Nissan Frontier Clutch CL 2000 Owner's Manual

SECTION CL

CONTENTS

CLUTCH

GI

MA

EM

LC

EC

PRECAUTIONS AND PREPARATION............................2

Precautions..................................................................2

Special Service Tools..................................................2

Commercial Service Tools...........................................2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................3

NVH Troubleshooting Chart.........................................3

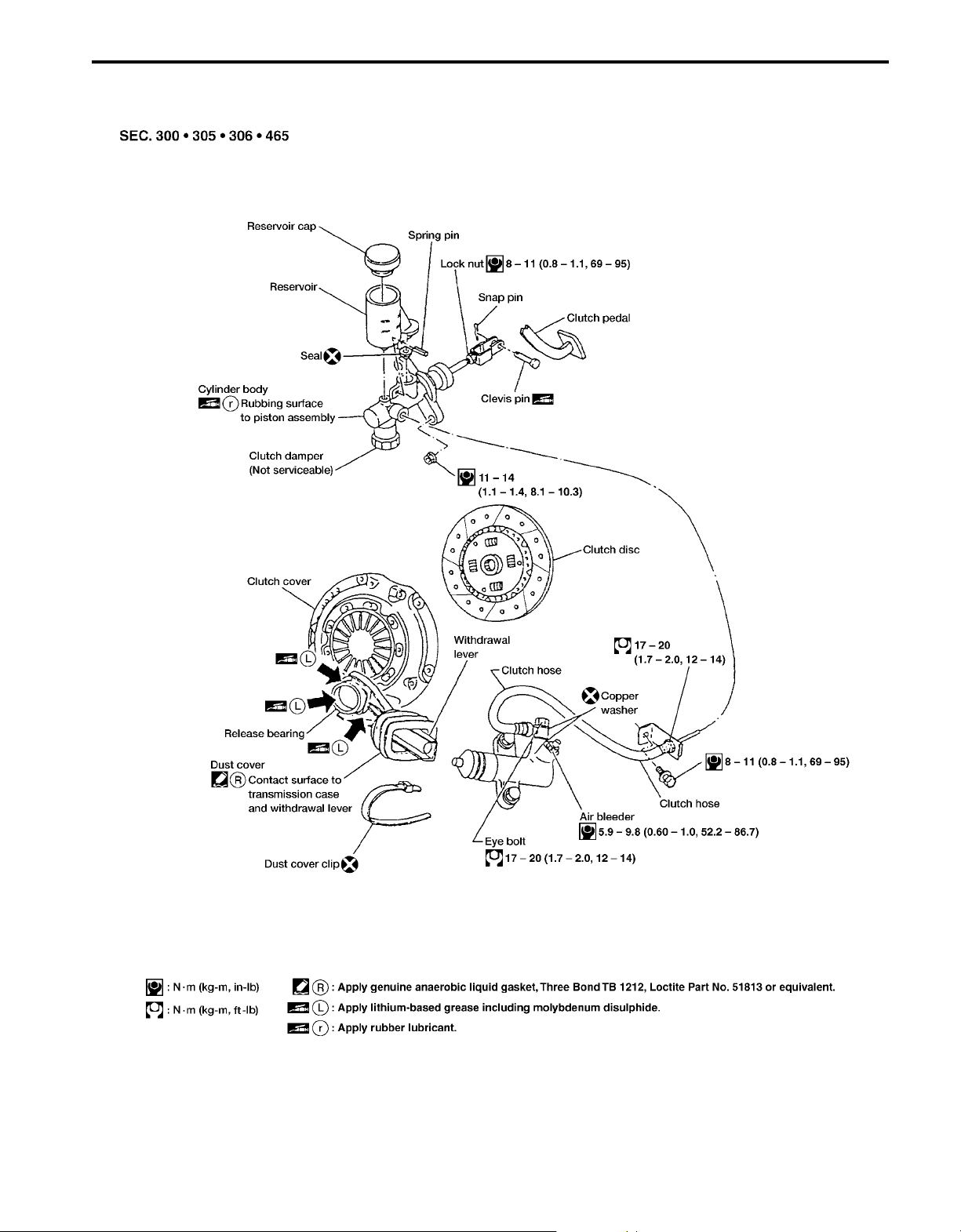

CLUTCH SYSTEM...........................................................4

Clutch Pedal ................................................................5

INSPECTION AND ADJUSTMENT.................................6

Adjusting Clutch Pedal ................................................6

Air Bleeding Procedure................................................7

HYDRAULIC CLUTCH CONTROL .................................8

Clutch Master Cylinder (With clutch damper) .............8

Operating Cylinder.......................................................9

CLUTCH RELEASE MECHANISM...............................10

CLUTCH DISC AND CLUTCH COVER........................12

Clutch Disc.................................................................12

Clutch Cover and Flywheel .......................................13

SERVICE DATA AND SPECIFICATIONS (SDS) ..........14

General Specifications...............................................14

Clutch Control System..........................................14

Inspection and Adjustment ........................................14

FE

CL

MT

AT

TF

PD

FA

RA

BR

ST

RS

BT

HA

EL

IDX

PRECAUTIONSANDPREPARATION

Precautions

●

RecommendedfluidisbrakefluidDOT3.

●

Neverreusedrainedbrakefluid.

●

Becarefulnottosplashbrakefluidonpaintedareas.

●

Whenremovingandinstallingclutchpiping,useasuitabletool.

●

Usenewbrakefluidtocleanorwashallpartsofmaster

cylinder,operatingcylinderandclutchdamper.

●

Neverusemineraloilssuchasgasolineorkerosene.They

willruintherubberpartsofthehydraulicsystem.

SBR686C

WARNING:

Aftercleaningtheclutchdisc,wipeitwithadustcollector.Do

notusecompressedair.

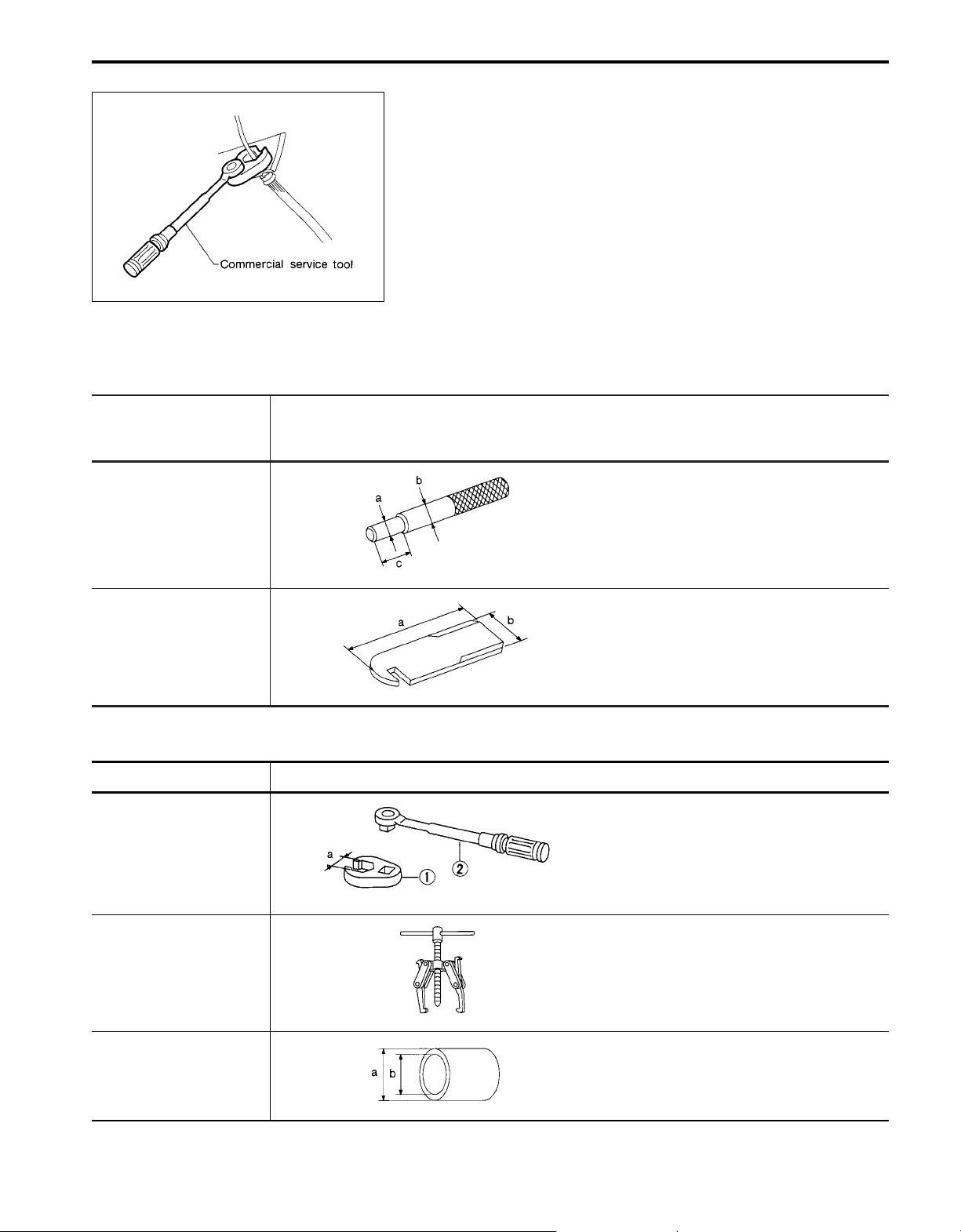

SpecialServiceTools

TheactualshapesofKent-Mooretoolsmaydifferfromthoseofspecialservicetoolsillustratedhere.

Toolnumber

(Kent-MooreNo.)

Toolname

Description

ST20630000

(J26366)

Clutchaligningbar

NT405

ST20050240

(—)

Diaphragmspring

adjustingwrench

NT404

Toolname Description

1

Flarenutcrowfoot

s

2

Torquewrench

s

NT360

Bearingpuller

Installingclutchcoverandclutchdisc

a:15.9mm(0.626in)dia.

b:22.8mm(0.898in)dia.

c:55mm(2.17in)

Adjustingunevennessofclutchcoverdiaphragmspring

a:150mm(5.91in)

b:25mm(0.98in)

CommercialServiceTools

Removingandinstallingclutchpiping

a:10mm(0.39in)

Removingreleasebearing

Bearingdrift

NT077

NT474

Installingreleasebearing

a:52mm(2.05in)dia.

b:45mm(1.77in)dia.

CL-2

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspection. If necessary, repair or replace these parts.

Reference page

SUSPECTED PARTS

(Possible cause)

CL-6

CL-7

CL-8

CL-9

CL-10

Refer to EM section

CL-12

CL-12

CL-12

CL-12

CL-12

CL-12

CL-12

CL-12

CL-13

CL-13

CL-13

CL-13

GI

MA

EM

LC

EC

FE

CL

MT

AT

Symptom

CLUTCH PEDAL (Free play out of adjustment)

CLUTCH LINE (Air in line)

MASTER CYLINDER PISTON CUP (Damaged)

OPERATING CYLINDER PISTON CUP (Damaged)

ENGINE MOUNTING (Loose)

RELEASE BEARING (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

CLUTCH COVER (Distortion)

Clutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1 2 2

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disengage 1234 55555 5667

TF

FLYWHEEL (Distortion)

PD

FA

RA

BR

ST

RS

BT

HA

CL-3

EL

IDX

CLUTCH SYSTEM

CL-4

ACL096

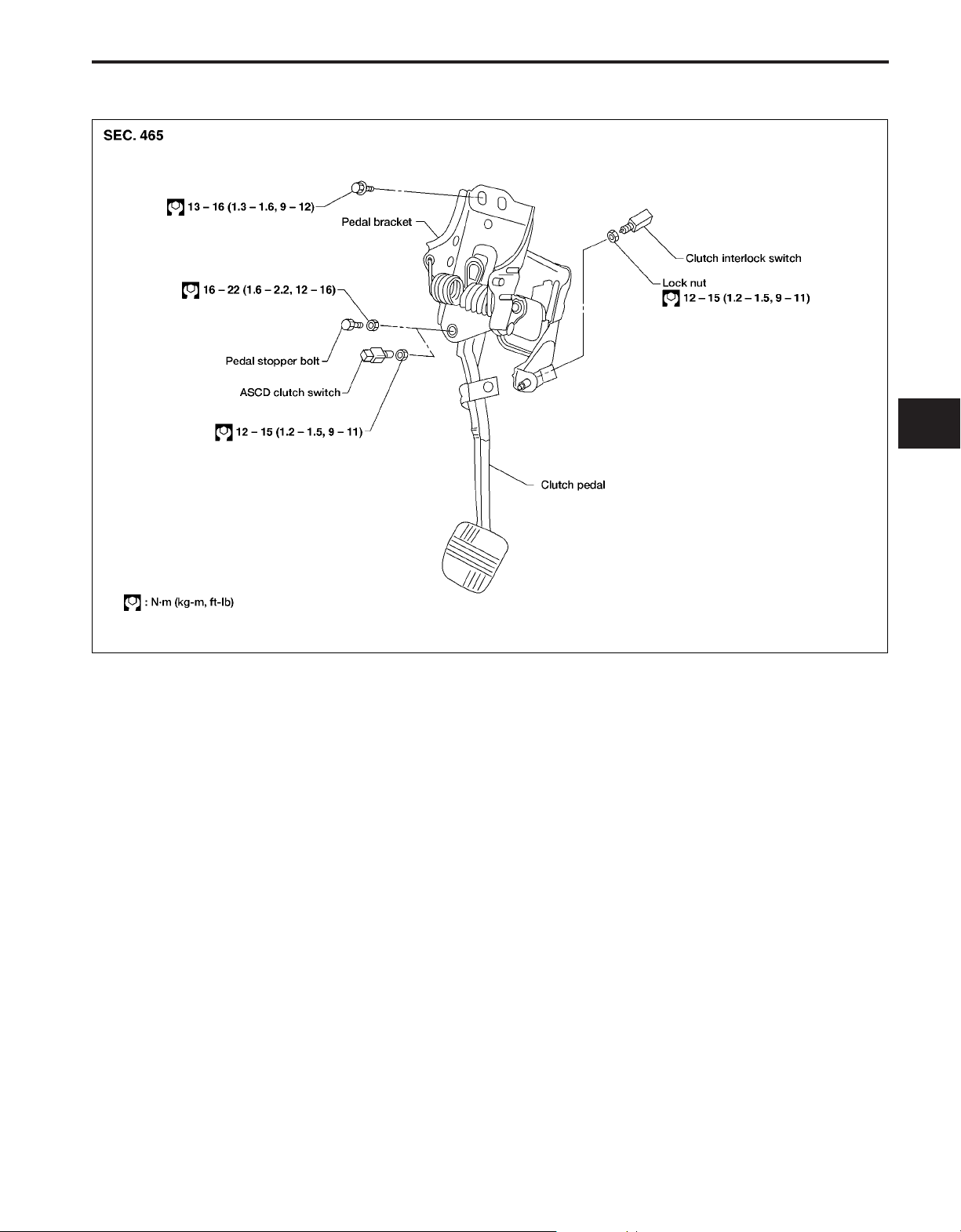

CLUTCH SYSTEM

Clutch Pedal

GI

MA

EM

LC

EC

FE

CL

MT

AT

ACL093

TF

PD

FA

RA

BR

ST

RS

BT

HA

CL-5

EL

IDX

Loading...

Loading...