ENGINE LUBRICATION &

COOLING SYSTEMS

CONTENTS

QG

ENGINE LUBRICATION SYSTEM..................................3

Precautions..................................................................3

LIQUID GASKET APPLICATION PROCEDURE

Preparation ..................................................................3

SPECIAL SERVICE TOOLS

Lubrication Circuit........................................................4

Oil Pressure Check......................................................5

Oil Pump......................................................................5

REMOVAL AND INSTALLATION

DISASSEMBLY AND ASSEMBLY

INSPECTION

REGULATOR VALVE INSPECTION

Changing Engine Oil....................................................8

Changing Oil Filter.......................................................9

Service Data and Specifications (SDS).....................10

OIL PRESSURE CHECK

OIL PUMP INSPECTION

REGULATOR VALVE INSPECTION

OIL CAPACITY

ENGINE COOLING SYSTEM........................................11

Precautions................................................................11

LIQUID GASKET APPLICATION PROCEDURE

Preparation ................................................................11

SPECIAL SERVICE TOOLS

Cooling Circuit ...........................................................12

System Check............................................................12

CHECKING COOLING SYSTEM HOSES

CHECKING RADIATOR

CHECKING RADIATOR CAP

CHECKING COOLING SYSTEM FOR LEAKS

Water Pump...............................................................14

REMOVAL AND INSTALLATION

INSPECTION

Thermostat.................................................................15

REMOVAL AND INSTALLATION

INSPECTION

Radiator .....................................................................17

COMPONENTS

Cooling Fan ...............................................................18

.............................................................7

........................................................10

...........................................................14

...........................................................16

.......................................................17

........................................3

.................................5

................................6

............................8

..........................................10

..........................................10

..........................10

......................................11

............................................13

....................................13

...............................14

...............................15

............3

..........11

...................12

............13

SECTION

COMPONENTS

CONTROL SYSTEM

Changing Engine Coolant..........................................18

- DRAINING ENGINE COOLANT -

- REFILLING ENGINE COOLANT -

- FLUSHING COOLING SYSTEM -

Radiator (Aluminum type)..........................................21

PREPARATION

DISASSEMBLY

ASSEMBLY

INSPECTION

Overheating Cause Analysis .....................................24

Service Data and Specifications (SDS).....................25

THERMOSTAT

RADIATOR

COOLANT CAPACITY

ENGINE LUBRICATION SYSTEM................................26

Precautions................................................................26

LIQUID GASKET APPLICATION PROCEDURE

Preparation ................................................................26

SPECIAL SERVICE TOOLS

Lubrication Circuit......................................................27

Oil Pressure Check....................................................28

Oil Pump....................................................................28

REMOVAL AND INSTALLATION

DISASSEMBLY AND ASSEMBLY

OIL PUMP INSPECTION

REGULATOR VALVE INSPECTION

Changing Engine Oil..................................................31

Oil Filter Bracket........................................................32

REMOVAL AND INSTALLATION

Changing Oil Filter.....................................................32

REMOVAL

INSTALLATION

Oil Cooler...................................................................34

REMOVAL AND INSTALLATION

Service Data and Specifications (SDS).....................35

OIL PRESSURE CHECK

.......................................................18

.......................................................21

........................................................21

.............................................................22

...........................................................23

........................................................25

..............................................................25

...............................................................33

........................................................33

LC

................................................18

............................18

...........................19

............................20

..............................................25

YD

..........26

......................................26

...............................28

..............................29

..........................................29

..........................30

...............................32

...............................34

..........................................35

CONTENTS (Cont’d)

REGULATOR VALVE INSPECTION

OIL PUMP INSPECTION

ENGINE OIL CAPACITY

..........................................35

...........................................35

..........................35

ENGINE COOLING SYSTEM........................................36

Precautions................................................................36

LIQUID GASKET APPLICATION PROCEDURE

..........36

Preparation ................................................................36

SPECIAL SERVICE TOOLS

......................................36

Cooling Circuit ...........................................................37

System Check............................................................38

CHECKING COOLING SYSTEM HOSES

CHECKING RADIATOR

CHECKING RADIATOR CAP

CHECKING COOLING SYSTEM FOR LEAKS

............................................38

....................................38

...................38

............39

Water Pump...............................................................39

REMOVAL AND INSTALLATION

REMOVAL

INSPECTION

INSTALLATION

...............................................................40

...........................................................40

........................................................40

...............................39

Thermostat.................................................................41

REMOVAL AND INSTALLATION

INSPECTION

...........................................................42

...............................41

Radiator .....................................................................42

COMPONENTS

REMOVAL AND INSTALLATION

.......................................................42

...............................43

Cooling Fan ...............................................................43

COMPONENTS

CONTROL SYSTEM

.......................................................43

................................................43

Changing Engine Coolant..........................................44

- DRAINING ENGINE COOLANT -

- REFILLING ENGINE COOLANT -

- FLUSHING COOLING SYSTEM -

............................44

...........................45

............................46

Radiator (Aluminum type)..........................................47

Overheating Cause Analysis .....................................47

Service Data and Specifications (SDS).....................48

THERMOSTAT

RADIATOR

ENGINE COOLANT CAPACITY

........................................................48

..............................................................48

................................48

LC-2

ENGINE LUBRICATION SYSTEM

Precautions

LIQUID GASKET APPLICATION PROCEDURE

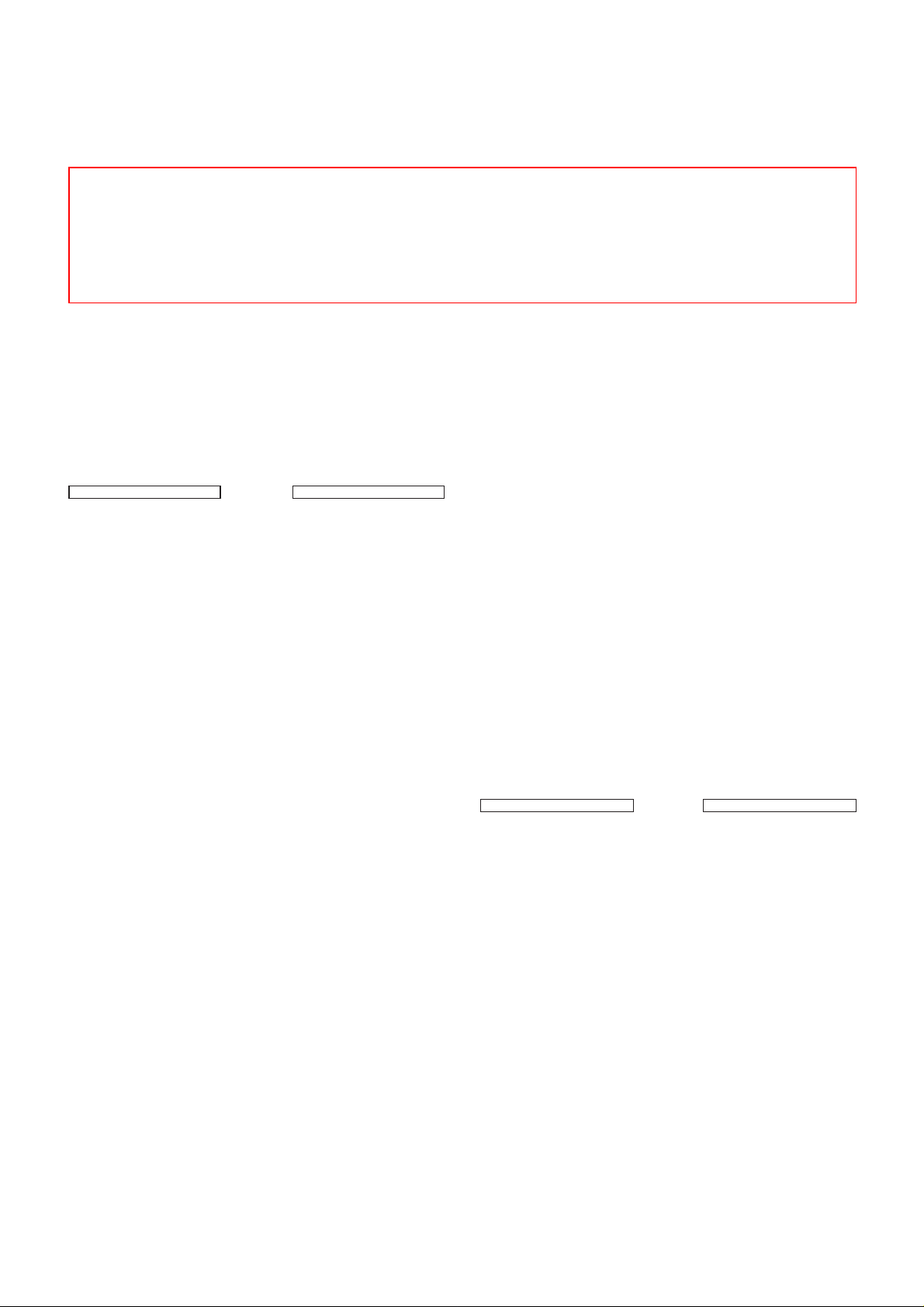

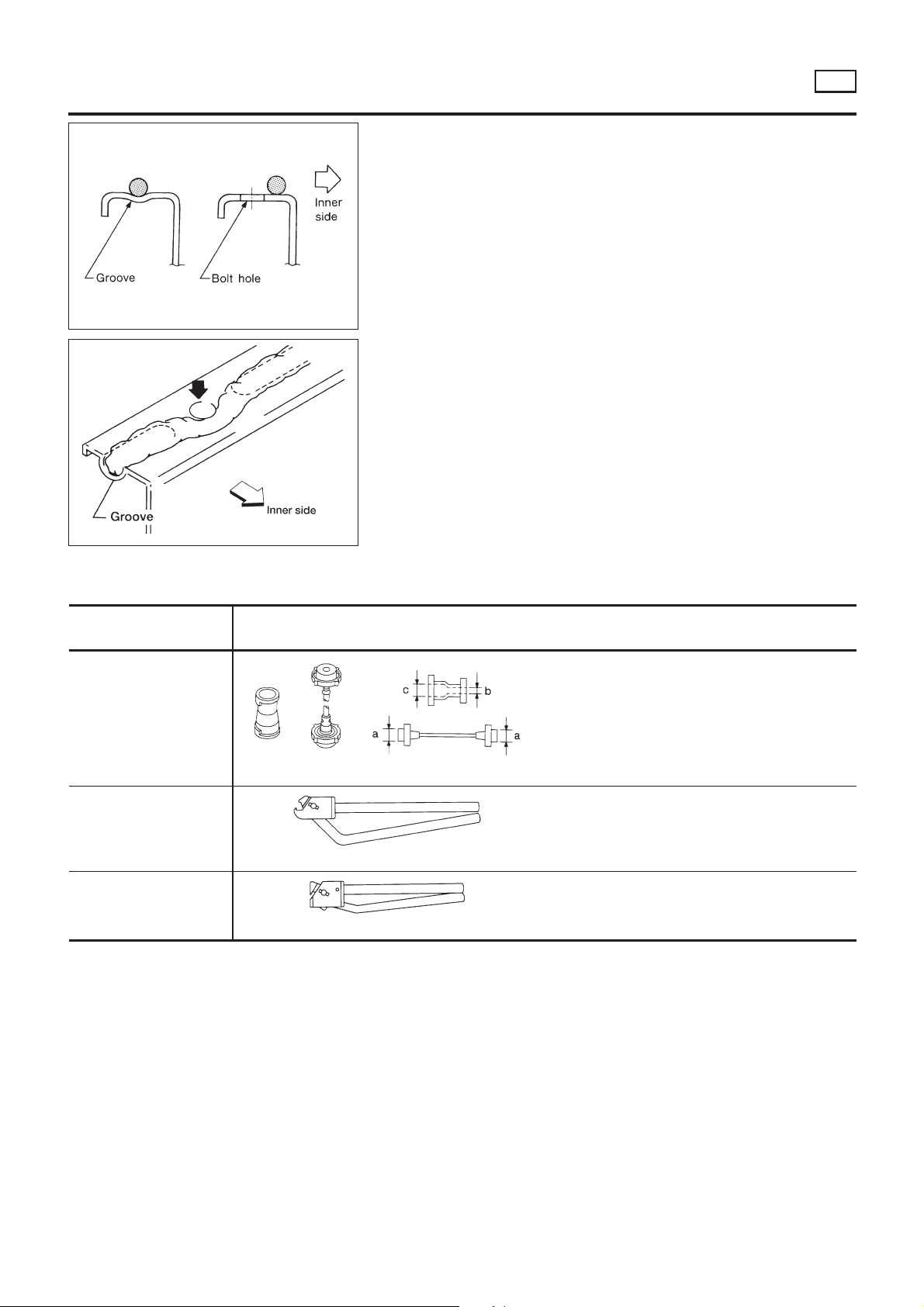

1. Use a scraper to remove all traces of old liquid gasket from

mating surfaces and grooves. Also, completely clean any oil

from these areas.

2. Apply a continuous bead of liquid gasket to mating surfaces.

(Use Genuine Liquid Gasket or equivalent.)

+ For oil pan, be sure liquid gasket diameter is 3.5 to 4.5 mm

(0.138 to 0.177 in).

SEM164F

+ For areas except oil pan, be sure liquid gasket diameter is 2.0

to 3.0 mm (0.079 to 0.118 in).

3. Apply liquid gasket around the inner side of bolt holes (unless

otherwise specified).

4. Assembly should be done within 5 minutes after coating.

5. Wait at least 30 minutes before refilling engine oil and engine

coolant.

QG

Precautions

NJLC0001

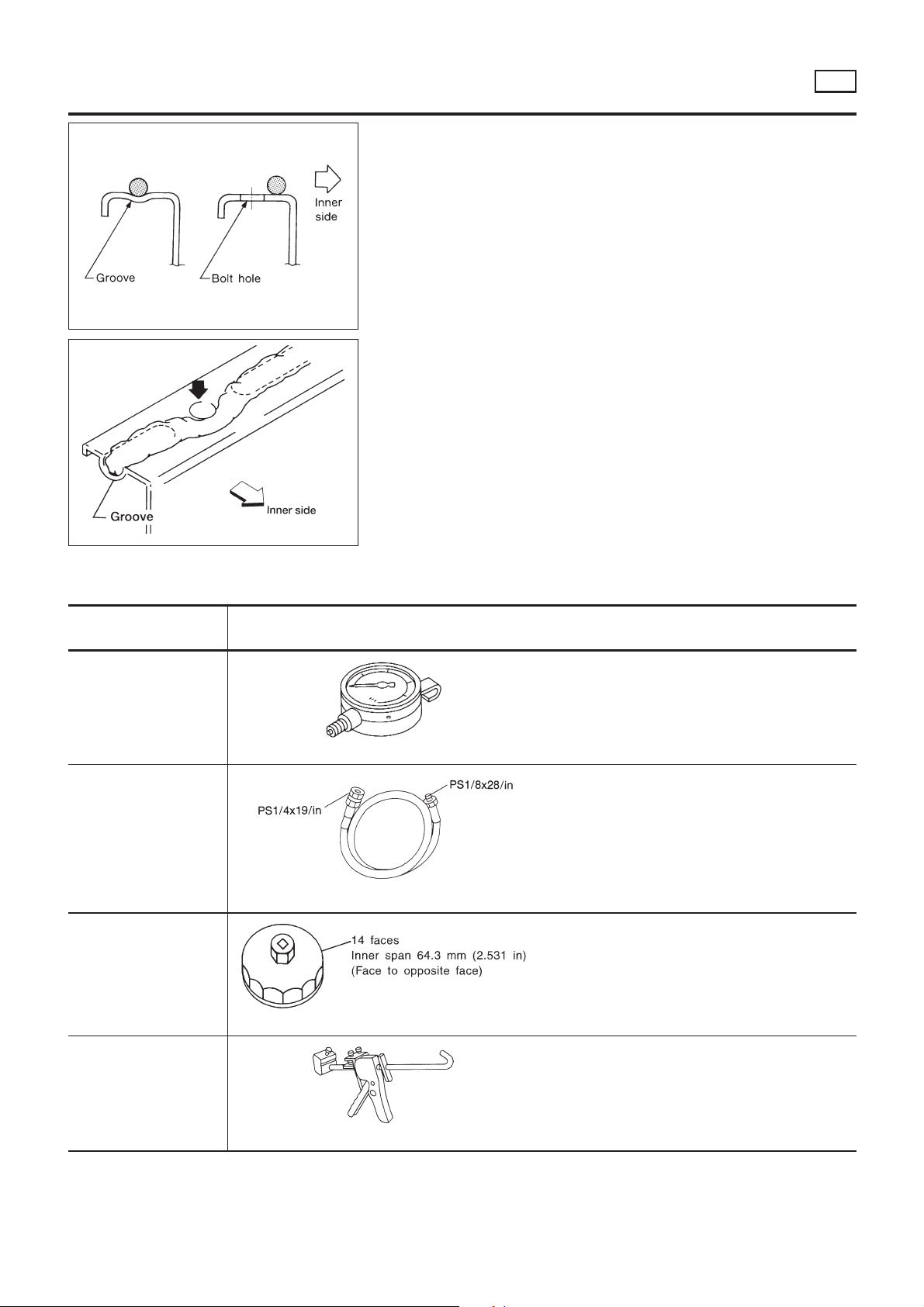

Tool number

Tool name

ST25051001

Oil pressure gauge

ST25052000

Hose

KV10115801

Oil filter wrench

Description

NT050

NT559

AEM080

Preparation

SPECIAL SERVICE TOOLS

Measuring oil pressure

Adapting oil pressure gauge to cylinder block

Removing oil filter

NJLC0002

WS39930000

Tube presser

NT772

Pressing the tube of liquid gasket

NT052

LC-3

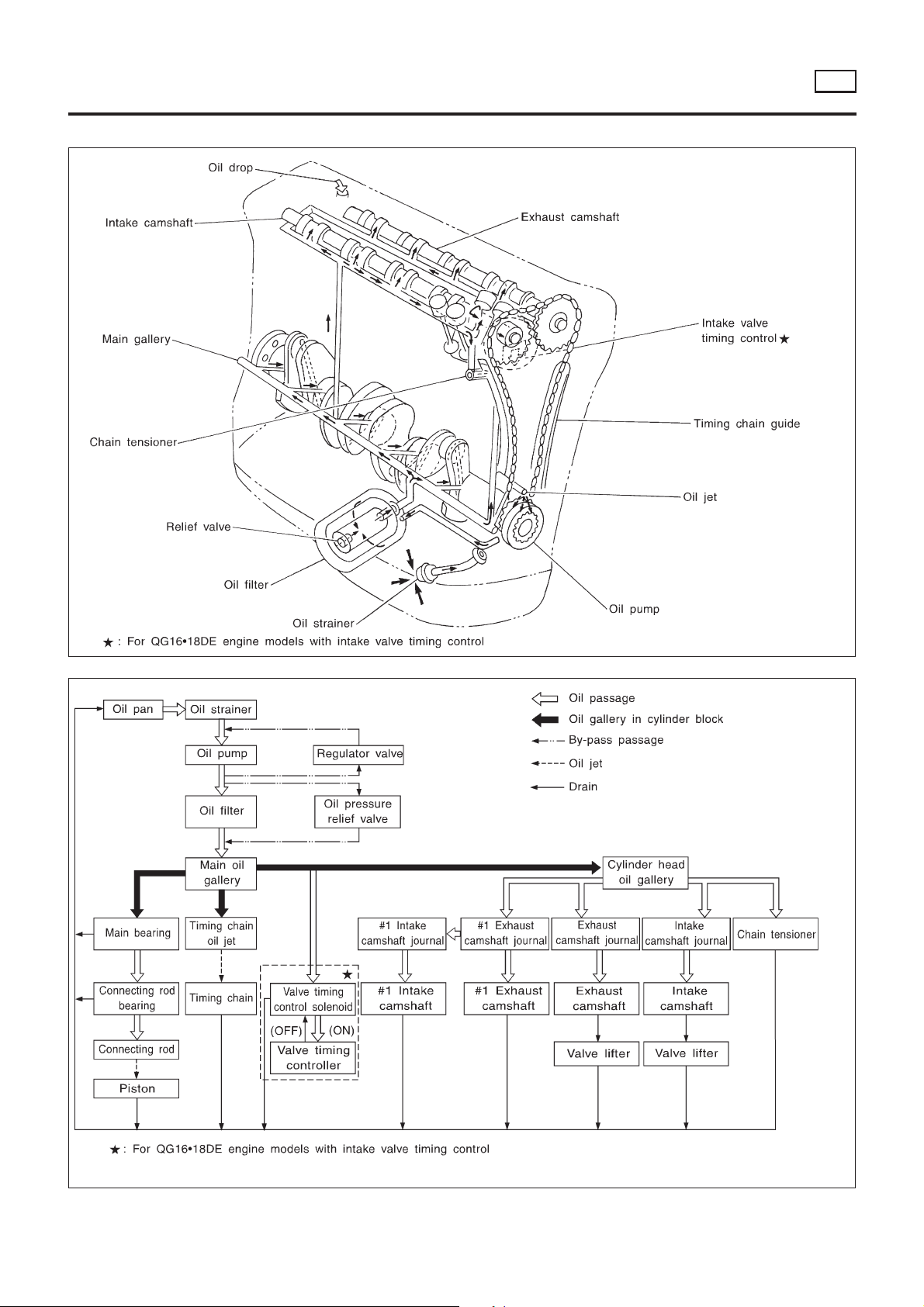

Lubrication Circuit

ENGINE LUBRICATION SYSTEM

QG

Lubrication Circuit

NJLC0003

SEM852FB

LC-4

SLC339B

ENGINELUBRICATIONSYSTEM

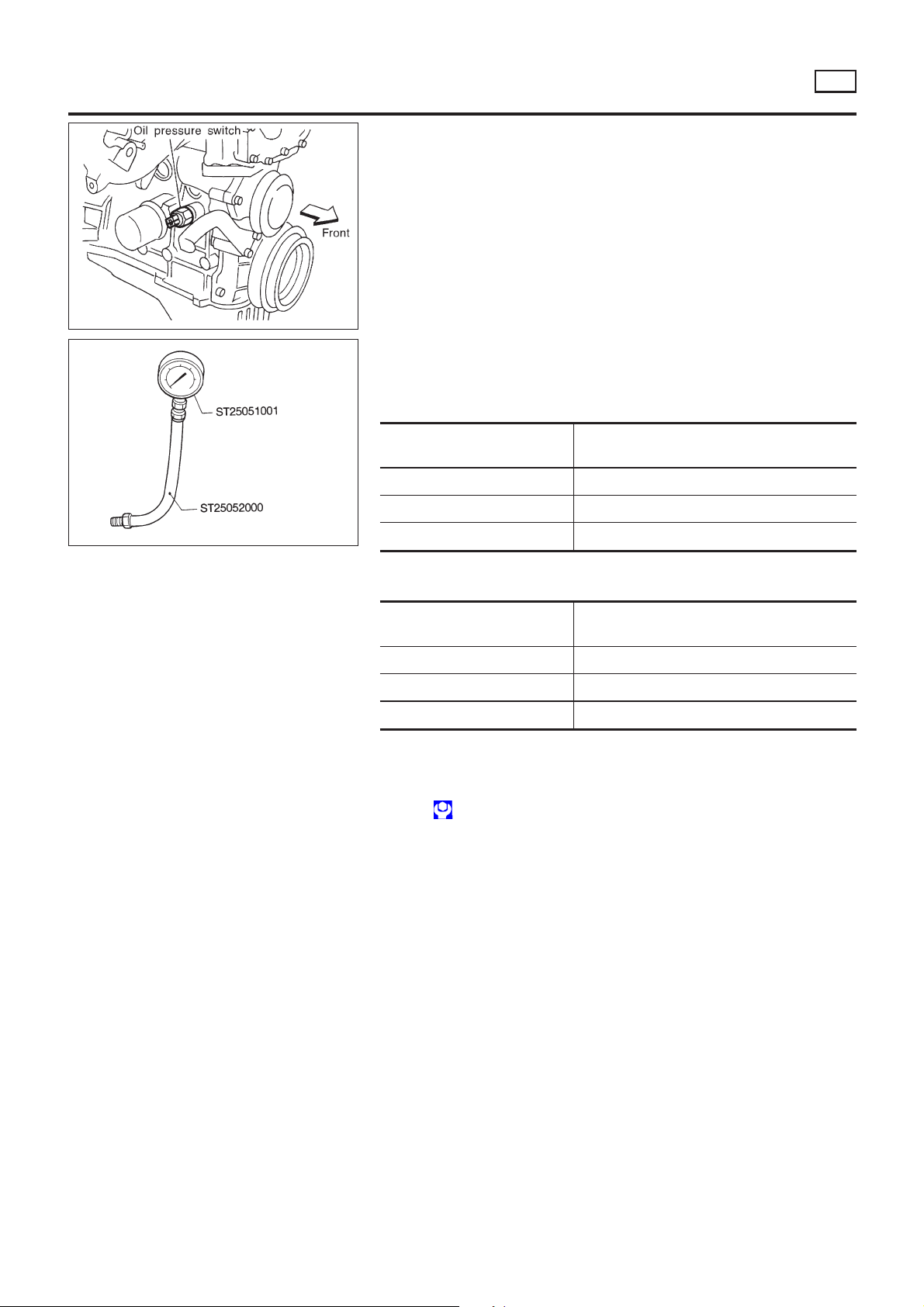

Oil Pressure Check

QG

SEM853F

SLC926-A

OilPressureCheck

NJLC0004

WARNING:

+ Becarefulnottoburnyourself,astheengineandoilmay

behot.

+ ForM/Tmodels,putgearshiftleverinNeutral“N”posi-

tion.ForA/Tmodels,putselectorleverinPark“P”position.

1. Checkoillevel.

2. Removeoilpressureswitch.

3. Installpressuregauge.

4. Startengineandwarmituptonormaloperatingtemperature.

5. Checkoilpressurewithenginerunningunderno-load.

ForSedan

Enginespeed

rpm

600 Morethan69(0.69,0.7,10)

2,000 Morethan284(2.84,2.9,41)

6,000 Morethan422(4.22,4.3,61)

Approximatedischargepressure

kPa(bar,kg/cm

2

,psi)

ForHatchback

Enginespeed

rpm

600 Morethan98(0.98,1.0,14)

2,000 Morethan294(2.94,3.0,43)

6,000 Morethan392(3.92,4.0,57)

Approximatedischargepressure

kPa(bar,kg/cm

2

,psi)

+ Ifdifferenceisextreme,checkoilpassageandoilpump

foroilleaks.

6. Installoilpressureswitchwithsealant.

:13-17N·m(1.25-1.75kg-m,9-12ft-lb)

OilPump

REMOVALANDINSTALLATION

+ MakesurethatO-ringisfittedproperly.

1. Drainengineoil.

2. Removedrivebelts.

3. Removeoilpan.Referto

4. Removeoilstrainer.

5. Removefrontcover.Referto

6. Installfrontcover.

7. Reinstallpartsinreverseorderofremoval.

EM-19

EM-22

, “OIL PAN”.

, “TIMING CHAIN”.

NJLC0005

LC-5

Oil Pump (Cont’d)

ENGINE LUBRICATION SYSTEM

QG

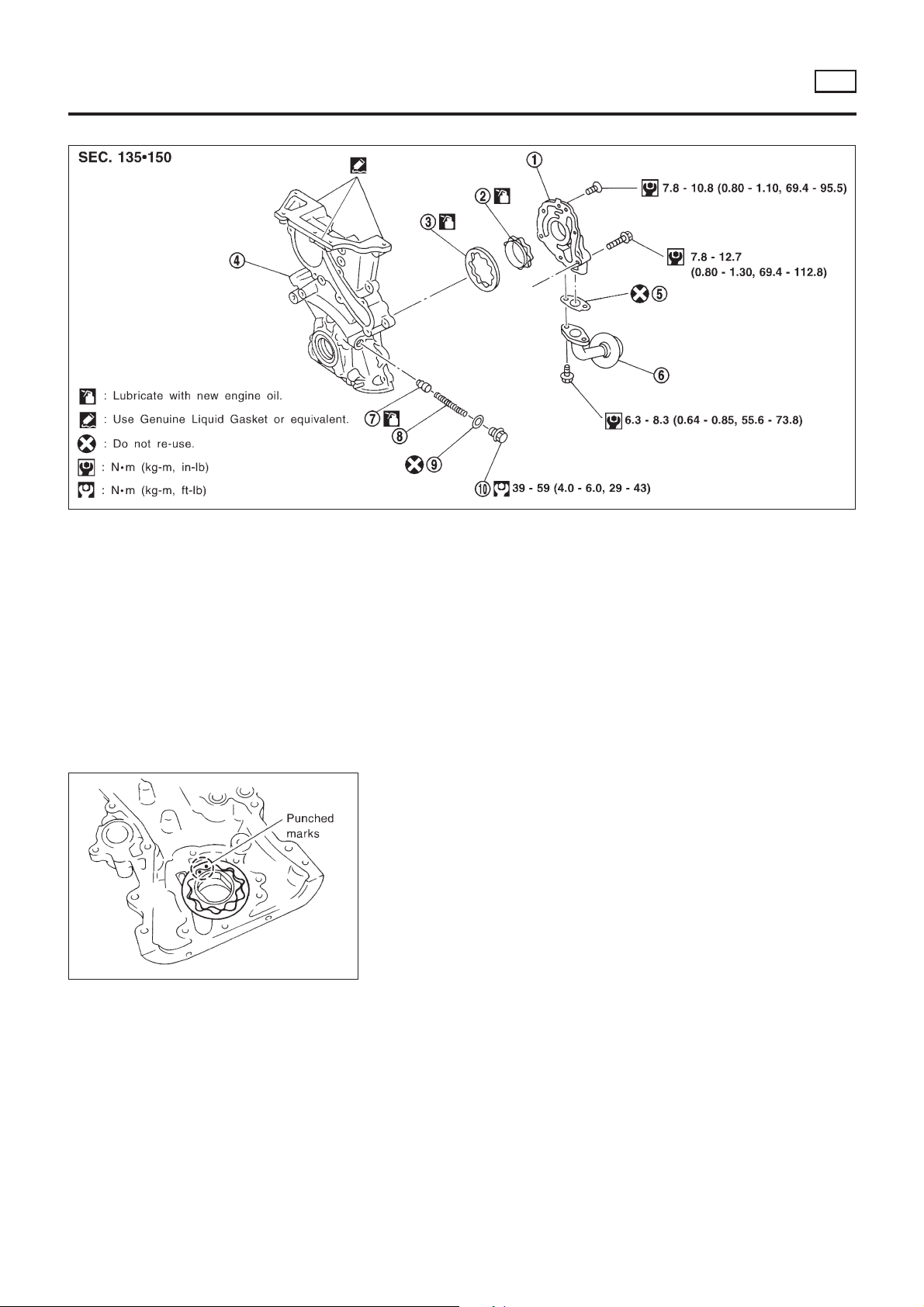

1. Oil pump cover

2. Inner rotor

3. Outer rotor

4. Front cover

DISASSEMBLY AND ASSEMBLY

5. Gasket

6. Oil strainer

7. Regulator valve

NJLC0006

SEM854FA

8. Spring

9. Washer

10. Plug

JLC307B

+ When installing oil pump, apply engine oil to rotors.

+ Install the inner rotor and outer rotor with the punched

marks on the oil pump cover side.

LC-6

ENGINE LUBRICATION SYSTEM

INSPECTION

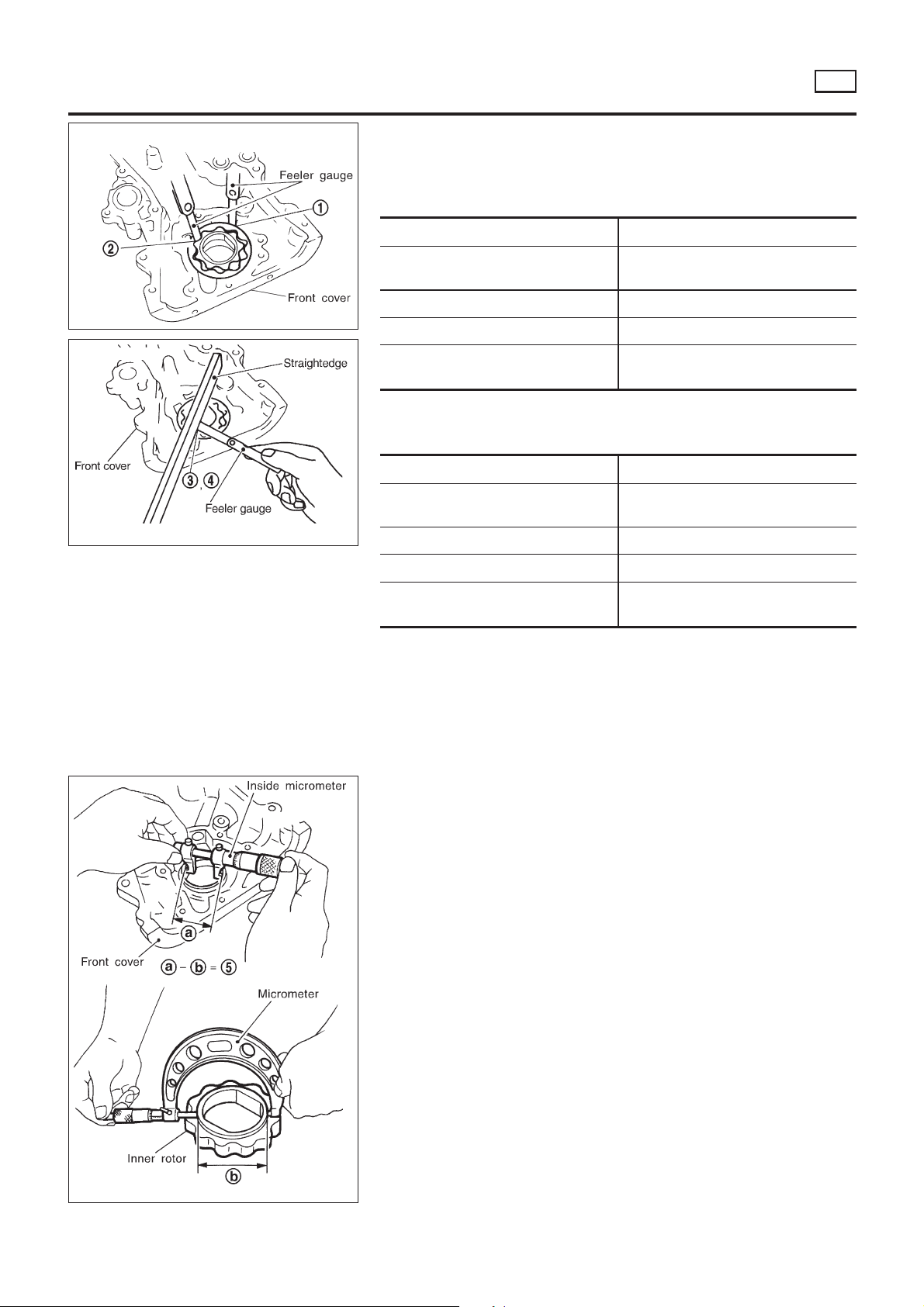

Using a feeler gauge, check the following clearances.

Standard clearance:

For Sedan

Body to outer rotor radial clearance 1 0.114 - 0.200 (0.0045 - 0.0079)

QG

Oil Pump (Cont’d)

NJLC0007

Unit: mm (in)

SEM855F

SEM856F

Inner rotor to outer rotor tip clearance

2

Body to inner rotor clearance 3 0.030 - 0.070 (0.0012 - 0.0028)

Body to outer rotor axial clearance 4 0.030 - 0.090 (0.0012 - 0.0035)

Inner rotor to brazed portion of hous-

ing clearance 5

Below 0.18 (0.0071)

0.045 - 0.091 (0.0018 - 0.0036)

For Hatchback

Unit: mm (in)

Body to outer rotor radial clearance 1 0.250 - 0.325 (0.0098 - 0.0128)

Inner rotor to outer rotor tip clearance

2

Body to inner rotor clearance 3 0.030 - 0.085 (0.0012 - 0.0033)

Body to outer rotor axial clearance 4 0.030 - 0.090 (0.0012 - 0.0035)

Inner rotor to brazed portion of hous-

ing clearance 5

Below 0.18 (0.0071)

0.045 - 0.091 (0.0018 - 0.0036)

SEM857FA

+ If the tip clearance (2) exceeds the limit, replace rotor set.

+ If body to rotor clearances (1, 3, 4, 5) exceed the limit,

replace front cover assembly.

LC-7

Oil Pump (Cont’d)

ENGINELUBRICATIONSYSTEM

QG

SLC986AA

SLC101B

SMA915C

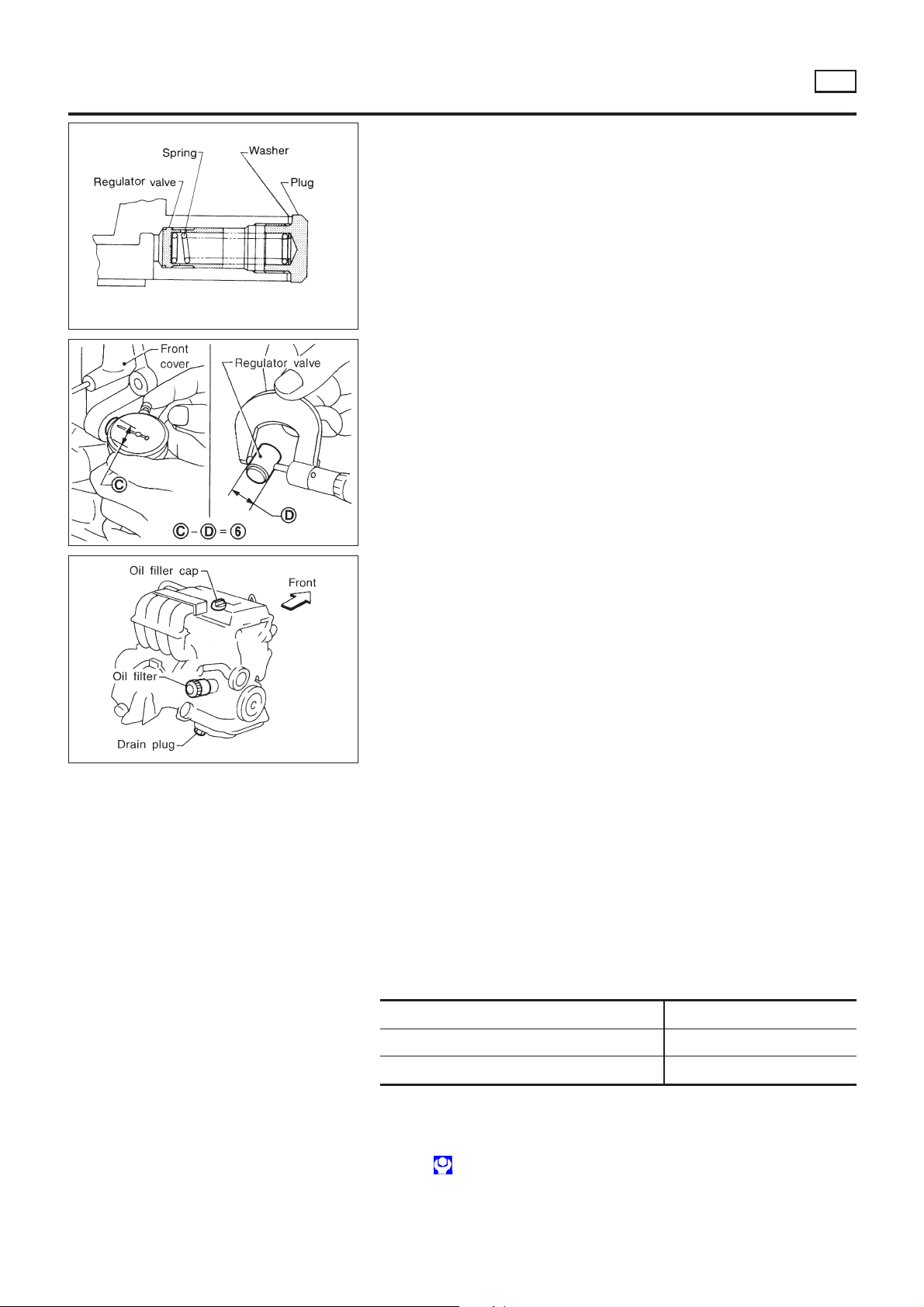

REGULATORVALVEINSPECTION

NJLC0008

1. Visuallyinspectcomponentsforwearanddamage.

2. Checkoilpressureregulatorvalveslidingsurfaceandvalve

spring.

3. Coatregulatorvalvewithengineoil.

Checkthatitfallssmoothlyintothevalveholebyitsown

weight.

Ifdamaged,replaceregulatorvalvesetorfrontcoverassembly.

4. Checkregulatorvalvetofrontcoverclearance.

Clearance6:

ForSedan

0.040-0.097mm(0.0016-0.0038in)

ForHatchback

0.052-0.088mm(0.0020-0.0035in)

Ifitexceedsthelimit,replacefrontcoverassembly.

ChangingEngineOil

NJLC0035

WARNING:

+ Becarefulnottoburnyourself,astheengineoilishot.

+ Prolongedandrepeatedcontactwithusedengineoilmay

causeskincancer;trytoavoiddirectskincontactwith

usedoil.Ifskincontactismade,washthoroughlywith

soaporhandcleanerassoonaspossible.

1. Warmupengine,andcheckforoilleakagefromenginecomponents.

2. Stopengineandwaitmorethan10minutes.

3. Removedrainplugandoilfillercap.

4. Drainoilandrefillwithnewengineoil.

Oilspecificationandviscosity(ExceptforEurope):

+ APIgradeSE,SF,SG,SHorSJ

+ ILSACgradeGF-I&GF-II

Oilspecificationandviscosity(ForEurope):

+ APIgradeSG,SHorSJ

+ ILSACgradeGF-I&GF-II

Referto

MA-18

, “RECOMMENDED FLUIDS AND LUBRI-

CANTS”.

Refilloilcapacity(Approximate):

Unit:!(Impqt)

Withoilfilterchange 2.7(2-3/8)

Withoutoilfilterchange 2.5(2-1/4)

Dryengine(engineoverhaul) 3.1(2-3/4)

CAUTION:

+ Besuretocleandrainplugandinstallwithnewwasher.

Drainplug:

:29-39N·m(3.0-4.0kg-m,22-29ft-lb)

+ Therefillcapacitychangesdependingontheoiltempera-

tureanddraintime,usethesevaluesasareferenceand

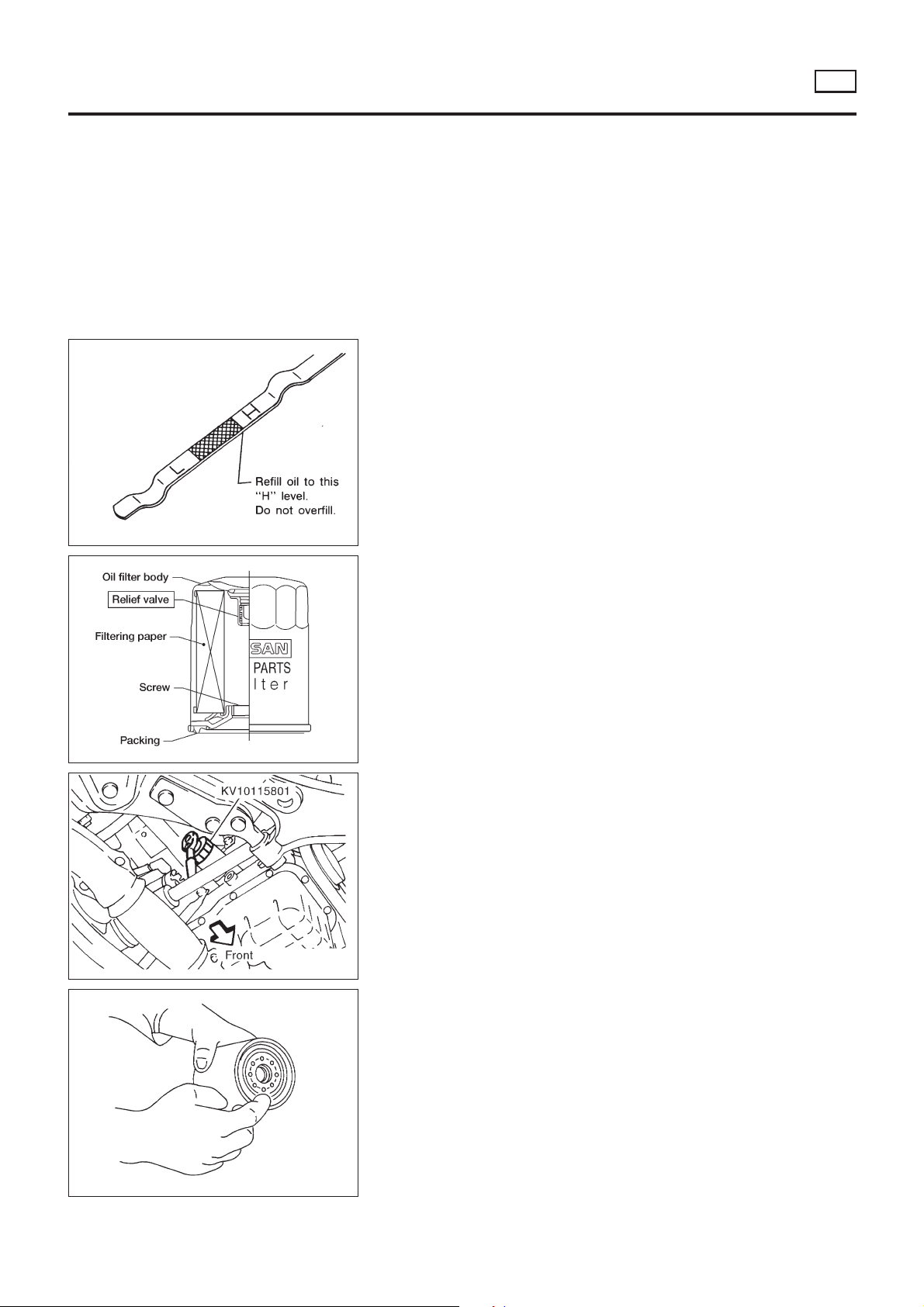

LC-8

ENGINE LUBRICATION SYSTEM

be certain to check with the dipstick when changing the

oil.

5. Check oil level.

6. Start engine and check area around drain plug and oil filter for

oil leakage.

7. Run engine for a few minutes, then turn it off. After several

minutes, check oil level.

QG

Changing Engine Oil (Cont’d)

SMA390C

ALC094

SLC275B

Changing Oil Filter

NJLC0010

The oil filter is a small, full-flow cartridge type and is provided with

a relief valve.

+ Use Tool KV10115801 for removing oil filter.

1. Remove oil filter with Tool.

WARNING:

Be careful not to burn yourself, as the engine and the engine

oil are hot.

2. Clean oil filter mounting surface on cylinder block. Coat rubber

seal of new oil filter with engine oil.

SMA010

LC-9

Changing Oil Filter (Cont’d)

OIL PRESSURE CHECK

Engine speed

rpm

600 More than 69 (0.69, 0.7, 10) More than 98 (0.98, 1.0, 14)

2,000 More than 284 (2.84, 2.9, 41) More than 294 (2.94, 3.0, 43)

6,000 More than 422 (4.22, 4.3, 61) More than 392 (3.92, 4.0, 57)

ENGINE LUBRICATION SYSTEM

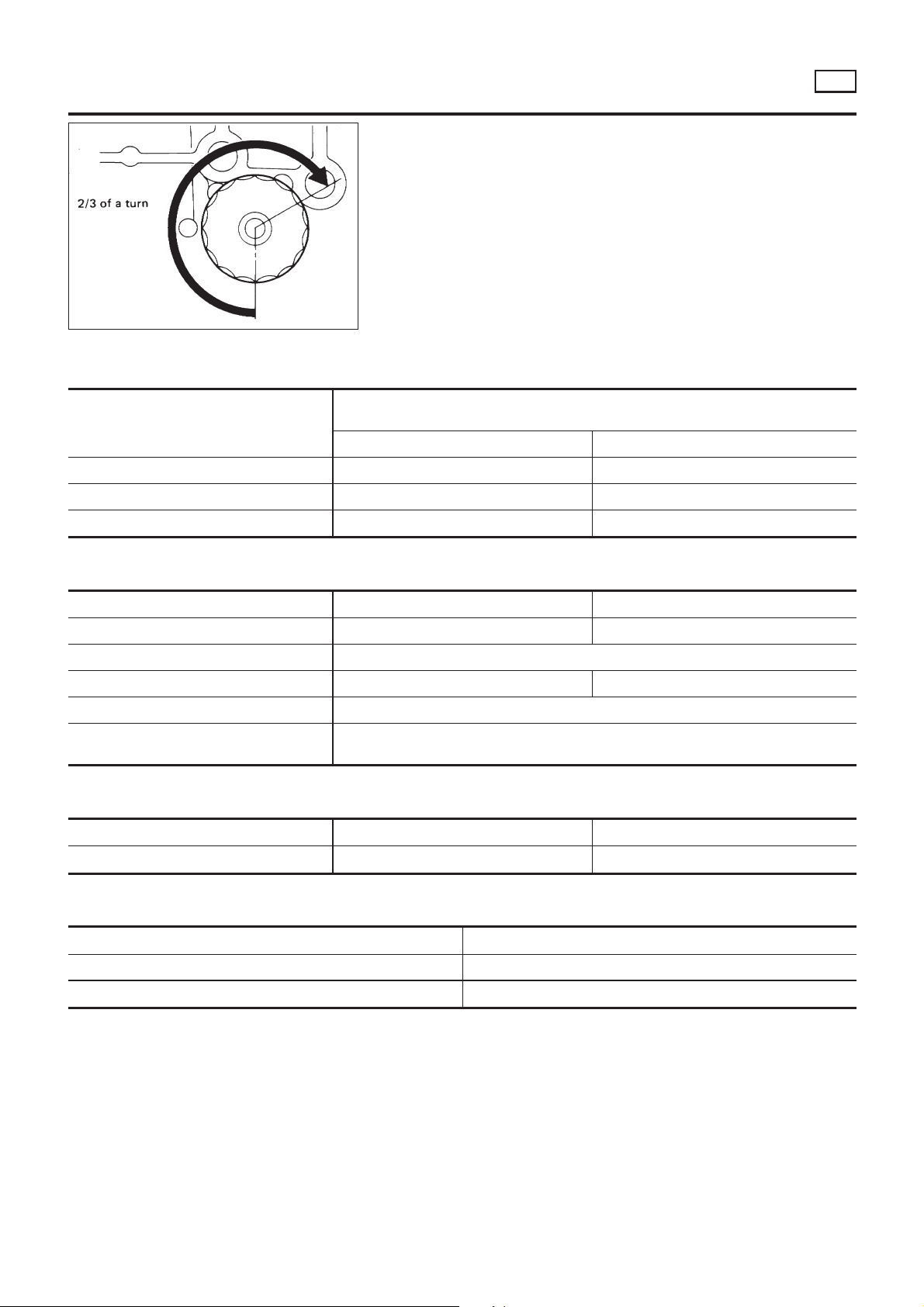

3. Screw in the oil filter until a slight resistance is felt, then tighten

an additional 2/3 turn.

4. Add engine oil.

Refer to Changing Engine Oil.

+ Clean excess oil from engine.

SMA229B

Service Data and Specifications (SDS)

Approximate discharge pressure

kPa (bar, kg/cm

Sedan Hatchback

2

, psi)

QG

NJLC0011

OIL PUMP INSPECTION

Model Sedan Hatchback

Body to outer rotor radial clearance 0.114 - 0.200 (0.0045 - 0.0079) 0.250 - 0.325 (0.0098 - 0.0128)

Inner rotor to outer rotor tip clearance Below 0.18 (0.0071)

Body to inner rotor clearance 0.030 - 0.070 (0.0012 - 0.0028) 0.030 - 0.085 (0.0012 - 0.0033)

Body to outer rotor axial clearance 0.030 - 0.090 (0.0012 - 0.0035)

Inner rotor to brazed portion of housing clear-

ance

0.045 - 0.091 (0.0018 - 0.0036)

REGULATOR VALVE INSPECTION

Model Sedan Hatchback

Regulator valve to oil pump cover clearance 0.040 - 0.097 (0.0016 - 0.0382) 0.052 - 0.088 (0.0020 - 0.0035)

OIL CAPACITY

Unit: ! (Imp qt)

With oil filter change 2.7 (2-3/8)

Without oil filter change 2.5 (2-1/4)

Dry engine (engine overhaul) 3.1 (2-3/4)

NJLC0013

Unit: mm (in)

NJLC0012

Unit: mm (in)

NJLC0036

LC-10

ENGINE COOLING SYSTEM

Precautions

LIQUID GASKET APPLICATION PROCEDURE

1. Use a scraper to remove all traces of old liquid gasket from

mating surfaces and grooves. Also, completely clean any oil

from these areas.

2. Apply a continuous bead of liquid gasket to mating surfaces.

(Use Genuine Liquid Gasket or equivalent.)

+ For oil pan, be sure liquid gasket diameter is 3.5 to 4.5 mm

(0.138 to 0.177 in).

SEM164F

+ For areas except oil pan, be sure liquid gasket diameter is 2.0

to 3.0 mm (0.079 to 0.118 in).

3. Apply liquid gasket around the inner side of bolt holes (unless

otherwise specified).

4. Assembly should be done within 5 minutes after coating.

5. Wait at least 30 minutes before refilling engine oil and engine

coolant.

QG

Precautions

NJLC0014

Tool number

Tool name

EG17650301

Radiator cap tester

adapter

KV99103510

Radiator plate pliers A

KV99103520

Radiator plate pliers B

Description

NT564

NT224

NT225

AEM080

Preparation

SPECIAL SERVICE TOOLS

Adapting radiator cap tester to radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

Installing radiator upper and lower tanks

Removing radiator upper and lower tanks

NJLC0015

LC-11

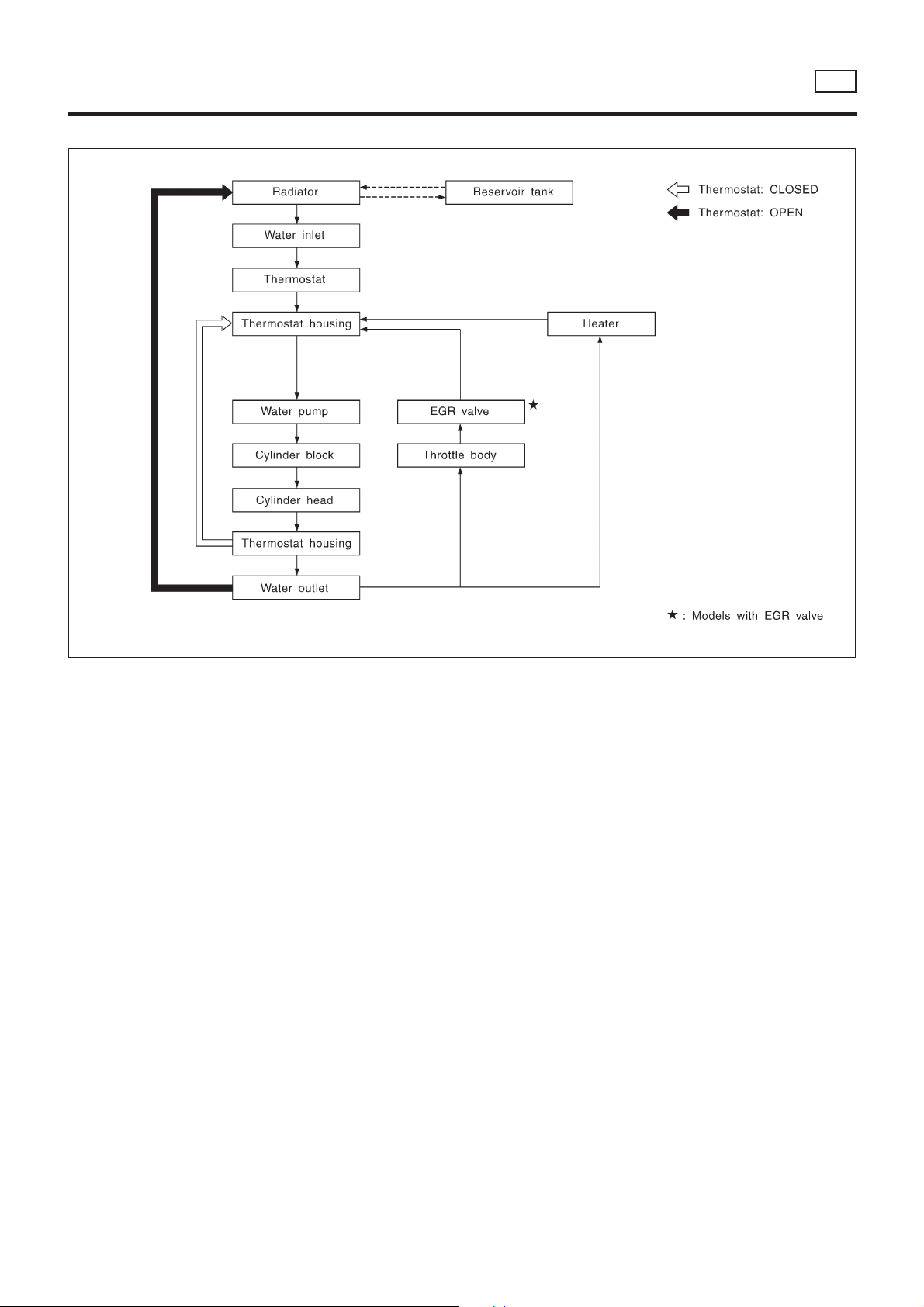

Cooling Circuit

ENGINE COOLING SYSTEM

QG

Cooling Circuit

NJLC0016

SLC317B

System Check

NJLC0017

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure fluid escaping from the

radiator.

Wrap a thick cloth around the cap. Slowly turn it a quarter turn

to allow built-up pressure to escape. Carefully remove the cap

by turning it all the way.

CHECKING COOLING SYSTEM HOSES

NJLC0017S01

Check hoses for the following:

+ Improper attachment

+ Leaks

+ Cracks

+ Damage

+ Loose connections

+ Chafing

+ Deterioration

LC-12

ENGINE COOLING SYSTEM

QG

System Check (Cont’d)

CHECKING RADIATOR

NJLC0017S04

Check radiator for mud or clogging. If necessary, clean radiator as

follows.

+ Be careful not to bend or damage the radiator fins.

+ When radiator is cleaned without removal, remove all sur-

rounding parts such as cooling fan, rediator shroud and horns.

Then tape the harness and connectors to prevent water from

entering.

1. Apply water by hose to the back side of the radiator core vertically download.

2. Apply water again to all radiator core surfaces once per

minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core vertically download.

+ Use compressesd air lower than 490 kPa (4.9 bar, 5 kg/cm

71 psi) and keep distance more than 30 cm (11.8 in).

5. Blow air again into all the radiator core surfaces once per

minute until no water sprays out.

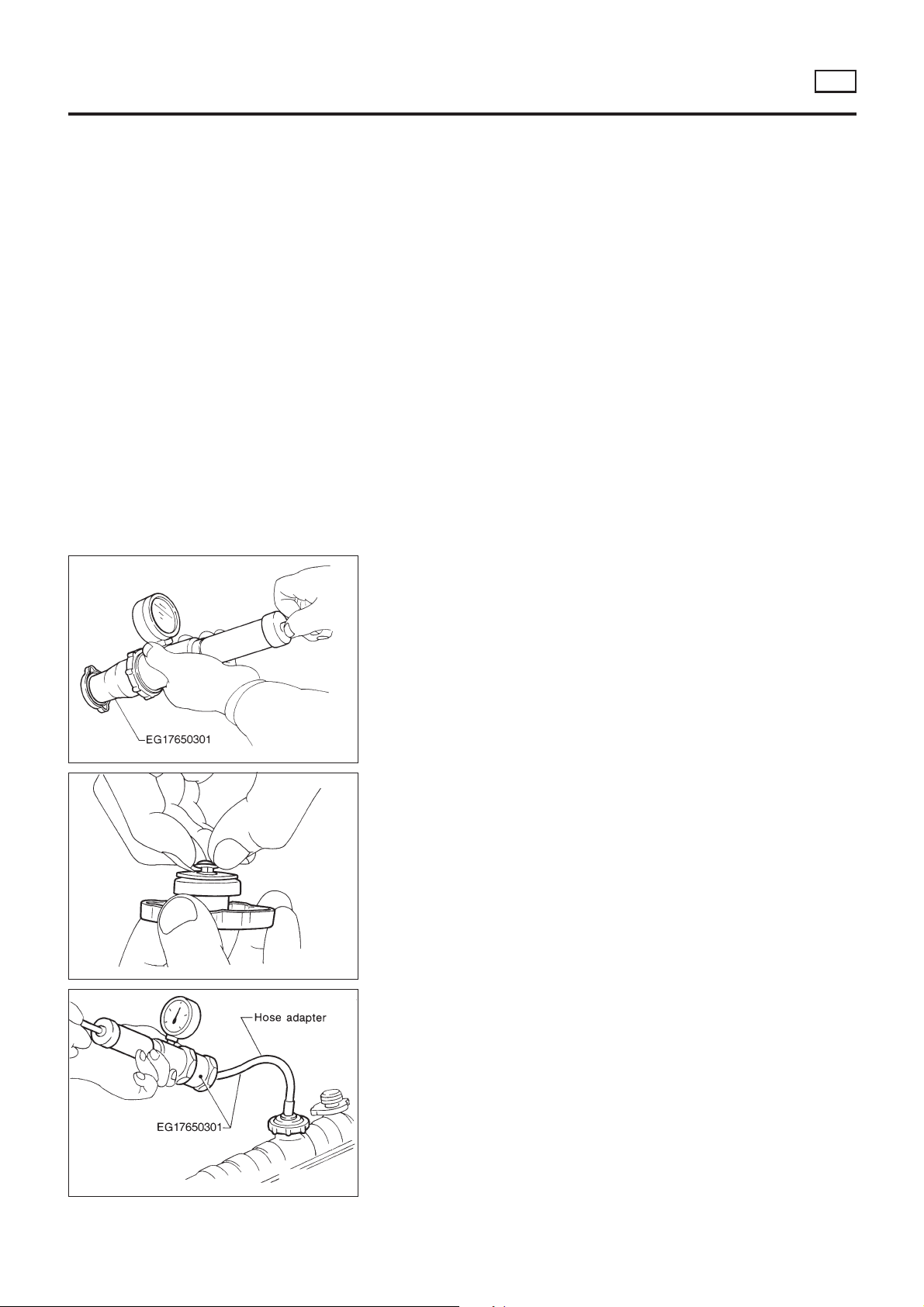

CHECKING RADIATOR CAP

NJLC0017S03

To check radiator cap, apply pressure to cap with a tester.

Radiator cap relief pressure:

Standard

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2

, 11 - 14 psi)

Limit

59-98kPa

(0.59 - 0.98 bar, 0.6 - 1.0 kg/cm

2

,9-14psi)

2

,

SLC613-A

SMA967B

SLC756AA

Pull the negative pressure valve to open it.

Check that it closes completely when released.

CHECKING COOLING SYSTEM FOR LEAKS

NJLC0017S02

To check for leakage, apply pressure to the cooling system with a

tester.

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2

, 23 psi)

CAUTION:

Higher pressure than specified may cause radiator damage.

LC-13

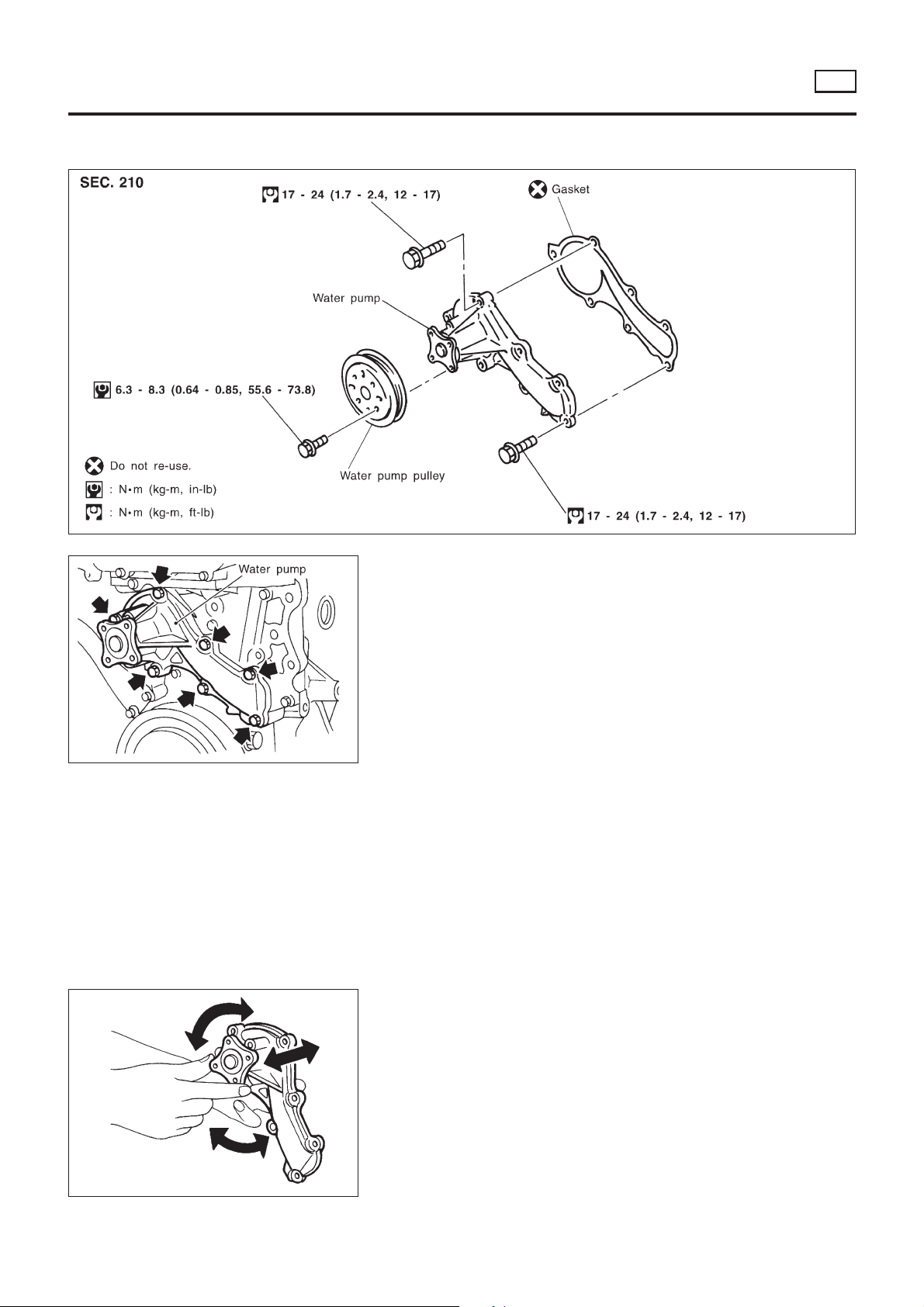

Water Pump

ENGINE COOLING SYSTEM

Water Pump

REMOVAL AND INSTALLATION

QG

NJLC0018

SEM858F

SEM859F

CAUTION:

+ When removing water pump assembly, be careful not to

get coolant on drive belt.

+ Water pump cannot be disassembled and should be

replaced as a unit.

+ After installing water pump, and check for leaks using

radiator cap tester.

1. Drain engine coolant.

Refer to LC-18, “Changing Engine Coolant”.

2. Remove drive belts and idler pulley.

3. Loosen water pump pulley bolts.

4. Remove water pump pulley.

5. Remove front right wheel.

6. Remove front right undercover and front right fender protector.

7. Remove water pump bolts.

8. Remove water pump.

9. Reinstall parts in reverse order of removal.

INSPECTION

NJLC0019

+ Check body assembly and vane for rust or corrosion.

+ Check for rough operation due to excessive end play.

SEM860F

LC-14

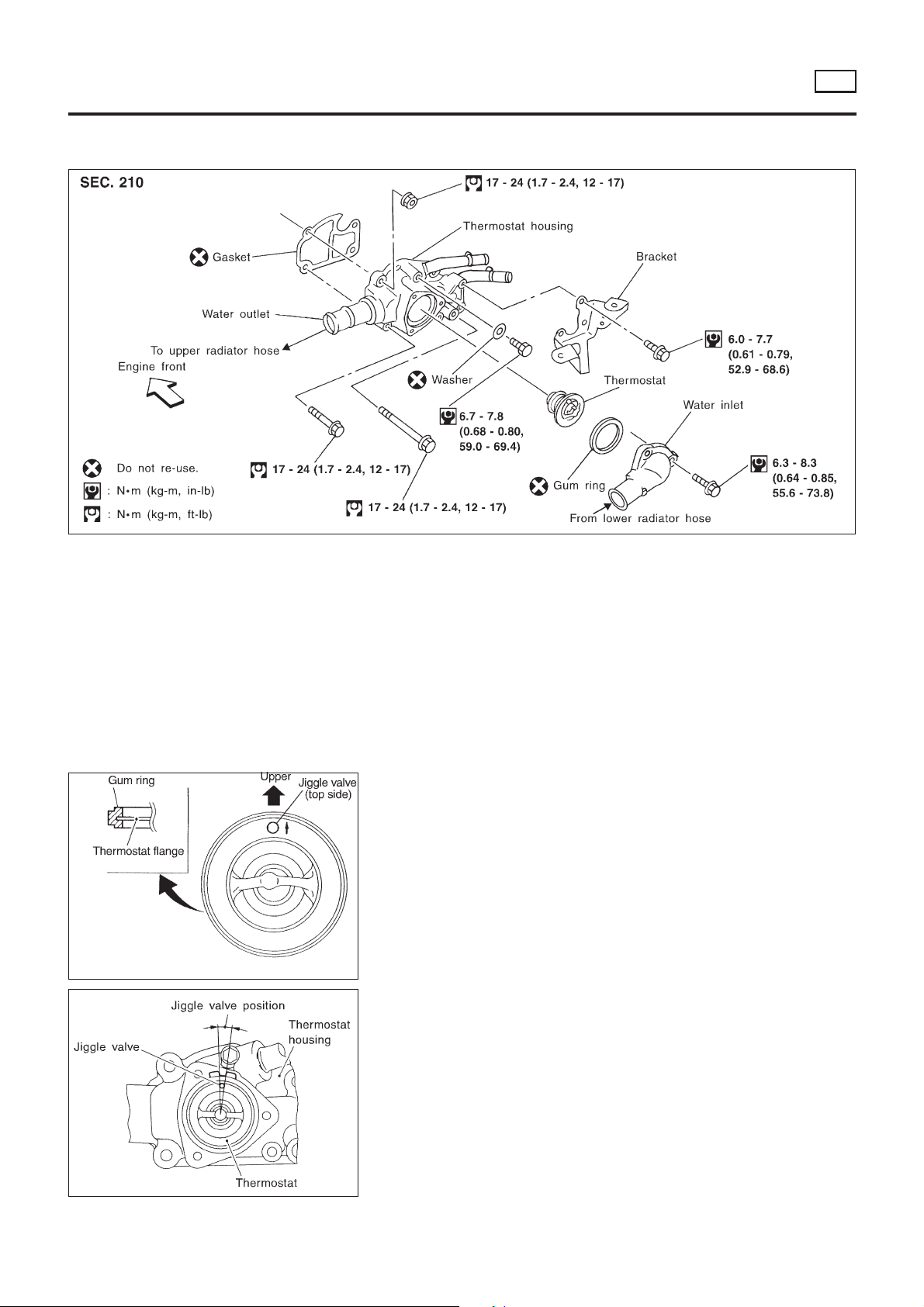

ENGINE COOLING SYSTEM

Thermostat

REMOVAL AND INSTALLATION

QG

Thermostat

NJLC0021

SEM861F

SEM862F

Be careful not to spill coolant over engine compartment. Use

a rag to absorb coolant.

1. Drain engine coolant.

Refer to LC-18, “Changing Engine Coolant”.

2. Remove water inlet, then take out thermostat.

3. Install gum ring to thermostat.

4. Install thermostat with jiggle valve or air bleeder at upper side.

After installation, run engine for a few minutes, and check

for leaks.

SEM863F

LC-15

Loading...

Loading...