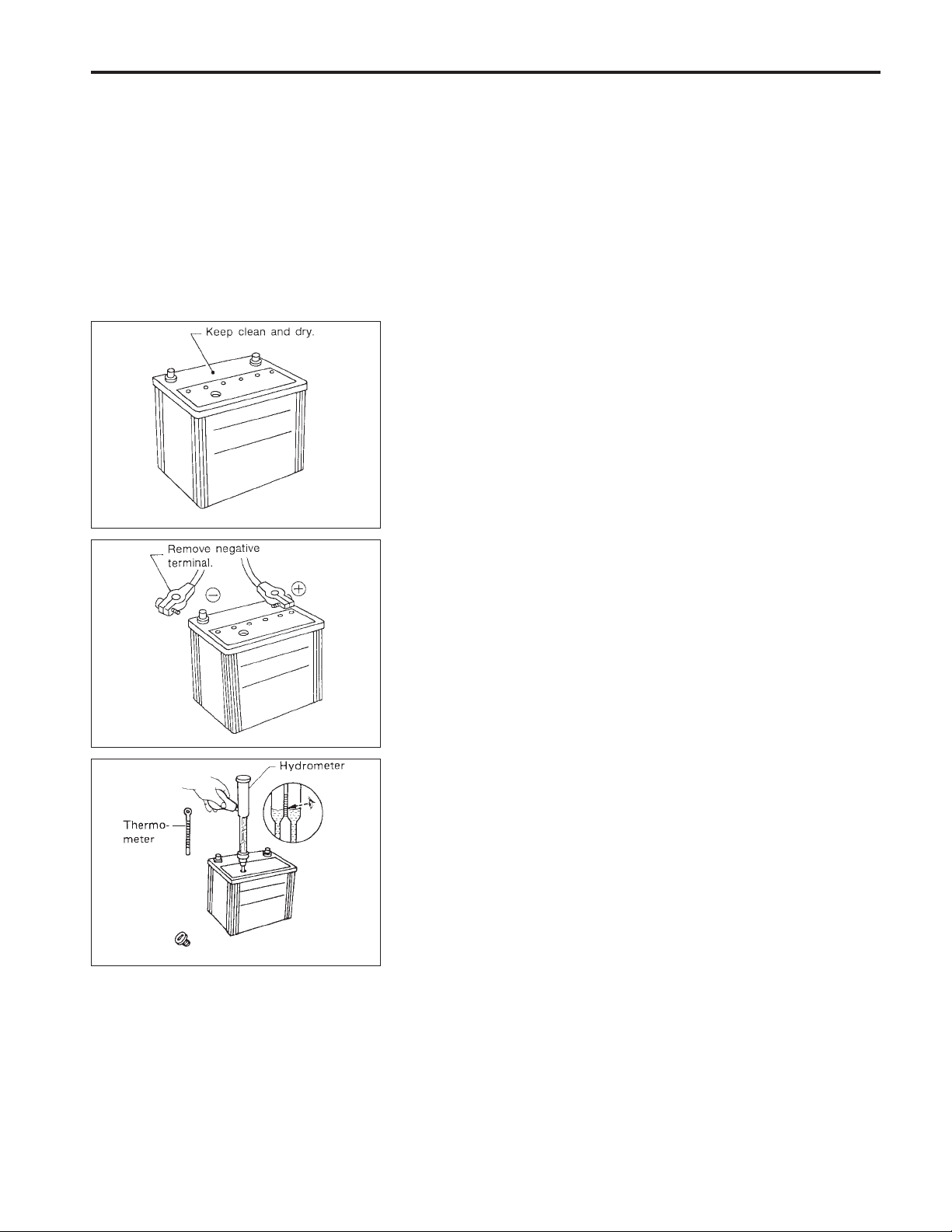

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharging a battery.

●

The battery surface (particularly its top) should always be kept

clean and dry.

●

The terminal connections should be clean and tight.

●

At every routine maintenance, check the electrolyte level.

SEL711E

SEL712E

SEL459R

●

When the vehicle is not going to be used over a long period of

time, disconnect the negative battery terminal. (If the vehicle

has an extended storage switch, turn it off.)

●

Check the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep

a close check on charge condition to prevent overdischarge.

EL-24

BATTERY

How to Handle Battery (Cont’d)

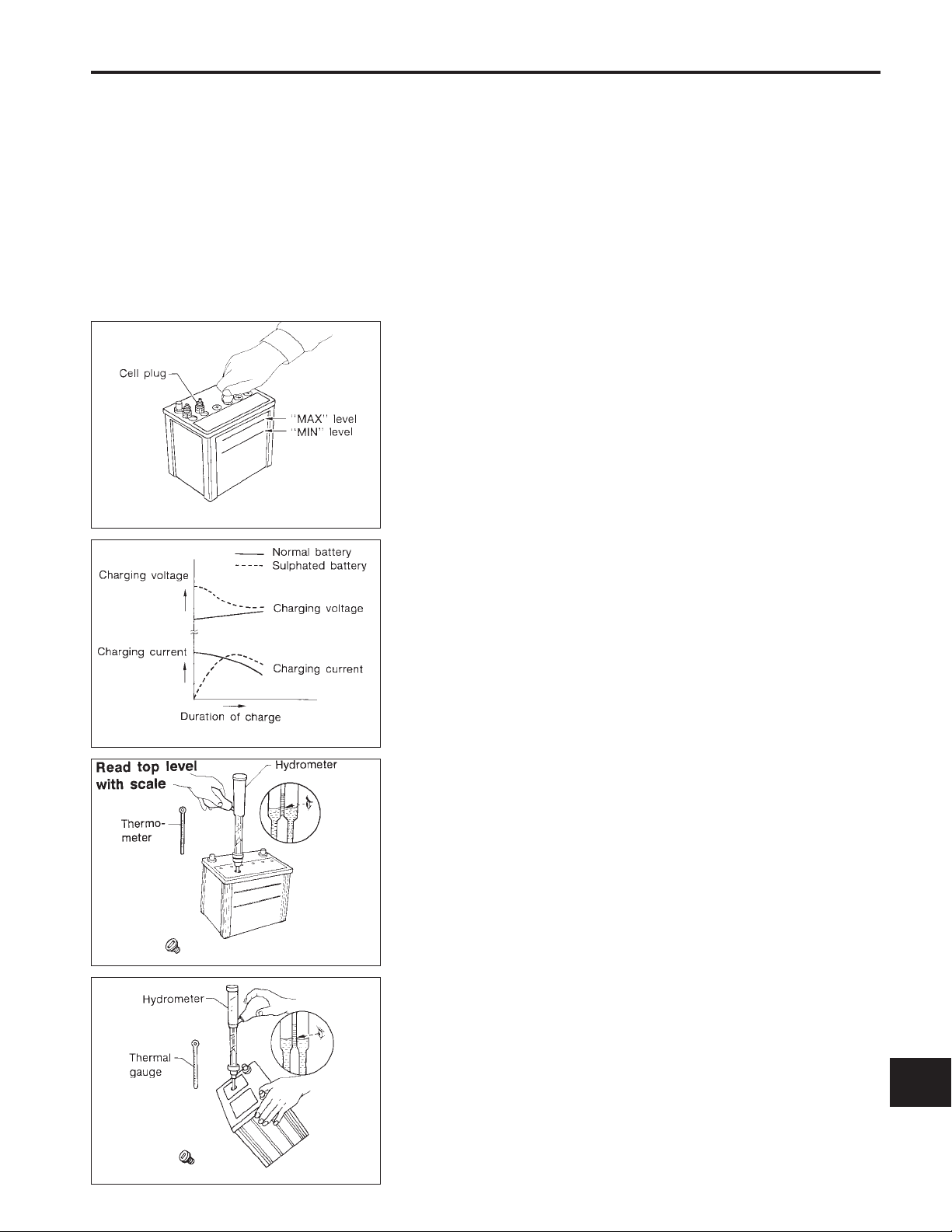

CHECKING ELECTROLYTE LEVEL

WARNING:

Do not allow battery fluid to come in contact with skin, eyes,

fabrics, or painted surfaces. After touching a battery, do not

touch or rub youreyes until you have thoroughly washed your

hands. If the acid contacts the eyes, skin or clothing, immediately flush with water for 15 minutes and seek medical attention.

Normally the battery does not require additional water.

However, when the battery is used under severe conditions,

adding distilled water may be necessary during the battery life.

GI

MA

EM

LC

SEL001K

SEL005Z

●

Remove the cell plug using a suitable tool.

●

Add distilled water up to the MAX level.

SULPHATION

A battery will be completely discharged if it is left unattended for a

long time and the specific gravity becomes less than 1.100. This

may result in sulphation on the cell plates.

To determineif a battery has been‘‘sulphated’’, note its voltageand

current when charging it. As shown in the figure, less current and

higher voltage are observed in the initial stage of charging sulphated batteries.

A sulphated battery may sometimes be brought back into service

by means of a long, slow charge, 12 hours or more, followed by a

battery capacity test.

SPECIFIC GRAVITY CHECK

1. Read hydrometer and thermometer indications at eye level.

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

SEL442D

SEL006Z

●

When electrolyte level is too low, tilt battery case to raise it for

easy measurement.

EL-25

ST

RS

BT

HA

EL

IDX

BATTERY

How to Handle Battery (Cont’d)

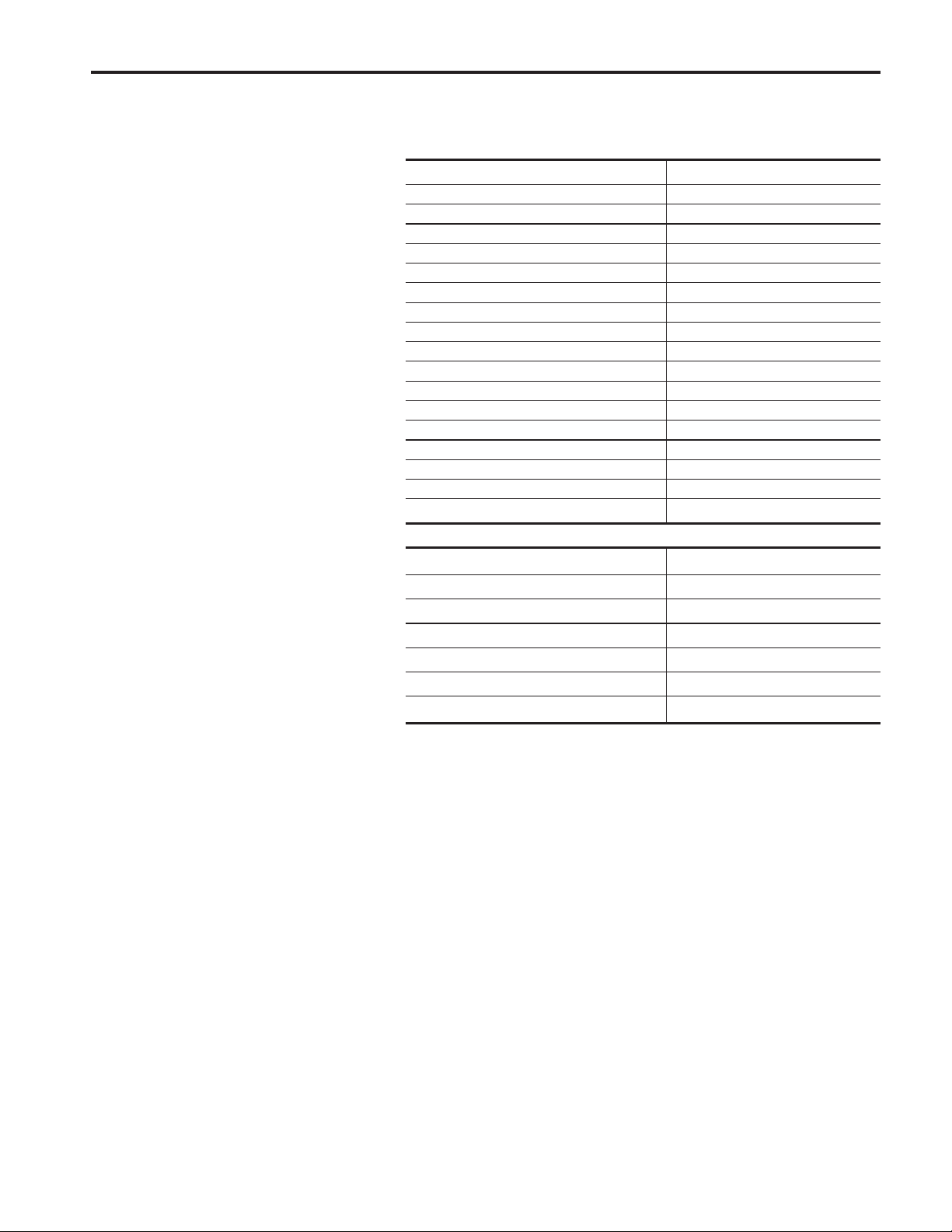

2. Use the chart below to correct your hydrometer reading

according to electrolyte temperature.

Hydrometer temperature correction

Battery electrolyte temperature °C (°F) Add to specific gravity reading

71 (160) 0.032

66 (150) 0.028

60 (140) 0.024

54 (129) 0.020

49 (120) 0.016

43 (110) 0.012

38 (100) 0.008

32 (90) 0.004

27 (80) 0

21 (70) −0.004

16 (60) −0.008

10 (50) −0.012

4 (39) −0.016

−1 (30) −0.020

−7 (20) −0.024

−12 (10) −0.028

−18 (0) −0.032

Corrected specific gravity Approximate charge condition

1.260 - 1.280 Fully charged

1.230 - 1.250 3/4 charged

1.200 - 1.220 1/2 charged

1.170 - 1.190 1/4 charged

1.140 - 1.160 Almost discharged

1.110 - 1.130 Completely discharged

EL-26

BATTERY

How to Handle Battery (Cont’d)

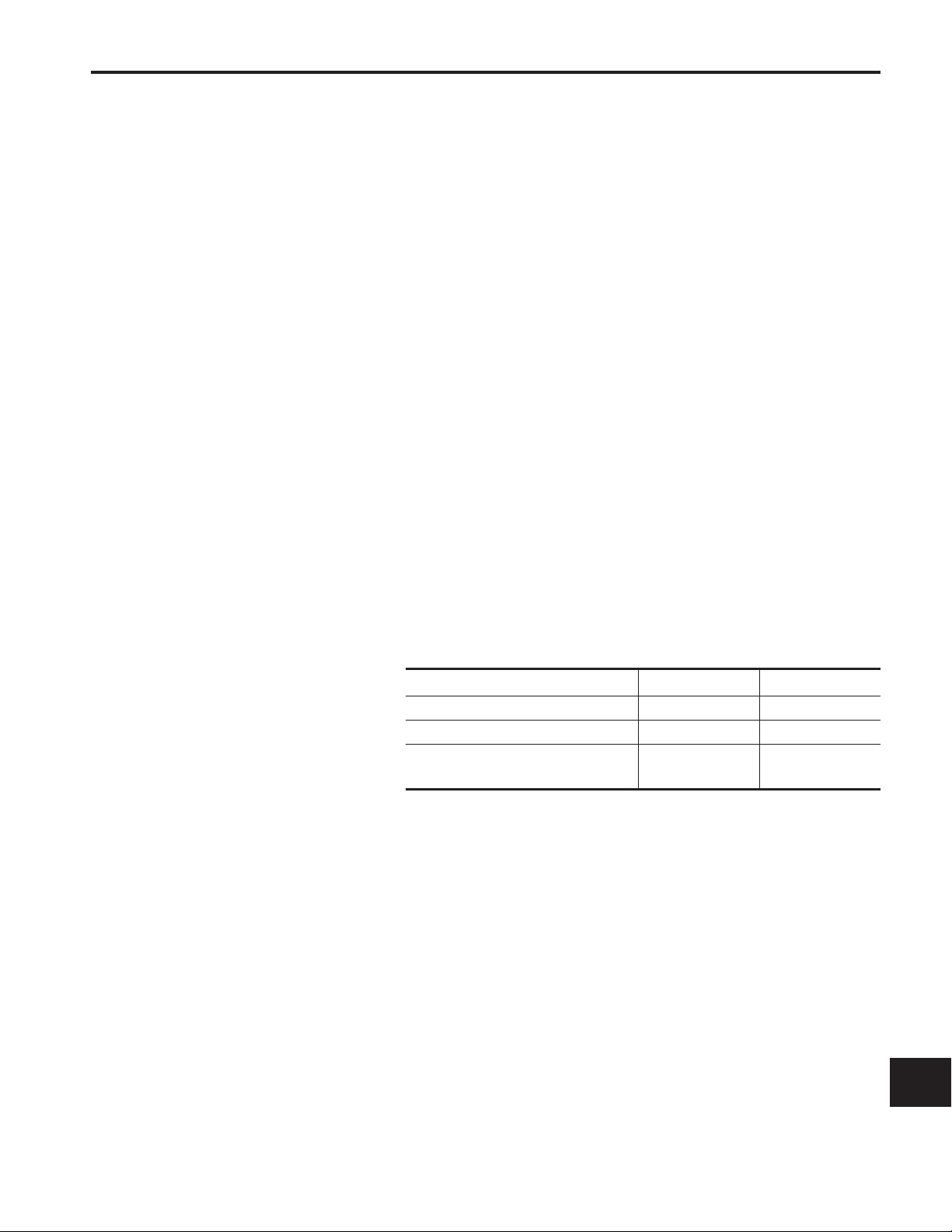

CHARGING THE BATTERY

CAUTION:

●

Do not ‘‘quick charge’’ a fully discharged battery.

●

Keep the battery away from open flame while it is being

charged.

●

When connecting the charger, connectthe leads first, then

turn on the charger. Do not turn on the charger first, as

this may cause a spark.

●

If battery electrolyte temperature rises above 60°C (140°F),

stop charging. Always charge battery at a temperature

below 60°C (140°F).

Charging rates

Amps Time

GI

MA

EM

LC

EC

50

25

10

5

Do not charge at more than 50 ampere rate.

Note: The ammeter reading on your battery charger will auto-

matically decrease as the battery charges. This indicates that the voltage of the battery is increasing normally as the state of charge improves. The charging

amps indicated above refer to initial charge rate.

●

If, after charging, the specific gravity of any two cells varies

more than .050, the battery should be replaced.

●

After the battery is charged, always perform a capacity test to

assure that the battery is serviceable.

1 hour

2 hours

5 hours

10 hours

Service Data and Specifications (SDS)

Applied area USA Canada

Type 55D23R 65D26R

Capacity V-AH 12-60 12-65

Cold cranking current A

(For reference value)

356 413

FE

CL

MT

AT

TF

PD

FA

RA

BR

EL-27

ST

RS

BT

HA

EL

IDX

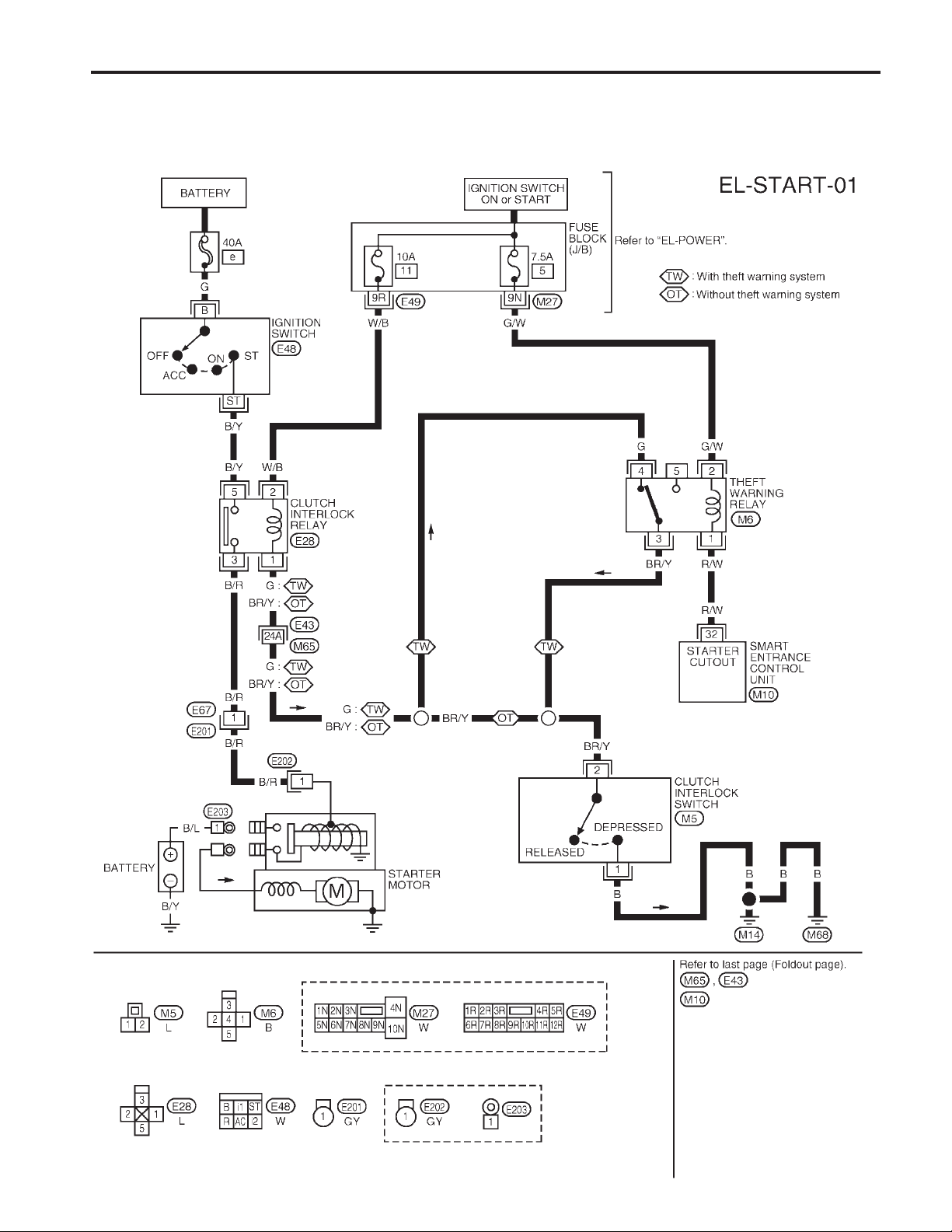

STARTING SYSTEM

System Description

M/T MODELS

Power is supplied at all times:

●

through 40A fusible link (letter , located in the fuse and fusible link box)

●

to ignition switch terminal

With the ignition switch in the START position, power is supplied:

●

through terminal

●

to clutch interlock relay terminal

ST

s

For models with theft warning system

With the ignition switch in the ON or START position, power is supplied:

●

through 7.5A fuse [No. , located in the fuse block (J/B)]

●

to theft warning relay terminal

With the ignition switch in the ON or START position, power is supplied:

●

through 10A fuse [No. , located in the fuse block (J/B)]

●

to clutch interlock relay terminal

If the theft warning system is triggered, terminal

of the smart entrance control unit and ground to the clutch interlock relay is interrupted.

When the theft warning system is not operating and clutch pedal is depressed, ground is supplied:

●

from clutch interlock switch terminal

●

to theft warning relay terminal

●

through theft warning relay terminal

●

to clutch interlock relay terminal

For models without theft warning system

With the ignition switch in the ON or START position, power is supplied:

●

through 10A fuse [No. , located in the fuse block (J/B)]

●

to clutch interlock relay terminal

When the clutch pedal is depressed, ground is supplied:

●

from clutch interlock switch terminal

●

to clutch interlock relay terminal

B

.

s

of the ignition switch

5

.

s

2

.

s

2

.

s

2

s

3

s

1

s

2

s

1

s

4

s

.

.

2

s

.

1

of the theft warning relay is grounded through terminal

s

32

s

Ground is supplied to clutch interlock switch terminal

1

through body grounds

s

s

M14

and

s

M68

.

The clutch interlock relay is energized and power is supplied:

●

from terminal

●

to terminal

3

of the clutch interlock relay

s

1

of the starter motor windings.

s

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motoris grounded to theengine block. With powerand ground supplied, crankingoccurs and the engine

starts.

EL-28

STARTING SYSTEM

System Description (Cont’d)

A/T MODELS

Power is supplied at all times:

●

through 40A fusible link (letter , located in the fuse and fusible link box)

●

to ignition switch terminal

With the ignition switch in the START position, power is supplied:

●

through terminal

●

to park/neutral position (PNP) relay terminal

ST

s

For models with theft warning system

With the ignition switch in the ON or START position, power is supplied:

●

through 7.5A fuse [No. , located in the fuse block (J/B)]

●

to theft warning relay terminal

With the ignition switch in the ON or START position, power is supplied:

●

through 10A fuse [No. , located in the fuse block (J/B)]

●

to PNP switch terminal

With the selector lever in the P or N position, power is supplied:

●

from PNP switch terminal

●

to PNP relay terminal

If the theft warning system is triggered, terminal

of the smart entrance control unit and ground to the PNP relay is interrupted.

When the theft warning system is not operating, ground is supplied:

●

from theft warning relay terminal

●

through theft warning relay terminal

●

to PNP relay terminal

For models without theft warning system

With the ignition switch in the ON or START position, power is supplied:

●

through 10A fuse [No. , located in the fuse block (J/B)]

●

to PNP switch terminal

With the selector lever in the P or N position, power is supplied:

●

from PNP switch terminal

●

to PNP relay terminal

B

.

s

of the ignition switch

2

.

s

1

.

s

2

s

2

.

s

3

s

4

1

s

2

s

1

s

.

.

2

s

.

s

5

.

s

1

of the theft warning relay is grounded through terminal

s

32

s

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

1

Ground is supplied to PNP relay terminal

The PNP relay is energized and power is supplied:

●

from terminal

●

to terminal

The starter motor plunger closes and provides a closed circuit between the battery and the starter motor. The

starter motoris grounded to theengine block. With powerand ground supplied, crankingoccurs and the engine

starts.

3

of the PNP relay

s

1

of the starter motor windings.

s

through body grounds

s

s

E12

and

s

E54

.

THEFT WARNING SYSTEM

The theft warning system will interrupt ground to clutch interlock relay (M/T models) or PNP relay (A/T models) if the system is triggered. The starter motor will then not crank, and the engine will not start. Refer to

‘‘THEFT WARNING SYSTEM’’ (EL-189).

FA

RA

BR

ST

RS

BT

HA

EL

IDX

EL-29

M/T MODELS

STARTING SYSTEM

Wiring Diagram — START —

EL-30

AEL268C

A/T MODELS

STARTING SYSTEM

Wiring Diagram — START — (Cont’d)

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

EL-31

HA

EL

IDX

AEL269C

STARTING SYSTEM

Construction

1

Gear case

s

2

Shift lever

s

3

Plate

s

4

Packing

s

5

Adjusting plate

s

6

Magnetic switch assembly

s

7

Pinion stopper set

s

8

Pinion assembly

s

9

Internal gear

s

10

Pinion shaft

s

11

Planetary gear

s

EL-32

12

Packing

s

13

Yoke

s

14

Armature

s

15

Brush holder assembly

s

16

Rear cover

s

AEL147C

STARTING SYSTEM

AEL148C

Removal and Installation

REMOVAL

1. Remove engine undercover.

2. Remove two bolts and starter.

INSTALLATION

To install, reverse the removal procedure.

Pinion/Clutch Check

1. Inspect pinion teeth.

●

Replace pinion if teeth are worn or damaged. (Also check

condition of ring gear teeth.)

2. Inspect reduction gear teeth.

●

Replace reduction gear if teeth are worn or damaged. (Also

check condition of armature shaft gear teeth.)

3. Check to see if pinion locks in one direction and rotates

smoothly in the opposite direction.

●

If it locks or rotates in both directions, or unusual resistance is

evident, replace.

Service Data and Specifications (SDS)

STARTER

M000T60185ZC

Type

System voltage V 12

No-load

Terminal voltage V 11.0

Current A 90 Max.

Motor revolution rpm 2,500 Min.

Minimum diameter of

commutator

mm (in)

Minimum length of brush

mm (in)

Brush spring tension

N (kg, lb)

Clearance of bearing metal and armature

shaft

mm (in)

Clearance between pinion front edge and

pinion stopper

mm (in)

MITSUBISHI

Reduction

28.8 (1.134)

7.0 (0.276)

11.8 - 23.5

(1.20 - 2.40, 2.65 - 5.28)

0.2 (0.008)

0.5 - 2.0

(0.020 - 0.079)

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

EL-33

HA

EL

IDX

CHARGING SYSTEM

System Description

The generator provides DC voltage to operate the vehicle’s electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to generator terminal

●

100A fusible link (letter , located in the fuse and fusible link box), and

●

7.5A fuse (No. , located in the fuse and fusible link box).

Terminal

is controlled by the IC regulator at terminal

the 100A fusible link.

Terminal

With the ignition switch in the ON or START position, power is supplied:

●

●

Ground is supplied to terminal

and ground supplied, the charge warning lamp will illuminate. When the generator is providing sufficient voltage with the engine running, the ground is opened and the charge warning lamp will not illuminate.

If the charge warning lamp illuminates with the engine running, a fault is indicated.

1

supplies power to charge the battery and operate the vehicle’s electrical system. Output voltage

s

2

of the generator supplies ground through body ground

s

through 10A fuse [No. , located in the fuse block (J/B)]

to combination meter terminal

29

s

27

of the combination meter through terminal

s

4

detecting the input voltage. The charging circuit is protected by

s

for the charge warning lamp.

4

s

through:

s

A1 .

3

of the generator. With power

s

EL-34

CHARGING SYSTEM

Wiring Diagram — CHARGE —

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-35

EL

IDX

AEL584C

CHARGING SYSTEM

Trouble Diagnoses

Before conducting a generator test, make sure that the battery is fully charged. A 30-volt voltmeter and suitable test probes are necessary for the test. The generator can be checked easily by referring to the Inspection Table.

●

Before starting, inspect the fusible link.

●

Use fully charged battery.

WITH IC REGULATOR

Check the following:

●

Ignition switch

‘‘ON’’

Warning lamp

‘‘OFF’’

Disconnect connector (S, L) and

ground L harness side.

Warning lamp

‘‘OFF’’

Warning

lamp bulb

●

Fuse for

warning lamp

Warning lamp

‘‘ON’’

Engine idling Warning lamp

Warning lamp

‘‘OFF’’

Warning lamp: ‘‘CHARGE’’ warning lamp in combination meter

‘‘ON’’

OK Engine speed:

Check the following:

●

Drive belt

●

B terminal connection

(Check the tightening torque)

●

Fuse for S terminal

●

Connector (S, L terminal) connection

Warning lamp

‘‘ON’’

Engine idling Warning lamp

Warning lamp

‘‘ON’’

1,500 rpm

(Measure B

terminal voltage)

‘‘OFF’’

More than

15.5V

No generation Field circuit is

Damaged IC

regulator.

Replace.

OK

Damaged IC

regulator.

Replace.

open.*

Note:

.: When field circuit is open, check condition of rotor coil, rotor slip ring and brush. If necessary,

replace faulty parts with new ones.

MALFUNCTION INDICATOR

The IC regulator warning function activates to illuminate ‘‘CHARGE’’ warning lamp, if any of the following

symptoms occur while generator is operating:

●

Excessive voltage is produced.

●

No voltage is produced.

EL-36

CHARGING SYSTEM

Construction

GI

MA

EM

LC

EC

FE

CL

MT

AT

1

Pulley assembly

s

2

Front cover

s

3

Front bearing

s

4

Retainer

s

5

s

6

s

7

s

8

s

Rotor

Slip ring

Stator

Fan guide

9

IC regulator assembly

s

10

Diode assembly

s

11

Packing

s

12

Rear cover

s

AEL149C

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-37

EL

IDX

AEL421C

CHARGING SYSTEM

Removal and Installation

REMOVAL

1. Disconnect harness connectors.

2. Remove engine undercover.

3. Back off adjustment bolt, remove belt.

4. Remove 3 generator bolts and generator.

INSTALLATION

To install, reverse the removal procedure.

Service Data and Specifications (SDS)

GENERATOR

Type

Nominal rating V-A 12-70

Ground polarity Negative

Minimum revolution under no-load

(When 13.5 volts is applied) rpm

Hot output current

(When 13.5 volts is applied) A/rpm

Regulated output voltage V 14.1 - 14.7

Minimum length of brush mm (in) 6.00 (0.236)

Brush spring pressure N (g, oz) 1.000 - 2.452 (102 - 250, 3.60 - 8.82)

Slip ring minimum diameter mm (in) 26.0 (1.024)

Rotor (field coil) resistance V 2.7

LR180-756

HAP

Less than 1,000

More than 23/1,300

More than 65/2,500

More than 77/5,000

EL-38

COMBINATION SWITCH

Check

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-39

EL

IDX

AEL122C

COMBINATION SWITCH

Replacement

For removal andinstallation of spiral cable, referto RS section

[‘‘Driver Air Bag Module and Spiral Cable’’, ‘‘SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)’’].

●

Each switch can be replaced without removing combination

switch base.

SEL865L

●

To remove combination switch base, remove base attaching

screws.

MEL205B

ARS152

●

Before installing the steering wheel, align the turn signal cancel tab with the notch of combination switch. Refer to RS section (‘‘INSTALLATION’’, ‘‘Driver Air Bag Module and Spiral

Cable’’).

EL-40

STEERING SWITCH

Check

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-41

EL

IDX

AEL603B

HEADLAMP

System Description (For USA)

The headlamps are controlled by the lighting switch which is built into the combination switch.

Power is supplied at all times:

●

to lighting switch terminal

●

through 15A fuse (No. , located in the fuse and fusible link box), and

●

to lighting switch terminal

●

through 15A fuse (No. , located in the fuse and fusible link box).

Low beam operation

When the lighting switch is turned to headlamp ON (2ND) position, LOW BEAM (B), power is supplied:

●

from lighting switch terminal

●

to terminal

●

from lighting switch terminal

●

to terminal

Terminal

With power and ground supplied, the headlamp(s) will illuminate.

s

D

of the LH headlamp, and

s

D

of the RH headlamp.

s

E

of each headlamp supplies ground through body grounds

High beam operation/flash-to-pass operation

When the lighting switch is turned to headlamp ON (2ND) position, HIGH BEAM (A) or FLASH TO PASS (C)

position, power is supplied:

●

from lighting switch terminal

●

to terminal

●

from lighting switch terminal

●

to terminal

●

to combination meter terminal

Ground is supplied to terminal

Terminal

With power and ground supplied, the high beams and the high beam indicator illuminate.

Theft warning system

The theft warning system will flash the high beams if the system is triggered. Refer to ‘‘THEFT WARNING

SYSTEM’’ (EL-189).

s

M

of RH headlamp, and

s

M

of LH headlamp, and

s

E

of each headlamp supplies ground through body grounds

5

s

8

s

10

s

7

s

s

6

s

9

s

17

for the high beam indicator.

s

16

of the combination meter through body grounds

s

s

E12

E12

and

and

s

s

s

E54

M14

E54

.

.

and

s

M68

.

EL-42

HEADLAMP

Wiring Diagram (For USA) — H/LAMP —

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-43

EL

IDX

AEL271C

Symptom Possible cause Repair order

LH headlamp does not operate. 1. Bulb

2. Grounds

3. 15A fuse

4. Lighting switch

RH headlamp does not operate. 1. Bulb

2. Grounds

3. 15A fuse

4. Lighting switch

LH high beam does not operate, but

LH low beam operates.

LH low beam does not operate, but

LH high beam operates.

RH high beam doesnot operate,but

RH low beam operates.

RH low beam does not operate, but

RH high beam operates.

High beam indicator does not work. 1. Bulb

1. Bulb

2. Open in LH high beam circuit

3. Lighting switch

1. Bulb

2. Open in LH low beam circuit

3. Lighting switch

1. Bulb

2. Open in RH high beam circuit

3. Lighting switch

1. Bulb

2. Open in RH low beam circuit

3. Lighting switch

2. Grounds

3. Open in high beam circuit

HEADLAMP

Trouble Diagnoses

1. Check bulb.

s

s

s

E12

E12

M14

and

and

and

s

s

s

E54

E54

M68

2. Check grounds

3. Check 15A fuse (No.

link box). Verify battery positive voltage is present at

terminal

4. Check lighting switch.

1. Check bulb.

2. Check grounds

3. Check 15A fuse (No.

link box). Verify battery positive voltage is present at

terminal

4. Check lighting switch.

1. Check bulb.

2. Check R/G wire between lighting switch and LH headlamp for an open circuit.

3. Check lighting switch.

1. Check bulb.

2. Check R wire between lighting switch and LH headlamp for an open circuit.

3. Check lighting switch.

1. Check bulb.

2. Check R/Wwire betweenlighting switch and RH headlamp for an open circuit.

3. Check lighting switch.

1. Check bulb.

2. Check R/B wire between lighting switch and RH headlamp for an open circuit.

3. Check lighting switch.

1. Check bulb in combination meter.

2. Check grounds

3. Check R/G wire between lighting switch and combination meter for an open circuit.

E12

s

8

of lighting switch.

s

E12

s

5

of lighting switch.

s

M14

s

E54

and

, located in fuse and fusible

and

, located in fuse and fusible

and

s

s

s

E54

M68

.

.

.

EL-44

HEADLAMP

AEL599B

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replaceable halogen bulb. The bulb can be replaced from the engine compartment side without removing the headlamp body.

●

Grasp only the plasticbase when handling the bulb. Never

touch the glass envelope.

1. Disconnect the battery cable.

2. Disconnect the harness connector from the back side of the

bulb.

3. Unclip the bulb retaining clip, and then remove it.

4. Remove the headlamp bulb carefully. Do not shake or rotate

the bulb when removing it.

5. Install in the reverse order of removal.

CAUTION:

●

Do not leave headlamp reflector without bulb for a long

period of time. Dust, moisture, smoke, etc. entering headlamp body may affect the performance of the headlamp.

Remove headlamp bulb from the headlamp reflector just

before a replacement bulb is installed.

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. Aimers should be

in good repair, calibrated and operated in accordance with respective operation manuals.

If any aimer is not available, aiming adjustment can be done as

follows:

For details, refer to the regulations in your own country.

a. Keep all tires inflated to correct pressures.

b. Place vehicle and tester on one and same flat surface.

c. See that there is no-load in vehicle (coolant, engine oil

filled up to correct level and full fuel tank) other than the

driver (or equivalent weight placed in driver’s position).

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL

IDX

EL-45

AEL601B

HEADLAMP

Aiming Adjustment (Cont’d)

AIMER ADJUSTMENT MARK

When using a mechanical aimer, adjust adapter legs to the data

marked on the headlamps.

Adjustment value for mechanical aimer

Mechanical aimer level

Horizontal side −4 to 4

Vertical side −4 to 4

LOW BEAM

1. Turn headlamp low beam on.

2. Use a

lamp.

●

Cover the opposite lamp.

#

2 cross-recessed screwdriver to adjust the aim of the

AEL671B

SEL866L

If the vehicle front body has been repaired and/or the headlamp

assembly has been replaced, check aiming. Use the aiming chart

shown in the figure.

●

Upper edge and left edge of high intensity zone should be

within the range shown at left. Adjust headlamps accordingly.

●

Dotted lines in illustration show center of headlamp.

‘‘H’’: Horizontal center line of headlamps

‘‘W

’’: Distance between each headlamp center

L

EL-46

HEADLAMP — Daytime Light System —

System Description (For Canada)

The headlamp system for Canada vehicles contains a daytime light control unit that activates the high beam

headlamps at approximately half illumination whenever the engine is running. If the parking brake is applied

before the engine is started, the daytime lights will not be illuminated. The daytime lights will illuminate once

the parking brake is released. Thereafter, the daytime lights will continue to operate when the parking brake

is applied. If the daytime light control unit receives a ground signal from the generator, the daytime lights will

not be illuminated. The daytime lights will illuminate once a battery positive voltage signal is sent to the daytime light control unit from the generator.

Power is supplied at all times:

●

through 15A fuse (No. , located in the fuse and fusible link box)

●

to daytime light control unit terminal

●

to lighting switch terminal

Power is also supplied at all times:

●

through 15A fuse (No. , located in the fuse and fusible link box)

●

to daytime light control unit terminal

●

to lighting switch terminal

With the ignition switch in the ON or START position, power is supplied:

●

through 7.5A fuse [No. , located in the fuse block (J/B)]

●

to daytime light control unit terminal

With the ignition switch in the START position, power is supplied:

●

through 7.5A fuse [No. , located in the fuse block (J/B)]

●

to daytime light control unit terminal

Ground is supplied to daytime light control unit terminal

8

s

5

s

.

.

HEADLAMP OPERATION

Low beam operation

When the lighting switch is turned to headlamp ON (2ND) position, LOW BEAM (B), power is supplied:

●

from lighting switch terminal

●

to RH headlamp terminal

●

to daytime light control unit terminal

Ground is supplied to RH headlamp terminal

Also, when the lighting switch is turned to headlamp ON (2ND) position, LOW BEAM (B), power is supplied:

●

from lighting switch terminal

●

to LH headlamp terminal

Ground is supplied:

●

to LH headlamp terminal

●

from daytime light control unit terminal

●

through daytime light control unit terminal

●

through body grounds

With power and ground supplied, the low beam headlamps illuminate.

High beam operation/flash-to-pass operation

When the lighting switch is turned to headlamp ON (2ND) position, HIGH BEAM (A) or FLASH TO PASS (C)

position, power is supplied:

●

from lighting switch terminal

●

to terminal

When the lighting switch is turned to headlamp ON (2ND) position, HIGH BEAM (A) or FLASH TO PASS (C)

position, power is supplied:

●

from lighting switch terminal

●

to daytime light control terminal

●

to combination meter terminal

●

through daytime light control terminal

●

to terminal

Ground is supplied in the same manner as low beam operation.

Ground is supplied to terminal

With power and ground supplied, the high beam headlamps and HI BEAM indicator illuminate.

M

of RH headlamp.

s

M

of LH headlamp.

s

s

7

s

D

s

10

s

D

.

s

E

s

E12

and

6

s

9

s

s

16

of the combination meter through body grounds

s

3

and

s

2

and

s

12

.

s

1

.

s

4

.

s

E

through body grounds

s

7

s

9

s

E54

6

s

.

s

5

s

17

for the high beam indicator

9

s

through body grounds

E12

s

and

s

s

s

E12

E54

M14

and

.

and

s

s

E54

M68

.

.

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL

EL-47

IDX

HEADLAMP — Daytime Light System —

System Description (For Canada) (Cont’d)

DAYTIME LIGHT OPERATION

With the engine running, the lighting switch in the OFF or parking lamp (1ST) position and parking brake

released, power is supplied:

●

to daytime light control unit terminal

●

through daytime light control unit terminal

●

to terminal

●

through terminal

●

to daytime light control unit terminal

●

through daytime light control unit terminal

●

to terminal

Ground is supplied to terminal

M

of LH headlamp

s

s

E

of LH headlamp

s

M

of RH headlamp.

E

of RH headlamp through body grounds

s

Because the high beam headlamps are now wired in series, they operate at half illumination.

3

s

7

s

6

s

8

s

s

E12

and

s

E54

.

Operation (For Canada)

After starting the engine with the lighting switch in the OFF or

parking lamp (1ST) position, the headlamp high beam automatically turns on. Lighting switch operations other than the above are

the same as conventional light systems.

Engine With engine stopped With engine running

Lighting switch

Headlamp

Parking and tail lamp X X X jjjjjj XXXjjjjjj

License and instrument illumination lamp X X X jjjjjjXXXjjjjjj

A : HIGH BEAM position

B : LOW BEAM position

C : FLASH TO PASS position

j : Lamp ON

X : Lamp OFF

n : Lamp dims.

: Added functions

*: When starting the engine with the parking brake released, the daytime light will come ON.

When starting the engine with the parking brake pulled, the daytime light won’t come ON.

High beam X X j XXjj X j n* n* j n* n* jj X j

Low beam XXXXXXXj XXXXXXXXj X

OFF 1ST 2ND OFF 1ST 2ND

ABCABCABCABCABCABC

EL-48

HEADLAMP — Daytime Light System —

Schematic (For Canada)

GI

MA

EM

LC

EC

FE

CL

MT

AT

AEL953A

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-49

EL

IDX

HEADLAMP — Daytime Light System —

Wiring Diagram (For Canada) — DTRL —

EL-50

AEL272C

HEADLAMP — Daytime Light System —

Wiring Diagram (For Canada) — DTRL —

(Cont’d)

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

EL-51

HA

EL

IDX

AEL273C

HEADLAMP — Daytime Light System —

Wiring Diagram (For Canada) — DTRL —

(Cont’d)

EL-52

AEL274C

HEADLAMP — Daytime Light System —

Trouble Diagnoses (For Canada)

DAYTIME LIGHT CONTROL UNIT INSPECTION TABLE

Terminal

No.

1 L/OR Start signal

2 Y/G Power source

3 Y/B Power source

4 R/B Lighting switch

Wire

color

Item Condition

When turning ignition switch to ST Battery voltage

When turning ignition switch to ON from ST Less than 1V

When turning ignition switch to OFF Less than 1V

When turning ignition switch to ON Battery voltage

When turning ignition switch to OFF Battery voltage

When turning ignition switch to ON Battery voltage

When turning ignition switch to OFF Battery voltage

When turning lighting switch to headlamp ON (2ND)

(Lo beam)

position, LOW BEAM

Voltage

(Approximate values)

Battery voltage

GI

MA

EM

LC

EC

FE

CL

MT

AT

5 R/G Lighting switch

(Hi beam)

6 R/Y LH hi beam When turning lighting switch to HI BEAM Battery voltage

7 B/W LH headlamp con-

trol (ground)

8 R/W RH hi beam When turning lighting switch to HI BEAM Battery voltage

When turning lighting switch to HI BEAM Battery voltage

When turning lighting switch to FLASH TO PASS Battery voltage

When releasing parking brake with engine running

and turning lighting switch to OFF (daytime light

operation)

CAUTION: Block wheels and ensure selector

lever is in N or P position.

When lighting switch is turned to headlamp ON

(2ND) position, LOW BEAM

When releasing parking brake with engine running

and turning lighting switch to OFF (daytime light

operation)

CAUTION: Block wheels and ensure selector

lever is in N or P position.

Battery voltage

Less than 1V

Approx. half battery

voltage

TF

PD

FA

RA

BR

ST

RS

BT

When releasing parking brake with engine running

and turning lighting switch to OFF (daytime light

operation)

CAUTION: Block wheels and ensure selector

lever is in N or P position.

9 B Ground — —

Approx. half battery

voltage

EL-53

HA

EL

IDX

HEADLAMP — Daytime Light System —

Trouble Diagnoses (For Canada) (Cont’d)

Terminal

No.

10 Y Parking brake

11 Y/B Generator

12 G/W Power source

Wire

color

switch

Item Condition

When parking brake is released Battery voltage

When parking brake is set Less than 1.5V

When turning ignition switch to ON Less than 1V

When engine is running Battery voltage

When turning ignition switch to OFF Less than 1V

When turning ignition switch to ON Battery voltage

When turning ignition switch to ST Battery voltage

When turning ignition switch to OFF Less than 1V

Bulb Replacement

Refer to ‘‘HEADLAMP’’ (EL-45).

Voltage

(Approximate values)

Aiming Adjustment

Refer to ‘‘HEADLAMP’’ (EL-45).

EL-54

PARKING, LICENSE AND TAIL LAMPS

Wiring Diagram — TAIL/L —

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-55

EL

IDX

AEL344B

PARKING, LICENSE AND TAIL LAMPS

Wiring Diagram — TAIL/L — (Cont’d)

EL-56

AEL275C

STOP LAMP

Wiring Diagram — STOP/L —

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-57

EL

IDX

AEL364B

BACK-UP LAMP

Wiring Diagram — BACK/L —

EL-58

AEL586C

FRONT FOG LAMP

System Description

Power is supplied at all times to front fog lamp relay terminal

●

15A fuse (No. , located in the fuse and fusible link box).

With the lighting switch in headlamp ON (2ND) position, LOW BEAM (B), power is supplied:

●

through 15A fuse (No. , located in the fuse and fusible link box)

●

to lighting switch terminal

●

through terminal

●

to front fog lamp relay terminal

Fog lamp operation

The fog lamp switch is built into the combination switch. The lighting switch must be in headlamp ON (2ND)

position, LOW BEAM (B) for fog lamp operation.

With the front fog lamp switch in the ON position:

●

ground is supplied to front fog lamp relay terminal

E12

s

The fog lamp relay is energized and power is supplied:

●

from front fog lamp relay terminal

●

to terminal

Ground is supplied to terminal

With power and ground supplied, the front fog lamps illuminate.

and

s

7

s

E54

s

.

1

of each front fog lamp.

5

s

of the lighting switch

2

.

s

3

s

2

of each front fog lamp through body grounds

s

1

s

5

through:

s

through the front fog lamp switch and body grounds

s

E12

and

s

E54

.

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-59

EL

IDX

FRONT FOG LAMP

Wiring Diagram — F/FOG —

EL-60

AEL587C

FRONT FOG LAMP

AEL160C

MEL327G

Aiming Adjustment

Before performing aiming adjustment, make sure of the following.

a. Keep all tires inflated to correct pressure.

b. Place vehicle on level ground.

c. Check that vehicle is unloaded (exceptfor full levels of coolant,

engine oil and fuel, and spare tire, jack, and tools). Have the

driver or equivalent weight placed in driver’s seat.

1. Set the distance between the screen and the center of the fog

lamp lens as shown at left.

2. Turn front fog lamps ON.

3. Adjust front fog lamps so that the top edge of the high intensity zone is 100 mm (4 in) below the height of the fog lamp

centers as shown at left.

●

When performing adjustment, if necessary, cover the

headlamps and opposite fog lamp.

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

MEL328G

PD

FA

RA

BR

ST

RS

BT

HA

EL

EL-61

IDX

FRONT FOG LAMP

Removal and Installation

AEL345C

AEL338C

1. Disconnect fog lampharness connector and separate fog lamp

connector from fog lamp bracket.

2. Remove mounting nut and remove lens and housing assembly from fog lamp bracket.

3. Install in reverse order ofremoval. Ensure top of lens faces up.

4. Tighten mounting nut.

:5-6Nzm (0.51 - 0.61 kg-m, 44.3 - 53.1 in-lb)

Bulb and Lens Replacement

1. Remove the two metal clips on sides of fog lamp.

2. Pull out and support fog lamp lens.

3. Disconnect fog lamp bulb connector.

AEL346C

4. Lift retaining spring.

5. Remove fog lamp bulb.

●

Fog lamp bulb cannot be separated from wire and is serviced

as an assembly.

6. For lens replacement, disconnect ground connector from bulb

retainer and remove lens.

7. Install in reverse order ofremoval. Ensure top of lens faces up.

DO NOT TOUCH BULB.

EL-62

TURN SIGNAL AND HAZARD WARNING LAMPS

System Description

TURN SIGNAL OPERATION

With the hazard switch in the OFF position and the ignition switch in the ON or STARTposition, power is supplied:

●

through 7.5A fuse [No. , located in the fuse block (J/B)]

●

to hazard switch terminal

●

through terminal

●

to combination flasher unit terminal

●

through terminal

●

to turn signal switch terminal

Ground is supplied to combination flasher unit terminal

LH turn

When the turn signal switch is moved to the LH position, power is supplied from turn signal switch terminal

to:

●

front combination lamp LH terminal

●

combination meter terminal

●

rear combination lamp LH terminal

Ground is supplied to the front combination lamp LH terminal

Ground is supplied to the rear combination lamp LH terminal

Ground is supplied to combination meter terminal

With power and ground supplied, the combination flasher unit controls the flashing of the LH combination

lamps.

RH turn

When the turn signal switch is moved to the RH position, power is supplied from turn signal switch terminal

2

to:

s

●

front combination lamp RH terminal

●

combination meter terminal

●

rear combination lamp RH terminal

Ground is supplied to the front combination lamp RH terminal

Ground is supplied to the rear combination lamp RH terminal

Ground is supplied to combination meter terminal

With power and ground supplied, the combination flasher unit controls the flashing of the RH combination

lamps.

1

s

L

s

2

s

of the hazard switch

B

of the combination flasher unit

s

24

s

40

s

s

1

.

1

s

2

.

s

33

s

1

s

2

.

s

33

s

E

through body grounds

s

2

through body grounds

s

1

through body grounds

s

through body grounds

2

through body grounds

s

1

through body grounds

s

through body grounds

s

s

M14

M14

s

M14

and

and

s

s

s

s

s

s

and

E12

M14

M68

E12

M14

M68

s

.

.

M68

and

and

and

and

.

s

s

s

s

E54

M68

E54

M68

3

s

.

.

.

.

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

HAZARD LAMP OPERATION

Power is supplied at all times to hazard switch terminal

●

10A fuse [No. , located in the fuse block (J/B)].

With the hazard switch in the ON position, power is supplied:

●

through terminal

●

to combination flasher unit terminal

●

through terminal

●

to hazard switch terminal

Ground is supplied to combination flasher unit terminal

Power is supplied through terminal

●

front combination lamp LH terminal

●

combination meter terminal

●

rear combination lamp LH terminal

Power is supplied through terminal

●

front combination lamp RH terminal

●

combination meter terminal

●

rear combination lamp RH terminal

Ground is supplied to terminal

Ground is supplied to terminal

Ground is supplied to combination meter terminal

With power and ground supplied, the combination flasher unit controls the flashing of the hazard warning

lamps.

1

of the hazard switch

s

L

of the combination flasher unit

s

4

s

s

s

2

s

s

.

24

40

1

B

s

5

of the hazard switch to:

s

1

s

2

.

s

6

of the hazard switch to:

s

1

s

2

.

s

of each front combination lamp through body grounds

of each rear combination lamp through body grounds

s

3

through:

s

E

through body grounds

s

33

through body grounds

s

M14

s

M14

and

and

s

s

E12

s

M68

M14

s

.

M68

and

and

.

s

s

E54

M68

RA

BR

ST

RS

BT

HA

.

.

EL

IDX

EL-63

TURN SIGNAL AND HAZARD WARNING LAMPS

System Description (Cont’d)

WITH MULTI-REMOTE CONTROL SYSTEM

Power is supplied at all times:

●

through 10A fuse [No. , located in the fuse block (J/B)]

●

to multi-remote control relay terminals

Ground is supplied to multi-remote control relay terminal

through the smart entrance control unit.

Refer to ‘‘MULTI-REMOTE CONTROL SYSTEM’’ (EL-174).

When multi-remote control relay is energized.

Power is supplied through terminal

●

to front combinaton lamp LH terminal

●

to combination meter terminal

●

to rear combination lamp LH terminal

Power is supplied through terminal

●

to front combination lamp RH terminal

●

to combination meter terminal

●

to rear combination lamp RH terminal

Ground is supplied to terminal

Ground is supplied to terminal

Ground is supplied to combination meter terminal

With power and ground supplied, the smart entrance control unit controls the flashing of the hazard warning

lamps.

3

s

24

s

6

s

40

s

2

of each front combination lamp through body grounds

s

1

of each rear combination lamp through body grounds

s

2

5

,

s

s

of the multi-remote control relay:

1

s

2

.

s

of the multi-remote control relay:

1

s

2

.

s

7

and

s

.

s

1

, when the multi-remote control system is triggered

s

33

through body grounds

s

M14

and

s

s

s

E12

M14

M68

.

and

and

s

s

E54

M68

.

.

EL-64

TURN SIGNAL AND HAZARD WARNING LAMPS

Wiring Diagram — TURN —

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL-65

EL

IDX

AEL278C

TURN SIGNAL AND HAZARD WARNING LAMPS

Wiring Diagram — TURN — (Cont’d)

EL-66

AEL279C

TURN SIGNAL AND HAZARD WARNING LAMPS

Symptom Possible cause Repair order

Turn signal and hazard warning

lamps do not operate.

Turn signal lamps do not operate

but hazard warning lamps operate.

Hazard warning lamps do not operate but turn signal lamps operate.

Front turn signal lamp LH or RH

does not operate.

Rear turn signal lamp LH or RH

does not operate.

LH and RH turn indicators do not

operate.

LH or RH turn indicator does not

operate.

Trouble Diagnoses

1. Hazard switch

2. Combination flasher unit

3. Open in combination flasher unit

circuit

1. 7.5A fuse

2. Hazard switch

3. Turn signal switch

4. Open in turn signal switch circuit

1. 10A fuse

2. Hazard switch

3. Open in hazard switch circuit

1. Bulb

2. Grounds

1. Bulb

2. Grounds

1. Ground 1. Check grounds

1. Bulb 1. Check bulb in combination meter.

s

s

E12

M14

and

and

s

s

E54

M68

1. Check hazard switch.

2. Refer to combination flasher unit check.

3. Check wiring to combination flasher unit for open circuit.

1. Check 7.5A fuse [No.

(J/B)]. Turn ignition switch ON and verify battery

positive voltage is present at terminal

switch.

2. Check hazard switch.

3. Check turn signal switch.

4. Check G wire between combination flasher unit and

turn signal switch for open circuit.

1. Check 10A fuse [No.

Verify battery positive voltage is present at terminal

3