Nissan 350Z 2005 User Manual

SEAT

I BODY

A

B

SECTION SE

CONTENTS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Service Notice .......................................................... 3

Precautions for Battery Service ................................ 3

Precautions for Work ................................................ 3

PREPARATION ........... ................... .................... ......... 5

Special Service Tools ............................................... 5

Commercial Service Tools ........................................ 5

SQUEAK AND RATTLE TROUBLE DIAGNOSES ..... 6

Work Flow ................................................................ 6

CUSTOMER INTERVIEW ..................................... 6

DUPLICATE THE NOISE AND TEST DRIVE ....... 7

CHECK RELATED SERVICE BULLETINS .. ......... 7

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................... ....... ......... 7

REP AIR THE CAUSE ........................................... 7

CONFIRM THE REPAIR ....................................... 8

Generic Squeak and Rattle Troubleshooting ........... 8

INSTRUMENT PANEL .......................................... 8

CENTER CONSOLE ............................................. 8

DOORS .............................. ................................... 8

TRUNK ............................... ................................... 9

SUNROOF/HEADLINING ..................................... 9

SEATS ................................................................... 9

UNDERHOOD .................... ............. ............. ......... 9

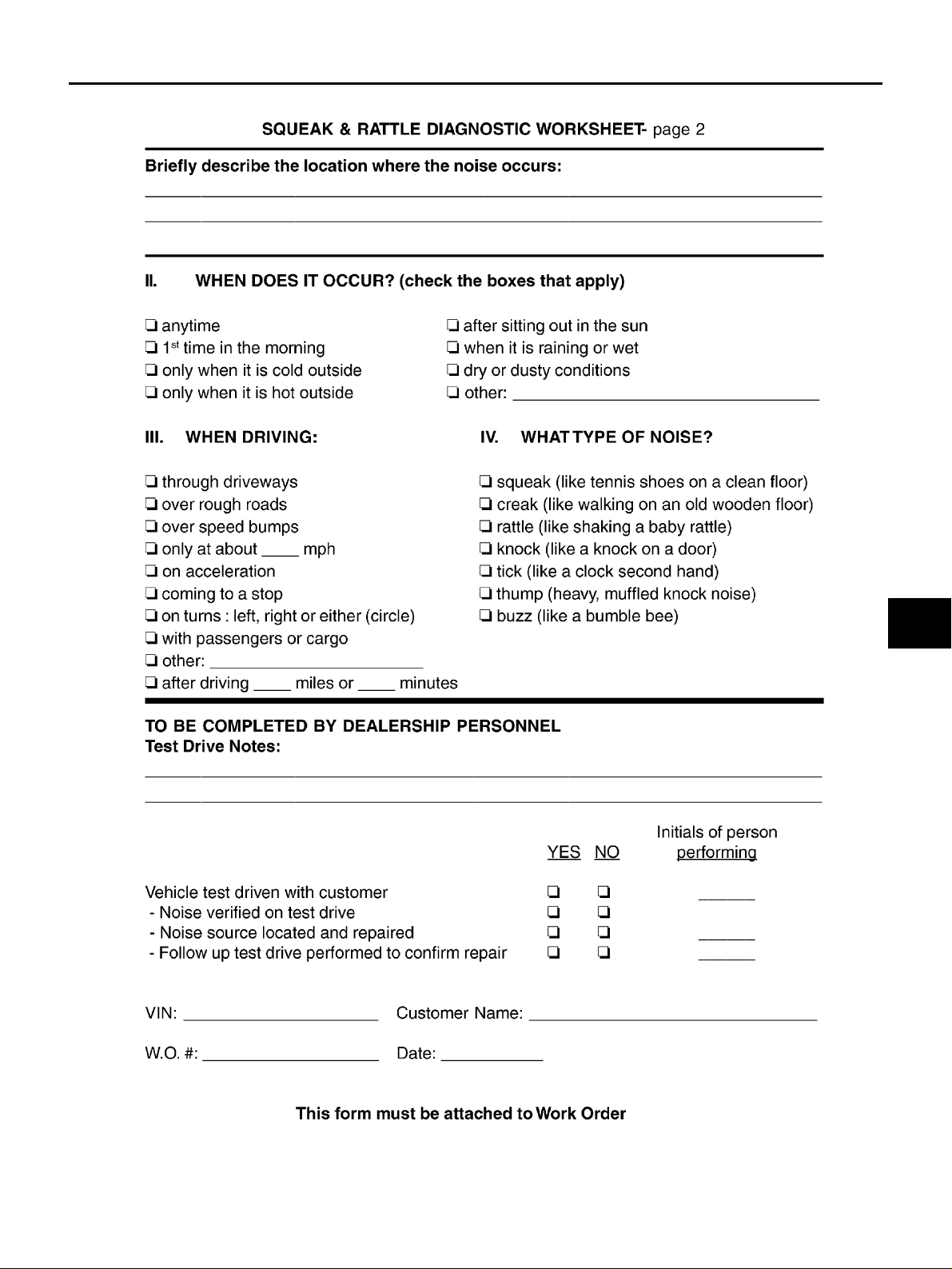

Diagnostic Worksheet ............................................ 10

POWER SEAT/FOR COUPE .................................... 12

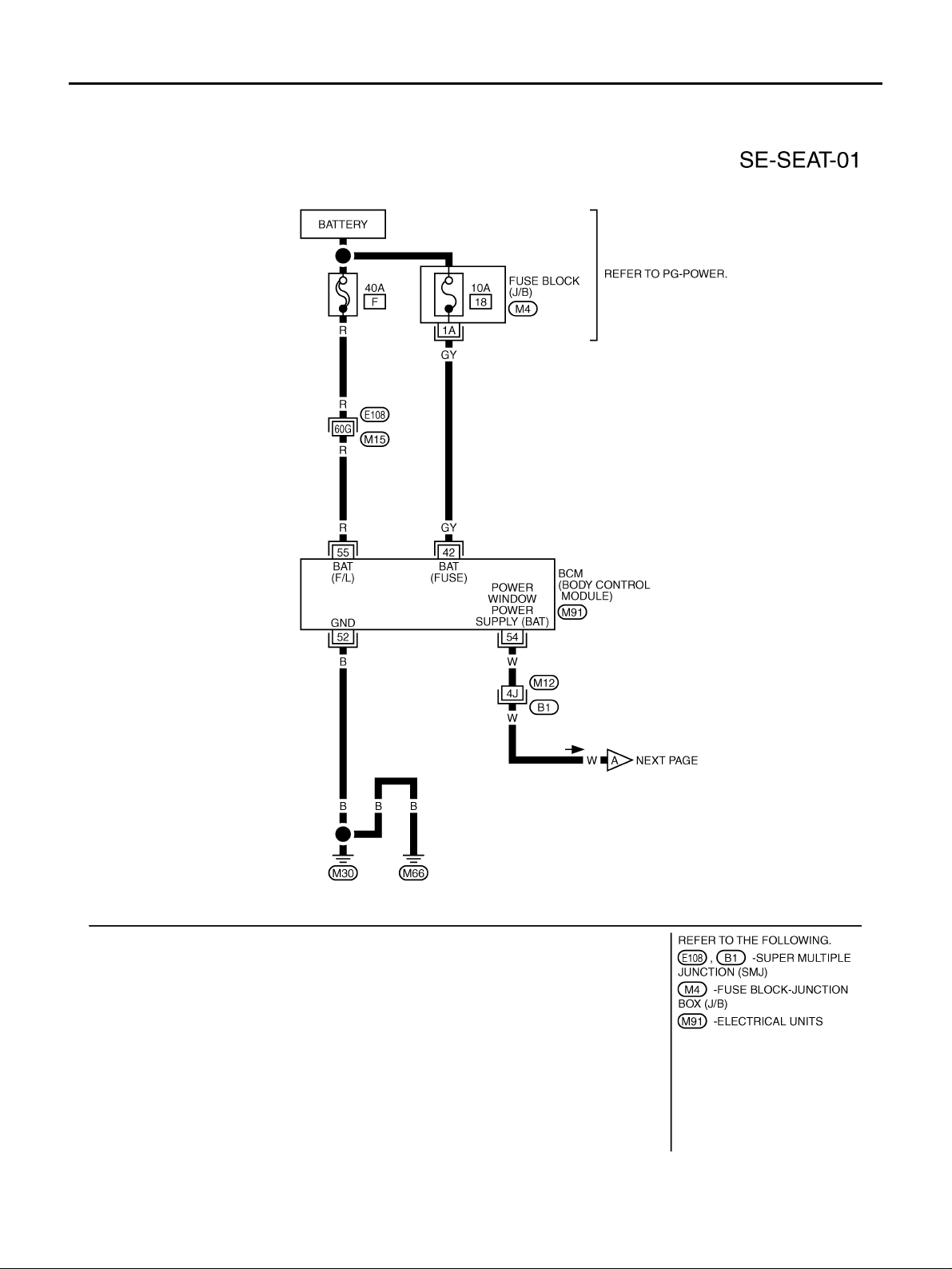

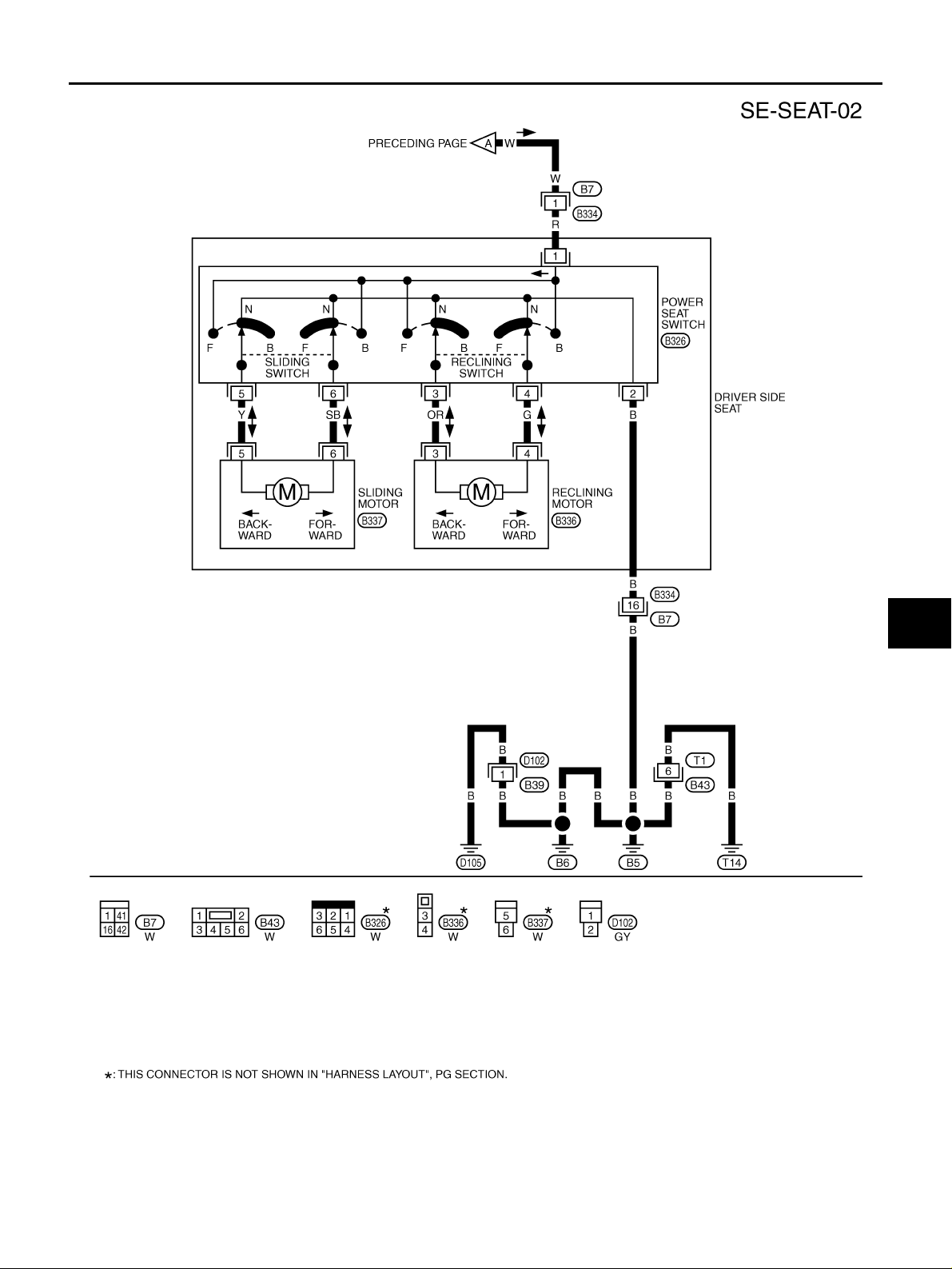

Wiring Diagram–SEAT– /For Driver Seat ............... 12

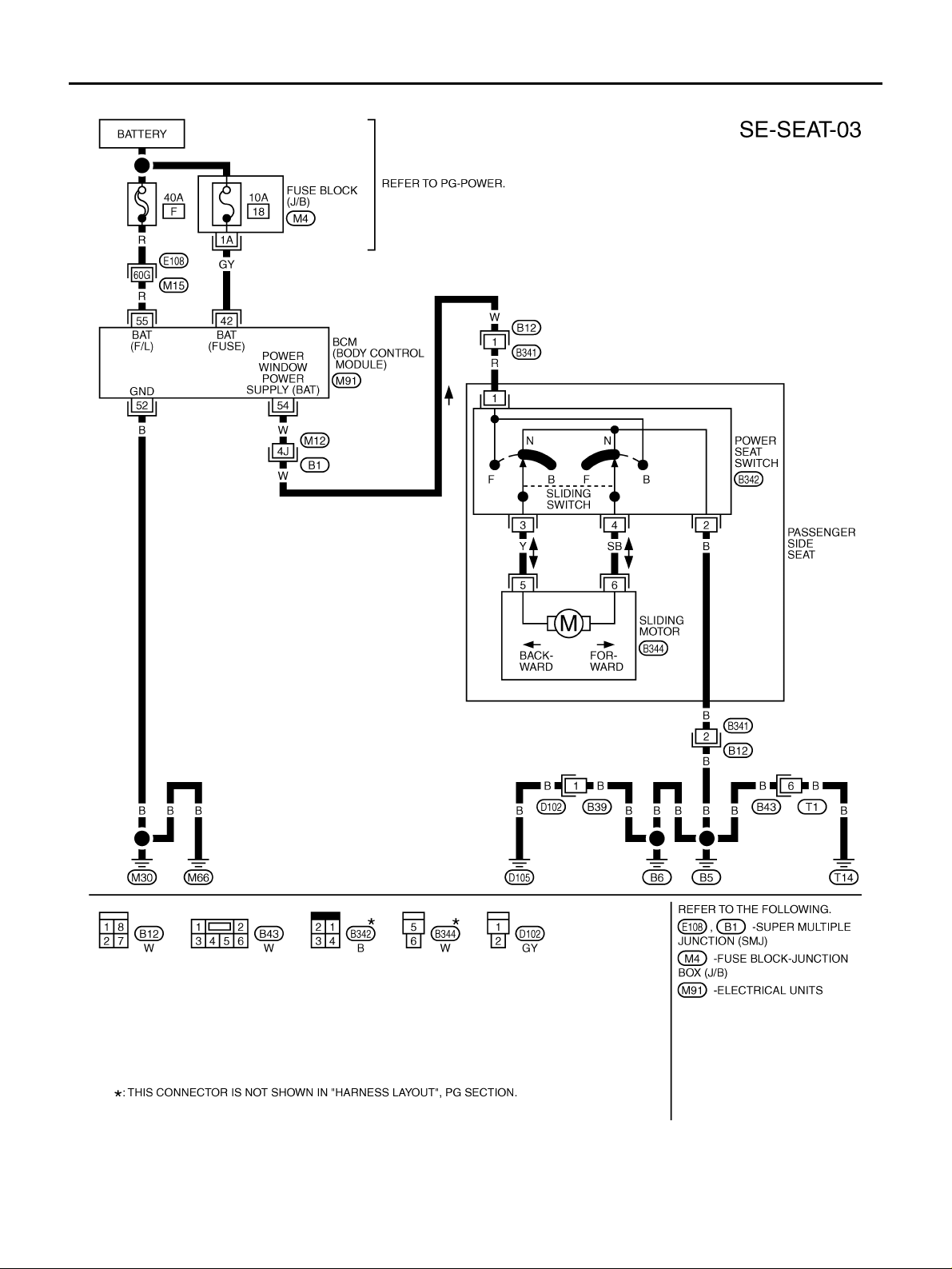

Wiring Diagram–SEAT– /For Passenger Seat ....... 14

POWER SEAT/FOR ROADSTER ............................. 15

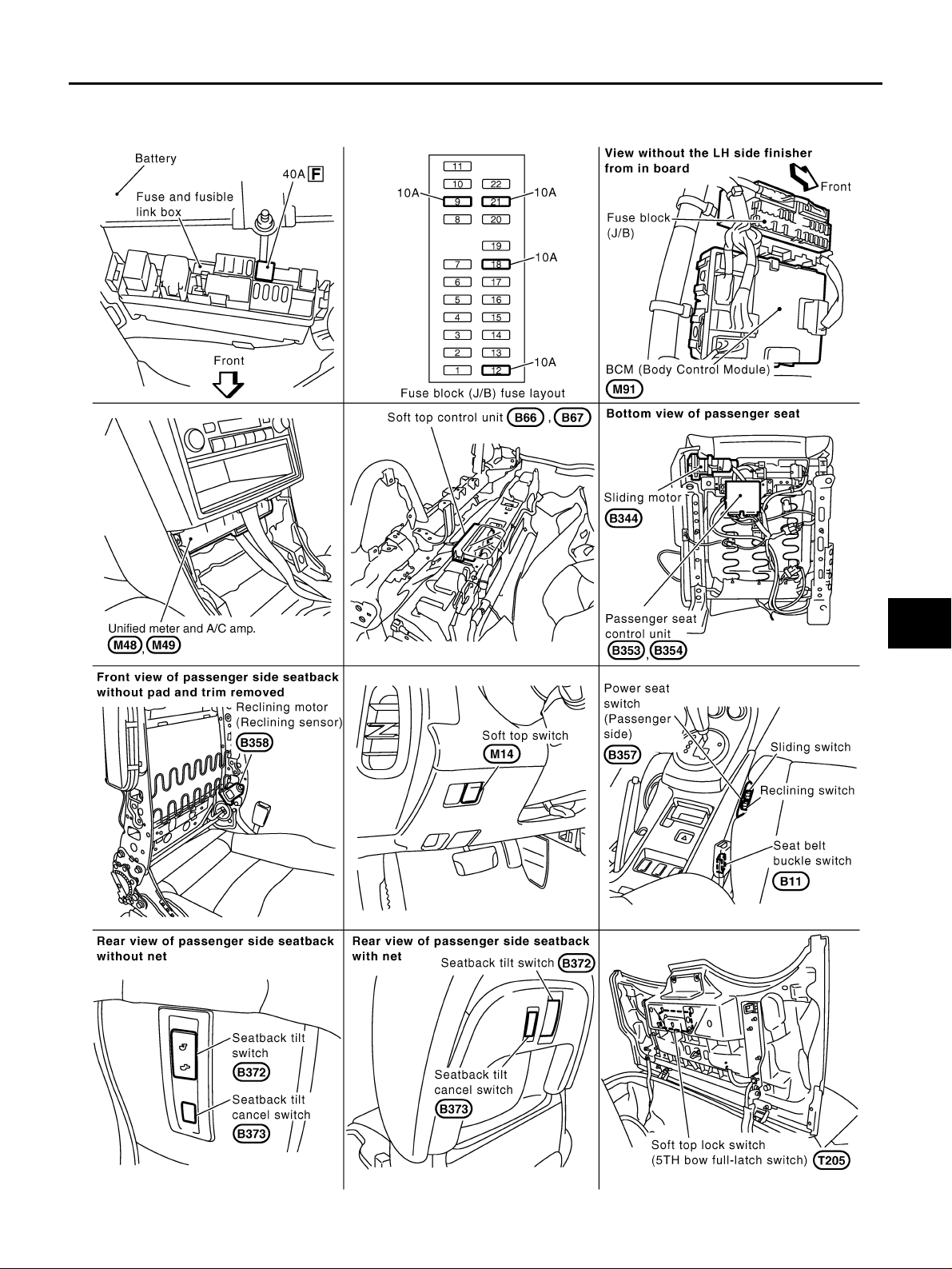

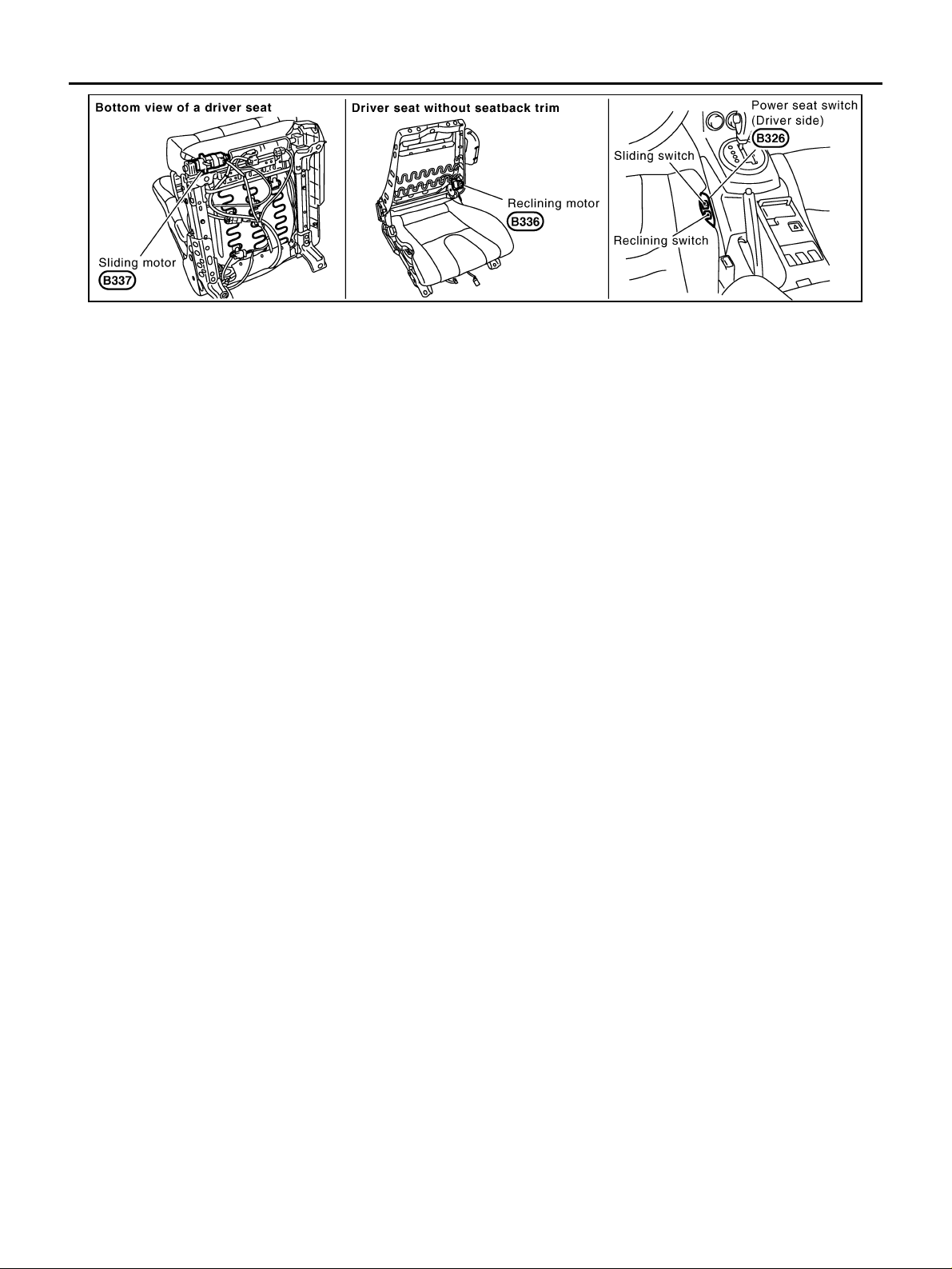

Component Parts and Harness Connector Location ... 15

System Description ................................................ 16

DRIVER SIDE SEAT OPERATION ..................... 16

PASSENGER SIDE SEAT MANUAL OPERA-

TION ............................ ....... ...... ....... ...... ....... ....... 17

PASSENGER SEATBACK TILT FORWARD/

BACKWARD OPERATION .................................. 18

INTERLOCKING OPERATION OF THE PAS-

SEAT

SENGER SEAT WITH THE SOFT TOP ..............19

PASSENGER SIDE RECLINING MOTOR

OPERATION ........................................................20

SEATBACK TILT CANCEL SWITCH OPERA-

TION ............................... .....................................20

MANUAL OPERATION ........................................21

AUTOMATIC OPERATION ..................................21

CANCEL FUNCTION ..........................................25

FAIL-SAFE MODE ...............................................25

Wiring Diagram–SEAT– / For Driver Seat ..............26

Schematic / For Passenger Seat ............................28

Wiring Diagram–SEAT– / For Passenger Seat .......29

Terminals and Reference Values of Passenger Seat

Control Unit .............................................................34

Terminals and Reference Values of BCM ...............35

T erminals and Reference Values of Soft T op Control

Unit .........................................................................35

Terminals and Reference Values of Unified Meter

and A/c Amp. ..........................................................36

Work Flow ...............................................................36

Trouble Diagnosis Symptom Chart .........................36

BCM Power Supply and Ground Check .................37

Driver Side Seat Power Supply and Ground Check ...39

Driver Side Seat Sliding Motor Circuit Check .........40

Driver Side Seat Reclining Motor Circuit Check .....41

Passenger Seat Control Unit Power Supply and

Ground Check ........................................................42

Passenger Seat Control Unit Ignition Signal Circuit

Check ..................................................................... 43

Passenger Side Seat Sliding Motor Circuit Check ...44

Passenger Side Seat Reclining Motor Circuit Check ...44

Passenger Side Seat Reclining Sensor Circuit

Check ..................................................................... 45

Passenger Side Seat Sliding Switch Circuit Check ...46

Passenger Side Seat Reclining Switch Circuit

Check ..................................................................... 47

Passenger Side Power Seat Switch Ground Circuit

Check ..................................................................... 48

Seatback Tilt Switch Circuit Check ........ ...... ....... ....49

Seatback Tilt Cancel Switch Circuit Check ............. 50

C

D

E

F

G

H

SE

J

K

L

M

Revision: 2005 August 2005 350Z

SE-1

Soft Top Switch Circuit Check ................................51

Power Window Down Request Signal Circuit Check ...52

Storage Lid Close Signal Circuit Check .................. 53

Soft Top Lock Switch Circuit Inspection ..................54

Seat Belt Buckle Switch Circuit Check ...................54

Vehicle Speed Signal Check ..................................56

HEATED SEAT .......................................................... 57

Description ................ .......................... ....................57

Schematic ................. ..............................................58

Wiring Diagram–HSEA T–/For Coupe .....................59

Wiring Diagram–For Roadster– ..............................62

SEAT .........................................................................65

Removal and Installation ........................................65

MANUAL SEAT (COUPE) ...................................65

POWER SEAT .....................................................67

NET SEAT (ROADSTER) ....................................69

REMOVAL ...........................................................70

INSTALLATION ................................................ ....70

Disassembly and Assembly ................................ ....71

SEATBACK TRIM AND PAD (MANUAL SEAT

AND POWER SEAT) ...........................................71

REMOVAL OF SEATBACK ASSEMBLY ..............71

INSTALLATION OF SEATBACK ASSEMBLY ......71

SEATBACK TRIM AND PAD (NET SEAT FOR

ROADSTER) ................... .....................................72

SEAT CUSHION TRIM AND P AD (POWER SEAT

AND NET SEAT) ..................................................74

SEAT CUSHION TRIM AND PAD (MANUAL

SEAT FOR COUPE) ............................................75

PASSENGER SIDE SEATBACK FORWARD

RECLINING (COUPE) .........................................76

PASSENGER SIDE SEATBACK FORWARD

RECLINING (ROADSTER) ..................................76

Revision: 2005 August 2005 350Z

SE-2

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

AIS000I2

A

The Supplemental Rest raint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used alon g

with a front seat belt, helps to redu ce th e risk or se verit y of i njury to the driv er and front passenge r for ce rtain

types of collision. This system includes sea t belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Manual.

WARNING:

● To avoid rendering the SRS inopera tive, whi ch could increa se the risk of perso nal injury or dea th

in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, inc luding incorrect removal and installation of the SRS, can lead to per-

sonal injury ca use d by unintentional ac tiv atio n of the system. F or r e mo va l o f Spi ral Cable and Air

Bag Module, see the SRS section.

● Do not use electrical test equ ipment o n any circu it related to the SRS unless in structed to in this

Service Manual. SRS wiring harnesses can be id entified by yellow and/or orange harnesses or

harness connectors.

Service Notice AIS000I1

● When removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

● Handle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to oil or

damage them.

● Apply sealing compound where necessary when installing parts.

● When applying sealing compound, be careful that the sealing compound does not protrude from parts.

● When replacing a ny metal parts (for e xample body oute r panel, mem bers, et c.), be sure to take rust pre-

vention measures.

B

C

D

E

F

G

H

SE

J

Precautions for Battery Service AIS001PC

Before disconnecting the battery, lower both the driver and passenger windows. This will prevent any interference between t h e wi nd ow ed ge an d th e v eh ic le wh en the do or is ope ne d/ cl o sed. Dur i n g nor ma l op era ti on, t he

window slightly raises and lowers automatically to prevent any window to vehicle interference. The automatic

window function will not work with the battery disconnected.

Precautions for Work AIS000I3

● When removing or disassembling each component, be careful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

● When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the compo-

nent with a shop cloth or vinyl tape to protec t it.

● Protect the removed part s with a shop cloth and keep them.

● Replace a deformed or damaged clip.

● If a part is s p ecified as a no n-reusable part, always r eplace it with new one.

● Be sure to tighten bolts and nuts securely to the specified torque.

● After re-installation is completed, be sure to check that each part works normally.

● Follow the steps below to clean components.

– Water soluble foul: Dip a soft cloth into lukewarm w ater, and wring the water out of the clot h to wipe the

fouled area.

Then rub with a soft and dry cloth.

– Oily foul: Dip a soft cloth i nto l ukewa rm wat er with mi ld det erg ent (c oncen trat ion : wit hin 2 t o 3%), and wi pe

the fouled area.

Then dip a cloth into fresh water, and wring the water out of the cloth to wipe the detergent off. Then rub

with a soft and dry cloth.

K

L

M

Revision: 2005 August 2005 350Z

SE-3

PRECAUTIONS

● Do not use organic solvent such as thinner, benzene, alcohol, and gasoline.

● For genuine leather seats, use a genuine leather seat cleaner.

Revision: 2005 August 2005 350Z

SE-4

PREPARATION

PREPARATION PFP:00002

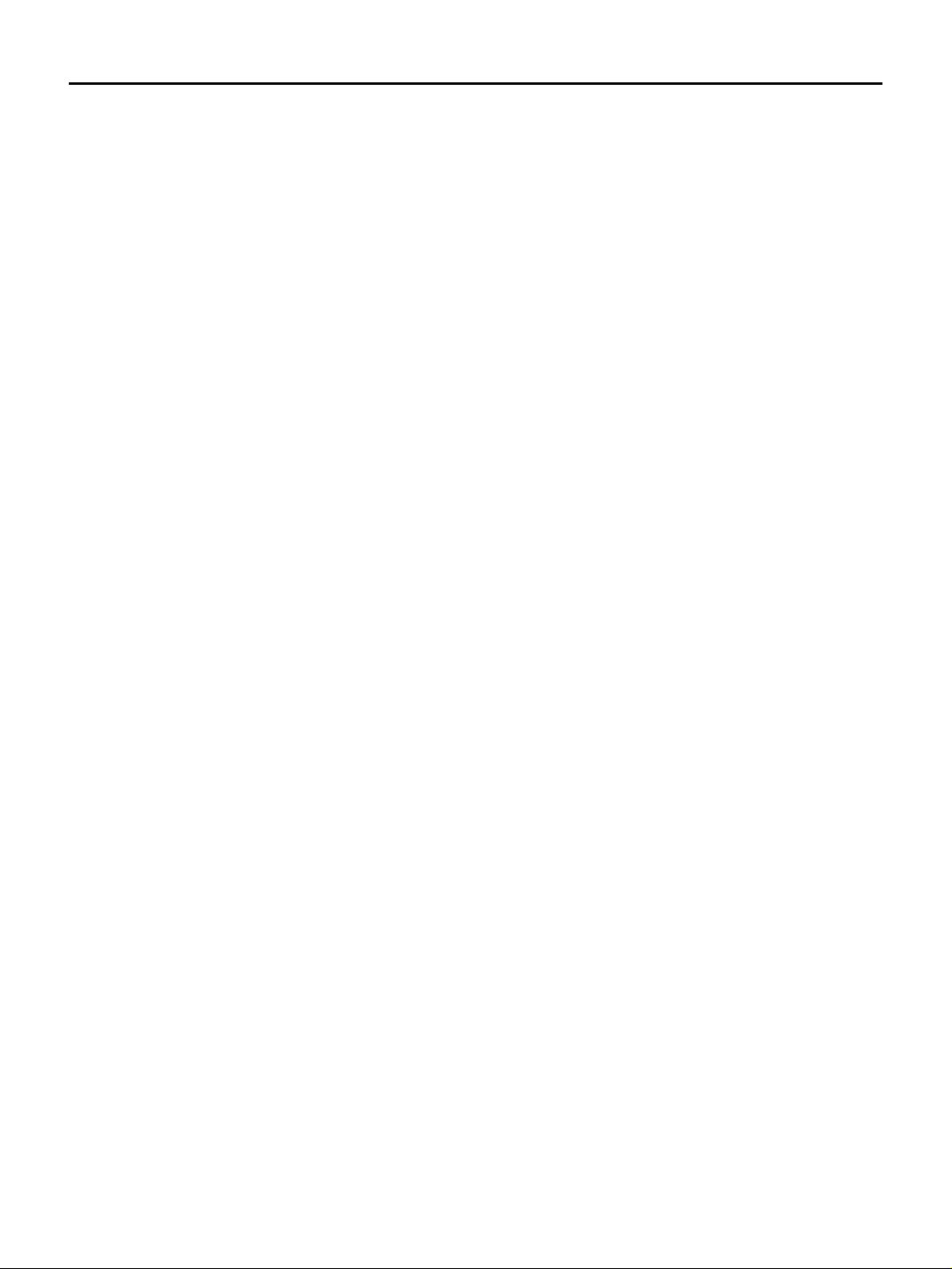

Special Service Tools AIS000I4

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

Description

A

B

C

(J39570)

Chassis ear

SIIA0993E

(J43980)

NISSAN Squeak and Rattle

Kit

SIIA0994E

Locating the noise

Repairing the cause of noise

Commercial Service Tools AIS000I5

Tool name Description

Engine ear Locating the noise

SIIA0995E

D

E

F

G

H

SE

J

K

Revision: 2005 August 2005 350Z

SE-5

L

M

SQUEAK AND RATTLE TROUBLE DIAGNOSES

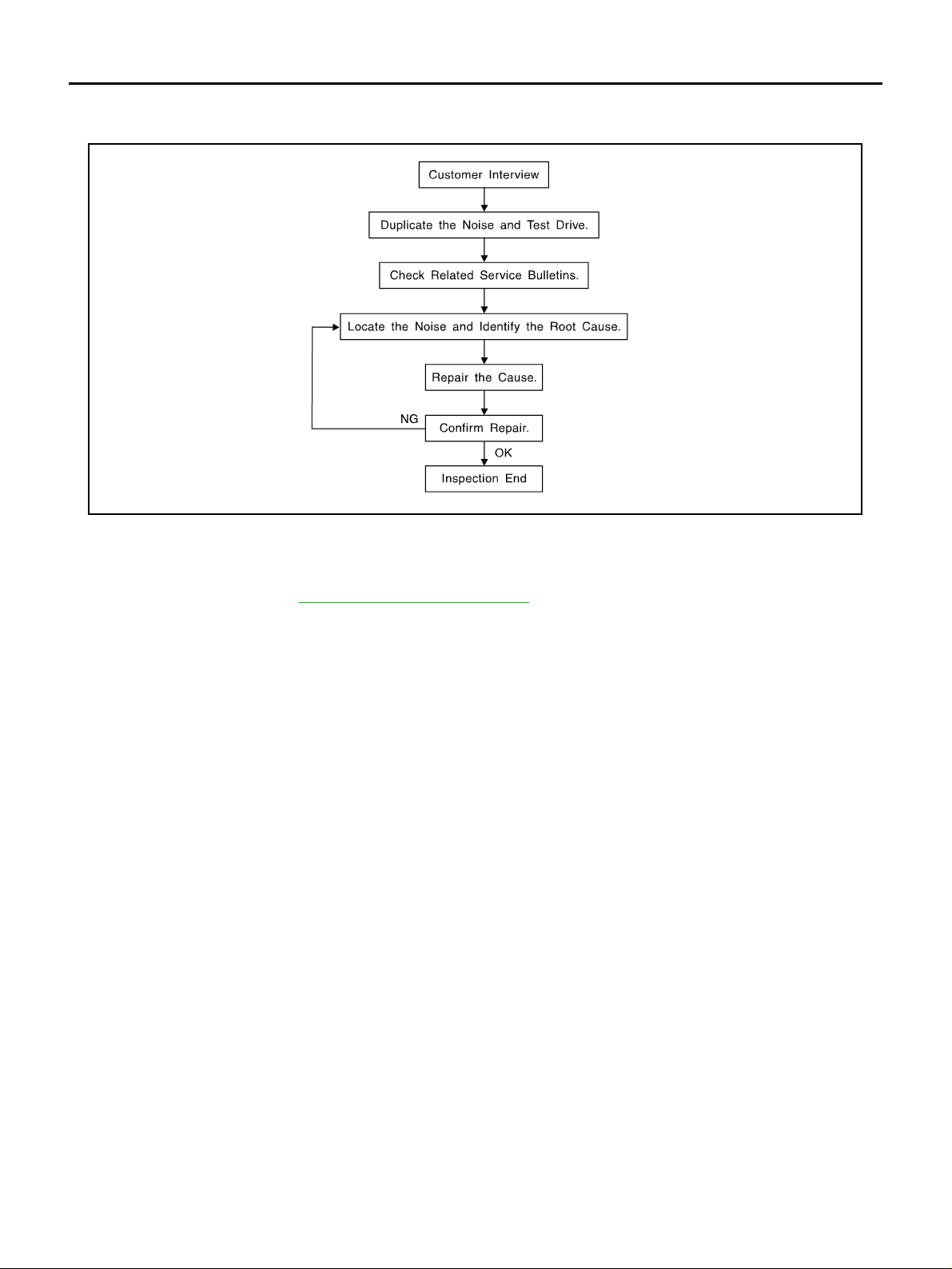

SQUEAK AND RATTLE TROUBLE DIAGNOSES PFP:00000 Work Flow AIS0066M

SBT842

CUSTOMER INTERVIEW

Interview the cus to me r if po ss ib le , to de t ermi n e th e co nd iti on s th at exi st whe n th e no is e occu r s. Use th e D iagnostic Worksheet durin g the interview to docum ent the facts and conditio ns when the noise occu rs and any

customer's comments; refer to SE-10, "

conditions that exist when the noise occu rs.

● The customer may not be able to p rovide a detailed d escription or the location of the noise. Attempt to

obtain all the facts and conditions that exist when the noise occurs (or does not occur).

● If there is more than on e noi se in the v ehic le, b e sure to diag nose and re pair the n oise that the cu stom er

is concerned about. This can be accomplished by test driving the vehicle with the customer.

● After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided s o the cus tomer, service adviser and techni cian are al l speaking the same language w hen

defining the noise.

● Squeak —(Li ke tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces=higher pitch noise/softer surfaces=lower pitch noises/edge to surface=chirping

● Creak—(Like walking on an old wooden floo r)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch

dependent on materials/often brought on by activity.

● Rattle—(Like shaking a baby rattle)

Rattle charac teristic s inclu de the fast repe ated c ontact/vibrat ion or simila r moveme nt/loose parts/missi ng

clip or fastener/incorrec t clearance.

● Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

● Tick—(Like a clock second hand)

Tick characteristics include ge ntle contacting of light materials/l oose components/can be caused by driver

action or road conditions.

● Thump—(Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

● Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact .

● Often the degree of acceptable noise level will vary depending upon the person. A noise that you may

judge as acceptable may be very irritating to the customer.

● Weath er conditions, especially humidity and temperature, may have a great effect on noise level.

Diagnostic Worksheet" . This information is necessary to duplicate the

Revision: 2005 August 2005 350Z

SE-6

SQUEAK AND RATTLE TROUBLE DIAGNOSES

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Works heet regarding the co nditions or locatio n of the noise. This in formation can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to duplicate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T models, drive position on A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

● Drive the vehicl e an d att em pt to dup li ca te th e co nd iti on s th e cust om er states exist whe n th e no is e oc cu rs.

● If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

A

B

C

D

E

F

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

● removing the components i n the area that you suspect the noise is coming from .

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

● tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or pu sh/pull the c omponent with excessive fo rce, otherwise the noise will be eliminated only

temporarily.

● feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

● placing a piece of paper between components that you suspect are causing the noise.

● looking for loose components and contact marks.

Refer to SE-8, "

Generic Squeak and Rattle Troubleshooting" .

REPAIR THE CAUSE

● If the cause is a loose component, tighten the component securely.

● If the cause is insufficient clearance between components:

– separate components by repositioning or loosening and retightening the component, if possible.

– insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A Nissan Squeak and Rattle Kit (J-43980) is available through your authorized Nissan Parts

Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

The following materials are contained in the Nissan Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 × 135 mm (3.94 × 5.31 in)/76884-71L01: 60 × 85 mm (2.36 × 3.35 in)/7688471L02: 15 × 25 mm (0.59 × 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 × 50 mm (1.97 × 1.97 in)/73982-50Y00:

10 mm (0.39 in) thick, 50 × 50 mm (1.97 × 1.97 in)

G

H

SE

J

K

L

M

Revision: 2005 August 2005 350Z

SE-7

SQUEAK AND RATTLE TROUBLE DIAGNOSES

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 × 50 mm (1.18 × 1.97 in)

FEL T CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applic ations.

68370-4B000: 15 × 25 mm (0.59 × 0.98 in) pad/68239-13E00: 5 mm (0. 20 in) wide t ape roll

The following materials , not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit. Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REP AIR

Confirm that the c ause of a n oise is repai red by test dr iving the ve hicle. Op erate the ve hicle und er the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle Troubleshooting AIS0066N

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instr ument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar ga rni sh

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defros ter duct and duct joint

These incide nts can usually b e located by tapping or moving the com ponents to duplicate the noise o r by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by applying felt cloth tape or silico n spray (in h ard to reac h areas ). Uret hane pads can be used to insul ate wiring harness.

CAUTION:

Do not use silicone s pray to isolate a s queak or rattle. If you saturate the ar ea with silicone , you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of thes e incidents. You can usuall y insulat e the areas with fel t cloth tape o r insulator foam bloc ks from

the Nissan Squeak and Rattle Kit (J-43980) to repair the noise.

Revision: 2005 August 2005 350Z

SE-8

SQUEAK AND RATTLE TROUBLE DIAGNOSES

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsio n ba rs kn oc king together

4. A loose licen s e pla te or bra ck et

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) causing the noise.

A

B

C

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, r ail, linkage or seals making a rat tle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolati ng sea t noise i t's im por t ant to no te th e posi tion th e seat is in a nd the load place d on the sea t when

the noise is present. These con ditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak betwe e n the seat pad cushion and f rame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the conditions under whi ch the no is e o cc urs . M os t of these incidents can be repaired by repo si tio ni ng the co m ponent

or applying ur ethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components und er the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise inc lude:

1. Any component mounted to the engine wall

2. Components that pass through the engi ne wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to is olate since they cann ot be reached fro m the int erior of th e vehic le. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be chan ged to isola te the noise . Repairs can usua lly be made by moving, adjusting, securing, or

insulating the component causing the noise.

D

E

F

G

H

SE

J

K

L

M

Revision: 2005 August 2005 350Z

SE-9

SQUEAK AND RATTLE TROUBLE DIAGNOSES

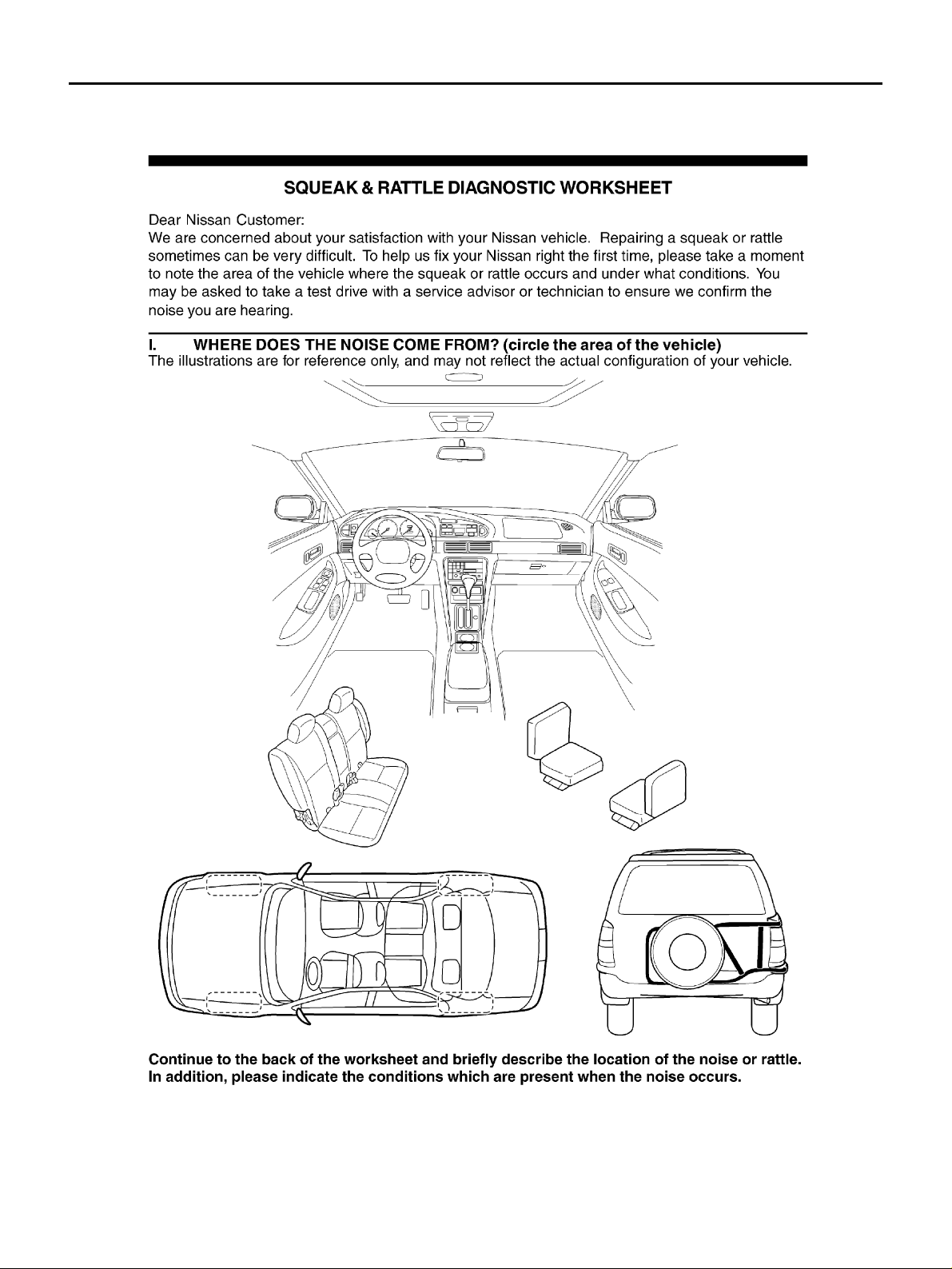

Diagnostic Worksheet AIS0066O

PIIB0723E

Revision: 2005 August 2005 350Z

SE-10

SQUEAK AND RATTLE TROUBLE DIAGNOSES

A

B

C

D

E

F

G

SE

H

J

K

L

M

SBT844

Revision: 2005 August 2005 350Z

SE-11

POWER SEAT/FOR COUPE

POWER SEAT/FOR COUPE PFP:87016 Wiring Diagram–SEAT– /For Driver Seat AIS004J0

TIWT0826E

Revision: 2005 August 2005 350Z

SE-12

POWER SEAT/FOR COUPE

A

B

C

D

E

F

G

SE

H

J

K

L

M

TIWT0723E

Revision: 2005 August 2005 350Z

SE-13

POWER SEAT/FOR COUPE

Wiring Diagram–SEAT– /For Passenger Seat AIS004J1

TIWT0829E

Revision: 2005 August 2005 350Z

SE-14

POWER SEAT/FOR ROADSTER

POWER SEAT/FOR ROADSTER PFP:25565

Component Parts and Harness Connector Location AIS004J2

A

B

C

D

E

F

G

SE

H

J

K

L

M

PIIB1157E

Revision: 2005 August 2005 350Z

SE-15

POWER SEAT/FOR ROADSTER

PIIA9747E

System Description AIS004J7

Power is supplied at all time s,

● through 40A fusible link (letter F , located in the fusible link)

● to BCM terminal 55,

● through 10A fuse [No.18, located in the fuse block (J/B)]

● to BCM terminal 42,

● through 10A fuse [No.21, located in the fuse block (J/B)]

● to passenger seat contr ol unit terminal 34,

● through BCM terminal 54

● to driver side power seat switch terminal 1 and passenger seat control unit terminal 39.

When ignition switch in ON or START position,

power is supplied

● thought 10A fuse [No. 12, located in the fuse block (J/B)]

● to passenger seat contr ol unit terminal 2.

When ignition switch in START position,

power is supplied

● thought 10A fuse [No. 9, located in the fuse block (J/B)]

● to passenger seat contr ol unit terminal 1.

Ground supplied

● to BCM terminal 52

● through body grounds M30 and M60,

● to power seat switch terminal 2 and

● to passenger side seat control unit terminals 40, 48

● through body grounds B5, B6 and T14.

DRIVER SIDE SEAT OPERATION

When a driver side seat sliding switch is operated forward,

power is supplied

● through power seat switch terminal 5

● to sliding motor terminal 5.

Then ground is supplied

● to sliding motor terminal 6

● through power seat switch terminal 6

● through power seat switch terminal 2

The driver side seat moves forw ard.

When a driver side seat sliding switch is operated backward,

power is supplied

● through power seat switch terminal 6

● to sliding motor terminal 6.

Then ground is supplied

● to sliding motor terminal 5

Revision: 2005 August 2005 350Z

SE-16

POWER SEAT/FOR ROADSTER

● through power seat switch terminal 5

● through power seat switch terminal 2

The driver side seat moves backward.

When a driver side seat reclining switch is operated forward,

power is supplied

● through power seat switch terminal 3

● to reclining motor terminal 3.

Then ground is supplied

● to reclining motor terminal 4

● through power seat switch terminal 4

● through power seat switch terminal 2

The driver side seat folds forward.

When a driver side seat reclining switch is op erated backward,

power is supplied

● through power seat switch terminal 4

● to reclining motor terminal 4.

Then ground is supplied

● to reclining motor terminal 3

● through power seat switch terminal 3

● through power seat switch terminal 2

The driver side seat reclines backward.

PASSENGER SIDE SEAT MANUAL OPERATION

When a passenger side seat sliding switch is operated forward,

ground is supplied

● to passenger seat control unit terminal 14

● through power seat switch terminal 14

● through power seat switch terminal 40B

● through body ground B5, B6 and T14.

Then passenger seat control unit recognizes the forward signal,

power is supplied simultaneously

● through pa ssenger seat control unit term inal 45

● to sliding motor terminal 45

Then ground is supplied

● to sliding motor terminal 37

● through pa ssenger seat control unit term inal 37

The passenger side seat moves forward.

When a passenger side seat sliding switch is operated backward,

ground is supplied

● to passenger seat control unit terminal 15

● through power seat switch terminal 15

● through power seat switch terminal 40B

● through body ground B5, B6 and T14.

Then passenger seat control unit recognizes the backward signal,

power is supplied simultaneously

● through pa ssenger seat control unit term inal 37

● to sliding motor terminal 37

Then ground is supplied.

● to sliding motor terminal 45

● through pa ssenger seat control unit term inal 45

The passenger side seat moves backward.

A

B

C

D

E

F

G

H

SE

J

K

L

M

Revision: 2005 August 2005 350Z

SE-17

POWER SEAT/FOR ROADSTER

When a passenger side seat reclining switch is operated forward,

ground is supplied

● to passenger seat contr ol unit terminal 12

● through power seat switch terminal 12

● through power seat switch terminal 40B

● through body ground B5, B6 and T14.

Then passenger seat control unit recognizes the forward signal,

power is supplied simultaneously

● through passenger seat control unit terminal 42

● to reclining motor terminal 42

Then ground is supplied

● to reclining motor terminal 35

● through passenger seat control unit terminal 35

The passenger side seat folds forward.

When a passenger side seat reclining switch is operated backward,

ground is supplied

● to passenger seat contr ol unit terminal 13

● through power seat switch terminal 13

● through power seat switch terminal 40B

● through body ground B5, B6 and T14.

Then passenger seat control unit recognizes the back ward signal,

power is supplied simultaneously

● through passenger seat control unit terminal 35

● to reclining motor terminal 35

Then ground is supplied

● to reclining motor terminal 42

● through passenger seat control unit terminal 42

The passenger side seat reclines backward.

PASSENGER SEATBACK TILT FORWARD/BACKWARD OPERATION

When a passenger side seatback tilt switch is operated forward,

ground is supplied

● to passenger seat contr ol unit terminal 8

● through seatback tilt switch terminal 8

● through seatback tilt switch terminal 40

● through body ground B5, B6 and T14.

Then passenger seat control unit recognizes the forward signal,

power is supplied simultaneously

● through passenger seat control unit terminal 42

● to reclining motor terminal 42

Then ground is supplied

● to reclining motor terminal 35

● through passenger seat control unit terminal 35

Then, a seat folds front most forward.

When a passenger side seatback tilt switch is operated backward,

ground is supplied

● to passenger seat contr ol unit terminal 9

● through seatback tilt switch terminal 9

● through seatback tilt switch terminal 40

● through body ground B5, B6 and T14.

Then passenger seat control unit recognizes the backward signal,

Revision: 2005 August 2005 350Z

SE-18

POWER SEAT/FOR ROADSTER

power is supplied simultaneously

● through pa ssenger seat control unit term inal 35

● to reclining motor terminal 35

Then ground is supplied

● to reclining motor terminal 42

● through pa ssenger seat control unit term inal 42.

The passenger side seat returns to former position.

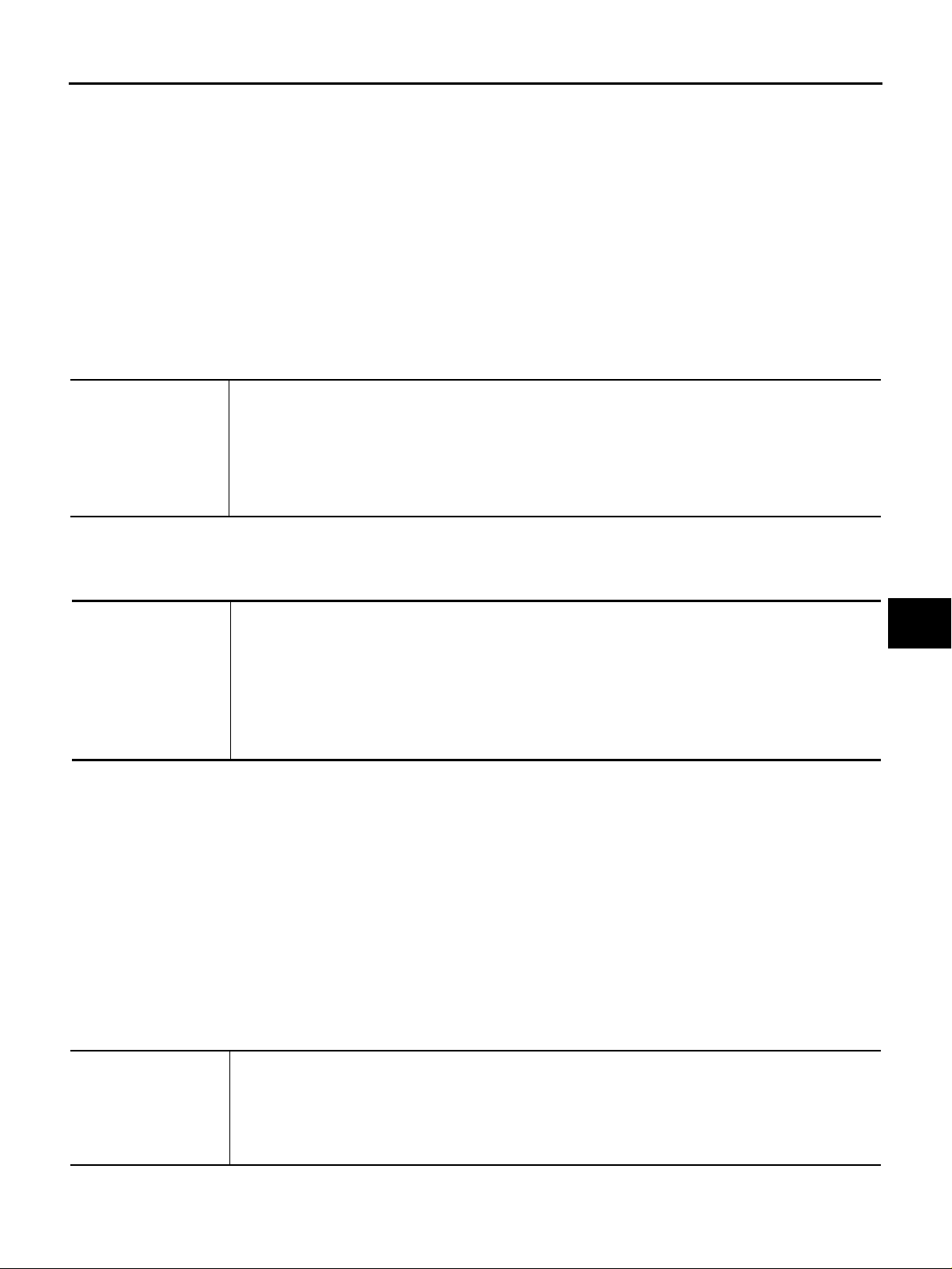

INTERLOCKING OPERATION OF THE PASSENGER SEAT WITH THE SOFT TOP

NOTE:

Refer to RF-12, "

CLOSE → OPEN

When a soft top switch is operated to OPEN,

ground is supplied

● to passenger seat control unit terminal 5

● through soft top switch terminal 3

● through soft top switch terminal 1

● through body groun d M3 0 an d M6 6.

Then passenger seat control unit recognizes the soft top OPEN signal,

Soft top control unit transmits power window down signal to passenger seat control unit,

● through soft top control unit terminal 36

● to passenger seat control unit terminal 16.

When passenger seat control unit receives power window down signal and soft top OPEN signal,

power is supplied simultaneously

● through pa ssenger seat control unit term inal 42

● to reclining motor terminal 42

Then ground is supplied

● to reclining motor terminal 35

● through pa ssenger seat control unit term inal 35

Then, a seat folds 6° forward.

When storage lid closed, soft top control unit transmits a storage lid close signal to passenger seat control

unit,

● through soft top control unit terminal 13

● to passenger seat control unit terminal 33.

When passenger seat control unit receives storage lid close signal,

power is supplied simultaneously

● through pa ssenger seat control unit term inal 35

● to reclining motor terminal 35

Then ground is supplied

● to reclining motor terminal 42

● through pa ssenger seat control unit term inal 42.

The passenger side seat returns to former position.

OPEN → CLOSE

When a soft top switch is operated to CLOSE,

ground is supplied

● to passenger seat control unit terminal 6

● through soft top switch terminal 4

● through soft top switch terminal 1

● through body groun d M3 0 an d M6 6.

Then passenger seat control unit recognizes the soft top CLOSE signal,

soft top control unit transmits power window down signal to passenger seat control unit,

● through soft top control unit terminal 36

System Descri ption" for detailed operation.

A

B

C

D

E

F

G

H

SE

J

K

L

M

Revision: 2005 August 2005 350Z

SE-19

POWER SEAT/FOR ROADSTER

● to passenger seat contr ol unit terminal 16.

When passenger seat control unit receives power window down signal and soft top CLOSE signal,

power is supplied simultaneously

● through passenger seat control unit terminal 42

● to reclining motor terminal 42

Then ground is supplied

● to reclining motor terminal 35

● through passenger seat control unit terminal 35

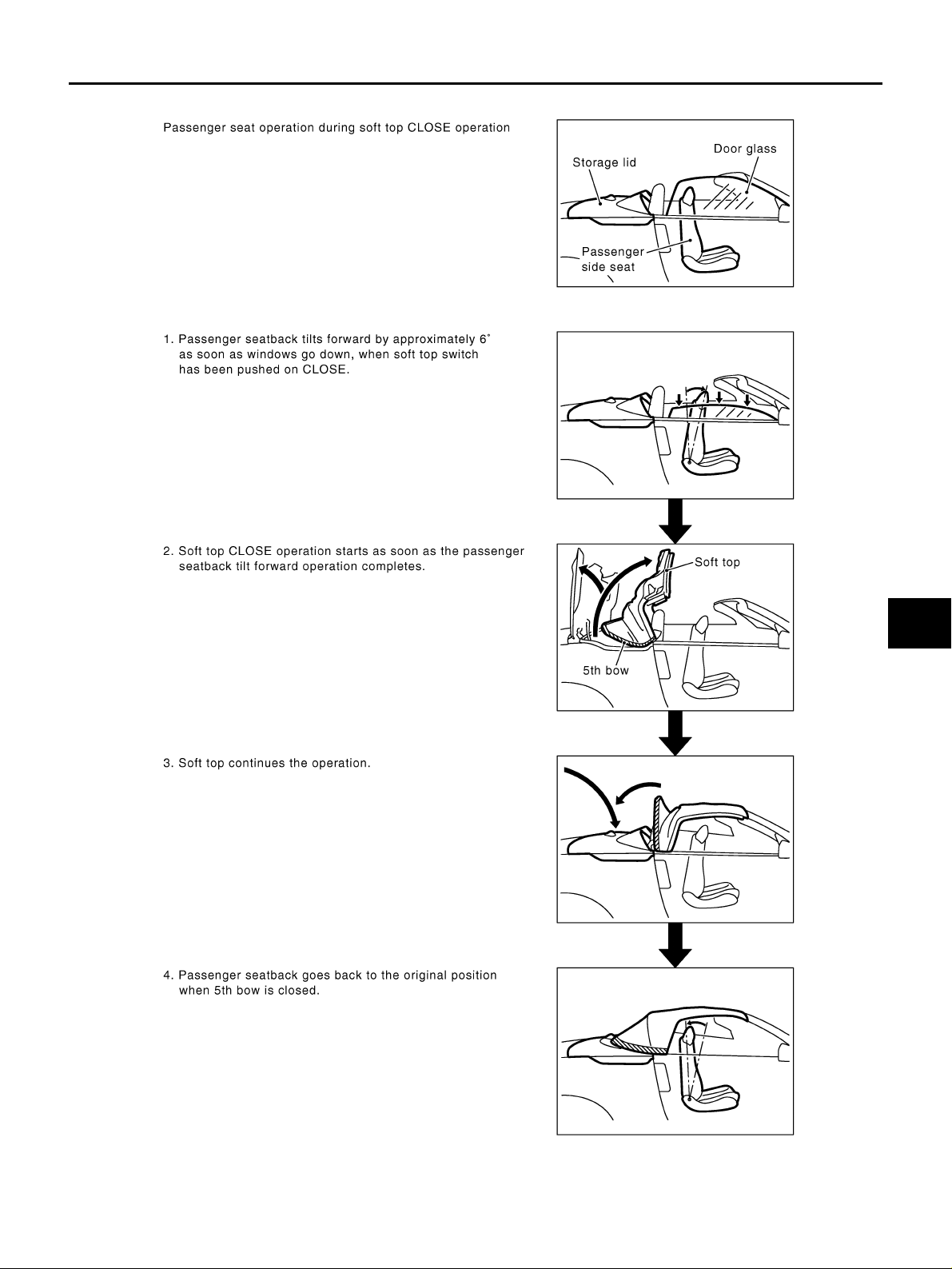

Then, a seat folds 6° forward .

When soft top lock switch (5th bow full latch switch) is turned ON, soft top control unit transmits a soft top lock

signal to pa ssenger seat cont rol unit,

ground is supplied

● to passenger seat contr ol unit terminal 11

● through soft top lock switch (5th bow full latch swtich) terminal 3

● through soft top lock switch (5th bow full latch swtich) terminal 4

● through body ground B5, B6 and T14.

When passenger seat contro l unit receives soft top lock swit ch ON signal,

power is supplied simultaneously

● through passenger seat control unit terminal 35

● to reclining motor terminal 35

Then ground is supplied

● to reclining motor terminal 42

● through passenger seat control unit terminal 42.

The passenger side seat returns to former position.

PASSENGER SIDE RECLINING MOTOR OPERATION

When a passenger side seat reclining motor is operated,

signal is transmitted

● to passenger seat contr ol unit terminal 3

● through reclining motor terminal 3

● through reclining motor terminal 41

● through passenger seat control unit terminal 41.

Then passenger seat control unit judges seatback angle by receiving reclining sensor signal.

SEATBACK TILT CANCEL SWITCH OPERATION

When a passenger side seatback tilt cancel switch is operated to CANCEL,

ground is supplied

● to passenger seat contr ol unit terminal 7

● through seatback tilt cancel switch terminal 7

● through seatback tilt cancel switch terminal 40C

● through body ground B5, B6 and T14.

Then passenger seat control unit recognizes the CANCEL signal.

When a “seatbac k tilt canc el switch” is opera ted to CAN CEL, the automatic operati on of a passe nger seat is

not performe d.

Revision: 2005 August 2005 350Z

SE-20

POWER SEAT/FOR ROADSTER

MANUAL OPERATION

The seat positio ns can b e adjust ed by ope ratin g the slid ing switc h and recl inin g switch lo cated on the si de of

both driver and passenger s eat cushions.

A

AUTOMATIC OPERATION

Passenger Seatback Tilting Function

● When theseatbac k tilt switch on the rear side of the passenger seatba ck is operated to tilt forward , the

seatback tilts forward to the front most position.

● To tilt the seatback backward or restore its position, push the seatback ti lt switch on the tilt-backward

direction. The seatback will be tilting backwards while the switch is operated. It can be moved backwards

until it reaches to its start position.

Conditions For the Operation

When the followin g conditi ons are s atisfied , the sea tback til ts forward or ba ckward by operatin g the sea tback

tilt switch.

● Power seat swi tch es (s liding and reclining) are OFF.

● The seat belt is not fastened.

Conditions

*1: The operation will be stopped only while the reclining motor is operating.

● The vehicle speed is approximately 6 km/h or less.

● The soft top is not cur ren tly in oper ation.*1

● The ignition sw itch is not in the START position.

● The seatback tilt cancel switch is in AUTO.

Conditions for Stopping the Operation

● Seatback tilting operation stops when any one of the conditions below is satisfied.

● A power seat switch (sliding or reclining) is operated.

● The seat belt is faste ned.

● The vehi cle speed is approximately 7 km/h or more.

Conditions

*2: Operation will be stopped only while the reclin ing mo tor is opera ting.

● The sof t top is in ope rati on. (Stops only tilt-forward operation.)*2

● The seat bac k til ting swi t ch is opera te d while th e seat bac k is in operat io n.

● The ignition sw itc h is turned to the START position.

● Reclining motor lock is detected.

B

C

D

E

F

G

H

SE

J

K

NOTE:

If operation stops as a result of the conditions below, use the reclining switch to tilt the seat backward.

● A power seat switch (sliding or reclining) is operated.

● The seat belt i s fastened.

● The seatback tilt cancel switch is turned to “CANCEL”.

Soft Top Interlocking Operation Function

● The seatback tilts forward by approximately 6° (tilt froward operation) when the soft top opens or closes.

● When open/close operation is completed, the seatback ret urns to the tilt start position (return operation).

Conditions for the Operation

When the soft top switch is pushed to OPEN or CLOSE, and all of the conditions below are satisfied, then the

seatback operates, linked with the operati on of the soft top.

● The power seat swi tch es (s liding and reclining) are OFF.

● The seatba ck tilt swi t ch is OFF.

Conditions

● The vehicle sp eed i s 6 km/h or less .

● The ignition swi tch is ON.

● The seatba ck tilt ca ncel sw i tch is turned to AUTO.

Conditions for the Pauseing/Stoppin g Operation

Operation is paused or stopped if any of the conditions below are satisfied during soft top operation.

Revision: 2005 August 2005 350Z

SE-21

L

M

POWER SEAT/FOR ROADSTER

● A power seat switc h (slidin g or recl in ing) is oper ate d.

Stop conditions

Pause condition

Seat Status Outpu t Sig nal

● Depending on the s ea t s tatus , th e “passenger se at co ntro l unit” sends the sea t s tatus output signal t o t he

“soft top control unit”.

● The “soft top control unit” controls the soft top open/close operation based on whether the seat status sig-

nal is ON or OFF. For details about soft top control, refer to RF-19, "

Seat status signal

OFF→ ON condition

Seat status signal

ON→ OFF condition

*3: After that, seat condition signal stays ON if cancel switch t urn s to AUTO.

The seat status signal turns ON only when power window DOWN signal input is ON.

*4: If tilt forward/backward operation stops as a result of the conditions below, the tilt start position does not change.

● The vehi cl e speed is approximately 7 km/h or more.

● The seat back tilt switch is operated while the seatback is operat in g.

● The ignition switch is turned to the START position.

● Reclining mot or lock is detected (return operation only).

● The seatback tilt switch is operated while the seatback is operating.

● The seatback tilt cancel switch is turned to CANCEL.

● The ignition switch is turned to the START position.

Operation Chart" .

● When a sea tb ack t ilt forwa rd mot io n has been completed.

(as a process during a soft top interlocking oper ation )

● When a sea tb ack t ilt forwa rd mot io n has been completed.

(during a automatic operation by using a sea tb ack t ilt swit ch)

● When a sea tb ack t ilt forwa rd pe rmis si on condition is satisfied for a soft top interlocking operation, and a tilt

forward / backward operation is under going, and if the seat back is tilte d more th an 6 degr ee f rom th e start

position of the tilt forward / backward operation.

(during a automatic operation by using a sea tb ack t ilt swit ch)

● When a sea tb ack t ilt forwa rd pe rmis si on condition is satisfied for a soft top interlocking operation, and a tilt

forward operation was under going, but the oper ation was stopped under some conditions, (See below *4.)

and if the seatback is tilted more than 6 degree from the start position of the tilt forw ar d oper ation.

(after an automatic operation by using a seatback tilt switch)

● When a sea tb ack t ilt forwa rd pe rmis si on condition is satisfied for a soft top interlocking operation, and also

the seatback tilt cancel switch is in “Cancel ” posit io n.

● When the ig ni tion swi tc h has been turned from “START” to “ON” position.

(during a soft top interlocking operation. After an engine start operation, the soft top interlocking operation is

accepted.)

● When a sea tb ack t ilt backw ar d m otion has been started.

(as a process during a soft top interlocking oper ation )

● When a sea tb ack t ilt backw ar d per m iss io n condition is satisfied for a soft top interlocking opera tion, after a

tilt forward operation has been finished.

(during a automatic operation by using a sea tb ack t ilt swit ch)

● When a seatback tilt backward permission condition is satisfied for a soft top interlocking operation, and a tilt

forward / backward operation is under going, and if the seat back is tilte d more th an 6 degr ee f rom th e start

position of the tilt forward / backward operation.

(during a automatic operation by using a sea tb ack t ilt swit ch)

● When a seatback tilt backward permission condition is satisfied for a soft top interlocking operation, and a tilt

forward operation was under going, but the oper ation was stopped under some conditions, (See below *4.)

and if the seatback is still tilted more than 6 degree from the start position of the til t forward operation.

(after an automatic operation by using a seatback tilt switch.)

● When the ig ni tion swi tc h has been turned from “ON” to “START” position.

(during a soft top interlocking operation. During an engine start operation, the soft top interlocking operation

is paused.)

● When a sea tb ack t ilt forwa rd mot io n has been started by the seatback tilt switch, just after the seatback tilt

forward motion has been finished for a soft top interlocking operation.

(for the seatback tilt switch operation during a sof t top inte rlocking operation)

● When a sea tb ack t ilt forwa rd mot io n has been started by the passenger seat reclining switch, just afte r the

seatback tilt forward motion has been finished for a soft top interlocking operation.

(for the seat reclining switch operation during a soft top interlocking operation)

Revision: 2005 August 2005 350Z

SE-22

POWER SEAT/FOR ROADSTER

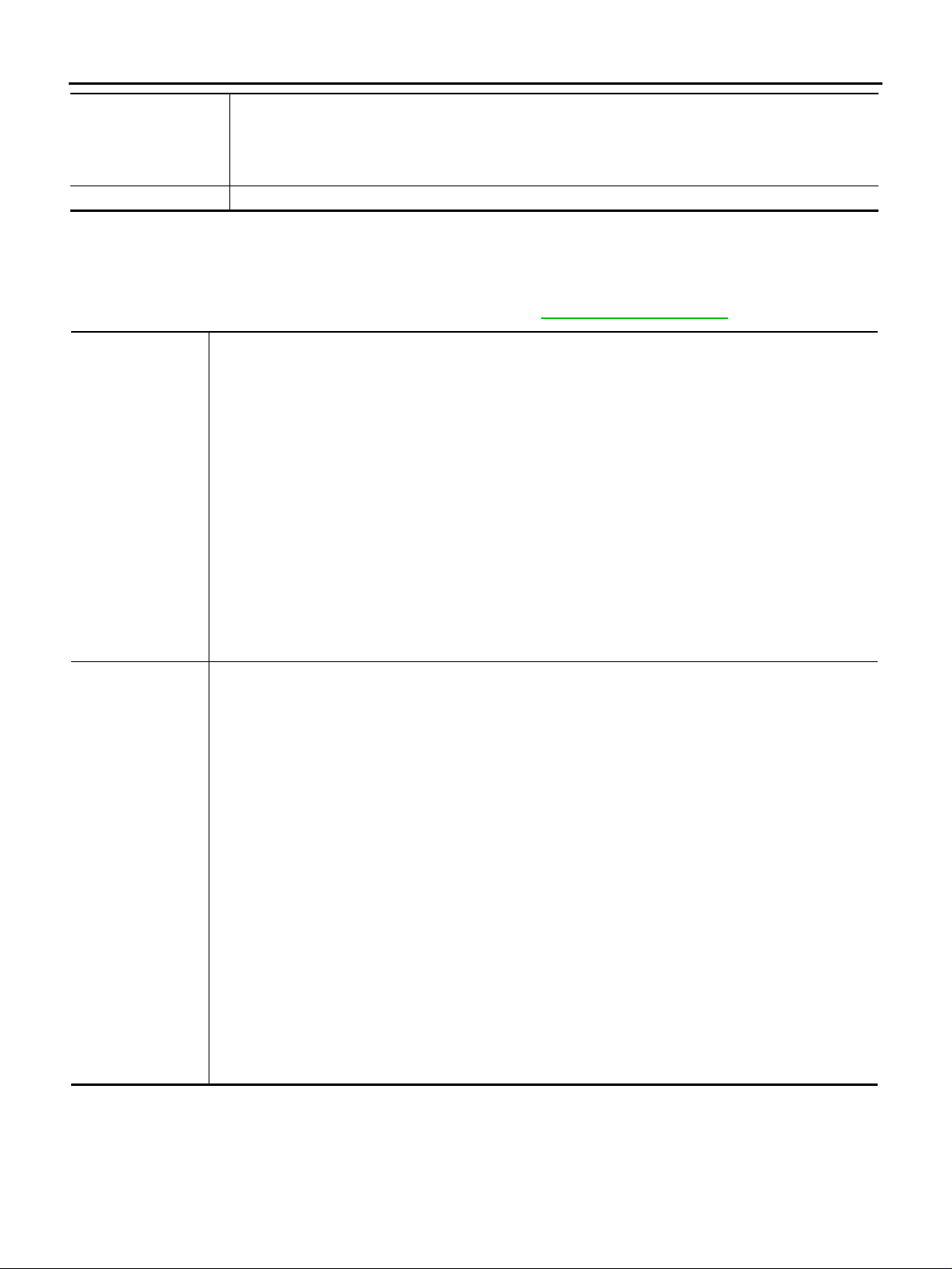

Operation of the Passenger Seat Linked with the Soft Top

A

B

C

D

E

F

G

SE

H

J

K

L

M

PIIA7847E

Revision: 2005 August 2005 350Z

SE-23

Loading...

Loading...