Page 1

M358 E 05.4.NF.1

ECLIPSE TE2000 INVERTED

MICROSCOPE

PERFECT FOCUS SYSTEM

T-PFB Perfect Focus Module

T-PFC Perfect Focus Controller

T-FLC2-E Motorized Cassette Holder

Instructions

Page 2

Page 3

Preface

Thank you for purchasing the Nikon products.

This instruction manual is written for the users of the Nikon’s Eclipse TE2000-E Inverted Microscope Perfect Focus

System.

To ensure correct usage, read this manual carefully before operating the instrument.

• It is prohibited to reproduce or transmit this manual in part or whole without Nikon’s expressed permission.

• The contents of this manual are subject to change without notice.

• Although every effort has been made to ensure the accuracy of this manual, if you note any points that are unclear or

incorrect, contact your nearest Nikon representative.

• Some of the products described in this manual may not be included in the set you have purchased.

• Be sure to read the instruction manuals for TE2000-E/U/S Inverted Microscope.

1

Page 4

Warning for Using this Product

WARNING and CAUTION Symbols

Although Nikon products are designed to provide the utmost safety during use, incorrect usage or failure to follow the

safety instructions provided may cause personal injury or property damage. To ensure correct use, read the instruction

manual carefully and thoroughly before using the instrument. Do not discard the manual; keep it handy for easy

reference.

Safety instructions within this manual are accompanied by the following symbols to highlight their importance. For your

safety, always follow the instructions accompanying these symbols.

Symbol Meaning

WARNING

CAUTION

Disregarding instructions accompanying this symbol may lead to serious injury or death.

Disregarding instructions accompanying this symbol may lead to injury or property

damage.

2

Page 5

Warning for Using this Product

A

t

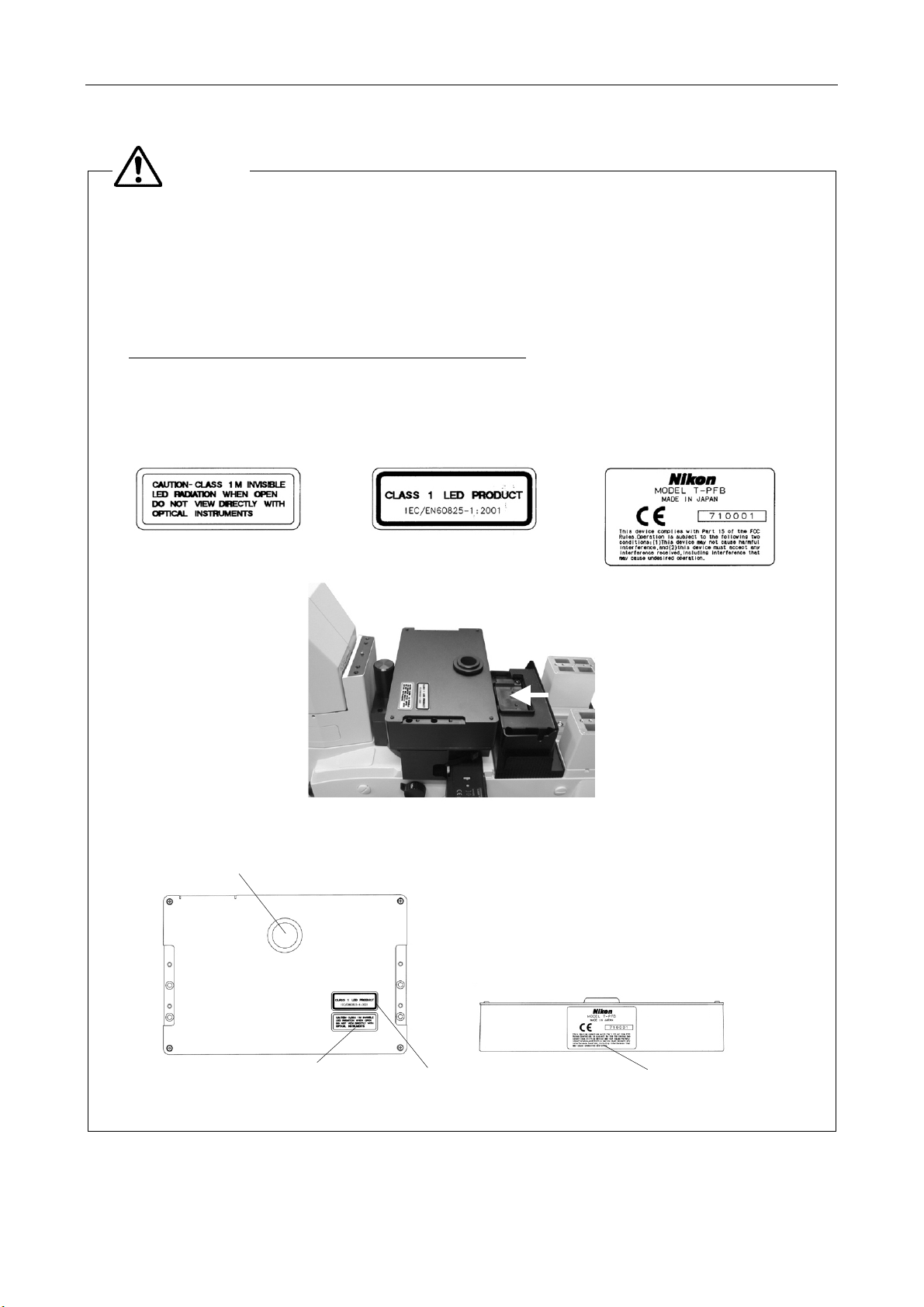

1. LED safety

WARNING

This product uses the near-infrared region lights (infrared band) emitted from an infrared LED to perform focus

control. This product has European safety standard EN60825-1: 2001 and International safety standard

IEC60825-1: 2001 approval. And its LED safety class is categorized as Class 1.

Use of controls or adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

Location of the safety labels on the T-PFB Perfect Focus module

• The safety labels are affixed on the T-PFB Perfect Focus module.

• Under normal conditions, infrared rays are irradiated from the part in the figure below. Be careful.

(1) Caution label (2) Class 1 LED product label (3) Safety standard label

A

T-PFB Perfect Focus module

(For easy understanding, each

perture for the infrared ligh

emission

(1)

part is removed in this picture.)

(2)

View A

(3)

3

Page 6

Warning for Using this Product

2. Handle the system gently.

3. Do not disassemble.

4. AC adapter of the perfect focus (PF) controller

WARNING

Components of this system are precision optical instruments. Handle them carefully, and do not subject them

to any shocks.

In particular, the precision of the objectives can be adversely affected even by weak shocks.

Disassembly may cause malfunction and / or electric shock, and will lead to the forfeiture of all claims against

warranty. Do not disassemble any part other than those described in this manual. If you experience any

problem with this product, contact your nearest Nikon representative.

The PF controller uses the AC adapter as the power source. Be sure to use the adapter specified in Chapter

IX, “Specification.” Use of other adapter may cause a malfunction, abnormal heating, or serious damage.

• To avoid malfunction or the risk of fire, locate the AC adapter on the well-ventilated place. Do not cover the AC

adapter with any materials, otherwise poor heat radiation may cause overheating of it.

• Before connecting the AC adapter to the PF controller, be sure to turn off the power switch of the PF controller (flip

to the O side) to avoid malfunctions.

5. Power cord for the AC adapter of the PF controller

To prevent electric shock, always turn off the power switch (switch to the O side) of the PF controller before

attaching or detaching the power cord. Use one of the power cords specified in Chapter IX, “Specification.”

Use of an improper power cord can result in fire or other hazard. Also note that the power supply is classified

as subject to the protection class I against electric shock. Therefore, be sure to connect it to a protective earth

terminal.

4

Page 7

Warning for Using this Product

1. Do not take a look at the radiation light from the LED.

2. Do not wet the instrument.

3. Dirt on the lens

4. Installation location

CAUTION

When this instrument is turned on, weak near-infrared rays (infrared band) are emitted through the objective.

The light intensity is categorized as Class 1 level and is not harmful. But avoid direct viewing.

If the instrument gets wet, a short circuit may cause a malfunction or abnormal heating. If you accidentally spill

a liquid on the instrument, immediately turn off the power switch (flip to the O side) and unplug the power cord

from the wall outlet. Then use a dry cloth to wipe away the moisture. If any liquid gets inside the instrument,

do not use it; instead, contact your nearest Nikon representative.

Scratches, dirt, and fingerprints on the optical parts, such as lenses and filters, will adversely affect the

microscope image. If these parts get dirty, clean them by following the instructions described in Chapter VIII,

“Care and maintenance.”

Using or storing this instrument under unsuitable conditions may damage it or may have an adverse effect on

its accuracy. The following conditions should be kept in mind when selecting the installation location:

• Choose a flat surface with little vibration.

• Choose a location less exposed to hazards in the event of collisions, earthquakes, or other potential disasters. If

required to keep the device from falling, use strong wires or other means to secure this product to the worktable or

to another heavy, stable item.

• Avoid a brightly lit location such as a room that receives direct sunlight.

• Choose a location that is free from dust or dirt.

• Do not install this product in a hot and humid location. (Mold or condensation will form on the lenses and filters.)

• The room light just above the microscope may come into the objective as an extraneous light. (Especially when

using a condenser lens with longer working distance such as SLWD, ELWD and LWD lenses.) To avoid this, Nikon

recommends turning off the room light above the microscope when observing the image.

• Install the equipment in a location where the power cord can be easily unplugged from the AC inlet of the AC

adapter in case of emergency.

5. Focusing knobs

• Never turn the focus knobs on the left and right sides of the microscope in opposite directions at the same time, as

doing so can result in damage to the microscope.

• Turning the coarse focus knob as far as it will go and then attempting to turn it further will result in damage to the

microscope. Never use undue force to turn the knob.

• The coarse focus knob turns in sync with the motorized escape, refocus movements, or calling of the nosepiece

up/down position. To prevent malfunctions, avoid contact with the coarse focus knob during the knob is rotating.

6. Vibrations during motorized operation

This product is designed to minimize vibrations caused by motors inside, however, note that even the

minimized vibration may affect on image observation depending on service condition.

7. Electromagnetic waves

This product emits weak electromagnetic waves. The accuracy of any precision electronic equipment may be

adversely affected if positioned too close. If this product affects TV or radio reception, move the radio or TV

further away from the product.

5

Page 8

Contents

Preface................................................................................................................................................................................ 1

Warning for Using this Product ........................................................................................................................................... 2

I Overview ...................................................................................................................................................................... 8

1 Overview.............................................................................................................................................................. 8

2 Features............................................................................................................................................................... 8

3 Offset function ........................................................................................................................................................ 8

4 Specimen ............................................................................................................................................................... 9

4.1 Suitable specimen ........................................................................................................................................... 9

4.2 Suitable objectives........................................................................................................................................... 9

4.3 Not-suitable specimen................................................................................................................................... 10

II Name and Function of Each Part ............................................................................................................................... 11

1 Name of Each Part .......................................................................................................................................... 11

2 T-PFC PF Controller............................................................................................................................................. 12

III Preparation................................................................................................................................................................. 14

1 T-RCP Remote Control Pad................................................................................................................................. 14

2 Startup and Shutdown of the Remote Control Pad............................................................................................... 16

3 Registering Data of the Objectives ....................................................................................................................... 17

For deleting the registered data........................................................................................................................... 19

Important: list of objectives requiring data registration......................................................................................... 19

4 Registering Installation Information of Objectives Mounted on Nosepiece........................................................... 19

IV Operating Procedures ................................................................................................................................................ 21

1 Basic Operation.................................................................................................................................................... 21

2 Registering and Restoring the Offset Amount ...................................................................................................... 23

2.1 Registering the Offset Amount....................................................................................................................... 23

2.2 Restoring the Offset Amount ......................................................................................................................... 24

3 Registering and Restoring the Vertical Position of the Nosepiece........................................................................ 24

3.1 Registering the Vertical Position of the Nosepiece........................................................................................ 24

3.2 Escaping the Objective.................................................................................................................................. 25

3.3 Restoring the Vertical Position of the Nosepiece........................................................................................... 25

3.4 About the Movement of the Objective in Registering and Restoring the Vertical Position of the Nosepiece. 26

V Connecting a PC........................................................................................................................................................ 27

Connecting a PC ................................................................................................................................................. 27

Communications cable........................................................................................................................................ 27

Specification for serial interface communication.................................................................................................. 27

Communication commands................................................................................................................................. 27

VI Assembling................................................................................................................................................................. 28

Required tools ..................................................................................................................................................... 28

Block diagram...................................................................................................................................................... 29

1 Checking Components ......................................................................................................................................... 30

2 Mounting the T-FLC2-E Motorized Cassette Holder............................................................................................. 30

3 Mounting the T-PFB PF Module........................................................................................................................... 31

6

Page 9

Contents

4 Mounting Stage-up Kits ........................................................................................................................................ 31

5 Mounting the Motorized Nosepiece ...................................................................................................................... 31

6 Mounting the Stage .............................................................................................................................................. 32

7 Mounting IR-cut Filters ......................................................................................................................................... 32

8 Connecting Cables ............................................................................................................................................... 33

Rear view of the PF Controller ............................................................................................................................ 33

Cables ................................................................................................................................................................. 33

Checking Connections......................................................................................................................................... 34

VII Troubleshooting ......................................................................................................................................................... 35

1 During System Startup ......................................................................................................................................... 35

2 While Using the Perfect Focus Functions............................................................................................................. 35

VIII Care and Maintenance............................................................................................................................................... 38

1 Lens Cleaning ...................................................................................................................................................... 38

2 Cleaning This Product ...................................................................................................................................... 38

3 Disinfecting This Product ................................................................................................................................. 38

4 Storage ............................................................................................................................................................... 38

5 Periodical Inspections (Expenses Charged) ................................................................................................. 38

IX Specifications ............................................................................................................................................................. 39

7

Page 10

I

Overview

This chapter explains the overview of the perfect focus system.

1 Overview

Nikon perfect focus system is provided for Nikon inverted microscope ECLIPSE TE2000-E to track the focus

automatically.

This system detects the boundary surface between the cover glass* and aqueous solution of the specimen. When a dry

type objective is used, this system detects the boundary surface between the cover glass and air. And the detection is

performed by using a near infrared light (infrared band), which does not interfere with general observations, and controls

the focus of the microscope by tracking the vertical fluctuation of the boundary surface. That is, this system is free from

the specimen’s state change and color fading during fluorescent observation and keeps the focus at a steady position by

automatically correcting the minute defocus caused by changes over time, stage movement, and so on. This system is,

therefore, suitable for continuous observations and capturing images with a camera for changes of a living organic cell

and so on.

*: The cover glass is the bottom part of the glass bottom dish.

2 Features

• As the infrared band light is used for the focusing control, which is insensitive to a specimen and does not interfere

with the fluorescent microscopy, the focus-keeping and the fluorescent microscopy can be done simultaneously.

• The focus position can be adjusted manually with the optical offset function.

• The vertical position (position on the Z-axis) of the nosepiece and the focus offset amount for each objective can be

registered.

• The focus can be kept on the image-capturing specimen located at any place in the view field.

• Automatic adjustment of the defocusing can be done for any type of observation cameras and methods including

observation by naked eyes, that is, without restriction by the camera type, not alike the image contrast method.

3 Offset function

This system detects the boundary surface between the cover glass and aqueous solution of the specimen using a near

infrared light (infrared band) and controls focusing using the boundary surface as the reference position.

The objective of the microscope tracks the up/down changes of the boundary surface caused by the defocusing over

time and the stage movement when controlling the focus.

To focus on a desired point on the specimen, adjust the OFFSET knob on the perfect focus controller.

The offset amount is defined as the deviation of the focus point from the reference position (boundary surface) to where

the focus point is moved by adjusting the OFFSET knob. Keeping the specified offset amount, focusing can be controlled

so as to track the up/down changes of the boundary surface. The range of the offset amount depends on the objective. In

particular, when a water or oil immersion type objective is used, the offset amount is limited in the downward.

8

Page 11

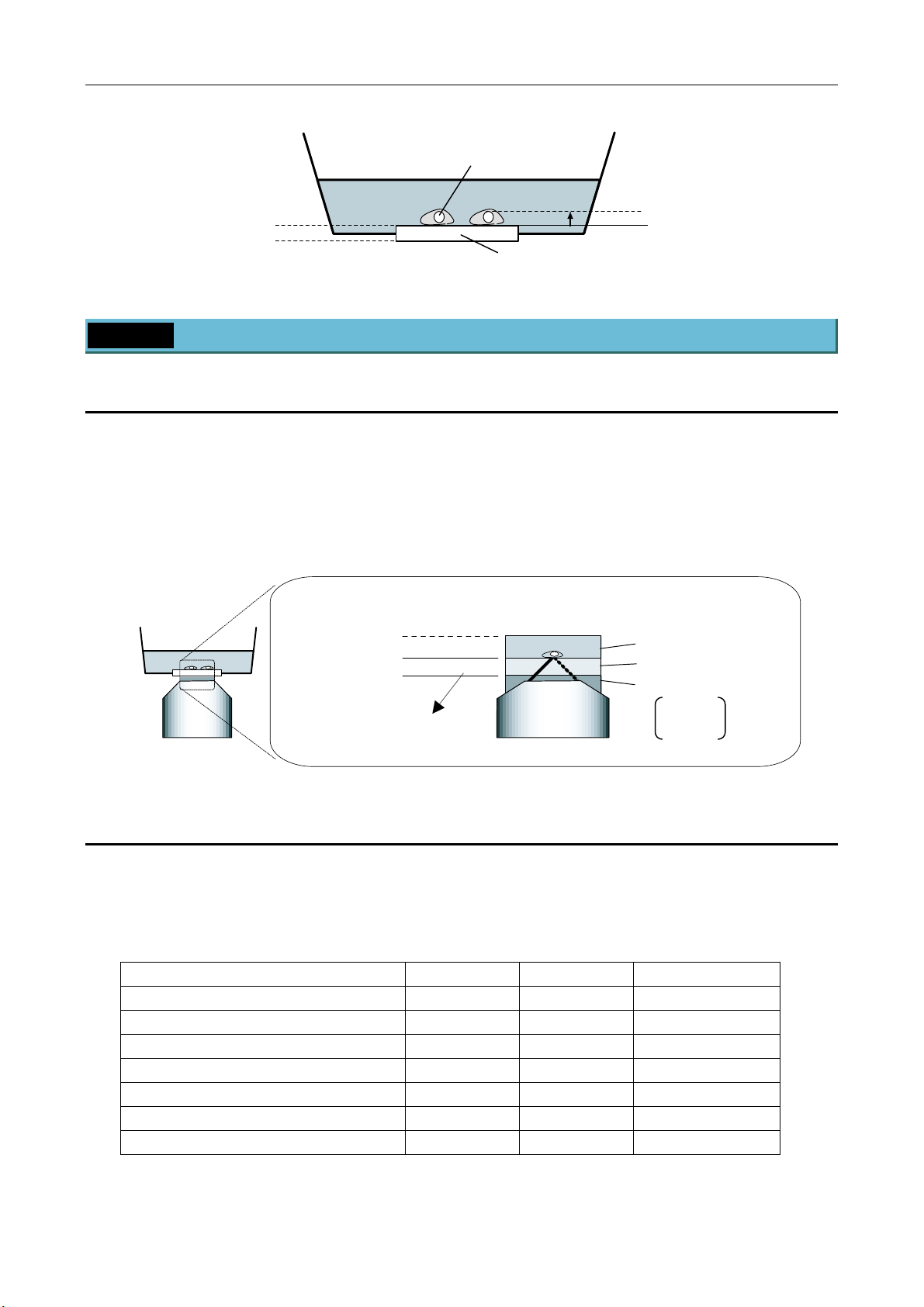

I Overview

Specimen

Detected boundary surface

(water or oil immersion)

Detected boundary surface

(dry type)

Aqueous solution

Cover glass

4 Specimen

4.1 Suitable specimen

Cells touching the upper surface of the cover glass of the glass bottom dish

Cover glass thickness: 150 to 180 µm (No.1S)

refractive index: 1.5

Aqueous solution (culture solution) depth: 3 mm or more

refractive index: 1.33 or near

Boundary surface

(water or oil immersion)

Boundary surface

(dry type)

t = 165±15 µm

(Standard: No.1S)

≥ 3 mm

t

Offset amount

Refractive index

Culture solution: up to 1.35

Cover glass: up to 1.5

Water: 1.33

Oil: 1.514

Air: 1.0

4.2 Suitable objectives

The following objectives are suitable for this system. If another objective is attempted to be used, an error will occur and

the LED of the [Obj Err] on the perfect focus controller will be lit.

If the LED of the [Obj Err] is lit, refer to the VII. Troubleshooting.

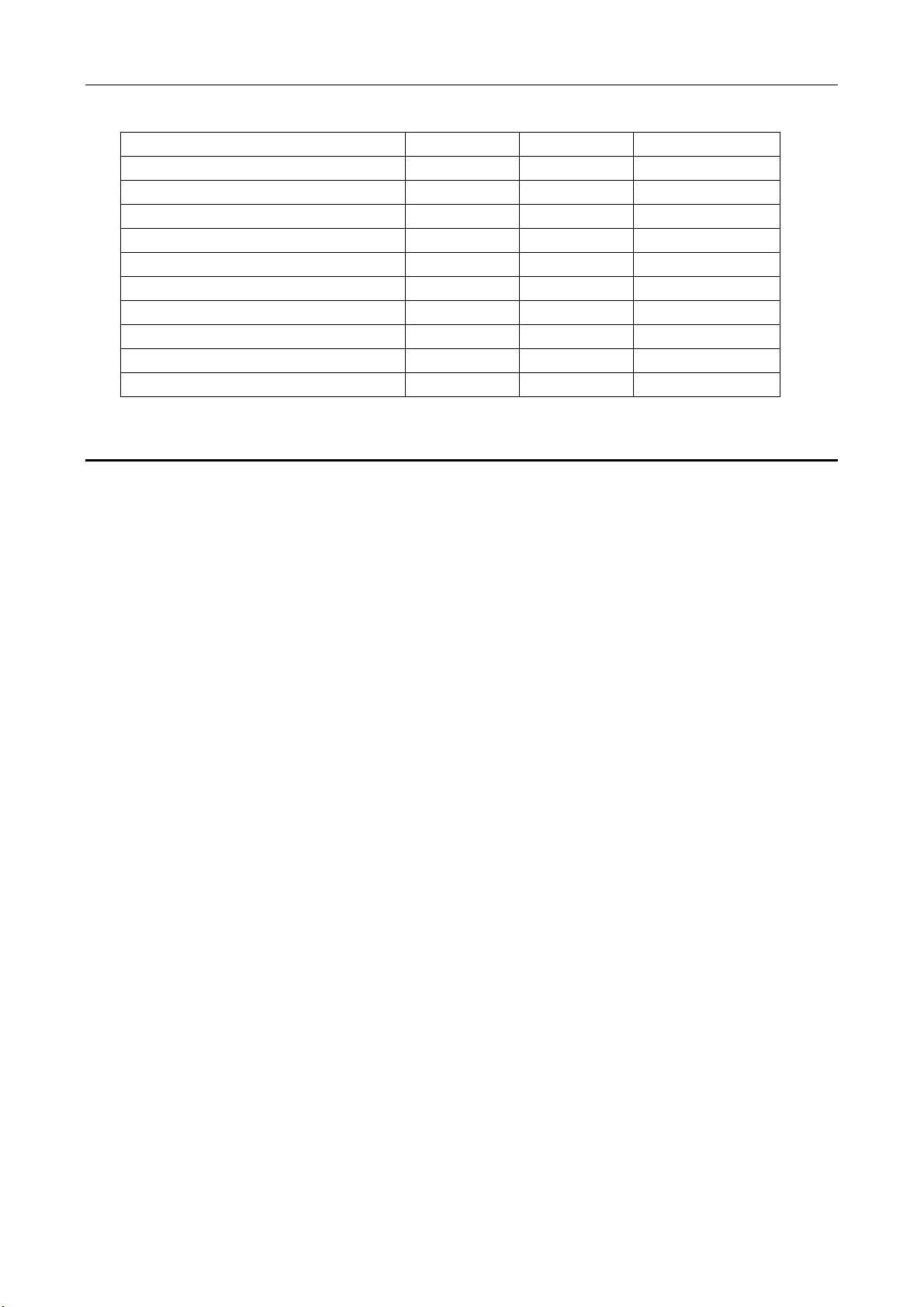

Name NA WD (mm) Type

Plan Fluor 40x 0.75 0.72 dry

Plan Fluor 40xH 1.30 0.2 oil immersion

Plan Fluor ELWD 20xC 0.45 7.6 dry

Plan Fluor ELWD 40xC 0.6 2.9 dry

Plan Fluor ELWD DM 20xC 0.45 7.6 dry

Plan Fluor ELWD ADL 20xC 0.45 7.6 dry

Plan Fluor ELWD ADL 40xC 0.6 2.9 dry

9

Page 12

I Overview

Name NA WD (mm) Type

Plan Apo VC 60xH 1.40 0.13 oil immersion

Plan Apo VC 100xH 1.40 0.13 oil immersion

Plan Apo VC 60xWI 1.20 0.27 water immersion

Plan Apo 60xHA 1.40 0.21 oil immersion

Plan Apo 100xH 1.40 0.13 oil immersion

Plan Apo 60xWI 1.20 0.22 water immersion

Plan Apo 20x 0.75 1.00 dry

Plan Apo DM 60xH 1.40 0.21 oil immersion

Plan Apo DM 100xH 1.40 0.13 oil immersion

Plan Apo TIRF 60x 1.45 0.13 oil immersion

4.3 Not-suitable specimen

The following specimens are hard to be observed. Because the focus control cannot be performed by reason of that the

reflection signal of the infrared is weak or the scattered light is strong.

(1) Fixed specimen

Usually a fixed specimen is filled with mounting medium. And this medium has a high refractive index. So, the

difference of the refractive indexes between the cover glass and the specimen is relatively small. Therefore,

enough reflection for the detection cannot be get.

(2) Sliced specimen

A sliced specimen is thick and its scattered light is strong. So, the reflection is hard to detect because the reflection

from the boundary surface is relatively weak.

(3) Specimen of strong reflection or strong light scattering

In addition to the sliced specimen, if a specimen has a strong light scattering, the weak reflection from the boundary

surface is hard to detect as is the case of (2).

(4) Cells touching the bottom glass with the thickness of 170 µm or more

When a dry type objective is used for a specimen with a thick bottom glass, the offset amount may be insufficient to

observe the boundary surface. So, the focusing range cannot be secured. (For an oil immersion type objective, the

boundary surface may be detected. But this method is not recommend. Use the cover glass of No.1S.)

(5) Specimen mounted on a plastic dish

A plastic dish is not recommended because the boundary surface is not suitable for the detection.

(6) Specimen mounted on a dirty cover glass

This system detects the surface of the cover glass and controls focusing. So, if the surface of the cover glass is not

clean, it will adversely affect the detection. Please clean the cover glass beforehand.

10

Page 13

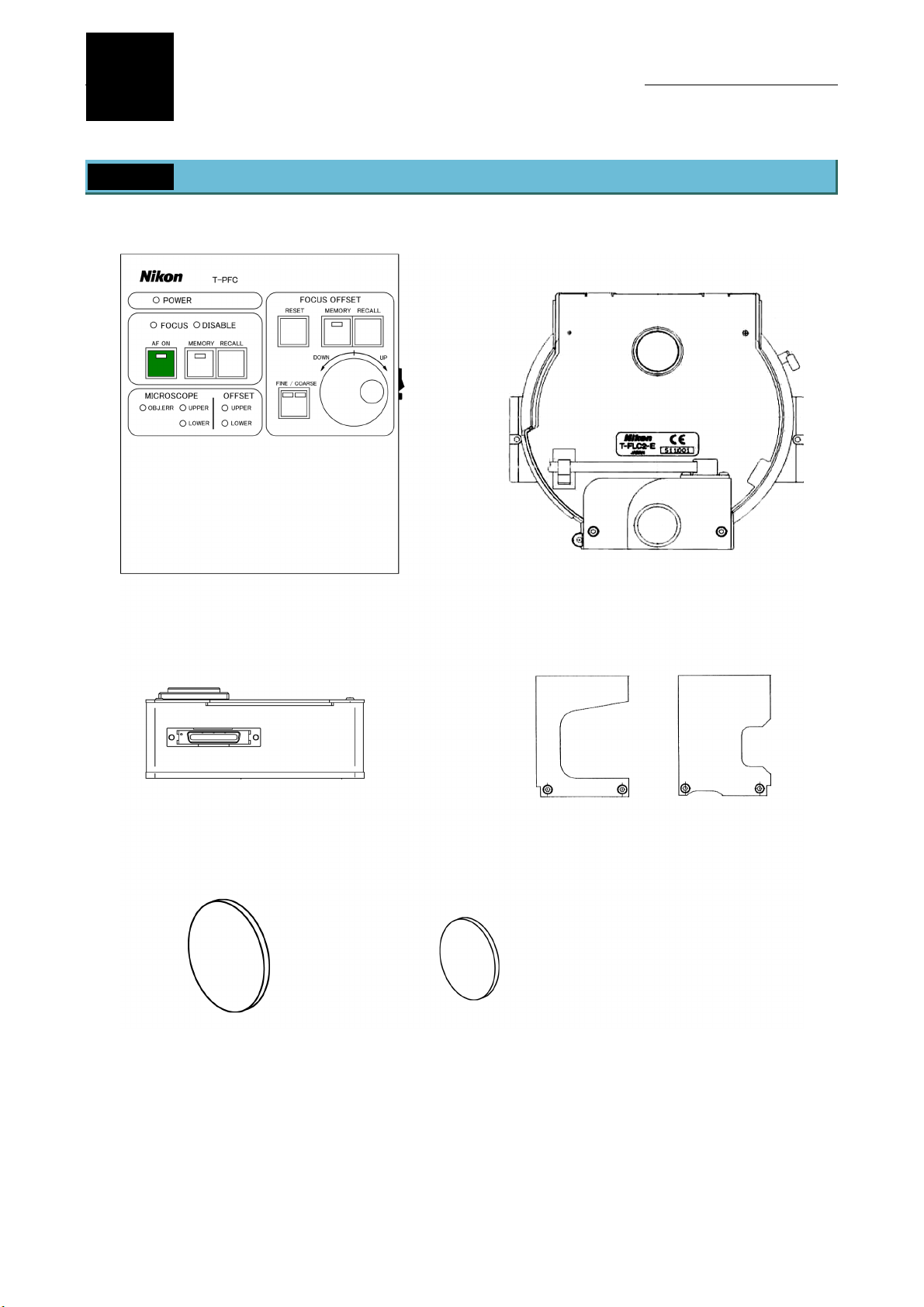

II

Name and Function of Each Part

1 Name of Each Part

T-PFC perfect focus controller

T-PFB perfect focus module

T-FLC2-E motorized cassette holder

T-PFB perfect focus module pillars

IR-CUT filter of 45 mm diameter IR-CUT filter of 25 mm diameter

11

Page 14

II Name and Function of Each Part

2 T-PFC PF Controller

T-PFC PF controller

(1) [POWER] LED

(2) [FOCUS] LED

(3) [DISABLE] LED

(4) [AF ON] key/LED

(5) [AF - MEMORY]

key/LED

(6) [AF - RECALL] key

(7) [MICROSCOPE -

OBJ.ERR] LED

(8) [MICROSCOPE -

UPPER] LED

(9) [MICROSCOPE -

LOWER] LED

(12) [FOCUS OFFSET -

RESET] key

(13) [FOCUS OFFSET -

MEMORY] key/LED

(14) [FOCUS OFFSET -

RECALL] key

(15) [FINE/COARSE]

key/LED

(16) [OFFSET] knob

(10) [OFFSET_UPPER]

LED

(11) [OFFSET - LOWER]

LED

(1) [POWER] LED

This LED indicates the power on or off state, and is lit when the power is on.

(2) [FOCUS] LED

This LED is lit when the boundary surface comes into focus when controlling the focus (or when the [AF ON]

LED is lit). And, this LED blinks when the boundary surface comes into the focus control range.

(3) [DISABLE] LED

This LED blinks when the boundary surface is out of the focus control range (or when the [AF ON] LED is lit). Or,

this LED blinks when the nosepiece vertical position (the Z-axis position) is being restored.

(4) [AF ON] key/LED

This key switches the focus control status. The LED is lit when the focus control is on.

(5) [AF - MEMORY] key/LED

This key registers the nosepiece vertical position (the Z-axis position). The LED is lit when the vertical position

is registered.

(17) [LED] switch (18) [POWER] switch

12

Page 15

(6) [AF - RECALL] key

This key restores the registered nosepiece vertical position (the Z-axis position), and starts the focus control.

(7) [MICROSCOPE - OBJ.ERR] LED

This LED is lit when an error occurs. (Refer to VII. Troubleshooting.)

(8) [MICROSCOPE - UPPER] LED

This LED is lit when the objective reaches the upper limit of its movable range.

(9) [MICROSCOPE - LOWER] LED

This LED is lit when the objective reaches the lower limit of its movable range.

(10) [OFFSET_UPPER] LED

This LED is lit when the offset amount reaches the upper limit of the adjustable range.

(11) [OFFSET - LOWER] LED

This LED is lit when the offset amount reaches the lower limit of the adjustable range.

(12) [FOCUS OFFSET - RESET] key

This key moves the vertical position to where the offset amount is zero.

(The position may be shifted from the boundary surface because of variations of cover glass thickness or

microscopy conditions.)

II Name and Function of Each Part

(13) [FOCUS OFFSET - MEMORY] key/LED

This key registers the offset amount. The LED is lit when the offset amount is registered.

(14) [FOCUS OFFSET - RECALL] key

This key calls the registered offset amount.

(15) [FINE/COARSE] key/LED

This key switches the [OFFSET] knob between the fine adjustment and the coarse adjustment. The left LED is

lit when the fine adjustment and the right LED is lit when the coarse adjustment.

(16) [OFFSET] knob

To adjust the offset amount, rotate this knob.

(17) [LED] switch

This switch turns on/off all LEDs on the controller.

(18) [POWER] switch

This switch turns on/off the power.

Electronic sound at operation

While performing the PF controller, pressing any of the usable keys issues a short electronic sound to notify an

operator that the specified operation is started. Pressing a key disabled by the device issues no sound and

executes nothing.

13

Page 16

III

Before using this system, information of objectives must be registered into the T-RCP remote control pad. This chapter

explains the procedure to register the information of objectives into the remote control pad.

Preparation

1 T-RCP Remote Control Pad

8

1

2

3

4

5

6

9

10

11

12

13

14

15

16

17

18

7

14

Page 17

III Preparation

No. Name Functions available when the operation window is displayed

Functions available when the setting menu

or maintenance menu is displayed

1 LCD

2 [OBJECTIVE] keys These keys switch the objectives.

3 [Shutter A] key This key opens/closes the shutter allocated to the shutter A.

4 [Shutter B] key This key opens/closes the shutter allocated to the shutter B.

5 [EXCITER] keys These keys switch the excitation filters.

6 [BARRIER] keys These keys switch the barrier filters.

7 [EPI-FILTER] keys These keys switch the filter blocks.

8 [Z-AXI.RESET] key This key resets the indication of the Z-axis position to “0.”

[CAMERA EXP.]

9

key

10 [LCD MODE] key This key switches the LCD display mode. This key switches the LCD display mode.

11 [LCD ON/OFF] key This key turns on/off the backlight of the LCD.

[LCD Bright/Dark]

12

keys

[DIA LAMP

13

REMOTE] key

[DIA LAMP

14

ON/OFF] key

The operation window displays the positions of motorized

parts and the information on the installed optical parts.

This key produces an external trigger output.

These keys adjust the brightness of the backlight of the LCD.

This key switches on/off the remote control for the

dia-illumination lamp.

This key turns on/off the dia-illumination lamp.

The setting menu displays the settings of

motorized parts.

These keys are used to enter alphanumeric

characters.

[DIA LAMP ADJ.]

15

keys

[CONDENSER]

16

keys

[ANALYZER

17

IN/OUT] key

18 [LIGHT PATH] keys These keys switch the optical path.

These keys adjust the lamp voltage for the dia-illumination.

These keys switch the condenser cassettes.

This key moves in/out the analyzer.

PREV and NEXT keys (These keys changes

the selection.)

BS key (This key deletes the entered

character.), CLR key (This key clears all

characters.)

Cursor keys (These keys select item.),

Return key (This key accepts the selection.)

15

Page 18

III Preparation

A

2 Startup and Shutdown of the Remote Control Pad

Startup

1

1) Turn on the power supply for the dia-illumination lamp.

When you use the Uniblitz shutter, be sure to power on

the Uniblitz shutter controller.

2) Power on the hub controller.

3) The hub controller supplies the power to the remote

control pad.

The [Title] window appears on the LCD of the remote control pad, then, the [Operation] window appears in a

few seconds.

T-RCP REMOTE CON TROL PAD

V2.10

Connect the designated

C adapter.

[HUB controller side view]

Power

switch

[Title] window [Operation] window

Note

When the remote control pad is used at the first time, the [Operation] window is displayed as shown below

because the default settings of the installation information for the objectives and so on are “not installed.”

“---“ denotes “not installed.”

Besides, if a motorized device is not connected to the hub controller, the display for it is left blank. If the

device is connected in a wrong way, the hub controller cannot recognize the device and the display for the

device is also left blank.

If all motorized devices are not connected, the subject field is displayed as shown below.

Shutdown

2

1) Power off the hub controller.

2) Power off the dia-illumination lamp and Uniblitz shutter

controller.

16

Page 19

III Preparation

3 Registering Data of the Objectives

Before shipping, most data of objectives available in this system have been registered into the remote control pad. To

use objectives not registered in the pad, such objectives as newly put in the market, data for the objectives concerned

must be newly registered into the remote control pad.

• Up to nine data of objectives can be registered.

• A wrong data registration disables this system for safety consideration.

• For the list of objectives those need registrations, see “List of objectives requiring registration,” in this section.

Press the [MODE] key. The [SETTING] menu appears.

1

Select “Objective” by manipulating the [S] or [T] key, then

press the [ ] key.

Objective

Condenser

Filter

Exciter

Barrier

Combination(O bj.>Condense r)

Combination(F ilter>EX/BA)

More

SETTING MENU

Select “Edit” by manipulating the [S] or [T] key, then press the

2

[ ] key.

By manipulating the [PREV] and [NEXT] keys, select one of

3

“Other 1” to “Other 9” in the “Location” field to register the

desired objective.

Move the cursor to “Series” by manipulating the [S] or [T] key.

4

Select the series name of the objective by using the [PREV] and

[NEXT] keys.

OBJECTIVE

Series Mag. Esc.

1[P Fluor ][DL 4x][-]

2[P Fluor ][DL 10x][-]

3[P Fluor ][ELW D DM 20x ][*]

4[P Fluor ][ELW D DM 40x ][*]

5[P Fluor ][ELW D DLL 60x][ *]

6[P Fluor ][DLL 100x][*]

Edit

EDIT OBJECTIV E DATA

Location:[

Series :[――――― ―――――]

Mag. :[0 ]x

N.A. :[0 ]

W.D. :[0 ]

Type :[――――― ―――――]

EDIT OBJECTIV E DATA

Location:[Other 1]

Series :[

Mag. :[1 ]x

N.A. :[0。001 ]

W.D. :[0。01 ]

Type :[dry ]

Other1]

Other ]

17

Page 20

III Preparation

Move the cursor to “Mag.” by manipulating the [S] or [T] key.

5

Select the magnification of the objective by using the [PREV]

and [NEXT] keys.

Note that the cursor may not move to “Mag.”, if any data is not

entered in the field of “Series” (shown as [-----]).

Move the cursor to “N.A.” by manipulating the [S] or [T] key.

6

By manipulating the numerical key, [W] key, and [X] key, enter

the numerical aperture.

Note that available values are from 0.001 to 2.000. If an entered

value exceeds the lower or upper limit, that value is

automatically set to the appropriate limit.

Move the cursor to “W.D.” by manipulating the [S] or [T] key.

7

By manipulating the numerical key, [W] key, and [X] key, enter

the working distance.

Note that available values are from 0.01 to 40.00. If an entered

value exceeds the lower or upper limit, that value is

automatically set to the appropriate limit.

EDIT OBJECTIV E DATA

Location:[Other 1]

Series :[Other ]

Mag. :[

N.A. :[0。001 ]

W.D. :[0。01 ]

Type :[dry ]

EDIT OBJECTIV E DATA

Location:[Other 1]

Series :[Other ]

Mag. :[10 ]x

N.A. :[

W.D. :[0。01 ]

Type :[dry ]

EDIT OBJECTIV E DATA

Location:[Other 1]

Series :[Other ]

Mag. :[10 ]x

N.A. :[0.25 ]

W.D. :[

Type :[dry ]

10 ]x

0.25 ]

6.2 ]

Move the cursor to “Type” by manipulating the [S] or [T] key.

8

Select the type of the objective by using the [PREV] and [NEXT]

keys.

To continue the registration, move the cursor to “Location” by

9

manipulating the [S] or [T] key.

Then repeat steps from 3 to 8.

When settings are completed, press the [MODE] key. The

10

[Operation] window reappears.

EDIT OBJECTIV E DATA

Location:[Other 1]

Series :[Other ]

Mag. :[10 ]x

N.A. :[0.25 ]

W.D. :[6.2 ]

Type :[

EDIT OBJECTIV E DATA

Location:[

Series :[――――― ―――――]

Mag. :[0 ]x

N.A. :[0 ]

W.D. :[0 ]

Type :[――――― ―――――]

dry ]

Other2]

18

Page 21

III Preparation

For deleting the registered data

(1) Manipulating the [▲] or [▼] key, move the cursor to “Location”. Then select the data to be deleted by using the

[PREV] and [NEXT] keys.

(2) Press the [CLR] key.

Important: list of objectives requiring data registration

To use the objectives below, data should be registered beforehand.

Name of objective

Value to be registered

Series Mag N.A. W.D. Type

Plan Apochromat VC60xH PlanApo 60 1.40 0.13 oil

Plan Apochromat VC100xH PlanApo 100 1.40 0.13 oil

Plan Apochromat VC60xWI PlanApo 60 1.20 0.27 WI/C

Plan Apochromat TIRF60xH PlanApo 60 1.45 0.13 oil

4 Registering Installation Information of Objectives Mounted

on Nosepiece

Register the installation information of the objectives mounted on the nosepiece.

• Register the installation information of each objective mounted on one of the six addresses on the nosepiece.

• If the corresponding objective has not been registered, its data must be registered. For the detailed information, see

Section 3, “Registering Data of Objectives” in this chapter.

Press the [MODE] key, then, the [SETTING MENU] window

1

appears.

Select “Objective” by manipulating the [S] or [T] key, then

press the [ ] key.

Objective

Condenser

Filter

Exciter

Barrier

Combination(O bj.>Condense r)

Combination(F ilter>EX/BA)

More

SETTING MENU

Select the “Series” type for the objective by manipulating the

2

[PREV] and [NEXT] keys. The number at the left denotes the

address on the nosepiece.

19

OBJECTIVE

Series Mag. Esc.

1[

P Flu or ][― ―――― ―――――― ――――][-

2[――――――――――][――――――― ―――――― ――][-

3[――――――――――][――――――― ―――――― ――][-

4[――――――――――][――――――― ―――――― ――][-

5[――――――――――][――――――― ―――――― ――][-]

6[――――――――――][――――――― ―――――― ――][-

Edit

Type N.A. W.D.

Dry 0.13 17.10

]

]

]

]

]

Page 22

III Preparation

Move the cursor by manipulating the [W] or [X] key.

3

Select the “Mag.” (magnification) for the objective, by using the

[PREV] and [NEXT] keys.

Move the cursor by manipulating the [W] or [X] key.

4

Specify the “Esc.” setting for the objective, by using the [PREV]

or [NEXT] key.

*: When changing the objective, the subject objective

automatically goes down to the escape position and

restores after the change is completed.

-: The objective is changed without escaping.

Note

When the “*” set objective exists between “-“ set

objectives, changing “-“ set objectives each other causes

automatic escape.

Change the objective address by using the [S] or [T] key and

5

repeat steps from 2 to 3.

OBJECTI VE

Series Mag. Esc.

1[P Flu or ][

2[――――― ―――――][―――――――――――――――][ -]

3[――――― ―――――][―――――――――――――――][ -]

4[――――― ―――――][―――――――――――――――][-

5[――――― ―――――][―――――――――――――――][ -]

6[――――― ―――――][―――――――――――――――][-

Edit

Type N.A. W.D.

Dry 0.13 17.10

OBJECTI VE

Series Mag. Esc.

1[P Flu or ][DL 4x][

2[――――― ―――――][―――――――――――――――][ -]

3[――――― ―――――][―――――――――――――――][ -]

4[――――― ―――――][―――――――――――――――][-

5[――――― ―――――][―――――――――――――――][ -]

6[――――― ―――――][―――――――――――――――][-

Edit

Type N.A. W.D.

Dry 0.13 17.10

OBJECTI VE

Series Mag. Esc.

1[P Flu or ][DL 4x][ ―]

2[

―――――― ――――][―――――――――――――――][-]

3[――――― ―――――][―――――――――――――――][ -]

4[――――― ―――――][―――――――――――――――][-

5[――――― ―――――][―――――――――――――――][ -]

6[――――― ―――――][―――――――――――――――][-

Edit

Type N.A. W.D.

―――――― ―――― ― ―――― ― ――――

DL 4x][-]

]

]

-]

]

]

]

]

When settings are completed, press the [MODE] key. The

6

[Operation] window reappears.

20

Page 23

V

I

This chapter explains the basic operation to observe specimens with the perfect focus system by following the actual

observation procedures.

• If the system has not been assembled, see Chapter VI, “ Assembling.”

• For operating procedures of each part of the microscope, see the instruction manual attached to the microscope.

(Inverted Microscope ECLIPSE TE2000-E Instructions)

• Before using this system, read warnings and cautions described in “Warning and Caution for Using this Product”

carefully and thoroughly, and be sure to follow them.

• For the devices using with this system (epi-fl attachment, differential interference contrast attachment, various

motorized devices, and so on), read warnings and cautions described in the instruction manuals of these devices

carefully and thoroughly, and be sure to follow them.

Operating Procedures

1 Basic Operation

Power on the microscope.

1

Caution: When the PF controller is turned on, the PF module will be initialized for about 10 seconds

and the information about the objectives on the nosepiece are acquired from the HUB

controller. So, before the PF controller, the microscope must be turned on.

Besides, if the information of the objectives is changed, the PF controller must be turned off

once, and then, turned on again.

Using the T-RCP remote control pad, register the information of the objectives mounted on the microscope into

2

the hub controller.

For detailed information about the registration procedure, see Chapter III, “Before Using this System.”

Turn on the power switch (switch to “I”) located on the right side face of the PF controller to power on the

3

controller.

The [POWER] LED, located on the front face of the PF controller, is lit.

Select the desired objective and put the specimen on the stage.

4

• Put the objective supported by this system into the optical path. Refer to IX. Specifications.

• The objective can be selected by using the remote control pad. For more information, see the instruction

manual of the remote control pad.

• Apply water immersion or oil immersion, if required. For more information, see, the instruction manual of the

microscope.

Focus on the specimen by using the coarse/fine focus knob on the microscope.

5

21

Page 24

IV Operating Procedures

Press the [AF ON] key on the PF controller.

6

(1) The LED of the [AF ON] key is lit and the focus control

starts.

Caution: Manual operation of the fine focus knob is

disabled during the focus control. Do not

touch the coarse focus knob, however,

because this knob is not disabled during the

focus control.

(2) When the objective comes into the focus control range,

the [FOCUS] LED blinks. When the reference position

(boundary surface) comes into focus, the [FOCUS] LED is

lit.

* The focus control range is defined that the focus control

can be performed, and is predetermined for each

objective.

For blinking of the [DISABLE] LED:

The reference position (boundary surface) is not in the focus

control range if the LED blinks. Adjust the objective position by

moving using the coarse/fine focus knob of the microscope so

that the reference position (boundary surface) comes into the

focus control range. When the reference position (boundary

surface) comes into the focus control range, the focus control

starts.

* The completion of focusing on the boundary surface does not mean that the target position of the

specimen comes into the focus. Perform the step 7 below, the [OFFSET] knob operation, for your

target. In particular, when a dry type objective is used, the initial position may be shifted from the

boundary surface because of variations of cover glass thickness. So, after the [FOCUS] LED is lit,

adjust the offset knob to focus on the target.

Time-out function:

This system has the time-out function to keep the objective from contact with specimen. This function will be

activated and the objective will be stopped if the signal cannot be detected within 5 seconds during the focusing

with the [AF ON] operation. (The objective moves about 400 µm for the 5 seconds.)

When the time-out function is activated, the buzzer beeps, the LED of the [AF-ON] turns off, and the up/down

movement of the objective stops.

Recovery from the time-out function:

The reference position (boundary surface) is out of the range. Push the [OFFSET-RESET] key to restore the

offset amount to its original status. Focus on the specimen manually. And then, push the [AF-ON] key again.

22

Page 25

IV Operating Procedures

Focus on the target of the specimen by manipulating the

7

[OFFSET] knob on the PF controller and start observation.

• Fine and coarse operations are provided for the function of

the [OFFSET] knob. The [FINE/COARSE] key can be used

to switch between the FINE operation and the COARSE

operation.

• The FINE/COARSE state can be checked with the LED on

the key.

Caution: The offset amount can be operated only when the

focus is being controlled (when the [AF ON] LED

is lit).

2 Registering and Restoring the Offset Amount

The offset amount specified during the observation can be registered into the memory of the PF controller. By pressing

the [FOCUS OFFSET – RECALL] key, the registered offset amount can be restored even after the offset amount is

changed by manipulating the [OFFSET] knob.

• The offset amount setting can be overwritten if required.

• Only one offset amount can be registered for one objective (one objective address). (Six positions are available in

total.)

• The registered offset amounts is stored while the PF controller is powered on.

2.1 Registering the Offset Amount

Adjust the offset amount by manipulating the [OFFSET] knob,

1

when the LED on the [AF ON] key of the PF controller is lit.

2

Press the [FOCUS OFFSET – MEMORY] key for over two

2

seconds.

The LED on the [MEMORY] key is lit and the offset amount is

registered.

1

23

Page 26

IV Operating Procedures

2.2 Restoring the Offset Amount

Press the [FOCUS OFFSET – RECALL] key.

1

The nosepiece automatically moves to the position for where

the offset is registered.

Caution: Manual operation of the fine focus knob is

disabled during the focus control. Do not touch

the coarse focus knob, however, because this

knob is not disabled during the focus control.

3 Registering and Restoring the Vertical Position of the

Nosepiece

The TE2000-E microscope has a linear encoder inside, and the vertical position (the Z-axis position) of the nosepiece

can be reproduced by using the coordinates of the linear encoder. With this function, the vertical position of the

nosepiece can be registered into the memory of the PF controller for the desired observation condition.

Once the position is registered, pressing the [AF – RECALL] key can return the nosepiece to the registered position or its

vicinity and then the system restarts the focus control even after the nosepiece position was changed by manipulating

the coarse and fine focus knobs. (Note: The nosepiece may not return to its registered absolute position of the vertical

movement. It will start the focus control again from the vicinity of the registered position.)

This function is useful for the case supplying oil to the objectives or replacing the specimen where the objectives must be

escape.

• The vertical position of the nosepiece can be overwritten if required.

• Only one offset amount can be registered for one objective (one objective address). (Six positions are available in

total.)

• The registered vertical position of the nosepiece is stored while the PF controller is powered on.

3.1 Registering the Vertical Position of the Nosepiece

Focus on the target of the specimen.

1

• When the [AF ON] LED is lit:

Focus on the target by rotating the [OFFSET] knob.

• When the [AF ON] LED is not lit:

Focus on the target by rotating the coarse/fine focus knob

on the microscope.

Press the [FOCUS OFFSET – MEMORY] key for over two

2

seconds.

The LED on the [MEMORY] key is lit and the vertical position

of the nosepiece is registered.

24

Page 27

IV Operating Procedures

3.2 Escaping the Objective

Press the [AF ON] key on the PF controller

1

(when the [AF ON] LED is lit).

The LED of the [AF ON] key is turned off and the focus control

is canceled.

Caution; The focusing control must be canceled before

changing or replacing the objectives.

Lower the nosepiece by manipulating the coarse focus knob, then, perform the required operation.

2

Examples of the operation:

• Replacing specimens

• Changing objectives

• Supplying oil or deionized water (or distilled water) to the objective

• The coarse focus knob is manipulated for other reasons, but the specimen is not moved.

3.3 Restoring the Vertical Position of the Nosepiece

The status must be one of the following two conditions.

1

[AF - MEMORY] LED: ON

[AF – ON] LED: OFF

Press the [AF – RECALL] key of the PF controller.

AF = OFF

or

[AF - MEMORY] LED: ON

[AF - ON] LED: ON

[DISABLE] LED: Blink

And no signal was detected although

the [AF - ON] key was pressed.

2

The buzzer sounds (one short beep). And then, the nosepiece

starts moving with blinking the [DISABLE] LED.

Caution: Manual operation of the fine focus knob is

disabled while restoring the nosepiece vertical

position. Do not touch the coarse focus knob,

however, because this knob is not disabled while

restoring.

Action of the equipment: When the nosepiece returned to the

3

registered vertical position or its vicinity, the [AF ON] LED is lit

and the focus control starts.

25

Page 28

IV Operating Procedures

If the buzzer sounds (twice short beep or one long beep),

the vertical position of the nosepiece could not be restored. Perform

the followings:

• Manipulate the [AF – MEMORY] operation at the focus position

again.

• Change the height of the stage by manipulating the coarse/fine

focus knob.

* The completion of focusing on the boundary surface does not mean that the target position of the specimen comes

into the focus. Perform the step 7, the [OFFSET] knob operation, in “Basic Operation ” for your target. In particular,

when a dry type objective is used, the initial position may be shifted from the boundary surface because of variations

of cover glass thickness. So, after the [FOCUS] LED is lit, adjust the offset knob to focus on the target.

3.4 About the Movement of the Objective in Registering and

Restoring the Vertical Position of the Nosepiece

(1) Push the [AF-MEMORY] key after focusing.

Glass bottom dish

(1)

(2)

WD/2

(4)

(5)

(6)

(7)

Beep!

The vertical position of the nosepiece is

stored. (The tip of the objective is defined as

“Z1” in this explanation.)

(2) Escape the objective to perform an operation

such as oil exchange or so on.

(3) Push the [AF-RECALL] key.

(4) The nosepiece is driven to the registered

vertical position, Z1, and additionally driven

upward at a distance of the half of the WD.

(The WD is the working distance of the

objective.)

However, if the half of the WD is greater than

750 µm, 750 µm is set in place of the

calculated value.

(5) The focus position (boundary surface) is

searched for downward.

(6) When the focus position is detected, the

searching operation ends and the AF is turned

on.

(7) If the focus position cannot be detected, the

search operation ends in 20 seconds and a

sound beeps.

Z1

26

Page 29

V

Connecting a PC

The hub controller can be controlled from the IBM PC-AT compatible computer connected to it.

Connecting a PC

Using a cross wired cable with D-SUB (9 pins) connectors, connect the “PC connector” of the hub controller and the

“serial port” of the PC.

Pin number of the PC

connector

1 DCD -

2 RxD Input

3 TxD Output

4 DTR Output

5 SG (GND)

6 DSR Input

7 RTS -

8 CTS -

9 RI -

Signal

Direction of the

signal

Communications cable

PC connector

PC connector: D-SUB (9pin) male

Pins numbered one, seven, eight, and nine

are opened inside the hub controller.

D-SUB (9 pins: female to female) and general cross wired cable (three meters maximum)

Specification for serial interface communication

Interactive signal connection circuit RS-232C (EIA standard compliant)

Baud rate 9600 bps

Data length 8 bit

Start bit 1

Stop bit 1

Parity check None

Communication commands

Contact your nearest Nikon representative.

27

Page 30

V

Assembling

I

This chapter explains how to assemble this system and how to connect required components.

• Before assembling, read warnings and cautions described in “Warning and Caution for Using this Product”

• To prevent electric shock and fire, always turn off the power switch (switch to “O”) of all devices and unplug the

• Do not let fingers or hands get caught in parts or components.

• Scratches or finger prints on the lens adversely affects the image quality. Pay close attention to assemble the

Warning

carefully and thoroughly, and be sure to follow them.

power cord from the wall outlet.

Caution

system and do not touch the lens.

• Components of this system are precision optical instruments. Handle them carefully, and do not subject them to

any shocks. The precision of the objectives in particular can be adversely affected even by a weak shock.

Required tools

Two 2-mm hexagonal screwdrivers (supplied with the microscope)

One 4-mm hexagonal wrench (supplied with the microscope)

One 2.5-mm hexagonal wrench (supplied with the motorized cassette holder)

28

Page 31

Block diagram

VI Assembling

T-PFB

perfect focus module *

Filter slider

Stage

Stage-up kit

T-PFC

perfect focus

controller *

Two pillars *

On the opposite side

T-FLC2-E

motorized cassette

holder *

Objective

Remote control

pad

AC

adapter

Motorized

nosepiece

Stage-up kit

Power cord

(for the AC adapter)

Stage-up kit

AC

adapter

Illumination pillar

Epi-fl attachment

Auxiliary filter

slider

Epi-illumination

lamp house

Power supply

Power cord

(for the power supply)

To the power

source for

the episcopic

illumination

External fine focus

knob (optional)

Either connection will do.

Power cord

(for the AC adapter)

”*” denotes the component of this system.

29

Page 32

VI Assembling

1 Checking Components

Check that the following components are prepared.

1. TE-2000E main body (including the hub controller and remote control pad)

2. TE-2000E stage-up kit

3. T-FLC2-E motorized cassette holder

4. T-PFB PF module (including two pillars)

5. T-PFC PF controller

6. Sensor cable

7. Control cable

8. Serial cable

9. AC adapter (for the PF controller)

10. IR-CUT filter (diameter 25 mm x 1 and 45 mm x 1)

2 Mounting the T-FLC2-E Motorized Cassette Holder

Insert the cassette holder into the attaching groove from over

1

the microscope.

Remove filter block cover. And fix the cassette holder with

2

screws on the left and right side by using the hexagonal

wrench.

Connect the cable of the cassette holder to the connector of the

3

FL block on the hub controller .

30

Page 33

VI Assembling

3 Mounting the T-PFB PF Module

Mount the two pillars for the PF module onto the motorized

1

cassette holder.

Viewing from the microscope’s front, mount the pillar with a

smaller cut on the right side of the holder facing the cut to the

rear.

On the left side of the holder, mount the pillar with a larger cut

facing to the front.

Fix each pillar using two hexagon socket headed bolts.

Mating the groove to the protrusions of each pillar, place the

2

module on the pillars.

Retain the PF module on the pillars using four hexagon socket

3

headed bolts.

4 Mounting Stage-up Kits

Mount three stage pillars.

1

Mating the positioning protrusions of the pillars to the grooves

of the microscope’s main body and retain each of them using

two hexagon socket headed bolts.

Fit the nosepiece pillar and retain it with two hexagon socket

2

headed bolts.

5 Mounting the Motorized Nosepiece

Mount the main body of the motorized nosepiece on the

1

nosepiece pillar attached in step 4, “Mounting Stage-up Kits.”

1

2

1

1

Retain the nosepiece with two M5-hexagon socket headed

2

bolts.

31

Page 34

VI Assembling

A

Connect the cable to the “Nosepiece connector” on the hub

3

controller.

Caution: Be sure to insert the objectives after mounting the stage

because they may be damaged if made contact.

6 Mounting the Stage

Place the stage on the stage pillars attached in step 4,

1

“Mounting Stage-up Kits.”

Retain the stage using four M5-hexagon socket headed bolts.

2

7 Mounting IR-cut Filters

This system uses the near infrared light (infrared band) derived from the infrared LED for the focus control. Since the

near infrared light (infrared band) used for the illumination system affects adversely on the focus control, therefore, place

the IR-cut filter on each optical path of the diascopic illumination and epi-fl illumination.

Caution: The Attached IR-cut filter reduces the intensity of ultraviolet rays too. Pay attention to observe with fluorescent

technique using the strong ultraviolet rays.

Attach the IR-cut filter (45 mm in diameter)

1

(1) Attach the filter to the filter slider.

(2) Insert the filter slider into the illumination pillar.

Attach the IR-cut filter (25 mm in diameter)

uxiliary filter slider

2

(1) Attach the filter to the auxiliary filter slider.

frame

IR-cut

filter

32

Page 35

VI Assembling

(2) Insert the filter slider into the epi-fl attachment.

8 Connecting Cables

Locate the PF controller on the stable place near the microscope, and then, connect the following cables. Be sure to

check that the hub controller and PF controller are both not powered when connecting cables.

Rear view of the PF Controller

(1) DCIN connector

Connects to the DC

power supply from the

AC adapter.

(2) CONTROL (EXP)

connector

Connects to the EXP

connector on the hub

controller with the control

cable.

Cables

1. Control cable

(3) SERIAL (STAGE) connector

Connects to the STAGE

connector on the hub

controller with the serial

communication cable,

(5) AUX. IN connector

Connects the cable of the

T-EFN external fine focus

knob (option). (This

connection is not required

if the T-EFN external fine

focus knob is not used.)

(4) SENSOR connector

Connects to the SENSOR connector

of the PF module with the sensor

cable.

Round type plug: to the EXP connector of the hub

controller

Rectangular type plug: to the control (EXP)

connector of the PF controller

Caution: Be sure to connect the round type plug to the EXP connector of the hub controller. Do not plug to

the AUX.IN connector of the PF controller.

33

Page 36

VI Assembling

2. Serial communication cable

3. Sensor cable

Rectangular type plug: to the STAGE connector of

the hub controller

Round type plug: to the SERIAL (STAGE)

connector of the PF controller

To the SENSOR connector of the PF controller

To the SENSOR connector of the PF module

Checking Connections

After connecting cables, power on the system and check to see each component.

Turn on the microscope.

1

Caution: When the PF controller is turned on, the PF module

will be initialized for about 10 seconds and the information

about the objectives on the nosepiece are acquired from the

HUB controller. So, before the PF controller, the microscope

must be turned on.

Besides, if the information of the objectives is changed, the PF

controller must be turned off once, and then, turned on again.

Turn on the [POWER] switch (switch to “I”) of the PF controller.

2

Check that the [POWER] LED is lit and the [OBJ.ERR] LED is

not lit.

34

Page 37

V

II

If the system does not function properly, take appropriate action as described below. If the problem is still not resolved

after referring to this section, please contact your nearest Nikon representative.

Troubleshooting

1 During System Startup

Problems Causes Countermeasures

The buzzer issues beeps

twice in a row.

Both the [OFFSET_UPPER]

LED and the

[OFFSET_LOWER] LED are

lit at the same time.

The

[MICROSCOPE-OBJ.ERR]

LED is blinking.

• The motorized nosepiece is not

mounted on the microscope.

• The objective is not in the click stop

position.

• The SENSOR connector of the PF

module and the SENSOR connector of

the PF controller are not connected

with the SENSOR cable.

• The EXP connector of the hub

controller and the CONTROL (EXP)

connector of the PF controller are not

connected with the CONTROL cable.

• Mount the motorized nosepiece on the

microscope.

• Rotate the objective into the click stop

position.

• Connect the SENSOR connector of the

PF module and the SENSOR

connector of the PF controller with the

SENSOR cable.

• Connect the EXP connector of the hub

controller and the CONTROL (EXP)

connector of the PF controller with the

CONTROL cable.

2 While Using the Perfect Focus Functions

Problems Causes Countermeasures

The [FOCUS] LED is lit at

times while the [AF ON] LED

is not lit.

-

It is normal. The [FOCUS] LED is lit when

the boundary surface is detected. Use it

as a guide of focusing.

The

[MICROSCOPE-OBJ.ERR]

LED is lit.

The

[MICROSCOPE-OBJ.ERR]

LED is lit. And the buzzer

issues beeps twice in a row.

The

[MICROSCOPE-UPPER]

LED is lit.

The

[MICROSCOPE-LOWER]

LED is lit.

• The hub controller has no usable

objective.

• No usable objective is selected.

• The cable connection is wrong.

The objective is not in the click stop

position.

The objective reaches the upper limit of

the vertical control.

The objective reaches the lower limit of

the vertical control.

• Register a usable objective into the hub

controller.

• Select a usable objective. For usable

objectives, see the list of objectives in

the Specification.

• Connect cables correctly referring to

the Chapter VI, “Assembling.”

Rotate the objective into the click stop

position.

Lower the specimen position (lower the

stage).

Raise the specimen position (raise the

stage).

35

Page 38

VII Troubleshooting

Problems Causes Countermeasures

The [OFFSET_UPPER] LED

is lit.

The [OFFSET_LOWER]

LED is lit.

Pressing the [FOCUS

OFFSET-MEMORY] key

causes nothing (no beep

from the buzzer).

Pressing the [AF-MEMORY]

key causes nothing (no beep

from the buzzer).

Pressing the [AF-RECALL]

key causes nothing (no

bleep from the buzzer).

Pressing the [AF-RECALL]

key causes beeps twice from

the buzzer and the

[AF-RECALL] does not work.

The [AF-RECALL] operation

ends after a long sound of

buzzer.

The offset amount reaches the upper limit

of the adjustable range.

The offset amount reaches the lower limit

of the adjustable range.

• The key was not pressed long enough.

• The [AF-RECALL] operation is in

progress.

• Press the key longer than two seconds.

• The [AF-MEMORY] operation has not

been done.

• No usable objective is selected (the

[MICROSCOPE-OBJ.ERR] LED is lit).

The objective is close to the upper or

lower limit of the vertical control.

• The focus position could not be

detected.

• The objective reached the upper or

lower limit of the vertical control while

focusing.

Lower the objective with the [OFFSET]

knob until the LED is turned off.

Raise the objective with the [OFFSET]

knob until the LED is turned off.

• Press the key longer than two seconds.

• The [FOCUS OFFSET-MEMORY] key

is disabled during the [AF-RECALL]

operation.

• The [AF-MEMORY] key is disabled

during the [AF-RECALL] operation.

• Perform the [AF-MEMORY] operation

in advance.

• Select a usable objective.

Change the stage position so that its

vertical position is apart from the upper or

lower limit.

• Perform the [AF-MEMORY] operation

at the focus position again.

• Change the stage position so that its

vertical position is apart from the upper

or lower limit.

• The nosepiece is rotated during the

[AF-RECALL] operation. (The system

operation is stopped for safety if the

nosepiece is rotated during the

[AF-RECALL] operation.)

• The focusing signal is distorted during

the [AF-RECALL] operation. If one of

the following actions is taken, the

focusing signal may be distorted and

the system stops its operation because

of safety:

* Abrupt vertical position change is

done by manipulating the coarse

focus knob of the microscope.

* The specimen is inclined.

* The specimen is removed.

36

Page 39

VII Troubleshooting

Problems Causes Countermeasures

Pressing the [AF ON] key

causes nothing (no bleep

from the buzzer).

The [DISABLE] LED is

blinking.

About 5 second after starting

the [AF ON] operation, the

buzzer beeps and the

focusing stops.

• No usable objective is selected (the

[MICROSCOPE-OBJ.ERR] LED is lit).

• No specimen is set.

• The objective is far from the boundary

surface of the specimen.

• The shape or material of the specimen

is not supported by this system.

• No specimen is set.

• The objective is far from the boundary

surface of the specimen.

• The shape or material of the specimen

is not supported by this system.

• Select a usable objective.

• Set a specimen and focus on it

manually.

• Adjust the objective closer to the

boundary surface of the glass by

manipulating the [OFFSET] knob.

• This perfect focus system may not

work precisely for specimens covered

by a thick glass plate or having a high

refractive index (n is nearly equal to

1.5). See p.7, 4.1 “Suitable specimen.”

• Set a specimen and focus on it

manually.

• Push the [OFFSET-RESET] key to

restore the offset amount to its original

status.

• This perfect focus system may not

work precisely if the specimen is

covered by a thick glass plate or the

aqueous solution has a high refractive

index (n is nearly equal to 1.5). See

p.7, 4.1 “Suitable specimen.”

37

Page 40

V

III

Care and Maintenance

1 Lens Cleaning

Do not let dust, fingerprints, and so on get on the lenses. Dirt on the lenses, filters, and so on will adversely affect the

view of the image. If any of the lenses get dirty, clean them as described below:

• Brush away dust with a soft brush, or wipe it away gently with gauze.

• Only if there are fingerprints or grease on a lens, dampen a piece of soft, clean cotton cloth, lens tissue, or gauze with

absolute alcohol (ethyl or methyl alcohol) and wipe.

• Only when removing the immersion oil off from the objective, use petroleum benzine. If you cannot obtain petroleum

benzine, use methyl alcohol. However, because methyl alcohol does not clean as well as petroleum benzine, it will be

necessary to wipe the surfaces repeatedly. (Usually, wiping three or four times is sufficient to clean the lenses.) Wipe

with absolute alcohol (ethyl or methyl alcohol) to finish.

• Never use petroleum benzine to clean the entrance lens at the bottom of the eyepiece tube and prism surface of the

eyepiece tube.

• Absolute alcohol and petroleum benzine are highly flammable. Be careful when handling it, when around open flames,

when turning the power switch on / off, and so on.

• When using absolute alcohol, be sure to follow the instructions provided by the manufacturer.

2 Cleaning This Product

• Nikon recommends that you use a silicon cloth to clean this product.

• For persistent dirt, dampen a piece of gauze with neutral detergent and wipe lightly.

• Note that using organic solvents could result in discoloration of the plastic parts.

3 Disinfecting This Product

• Nikon recommends that you use 70% medical alcohol for normal disinfection of this product.

• If a specimen is spilled, check that the specimen is a safe material or not. In case of spillage of a hazardous

specimen onto this product, follow your standard laboratory procedures.

• Note that using organic solvents could result in discoloration of the plastic parts.

4 Storage

Store this product in a dry place where mold is not likely to form.

Store the objectives and eyepieces in a desiccator or similar container with a drying agent.

Put a vinyl cover over this product to protect them from dust.

Before putting on the vinyl cover, turn off the power switch on the microscope (flip it to the “O” side) and wait until the

lamphouse is cooled down.

5 Periodical Inspections (Expenses Charged)

Nikon recommends inspecting this product periodically (expenses charged) in order to maintain peak performance.

Contact your nearest Nikon representative for details.

38

Page 41

IX

Microscope model TE2000-E

Target specimen Specimen in liquid (culture cell and so on)

Available container Glass bottom dish (glass thickness: No. 1S)

Glass thickness Standard No. 1S (150 to 180 µm)

Detection method Active type, infrared LED image projection method

Specifications

Detected

boundary

surface

Detector Inline CCD

Detector light source

Offset method Optical offset type: The offset value can be operated with the knob of the controller.

Offset amount

Focusing time 700 msec or less (near the boundary surface)

Focusing accuracy 1/3 of the depth of focus for each objective

Available microscopy

Available objective

Water or oil

immersion type

objective

Dry type objective Boundary surface between the glass and the air

Boundary surface between the glass and specimen (culture medium)

Refer to the figure on p.6 in Chapter I. “3. Offset function.”

Refer to the figure on p.6 in Chapter I. “3. Offset function.”

Infrared LED wavelength: 770 nm

illumination power: 0.1 mW or less

Dry type objective: +100 to –10 µm

Water immersion type objective: +50 to –2 µm

Oil immersion type objective: +10 to –0.5 µm

Note: Some objectives are available for greater offset amount than above.

Bright field microscopy, phase contrast microscopy, DIC microscopy, epi-fl

microscopy, TIRF microscopy

Name NA WD (mm) Type

Plan Fluor 40x 0.75 0.72 dry

Plan Fluor 40xH 1.30 0.2 oil immersion

Plan Fluor ELWD 20xC 0.45 7.6 dry

Plan Fluor ELWD 40xC 0.6 2.9 dry

Plan Fluor ELWD DM 20xC 0.45 7.6 dry

Plan Fluor ELWD ADL 20xC 0.45 7.6 dry

Plan Fluor ELWD ADL 40xC 0.6 2.9 dry

Plan Apo VC 60xH 1.40 0.13 oil immersion

Plan Apo VC 100xH 1.40 0.13 oil immersion

Plan Apo VC 60xWI 1.20 0.27 water immersion

Plan Apo 60xHA 1.40 0.21 oil immersion

Plan Apo 100xH 1.40 0.13 oil immersion

Plan Apo 60xWI 1.20 0.22 water immersion

Plan Apo 20x 0.75 1.00 dry

Plan Apo DM 60xH 1.40 0.21 oil immersion

Plan Apo DM 100xH 1.40 0.13 oil immersion

Plan Apo TIRF 60x 1.45 0.13 oil immersion

39

Page 42

IX Specifications

Memory function 1 Offset value registering/calling (for each objective, up to 6 values)

Memory function 2

Dimensions and weight T-PFB: H 46 x W 210 x D 125 mm (without protrusions) 1.5 Kg

Service condition

Designated AC adapter

Nosepiece up/down position registering/calling (for each objective, up to 6

positions)

T-PFC: H 65 x W 150 x D 202 mm (without protrusions) 2.2 Kg

T-FLC2-E: H 56 x W 166 x D 165 mm (partially H 117) 1.3 Kg

Operating environment

Temperature: +20 to +38 °C (for control unit: 0 to +40 °C).

Relative humidity: 60% or less (for control unit: 80% or less) * No condensation.

Altitude: 2000m max.

Pollution degree: Degree 2

Installation category: Category II

Electric shock protection class: Class I (AC adapter)

Indoor use only

Storage environment

Temperature: - 20 to +60 °C

Relative humidity: 90% or less. * No condensation.

Manufacturer: ILAN Electronics Ltd.

Type: F1650K

Input ratings: 100 to 240 VAC, max 1.2 A, 50-60 Hz.

Output ratings: 12 VDC, max 3.5 A

Others: UL listed product, GS approved, and CE satisfied.

Power cord

Safety standards compliance

For using in the area supplied voltage is 100 to 120 V:

UL listed detachable cord set, 3 conductor grounding Type SVT, AWG 18, 3 m

long maximum, rated at 125 V AC minimum.

For using in the area supplied voltage is 220 to 240 V:

Approved cord set according to EU/EN standards, 3 conductor grounding type

HO5VV-F, AWG 18, 3 m long maximum, rated at 250 V AC minimum.

LED product category:

Class 1 LED Product

CE marking

This product meets EU Low Voltage Directive requirements.

This product meets EU EMC Directive requirements. (EN61326)

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful

interference

when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if

not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference

in which case the user will be required to correct the interference at his own

expense.

This Class A digital apparatus complies with Canadian ICES-003.