Page 1

MULTICLEANER 7-53

User Manual

107309941

Page 2

Page 3

MULTICLEANER 7-53

Index

1 Introduction ..................................................................................5

1.1 Preface ..................................................................................5

2 Important information ..................................................................................5

2.1 Warranty conditions ................................................................5

2.2 Safety ..................................................................................5

3 Application/operation ..................................................................................6

3.1 Safety ..................................................................................6

3.1.1 Warning sign on the door ..........................................7

3.1.2 Access to robot during operation...............................7

3.1.3 Training of staff ..........................................................7

4 Service ..................................................................................7

4.1 Safety ..................................................................................7

5 Description of plant ..................................................................................8

5.1 Operating principle .................................................................8

5.2 Field of application .................................................................8

5.3 Automatic washing .................................................................9

5.4 Mechanics ............................................................................10

5.4.1 Tyres ........................................................................10

5.4.2 Nozzle .....................................................................10

5.4.3 Materials ..................................................................10

5.4.4 Ultrasonic sensors ...................................................10

5.5 Components in the water supply ..........................................10

5.5.1 Water filter ...............................................................10

5.5.2 Water valve .............................................................10

5.5.3 Flow switch ..............................................................10

5.6 Control ................................................................................11

5.7 Cable reel .............................................................................11

5.7.1 Cable type ............................................................... 11

5.7.2 Cable strain relief ....................................................11

5.8 Motor pump unit/compressor................................................11

5.9 Motors/gear .......................................................................... 11

5.9.1 Types ....................................................................... 11

5.10 Safety device ........................................................................12

5.10.1 Emergency switch ...................................................12

6 Requirements for the existing

installation/ inventory ................................................................................12

6.1 Power supply ........................................................................12

6.2 Water ................................................................................12

6.3 Running sands filter .............................................................12

6.4 Hose dimension / quality ......................................................12

6.5 Ambient temperature - operation / storage ..........................13

6.6 Inventory in inspection gallery ..............................................13

6.7 Floor finish in inspection gallery ...........................................13

6.8 The pens ..............................................................................13

7 Servicing ................................................................................14

7.1 Safety during the application of the

MULTICLEANER ..................................................................14

Original Instructions

3

Page 4

MULTICLEANER 7-53

7.2 Installation ............................................................................15

7.2.1 Frost in the MULTICLEANER ..................................15

7.2.2 Placement of robot in inspection gallery..................15

7.2.3 Laying/connection of water hose .............................15

7.2.4 Fixing of cable in inspection gallery.........................15

7.2.5 Adjustment of washing arm .....................................16

7.2.6 Engagement of propulsion wheels ..........................16

7.3 Menu ................................................................................16

7.4 Cleaning of robot ..................................................................18

7.4.1 General ....................................................................18

7.5 Storage ................................................................................18

7.5.1 Frost protection .......................................................18

7.6 Transport ..............................................................................18

7.6.1 Trailer ......................................................................18

7.6.2 Application of ramps/winches ..................................18

7.6.3 Fastening during transport ......................................18

8 Operation ................................................................................19

8.1 Indicator lamp .......................................................................19

9 Maintenance ................................................................................19

9.1 General ................................................................................19

9.2 Maintenance procedures ......................................................19

9.2.1 Service interval of motor/pump unit according

to Nilfisk-ALTO ........................................................19

9.2.2 Oil change ...............................................................20

9.2.3 Inspection of long distance nozzle ..........................20

9.2.4 Cleaning of filter in dirt collector ..............................20

9.2.5 Inspection of pressure in tyres ................................20

9.2.6 Banjo bolt at the nozzle head ..................................20

9.2.7 Lubrication ...............................................................20

9.2.8 Inspection of initial tension of the springs in

the cable reel ...........................................................20

10 Service ................................................................................21

10.1 Service visit ..........................................................................21

10.2 Trouble shooting/correction ..................................................21

10.2.1 Error list ...................................................................21

10.2.2 Other malfunctions ..................................................22

11 Specifications ................................................................................23

11.1 Robot and motor/pump unit ..................................................23

12 EU Declaration of Conformity ................................................................................23

4

Original Instructions

Page 5

1 Introduction

1.1 Preface We congratulate you on your new MULTICLEANER.

To get the most out of your new MULTICLEANER it is important that

you read the user manual carefully through and follow the advice

given about safety, operation and maintenance.

This safety and warning symbol indicates that the section concerned contains important safety rules and recommendations to

prevent accidents.

Important

MULTICLEANER 7-53

Safety

We reserve the right to alter the specifications.

2 Important information

2.1 Warranty conditions Concerning warranty our general sales and delivery conditions

apply.

We reserve the right to further technical developments.

2.2 Safety CAREFULLY READ THROUGH THIS USER MANUAL BEFORE

STARTING TO USE THE ROBOT !

Original Instructions

5

Page 6

MULTICLEANER 7-53

3 Application/operation

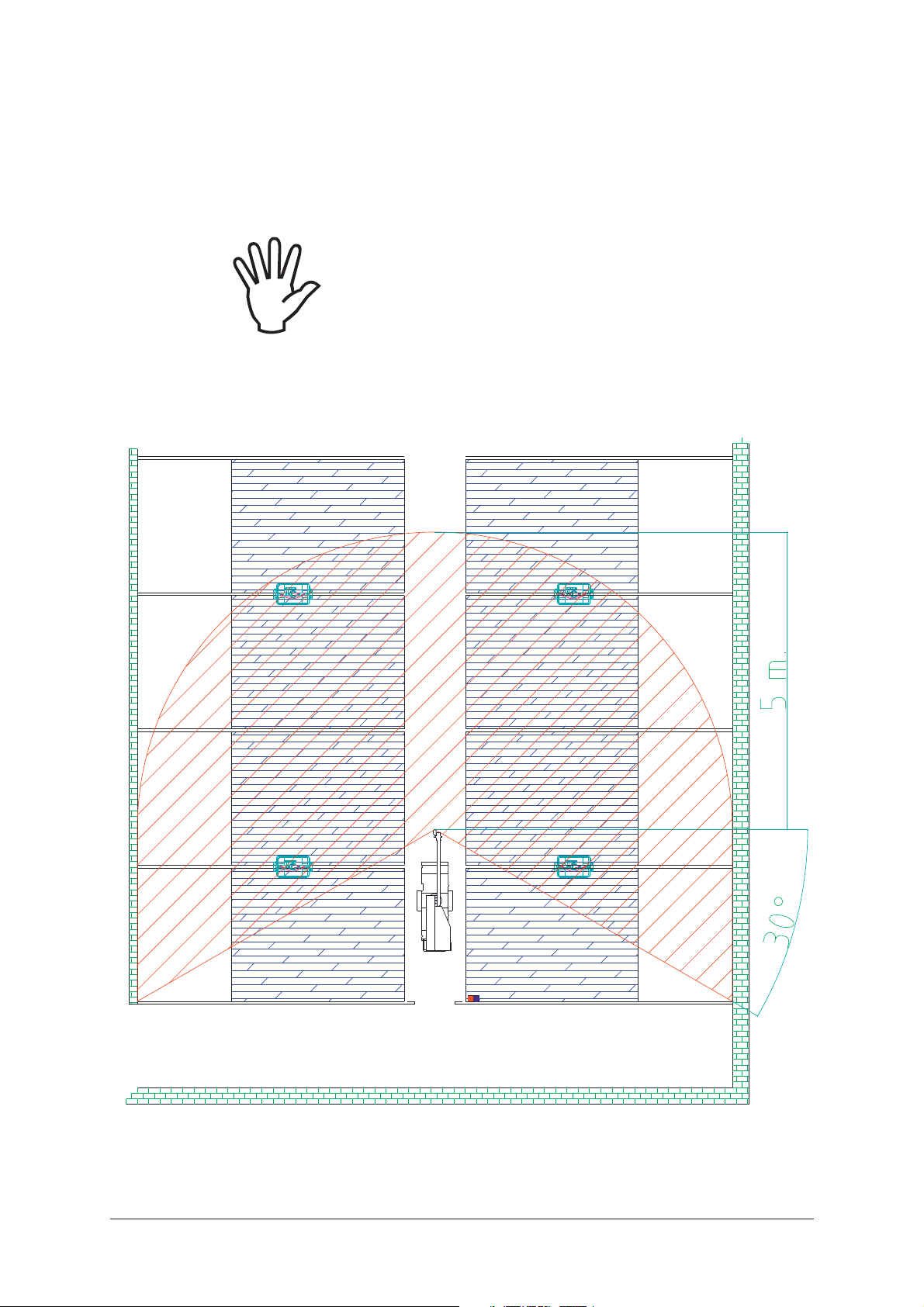

3.1 Safety When the washing robot is in operation all shieldings must be

in place. During automatic washing no persons must stay in the

washing field of the robot (hatching). See illustration below.

Only persons who have been specially instructed must stay in the

pig house section where the robot is working.

6

Original Instructions

Page 7

MULTICLEANER 7-53

3.1.1 Warning sign on the

door

3.1.2 Access to robot during

operation

3.1.3 Training of staff Employees who are to operate the robot will beyond the written in-

The accompanying warning sign must be placed on the door leading to the pig house section where the automatic washing is taking

place. The sign must be visible to any person who may have access

to the pig house section.

If the sign is lost or if there is more than one access, a new sign can

be ordered from Nilfisk-ALTO. Order no. 107307061.

The robot must be placed so that the operator has always got access to the display and the control knobs without having to pass

the robot during the automatic washing, meaning that the end of

the robot where the display is placed must turn to the access side

during operation.

structions always receive a verbal instruction from a staff member of

Nilfisk-ALTO in connection with the delivery and starting up of a new

robot.

4 Service

4.1 Safety Always disconnect the electrical plug from the socket prior to

service, maintenance, repair or other works on the washing robot.

Repairs to the control pen of stainless steel must be carried out by

an electrician as it contains automatic fuses, contactor, emergency

stop module and power supplies.

The control pen of plastic contains the control system and must only

be serviced by a Nilfisk-ALTO service technician.

When working underneath the robot you should be very careful as it

weighs 285 kg.

Original Instructions

7

Page 8

MULTICLEANER 7-53

5 Description of plant

5.1 Operating principle The MULTICLEANER is used for the cleaning of pig houses. It takes

over most of the heavy, trivial and time consuming manual cleaning

job. Using the robot the manual high pressure washing is reduced

by up to 80%. The remaining 20% high pressure washing is quickly

done because of the long soaking time of the impurities.

The control of the robot is automatic when the user has made a few

choices on the display.

The washing sequency of the MULTICLEANER is programmed by

the user before each cleaning. The user may adapt the washing

sequency to achieve an optimum cleaning of the actual pig house

section.

Distance and course of the MULTICLEANER is controlled by two

ultrasonic sensors, which "feel" against the inventory in the aisle.

The washing arm consists of a vertical tower and a horizontal arm.

The tower is mounted on a turntable on the chassis, which can rotate 90 degrees sideways proportional to the direction of movement.

At the top of the tower the horizontal arm is mounted in a swivel.

The tower and the arm can be locked in fixed positions in proportion

to each other.

At the end of the horizontal arm the high pressure nozzle is mounted on a spindle stretching through the horizontal arm. The nozzle

can rotate 360 degrees. The outermost part of the horizontal arm

can rotate around its own spindle, and the angle of the water jet can

be turned +/- 90 degrees in proportion to vertical position.

The high pressure nozzle turns like a fan forwards and backwards

within a limited angle. The speed of the nozzle is variable, thus minimising the water consumption.

In order that the nozzle is washing at an optimum, it is important

that the tower and the arm are adjusted so that the nozzle head is

placed in the middle of the aisle and so close to the inventory and

the floor as possible.

It is the responsibility of the user that the arm is adjusted so that it

will not bump into the inventory of the pig house.

Stop-lists on front and rear bumper signal to the control unit in case

of bumping assuming that the MULTICLEANER has reached the

opposite end of the aisle, and the direction of movement will be

changed and the next step of the washing sequence will be started.

5.2 Field of application The MULTICLEANER is mainly intended for use in pig fattening

houses, climate-controlled livestock buildings and farrowing houses.

To optimise the washing result and minimise the water consumption,

it will be an advantage to use a dustbinding or a soaking system to

soak the pig house before using the MULTICLEANER. However, this

is not required.

8

Original Instructions

Page 9

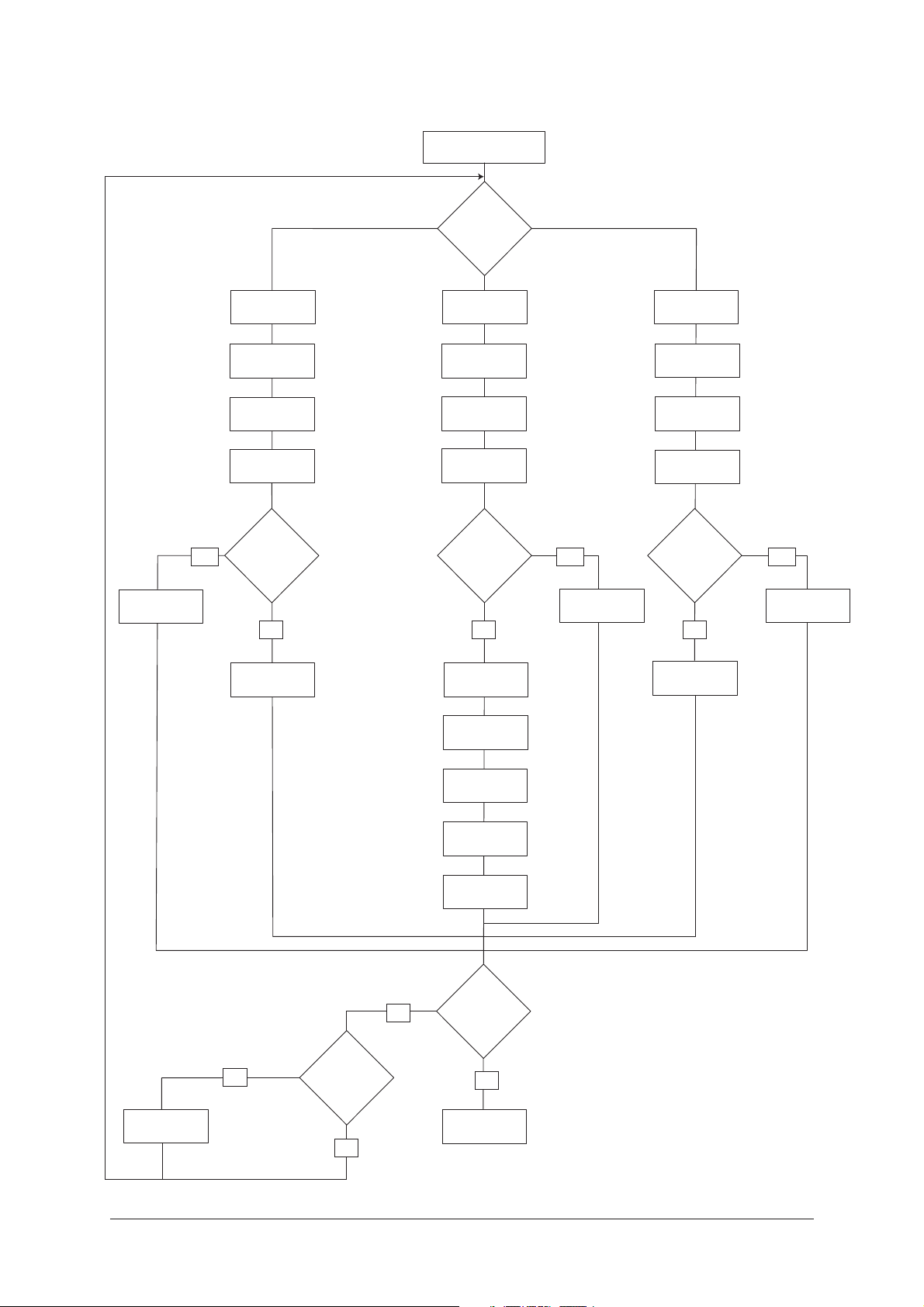

5.3 Automatic washing

MULTICLEANER 7-53

Start washing

Side?

Aisle washing

Yes

Left

Left

endwall

Wash left

forwards

Left

endwall

Aisle washing ?

(only 1st wash)

No

Wash left

backwards

Both

Right

endwall

Wash right

forwards

Right

endwall

Aisle washing ?

(only 1st wash)

No

Wash right

backwards

Left

endwall

Yes

Aisle washing

Right

Right

endwall

Wash right

forwards

Right

endwall

Aisle washing ?

(only 1st wash)

No

Wash right

backwards

Yes

Aisle washing

Pausing

Yes

Pause ?

No

No

Wash left

forwards

Left

endwall

Wash left

backwards

Final

washing ?

Yes

Wash finished

Original Instructions

9

Page 10

MULTICLEANER 7-53

5.4 Mechanics

5.4.1 Tyres

5.4.2 Nozzle Special corrosion-resistant long distance pencil jet nozzle with 1/4"

5.4.3 Materials The MULTICLEANER is mainly produced of corrosion-resistant,

5.4.4 Ultrasonic sensors The MULTICLEANER features two ultrasonic sensors on the right

The driving wheels are fitted with rubber tyres in the size 4.00 x 6

on rims made in one piece with the toothed wheel in a synthetic

material.

Stand wheels are solid rubber tyres on synthetic rims.

pipe thread and 14 mm hexagon. The nozzle opening is 1.5 mm.

synthetic and rubber materials.

In a few cases it has not been possible to produce or require parts

made of above-mentioned materials. Instead we have chosen other

but also very durable parts to diminish wear and corrosion.

These materials have been chosen to protect the robot from the

extremely tough environment (water and ammoniac fumes) in which

it has to work and thus to avoid increased risk of stoppage because

of corrosion, unnecessary wear etc.

side of the robot, which are used for regulation of direction and

distance.

The sensors emit/pick up sound impulses and the controller then

calculates the distance to the inventory in the aisle. It measures the

time from the emission of the sound impulse till the pick up of the

echo.

This information is then converted to a real distance.

If an echo has not been picked up within a short time because of

missing inventory sides, the control will activate the alarm.

If the ultrasonic sensors are covered by a lot of dirt, the reliability

may be affected. Note! Check that the two ultrasonic sensors are

clean before starting the robot and that the gates into the individual

pens are closed.

5.5 Components in the

water supply

5.5.1 Water filter

5.5.2 Water valve On the water inlet side a 24 VDC, solenoid valve is mounted. This

Before the water valve there is a water filter with a rustproof strainer

with a mesh size of 0.25 mm, which strains impurities out before

they reach the water valve. The water filter should be cleaned/

checked each 100 operating hours.

valve is open or closed depending on the working phase of the machine. The function of the valve is to disconnect the water supply

when the arm turns or the robot is in stand-by mode.

The valve is closed when the there is no voltage to the coil.

5.5.3 Flow switch In extension of the water valve a flow switch is mounted, which

continually checks the water supply. In case the water supply fails, if

for instance the water hose comes off, a signal is transmitted to the

control, which shuts down the MULTICLEANER and activates the

alarm. Thus it is avoided that the pump unit breaks down. The flow

switch has been adjusted from the factory.

10

Original Instructions

Page 11

MULTICLEANER 7-53

5.6 Control The control is mainly built up of a control card with related module

based add-on cards.

5.7 Cable reel

The robot features a built-in automatic cable reel unwinding/winding

up the power cable during operation and keeping it tight all the time

dependent on the direction of travel, and running over of the cable is

avoided. The cable reel carries 35 metres of cable.

During operation it is important that the cable is fastened to the concrete/slotted floor straight in front of the cable reel to ensure an even

unwinding/winding up.

Do not lead the cable under the machine as the bending radius will

then be too small.

A revolution counter has been built into the cable reel to avoid the

cable from being pulled too far out.

Important! The cable reel must only be adjusted by a NilfiskALTO service technician.

Important! If the pig house is longer than 35 metres, it must be

divided into two washes. It is not allowed to connect an extension

cable to the 35 metres of available cable on the cable reel to increase the operational range.

The power cable must not be pulled over a concrete floor, and the

machine must not run over the cable according to the Heavy Current Regulation, section 204-1, §14, EN 60204-1.

5.7.1 Cable type The cable mounted on the cable reel to supply the robot with cur-

rent is the type Buflex 4G 2.5 square, which is a cable with a special

armouring in the outer sheating.

Other cables on the machine are of the type SY, which are armoured/gnaw protected cables to avoid charges of mice among

other things.

5.7.2 Cable strain

relief

5.8 Motor pump unit/

compressor

5.9 Motors/gear

5.9.1 Types

A cable strain relief has been mounted so that the CEE plug is not

jerked directly. This relief must be fixed to the floor or the inventory

while the robot is working.

The pump unit is of the type Nilfisk-ALTO, C3. The pump yields a

pressure of 195 bar and consumes 16.5 litres of water in the minute.

Reference is made to section 11 for further technical information.

An internal pressure relief valve has been mounted. Thus the pump

will not retain the pressure if there is no consumption.

The motors are all 24 VDC mounted with angular gear and planetary gear respectively dependent on function and placement. All

motors are additionally screened from water and dirt.

Original Instructions

All toothed wheels are made of stainless steel.

11

Page 12

MULTICLEANER 7-53

5.10 Safety device

5.10.1 Emergency switch

The robot features an emergency switch in each end. Thus it will

always be possible to interrupt all functions in case of an emergency. These press buttons are connected to an emergency module

ensuring that no motors can be started until the user has made a

delibe rate action by re-setting the module. The module is re-set by

pressing the arrow next to the display.

6 Requirements for the existing

installation/inventory

6.1 Power supply The machine must be connected to a CEE wall plug, 400 volts, 16

amp or extension cord from the same of at least 2.5 square millimetres.

The extension cord must only be used for supplying the robot and

it must be fixed. It must not be used for the extension of the internal

cable reel to increase the reach of the machine as the consequence

will be that the cord is dragged across the concrete floor which is

not allowed according to the Heavy Current Regulation, paragraph

204-1, §14, EN 60204-1. The robot must not be secured with more

than 16 amp. If there is only a 32 amp wall plug available, the fuses

must be replaced by 16 amp fuses.

6.2 Water The required water volume is 16.5 l/min. The inlet pressure must be

max./min. 10/1 bar and the water inlet temperature must not exceed

60°C. You should know that the warmer the water is on the inlet

side, the faster the components in the MULTICLEANER will be worn

out. Therefore these components must be checked more frequently

than mentioned in the maintenance section if you use hot water.

Connect the water hose, ¾", by means of the quick coupling placed

below the front bumper. The quick coupling also functions as a pivot

joint always ensuring a natural hose run to minimise the risk of

bending the water hose.

6.3 Running sands filter If the connected water supply contains running sand, a running

sand filter must be mounted. Damages or abnormal wear caused by

running sand are not covered by the warranty or service contracts.

Clean or replace the filter as needed.

6.4 Hose dimension /quality The robot must be supplied with water from a two-layered ¾" water

hose. No joints on the hose between the MULTICLEANER and the

water outlet are allowed. For mounting of connecting branch and

quick coupling use hose clips of stainless steel.

12

Original Instructions

Page 13

MULTICLEANER 7-53

6.5 Ambient temperature,

operation/storage

6.6 Inventory in aisle The sides of the inventory in the aisle, towards which the MUL-

During operation the ambient temperature must always be above

+10 degrees Celcius. During storage the temperature must never

go below freezing point unless the MULTICLEANER has been frost

protected as described in section 7.5.1.

TICLEANER regulates its course by means of the two ultrasonic

sensors must be present and even. The ultrasonic sensors can be

regulated up and down and must be set to touch on an even side.

All gaps exceeding 50 mm in the inventory side should be covered.

If the MULTICLEANER cannot detect the inventory side, it will

proceed forwards for approximately 10 seconds. Then the MULTICLEANER will report an error because of a missing inventory side.

The end wall of the aisle against which the rubber bumpers of the

MULTICLEANER are activated, must be plane and without any

sharp objects which may puncture the bumpers. The height of the

plane surface must be 450 mm at a minimum. Profiled end walls

such as steel gates must be covered with a plate.

If the tower and the arm are placed in a position so that during the

aisle washing they protrude backwards above the bumper, an object

must be placed so that the rear bumper can be activated during

backward movement.

6.7 Floor finish in aisle In connection with washing of the aisle it is important that the dirt

which the MULTICLEANER drags along can be led away in a natural way as the machine is progressing. A slotted floor is preferred off

course, but if it is a solid floor, there must be a clearance under the

gates of 40 mm at a minimum. If it is a combination of a slotted and

a solid floor, a clearance below the gates is not necessary.

Note! Large amounts of muck and foreign bodies as for instance

remains of concrete and stones must be removed before starting

the cleaning.

6.8 Pens The optimal layout of a pen will be :

The depth of the pen does not increase 4.8 m.

The plastic inventory and the latch do not exceed 1000 mm in the

height.

The stomas are perpendicular to the aisle.

The width of the aisle is 800 mm.

Stomas in the aisle.

Automatic feeders, down-leads and water pipes are placed at least

2 m inside the pen from the front edge of the inventory side in the

aisle, enabling the washing arm to reach the middle of the pen.

Original Instructions

On potential rest areas to the stoma area there is a minimum gradient of 3%.

3/4" water connection at one of the ends of the aisle. Availability of

17 l water per minute.

CEE-plug at the end of the aisle, 400 V / 16 A.

13

Page 14

MULTICLEANER 7-53

7 Operation

The washing arm has an operational range of 1000 mm from the

front edge of the inventory side in the aisle when locked in the inmost position and an operational range of 2000 mm when locked in

the outmost position.

7.1 Safety during the

application of the

MULTICLEANER

When using the MULTICLEANER all existing national regulations

must be observed.

No other persons than the one using the MULTICLEANER must

stay in the area where there is a risk of being struck by the water

jet. The user must make sure that he/she is standing firmly and with

sufficient space around enabling him/her to take a sensible work

posture.

Use flexible and close-fitting footwear with nonslip soles.

Do not use the MULTICLEANER on a ladder unless equipped with

a working platform with a railing or unless precautionary measures

have been taken which provide the same security at a minimum.

Hold spray lance or nozzle with both hands and do not block the

dead man's function.

A relief in the shape of a ergonomic and suitable shoulder brace or

the like must be used if the work lasts more than half an hour or if

the work is performed in a stressing working posture.

Never direct the water jet towards electric installations risking that

the jet will become conductive.

Persons working with the MULTICLEANER must also:

14

Have a good knowledge of the safety functions of the machine,

equipment and care.

Be well informed about the safety and health related requirements

applying to the operation of the robot.

Have acquired a safe working technique protecting against accidents and hazards to health during the work.

It is the responsibility of the employer to make sure that all persons

operating the MULTICLEANER meet the above-mentioned three

requirement.

Original Instructions

Page 15

MULTICLEANER 7-53

7.2 Installation

7.2.1 Frost in the

MULTICLEANER

7.2.2 Placing of the robot in

the aisle

7.2.3 Laying/connection of

water hose

Do not operate the robot if it has been exposed to frost without

having been frost protected. Then at first let it thaw. If parts of the

motor / motor pump unit are frozen, the safety valve will open and

the pump block will burst.

The robot must be placed so that the operator will always have access to the display and the knobs during the automatic operation

without having to pass the robot, meaning that the display end of

the robot must turn to the access side during operation.

Lead the robot into the aisle ensuring that the distance between the

aisle and the right driving wheel is 5-10 cm.

The MULTICLEANER is fitted with a pivot joint/quick connector

placed under the front bumper for connection of a ¾" water hose for

the supply of water to the high pressure washer.

The water hose between the water tap and the MULTICLEANER

must have a minimum length of:

7.2.4 Fixing of cable in the

aisle

Minimum length of water hose = length of aisle + 3 metres

It is assumed that the water tap is placed at the end of the aisle.

Check that the water hose is not twisted before starting the operation as this may lead to stoppage.

Place the water hose parallel to the inventory side on the opposite

side of the sensors to avoid that the MULTICLEANER runs over the

water hose.

Connect the electric plug on the cable reel to the power take-off,

3x400V, 16A at the end of the aisle. The cable must be centred and

fixed with the cable relief in front of the cable reel to ensure an even

winding up / unwinding during operation. At the same time the cable between the cable relief and the power take-off will be relieved.

Check that the cable is tense before starting the machine.

Note ! The cable reel provides 35 m cable. Check that the travel

length of the MULTICLEANER is consistent to the length of the

cable on the drum. This is done by connecting the CEE plug to the

power take-off and centre and fix the cable to the floor in the driving

aisle in the front of the cable reel. Manually push the machine forwards until there are approximately two turns left on the cable reel

and then mount stop plate in front of the machine. Pull the machine

backwards to starting position. Now the washing can be started.

Original Instructions

It is the responsibility of the user to make sure that there is an obstacle to activate the front bumper at max. 35 metres.

15

Page 16

MULTICLEANER 7-53

7.2.5 Adjustment of washing

arm

The optimum position of the washing arm is that the nozzle head is

centred over the pen with the horizontal arm as close to vertical position as possible. It may be necessary to adjust the arm differently

in order to provide for the inventory.

Note! It is the responsibility of the user that the washing arm is adjusted so that it does not collide with feed / water pipes or the like

during operation.

7.2.6 Engagement of

propulsion wheels

The gear motors for the driving wheels are engaged by means of

two handles placed on each side of the chassis. The handles can

be placed in two positions. In the upper position the gear motors are

not engaged, which position is used during transport. In the lower

position the gear motors are engaged, which position is used during

operation.

7.3 Menu The diagram below figures the menu of the MULTICLEANER.

Start display

Auto-routines

Washing

routine

Tower angle

Arm angle

Pen depth

Manual

Settings

Fence Back wall Washing side

No. of washes

Soap in wash

Disinfection

Right wheel Left wheel

Language

Tower angle

Fence Back wall

No. of washes

Nozzle

Operational

hours

Pause

Aisle washing

Arm angle

Pause

Tower Arm

Pump

Distance

to wall

Aisle washing

Start

Pen depth

Washing side

Start

Soap pump

Ultrasonic

sensor

By-pass valve

Version

Obstacle

16

NB:

Only soap/dis-

infection option

Soap

Soap %

Disinfection %

Original Instructions

Page 17

MULTICLEANER 7-53

By means of the arrows the user can get around in the menu

system. When the MULTICLEANER has been connected to the

power supply, it will be ready for operation after 30 sec. Then the

display will show a start-up screen, on which the user will be asked

to press arrow the right to initiate the MULTICLEANER.

Now the user has entered the main menu and it will be possible to

select between 3 menu options using arrows up and down.

• Auto-routines

This menu option is used for programming the washing

sequence.

• Manual control

This menu option can be used for controlling the

MULTICLEANER manually.

• Settings

This menu option can be used for making changes in the

configuration of the MULTICLEANER.

Submenu:

They user can enter and exit the submenus by pressing the arrows

to the right and the left. Using the arrows up and down, the values in

the submenus can be changed.

Washing routine:

Tower angle: Select the hole number in which the tower

is placed.

Arm angle: Select the hole number in which the arm is

placed.

Pen depth: Select pen depth measured from the fence

to the back wall of the pen.

Fence: Select washing height of fence.

Back wall: Select washing height of back wall.

Washing side: Select washing of either right, left or both

sides.

No. of washes: Select the number of washes you want to

have done.

Pause: Select pause between each washing.

Aisle washing: Select if you want washing of the aisle.

Start: By pressing arrow to the right, the settings

of the washing sequence are saved and the

MULTICLEANER will start up the washing

sequence.

Original Instructions

Soap/disinfection option:

If this option has been mounted on the MULTICLEANER, it must be

activated in the menu "Settings" under "Soap". When this option is

activated, the soap and disinfection solution can be set in the menu

"Settings" and a soap application menu will appear in the washing

routine.

Obstacle detection option:

If this option has been mounted on the MULTICLEANER, it can be

activated and deactivated in the menu "Settings".

17

Page 18

MULTICLEANER 7-53

7.4 Cleaning of robot

7.4.1 General

7.5 Storage

7.5.1 Frost protection

7.6 Transport

7.6.1 Trailer

After use, the robot must be cleaned. This can be done with a high

pressure washer. Never point the high pressure jet directly at the

internal parts of the MULTICLEANER. Always make sure that the

ultrasonic sensors on the side of the MULTICLEANER are clean.

Important: The high pressure water jet must never point directly at

electricity boxes, wires or ultrasonic sensors. It is also important that

the two electricity boxes are always kept closed.

The best frost protection will be to store the MULTICLEANER in a

frost free area. If not possible, the following precautions must be

taken to protect the motor/pump unit against frost.

Lead the water inlet hose into a 5 l container with an anti-freeze.

Under manual control select HPW and press arrow up to activate

the pump.

After approximately 5 sec. the anti-freeze has reached the nozzle of

the horizontal arm.

Now press arrow up to deactivate the pump again.

The anti-freeze can be collected and re-used.

When transporting the MULTICLEANER on a trailer or in a car, it

must be placed so that its weight is evenly distributed on the transporting axles. Its dead weight is 285 kg. If the outdoor temperature

is below +2 degrees, the MULTICLEANER must be frost protected

as described in section 7.5.1.

7.6.2 Application of ramps/

winches

7.6.3 Fastening during

transport

Note: The gear of the machine must not be engaged during trans-

port.

If applying chutes these must be correctly mounted on the truck

bed so that the contact surface is close to the edge of the truck

bed. Thus the biggest contact surface will be supported by the truck

bed. The chutes must be approved for carrying the weight of the

MULTICLEANER at a minimum (285 kg).

The trailer or the vehicle must have a winch so that the MULTICLEANER can be safely loaded/unloaded without getting out of

control.

Use band lashings/polyester bands for fixing of the MULTICLEANER during transport. Place a chock under the wheels.

Note! The MULTICLEANER must be secured during transport.

18

Original Instructions

Page 19

MULTICLEANER 7-53

8 Operation

8.1 Indicator lamp The MULTICLEANER features an indicator lamp on the horizontal

arm indicating the working condition of the robot.

Gone off: : The MULTICLEANER must

be programmed.

Flashing light: : Auto-routine in progress.

Constant light: : The MULTICLEANER has

finished the auto-routine or it

is in error-proof condition -

see list of alarms.

9 Maintenance

9.1 General Always visually check the robot before starting it up. If you find loose

shields or any other loose parts, these must be mounted/fixed again

to avoid stoppage and worsening of the fault. If the cables or the like

are damaged, do not start up the MULTICLEANER until the damage

has been fixed.

9.2 Maintenance

procedures

9.2.1 Service interval on

motor/pump unit.

Check the following:

Each 6

Check oil level

Renew oil

Clean high pressure nozzle

Weekly

Each 100

hours of op-

eration

months or

each 500

hours of

operation

As required

Clean water filter

Replace o-rings in banjo bolt in

nozzle head

Inspection of pressure in tyres

The life of the various components in the pump very much depends on the number of particles in the water

supply.

Original Instructions

19

Page 20

MULTICLEANER 7-53

9.2.2 Oil change

9.2.3 Inspection of long

distance nozzle

9.2.4 Cleaning of filter in dirt

collector

The pump oil must be replaced after max. 500 hours of operation,

however at least each 6 months. If water in the oil is observed, replace the oil and refill with oil of the type Castrol Alphasyn T 150.

Normally the long distance nozzle can only be checked visually as it

requires a special equipment to measure it up. If the spray is very

diffuse and not concentrated as usually, the reason may be that it is

either clogged up or worn.

Before the water valve there is a water filter with a stainless strainer

with a mesh size of 0.25 mm filtering out impurities before they

reach the water valve.

Clean/check the water filter each week or for each 100 operating

hours. This is easily done by using a ratchet wrench with a 24 mm

head and a long adapter and loosening the nut for the dirt collector

from below. If not possible an alternative solution will be to loosen

the union nut of the 3/4" union, remove the hose clamp and the

water hose between the flow switch and the motor/pump unit and

then dismount the tube support. Now the complete unit with components for the water supply can be turned around and the nut for the

strainer dismounted.

9.2.5 Inspection of pressure

in tyres

9.2.6 Banjo bolt at the

nozzle head

9.2.7 Lubrication

Rinse/clean the strainer and remount in reverse order. If the strainer

cannot be cleaned, it is possible to buy one separately. It is not

necessary to replace the complete dirt collector.

The air pressure in the pneumatic tyred wheels must be approximately 2.5-2.8 bars. There must be a clearance between the concrete floor and the underside of one set of the supporting wheels of

2.5-3 cm, when the MULTICLEANER rests on the two other set of

wheels.

O-rings and back-up-rings on the banjo bolt at the nozzle head must

be lubricated each 100 operating hours and replaced at regular intervals.

Lubrication must be made each 200 operation hours.

Shafts for the driving and supporting wheels of the MULTICLEANER

must be lubricated with ordinary lubricant grease. Positioning bolts,

quick connectors, movable segments in the arm, hinges and the en-

of the tow handle must be lubricated with a lubricant containing

try

teflon. The easiest way out will be to use a spray with the lubricant.

9.2.8 Inspection of initial

tension of the springs

in the cable reel

20

Inspection of the initial tension of the cable:

If 5 metres of cable have been laid out, the springs in the reel must

provide a tractive effort of 4 kg at a minimum corresponding to a

tractive effort of approximately 8.5 kg at a layout of 30 metres.

Let a Nilfisk-ALTO service technician set the initial tension of the

cable reel.

The life of the springs in the cable reel is approximately 5,000 hours

and the life of the collector ring is approximately 12,000 hours.

Original Instructions

Page 21

MULTICLEANER 7-53

10 Service

10.1 Service visit A service visit must be paid after the first 50 hours of operation and

then for each 500 hours of operation according to the hour counter.

These service visits are important as neglect may cause stoppage

causing injury to incompetent persons.

The service check must be made by an authorized service technician from Nilfisk-ALTO.

Any change of the machine must only be made by persons

authorized by the supplier to evaluate whether the change will comply with the requirements of the EU Machinery Directive and who

can issue an EU Declaration of Conformity if required.

When ordering spare parts or calling concerning service questions,

please state the type and serial number of the robot. This information can be found on the model tag of the MULTICLEANER.

10.2 Trouble-shooting/

correction

10.2.1 Error list

Error code Meaning Possible errors Correction

2000 Overcurrent on a motor This error occurs if a motor

2001 --2002 No aisle side for 10 sec. Too big gaps in inventory

2003 --2004 Low oil level Oil level too low.

When pressing the arrow to the right, the error will be re-set and the

MULTICLEANER will resume the auto-routine. If a problem occurs

several times, call a service technician.

Check whether the motor

is briefl y overloaded

side

Gates not closed

works when operated

manually.

If the motor is defective, call

a service technician.

Check inventory side.

Close gates.

Refi ll with Castrol Alphasyn

T 150 oil.

Pump defective.

2005 Insuffi cient water supply Water pressure too low

Hose jammed

Flow sensor not adjusted

correctly

Original Instructions

Call a service technician.

Mount a feed pump - can

be done by a service

technician.

Fix the hose.

Call a service technician.

21

Page 22

MULTICLEANER 7-53

Error code Meaning Possible errors Correction

2006 Cable pulled too far out Depth of pig house too long Pull the MULTICLEANER

2007 Pump too hot Pump overheated Call a service technician.

2008 ---

backwards.

Make sure that the cable is

not pulled out more than 35

m.

2009 Emergency stop activated One of the two emergency

stops has been activated

2010 FPGA in safe mode Error in control system Call a service technician.

2011 Both bumpers are activated

at one time

2012 Front bumper activated

more than 10 sec.

2013 Rear bumper activated

more than 10 sec.

2014 Tower cannot turn right Object to the right Remove object to the right.

2015 Tower cannot turn left Object to the left Remove object to the left.

2016 The MULTICLEANER sticks Bumper has not been

2017 Tower position unknow for

3 min.

Bumper system defective Call a service technician.

Front bumper sticks Activate the front bumper

Rear bumper sticks Activate the rear bumper

activated for 3 hours

Tower sensor not adjusted

Make sure that both

emergency stops are

deactivated.

repeatedly by hand. If this

does not solve the problem,

call a service technician.

repeatedly by hand. If this

does not solve the problem,

call a service technician.

Extricate the

MULTICLEANER and

resume the auto routine.

Check that the tower sensor

works.

Check that the tower sensor

has been correctly adjusted.

2018 Arm position unknown for 3

min.

2019 Nozzle position unknown for

3 min.

2020 Tower sensor left active for

30 sec.

22

Tower sensor defective

Arm sensor not adjusted

Arm sensor defective

Nozzle sensor not adjusted

Nozzle sensor defektive

Sensor not adjusted

correctly

Sensor defective

Sensor cable defective

Call a service technician.

Check that the arm sensor

works.

Check that the arm sensor

has been correctly adjusted.

Call a service technician.

Check that the nozzle sensor

works.

Check that the nozzle sensor

has been correctly adjusted.

Call a service technician.

Adjust sensor.

Call a service technician.

Call a service technician.

Original Instructions

Page 23

Error code Meaning Possible errors Correction

MULTICLEANER 7-53

2021 Tower sensor right active for

30 sec.

2022 Arm sensor bottom active

for 30 sec.

2023 Arm sensor top active for 30

sec.

2024 Nozzle sensor bottom active

for 30 sec.

2025 Both tower sensors active Sensor not adjusted

2026 Both arm sensors active Sensor not adjusted

Sensor not adjusted

correctly

Sensor defective

Sensor cable defective

Sensor not adjusted

correctly

Sensor defective

Sensor cable defective

Sensor not adjusted

correctly

Sensor defective

Sensor cable defective

Sensor not adjusted

correctly

Sensor defective

Sensor cable defective

correctly

Sensor defective

Sensor cable defective

correctly

Sensor defective

Sensor cable defective

Adjust sensor.

Call a service technician.

Call a service technician.

Adjust sensor.

Call a service technician.

Call a service technician.

Adjust sensor.

Call a service technician.

Call a service technician.

Adjust sensor.

Call a service technician.

Call a service technician.

Adjust sensor.

Call a service technician.

Call a service technician.

Adjust sensor.

Call a service technician.

Call a service technician.

10.2.2 Other errors

Error symptom Possible errors Correction of error

Water supply to the nozzle is not being

stopped although the high pressure

washer has been shut down.

If none of the above-mentioned corrections work, call a service technician.

Dirt in water valve. Clean water valve by

dismounting the cover and

cleaning the diaphragm

and the valve seat.

Do the same to the pilot

valve (the small cover

at top of the valve. Blow

through the hole to the

pilot valve to make sure

that this duct is free of dirt.

Original Instructions

23

Page 24

MULTICLEANER 7-53

11 Specifications

11.1 Robot and motor/pump unit

Weight kg 285

LxBxH mm 1,500 x 615 x 1,000

Power input kW 6.8

Power supply A 400 V, 16 A

Water volume, min/max. l/h 1,000 - 1,070

Pressure of inlet water, min/max. bar 1 - 10

Max. temp. inlet water °C 60

Pump pressure bar 195

Long distance nozzle mm 1.5

Nozzle, manual cleaning 0500

Effective cleaning depth mm 4,800

Reach of arm from edge of inventory, min. mm 1,000

Reach of arm from edge of inventory, max. mm 2,000

Length of cable on reel mm 35,000

Noise level db(A), (EN 60704-1), (EN ISO 3746) Lpa/Lwa 83/96

12 EU Declaration of conformity

EU-declaration of conformity

Product:

Type:

Description:

The design of the unit corresponds to the

following pertinent regulations:

Applied harmonised standards:

Applied national standards and technical

specifi cations:

Anton Sørensen

General Manager of Technical Operations EAPC

High pressure washer

MULTICLEANER 7-53

400 V 3~, 50 Hz - IP X5

EF-Machine Directive 2006/42/EC

EF-Low-voltage Directive 2006/95/EC

EF-direktiv vedr. elektromagnetisk fordragelighed 2004/108/EC

EN 60335-2-79 (2006), EN 55014/108/EC

EN 55014-2 (2001), EN 61000-3-2 (2006)

EN 60335-2-79

Nilfi sk ALTO

Division of Nilfi sk-Advance AG

Industrivej 1

DK-9560 Hadsund

Hadsund, 01.07.2010

24

Original Instructions

Page 25

Page 26

Page 27

Page 28

Nilfi sk-ALTO

Division of Nilfi sk-Advance A/S

Industrivej 1

DK - 9560 Hadsund

tel.: (+45) 7218 2100

www.nilfi sk-alto.com

Loading...

Loading...