Nissan Frontier Cooling Systems LC 2000 Owner's Manual

ENGINE LUBRICATION &

COOLING SYSTEMS

SECTION LC

GI

MA

EM

LC

EC

CONTENTS

PREPARATION/PRECAUTION.......................................2

Special Service Tools ..................................................2

Liquid Gasket Application Procedure..........................3

ENGINE LUBRICATION SYSTEM..................................4

Lubrication Circuit........................................................4

Oil Pressure Check......................................................4

Oil Pump......................................................................5

Removal And Installation........................................5

Disassembly And Assembly....................................5

Inspection................................................................6

Regulator Valve Inspection .....................................6

Oil Filter...................................................................6

Oil Filter Bracket .....................................................7

ENGINE COOLING SYSTEM..........................................8

Cooling Circuit .............................................................8

System Check..............................................................8

Checking Cooling System Hoses ...........................8

Checking Cooling System For Leaks .....................8

Checking Radiator...................................................8

Checking Radiator Cap...........................................9

Water Pump...............................................................10

Removal And Installation ......................................10

Inspection..............................................................11

Thermostat.................................................................11

Removal................................................................11

Inspection..............................................................11

Installation.............................................................12

Radiator .....................................................................12

Removal And Installation ......................................12

Cooling Fan (Crankshaft driven) ...............................13

Removal And Installation ......................................13

Inspection..............................................................14

Refilling Engine Coolant............................................14

Inspection..............................................................14

Overheating Cause Analysis .....................................15

SERVICE DATA AND SPECIFICATIONS (SDS) ..........16

Engine Lubrication System........................................16

Oil pressure......................................................16

Regulator valve.................................................16

Oil pump...........................................................16

Engine Cooling System.............................................16

Thermostat........................................................16

Radiator............................................................16

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL

IDX

PREPARATION/PRECAUTION

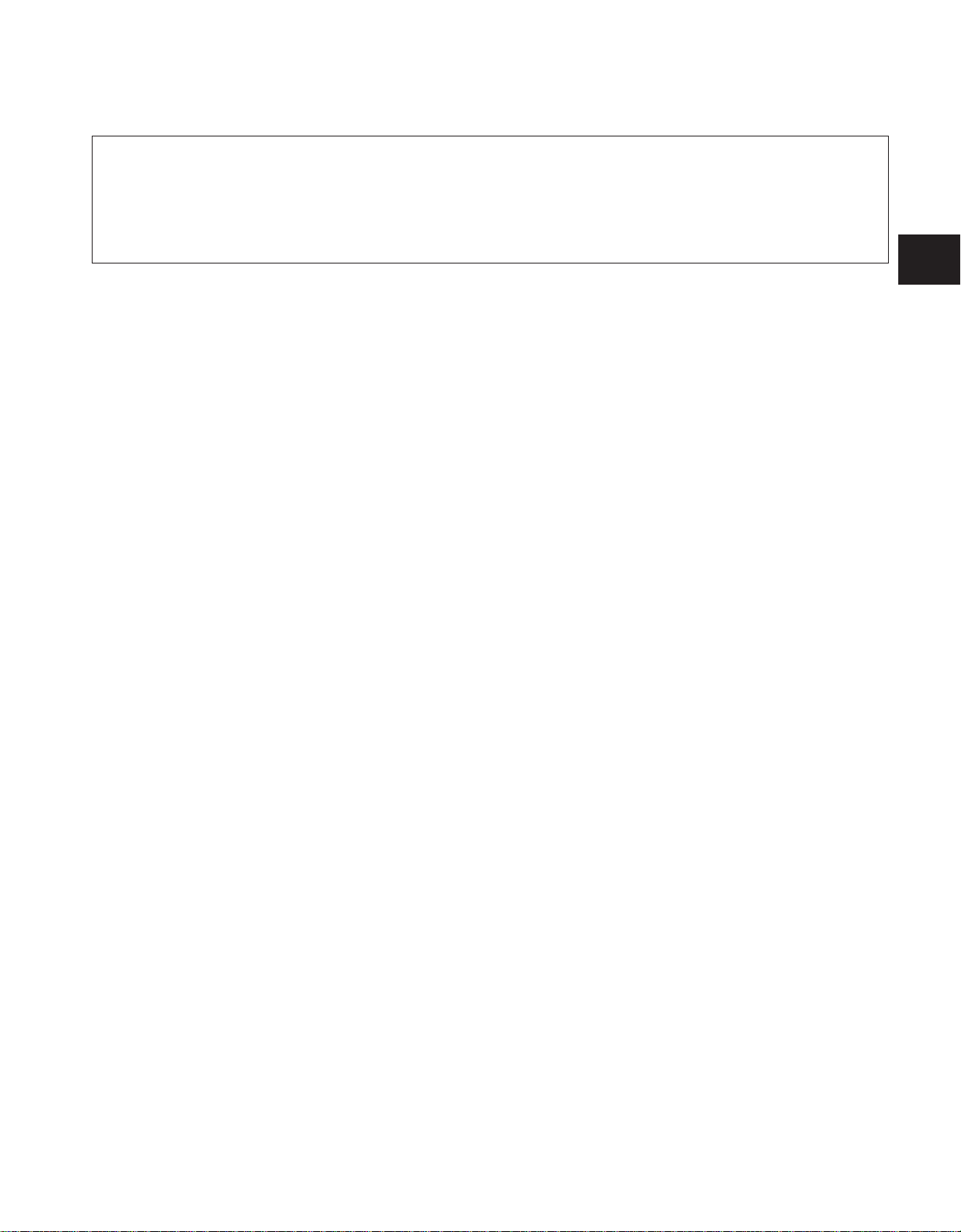

Special Service Tools

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

ST25051001

(J25695-1)

Oil pressure gauge

Description

Measuring oil pressure

ST25052000

(J25695-2)

Hose

KV10115801

(J38956)

Oil filter wrench

EG17650301

(J33984-A)

Radiator cap tester adapter

WS39930000

(—)

Tube presser

NT558

NT559

NT362

NT564

Maximum measuring range:

2,452 kPa (25 kg/cm

Adapting oil pressure gauge to cylinder block

Removing oil filter

Adapting radiator cap tester to radiator filler

neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

Pressing the tube of liquid gasket

2

, 356 psi)

NT052

LC-2

PREPARATION/PRECAUTION

SEM371C

AEM080

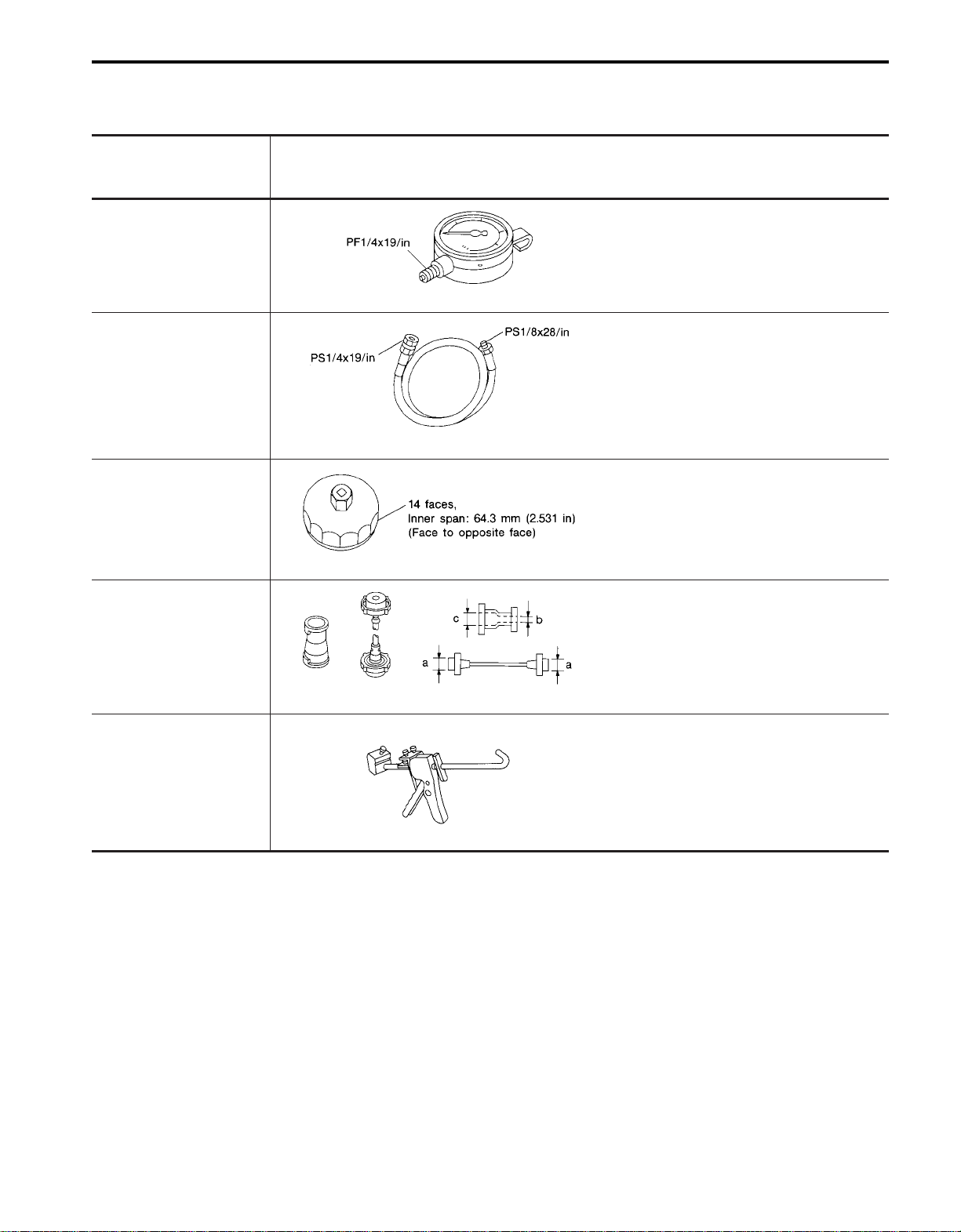

Liquid Gasket Application Procedure

a. Use a scraper to remove all traces of old liquid gasket

from mating surface and grooves. Also, completely clean

any oil from these areas.

b. Apply a continuous bead of liquid gasket to mating sur-

faces. (Use Genuine RTV silicone sealant part No. 999

MP-A7007 or equivalent.)

●

Be sure liquid gasket is 3.5 to 4.5 mm (0.138 to 0.177 in)

dia. (for oil pan).

●

Be sure liquid gasket is 2.0 to 3.0 mm (0.079 to 0.118 in)

dia. (in areas except oil pan).

c. Apply liquid gasket around the inner side of bolt holes

(unless otherwise specified).

d. Assembly should be done within 5 minutes after coating.

e. Wait at least 30 minutes before refilling engine oil and

engine coolant.

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

LC-3

EL

IDX

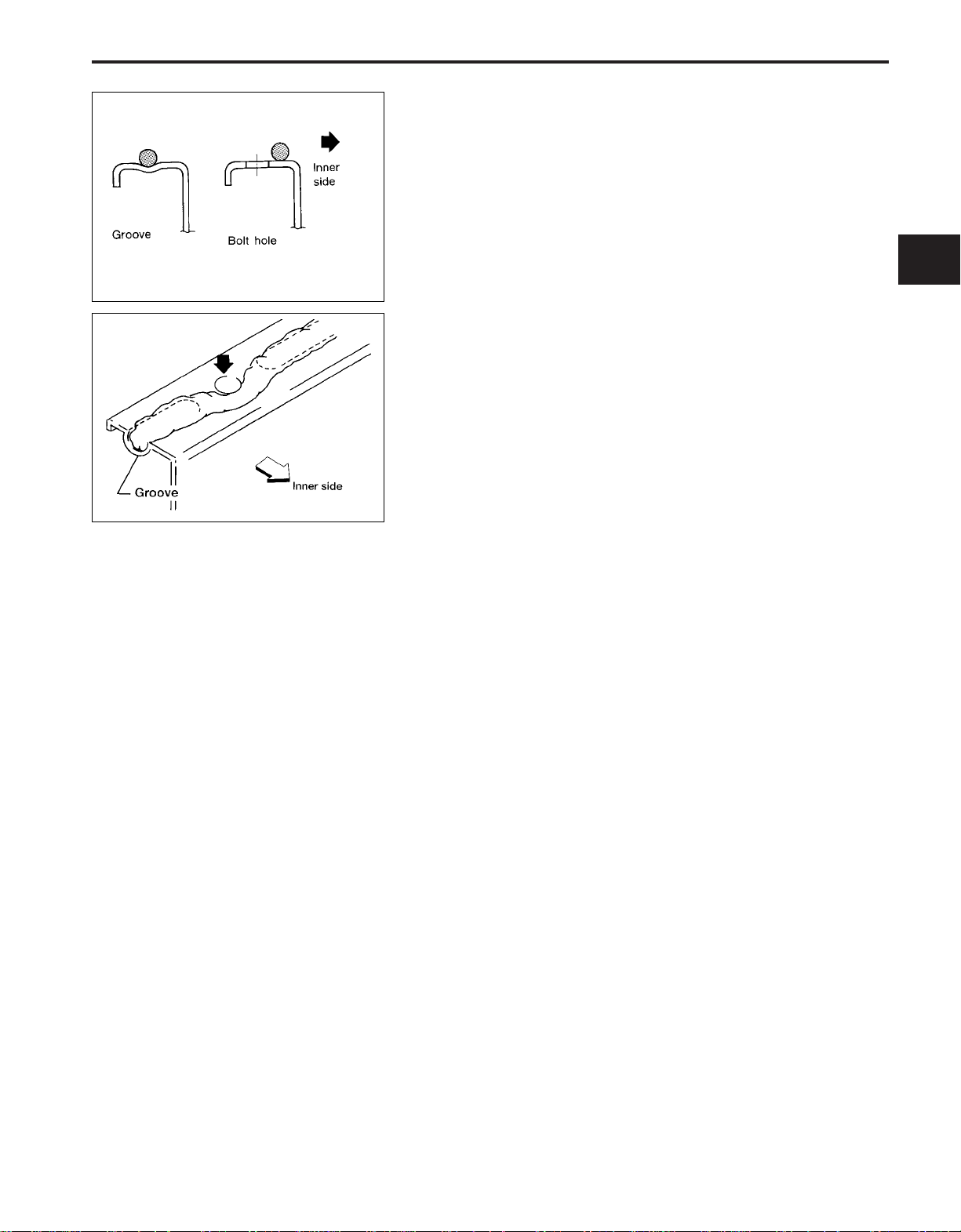

ENGINELUBRICATIONSYSTEM

LubricationCircuit

SLC082B

ALC120

SLC926

OilPressureCheck

WARNING:

●

Becarefulnottoburnyourself,astheengineandoilmay

behot.

●

Oilpressurecheckshouldbedonein‘‘Neutralposition’’

(M/T)or‘‘Parkingposition’’(A/T).

1. Checkoillevel.

2. Removeoilpressureswitch.

3. Installpressuregauge.

4. Startengineandwarmituptonormaloperatingtemperature.

5. Checkoilpressurewithenginerunningunderno-load.

Enginespeed

rpm

Idlespeed Morethan59(0.6,9)

2,000 412-451(4.2-4.6,60-65)

Ifdifferenceisextreme,checkoilpassageandoilpumpforoil

leaks.

6. Installoilpressureswitchwithsealant.

:12.25-17.15Nzm(1.3-1.7kg-m,9-12ft-lb)

Approximatedischargepressure

kPa(kg/cm

2

,psi)

LC-4

ENGINE LUBRICATION SYSTEM

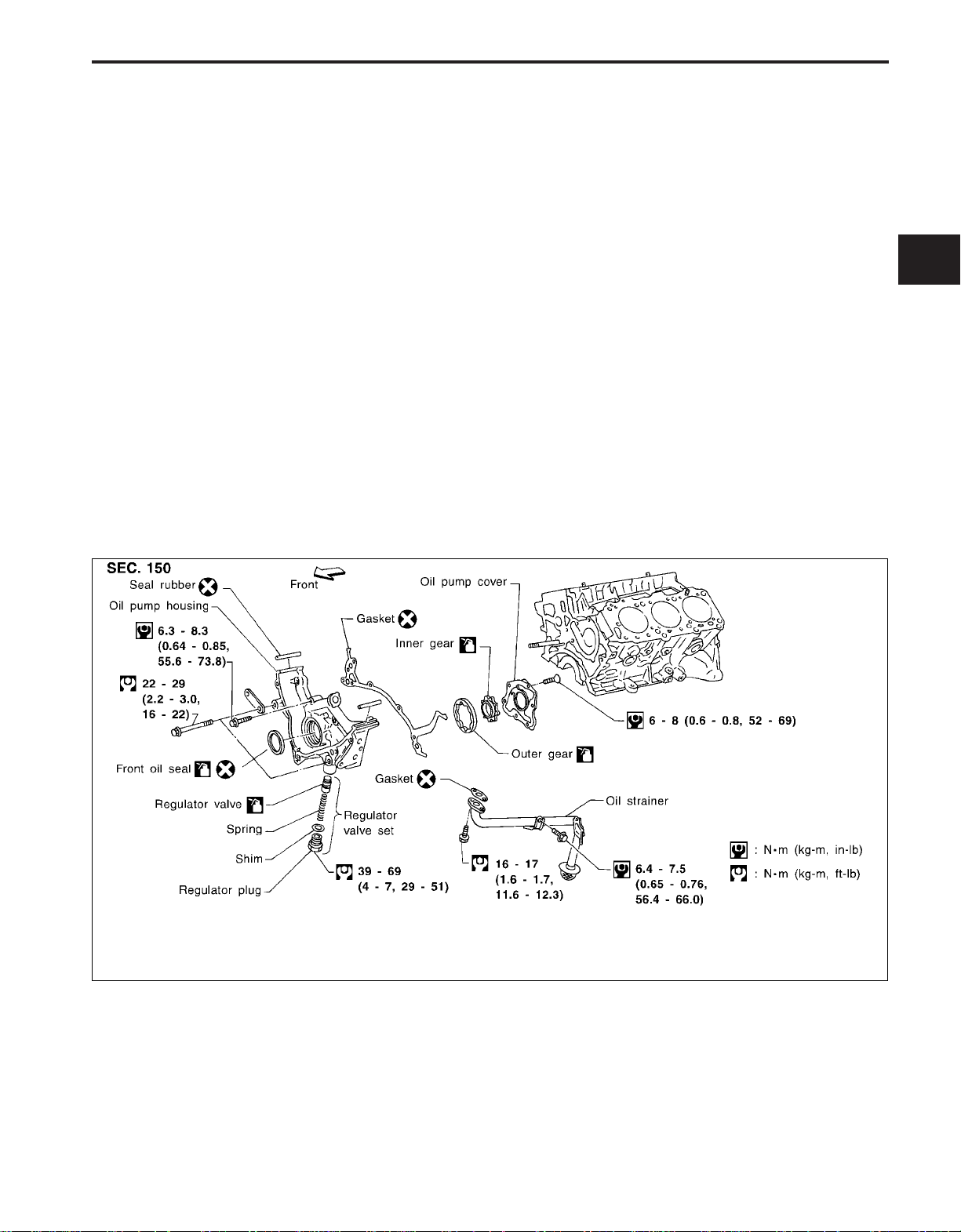

Oil Pump

REMOVAL AND INSTALLATION

1. Drain engine oil.

2. Drain engine coolant from drain plug on radiator.

3. Remove air duct (from mass air flow sensor to throttle body).

4. Remove cooling fan.

5. Remove radiator hoses (upper and lower) and fan shroud.

Refer to ‘‘Radiator’’.

6. Remove drive belts. Refer to MA section (‘‘Checking Drive

Belts’’).

7. Remove crankshaft pulley and front upper and lower belt cov-

ers. Refer to EM section (‘‘TIMING BELT’’).

8. Remove oil pan. Refer to EM section (‘‘OIL PAN’’).

9. Remove oil strainer.

10. Remove oil pump assembly.

DISASSEMBLY AND ASSEMBLY

GI

MA

EM

LC

EC

FE

CL

MT

AT

●

Always replace with new oil seal and gasket.

●

When installing oil pump, apply engine oil to inner and

outer gears.

●

Be sure that O-ring is properly installed.

SLC117B

TF

PD

FA

RA

BR

ST

RS

BT

HA

LC-5

EL

IDX

Loading...

Loading...