Nissan Almera 2002 User Manual

MAINTENANCE

CONTENTS

PRE-DELIVERY INSPECTION ITEMS............................2

GENERAL MAINTENANCE............................................3

PERIODIC MAINTENANCE (EXCEPT FOR

EUROPE).........................................................................4

Engine and Emission Control Maintenance

(QG18DE/SR20DE engine).........................................4

Engine Maintenance (YD22DDTi engine)...................6

Chassis and Body Maintenance..................................7

Maintenance Under Severe Driving Conditions..........8

SEVERE DRIVING CONDITIONS

PERIODIC MAINTENANCE ............................................9

Maintenance Schedule for Petrol Engines

(Annual Mileage < 30,000 km/year)............................9

QG18DE/SR20DE ENGINES

CHASSIS AND BODY MAINTENANCE

Maintenance Schedule for Diesel Engines

(Annual Mileage < 30,000 km/year)..........................11

YD22DDTI ENGINE

CHASSIS AND BODY MAINTENANCE

..................................................11

................................8

......................................9

......................10

......................12

SECTION

Maintenance Under Severe Driving Conditions

(Annual Driving Distance < 30,000 km/year)............13

Maintenance Schedule for Petrol Engines

(Annual Mileage > 30,000 km/year)..........................15

QG18DE/SR20DE ENGINES

CHASSIS AND BODY MAINTENANCE

Maintenance Schedule for Diesel Engines

(Annual Mileage > 30,000 km/year)..........................17

YD22DDTI ENGINE

CHASSIS AND BODY MAINTENANCE

Maintenance Under Severe Driving Conditions

(Annual Driving Distance > 30,000 km/year)............19

RECOMMENDED FLUIDS AND LUBRICANTS...........20

Fluids and Lubricants ................................................20

SAE Viscosity Number ..............................................21

GASOLINE ENGINE

DIESEL ENGINE

Engine Coolant Mixture Ratio....................................22

MA

....................................15

......................16

..................................................17

......................18

.................................................21

......................................................21

NLMA0036

PRE-DELIVERY INSPECTION ITEMS

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD — engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

MA-2

NLMA0004

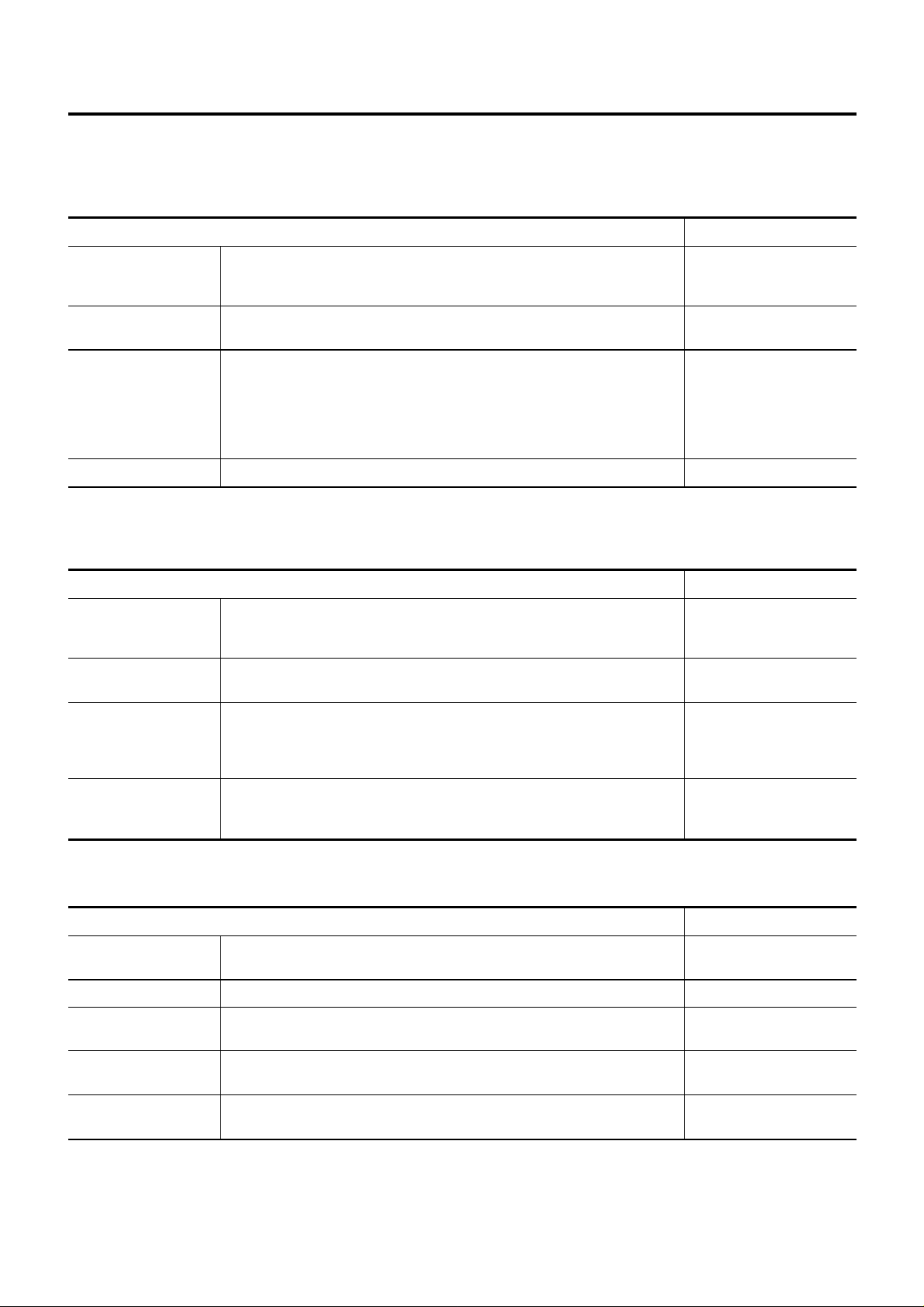

GENERAL MAINTENANCE

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

Tires Check the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.

—

Windshield wiper

blades

Doors and engine

hood

Tire rotation Tires should be rotated every 10,000 km (6,000 miles). SU-8

Check for cracks or wear if not functioning correctly. —

Check that all doors, the engine hood, the trunk lid and back door operate

properly.Also ensure that all latches lock securely. Lubricate if necessary.

Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.

BT-7

BT-13

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

Item Reference page

Lamps Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps,

and other lamps are all operating properly and installed securely. Also check

headlamp aim.

Warning lamps and

chimes

Steering wheel Check that it has the specified play.

Make sure that all warning lamps and buzzers/chimes are operating properly.

Check for changes in the steering conditions, such as excessive free play,

hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)

—

—

—

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.

RS-3

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.

Item Reference page

Windshield washer

fluid

Engine coolant level Check the coolant level when the engine is cold. LC-19, LC-59

Engine oil level Check the level after parking the vehicle (on level ground) and turning off

Brake and clutch

fluid levels

Battery Check the fluid level in each cell. It should be between the “MAX” and “MIN”

Check that there is adequate fluid in the tank. —

the engine.

Make sure that the brake and clutch fluid levels are between the “MAX” and

“MIN” lines on the reservoir.

lines.

LC-8, LC-28

BR-7

—

MA-3

NLMA0046

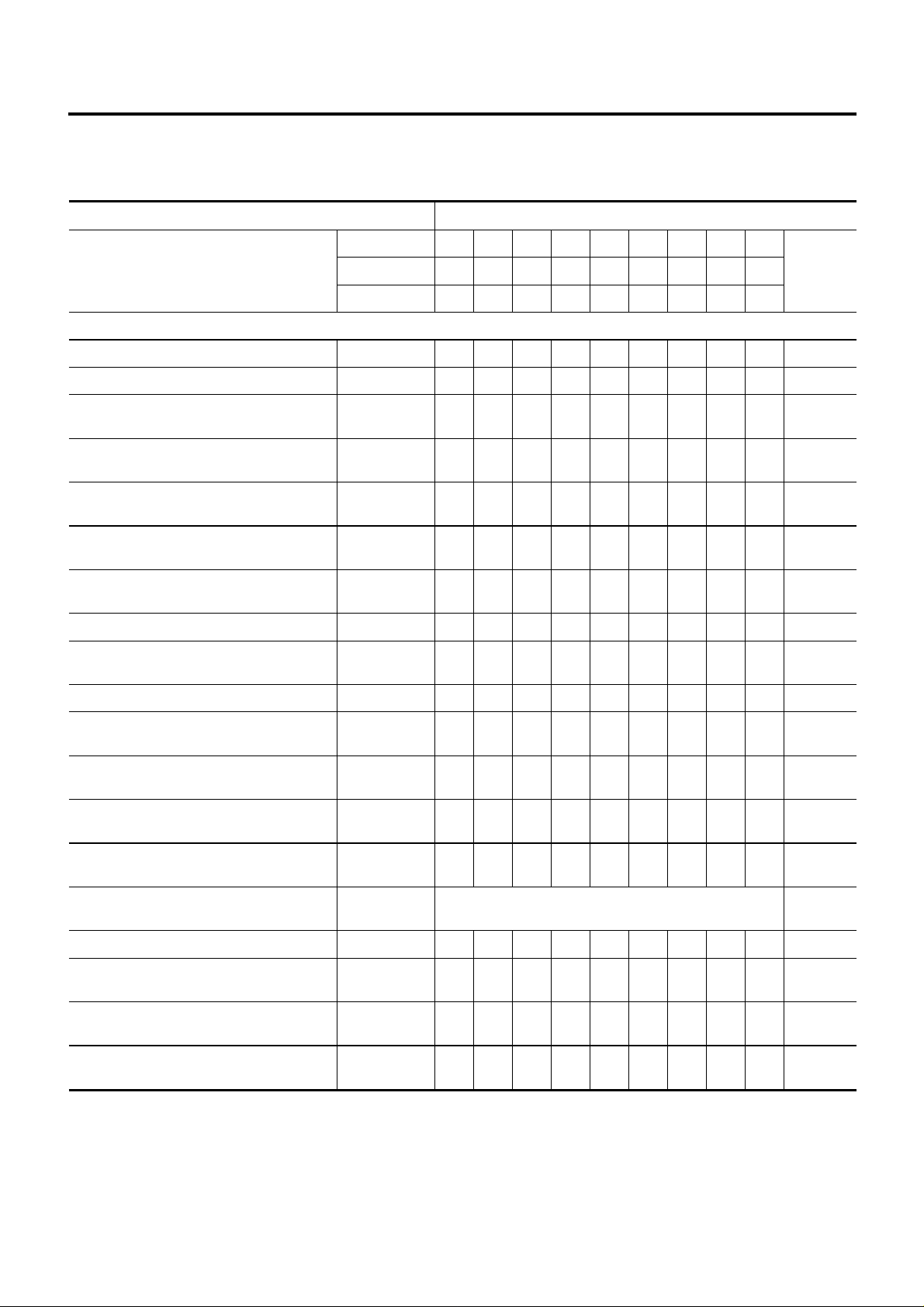

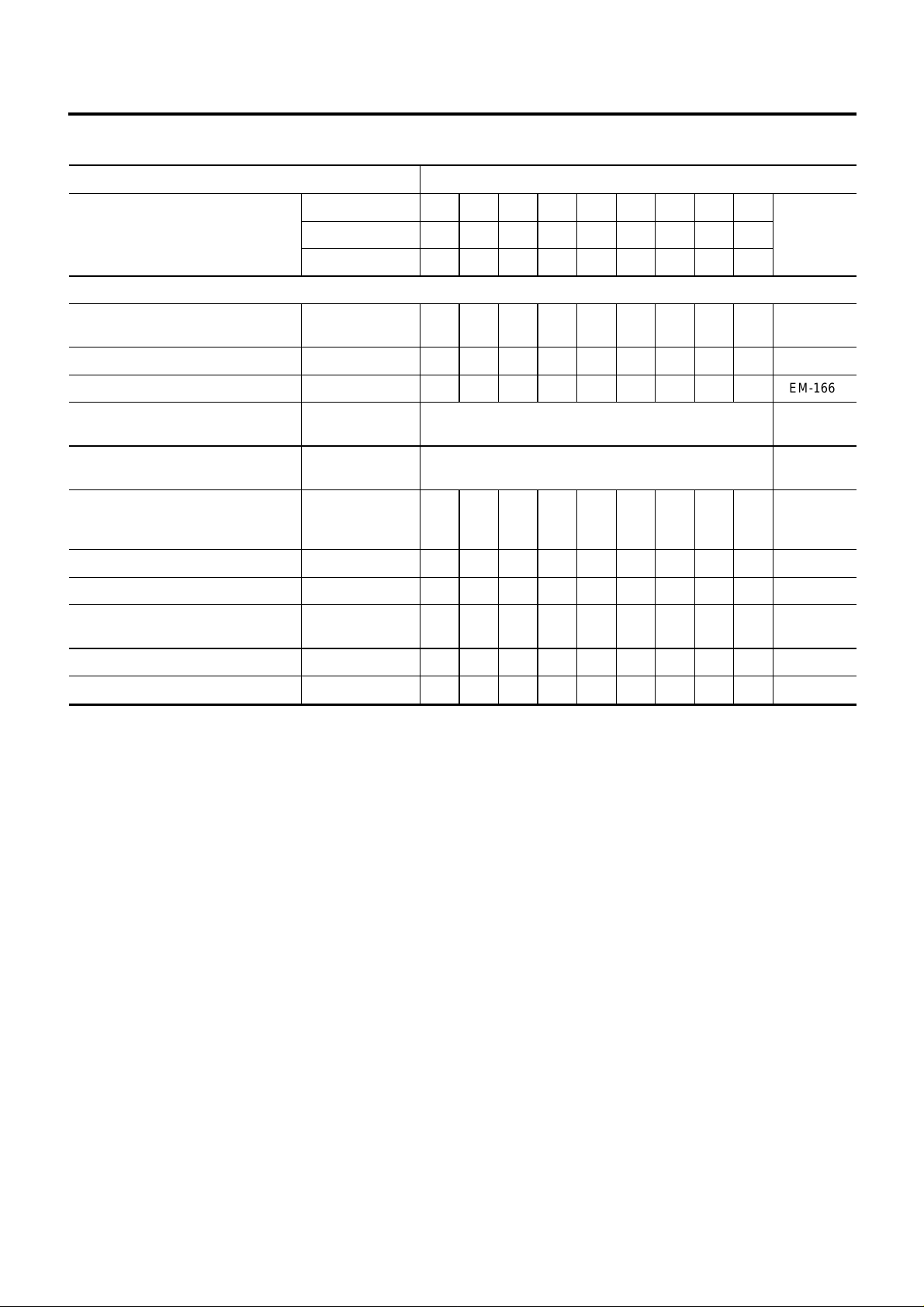

PERIODICMAINTENANCE(EXCEPTFOREUROPE)

EngineandEmissionControlMaintenance(QG18DE/SR20DEengine)

EngineandEmissionControlMaintenance

(QG18DE/SR20DEengine)

Abbreviations: I=Inspectandcorrectorreplaceasnecessary,R=Replace,A=Adjust,C=Clean,E=Checkandcorrectthe

enginecoolantmixtureratio.

MAINTENANCEOPERATION MAINTENANCEINTERVAL

NLMA0046S01

km×1,000 1 10 20 30 40 50 60 70 80

Performeitheratnumberofkilometers

(miles)ormonths,whichevercomesfirst.

Torqueofmanifolds&exhausttubenuts*1 I —

Intake&exhaustvalveclearance*2 AAAAEM-42

DriveBelts I*1 I*1 I I*1 I

Engineoil(UseAPISE,SF,SG,SHorSJ

oil.)★

Engineoilfilter(UsePartNo.15208

65F01orequivalent)★

Enginecoolant(UseNissangenuine

enginecoolantorequivalentinitsquality.)

Coolingsystem IIII

Fuellines I I FE-5

Aircleanerfilter(Viscouspapertype)★ RR

(mile×1,000) (0.6) (6) (12) (18) (24) (30) (36) (42) (48)

Months — 612182430364248

Underhoodandundervehicle

RRRRRRRR

RRRRRRRR

SeeNOTE(1)

ER

Refer-

ence

page

EM-17,

EM-86

LC-8,

LC-28

LC-9,

LC-28

LC-19,

LC-59

LC-12,

LC-32

EM-18,

EM-88

Fuelfilter SeeNOTE(2) FE-9

Positivecrankcaseventilation(PCV)sys-

tem

Sparkplugs(Conventionaltype)*3 R R

Sparkplugs(Conventionaltype,For

leadedfuel)*1

Sparkplugs(Conventionaltype,For

unleadedfuel)*1

Sparkplugs(PLATINUMTYPE) Replaceevery100,000km(60,000miles)

Ignitionleads I I EC-816

EVAPvaporlines(Withcarboncanister) I I

Vacuumhoses&connections*1 IIII

Heatedoxygensensor(Exhaustgassensor)

NOTE:

Maintenanceitemwith“★”shouldbeperformedmorefrequentlyaccordingto“MaintenanceUnderSevereDrivingCondi-

tions”.

(1)UseNissangenuineenginecoolantorequivalentinitsquality,inordertoavoidpossiblealuminiumcorrosionwithinthe

enginecoolingsystemcausedbytheuseofnon-genuineenginecoolant.Afterfirstreplacement,replaceevery40,000km(24,

000miles)or24months.

(2)Maintenance-freeitem.Forserviceprocedures,refertoFEsection.

I*1 I*1 I*1 I*1

IRIRIRIR

IIIRIIIR

II

EC-42,

EC-576

EM-19,

EM-89

EM-19,

EM-89

EM-19,

EM-89

EM-19,

EM-89

EC-41,

EC-575

EC-33,

EC-568

EC-191,

EC-717

MA-4

PERIODIC MAINTENANCE (EXCEPT FOR EUROPE)

Engine and Emission Control Maintenance (QG18DE/SR20DE engine) (Cont’d)

*1: Models without three way catalyst

*2: For models with three way catalyst, periodic maintenance is not required. However, if valve noise increases, check valve clearance.

*3: Models with three way catalyst

MA-5

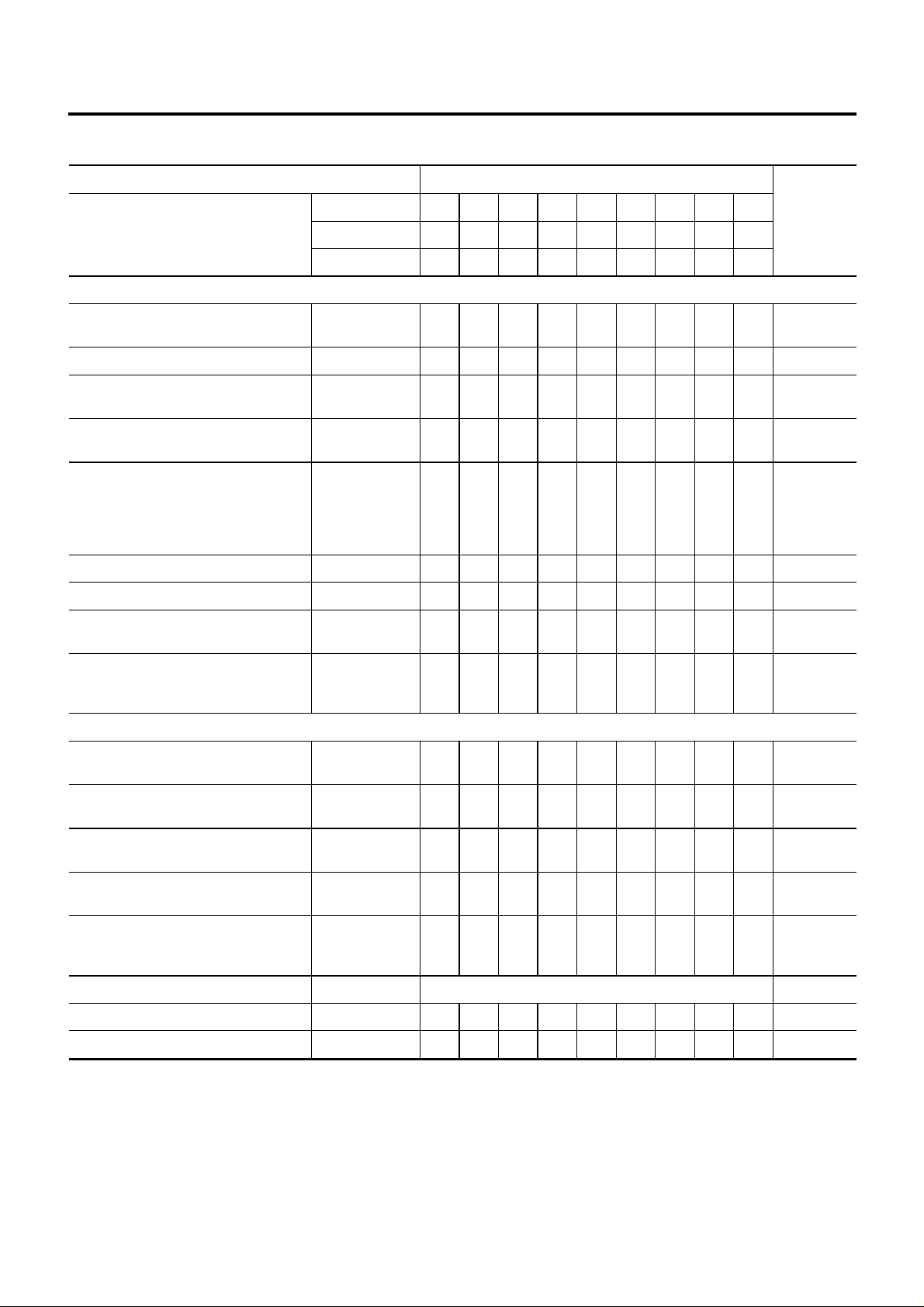

PERIODIC MAINTENANCE (EXCEPT FOR EUROPE)

Engine Maintenance (YD22DDTi engine)

Engine Maintenance (YD22DDTi engine)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, A = Adjust, D = Check filter and drain water.

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of kilometers (miles) or months, whichever

comes first.

Torque of manifolds & exhaust tube

nuts

Intake & exhaust valve clearance See NOTE (1) EM-214

Drive belts IIIIIEM-166

Engine oil (Use API CD, CE, CF,

CF-4 oil.)★

Engine oil filter (Use Eco filter or

equivalent)★

Engine coolant (Use Nissan genuine

engine coolant or equivalent in its

quality.)

Cooling system IIIILC-53

km × 1,000 1 10 20 30 40 50 60 70 80

(mile × 1,000) (0.6) (6) (12) (18) (24) (30) (36) (42) (48)

Months — 6 12182430364248

Underhood and under vehicle

I —

See NOTE (5) Replace every 15,000 km (9,000 miles) or 12 months LC-47

See NOTE (2) Replace every 15,000 km (9,000 miles) or 12 months LC-48

See NOTE (3) E R LC-59

=NLMA0046S02

Reference

page

Fuel lines I I FE-15

Air cleaner filter (Viscous paper

type)★

Fuel filter★ DDDRDDDR FE-15

Injection nozzles See NOTE (4) EC-1085

NOTE:

Maintenance item with “★” should be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

(1) If valve noise increases, check valve clearance.

(2) Oil filter element assembly (part No. 15208 AD200) and O-ring seal (part No. 15226 AD200) are replacement parts.

(3) Use Nissan genuine engine coolant or equivalent in its quality, in order to avoid possible aluminium corrosion within the

engine cooling system caused by the use of non-genuine engine coolant. After first replacement, replace every 40,000 km (24,

000 miles) or 24 months.

(4) If engine power decreases, black exhaust smoke is emitted or engine noise increases, check injection nozzles and, if

necessary, replace injection nozzle assembly.

(5) Never use CG-4 oil.

R R EM-169

MA-6

PERIODIC MAINTENANCE (EXCEPT FOR EUROPE)

Chassis and Body Maintenance

Chassis and Body Maintenance

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, A = Adjust, L = Lubricate

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform either at number of kilometers

(miles) or months, whichever comes

first.

Brake & clutch fluid (For level &

leaks)★

Brake fluid★ R R BR-7

Brake booster vacuum hoses, connec-

tions & check valve

Power steering fluid & lines (For level

& leaks)

Brake, clutch & exhaust systems IIIIIIII

H·CVT fluid (For level and leaks) IIIIIIII AT-10

km × 1,000 1 10 20 30 40 50 60 70 80

(mile × 1,000) (0.6) (6) (12) (18) (24) (30) (36) (42) (48)

Months — 6 12182430364248

Underhood and under vehicle

IIIIIIII BR-7

I I BR-16

I*1 I I*1 I I*1 I I*1 I ST-7

=NLMA0046S03

Reference

page

BR-7,

CL-5,

FE-13,

FE-15,

FE-23

H·CVT fluid★ R R AT-11

Manual transaxle gear oil (For level &

leaks)

Steering gear & linkage, axle & suspension parts & drive shafts★

Outside and inside

Wheel alignment (if necessary, rotate

& balance wheels)

Brake pads, rotors & other brake components★

Lock, hinges & hoods latch★ L*1 L L*1 L L*1 L L*1 L

Seat belts, buckles, retractors,

anchors & adjuster

Foot brake, parking brake & clutch

(For free play, stroke & operation)

Ventilation air filter★ Replace every 12,000 km (7,500 miles) or 12 months HA-103

Supplemental air bag systems See NOTE (1) RS-16

NISSAN Mobility System See NOTE (2) IIIII —

NOTE:

(1) Inspect at the first 10 years, and then every 2 years.

Maintenance item with “★” should be performed more frequently according to “Maintenance Under Severe Driving Conditions”.

(2) Check expiration date of the tyre sealant bottle. Replace if necessary.

*1: Models except for Australia

*2: Models without three way catalyst

I*1 I I*1 I I*1 I I*1 I

I*2IIII

IIII

IIIIIIII

IIIIRS-3

I*1 I I*1 I I*1 I I*1 I

MT-10,

MT-11

ST-7,

SU-5,

SU-18

SU-15,

SU-27

BR-24,

BR-28

BT-7,

BT-13

BR-11,

BR-40,

CL-5

MA-7

Loading...

Loading...