Nipro Surdial 55+ Maintenance manual 2

Maintenance tool List

Caution

Use the following tools or equal tools for maintenance.

Each part or a part of each part may be changed for improvement without notice. Be forewarned that a part of using product may be differed from this document.

Name of product |

Gauge |

|

|

Flow meter |

Manufacturer RYUKI |

|

Model PL4D3P |

|

Measure range 300 1500mL/min |

|

|

Circuit tester |

Manufacturer FLUKE |

|

Model 87V |

|

|

SPEC

Function |

Range |

Reference accuracy |

|

|

|

|

|

DC |

600.0mV, 6.000V, 60.00V, |

0.05% |

|

600.0V, 1000V |

|||

|

|

||

|

|

|

|

AC |

600.0mV, 6.000V, 60.00V, |

0.7% |

|

600.0V, 1000V |

True RMS value |

||

|

|||

|

|

|

|

DC |

600.0μA, 6000μA, 60.00mA, |

0.2% |

|

600.0mA, 6.000A, 10.00A |

|||

|

|

||

|

|

|

|

AC |

600.0μA, 6000μA, 60.00mA, |

1.0% |

|

600.0mA, 6.000A, 10.00A |

True RMS value |

||

|

|||

Resistance |

600.0Ω, 6.000kΩ, 60.00kΩ |

0.2% |

|

|

600.0kΩ, 6.000MΩ, 50.00MΩ |

|

● Use a tester which is “True RMS TYPE” to measure precise alternating current value.

* RMS: Root Mean Square

1/

Name of product |

Gauge |

|

|

Probe |

Name of product DIY SMD Test clip |

|

Manufacturer Tokiwa |

|

Model 5243-Red 5243-Black |

|

Name of product Chip Jack |

|

Manufacturer SATO PARTS |

|

Model TJ-2167 (Red |

|

TJ-2167 Black |

|

|

Stopwatch |

Manufacturer CASIO |

|

Model HS-3C-8AJH |

|

|

Electronic balance |

Manufacturer SINKO DENSHI |

|

Model AG-5000 |

|

Measure range 0 5000g |

|

-5000 0g |

|

|

Container |

SPEC About |

|

|

Container |

SPEC About |

|

|

2/

Name of product |

Gauge |

|

|

|

|

Slide gauge |

Manufacturer Mitutoyo |

|

|

Model N15 |

|

|

Measure range 0 150mm |

|

|

|

|

Calculator |

― |

|

|

|

|

Torque screwdriver |

Name of product |

Torque |

|

screwdriver |

|

|

Manufacturer KANON |

|

|

Model 20LTDK |

|

|

SPEC 4 20kgf cm |

|

|

Name of product Bit |

|

|

Manufacturer VESSEL |

|

|

Model B35-2050G |

|

|

|

|

Torque wrench |

Name of product Torque wrench |

|

|

Manufacturer KANON |

|

|

Model 60LCK |

|

|

SPEC 20 60kgf cm |

|

|

|

|

|

Manufacturer Copal Electronics |

|

Digital manometer |

Model PG-100 102GH |

|

|

Measure range 0 735mmHg |

|

|

|

|

3/

Name of product of product |

Gauge |

|

|

Analog manometer |

Manufacturer KOGANEI |

|

Measure range 0 1MPa |

|

|

Piping material |

Name of product of product T-tube |

|

Manufacturer SHIBUYA |

|

Model 93613911100* |

|

Name of product of product Silicon |

|

tube |

|

SPEC d5×D11×L150 |

|

Name of product of product |

|

TE-6-100 |

|

SPEC d4×D6×L100 |

|

|

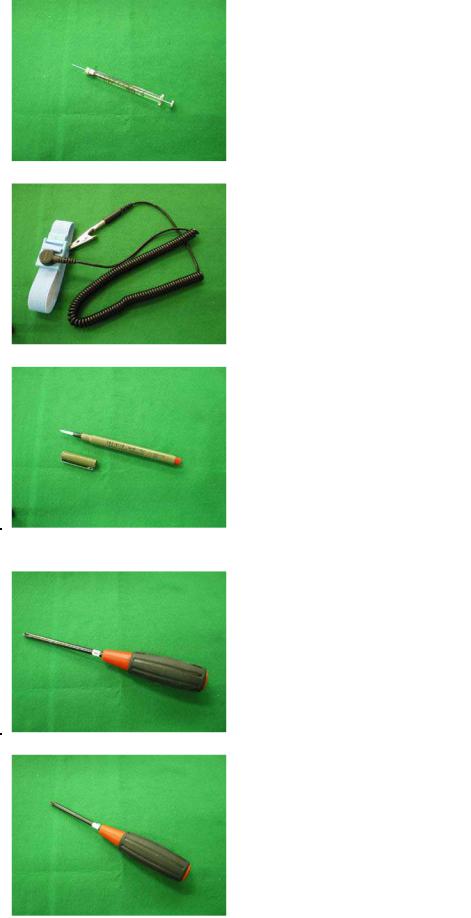

Syringe |

Manufacturer NIPRO |

|

SPEC mL |

|

|

Blood circuit |

Manufacturer NIPRO |

|

SPEC φ8.00×φ12.00±0.15mm |

|

L 210mm |

|

T 2.00±0.1mm |

|

|

Dialyzer |

Manufacturer NIPRO |

|

|

4/

Name of product of product |

Gauge |

|

|

Micro syringe |

Manufacturer HAMILTON |

|

Model 710RN |

|

SPEC 10 100μL |

|

|

Wrist strap |

Manufacturer HOZAN |

|

Model F-153 |

|

|

Ceramic driver |

Manufacturer ENGINEER |

|

Model DA-55 |

|

|

Driver |

Manufacturer VESSEL |

|

Model 600P.2-100 |

|

|

Driver |

Manufacturer VESSEL |

|

Model 600P.1-75 |

|

|

5/

Name of product of product |

Gauge |

|

|

Driver |

Manufacturer VESSEL |

|

Model 600 6-100 |

|

|

Replacement Driver |

Manufacturer VESSEL |

|

Model D-2 |

|

|

Power socket driver |

Manufacturer VESSEL |

|

Model 4100 7-125 |

|

|

Power socket driver |

Manufacturer VESSEL |

|

Model 4100 8-125 |

|

|

Pean |

Manufacturer REDA |

|

Model 13710-18 |

|

|

6/

Name of product of product |

Gauge |

|

|

Needle-nose pliers |

Manufacturer HOZAN |

|

Model P-15-125 |

|

|

Nipper |

Manufacturer HOZAN |

|

Model N-4-125 |

|

|

Tweezers |

Manufacturer HOZAN |

|

Model P-887 |

|

|

Spanner |

Manufacturer HOZAN |

|

Model W-521 |

|

|

Hexagonal wrench |

Manufacturer PB |

|

Model 211HC-6 |

|

|

7/

Name of product of product |

Gauge |

|

|

Monkey wrench |

SPEC mm |

|

|

Pliers |

SPEC mm |

|

|

Temperature calibrator |

Manufacturer SHIBUYA |

|

Code 0-506-001 |

|

|

Conductivity calibrator |

Manufacturer SHIBUYA |

|

Code 0-506-007 |

|

|

Cartridge for calibration |

Manufacturer SHIBUYA |

|

Code 4-30-77 |

|

|

8/

Name of product of product |

Gauge |

|

|

MOLYKOTE grease |

Manufacturer MOLYKOTE |

|

Model BR2-PLUS |

|

|

Bond |

Manufacturer Three Bond |

|

Model 1401C |

|

|

Silicon sealant |

Manufacturer GE TOSHIBA Silicon |

|

Model TSE382-W |

|

|

Seal tape |

Gauge 0.1mm×8mm |

|

|

Seal tape |

Gauge 0.1mm×13mm |

|

|

9/

Service Manual ist Machine Parts

o. |

enti ication |

|

|

ocument |

ame |

ption |

||

|

um er |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SM |

Two wa |

|

Solenoi |

|

alve |

|

|

|

|

|

|

|

|

|

|

|

|

SM |

Two wa |

|

Solenoi |

|

alve |

hemical Solution |

|

|

|

|

|

|

|

|

||

|

SM |

eparin Pump |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

SM |

eater |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SM |

Relie |

|

alve |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SM |

ham er |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SM |

Magnet |

|

ear Pump |

|

|

|

|

|

|

|

|

|

|

|||

|

SM |

Temperature Sensor |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

SM |

lamp |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SM |

ir u |

|

le Sensor |

|

|

|

|

|

|

|

|

|

||||

|

SM |

on uctivit Sensor |

|

|

||||

|

|

|

|

|

|

|

||

|

SM |

low Sensor |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

SM |

loo |

Pump |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SM |

Re ucing |

alve |

|

|

|

|

|

|

|

|

|

|

||||

|

SM |

ir Elimination Tan |

|

|

||||

|

|

|

|

|

|

|

||

|

SM |

egassing Tan |

|

|

|

|

||

|

|

|

|

|

|

|

||

|

SM |

lowmeter |

|

|

|

|

||

|

|

|

|

|

|

|||

|

SM |

loo |

ea age Sensor |

|

|

|||

|

|

|

|

|||||

|

SM |

ial sate Pressure Sensor |

|

|||||

|

|

|

|

|

|

|

|

|

|

SM |

ee le |

|

alve |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SM |

Piston |

Pump |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

SM |

Relie |

Solenoi |

alve |

|

|

||

|

|

|

|

|

||||

|

SM |

pow er |

oncentrate Solution air Elimination |

|

||||

|

|

Tan |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

SM |

pow er |

artri ge |

ol er |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

aution: |

|

|

Each |

part an |

part o some parts can |

e mo i ie |

or improvement without prece ing |

|

noti |

ication. Therewith our un erstan ing will |

e requeste |

in a vance i the parts |

||

o the pro uct |

ou are using are i |

erent rom those liste |

a ove. |

||

|

|

Tightening Torque |

ist |

|

|

|

|

|

||||

Tightening torque |

|

|

|

|

|

|

|

|

|

|

|

|

● Torque speci ie in the main o |

o the service manual is as |

ollows: |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|||

|

um er |

|

|

Usage |

|

|

|

Requirement |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SM** |

|

Tighten screws |

an |

. |

|

. |

m |

g |

cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SM** |

|

Tighten screw |

. |

|

|

. |

m |

g |

cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SM** |

|

Tighten screw |

. |

|

|

|

m |

g |

cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tighten hose opening |

. |

|

. |

m |

g |

cm |

|

|||

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SM** |

|

Tighten screw |

. |

|

|

. |

m |

g |

cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tighten screw |

. |

|

|

. |

m |

g |

cm |

|

||

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SM** |

|

Tighten screws |

an |

. |

|

. |

m |

g |

cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

SM** |

|

Tighten hose opening |

. |

|

|

m |

g |

cm |

|

||

|

|

|

|

|

|

|

|

|

ter tightening |

|

||

|

|

|

|

|

|

|

|

|

|

|||

|

SM** |

|

Tighten nut |

|

. |

|

|

manuall |

give |

|

||

|

|

|

|

|

|

|

|

revolution |

|

tool. |

|

|

|

|

|

|

|

|

|

|

|

||||

|

SM** |

|

ttach to nee le valve evice. |

|

m |

g |

cm |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SM** |

|

Tighten screw |

. |

|

|

. |

m |

g |

cm |

|

|

|

|

|

|

|

|

|

||||||

● or tightening torque unspeci ie |

in the service manual |

re er to the |

ollowings: |

|||||||||

|

|

|

|

|

|

|

|

|

||||

|

ect |

|

|

pplication |

|

|

Requirement |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Metal |

|

Tighten M |

screw an |

nut. |

|

. |

m |

g |

cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Metal |

|

Tighten M . |

screw an |

nut. |

|

. |

m |

g |

cm |

|

|

|

Metal |

|

Tighten M . |

screw an |

nut. |

|

. |

m |

g |

cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Metal |

|

Tighten M |

screw an |

nut. |

|

. |

m |

g |

cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Metal |

|

Tighten M |

screw an |

nut. |

|

. |

m |

g |

cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Metal |

|

Tighten M |

screw an |

nut. |

|

. |

m |

g |

cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Metal |

|

Tighten M |

screw an |

nut. |

|

. |

m |

g |

cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Resin |

|

Tighten M |

screw an |

nut. |

|

. |

m |

g |

cm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

● Ensure the a ove requirement so as not to tighten them too much or tighten them less than nee e .

BHSM01-001

. Two wa valve

. . verall con iguration S |

*** |

Assy

. . ist o |

components |

|

S |

S |

|

|

|

||

ormal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

o |

|

|

ame |

|

|

Mo el o. |

Torque |

ote |

|

|

|

|

|

|

|

|

|

|

|

|

ctuator |

ss |

|

Y |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ore |

|

|

|

E |

|

|

|

|

|

Pac less pipe |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Soun |

ea ening sheet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Spring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plunger |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

iaphragm presser |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

|

iaphragm |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

alve |

o |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screw |

|

|

M |

P |

|

. |

m |

|

|

|

|

|

|

|

|

|

|

|

|

Two wa |

|

valve |

S |

|

S |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 1

|

|

|

|

|

|

|

|

|

|

|

BHSM01-001 |

|

. . |

|

ist o |

components |

S |

S |

|

|

|

|

|

|

|

ot |

isin ection with citric aci |

SSY |

ial sate low |

SSY an high low SSY |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

o |

|

|

|

ame |

|

Mo el |

o. |

|

Torque |

|

ote |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ctuator |

ss |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ore |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Pac less pipe |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Soun |

ea ening sheet |

|

|

|

|

|

|

|

|

|

|

|

Spring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plunger |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

iaphragm presser |

|

|

|

|

|

|

|

|

||

|

|

iaphragm |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

alve |

o |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screw |

|

|

M P |

|

|

|

. m |

|

|

|

|

|

Two wa |

|

valve |

S |

S |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 2

BHSM01-001

. . verall con iguration S |

*** |

|

|

|

|

|

|

|

. . |

|

ist o |

components |

S |

S |

|

|

|

|

|

|

|

ot |

isin ection with citric aci |

SSY |

ial sate low SSY an |

high low SSY |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

o |

|

|

|

ame |

|

Mo el |

o. |

|

Torque |

|

ote |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ctuator |

ss |

Y |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ore |

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Pac less pipe |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Soun |

ea ening sheet |

|

|

|

|

|

|

|

|

|

|

|

Spring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plunger |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

iaphragm presser |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

iaphragm |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

alve |

o |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screw |

|

|

M |

P |

|

|

. |

m |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a |

a |

|

|

Two wa |

|

valve |

S |

S |

|

|

|

|

a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 3

|

|

|

|

|

|

|

|

|

|

|

BHSM01-001 |

|

. . |

|

ist o |

components |

S |

S |

|

|

|

|

|

|

|

ot |

isin ection with citric aci |

SSY |

ial sate low SSY an |

high low SSY |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

o |

|

|

|

ame |

|

Mo el |

o. |

|

Torque |

|

ote |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ctuator |

ss |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ore |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Pac less pipe |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Soun |

ea ening sheet |

|

|

|

|

|

|

|

|

|

|

|

Spring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plunger |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

iaphragm presser |

|

|

|

|

|

|

|

|

||

|

|

iaphragm |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

alve |

o |

|

|

|

|

|

|

|

|

|

|

|

Screw |

|

|

M |

P |

|

|

. m |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Two wa |

|

valve |

S |

S |

|

|

|

a |

a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

. . |

|

ist o |

components |

S |

S P |

|

|

|

|

|

||

ot |

isin ection with citric aci |

SSY |

ial sate low |

SSY an high low SSY |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

o |

|

|

|

ame |

|

Mo el |

o. |

|

Torque |

|

ote |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ctuator |

ss |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ore |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Pac less pipe |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Soun |

ea ening sheet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Spring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plunger |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

iaphragm presser |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

iaphragm |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

alve |

o |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screw |

|

|

M |

P |

|

|

. |

m |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Two wa |

|

valve |

S |

S P |

|

|

|

|

a |

a |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 4

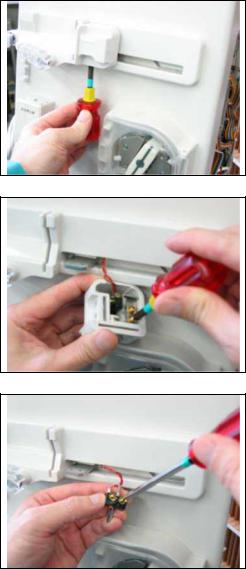

. . Removal |

installation |

llustration

BHSM01-001

Removal proce ure aution:

z |

e sure to turn |

the rea er. |

|

|

|

Remove the ront cover.

Remove the right an le t si e ace covers at the lower parts.

Remove the connector to the Two wa valve that is to e remove .

Shut o the silicon tu es on oth e ges |

a pean pincer |

an remove the silicon tu es. |

|

aution:

zPut waste cloths so that liqui s are not spille in the evice.

oosen the |

screws i ing the valve rac et an remove |

the Two wa |

valve together with it. |

Remove the Two wa valve o the valve rac et.

nstallation

nstall the valve in the reverse or er o the removal proce ure.

1 5

. . isassem l an assem l

llustration

BHSM01-001

isassem l

Remove the screws.

To e isassem le into the ollowings: ctuator ss

ore

Pac less pipe Spring Plunger

iaphragm presser iaphragm

alve |

o |

|

|

|

Ring |

in |

the cases o |

S |

*** t pes |

Remove the iaphragm |

o |

the plunger. |

||

|

|

|

ssem l |

|

ssem le the parts in the reverse or er o the isassem l proce ure.

aution:

z |

hen assem ling the |

iaphragm |

e sure to |

|

|

secure it tightl to the plunger |

rotating |

||

|

two or three times. Ma e sure that the screw |

|||

|

tightening torque is |

. |

m |

g cm . |

|

|

|

|

|

1 6

BHSM01-001

. . nspection an replacement

-Replace parts whose regular replacement perio has come.

- Ma e sure that no oreign o ect is insi e.

- Replace parts that have an mo i ication amage or mal unction.

. . on irmation proce ure

- |

n Maintenance |

“ peration Status ” manuall |

turn |

||||

|

|

the Two wa valve an |

con irm the operation |

||||

|

soun . |

|

|

|

|

|

|

- |

ttach pressure gauge on the |

si e o the Two wa |

|||||

|

valve |

an |

maintain it |

putting pressure o |

. MPa |

||

|

. |

g |

cm |

on the |

si e o the solenoi |

valve |

|

|

using s ringe |

with no |

current applie |

|

con irming there |

is no lea age. |

|

- |

on irm there is |

no lui |

lea age in operation. |

1 7

BHSM00-002

. Two wa Solenoi alve hemical Solution

. . verall con iguration

ssy

. . ist o |

components |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

o |

|

ame |

|

Mo el o. |

Torque |

ote |

|

|

|

|

|

|

|

|

|

|

ctuator ss |

Y |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ore |

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

Pac less pipe |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Soun |

ea ening sheet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Spring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plunger |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

iaphragm presser |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

iaphragm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

alve |

o |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screw |

|

M * |

P |

. |

m |

|

|

|

|

|

|

|

|

|

|

Two wa |

solenoi valve |

S |

S |

|

|

|

|

|

|

|

|

|

|

|

2 1

. . Removal an installation

llustration

BHSM00-002

Removal proce ure aution:

z |

e sure to turn |

the rea er. |

|

|

|

Remover the lower right si e ace cover

Remove the connector.

Shut o the silicon tu es on oth e ges o the valve a pean pincer an pull them out.

oosen screws that i the valve an remove it.

aution:

zPut waste cloths so that liqui s are not spille in the evice.

nstallation

nstall the valve in the reversal or er o the removal proce ure.

2 2

BHSM00-002

. . isassem l an assem l

llustration |

isassem l |

|

Remove the screws. |

|

|

|

|

To e |

isassem le into the ollowings: |

|

|

||||

ctuator |

ss |

|

|

|

|

|

|

ore |

|

|

|

|

|

|

|

Pac less pipe |

|

|

|

|

|

||

Spring |

|

|

|

|

|

|

|

Plunger |

|

|

|

|

|

|

|

iaphragm presser |

|

|

|

|

|

||

iaphragm |

|

|

|

|

|

|

|

alve |

o |

|

|

|

|

|

|

Ring |

|

|

|

|

|

|

|

Remove the |

iaphragm o |

the plunger. |

|

|

|

||

|

|

|

ssem l |

|

|

|

|

ssem le the parts in the reverse or er o |

the |

||||||

isassem l |

proce ure. |

|

|

|

|

||

|

|

|

aution: |

|

|

|

|

|

|

|

|

|

|

||

z |

hen assem ling |

the |

iaphragm |

e |

sure to |

||

secure it tightl |

to the plunger |

|

rotating |

||||

two or three times. Ma e sure that the |

|||||||

tightening torque o |

screws is . |

|

m |

g |

|||

|

cm . |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 3

BHSM00-002

. . nspection an replacement

-Replace parts whose regular replacement perio has come.

- Ma e sure that no oreign o ect is insi e.

- Replace parts that have an mo i ication amage or mal unction.

. . on irmation proce ure

- |

n Maintenance |

“ peration Status ” manuall turn |

|||||

|

|

the two wa |

solenoi |

valve an |

con irm the |

||

|

operation soun . |

|

|

|

|

||

- |

ttach pressure gauge on the |

si e o the two wa |

|||||

|

solenoi |

valve |

an |

maintain it |

putting pressure o |

||

|

. MPa |

. g |

cm |

on the |

si e o |

the solenoi |

|

|

valve |

using s ringe with no current applie |

|||||

|

con irming there is no lea age. |

|

|

||||

|

on irm there is no lui |

lea age in operation. |

|||||

2 4

BHSM01-003

. eparin Pump

. . verall con iguration

. . |

ist o |

components |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

o |

|

ame |

|

|

Mo el um er |

Torque |

|

ote |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pusher |

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

utton |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

oil spring |

|

|

o. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pin |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screw |

|

|

M |

|

. |

m |

ith a |

lat washer an |

a spring washer |

|

Metal |

itting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

arness |

presser |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screw |

|

|

M |

|

. |

m |

ith a |

lat washer an |

a spring washer |

|

Sensor |

rac |

et |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

imit switch |

|

SS |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Screw |

|

|

M |

. |

. |

m |

ith a |

lat washer an |

a spring washer |

3 1

|

|

|

|

|

|

|

|

|

|

|

|

|

BHSM01-003 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

o |

|

|

|

ame |

|

Mo el um er |

Torque |

|

|

ote |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Screw |

|

|

|

M |

|

. |

m |

ith a |

lat washer an |

a spring washer |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

S ringe |

presser |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sha |

t |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screw |

|

|

|

M |

|

. |

m |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

oil |

spring |

o. |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Stopper |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Screw |

|

|

|

M |

|

. |

m |

ith a |

lat washer an |

a spring washer |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

S ringe |

|

ase |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pac |

ing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screw |

|

|

|

M |

|

. |

m |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

hassis |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Motor |

plate |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Screw |

|

|

|

M |

|

. |

m |

ith a |

lat washer an |

a spring washer |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Stepping |

motor |

T |

M |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Screw |

|

|

|

M |

|

. |

m |

ith a |

lat washer an |

a spring washer |

|

||

|

Timing |

|

pulle |

|

|

|

|

Small |

in |

iameter |

|

|

||

|

Timing |

|

pulle |

|

|

|

|

arge |

in |

iameter |

|

|

||

|

Timing |

|

elt |

|

U |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Setscrew |

|

M |

|

. |

m |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Screw |

|

|

|

M |

|

. |

m |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sha |

t |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

al |

nut |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

lutch |

|

spring |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Spring |

|

case |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Screw |

|

|

|

M |

|

. |

m |

ith a |

lat washer an |

a spring washer |

|

||

|

Rotation |

etection |

|

|

|

|

|

|

|

|

|

|||

|

sensor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

og |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

earing |

|

|

R |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

ee |

screw |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

ousing |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ui |

e |

sha |

t |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

imit |

switch |

SS |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Screw |

|

|

|

M . |

|

. |

m |

ith a |

lat washer an |

a spring washer |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ut |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ever |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

. |

spring |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

eparin |

pump ss |

|

|

|

|

P |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 2

|

|

|

|

BHSM01-003 |

|

. . Removal an installation |

|

|

|

|

|

llustration |

Removal |

proce ure |

|||

|

|

aution: |

|||

|

|

|

|

|

|

|

z e |

sure to turn |

the |

rea er. |

|

|

|

|

|

|

|

|

Remove the right an le |

t si |

e ace covers at the |

||

|

upper |

parts. |

|

|

|

Remove the screw |

an then pusher |

. |

Remove the screw |

an then sensor rac et |

. |

Remove the screw |

|

an then limit switch |

o |

rom sensor rac |

et |

. |

|

3 3

|

|

|

|

|

BHSM01-003 |

Move the metal |

itting |

to |

the ull right. |

||

Remove |

the |

ollowings: |

|

|

|

U P sensor |

oar |

connector |

|

||

Motor |

rive |

connector |

P |

|

|

imit |

switch |

connector |

S |

S |

|

roun |

ing ca |

le |

|

|

|

Remove all the our screws that i the heparin pump.

raw out the heparin pump rom the le t si e o the evice.

nstallation

nstall the pump in the reverse or er o the removal proce ure.

3 4

BHSM01-003

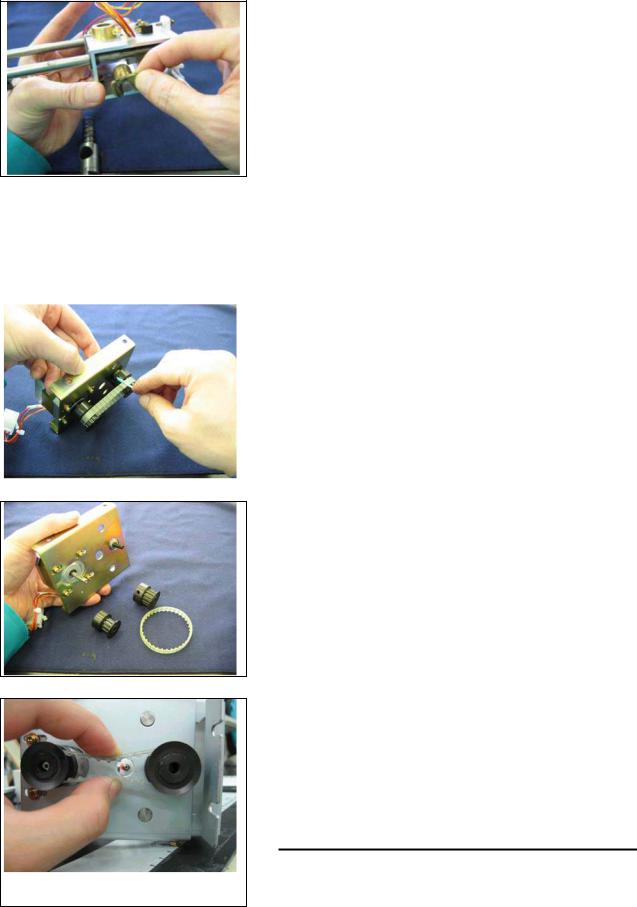

. . isassem l an |

assem l |

|

|

|

|

|

Replacement |

o |

hal nuts |

llustration |

|

isassem |

l |

|

|

|

oosen the screws that |

i |

og . |

|

|

|||

|

|

|

|

|

Remove the screw |

an then metal itting |

an |

harness presser |

. |

|

Remove the our screws o |

. |

isassem le |

the |

chassis |

an motor plate |

. |

|

Then remove |

the |

og |

. |

|

|

3 5

BHSM01-003

Pull out the earing |

. |

Push in the sha t the whole set o screw .

to ma |

e it ree |

an then remove |

housing |

parts o |

rom the ee |

Remove the screw |

an then plate |

an plate |

. |

|

|

hile hol ing the housing |

|

push the nut |

in the |

|||||||

housing |

towar |

the |

irection that |

. . spring |

||||||

shrin s |

an |

then |

insert |

a |

tool li e screw river |

|||||

etween the housing |

an |

lever |

to eep the . . |

|||||||

spring |

in |

the |

shrin ing |

state. |

|

|

|

|||

Unless there is a space |

etween the lever |

an |

hal |

|||||||

hut |

the hal |

nut |

never turns aroun |

an |

it |

|||||

is impossi le to remove it |

an so it is necessar |

|||||||||

to maintain this |

status. |

|

|

|

|

|

||||

3 6

BHSM01-003

Rotate |

the |

sha t |

or |

egrees an then pull |

out the |

hal |

nut |

in |

the sha t. |

|

|

|

|

|

ssem l |

|

|

|

|

ssem |

le |

the |

parts |

in the |

reverse or |

er o |

the |

|

isassem |

l proce |

ure. |

|

|

|

||

|

|

|

|

|

Motor |

Part |

|

|

llustration |

|

|

|

isassem l |

|

|

||

|

oosen |

the screw |

an |

then remove |

the |

timing |

||

|

||||||||

|

pulle |

s |

an |

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Remove |

the screw |

an remove motor |

rom the |

|

motor |

plate |

. |

|

|

ssem l

nstall the parts in the reversal o the isassem l

proce ure. |

|

|

|

|

Ma |

e sure that the tension o |

timing |

elt |

is |

to |

mm when pinche in the |

mi le |

ingers. |

|

memo

zThe timing pulle s are small in iameter

on |

the motor si e large |

on the riven |

si |

e. |

|

|

|

|

3 7

BHSM01-003

. . nspection an replacement

Ma e sure that isassem le parts are ull cleane up.

Replace parts whose regular replacement perio has

come. |

|

|

|

|

|

|

|

|

|

|

|

|

al |

nut: |

|

|

|

|

|

|

|

|

|

|

|

E |

tremel |

worn |

hal |

nut |

is to |

e replace . |

||||||

Timing |

elt: |

|

|

|

|

|

|

|

|

|

||

Replace |

them |

when |

|

amage |

or crac |

e . |

|

|||||

Replace them i |

their |

ent is e |

tremel |

large an |

||||||||

it |

is |

impossi |

le |

to |

a |

ust |

it. |

|

|

|

||

imit |

switch: |

|

|

|

|

|

|

|

|

|

||

hec |

con uctivit |

|

using tester |

replace those |

||||||||

with mal unction |

|

using sol er an |

sol |

ering iron. |

||||||||

ee |

screw: |

|

|

|

|

|

|

|

|

|

||

|

rease them |

up |

ever |

si |

months. |

|

|

|||||

rease |

to |

use: |

Mori |

coat |

grease |

R |

P |

US |

||||

. . ustment

S ringe test |

** |

3 8

Loading...

Loading...