APC 328

INSTRUCTIONS FOR USE-ORIGINAL INSTRUCTIONS

AND PARTS LIST

Models: 600303281, 600303282

5/10 revise 7/10

FORM NO. 56041948

IMPORTANT SAFETY INSTRUCTIONS

This machine is only suitable for commercial use, for example in hotels, schools, hospitals, factories, shops, and offi ces other than

normal residential housekeeping purposes.

When using any electrical appliance, basic precautions should always be followed, including the following:

WARNING!

To reduce the risk of fi re, electric shock, or injury:

• Do not leave the machine unattended when it is plugged-in. Unplug the unit from the power outlet when not in use.

• Always use a defoamer when foaming occurs to prevent damage to vacuum motor(s).

• Unplug the machine from the power outlet before cleaning or servicing.

• To avoid electric shock, do not expose to rain or snow. Store, and use, indoors.

• Wear hearing protection if desired.

• Do not allow to be used as a toy. Close attention is necessary when used near children.

• Use only the manufacturer’s recommended attachments.

• Inspect the power cord regularly for damage, such as cracking, ageing, or damaged insulation. Replace the power cord with the

same type as original if any damage is found. Do not use with damaged cord or plug.

• Use approved chemicals only. Never use solvents.

• Do not let the pump run dry.

• If the machine is not working as it should, has been dropped, damaged, left outdoors or fl ooded with water, return it to a service

center.

• Do not pull the machine by the cord, do not use the cord as a handle, close a door on the cord, or pull the cord around sharp

edges or corners. Do not run the machine over the cord. Keep the cord away from heated surfaces. To unplug, grasp the plug,

not the cord.

• Extension cords must be 12 gauge and no longer than 15 m. Replace the cord or unplug immediately if the ground prong

becomes damaged.

• Never fi ll the tank with water above 54º C.

• Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair, and anything that may

reduce air fl ow.

• Keep loose clothing, hair, fi ngers, and all parts of body away from openings and moving parts.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes, or any health endangering dusts.

Do not use to pick up fl ammable or combustible liquids such as gasoline or use in areas where they may be present.

• Turn off all controls before unplugging.

• Use extra care when cleaning on stairs.

• Liquid ejected at the spray nozzle could be dangerous as a result of its temperature, pressure,or chemical content.

2 - FORM NO. 56041948 - APC 328

SAVE THESE INSTRUCTIONS

INSPECTION:

Carefully unpack and inspect your APC 328 for shipping damage. Each machine is tested and inspected before shipping. Any shipping damage

incurred is the responsibility of the carrier. You should notify the carrier immediately if you notice damage to the box or to the machine or parts.

CLEANING SOLUTIONS:

We recommend liquid cleaning chemicals. Powder chemicals may be used, but unless mixed very thoroughly they could cause a build-up in the

pump, lines, heat exchanger and/or quick disconnects. Any problem caused by a chemical build-up is not covered by warranty. Use a neutral

cleaner with a pH between 5 and 10 to avoid premature wear of the pump, seals, and/or other components.

MAINTENANCE:

For optimum performance fl ush the machine with clear water at the end of each working day. Once a month, minimum, run a fl ushing compound

through the machine to break up any mineral or chemical build-up that may have formed. The vacuum motor and the pump do not require any

scheduled maintenance; however, the motor may require replacement brushes after 1000 - 1500 hours. Clean the body with an all-purpose

detergent, and protect it with an automobile interior polish. Lubricate the wheels, castors, and quick disconnects with an all purpose silicone

spray. Refer to the maintenance schedule on page 9.

PARTS AND SERVICE:

Repairs, when required, should be performed by your authorized distributor who maintains an inventory of original replacement parts and

accessories. Call the distributor from whom you purchased this machine if you need parts and service. Be sure to specify the machine model.

Have your serial number at hand.

Serial Number: __________________ Model: APC 328

Purchase Date:_____________

Write the name and phone number of your distributor:

____________________________________________________________________

____________________________________________________________________

Be sure to register your purchase to activate your warranty

FORM NO. 56041948 - APC 328 - 3

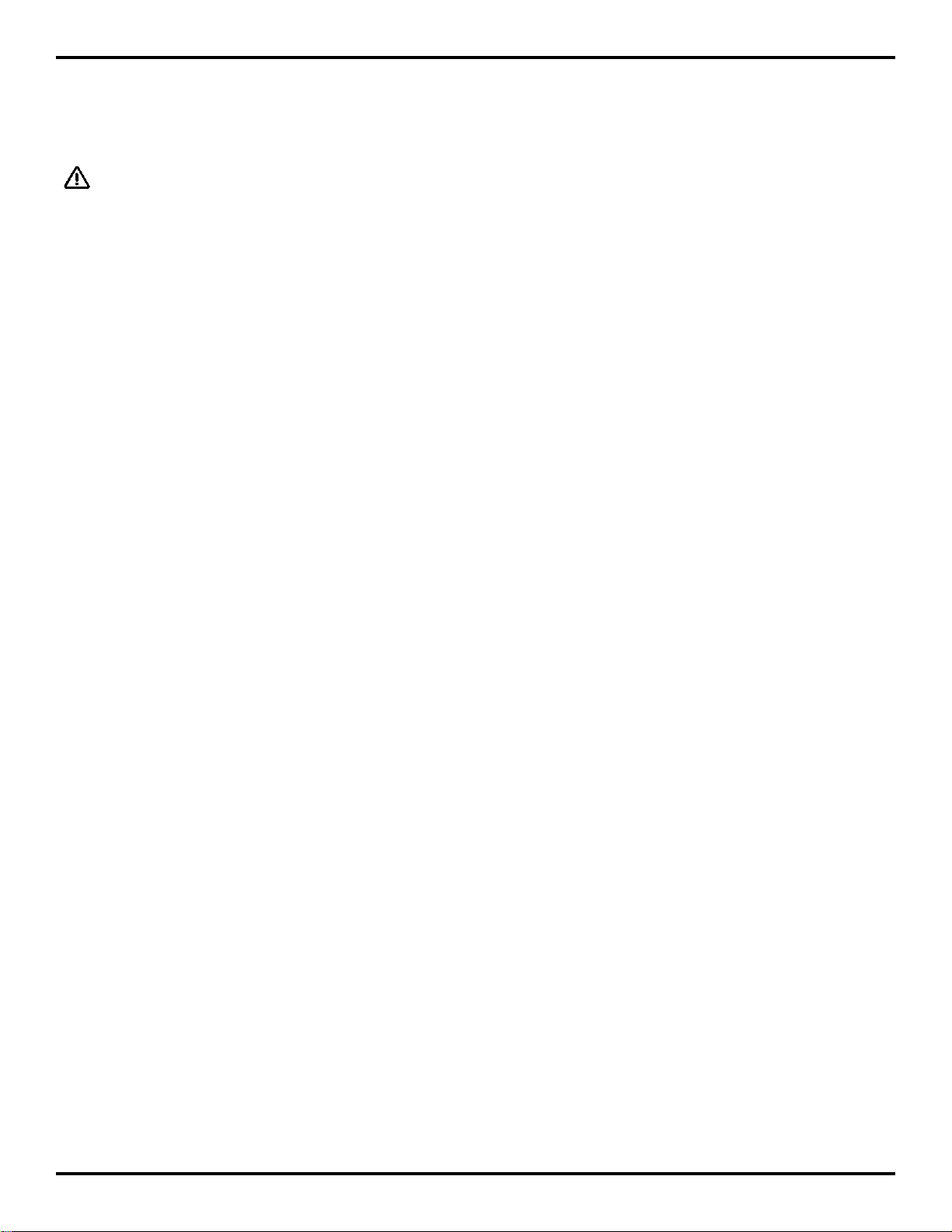

KNOW YOUR MACHINE

Operator Handle (1): Operator holds onto this handle to move the machine from one location to another.

Solution Tank Lid (2): This lid screws off so the tank can be fi lled. The solution fi ll hose is tethered to the lid, and hangs inside the arm of the

Operator Handle.

Maid’s tote and Recovery tank lid (3): This removable container holds often-used items and has a handle for easy carrying. The recovery

tank lid sits under the maid’s tote and covers the opening in the Recovery Tank. This is where the operator can access the tank to clean it

and the ball fl oat cage. The tank can be fl ushed out by running clean warm water into this opening and laying the open drain hose into a

bucket or drain.

Recovery Hose (4): Waste water is picked-up through this hose.

Spray Hose (5): This hose delivers water from the machine to the cleaning tool.

Drain Hose (6): This hose is used to empty the recovery tank. NOTE: hold the end of the hose above the water level in the tank to avoid

sudden, uncontrolled fl ow of waste water when you remove the cap, then lower the hose slowly to control the rate of discharge.

Quick Disconnect (7): Point of attachment for the Spray Hose (5).

Castors and Wheels (8): Castors pivot for ease of steering, and large back wheels make it easy to roll the machine from location to

location.

Chemical Feed Lines (9): These clear tubes connect the cleaning chemical containers to the machine where the chemical can be

siphoned into the outlet water from the pump. Metering tips -- used to change the ratio of water to chemical -- are installed here.

Switch Plate (10): The machine’s on/off switches for the vacuum and for the pump are located here and this is where the valve to change

chemical feeds is located.

Power Cord (11): The 25 ft. power cord connects to a power cord pigtail on the rear of the machine.

Chemical Container Holders (12): Two molded-in bottle holders for chemical jugs.

11

12

1

4

2

3

9

5

6

10

7

8

4 - FORM NO. 56041948 - APC 328

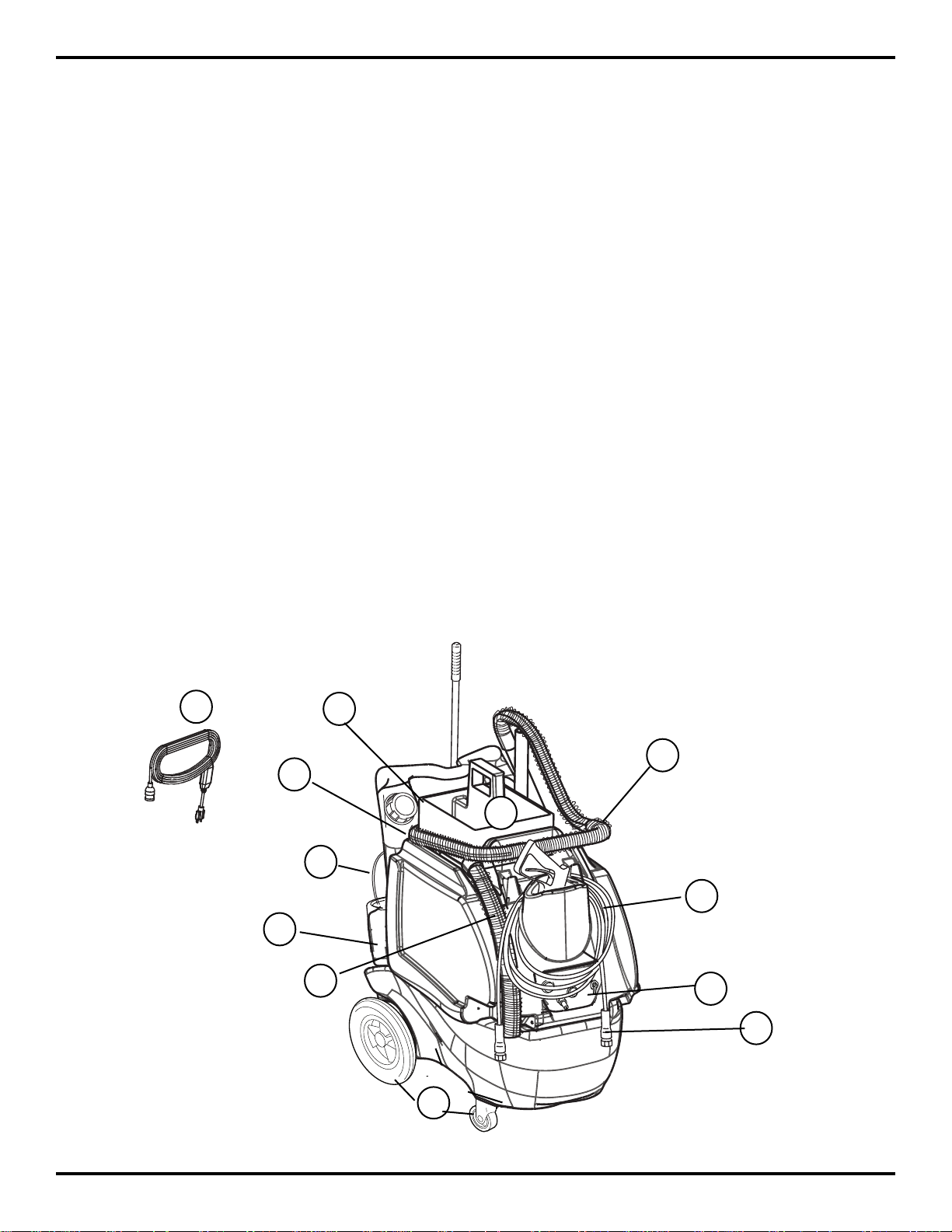

O

I

O

COLOR HOLE SIZE MIX RATION FLOW RATE

Orange 0.007 1 to 128 7,81 ml per 1 l

Pink 0.012 1 to 64 19,53 ml per 1 l

Dark Green 0.014 1 to 50 23,44 ml per 1 l

Yellow 0.016 1 to 32 39,06 ml per 1 l

Light Blue 0.020 1 to 20 46,87 ml per 1 l

Burgandy 0.022 1 to 15 70,33 ml per 1 l

Black 0.048 1 to 5 156,27 ml per 1 l

METERING TIPS

KNOW YOUR SWITCH PLATE

2

1

4

Vacuum Switch (1): turns on the vacuum motor.

Chemical Valve (2): switches between the two chemical containers. When the selector is pointed straight down, the valve is off and neither

chemical is selected. When the selector is pointed directly towards one or the other symbols, that chemical is selected.

Solution Pump Switch (3): turns on the solution pump.

Quick Connect (4): this is where solution comes out of the machine and the attachment point for the solution hose.

3

METERING TIPS

The chemical metering tips allow you to select the ratio of chemical to water, as the water fl ows out of the machine. Insert the correct metering tip

for the desired mixture into the chemical siphon tube.

FORM NO. 56041948 - APC 328 - 5

SET-UP AND USE

1) Insert the appropriate metering tips into the chemical feed lines (see illustration, page 5).

2) Fill the holding tank with warm water (not exceeding 54 °C). Do not add any chemical to the tank.

3) Prepare the area for cleaning by emptying waste receptacles, clearing debris, removing paper products, blowing out vents, and sweeping

fl oors.

4) Connect the 25 ft power cord to the pig-tail on the rear of the machine.

5) PRIME THE PUMP: Attach the priming hose to the outlet quick disconnect and place the open end of the hose into the recovery tank. Turn

on the pump and let it run until the pump is completely primed (no visible air in the water stream). Turn the pump off.

NOTE: prime the machine before you place the chemical feed tubes into chemical containers.

6) Disconnect the priming hose and attach the solution hose to the quick disconnect.

7) Attach the spray gun to the other end of the solution line.

8) Place chemicals in the molded-in chemical bottle containers on the rear of the machine. Insert one of the feed lines into one of the chemical

containers. Secure the line by screwing on the cap. The chemical will feed from which ever container the selector valve on the switch plate is

turned towards and when the gun is used in the low pressure setting. Use chemicals with a pH of between 5 and 10. Never add chemicals to

the clean water tank.

9) Set the spray gun to low pressure by sliding the pressure selector forward (low pressure = forward; high pressure = back).

10) Turn on the pump switch (push button) and spray through the gun for a few seconds to fi ll the line with solution.

11) Apply the chemical to the walls and fi xtures from the bottom up. Spray the fl oor last as you work your way out of the room.

12) Allow the chemical to work for the proper amount of dwell time, according to the chemical manufacturer’s directions. Agitate heavily soiled

areas with a scrub brush.

13) Turn off the chemical injector valve by turning the selector to the down position.

14) Set the spray gun to high pressure and rinse the area from the top down.

15) Connect the vacuum hose, attach the squeegee, and turn on the vacuum (rocker switch).

16) Squeegee off the mirrors, pick up the liquid off the fl oor with the fl oor tool. If you have the optional blow dry hose, use it to dry the fi xtures.

17) Drain the recovered water into a utility sink or toilet. NOTE: Keep the top of the drain hose higher than the water level in the tank to avoid

uncontrolled discharge of water when you open the cap on the hose.

CAUTION

To avoid vacuum motor damage, always use a defoamer any time foam is present.

Before you turn on the vacuum always make sure the fi lter screen on the ball fl oat is clean and that the ball can travel freely.

RE-PRIMING THE PUMP

If the pump looses prime between jobs, follow the instructions to PRIME THE PUMP, above. If that doesn’t get water fl owing, put the priming hose

into the vacuum inlet hose barb and cover the rest of the space around the priming hose with your hand. Turn on the vacuum (with the pump also

running) and let the suction of the vacuum assist in getting water into the pump.

6 - FORM NO. 56041948 - APC 328

MAINTENANCE

1) Use only approved chemicals at the recommended mix ratios. All chemicals should be added through the feed system and NOT added

directly to the water in the solution tank to prevent possible damage to the pump, seals, or other components.

2) For optimum performance, fl ush the Chemical Feed lines after every job by replacing the chemical containers with containers of clear water

and spraying through the gun until the fl uid stream is clear. See the Maintenance Schedule, below.

3) The pump seals and/or valves in the high pressure pumps may need to be replaced after about 1000 hours of use, if the pump begins to lose

performance or to leak. The pressure regulator valve may need to be when a drop in the spraying pressure at the tool is apparent.

MAINTENANCE SCHEDULE

ITEM DAILY WEEKLY YEARLY

Flush chemical lines X

Check/clean vac inlet fi lter X

Clean solution fi lter X

Check vacuum motor airways X

Check pump for leaks X

Check vacuum motor brushes * X

* Have your distributor check the carbon brushes once a year or after about 500 hours of operation.

TECHNICAL SPECIFICATIONS (as installed and tested on the unit)

MODELS 600303281, 600303282

VACUUM MOTOR(s):

WATER LIFT:

AIR FLOW:

TANK CONSTRUCTION:

HEIGHT:

WEIGHT

Two stage, 8 Amp

23 kpa

100 CFM

Rotationally molded polyethylene

98 cm X 59 X 86.5 cm

50 KG

FORM NO. 56041948 - APC 328 - 7

APC 328

01-11-09

O

I

O

1

2

4

6

10

16

11

12

13

18

21

14

24

22

23

25

9

20

16A

3

19

7

8

17

15

26

17A

5

8 - FORM NO. 56041948 - APC 328

ITEM PART No. DESCRIPTION

1 600732869 Lid and gasket, recovery tank

2 600732846 Hose kit, drain, priming and vac inlet

3 600732882 Hose kit, water and chemical metering

4 600732871 Metering tips and chemical injector

5 600732889 Filter, electrical noise suppression

6 600732883 Vacuum motor kit, with gasket and hose

7 600732884 Tank, recovery, complete

8 600732874 Vacuum inlet kit

9 600732886 Switch plate kit, complete

10 600732885 Switch kit, two switches

11 600732876 Pallet, component mounting, complete

12 600732848 Lid, with fi ll hose, holding tank/base

13 600732858 Fasteners kit

14 600732856 Lid and ring, 4”

15 600732873 Power cord, EU

600732887 Power cord, UK

16 600732866 Pump and motor, complete

16A 600732868 Motor, pump drive

17 600732865 Pump, solution, complete, no motor

17A 600732875 Pressure regulator, for solution pump

18 600732877 Filter, pump in-line, with hoses

19 600732854 Vacuum recovery hose, complete, 8 M

20 600732855 Solution hose assembly, 8 M

21 600732847 Quick disconnect kit, with washers

22 600732859 Grommets and foam

23 600732849 Cap, drain, and brass fi t ting

24 600732850 Castor kit, includes bracket

25 600732852 Wheel kit

26 600732879 Holding tank/base, complete

MISCELLANEOUS PARTS

600732872 Label kit, APC 328

600732888 Repair kit, solution pump

FORM NO. 56041948 - APC 328 - 9

1

2

4

5

6

7

8

3

9

10

11

12

TOOLS AND ACCESSORIES

1

2

3 or 4

5

6

Tool kit, standard, complete

1 600732862 Squeegee, hand held

2 600732893 Handle, for hand held squeegee

3 600732855 Solution hose

4 600732863 Brush, dual surface

5 600732894 Handle, two piece

6 600732895 Squeegee, for fl oor

7 600732896 Gun, spray, dual pressure

8 600732860 Handle, straight, black

9 600732881 Tote, carry all

10 600732853 Metering tips, two each

11 600752127 Priming hose, for solution pump

12 600732854 Recovery hose

Optional accessories

1 600732897 Frame, micro fi ber mop

2 600732898 Mop, micro fi ber (6)

3 56380888 Squeegee assembly, 61 cm

4 56209089 Squeegee assembly, 76 cm

5 600732901 Mount assembly, mechanical, for squeegee heads

6 600732864 Blower hose assembly, with nozzle

10 - FORM NO. 56041948 - APC 328

2010

Overenstemmelseserklaering Declaration de conformit é Samsvarserklaering

Declaration of conformi ty Verklaring van overeenstemm i ng Vaatimustenmukaisuusvakuutus

Konformitätserklärung Dichiarazione di conformità Atitikties deklaracija

Declaración de conformidad Vastavussertifikaat Osvědčení o shodě

Atbilstības deklarācija Deklaracja zgodności Certifikát súladu

Megfelelősségi nyilatkozat Försäkran om överensstämmel se

Certifikat o ustreznost i

Modell/ Modèle/ Model/ Malli/ Modelo/ Μοντέλο/ Modelo/ Modelis/Модель: APC 328C

Typ e/ Tyyppi/ T ipo/ Τύπος/ Tüüp/ Tipas/ Tips/ Typ/ Típus/ Тип/ Tip: Carpet Cleaner

Year of Affixing CE marking: 2010

Brand: Nilfisk

D Der Unterzeichner bestätigt hierm i t dass die oben erwähnten Modelle gemäß den folgenden Richt l i ni en und Normen hergestellt

wurden.

GB The undersigned certify that the above mentioned model is produced in accordance with the following directives and standards.

DK Undertegnede attesterer herved, at ovennævnte m odel er produc eret i overensstemmel s e med følgende direktiver og standarder.

N Undertegnede attesterer att ovennevnte m odel l är produs ert I overensstemmel se med fölgende direktiv og st andarder.

E El abajo fi rmante certifica que los modelos arriba mencionados han sido producidos de acuerdo con las siguientes directivas y

estandares.

I Il sottoscri tto dichiara che i modelli sopra menzionati sono prodotti in accordo con le seguenti diretti ve e s tandard.

EST Allakirjutanu kinnitab, et ülalni metatud mudel on valmi statud kooskõlas järgmiste direktiivide ja normidega.

LV Ar šo tiek apliecināts, ka augstākminētais modelis ir izgatavots atbilstoši šādām direktīvām un standartiem.

CZ Níže podepsaný stvrzuje, že výše uvedený model byl vyroben v souladu s následujícími směrnicemi a normami.

SLO Spodaj podpis ani potrjujem, da je zgoraj omenjeni model izdelan v skladu z naslednjimi smernicami i n standardi.

F Je soussigné certifie que les modèles ci -des sus sont fabriqués conformément aux directives et normes suivantes.

NL Ondergetekende verzekert dat de bovengenoemde m odel l en geproduceerd zijn in overeenstemming met de volgende richtlij nen

en standaards.

FIN Allekirjoittaia vakuuttaa että yllämainittu malli on tuotettu seuraavien di rektiivien ja standardien muk aan.

S Undertecknad i ntygar att ovannämnda modell är producerad i överens stämmelse med följande direktiv och standarder.

GR Ο κάτωθι υπογεγραμμένος πιστοποιεί ότι η παραγωγή του προαναφερθέντος μοντέλου γίνεται σύμφωνα με τις ακόλουθες οδηγίες

και πρότυπα.

P A presente assinatura serve para declarar que os model os supramencionados são produtos em conformidade com as seguintes

directivas e normas.

LT Toliau pateiktu dokumentu patvirtinama, kad minėtas modelis yra pagamintas laikantis nurodytų direktyvų bei standartų.

PL Niżej podpisany zaświadcza, że wymieniony powyżej model produkowany jest zgodnie z następującymi dyrektywami I normami.

H Alulírottak igazoljuk, hogy a fent említett modellt a következő irányelvek és szabványok alapján hoztuk létre.

SK Dolu podpísaný osvedčuje, že hore uvedený model sa vyrába v súlade s nasledujúcimi smernicami a norm ami.

EC Low Voltage Directive 2006/95/EC EN 60335-1, EN 60335-2-68

EC EMC Directive 2004/108/EC EN 61000, EN 50366, EN 55014-1,-2

This product is declare d o n o u r sole responsibility.

7.6.2010

Don Legatt, Engineering Director

Manufacturer :

Nilfisk-Advance, Inc. Nilfisk-Advance A/S

14600 21st Avenue North Sognevej 25

Plymouth, MN 55447 USA DK-2605 Brøndby, Denmark

©Nilfisk-Advance Incorporated, 2010

.pas

Nilfi sk-Advance A/S

Sognevej 25

DK-2605 Brøndby

Denmark

Tel: +45 43 23 81 00

Fax: +45 43 43 77 00

www.nilfi sk-advance.com

Loading...

Loading...