Nissan 350Z 2006 User Manual

GLASSES, WINDOW SYSTEM & MIRRORS

I BODY

A

B

SECTION GW

GLASSES, WINDOW SYSTEM & MIRRORS

CONTENTS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Rest raint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for Battery Service ................................ 3

Precautions for Procedures without Cowl Top Cover ..... 3

Handling for Adhesive and Primer ........................... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 4

SQUEAK AND RATTLE TROUBLE DIAGNOSES ..... 5

Work Flow ................................................................ 5

CUSTOMER INTERVIEW ..................................... 5

DUPLICATE THE NOISE AND TEST DRIVE ....... 6

CHECK RELATED SERVICE BULLETINS .. ......... 6

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 6

REP AIR THE CAUSE ........................................... 6

CONFIRM THE REPAIR ....................................... 7

Generic Squeak and Rattle Troubleshooting ........... 7

INSTRUMENT PANEL .......................................... 7

CENTER CONSOLE ............................................. 7

DOORS .............................. ................................... 7

TRUNK ............................... ................................... 8

SUNROOF/HEADLINING ..................................... 8

SEATS ................................................................... 8

UNDERHOOD .................... ............. ............. ......... 8

Diagnostic Worksheet .............................................. 9

WINDSHIELD GLASS ...............................................11

Removal and Installation .........................................11

REMOVAL (COUPE) ............................................11

REMOVAL (ROADSTER) ................................... 12

INSTALLATION ................................................... 12

BACK DOOR WINDOW GLASS .............................. 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 15

SIDE WINDOW GLASS ............................................16

Removal and Installation ........................................ 16

REMOVAL ........................................................... 16

INSTALLATION ................................................... 17

POWER WINDOW SYSTEM .................................... 18

Component Parts and Harness Connector Location ...18

System Description .................................................19

MANUAL OPERATION ........................................ 19

POWER WINDOW SERIAL LINK .......................20

AUTO OPERATION .............................................20

POWER WINDOW LOCK ................................... 20

RETAINED POWER OPERATION ......................20

ANTI-PINCH SYSTEM ........................................ 21

POWER WINDOW CONTROL BY THE KEY

CYLINDER SWITCH ........................................... 21

AUTOMATIC WINDOW ADJUSTING FUNC-

TION ............................... .....................................21

Schematic .................... ....................................... ....22

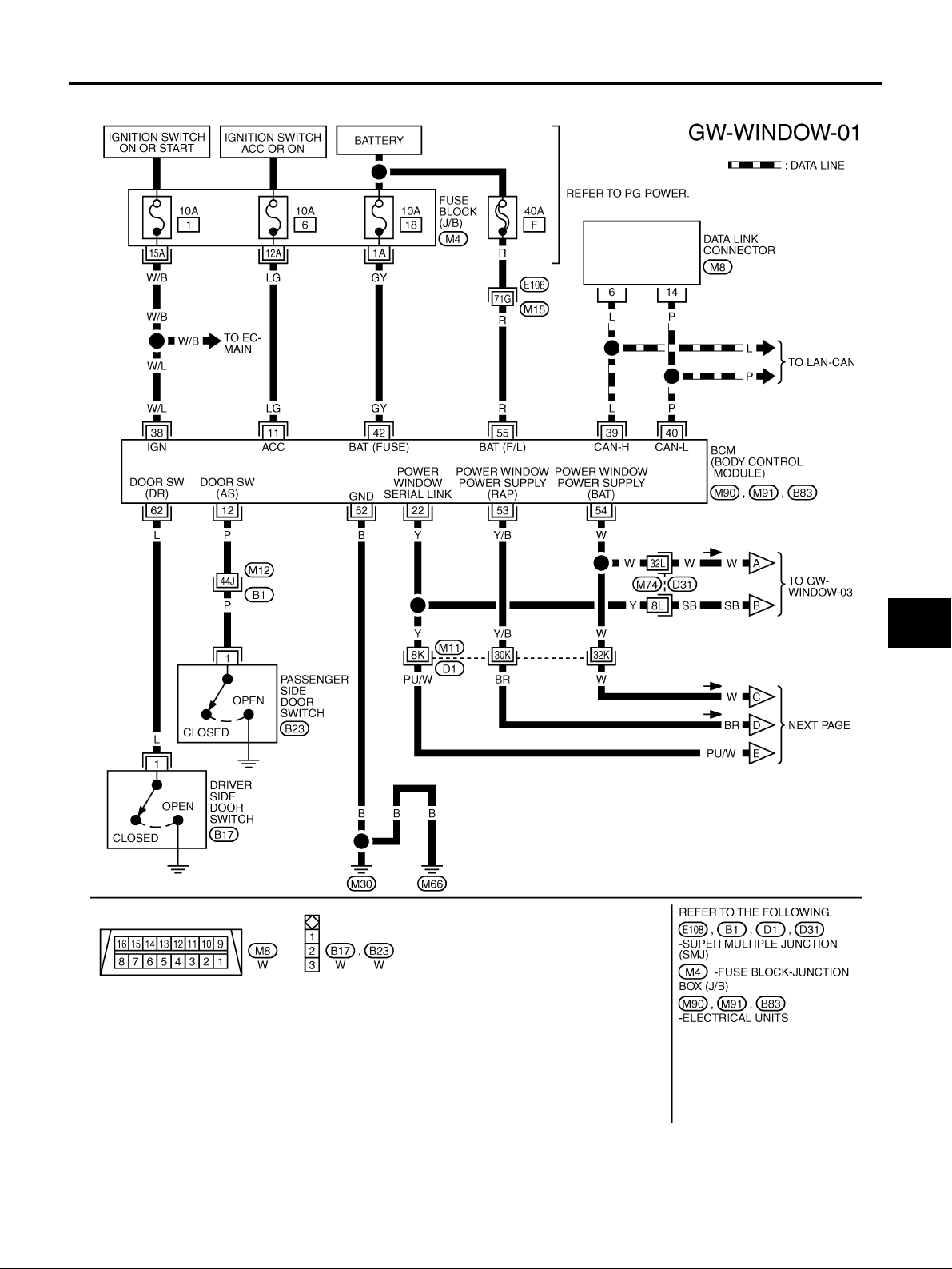

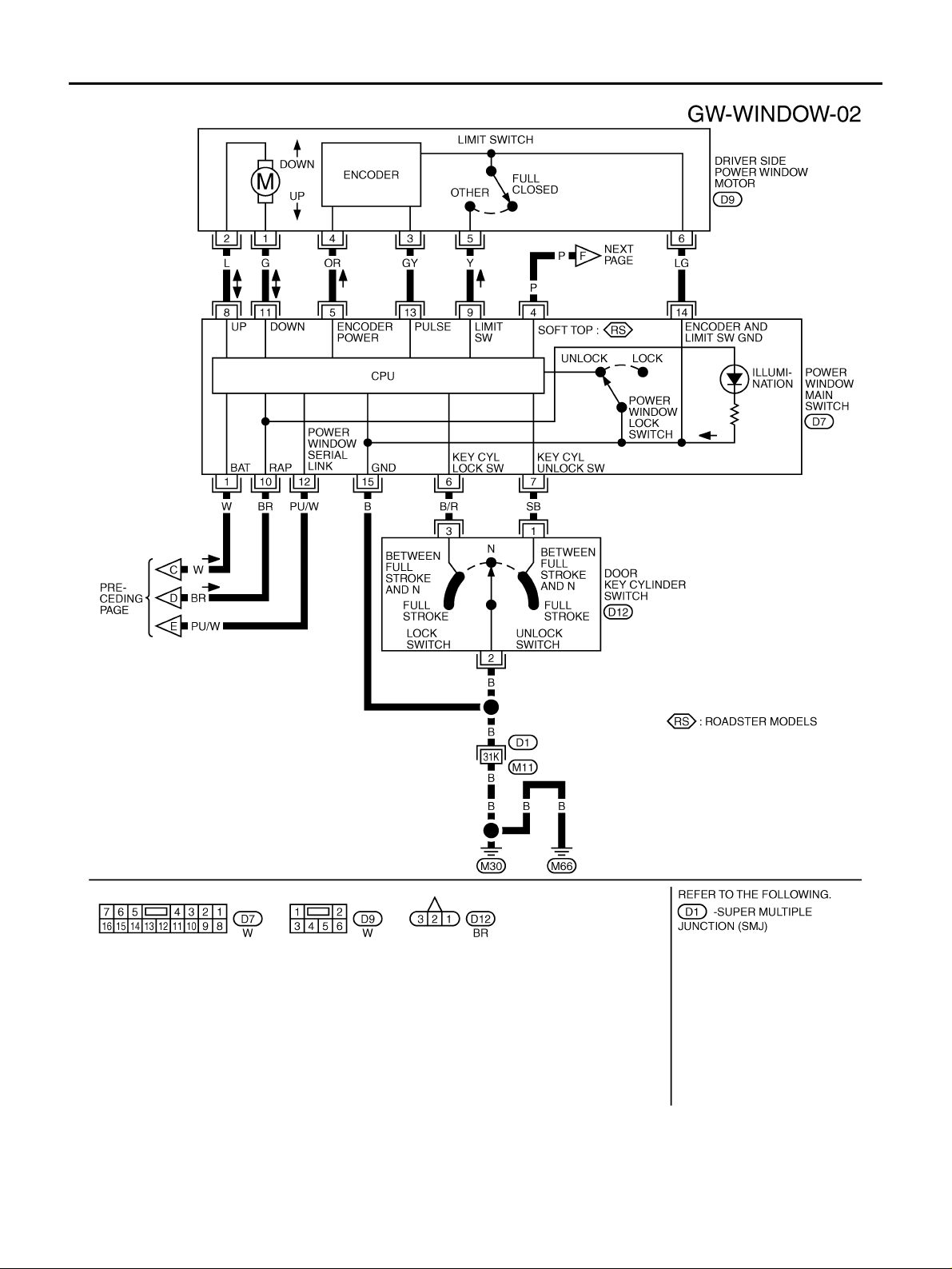

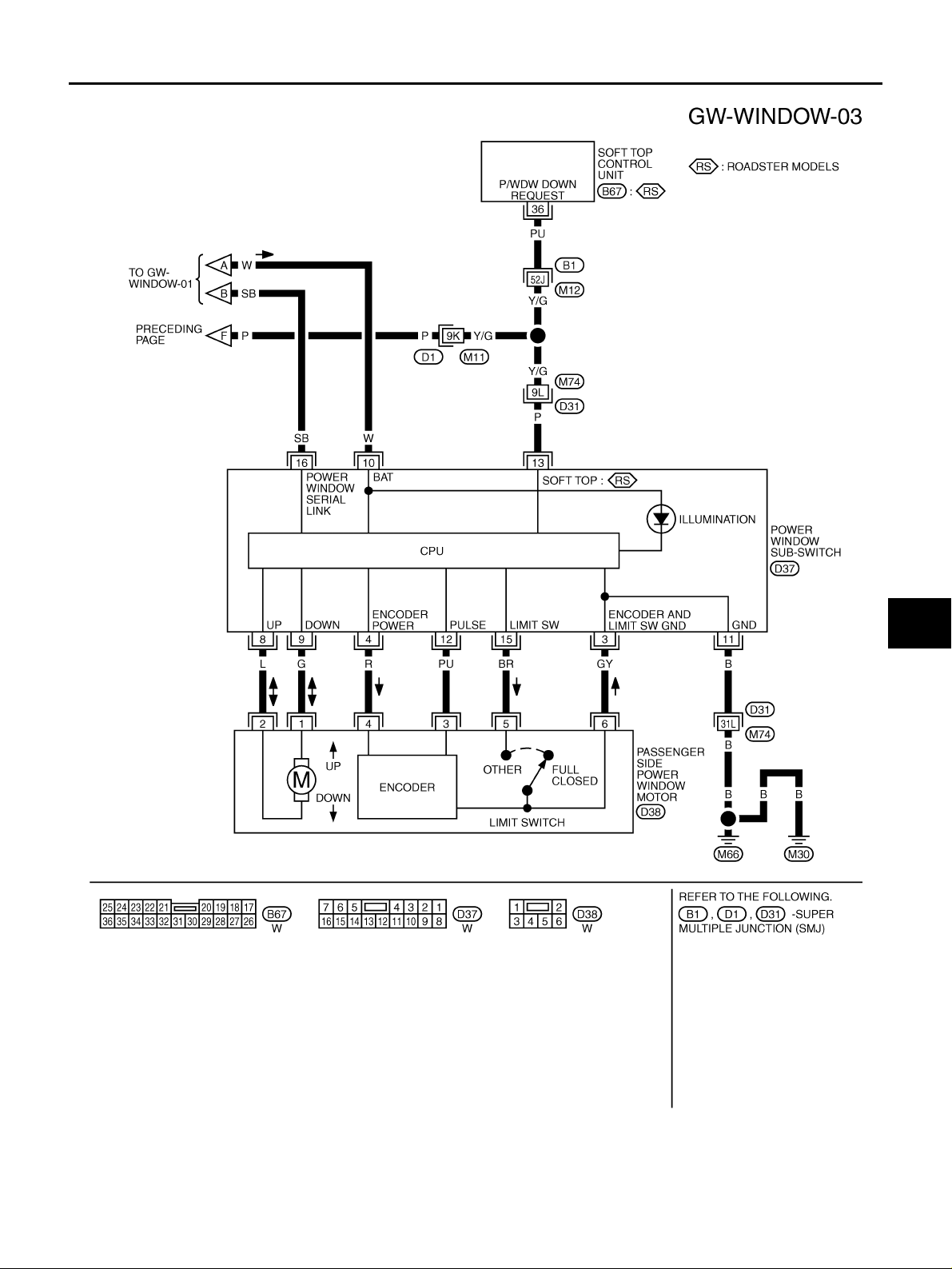

Wiring Diagram — WINDOW — .............................23

Terminal and Reference Value for BCM .................26

Terminal and Reference Value for Power Window

Main Switch ............................................................ 27

Terminal and Reference Value for Power Window

Sub-Switch .............................................................28

CONSULT-II Function (BCM) .................................29

CONSULT-II INSPECTION PROCEDURE ..........29

WORK SUPPORT ...............................................30

DATE MONITOR .................................................30

ACTIVE TEST ..................................................... 30

Work Flow ...............................................................31

Trouble Diagnoses Symptom Chart .......................31

Check BCM Power Supply and Grou nd Circ uit ...... 33

Check Drive Side Power Window Motor Circuit .....34

Check Passenger Side Power Window Motor Cir-

cuit ............................... ...........................................34

Check Limit Switch Circuit (Driver Side) .................35

Check Limit Switch Circuit (Passenger Side) ......... 37

Check Encoder Circuit (Driver Side) ....................... 38

Check Encoder Circuit (Passenger Side) ............... 40

Check Door Switch ................................................. 43

C

D

E

F

G

H

GW

J

K

L

M

Revision: 2005 August 2006 350Z

GW-1

Check Power Window Serial Link ...........................45

Check Power Window Main Switch Power Supply

and Ground Circuit ................................................. 47

Check Power Window Sub-switch Power Supply

and Ground ............................................................. 48

Check Door Key Cylinder Switch ............................49

FRONT DOOR GLASS AND REGULATOR .............52

Removal and Installation ........................................52

DOOR GLASS .....................................................52

REGULAT OR ASSEMBLY ..................................53

Disassembly and Assembly .................................... 53

REGULAT OR ASSEMBLY ..................................53

Inspection after Installation .....................................53

SETTING OF LIMIT SWITCH ..............................53

FITTING INSPECTION ........................................54

INSIDE MIRROR .......................................................55

Wiring Diagram –I/MIRR– ...................................... 55

Removal and Installation ........................................56

REMOVAL ...........................................................56

INSTALLATION ....................................................56

REAR WINDOW DEFOGGER ....... ....... ...... ....... ....... 57

Component Parts and Harness Connector Location ...57

System Description ................................................. 57

CAN Communication System Description ..............59

CAN Communication Unit .......................................59

Schematic – DEF –/ For Coupe ..............................60

Wiring Diagram –DEF–/ For Coupe ........................61

Schematic – DEF –/ For Roadster ..........................64

Wiring Diagram –DEF–/ For Roadster ....................65

Terminal and Reference Value for BCM .................68

Terminal and Reference Value for IPDM E/R. ........68

T erminal and Reference Value for Unified Meter and

A/C Amp. ................................................................ 68

CONSULT-II Function (BCM) ..................................69

CONSUL T-II INSPECTION PROCEDURE FOR

REAR WINDOW DEFOGGER .............................69

DATA MONITOR ..................................................70

ACTIVE TEST ......................................................70

CONSULT-II Function (IPDM E/R) ..........................71

CONSUL T-II INSPECTION PROCEDURE FOR

REAR WINDOW DEFOGGER .............................71

DATA MONITOR ..................................................72

ACTIVE TEST ......................................................72

Work Flow ...............................................................73

Trouble Diagnoses Symptom Chart ........................73

Check IPDM E/R Operation ....................................74

Check Rear Window Defogger Switch Circuit .........74

Check Rear Window Defogger Power Suppl y Cir-

cuit ..........................................................................75

Check Rear Window Defogger Circuit / For Coupe ...77

Check Rear Window Defogger Circuit / For Road-

ster ..........................................................................78

Check Door Mirror Defogger Power Supply Circuit ...79

Check Driver Side Door Mirror Defogger Circuit .....80

Check Passenger Side Door Mirror Defogger Circuit

...80

Check Filament ...................................... ...... ....... ....82

Filament Repair .......................................................83

REP AIR EQUIPMENT .........................................83

REP AIRING PROCEDURE .................................83

DOOR MIRROR . ...... ....... ...... ....... ...... ....... ...... ....... ....84

Wring Diagram –MIRROR– ......................... ...........84

Removal and Installation .........................................85

REMOVAL ........................................................ ....85

INSTALLATION ................................................ ....85

DISASSEMBLY ................................................ ....85

ASSEMBLY ...................................................... ....86

Revision: 2005 August 2006 350Z

GW-2

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

NIS00049

A

The Supplemental Rest raint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used al ong

with a front seat belt, helps to redu ce th e risk or se verit y of i njury to the driv er and front passenge r for ce rtain

types of collision. This system includes seat belt switch inputs and dual st age front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Manual.

WARNING:

● To avoid rendering the SRS inopera tive, whi ch could incr ease the risk of pe rsonal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, inc luding incorrect removal and installation of the SRS, can lead to per-

sonal injury ca use d by unintentional ac tiv atio n of the system. F or r e mo va l o f Spi ral Cable and Air

Bag Module, see the SRS sec tion.

● Do not use electrical test equ ipment o n any circu it related to the SRS unless in structed to in this

Service Manual. SRS wiring harnesses can be id entified by yellow and/or orange harnesses or

harness connectors.

Precautions for Battery Service NIS0004A

Before disconnecting the battery, lower both the driver and passenger windows. This will prevent any interference between t h e wi nd ow ed ge an d th e v eh ic le wh en the do or is ope ne d/ cl o sed. Dur i n g nor ma l op era ti on, t he

window slightly raises and lowers automatically to prevent any window to vehicle interference. The automatic

window function will not work with the battery disconnected.

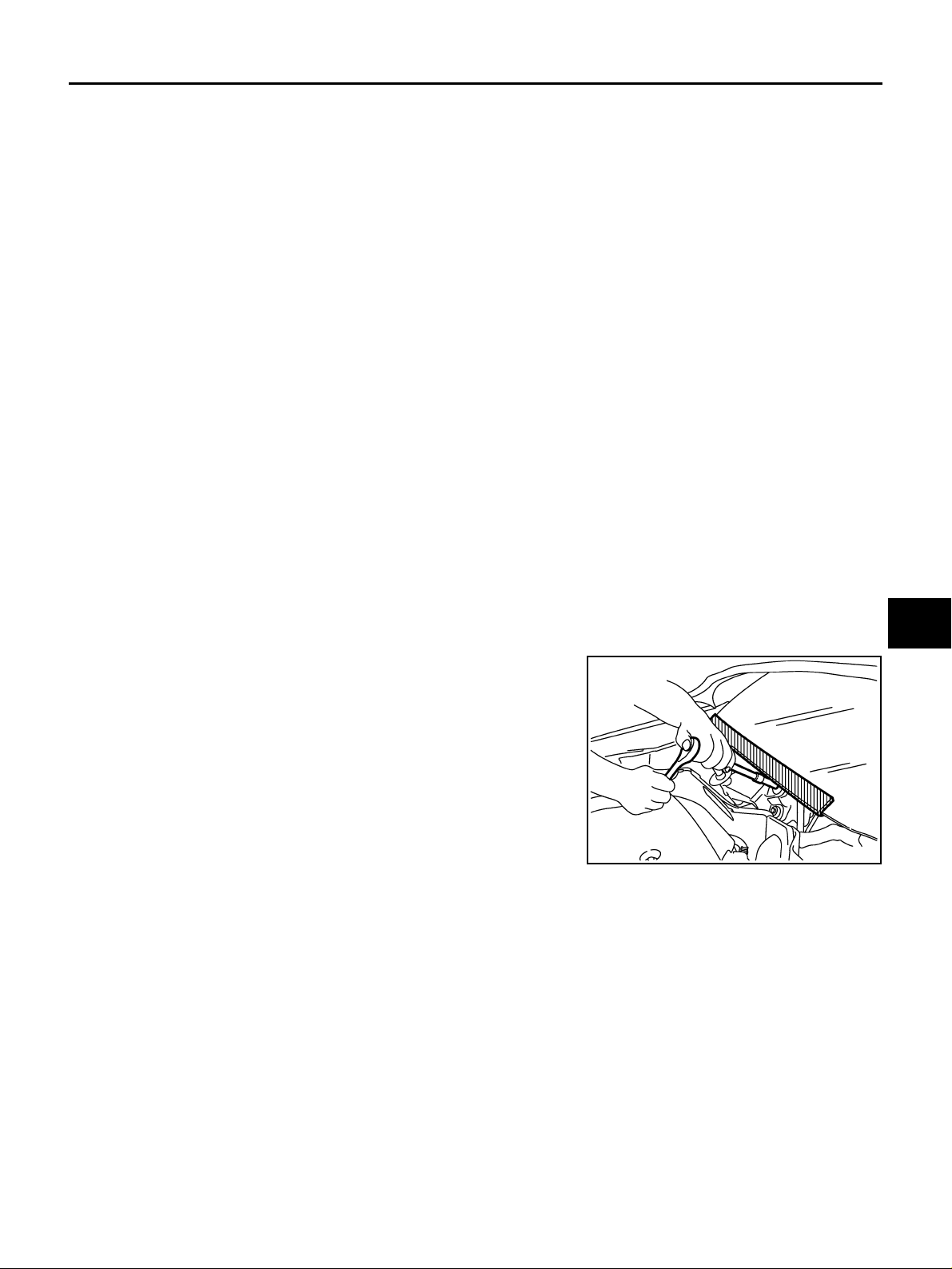

Precautions for Procedures without Cowl Top Cover NIS001L6

B

C

D

E

F

G

H

GW

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

PIIB3706J

Handling for Adhesive and Primer NIS0004B

● Do not use an adhesive which is past its usable date. Shelf life of this product is limited to six months after

the date of manufacture. Carefully adhere to the expiration or manufacture date printed on the box.

● Keep primers and adhesive in a cool, dry place. Ideally, they should be stored in a refrigerator.

● Open the seal of the primer and adhesive just before application. Discard the remainder.

● Before applicat ion, be sure to shake the primer container to stir the contents. If any floating material is

found, do not use it.

● If any primer o r adhe sive co ntacts the sk in, wi pe it off with gasol ine or eq uivalen t and wash the skin w ith

soap.

● When using primer and adhesive, always observe the precautions in the instruction manual.

J

K

L

M

Revision: 2005 August 2006 350Z

GW-3

PREPARATION

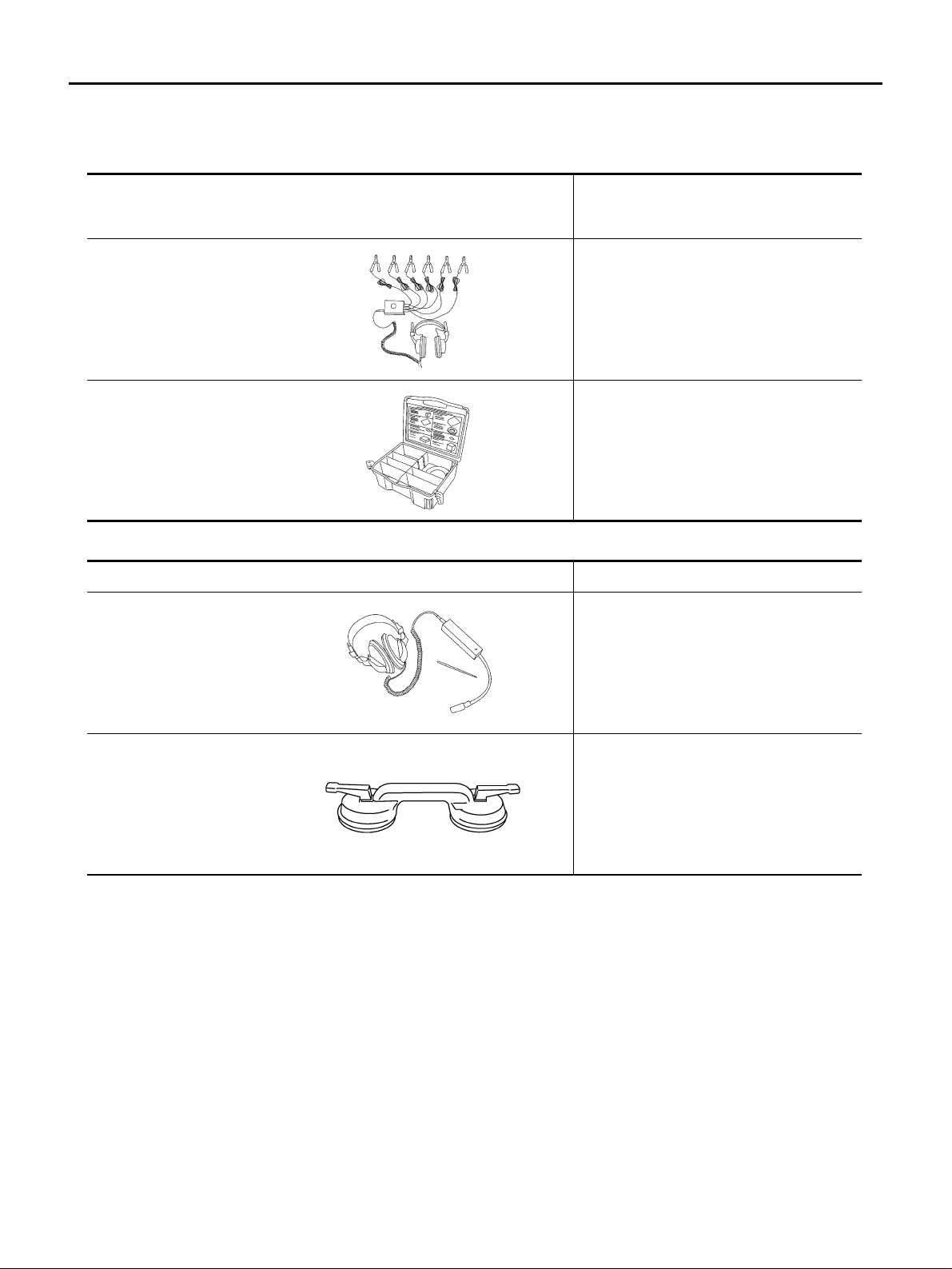

PREPARATION PFP:00002 Special Service Tools NIS0004D

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

Description

(J39570)

Chassis ear

SIIA0993E

(J43980)

NISSAN Squeak and

Rattle Kit

SIIA0994E

Locating the noise

Repairing the cause of noise

Commercial Service Tools NIS0004E

Tool name Description

Engine ear Locating the noise

SIIA0995E

Suction lifter

PIIB1805J

Revision: 2005 August 2006 350Z

GW-4

Remove the windshield,

back door window glass

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES PFP:00000

Work Flow NIS0004F

A

B

C

D

E

F

SBT842

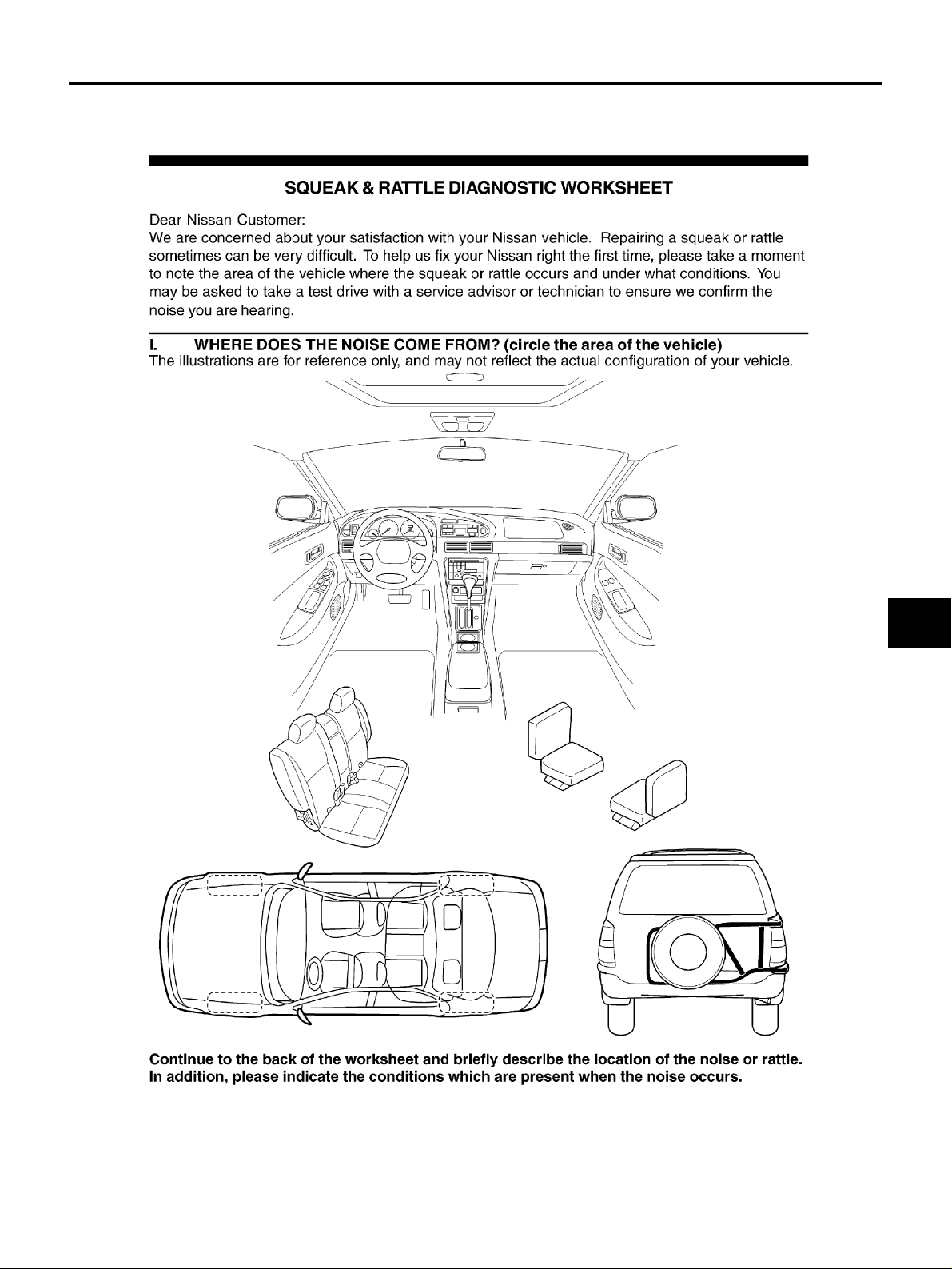

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diagnostic Worksheet during the interview to docume nt the facts and conditions w hen the noise occurs and an y

customer's comments; refer to GW-9, "

conditions that exist when the noise occurs.

● The customer may not be able to provide a detailed description or the location of the noise. Attempt to

obtain all the facts and conditions that exist when the noise occurs (or does not occur).

● If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer

is concerned about. This can be accomplished by test driving the vehicle with the customer.

● After ident if yi ng th e t y pe of no is e, i so lat e th e no is e in t er ms o f i t s c ha r ac te ris t ic s. T he n oi se c ha ract e ris ti cs

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

● Squeak —(Like tennis shoes on a clean floor)

Squeak charact eristics include the lig ht contact/fast movement/ brought on by road condi tions/hard surfaces=higher pitch noise/softer surfaces=lower pitch noises/edge to surface=chirping

● Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch

dependent on materials/often brought on by activity.

● Rattle—(Like shaking a baby rattle)

Rattle charact eristics inclu de the f ast repe ated co ntact/vibra tion or similar mov ement/l oose parts/mi ssing

clip or fastener/incorrect clearance.

● Knock —(Like a knoc k on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

● Tick —(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road co nditions.

● Thump—(Hea vy, muffled knock noise)

Thump characteristics include softer knock/d ead sound often brought on by activity.

● Buzz—(Like a bumble bee)

Buzz characteristics include high freque ncy rattle/firm contact.

● Often the de gree of acceptable nois e level will vary d epending upon the person. A noise that you may

judge as acceptable may be very irritating to the custome r.

● Weather conditions, especially humidit y and temperature, may have a great effect on noise level.

Diagnostic Worksh eet " . This info rmatio n is n ecess ary to dupl icate the

G

H

GW

J

K

L

M

Revision: 2005 August 2006 350Z

GW-5

SQUEAK AND RATTLE TROUBLE DIAGNOSES

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the con ditions or location of the noise. This inform ation can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to duplicate the noise with the vehicle stopped by doin g one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from .

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twis t”.

5) At id le, apply engine load (electrical load, half-clutch on M/ T models, drive position on A/ T models).

6) Raise the vehicle on a hoist and hit a tir e with a rubber ha mmer .

● Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

● If it is difficult to duplicate the nois e, drive th e vehic le slowly on an und ulating or ro ugh road t o stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the pr ocedure to repair the nois e.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the nois e to a general area. To help pinpoint the source of the noise, use a lis tening tool

(Chassis Ear: J-39570, Engine Ear and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

● removing the components in the area that you suspect the noise is coming from.

Do not use too much force when remo ving clip s an d fa stener s, o ther wise c lip s a nd fa stener can be br oken

or lost during the repair, resulting in the creation of new noise.

● tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or pus h/pull the com ponent with ex cessive force, otherwise the noise will b e eliminated on ly

temporarily.

● feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

● placing a piece of paper between components that you suspect are causing the noise.

● looking for loose components and cont act marks.

Refer to GW-7, "

Generic Squeak and Rattl e Troubles ho oti ng " .

REPAIR THE CAUSE

● If the cause is a loose component, tighten the component secur ely.

● If the cause is insufficient clearance between components:

– separate components by repositioning or loosening and retightening the component, if possible.

– insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A Niss an Squeak a nd Rattl e Kit (J-439 80) is avai lable thro ugh your authorized Nissan Pa rts

Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

The following materials are contained in the Nissan Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 × 135 mm (3.94 × 5.31 in)/76884-71L01: 60 × 85 mm (2.36 × 3.35 in)/7688471L02: 15 × 25 mm (0.59 × 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 × 50 mm (1.97 × 1.97 in)/73982-50Y00:

10 mm (0.39 in) thick, 50 × 50 mm (1.97 × 1.97 in)

Revision: 2005 August 2006 350Z

GW-6

SQUEAK AND RATTLE TROUBLE DIAGNOSES

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 × 50 mm (1.18 × 1.97 in)

FELT CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrum ent panel applications.

68370-4B000: 15 × 25 mm (0.59 × 0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit. Will only last a few months.

SILICONE SPRAY

Use when greas e cannot be applied.

DUCT TAPE

Use to elimin ate movement.

A

B

C

D

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle Troubleshooting NIS0004G

Refer to Table of Contents for specific comp on en t rem ov al and in stalla tion information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter hous ing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the co mponents while drivi ng to s t op th e no is e. Most of these in c ide nts c an be re paired by applying felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring harness.

CAUTION:

Do not use silicone s pray to isolate a sq ueak or rattle. If you saturate the area with silicone, you w ill

not be able to recheck the repair.

E

F

G

H

GW

J

K

L

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and clust er lid C

3. Wiring harnes se s be hin d audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the Nissan Squeak and Rattle Kit (J-43980) to repair the noise.

Revision: 2005 August 2006 350Z

GW-7

M

SQUEAK AND RATTLE TROUBLE DIAGNOSES

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trun k by the owner.

In addition look for:

1. T runk lid dumpers out of adjustment

2. T runk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose l icense plate or b racket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or compo nent(s) causing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshiel d touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolatin g seat no ise it 's imp ort ant to not e the p ositi on th e seat is in and t he loa d plac ed on t he sea t when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the conditions under wh ic h th e n ois e oc cu rs. Most of these in ci de nts ca n b e re pair ed by rep os iti on in g th e c om po ne nt

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noi se may be caus ed by componen ts under the hood or o n the engine wall . The noise is th en

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Compon ents that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator moun tin g pi ns

5. Hood bumpers out of adjus tm e nt

6. Hood striker out of adjustment

These noises can be difficu lt to isol ate sin ce the y cann ot be rea ched from the inter ior of the ve hi cle. The best

method is to sec ure, mov e or insul ate one com ponen t at a time and test drive the vehicle . Also , engine RPM

or load can be cha nged to isol ate the noise. Repairs can usu ally be made by moving, adj usting, securing, or

insulating the component causing the noise.

Revision: 2005 August 2006 350Z

GW-8

SQUEAK AND RATTLE TROUBLE DIAGNOSES

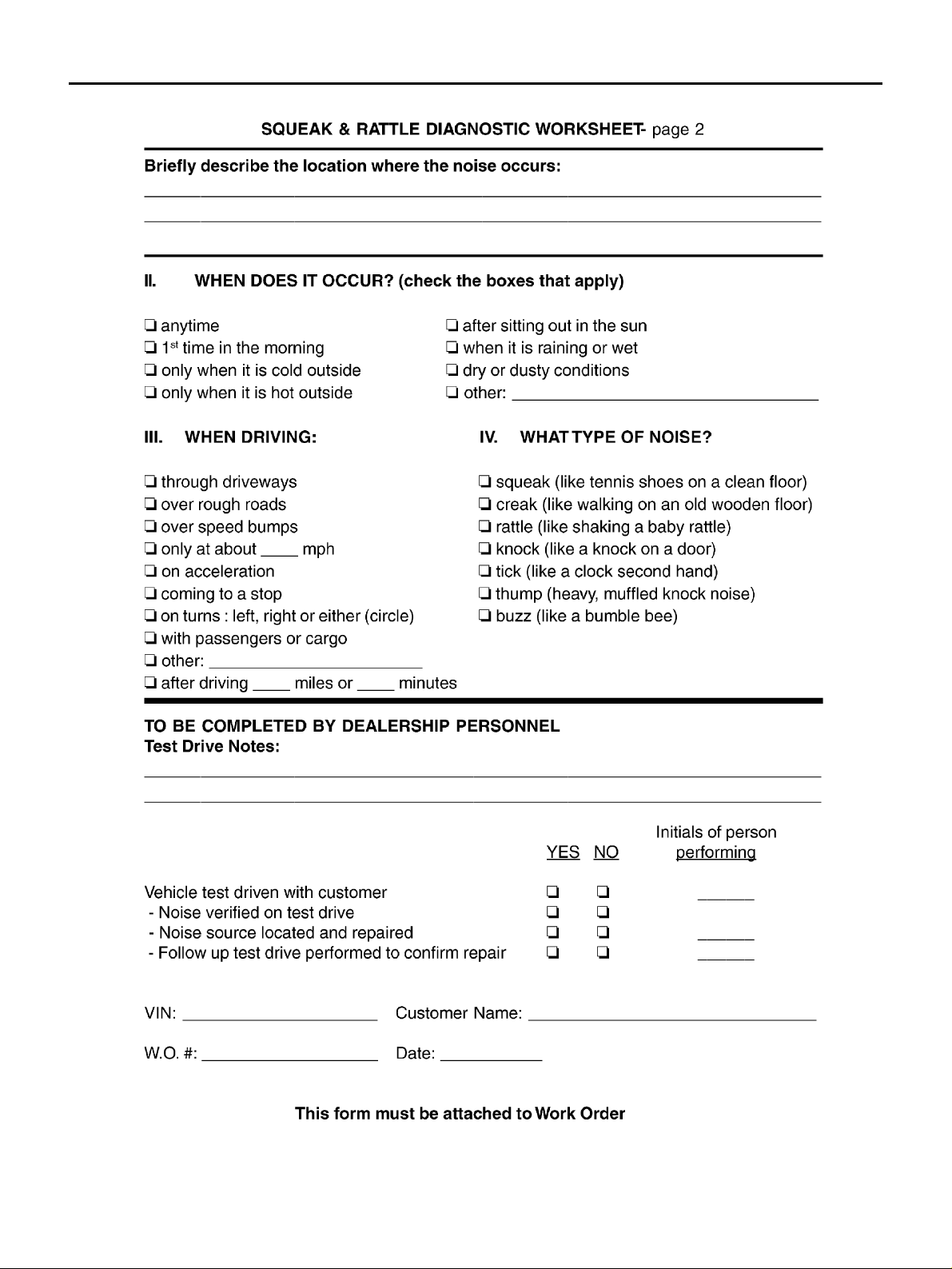

Diagnostic Worksheet NIS0004H

A

B

C

D

E

F

G

H

GW

J

K

L

M

PIIB0723E

Revision: 2005 August 2006 350Z

GW-9

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SBT844

Revision: 2005 August 2006 350Z

GW-10

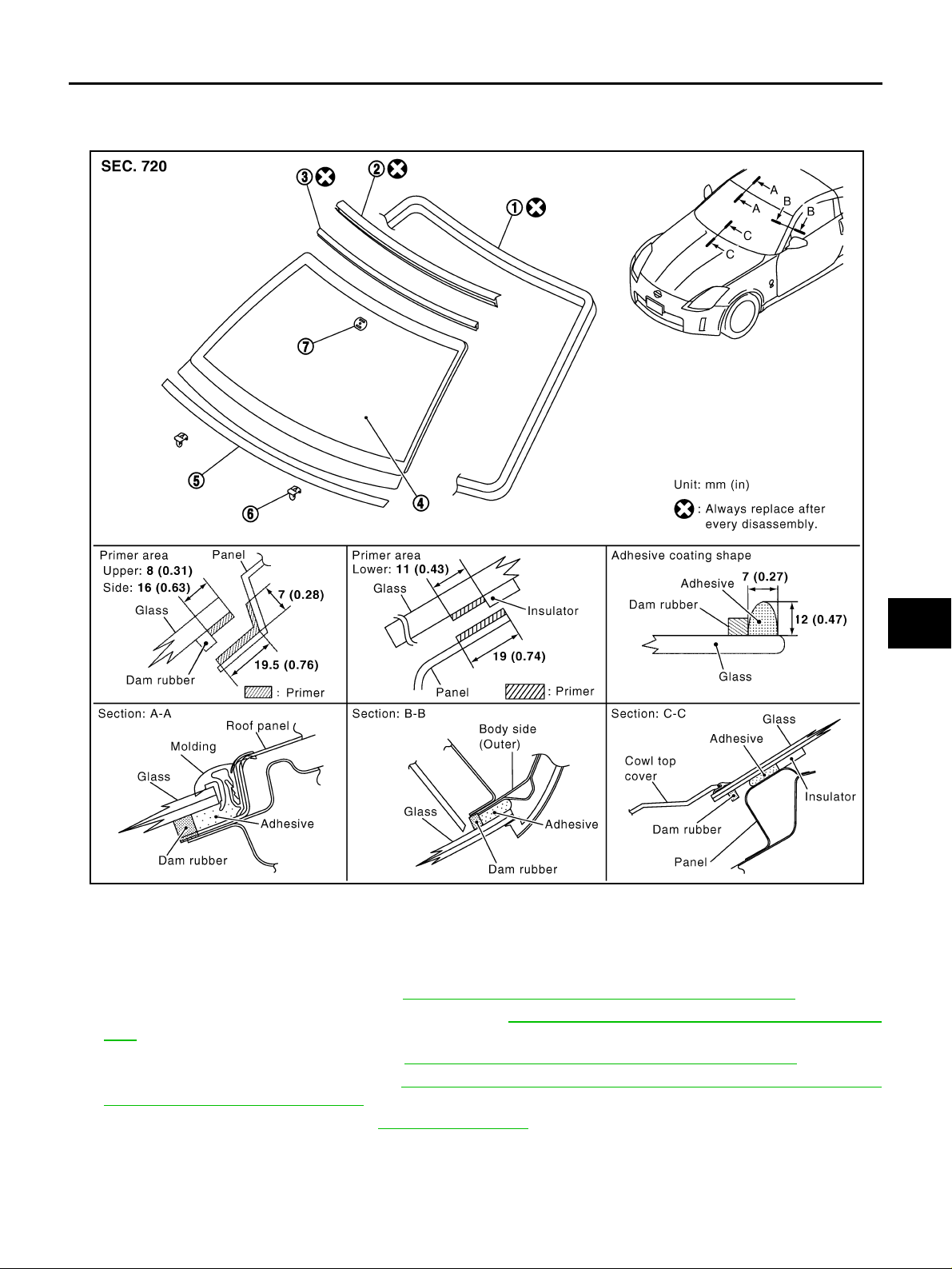

WINDSHIELD GLASS

WINDSHIELD GLASS PFP:72712

Removal and Installation NIS0004I

A

B

C

D

E

F

G

PIIA8724E

1. Dam rubber 2. Fastener 3. Molding (upper)

4. Windshield glass 5. Insulator 6. Spacer

7. Mirror base

REMOVAL (COUPE)

1. Remove the front pillar finisher. Refer to EI-31, "Removal and Instal lation (for Coupe Models)" .

2. Partially remov e the headlining (front edge). Ref er to EI-44, "

els)" .

3. Remove the front pillar ga rnish. Refer to EI-35, "

4. Remove the front wiper arms. Refer to WW-34, "

Removal and Installation (for Coupe Models)" .

Removal and Installation of Front Wiper Arms, Adjust-

ment of Wiper Arms Stop Location" .

5. Remove the cowl top cover. Refer to EI-20, "

COWL TOP" .

6. Apply a protective tape around the windshield glass to protect the painted surface from damage.

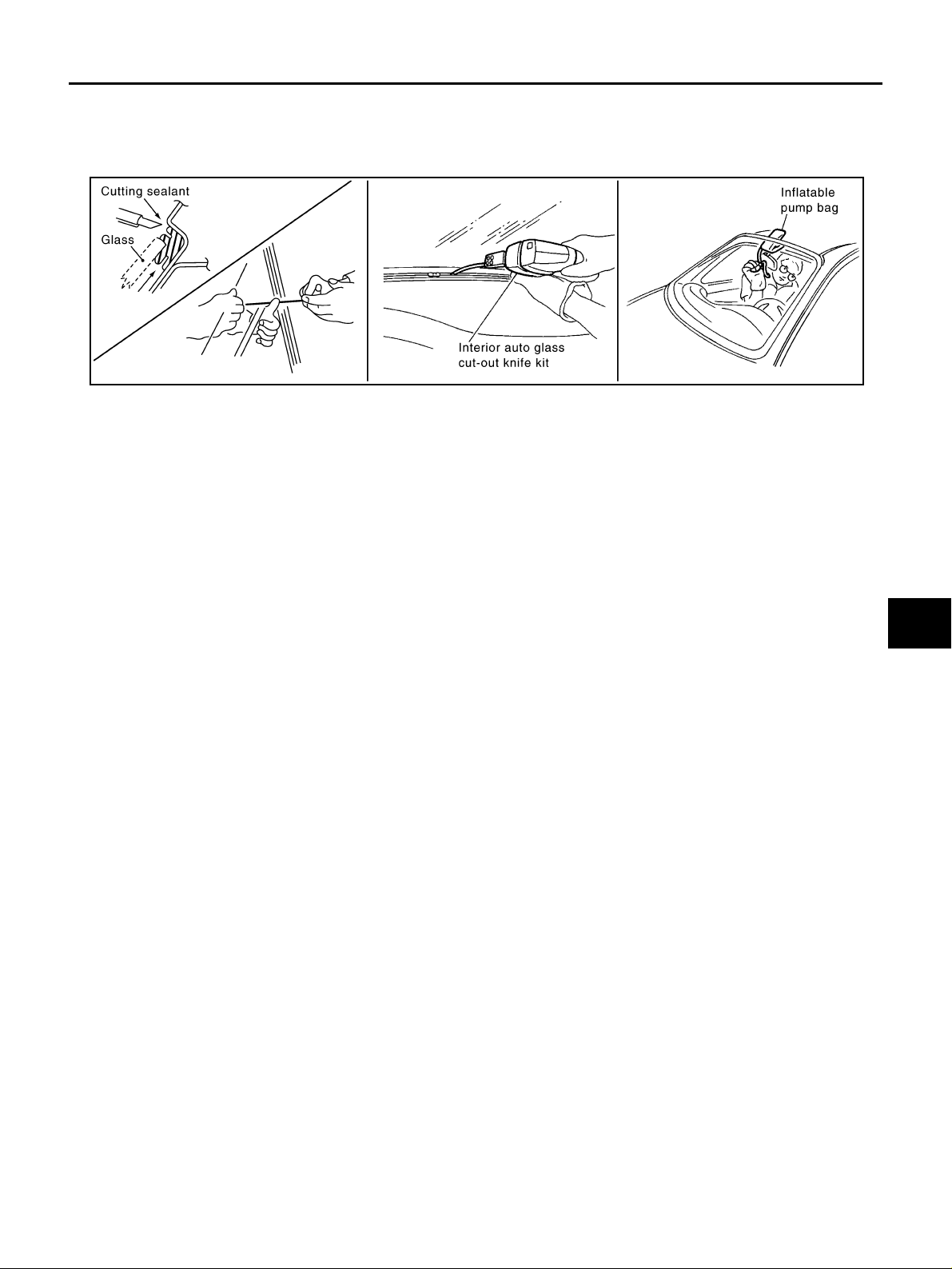

After removing moldings, remove glass using piano wire or power cutting tool an d an inflatab le pump bag.

● If a windshield glass is to be re used, mark the body and the glass with mating marks.

Removal and Installation (for Coupe Mod-

H

GW

J

K

L

M

Revision: 2005 August 2006 350Z

GW-11

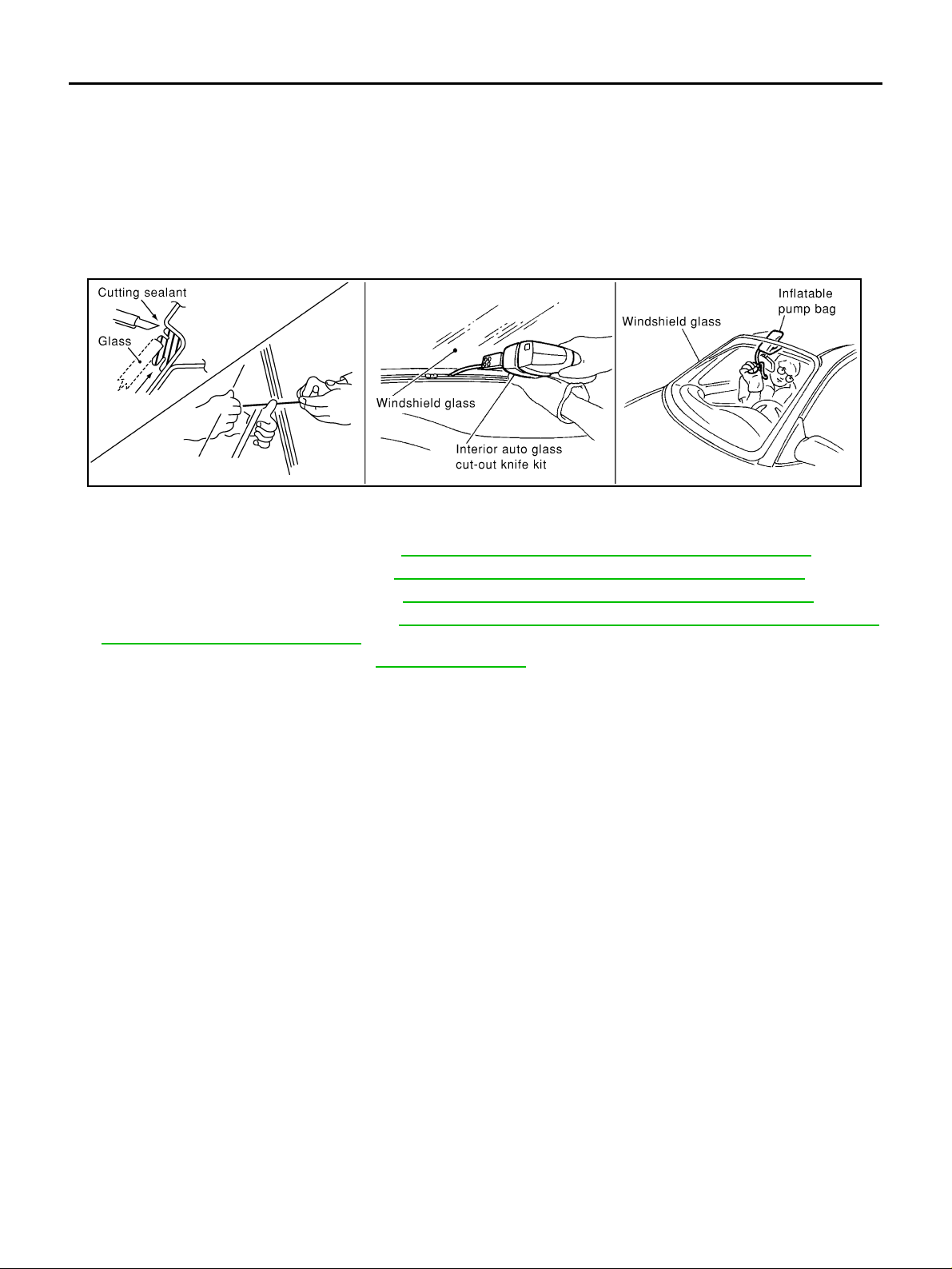

WINDSHIELD GLASS

WARNING:

When cutting the glass from the vehicle, always wear safety glasses and heavy gloves to help prevent

glass splinters from entering your eyes or cutting your hands.

CAUTION:

● When a windshield glass is to be reused, do not use a cutting knife or power cutting tool.

● Be carefu l not to scratch the glass when r emoving.

7. Remove the windshield glass, using suction lifter.

NOTE:

Do not set or stand the glass on its edge. Small chips may devel op into cracks.

PIIA0186E

REMOVAL (ROADSTER)

1. Open the so ft top.

2. Remove the front pillar finisher. Refer to EI-32, "

3. Remove the roof front finisher. Refer to EI-46, "

4. Remove the front pillar garnish. Refer to EI-37, "

5. Remove the front wiper arms. Refer to WW-34, "

ment of Wiper Arms Stop Location" .

6. Remove the cowl top cover. Refer to EI-20, "

7. Apply a protective tape around the windshield glass to protect the painted surface from damage.

After removing moldings, remove glass using piano wire or power cutting tool and an inflat able pump bag.

● If a windshield glass is to be reused, mark the body and the glass with mating marks.

WARNING:

When cutting the glass from the vehicle, always wear safety glasses and heavy gloves to help prevent

glass splinters from entering your eyes or cutting your hands.

CAUTION:

● When a windshield glass is to be reused, do not use a cutting knife or power cutting tool.

● Be carefu l not to scratch the glass when r emoving.

8. Remove the windshield glass, using suction lifter.

NOTE:

Do not set or stand the glass on its edge. Small chips may devel op into cracks.

Removal and Installatio n (for Roadster Models)" .

Removal and Installation (for Roadster Models)" .

Removal and Installation (for Roadster Models)" .

Removal and I nstallation of Front Wi per Arms, Adjust-

COWL TOP" .

INSTALLATION

● Use a genuine Nissan Urethane Adhesive Kit (if available) or equivalent and follow the instructions fur-

nished with it.

● While the urethane ad hesi ve is curing , open a door wi nd ow. This will prevent t he glass from b eing fo rced

out by passenger compartment air pressure when a door is cl osed.

● The molding must be installed securely so that it is in position and leaves no gap.

● Inform the customer that the vehicle should remain stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

● Keep heat and open flames away as primers and adhesive are flammable.

● The materials contained in the kit are ha rmful if swallowe d, and may irritate skin and eye s. Avoid

contact with the skin and eyes.

Revision: 2005 August 2006 350Z

GW-12

WINDSHIELD GLASS

● Use in an open, well ventilated location. Avoid breathing the vapors. They can be harmful if

inhaled. If affected by vapor inhalation, immediately move to an area with fresh air.

● Driving the vehicle before the urethane adhesive has completely cured may affect the perfor-

mance of the windshield in case of an accident.

CAUTION:

● Do not use an adh esive which is past its usable term. Shelf life of this product is limited to six

months after the date of manufacture. Carefully adhere to the expiration or manufacture date

printed on the box.

● Keep primers and adhesive in a cool, dry place. Ideally, they should be stored in a refrigerator.

● Do not leave primers or adhesive cartridge unattended with their caps open or off.

● The vehicle shoul d not be driven for at least 24 hou rs or until the urethane adhesive has com-

pletely cured. Curing time varies depending on temperature and humidity. The curing time will

increase unde r lower temperature and lower humidity.

A

B

C

D

Repairing Water Leaks

Leaks can be repaired withou t removing and reinstalling glass.

If water is leaking between the urethane adhesive material and body or glass, determine the extent of leakage.

This can be done by applying water to the windshield area while pushing glass out ward.

To stop the leak, apply primer (if necessary) and then urethane adhesive to the leak point.

E

F

G

H

GW

J

K

L

Revision: 2005 August 2006 350Z

GW-13

M

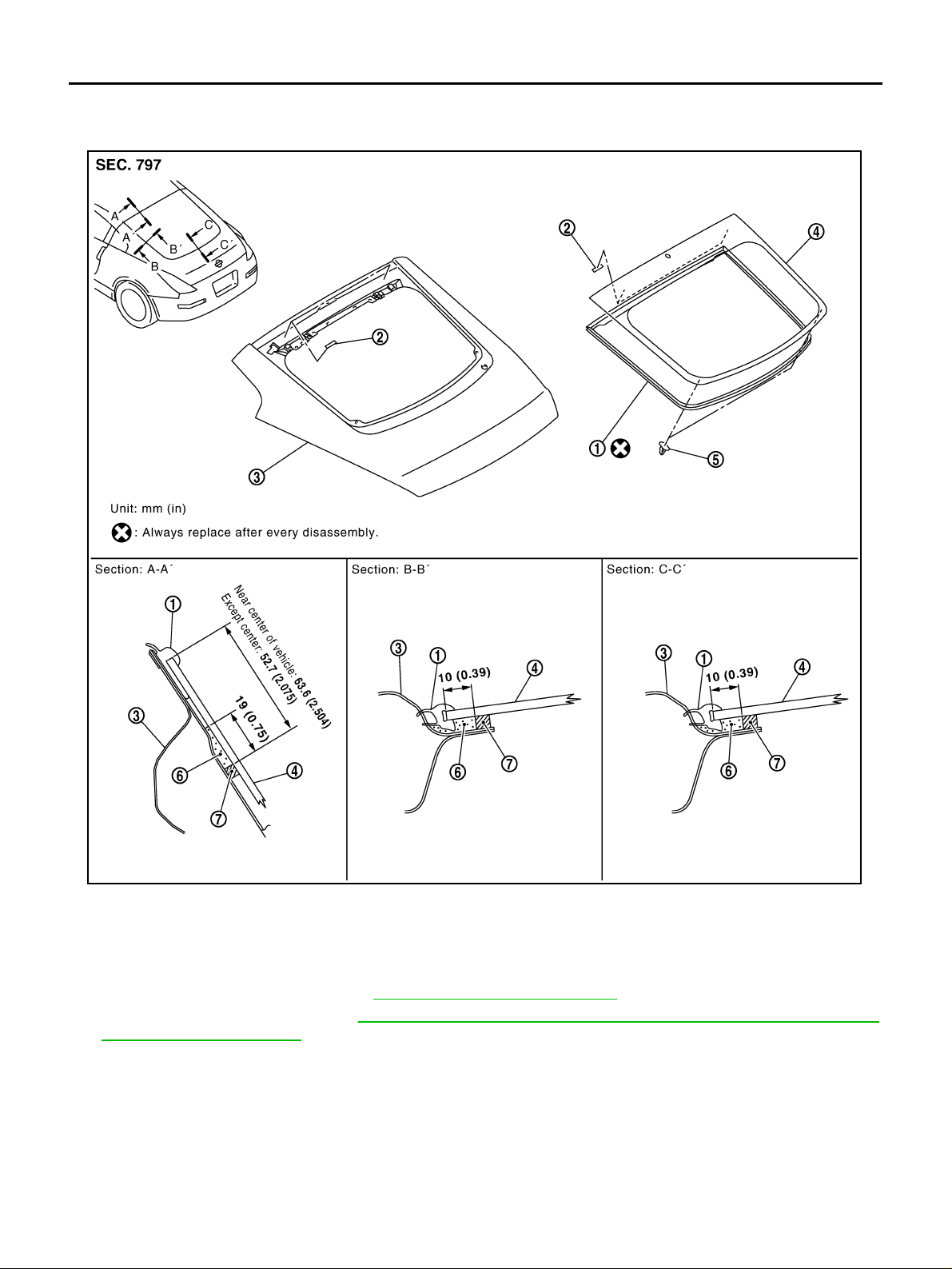

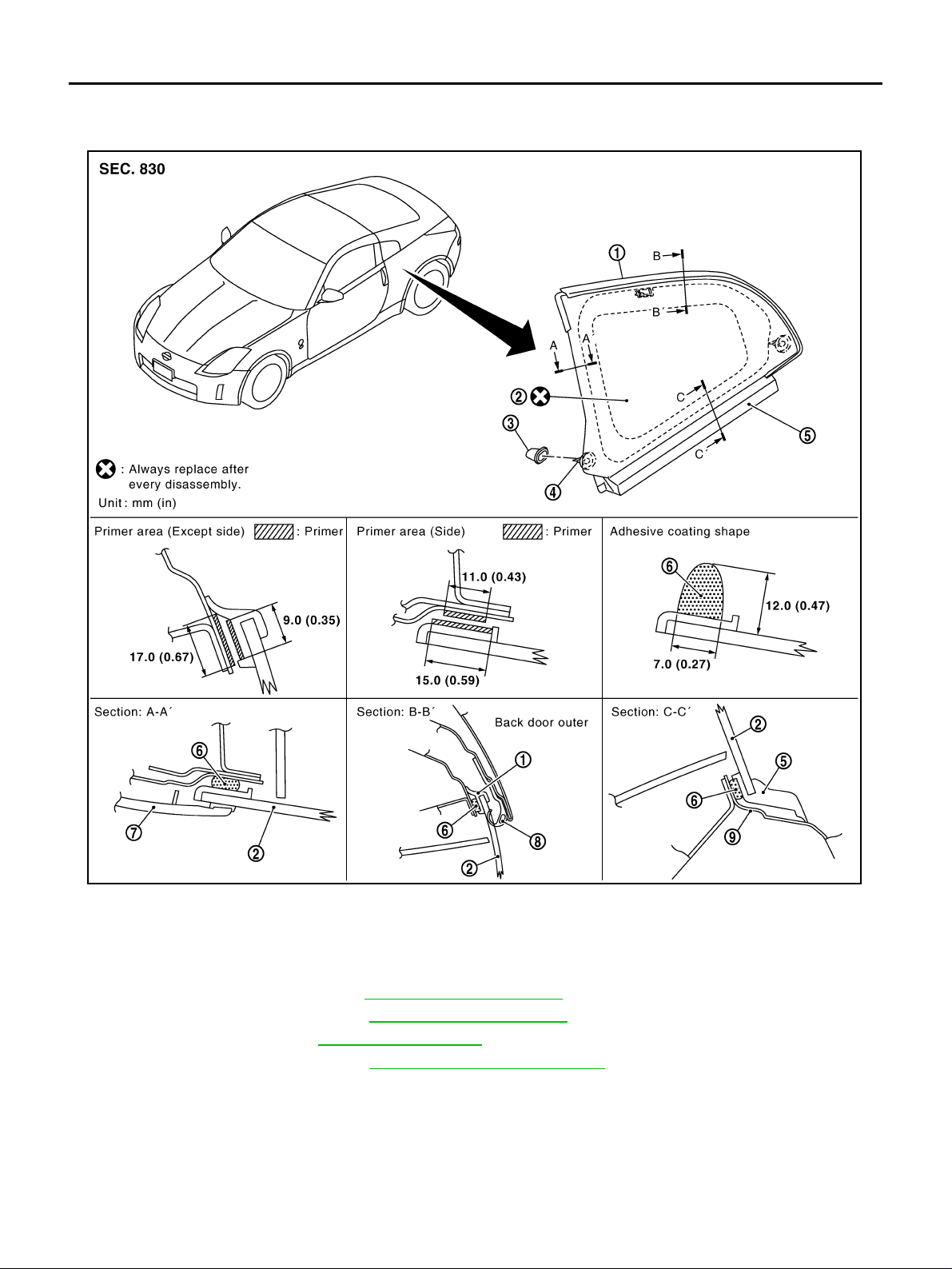

BACK DOOR WINDOW GLASS

BACK DOOR WINDOW GLASS PFP:90300 Removal and Installation NIS0004J

PIIB0822E

1. Back door window molding 2. Dual lock fastener 3. Back door

4. Back door window glass 5. Holder 6. Adhesive

7. Dam rubber

REMOVAL

1. Remove b ack door finisher. Refer to EI-48, "BACK DOOR FINISHER" .

2. Remove rear wiper arm. Refer to WW-52, "

Wiper Arms Stop Location" .

3. Remove connectors and grounds for rear window defogger.

4. Apply a protective tape around the back door window glass to protect the painted surface from damage.

remove glass using piano wire or power cutting tool and an inflatable pump bag.

● If a back door window glass is to be reused, mark the body and the glass with mating marks.

WARNING:

When cutting the glass from the vehicle, always wear safety glasses and heavy gloves to help prevent

glass splinters from entering your eyes or cutting your hands.

Revision: 2005 August 2006 350Z

Removal and Installatio n of Rear Wiper Arm, Adjustment of

GW-14

BACK DOOR WINDOW GLASS

CAUTION:

● When a back door window glass is to be reused, do not use a cutting knife or power cutting tool.

● Be careful not to scratch the glass when removing.

● Do not set or stand the glass on its edge. Small chips may develop into cracks.

A

B

C

D

PIIB0415E

5. Remove the back door window glass, using suction lifter.

INSTALLATION

● Use a genuine Nissa n Urethane Adhesive Kit (if av ailable) or equivalent and fol low the instructions fur-

nished with it.

● While the uretha ne adh esiv e is curi ng, op en a do or win dow. This will prevent th e glas s from bein g force d

out by passenger compartment air pressure when a door is closed.

● Inform the c us tom e r that the vehi cl e sh ould remain stat io na ry un til the urethan e ad he sive has comp le tely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

● Keep heat and open flames away as primers and adhesive are flammable.

● The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin an d eyes.

● Use in an open, well ventilated location. Avoid breathing the vapors. They can be harmful if

inhaled. If affected by vapor inhalation, immediately move to an area with fresh air.

● Driving the vehicle before the urethane adhesive has completely cured may affect the perfor-

mance of the back door window in case of an accident.

CAUTION:

● Do not use an adh esive which is past its usable term. Shelf life of this product is limited to six

months after the date of manufacture. Carefully adhere to the expiration or manufacture date

printed on the box.

● Keep primers and adhesive in a cool, dry place. Ideally, they should be stored in a refrigerator.

● Do not leave primers or adhesive cartridge unattended with their caps open or off.

● The vehicle shoul d not be driven for at least 24 hou rs or until the urethane adhesive has com-

pletely cured. Curing time varies depending on temperature and humidity. The curing time will

increase unde r lower temperature and lower humidity.

E

F

G

H

GW

J

K

L

M

Repairing Water Leaks

Leaks can be repaired withou t removing and reinstalling glass.

If water is leaking between the urethane adhesive material and body or glass, determine the extent of leakage.

This can be done by applying water to the back door window area while pushing glass outward.

To stop the leak, apply primer (if necessary) and then urethane adhesive to the leak point.

Revision: 2005 August 2006 350Z

GW-15

SIDE WINDOW GLASS

SIDE WINDOW GLASS PFP:83300 Removal and Installation NIS0004K

PIIB1358E

1. Side window glass molding (upper) 2. Side window glas s 3. Grommet

4. Clip 5. Side window glass molding (lower) 6. Adhesive

7. Lock pillar finisher 8. Back door mold ing 9. Rear fender

REMOVAL

1. Remove rear side finisher. Refer to EI-35, "BODY SIDE TRIM" .

2. Remove rear pillar finisher. Refer to EI-35, "

3. Remove headlining. Refer to EI-44, "

HEADLINING" .

4. Remove lock pillar finisher. Refer to EI-31, "

● If a side window glass is to be reused, mark the body and the glass with mating marks.

WARNING:

When cutting the glass from the vehicle, always wear safety glasses and heavy gloves to help prevent

glass splinters from entering your eyes or cutting your hands.

CAUTION:

● Be carefu l not to scratch the glass when r emoving.

● Do not set or stand t he glass on its edge. Small chips ma y develop into cracks.

Revision: 2005 August 2006 350Z

BODY SIDE TRIM" .

ROOF SIDE MOLDING" .

GW-16

SIDE WINDOW GLASS

INSTALLATION

● Use a genuine Nissa n Urethane Adhesive Kit (if av ailable) or equivalent and fol low the instructions fur-

nished with it.

● While the uretha ne adh esiv e is curi ng, op en a do or win dow. This will prevent th e glas s from bein g force d

out by passenger compartment air pressure when a door is closed.

● The molding must be installed securely so that it is in position and leaves no gap.

● Inform the c us tom e r that the vehi cl e sh ould remain stat io na ry un til the urethan e ad he sive has comp le tely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

● Keep heat and open flames away as primers and adhesive are flammable.

● The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin an d eyes.

● Use in an open, well ventilated location. Avoid breathing the vapors. They can be harmful if

inhaled. If affected by vapor inhalation, immediately move to an area with fresh air.

● Driving the vehicle before the urethane adhesive has completely cured may affect the perfor-

mance of the side window in case of an accident.

CAUTION:

● Do not use an adh esive which is past its usable term. Shelf life of this product is limited to six

months after the date of manufacture. Carefully adhere to the expiration or manufacture date

printed on the box.

● Keep primers and adhesive in a cool, dry place. Ideally, they should be stored in a refrigerator.

● Do not leave primers or adhesive cartridge unattended with their caps open or off.

● The vehicle shoul d not be driven for at least 24 hou rs or until the urethane adhesive has com-

pletely cured. Curing time varies depending on temperature and humidity. The curing time will

increase unde r lower temperature and lower humidity.

A

B

C

D

E

F

G

H

Repairing Water Leaks

Leaks can be repaired withou t removing and reinstalling glass.

If water is leaking between the urethane adhesive material and body or glass, determine the extent of leakage.

This can be done by applying water to the side window area while pushing glass outward.

To stop the leak, apply primer (if necessary) and then urethane adhesive to the leak point.

GW

J

K

L

M

Revision: 2005 August 2006 350Z

GW-17

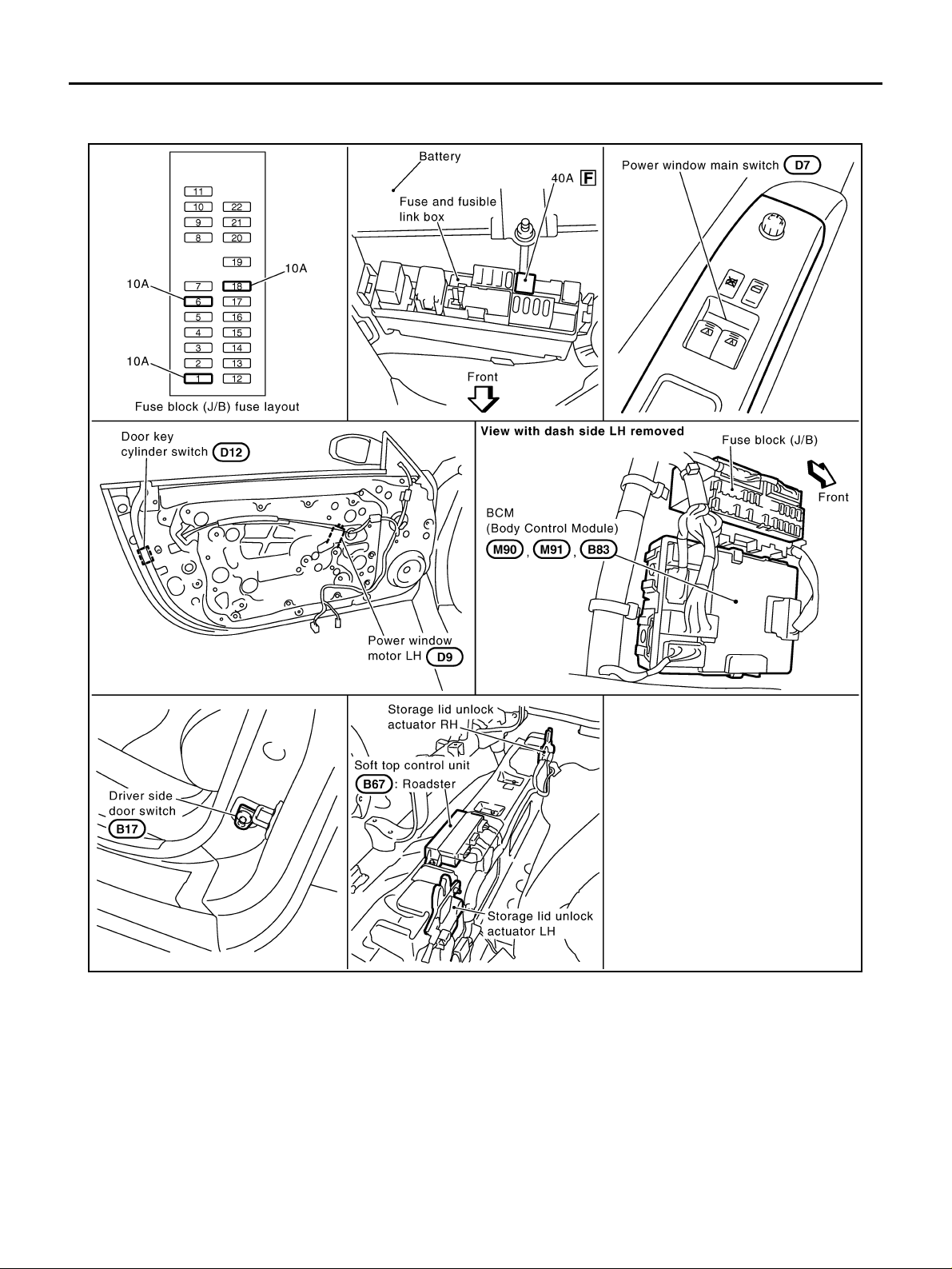

POWER WINDOW SYSTEM

POWER WINDOW SYSTEM PFP:25401 Component Parts and Harness Connector Location NIS0004L

PIIB0804E

Revision: 2005 August 2006 350Z

GW-18

POWER WINDOW SYSTEM

System Description NIS0004M

Power is supplied at all times

● through 40A fusible link (letter F , located in the fuse and fusible link box)

● to BCM terminal 55.

● through 10A fuse [No. 18, located in the fuse block (J/B)]

● to BCM terminal 42.

● through BCM terminal 54

● to power window main switch terminal 1.

● to power window sub-switch terminal 10.

With ignition switch in ON or START position, power is supplied

● through 10A fuse [No.1, located in the fuse block (J/B)]

● to BCM terminal 38.

● through BCM terminal 53

● to power window main switch terminal 10.

Ground is supplie d at all time s

● to BCM terminal 52

● through body g rounds M30 and M66.

● to power window main switch terminal 15

● through body g rounds M30 and M66.

● to power window sub-switch terminal 11

● through body g rounds M30 and M66.

A

B

C

D

E

F

G

H

MANUAL OPERATION

Driver Side Door

WINDOW UP

When the driver side window switch in the power window main switch is pressed in the up position,

Power is supplied

● through power window main switch terminal 8

● to driver side power window motor terminal 2.

Ground is supplied

● to driver side power window motor terminal 1

● through power window main switch terminal 11.

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the driver side window switch in the power window main switch is pressed in the down position,

Power is supplied

● through power window main switch terminal 11

● to driver side power window motor terminal 1.

Ground is supplied

● through power window main switch terminal 8

● to driver side power window motor terminal 2.

Then, the motor lowers the window until the switch is released.

Passenger Side Door

POWER WINDOW SUB-SWITCH OPERATION

WINDOW UP

When the power window su b-s witc h is pressed in the up positio n,

Power is supplied

● through power window sub-switch terminal 8

● to passenger side power window motor terminal 2.

Ground is supplied

● through power window sub-switch terminal 9

GW

J

K

L

M

Revision: 2005 August 2006 350Z

GW-19

POWER WINDOW SYSTEM

● to passenger side power window motor terminal 1.

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the power window sub-switch is pressed in the down position,

Power is supplied

● through power window sub-switch terminal 9

● to passenger side power window motor terminal 1.

Ground is supplied

● through power window sub-switch terminal 8

● to passenger side power window motor terminal 2.

Then, the motor lowers the window until the switch is released.

POWER WINDOW MAIN SWITCH OPERATION

Signal is sent

● though power window main switc h term in al 12.

● to power window sub-switch terminal 16

The operation of passenger side power window with power window main switch is as same as the operation

with power window sub-s w it ch .

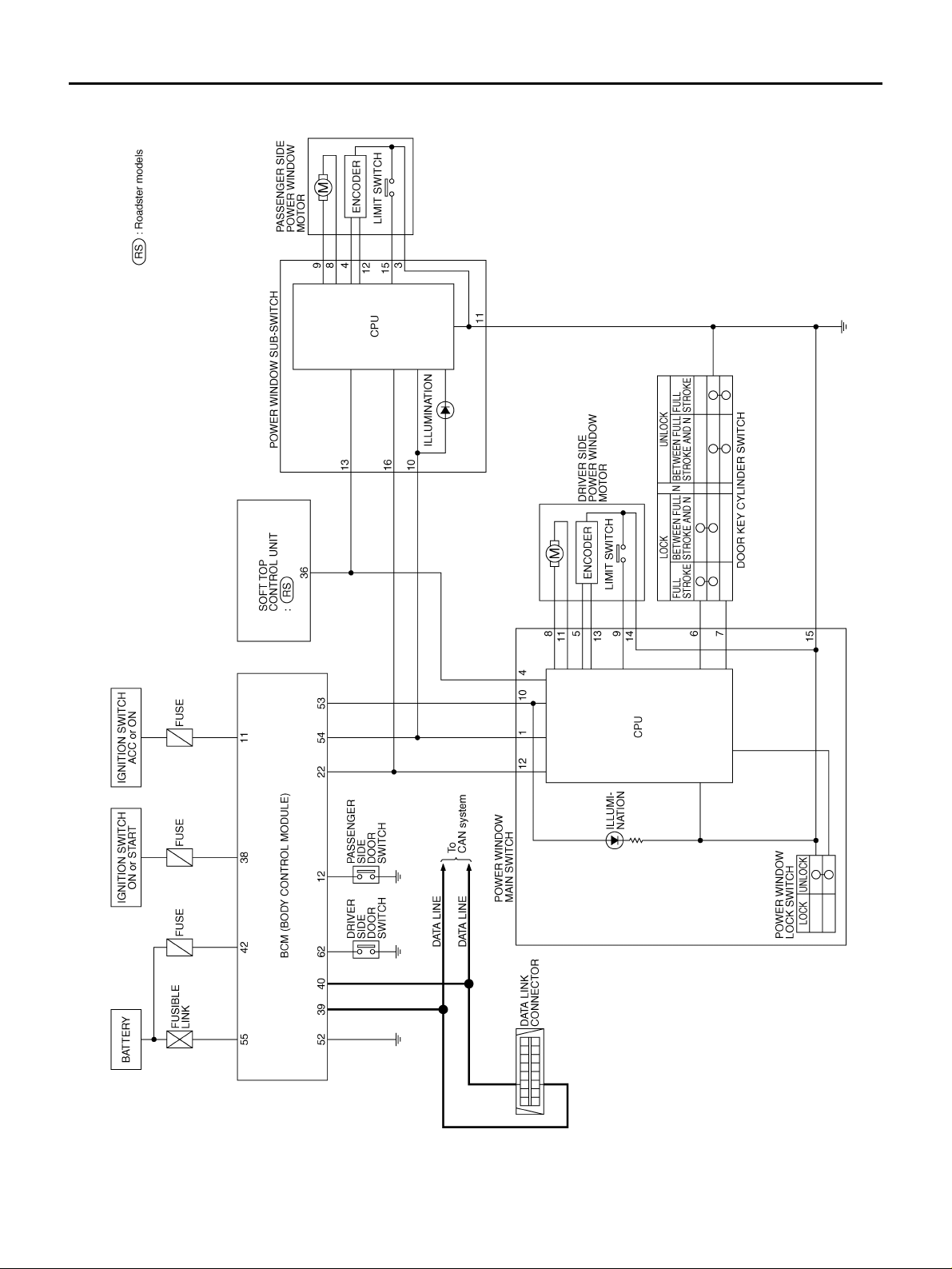

POWER WINDOW SERIAL LINK

Power window main switch, power window sub-switch and BCM transmit and receive the signal by power window serial link.

The under ment ioned signal is transmitted from BCM to power window main switch.

● Driver side door switch sig na l

● Keyless power window down signal

The under mentioned signal is transmitted from BCM to power window sub-switch.

● Passenger side door switch signal

● Keyless power window down signal

The under mentioned signal is transmitted from power window main switch to power window sub-switch.

● Passenger side door window operation signal

● Power window control by key cylinder switch signal

● Retained power operation si gn al

● Power window lock signal

AUTO OPERATION

The power window AUTO feature enables the driver to open or close the window without holding the window

switch in the down or up position.

POWER WINDOW LOCK

The power window lock is designed to lock oper ation of passenger side door window.

When the lock position , power wi ndow lock signal i s sent by using p ower window serial link from power win dow main switch to power window sub-switch.

When power window sub-switch is receiving the lock signal, prohibits the operation of passenger side power

window by power window sub-switch.

RETAINED POWER OPERATION

When the ignition switch is turned to the OFF position from ON or START position.

Power is supplied for 45 seconds

● through BCM terminal 53.

● to power window main switch termin al 10

When power and ground are supplied, the BCM continues to be energized, and the power window can be

operated.

The retained power operation is canceled when the driver side door or the passenger side door is opened.

RAP signal period can be changed by CONSULT-II. Refer to GW-29, "

Revision: 2005 August 2006 350Z

GW-20

CONSULT-II Function (BCM)" .

POWER WINDOW SYSTEM

ANTI-PINCH SYSTEM

Power window m ain s witch and power win dow su b-s witch moni tors the power wind ow mot or op era tion a nd t he

power window pos ition (full closed or other) for driver side and passenge r side power window by the signals

from encoder and limit switch in power window motor (driver side and passenger side).

When power window main switch detects interruption duri ng the following close operati on,

● automatic close operation when ignition switch is in the “ON” position

● automatic close op era tion during retained power operation

● manual close operation during retained power operation

Power window main switch or power window sub-switch controls each power window motor for open and the

power window will be lowered about 150 mm (5.91 in).

POWER WINDOW CONTROL BY THE KEY CYLINDER SWITCH

When ignition k ey switch is OFF, power window can be opene d or closed by turning the door k ey cylinder

UNLOCK / LOCK position more then 1.5 second over condition.

● Power window can be opened as the door key cylinder is kept fully turning to the UNLOCK position.

● Power window can be closed as the door key cylinder is kept fully turning to the LOCK position.

The power window operation by the key cylinder switch stops when the following operations are performed.

● While performing open / close the window with power window main switch.

● When the ignition switch is turned ON while the power window control operation by the key cylinder

switch.

AUTOMATIC WINDOW ADJUSTING FUNCTION

When the driver 's / pas seng er's door( s) is open ed, t he w indo w of the open ed d oor i s low ered app rox. 10 m m

(0.39in).

When the door is closed, the window is raised to fully-closed positions.

Automatic window adjusting function system (opening operation) does not operate when the following.

● The window is 10 mm (0.39 in) or more open from ful ly-closed positions.

Automatic window adjusting function system (closing operation) does not operate when the following.

● The automatic window adjusting function system (opening operation) operation.

● The keyless power window operation.

● The power wind ow control by the key cylinder switch operation.

A

B

C

D

E

F

G

H

GW

J

K

M

L

Revision: 2005 August 2006 350Z

GW-21

POWER WINDOW SYSTEM

Schematic NIS0004N

TIWT0969E

Revision: 2005 August 2006 350Z

GW-22

POWER WINDOW SYSTEM

Wiring Diagram — WINDOW — NIS0004O

A

B

C

D

E

F

G

H

GW

J

K

L

M

TIWT1592E

Revision: 2005 August 2006 350Z

GW-23

POWER WINDOW SYSTEM

TIWT1593E

Revision: 2005 August 2006 350Z

GW-24

POWER WINDOW SYSTEM

A

B

C

D

E

F

G

H

GW

J

K

L

M

TIWT1594E

Revision: 2005 August 2006 350Z

GW-25

POWER WINDOW SYSTEM

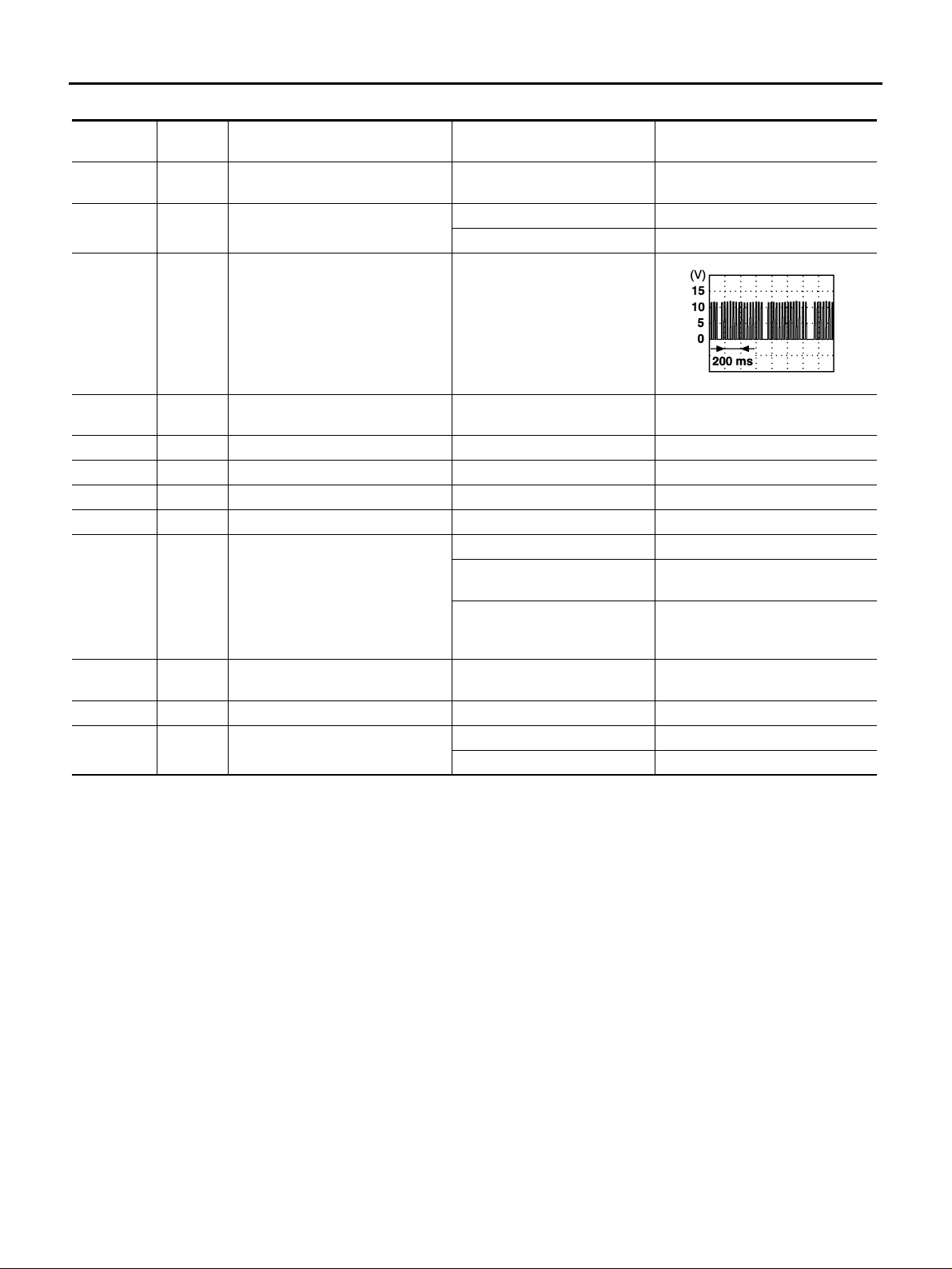

Terminal and Reference Value for BCM NIS0004P

TERMINAL

11 LG

12 P Passenger side door switch

22 Y Power window serial link —

38 W/L

39 L CAN-H — —

40 P CAN-L — —

42 GY Power source (Fuse) — Battery voltage

52 B Ground — 0

53 Y/B Rap signal

54 W

55 R Power source (Fusible link) — Battery voltage

62 L Driver side door switch

WIRE

COLOR

Ignition switch ACC power supply

(ACC or ON)

Ignition switch ON power supply

(ON or START)

Power window switch power

supply

ITEM CONDITION

Ignition switch

(ACC or ON position)

ON (open) 0

OFF (closed) Battery voltage

Ignition switch

(ON or START position)

IGN SW ON Battery voltage

Within 45 second after i gnition

switch is turned to OFF

When driver side or passenger

side door is open in power window timer operates

— Battery voltage

ON (open) 0

OFF (closed) Battery voltage

VOLTAGE (V)

(Approx.)

Battery voltage

Battery voltage

Battery voltage

PIIA2344J

0

Revision: 2005 August 2006 350Z

GW-26

Loading...

Loading...