Page 1

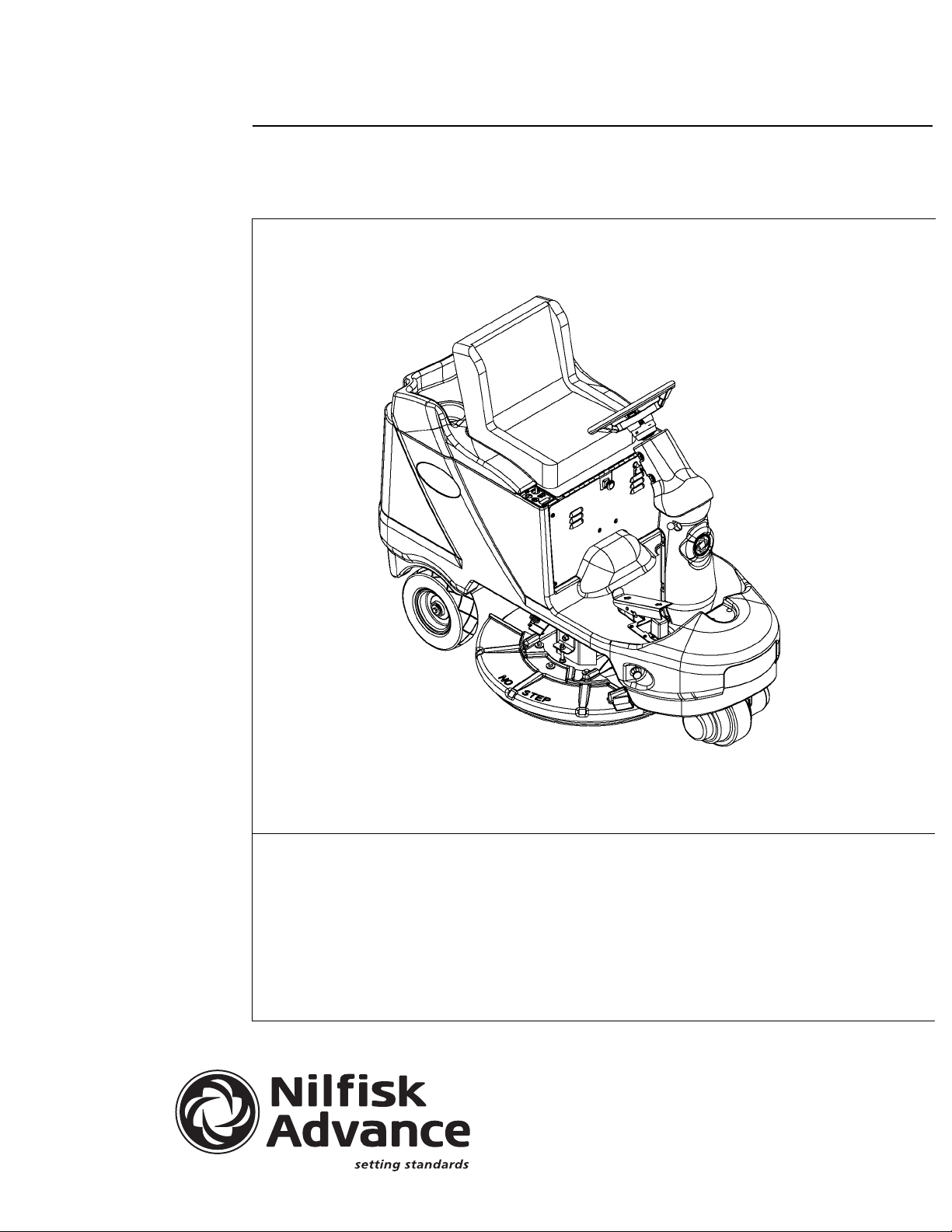

Advolution™ 2710

UHR 70-1700

Service Manual

Advance Models: 56422000, 56422002

Nilfi sk Model: 56422001

7/06 revised 6/08 FORM NO. 56043107

Page 2

TABLE OF CONTENTS

INTRODUCTION .................................................................................................................4

IMPORTANT SAFETY INSTRUCTIONS .............................................................................5

TECHNICAL SPECIFICATIONS ..........................................................................................6

MAINTENANCE SCHEDULE ..............................................................................................8

KNOW YOUR MACHINE ..............................................................................................10-11

FUNCTIONAL DESCRIPTION OF CONTROL BUTTONS: ...............................................12

BURNISHING SYSTEM ....................................................................................................13

FUNCTIONAL OVERVIEW ........................................................................................13

PAD LIFT ACTUATOR REMOVAL AND INSTALLATION ...........................................14

PAD DRIVE DECK REMOVAL ...................................................................................14

PAD DRIVE MOTOR CARBON BRUSH INSPECTION .............................................14

PAD DRIVE MOTOR REMOVAL ................................................................................15

DUST SHROUD REMOVAL .......................................................................................15

DUST SHROUD EDGING REPLACEMENT ..............................................................16

PAD DRIVE DECK LEVEL ADJUSTMENT .................................................................17

PAD DRIVE DECK LEVEL ADJUSTMENT .................................................................18

INSTALLATION OF THE BURNISHING PAD .............................................................19

INSTALLATION OF THE DUST COLLECTION BAG .................................................20

TROUBLESHOOTING GUIDE ELECTRICAL ............................................................21

WHEEL DRIVE SYSTEM ..................................................................................................25

GENERAL FUNCTIONAL OVERVIEW ......................................................................25

DRIVE MOTOR SYSTEM CONTROLLER FUNCTION OVERVIEW .........................25

DRIVE MODE SELECTION OPERATION OVERVIEW .............................................25

WHEEL DRIVE TROUBLESHOOTING GUIDE .........................................................28

WHEEL DRIVE ASSEMBLY REMOVAL .....................................................................30

WHEEL DRIVE MOTOR REMOVAL ..........................................................................31

DRIVE WHEEL REMOVAL .........................................................................................32

ELECTROMAGNETIC BRAKE ASSEMBLY REMOVAL ............................................33

STEERING CHAIN REMOVAL AND TENSIONING ...................................................34

POTENTIOMETER REMOVAL AND TESTING ..........................................................35

POTENTIOMETER INSTALLATION AND ADJUSTMENT: .........................................35

ALTERNATE METHOD FOR THROTTLE ADJUSTMENT .........................................35

DRIVE PEDAL NEUTRAL ADJUSTMENT & PEDAL REPLACEMENT .....................37

TROUBLESHOOTING GUIDE ELECTRICAL ............................................................38

2 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 3

TABLE OF CONTENTS (CONTINUED)

ELECTRICAL SYSTEM .....................................................................................................40

BATTERIES ................................................................................................................40

CHARGING THE BATTERIES ...................................................................................41

CHECKING THE BATTERY WATER LEVEL ..............................................................41

BATTERY MAINTENANCE ........................................................................................41

CHARGING THE BATTERIES (CONTINUED) ...........................................................42

BATTERY TESTING ...................................................................................................42

BATTERY SPECIFICATIONS .....................................................................................42

BATTERY CHARGER SPECIFICATIONS ..................................................................42

ACTUATOR DRIVE NUT ADJUSTMENT ...................................................................43

CURTIS CONTROLLER DIAGNOSTICS: ..................................................................44

FUNCTION OF THE SPEED CONTROLLER STATUS LIGHT AND DISPLAY ..........44

PROGRAMMER DIAGNOSTICS: ..............................................................................44

DIAGNOSTIC HISTORY ............................................................................................44

SPEED CONTROL PROGRAMMING OPTIONS .......................................................45

INSTALLATION CHECKOUT FOR THE CURTIS SPEED CONTROLLER ................47

PROGRAMMING VEHICLE SPEED CHANGES .......................................................47

FUNCTIONAL OVERVIEW OF MAIN CONTROL BOARD ........................................48

MAIN CONTROLLER ERROR CODES .....................................................................48

ADVOLUTION PROGRAMMING MODES .................................................................49

FAULT RECALL MODE / REVISION DISPLAY: .............................................................................. 49

SERVICE TEST MODE: ..................................................................................................................49

STATUS DISPLAY: ..........................................................................................................................50

OUTPUT CONTROLS: .................................................................................................................... 50

HORN SWITCH: .............................................................................................................................. 50

PAD SWITCH: ..................................................................................................................................50

LOW VOLTAGE CUTOUT THRESHOLD SELECTION MODE: ...................................................... 51

FAULT DETECTION ENABLE/DISABLE MODE: ............................................................................51

PAD PRESSURE ADJUSTMENT MODE: ....................................................................................... 51

FORWARD MOTION ALARM VOLUME LEVEL ADJUSTMENT MODE: ........................................52

REVERSE MOTION ALARM (BACK-UP ALARM) VOLUME LEVEL ADJUSTMENT MODE: ......... 52

BURNISHING SPEED LIMIT ENABLE/DISABLE MODE: ............................................................... 52

TROUBLESHOOTING GUIDE ..........................................................................................53

COMPONENT LOCATION ..............................................................................................................55

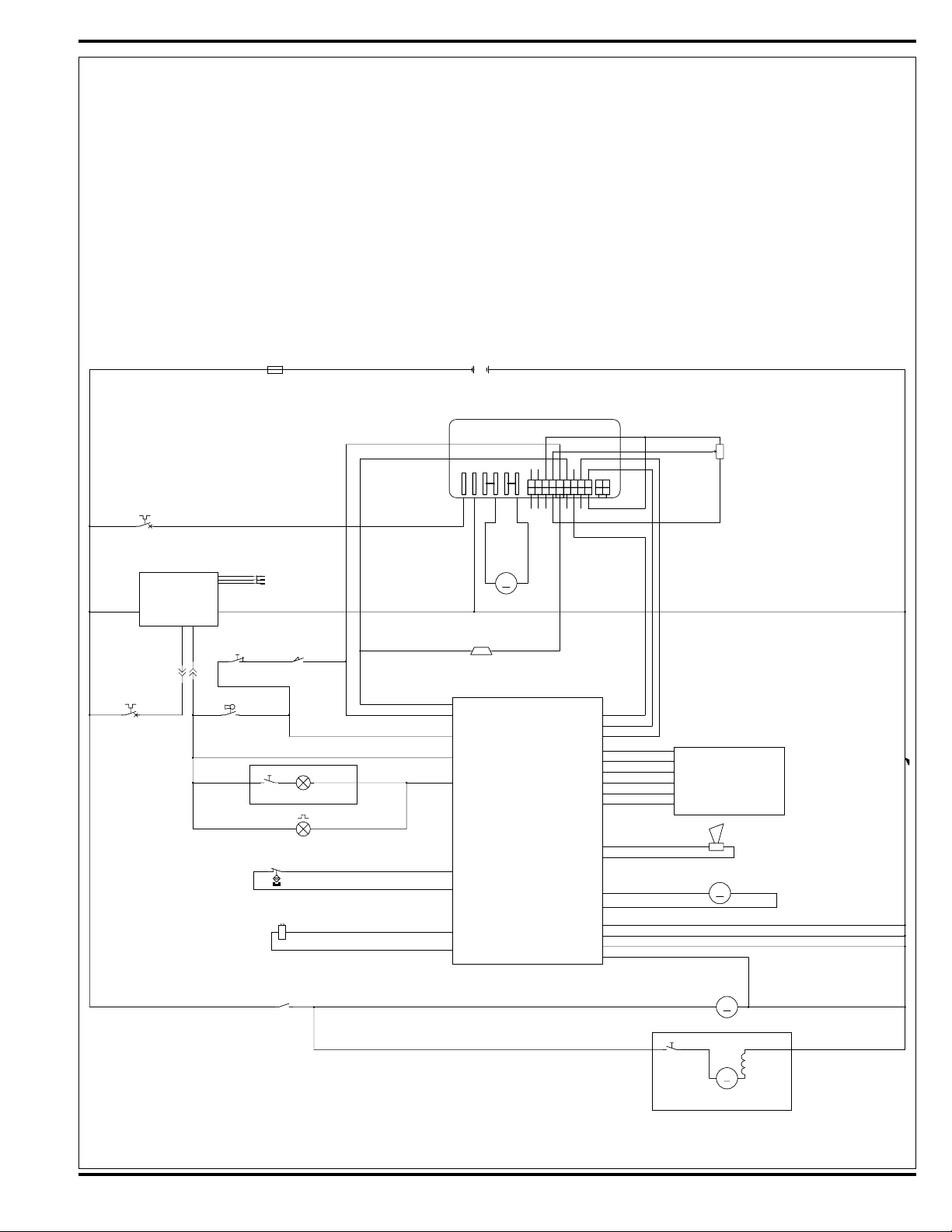

WIRING DIAGRAM / SCHEMATIC .............................................................................................56-57

Note: All references to right, left, front, or rear in this manual are as seen from the operator’s standpoint.

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 3

Page 4

INTRODUCTION

This manual will help you get the most from your Nilfi sk-Advance Advolution™ 2710 / UHR 70-1700. Read it thoroughly before operating the

machine.

Note: Bold numbers in parentheses indicate an item illustrated on pages 10 – 11.

This product is intended for commercial use only.

PARTS AND SERVICE

Repairs, when required, should be performed by Nilfi sk-Advance service personnel using Nilfi sk-Advance original replacement parts and

accessories.

Call Nilfi sk-Advance for repair parts or service. Please specify the Model and Serial Number when discussing your machine.

NAME PLATE

The Model and Serial Number of your machine are shown on the Nameplate on the machine. This information is needed when ordering repair

parts for the machine. Use the space below to note the Model and Serial Number of your machine for future reference.

MODEL ________________________________________________

SERIAL NUMBER ________________________________________

TRANSPORTING THE MACHINE

CAUTION!

Before transporting the machine on an open truck or trailer, make sure that . . .

• The machine is tied down securely.

• All access doors and covers are secured (tape and strap as needed).

TOWING

Reference page 8 for towing instructions.

OTHER MANUALS AVAILABLE FOR YOUR MACHINE

The manuals listed below can be found via Nilfi sk-Advance’s two electronic supported databases. They are:

• Nilfi sk-Advance Dealer Customer Zone

• Ezparts service / parts CD-Rom

• Parts List - Form Number 56042468

• Instructions for Use - Form Number 56041634 (English, Spanish)

56041635 (Danish, Norwegian, Swedish, Finnish)

56041636 (German, French, Dutch, Russian)

56041637 (Spanish, Portuguese, Italian, Greek)

56041638 (Estonian, Latvian, Lithuanian, Slovenian)

56041639 (Slovakian, Czech, Polish, Hungarian)

56041655 (Turkish)

4 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 5

IMPORTANT SAFETY INSTRUCTIONS

This machine is only suitable for commercial use, for example in hotels, schools, hospitals, factories, shops and offi ces other than

normal residential housekeeping purposes.

Read all instructions before using.

WARNING!

To reduce risk of fi re, electric shock, or injury:

• Use only as described in this manual. Use only manufacturer’s recommended attachments.

• This machine shall be used only by properly trained and authorized persons.

• This machine is for dry use only and shall not be used or stored outdoors in wet conditions.

• Do not allow to be used as a toy. Close attention is necessary when used by or near children.

• Keep sparks, fl ame and smoking materials away from batteries. Explosive gases are vented during normal operation.

• Charging the batteries produces highly explosive hydrogen gas. Charge batteries with seat cover open in well-ventilated areas,

away from open fl ame. Do not smoke while charging the batteries.

• Remove all jewelry when working near electrical components.

• Turn the key switch off (O) and disconnect the batteries before servicing electrical components.

• Never work under a machine without safety blocks or stands to support the machine.

• Do not dispense fl ammable cleaning agents, operate the machine on or near these agents, or operate in areas where fl ammable

liquids exist.

• Do not clean this machine with a pressure washer.

• This machine is not approved for use on public paths or roads.

• Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair, and anything that may

reduce air fl ow.

• Do not use on surfaces having a gradient exceeding that marked on the machine.

• When operating this machine, ensure that third parties, particularly children, are not endangered.

• Before performing any service function, carefully read all instructions pertaining to that function.

• Do not leave the machine unattended without fi rst turning the key switch off (O) and removing the key. The parking brake is

automatically activated at this time.

• Turn the key switch off (O) and remove the key, before changing the brushes, and before opening any access panels.

• Take precautions to prevent hair, jewelry, or loose clothing from becoming caught in moving parts.

• Do not use without dust bag and / or fi lters in place.

• Do not stand on the pad housing.

• This machine is not suitable for picking up health endangering dust.

• The batteries must be removed from the machine before the machine is scrapped. The disposal of the batteries should be

safely done in accordance with your local environmental regulations.

• All doors and covers are to be positioned as indicated in the instruction manual before using the machine.

• Refer to the battery charger OEM product manual for additional specifi c battery charger warnings.

SAVE THESE INSTRUCTIONS

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 5

Page 6

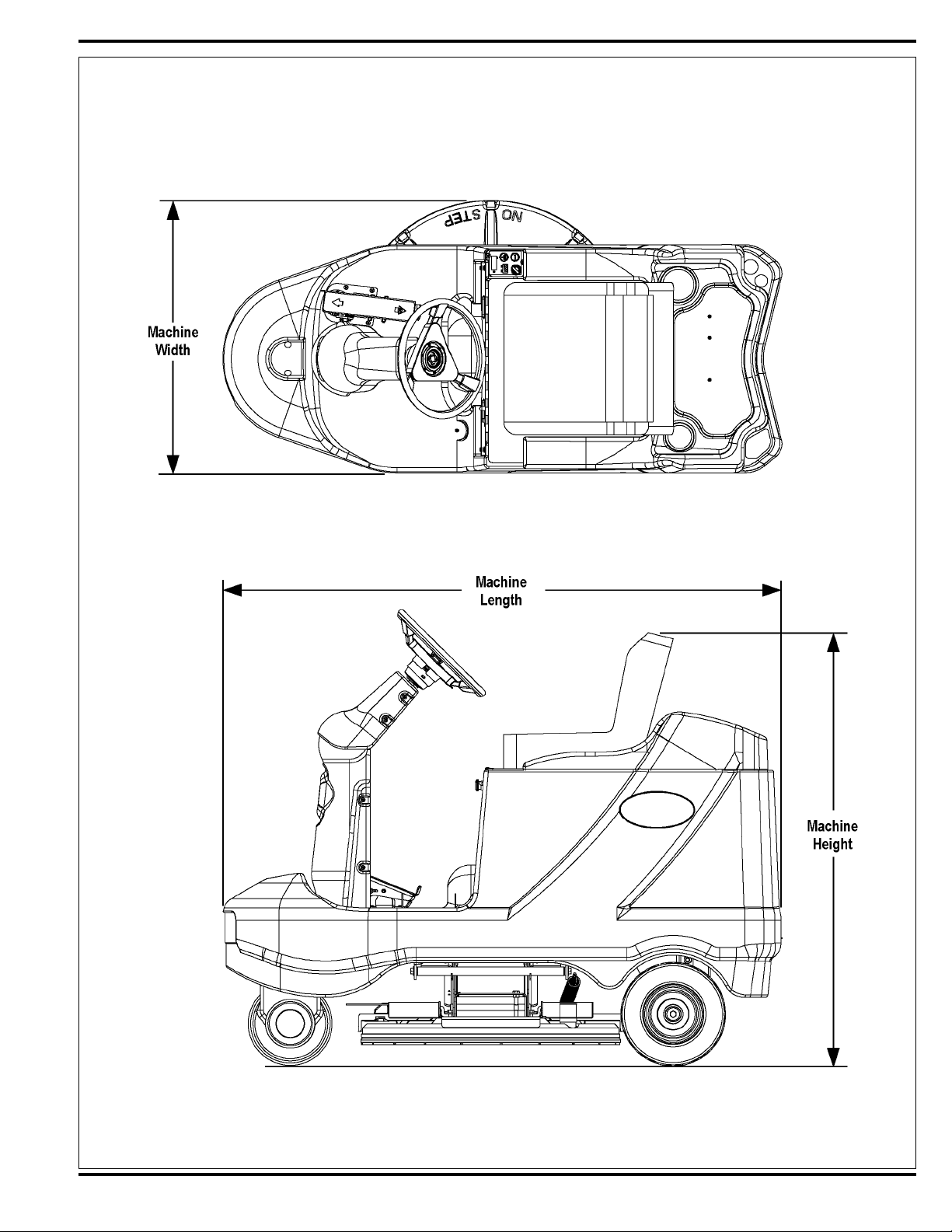

TECHNICAL SPECIFICATIONS

General Specifi cations English (Metric)

Burnishing Pad Diameter 27 inches (68.58 cm)

Machine Length 65.5 inches (166.37 cm)

Machine Width 32 inches (81.28 cm)

Machine Height 54 inches (137.16 cm)

Machine Weight

Front Wheel Weight (w/six 395 AH batteries) 308 lbs. (139.7 kg)

Rear Right Wheel Weight (w/six 395 AH batteries) 445 lbs. (201.8 kg)

Rear Left Wheel Weight (w/six 395 AH batteries) 451 lbs. (204.5 kg)

Front Wheel Pressure (w/six 395 AH batteries) 128 PSI

Rear Right Wheel Pressure (w/six 395 AH batteries) 72 PSI

Rear Left Wheel Pressure (w/six 395 AH batteries) 105 PSI

Average Coverage Rate 41,580 sq. ft (3,862m

Average Run Time 3 hours per battery charge

Batteries Recommended Six 6 volt, 395 A/H @ 20 hour rate,

Battery Compartment Size

Battery Charger Recommendation 25 or 36 Amp output, 36 volt charger

Burnisher Pad Motor 36 volt, 3.25 hp, 85 Amp

484 lbs. (219.53 kg) net w/o batteries

1,379 lbs. (626 kg) gross w/six 395 AH batteries

2

) per hour

120 lbs. (54.4 kg) each

25 inches (63.50 cm) long

22.5 inches (57.15 cm) wide

17.50 inches (44.45 cm) high

Wheel Drive Motor 36 volt, 1 hp, 27 Amp

Pad Lift Motor 36 volt, 1/6 hp, 6.7 Amp

Drive System Speed Control Electronic, fully variable Fwd/Rev

Max Transport Speed 396 FT/min

Max Burnish Speed 308 FT/min

Turning Radius 72 inches (182.88 cm)

Wheels

Ramp Climbing Ability 12.3% grade

Sound Pressure Level (IEC 60704-1) 69 dB(A)/20μPa (at operator’s ear)

9.75 inch (24.76 cm) drive wheel

12 inch (30.48 cm) rear wheels

6 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 7

TECHNICAL SPECIFICATIONS

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 7

Page 8

MAINTENANCE SCHEDULE

MAINTENANCE ITEM Daily Weekly Monthly Yearly

Charge Batteries X

Check/Clean/Replace Burnishing Pad X

Check/Replace Dust Collection Bag X

Check Battery Water Level(s) X

Check/Replace Pad Shroud Skirt X

Chain Tension - Steering X

Lubrication - Grease Fittings X

Check Carbon Brush Wear On Pad/Drive/Vacuum Motors X

Note: See the individual machine system sections for maintenance information.

* Have Nilfi sk-Advance check the vacuum motor carbon motor brushes once a year or after 300 operating hours. The pad and drive motor carbon

brushes check every 500 hours or once a year.

WARNING!

Turn the key switch off and disconnect the batteries before servicing the machine.

* Check vacuum motor carbon brushes (Qty 2) once a year or after 300 operating hours.

* Check pad and wheel drive motor(s) carbon brushes (Qty 4 per motor) once a year or after 500 operating hours.

* The original (new) length of each carbon brush is 1-3/32” (27.76mm) on all 36 volt machine models brush and wheel drive motors.

* All motors: Replace carbon brushes when shorter than 3/8” (9.5mm) to obtain the same motor effi ciency as new brushes.

IMPORTANT!

Motor damage resulting from failure to service the carbon brushes is not covered under warranty. See the Limited Warranty

Statement.

BATTERIES AND CHARGERS

Attention: See the ELECTRICAL SYSTEM section for battery installation, battery maintenance and charger system requirements.

LUBRICATING THE MACHINE

Locations requiring periodic oiling are:

Qty 1 - Steering Wheel Shaft Universal Joint (oil hole or port)

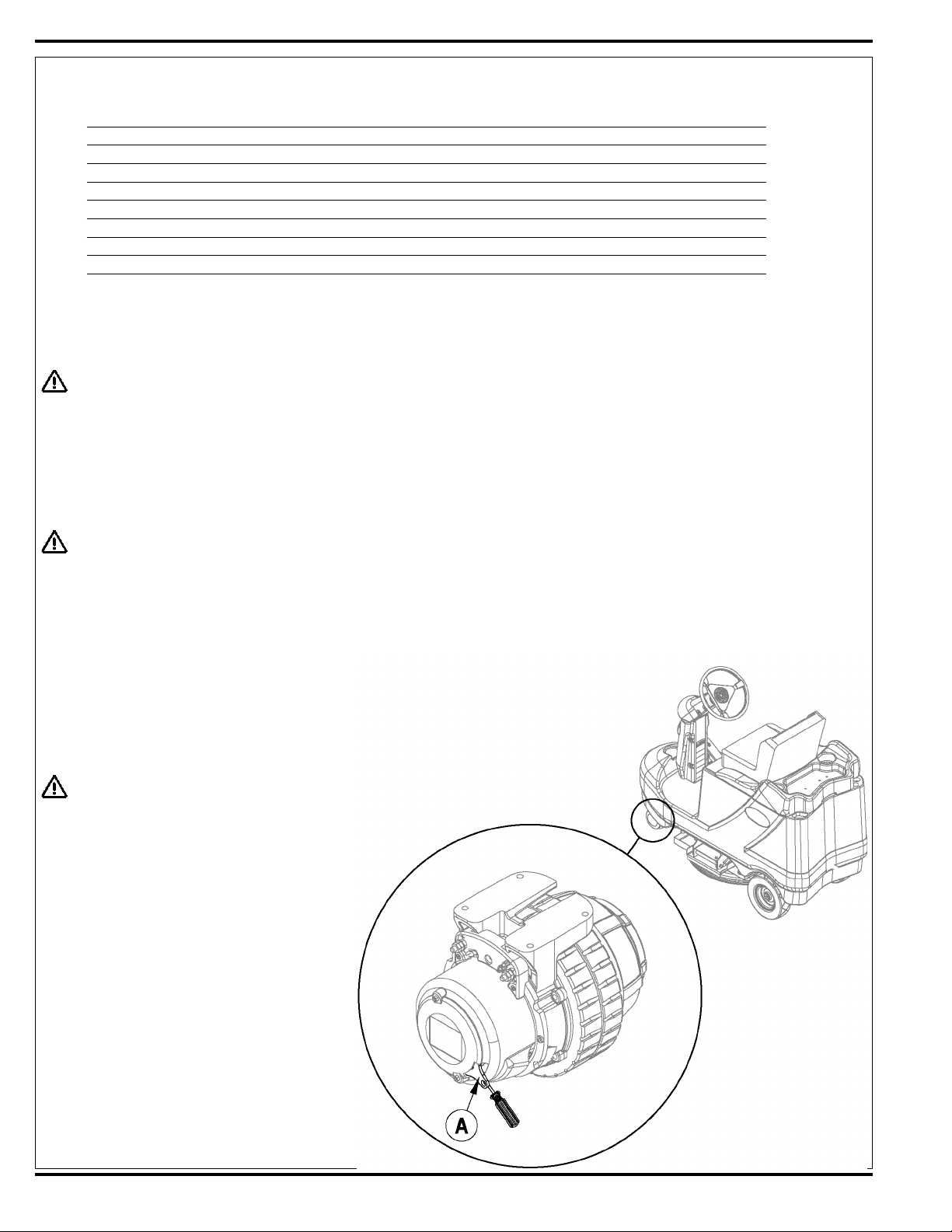

TOWING THE MACHINE

CAUTION!

The Drive / Steer Wheel Assembly (14) has a built in

electromagnetic brake that is engaged whenever the

Master Key Switch (AA) is OFF or the FWD / REV Drive

Pedal (8) is in the neutral position. This brake can be

manually over ridden if necessary by inserting a medium

to large screwdriver behind the Yoke (A) as shown. This

should only be done in the event you need to push or pull

the unit.

8 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 9

Advance Advolution 2710 & Nilfisk UHR 70-1700

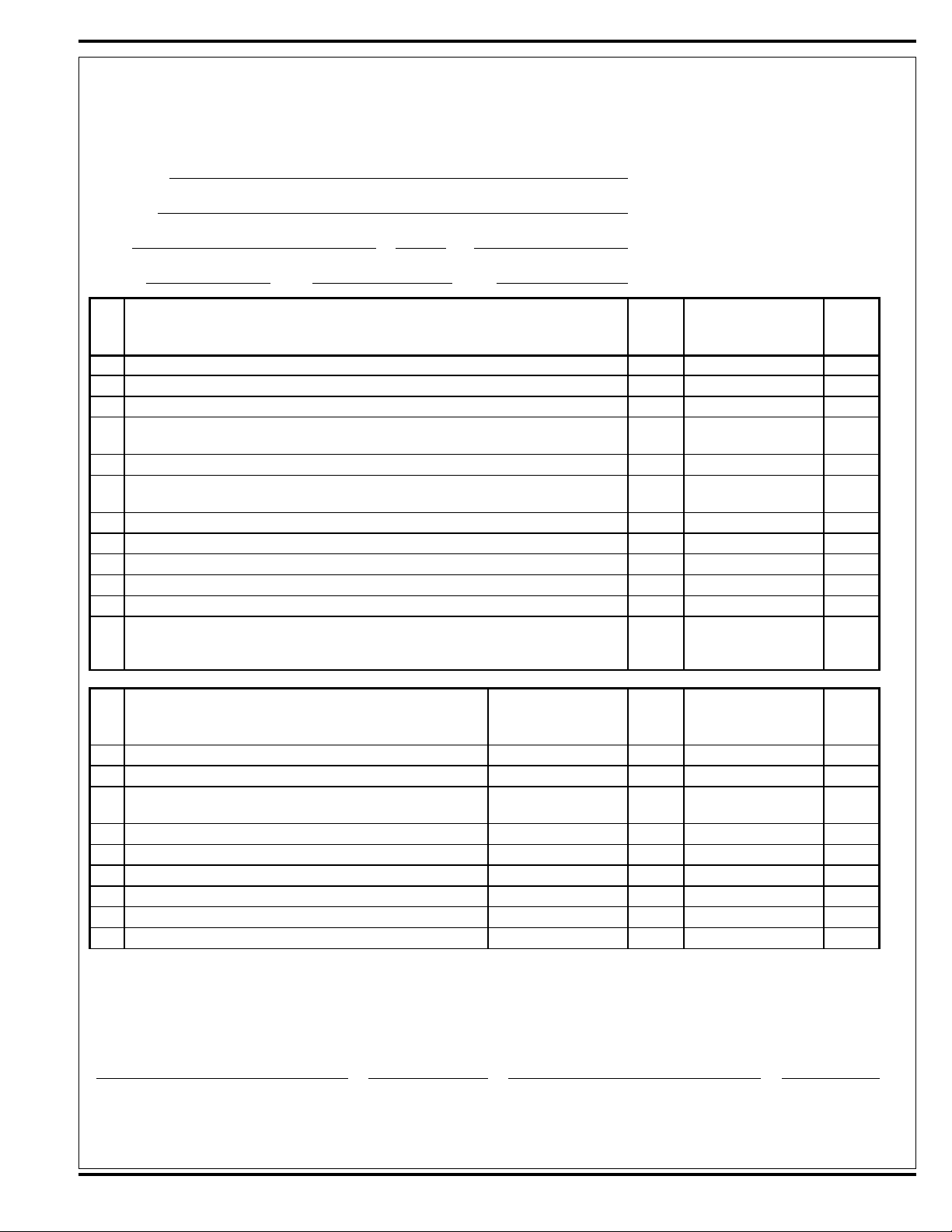

Rider Burnisher

PM Checklist

Defect Codes

Customer A needs adjustment

B binding

Address C dirty or contaminated

D damaged, bent or torn

City St Zip L leaks

M missing

Model Serial Hours W worn out

Ref

1 Steering A B

2 Drive System Pedal Operation (check for Fwd/Rev drive & any neutral creep) A B D

3 Seat Safety Switch D W

4 Electrical Parking Brake (Brake releases when the key is turned on & the drive pedal is

engaged. Note machine should not move when machine is at rest.)

5 Drive System Performance noisy sluggish

6 Burnishing System Deck & Motor Operation (pad deck raise/lower & pad motor auto

functions)

7 Burnishing System performance (even shine) A W

8 Emergency Battery Disconnect Control Knob B D

9 Tilt Steering Mechanism A B

10 Optional Accessories (Headlight, Safety Beacon, Active Dust Control System, Etc.) <----->

11 Battery Charger (auto turn ON & OFF)

12 Main Control Board Special Program Options (Reference SVR Manual 56043107) and

check all applicable program settings. Examples stored error fault codes, diagnostic

SVR test mode, pad pressure settings etc.

OK

OPERATIONAL INSPECTION ITEMS

Defect Codes

(circle)

A B W

A B C D

A

Does

Not

Work

Ref

13 Pad Motor Carbon Brushes (check for wear) C D W

14 Wheel Drive Motor Carbon Brushes (check for wear) C D W

15 Pad Deck Actuator Motor and Pad Drive Deck Levelness Perform a pad pattern

16 Pad Retainer, Pad Driver and Burnishing Pad (check for wear) D M

17 Dust Shroud Assembly Edging and Dust collection Bag D M W

18 Battery Condition (load test, clean & water) D L W

19 Check and Lubricate the Steering Wheel Universal Joint A B D W

20 Steer Chain Tension adjust A B C W

21 Drive and Steer wheels (thread wear) A D W

Comments OK

test

VISUAL INSPECTION ITEMS

Defect Codes

(circle)

A B D

NOTE: For additional service information see service manual form number 56043107 and

operators manual (English & Spanish) form number 56041634.

WORK COMPLETED BY: ACKNOWLEDGED BY:

Service Technician Signature Date Customer Signature Date

Does

Not

Work

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 9

Page 10

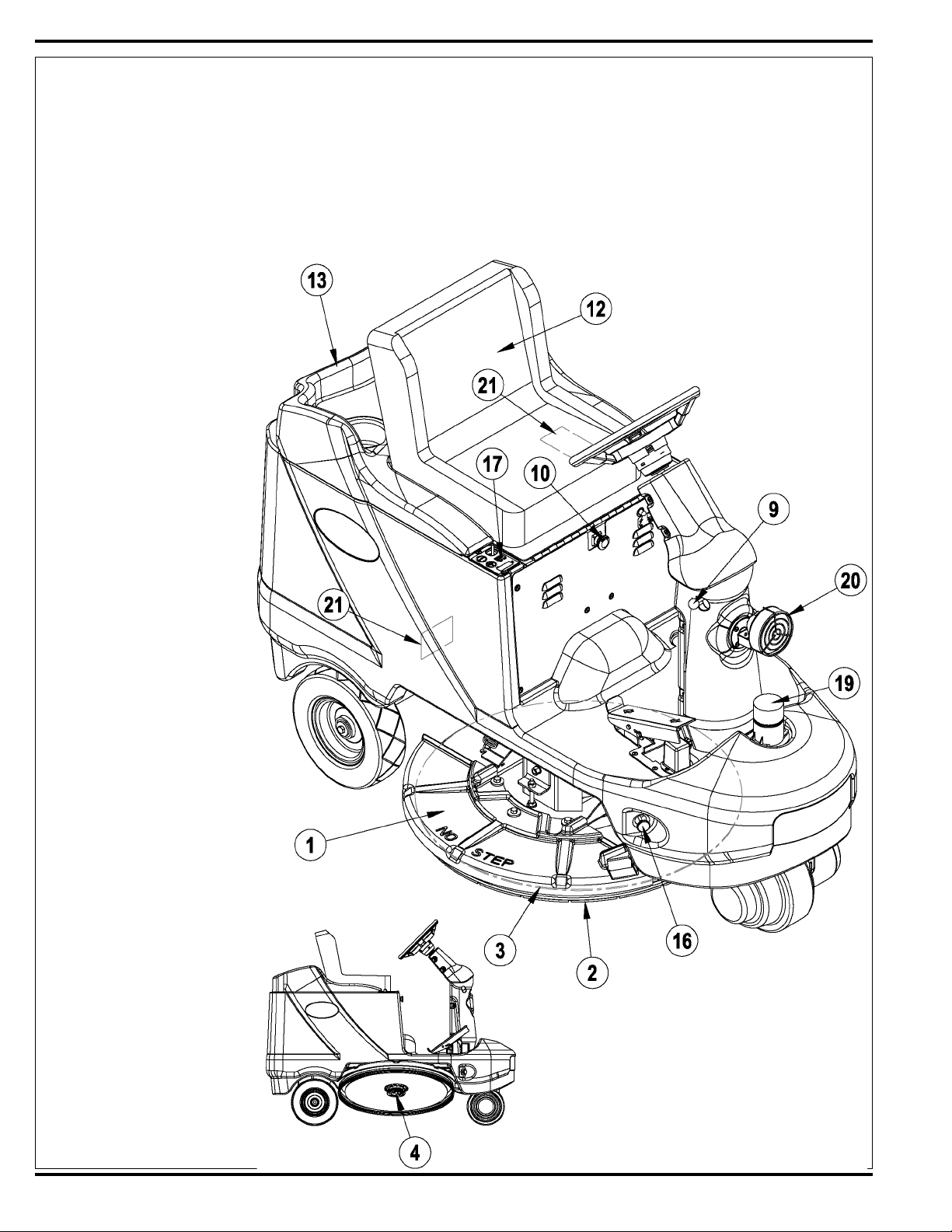

KNOW YOUR MACHINE

As you read this manual, you will occasionally run across a bold number or letter in parentheses - example: (2). These numbers refer to an item

shown on these pages unless otherwise noted. Refer back to these pages whenever necessary to pinpoint the location of an item mentioned in

the text.

1 Pad Drive Deck

2 Dust Control Shroud

3 Burnishing Pad

4 Pad Retainer

5 Dust Collection Bag

6 Machine Tie Down

7 Battery Connector Assembly

8 FWD/REV Drive Pedal

9 Tilt Steering Wheel Adjuster

10 Emergency Power Disconnect

11 Steering Wheel

12 Operator’s Seat W/Safety

Switch

13 Battery Compartment Cover

14 Drive / Steer Wheel

15 Circuit Breakers

40 Amp (Wheel Drive)

5 Amp (Control Circuit)

16 Deck Latch

17 I/O Panel (Indicator /

Operation Panel)

18 Spare Dust Bag Storage

19 Beacon (Optional)

20 Headlight (Optional)

21 Active Dust Control (Optional)

22 Onboard Charger (Optional)

23 Serial Plate (qty of 2)

10 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 11

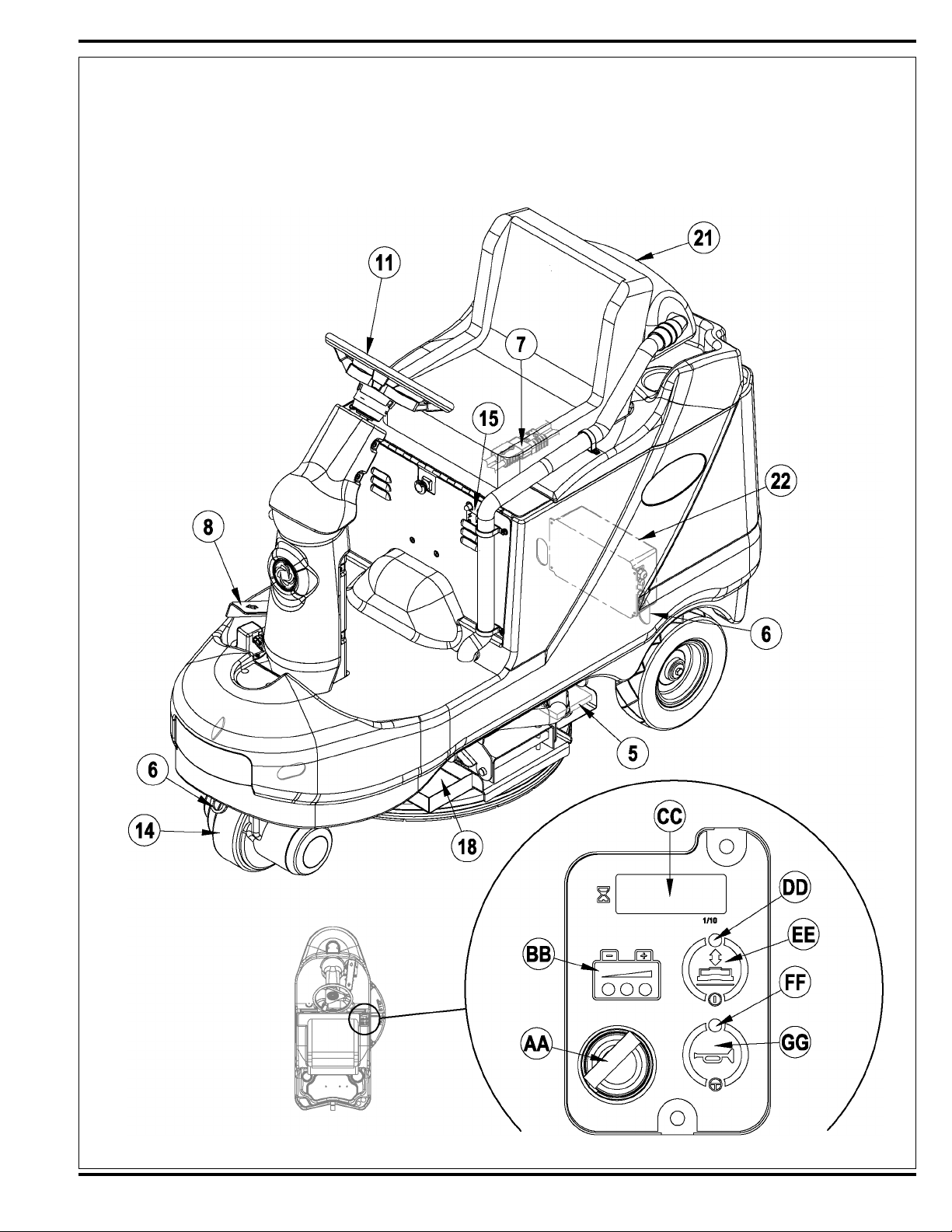

KNOW YOUR MACHINE

AA Master Key Switch

BB Battery Condition Indicator

CC Hour Meter / Error Display

DD Pad Drive Indicator Light

EE Pad Drive Raise / Lower Switch

FF Horn Indicator Light

GG Horn Switch

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 11

Page 12

FUNCTIONAL DESCRIPTION OF CONTROL BUTTONS:

Key Switch (AA) – Main Power Switch, when turned on controls battery input to machine’s main control board and wheel drive speed control.

Battery Condition Indicator (BB) – The Battery Condition Indicator will give an indication of the state of charge of the batteries. Three lights

make up the Indicator Display (Red-Yellow-Green). See the electrical system in this manual for discharge percentage details of each indicator

light.

Hour Meter/Error Display (CC) The 5-character display on the I/O Panel is primarily used as a display for the hour meter function. When the Key

Switch (A) is activated pad pressure setting 1,2, or 3 will appear briefl y in the right corner of the display. Followed by fi ve 8’s to show functionality

of the L.E.D. Display, then switching to hours on the unit. This display is also used to display the following information depending upon which

mode the control is in:

• Error Codes*

• Pad Pressure Settings (1,2, and 3)

• Display of control system default parameters*

*Service Note: Have a qualifi ed Service Technician reference the Service Manual for explanations about Error Codes and Control Fault + Parameter Changes. A

description of Error Codes can be found in the electrical section of this manual

Pad Drive Indicator Light (DD) –

• Indicator will be blank (off) when deck is in the raised position.

• Indicator will be light Green when lowering the deck as the pad drive raise-lower switch is activated.

• Indicator will be dark Green when the Drive Pedal is engaged in Forward or Reverse activating the pad motor.

• Indicator will be Red when raising the deck as the pad drive/raise-lower switch is activated.

• At full raised position the Red light will go out.

Pad Drive Raise-Lower Switch (EE) – Pressing this switch will activate (turn on) the Lower/Raise burnishing deck lift actuator functions – see

indicator lights description for further information.

Horn Indicator Light (FF) – Indicator Light will turn Green when Horn Switch is depressed. And also displays fault fl ash codes. NOTE: See

electrical system Curtis Control diagnostics in this manual.

Horn Indicator Switch (GG) – Pressing this switch will activate (turn on) the horn, causing a horn like sound to emanate from the machine.

12 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 13

BURNISHING SYSTEM

A

FUNCTIONAL OVERVIEW

The machines: Advolution 2710 / UHR 70-1700 (Model numbers 56422000, 56422001 & 56411002) use the disk type burnishing system. The pad

driver assembly is directly attached to a single 3.25hp – 36v DC permanent magnet motor.

The burnishing deck is raised and lowered by a horizontally mounted electric lift actuator motor. The operation of the machine’s burnishing

functions are activated when the operator presses the main I/O Panel’s pad drive raise/lower switch (EE). NOTE: See the Electrical SystemAdvolution programming modes section of this manual for more detailed operation and instructions to change the burnishing pad pressure setting.

The machines main burnishing system input and output operating functions are regulated (managed) by the I/O Panel and the Control Box. For

the Pad motor to function the operator must turn on (energize) the (K1) pad motor solenoid by pressing the Pad drive Raise/Lower switch (EE) on

the I/O Panel and press the drive pedal moving it off it’s neutral position. These two operator functions deliver the required (A1) Speed control and

Control Box circuit inputs and outputs for the burnishing operation. NOTE: See troubleshooting (page 22) section for more details.

F1

F1

RED RED

FUSE, 150 A.

FUSE, 150 A.

12

BT1

BT1

---

---

BATTERY, 36 VDC

BATTERY, 36 VDC

1

CURTIS 1228 SPEED CONTROLLER

CURTIS 1228 SPEED CONTROLLER

A1

A1

GRN

RED/WHT

J7J7

123456789

GRN/BLK

ORN/BLK

VIO/BRN

GRA

2

3

R1

R1

POT. 5K OHM

POT. 5K OHM

1

BLK

CB2

CB2

RED

1 2

CIRCUIT BREAKER, 40 AMP

CIRCUIT BREAKER, 40 AMP

ON-BOARD

BATTERY CHARGER

(OPTIONAL)

RED BLK

CB1

CB1

RED

1 2

CIRCUIT BREAKER, 5 AMP

CIRCUIT BREAKER, 5 AMP

VIO

S10

S10

EMERGENCY STOP

EMERGENCY STOP

WHT/ORN

WHT/ORN

1 2

SWITCH, KEY

SWITCH, KEY

S1

S1

VIO

SWITCH, DECK INTERLOCK

SWITCH, DECK INTERLOCK

PLUG AC MALEPLUG AC MALE

S5

1 2

SW SPSTS5SW SPST

VIO

S3

S3

1 2

GRN/WHT

S2

S2

SWITCH, SEAT

SWITCH, SEAT

21

LP5

LP5

1 2

LAMP, HEAD

LAMP, HEAD

(OPTIONAL)

(OPTIONAL)

LP6

LP6

1 2

LAMP, FLASHING

LAMP, FLASHING

(OPTIONAL)

(OPTIONAL)

K1

K1

K1

COIL, RELAY

COIL, RELAY

B-

B+

RED/GRN

BLK

MOTOR, TRACTION

MOTOR, TRACTION

J3-10 (F/R)

J3-9 (SEAT SW)

J3-2 (KEY SW)

VIO

J3-1 (B+)

J2-4 (ACC (-))

J3-7 (INTERLOCK B-)

J3-5 (INTERLOCK)

J2-5 (PAD CONT -)

J2-11 (PAD CONT +)

Y1

BRAKEY1BRAKE

WHT/BRN

RED/WHT

RED/WHT

GRNVIO

WHT/ORN

WHT/BRN

GRA/BLK

VIO/BLK

BLK/WHT

BLU/WHT

GRNYEL

101112131415161718

M1 (a)

M2 (a)

M1 (b)

M2 (b)

YEL/BLK

M1

M1

- +

M

M

12

CONTROL BOX

YEL/WHT

ORN

(REV) J3-6

(STATUS) J3-4

(MODE) J2-2

(SDA) J1-1

(SCL) J1-2

(+5 V) J1-3

(HORN SW) J1-4

(B-) J1-5

(PAD SW) J1-6

(HORN +) J2-7

(HORN -) J2-1

(ACT 1) J2-12

(ACT 2) J2-6

(B-) J2-9

(B-) J2-10

(B-) J3-8

(SENSE) J3-3

VIO/BRN

YEL/WHT

ORN/BLK

GRN/BLK

PINK

ORN/WHT

BLU/BLK

BRN

BLK/GRA

BLU

GRA/WHT

BRN/WHT

WHT/RED

ORN/BLU

BLK

BLK

BLK

BLK/YEL

BRN/BLK

J4-1 (SDA)

J4-2 (SCL)

J4-3 (+5 V)

J4-4 (HORN SW)

J4-5 (B-)

J4-6 (PAD SW)

HORN/BACK-UP ALARM

HORN/BACK-UP ALARM

H1

H1

+ -

M3

M3

- +

M

M

ACTUATOR

ACTUATOR

I/O PANEL

RED

K1

K1K1

1 2

RED BLK

S9

1 2

SW SPSTS9SW SPST

M2

M2

-+

M

M

MOTOR, PAD

MOTOR, PAD

1 2

M4

M4

M

M

MOTOR, DUST CONTROL VAC

MOTOR, DUST CONTROL VAC

(OPTIONAL)

(OPTIONAL)

BLKWHT

56015612 REV. F

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 13

Page 14

BURNISHING SYSTEM

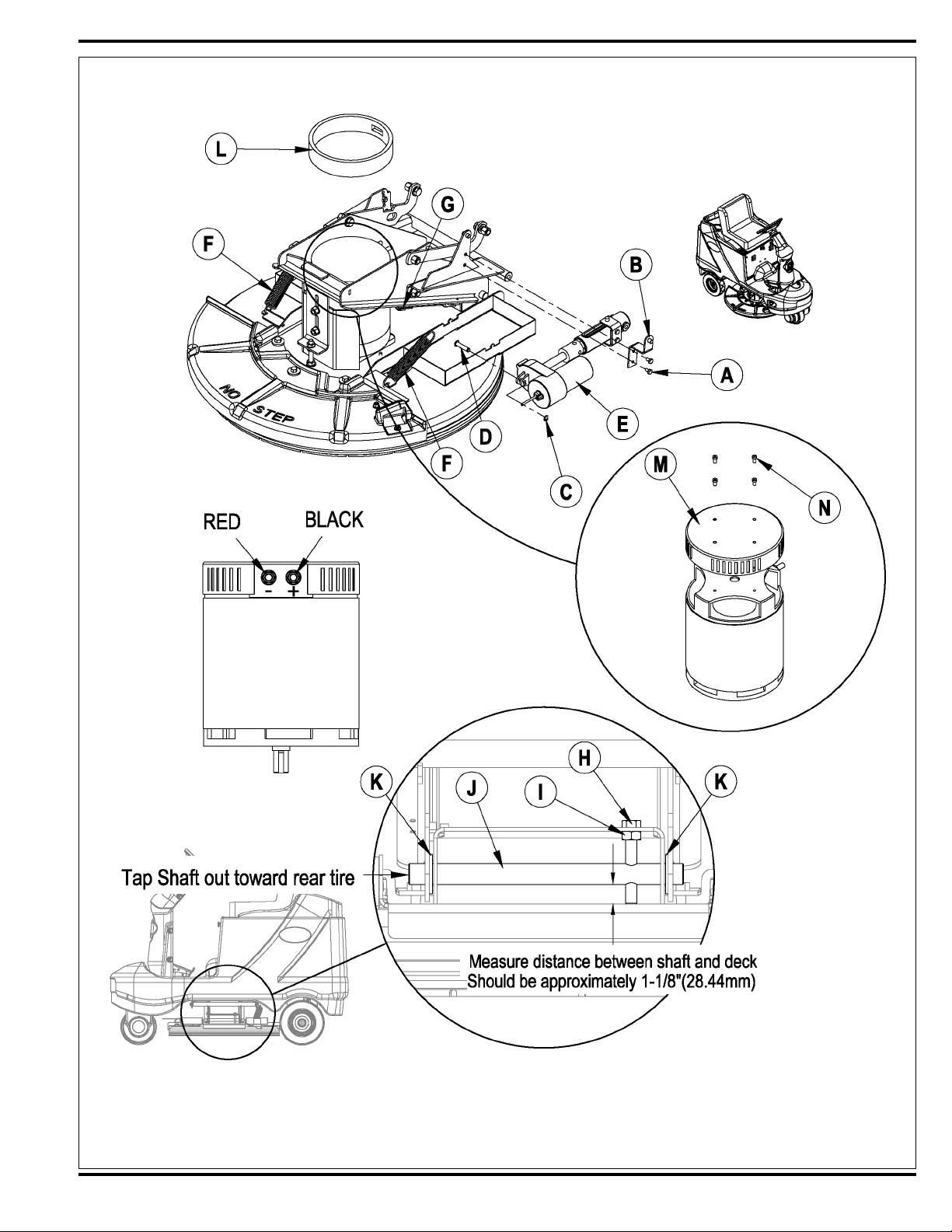

PAD LIFT ACTUATOR REMOVAL AND INSTALLATION

WARNING!

Disconnect the battery pack by separating the battery connectors (7) whenever servicing the machine.

1 Disconnect the battery pack by separating the battery connectors (7) located underneath the drivers seat.

2 Disconnect the actuator wiring harness at the actuator lift motor.

3 See Figure 1. Remove the (2) Hex Screws (A) that fasten the actuator Mount Bracket (B).

4 Remove the Retainer Ring (C). NOTE: Remove the retainer closest to the front of the machine. Then slide the mount pin (D) to the rear to

allow removal of the Actuator (E) from the machine.

5 To re-install follow the above instructions in reverse order. NOTE: See the Actuator Lift Nut Adjustment section in this manual for correct

lift nut adjustment setting as new actuators do not come pre-set.

PAD DRIVE DECK REMOVAL

WARNING!

Disconnect the battery pack by separating the battery connectors (7) whenever servicing the machine.

1 Disconnect the battery pack by separating the battery connectors (7) located underneath the drivers seat.

2 See Figure 1. Remove the (2) Deck Springs (F) from the right side of the lower deck housing. NOTE: Use a pliers to assist in disconnecting

the springs. Having the deck in the up position will also make it easier (less tension).

3 Attach the Advance actuator adapter cord (P.N. 56407502) to the deck Actuator (E) and lower deck. This step is done to gain service access

to the motor wiring and lift linkage mount hardware.

4 Disconnect the deck’s Safety Switch (G) at its harness connector.

5 Remove the (2) pad motor wires. NOTE: Mark the Red (-) & Black (+)wire locations.

Service Tip: Measure the height of the Front to Back Deck Level Adjustment Screw (H) before disassembling (should be approximately 11/8”(28.44mm)).

6 Loosen Lock Nut (I) and thread it down. At the same time remove the Adjustment Screw (H) from the Pivot Shaft (J).

7 Tap the Shaft (J) toward the rear tire to complete its removal.

Service Tip: The shaft is spaced with (2) Nylon Washers (K), note their location for reassembly.

8 Slide the deck assembly out from under the machine.

PAD DRIVE MOTOR CARBON BRUSH INSPECTION

1 Follow instructions for Pad Drive Deck Removal.

2 See Figure 1. Remove the Motor Air Filter (L). NOTE: Inspect the condition of the fi lter band and clean or replace as needed.

3 Remove the motor Brush Cover (M) secured by (4) Phillips head screws (N).

4 Inspect carbon brushes and springs. NOTE: New carbon brushes measure 1-3/32 (28mm). If the brushes are less than 3/8” (10mm) long

they should be replaced.

5 Important Maintenance Tip: Always blow out motor before reassembling

6 Motor wiring tip: The Red cable goes to NEGATIVE Stand off on the motor and the Black cable goes to the POSITIVE Stand off on the

motor.

14 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 15

FIGURE 1

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 15

Page 16

BURNISHING SYSTEM

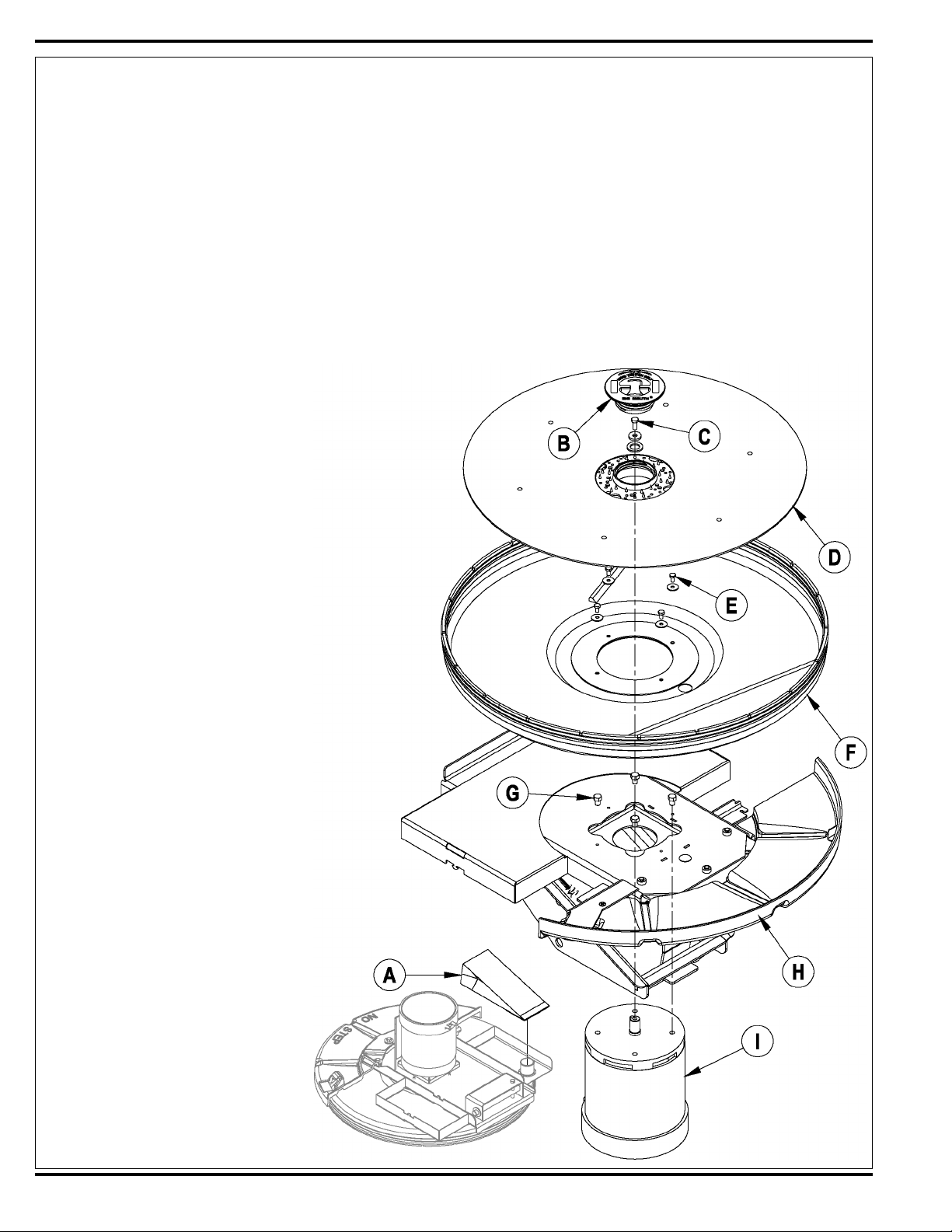

PAD DRIVE MOTOR REMOVAL

1 Follow instructions for Pad Drive Deck Removal.

2 See Figure 2. Remove the Dust Bag (A).

3 Tip the deck assembly over and remove the Pad Retainer (B), pad (if installed) and the Motor Shaft Screw (C) that fastens the Pad Driver

Assembly (D) to the motor shaft.

4 Remove the Pad Driver Assembly (D) from the motor shaft. NOTE: Do not lose the motor shaft key.

5 Remove the (4) Screws (E) and the Dust Shroud (F).

6 Remove the (4) Screws (G) that fasten the motor to the deck plate. Lift the remaining Deck Assembly (H) off the Motor (I) to complete its

removal. NOTE: Mark motor terminal location for reassembly.

7 Follow the above steps in reverse order to reinstall the Pad Drive Motor.

DUST SHROUD REMOVAL

1 See Figure 2. Remove the Dust Bag (A).

2 Remove the Pad Retainer (B), pad (if installed) and the Motor Shaft

Screw (C) that fastens the Pad Driver Assembly (D) to the motor

shaft.

3 Remove the Pad Driver Assembly (D) from the motor shaft. NOTE:

Do not lose the motor shaft key.

4 Remove the (4) Screws (E) and the Dust Shroud (F).

FIGURE 2

16 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 17

BURNISHING SYSTEM

DUST SHROUD EDGING REPLACEMENT

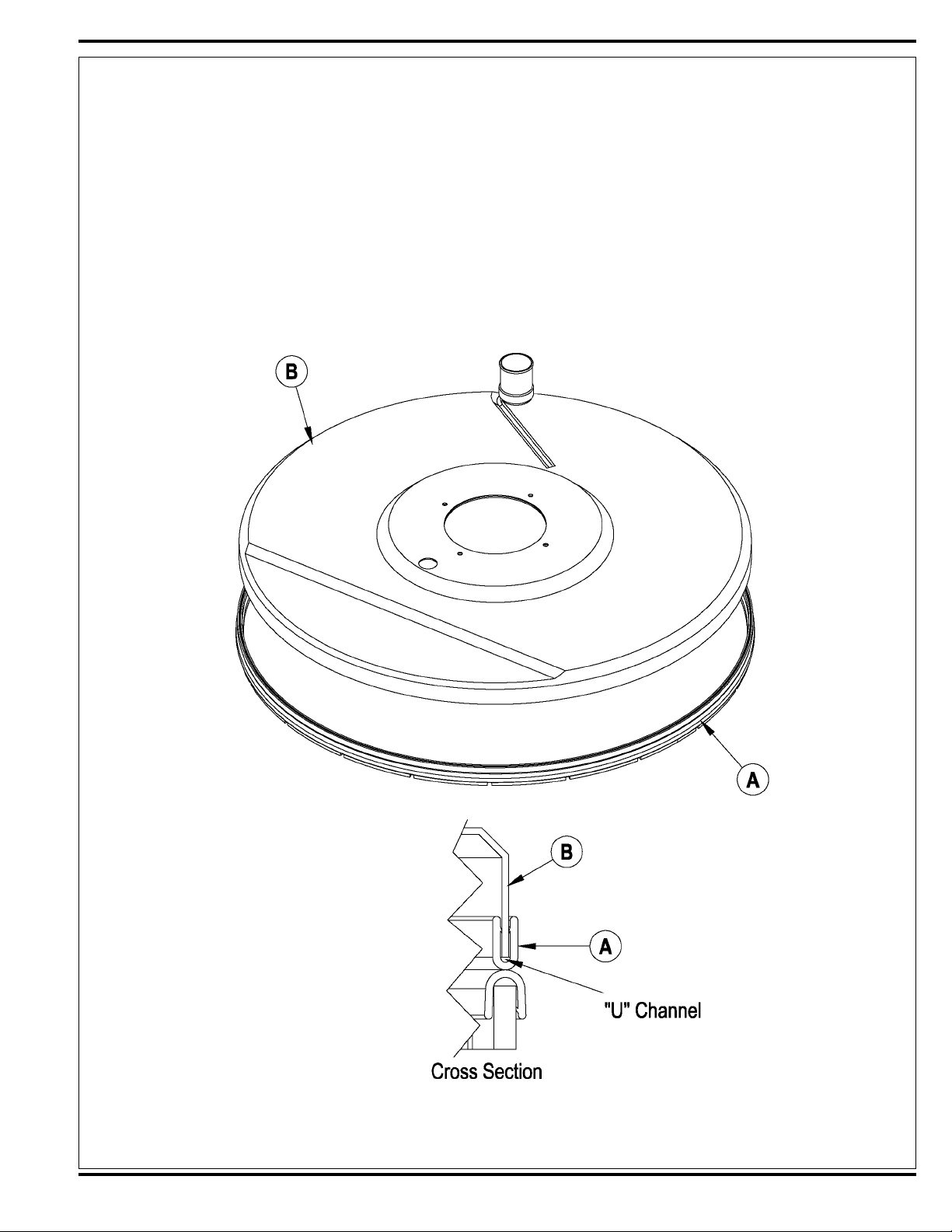

1 See Figure 3. Remove existing Edging (A) by pulling it away from the Shroud (B).

2 To install start at the rear of the Shroud (B) with one end of the new Edging (A) so that the seam is hidden. Push “U” channel onto Shroud

(B), work edging assembly around Shroud (B).

3 Check that Edging (A) “U” channel is fi rmly in place all around Shroud (B). NOTE: Pinch the “U” channel every 3 to 4 inches with a vise-

grips to ensure it is securely fastened to the shroud.

FIGURE 3

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 17

Page 18

BURNISHING SYSTEM

PAD DRIVE DECK LEVEL ADJUSTMENT

NOTE: Install a new pad before performing this adjustment.

1 Put the pad drive deck in the down position.

2 Briefl y run the pad drive motor to get a pattern on the fl oor.

CAUTION!

Do not run pad motor for an extended period without moving machine.

FIGURE 4

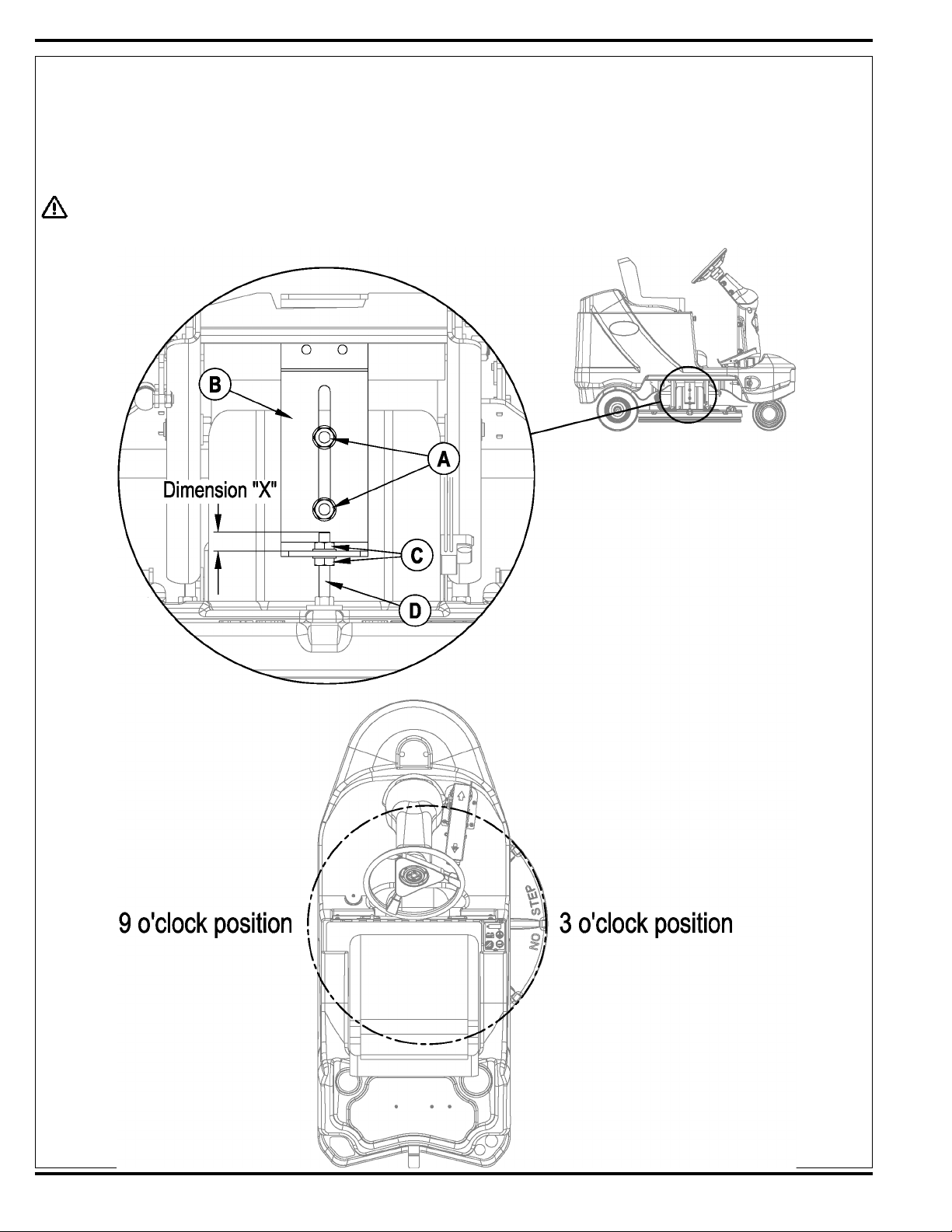

Left to Right Pad Contact Adjustment – See Figure 4.

1 Loosen the (2) Nuts (A) on the Adjustable Bracket (B).

2 Turn the (2) Lock Nuts (C) on the Carriage Screw (D) either

down to increase or up to decrease Dimension “X”.

Decreasing Dimension “X” will increase the pad pressure at

the 3 O’clock position.

Increasing Dimension “X” will increase the pad pressure at the

9 O’clock position.

NOTE: As a general rule the

measurement at the 3 o’clock and the

9 o’clock position should be the same

when measured from the fl oor to the

edge of the dust shroud.

18 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

revised 6/08

Page 19

BURNISHING SYSTEM

PAD DRIVE DECK LEVEL ADJUSTMENT

NOTE: Install a new pad before performing this adjustment.

1 Put the pad drive deck in the down position.

2 Briefl y run the pad drive motor to get a pattern on the fl oor.

CAUTION!

Do not run pad motor for an extended period without moving machine.

Front to Back Pad Contact Adjustment – See Figure 5.

1 Loosen Lock Nut (A) and turn the Adjustment Screw (B) clockwise to

increase or counter-clockwise to decrease Dimension “X”.

Increasing Dimension “X” will increase the pad pressure to the front of the

pad assembly at the 12 O’clock position.

Decreasing Dimension “X” will increase the pad pressure to the rear of the

pad assembly at the 6 O’clock position.

FIGURE 5

NOTE: As general rule the pad should

be approximately 3/8” higher at the 12

o’clock position than at the 6 o’clock

position.

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 19

Page 20

BURNISHING SYSTEM

INSTALLATION OF THE BURNISHING PAD

WARNING!

Disconnect the machines Battery Pack Connector (7) when ever servicing the machine.

CAUTION!

Turn the key switch off (O) and remove the key, before changing the pad, and before opening any access panels.

1 See Figure 6. Grab hold of the right side of the Pad Drive Deck (1) and lift up until it Latches (16) in place as shown.

2 Place your hand underneath the Dust Control Shroud (2) and remove the Pad Retainer (4) from the fl exible pad holder assembly. NOTE:

Grip the retainer fi rmly and turn clockwise (to the right) as the retainer uses a Left Hand thread.

3 Select a 27 inch (68 cm) Dia. Burnishing Pad (A). See your local Nilfi sk-Advance Distributor for a complete selection of pads and

accessories.

4 Insert the plastic Pad Retainer (4) into the center of the Pad (A). Then reinstall by turning the retainer counter-clockwise (to the left). NOTE:

Important !!! Turn the retainer in until you hear a clicking ratchet sound, this insures proper tightening of the pad by properly compressing the

pad material and drawing up the retainer so it will not strike the fl oor.

FIGURE 6

20 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 21

BURNISHING SYSTEM

INSTALLATION OF THE DUST COLLECTION BAG

The Advolution™ 2710 / UHR 70-1700 uses dust collection bag PN 56391185 (sold 6 to a Package).

See Figure 7. Unfold the Dust Collection Bag (5) and while holding onto the Card Board Retainer (A) insert it over the Collection Tube (B) found

on the top of the Pad Drive Deck (1) on the left side of the machine.

NOTE: Never operate the Advolution™ 2710 / UHR 70-1700 without a Dust Collection Bag (5) or the optional Active Dust Control Kit (21)

PN56422083 installed. Failure to do so will allow the burnishing dust to become airborne. The Active Dust Control Kit (21) is operational when

ever the vacuum switch on the vacuum is in the ON position, the Master Key Switch (A) is ON, the Pad Drive Deck (1) is down and the FWD/REV

Drive Pedal (8) is off the neutral position.

Extra Dust Collection Bags can be stored in the Spare Dust Bag Storage (18) box as shown. Install the Rubber Strap (C) as shown to secure the

bags.

FIGURE 7

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 21

Page 22

BURNISHING SYSTEM

TROUBLESHOOTING GUIDE ELECTRICAL

Symptom

Burnishing deck will not raise or lower. Part A, Chart 1 (Control Circuit)

Note :Do all testing with key switch on and seat switch activated. Have Pad R/L switch activated and deck in the burnishing position.

22 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 23

BURNISHING SYSTEM

TROUBLESHOOTING GUIDE ELECTRICAL

Symptom

Burnishing deck will not raise or lower. Part A, Chart 2 (Control Circuit)

Note :Do all testing with key switch on and seat switch activated. Have Pad R/L switch activated and deck in the burnishing position.

Symptom

Burnishing deck will not raise or lower. Part B (Load Circuit)

Note :Do all testing with key switch on and seat switch activated. Have Pad R/L switch activated and deck in the burnishing position.

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 23

Page 24

BURNISHING SYSTEM

TROUBLESHOOTING GUIDE ELECTRICAL

Symptom

Pad drive motor will not run. Part A (Control Circuit)

Note :Do all testing with key switch on and seat switch activated. Have Pad R/L switch activated and deck in the burnishing position and drive

engaged.

24 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 25

BURNISHING SYSTEM

TROUBLESHOOTING GUIDE ELECTRICAL

Symptom

Pad drive motor will not run. Part B (Load Circuit)

Note :Do all testing with key switch on and seat switch activated. Have Pad R/L switch activated and deck in burnishing ready position and drive pedal

engaged.

BURNISHING SYSTEM

TROUBLESHOOTING GUIDE ELECTRICAL

Symptom

Active dust control not working.

Note :Do all testing with the key switch ON, emergency switch closed, seat switch activated, pad switch activated, drive pedal engaged and the vac motor

switch turned ON.

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 25

Page 26

WHEEL DRIVE SYSTEM

GENERAL FUNCTIONAL OVERVIEW

See Figures 1 & 2. A 700-watt .9 HP (permanent magnet) 36V motor/gear transmission combination wheel (M1) unit is used to propel all

machines. A Curtis model 1228 PMC solid state speed controller (A1) regulates (outputs) the variable speed Fwd/Rev wheel drive motor

functions. The controller unit is located underneath the front of the operator seat, behind the electrical access panel. The potentiometer R1

mounted to the operator’s foot pedal, inputs to the (A1) controller the machine operator’s desired speed and directional demands.

DRIVE MOTOR SYSTEM CONTROLLER FUNCTION OVERVIEW

See Figure 1. To make the A1 speed controllers internal control circuits operational (power it up) the three switches S1 (key), S2 (seat) and S10

(emergency stop knob) must be closed. This circuit inputs a positive (+) 36V to the A1 speed controls pin terminal #5 (*KSI). The CB2 circuit

breaker 40 Amp supplies the positive high current (load) circuit input to the B+ controller terminal (Grn/Wht wire). The black wire from the negative

(-) battery standoff supplies the battery ground input to the B- terminal for both the control and load circuits.

See Figure 3. Depressing the foot pedal in either Fwd or Rev will move the 5K Ohm (R1) potentiometer shaft off its centered balanced (neutral)

setting of approximately 2500 Ohms. With this pot shaft movement the pot’s resistance value changes which generates a variable voltage signal

(0-5 volts). These control board voltage input signals are what energizes the Fwd & Rev directional relays, which selects the motor polarity and

also switches the battery voltage On and Off (**PWM) which varies the motor speed.

*KSI: Key Switch Input

**PWM: Pulse Width Modulation, also called “chopping” is a technique that switches battery voltage to the motor ON and OFF very quickly,

thereby controlling the speed of the motor.

DRIVE MODE SELECTION OPERATION OVERVIEW

The A1 speed Controller allows operation in two distinct modes: mode 1 (M1) & mode 2 (M2).

Mode 1 (M1) is the transport speed range and is automatically selected when the burnishing system is OFF (deck up). This allows maximum

variable vehicle speed operation.

Mode 2 (M2) is the reduced slower burnishing speed range and is automatically selected when the burnishing mode is ON (deck down).

Note: The maximum machine drive wheel speed setting for the two drive modes 1 & 2 can be changed by using the Curtis handheld programmer.

Reference the Curtis programmer instructions found in the electrical system manual section to change speed settings from their original factory

specifi cations.

FIGURE 1

CB2

CB2

RED

12

CIRCUIT BREAKER, 40 AMP

CIRCUIT BREAKER, 40 AMP

ON-BOARD

BATTERY CHARGER

(OPTIONAL)

RED BLK

CB1

CB1

RED

12

CIRCUIT BREAKER, 5 AMP

CIRCUIT BREAKER, 5 AMP

VIO

F1

F1

RED RED

S10

S10

EMERGENCY STOP

EMERGENCY STOP

WHT/ORN

12

SWITCH, KEY

SWITCH, KEY

S1

S1

FUSE, 150 A.

FUSE, 150 A.

PLUG AC MALEPLUG AC MALE

WHT/ORN

12

GRN/WHT

S2

S2

SWITCH, SEAT

SWITCH, SEAT

21

GRNYEL

RED/WHT

RED/WHT

GRNVIO

WHT/ORN

BT1

BT1

---

---

BATTERY, 36 VDC

BATTERY, 36 VDC

CURTIS 1228 SPEED CONTROLLER

CURTIS 1228 SPEED CONTROLLER

A1

A1

GRN

RED/WHT

B-

B+

M2 (a)

M2 (b)

RED/GRN

BLK

M1

M1

-+

M

M

MOTOR, TRACTION

MOTOR, TRACTION

Y1

12

BRAKEY1BRAKE

J3-10 (F/R)

J3-9 (SEAT SW)

J3-2 (KEY SW)

J7J7

123456789

101112131415161718

M1 (a)

M1 (b)

YEL/BLK

GRN/BLK

YEL/WHT

ORN

(REV) J3-6

(STATUS) J3-4

(MODE) J2-2

ORN/BLK

VIO/BRN

YEL/WHT

ORN/BLK

GRN/BLK

VIO/BRN

GRA

BRN/BLK

2

3

R1

R1

POT. 5K OHM

POT. 5K OHM

1

BLK

26 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 27

WHEEL DRIVE SYSTEM

FIGURE 2

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 27

Page 28

WHEEL DRIVE SYSTEM

R1 Voltage Values

0 – 2.5V Reverse

2.5 – 5V Forward

This drawing shows additional controller input circuit detail. The R1 pot is shown in the neutral position. Resistance is measured between pot low

and pot wiper.

FIGURE 3

FIGURE 4

28 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 29

WHEEL DRIVE SYSTEM

Low Current A1 Speed Control Pin Key Detail

Pin # Wire Color Controller Pin Description & Function

1 - Open not used

2 - Open not used

3 Vio/Brn Throttle Pot R1 pot high input

4 Gry Throttle Pot R1 pot wiper input

5 Grn KSI (key switch input) : Battery (+) powers up controller logic circuits

Auxiliary Driver: Battery (-) output to main control box to turn on (activate) the pad motor & release

6 Red/Wht

7 - Open not used

8 Grn/Blk

9 Orn/Blk Status Fault: Speed controller fault output to the main I/O Panel indicator light (horn LED).

10 – Open not used

11 – Open not used

12 – Open not used

13 Brn/Blk Throttle Pot R1: pot low input (-)

14 Orn Electromagnetic Brake: Parking brake output (+)

15 – Open not used

16 Yel/Wht Rev/Alarm Driver output: Battery (-) command turns on back up alarm

17 – Open not used

18 Vio/Brn Speed limit pot input connection (+). Note in this application it is tied to the pot high pin # 3.

the electromagnetic parking brake. Pin #6 will read approximately 36 volts when the foot-pedal is in

Fwd or Rev.

Battery (+) from the main control box (J2-2) 0 volts M1 (open) max transport speed selected.

36V M2 (closed) burnishing speed selected.

WHEEL DRIVE TROUBLESHOOTING GUIDE

Problem Possible Cause

• Wheel drive motor will not run in

forward and reverse.

• Wheel drive in one direction only, loss of either

forward or reverse.

• Hour meter/status display shows an error

03 fault code.

• Batteries need charging (low battery voltage, recharge batteries)

• Wheel Drive Motor Circuit Breaker (CB2) tripped

(reset 40A circuit breaker)

• Control Circuit Breaker (CB1) tripped

(reset 5A circuit breaker)

• Y1 parking brake (electromagnetic) not releasing. Note: Check

system voltage at brake, a reading of O volts brake is set and at 36

volts brake is released with foot pedal activated.

• Emergency Stop Switch (S10) tripped (Turn knob CW to reset)

• Safety Switch (S2) in seat not closed (check seat switch)

• Defective Wheel Drive Motor (replace motor) *

• Defective Throttle Potentiometer (R1) (replace) *

• Test the Fwd & Rev (R1) wiring outputs (pins 3, 4 & 13) at the

speed control for an open. Repair wiring or replace the R1 pot.

• Check potentiometer.

• Controller can’t change electrical polarity to wheel motor

replace the (A1) speed control.

• Speed controller has sensed an operation error code fault.

(see the Status LED Fault Codes (Table 1) in the Electrical

System)

* = See Curtis Speed Control Troubleshooting Section.

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 29

Page 30

WHEEL DRIVE SYSTEM

WHEEL DRIVE ASSEMBLY REMOVAL

FIGURE 5

WARNING!

Disconnect the battery pack by separating the battery connectors (7)

whenever servicing the machine.

1 Disconnect the battery pack by separating the battery connectors (7) located

underneath the drivers seat.

2 See Figure 5. Pull or pry off the Cover Plate (A) to access the Steering

Spindle Retainer Nut (B).

3 From underneath the front of the machine loosen the (4) steering column base

mount Screws (C). Service Tip: Use a 17mm socket wrench.

4 Observe and mark the drive motor wiring connections, then remove the two

large wires from their motor terminals.

5 Remove the P-Clamp (D) that fastens the drive motor wiring harness to the

Steer Plate (E).

6 Temporarily disconnect one end of the steering chain (remove the master

link) and separate the chain from the Steering Shaft Sprocket (F). NOTE:

Reassemble the master link (clip) back onto the end of the chain so that it is

not lost.

7 Remove the Steering Spindle Retainer Nut (B) with the use of a 1-7/16 inch

socket.

WARNING !

Never work under machine without safety stands or blocking to support the

machine.

8 Safely jack up the front of the machine 16 – 18 inches (40-45 cm) to remove

the wheel motor spindle assembly by carefully guiding it down through the

bottom of the frame opening and out from underneath the machine. NOTE:

Be careful not to damage the threads and bearing surfaces when dropping the

spindle through the frame when removing.

9 Inspect bearings and seal, replace as needed. Remove the (4) Screws (G) to

separate the Steer Plate (E) from the spindle weldment.

10 To make further service repairs see the Wheel Drive Motor Removal section.

11 Re-assemble in reverse order and tighten the Steering Spindle Retainer Nut

(B) just enough to eliminate any bearing free play.

30 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 31

WHEEL DRIVE SYSTEM

WHEEL DRIVE MOTOR REMOVAL

WARNING!

Disconnect the battery pack by separating the battery connectors (7) whenever servicing the machine.

1 Follow the Wheel Drive Assembly Removal Instructions.

2 See Figure 6. Place motor assembly upright (tire side down) as shown.

3 Remove the (4) Socket Head Cap Screws (A) that secure the electric drive motor to the motor housing casting.

4 Use a hard piece of wood or a brass drift punch to tap the motor mounting fl ange (3 notched locations B) to loosen.

5 Grip the motor / brake end bell (C) and pull the motor up and out of its housing.

6 Inspect the 4 carbon brushes & springs. A new carbon brush measures 3/4”. If less than 1/4” replace.

NOTE: Clean foam fi lters, blow out motor & inspect the oil level in the gear case. Gear case oil is 130GR. Gear case capacity is approx. 4.5 oz.

FIGURE 6

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 31

Page 32

WHEEL DRIVE SYSTEM

DRIVE WHEEL REMOVAL

WARNING!

Disconnect the battery pack by separating the battery connectors (7) whenever servicing the machine.

1 Disconnect battery and block rear wheels.

2 See Figure 7. Using a 5mm hex key wrench remove the (4) Screws (A) that secure the Tire/Hub Assembly (B) to the gearbox out put fl ange.

3 Safely lift or jack the front of the machine 1 – 2 inches (25 – 50 mm) and block both sides of the machine body in front of the burnishing deck.

4 While rotating the Tire/Hub Assembly (B), tap on the tire with a block of wood or dead blow hammer until tire hub separates from the gear

box.

FIGURE 7

32 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 33

WHEEL DRIVE SYSTEM

ELECTROMAGNETIC BRAKE ASSEMBLY REMOVAL

WARNING!

Disconnect the battery pack by separating the battery connectors (7) whenever servicing the machine.

1 Disconnect battery and block rear wheels so that the machine will not roll when the brake is removed.

2 See Figure 8. Remove the (2) Nuts (A) then the Brake Cover (B).

3 Remove brake wiring at motor terminal block secured by (2) hex nuts.

4 Remove the (3) Screws (C) using a 4mm socket key wrench.

5 Separate the 3 parts that make up the brake assembly, items (D) Electromagnetic Housing, (E) Brake Rotor and (F) Brake Backing Ring.

FIGURE 8

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 33

Page 34

WHEEL DRIVE SYSTEM

STEERING CHAIN REMOVAL AND TENSIONING

WARNING!

Disconnect the battery pack by separating the battery connectors (7) whenever servicing the machine.

1 Turn the master key switch off and separate the Battery Connector Assembly.

2 See Figure 9. From underneath the front of the machine loosen the (4) (A) Screws and push the lower steering column toward the front of the machine.

This is done to separate the Chain

3 Remove both Master Links (D) that secure the chain to the steer plate then remove the Chain (B) from the machine.

4 Reassemble parts in reverse order and adjust chain tension so that there is about 3/16”-1/4” (4.7 – 6.4mm) total defl ection with moderate pressure applied at

the Mid-point

tightening the (4) steering column mounting screws.

(E) (as shown). Service Note: Use a pry bar or shims between the chassis and steer column to help secure the tension adjustment when

(B) from the Steer Sprocket (C). Service Note: Use a 17mm socket with 3” extension to loosen screws.

FIGURE 9

34 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 35

WHEEL DRIVE SYSTEM

POTENTIOMETER REMOVAL AND TESTING

WARNING!

Disconnect the battery pack by separating the battery connectors (7) whenever servicing the machine.

Potentiometer Removal

1 See Figure 10. Remove the (5) Screws (A) securing the drive pedal mount assembly to the chassis then carefully lift the pedal assembly up

and lay it on its side.

2 Observe the (3) wires connected to the Drive Pedal Potentiometer (pot) (B) and also the single GRN/YEL throttle ground wire (C), note the

proper wire colors and their terminal connections for re-assembly. Then disconnect wiring and remove the pedal mount assembly from the

machine.

3 Remove the Link Rod (D) from the Pedal (E). Note: Be careful not to lose the link rod mounting hardware items (F).

4 Loosen the Nut (G) and Screw (H) at the drive pedal Throttle Lever (I). Then pry the lever off from the end of the item (B) potentiometer

shaft. Next remove the pot from the Mount Housing (J).

Testing the Potentiometer

Note: The pot doesn’t have to be removed from the housing to test.

1 Test the potentiometer using an Ohmmeter (the pot specifi cation is 5K Ohms).

2 Connect the meter leads to each of the outside connections on the potentiometer. The meter should read approximately 5000 Ohms (plus or

minus 500 Ohms).

3 Next, move one of the test leads to the middle connection and turn the stem in both directions. The range of the readings should be

approximately 1300-2500 Ohms or 2500-3700 Ohms increasing and decreasing through its full range.

4 If you do not get these readings replace the potentiometer.

Technical Service Tip: A simple short cut method for testing and adjusting the pot resistance values is at the speed controller’s 18 pin plug. Just

disconnect plug and back probe pins 3, 4 & 13 (wire colors VIO/BRN, GRA and BRN/BLK). The controller can be easily accessed by removing the

electrical panel door located in the operator’s compartment.

POTENTIOMETER INSTALLATION AND ADJUSTMENT:

WARNING!

The adjustment of the potentiometer is to set the drive pedal for a neutral drive motor operation. If the pot is not adjusted properly, the machine

will creep in either FWD or REV.

1 See Figure 10. Install the pot into the Mount Housing (J) and tighten the attachment nut.

2 Connect together loosely both the Link Rod (D) to the Pedal (E), and the Throttle Lever (I) to the potentiometer input shaft. Then tighten only

the Link Rod (D) pedal mounting Hardware (F). Note: Check the movement of the Foot Pedal (E) it must move freely in both Fwd and Rev.

3 See Figure 10 inset. Attach test leads from a volt/ohm meter to the VIO/BRN and BRN/BLK wire connection points on the potentiometer to

check it’s total resistance (example 4800 Ohms).

4 Next connect the ohmmeter test leads to the VIO/BRN and GRA potentiometer connection points. Then using a small screwdriver, turn the

shaft end on the pot to half the total resistance previously measured. Example: 4800 Ohms divided by 2 = 2400 Ohms. Then without turning

the shaft, tighten the Screw (H) and Nut (G) to secure the setting at the Throttle Lever (I).

5 Follow steps 1-2 in reverse order (see Potentiometer Removal steps) to fi nish the installation. Then test-drive the machine for proper speed

and FWD/REV directional control.

ALTERNATE METHOD FOR THROTTLE ADJUSTMENT

The throttle adjustment is easier and more accurately adjusted by measuring the throttle potentiometer wiper voltage with respect to B (-).

To set throttle neutral:

1 See Figure 11. Connect a voltmeter to B (-) on the speed controller and the GRA wire. A thin probe can be inserted into the connector at pin

4 on the speed controller, or an insulation piercing probe can be used on the GRA wire.

2 Adjust the throttle potentiometer to 2.50 +/- .05 volts with the throttle pedal in neutral.

This will insure that the throttle is centered on neutral and there is 100% throttle when the pedal is fully depressed in the forward direction. A

Curtis programmer can be used to check that there is 100% throttle in forward.

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 35

Page 36

FIGURE 10

FIGURE 11

36 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 37

WHEEL DRIVE SYSTEM

DRIVE PEDAL NEUTRAL ADJUSTMENT & PEDAL REPLACEMENT

If the drive pedal has been removed or replaced, the neutral position for the pedal will have to be set. Follow the steps below to accomplish this.

WARNING!

Disconnect the machine’s battery pack connector (7) before servicing.

• Note: See Figures 10 & 12. Before making any adjustments, inspect the Torsion Spring (K) for defects and the correct positions of both

spring ends (repair or replace).

To Adjust Pedal Spring

1 Loosen the Screw (L) & Nut (M), the screw with Bushing (N) is positioned between both Fwd & Rev torsion spring ends. Its placement

controls the needed pre-load pressure to eliminate excessive pedal free-play and a balanced spring rate to return the pedal to a centered

(neutral) position.

2 Push the screw back into the pedal frame slot to increase spring tension and eliminate pedal free play. Then tighten the screw & nut being

careful not to pull on the linkage connection to the pot shaft and disturb (move) its neutral setting.

To Replace Pedal or Spring

3 Position the torsion spring ends (O & P) as shown. This is with the Bushing (N) and Screw (L) not installed.

4 Place the bushing inside the pedal channel pilot it into position using a scratch awl or a pin punch.

5 Then pivot (press) the pedal and insert the screw from the opposite side pushing the guide tool out.

6 Use a screwdriver to tap and pry the bushing back in the pedal slot to increase spring tension

7 Work the bushing back & forth on both sides of the pedal to obtain equal spacing. Then tighten the screw and nut.

8 A correctly adjusted drive pedal will have minimal amount of free-play when selecting a drive direction.

9 Reconnect the batteries and test the machine to make sure it does not “creep” forward or reverse when the pedal returns to neutral.

FIGURE 12

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 37

Page 38

WHEEL DRIVE SYSTEM

TROUBLESHOOTING GUIDE ELECTRICAL

Symptom

Wheel drive motor will not run. Part A (load circuit)

38 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 39

WHEEL DRIVE SYSTEM

TROUBLESHOOTING GUIDE ELECTRICAL

Symptom

Wheel drive motor will not run. Part B (control circuit)

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 39

Page 40

ELECTRICAL SYSTEM

BATTERIES

If your machine shipped with batteries installed do the following:

• Check that the batteries are connected to the machine (7).

• Turn ON the Key Switch (AA) and check the Battery Indicator (BB). If the green light is ON, the batteries are ready for use. If the green light is OFF, the

batteries should be charged before use. See the “Charging The Batteries” section.

If your machine shipped without batteries installed do the following:

• Consult your Authorized Nilfi sk-Advance dealer for recommended batteries.

• Install the batteries by following the instructions below.

• DO NOT install three 12 volt batteries in your machine. This affects the stability of the machine.

WARNING!

Use extreme caution when working with batteries. Sulfuric acid in batteries can cause severe injury if allowed to contact the skin

or eyes. Explosive hydrogen gas is vented from the batteries through openings in the battery caps. This gas can be ignited by

any electrical arc, spark or fl ame. Do not install any lead-acid battery in a sealed container or enclosure. Hydrogen gas from

overcharging must be allowed to escape.

When Servicing Batteries...

* Remove all jewelry

* Do not smoke

* Wear safety glasses, rubber gloves and a rubber apron

* Work in a well-ventilated area

* Do not allow tools to touch more than one battery terminal at a time

* ALWAYS disconnect the negative (ground) cable fi rst when replacing batteries to prevent sparks.

* ALWAYS connect the negative cable last when installing batteries.

CAUTION!

Electrical components in this machine can be severely damaged if the batteries are not installed and connected properly. Nilfi sk-

Advance, a qualifi ed electrician, or the battery manufacturer should install batteries.

1 Remove the batteries from their shipping crate and carefully inspect them for cracks or other damage. If damage is evident, contact the carrier that delivered

them or the battery manufacturer to fi le a damage claim.

2 Turn the Master Key Switch (AA) OFF and remove the key.

3 Open and prop the Battery Compartment Cover (13). Remove the battery cables from inside the battery compartment.

4 Your machine comes from the factory with enough battery cables to install six 6 volt batteries. Carefully lift the batteries into the battery compartment and

arrange them exactly as shown in FIGURE 1. Secure the batteries as close to the back of the machine as possible.

5 Install the battery cables as shown. Position the cables so the battery caps can be easily removed for battery service.

6 Carefully tighten the nut in each battery terminal until the terminal will not turn. Do not over-tighten the terminals, or they will be very diffi cult to remove for

future service.

7 Coat the terminals with spray-on battery terminal coating (available at most auto parts stores).

8 Put one of the black rubber boots over each of the terminals and connect the Battery Connector Assembly (7). NOTE: Secure rubber boots with supplied tie

straps.

FIGURE 1

40 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 41

ELECTRICAL SYSTEM

CHARGING THE BATTERIES

Charge the batteries each time the machine is used for 1 hour or longer, or whenever the Battery Condition Indicator Lights (BB) light up red.

To Charge the Batteries...

1 IMPORTANT!: Open the Battery Compartment Cover (13) to provide proper ventilation.

2 Disconnect the Battery Connector Assembly (7) and plug the battery charger into the plug connected to the batteries.

4 Follow the instructions on the battery charger.

5 Check the fl uid level in all battery cells after charging the batteries. Add distilled water, if necessary, to bring the fl uid level up to the bottom of

the fi ller tubes.

WARNING!

Do not fi ll the batteries before charging.

Charge batteries in a well-ventilated area.

Do not smoke while servicing the batteries.

When Servicing Batteries...

* Remove all jewelry

* Do not smoke

* Wear safety glasses, rubber gloves and a rubber apron

* Work in a well-ventilated area

* Do not allow tools to touch more than one battery terminal at a time

* ALWAYS disconnect the negative (ground) cable fi rst when replacing batteries to prevent sparks.

* ALWAYS connect the negative cable last when installing batteries.

CAUTION!

To avoid damage to fl oor surfaces, wipe water and acid from the top of the batteries after charging.

CHECKING THE BATTERY WATER LEVEL

Check the water level of the batteries at least once a week.

After charging the batteries, remove the vent caps and check the water level in each battery cell. Use distilled or demineralized water in a battery

fi lling dispenser (available at most auto parts stores) to fi ll each cell to the level indicator (or to 10 mm over the top of the separators). DO NOT

over-fi ll the batteries!

CAUTION!

Acid can spill onto the fl oor if the batteries are overfi lled.

Tighten the vent caps. Wash the tops of the batteries with a solution of baking soda and water (2 tablespoons of baking soda to 1 liter of water).

Service Note: There is a drain plug in the bottom of the battery compartment.

BATTERY MAINTENANCE

Proper maintenance of electric vehicle batteries can greatly extend their life. Well-maintained batteries may last up to 3 years, but failure after 1

year is common if maintenance has been poor.

There are 3 simple rules for good battery maintenance:

• Maintain Proper Electrolyte Level (Weekly) - Use distilled water in batteries whenever possible. If batteries are discharged, add just

enough water to cover the plates in each cell. If batteries are fully charged, fi ll each cell to the bottom of the fi ller tube. Do not over-fi ll the

batteries! Do not add acid to batteries!

• Keep the Batteries Charged (Weekly) - Batteries should be charged each time that a machine is used for more than 60 minutes. Machine

operators should open the battery compartment cover for charging, to avoid a concentrated build-up of hydrogen gas. Operators should

follow the instructions provided with their specifi c battery charger, to determine how long the batteries should be charged. Even when a

machine is stored, the batteries should be charged once a month to prevent the batteries from “sulfating”. Almost all battery caps are vented,

so there’s no need to loosen or remove them for charging.

• Keep the Batteries Clean (Monthly) - Use a damp cloth to wipe dirt from the top of the batteries. Battery terminals must be clean and tight.

If the tops of the batteries are wet after charging, the batteries have probably been over-fi lled or over-charged. Note: If there is acid on the

batteries, wash the tops of the batteries with a solution of baking soda and water (2) tablespoons of baking soda to 1 quart of water.

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 41

Page 42

ELECTRICAL SYSTEM

CHARGING THE BATTERIES (CONTINUED)

The following lights indicate the percentage of discharge in the battery pack:

Battery Voltage

Indication Standard Alternate

Green 33.5+ 33.7+

Green/Yellow 33.4 33.6

Yellow 32.8 33.4

Yellow/Red 31.9 33.2

Red 31.3 33

Red Flashing 30.6 32.8

FIGURE 2

BATTERY TESTING

A battery problem is usually recognized by the machine operator, as a decrease in the machine’s running time. This condition is usually caused

by one (or more) “dead cell” in the battery system- that is, one (or more) cell that is putting out less voltage than the other cells.

Note: Always charge batteries before testing.

There are 2 ways to fi nd a dead cell:

• Use a hydrometer to check the specifi c gravity (or “state of charge”) of the fl uid in each cell. A dead cell is one that reads 50 points (or more)

lower than the other cells.

• Use a voltmeter to check the voltage of each battery with the pad drive motor running. The battery with the dead cell will read 1 or 2 volts

lower than the other batteries in the system.

If the batteries in the machine are more than 1 year old, it’s usually best to replace the whole set, rather than replacing just one battery.

BATTERY SPECIFICATIONS

Use a combination of multiple 2-volt cell units to construct a 36 Volt DC battery pack system.

Nilfi sk-Advance recommended battery pack capacity is a 395 AH @ 20 Hour Rate deep cycle battery system. Note: The battery pack must fi t the

battery compartment size listed below.

Battery compartment size

Height 17-1/2 inches (44 cm)

Width 22-1/2 inches (57 cm)

Length 25 inches (63 cm)

BATTERY CHARGER SPECIFICATIONS

Use a 36 Volt DC output charger matching the AC input line voltage supply to be used.

Always when selecting a battery charger follow the recommendation of the battery supplier to match the proper charger DC output amperage to

the amp/hour rating batteries being installed. This will prevent the battery pack from being over or under charged.

The recommended 395 AH battery should be matched to a 36V, 25 or 36 Amp output charger.

42 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 43

ELECTRICAL SYSTEM

ACTUATOR DRIVE NUT ADJUSTMENT

This manual section explains the steps for adjusting the drive nut (spring housing) setting for all the pad drive lift actuator motor. Reference the chart below to fi nd

the IN & OUT dimensional specifi cation for an actuator motor needing adjustment.

Part # Actuator Motor Spring Housing IN Position Spring Housing OUT Position Models

56393303 Pad Drive Lift 3-3/8”(8.58cm) 6-3/8”(16.20cm) ALL

*The “Spring Housing IN/OUT Position” dimensions are measured when completely assembled. Reference points are the gear box step to the

edge of the Spring Housing Assembly (A) as shown in Figure 4 & 5.

General Instructions

1 See Figure 3. This shows the special actuator power cord adapter (PN

56407502) that is needed to connect the machine’s battery pack and

actuator motor for setting the drive nut limit settings.

2 Open the machine battery compartment and disconnect the battery

connector. The battery pack is needed to power the lift actuator motor to

properly set the IN & OUT limit switches.

3 Connect the actuator motor to be tested to the power cord adapter end.

Then connect the alligator clips from the cord adapter (red clip to the positive

and black to negative) to battery connector or battery posts. The rocker

switch is used to change the motor rotation in setting the correct drive nut

dimension.

Instructions for Pad Drive Deck Lift Actuator Drive Nut Adjustment

1 See Figure 4 and 5. On a new pad lift actuator motor fi rst install the Compression Spring (B) then slide on the Spring Housing Guide (A),

followed by the Mounting Hardware (C).

2 Hold onto the spring housing assembly and press the rocker switch to run the drive motor and retract the spring housing towards the motor

housing (its IN limit).

3 Measure the position of the spring housing assembly on the actuator shaft. Manually turn the spring housing assembly to the appropriate IN

position shown in the chart above.

4 Hold the spring housing assembly, then press the adapter cord rocker switch to run the drive motor to the OUT position (wait until the motor

stops).

5 Measure the position of the spring housing assembly on the shaft and compare the measurement with the OUT position shown in the chart.

6 If the measurement doesn’t match the dimension shown in the chart it is necessary to remove the Adjuster Cover (D) and adjust the OUT

position.

7 To increase the travel of the spring housing assembly, turn the adjuster clockwise. To decrease the travel of the assembly, turn the adjuster

counter clockwise.

NOTE: Use a 1/2” (13mm) socket to turn the adjuster.

Each click of the adjuster will change the spring

housing assembly travel 1/16 inch (1.6mm).

8 After each adjustment, hold the spring housing

assembly, run the actuator IN & OUT and check both

dimensions. After checking that the spring housing

limits are set correctly replace the adjuster cover.

Service Tip: Use the above power cord adapter to help

position the spring housing assembly (in or out) for

ease in actuator motor installations.

9 After adjusting the actuator spring housing dimensions,

follow the Pad Lift Actuator Removal And Installation

section to reassemble.

FIGURE 3

FIGURE 4

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 43

Page 44

FIGURE 5

44 - FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700

Page 45

ELECTRICAL SYSTEM

CURTIS CONTROLLER DIAGNOSTICS:

Diagnostics Method A: Uses the machine’s control display LED panel and Horn Indicator Light (FF).

FUNCTION OF THE SPEED CONTROLLER STATUS LIGHT AND DISPLAY

The Curtis 1228 (36V) speed control will output a fault code if there is a problem associated with the speed control and wheel drive system. See

Figure 6. If a speed control fault occurs, the display LED panel (CC) will indicate Err 03. When the Err 03 error code is displayed and detects

a fault the Red Horn Indicator (FF) will fl ash a special error code sequence until the fault is corrected. See “Table 1” for a description of the fault

indications. Service Note: Instructions on how to read the error code status light. Example, OO O = two light fl ashes, a short pause. One fl ash,

long pause and the code will be repeated. This indicates a fault code 2,1.

Diagnostics Method B: Uses the optional hand held Curtis programmer model 1307 or the new model 1311 MP1101.

PROGRAMMER DIAGNOSTICS:

With a programmer, diagnostics and troubleshooting is more direct than with the LED status light alone. The programmer presents complete

diagnostic information in plain language, no codes to decipher. Faults are displayed in the Diagnostic Menu, and the status of the controller inputs/

outputs is displayed in the Test Menu.

The following 4-step process is generally used for diagnosing and troubleshooting an inoperative vehicle: (1) visually inspect the vehicle for

obvious problems; (2) diagnose the problem, using the programmer; (3) test the circuitry with the programmer: and (4) correct the problem. Repeat

the last three steps as necessary until the vehicle is operational.

Example: A vehicle that does not operate in “forward” is brought in for repair.

1 Examine the vehicle and its wiring for any obvious problems, such as broken wires or loose connections.

2 Connect the programmer, put it in diagnostic mode, and read the displayed fault information. In this example, the display shows “No Faults

Present”, indicating that the controller has not detected anything out of the norm.

3 Put the programmer in test mode, and observe the status of inputs and outputs in the forward direction. In this example, the display shows

that the forward input did not activate when “forward” was selected, which means the problem is either in the electronic throttle or the throttle

wiring.

4 Check or replace the electronic throttle and wiring and repeat the test. If the programmer shows the forward switch closing and the vehicle

now drives normally, the problem has been corrected.

Refer to the Status Fault Codes (Table 1) for suggestions covering a wide range of possible faults.

DIAGNOSTIC HISTORY

The handheld programmer can be used to access the controller’s diagnostic history fi le. Connect the programmer, press the MORE INFO key, and

then while continuing to hold the MORE INFO key, press the DIAGNOSTICS key. The programmer will read out all the faults that the controller has

experienced since the last time the diagnostic history fi le was cleared. The faults may be intermittent faults, faults caused by loose wires, or faults

caused by operator errors. Faults such as HPD or over temperature may be caused by operator habits or by overloading.

After a problem has been diagnosed and corrected, clearing the diagnostic history fi le is advisable. This allows the controller to accumulate a new

fi le of faults. By checking the new diagnostic history fi le at a later date, you can readily determine whether the problem was indeed completely

fi xed.

To clear the diagnostic history fi le, go to the Special Program Menu (by pressing and holding the MORE INFO key, and then pressing the

PROGRAM key), scroll through the menu until “Clear Diagnostic History” is the top line in the display, and then press MORE INFO again. The

programmer will prompt you to acknowledge or cancel.

See the Curtis programmer manual 56043101 for more detail on programmer operation.

FIGURE 6

FORM NO. 56043107 - Advolution™ 2710 / UHR 70-1700 - 45

Page 46

ELECTRICAL SYSTEM

STATUS LED FAULT CODES (TABLE 1)

LED

CODE

1,1 0 0 over-/under-temperature cutback 1. Temperature >92°C or < -25°C.

1,2 0 00 throttle fault 1. Throttle input wire open or shorted

1,3 0 000 speed limit pot fault 1. Speed limit pot wire(s) broken or shorted.

1,4 0 0000 battery voltage too low 1. Battery voltage <17 volts.

1,5 0 00000 battery voltage too high 1. Battery voltage >36 volts.

2,1 00 0 main contactor driver Off fault 1. Main contactor driver failed open.

2,3 00 000 main contactor fault 1. Main contactor welded or stuck open.

2,4 00 0000 main contactor driver On fault 1. Main contactor driver failed closed.

STATUS LIGHT

DISPLAY

EXPLANATION POSSIBLE CAUSE

2. Excessive load on vehicle

3. Operation in extreme environments.

4. Electromagnetic brake not releasing.

2. Throttle pot defective.

3. Wrong throttle type selected.

2. Broken speed limit pot.

2. Bad connection at battery or controller.