Page 1

Automated IC Inspection Microscope

Automated IC Inspection Microscope L200A

Page 2

The next generation in automated

IC inspection microscopy

The Eclipse L200A has scored major

advances in the standardization of

inspection and safeguards against

contamination. In a new design that

combines motorized control with

automated operation, observation

conditions can be programmed for

each individual objective or for each

substrate to be inspected. Focus position,

objective magnification, illumination control

and other microscope methods are fully

programmable and can be recalled instantly.

This eliminates deviation in inspection

results that might occur due to different

settings made by multiple users.

To minimize the chance of

contamination, the L200A's aperture

control and other major operations

are now motorized, enabling remote

control for use on unattended IC

production lines. Like other Eclipse-

series microscopes from Nikon, the

L200A features industry-acclaimed CFI60

infinity optics.

Include an ergonomic design for comfortable

viewing, a rigid, vibration resistant

construction, and you have a microscope

unsurpassed to meet the stringent

requirements of the latest semiconductor fabs.

The L200A is the next step upward in

automated IC inspection microscopy.

Standardized, contamination-free inspections

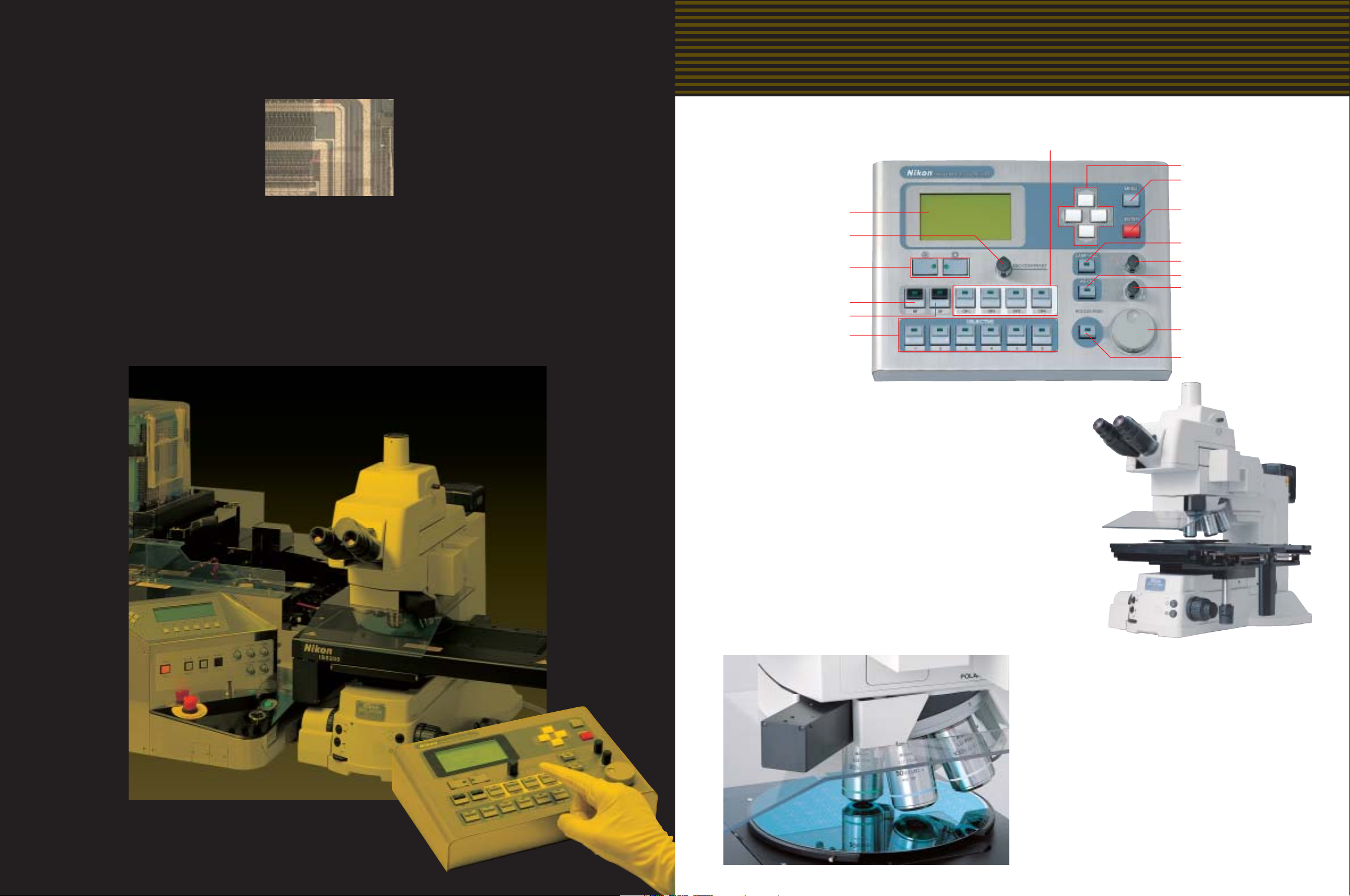

Cursor keys

LCD screen

DIC adjustment

knob*

Aperture keys

Darkfield key

Brightfield key

Option keys

Objective

selection keys

Enter key

Menu key

Focus dial

Focus Coarse/Fine

changeover key

AF-MF changeover key*

Focus fine adjustment knob*

(When AF is ON)

Lamp intensity Auto/

Manual changeover key

Lamp intensity control knob

Motorized, remote control minimizes

the chance of contamination, while

enhancing productivity

Frequently used operations such as aperture control, focusing, brightfielddarkfield changeover, nosepiece rotation, lamp intensity control, and DIC

setting (option) are all motorized and can be controlled by the remote

controller or a PC. In addition, there is virtually no operation that requires

manual adjustment above the sample, therefore preventing particle

contamination introduced from the operator.

Free from deviations in

inspection results, due to

human errors and differences in

microscope settings

Optimum observation conditions including focus position,

aperture, light intensity, as well as DIC prism and polarizer

position can be preset objective-by-objective and recalled

simply by selecting the objective. This eliminates the need

to configure these settings each time the microscope is

used, providing standardized observation regardless of

who operates the microscope.

3

*Active when the respective optional module is attached.

Remote Controller

Page 3

Easy configuration into an automated inspection system

Programmed settings

As an inspection process varies depending on substrate,

layer, and even the operator, it has been necessary to readjust settings for each inspection process.

The L200A's programming feature eliminates this process.

You just select the settings-such as observation method,

objective magnification, point to be checked, focus

position, aperture, and light intensity-and save them by

attaching appropriate file names. All you need do to begin

your inspection is just to specify the file name.

DART software (option)

AF

RS232C (Binary)

Local

Local

Scanning

stage

(ISS)

Wafer

Loader

NWL860

Local

PC

(DART Software)

(Other Software)

Other Euipment

Local

Local

RS232C

(Binary)

RS232C (Binary)

RS232C (SECS)

L200A

DIC

Confocal

DUV

Filing

System

Host

Computer

Auto Inspection

Machine

4 5

In combination with

wafer loaders

Of course, the L200A can be configured with

Nikon's NWL-860 series of wafer loaders and

manual or motorized scanning stages to

create a wafer inspection system at a

minimum cost.

DART Software is an integrated software package

that can fully automate the inspection process.

DART combined with an NWL860 wafer loader,

ISS200 Motorized Stage and a L200A Auto Focus

offers a complete automated wafer inspection

station. DART software modules allow further

upgrades with options such as image archiving,

defect review, post probe review and online

communications.

Communication System Diagram

L200A configured with NWL-860 INX

Page 4

Top-notch basic performance facilitates inspections Accessories to enhance performance

High-contrast darkfield images

A new illumination

system produces a

Signal to Background

(S/B) ratio that is

nearly three times

greater than former

models. This

improves sensitivity

during darkfield

observations, enabling the detection of minute scratches

and surface irregularities within the sample, and provides

exceptionally high contrast.

CFI LU/L Plan series objectives

Illumination systems

•12V-100W halogen lamphouse

•100W mercury lamphouse

•150W metal halide

lamphouse

•75W xenon lamphouse

Stages and wafer

holders

•8x8 Stage

•8-inch (200mm) wafer holder

•6-inch (150mm) wafer holder

•6-inch (150mm) mask holder

•5-inch (125mm) mask holder

•4-inch (100mm) mask holder

DXM1200 digital camera

The DXM1200 Digital Camera achieves ultrahigh-quality digital images equivalent to

approximately 12 million output pixels, plus

has a low-noise design for clear, low-light

image capture. The camera's software can be

set to automatically categorize the images

taken, sort them and save them, all

automatically—a powerful feature when you

take a large number of photomicrographs.

SEMI S2-93A, S8-95 compliant

design

Centerable motorized

nosepiece

The sextuple motorized

nosepiece not only has

the same encoded

positioning system

offered on the Eclipse

L200, but it also offers

three adjustable objective

positions that improve

par-centricity even more.

Safeguards against

contamination

The body of this microscope is finished with electrostatic

discharge (ESD) coatings to prevent foreign particles from

adhering to it. Furthermore, the motorized nosepiece uses

a shielded center-motor that traps foreign particles inside,

preventing them from falling onto the sample.

Vibration-isolation design

Thanks to Computer-Aided

Engineering, the L200A is three

times less susceptible to

floor vibrations when

compared with conventional

models in this class. This

reduces the chance of

unwanted blur or image

shifts even during highmagnification

observations.

6 7

Nikon's renowned CFI60 optics are the fusion of CF design

and infinity optics. These new optics feature longer working

distances and high N.A.'s. They also produce brighter

images with more contrast and reduced flare.

Optical System

A tilting trinocular eyepiece tube with a lower eyepoint

designed to be closer to the operator allows you to sit in a

more natural erect position. Microscope controls located

comfortably up-front in the microscope base minimize

hand movement, allowing you to concentrate on the

inspection process.

System Diagram

ECLIPSE L200A Conventional model

Type Magnifi- N.A. W.D.

cation (mm)

CFI L Plan Epi* 2.5X 0.075 8.80

CFI LU Plan Epi* 5X 0.15 23.50

10X 0.30 17.30

20X 0.45 4.50

50X 0.80 1.00

100X 0.90 1.00

CFI LU Plan Epi ELWD* 20X 0.40 13.00

50X 0.55 10.10

100X 0.80 3.50

CFI L Plan Epi SLWD* 20X 0.35 24.00

50X 0.45 17.00

100X 0.70 6.50

CFI LU Plan Apo Epi* 150X 0.95 0.30

CFI L Plan Apo Epi WI* 150X 1.25 0.25

CFI LU Plan BD 5X 0.15 18.00

10X 0.30 15.00

20X 0.45 4.50

50X 0.80 1.00

100X 0.90 1.00

CFI LU Plan BD ELWD 20X 0.40 13.00

50X 0.55 9.80

100X 0.80 3.50

CFI LU Plan Apo BD 150X 0.90 0.42

* A nosepiece adapter is needed to use these objectives.

Photomicrographic System

CF Projection Lenses

PLI 2X, 2.5X, 4X, 5X

V-T Photo Adapter

Illumination

Systems

HMX-3

Lamphouse

Adapter

Epi

Collector

Lens

Fiber

Guide

Adapter

FX-III Series

Mercury

Lampsocket

100W

Xenon

Lampsocket 75W

Metal Halide Starter

12V-100W Halogen

Lamphouse

C-Mount/ENG-Mount TV

Zooming Adapter

Confocal Unit

(Under development)

Mercury Lamphouse

HMX-3B

Xenon Lamphouse

HMX-4

Liquid Fiber Guide

C-Mount/ENG-Mount

CCD Camera

TV Adapter TV Adapter

L2-TT Trinocular Tilting

Eyepiece Tube

Double Port

(Under

development)

Stages

Auto Focus Module

Filter Sliders Pinhole Slider

8x8 Stage

Motorized Scanning

Stage ISS200

ISS200 Remote Controller

L Stage for NWL860

Wafer Loader

Digital Still Camera/

C-Mount CCD Camera

YM-TI Trinocular

Eyepiece Tube

8" Wafer

Holder

CFI LU/L Plan

Epi Objectives

4-6-inch

Wafer Holder

LU Nosepiece

Adapter

CFI UW 10X

CFI UW 10XM

CFI 10X

CFI 10XM

CFI 12.5X

CFI 15X

Adapter

Filar Micrometer

Motorized

DIC Module

Breadth Shield

L200A

Remote

Controller

4-6-inch

Mask Holder

Eyepieces

10XA

CFI LU Plan BD

Objectives

Page 5

En

WARNING

TO ENSURE CORRECT USAGE, READ THE CORRESPONDING

MANUALS CAREFULLY BEFORE USING YOUR EQUIPMENT.

Specifications and equipment are subject to change without any notice or

obligation on the part of the manufacturer. September 2002.

DART software is developed by Nikon Inc.

NIKON CORPORATION

Yokohama Plant

NIKON CORPORATION

Instruments Company

ISO 9001

Accredited by the

Dutch Council for

Accreditation

ISO 14001

©2000-02 NIKON CORPORATION

160 (6.3)

180 (7.1)

360 (14.2)

189 (7.4)

473 (18.6) max.

653 (25.7) max.

798-816 (31.4-32.1)

175 (6.9) 373 (14.7)

649 (25.6)

324-342 (12.8-13.5)

798-816 (31.4-32.1)

244 (9.6)

429-544 (16.9-21.4)

E.P.

662 (26.1)

430 (16.9)

157 (6.2)

Specifications

Dimensional diagram

(When AF Module is mounted)

Printed in Japan (0209-03)T

Code No. 2CE-KWLH-1

This brochure is printed on recycled paper made from 40% used material.

Observation method Brightfield, darkfield, DIC, simple polarizing

Main body Episcopic stand, Power supply built-in

Focusing mechanism Stroke: 29mm, Coarse: 12.7mm per rotation

(torque adjustable, focusing stop mechanism

provided), Fine: 0.1mm per rotation (in 1µm

increments), Guide: 4-guide (two roller-race,

torque adjustable)

Episcopic illuminator Motorized aperture diaphragm (centerable,

pinhole slider incorporated )

Fixed field diaphragm (with focus target), Four

ø25mm filters (NCB11/ND4,16) can be mounted;

Polarizer, Analyzer

Light sources 100W halogen, 150W metal halide, 100W mercury,

75W Xenon

Eyepiece tube UW tilting trinocular eyepiece tube (tilt angle: 0˚-

30˚; erect images), F.O.V.: 25mm, Optical path

changeover: 2-way (Bino: Photo 100:0/0:100)

Nosepiece Fixed-motorized sextuple universal nosepiece

(centarable), Highly durable

Stage 8x8 Stage, Cross travel: 205 x 205 mm,

Coarse/fine-movement changeover: manual,

Wafer holders: 4-8 in., Mask holders: 4-6 in.

Control Front panel: Nosepiece rotation buttons,

Episcopic aperture diaphragm stop buttons, Light

intensity control knob

Remote control: LCD panel, Magnification

changeover, Motorized Z-axis, Episcopic aperture

diaphragm stop buttons, Light intensity control

knob, Motorized bright/darkfield changeover key,

DIC adjustment knob, Option keys

Eyepieces CFI eyepiece lens series

Objectives CFI LU/L Plan series

Auto focus unit Optional (LED)

Automated function Recipe Programming

Communication RS-232C

Weight Approx. 45kg (when 8x8 Stage and UW eyepiece

tube are used.)

Unit: mm (inch)

NIKON INSTECH CO., LTD.

Parale Mitsui Bldg., 8, Higashida-cho, Kawasaki-ku,

Kawasaki, Kanagawa 210-0005, Japan

phone: +81-44-223-2175 fax: +81-44-223-2182

http://www.ave.nikon.co.jp/inst/

NIKON INSTRUMENTS EUROPE B.V.

P.O. Box 222, 1170 AE Badhoevedorp, The Netherlands

phone: +31-20-44-96-222 fax: +31-20-44-96-298

http://www.nikon-instruments.com/

NIKON INSTRUMENTS INC.

1300 Walt Whitman Road, Melville, N.Y. 11747-3064, U.S.A.

phone: +1-631-547-8500; +1-800-52-NIKON (within the U.S.A.only) fax: +1-631-547-0306

http://www.nikonusa.com/

NIKON CANADA INC.

CANADA phone: +1-905-625-9910 fax: +1-905-625-0103

NIKON FRANCE S.A.

FRANCE phone: +33-1-45-16-45-16 fax: +33-1-45-16-00-33

NIKON GMBH

GERMANY phone: +49-211-9414-0 fax: +49-211-9414-322

NIKON INSTRUMENTS S.p.A.

ITALY phone: + 39-55-3009601 fax: + 39-55-300993

NIKON AG

SWITZERLAND phone: +41-1-913-62 00 fax: +41-1-910-37 44

NIKON UK LTD.

UNITED KINGDOM phone: +44-20-8541-4440 fax: +44-20-8541-4584

NIKON SINGAPORE PTE LTD

SINGAPORE phone: +65-5593618 fax: +65-5593668

NIKON MALAYSIA SDN. BHD.

MALAYSIA phone: +60-3-78763887 fax: +60-3-78763387

Loading...

Loading...