Page 1

Radius CM200

™

/

CM300

™

& Motorola PM400

™

Commercial Series

Mobile Radio Basic Service Manual

Page 2

Page 3

CM200/CM300/PM400

Radios

i

Basic Service Manual

6802966C15-A

Issue: August, 2004

Page 4

ii

Foreword

This manual is intended for use by service technicians familiar with similar types of equipment. It contains

service information required for the equipment described and is current as of th e printing date. Changes which

occur after the printing date may be incorporated by a complete Manual revision or alternatively as additions.

Note:

Before operating or testing these units, please read the Product Safety and RF Exposure

Compliance section.

Computer Software Copyrights

The Motorola products described in this manual may include copyrighted Motorola computer prog r ams stor ed

in semiconductor memories or other media. Laws in the United States and other countries preserve for

Motorola certain exclusive rights for copyrighted computer programs, including , but not limited to, the

exclusive right to copy or reproduce in any form the copyrighted computer program. Accordingly, any

copyrighted Motorola computer programs contained in the Motorola products described in this manual may

not be copied, reproduced, modified, reverse-engineered, or distributed in any manner without the express

written permission of Motorola. Furthermore, the purchase of Motorola products shall not be deemed to grant

either directly or by implication, estoppe l, or otherwise, any license under the copyrights, patents or patent

applications of Motorola, except for the normal non-exclusive license to use that arises by operation of law in

the sale of a product.

Document Copyrights

No duplication or distribution of this document or any portion thereof shall take place without the express

written permission of Motorola. No part of this manual may be reproduced, distributed, or transmitted in any

form or by any means, electronic or mechanical, for any purpose without the express written permission of

Motorola.

Disclaimer

The information in this document is carefully examined, and is believed to be entirely reliable. However, no

responsibility is assumed for inaccuracies. Furthermore, Motorola reserves the right to make changes to any

products herein to improve readability, function, or design. Motorola does not assume any liability arising out

of the applications or use of any product or circuit described herein; nor does it cover any license under its

patent rights nor the rights of others.

MOTOROLA, The Stylized M logo, and Radius are trademarks of Motorola, Inc.

All other product or servic e na m es are the property of their respective owners.

© 2004 Motorola, Inc. All rights reserved. Printed in U.S.A.

Page 5

Table of Contents

Foreword......................................................................................................................... ii

Computer Software Copyrights....................................................................................... ii

Document Copyrights ..................................................................................................... ii

Disclaimer ....................................................................................................................... ii

Product Safety and RF Exposure Compliance ..............................................................vii

Chapter 1 INTRODUCTION

1.0 Scope of Manual ..................................................................................................1-1

2.0 Warranty and Service Support.............................................................................1-1

2.1 Warranty Period and Return Instructions ....................................................1-1

2.2 After Warranty Period..................................................................................1-1

3.0 Replacement Parts Ordering ............................................................................... 1-2

3.1 Basic Ordering Information..........................................................................1-2

3.2 Motorola Online ...........................................................................................1-2

3.3 Mail Orders..................................................................................................1-2

3.4 Telephone Orders .......................................................................................1-2

3.5 Fax Orders .................................................................................................. 1-2

3.6 Parts Identification.......................................................................................1-3

4.0 Radio Model Information......................................................................................1-3

iii

Chapter 2 MAINTENANCE

1.0 Introduction ..........................................................................................................2-1

2.0 Preventive Maintenance ......................................................................................2-1

2.1 Inspection ....................................................................................................2-1

2.2 Cleaning Procedures...................................................................................2-1

3.0 Safe Handling of CMOS and LDMOS Devices ....................................................2-2

4.0 Repair Procedures and Techniques — General ..................................................2-3

5.0 Disassembling and Reassembling the Radio — General ....................................2-3

6.0 Radio Disassembly - Detailed..............................................................................2-4

6.1 Control Head Removal ................................................................................2-4

6.2 Top Cover Removal ....................................................................................2-6

6.3 Main Shield Removal ..................................................................................2-7

6.4 PA Shield and DC Cable Removal..............................................................2-7

6.5 PA Clip and Main PCB Removal (for Low Power Models) ..........................2-8

6.6 Main PCB Removal (for High Power Models) ............................................. 2-9

6.7 Disassembly of Control Head - CM200 .....................................................2-10

6.8 Disassembly of Control Heads - CM300/PM400....................................... 2-11

7.0 Radio Assembly.................................................................................................2-12

7.1 Chassis Assembly (for Low Power Models) ..............................................2-12

7.2 Chassis Assembly (for High Power Models) .............................................2-12

Page 6

iv

7.3 Control Heads Assembly...........................................................................2-13

7.4 Control Head Fitting .................................................................................. 2-13

7.5 Option Board Installation...........................................................................2-14

8.0 Radio Exploded Mechanical Views and Parts Lists........................................... 2-15

8.1 Radio Assembly - 1-25 W Models .............................................................2-15

8.2 Radio Assembly - 25-40 W/25-45 W Models ............................................2-16

8.3 Control Head - CM200 .............................................................................. 2-17

8.4 Control Head - CM300/PM400 ..................................................................2-18

9.0 Service Aids.......................................................................................................2-19

10.0 Test Equipment..................................................................................................2-20

11.0 Programming/Test Cable - RKN4083_ .............................................................. 2-21

12.0 Adapter Cable - FKN8113_ ...............................................................................2-22

Chapter 3 TRANSCEIVER PERFORMANCE TESTING

1.0 General ................................................................................................................3-1

2.0 Setup ................................................................................................................... 3-1

3.0 RF Test Mode ......................................................................................................3-2

Chapter 4 RADIO TUNING AND PROGRAMMING

1.0 Introduction ..........................................................................................................4-1

2.0 CPS Programming/Flashing Setup with RIB .......................................................4-1

3.0 CPS Programming/Flashing Setup Ribless ......................................................... 4-2

4.0 CPS Programming Setup with RIB (with Telco Connector)................................. 4-2

5.0 CPS Programming Setup with RIB (Accessory Connector) ................................4-3

6.0 CPS Programming Setup with RIB ...................................................................... 4-3

7.0 Radio Tuning Setup .............................................................................................4-4

7.1 Initial Test Equipment Control Settings .......................................................4-4

Chapter 5 POWER UP SELF-TEST

1.0 Error Codes ......................................................................................................... 5-1

Chapter 6 ACCESSORIES & CONNECTOR PIN FUNCTIONS

1.0 Accessories ......................................................................................................... 6-1

1.1 Antennas ..................................................................................................... 6-1

1.2 Audio ........................................................................................................... 6-2

1.3 Alarms and Accessories..............................................................................6-2

1.4 Control Station.............................................................................................6-3

1.5 Public Address ............................................................................................ 6-3

1.6 Cables ......................................................................................................... 6-3

1.7 Mounting......................................................................................................6-3

1.8 Data - CES Wireless Technologies .............................................................6-4

Page 7

1.9 Peripherals ..................................................................................................6-4

2.0 Accessory Connector Pin Function......................................................................6-5

3.0 Microphone Connector Pin Function....................................................................6-6

Chapter 7 MODEL CHART AND TEST SPECIFICATION

1.0 Low Power Radios ...............................................................................................7-1

1.1 146-174 MHz CM200/CM300/PM400 Model Chart.....................................7-1

1.2 438-370 MHz CM200/CM300/PM400 Model Chart.....................................7-2

1.3 Specifications .............................................................................................7-3

2.0 High Power Radios .............................................................................................. 7-5

2.1 136-162 MHz CM300 Model Chart..............................................................7-5

2.2 146-174 MHz CM200/CM300/PM400 Model Chart.....................................7-5

2.3 438-470 MHz CM200/CM300/PM400 Model Chart.....................................7-6

2.4 465-495 MHz PM400 Model Chart..............................................................7-7

2.5 Specifications .............................................................................................7-8

3.0 MIL Standards....................................................................................................7-10

v

GLOSSARY ...................................................................................... G-i

Page 8

vi

THIS PAGE INTENTIONALLY LEFT BLANK

Page 9

SAFETY INFORMATION

!

Product Safety and RF Exposure Compliance

Note:

Before using this product, read the operating instructions for safe usage contained in the

Product Safety and RF Exposure booklet enclosed with your radio.

C a u t i o n

ATTENTION!

This radio is restricted to occupational use only to satisfy FCC RF energy exposure requirements.

Before using this product, read the RF energy awareness information and operating instructions in the

Product Safety and RF Exposure booklet enclosed with your radio (Motorola Publication part number

68P81095C99) to ensure compliance with RF energy exposure limits.

For a list of Motorola-approved antennas, batteries, and other accessories, visit the following web site which

lists approved accessories: http://www.motorola.com/cgiss/index.shtml.

vii

Page 10

viii

THIS PAGE IS INTENTIONALLY BLANK

Page 11

1.0 Scope of Manual

This manual is intended for use by service technicians familiar with similar types of equipment. It

contains service information required for the equipment described and is current as of the printing

date. Changes which occur after the printing date may be incorporated by a complete Manual

revision or alternatively as additions.

Chapter 1

INTRODUCTION

NOTE

Before operating or testing these units, please read the Safety Infor mation Section in the

front of this manual.

2.0 Warranty and Service Support

Motorola offers long term support for its products. This support includes full exchange and/or repair

of the product during the warr anty p eriod, and service/ repair or spare parts support out of warran ty.

Any "return for exchange" or "return for repair" by an authorised Motorola Dealer must be

accompanied by a Warranty Claim Form. Warranty Claim Fo rms are obtained by contacting an

Authorized Motorola Dealer.

2.1 Warranty Period and Return Instructions

The terms and conditions of warranty are defined fully in the Motorola Dealer or Distributor or

Reseller contract. These conditions may change from time to time and the following notes are for

guidance purposes only.

In instances where the product is covered under a "return for replacement" or "return for repair"

warranty, a check of the product should be performed prior to shipping the unit back to Motorola.

This is to ensure that the product has been correctly programmed or has not been subjected to

damage outside the terms of the warranty.

Prior to shipping any radio back to the appropriate Motorola warranty depot, please contact

Customer Resources (Please see page 2 and page 3 in this Chapter). All returns must be

accompanied by a Warranty Claim Form, available fr om your Customer Services representative.

Products should be shipped back in the original packaging, or correctly packaged to ensure no

damage occurs in transit.

2.2 After Warranty Period

After the Warr anty period, Motorola continues to support its products in two ways.

1. Motorola's Radio Products and Services Division (RPSD) off ers a repair service to both end users

and dealers at competitive prices.

2. Radio Products and Services Division (RPSD) supplies individual parts and modules that can be

purchased by dealers who are technically capable of performing fault analysis and repair.

* The Radio Products and Services Division (RPSD) was formerly knows as the Accessories and

Aftermarket Division (AAD)

Page 12

1-2 INTRODUCTION

3.0 Replacement Parts Ordering

3.1 Basic Ordering Information

When ordering replacement parts or equipment information, the complete identification number

should be included. This applied to all components , kits, and chassis . If the componen t part number is

not known, the order should include the number of the chassis or kit of which it is a part, a sufficient

description of the desired component to identify it.

3.2 Motorola Online

Motorola online users can access our on-line catalog at:

HTTPS://WWW.MOTOROLA.COM/BUSINESSONLINE

To register for online access, please call 800-814-0601 (for U.S. and Canada Service Centers only).

3.3 Mail Orders

Send written orders to the following addresses:

Replacement Parts/Test

Equipment/Manuals/Crystal

Service Items:

Motorola, Inc.

Radio Products and Services Division

Attention: Order Processing

2200 Galvin Dr.

Elgin, IL 60123

U.S.A.

3.4 Telephone Orders

Radio Products and Services Division (RPSD)

(United States and Canada)

7:00 AM to 7:00 PM (Central Standard Time)

Monday through Friday (Chicago, U.S.A.)

1-800-422-4210

847-538-8023 (International Orders

U.S. Federal Government Markets Division (USFGMD)

1-800-826-1913 Federal Government Parts - Credit Card Only

8:30 AM to 5:00 PM (Eastern Standard Time)

Federal Government Orders: International Orders:

Motorola, Inc.

U.S. Federal Government

Markets Division

Attention: Order Processing

7230 Parkway Drive

Landover , MD21076

U.S.A.

Motorola, Inc.

Radio Products and Services

Division

Attention: Order Processing

2200 Galvin Dr.

Elgin, IL 60123

U.S.A.

3.5 Fax Orders

Radio Products and Services Division (RPSD)

(United States and Canada)

1-800-622-6210

847-576-3023 (International)

USFGMD

(Federal Government Orders)

1-800-526-8641 (For Parts and Equipment Purchased Orders)

Page 13

Radio Model Information 1-3

3.6 Parts Identification

Radio Products and Services Division (RPSD)*

(United States and Canada)

1-800-422-4210, menu 3

* The Radio Products and Services Division (RPSD) was formerly known as the Accessories and

Aftermarket Division (AAD)

4.0 Radio Model Information

The model number and serial number are located on a label attached to the back of your radio. You

can determine the RF output power, frequency band, protocols, and physical packages. The

example below shows one mobile radio model number and its specific characteristics.

Table 1-1 Radio Model Number (Example: AAM50KNC9AA1)

Type of

Unit

AA M 50 J

Model

Series

Freq.

Band

VHF1

(136-162

MHz)

M = Mobile

AA = Country Code

VHF2

(146-174

MHz)

UHF2

(438-470

MHz)

UHF3

(465-495

MHz)

Power

Level

1-25 WCCM2009Program-

K

25-40 WFCM300

R

25-45 W

S

N

P

Q

Physical

Packages

PM400

Channel

Spacing

mable

Protocol

AA

Conven-

tional

MDC

Feature

Level

1

4/32 mini-U

3

64 mini-U

Page 14

1-4 INTRODUCTION

THIS PAGE INTENTIONALLY LEFT BLANK

Page 15

1.0 Introduction

!

This chapter provides details about the following:

• Preventive maintenance (inspection and cleaning).

• Safe handling of CMOS and LDMOS devices.

• Disassembly and reassembly of the radio.

• Repair procedures and techniques.

• Installation of Option Boards.

2.0 Preventive Maintenance

The radios do not require a scheduled preventive maintenance program; however, periodic visual

inspection and cleaning is recommended.

2.1 Inspection

Chapter 2

MAINTENANCE

Check that the external surfaces of the radio are clean, and that all external controls and switches

are functional. It is not recommended to inspect the interior electronic circuitry.

2.2 Cleaning Procedures

The following procedures describe the recommended cleaning agents and the methods to be used

when cleaning the external and internal surfaces of the radio. External surfaces include the front

cover and housing assembly. These surfaces should be cleaned whenever a periodic visual

inspection reveals the presence of smudges, grease, and/or grime.

NOTE

The only recommended agent for cleaning the external radio surfaces is a 0.5% solution of a mild

dishwashing detergent in water. The only factory recommended liquid for cleaning the printed circuit

boards and their components is isopropyl alcohol (70% by volume).

CAUTION: The effects of certain chemicals and their vapors can have harmful results on

certain plastics. Avoid using aerosol sprays, tuner cleaners, and other chemicals.

Cleaning External Plastic Surfaces

Apply the 0.5% detergent-water solution sparingly with a stiff, non-metallic, short-bristled brush to

work all loose dirt away from the radio. Use a soft, absorbent, lintless cloth or tissue to remove the

solution and dry the radio. Make sure that no water remains entrapped near the connectors, cracks,

or crevices.

Internal surfaces should be cleaned only when the radio is disassembled for service or

repair.

Page 16

2-2 MAINTENANCE

!

Cleaning Internal Circuit Boards and Components

Isopropyl alcohol (100%) may be applied with a stiff, non-metallic, short-bristled brush to dislodge

embedded or caked materials located in hard-to-reach areas. The brush stroke should direct the

dislodged material out and away from the inside of the radio. Make sure that controls are not soaked

with alcohol. Do not use high-pressure air to hasten the drying process since this could cause the

liquid to collect in unwanted places. After completing of the cleaning process, use a soft, absorbent,

lintless cloth to dry the area. Do not brush or apply any isopropyl alcohol to the frame, front cover, or

top cover.

NOTE

Always use a fresh supply of alcohol and a clean container to prevent contamination by

dissolved material (from previous usage).

3.0 Safe Handling of CMOS and LDMOS Devices

Complementary metal-oxide semiconductor (CMOS) devices are used in this family of radios, and

are susceptible to damage by electrostatic or high voltage charges. Damage can be latent, resulting

in failures occurring weeks or months later. Therefore, special precautions must be taken to prevent

device damage during disassembly, troubleshooting, and repair.

Handling precautions are mandatory for CMOS circuits and are especially important in low humidity

conditions. DO NOT attempt to disassemble the radio without first referring to the following

CAUTION statement.

CAUTION: This radio contains static-sensitive devices. Do not open the radio unless you are

properly grounded. Take the following precautions when working on this unit:

• Store and transport all CMOS devices in conductive material so that all exposed

leads are shorted together. Do not insert CMOS devices into conventional plastic

“snow” trays used for storage and transportation of other semiconductor devices.

• Ground the working surface of the service bench to protect the CMOS device. We

recommend using the Motorola Static Protection Assembly (part number

0180386A82), which includes a wrist strap, two ground cords, a table mat, and a

floor mat.

• Wear a conductive wrist strap in series with a 100k resistor to ground.

(Replacement wrist straps that connect to the bench top covering are Motorola part

number 4280385A59)

• Do not wear nylon clothing while handling CMOS devices.

• Do not insert or remove CMOS devices with power applied. Check all power

supplies used for testing CMOS devices to be certain that there are no voltage

transients present.

• When straightening CMOS pins, provide ground straps for the apparatus used.

• When soldering, use a grounded soldering iron.

• If at all possible, handle CMOS devices by the package and not by the leads. Prior

to touching the unit, touch an electrical ground to remove any static charge that you

may have accumulated. The package and substrate may be electrically common. If

so, the reaction of a discharge to the case would cause the same damage as

touching the leads.

Page 17

Repair Procedures and Techniques — General 2-3

4.0 Repair Procedures and Techniques — General

Parts Replacement and Substitution

When damaged parts are replaced, identical parts should be used. If the identical replacement part

is not locally available, check the parts list for the proper Motorola part number and order the part

from the nearest Motorola Parts center listed in the “Piece Parts” section in Chapter 1 of this manual.

Rigid Circuit Boards

This family of radios uses bonded, multi-layer, printed circuit boards. Since the inner layers are not

accessible, some special considerations are required when soldering and unsoldering components.

The printed-through holes may interconnect multiple layers of the printed circuit. Therefore, exercise

care to avoid pulling the plated circuit out of the hole.

When soldering near the RF connector, potentiometer, 16-pin and 20-pin connectors:

• Avoid accidentally getting solder in the connector.

• Be careful not to form solder bridges between the connector pins.

• Examine your work closely for shorts due to solder bridges.

5.0 Disassembling and Reassembling the Radio — General

Since these radios may be disassembled and reassembled with the use of only 14 (board to casting)

screws, it is important to pay particular attention to the snaps and tabs, and how parts align with

each other.

The following tools are required for disassembling/assembling the radio:

• Small flat blade screwdriver

• Phillips small 1# screwdriver

• TORX™ T9 screwdriver

• TORX™ T10 screwdriver

• Torque screwdriver set

• Torque spanner

• Hex tool (part no. 6680334F39)

If a unit requires more complete testing or service than is customarily performed at the basic level,

send this unit to a Motorola Authorized Service Center. (See Chapter 1 for a list of authorized

service centers.)

The following disassembly procedures should be performed only if necessary:

Page 18

2-4 MAINTENANCE

6.0 Radio Disassembly - Detailed

The procedure to remove and replace a Control Head, Top Cover or Transceiver Board is similar for

all models of radio. A typical procedure is therefore shown followed by specific disassembly

procedures for Control Heads on radio models without a display and radio models fitted with a

display.

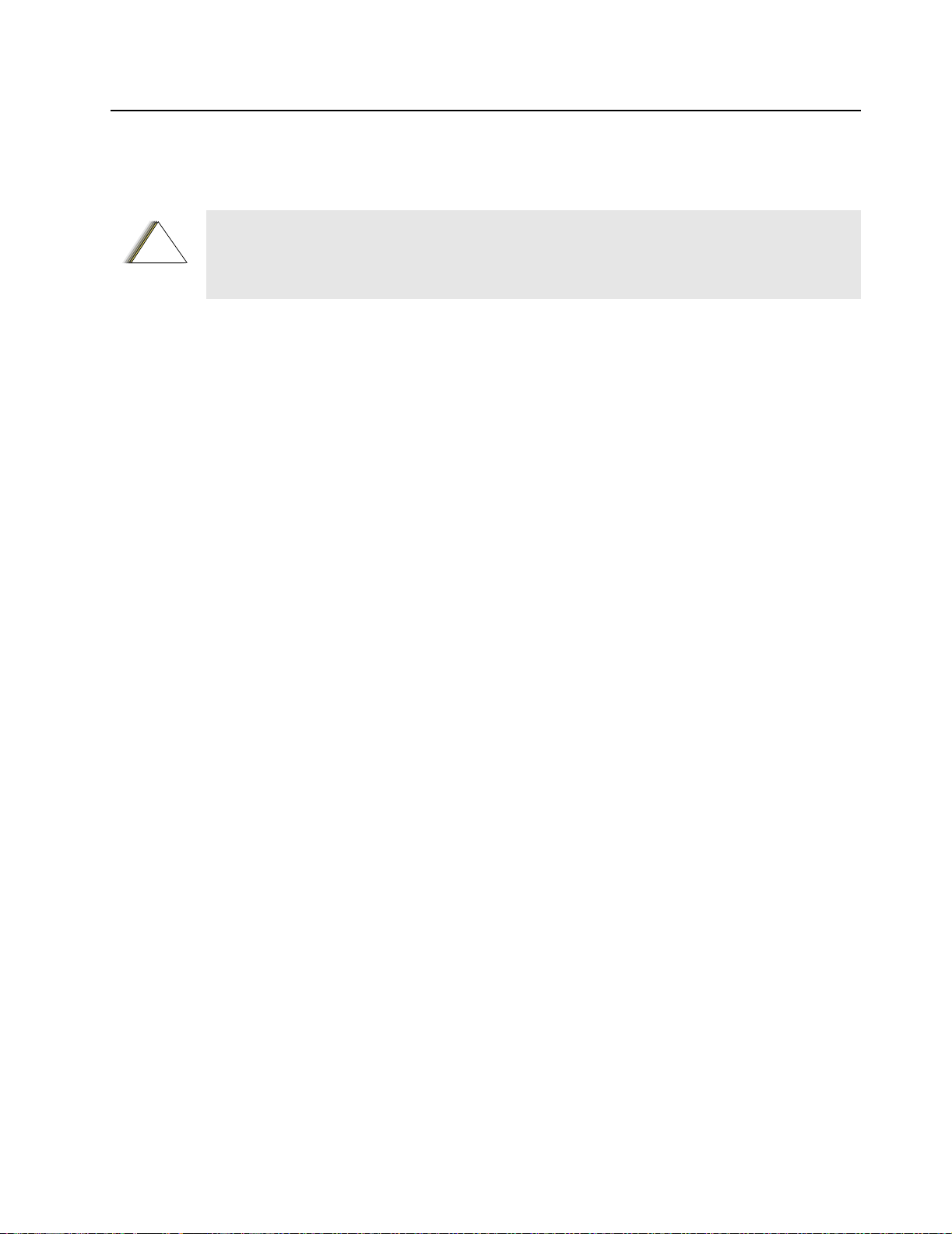

6.1 Control Head Removal

NOTE

Volume Knob Removal

Ensure that the volume knob is in the OFF position before disassembling the radio.

1. Insert the flat screwdriver between the control head plastic and the volume knob and push the

volume knob upwards. See Figure 2-1.

Figure 2-1 Volume Knob Removal.

2. Insert the flat screw driver (4 mm maximum) into the slot and push the plastic up.

Do the same with the second slot to free the control head from the chassis assembly. See

Figure 2-2.

Page 19

Radio Disassembly - Detailed 2-5

Figure 2-2 Control Head Removal

3. To free the control head, disconnect the flat cable from the chassis assembly See Figure 2-3.

Main PCB Connector

Figure 2-3 Flat Cable Removal

Page 20

2-6 MAINTENANCE

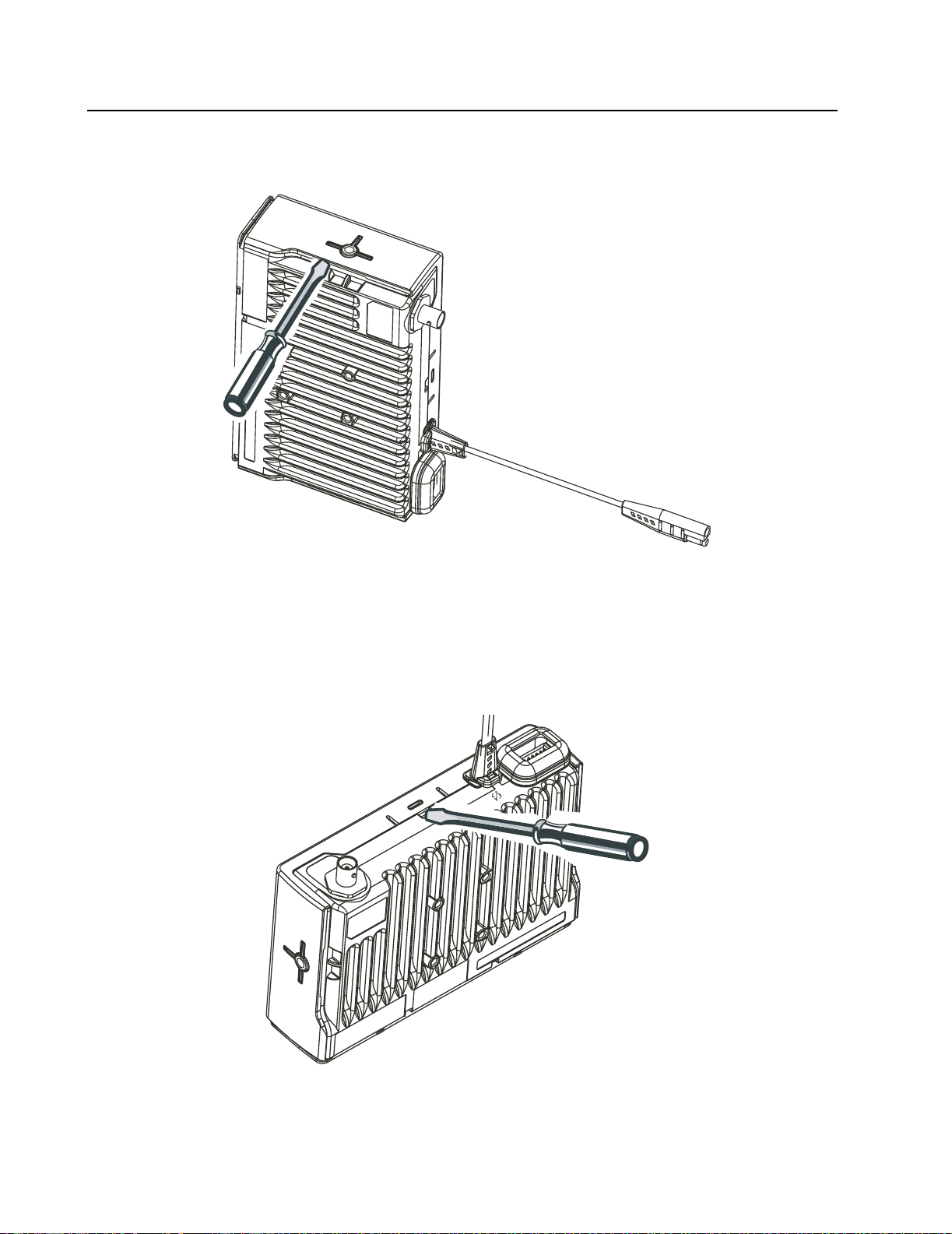

6.2 Top Cover Removal

1. Place the radio in a vertical position as shown in Figure 2-4.

Figure 2-4 Top Cover Removal (Chassis Vertical).

2. Insert the flat screw driver near the ‘T’ and push the plastic cover up until it pops over the ‘T’

mount boss. Perform the same function on the ‘T’ location on the other side of the chassis.

3. Next place the radio in a horizontal position as shown in Figure 2-5 and insert the flat screw

driver into the slot to release the upper cover.

Figure 2-5 Top Cover Removal (Chassis Horizontal)

Page 21

Radio Disassembly - Detailed 2-7

6.3 Main Shield Removal

1. Insert the screw driver in the gap between the main shield and chassis (speaker cutout area)

and push the shield up. See Figure 2-6.

2. Lift the cover from the chassis.

Figure 2-6 Main Shield Removal

6.4 PA Shield and DC Cable Removal

1. Remove the three screws that attach the PA shield to PCB, and remove the PA shield.

2. Remove the accessory Connector cap.

3. Remove the two screws that attach the DC power cable to the PCB and pull it out from the

side.

DC

Cable

DC Cable

Accessory

Connector

Cap

Fixing Screws

(2)

PA Shield

Fixing Screws (3)

Figure 2-7 PA Shield and DC Cable Removal (for Low Power Models)

Page 22

2-8 MAINTENANCE

Figure 2-8 PA Shield and DC Cable Removal (for High Power Models)

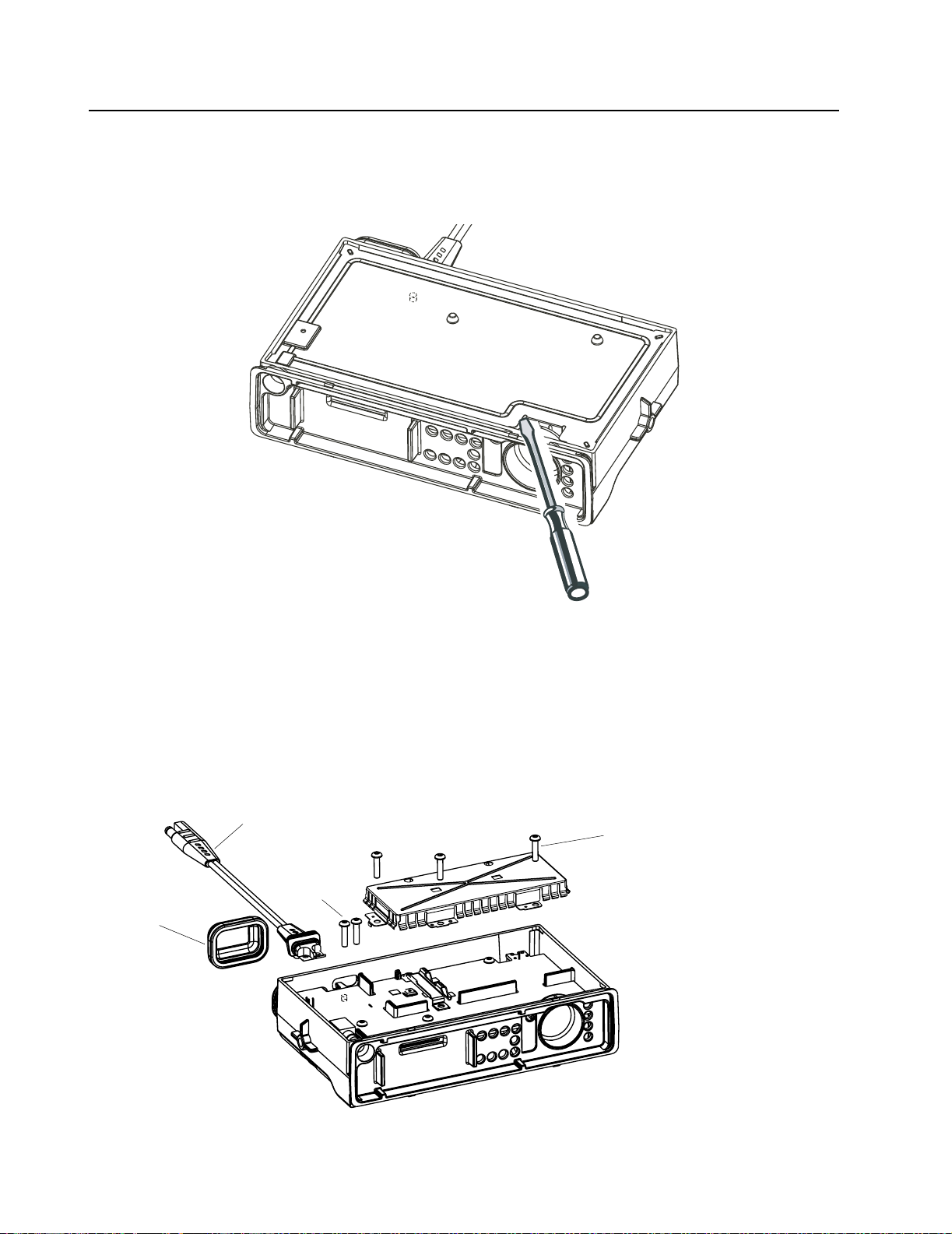

6.5 PA Clip and Main PCB Removal (for Low Power Models)

1. Remove the screw that attaches the PA clip to the chassis. See Figure 2-9.

2. Remove the PA clip.

3. Remove all the screws that fix the PCB to the chassis.

4. Loosen the M2 screw (about 3 to 4 turns) on the RF connector using hex tool

(Part number: 6680334F39).

5. Loosening this screw, enables you to unscrew the RF connector from outside.

6. Carefully remove the main PCB in a diagonal manner.

NOTE

It is recommended to grip the volume potentiometer and remove the PCB board

Main PCB

PA Clip

M2 Screw

Figure 2-9 PA Clip and Main PCB Removal (for Low Power Models)

Page 23

Radio Disassembly - Detailed 2-9

6.6 Main PCB Removal (for High Power Models)

1. Remove the PA screws. See Figure 2-10.

2. Remove all the screws that fix the PCB to the chassis.

3. Loosen the M2 screw (about 3 to 4 turns) on the RF connector using hex tool

(Part number: 6680334F39).

4. Loosening this screw, enables you to unscrew the RF connector from outside.

5. Carefully remove the main PCB in a diagonal manner.

NOTE

It is recommended to grip the volume potentiometer and remove the PCB board

Figure 2-10 PA Clip and Main PCB Removal (for High Power Models)

Page 24

2-10 MAINTENANCE

6.7 Disassembly of Control Head - CM200

1. Disconnect the flat cable from the Control Head PCB connector. See Figure 2-11.

2. Remove the PCB from the keypad assembly.

3. Remove the LENs from the rubber keypad assembly.

4. Remove the keypad assembly from the control head housing by lifting it up from the face

side.

5. Disconnect the speaker socket and remove the speaker from the keypad assembly.

NOTE

.

DO NOT touch or contaminate the conductive pads on the under side of the keypad

or the conductive contacts on the printed circuit board.

Control Head Housing

Keypad Assembly

Lens

PCB

Speaker

Figure 2-11 Control Head Housing Removal CM200

Page 25

Radio Disassembly - Detailed 2-11

6.8 Disassembly of Control Heads - CM300/PM400

1. Disconnect the flat cable from the Control Head PCB connector. See Figure 2-12.

2. Remove the PCB from the keypad assembly.

3. Remove the LCD assembly from the rubber keypad assembly.

4. Remove the keypad assembly from the control head housing by lifting it up from the face side.

5. Disconnect the speaker socket and remove the speaker from the keypad assembly.

NOTE

DO NOT touch or contaminate the conductive pads on the under side of the keypad,

the conductive contacts on the printed circuit board or the elastomeric connector.

Control Head Housing

Speaker

Figure 2-12 Control Head Housing Removal CM300/PM400

Keypad Assembly

LCD Assembly

PCB

Page 26

2-12 MAINTENANCE

7.0 Radio Assembly

7.1 Chassis Assembly (for Low Power Models)

1. Ensure that the Fuji Poly Thermal Pad is on the small pedestal located on the PA

compartment of the chassis.

2. Verify that the potentiometer is soldered properly.

3. Take the main PCB and smear thermal paste on LDMOS Power Amplifier, TO220, and Audio

Power Amplifier.

4. Slide the main board diagonally into the chassis.

5. Tighten all eight screws (Torx T10).

6. Assemble the O-ring on the RF connector and tighten it using Torque 22 lb.in.

7. Tighten the RF connector security screw M2 using Torque 1.5 lb. (through the opening in the

PCB).

8. Take the Power Amplifier Clip and insert the leg-shape side into the opening groove located

on the PCB. Tighten the screw using Torque 13 lb.in

9. Take the PA Shield and place it on the PA compartment. Tighten the three screws using

Torque 13 lb.in. Tighten the middle screw first, then the screw located on the left side, and

lastly the screw located on the right side.

10. Insert the DC cable into the slot. Ensure that it is seated correctly on the chassis hook located

below the DC cable. Attach it to the chassis and PCB by tightening the two screws using

Torque 13 lb.in (Torx T10).

11. Take the main shield and place it on the chassis. Check that the corners of the main shield

are seated properly on the corner supports.

12. Take the main seal and place it inside the top cover. Verify that the main seal is seated properly on its placement ribs and all around the groove.

13. Take the upper cover, place it properly on the chassis, and push it down. Three click sounds

are heard from both sides and back.

7.2 Chassis Assembly (for High Power Models)

1. Verify that the potentiometer is soldered properly.

2. Take the main PCB and smear thermal paste on T0220 and Audio Power Amplifier.

3. Slide the main board diagonally into the chassis.

4. Tighten all eight screws (Torx T10).

5. Assemble the O-ring on the RF connector and tighten it using Torque 22 lb.in.

6. Tighten the RF connector security screw M2 using Torque 1.5 lb. (through the opening in the

PCB).

7. Take two PA Screws and place in screw holes over PA. Tighten the screws using Torque 13

lb.in.

8. Take the PA Shield and place it on the PA compartment. Tighten the three screws using

Torque 13 lb.in. Tighten the middle screw first, then the screw located on the left side, and

lastly the screw located on the right side.

9. Insert the DC cable into the slot. Ensure that it is seated correctly on the chassis hook located

below the DC cable. Attach it to the chassis and PCB by tightening the two screws using

Torque 13 lb.in. (Torx T10).

Page 27

Radio Assembly 2-13

10. Take the main shield and place it on the chassis. Check that the corners of the main shield are

seated properly on the corner supports.

11. Take the main seal and place it inside the top cover. Verify that the main seal is seated properly on its placement ribs and all around the groove.

12. Take the upper cover, place it properly on the chassis, and push it down. Three click sounds

are heard from both sides and back.

7.3 Control Heads Assembly

1. Assemble the Control Heads by reversing the procedure for dis-assembly..

NOTE

Care should be taken not to touch or contaminate the conductive strip connectors and keypad conductors on the underside of the display and the elastomeric connectors (GM3689

only).

7.4 Control Head Fitting

1. Hold the Control Head in one hand and the chassis assembly in the other hand.

2. Insert the flat cable into the main PCB connector through the slot in the chassis.

3. Place the Control Head Assembly on the chassis assembly in a diagonal manner. Two clicking

sounds are heard.

4. Insert the Volume Knob into its groove and push it in.

5. Place the cap of the accessory connector over the accessory pin.

Page 28

2-14 MAINTENANCE

7.5 Option Board Installation

1. Follow the disassembly procedure in paragraphs 6.1 to 6.3.

2. Remove and discard the 4xM3 screws holding the main pcb and replace with the 4 spacers

provided. Torque the spacers to 10 lbs.

3. Insert the jumper flex into the connector on the option board. Notice the orientation of the

right-angle flex circuit.

4. Insert the other end of the jumper flex into the connector on the main pcb.

5. Fold the flex circuit under the option board.

6. Position the option board over the spacers and retain using the 4xM2 screws provided.

M2 Screws

Option Board

Flex

Spacers

4xM3 screws

(replaced by spacers)

Figure 2-13 Option Board Installation

7. With the option board correctly in place, the main shield and top cover can be assembled as

detailed in paragraph 7.1 steps 11 to 13.

Page 29

Radio Exploded Mechanical Views and Parts Lists 2-15

8.0 Radio Exploded Mechanical Views and Parts Lists

8.1 Radio Assembly - 1-25 W Models

Figure 2-14 Radio Assembly - 1-25 W Models

Table 2-1 Radio Assembly Parts List - 1-25 W Models

Item No. Description Part Number

1 Upper Cover 1589224U01

2 Main Seal 3289329U01

3 Bumper 7587509V06

4 Main Shield 2689338U01

5 PA Shield 2689337U01

6 Screw 0310943J12

7 PA Clip 0789352U01

8 VHF Main PCB

UHF Main PCB

9 Connector Jack:

Mini UHF

BNC

10 O-Ring 5802810C15

11 Power Cable Assembly 0189484U01

12 Cap, Accessory Connector 3202607Y01

13 Chassis 25W 2789223U01

14 Felt 3586661Z01

See Chapter 7 Model

Charts and

Specifications.

5802810C15

5802810C16

Page 30

2-16 MAINTENANCE

8.2 Radio Assembly - 25-40 W/25-45 W Models

Figure 2-15 Radio Assembly - 25-40 W/25-45 W Models

Table 2-2 Radio Assembly Parts List - 25-40 W/25-45 W Models

Item No. Description Part Number

1 Upper Cover 1589224U01

2 Main Seal 3289329U01

3 Main Shield 2689338U01

4 PA Shield 2689337U01

5 Screw 0310943J12

6 VHF Main PCB (45W)

UHF Main PCB (40W)

7 Connector Jack:

Mini UHF

BNC

8 O-Ring 5802810C15

9 Power Cable Assembly 0189484U01

10 Cap, Accessory Connector 3202607Y01

11 Chassis 40W 2789223U02

12 Felt 3586661Z01

13 PA S c r e w 0386663Z01

14 Bumper 7587509V06

See Chapter 7 Model

Charts and

Specifications.

5802810C15

5802810C16

Page 31

Radio Exploded Mechanical Views and Parts Lists 2-17

8.3 Control Head - CM200

1

2

3

4

5

Figure 2-16 Control Head CM200

Table 2-3 Control Head CM200 Parts List

7

9

6

Item no Description Part No

1 Control Head PCB 8488998U01

2 Lens 6189338U01

3 Keypad 7589330U01

4 Control Head Plastic 1589332U01

5 Knob Spring (part of knob - item 6)

6 Knob, Volume 3689331U02

7 Speaker 5005156Z02

8 Flat Cable (not shown) 3089305U01

9 Nameplate 5487790V03

Page 32

2-18 MAINTENANCE

8.4 Control Head - CM300/PM400

1

4

5

7

2

3

6

8

9

Figure 2-17 Control Head - CM300/PM400

Table 2-4 Control Head CM300/PM400 Parts List

Item no Description Part No.

1 Control Head PCB 8489714U01

2 Light Guide 6189624U01

3 Elastomeric Connector 2802619S03

4 LCD Holder 0789623U01

5 LCD 7202421H33

6 Keypad 7589340U01

7 Speaker 5005156Z02

8 Control Head Plastic

CM300

PM400

9 Knob Spring (part of Knob - item 10)

10 Knob 3689331U02

11 Lens:

CM300

PM400

12 Flat Cable (Not Shown) 3089305U01

1586605Z01

1589333U01

6189339U07

6189339U04

11

10

Page 33

Service Aids 2-19

9.0 Service Aids

Table 2-5 lists the service aids recommended for working on the radio. While all of these items are

available from Motorola, most are standard workshop equipment items, and any equivalent item

capable of the same performance may be substituted for the item listed.

Table 2-5 Service Aids

Motorola Part

No.

RLN4460_ Portable Test Set Enables connection to audio/accessory jack.

HVN4191_ Customer Programming

Software (CPS) - Software on

CDROM & Global Tuner

RKN4081_ Programming Cable with

Internal RIB

FKN8096_ Data/Flash Adapter Key Used with RKN4081 (10 to 8 pin adapter for

RKN4083_ Mobile Programming/Test Cable Connects radio to RIB (RLN4008_).via rear

FKN8113_ Adapter Cable Used with RKN4083 (20 to 16 pin adapter for

GTF 37 4 _ Program Cable Connects RIB to Radio microphone input.

RLN4008_ Radio Interface Box Enables communications between radio and

Description Application

Allows switching for radio testing.

Programs customer options and channel data.

Includes radio interface box (RIB) capability.

front Telco connector with Data/Flash switch).

accessory connector

rear accessory connector).

computer’s serial communications adapter.

HSN9412_ Wall-Mounted Power Suppy Used to power the RIB. (120 V ac)

HLN8027_ Mini UHF to BNC Adaptor Adapts radio antenna port to BNC cabling of

test equipment.

8180384N64 Housing Eliminator (25W) Test Fixture used to bench test the radio pcb.

3080369B71 Computer Interface Cable Connects the RIB to the Computer (25-pin).

3080369B72 Computer Interface Cable Connects the RIB to the Computer (9-pin)

(Use for IBM PC AT - other IBM models use

the B71 cable above).

6686119B01 Removal Tool Assists in the removal of radio control head.

6680334F39 Hex Tool Assists in the removal of antenna connector.

Page 34

2-20 MAINTENANCE

10.0 Test Equipment

Table 2-6 lists test equipment required to service the radio and other two-way radios

.

Table 2-6 Recommended Test Equipment

Motorola Part No. Description Characteristics Application

R2000, R2600

R2400, or R2001

with trunking

option for Privacy Plus™ and

Smartnet Systems™

*R1049 Digital Multimeter Two meters recommended for AC/

*S1100 Audio Oscillator 67 to 200Hz tones Used with service monitor for injec-

*S1053,

*S K N6009,

*SKN6001

R1053 Dual-trace Oscillo-

R1443A Broadband Watt-

†

Service Monitor This monitor will

substitute for items

listed below with an

asterisk *

AC Voltmeter,

Power Cable

for meter,

Test leads for meter

scope

meter

• 1 mV to 300 V

• 10 MΩ input impedance

20 MHz bandwidth,

5 mV/cm - 20 V/cm

Frequency/deviation meter and signal generator for wide-range troubleshooting and alignment

DC voltage and current measurements

tion of PL tones

Audio voltage measurements

Waveform measurements

Transmitter power output measurements

S1339 RF Millivolt Meter 100 µV to 3 VRF, 10

kHz to 1.2 GHz

*R1013 SINAD Meter Receiver sensitivity measurements

S1348 (prog) DC Power Supply 0-20 Vdc, 0-20 Amps Bench supply for 13.8Vdc

RF level measurements

Page 35

Programming/Test Cable - RKN4083_ 2-21

11.0 Programming/Test Cable - RKN4083_

FLO830308-0

J1 (Female)

To RIB

RLN4008

13

25

+

_

1

14

1

14

+

_

1000 50mm

Cable

1

19

20

2

P1 (Male)

To Radio

Test Set

13

25

1000 50mm

To Mobile Radio

17

18

Cable

J2 (Female)

Accessory

Connector

Viewed from

Front (pin end)

of Connector

Note: Use with Adapter Cable FKN8113_

FL0830308O

Figure 2-18 Programming/Test Cable

SPEAKER -

EXTERNAL MIC

DIGITAL IN 1 (EXT. PTT)

DIGITAL OUT 2 (EXT. ALARM)

FLAT TX AUDIO SENSITIVITY

DIGITAL IN 3/MPT MAP 27 RX

DIGITAL IN/OUT 4/MPT MAP 27 TX

DIGITAL IN 5 w WAKEUP (EMG)

FLAT/FILTERED RX AUDIO

SWITCHED BATTERY VOLTAGE

BUS + (FOR CPS AND FLASHING)

FL0830307O

IGNITION

DIGITAL IN/OUT 7

DIGITAL IN/OUT 8

SPEAKER +

BOOT CONTROL

GND

RSSI

N/C

N/C

J2 Mobile

Radio

Accessory

Connector

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

P1

To Radio

Test Set

RLN4460

10

15

16

18

19

20

25

J1

To RIB

RLN4008

11

12

15

25

AUDIO +

1

AUDIO -

2

AUDIO +

5

AUDIO -

7

MIC AUDIO

MIC AUDIO

GND

VOL CTRL

DISC

PTT

BOOT CTRL

1

GND

4

BIAS

BUS SW B +

BUS +

BOOT CTRL

Figure 2-19 Pin Configuration of RKN4083

FLO830307-0

Page 36

2-22 MAINTENANCE

12.0 Adapter Cable - FKN8113_

SPEAKER -

EXTERNAL MIC

EXT. PTT

FLAT TX AUDIO SENSITIVITY

BUS+ (FOR CPS AND FLASHING)

GND

SWITCHED BATTERY VOLTAGE

SPEAKER +

1

2

16-pin Female

To Radio

Accessory

Connector

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

15

16

20-pin Male

To Prog/Test

Cable

RKN4083_

SPEAKER -

1

EXTERNAL MIC

2

EXT.PTT

3

EXT ALARM

4

FLA T TX AUDIO

5

DIG IN

6

GND

7

DIG I/O

8

DIG IN

9

IGNITION

10

FLAT/FILTERED RX AUDIO

11

DIG IN

12

SWITCHED BATTERY VOLTAGE

13

DIG IN

14

RSSI

15

SPEAKER +

16

BUS +

17

BOOT CONTROL

18

N/C

19

N/C

20

Viewed from

Front (pin end)

of Connector

Figure 2-20 Pin Configuration of FKN8113

Page 37

1.0 General

These radios meet published specifications through their manufacturing process by utilizing highaccuracy laboratory-quality test equipment. The recommended field service equipment approaches

the accuracy of the manufacturing equipment with few exceptions. This accuracy must be

maintained in compliance with the manufacturer’s recommended calibration schedule.

2.0 Setup

Supply voltage is provided using a power supply (13.8 Vdc for low power models, 13.6 Vdc for high

power models). The equipment required for alignment procedures is connected as shown in the

Radio Tuning Test Setup Diagram, Chapter 4, Figure 4-6.

Initial equipment control settings should be as indicated in Table 3-1. The remaining tables in this

chapter contain the following related technical data:

Chapter 3

TRANSCEIVER PERFORMANCE TESTING

Table Number Title

3-2 Test Environments

3-3 Test Channel Spacing

3-4 Test Frequencies

3-5 Transmitter Performance Checks

3-6 Receiver Performance Checks

Table 3-1 Initial Equipment Control Settings

Service Monitor Test Set Power Supply

Monitor Mode: Power Monitor Spkr set: A Voltage: 13.8 Vdc (low

power models) 13.6 Vdc

(high power models)

RF Attn: -70 Spkr/load:

Speaker

AM, CW, FM: FM PTT: OFF Volt Range: 20V

Oscilloscope Source: Mod

Oscilloscope Horiz: 10mSec/Div

Oscilloscope Vert: 2.5 kHz/Div

Oscilloscope Trig: Auto

Monitor Image: Hi

Monitor BW: Nar

Monitor Squelch: mid CW

Monitor Vol: 1/4 CW

DC On/Standby:

Standby

Current: 20A

Page 38

3-2 TRANSCEIVER PERFORMANCE TESTING

3.0 RF Test Mode

When the radio is operating in its normal environment, it is not possible to test all individual aspects

of the transmitter and receiver performance. Therefore a special “test mode” is used to allow the

service technician to perform certain functional tests on the product. A control head fuctional test

mode is also available.

To enter test mode (display radios):

1. Turn the radio on.

2. Within ten seconds after the self test is complete, press button P2, five times in succession.

3. Channel number appears in the display. The radio is on channel XX*, carrier squelch mode,

25 kHz channel spacing.

4. Each additional press of P2 scrolls through to the next channel spacing and a corresponding

set of tones are sounded.

5. Pressing P1 scrolls through and accesses test environments as shown in Table 3-2.

6. Pressing P2 for three seconds switches the radio to the control head test mode and zero

appears on the display.

7. Pressing P1 causes the radio to display the channel number “1”. Another P1 press causes

the radio to display the next channel “2”, and so on until channel “9”.

8. Pressing P1 at the end of the LCD test activates the ‘LED Test’. The next P1 press turns the

LEDs and dot On/Off.

9. Pressing P1 at the end of the LED test activates the button test. Pressing any button (except

P1) or any keypad button during the LCD test or Icon test immediately activates this test.

10. Pressing P2 for 3 seconds in the control head test mode causes the radio to return to the RF

test mode.

*XX = channel number (01 - 06)

Table 3-2 Test Environments

No. of

Beeps

1 Carrier Squelch RX: if carrier detected

1Tone

2 Digital

3Dual-Tone

9 MDC1200

5 Unsquelch

11 CMP RX: if carrier detected

Description Function

TX: mic audio

RX: unsquelch if carrier and tone (192.8H z) detected

Private-Line

RX: unsquelch if carrier and digital code (131) detected

Private-Line

multiple

frequency

HSS

Open

TX: mic audio + tone (192.8 Hz)

TX: mic audio + digital code (131)

RX: unsquelch if carrier detected

TX: selected DTMF tone pair

RX: unsquelch if carrier detected

TX: 1500 Hz tone

RX: constant unsquelch

TX: mic audio

TX: mic audio

Page 39

RF Test Mode 3-3

Table 3-3 Test Channel Spacing

Number of Beeps Channel Spacing

1 25 kHz

2 12.5 kHz

3 20 kHz

Table 3-4 Test Frequencies

Channel Display Test Channel

1 Low Power

8 High Power

2 Low Power

9 High Power

3 Low Power

10* High Power

4 Low Power

11* High Power

5 Low Power

12* High Power

6 Low Power

13* High Power

7 Low Power

14* High Power

TX#1 or #8

RX#1 or #8

TX#2 or #9

RX#2 or #9

TX#3 or #10

RX#3 or #10

TX#4 or #11

RX#4 or #11

TX#5 or #12

RX#5 or #12

TX#6 or #13

RX#6 or #13

TX#7 or #14

RX#7 or #14

VHF

(136-162

MHz)

136.125 146.025 438.025 465.225

140.275 150.700 443.300 470.225

144.675 155.300 448.700 475.225

149.125 160.000 454.000 480.225

153.475 164.700 459.300 485.225

157.775 169.300 464.700 490.225

161.775 173.025 469.025 494.775

VHF

(146-174

MHz)

UHF

(438-470

MHz)

* The CM200 displays only the 2nd digit and the high power indicator is illuminated.

UHF

(465-495

MHz)

Table 3-5 Transmitter Performance Checks

Test Name Communications Analyzer Radio Test Set Comment

Reference

Frequency

Mode: PWR MON

4th channel test frequency*

Monitor: Frequency error

Input at RF In/Out

TEST MODE,

Test Channel 4

carrier squelch

PTT to

continuous

(during the

performance

check)

Frequency error to

be: ±186 Hz VHF1

±200 Hz VHF2

±568 Hz UHF2

±600 Hz UHF3

Power RF As above As above As above 1-25 W

Page 40

3-4 TRANSCEIVER PERFORMANCE TESTING

Table 3-5 Transmitter Performance Checks (Continued)

Test Name Communications Analyzer Radio Test Set Comment

Voice

Modulation

Voice

Modulation

(internal)

High-Speed

Data

Modulation

Mode: PWR MON

As above As above,

4th channel test frequency*

atten to -70, input to RF In/ Out

Monitor: DVM, AC Volts

Set 1kHz Mod Out level for

800mVrms at test set,

800mVrms at AC/DC test set

jack

Mode: PWR MON

4th channel test frequency*

atten to -70, input to RF In/ Out

TEST MODE,

Test Channel 4

carrier squelch

output at

antenna

As above TEST MODE,

Test Channel 4

high speed

output at

antenna

meter selector

to mic

Remove

modulation

input

PTT to

continuous

(during the

performance

check).

Deviation:

2.5 kHz Max.

(12.5 kHz Ch. Sp).

4 kHz Max.

(20 kHz Ch. Sp).

5 kHz Max.

(25 kHz Ch. Sp).

Deviation:

2.5 kHz Max.

(12.5 kHz Ch. Sp.).

4 kHz Max.

(20 kHz Ch. Sp.).

5 kHz Max.

(25 kHz Ch. Sp.).

Deviation:

1.5-2.0 kHz

(12.5 kHz Ch. Sp.).

2.3-3.2 kHz

(20 kHz Ch. Sp.).

3.0-4.0 kHz

(25 kHz Ch. Sp.).

DTMF

Modulation

PL/DPL

Modulation

* See Table 3-4.

As above,

4th channel test frequency*

As above

4th channel test frequency*

BW to narrow

TEST MODE,

Test Channel 4

DTMF output at

antenna

TEST MODE,

Test Channel 4

TPL

DPL

As above Deviation:

1.4-1.9 kHz

(12.5 kHz Ch. Sp.).

2.3-3.0 kHz

(20 kHz Ch. Sp.).

2.9-3.8 kHz

(25 kHz Ch. Sp.).

As above Deviation:

0.25-0.5 kHz

(12.5 kHz Ch. Sp.).

0.4-0.8 kHz

(20 kHz Ch. Sp.)

0.5-1.0 kHz

(25 kHz Ch. Sp.).

Page 41

RF Test Mode 3-5

Table 3-6 Receiver Performance Checks

Test Name Communications Analyzer Radio Test Set Comment

Reference

Frequency

Rated Audio Mode: GEN

Mode: PWR MON

4th channel test frequency*

Monitor: Frequency error

Input at RF In/Out

Output level: 1.0mV RF

4th channel test frequency*

Mod: 1kHz tone at

TEST MODE,

Test Channel 4

carrier squelch

output at

antenna

TEST MODE

Test Channel 4

carrier squelch

PTT to

continuous

(during the

performance

check)

PTT to OFF

(center),

meter selector

to Audio PA

Frequency error to

be: ±186 Hz VHF1

±200 Hz VHF2

±568 Hz UHF2

±600 Hz UHF3

Set volume control

to 8.10Vrms

3kHz deviation

Monitor: DVM: AC Volts

Distortion As above, except to distortion As above As above Distortion <5.0%

Sensitivity

(SINAD)

As above, except SINAD,

lower the RF level for 12dB

As above PTT to OFF

(center)

RF input to be

<0.3µV

SINAD.

Noise

Squelch

Threshold

(only radios

with

conventiona

l system

RF level set to 1mV RF As above PTT to OFF

(center),

meter

selection to

Audio PA,

spkr/ load to

speaker

Set volume control

to 3.16Vrms

need to be

tested)

As above, except change

frequency to a conventional

system. Raise RF level from

zero until radio unsquelches.

* See Tables 3-4.

out of TEST

MODE; select a

conventional

system

As above Unsquelch to occur

at <0.25µV.

Preferred SINAD =

9-10dB

Page 42

3-6 TRANSCEIVER PERFORMANCE TESTING

THIS PAGE INTENTIONALLY LEFT BLANK

Page 43

1.0 Introduction

This chapter provides an overview of the Customer Programming Software (CPS) and tuner

program designed for use in a Windows 98/ME/NT/2000 environment.

Chapter 4

RADIO TUNING AND PROGRAMMING

NOTE

Refer to the CPS on-line help files for programming procedures.

Table 4-1 Software Installation Kits Radio Tuning Setup

Description Kit Number

CPS RVN4191_

2.0 CPS Programming/Flashing Setup with RIB

The CPS programming setup, shown in Figure 4-1 is used to program and flash the radio using the

Radio front Telco connector.

ACC

FKN8096

Data =Programming

Boot = Flashing

8-pin Telco

FKN8096

10-pin Telco

Radio

DC

RF

Power

Supply

Programming

Cable

3080070N01

DB25

RIB

RLN-4008

DB15

Cable 3080369B72 (9 PIN)

Cable 3080369B71 (25 PIN)

Tx Data

Rx

Data

Gnd

Figure 4-1 CPS Programming/Flashing Setup with RIB

Page 44

4-2 RADIO TUNING AND PROGRAMMING

3.0 CPS Programming/Flashing Setup Ribless

The CPS programming setup, shown in Figure 4-2 is used to program and flash the radio using the

Radio front Telco connector.

ACC

FKN8096

Data =Programming

Boot = Flashing

8-pin Telco

FKN8096

10-pin Telco

Radio

DC

RF

Power

Supply

DB25

Tx Data

Rx Data

Gnd

Ribless Programming Cable RKN4081

Figure 4-2 CPS Programming/Flashing Setup Cable with Internal RIB

4.0 CPS Programming Setup with RIB (with Telco Connector)

The CPS programming setup, shown in Figure 4-3 is used to program the radio using the Radio front

Telco connector.

ACC

Programming

Cable

GTF374

Radio

DB25

DC

RF

RLN-4008

Power

Supply

DB15

RIB

Cable 3080369B72 (9 PIN)

Cable 3080369B71 (25 PIN)

Tx Data

Rx

Data

Gnd

Figure 4-3 CPS Programming Setup with RIB

Page 45

CPS Programming Setup with RIB (Accessory Connector) 4-3

5.0 CPS Programming Setup with RIB (Accessory Connector)

The CPS programming setup, shown in Figure 4-4 is used to program the radio using the Radio rear

accessory connector.

Adapter Cable

FKN8113

Power

Supply

Programming/Test

Cable

RKN4083

Figure 4-4 CPS Programming Setup Cable with RIB and Rear Adapter Cable

ACC

DC

RF

DB25

Radio

RIB

RLN-4008

DB15

Cable 3080369B72 (9 PIN)

Cable 3080369B71 (25 PIN)

Tx Data

Rx

Data

Gnd

6.0 CPS Programming Setup with RIB

The CPS programming setup, shown in Figure 4-5 is used to program the radio using the Radio rear

accessory connector.

Cable

GTF377

Power

Supply

Programming

Cable

GTF374

Figure 4-5 CPS Programming Setup Cable with RIB and Rear Adapter Cable

ACC

DC

RF

DB25

Radio

RIB

RLN-4008

DB15

Cable 3080369B72 (9 PIN)

Cable 3080369B71 (25 PIN)

Tx Data

Rx

Data

Gnd

Page 46

4-4 RADIO TUNING AND PROGRAMMING

7.0 Radio Tuning Setup

A personal computer (PC), Windows 95/98/NT and a tuner program are required to tune the radio.

To perform the tuning procedures, the radio must be connected to the PC, radio interface box (RIB),

and test equipment setup as shown in Figure 4-6.

Tes t B ox

RLN4460

ELM Adapter

cable FKN8113

ACC

DC

Radio

RF

Program/

RKN4083

Power

Supply

30 dB Pad

Tes t Ca b le

RLN-4008

RIB

Cable 3080369B72 (9 PIN)

Cable 3080369B71 (25 PIN)

Figure 4-6 Radio Tuning Test Equipment Setup with External RIB

7.1 Initial Test Equipment Control Settings

The initial test equipment control settings are listed in Table 4-2.

DB15

Audio In

Transmit

Receive

Tx

Audio Generator

Rx

Sinad Meter

AC Voltmeter

Tx Data

Rx Data

Gnd

RF Generator

Service Monitor

or Counter

Wattmeter

Table 4-2 Initial Equipment Control Settings

Service Monitor Test Set Power Supply

Monitor Mode: Power Monitor Speaker set: A Voltage: 13.8 Vdc (low

power models)

13.6 Vdc (high power

models)

RF Attenuation: -70 Speaker/load:

Speaker

AM, CW, FM: FM PTT: OFF Volt Range: 20 V

Oscilloscope Source: Mod

Oscilloscope Horizontal: 10mSec/Div

Oscilloscope Vertical: 2.5 kHz/Div

Oscilloscope Trigger: Auto

Monitor Image: Hi

Monitor BW: Nar

Monitor Squelch: mid CW

Monitor Volume: 1/4 CW

NOTE

Refer to Tuner on-line help files for tuning procedures.

DC on/standby:

Standby

Current: 20A

Page 47

1.0 Error Codes

Turning on the radio starts a self-test routine that checks the RAM, ROM checksum, EEPROM

hardware, and EEPROM checksum. If these checks are successful, the radio generates two high-

pitched self-test pass tones. If the self-test is not successful, one low-pitched tone is heard. Radios

with displays are able to display the error codes. Following are the possible errors and the related

connections.

Possible Errors To correct the problem...

RAM test failure. Retest the radio by turning it off and turning it on

Chapter 5

POWER UP SELF-TEST

Table 5-1 Power Up Error Codes

again. If bad tone reoccurs, replace RAM (U0122).

Codeplug structure mismatch or non existence of

codeplug.

Wrong codeplug checksum. Reprogram codeplug.

Reprogram codeplug with correct version and retest

radio. If message reoccurs, replace EEPROM

(U0111).

Page 48

5-2 POWER UP SELF-TEST

THIS PAGE INTENTIONALLY LEFT BLANK

Page 49

ACCESSORIES & CONNECTOR PIN FUNCTIONS

1.0 Accessories

To order, refer to Chapter 1 (paragraph 3.0 - ‘Replacement Parts Ordering’) of this manual.

1.1 Antennas

VHF

HAD4006_ 136 - 144 MHz, 1/4 Wave Roof Mount

HAD4007_ 144 - 150.8 MHz, 1/4 Wave Roof Mount

HAD4008_ 150.8 - 162 MHz, 1/4 Wave Roof Mount

HAD4009_ 162 - 174 MHz, 1/4 Wave Roof Mount

RAD4000_ 136 - 174 MHz, 3 dB Gain (No Mount)

HAD4014_ 140 - 174 MHz, 3.5 dB Gain Roof Mount

UHF

Chapter 6

HAE4002_ 403 - 430 MHz, 1/4 Wave Roof Mount

HAE4003_ 450 - 470 MHz, 1/4 Wave Roof Mount

HAE4004 470 - 512 MHz, 1/4 Wave Roof Mount

HAE4010_ 406 - 420 MHz, 3.5 dB Gain Roof Mount

HAE4011_ 450 - 470 MHz, 3.5 dB Gain Roof Mount

RAE4004_RB 445 - 470 MHz, 5 dB Gain Roof Mount

RAE4004_MB 445 - 470 MHz, 5 dB Gain Magnetic Mounts

TAE6053_ 430 - 450 MHz, 1/4 Wave Roof Mount

Page 50

6-2 ACCESSORIES & CONNECTOR PIN FUNCTIONS

1.2 Audio

HMN3596_ Compact Palm Microphone (Std. Mic)

HMN1035_ Heavy Duty Microphone

RMN5029_ Enhanced Keypad Microphone

RMN5018_ Mag One Microphone (Low Cost) (6 months warranty only)

RMN5019_ Mag One Keypad Microphone (Low Cost) (6 months warranty only)

AAREX4617_ Telephone Style Handset Kit

GMMN4065_ Visor Microphone (Omni Direction)

AARMN4027_ Visor Microphone - High Noise (Uni-Direction)

RSN4001_ External Speaker, 13 W

HSN8145_ External Speaker, 7.5 W

HLN9073_ Microphone Hang-up Clip (requires install)

HLN9414_ Microphone Hang-up Clip (Universal - no install required)

1.3 Alarms and Accessories

RLN4856_ Footswitch with Remote PTT

RLN4857_ Pushbutton with Remote PTT

RLN4858_ Gooseneck PTT

RLN4836_ External PTT with Emergency Footswitch

HLN9328_ External Alarm Relay (used in conjunction with GLN7282)

GLN7282_ Buzzer Kit (used in conjunction with HLN9328)

Page 51

Accessories 6-3

1.4 Control Station

HPN4002_ Desktop Power Supply 1-25 W

HPN4001_ Desktop Power Supply 25-60 W

HMN3000_ Black Desk Microphone

RLN5390_ Desktop Tray with Speaker

RLN5391_ Desktop Tray without Speaker

RLN5492 Low Power Control Station Kit (1-25 W) (includes power supply,

desktop tray, and desk mic)

RLN5493 High Power Control Station Kit (25-60 W) (includes power supply,

desktop tray, and desk mic)

1.5 Public Address

RLN5288_ Public Address Kit (includes switch box and cabling)

HKN9324_R Speaker Cable for PA (15 ft.)

HSN1000_R External Speaker, 6 W for public address

1.6 Cables

HKN9327_R Ignition Switch Cable

HKN4137_ Low Power Cable to Battery (1-25 W)

HKN4191_ High Power Cable to Battery (25-60 W)

1.7 Mounting

GLN7324_ Low Profile Mounting Bracket

GLN7317_ High Profile Mounting Bracket

FTN6083_ DIN Mount

HLN8097_ Removable Slide Mount with Mini_U connector

HLN9227_ 8 in. Gooseneck Trunnion

RLN4779_ Keylock Mounting Bracket

Page 52

6-4 ACCESSORIES & CONNECTOR PIN FUNCTIONS

1.8 Data - CES Wireless Technologies

RDN7364_ Base Modem

RDN7367_ Mobile Display Terminal with GPS

RDN7368_ Mobile Display Terminal

RDN7369_ Stand Alone Modem with GPS

RDN7370_ Interface Cable, 3 ft

RDN7376_ Interface Cable, 15 ft

RDN7372_ Fixed Mount GPS Active Antenna

RDN7373_ Mobile Printer

RDN7374_ Programming Software for CES Equipment

RDN7380_ Mobile Programming Hardware

RDN7375_ Magnetic Mount GPS Antenna

RDN7377_ MAPS (US) Regional

RDN7378_ AVL Messaging Statue Software

RDN7371_ Credit Card Reader

RDN7738_ Serial Breakout Unit (multiple modems)

RDN7739_ Flying Lead Cable, 3 ft.

RDN7740_ Flying Lead Cable, 15 ft.

1.9 Peripherals

HLN3948 Basic RICK (Repeater Interface Comm Kit)

HLN3333 RICK (Repeater Interface Comm Kit)

Page 53

Accessory Connector Pin Function 6-5

2.0 Accessory Connector Pin Function

Pin Function Description

1 External Speaker (-) Connect external 8 or 4 ohms speaker to pin 1 and 16.

Caution: Bridge-type output. Neither pin 1 or 16 is grounded.

2 External Mic Audio Input impedence:500 ohms

80 mV rms at 1 kHz for 60% deviation.

This path is enabled when external mic PTT is keyed.

3 External Mic PTT Put this pin low (less than 0.66 Vdc) to key transmitter and enable

external mic audio path. This path is pulled low via a diode when front

panel mic PTT is pulled low to allow sensing of mic PTT by accessory.

This pin pulled high to 3.3 Vdc via 3.3k ohms

4 Programmable

Output

5 Flat_TX_Audio Input Input impedance: Greater than 35k ohms. The nominal input level is 150

6 SCI Serial Communication Interface. This pin can be configured as a general

7 Ground Used as ground.

8 Programmable I/O Input or output depending on dealer programming.

9 Emergency Input When connecting the Emergency Footswitch between pin 9 and 7, the

10 Ignition Sense For optional 3-wire ignition control, connect this pin to the vehicle

Defaults to External Alarm. Provides an active high to 13.8 Vdc battery

supply, maximum current: 0.15 amps. CAUTION: Do not short to ground,

this may damage the radio.

mV rms for 60% deviation.

purpose input by removing resistor R421.

radio will sense the connection upon Power-up.

Shorting this pin to Ground by pressing the switch when the radio is OFF,

turns ON the radio in Emergency Mode.

Shorting this pin to Ground by pressing the switch when the radio is ON,

activates Emergency Mode.

To turn OFF a radio that was turned ON by Emergency Footswitch (ON/

OFF knob in OFF position) turn knob to ON and then to OFF position.

ignition-controlled voltage source for ignition-controlled radio ON/OFF.

To resume NON ignition state, remove the battery connection for 10

seconds; remove the ignition connection from this pin and re-connect the

battery connections.

11 Receive Audio

Output

12 Programmable I/O Input or Output

13 Switched B+ (Switched Battery Voltage) 13.8Vdc (500mA max.) when radio is ON

14 Programmable I/O Input or Output

15 Internal Speaker Connect to internal speaker (+) and by internal jumper to pin 16

16 External Speaker (+) Connect external 8 or 4 ohms speaker to pins 1 and 16.

Programmable (using CPS in the RX Audio Type): 660mV rms (deemphasized/muted) or 330mV rms (non de-emphasized muted.

Minimum load resistance: 5k ohms

CAUTION: Bridge type output. Neither pin 1 nor 16 is grounded.

Page 54

6-6 ACCESSORIES & CONNECTOR PIN FUNCTIONS

3.0 Microphone Connector Pin Function

Pin Function Description

1 9.3V Regulated 9.3V Supply (50mA max.)

2Boot/DTMF

Keypad Column

3 Hook When 0V is applied to this pin (mic on hook), pins 2 and 7 will be

4 Ground Used as ground

5 Mic. Audio Audio input impedance: 500 ohms

THIS PAGE INTENTIONALLY LEFT BLANK

6 Mic. PTT Microphone PTT is active low, so this port reads “0” when PTT is pressed

This pin function depends on the voltage applied to pin 3 (See pin 3, Hook

description).

When configured as “Boot”, applying 5V to this pin will set the radio to Boot

state.

When configured as “DTMF Keypad Column”, this pin will carry column

voltages generated by the DTMF microphone (RMN5029).

configured to “Column” and “Row”.

When no voltage is applied to this pin (mic off hook), this pin will read 2.7V,

and pins 2 and 7 will be configured to “Column” and “Row”.

When 9.3V is applied to this pin (programming cables or Mag One mic

RMN5018), pins 2 and 7 will be configured to “Boot” and “SCI”.

80 mV rms input (standard mic) or 1.8 mV rms (low cost mic) at 1 kHz for

60% deviation.

This path is enabled when Mic. PTT (pin 6) is keyed

and “1” when PTT is released.

10 K ohms internal pull up resistor to 9.3 V.

Pulling low this pin will also pull low, via a diode, pin 3 (external MIC PTT)

of the accessory connector.

7 SCI/DTMF

Keypad Row

8 Handset Rx

Audio

The function of this pin depends on the voltage applied to pin 3 (see pin 3

description).

When configured as “SCI”, serial communication with the radio is

facilitated.

When configured as “DTMF Keypad Row” this pin will carry new voltages

generated by the DTMF mic (RMN5029)

Handset audio output provides de-emphasized, muted Rx audio. The

source impedance is 10 ohms and the output level (open circuit) is

controlled by the volume control setting.

Page 55

MODEL CHART AND TEST SPECIFICATION

1.0 Low Power Radios

1.1 146-174 MHz CM200/CM300/PM400 Model Chart

VHF2, 1-25 W, 146-174 MHz

Model Description

AAM50KNC9AA1AN CM200 146-174 MHz, 1-25 W, 4 CH

AAM50KNF9AA1AN CM300 146-174 MHz, 1-25 W, 32 CH

AAM50KNF9AA3AN PM400 146-174 MHz, 1-25 W, 64 CH

Item Description

X PMUD1871_ CM200 Super Tanapa VHF2, 1-25 W, 4 CH

X PMUD1873_ CM300 Super Tanapa VHF2, 1-25 W, 32 CH

X PMUD1904_ PM400 Super Tanapa VHF2, 1-25 W, 64 CH

X FLD1933_ CM200 Tenapa VHF2, 1-25 W 4 CH

X PMUD1882_ CM300 Tanapa VHF2, 1-25 W, 32 CH

X PMUD1882_ PM400 Tanapa VHF2, 1-25 W, 64 CH

X PMLN4598_ Control Head

X PMLN4599_ Control Head

X FLN3108_AN Control Head

X FLD1933_S CM200 VHF2 Service Board

X PMUD1882_S CM300 VHF2 Service Board

X PMUD1882_S PM400 VHF2 Service Board

X 6902966C30 CM200 User Guide (bilingual)

X 6881096C22 CM300 User Guide (bilingual)

X 6881096C32 PM400 User Guide (bilingual)

X X HKLN4220 CM200/CM300 User Guide CDROM (bilingual)

X HKLN4219 PM400 User Guide CDROM (blilingual)

x = Indicates one of each is required.

Chapter 7

Page 56

7-2 MODEL CHART AND TEST SPECIFICATION

1.2 438-370 MHz CM200/CM300/PM400 Model Chart

UHF2, 1-25 W, 438-470 MHz

Model Description

AAM50RNC9AA1A CM200 438-470 MHz, 1-25 W, 4 CH

AAM50RNF9AA1AN CM300 438-470 MHz, 1-25 W, 32 CH

AAN50RNF9AA3AN PM400 438-470 MHz, 1-25 W, 64 CH

Item Description

X PMUE1996_ CM200 Super Tanapa UHF2, 1-25 W, 4 CH

X PMUE1998_ CM300 Super Tanapa UHF2, 1-25 W, 32 CH

X PMUE2090_ PM400 Super Tanapa UHF2, 1-25 W, 64 CH

X FLE1620_ CM200 Tanapa UHF2, 1-25 W, 4 CH

X PMUE2026_ CM300 Tanapa UHF2, 1-25 W, 32 CH

X PMUE2026_ PM400 Tanapa UHF2, 1-25 W, 64 CH

X PMLN4598_ Control Head

X PMLN4599_ Control Head

X FLN3108_AN Control Head

X FLE1620_S CM200 UHF2 Service Board

X PMUE2026_S CM300 UHF2 Service Board

X PMUE2026_S PM400 UHF2 Service Board

X 6902966C30 CM200 User Guide (bilingual)

X 6881096C22 CM300 User Guide (bilingual)

X 6881096C32 PM400 User Guide (bilingual)

X X HKLN4220 CM200/CM300 User Guide CDROM (bilingual)

X HKLN4219 PM400 User Guide CDROM (blilingual)

x = Indicates one of each is required.

Page 57

Low Power Radios 7-3

1.3 Specifications

General

Specification VHF2 UHF2

Frequency Range: 146-174 MHz 438-470 MHz

Frequency Stability

(-30°C to +60°C, 25°C Ref.)

Channel Capacity: CM200 - 4

Channel Spacing: 12.5/20/25 kHz

Power Supply: 13.8 Vdc (11 Vdc - 16.6 Vdc) negative Vehicle ground

Dimensions (L x W x H) 4.65” X 6.67” X 1.73”

(118mm X 169.5mm X 44mm)

Weight 2.25 lbs (1.01 kg)

FCC Description AZ492FT3805 AZ492FT4856

Operating Temperature -30 to 60° C (Display only -20°C to 60°C)

Storage Temperature -40 to 85° C

Thermal Shock -40 to 80° C

High Humidity 95% RH @ 50° C for 8 hrs

±2.5 PPM

CM300 - 32

PM400 - 64

ESD 15KV air discharge

Packing Test Impact Test

Page 58

7-4 MODEL CHART AND TEST SPECIFICATION

Transmitter

Specification VHF2 UHF2

Power Output 1-25W

Conducted/Radiated

Emissions:

Audio Response: (from 6

dB/oct. Pre-Emphasis, 300

to 3000Hz)

Tx Audio Distortion < 3%

Modulation Limiting: ±2.5 kHz @ 12.5 kHz

FM Hum and Noise: -40 dB@12.5 kHz

-45 dB@25 kHz

-36 dBm < 1 GHz

-30 dBm > 1 GHz

TIA603 and CEPT

±4.0 kHz @ 20 kHz

±5.0 kHz @ 25 kHz

-35 dB@12.5 kHz

-40 dB@25 kHz

Receiver

Specification VHF2 UHF2

Sensitivity (12 dB SINAD): 0.35 µV @ 12.5 kHz

0.3 µV @ 25 kHz

Intermodulation: 65 dB@12.5 kHz

75 dB@25 kHz

Adjacent Channel

Selectivity:

Spurious Response 75 dB 70 dB

Rated Audio Power 4 W (typ.) Internal

Audio Distortion < 5 %

Hum and Noise: -40 dB @ 12.5 kHz

Audio Response TIA603 and CEPT

Conducted Spurious

Emission per FCC Part 15:

Specifications subject to change without notice. All electrical specifications and methods refer

to EIA/TIA 603 standards.

65 dB @ 12.5 kHz

75 dB @ 25 kHz

7.5 W @ 5 % External

-45 dB @ 25 kHz

-57 dBm <1 Ghz

-47 dBm >1 Ghz

60 dB@12.5 kHz

70 dB@25 kHz

60 dB @ 12.5 kHz

70 dB @ 25 kHz

-35 dB @ 12.5 kHz

-40 dB @ 25 kHz

Page 59

High Power Radios 7-5

2.0 High Power Radios

2.1 136-162 MHz CM300 Model Chart

VHF1, 25-45 W, 136-162 MHz

Model Description

AAM50JQF9AA1AN CM300 136-162 MHz, 25-45 W, 32 CH

Item Description

X PMUD1946_ CM300 Super Tanapa VHF1, 25-45 W, 32 CH

X PMUD1962_ CM300 Tanapa VHF1, 25-45 W, 32 CH

X PMLN4599_ Control Head

X PMUD1962_S CM300 VHF1 Service Board

X 6881096C22 CM300 User Guide (bilingual)

X HKLN4220 CM300 User Guide CMROM (bilingual)

x = Indicates one of each is required.

2.2 146-174 MHz CM200/CM300/PM400 Model Chart

VHF2, 25-45 W, 146-174 MHz

Model Description

AAM50KQC9AA1AN CM200 146-174 MHz, 25-45 W, 4 CH

AAM50KQF9AA1AN CM300 146-174 MHz, 25-45 W, 32 CH

AAM50KQF9AA3AN PM400 146-174 MHz, 25-45 W, 64 CH

Item Description

X PMUD1875_ CM200 Super Tanapa VHF2, 25-45 W, 4 CH