Nipro Surdial Trouble shooting manual

TROUBLE SHOOTING MANUAL

SINGLE PATIENT DIALYSIS MACHINE

Manufacturer NIPRO CORPORATION

3-9-3, Honjo-Nishi, Kita-Ku, OSAKA 531-8510, JAPAN

PHONE +81-6-6372-2331 / FAX +81-6-6371-7422

Version No.

1.GENERAL DESCRIPTION

When TROUBLE is detected,

check symptom and condition and perform

TROUBLE SHOOTING

to check them for finding trouble cause to determine action to be taken.

Condition, check method, cause and action to be taken for each trouble are described in this Manual.

Perform check after reading Cautions for Safety thoroughly contained in Service Manual.

When power ON of SURDIAL is required to perform check, take care of electric shock.

↓

In accordance with procedure specified in

SERVICE MANUAL,

take action and check the result.

Construction drawings and adjusting procedures of each Assy and component, list of components and the like are contained in Service Manual.

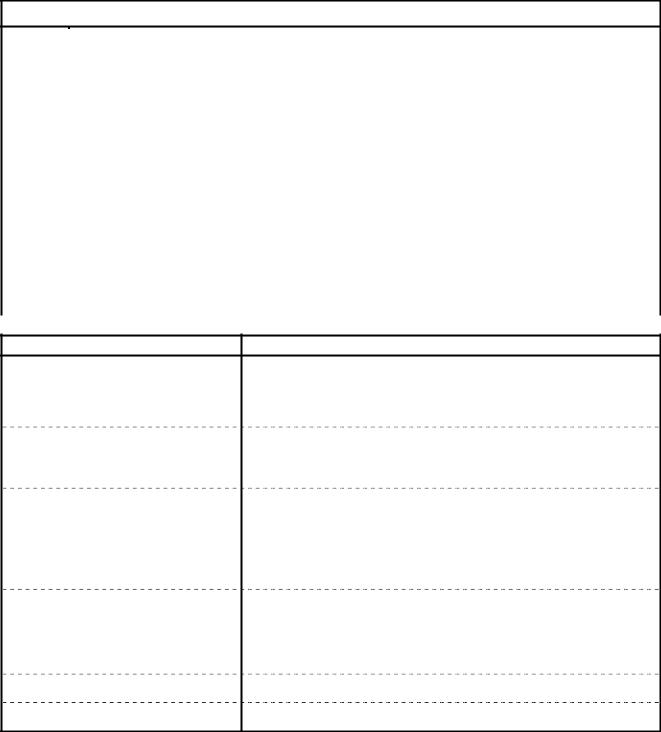

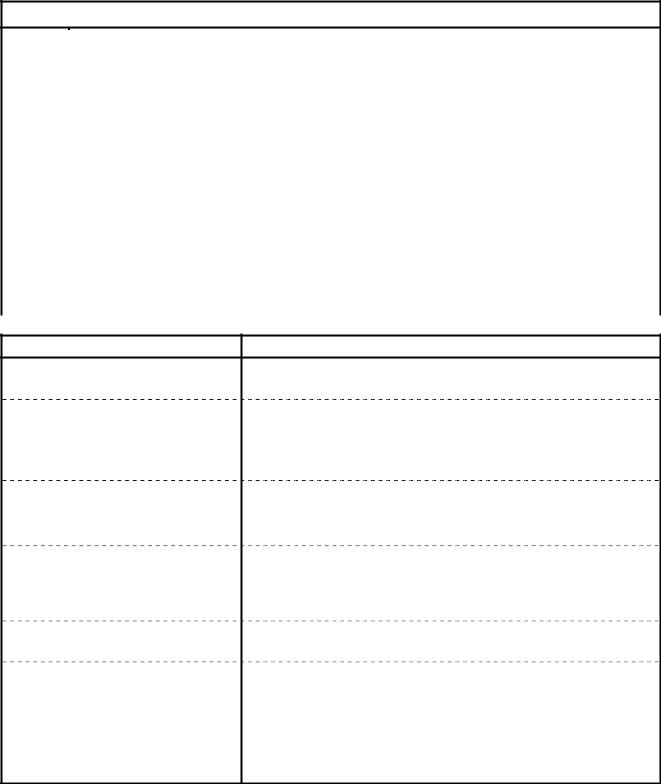

2.ALARM/ERROR INDICATIONS AND DESCRIPTION

NO. |

ALARM/ERROR INDICATION |

NO. |

ALARM/ERROR INDICATION |

|

|

|

|

|

|

|

|

E01 |

RECOVER FROM EMERGENCY STOP |

E41 |

VCa CLOSED CIRCUIT LEAK ERROR |

E02 |

T1 TEMPERATURE SENSOR ERROR |

E42 |

VCb CLOSED CIRCUIT LEAK ERROR |

E03 |

T2 TEMPERATURE SENSOR ERROR |

E43 |

VCb CLOSED CIRCUIT LEAK ERROR |

E04 |

T3 TEMPERATURE SENSOR ERROR |

E44 |

AIR ELIMINATION TANK ERROR |

E05 |

DIALYSATE TEMPERATURE MAX ALARM |

E45 |

BLOWN-OUT FUSE DETECTION |

E06 |

DIALYSATE TEMPARATURE MIN ALARM |

E46 |

WATCH-DOG ERROR |

E07 |

DIALYSATE PRESSURE MAXLIMIT |

E47 |

RAM ERROR |

E08 |

DIALYSATE PRESSURE MINLIMIT |

E48 |

EEPROM ERROR |

E09 |

DAIALYSATE PRESSUREMAX ALARM |

E49 |

EPROM ERROR |

E10 |

DIALYSATE PRESSUREMIN ALARM |

E50 |

RAM INITIALIZE |

E11 |

VENOUS PRESSURE MAX LIMIT |

E51 |

EEPROM INITIALIZE |

E12 |

VENOUS PRESSURE MIN LIMIT |

E52 |

SWITCH ERROR |

E13 |

VENOUS PRESSURE MAX ALARM |

E53 |

I/O PORT ERROR |

E14 |

VENOUS PRESSURE MIN ALARM |

E54 |

CONNECTION ERROR SBY0151-SBY0156 |

E15 |

ARTERIAL PRESSURE MAX LIMIT |

E55 |

BP BATTERY ERROR |

E16 |

ARTERIAL PRESSURE MIN LIMIT |

E56 |

COUPLER SW ON ALARM(DIALYSIS) |

E17 |

ARTERIAL PRESSURE MAX ALARM |

E57 |

COUPLER SW ON ALARM(PREP.) |

E18 |

ARTERIAL PRESSURE MIN ALARM |

E58 |

COUPLER SW OFF ALARM |

E19 |

TMP ALARM |

E59 |

UF MAX ALARM |

E20 |

DIALYSATE CONDUCTIVITY MAX ALARM |

E60 |

SYRINGE INFUSION COMPLETION |

E21 |

DIALYSATE CONDUCTIVITY MIN ALARM |

E61 |

COMPLETION OF SYRINGE.P INFUSION |

E22 |

BLOOD LEAK SENSOR ERROR |

E62 |

PERFORMED PRIMING |

E23 |

BLOOD LEAK ALARM |

E63 |

PREFORMED TARGET UF. |

E24 |

AIR BUBBLES ARE DETECTED |

E64 |

NO WATER RINSING |

E25 |

HEATER OVER HEAT ALARM |

E65 |

PREPARE DIALYSATE CONC. |

E26 |

SHORT WATER SUPPLY |

E66 |

CONC CONNECTOR TO RINSING PORT. |

E27 |

SHORT DIALYSATE FLOW |

E67 |

RESET SW |

E28 |

DIALYSATE FLOW STOP |

E68 |

UF DIALYSE SW |

E29 |

SN SWITCH TIME ALARM |

E69 |

BYPASS SW |

E30 |

BLOOD PUMP ERROR |

|

ALARM/ERROR DESCRIPTION |

E31 |

BLOOD PUMP STOP ERROR |

|

Disabled LCD indication |

E32 |

CLV POSITION ERROR |

|

Disabled SW function |

E33 |

VISCOUS PUMP DRIVING ERROR(VPa) |

|

Disabled syringe pump operation |

E34 |

VISCOUS PUMP DRIVING ERROR(VPb) |

|

Blood pump error |

E35 |

VP DRAWING VOLUME IS AT MAX LIM. |

|

Level change in venous drip chamber |

E36 |

VCa CLOSED CIRCUIT LEAK ERROR |

|

Air inclusion in dialysate |

E37 |

VCa CLOSED CIRCUIT LEAK ERROR |

|

Unstable dialysate flow rate |

E38 |

VCb CLOSED CIRCUIT LEAK ERROR |

|

Disabled discharge by pressing drain SW |

E39 |

VCb CLOSED CIRCUIT LEAK ERROR |

|

UFR error exceeding allowable upper/lower limits |

E40 |

VCa CLOSED CIRCUIT LEAK ERROR |

|

Date and time are initialized. |

PREFACE

Thank you for purchase of NIPRO Single Patient Dialysis Machine “SURDIAL”.

Information for serviceman or technician required to perform check and maintenance of SURDIAL is given by this Trouble Shooting Manual. All operations described in this Manual should be performed by only qualified serviceman or technician who should be familiar with replacement of components of microprocessor based electronic devices and should have basic knowledge concerning conventional dialysate line of dialysis machine. The serviceman or technician should be familiar with all operations contained in this Manual by reading it thoroughly to full understand them before starting trouble shooting.

Use this Manual together with Operation and Service Manuals of SURDIAL. Same descriptions contained in them are minimal.

Generally, information required to operate SURDIAL is contained in Operation Manual of SURDIAL though technical description is also contained partially. Information related to maintenance, component replacement and various settings is contained in Service Manual of SURDIAL. In this Manual, information related to method of trouble shooting is contained.

Description concerning the trouble shooting contained in this Manual is protected by copyright owned by the manufacturer. Partial or whole copy, duplication or preparation of version in any foreign language of this Manual should not be allowed without obtaining prior written approval of the manufacturer.

E01 RECOVER FROM EMERGENCY STOP

Detection |

|

|

Recovery to normal from emergency machine stop due to power failure caused during execution of sequence |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Detection |

|

Audible |

Dialysate line function |

|

BP/SP stop |

CLV function |

Reset |

|||||

process |

|

alarm |

|

|||||||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Rinse |

|

|

|

○ (3 times) |

Execution of sequence |

before |

|

― |

― |

― |

||

Preparation |

|

|

error detection |

|

|

|

|

|

|

|||

Prep. end |

|

|

|

|

|

|

|

|

|

|

|

|

Dialysis |

|

|

|

|

|

|

|

|

|

|

|

|

Recovery |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Becoming error free of upper/lower alarm limits of |

||

Reset |

|

Automatic recovery to normal |

|

Note |

|

venous, arterial and dialysate pressures by error |

||||||

|

|

|

|

|

|

|

|

|

|

detection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Conditionor cause |

Check and action |

|

Recovery from power failure |

Not required |

|

Intentional OFF-ON of power breaker |

Not required |

|

Intentional OFF-ON of power SW |

Not required |

|

|

Check Identify position(s) of leakage or short-circuit of AC230V |

|

|

(AC110V) line. |

|

|

Disconnect components one by one from the line to identify |

|

OFF of breaker due to leakage or short |

damaged one(s) by testing or operate components in the line |

|

one by one manually to do so. |

||

circuit of AC230V (AC110V) line |

||

|

||

|

||

|

Check correct earth connection of SURDIAL and disconnect |

|

|

components after disconnecting power plug from receptacle. |

|

|

Action: Repair or replace damaged one(s). |

|

Incorrect power plug connection |

Action: Connect the plug to receptacle securely. |

|

|

Check: Pull lightly each of harnesses connecting POWER PLUG |

|

|

SWITCH GEAR TERMINAL BLOCK2 POWER SWITCH |

|

|

NOISE FILTER TERMINAL BLOCK1 POWER SUPPLY |

|

|

SUB-BOARD CN412 SUB-BOARD CN413 MAIN BOARD |

|

Incorrect power line connection |

CN1 in series to check loosening, incorrect contact and |

|

|

disconnection. |

|

|

Action If the loosening is detected, tighten securely. If the incorrect |

|

|

contact and/or disconnection are/is detected, replace relevant |

|

|

harness(es) with new one(s). |

Conditionor cause |

|

|

Check and action |

|

|

||

|

Check: Identify |

whether |

error |

cause(s) |

is (are) |

main board, |

|

|

sub-board and/or DC+5V/±12V switching power supply. |

||||||

|

Check that |

actual |

output |

voltage is |

4.8V |

(nominal: 5VDC) |

|

|

when measured at test points on main and sub-board. |

||||||

|

Action |

|

|

|

|

|

|

Repetition of error of recovery from |

When 4.8V is not outputted to the main board and sub-board: |

||||||

Replace sub-board with new one or the switching power |

|||||||

emergency stop |

|||||||

supply with new one. |

|

|

|

||||

|

|

|

|

||||

|

When it is outputted to sub-board, while it is not outputted to |

||||||

|

main board: |

|

|

|

|

||

|

Replace main board with new one. |

|

|

||||

|

When it is outputted to the main board and sub-board: |

||||||

|

Replace main board with new one. |

|

|

||||

E02 T1 TEMPERATURE SENSOR ERROR

Detection |

|

T1 temperature exceeding measurable limit |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Detection |

|

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

Reset |

||

process |

|

alarm |

|

|

||||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

Rinse wait |

|

○ (7 times) |

Continuance |

|

|

― |

― |

○ |

||

Rinse |

|

↑ |

↑ |

|

|

|

|

|

||

Rinse end |

|

↑ |

↑ |

|

|

|

|

|

||

Air purge |

|

↑ |

↑ |

|

|

|

|

|

||

Dialysis |

|

○ (Continuous) |

↑ |

|

|

|

|

|

||

wait |

|

↑ |

Dialysate line stop |

|

|

|

|

|

||

Preparation |

|

↑ |

↑ |

|

|

|

|

|

||

Prep. end |

|

↑ |

↑ |

|

|

|

|

|

||

Dialysis |

|

↑ |

↑ |

|

|

|

|

|

||

Recovery |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Rese |

Press [RESET] SW. |

|

Note |

|

|

|

||||

t |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

|

|

|

|

|

Check: Check whether indications of all temperature sensors and other |

|

|

|

|

sensors such as dialysate pressure sensor are incorrect. |

|

Indication error of temperature and |

Check stable output of voltage of 4.9V (nominal: 5Vref) at test |

|||

other analog system |

|

point on main board. |

|

|

|

|

|

Action: Replace main board with new one. |

|

|

|

|

Check: Check no incorrect wiring, loosening, corrosion and/or |

|

|

|

|

disconnection at TM1 T1 terminal of main board. |

|

Incorrect [ ] terminal connection |

Action: If loosened, tighten securely. |

|

||

|

|

|

|

|

|

|

|

If incorrectly wired, correct. |

|

|

|

|

If corroded or disconnected, replace [T1] with new one. |

|

|

|

|

Check: Remove TM1 T1 terminal from main board |

and measure |

Internal disconnection or |

short circuit |

resistance between Red and White to find |

short circuit, |

|

disconnection and fluctuation. |

|

|||

of [T1] |

|

|

|

|

|

|

|

|

|

|

|

|

Action: Replace [T1] with new one. |

|

Introduction of high temperature water |

Action: Overhaul dialysate line to correct potential damage. |

|||

from water supply source |

|

|

|

|

|

|

|

Action: Calibrate temperatures indicated by [T1], [T2] and [T3] circuits |

|

Incorrect |

indicated |

temperature |

of main board using temperature calibrator. |

|

calibration of main board |

|

If the calibration is impossible, replace main board with new |

||

|

|

|

one. |

|

E03 T2 TEMPERATURE SENSOR ERROR

Detection |

|

T2 temperature exceeding measurable limit |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Detection |

|

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

Reset |

||

process |

|

alarm |

|

|

||||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

Rinse wait |

|

○ (7 times) |

Continuance |

|

|

― |

― |

○ |

||

Rinse |

|

↑ |

↑ |

|

|

|

|

|

||

Rinse end |

|

↑ |

↑ |

|

|

|

|

|

||

Air purge |

|

↑ |

↑ |

|

|

|

|

|

||

Dialysis |

|

○ (Continuous) |

↑ |

|

|

|

|

|

||

wait |

|

↑ |

Dialysate line stop |

|

|

|

|

|

||

Preparation |

|

↑ |

↑ |

|

|

|

|

|

||

Prep. end |

|

↑ |

↑ |

|

|

|

|

|

||

Dialysis |

|

↑ |

↑ |

|

|

|

|

|

||

Recovery |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Rese |

Press [RESET] SW. |

|

Note |

After Ver 3, measurable extent of upper limit while |

||||||

t |

|

rinse isn’t detectable. |

|

|||||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

|

|

|

|

|

Check: Check whether indications of all temperature sensors and other |

|

|

|

|

sensors such as dialysate pressure sensor are incorrect. |

|

Indication error of temperature and |

Check stable output of voltage of 4.9V (nominal: 5Vref) at test |

|||

other analog system |

|

point on main board. |

|

|

|

|

|

Action: Replace main board with new one. |

|

|

|

|

Check: Check no incorrect wiring, loosening, corrosion and/or |

|

|

|

|

disconnection at TM1 T2 terminal of main board. |

|

Incorrect [ 2] terminal connection |

Action: If loosened, tighten securely. |

|

||

|

|

|

|

|

|

|

|

If incorrectly wired, correct. |

|

|

|

|

If corroded or disconnected, replace [T2] with new one |

|

|

|

|

Check: Remove TM1 T2 terminal from main board |

and measure |

Internal disconnection or |

short circuit |

resistance between Red and White to find |

short circuit, |

|

disconnection and fluctuation. |

|

|||

of [T2] |

|

|

|

|

|

|

|

|

|

|

|

|

Action: Replace [T2] with new one. |

|

|

|

|

Action: Calibrate temperatures indicated by [T1], [T2] and [T3] circuits |

|

Incorrect |

indicated |

temperature |

of main board using temperature calibrator. |

|

calibration of main board |

|

If the calibration is impossible, replace main board with new |

||

|

|

|

one. |

|

E04 T3 TEMPERATURE SENSOR ERROR

Detection |

|

|

T3 temperature exceeding measurable limit |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Detection |

|

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

Reset |

|||

process |

|

alarm |

|

|

|||||||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||

Rinse wait |

|

○ (7 times) |

Continuance |

|

|

― |

― |

○ |

|||

Rinse |

|

|

|

↑ |

↑ |

|

|

|

|

|

|

Rinse end |

|

↑ |

↑ |

|

|

|

|

|

|||

Air purge |

|

|

|

↑ |

↑ |

|

|

|

|

|

|

Dialysis |

|

|

|

○ (Continuous) |

↑ |

|

|

|

|

|

|

wait |

|

|

|

↑ |

Dialysate line stop |

|

|

|

|

|

|

Preparation |

|

↑ |

↑ |

|

|

|

|

|

|||

Prep. end |

|

|

|

↑ |

↑ |

|

|

|

|

|

|

Dialysis |

|

|

|

↑ |

↑ |

|

|

|

|

|

|

Recovery |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Reset |

|

Press [RESET] SW. |

|

Note |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

|

|

|

|

|

Check: Check whether indications of all temperature sensors and other |

|

|

|

|

sensors such as dialysate pressure sensor are incorrect. |

|

Indication error of temperature and |

Check stable output of voltage of 4.9V (nominal: 5Vref) at test |

|||

other analog system |

|

point on main board. |

|

|

|

|

|

Action: Replace main board with new one. |

|

|

|

|

Check: Check no incorrect wiring, loosening, corrosion and/or |

|

|

|

|

disconnection at TM1 T3 terminal of main board. |

|

Incorrect [ 3] terminal connection |

Action: If loosened, tighten securely. |

|

||

|

|

|

|

|

|

|

|

If incorrectly wired, correct. |

|

|

|

|

If corroded or disconnected, replace [T2] with new one |

|

|

|

|

Check: Remove TM1 T3 terminal from main board |

and measure |

Internal disconnection or |

short circuit |

resistance between Red and White to find |

short circuit, |

|

disconnection and fluctuation. |

|

|||

of [T3] |

|

|

|

|

|

|

|

|

|

|

|

|

Action: Replace [T3] with new one. |

|

|

|

|

Action: Calibrate temperatures indicated by [T1], [T2] and [T3] circuits |

|

Incorrect |

indicated |

temperature |

of main board using temperature calibrator. |

|

calibration of main board |

|

If the calibration is impossible, replace main board with new |

||

|

|

|

one. |

|

E05 DIALYSATE TEMPERATURE MAX ALARM

Detection |

|

Dialysate temperature T3 of upper alarm limit during heater ON |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

Detection |

|

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

Reset |

|||

process |

|

alarm |

|

|

|||||||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||

Preparation |

|

○ (Continuous) |

Auto bypass |

|

|

― |

― |

○ |

|||

Prep. end |

|

|

|

|

Heater OFF |

|

|

|

|

|

|

Dialysis |

|

|

|

|

|

|

|

|

|

|

|

Recovery |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Press [RESET] SW to reset. |

|

|

|

|

|

||||

Reset |

|

Auto |

reset is caused after release from alarm |

Note |

|

|

|

||||

|

|

condition for 10 seconds. |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

|

Actually higher dialysate temperature |

Check: Check whether actual dialysate temperature is higher than |

|

upper alarm limit by touching dialysate supply line with hand |

||

|

||

|

when the line is connected to dialyzer or by measurement of |

|

|

temperature of dialysate discharged from coupler outlet using |

|

|

thermometer when patient is not connected to the machine. |

|

○Failure of main board |

Action: Replace main board with new one. |

|

|

○Incorrect calibration of indicated

Action: Calibrate temperatures indicated by [T1], [T2] and [T3] circuits

temperature of main board

of main board using temperature calibrator.

If the calibration is impossible, replace main board with new one.

○Higher supply water temperature

Action: Adjust supply water temperature as specified.When heat exchanger is used : 5 to 30When heat exchanger is not used 17 to 30

○Lower priming flow rate

Action: Adjust priming flow rate to 700 to 750mL/min.

Actually |

acceptable |

dialysate |

Check: Check whether actual dialysate temperature is acceptable by |

temperature |

|

touching dialysate supply line with hand when the line is |

|

|

|

|

connected to dialyzer or by measurement of temperature of |

|

|

|

dialysate discharged from coupler outlet using thermometer |

|

|

|

when patient is not connected to the machine. |

|

|

|

Check: Check whether indicated temperature is fluctuated when |

○Failure of T3 temperature sensor |

harness of T3 temperature sensor is shaken. |

||

|

|

|

Check also whether indicated T3 temperature is deviated when |

|

|

|

temperature calibrator is connected. |

|

|

|

Action: If check result is unacceptable, replace T3 temperature sensor |

|

|

|

with new one. |

|

|

|

Check: Check whether indicated T3 temperature is deviated when |

○Incorrect calibration of main board |

temperature calibrator is connected. |

||

|

|

|

Action: Calibrate [T3] circuit of main board using temperature |

|

|

|

calibrator. |

|

|

|

If the calibration is impossible, replace main board with new |

|

|

|

one. |

E06 DIALYSATE TEMPERATURE MIN ALARM

Detection |

|

Dialysate temperature T3 of lower alarm limit |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Detection |

|

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

Reset |

||

process |

|

alarm |

|

|

||||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

Dialysis |

|

|

○ (3 times) |

Auto bypass |

|

|

― |

― |

○ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Press [RESET] SW to reset. |

|

|

|

|

|

|||

Reset |

|

Auto reset is caused |

after release from alarm |

Note |

|

|

|

|||

|

|

condition for 10 seconds. |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

Actually lower dialysate temperature

○Failure of main board

○Incorrect calibration of indicated temperature of main board

○Lower supply water temperature

○Failure of heater

○ Higher priming flow rate

Actually acceptable dialysate temperature

○ Failure of T3 temperature sensor

○ Incorrect calibration of main board

Check: Check whether actual dialysate temperature is lower than lower alarm limit by touching dialysate supply line with hand when the line is connected to dialyzer or by measurement of temperature of dialysate discharged from coupler outlet using thermometer when patient is not connected to the machine.

Action: Replace main board with new one.

Action: Calibrate temperatures indicated by [T1], [T2] and [T3] circuits of main board using temperature calibrator.

If the calibration is impossible, replace main board with new one.

Action: Adjust supply water temperature as specified.When heat exchanger is used : 5 to 30When heat exchanger is not used 17 to 30

Check: Measure resistance between both ends of heater at room temperature after power OFF.

Action: Replace heater if the resistance is out of the below ranges: 230V spec. 38.3 to 44.1Ω

110V spec. 8.7 to 10.0Ω

Action: Adjust priming flow rate to 700 to 750ml/min.

Check: Check whether actual dialysate temperature is acceptable by touching dialysate supply line with hand when the line is connected to dialyzer or by measurement of temperature of dialysate discharged from coupler outlet using thermometer when patient is not connected to the machine.

Check: Check whether indicated temperature is fluctuated when harness of T3 temperature sensor is shaken.

Check also whether indicated T3 temperature is deviated when temperature calibrator is connected.

Action: If check result is unacceptable, replace T3 temperature sensor with new one.

Check: Check whether indicated T3 temperature is deviated when temperature calibrator is connected.

Action: Calibrate [T3] circuit of main board using temperature calibrator.

If the calibration is impossible, replace main board with new one.

E07 DIALYSATE PRESSURE MAX LIMIT

Detection Dialysate pressure of +400mmHg

Detection |

Audible |

Dialysate line function |

|

BP/SP stop |

CLV function |

Reset |

||

process |

alarm |

|

||||||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Rinse wait |

○ (7 times) |

UF stop |

|

2 sec. |

2 sec. |

○ |

||

Rinse |

↑ |

ON of V4 and V10 for 2 sec. |

|

|

|

|

||

Rinse end |

↑ |

|

|

|

|

|

|

|

Air purge |

↑ |

|

|

|

|

|

|

|

Dialysis wait |

○ (Continuous) |

|

|

|

|

|

|

|

Preparation |

↑ |

|

|

|

|

|

|

|

Prep. end |

↑ |

|

|

|

|

|

|

|

Dialysis |

↑ |

|

|

|

|

|

|

|

Recovery |

↑ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset |

Auto reset of BP, SP and CLV |

Note |

|

|

|

|||

Press [RESET] SW to reset UF stop. |

|

|

|

|||||

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

|

Pressure rise due to failure of [PR1] |

Action: Adjustment of [PR1] |

|

In adjustment is impossible, repair or replace [PR1]. |

||

|

||

Leak from [V10] |

Action: Repair or replacement of [V10] |

|

Error occurrence at gas purge |

|

|

○Occlusion of [R2] |

Action: Change [R2] so that dialysate pressure becomes 0 to |

|

|

100mmHg during gas purge. |

|

○Excess tightening of [PC2] |

Action: Adjust [PC2] so that dialysate pressure becomes 0 to |

|

|

100mmHg during gas purge. |

|

○Impossible opening of [V4] |

Check: Check whether [V4] functions when it is turned on or off in |

|

|

maintenance mode 4 screen. |

|

|

If not functions, remove connector from [V4] and check whether |

|

|

24V is outputted to the connector when [V4] is ON in |

|

|

maintenance mode 4 screen. |

Action: If 24V is not outputted, replace main board with mew one.

If it is outputted, replace [V4] with mew one.

Pressure rise due to folding of blood

Action: Correct folding.

line

|

Check: Disconnect hose from the sensor Assy to expose to |

|

atmosphere for checking whether indicated pressure is nearly |

|

0mmHg. |

Failure of dialysate pressure sensor |

|

board or the sensor |

Action: If the indicated pressure is not nearly 0mmHg, calibrate the |

|

sensor board. |

|

If calibration is impossible, replace the board or sensor with new |

|

one. |

|

|

E07 DIALYSATE PRESSURE MAX LIMIT

Condition or cause |

Check and action |

|

Disconnection of harness from the |

Check: Pull lead wire (harness) lightly to check whether it is separated |

|

or loosened. |

||

sensor Assy or insufficient contact of |

||

|

||

connector of it |

Action: Repair |

|

|

||

Drain tube is blocked. |

Check Remove drain tube from drain port and check drain liquid is |

|

|

drained from port correctly or not. |

|

○No folding/kinking of Drain tube |

Action Remove the trouble cause. |

|

○Drain tube tip is placed too higher |

Action Drain tube tip must be placed above the machine floor by 0 to |

|

position. |

60 cm. |

|

○Drain tube is too long. |

Action Use tube of an inter diameter of 8 mm and a length of 2 m or |

|

|

shorter to connect to the port. |

|

|

|

E08 DIALYSATE PRESSURE MIN LIMIT

Detection Dialysate pressure of -400mmHg

Detection |

Audible |

Dialysate line function |

|

BP/SP stop |

CLV function |

Reset |

||

process |

alarm |

|

||||||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Rinse wait |

○ (7 times) |

UF stop |

|

2 ses. |

2 sec. |

○ |

||

Rinse |

↑ |

ON of V4 and V10 for 2 sec. |

|

|

|

|

||

Rinse end |

↑ |

|

|

|

|

|

|

|

Air purge |

↑ |

|

|

|

|

|

|

|

Dialysis wait |

○ (Continuous) |

|

|

|

|

|

|

|

Preparation |

↑ |

|

|

|

|

|

|

|

Prep. end |

↑ |

|

|

|

|

|

|

|

Dialysis |

↑ |

|

|

|

|

|

|

|

Recovery |

↑ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset |

Auto reset of BP, SP and CLV |

Note |

|

|

|

|||

Press [RESET] SW to reset UF stop. |

|

|

|

|||||

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

|

Check: Check whether the line is folded or clamped by forceps |

Occlusion of dialysate line to dialyzer |

visually. |

|

|

|

Action: Correct folding or clamp. |

Excess occlusion in dialyzer |

Action: Replace dialyzer with new one. |

|

Check: Check stop of leak by clamping [V4] line with forceps. |

Leak from [V4] |

Action: Clean [V4] by rinsing after disassembling or replace it with new |

|

|

|

one. |

Opening of [V4] due to malfunction of |

Action: Clean air-elimination tank [AS2] by rinsing after disassembling |

[FSW] |

or replace it with new one. |

|

Action: Adjust pressure in closed line. |

Occlusion of [RV2] |

If adjustment is impossible, Clean [RV2] by rinsing after |

|

disassembling or replace it with new one. |

Error occurrence during gas purge

○Failure of [V10] Check: Check whether [V10] functions when it is turned on or off in maintenance mode 4 screen.

If not functions, disconnect connector from [V10] and turn on it in maintenance mode 4 screen to check whether 24V is outputted to the connector.

Action: If 24V is not outputted, replace main board with new one.

If it is outputted, replace [V10] with new one.

Failure of dialysate pressure sensor board or the sensor

Disconnection of harness from the sensor Assy or insufficient contact of connector of it

Low water supply flow

No water supply

Low water supply pressure

Alarm while gaspurge

On the acid rince without an acid rince option.

Check: Disconnect hose from the sensor Assy to expose to atmosphere for checking whether indicated pressure is nearly 0mmHg.

Action: If the indicated pressure is not nearly 0mmHg, calibrate the sensor board.

If calibration is impossible, replace the board or sensor with new one.

Check: Pull lead wire (harness) lightly to check whether it is separated or loosened.

Action: Repair

Action Increase water supply flow rate more than 750 mL/min. Check/Action See E26 SHORT WATER SUPPLY. Check/Action See E26 SHORT WATER SUPPLY. Check/Action See E26 SHORT WATER SUPPLY. Check/Action See E26 SHORT WATER SUPPLY.

E09 DIALYSATE PRESSURE MAX ALARM

Detection Dialysate pressure of set upper alarm limit

Detection |

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

|

Reset |

|

process |

alarm |

|

|

|

|||||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

Dialysis wait |

○ (Continuous) |

UF stop |

|

|

2 sec. |

2 sec. |

|

○ |

|

Preparation |

|

ON of V4 and V10 for 2 sec. |

|

|

|

|

|

||

Prep. end |

|

|

|

|

|

|

|

|

|

Dialysis |

|

|

|

|

|

|

|

|

|

Recovery |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset |

Auto reset of BP, SP and CLV |

Note |

By the alarm actuation, upper/lower alarm limits of |

||||||

Press [RESET] SW to reset UF stop. |

venous pressure become error free. |

|

|||||||

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

|

Simultaneous actuation of this alarm |

Check: See E13 VENOUS PRESSURE MAX ALARM. |

|

with venous pressure max alarm |

Action: See E13 VENOUS PRESSURE MAX ALARM. |

|

|

||

Dialysate pressure rise due to UF stop |

Action: Remove cause of UF stop. |

|

Dialysate pressure rise due to failure of |

Action: Adjust [PR1]. |

|

[PR1] |

If adjustment is impossible, repair [PR1] or replace it with new |

|

one. |

||

|

||

Leak from [V10] |

Action: Repair [V10] or replace it with new one. |

|

Leak from [V5] and [V7] |

Action: Repair [V5] and [V7] or replace them with new ones. |

|

|

|

E10 DIALYSATE PRESSURE MIN ALARM

Detection |

|

Dialysate pressure of set lower alarm limit |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Detection |

|

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

|

Reset |

|

process |

|

alarm |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||

Dialysis wait |

○ (Continuous) |

UF stop |

|

|

2 sec. |

2 sec. |

|

○ |

||

Preparation |

|

|

ON of V4 and V10 for 2 sec. |

|

|

|

|

|

||

Prep. end |

|

|

|

|

|

|

|

|

|

|

Dialysis |

|

|

|

|

|

|

|

|

|

|

Recovery |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset |

|

Auto reset of BP, SP and CLV |

Note |

By the alarm actuation, upper/lower alarm limits of |

||||||

|

Press [RESET] SW to reset UF stop. |

venous pressure become error free. |

|

|||||||

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

Simultaneous actuation of this alarm with venous pressure min alarm

Check: See E14 Venous pressure min alarm.

Action: See E14 Venous pressure min alarm.

|

Action: Adjust pressure in closed line. |

|

Occlusion of [RV2] |

If adjustment is impossible, clean [RV2] by rinsing after |

|

|

disassembling or replace it with new one. |

|

|

Check: Check no dialysate pressure change by clamping [V4] line with |

|

|

forceps. |

|

Leak from [V4] |

|

|

|

Action: In the case of no change, clean [V4] by rinsing after |

|

|

disassembling or replace it with new one. |

|

Opening of [V4] due to failure of [FSW] |

Check: See E44 AIR ELIMINATION TANK ERROR |

|

The opening may be simultaneously |

||

|

||

caused with E44 AIR ELIMINATION |

Action: See E44 AIR ELIMINATION TANK ERROR |

|

TANK ERROR |

||

|

||

Leak from [V6] and [V8] |

Action: Repair [V6] and [V8] or replace them with new ones. |

|

Excess occlusion in dialyzer |

Action: Replace dialyzer with new one if required. |

E11 VENOUS PRESSURE MAX LIMIT

Detection |

|

Venous pressure of +400mmHg |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Detection |

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

Reset |

|||

process |

alarm |

|

|

|||||||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||

Dialysis wait |

○ (7 times) |

UF stop |

|

|

○ |

― |

○ |

|||

Rinse |

|

|

↑ |

|

|

|

|

|

|

|

Rinse end |

↑ |

|

|

|

|

|

|

|||

Air purge |

|

|

↑ |

|

|

|

|

|

|

|

Dialysis wait |

○ (Continuous) |

|

|

|

|

|

|

|||

Preparation |

↑ |

|

|

|

|

|

|

|||

Prep. end |

|

|

↑ |

|

|

|

|

|

|

|

Dialysis |

|

|

↑ |

|

|

|

|

|

|

|

Recovery |

|

|

↑ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset |

|

Press [RESET] SW to recover. |

Note |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

|

Folding or occlusion of blood line |

|

|

between Venous Drip Chamber and |

Action: Remove the trouble cause. |

|

patient or occlusion of the line with |

||

|

||

Robert clamp |

|

|

Thrombus formed at mesh of venous |

Action: Remove thrombus or replace blood line with new one. |

|

drip chamber or at shunt connector |

||

|

||

Error occurrence during single needle |

Action: Set upper pressure change limit of SN correctly. |

|

dialysis |

|

|

|

Check: Disconnect blood line from venous pressure inlet port to |

|

|

expose to atmosphere and check indicated venous pressure is |

|

Failure of venous pressure sensor |

nearly 0mmHg. |

|

board |

|

|

|

Action: If nearly 0mmHg is not indicated, calibrate the board. |

|

|

If calibration is impossible, replace the board with new one. |

E12 VENOUS PRESSURE MIN LIMIT

Detection |

|

Venous pressure of -400mmHg |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Detection |

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

Reset |

|||

process |

alarm |

|

|

|||||||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||

Dialysis wait |

○ (7 times) |

UF stop |

|

|

○ |

― |

○ |

|||

Rinse |

|

|

↑ |

|

|

|

|

|

|

|

Rinse end |

↑ |

|

|

|

|

|

|

|||

Air purge |

|

|

↑ |

|

|

|

|

|

|

|

Dialysis wait |

○ (Continuous) |

|

|

|

|

|

|

|||

Preparation |

↑ |

|

|

|

|

|

|

|||

Prep. end |

|

|

↑ |

|

|

|

|

|

|

|

Dialysis |

|

|

↑ |

|

|

|

|

|

|

|

Recovery |

|

|

↑ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset |

|

Press [RESET] SW to recover. |

Note |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

|

Simultaneous occurrence of this error |

Action: Remove cause of dialysate related error. |

|

with dialysate related error |

|

|

Simultaneous occurrence of this error |

Action: Remove cause of arterial pressure related error |

|

with arterial pressure related error |

||

|

||

Press of DRAIN SW without removing |

|

|

coupler of dialyzer under occluding |

Note: DRAIN SW operation-miss |

|

venous line with Robert clamp |

|

|

|

Check: Disconnect blood line from venous pressure inlet port to |

|

|

expose to atmosphere and check indicated venous pressure is |

|

Failure of venous pressure sensor |

nearly 0mmHg. |

|

board |

|

|

|

Action: If nearly 0mmHg is not indicated, calibrate the board. |

|

|

If calibration is impossible, replace the board with new one. |

E13 VENOUS PRESSURE MAX ALARM

Detection |

|

Venous pressure of set upper alarm limit |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Detection |

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

|

Reset |

|||

process |

alarm |

|

|

|

|||||||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||

Dialysis wait |

○ (Continuous) |

UF stop |

|

|

○ |

― |

|

○ |

|||

Preparation |

|

|

|

|

|

|

|

|

|||

Prep. end |

|

|

|

|

|

|

|

|

|

|

|

Dialysis |

|

|

|

|

|

|

|

|

|

|

|

Recovery |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset |

|

Press [RESET] SW to recover. |

Note |

By the alarm actuation, upper/lower alarm limits of |

|||||||

|

dialysate pressure become error free. |

|

|||||||||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

|

Check: Check shunt occlusion or blood line folding. |

Occlusion of venous line. |

|

|

Action: Remove the trouble. |

|

Check: Check shunt occlusion or blood line folding. |

Occlusion of arterial line |

|

|

Action: Remove the trouble. |

Venous pressure change due to patient |

Action: If the change is significant, raise somewhat upper alarm limit of |

movement |

venous pressure at discretion of doctor. |

|

Check: Check whether discharge flow rate, pressure applied to rolling |

|

tube and rotor rotation of blood pump are normal. |

Significant discharge pressure change |

|

of blood pump |

Action: Adjust the occlusion or the pump rpm correctly. |

|

If adjustment is impossible, replace the pump or sub-board |

|

with new one. |

E14 VENOUS PRESSURE MIN ALARM

Detection |

|

Venous pressure of set lower alarm limit |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Detection |

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

|

Reset |

|||

process |

alarm |

|

|

|

|||||||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||

Dialysis wait |

○ (Continuous) |

UF stop |

|

|

○ |

― |

|

○ |

|||

Preparation |

|

|

|

|

|

|

|

|

|||

Prep. end |

|

|

|

|

|

|

|

|

|

|

|

Dialysis |

|

|

|

|

|

|

|

|

|

|

|

Recovery |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset |

|

Press [RESET] SW to recover. |

Note |

By the alarm actuation, upper/lower alarm limits of |

|||||||

|

dialysate pressure become error free. |

|

|||||||||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

Blood pressure drop of patient

Action: Stop UF and monitor patient condition.

Correct if set lower alarm limit of venous pressure is incorrect.

Check: Check no introduction of blood in venous pressure sensor line.

Dislodgment of venous line from |

|

venous pressure inlet port |

Action: When blood is not introduced in the line, connect venous line |

|

to the port. If introduced, replace the sensor line with new one. |

|

Check: Check shunt occlusion or venous line folding. |

Occlusion of venous line |

|

|

Action: Remove the trouble. |

|

Check: Check shunt occlusion or arterial line folding. |

Occlusion of arterial line. |

|

|

Action: Remove the trouble. |

Venous pressure change due to patient |

Action: If the change is significant, lower somewhat lower alarm limit |

movement |

of venous pressure at discretion of doctor. |

|

Check: Check whether discharge flow rate, pressure applied to rolling |

|

tube and rotor rotation of blood pump are normal. |

Significant discharge pressure change |

|

of blood pump |

Action: Adjust the occlusion or the pump rpm correctly. |

|

If adjustment is impossible, replace the pump or sub-board |

|

with new one. |

E15 ARTERIAL PRESSURE MAX LIMIT

Detection |

|

Arterial pressure of +400mmHg |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Detection |

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

Reset |

|||

process |

alarm |

|

|

|||||||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||

Dialysis wait |

○ ( times) |

UF stop |

|

|

○ |

― |

○ |

|||

Rinse |

|

|

↑ |

|

|

|

|

|

|

|

Rinse end |

↑ |

|

|

|

|

|

|

|||

Air purge |

|

|

↑ |

|

|

|

|

|

|

|

Dialysis wait |

○ (Continuous) |

|

|

|

|

|

|

|||

Preparation |

↑ |

|

|

|

|

|

|

|||

Prep. end |

|

|

↑ |

|

|

|

|

|

|

|

Dialysis |

|

|

↑ |

|

|

|

|

|

|

|

Recovery |

|

|

↑ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset |

|

Press [RESET] SW to recover. |

Note |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

|

Simultaneous actuation of this error |

Action: Remove cause of dialysate pressure related error. |

|

with dialysate pressure related error |

|

|

Simultaneous actuation of this error |

Action: Remove cause of venous pressure related error. |

|

with venous pressure related error |

|

|

Folding or occlusion of blood line |

|

|

between arterial Drip chamber and |

Action: Remove the trouble cause. |

|

dialyzer or occlusion of the line with |

||

|

||

Robert clamp |

|

|

Folding or occlusion of blood line |

|

|

between venous Drip chamber and |

Action: Remove the trouble cause. |

|

patient or occlusion of the line with |

||

|

||

Robert clamp |

|

|

Thrombus formed at mesh of arterial |

Action: Remove thrombus or replace blood line with new one. |

|

drip chamber or |

||

|

||

|

Check: Disconnect blood line from arterial pressure inlet port to |

|

|

expose to atmosphere and check indicated arterial pressure is |

|

Failure of arterial pressure sensor |

nearly 0mmHg. |

|

board |

|

|

|

Action: If nearly 0mmHg is not indicated, calibrate the board. |

|

|

If calibration is impossible, replace the board with new one. |

E16 ARTERIAL PRESSURE MIN LIMIT

Detection |

|

Arterial pressure of -400mmHg |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Detection |

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

Reset |

|||

process |

alarm |

|

|

|||||||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||

Dialysis wait |

○ ( times) |

UF stop |

|

|

○ |

― |

○ |

|||

Rinse |

|

|

↑ |

|

|

|

|

|

|

|

Rinse end |

↑ |

|

|

|

|

|

|

|||

Air purge |

|

|

↑ |

|

|

|

|

|

|

|

Dialysis wait |

○ (Continuous) |

|

|

|

|

|

|

|||

Preparation |

↑ |

|

|

|

|

|

|

|||

Prep. end |

|

|

↑ |

|

|

|

|

|

|

|

Dialysis |

|

|

↑ |

|

|

|

|

|

|

|

Recovery |

|

|

↑ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset |

|

Press [RESET] SW to recover. |

Note |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

Condition or cause |

|

Check and action |

|

Simultaneous actuation of this error |

Action: Remove cause of dialysate pressure related error. |

||

with dialysate pressure related error |

|

||

Thrombus formed at arterial |

shunt |

Action: Remove thrombus or replace blood line with new one. |

|

connector |

|

||

|

|

||

Folding or occlusion of blood line |

|

||

between arterial drip chamber |

and |

Action: Remove the trouble cause. |

|

patient or occlusion of the line with |

|||

|

|||

Robert clamp |

|

|

|

|

|

Check: Disconnect blood line from arterial pressure inlet port to |

|

|

|

expose to atmosphere and check indicated arterial pressure is |

|

Failure of arterial pressure sensor |

nearly 0mmHg. |

||

board |

|

|

|

|

|

Action: If nearly 0mmHg is not indicated, calibrate the board. |

|

|

|

If calibration is impossible, replace the board with new one. |

|

E17 ARTERIAL PRESSURE MAX ALARM

Detection |

|

Arterial pressure of set upper alarm limit |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Detection |

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

|

Reset |

|||

process |

alarm |

|

|

|

|||||||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||

Dialysis wait |

○ (Continuous) |

UF stop |

|

|

○ |

― |

|

○ |

|||

Preparation |

|

|

|

|

|

|

|

|

|||

Prep. end |

|

|

|

|

|

|

|

|

|

|

|

Dialysis |

|

|

|

|

|

|

|

|

|

|

|

Recovery |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset |

|

Press [RESET] SW to recover. |

Note |

By the alarm actuation, set upper/lower alarm limits |

|||||||

|

of dialysate pressure become error free. |

|

|||||||||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

|

Check: Check shunt occlusion and blood line folding. |

Occlusion of venous line. |

|

|

Action: Correct the trouble. |

|

Check: Check shunt occlusion and blood line folding. |

Occlusion of arterial line. |

|

|

Action: Correct the trouble. |

Arterial pressure change due to patient |

Action: If the change is significant, raise set upper alarm limit of |

movement |

arterial pressure somewhat at discretion of doctor. |

|

Check: Check whether discharge flow rate, pressure applied to rolling |

|

tube and rotor rotation of blood pump are normal. |

Significant discharge pressure change |

|

of blood pump |

Action: Adjust the occlusion or the pump rpm correctly. |

|

If adjustment is impossible, replace the pump or sub-board |

|

with new one. |

E18 ARTERIAL PRESSURE MIN ALARM

Detection |

|

Arterial pressure of set lower alarm limit |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Detection |

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

|

Reset |

|||

process |

alarm |

|

|

|

|||||||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||

Dialysis wait |

○ (Continuous) |

UF stop |

|

|

○ |

― |

|

○ |

|||

Preparation |

|

|

|

|

|

|

|

|

|||

Prep. end |

|

|

|

|

|

|

|

|

|

|

|

Dialysis |

|

|

|

|

|

|

|

|

|

|

|

Recovery |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset |

|

Press [RESET] SW to recover. |

Note |

By the alarm actuation, set upper/lower alarm limits |

|||||||

|

of dialysate pressure become error free. |

|

|||||||||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Condition or cause |

Check and action |

Blood pressure drop of patient

Action: Stop UF and monitor patient condition.

Correct if set lower alarm limit of venous pressure is incorrect.

Check: Check no introduction of blood in arterial pressure sensor line.

Dislodgment of blood line form arterial

pressure inlet port Action: When blood is not introduced in the line, connect arterial line to the port. If introduced, replace the arterial line with new one.

Check: Check shunt occlusion and blood line folding.

Occlusion of venous line.

|

Action: Correct the trouble. |

|

|

Check: Check shunt occlusion and blood line folding. |

|

Occlusion of arterial line. |

|

|

|

Action: Correct the trouble. |

|

Arterial pressure change due to patient |

Action: If the change is significant, raise set upper alarm limit of |

|

movement |

arterial pressure somewhat at discretion of doctor. |

|

|

Check: Check whether discharge flow rate, pressure applied to rolling |

|

|

tube and rotor rotation of blood pump are normal. |

|

Significant discharge pressure change |

Action: Adjust the occlusion or the pump rpm correctly. |

|

of blood pump |

||

If adjustment is impossible, replace the pump or sub-board |

||

|

||

|

with new one |

E19 TMP ALARM

Detection TMP (VP - DP) of set alarm limit

Detection |

Audible |

Dialysate line function |

|

|

BP/SP stop |

CLV function |

Reset |

||

process |

alarm |

|

|

||||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Dialysis |

|

○ (Continuous) |

UF stop |

|

|

○ |

○ |

○ |

|

Recovery |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reset |

|

Press [RESET] SW to recover. |

Note |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Condition or cause |

|

Check and action |

|

Excess occlusion in dialyzer |

|

Action: Replace dialyzer with new one at discretion of doctor. |

||

Lower setting of TMP alarm limit |

|

Action: Set TMP to appropriate value. |

||

E09 |

DIALYSATE |

PRESSURE |

MAX |

|

ALARM |

|

|

|

|

E10 |

DIALYSATE |

PRESSURE |

MIN |

Action: See E09 DIALYSATE PRESSURE MAX ALARM |

ALARM |

|

|

See E10 DIALYSATE PRESSURE MIN ALARM |

|

E13 VENOUS PRESSURE MAX ALARM |

See E13 VENOUS PRESSURE MAX ALARM |

|||

Simultaneous actuation of this alarm |

See E14 VENOUS PRESSURE MIN ALARM |

|||

with E14 VENOUS PRESSURE MIN |

|

|||

ALARM |

|

|

|

|

E07 DIALYSATE PRESSURE MAX LIMIT |

|

|||

E08 DIALYSATE PRESSURE MIN LIMIT |

Action: See E07 DIALYSATE PRESSURE MAX LIMIT. |

|||

E11 VENOUS PRESSURE MAX LIMIT |

See E08 DIALYSATE PRESSURE MIN LIMIT. |

|||

Simultaneous actuation of this alarm |

See E11 VENOUS PRESSURE MAX LIMIT. |

|||

with |

E12 VENOUS PRESSURE |

MIN |

See E12 VENOUS PRESSURE MIN LIMIT. |

|

LIMIT |

|

|

|

|

E20 DIALYSATE CONDUCTIVITY MAX ALARM

Detection |

|

Dialysate conductivity of upper alarm limit |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detection |

|

Audible |

|

|

Dialysate line function |

|

|

BP/SP stop |

CLV function |

|

Reset |

|||

process |

|

alarm |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Dialysis |

|

○ (Continuous) |

|

Auto bypass |

|

|

― |

― |

|

― |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Press [RESET]SW. |

|

|

|

|

|

|

|

|

|

||||

Reset |

Auto reset after release from alarm condition for 10 |

Note |

|

|

|

|

||||||||

|

sec. |

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

Condition or cause |

|

|

|

|

|

Check and action |

|

|||||

Abnormal actual conductivity |

|

|

Check: Take dialysate sample from [SL] to measure actual |

|||||||||||

|

|

|

|

|

|

|

|

conductivity by specified method. |

|

|||||

○No adjustment of conductivity |

|

|

Action: Set conductivity correctly and calibrate indicated conductivity |

|||||||||||

|

|

|

|

|

|

|

|

in maintenance mode 5 screen. |

|

|||||

○Failure of main board |

|

|

Check: See E33 VISCOUS PUMP DRIVING ERROR(VPa) and |

|

||||||||||

|

|

|

|

|

|

|

|

E34 VISCOUS PUMP DRIVING ERROR(VPb). |

|

|||||

|

|

|

|

|

|

|

|

Action: See E33 VISCOUS PUMP DRIVING ERROR(VPa) and |

|

|||||

|

|

|

|

|

|

|

|

E34 VISCOUS PUMP DRIVING ERROR(VPb). |

|

|||||

○Failure of [V13] or [V14] |

|

|

Action: Repair [V13] or [V14] (V15)) or replace it with new one. |

|||||||||||

○Failure of [V2] or [V3] |

|

|

Action Repair [V2] or [V3] or replace it with new one. |

|

||||||||||

○Higher or lower priming flow rate |

|

|

Action: Adjust the flow rate to 700-750mL/min. |

|

||||||||||

○Failure of [C2] |

|

|

Action: Replace [C2] with new one. |

|

|

|

||||||||

○Folding, |

occlusion or collapsing |

of |

Action: Correct the trouble. |

|

|

|

||||||||

concentrate line tube |

|

|

|

|

|

|

|

|

|

|||||

E20 DIALYSATE CONDUCTIVITY MAX ALARM

Condition or cause |

|

Check and action |

Normal actual conductivity |

|

Check: Take dialysate sample from [SL] to measure conductivity by |

|

|

specified method. |

○[CD] electrode contaminated with dirt |

Action: Rinse the electrode with acetic acid followed by water rinsing |

|

such as CaCO3 or leak from |

sufficiently. |

|

conductivity sensor |

|

If the dirt can not be removed, use specified detergent such |

|

|

as CARON or SYUNMA to remove it after disassembling |

|

|

conductivity sensor. |

○Incorrect [CD] terminal connection |

Check: Check no miss-wiring, loosening, corrosion and |

|

|

|

disconnection of TM1 CD terminal of main board. |

|

|

Action: If loosened, tighten the connection securely. |

|

|

If miss-wired, correct. |

|

|

If corroded or disconnected, replace harness with mew one. |

○Internal disconnection or short circuit |

Check: After disconnecting TM1 CD terminal from main board, |

|

of [CD] harness |

|

measure resistance between [CD] and [GND] to check no short |

|

|

circuit, disconnection and fluctuation of measured resistance. |

|

|

Action: Replace [CD] harness with new one. |

○Failure of main board |

|

Check: Change ambient temperature of main board to check whether |

|

|

conductivity and temperature indications are changed. |

|

|

Action: If incorrectly indicated, replace main board with new one. |

When Na infusion unit (option) is used: |

|

|

○Higher or lower concentration |

of Na |

Action: Use 10% Na concentrate. |

concentrate |

|

|

|

|

|

○ Use of other chemical |

added |

Action: Set proper upper alarm limit of conductivity by considering |

concentrate |

|

|

|

electrolyte concentration. |

|

|

|

|

○Use of other concentrate |

|