ALPHA BOOSTER 3 & 5

Instruction manual .............................. 3 - 17

Betriebsanleitung ................................ 18 - 32

Manuel d’Instructions .......................... 33 - 47

Gebruikershandleiding ........................ 48 - 62

Manuale di istruzioni ........................... 63 - 77

Manual de instrucciones ..................... 78 - 92

Priročnik z navodili za uporabo ........... 93 - 107

Руководство ....................................... 108 - 124

Nilfisk

ALTO

ALPHA BOOSTER

Contents

1 Important safety

instructions

..................................................................................4

2 Description

3 Before starting the washer

4 Operation

5 Applications and methods

2.1 Purpose ................................................................................6

2.2 Operating elements ..............................................................6

3.1 Installation environment .......................................................7

3.1.1 Temperature conditions .............................................7

3.1.2 Conditions of distance ...............................................7

3.2 Mounting instructions ...........................................................7

3.3 Setting up the machine .........................................................8

3.4 Connecting the high pressure hose ......................................8

3.5 Connecting the water supply ................................................8

3.6 Electrical connection ............................................................8

4.1 Connecting the spray lance to the spray gun .......................9

4.2 Switching on the washer ......................................................9

4.2.1 Switching on the washer when it is connected

to a water supply .......................................................9

4.2.2 Switching on the cleaner when it is connected

to open tanks (suction mode) ....................................9

4.3 Using detergents ................................................................10

5.1 General information ............................................................11

5.1.1 Soaking ..................................................................11

5.1.2 Detergent and foam ................................................11

5.1.3 Temperature ...........................................................11

5.1.4 Mechanical effect ....................................................11

5.1.5 High water flow or high pressure ...........................11

5.2 Some typical cleaning ........................................................12

5.2.1 Agriculture ...............................................................12

5.2.2 Vehicles ...................................................................12

5.2.3 Building & construction / industry ............................13

6 After using the machine

7 Maintenance

8 Troubleshooting

9 Further information

6.1 Switching off the machine ..................................................14

6.2 Disconnecting supply lines .................................................14

7.1 Maintenance plan ...............................................................14

7.2 Maintenance work ..............................................................14

7.2.1 Cleaning water inlet filter .........................................14

7.2.2 Checking the pump oil level ....................................15

7.2.3 Changing the pump oil ............................................15

...............................................................................16

9.1 Recycling the washer .........................................................17

9.2 Guarantee ..........................................................................17

9.3 Technical Specifications .....................................................17

9.4 EU Declaration of Conformity .............................................17

3

1 Important safety instructions

Symbols used to mark instructions

For your own safety

The high-pressure washer

may only be used by persons

instruc ed in its use and who

have been expressly authorised

to do so.

Although extremely easy to

operate, children should not be

allowed to use the washer.

General

Use of the high-pressure washer is subject to the applicable

local regulations.

Besides the operating instructions and the binding accident

prevention regulations valid

in the country of use, observe

recognised regulations for safety and proper use.

Do not use any unsafe work

techniques.

Before using the

high-pressure

washer, be sure

to also read the

enclosed operat-

ing instructions

and keep them within reach at

all times.

Safety instructions

in these operating

instructions which

must be observed

to prevent risks to

persons are marked with this

danger symbol.

Before starting the washer

If your washer was supplied

without a plug, have it fitted with

a suitable plug with earth conductor, by an electrician.

Before use, check that the highpressure washer is safe and in

proper condition.

Regularly check whether the

electric cable is damaged or

shows signs of ageing.

Use the high-pressure washer

only when the electric cable is

in a safe condition. (risk of electric shock if damaged!).

Check the rated voltage of the

high-pressure washer before

connecting it to the mains

power supply. Ensure that the

voltage shown on the rating

plate corresponds to the voltage of the local mains power

supply.

This symbol is

used to mark

safety instructions that must

be observed to

prevent damage

to the machine and its performance.

This indicates tips

and in structions

to simplify work

and to ensure safe operation.

We strongly recommend that

the power supply to the high

pressure washer be connected

via a residual current circuit

breaker.

This device stops the supply

of electricity if the leakage current to earth exceeds 30 mA for

30 ms or it has an earth tester

circuit.

Please observe the regulations and provisions applicable

in your country. Before putting

the high-pressure washer into

service, carry out a visual check

of all the major components.

CAUTION!

High-pressure water jets can

be dangerous if misused. The

jet must not be directed at

persons, animals, live electrical equipment or the washer

itself.

Wear appropriate protective

clothing and eye protectors.

4

Do not direct the jet towards

yourself or towards other persons in order to clean clothes

or footwear.

During operation of the washer,

recoil forces are produced at

the spraying device and, when

the spray lance is held at an

angle, a torque is also created.

The spraying device must

therefore be held firmly in both

hands.

Do not use the washer when

other people without protective

clothing are in the working area.

Check that cleaning will not

result in dangerous substances

(e.g. asbestos, oil) being

washed off the object to be

cleaned and harming the environment.

Do not clean delicate parts

made of rubber, fabric, etc. with

the 0° jet. Keep some distance

between high pressure nozzle

and surface in order to prevent

the surface from damage.

Operation

CAUTION!

Unsuitable extension cords can

represent a source of danger.

Always unwind cord from the

reels completely to prevent the

electric cable overheating.

When using an extension cord,

connectors must be of watertight construction.

When using an extension cord,

check the minimum cross-sections of the cable:

Cable length

m

up to 20 m

20 to 50 m

Cross section

<16 A <25 A

ø1.5mm² ø2.5mm²

ø2.5mm² ø4.0mm²

Do not damage the electric

cable (e.g. by driving over it,

pulling or crushing it).

Disconnect the electric cable by

pulling the plug only (do not pull

or tug the electric cable).

Electrical equipment

Maintenance and repair

CAUTION!

Always disconnect the machine from the mains plug

socket before cleaning or carrying out maintenance work

on the washer.

Carry out only the maintenance

operations described in the

operating instructions. Use only

original spare parts.

Do not make any technical

modifications to the high-pressure washer.

Ensure that the machine is

regularly serviced by Authorised dealers in accordance

with the maintenance plan.

Failure to do so will invalidate

the warranty.

CAUTION!

High-pressure hoses, fittings

and couplings are important

for the safety of the washer.

Use only high-pressure parts

approved by the manufacturer!

Do not use the high-pressure

hose for lifting loads.

NOTE!

The specifications of the highpressure hose (max. permissible pressure and temperature)

are printed on the hose.

Do not continue to use the

washer if the electric cable

or high-pressure hose is

damaged.

Ensure adequate air circulation.

Do not cover the washer or operate it in inadequately ventilated rooms!

Store the washer

where it will not be

exposed to frost!

Never operate the washer

without water. Even brief shortages of water result in severe

damage to the pump seals.

CAUTION!

Never spray electrical equipment with water: danger

for persons, risk of shortcircuiting.

The washer may only be connected to a correctly installed

plug socket.

Switching on the washer may

cause voltage fluctuations.

Voltage fluctuations should not

occur if the impedance at the

transfer point is less than 0.15

Ω. If in doubt ask your local

electricity supplier.

If the electric cable is damaged,

it must be replaced by authorized Service or an electrician

to avoid danger before use of

the cleaner is continued.

Use only the type of electric

cable specified in the operating

manual.

Please contact the Service department or an authorised specialist work-shop for all other

maintenance or repair work!

Testing

The washer conforms to the

German „Guidelines for Liquid Spray Jet Devices“. The

high-pressure washer must be

subjected to a safety examination in accordance with the „Accident Prevention Regulations

for Working with Liquid Spray

Jet Devices“ as required, but at

least every 12 months, by an

authorised inspector.

5

After all repairs or modifications

to electrical equipment, the

protective conductor resistance,

the insulation resistance and

the leakage current must be

measured. Furthermore, a

visual inspection of the electric

cable, a voltage and current

measurement and a function

test must be carried out. Our

after-sales service technicians

are at your disposal as authorised inspectors.

The complete „Accident Prevention Regulations for Working

with Liquid Spray Jet Devices“

are available from the Carl Heymanns Verlag KG, Luxemburger

Strasse 449, 50939 Cologne or

from the appropriate association of employers’ liability insurances.

2 Description

2.1 Purpose Always use the washer as

described in these operating

instructions. Any other use may

damage the washer or the surface to be cleaned or may result

in severe injury to persons.

Unloader valve

Unacceptably high pressure is

fed back without residual pressure via a bypass line into the

intake line of the pump when

the safety device is tripped.

The unloader valve is set and

sealed at the factory and must

not be adjusted.

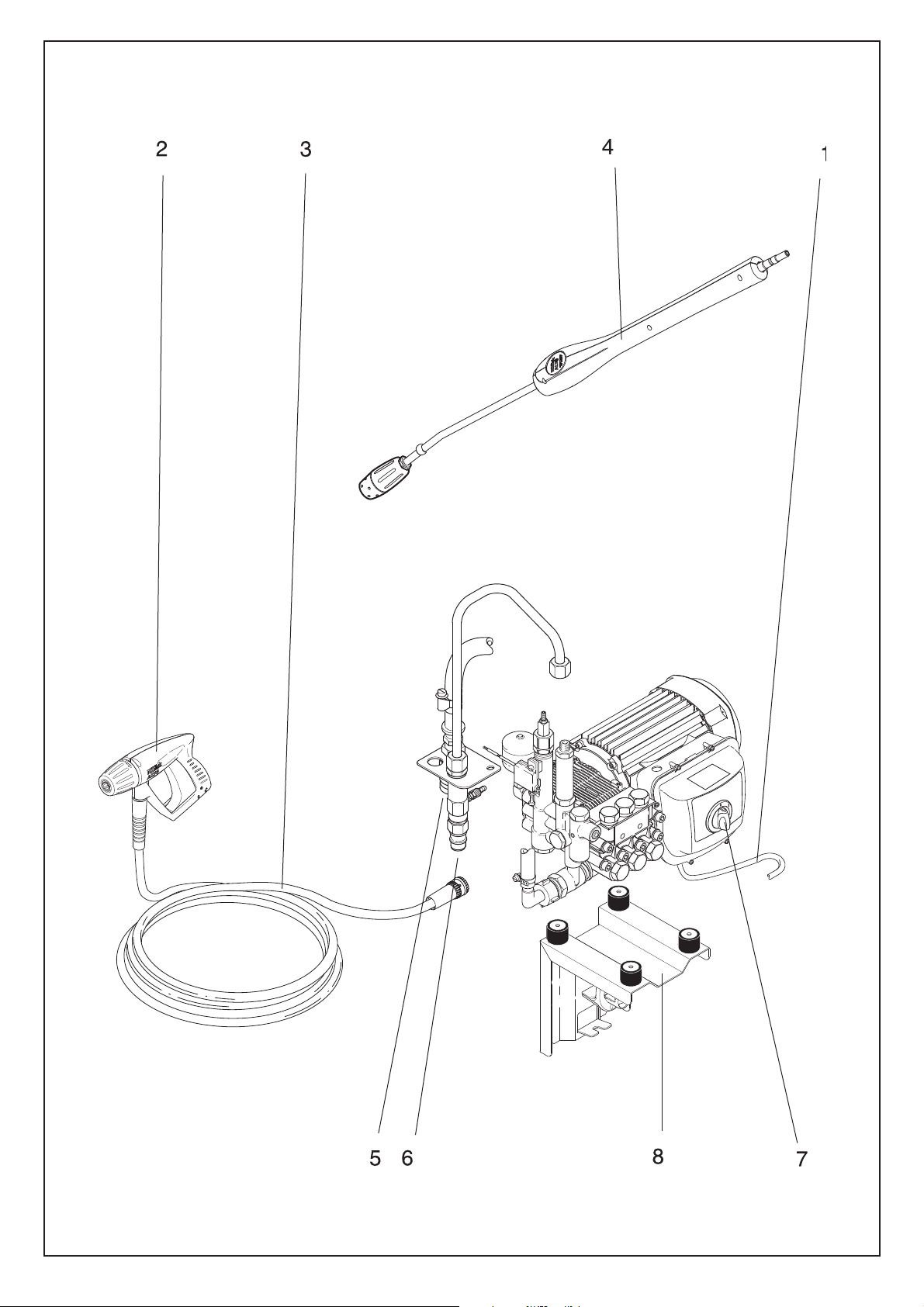

2.2 Operating elements See fold-out page at the front

of these operating instructions.

1 Electric cable

2 Spray gun

3 High-pressure hose

4 Spray lance

5 Supply water connection

with water inlet filter

6 High pressure hose connec-

tion

7 Main switch

8 Wall bracket

6

3 Before starting the washer

3.1 Installation environment

3.1.1 Temperature conditions

The machine should be installed in a frost-free room.

This applies to pump as well as

pipelines incl. of outlet points.

-AX#

-IN#

Concerning outdoor outlet

points, it should be possible to

close and empty that part of the

line which is exposed to frost.

The maximum ambient temperature for the machine is 40°C.

3.1.2 Conditions of distance Out of consideration for the

cooling system of the machine

and the accessibility of service,

there must be wall space on

-INMM

both sides of the machine. To

the right 150 mm at a minimum

and to the left 400 mm at a

minimum.

The recommended installation

-INMM

height fot he machine is max.

1700 mm and min. 1550 mm to

the upper edge of the machine.

3.2 Mounting instructions 1. Hold the mounting bracket

against the wall and mark

the hole positions.

2. Drill four holes at the size

matching the fasteners to

ATTENTION: Be-

ware that the

machine weighs

approx. 40-60 kg.

Choose fasteners

and screws suited for

this weight.

be used. Pre-mount the

fasteners and the screws.

3. Mount the machine onto the

bracket's four rubber feet

and fasten with the enclosed

.ILFISK

!,4/

2

%

4

3

//

"

(!

!,0

washers and nuts.

4. Hang the assembly of ma-

chine/bracket on the four

pre-mounted screws and

tighten.

7

3.3 Setting up the machine 1. Before using the machine for

the first time, check it carefully to detect any faults or

damage.

2. In the event of any damage

contact your dealer immediately.

CAUTION!

Never lift the machine alone

(weight 40-60 kg). Always ask a

second person to help

.

3. Check whether the oil level

is between the minimum and

maximum marks. If necessary, add oil (see section 9.3

for type of oil).

3.4 Connecting the high

pressure hose

3.5 Connecting the water

supply

Do not connect the

washer directly to

the public drinking water mains.

Obsererve the regulations of your

water supply company to prevent

backflow of water into the supply

line.

A connection is permitted, however:

- briefly to a pipe interrupter with

moving section

- with a free outlet

- water break tank (coming with

this product).

See separate instructions on how

to install the water break tank.

1. Attach the high pressure

hose to the high pressure

inlet by means of the quick

coupling.

See section 9.3 Technical Data for

required quantity of water and water pressure.

In the case of poor water quality

(sand, etc.), we recommend that a

fine water filter is fitted in the water

inlet.

1. Rinse the water supply hose

briefly in order to prevent

sand an other dirt particles

entering into the machine.

2. Connect water supply hose

to the machine (3/4").

3. Open water tap.

3.6 Electrical connection 1. Observe safety instructions

CAUTION!

The washer may only be connected to a correctly installed

electrical installation.

in chapter 1.

2. Mount the electrical cable to

a fixed wall outlet or mount

a suitable plug and connect

to a socket. Observe correct

amperage !

8

4 Operation

4.1 Connecting the spray

lance to the spray gun

NOTE!

Always remove any dirt from the

nipple before connecting the spray

lance to the spray gun.

4.2 Switching on the washer

4.2.1 Switching on the washer

when it is connected to a

water supply

NOTE!

Operate the spray gun several

times at short intervals to vent the

system.

A

1. Pull the blue quick-release

grip (A) of the spray gun

forwards and lock it by turn-

C

ing it to the left.

2. Insert the nipple of the spray

B

lance (C) into the quick-release connection and turn

the blue quick-release grip

to the right (B)

3. Pull the spray lance (or

other accessory) forwards to

check that it is securely attached to the spray gun.

1. Turn the main switch to position " 1 ".

2. Unlock the spray gun and

operate it.

3. Lock the spray gun even

during short pauses.

The washer switches off automatically1) after the spray

gun has been closed. To start

the washer again, operate the

spray gun.

4.2.2 Switching on the

cleaner when it is

connected to open

tanks (suction mode)

1)

A delay of 20 sec. is incorporated

2)

Accessory

1. Before connecting the detergent intake set 2) to the

cleaner, fill the hose with

water.

2. Turn the main switch to position »I«.

3. Unlock the spray handle and

activate it.

Max. suction height = 1 m.

9

4.3 Using detergents Detergentscan be drawn in via

the injector installed as standard only in low-pressure mode:

1. Dilute detergents according

to the manufacturer's instructions. Capacity, see section

CAUTION!

Never allow detergents to dry

on the surface to be cleaned.

The surface may be damaged.

9.3 Technical Data.

2. Tornado lance

1)

:

Set pressure regulation on

spray lance to low pressure

(-), or

Flexo Power 3000 nozzle

1)

Turn cap of the Flexo Power

3000 nozzle towards "CHEM"

up to the stop.

3. The intaken volume of de-

tergent can be regulated by

turning the metering valve.

4. Main switch:

Turn the switch to position "I".

5. Activate the spray gun.

:

10

1)

Options / model variants

5 Applications and methods

5.1 General information Efficient high pressure cleaning is achieved by following a few gui-

delines, combined with your own personal experience of specific

cleaning tasks. Accessories and detergents, when correctly chosen, can increase the efficiency of your pressure washer. Here is

some basic information about cleaning.

5.1.1 Soaking Incrusted or thick layers of dirt can be loosened or softened up by

a period of soaking. This is for example an ideal method within agriculture – for example, within pig sties. The ideal soaking method

can be achieved via use of foam or simple alcaline detergent. Let

the product lie on the dirty surfaces for around 30 minutes before

pressure washing. The result will be a much quicker high-pressure

cleaning process.

5.1.2 Detergent and foam Foam or detergent should be applied onto dry surfaces so that the

chemical product is in direct contact with the dirt. Detergents are

applied from bottom to top, for example on a car bodywork, in order

to avoid “super clean” areas, where the detergent collects in higher

concentration and streams downwards. Let the detergent react several minutes before cleaning off.

5.1.3 Temperature Detergents are more effective at higher temperatures. Greases, oils

and fats can be broken down more easily at higher temperatures

also. Proteins can be cleaned at temperatures of around 60°C. Oils,

pollution and grease can be cleaned between 70° and 90°C.

5.1.4 Mechanical effect In order to break down tough layers of dirt, additional mechanical

effect may be required. Special lances and rotary or wash brushes

offer this supplementary effect that cuts through dirt. Use a brush

to cut through e.g. traffic film.

5.1.5 High water flow or high

pressure

High pressure is not always the best solution and high pressure

may damage surfaces. The cleaning effect also depends upon

water flow. Pressure levels of around 100 bar may be sufficient for

vehicle cleaning (in association with hot water). Higher flow levels

give the possibility to rinse and flush away large amounts of dirt

easily.

11

5.2 Some typical cleaning

tasks

5.2.1 Agriculture

Task Accessories Method

Stables

Pig Pens, sties

Cleaning of

walls, floors and

equipment

Disinfection

Machinery

Tractors,

ploughs etc.

5.2.2 Vehicles

Foam Injector

Foam lance

Powerspeed lance

Floor Cleaner

Powerlift lance

Detergents

Universal

Alkafoam

Disinfectant

DES 3000

Standard lance

Detergent injector

Powerspeed lance

Curved lance and underchassis washer

Brushes

1. Soaking – apply foam to all surfaces (bottom to top)

and wait for approx 30 minutes.

2. Remove the dirt from surfaces with the high-pressure lance or chosen accessory. Clean from bottom to

top on vertical surfaces.

3. To flush away large quantities of dirt, change to lowpressure mode and use the higher flow to push away

the dirt.

4. Use recommended disinfectant products and methods to ensure hygiene.

Only apply disinfectants once the dirt has been fully

removed.

1. Apply detergent to vehicle or equipment surfaces in

order to soften up dirt and grime. Work from bottom

to top.

2. Proceed with cleaning using the high-pressure lance.

Clean again from bottom to top. Use accessories to

clean in difficult to reach places.

3. Clean fragile areas such as motors or rubber parts

at lower pressure levels to avoid damage.

Task Accessories Method

Vehicle bodywork

Standard lance

Detergent injector

Curved lances and

underchassis washer

Brushes

Detergents

Aktive Shampoo

Aktive Foam

Sapphire

Super Plus

Aktive Wax

Allosil

RimTop

1. Apply detergent to vehicle or equipment surfaces

in order to soften up dirt and grime. Apply from bottom to top. In cases of particularly dirty vehicles,

pre-spray with a product such as Allosil in order to

remove traces of insects etc, then rinse at low pressure and apply normal car cleaning detergent. Let

detergents settle for five minutes before cleaning off.

Metallic surfaces can be cleaned using RimTop.

2. Proceed with cleaning using the high-pressure lance.

Clean again from bottom to top. Use accessories

to clean in difficult-to-reach places. Use brushes

in order to add a mechanical cleaning effect. Short

lances can help for cleaning of motors and wheel

arches. Curved lances or the undercarriage washer

are also ideal for the cleaning of car underchassis

and wheel arches.

3. Clean fragile areas such as motors or rubber parts

at lower pressure levels to avoid damage.

4. Apply a liquid wax using the pressure washer in order to protect the bodywork from pollution.

12

5.2.3 Building & construction

/ industry

Task Accessories Method

General surfaces

Metallic equipment

Rusted or damages surfaces prior to treatment

Foam injector

Standard lance

Curved lance

Tank cleaner

Detergents

Intensive

J25 Multi

Combi Aktive

Alkafoam

Disinfectant

DES 3000

Wet Sandblasting

equipment

1. Apply thick foam over the surfaces to be cleaned.

Apply on dry surface. Apply from top to bottom on

vertical surfaces. Let the foam act for up to 30 minutes for the optimal effect.

2. After this time, clean down with the high-pressure

lance or relevant accessory. Use high pressure to

dislodge large amounts of incrusted dirt or grime.

Use lower pressure and high water volume in order

to flush away loose dirt and rinse surfaces.

3. Apply DES 3000 disinfectant once the surfaces are

perfectly clean.

Areas covered by amounts of loose dirt, such as animal

remains in slaughterhouses, can be removed by using

high water flow to flush away the dirt to evacuation pits

or drains.

The tank cleaner can be used to clean barrels, vats,

mixing tanks etc. Tank cleaners may be hydraulically or

electrically powered and give the possibility for automatic cleaning without constant monitoring.

1. Connect the sandblasting equipment to the pressure

washer and place the suction tube in the sand.

2. Always wear protective equipment during sandblasting.

3. Spray the surfaces to be treated with the mix of water

and sand. Rust, paint etc will be stripped off.

4. Following sandblasting, protect surfaces against rust

(metal) or rot (wood).

These are merely examples of cleaning tasks that can be solved by a pressure washer in association

with accessories and detergents. Each cleaning task is different, so please consult your local dealer or

Nilfisk-ALTO representative in order to discuss the best solution for your own cleaning problem.

13

6 After using the machine

6.1 Switching off the

machine

6.2 Disconnecting supply

lines

7 Maintenance

1. Turn the main switch to position " 0 ".

2. Close water tap.

3. Squeeze the spray gun

handle until the washer is

depressurised.

4. Lock the safety catch on the

spray gun.

1. Switch off the mains supply.

2. Close all outlet taps and/or

remove hoses.

7.1 Maintenance plan

7.2 Maintenance work

7.2.1 Cleaning water inlet fi lter

7.2.2 Checking pump oil level

7.2.3 Changing pump oil

7.2.1 Cleaning water inlet

filter

Weekly

QQ

Q

After the fi rst 50

operating hours

QQ

Every six months

or 400 operating

hours

A water filter is fitted on the

water inlet to prevent large particles of dirt from entering into

the pump.

1. Unscrew the quick-release

connection.

2. Remove the filter and rinse

it. Replace damaged filter.

As required

14

7.2.2 Checking the pump oil

level

1. Check whether the oil level

is between the minimum and

maximum marks. If necessary, add oil (see chapter

9.3 for type of oil).

7.2.3 Changing the pump oil 1. Unscrew the oil drain plug (1)

on the pump housing and

dispose of the old oil in accordance with the disposal

regulations.

2. Check the drain plug gasket

and screw in the plug again.

3. Fill with fresh oil and close

CAUTION!

Special pump oil is required if the

washer is used near food. Please

consult your dealer.

the oil filler plug.

Oil grade and capacity see

chapter ‘9.3 Technical Data’.

15

8 Troubleshooting

Fault Cause Remedy

Pressure drop > Air in the system • Vent the system by operating

the spray gun several times at

short intervals. If necessary,

operate the washer for a short

time without the high-pressure

hose connected.

> High pressure nozzle blocked

worn

Pressure fl uctuations > Pump draws in air (only possible

in suction mode)

> Lack of water • Open water tap.

> Water inlet hose is too long or its

cross-section too small

> Injector open • Close injector.

> Detergent container empty • Refi ll detergent container.

> Lack of water caused by blocked

water fi lter

> Lack of water because max.

permissible suction height has

not been observed

The motor does not start when the

washer is switched on

When the washer is switched on

the motor buzzes without starting

The motor switches off > The overload protection has

> The plug/mains is not connected

properly, i.e. there is no current

> The mains fuse is switched off • Switch on/exchange the mains

> The mains voltage is too low or

there is a phase failure.

> The pump is blocked • Contact the customer service

> Incorrect cross-section or length

of the extension cable

been activated due to overheating or overloading of the motor

> High-pressure nozzle is dirty • Change the high-pressure

• Clean/replace the high pressure nozzle.

• Check that the suction set is

air-tight.

• Use specifi ed water inlet hose.

• Clean the water fi lter in the

water connection (never work

without water fi lter)

• See instructions, section 4.2.2.

• Check the plug, cable and

mains switch and if necessary have them replaced by a

trained electrician.

fuse.

• Have the electrical connection

checked.

• Use cable with correct cross

section or length.

• Check that the mains vol tage

and the machine voltage are

the same. Switch off the machine and allow it to cool for at

least 3 minutes.

nozzle.

Any other failure: Contact your nearest Nilfisk-ALTO service centre.

16

9 Further information

9.1 Recycling the washer If the washer is discarded,

make it unusable immediately

The washer contains valuable

materials that should be recycled. Therefore, make use of

1. Unplug the washer and cut

the electric cable.

your local waste disposal site.

Contact your local authorities or

your nearest dealer for further

information.

9.2 Guarantee Our general conditions of business are applicable with regard

change as a result of technical

advances.

to the guarantee. Subject to

9.3 Technical Specifications

ALPHA

BOOSTER

3-26

Voltage V 230 400 230 230 400 230

Fuse (slow) A 16 16 16 16 16 25

Power rating kW 3.3 5.2 5.2 3.3 6.9 6.9

Working pressure bar 135 180 180 110 180 180

Water volume l/h 600 810 810 720 970 970

Water volume Q

Max. water inlet temperature

(Intake-/Pressure operation)

Max. water supply pressure bar 10 10 10 10 10 10

Dimensions l x w x h mm 560 x 350 x 370 357 x 643 x 365

Weight kg 39 39 39 48 48 48

Noise level at a distance of 1m DIN

45635

Sound power level Lwa 88 88 88 85 85 85

Vibration level at spray gun m/s² ≤ 2.5 ≤ 2.5 ≤ 2.5 ≤ 2.5 ≤ 2.5 ≤ 2.5

Recoil forces N 22 40 40 26 47 47

Oil quantity l 0.45 0,45 0.45 0.45 0.45 0.45

Oil type SAE 15 W 40

IEC

l/h 570 750 750 630 900 900

°C

dB(A)

50 50 50 50 50 50

73.5 73.5 73.5 70.8 70.8 70.8

ALPHA

BOOSTER

3-41

ALPHA

BOOSTER

3-41

ALPHA

BOOSTER

5-27

ALPHA

BOOSTER

5-49

ALPHA

BOOSTER

5-49

9.4 EU Declaration of Conformity

EU Declaration of Conformity

Product:

Type:

Description:

The design of the unit corresponds to

the following pertinent regulations:

Applied harmonised standards:

Applied national standards and technical

specifi cations:

Dipl. Ing. Wolfgang Nieuwkamp

Tests and approvals

High Pressure Washer

ALPHA BOOSTER 3, ALPHA BOOSTER 5

400 V 3~, 50 Hz - 230 V 1~, 50 Hz - IP X5

EC Machine Directive 98/37/EEG

EC Low-voltage Directive 73/23/EEG

EC EMV Directive 89/336/EEG

EN 292-1, EN 292-2, EN 60335-2-79

EN 55014-1, EN 55014-2, EN 61000-3-2

DIN EN 60335-2-79

Nilfi sk ALTO

Division of Nilfi sk-Advance AG

Guido-Oberdorfer-Straße 2-8

D-89287 Bellenberg

Bellenberg, 01.02.2006

17

http://www.nilfi sk-alto.com

HEAD QUARTER

DENMARK

Nilfi sk-Advance Group

Sognevej 25

DK-2605 Brøndby

Tel.: +45 4323 8100

Fax: +45 4343 7700

E-mail: mail@nilfi sk-advance.dk

SALES COMPANIES

AUSTRALIA

Nilfi sk-ALTO

48 Egerton St.

P.O. Box 6046

Silverwater, N.S.W. 2128

Tel.: +61 2 8748 5966

Fax: +61 2 8748 5960

AUSTRIA

Nilfi sk-Advance GmbH

Nilfi sk-ALTO

Metzgerstrasse 68

5101 Bergheim/Salzburg

Tel.: +43 662 456 400-0

Fax: +43 662 456 400-34

E-mail: info@nilfi sk-alto.at

www.nilfi sk-alto.at

BELGIUM

Nilfi sk-ALTO

Division of Nilfi sk-Advance n.v-s.a.

Internationalelaan 55 (Gebouw C3/C4)

1070 Brussel

Tel.: +32 02 467 60 40

Fax: +32 02 466 61 50

E-mail: info.be-@nilfi sk-alto.com

CANADA

Clarke Canada

Part of the Nilfi sk-Advance Group

4080 B Sladeview Crescent, Unit 1

Mississauga, Ontario L5L 5Y5

Tel.: +1 905 569 0266

Fax: +1 905 569 8586

CHINA

Nilfi sk-Advance (Shenzhen) Ltd.

Blok 3, Unit 130 1001 Honghua Road

Int. Commercial & Trade Center

Fuitian Free Trade Zone

518038 Shenzhen

Tel.: +86 755 8359 7937

Fax: +86 755 8359 1063

CZECH REPUBLIC

ALTO Ceská Republika s.r.o.

Zateckých 9

14000 Praha 4

Tel.: +420 24 14 08 419

Fax: +420 24 14 08 439

E-mail: info@alto-cz.com

DENMARK

Nilfi sk-ALTO

Division of Nilfi sk-Advance A/S

Industrivej 1

9560 Hadsund

Tel.: +45 7218 2100

Fax: +45 7218 2105

E-mail: salg@nilfi sk-alto.dk

E-mail: service@nilfi sk-alto.dk

www.nilfi sk-alto.dk

Nilfi sk-ALTO Food division

Division of Nilfi sk-Advance A/S

Blytækkervej 2

9000 Aalborg

Tel.: +45 7218 2100

Fax: +45 7218 2099

E-mail: scanio.technology@nilfi sk-alto.dk

FINLAND

Nilfi sk-Advance Oy Ab

Piispantilankuja 4

02240 Espoo

107309106 c (01.2008)

Tel.: +358 207 890 600

Fax: +358 207 890 601

E-mail: jukka.lehtonen@nilfi sk-alto.com

www.nilfi sk-advance.fi

FRANCE

Nilfi sk-ALTO

ALTO France SAS

Aéroparc 1

19 rue Icare

67960 Entzheim

Tel.: +33 3 88 28 84 00

Fax: +33 3 88 30 05 00

E-mail: info@nilfi sk-alto.fr

www.nilfi sk-alto.com

GERMANY

Nilfi sk-ALTO

Division of Nilfi sk-Advance AG

Guido-Oberdorfer-Strasse 10

89287 Bellenberg

Tel.: +49 0180 5 37 37 37

Fax: +49 0180 5 37 37 38

E-mail: info@nilfi sk-alto.de

www.nilfi sk-alto.de

GREECE

Nilfi sk-Advance SA

8, Thoukididou str.

164 52 Argiroupolis

Tel.: +30 210 96 33443

Fax: +30 210 96 52187

E-mail: nilfi sk-advance@clean.gr

HOLLAND

Nilfi sk-ALTO

Division of Nilfi sk-Advance BV

Camerastraat 9

3322 BB Almere

Tel.: +31 36 546 07 60

Fax: +31 36 546 07 61

E-mail: info@nilfi sk-alto.nl

www.nilfi sk-alto.nl

HONG KONG

Nilfi sk-Advance Ltd.

2001 HK Worsted Mills Ind’l Bldg.

31-39 Wo Tong Tsui St.

Kwai Chung

Tel.: +852 2427 5951

Fax: +852 2487 5828

HUNGARY

Nilfi sk-Advance Kereskedelmi Kft.

II. Rákóczi Ferenc út 10

2310 Szigetszentmiklos-Lakihegy

Tel: +36 2447 5550

Fax: +36 2447 5551

E-mail: info@nilfi sk-advance.hu

www.nilfi sk-advance.hu

ITALY

Nilfi sk-ALTO

Divisione di Nilfi sk-Advance A/S

Località Novella Terza

26862 Guardamiglio (LO)

E-mail: d.puglia@nilfi sk-advance.it

JAPAN

Nilfi sk-Advance Inc.

247 Nippa-cho, Kouhoku-ku

Yokohama, 223-0057

Tel.: +8145 548 2571

Fax: +8145 548 2541

MALAYSIA

Nillfi sk-Advance Sdn Bhd

Sd 14, Jalan KIP 11

Taman Perindustrian KIP

Sri Damansara

52200 Kuala Lumpur

Tel.: +60 3 603 6275 3120

Fax: +60 3 603 6274 6318

NORWAY

Nilfi sk-Advance AS

Bjørnerudveien 24

1266 Oslo

Tel.: +47 22 75 17 70

Fax: +47 22 75 17 71

E-mail: info@nilfi sk-alto.no

www.nilfi sk-alto.no

POLAND

Nilfi sk-Advance Sp. Z.O.O.

05-800 Pruszków

ul. 3-go MAJA 8

Tel.: +48 22 738 37 50

Fax: +48 22 738 37 51

E-mail: info@nilfi sk-alto.pl

www.nilfi sk-alto.pl

PORTUGAL

Nilfi sk-ALTO

Division of Nilfi sk-Advance Lda.

Sintra Business Park

Zona Industrial Da Abrunheira

Edifi cio 1, 1° A

P2710-089 Sintra

Tel.: +35 808 200 537

Fax: +35 121 911 2679

E-mail: mkt@nilfi sk-advance.es

RUSSIA

Nilfi sk-Advance LLC

Vyatskaya str. 27, bld. 7

127015 Moskow

Tel.: +7 495 783 96 02

Fax: +7 495 783 96 03

E-mail: info@nilfi sk-advance.ru

SINGAPORE

Nilfi sk-Advance Pte. Ltd.

Nilfi sk-ALTO Division

40 Loyang Drive

Singapore 508961

Tel.: +65 6 759 9100

Fax: +65 6 759 9133

E-mail: sales@nilfi sk-advance.com.sg

SPAIN

Nilfi sk-ALTO

Division of Nilfi sk-Advance S.A.

Torre D’Ara

Paseo del Rengle, 5 Pl. 10

08302 Mataró

Tel.: +3 4 902 200 201

Fax: +34 93 757 8020

E-mail: mkt@nilfi sk-advance.es

SWEDEN

ALTO Sverige AB

Member of Nilfi sk-Advance Group

Aminogatan 18, Box 4029

431 04 Mölndal

Tel.: +46 31 706 73 00

Fax: +46 31 706 @nilfi sk-alto.se

www.nilfi sk-alto.se

TAIWAN

Nilfi sk-Advance Taiwan Branch

No. 5, Wan Fang Road

Taipei

Tel.: +886 227 002 268

Fax: +886 227 840 843

THAILAND

Nilfi sk-Advance Co. Ltd.

89 Soi Chokechai-Ruammitr

Viphavadee-Rangsit Road

Layao, Jatuchak, Bangkok 10900

Tel.: +66 2 275 5630

Fax: +66 2 691 4079

TURKEY

Nilfi sk-Advance Profesional Temizlik

Ekipmanlari Tic. A/S.

Necla Cad. NI.: 48

Yenisahra / Kadiköy

Istanbul

Tel.: +90 216 470 08 - 60

Fax: +90 216 470 08 - 63

www. nilfi sk-advance.com

UNITED KINGDOM

Nilfi sk-ALTO

Division of Nilfi sk-Advance Ltd.

Bowerbank Way

Gilwilly Industrial Estate, Penrith

Cumbria CA11 9BQ

Tel.: +44 1 768 86 89 95

Fax: +44 1 768 86 47 13

E-mail: sales@nilfi sk-alto.co.uk

www.nilfi sk-alto.co.uk

USA

Nilfi sk-Advance Inc.

14600 21st Avenue North

Plymouth, MN 55447-3408

Tel.: +1 763 745 3500

Fax: +1 763 745 3718

E-mail: info@nilfi sk-advance-us.com

www.advance-us.com

VIETNAM

Nilfi sk-Advance Representative Offi ce

No. 46 Doc Ngu Str.

Ba Dinh Dist.

Hanoi

Tel.: +84 4 761 5642

Fax: +84 4 761 5643

E-mail: nilfi sk@vnn.vn

Loading...

Loading...