STEERING SYSTEM

GI

MA

CONTENTS

PRECAUTIONS ...............................................................2

Precautions for Supplemental Restraint System

(SRS) ″AIR BAG″ and ″SEAT BELT

PRE-TENSIONER″......................................................2

Precautions for Steering System.................................2

PREPARATION ...............................................................3

Special Service Tools..................................................3

Commercial Service Tool.............................................4

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................5

NVH Troubleshooting Chart.........................................5

ON-VEHICLE SERVICE ..................................................6

Checking Steering Wheel Play....................................6

Checking Neutral Position on Steering Wheel............6

PRE-CHECKING

CHECKING

Front Wheel Turning Angle..........................................6

Checking Gear Housing Movement ............................6

Checking and Adjusting Drive Belts ............................7

Checking Fluid Level...................................................7

Checking Fluid Leakage..............................................7

Bleeding Hydraulic System..........................................7

Checking Steering Wheel Turning Force ....................8

Checking Hydraulic System.........................................9

STEERING WHEEL AND STEERING COLUMN .........10

Components...............................................................10

Removal and Installation...........................................10

STEERING WHEEL

........................................................6

...............................................................6

.................................................10

SECTION

STEERING COLUMN

Disassembly and Assembly.......................................13

Inspection...................................................................14

TILT MECHANISM

POWER STEERING GEAR AND LINKAGE ................15

Components...............................................................15

Removal and Installation...........................................16

Disassembly...............................................................18

Inspection...................................................................19

.....................................................................19

BOOT

.....................................................................19

RACK

GEAR SUB-ASSEMBLY

GEAR HOUSING CYLINDER

TIE-ROD OUTER AND INNER SOCKETS

Assembly ...................................................................20

Adjustment.................................................................23

POWER STEERING OIL PUMP....................................25

Components...............................................................25

Pre-disassembly Inspection.......................................25

Disassembly...............................................................26

Inspection...................................................................27

Assembly ...................................................................27

SERVICE DATA AND SPECIFICATIONS (SDS).........29

General Specifications...............................................29

Steering Wheel..........................................................29

Steering Column........................................................29

Steering Gear and Linkage .......................................30

Power Steering..........................................................31

...................................................14

ST

...............................................11

...........................................19

....................................19

..................19

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT

PRE-TENSIONER”

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELTPRE-TENSIONER” used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL A33 is as follows (The composition varies according to optional equipment.):

I For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steering wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

I For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring

harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in the RS section of this Service Manual.

WARNING:

I To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be performed by an authorized NISSAN dealer.

I Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by intentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the RS section.

I Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

NFST0037

Precautions for Steering System

I Before disassembly, thoroughly clean the outside of the unit.

I Disassembly should be done in a clean work area. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

I Place disassembled parts in order, on a parts rack, for easier and proper assembly.

I Use nylon cloths or paper towels to clean the parts; common shop rags can leave lint that might

interfere with their operation.

I Before inspection or reassembly, carefully clean all parts with a general purpose, non-flammable

solvent.

I Before assembly, apply a coat of recommended power steering fluid* to hydraulic parts. Vaseline

may be applied to O-rings and seals. Do not use any grease.

I Replace all gaskets, seals and O-rings. Avoid damaging O-rings, seals and gaskets during instal-

lation. Perform functional tests whenever designated.

*: Genuine Nissan PSF II or equivalent. Refer to MA-11, “Fluids and Lubricants”.

NFST0003

ST-2

PREPARATION

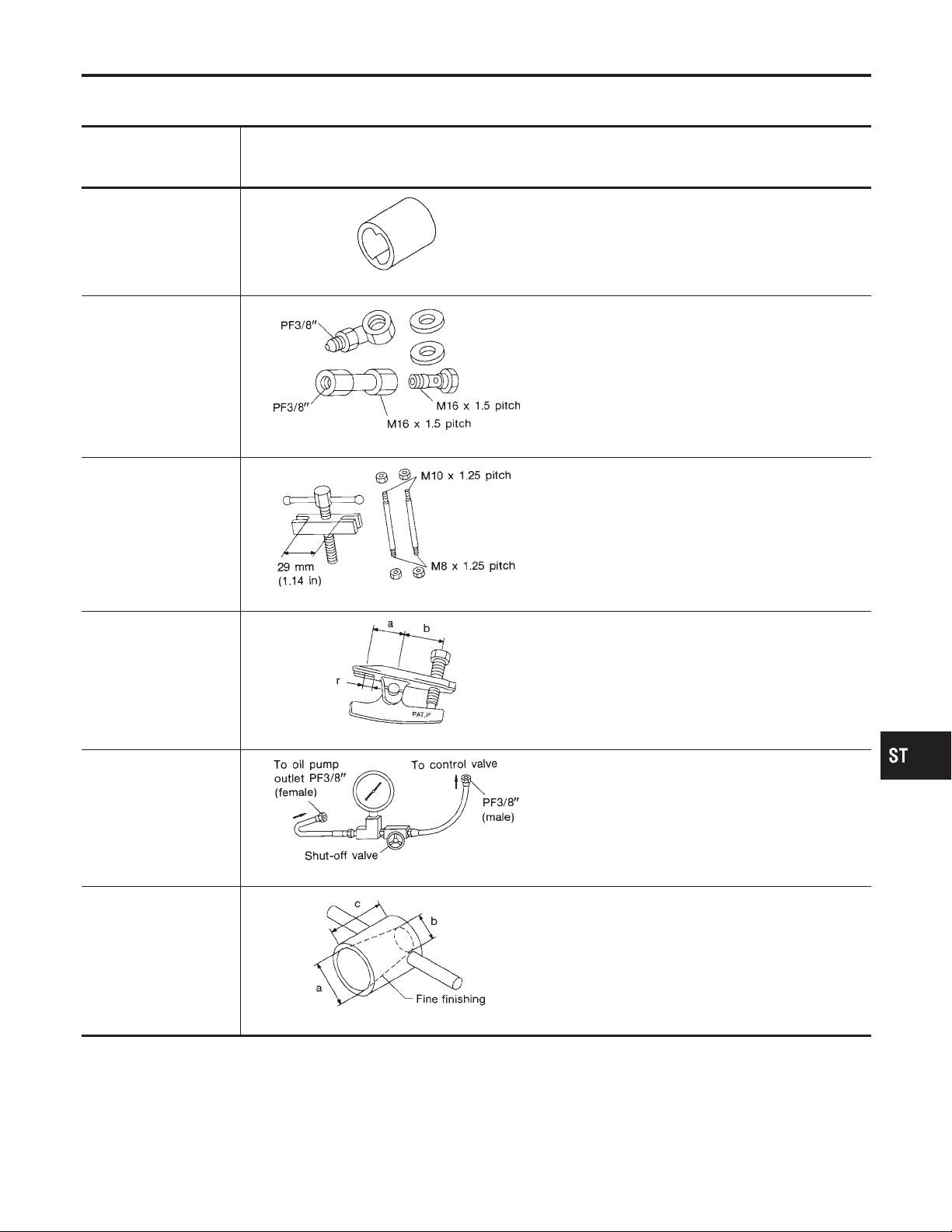

Special Service Tools

Special Service Tools

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

KV48100700

(J26364)

Torque adapter

KV48102500

(J33914)

Pressure gauge adapter

ST27180001

(J25726-A)

Steering wheel puller

Description

Measuring pinion rotating torque

NT169

Measuring oil pressure

NT542

Removing steering wheel

NFST0004

GI

MA

EM

LC

EC

FE

CL

MT

HT72520000

(J25730-B)

Ball joint remover

KV48103500

(J26357 and J26357-

10)

Pressure gauge

KV48104400

(—)

Rack seal ring reformer

NT544

NT546

NT547

Removing ball joint

a: 33 mm (1.30 in)

b: 50 mm (1.97 in)

r: R11.5 mm (0.453 in)

Measuring oil pressure

Reforming teflon ring

a: 50 mm (1.97 in) dia.

b: 36 mm (1.42 in) dia.

c: 100 mm (3.94 in)

AT

AX

SU

BR

RS

BT

HA

SC

NT550

EL

IDX

ST-3

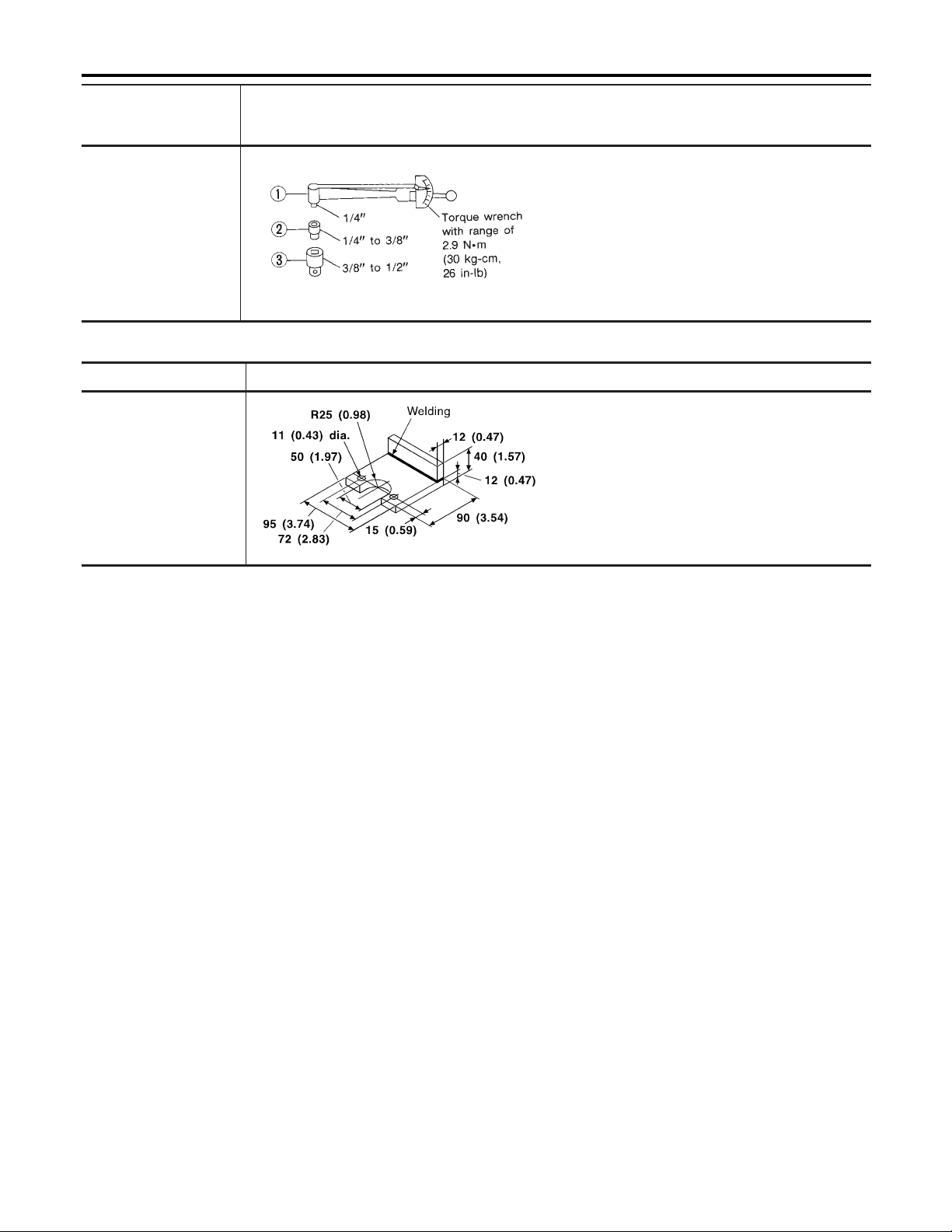

Special Service Tools (Cont’d)

Tool number

(Kent-Moore No.)

Tool name

Description

PREPARATION

ST3127S000

1 GG91030000

(See J25765-A)

Torque wrench

2 HT62940000

(—)

Socket adapter

3 HT62900000

(—)

Socket adapter

Tool number Description

Oil pump attachment

NT541

NT774

Measuring turning torque

Commercial Service Tool

Disassembling and assembling oil pump

Unit: mm (in)

NFST0005

ST-4

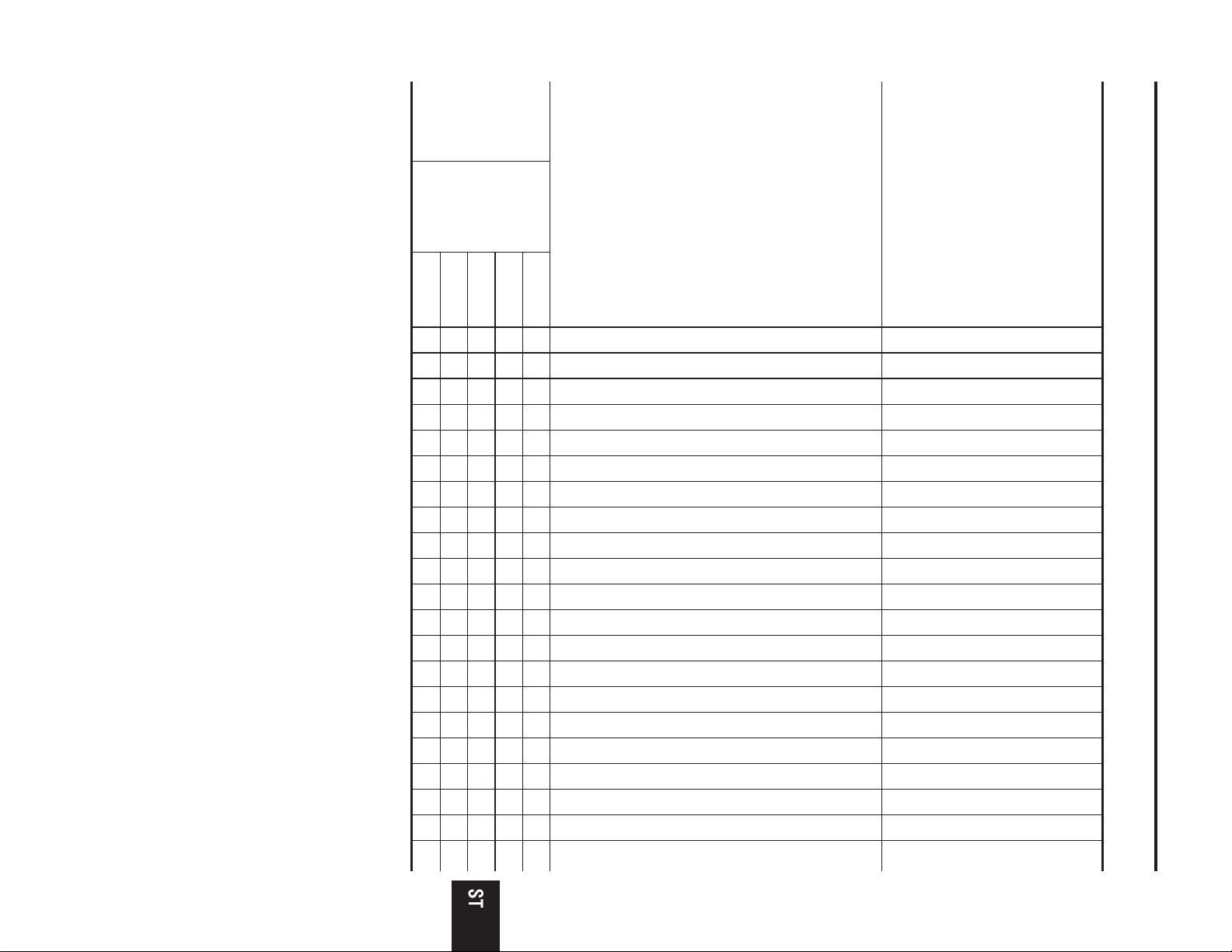

×: Applicable

Judder × × ЧЧЧЧЧ

Symptom STEERING

Vibration ЧЧЧЧЧ ××××

Shimmy ××× × ЧЧЧЧЧ

Noise ЧЧЧЧЧЧЧЧЧ ЧЧЧЧЧЧ

Shake ××× ЧЧЧЧЧЧ

Possible cause and

SUSPECTED PARTS

Reference page

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

ST-5

Fluid level

Air in hydraulic system

Tie-rod ball joint swinging force

Tie-rod ball joint rotating torque

Tie-rod ball joint end play

Steering gear fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness or tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

ST-7

ST-7

ST-19

ST-19

ST-19

ST-7

ST-6

ST-8

Refer to MA-13.

—

ST-10

ST-6

ST-14

ST-13

ST-15

NVH in AX section Refer to AX-3.

NVH in AX section Refer to AX-3.

NVH in SU section Refer to SU-4.

NVH in SU section Refer to SU-4.

NVH in SU section Refer to SU-4.

NVH in BR section Refer to BR-7.

NVH Troubleshooting Chart

NVH Troubleshooting Chart

NFST0006S01

NFST0006

IDX

EL

SC

HA

BT

RS

BR

SU

AX

AT

MT

CL

FE

EC

LC

EM

MA

GI

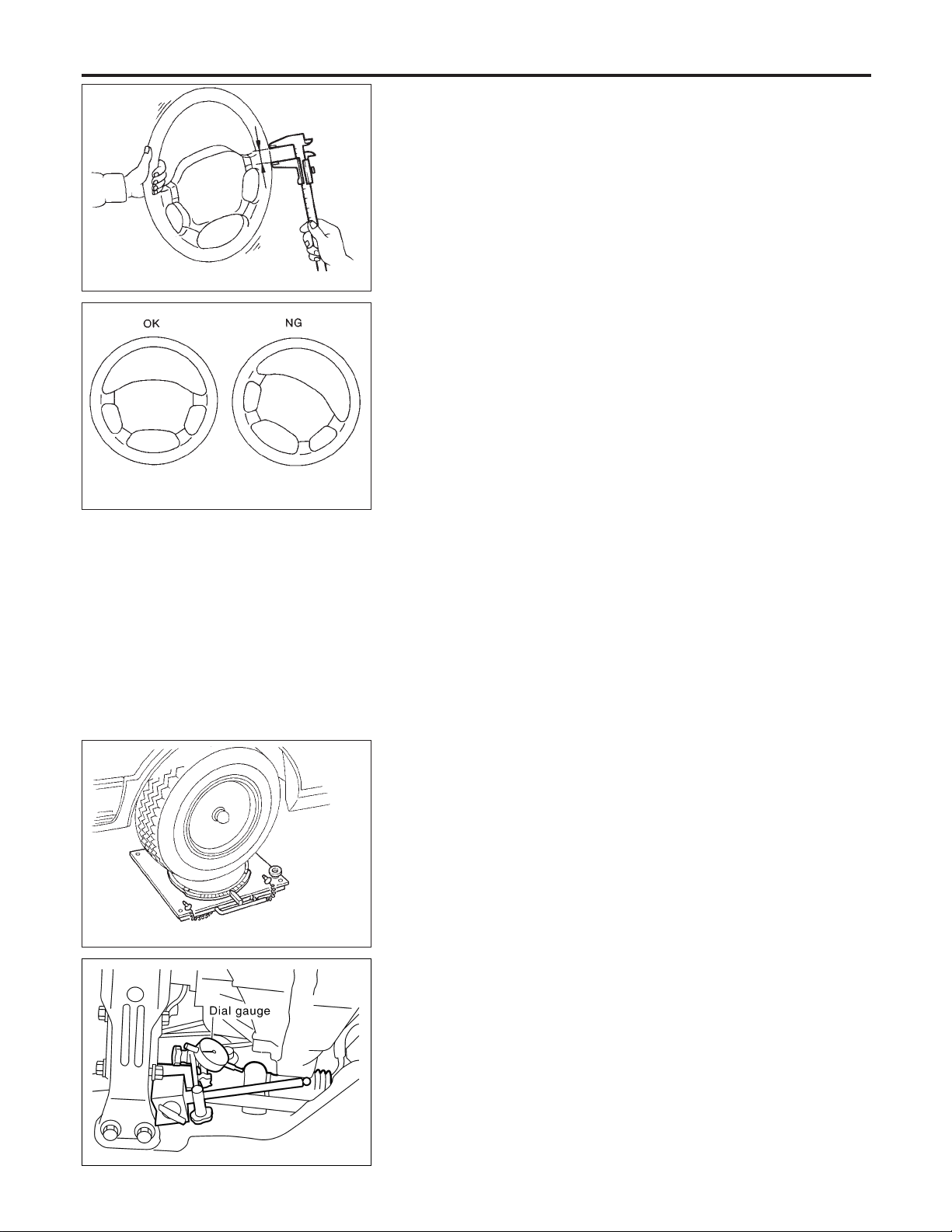

Checking Steering Wheel Play

ON-VEHICLE SERVICE

SST489B

SST490BA

Checking Steering Wheel Play

NFST0007

I With wheels in a straight-ahead position, check steering wheel

play.

Steering wheel play:

35 mm (1.38 in) or less

I If it is not within specification, check the following for loose or

worn components.

Steering gear assembly

Steering column

Front suspension and axle

Checking Neutral Position on Steering Wheel

PRE-CHECKING

NFST0008

NFST0008S01

I Make sure that wheel alignment is correct.

Wheel alignment:

Refer to SU-16, SDS.

I Verify that the steering gear is centered before removing the

steering wheel.

CHECKING

NFST0008S02

1. Check that the steering wheel is in the neutral position when

driving straight ahead.

2. If it isnot in the neutral position, remove the steeringwheel and

reinstall it correctly.

3. If the neutral position is between two teeth, loosen tie-rod lock

nuts. Turn the tie-rods by the same amount in opposite directions on both left and right sides.

SMA127

SST849C

Front Wheel Turning Angle

NFST0009

1. Rotate steering wheel all the way right and left; measure turning angle.

Turning angle of full turns:

Refer to SU-16, SDS.

2. If it is not within specification, check rack stroke.

Rack stroke “S”:

Refer to SDS, ST-30.

Checking Gear Housing Movement

NFST0010

1. Check the movement of steering gear housing during stationary steering on a dry paved surface.

I Apply a force of 49 N (5 kg, 11 lb) to steering wheel to check

the gear housing movement.

Turn off ignition key while checking.

Movement of gear housing:

±2mm(±0.08 in) or less

2. If movement exceeds the limit, replace mount insulator after

confirming proper installation of gear housing clamps.

ST-6

ON-VEHICLE SERVICE

Checking and Adjusting Drive Belts

SST850C

SST851C

Checking and Adjusting Drive Belts

Refer to MA-13, “Checking Drive Belts”.

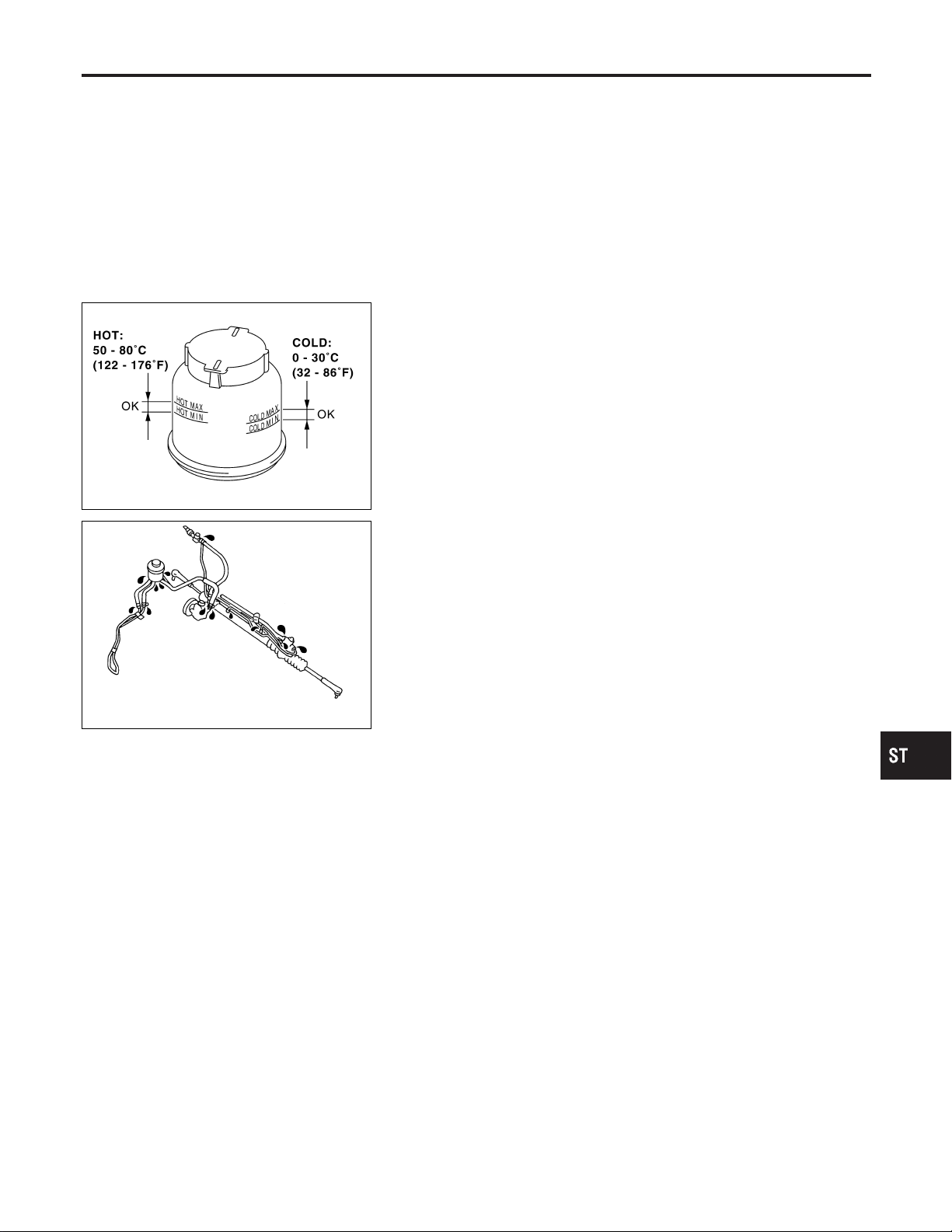

Checking Fluid Level

Check fluid level, referring to the scale on reservoir tank.

Use “HOT” range for fluid temperatures of 50 to 80°C (122 to

176°F).

Use “COLD” range for fluid temperatures of 0 to 30°C (32 to 86°F).

CAUTION:

I Do not overfill.

I Recommended fluid is Genuine Nissan PSF II or equiva-

lent. Refer to MA-11, “Fluids and Lubricants”.

Checking Fluid Leakage

Check the lines for improper attachment and for leaks, cracks,

damage, loose connections, chafing and deterioration.

1. Run engine between idle speed and 1,000 rpm.

Make sure temperature of fluid in oil tank rises to 60 to 80°C

(140 to 176°F).

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each “lock” position for five seconds

and carefully check for fluid leakage.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

4. If fluid leakage at connectors is noticed, loosen flare nut and

then retighten.

Do not overtighten connector as this can damage O-ring,

washer and connector.

5. If fluid leakage from power steering pump is noticed, check

power steering pump. Refer to ST-25.

6. Check rack boots for accumulation of power steering fluid.

NFST0011

NFST0012

NFST0013

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

RS

BT

Bleeding Hydraulic System

1. Raise front end of vehicle until wheels are clear of the ground.

2. Add fluid into oil tank to specified level. Then quickly turn steering wheel fully to right and left and lightly touch steering stoppers.

Repeat steering wheel operation until fluid level no longer

decreases.

3. Start engine.

Repeat step 2. above.

I Incomplete air bleeding will cause the following to occur. When

this happens, bleed air again.

NFST0014

ST-7

HA

SC

EL

IDX

Bleeding Hydraulic System (Cont’d)

ON-VEHICLE SERVICE

a) Air bubbles in reservoir tank

b) Clicking noise in oil pump

c) Excessive buzzing in oil pump

Fluid noise may occur in the valve or oil pump. This is common

when the vehicle is stationary or while turning the steering wheel

slowly. This does not affect the performance or durability of the

system.

SST491B

SST090B

Checking Steering Wheel Turning Force

NFST0015

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating temperature. [Make sure temperature of fluid is approximately 60 to

80°C (140 to 176°F).]

Tires need to be inflated to normal pressure.

4. Check steering wheel turning force when steering wheel has

been turned 360° from the neutral position.

Steering wheel turning force:

39 N (4 kg, 9 lb) or less

5. If steering wheel turning force is out of specification, check

rack sliding force.

a. Disconnect steering column lower joint and knuckle arms from

the gear.

b. Start and run engine at idle to make sure steering fluid has

reached normal operating temperature.

c. Pull tie-rod slowly to move it from neutral position to ±11.5 mm

(±0.453 in) at speed of 3.5 mm (0.138 in)/s. Check that rack

sliding force is within specification.

Average rack sliding force:

216 - 284 N (22 - 29 kg, 49 - 64 lb)

Maximum force deviation:

98 N (10 kg, 22 lb)

d. Check sliding force outside the above range at rack speed of

40 mm (1.75 in)/s.

Rack sliding force:

Not more than 294 N (30 kg, 66 lb)

Maximum force deviation:

147 N (15 kg, 33 lb)

6. If rack sliding force is not within specification, overhaul steering gear assembly.

7. If rack sliding force is OK, inspect steering column. Refer to

ST-13.

ST-8

ON-VEHICLE SERVICE

Checking Hydraulic System

SST834-F

Checking Hydraulic System

Before starting, check belt tension, driving pulley and tire pressure.

1. Set Tool. Open shut-off valve. Then bleed air. Refer to “Bleeding Hydraulic System”, ST-7.

2. Run engine at idle speed or 1,000 rpm.

Make sure temperature of fluid in tank rises to 60 to 80°C (140

to 176°F).

WARNING:

Warm up engine with shut-off valve fully opened. If engine is

started with shut-off valve closed, fluid pressure in oil pump

increases to maximum. This will raise oil temperature abnormally.

3. Check pressure with steering wheel fully turned to leftand right

positions with engine idling at 1,000 rpm.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

Oil pump maximum standard pressure:

8,140 - 8,728 kPa (83 - 89 kg/cm

I If pressure reaches maximum operating pressure, system is

OK.

I If pressure increases above maximum operating pressure,

check power steering pump flow control valve. Refer to ST-25.

4. If power steering pressure is below the maximum operating

pressure, slowly close shut-off valve and check pressure

again.

CAUTION:

Do not close shut-off valve for more than 15 seconds.

I If pressure increases to maximum operating pressure, gear is

damaged. Refer to “Removal and Installation”, ST-16.

I If pressure remains below maximum operating pressure, pump

is damaged. Refer to “Disassembly”, ST-26.

5. After checking hydraulic system, remove Tool and add fluid as

necessary. Then completely bleed air out of system. Refer to

ST-7.

2

, 1,180 - 1,266 psi)

NFST0016

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST-9

RS

BT

HA

SC

EL

IDX

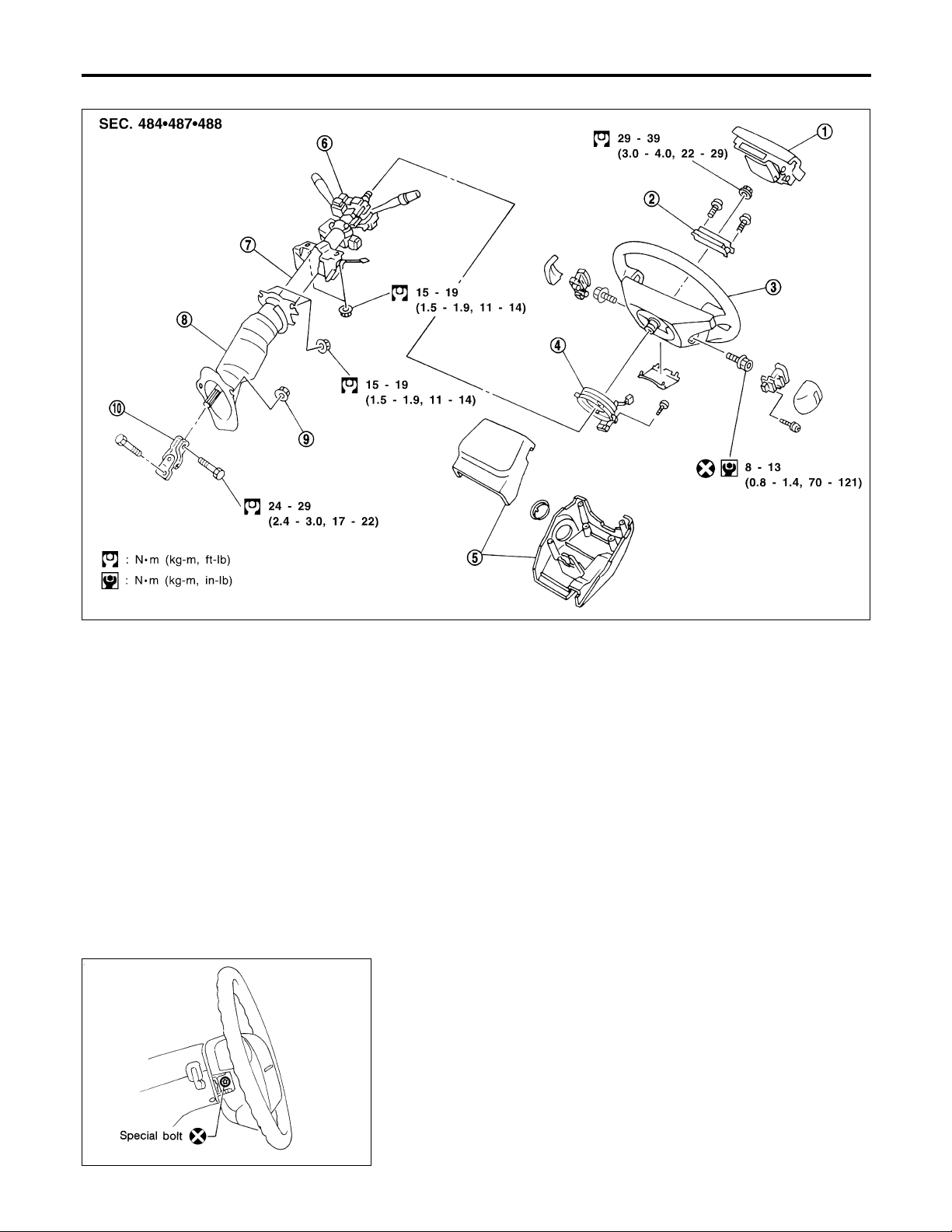

Components

STEERING WHEEL AND STEERING COLUMN

Components

NFST0017

1. Air bag module

2. Damper

3. Steering wheel

4. Spiral cable

5. Column cover

6. Combination switch

7. Steering column assembly

8. Boot

9. Clip

10. Lower joint

CAUTION:

I The rotation of the spiral cable (SRS “Air bag” component

part) is limited. If the steering gear must be removed, set

the front wheels in the straight-ahead direction. Do not

rotate the steering column while the steering gear is

removed.

I Remove the steering wheel before removing the steering

lower joint to avoid damaging the SRS spiral cable.

Removal and Installation

STEERING WHEEL

I Remove air bag module and spiral cable.

Refer to RS-20, “Removal —Air Bag ModuleandSpiral Cable”.

SST852C

NFST0018

NFST0018S01

SBF812E

ST-10

Loading...

Loading...