Page 1

Instructions for Use Manual

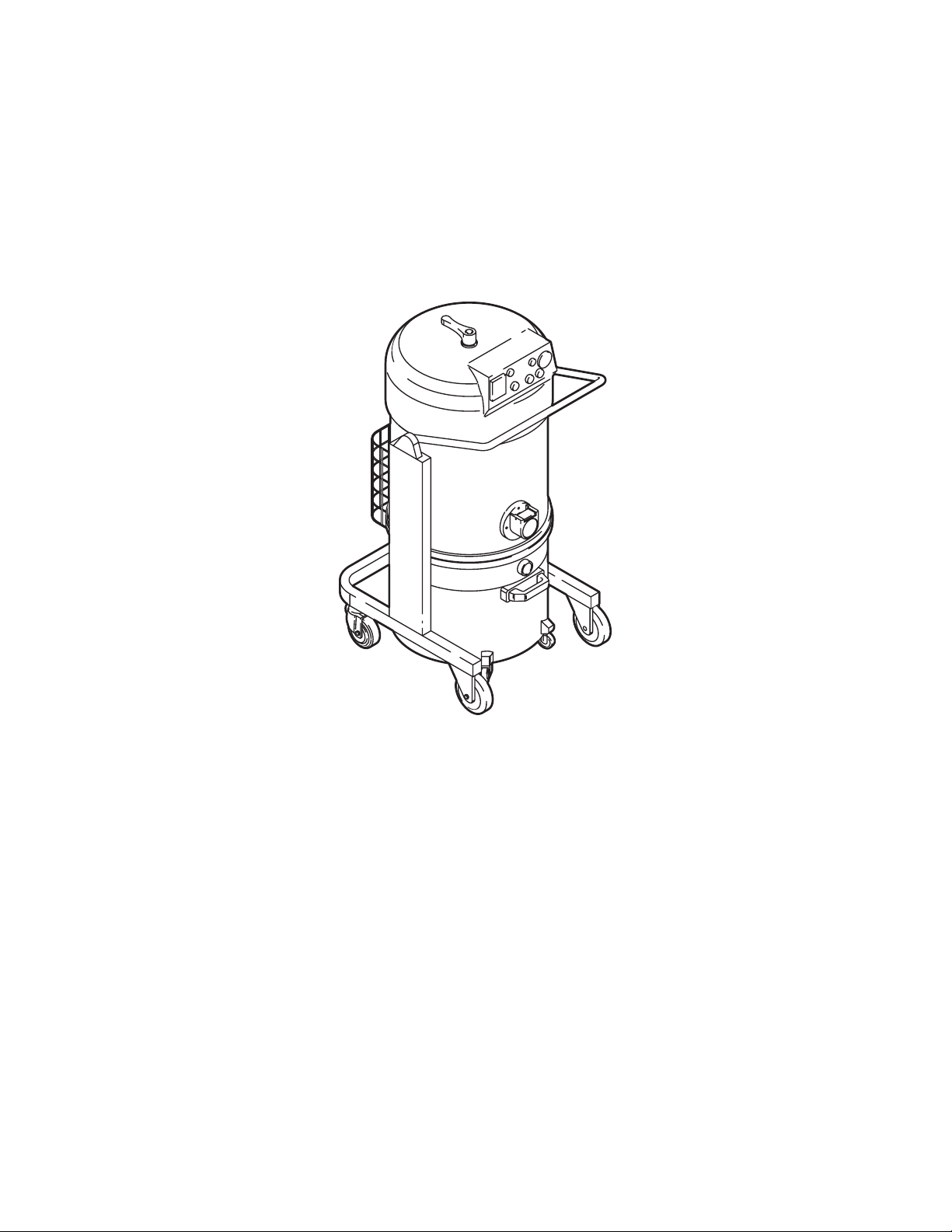

Nilsk CFM 127 and 137 Industrial Vacuums

04/2009

Page 2

Page 3

127 / 137

INDEX

Operating instructions .......................................................................................................................................... page 2

Operator safety ............................................................................................................................................... page 2

General information about use of the vacuum cleaner ................................................................................... page 2

Proper uses ..................................................................................................................................................... page 2

General recommendations.............................................................................................................................. page 3

Description of the vacuum cleaner - Labels .................................................................................................... page 3

Optional kits .................................................................................................................................................... page 4

Accessories ..................................................................................................................................................... page 4

Packing and unpacking ................................................................................................................................... page 4

Connection to the power supply...................................................................................................................... page 5

Extensions ...................................................................................................................................................... page 5

Wet and dry applications ................................................................................................................................. page 5

Maintenance and repairs ................................................................................................................................ page 6

Technical data - Dimensions ........................................................................................................................... page 6

Controls and indicators (g. 4) ........................................................................................................................ page 7

Inspections prior to starting ............................................................................................................................. page 7

Starting-up ...................................................................................................................................................... page 7

Operation ........................................................................................................................................................ page 7

Operating lter shaker..................................................................................................................................... page 7

Emergency stopping ....................................................................................................................................... page 7

Emptying the container ................................................................................................................................... page 7

At the end of a cleaning session ..................................................................................................................... page 8

Maintenance, cleaning and decontamination.................................................................................................. page 8

How to disassemble and replace the main and Hepa lters ........................................................................... page 9

Main lter replacement .................................................................................................................................... page 9

Replacing the Hepa lter................................................................................................................................. page 10

Checking and cleaning the motor cooling fan ................................................................................................. page 10

Seal inspection................................................................................................................................................ page 10

Cleaning and replacing the separator (g. 17) ................................................................................................ page 10

Disposal of the machine.................................................................................................................................. page 11

Wiring diagrams .............................................................................................................................................. page 11

Recommended spares .................................................................................................................................... page 11

Troubleshooting .............................................................................................................................................. page 12

Manufacturer’s assistance center ................................................................................................................ pages12-15

I

04/2009

GB

F

D

E

1

C338

Page 4

127 / 137

Operating instructions

Read the operating instructions and comply with the important safety recommendations identied by the words:

WARNING !

Before starting the machine, it is absolutely essential to read these operating instructions and to keep them on le

for consultation. The vacuum cleaner can only be used by people who are familiar with the way it works and who

have been explicitly authorized and trained for the purpose. Before using the vacuum cleaner, operators must be

informed, instructed and trained on how to work it and for which substances its usage is permitted including the

safe method for removing and disposing of the vacuumed material.

- Operator Safety

WARNING !

To reduce the risk of re, electric shock, or injury:

• Do not leave appliance when plugged in. Unplug from

outlet when not in use and before servicing.

• To reduce the risk of electrical shock, do not use outdoors

or on wet surfaces.

• Do not allow this appliance to be used as a toy. This

machine is for adult-use only.

• Use only as described in this manual. Use only the

• manufacturer’s recommended attachments.

• Do not use with damaged cord or plug. If appliance is not

working as it should, has been dropped, damaged, left

outdoors or dropped into water, return it to a service center.

• Do not pull or carry by the cord, use cord as a handle,

close a door on cord, or pull cord around sharp edges

or corners. Do not run the appliance over the cord. Keep

cord away from heated surfaces.

• Do not unplug by pulling on cord. To unplug, grasp the

plug, not the cord.

• Do not handle plug, cord or appliance with wet hands.

• Do not put any object into the openings. Do not use with

any opening blocked; keep free from dust, lint, hair, and

anything that may reduce airow.

• Keep hair, loose clothing, ngers, and all parts of the body

away from openings and moving parts.

• Turn off all controls before unplugging.

I

• Use extra care when cleaning stairs.

• Do not use to pick up ammable or combustible liquids such

as gasoline or use in areas where they may be present.

GB

• Do not pick up anything that is burning or smoking, such as

cigarettes, matches, or hot ashes, or any hazardous dusts.

• Do not use without dust bag/or lters in place.

F

• Connect to a properly grounded outlet only. See grounding instructions.

D

GROUNDING INSTRUCTIONS

This appliance must be grounded. If it should malfunction or

breakdown, grounding provides a path of least resistance for

E

electric current to reduce the risk of electric shock. This appli-

ance is equipped with a cord that has an equipment-grounding

conductor and grounding plug. The plug must be inserted into

an appropriate outlet that is properly installed and grounded

in accordance with all local codes and ordinances.

Improper connection of the equipment-grounding conductor

can result in a risk of electric shock. Check with a qualied

electrician or service person if you are in the doubt as to

whether the outlet is properly grounded. Do not modify the

plug provided with the appliance-if it will not t the outlet, have

a proper outlet installed by a qualied electrician.

Make sure that the appliance is connected to an outlet hav-

ing the same conguration as the plug. No adapter should be

used with this appliance. If the appliance must be reconnected

for use on a different type of electric circuit, the reconnection

should be made by a qualied service personnel.

- General information about use of the vacuum

cleaner

Use of the vacuum cleaner is governed by the laws in force

in the country where it is used.

Besides the operating instructions and the laws in force in

the country where the vacuum cleaner is used, the technical

regulations for ensuring safe and correct work must also be

observed (Legislation concerning environmental and labor

safety).

Do not carry out any work that could jeopardize the safety of

people, property and the environment.

Comply with the safety indications and recommendations in

this instruction manual.

- Proper uses

This appliance is suitable for collective use, e.g. in hotels,

schools, hospitals, and factories.The vacuum cleaners

described in this instruction manual are appliances designed

for industrial use. They are produced in different versions and

for different applications.

C338

2

04/2009

Page 5

127 / 137

- General recommendations

WARNING !

Risk of re outbreaks and explosions.

The vacuum cleaner can only be used when it is certain that

active sources of ignition are not going to be vacuumed.

Do not vacuum the following materials: burning materials

(hot ashes, lighted cigarettes, etc.), ammable liquids,

aggressive fuels (e.g. gasoline, solvents, acids, alkaline

solutions, etc.).

Do not vacuum the following materials: explosive dusts or

ones liable to ignite spontaneously (such as magnesium

or aluminium dusts, etc.).

The vacuum cleaner is not suitable for vacuuming explosive or similar substances, as established by the laws

governing explosive substances, particularly: liquid fuels

and mixtures of ammable dusts and liquids.

WARNING !

Emergency

If an emergency situation occurs:

- lter breakage

- re outbreak;

- short-circuit;

- motor block;

- electric shock;

- etc.;

turn off the vacuum cleaner, unplug it and ask for assist-

ance from a qualied person.

Note

Check the place of work and substances tolerated for the

vacuum cleaner in version for liquids.

WARNING !

The vacuum cleaners must not be used or stored

outdoors, or in damp places.

Only versions with the level sensor can be used for

liquids.

If not, they can only be used to vacuum dry materials.

WARNING !

Version for liquids.

If foam or liquid spills from the machine, switch off

immediately and check for the cause.

- Description of the vacuum cleaner - Labels

See g. 1.

- Labels key of g. 1

A- Identication plate: Code of the Model which include,

Technical Specications, Serial Number, CE marking, and

Year of manufacturing

B- Dust container

C- Fastening latches

D- Container lever

E- Inlet

H- Exhaust

I- Warning label

L- Panel power plate: Indicates that the panel is powered

by the voltage given on the data plate.

I

04/2009

GB

WARNING !

This vacuum cleaner creates a strong air ow which is drawn

in through inlet “E” and blows out through exhaust “H”.

Before turning on the vacuum cleaner, t the hose into the

inlet and then t the required tool to the end part. Refer to

Manufacturer’s accessory catalog or the service center.

The diameters of the authorized hoses are given in the

technical specications table.

This vacuum cleaner is equipped with an internal deector

which subjects the vacuumed substances to a circular cen-

trifugal movement that makes them drop into the container.

The vacuum cleaner is equipped with a main lter which

enables it to be used for multiple applications.

Different types of main lters are available: standard and

HEPA (for dusts that are hazardous for the health).

3

C338

F

D

E

Page 6

127 / 137

- Optional kits

Various optional kits are available for converting the vacuum

cleaner.

Component 127 137

Polyliner adapter kit • •

Fixed oor nozzle • •

Electric oat shut-off •

Dust bag kit • •

Cyclone lter protector • •

HEPA lter • •

On request, the vacuum cleaner can be supplied with optional

kits already installed. However, they can also be installed at

a later date.

Please contact Manufacturer’s sales network for further details.

Instructions describing how to t and operate the optional

kits as well as maintenance manuals are supplied with the

optional kits themselves.

WARNING !

Use only genuine spare parts supplied and authorized

by the Manufacturer.

- Accessories

Various accessories are available; refer to Manufacturer’s

Accessories Catalogue.

WARNING !

Only use genuine accessories supplied and authorized

by the Manufacturer.

- Packing and unpacking

GB

Dispose of the packing materials in compliance with any current laws and regulations.

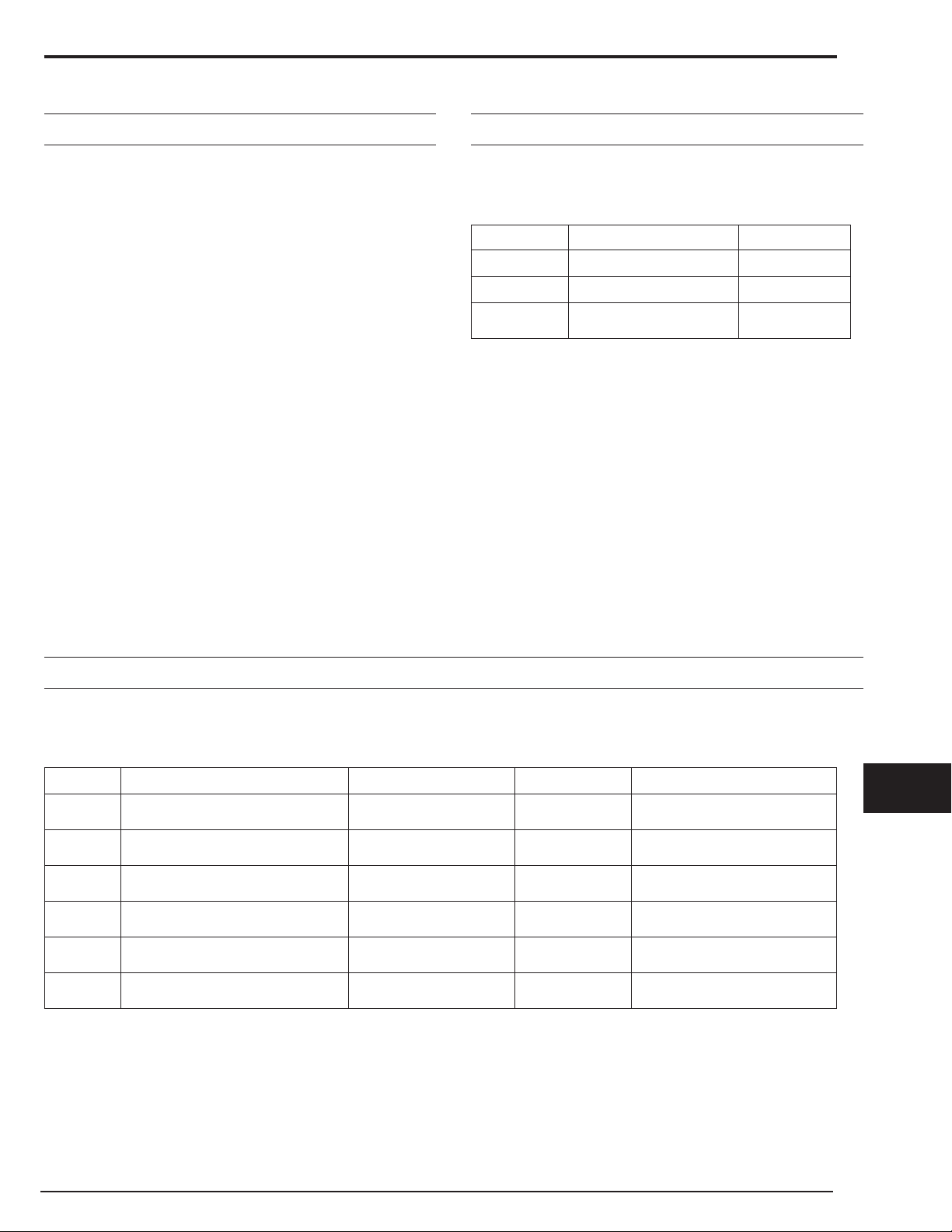

- Cardboard packing (g. 2)

Model

A (in) 24 28 28

B (in) 28 32 32

I

C (in) 50 61 67

Weight with

packing (lbs.)

127 137

(60 liter)

111 168 177

137

(100 liter)

F

D

E

C338

4

04/2009

Page 7

- Connection to the power supply

127 / 137

WARNING !

- Make sure that the vacuum cleaner is in good condition before commencing work.

- Before plugging the vacuum cleaner into the power

supply, make sure that the voltage rating indicated on

the data plate corresponds to that of the power supply.

- Plug the vacuum into a socket with a correctly installed

ground contact/connection.

- Make sure that the vacuum cleaner is off.

- The plugs and connectors of the connection cables

must be protected against splashed water.

- Make sure that connections to the power supply and

plug are correct.

- Use vacuum cleaner only when the cables that connect

to the power supply are in good condition (damaged

cables could lead to electric shocks!).

- Regularly check that the electric cable does not show

signs of damage, excessive wear, cracks, or aging.

WARNING !

When the vacuum cleaner is operating, do not:

- crush, pull, damage, or tread on the cable that con-

nects to the power supply;

- only disconnect the cable from the power supply by

removing the plug (do not pull the cord);

- only replace the electric power cable with one of the

same type as the original. The same rule applies if an

extension is used;

- the cable should be replaced by an authorized service

center or qualied electrician.

WARNING !

Never spray water on the vacuum cleaner: such action

constitutes a danger hazard for persons and could shortcircuit the power supply.

- Wet and dry applications

Note

The vacuum lters and the safety container (if applicable)

must be installed correctly.

If the machine is used to clean up liquids, make sure that the

liquid level sensor is activated and installed correctly.

WARNING !

Comply with the safety regulations governing the materials for which the vacuum cleaner is used.

WARNING !

If the wet cleaning model is used:

- Make sure that the liquid level sensor operates correctly

before using the vacuum cleaner to clean up liquids;

- If foam forms, immediately stop work and empty the

container.

- Warning: switch off the vacuum cleaner immediately

if foam or liquid leaks out.

- Regularly clean the liquid level monitoring device and

check to make sure that there are no signs of damage.

- Warning: the dirty liquid collected by the vacuum must

be considered conductive.

I

- Extensions

If an extension is used, make sure it is sized properly for the

power requirements of the vacuum cleaner.

04/2009

GB

F

D

E

5

C338

Page 8

127 / 137

- Maintenance and repairs

WARNING !

Disconnect the vacuum cleaner from its power source

before cleaning, servicing, replacing parts or converting

it to another model

The plug must be removed from the socket.

- Only carry out the maintenance work described in

this manual.

- Only use original spare parts.

- Do not modify the vacuum cleaner in any way. Failure

to comply with these instructions could jeopardize

your safety. Moreover, such action would immediately void the CE declaration of conformity issued

with the machine.

WARNING !

Contact Manufacturer’s technical assistance service or

sales network for maintenance operations not described

in this manual.

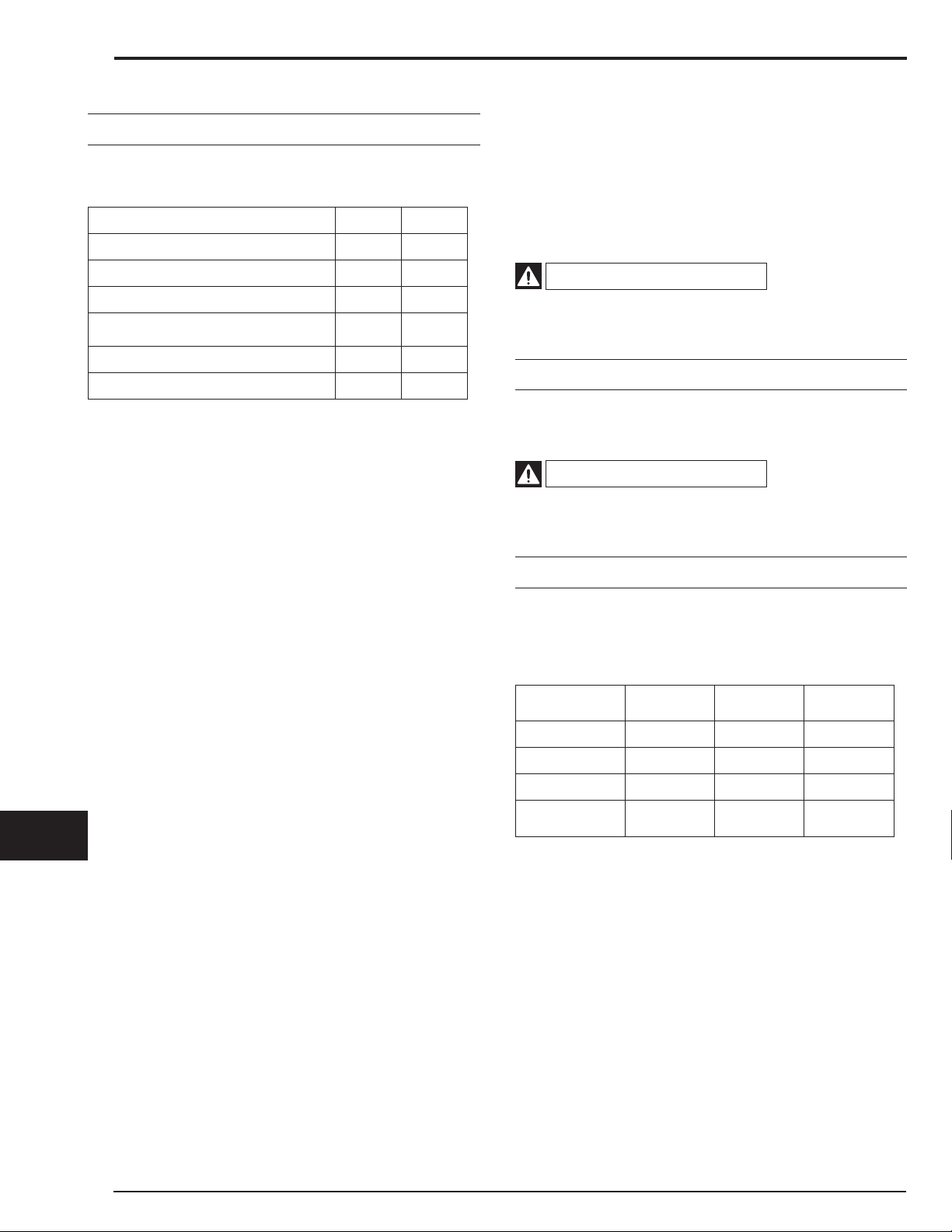

- Technical data - Dimensions

- Technical data

Parameter Unit

Voltage @ 60Hz volts 120 120 120

Type of Power no. of phases 1 1 1

Power kW 2 2.4 2.4

Current Draw amps 13.5 15.5 15.5

Waterlift, max. inches of H2O 93 82 82

127 137

(60 l)

137

(100 l)

Airow, max. cfm 190 286 286

Filter Area, main sq. ft. 21 21 21

Filter Area, optional HEPA (upstream) sq. ft. 32.3 32.3 32.3

Noise Level, @ 3’ 3” (1 meter) dB(A) 68 70 70

Tank Capacity gallons/liters 10/38 16/60 26/100

Machine Inlet inches 3 3 3

Dimensions (l x wx h) inches 26 x 22.8 x 41.3 31 x 25.6 x 53.2 31 x 25.6 x 61

I

Weight lbs. 92.4 136 143

Cord Length ft. 30 30 30

GB

Filter Efciency, HEPA DOP tested

99.995% @

0.18 micron

99.995% @

0.18 micron

F

- Storage conditions:

T: -10...+40°C

D

Humidity : ≤ 85%

- Operating Conditions:

Maximum altitude 800 m (up to 2000 m with reduced performances)

E

T: -10 ...+40° C

Humidity: ≤ 85%

99.995% @

0.18 micron

C338

6

04/2009

Page 9

- Dimensions (g. 3)

127 / 137

Model

A (in) 22.8 25.6 25.6

B (in) 26 31 31

C (in) 41.3 53.2 61

127 137

(60 l)

137

(100 l)

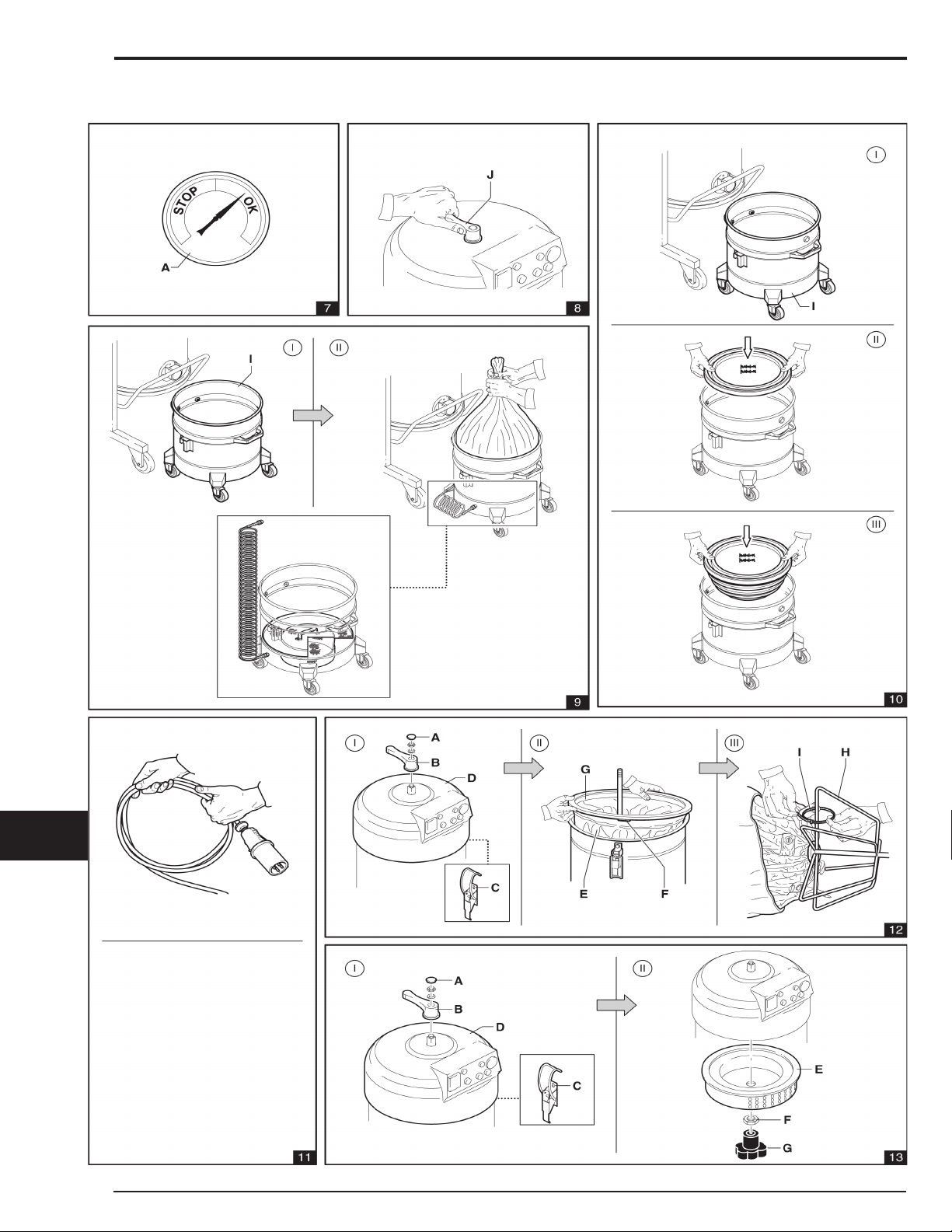

- Controls and indicators (g. 4)

A- Vacuum gauge

B- Switch button

C- Lighted mains voltage indicator

- Inspections prior to starting

Prior to starting, check that:

- the lters are installed;

- all latches are tightly locked;

- the hose and tools have been correctly tted into inlet “A”

(g. 5);

- the bag or safety container is installed, if applicable.

- Do not use the vacuum cleaner if the lter is damaged.

WARNING !

When the vacuum cleaner is operating, always check to

make sure that the vacuum gauge pointer remains in the

green zone (OK).

Consult the “Troubleshooting” chapter if problems occur.

- Cleaning/Purging the main lter

Clean the main lter by means of the lever “J” (g. 8) when

the vacuum gauge pointer (“A” g. 8) switches from the green

zone (OK) to the red zone (STOP).

WARNING !

Stop the machine before cleaning the lter.

Do not purge the lter while the machine is on, as this

could damage the lter itself.

Wait before restarting the vacuum cleaner, to allow the dust

to settle.

Replace the lter if the pointer still remains in the red zone

(STOP) even after the lter has been shaken (consult the

“Main lter replacement” section).

- Starting-up

- Lock the castor brakes “E” (if present) before starting the

vacuum cleaner (g. 6);

- press the buttons “B” - g. 4.

- Operation

Check the ow rate:

- when the vacuum cleaner is operating, the pointer of the

vacuum gauge (“A” - g. 7) must remain in the green zone

(OK) to ensure that the speed of the intake air does not

drop below the safety value of 20 m/sec;

- if the pointer is in the red zone (STOP), it means that the

speed of the air in the hose is below 20 m/s and that the

vacuum cleaner is not working optimally - clean or replace

the lters;

- when the hose is blocked, the pointer of the vacuum gauge

will switch from the green zone (OK) to the red zone (STOP).

- Emergency stopping

Press the push-buttons “B” (g. 4).

- Emptying the container

WARNING !

Turn off the machine and remove the plug from the power

socket before proceeding with this operation.

I

GB

F

D

E

04/2009

7

C338

Page 10

127 / 137

- Before emptying the container it is a advisable to clean the

lter (see “Cleaning the main lter” sect.).

a) Standard model, not suitable for treating hazardous dust

- Release the container “I” (g. 9), then remove and empty it.

- Make sure that the seal is in good condition and correctly

positioned.

- Place the container back in position and use the lever to

secure it again.

Plastic liner

A plastic liner (our code 40100) can be used to collect dust

(see g. 9).

In this case, the machine must be equipped with optional accessories (grate and bypass hose - g. 9).

WARNING !

- In compliance with current laws, these operations can

only be carried out by trained and specialized personnel

who must wear adequate clothing.

- Do not agitate the dust during this operation. Wear a

protective mask.

- A plastic liner can be used (our code 40100) or ABS safety

container (our code 8 30202 - 8 31685) if dust that is

dangerous and/or hazardous for the health is vacuumed.

- The container and/or liner must only be disposed of by

trained personnel and in compliance with the current

laws in force.

Use as a wet cleaner

Make sure that the vacuum cleaner is equipped with a oat

(liquid level sensor) and is suitable for use as a wet cleaner.

(137 model only).

Do not clean up ammable liquids.

If foam forms, stop work immediately and empty the container.

The lter element will be wet after liquids have been cleaned up.

A wet lter can quickly become clogged if the vacuum cleaner

is then used to clean up dry substances.

For this reason, make sure that the lter is dry or replace it

with another one before using the vacuum cleaner to clean

up dry materials.

- At the end of a cleaning session

1- Turn off the vacuum cleaner and remove the plug from

the socket.

2- Wind the connection cable (g. 11).

3- Empty the container as described in the “Emptying the con-

tainer” section. Clean the vacuum cleaner as described in

the “Maintenance, cleaning and decontamination” section.

4- Wash the container with clean water if aggressive sub-

stances have been cleaned up.

5- Store the vacuum in a safe, dry place, out of the reach of

unauthorized people.

- Maintenance, cleaning and decontamination

How to replace the safety container

- Place the hose in a safe, dust-free place;

- Release the dusts container “I” (g. 10);

- Close the safety container with the supplied cover and re-

move it from the dusts container “I” (g. 10). Fit an empty

container in its place.

I

- Start the motor again to prevent dust from being blown out.

- Make sure that the seal is in good condition and correctly

positioned.

GB

- Switch off the motor, t an empty drum in place and fasten

it in position.

F

D

E

WARNING !

Note: the precautions described below must be taken

during all the maintenance operations, including cleaning

and replacing the main and Hepa lters.

a) To allow the user to carry out maintenance operations,

the vacuum must be disassembled, cleaned and overhauled as much as reasonably possible, without causing hazards for the maintenance staff or other people.

The suitable precautions include decontamination

before disassembling the vacuum, adequate ltered

ventilation for the air exhausted from the room in which

it is disassembled, cleaning of the maintenance area

and suitable personal protection.

C338

8

04/2009

Page 11

127 / 137

b) All parts of the appliance must be considered as con-

taminated when they are removed from a hazardous

zone and appropriate actions must be taken to prevent

dust from dispersing.

When service work or repairs are carried out, all the

contaminated elements that cannot be cleaned well

must be eliminated.

These elements must be disposed of in sealed bags

conforming to the applicable regulations and in accordance with the local laws governing the disposal

of such material.

This procedure must also be followed when the lters

are removed (main, Hepa and downstream lters).

Note: Compartments that are not dust-tight must be

opened with suitable tools (screwdrivers, wrenches,

etc.) and thoroughly cleaned.

c) ATTENTION: this appliance is designed to be able to

collect powders that are harmful for one’s health. All

maintenance work and emptying, including removing the powder from the container, must be done by

specialized personnel only and they must wear protec-

tive clothing. Do not start without the complete lter

system in place.

WARNING !

- How to disassemble and replace the main and

Hepa lters

WARNING !

When the vacuum cleaner is used to clean up hazardous

substances, and the lters become contaminated:

- work with care and avoid spilling the vacuumed dust

and/or material;

- place the disassembled and/or replaced lter in a

sealed plastic bag;

- close the bag tightly;

- dispose of the lter in accordance with the current laws.

WARNING !

Filter replacement is a serious matter.

The lter must be replaced with one of identical characteristics, lter surface and category.

Otherwise, the vacuum cleaner will not operate correctly.

- Main lter replacement

WARNING !

Use only spare parts supplied and authorized by the

Manufacturer.

Do not to agitate dust when this operation is carried out.

Wear a mask and other protective clothing plus protective gloves suited to the hazardous nature of the dust

collected. Refer to the regulations governing the handling

of hazardous materials.

Before proceeding with this operation, turn off the machine

and remove the plug from the power socket.

- Replace the main lter

Disassembly (g. 12)

- Remove plug “A”, unscrew the nut underneath and remove

lever “B”.

- Release the closing clips “C” and remove the head “D”.

- Lift lter “E”, unscrew clamp “F” and remove ring “G”.

- Unscrew cage “H” and turn the lter upside down.

- Cut the plastic clamps “I” and detach the cage from the lter.

I

GB

F

D

E

04/2009

9

C338

Page 12

127 / 137

Assembly (g. 12)

- Mount the lter catch and retention ring of the old lter on

to the new one.

- Insert cage “H” and x it to the lter by means of clamps

“I” at the bottom of the lter itself.

- Fit the lter into lter chamber.

- Mount the head “D” and lock it in place with the closing

clips “C”.

- Mount the lever “B” in position with the nut and relative

washer.

- Fit on the plug “A” by exercising slight pressure.

- Replacing the Hepa lter

WARNING !

Do not agitate the dust when this operation is carried out.

Wear a mask and other protective clothing plus protective gloves suited to the hazardous nature of the dust

collected. Refer to the regulations governing the handling

of hazardous materials.

- Replacing the upstream Hepa lter (g. 13)

- Remove the plug “A”, unscrew the nut underneath and

remove the lever “B”.

- Release the hooks “C” and lift the head “D”.

- Unsrew the knob “G” and take the nut “F” under the lter “E”;

- Cover the lter “E” with a plastic bag and remove it;

- Seal the bag, t the new lter and close the cover.

Mount the following parts in the given order:

- the HEPA lter;

- nut and central knob for locking;

- the head, locking it to the lter chamber “C”;

I

- the lever with the relative washer, nut and plug.

GB

- Checking and cleaning the motor cooling fan

Periodically clean the motor(s) cooling fan to prevent the

F

electric motor(s) from overheating, particularly if the appliance

is used in a dusty place.

D

- Seal inspection

- Checking the condition of the hoses

Make sure that connecting hose “A” is in good condition and

correctly secured to the inlet.

If the hose is damaged, broken or badly connected to the inlet,

it must be replaced.

When sticky materials are collected, check for possible clog-

ging along the hose, in outlet and in the lter chamber.

Scrape the inside of the outlet and remove the deposited waste

as indicated in g. 14.

- Checking the lid seal

If seal “A” under head “D” has become slack, unfasten screws

“B” that lock fastening latches “C” in place and allow them to

slide downward until lid “D” closes securely.

Now tighten locking screws“B”.

Replace seal “A” - g. 15 - if an optimum seal cannot be obtained.

- Checking the seal of lter chamber

If seal “A” - g. 16 - between the container and lter chamber

“C” is not secure:

- loosen the four screws “B” that lock lter chamber “C”

against vacuum structure.

- Allow lter chamber “C” to lower down and relock screws

“B” once it has reached the retention position.

The seal must be replaced if it is torn, cut, etc.

Replace seal “A” if it does not secure adequately

- Cleaning and replacing the separator (g. 17)

Note

If there is only a dust deposit on separator “D”, allow the dust

to drop through the central hole.

Separator “D” should rst be disassembled in order to be

cleaned:

- release lock fastening latches “A” and remove the head “B”;

- remove the lter;

- unscrew the two screws “C” and remove separator from

the container.

- Replace the part if excessively worn.

- Assemble separator “D” again.

- Lock it in position by screwing the two screws “C”.

- Ret the lter and close head “B”, locking it in place with

the two fastening latches “A”.

E

C338

10

04/2009

Page 13

127 / 137

- Disposal of the machine

Dispose of the machine in compliance with laws.

- Correct Disposal of This Product (Waste Electrical &

Electronic Equipment)

This marking (pos. N - g. 1) shown on the product or its literature, indicates that it should not be disposed of with other

household wastes at the end of its working life. To prevent

possible harm to the environment or human health from

uncontrolled waste disposal, please separate this from other

types of wastes and recycle it responsibly to promote the sustainable reuse of material resources. Business users should

contact their supplier and check the terms and conditions of

the purchase contract. This product should not be mixed with

other commercial waste for disposal.

- Wiring diagrams

See g. 18.

Wiring diagram key

Abbrev. Component Code

M1 - M2 - M3 Motor see table below

S1 - S2 - S3 Motors switches 8 39525

H2 Voltage indicator light 8 39526

- Recommended spares

The following is a list of spare parts that should be kept ready to hand in order to speed up maintenance work. (g. 19).

Recommended spare parts list (g. 19)

Pos. Description Model Dim. (mm) Code number

1 Main lter “L”

3 Filter ring

4

5 Filter ring seal

6 Filter clamp

7 HEPA lter

800 W single-phase motor

1000 W single-phase motor

127

137

127

137

127

137

127

137

127

137

127

137

Ø 460 8-17080

Ø 460 8-15003

N/A

Ø 460 8-17026

Ø 460 8-18079

Ø 460 8-17455

8-54006

8-54002.115

I

GB

F

D

E

04/2009

11

C338

Page 14

127 / 137

- Troubleshooting

Fault Causes Remedies

Check whether power is reaching the socket

Check whether the plug and cable are in good

The vacuum fails to start No power

Clogged main lter Clean the lter. Replace it if this is not sufcient

The rpm rate of the vacuum increases

Clogged hose Check the hose and clean it

condition

Ask for assistance from an authorized manufacturer’s technician

Dust leaks from the vacuum

Noisy suction motor Worn or broken carbon brushes Remove and replace the motor carbons

Electrostatic current on the vacuum non-existent or inefcient grounding

The lter is torn Change it for another of identical type

Inadequate lter Change it for another of suitable type and check

Check all ground connections. Particularly

check the suction inlet tting; lastly, the hose

must be strictly antistatic

- Manufacturer’s assistance center

See appendix.

I

GB

F

D

E

C338

12

04/2009

Page 15

127 / 137

I

GB

F

D

E

04/2009

13

C338

Page 16

127 / 137

GB

I

F

D

E

C338

14

04/2009

Page 17

127 / 137

I

GB

F

D

E

04/2009

15

C338

Page 18

Nilsk-Advance America

300 Technology Drive

Malvern, PA 19355

1-800-645-3475

questions@nilsk-advance.com

www.nilskcfm.com

Loading...

Loading...