Nilfisk-Advance 56395101, 56372947, 56206981, 56388109, 56388120 Service Manual

...

FORM NO. 56041170 / BATTERY CHARGER SERVICE MANUAL / PARTS LIST - 45

Revised 8/00 Form Number 56041170

Battery Chargers

SERVICE MANUAL / PARTS LIST

AUTOMATIC Advance MODELS 56206980, 56206981, 56372947, 56388109,

56395101, 56388502, 56388120, 56409494, 56411058, 56411643, 56409788,

56205983, 56412272, 56206973, 56372203, 56372190, 56388119

Lester MODELS 56031407, 56632342, 56638431, 56638436, 56638439,

56638440, 56632293, 56031403, 56031405, 56031408

MANUAL MODELS (obsolete) 56206975, 56372945, 56372955

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

FORM NO. 56041170 / BATTERY CHARGER SERVICE MANUAL / PARTS LIST - 1

_______________________________________________________________________________________

TABLE OF CONTENTS

Safety ......................................................................................................................... 2

General Information.................................................................................................... 3

Transformer / Rectifier or Power Section.................................................................... 3

On / Off Control Section ............................................................................................. 4

Automatic and Manual Timer Battery Charger Troubleshooting................................. 5

Manual Charger PN 56206975................................................................................. 16

Automatic Chargers PN 56206980........................................................................... 17

Manual Charger PN 56372945................................................................................. 18

Automatic Charger PN 56372947............................................................................. 19

Automatic Charger PN 56388109............................................................................. 20

Manual Charger PN 56372955................................................................................. 21

Automatic Charger PN 56395101 (replaces PN’s 56372947 & 56395347).............. 22

Automatic Charger PN 56388502............................................................................. 23

Automatic Charger PN 56388120............................................................................. 24

Automatic Charger PN 56409494............................................................................. 25

Automatic Charger PN 56411058 ............................................................................. 26

Automatic Charger PN 56411643 ............................................................................. 27

Automatic Charger PN 56409788............................................................................. 28

Automatic Charger PN 56205983 (replaces PN 56206981)..................................... 29

Automatic Charger PN 56412272............................................................................. 30

Automatic Charger PN 56206973............................................................................. 31

Automatic Charger PN 56372203............................................................................. 32

Automatic Charger PN 56372190............................................................................. 33

Automatic Charger PN 56388119 ............................................................................. 34

Automatic Charger PN 56031407............................................................................. 35

Automatic Charger PN 56632342............................................................................. 36

Automatic Charger PN 56638431............................................................................. 37

Automatic Charger PN 56638436............................................................................. 38

Automatic Charger PN 56638439............................................................................. 39

Automatic Charger PN 56638440............................................................................. 40

Automatic Charger PN 56632293............................................................................. 41

Automatic Charger PN 56031403............................................................................. 42

Automatic Charger PN 56031405............................................................................. 43

Automatic Charger PN 56031408............................................................................. 44

BATTERY CHARGER SERVICE MANUAL / PARTS LIST

revised 8/00

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

2 - FORM NO. 56041170 / BATTERY CHARGER SERVICE MANUAL / PARTS LIST

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

SYMBOLS

Nilfisk-Advance uses the symbols below to signal potentially dangerous conditions. Always read this information carefully and take the necessary steps to protect personnel and property.

DANGER!

Is used to warn of immediate hazards that will cause severe personal injury or death.

WARNING!

Is used to call attention to a situation that could cause severe personal injury.

CAUTION!

Is used to call attention to a situation that could cause minor personal injury or damage to the machine or other

property.

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

GENERAL SAFETY INSTRUCTIONS

DANGER!

HIGH VOLTAGE! With the charger on, the internal charger capacitor voltage is approximately 650

volts.

WARNING!

Do not operate the charger if it is malfunctioning. Personal injury or property damage could result.

Remove all jewelry when working near electrical components.

CAUTION!

To be able to use the troubleshooting guide safely and effectively it is important to read this manual

completely before beginning any tests.

Incorrect assembly may result in a risk of electric shock or fire.

Always unplug the electrical cords, first from the AC outlet and then from the charger receptacle

before attempting any repairs or service to the charger.

REPAIRS BY QUALIFIED PERSONNEL ONLY. NOTE: Modifying this charger for use other than that

for which it was intended, repairs by persons not qualified, or not using original equipment replacement parts will void the manufacturer’s warranty and liability.

BATTERY CHARGER SERVICE MANUAL

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

FORM NO. 56041170 / BATTERY CHARGER SERVICE MANUAL / PARTS LIST - 3

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

GENERAL INFORMATION

The Nilfisk-Advance Battery Chargers are designed to recharge deep-cycling lead acid batteries. A

ferroresonant transformer is used to provide a highly reliable, line compensating unit with a minimum of

moving parts, designed for long trouble-free service. The chargers are constructed so that all parts can be

tested and replaced with basic hand tools. In addition, an analog multimeter of 10,000 ohms per volt sensitivity

or better is required.

The Nilfisk-Advance battery charger is comprised of two basic sections; the transformer/rectifier or power

section, and the on/off control section.

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

TRANSFORMER / RECTIFIER OR POWER SECTION

The power or charging section consists of a transformer with its specified part number and rating capacitor and

rectifying diodes attached to a heat sink. The ammeter displays charging current and the fusing provides

electrical protection.

The transformer consists of primary coil or coils separated from the capacitor and secondary coils by a stack

of transformer grade steel pieces called a shunt pack. The transformer coils are wound with high temperature

double insulated magnet wire. The leads are covered with tan or black sleeving and all termination connectors

are crimped and soldered. The transformer must be properly connected in accordance with the correct wiring

diagram for each specific part number charger.

The capacitor functions in combination with the specific transformer to provide the correct charger output with

variation in AC line voltage. The correct part number and rating capacitor as listed on the parts list must be

used with the correct part number transformer and charger.

CAUTION!

Use only the correct part number and rating capacitor. Use of a different capacitor may result in

improper charging, capacitor failure, transformer burnout and / or battery damage.

The rectifier diodes are attached to a heatsink plate or bracket that is fastened to, but electrically isolated from,

the charger chassis. Connection points are provided on the heatsink assembly with diodes. One connection

point is to the heatsink plate itself or a tab attached to it, the remaining connections are to individual diode tabs

or leads. More than one lead can be attached to each connection point and the heatsink assembly with diodes

must be the right part number and connected in accordance with the correct wiring diagram for the specific

part number charger.

The ammeter needle deflects in response to current flow indicating charge current. Connections to the

ammeter terminals are either push on or with jam nuts. When tightening the jam nuts, insure the threaded stud

does not turn, or damage to the ammeter can occur. Use only the correct ammeter as specified in the appropriate wiring diagram and parts list.

BATTERY CHARGER SERVICE MANUAL

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

4 - FORM NO. 56041170 / BATTERY CHARGER SERVICE MANUAL / PARTS LIST

The fusing consists of a fuse link in series with each diode and provides overcurrent protection should one or

both diodes fail in the shorted mode. When both fuses or fuse links blow, this is usually due to a reverse

polarity connection to the batteries. Either two individual fuseholders with fuses or a single dual element fuse

assembly provides this protection. The fuse assembly consists of a double ended fuse wire visable through a

transparent bubble mounted on the front panel. Each half of the fuse wire serves as an individual fuse element. After correcting the reason for the fuse blowing, replace the fuse or fuse assembly only with the correct

rating and part number in accordance with the correct wiring diagram and parts list for the specific part number

charger.

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

ON/OFF CONTROL SECTION

The ON/OFF control is provided by either a manually set hours of charge timer or the fully automatic battery

condition sensing electronic timer kit.

The fully automatic timer section has three main components.

The, “Electronic Timer Kit”, consist of state of the art electronic circuitry on a printed circuit board contained in

a protective sheet metal housing.

The “Control Cable Assembly”, has a polarized edge connector that mates with the circuit board pads on the

rear of the electronic timer kit. The wires attached to the edge connector are the correct length, position and

color to be connected in accordance with the proper wiring diagram for each specific part number charger.

The “On/Off Control Relay”, responds to signals from the electronic timer kit to either turn the AC power on or

off to the transformer of the power section. The relay terminal nomenclature is printed on each relay case and

should be connected according to the correct wiring diagram for each specific part number charger.

The manually set hours of charge timer is a simple electric clock motor operated on/off switch that turns off

after the preset number of hours has elapsed. The push on connections are numbered and must be connected according to the correct wiring diagram for each specific part number charger.

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

TRANSFORMER / RECTIFIER OR POWER SECTION (continued)

BATTERY CHARGER SERVICE MANUAL

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

FORM NO. 56041170 / BATTERY CHARGER SERVICE MANUAL / PARTS LIST - 5

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

AUTOMATIC TIMER BATTERY CHARGER TROUBLESHOOTING

Proper functioning of the Automatic Battery Charger is indicated by the following sequence of events. Three to

five seconds after the DC plug is connected to the charger receptacle the control relay “clicks” on, the transformer hums and the ammeter registers proper charge.

Proper diagnosing and repair requires identifying the malfunction from the following list, performing the indicated tests and repairing or replacing the malfunctioning items.

Malfunction Descrip1ion Test Procedures / Section Number

Relay does not “click” on when DC plug is Test for complete electrical connection to

connected to the charger receptacle. batteries / 1.

Test for proper functioning of automatic timer

components / 2.

Relay “clicks” on, but transformer does not Test AC power circuit / 3.

hum.

Transformer hums but no ammeter indication. Test Charger DC Circuit / 7.

Test Fuses and Diodes / 6.

Test Capacitor / 4.

Test Transformer / 5.

Transformer hums but charger output is low. Test Fuses and Diodes / 6.

Test Transformer / 5.

Fuse blows as soon as DC plug is connected Test Charger DC Circuit / 7.

to the charger receptacle. Test Fuses and Diodes / 6.

Ammeter remains pegged at maximum Check Battery System Voltage / 8.

charge for more than 30 minutes.

Charger does not turn off. Test Automatic Timer Section for “Does Not

Turn Off” / 9.

WARNING!

Do not touch the battery terminals or contacts on the charging plug. An electrical shock could result.

BATTERY CHARGER SERVICE MANUAL

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

6 - FORM NO. 56041170 / BATTERY CHARGER SERVICE MANUAL / PARTS LIST

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

MANUAL TIMER BATTERY CHARGER TROUBLESHOOTING

Proper functioning of the charger is indicated by the following sequence of events. When the timer knob is

turned to “ON”, the transformer hums and the ammeter registers proper charge.

Proper diagnosing and repair requires identifying the malfunction from the following list, performing the indicated tests and repairing or replacing the malfunctioning items.

Malfunction Description Test Procedures / Section Number

Transformer does not hum when the timer is Test AC Power Circuit / 3.

turned to “ON”.

Transformer hums but no ammeter indication. Test for complete electrical connection

to battery system / 1.

Test Charger DC Circuit / 7.

Test Fuses and Diodes / 6.

Test Capacitor / 4.

Test Transformer / 5.

Transformer hums but charger output is low. Test Fuses and Diodes / 6.

Test Transformer / 5.

Fuse blows as soon as the charger is Test Fuses and Diodes / 6.

connected to the batteries.

Ammeter remains pegged at maximum charge Check Battery System Voltage / 8.

for more than 30 minutes.

Charger does not turn off. Replace Manual Timer.

WARNING!

Do not touch the battery terminals or contacts on the charging plug. An electrical shock could result.

BATTERY CHARGER SERVICE MANUAL

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

FORM NO. 56041170 / BATTERY CHARGER SERVICE MANUAL / PARTS LIST - 7

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

1-CHECKING FOR COMPLETE ELECTRICAL CONNECTION TO THE BATTERIES

A Measure and record battery system voltage at the battery posts of the machine. Connect the positive (+)

voltmeter lead to the positive (+) battery system post and the negative (-) voltmeter lead to the negative

(-) battery system post.

B Measure and record battery voltage at the charger receptacle. If no voltage is measured or the voltage

measured is lower than the voltage measured in step A, repair or replace connections to batteries in

machine.

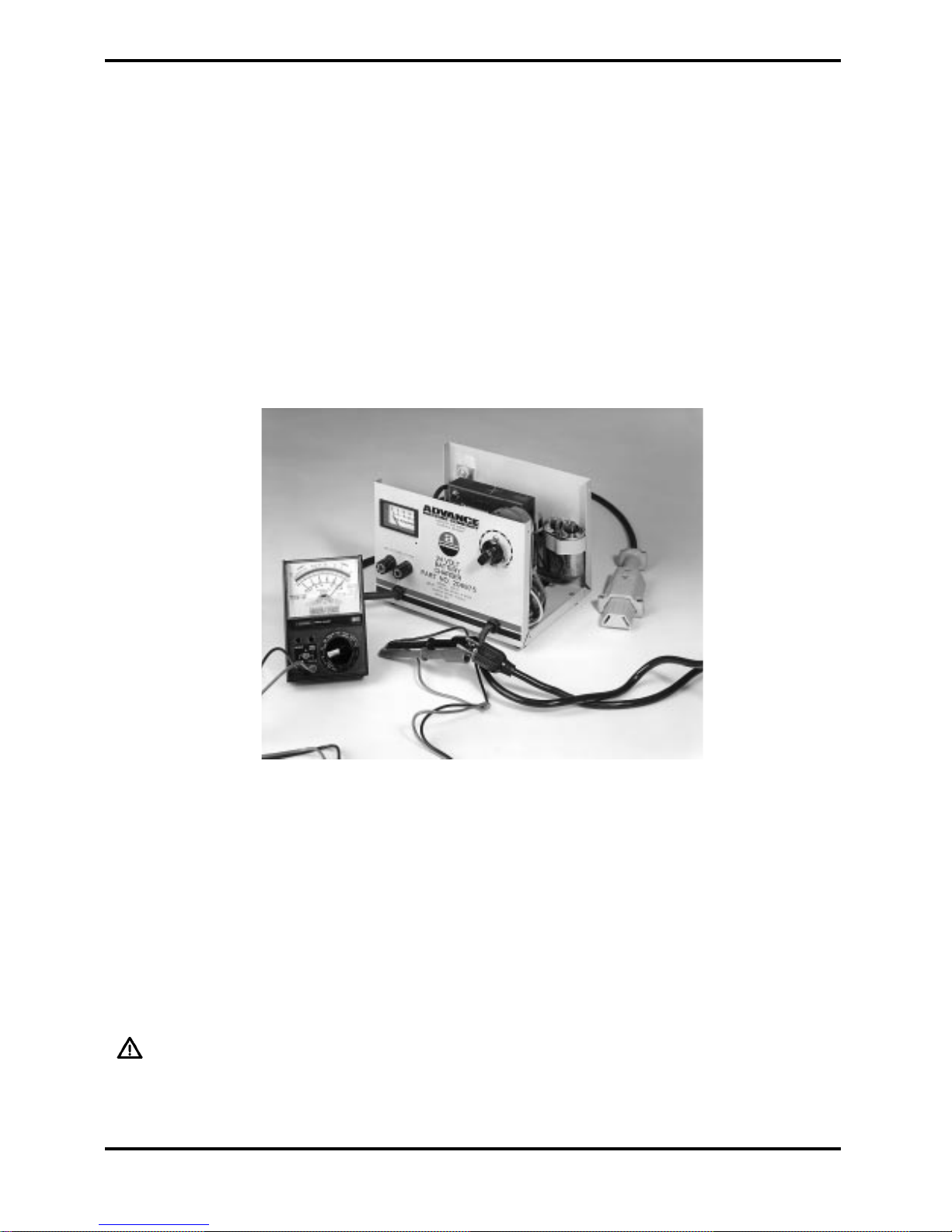

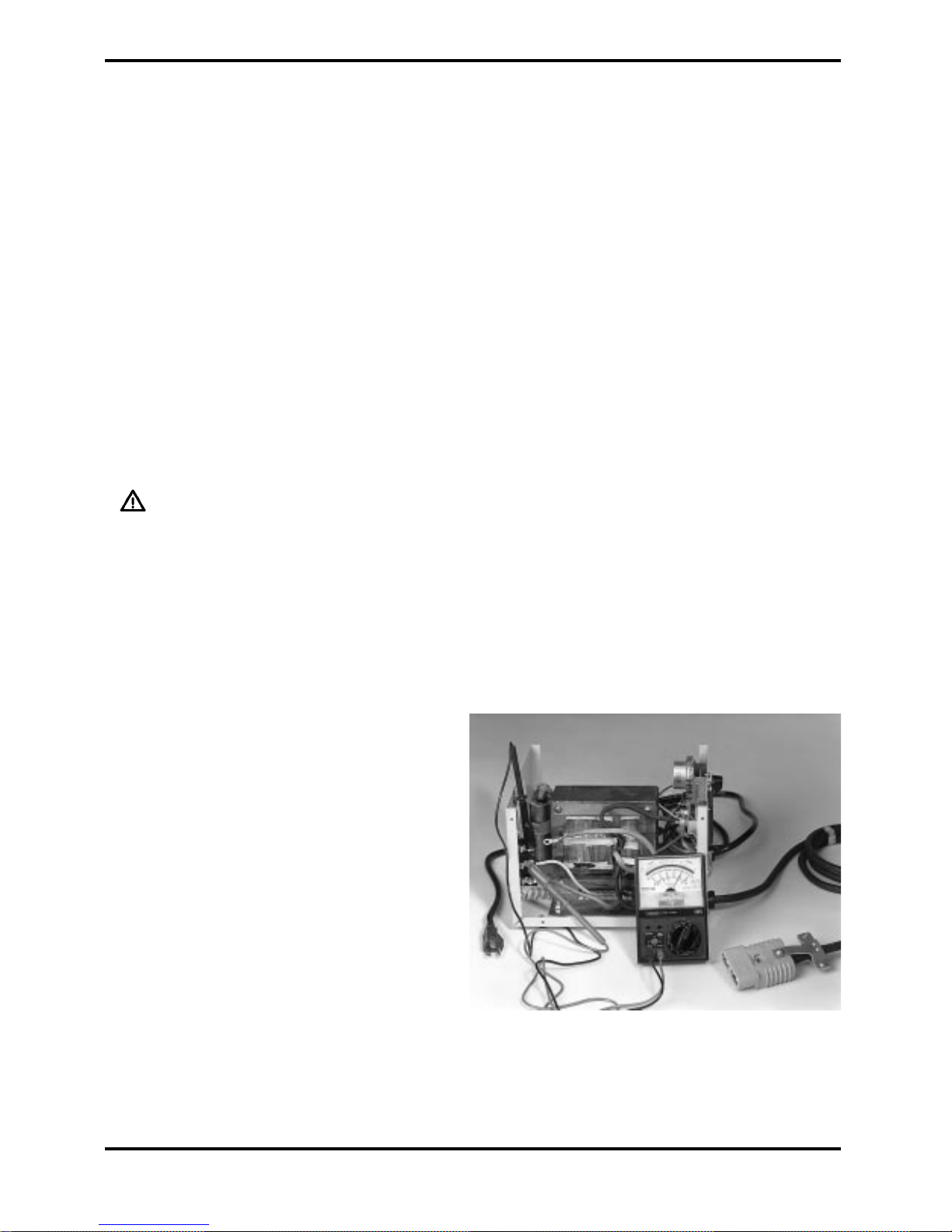

C See Figure 1. With both the AC cord and the charging plug disconnected, remove the cover from the

charger. Connect the positive voltmeter lead to the same point inside the charger where the white (+) DC

cord lead connects. Connect the negative voltmeter lead to the same point inside the charger where the

black (-) DC cord lead connects.

D Connect the DC Output cord to the charger receptacle and record the voltage measured. It should be the

same voltage as measured in step A.

E If no voltage is measured or the voltage measured is lower than the voltage measured in step A, repair or

replace the receptacle, charger plug and / or the cordset and re-test.

FIGURE 1. Testing for complete electrical connection to the battery system.

BATTERY CHARGER SERVICE MANUAL

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

8 - FORM NO. 56041170 / BATTERY CHARGER SERVICE MANUAL / PARTS LIST

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

2-TEST FOR PROPER FUNCTIONING OF AUTOMATIC TIMER COMPONENTS

A With both the AC cord and the charging plug disconnected, remove the cover from the charger. Verify

that the charger is wired correctly according to appropriate wiring diagram for the specific part number

charger.

B Remove the retaining screws and slide the

automatic timer kit out the front of the

charger. Disconnect the edge connector

from the automatic timer kit and insert the

test kit (Fig. 2). Connect the DC plug to the

charging receptacle and listen for the relay

to “click” on. If the relay now “clicks” on,

install a new automatic timer kit and re-test.

If the relay does not “click” on, continue with

the next test.

C Measure DC voltage across the pads on the

test kit that the red (Positive) and black

(Negative) wires contact (Fig. 3). The meter

should read the same battery voltage as

recorded in 1-C. If no voltage is measured

or the voltage measured is lower, repair or

replace the control cable assembly and

retest.

D Measure DC voltage across the pads on the

test kit that the black (Negative) and brown

(Positive) wires contact. It should read the

same battery voltage as recorded in 2-C. If

no voltage is measured install a new control

relay and retest.

FIGURE 2. Insert the test kit.

FIGURE 3. Measure battery system voltage

at the test kit pads.

BATTERY CHARGER SERVICE MANUAL

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

FORM NO. 56041170 / BATTERY CHARGER SERVICE MANUAL / PARTS LIST - 9

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

3-TEST AC POWER CIRCUIT

A Measure AC line voltage at the outlet to be sure the correct AC voltage for the specific part number

charger is present (115 VAC, or 230 VAC). If the correct AC power is present, disconnect the AC plug

and the charging plug.

B Adjust the multimeter to the low resistance scale (R X 1) or use a low voltage continuity tester. Connect

the tester leads to the flat prongs on the AC plug.

• MANUAL TIMER CHARGER

Turn the timer knob to “ON” and note the response. The circuit should be complete when the timer knob

is turned to “ON”, (Fig. 4) and open when the timer knob is turned to “OFF”.

• AUTOMATIC TIMER CHARGER

Connect the charging plug to the charging receptacle and listen for the control relay to “click” on, 2 to 5

seconds after connection.

• The circuit should be open before the relay “clicks” on and the circuit should be complete after the relay

“clicks” on.

C If the circuit does not test as described, individually check the AC cord, manual timer contacts, control

relay contacts, primary transformer coil(s) and all connections.

DANGER!

HIGH VOLTAGE! With the charger on, the charger capacitor voltage is approximately 650 volts AC.

Use extreme caution when working near the capacitor terminals.

FIGURE 4. Test AC circuit for continuity.

BATTERY CHARGER SERVICE MANUAL

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

10 - FORM NO. 56041170 / BATTERY CHARGER SERVICE MANUAL / PARTS LIST

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

4-TEST THE CAPACITOR

WARNING!

It is possible for the capacitor to not be fully discharged. To test for this, adjust your meter to the

highest DC voltage scale and touch the test leads to the capacitor terminals and note the reading. If

the meter needle deflects in the wrong direction reverse the test leads and repeat. If the capacitor was

not fully discharged a voltmeter reading will indicate this. Continue holding the voltmeter leads on the

capacitor terminals until the voltage reading drops to zero.

A Using the analog ohmmeter adjust the scale to R X 10,000 (1 Ok) Ohms. Loosen the capacitor clamp

and carefully remove both transformer leads from the capacitor terminals so the wires do not break.

Touch the ohmmeter leads to the capacitor terminals and note the results. Reverse the test leads, repeat

the test and compare to the following:

• GOOD CAPACITOR: When the ohmmeter leads are connected to the capacitor terminals the meter

needle bumps up to mid scale and quickly coasts back to high resistance (∞).

• OPEN CAPACITOR: When the ohmmeter leads are connected to the capacitor the meter needle does

not move and stays at high resistance (∞). A bulge in the top of the capacitor may be visable if the

capacitor has failed “OPEN”.

• SHORTED CAPACITOR: When the ohmmeter leads are connected to the capacitor terminals, the meter

needle jumps to full scale, zero ohms and remains there.

B If the capacitor is “Open” or “Shorted” it must be replaced.

CAUTION!

Use only the correct part number and rating capacitor as specified on the correct parts list for the

specific part number charger. The use of a different part number or rating capacitor may result in

improper charging, capacitor failure, transformer burnout, and / or battery damage.

BATTERY CHARGER SERVICE MANUAL

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

FORM NO. 56041170 / BATTERY CHARGER SERVICE MANUAL / PARTS LIST - 11

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

5-TRANSFORMER TESTING

Testing the transformer consists of measuring the AC voltage across the transformer secondary leads that

connect to the diodes. This voltage is measured first with the capacitor disconnected and compared to the

voltage measured with a capacitor connected that has been tested and found good.

DANGER!

HIGH VOLTAGE! With the charger operating, the charger capacitor voltage is approximately 650 volts

AC. Use extreme caution when working near capacitor terminals.

A Disconnect the transformer secondary coil leads #1 and #4 (TAN SLEEVING) from the diode terminals.

Loosen the capacitor strap and carefully disconnect the transformer capacitor coil leads from the capacitor terminals.

B Refer to the transformer test voltages diagram on the wiring diagram and parts list page for the specific

part number charger and adjust the voltmeter to an appropriate AC voltage range. Attach the meter test

leads to the identified transformer coil leads.

C Checking to be sure for personal safety, and that no leads have been accidentally allowed to short, follow

the instructions below to energize the transformer primary.

• MANUAL TIMER CHARGER

Turn the timer knob to “ON” and connect the power supply cord to an outlet while recording the voltage

reading and unplug as soon as the reading is noted.

• AUTOMATIC TIMER CHARGER

Connect the DC plug to the charger receptacle and listen for the relay to “click” on 2 to 5 seconds after

the connection. Connect the AC power supply cord to an outlet while recording the voltage reading and

unplug as soon as the reading is noted.

BATTERY CHARGER SERVICE MANUAL

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

12 - FORM NO. 56041170 / BATTERY CHARGER SERVICE MANUAL / PARTS LIST

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

5-TRANSFORMER TESTING (continued)

• ALTERNATELY

The relay contacts can be bypassed to enable transformer testing when the battery system is not

present. Make up jumper leads (1 for 115 VAC, 2 for 230 VAC) with 3/16" (4.56 mm) wide flat blade

push in connectors on both ends of a piece of 14 gauge flexible wire (Fig. 5). Carefully disconnect the

AC cord lead and transformer primary lead (1 each 115 VAC, 2 each 230 VAC) from the relay terminals.

Connect the jumper lead (1 for 115 VAC, 2 for 230 VAC) according to the transformer test diagram on the

wiring diagram and parts list for the specific part number charger. Connect the AC power supply cord to

an outlet while recording the voltage reading and unplug as soon as the reading is noted (Fig. 5).

D If the AC line fuse or circuit breaker blows, the transformer is shorted internally and must be replaced.

E Check the transformer secondary coil and capacitor coil voltage and compare to voltages on the trans-

former test diagram for the specific part number charger. If the voltages are substantially lower than

those shown, the transformer is shorted internally and must be replaced.

F If the secondary coil voltage and capacitor coil voltage check good, re-test the secondary coil voltage with

the correct capacitor connected. If the secondary coil voltage is the same measured with the capacitor

disconnected, the capacitor may be open, or the capacitor coil terminals may not be making proper

contact.

FIGURE 5. Transformer test.

BATTERY CHARGER SERVICE MANUAL

Jumper Leads

Capacitor

Leads

Disconnected

Jumper

Lead

Connected

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

FORM NO. 56041170 / BATTERY CHARGER SERVICE MANUAL / PARTS LIST - 13

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

6-TEST FUSES AND DIODES

Disconnect the AC power cord and the charging cord.

A Set the multimeter to the low resistance scale (R X 1 ) or use a low voltage continuity test light.

B Excessive heat due to a loose, corroded or distressed connection can cause one or both fuse assembly

links to melt and open. Fuseholders that are worn, corroded, bent or broken can result in an open circuit

even when a good fuse is installed. Isolate the fuseholder assembly electrically and test for continuity

with a good fuse installed.

C Electrically test and visually check the fuses and fuse assembly for continuity. A single blown fuse or

fuse link is normally caused by a short circuit failure of a single diode. When both fuses or fuse links are

blown, this is usually due to a reverse polarity connection to the batteries. Test the diodes and correct

the problem before replacing the fuse.

DANGER!

Replace the fuse or fuse assembly only with the correct fuse or fuse assembly. FIRE, PROPERTY

DAMAGE AND PERSONAL INJURY CAN RESULT IF THE CHARGER IS USED WITH AN INCORRECT

FUSE INSTALLED.

D To test the diodes, disconnect one transformer secondary coil lead (TAN SLEEVING) from the diode

terminal. Using the multimeter or a low voltage continuity tester, connect one lead to the diode heatsink

plate or terminal, and the other lead to a diode terminal (Fig. 6). Note the response and then reverse the

tester leads and check each diode again.

• GOOD DIODE: When the diode shows

continuity in one direction but not the other.

• SHORTED DIODE: When the diode shows

continuity in both directions.

• OPEN DIODE: When the diode does not

show continuity in either direction.

E If the diode(s) is OPEN or SHORTED the

complete heatsink assembly with diode(s)

must be replaced.

FIGURE 6. Test diodes.

BATTERY CHARGER SERVICE MANUAL

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

For new, refurbished and used cleaning equipment and supplies visit www.southeasternequipment.net

Loading...

Loading...