GEO D Series

D10 10° Tangent Array Module

Geo Sub Directional Sub-bass

User Manual

GEO D Series User Manual V1.06

Date: 05/10/2010

Page 2/97 PLEASE READ CAREFULLY BEFORE PROCEEDING

GEO Technology is radically new thinking

The GEO R&D Project has, to date, resulted in the following patent applications:

• The GEO Hyperboloid Reflective Wavesource™ differs radically from the megaphone-variant

type horns you know and love (or hate). “Tried and true” methods will produce entirely

unexpected results. HRW technology produces precise and predictable results.

• The Configurable Directivity Flange. A waveguide that allows the operator to alter its behaviour.

An unprecedented NEXO development that is easy to use – once you know how and when.

• The Directivity Phase Device needs no operator input to function, but it is reassuring to know that

the coupling of the midrange of the system is considered as important as the high frequencies…

• GEO’s DSP-driven Cardioid Dipolar Sub-bass devices are a new approach to controlling LF/VLF

acoustic energy.

GEO is not hard to use when you understand how…

The technology behind GEO is revolutionary, but it is grounded in years of practical experience with the

problems of delivering high quality professional sound to large audiences at high SPL levels. The GEO

toolbox includes GEOSoft -a simple yet powerful and highly predictive design tool. The array assembly

system is keyed to the design software and will easily enable you to deploy your design with great

precision. The NX 242 Di gita l TDc ontrol ler p rovi des dr iver p rot ecti on and s yste m opti miza tion as wel l as

DSP-driven cardioid pattern control for the GEO D10 Tangent Array Module and the GEO SUB Cardioid

Dipole Sub-bass.

GEO is a high precision system

The GEO HRW™ controls acoustic energy more precisely than other multiple element waveguides. It

also makes GEO less forgiving of mistakes. Whilst conventional horns never combine into a coherent

array, they may deliver acceptable results even if the design and deployment of the system is less than

optimal. This is not the case with GEO where careless installation produces catastrophic results.

A GEO Tangent Array is no t a “line array”

GEO Technology is equally effective in designing and deploying tangent horizontal arrays or curved

vertical arrays. For best results in a specific application the user needs to know how multi-speaker

arrays interact with audience geometry, along with the benefits and drawbacks of curved vertical arrays

and horizontal arrays.

Curved vertical ta ngent arrays requir e different design techni ques

For the past 20 years, sound reinforcement professionals have worked with horizontal arrays that use

conventional horns to deliver [more or less] ‘equal power to equal angles’. Curved vertical arrays are

designed to deliver [more or less] equal power to equal areas’. When arrays use conventional horns ,

the lack of precision, overlap and interference masks errors in array design and aiming. The highly

precise GEO wavesource responds accurately, consistently and predictably to the design and

deployment of a curved vertical tangent array. This is why the GEO rigging system is designed to

control angular splay to 0.01° precision.

GEO curved vertical ta ngent arrays require d ifferent operati onal techniques

Over the years, system designers and operators have developed a number of signal processing

techniques to disguise and partly overcome the limitations of horn design. “Frequency shading,”

“amplitude shading,” “system tuning,” all of these are tools of the advanced sound system operator.

NONE OF THESE TECHNIQUES ARE APPLICABLE TO GEO TANGENT ARRAYS. Instead of

enhancing the array’s performance they will severely degrade it.

Take time to learn how to get great results with GEO Technology. It is an investment that will pay off in

more satisfied clients, more efficient operating procedures and more recognition for your skill as a

sound system designer and operator. A comprehensive understanding of GEO t heory, tangent arrays,

and specific features of the GEO D Series will help you to operate your system at its full potential.

PLEASE READ CAREFULLY BEFORE PROCEEDING Page 3/97

PLEASE READ CAREFULLY BEFORE PROCEEDING

BASIC PRECAUTIONS

Do not open the speaker system or attempt to disassemble the internal parts or modify them in any

way. The speaker system contains no user-serviceable parts. If it should appear to be malfunctioning

or damaged, discontinue use immediately and have it inspected by qualified NEXO service personnel.

Water exposure: Do not expose the speaker s ystem to direct rain, do not use it near water or in wet

conditions. Do not place containers with liquid on speaker system as they might spill into openings. If

any liquid such as water seeps into the speaker system, have it inspected by qualified NEXO

personnel.

SYSTEM DEPLOYMENT SAFETY RULES

Read User Manual before deployment. Before use of enclosed speaker system,

please ensure that anyone involved in system deployment understands the rigging –

stacking – pole mounting safety rules as described in the speaker system User Manual.

Failure to do this exposes people to potential injury or death.

Always consult qualified NEXO personnel if the device installation requires construction work and make

sure to observe the following precautions:

Mounting precautions

- c hoose mounting hardware and an installation location that can support the weight of the speaker

system;

- do not use speaker system handles for suspended installation;

- do not expose speaker system to excessive dust or vibration, or extreme cold or h eat to prevent

possibility of component damage;

- do not place the speaker system in an unstable position from which it might fall accidentally;

- if speaker systems uses a stand, ensure that stand specifications are adapted, and that stand

height does not exceed 1.40m/55”; never move the stand while the speaker is in position.

Connection and powering precautions

- remove all connected cables before moving the speaker system;

- turn off AC power of all power amplifier units before connecting the speaker system;

- when turning on the AC power to the audio system, always turn on the power amplifier last; when

turning the AC power off, always turn off the power amplifier first;

- when used in cold conditions, a gradual power ramp up should applied to the system on an 5 mn

period to allow the loudspeaker components to stabilize during the very first minutes of usage.

Inspect the speaker system periodically.

Page 4/97 PLEASE READ CAREFULLY BEFORE PROCEEDING

SAFETY INSTRUCTIONS FOR NEXO TD CONTROLLERS

NEXO ANALOGUE PSTDCONTROLLERS, NX242 DIGITAL CONTROLLER,

NXAMP4x1 AND NXAMP4x4 POWERED CONTROLLERS ARE CLASS 1

APPARATUS AND MUST BE EARTHED.

THE GREEN AND YELLOW WIRE OF THE MAINS CORD MUST ALWAYS BE CONNECTED TO AN

INSTALLATION SAFETY EARTH OR GROUND. THE EARTH IS ESSENTIAL FOR PERSONAL

SAFETY AS WELL AS THE CORRECT OPERATION OF THE SYSTEM, AND IS INTERNALLY

CONNECTED TO ALL EXPOSED METAL SURFACES.

- Read these instructions.

- Keep these instructions.

- Heed all warnings.

- Follow all instructions.

- Do not use this apparatus near water.

- Clean only with dry cloth.

- Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

- Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus

(including amplifiers) that produce heat.

- Do not defeat the s afety purpose of the polarized or grounding-type plug. A polarized plug has two

blades with one wider than the other. A grounding type plug has two blades and a third grounding

prong. The wide blade or the third prong are provided for your safety. If the provided plug does not

fit into your outlet, consult an electrician for replacement of the obsolete outlet. (US market)

- Protect the power cord from being walked on or pinched particularly at plugs, convenience

receptacles, and the point where they exit from the apparatus.

- Only use attachments/accessories specified by the manufacturer.

- Unplug this apparatus during lightning storms or when unused for long periods of time.

- Refer all servicing to qualified service personnel. Servicing is required when the apparatus has

been damaged in any way, such as power-supply cord or plug is damaged, liquid has b een spilled

or objects have fallen into the apparatus, the apparatus has been exposed to rain or moisture, does

not operate normally, or has been dropped.

The lightning flash with arrowhead

symbol, within an equilateral triangle

is intended to alert the user to the

presence of uninsulated “dangerous

voltage” within the product's

enclosure that may be of sufficient

magnitude to constitute a risk of

electric shock to persons.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

WARNING: To reduce the risk of fire or electric shock,

do not expose this apparatus to rain or moisture.

To avoid electrical shock, do not remove covers.

Dangerous voltages exist inside.

Refer all servicing to qualified personnel only.

The exclamation point within an

equilateral triangle is intended to

alert the user to the presence of

important operating and

maintenance (servicing) instructions

in the literature accompanying

the appliance.

PLEASE READ CAREFULLY BEFORE PROCEEDING Page 5/97

HIGH SOUND PRESSURE LEVELS

Exposure to extremely high noise levels may cause permanent hearing loss.

Individuals vary considerably in susceptibility to noise-induced hearing loss but nearly

everyone will lose some hearing if exposed to sufficiently intense noise for a sufficient

period of time. The U.S. Government’s Occupational and Health Administration (OSHA)

has specified the following permissible noise level exposures: Sound Duration Per

Day In Hours Sound Level dBA, Slow Response

8 90

6 92

4 65

3 97

2 100

1 ½ 102

1 105

½ 110

¼ or less 115

According to OSHA, any exposure in excess of the above permissible limits could result in some

hearing loss. Ear plugs or protectors to the ear canals or over the ears must be worn when operating

this amplification system in order to prevent permanent hearing loss, if exposure is in excess of the

limits as set forth above. To ensure against potentially dangerous exposure to high sound pressure

levels, it is recommended that all persons exposed to equipment capable of producing high sound

pressure levels such as this amplification system be protected by hearing protectors while this unit is in

operation.

DISPOSAL OF OLD ELECTRICAL & ELECTRONIC EQUIPMENT

This symbol on the product or on its packaging indicates that it shall not be treated

as household waste. Instead it shall be handed over to the applicable collection

point for the recycling of electrical and electronic equipment. By ensuring this

product is disposed of correctly, you will help prevent potential negative

consequence for the environment and human health, which could otherwise be

caused by inappropriate waste handling of this product. The recycling of materials

will help to conserve natural resources. For more detailed information about

recycling of this product, please contact your local city office, your household waste

disposal service or the shop where you purchased the product.

Page 6/97 CONTENTS

CONTENTS

PLEASE READ CAREFULLY BEFORE PROCEEDING ............................................ ............ 3

CONTENTS............................................................................................................................... 6

1 Introduction...................................................................................................................... 8

2 GEO D General Set-up Instructions............................................................................. 10

2.1 Speaker Wiring .................................................... .... ........ .... .... ....... .... .... ........ .... .... ..10

2.2 Amplifier Selection............................................... ........ .... .... ........ ... .... ........ .... ........ ..12

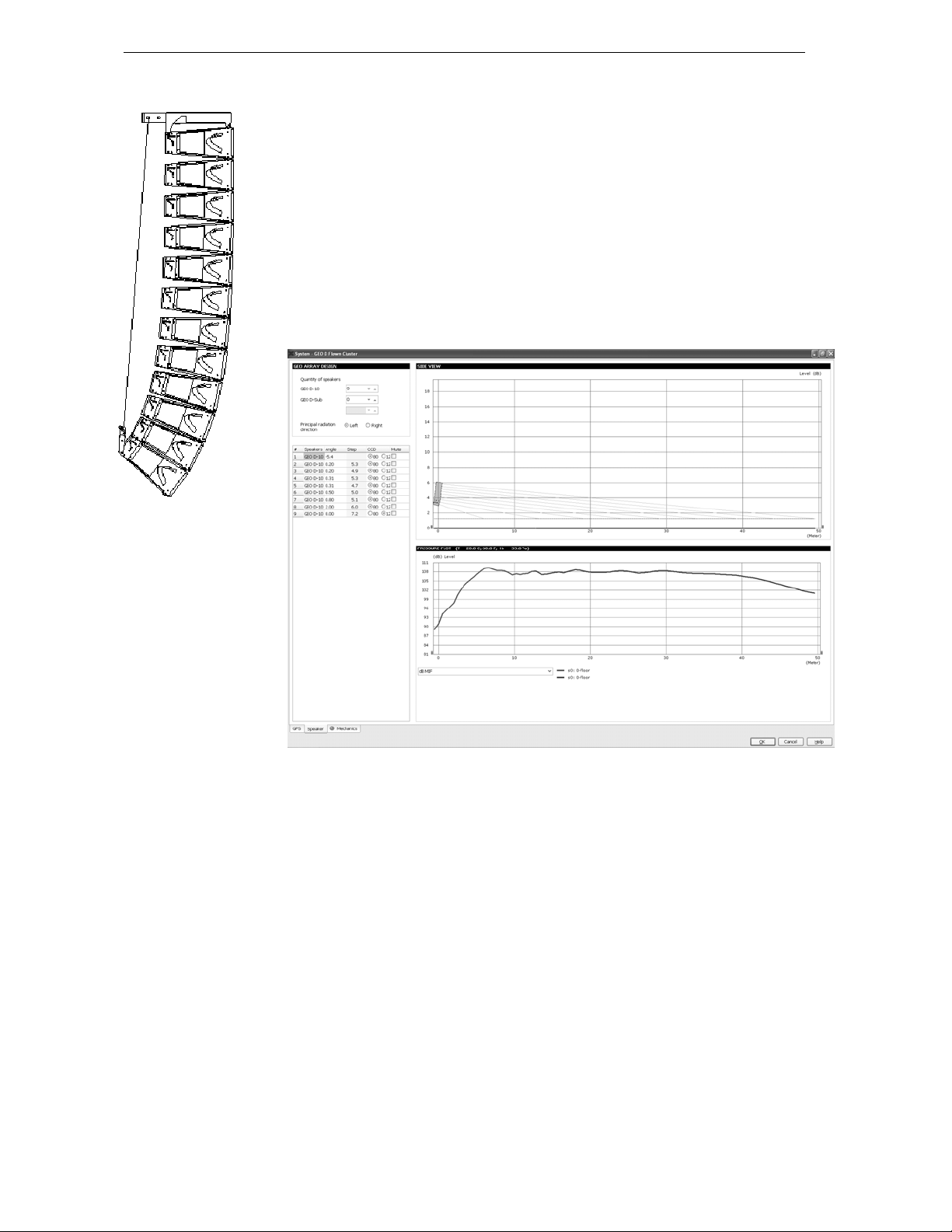

3 NS-1 Simulation software.............................................................................................. 16

4 Configurable Directivity Device............................................... .... .... ... .... .... .... .... ........ .. 17

4.1 Installing & removing GEO’s Configurable Directivity flanges ................................. 17

4.2 When & where to use Configurable Directivity flanges ............................................18

5 GEO D rigging procedure............................. ................................................................. 19

5.1 SAFETY FIRST ........................................................................................................ 19

5.2 General Description................................................. .... ........ .... .... ....... .... .... ........ .... ..22

5.3 GEO D – GEO SUB Ground Stacked ...................................................................... 27

5.4 GEO D Cluster Flying Setup (1 motor)........................................... .... .... .... .... .... .... ..32

5.5 GEO D Cluster Flying Setup (2 motors)................................................................... 41

5.6 GEO SUB – GEO D Combined Cluster Flying Setup (2 motors required)............... 49

5.7 GEO SUB Cluster Flying Setup (2 motors required)................................................ 58

5.8 Fixed installations..................................................................................................... 65

5.9 Testing and Maintenance of the system...................................................................66

6 NEXO NX242 Digital Controller for GEO D and GEO SUB......................................... 67

6.1 NX242 Proprietary Functions ............................................................................. .... ..67

6.2 Cardioid LF and VLF................................................................................... ........ .... ..69

6.3 GEO D NX242 Setups description .......................... .... .... ....... .... .... ........ .... ........ .... ..69

6.4 Trouble shooting.............................................................. .... ....... .... .... ........ .... .... ......70

CONTENTS Page 7/97

7 System alignment guidelines...................................................... ..................................72

7.1 GEO SUB – GEO D Cluster design..........................................................................72

7.2 Stacked GEO SUB’s and Flown GEO D’s ................................................................72

7.3 Flown or Stacked combined GEO SUB’s and GEO D’s clusters..............................73

7.4 Separate GEO SUB and GEO D clusters.................................................................73

7.5 Driving the GEO SUB’s from the AUX send .............................................................73

7.6 Recommended installation tools and equipment......................................................74

8 GEO D – GEO SUB Array System Check List..............................................................75

8.1 Are the NX242 Digital TDcontrollers properly configured?.......................................75

8.2 Are the amplifiers properly configured? ....................................................................75

8.3 Are the amps and the NX properly connected?........................................................75

8.4 Are the speakers properly connected and angled ? .................................................75

8.5 Final Pre-Sound Check Check..................................................................................76

9 Technical Specifications.......................... .... .... ........ .... .... .... ... .... .... ........ .... .... .... .... .... ...77

9.1 GEO D10 Vertical Tangent Array Module.................................................................77

9.2 GEO SUB Directional Sub-Bass ...............................................................................79

9.3 GEO D / GEO SUB Rigging system....................................................................... ...81

9.4 NX242 TDcontroller with NX-Tension Card ..............................................................85

10 Connection diagrams .................................................................................................87

10.1 GEO D cluster to amplifiers and NX242 (Stereo passive mode)..............................87

10.2 GEO D cluster to amplifiers and NX242 (Mono active mode) ..................................88

10.3 GEO SUB - GEO D cluster to amplifiers and NX242 (GeoD in Passive Mode).......89

11 GEO D Series Parts & Accessories List...................................................................90

11.1 Array Modules & Control Electronics List................................................... ...............90

11.2

Accessories List ........................................................................................................90

12 USER NOTES................................................................. .... ....... .... .... ........ .... .... ........ ...93

Page 8/97 INTRODUCTION

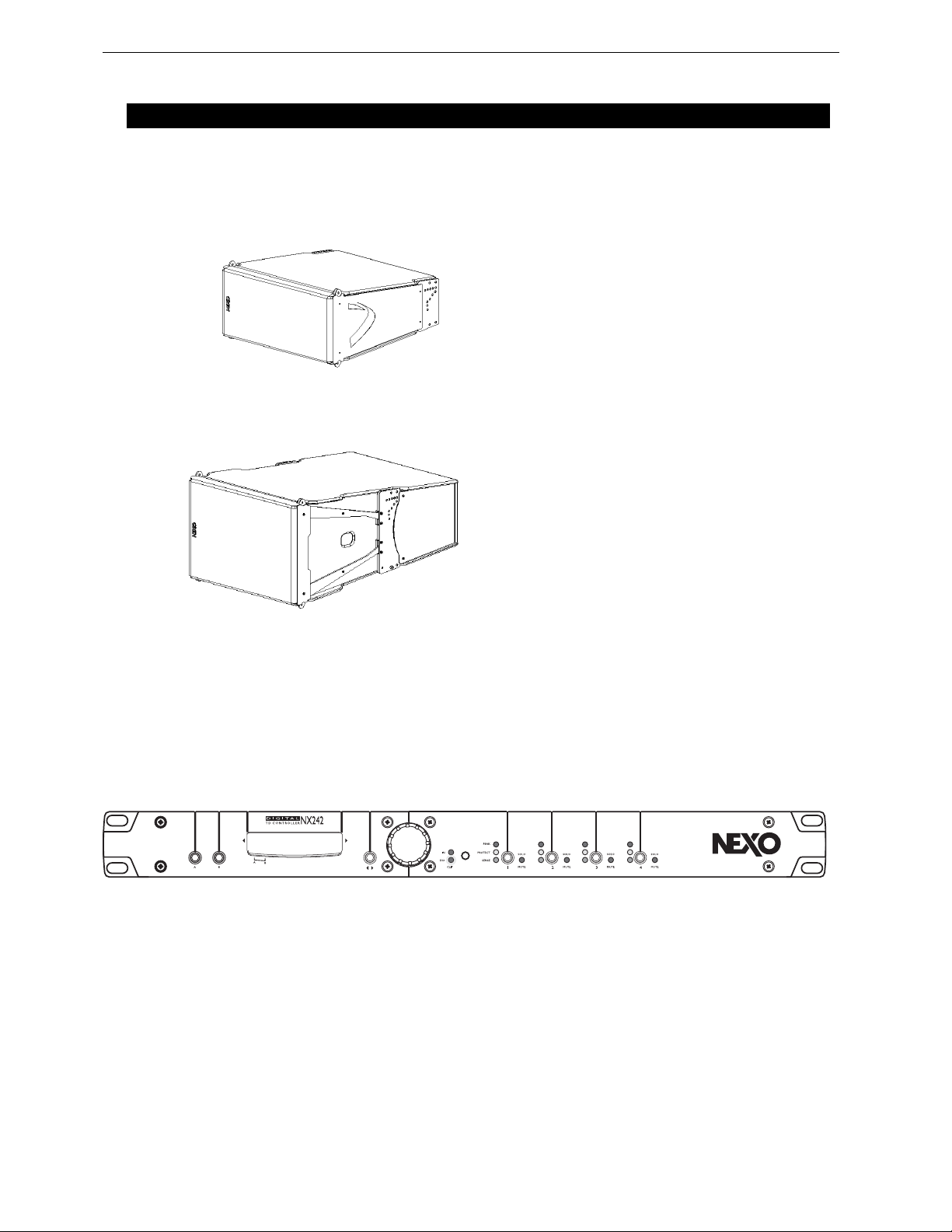

1 INTRODUCTION

Thank you for selecting a NEXO GEO D Series Tangent Array System. This manual is intended to

provide you with necessary and useful information about your GEO System, which includes the

following products:

• D10 is a 10° Tangent Array Module. It

comprises 2 x8” (20cm) 8 Ohms LF D rivers

(side firing), 1x12” (30cm) Neodynium 16

ohms LF/MF driver (front) and 1x3” voice

coil, 1.4” Throat 16 Ohm HF Driver loaded

by a 5° Hyperboloid Reflective

Wavesource™.

• Geo Sub is a Cardioid Dipole Sub-bass. It

comprises 1x18” (46cm) Long Excursion

Neodymium 8 Ohm Driver and 2x 12”

(30cm) Neodynium 16 ohms LF drivers,

controlled by DSP advanced proprietary

algorithm, producing a 1 20° x 120° car dioid

pattern. Can be used in conjunction with

GeoD in flown clusters or in ground-stacked

configuration.

• NX242 Digital TDcontroller and NXtension-ES4 provides comprehensive control of GEO D

loudspeakers in multiple configurations. It allows Ethersound

TM

digital audio networking, as well

as remote control for all units in the network.

For a complete description of this unit, please refer to the NX242 User Manual. The NX242 DSP

algorithms and parameters are fixed in software and updated regularly: please consult the NEXO

web site (www.NEXO.fr or w ww.NEXO-sa.com) for the latest software releases.

GeoD Passive mode

Crossover 80Hz

INTRODUCTION Page 9/97

• GEO D Array Flying System. A fully integrated and accurate flying system that

provides safe, flexible and simple means of flying GEO D Tangent Arrays. NOTE:

GEO Tangent Arrays control the dispersion of acoustic energy with a high de gree of

precision. Inclinometers and laser aiming tools are essential to ensure proper

audience coverage when installing a GEO Tangent Array.

• NS-1 simulation software (previously GEOSoft2) assists in the design and

implementation of vertical tangent GEO arrays. Please consult the NEXO web site

(www.NEXO.fr or www.NEXO-sa.com) for the latest software releases.

Please devote your time and attention to reading this manual. A comprehensive

understanding of GEO theory, tangent arrays, and specific features of GEO D10 and

GEO SUB and will help you to operate your system at its full potential.

Page 10/97 GEO D GENERAL SET-UP INSTRUCTIONS

IN

OUT

2 GEO D GENERAL SET-UP INSTRUCTIONS

2.1 Speaker Wiring

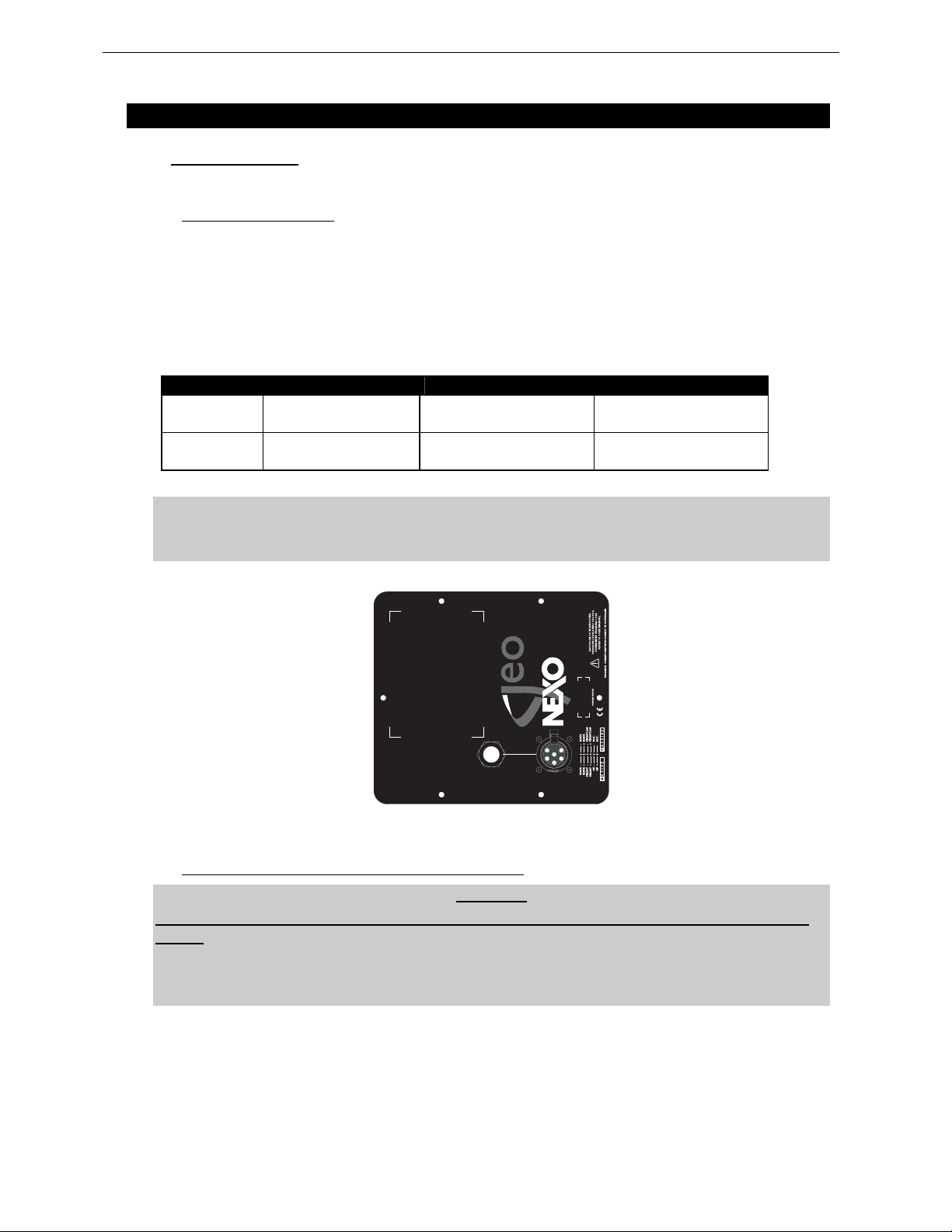

2.1.1 GEO D10 connectors

GEO D’s are connected to power amplifiers via one AP6 Male Connector (GEOT-612M) on a link cable

that is stowed in the rear vent port. One EP6 Female Chassis (GEOT-613F) on the back connector

panel is used as output to feed the next GEO D.

A wiring diagram is printed on the connection panel located on the back of each cabinet. The EP6 / AP6

connectors are linked in parallel within the enclosures (see the Connections Diagrams section of this

manual).

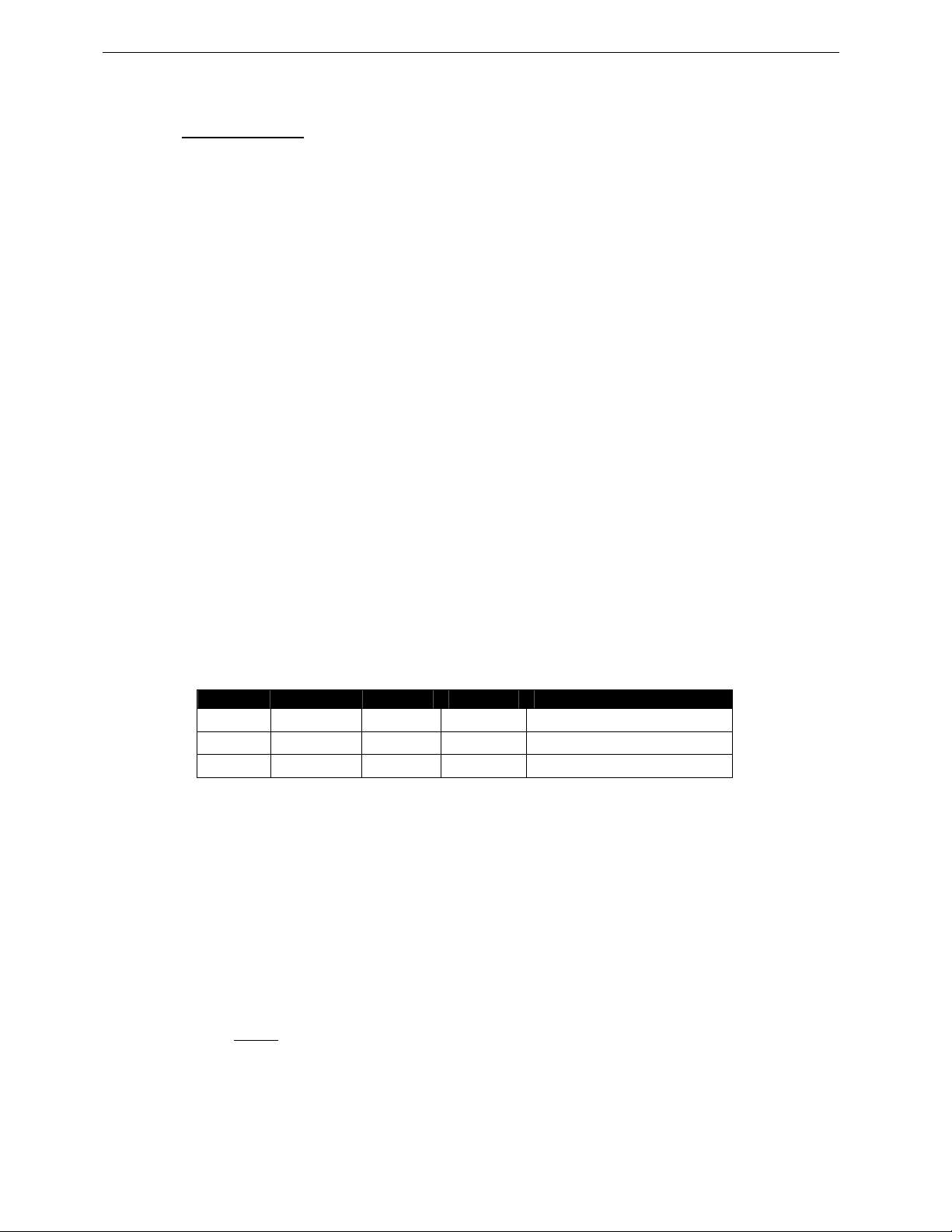

EP6/AP6 Pin # 1 / 2 3 / 4 5 / 6-

GEO D10

Passive Mode

GEO D10

Active Mode

High voltages and currents are delivered from the amplifiers to the GEO D system.

Rear 8” LF - 16 Ω

1 Negative – 2 Positive

Rear 8” LF - 16 Ω

1 Negative – 2 Positive

Front 12” LF/MF & 1.4”HF - 16 Ω

3 Negative – 4 Positive

Front 12” LF/MF - 16 Ω

3 Negative – 4 Positive

IMPORTANT

NEVER USE a male AP6 connector to feed the signal:

Not Connecte d

1.4” HF – 16 Ω

5 Negative – 6 Positive

REFER TO USER MANUAL.

EXPOSURE TO HIGH SOUND

PERMANENT HEARING LOSS.

PRESSURE LEVELS MAY CAUSE A

IN

OUT

GEO D10 REAR CONNECTOR PANEL

2.1.2 Configuring GeoD10 for Passive or Active Mode

WARNING

GEO D SERIAL #0100 to #1610 PASSIVE FI LTERS DO NOT OPERATE P ROPERLY IN ACTIVE

MODE:

IF YOUR GEO D’s ARE WITHIN THESE NUMBERS, PLEASE CONTACT NEXO OR YOUR LOCAL

DISTRIBUTOR SO THAT INSTRUCTIONS AND COMPONENTS ARE SENT TO YOU FOR FILTER

MODIFICATION

GEO D GENERAL SET-UP INSTRUCTIONS Page 11/97

(

p

GEO D SERIAL #0100 to #1610

Please contact NEXO or your local distributor so that instructions and components are sent to you for

filter modification

GEO D Serial #1611 to above

Configuring for Passive Mode (default configuration)

• Connector A & B are link together.

• Speaker Connector is in the CN1 (passive) connector located on the PCB

Speaker Connector

Configuring for Active Mode

• Speaker connector is directly plugged in connector B.

• Connector A is not used, PCB is byp assed.

Connector B

S

eaker Connector

2.1.3 GEO SUB connectors

The GEO SUB’s are connected to power amplifiers via NL4FC SPEAKON connectors (not supplied). A

wiring diagram is printed on the connection panel located on the back of each cabinet. The in/out pins of

the SPEAKON sockets are identified. The sockets are connected in parallel within the enclosures (see

the Connections Diagrams section of this manual).

NL4FC # 1- / 1+- 2- / 2+

GEO SUB

Rear 12”’s VLF - 8 Ω

1(-) Negative – 1(+) Positive

Front 18” VLF-LF - 8 Ω

2(-) Negative – 2(+) Positive

Connector B

Connector A

Connector A

unused)

Page 12/97 GEO D GENERAL SET-UP INSTRUCTIONS

2.1.4 Cabling

NEXO recommends the exclusive use of multi-conductor cables to connect the system: the cable kit is

compatible with all the cabinets, and there is no possible confu sion between LF, MF and HF sections.

Cable choice consists mainly of selecting cables of the correct sectional dimension (size) in relation to

the load resistance and the cable length. Too small a cable section will increase both its serial

resistance and its capacitance; this reduces the electrical po wer delivered to the loudspeaker and can

also induce response (damping factor) variations.

For a serial resistance less or equal to 4% of the load impedance (damping factor = 25), the maximum

cable length is given by:

= Z x S S in mm2, Z in Ohm, L

L

max

The table below indicates these values, for 3 common sizes.

in meters

max

Load Impedance (Ω)

Cable section Maximum Length (meters)

1,5 mm² (AWG #14) 3 4.5 6 9 12 18 24

2,5 mm² (AWG #12) 5 7.5 10 15 20 30 40

4 mm² (AWG #10) 8 12 16 24 32 48 64

2.1.5 Examples:

• The GEO D10 LF section has a 16 Ohms nominal impedance, so 4x GEO D10 LF section wired

in parallel will present a 16/4 = 4 Ohm load impedance. The maximum acceptable 2x2.5 mm

(AWG #12) cable length L

• The GEO SUB subwoofer has a 2 x 8 Ohms nominal impedance, therefore 2 GEO SUB’s wired

in parallel will present a 2 x 4 Ohm load impedance. The maximum acceptable 2x4 mm

#10) cable length L

Long speaker cables induce capacitive effects – up to hundreds of pF depending on the

quality of the cable - with a low-pass effect on high frequencies. If long speaker cables

must be used, ensure that they do not remain coiled while in use.

2.2 Amplifier Selection

NEXO recommends high power amplifiers in all cases. Budget constraints are the only reason to select

lower power amplifiers. A lower power amplifier will not reduce the chances of driver damage due to

over-excursion, and may actually increase the risk of thermal damage due to sustained clipping. If an

incident occurs on an installation without protection, the fact that amplifiers only generating half their

rated output power (-3dB) are used will not change anything in respect of possible damage. This is due

to the fact that the RMS power handling of the weakest component in the sys tem is alwa ys 6 to 10 dB

lower than the amplifier rating.

2 3 4 6 8 12 16

for such a cl us ter is 10 m et er s.

max

is then 16 meters.

max

IMPORTANT

2

(AWG

2

GEO D GENERAL SET-UP INSTRUCTIONS Page 13/97

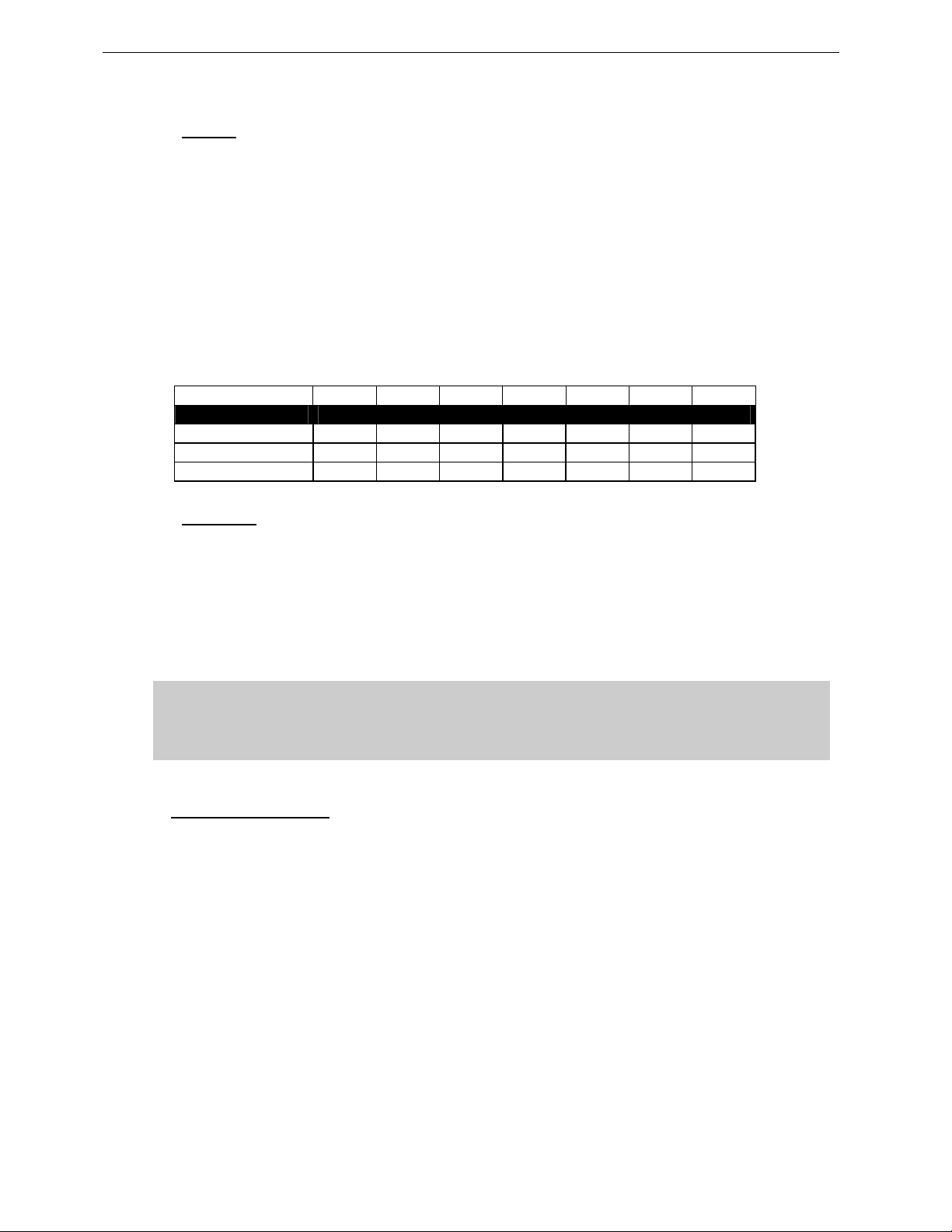

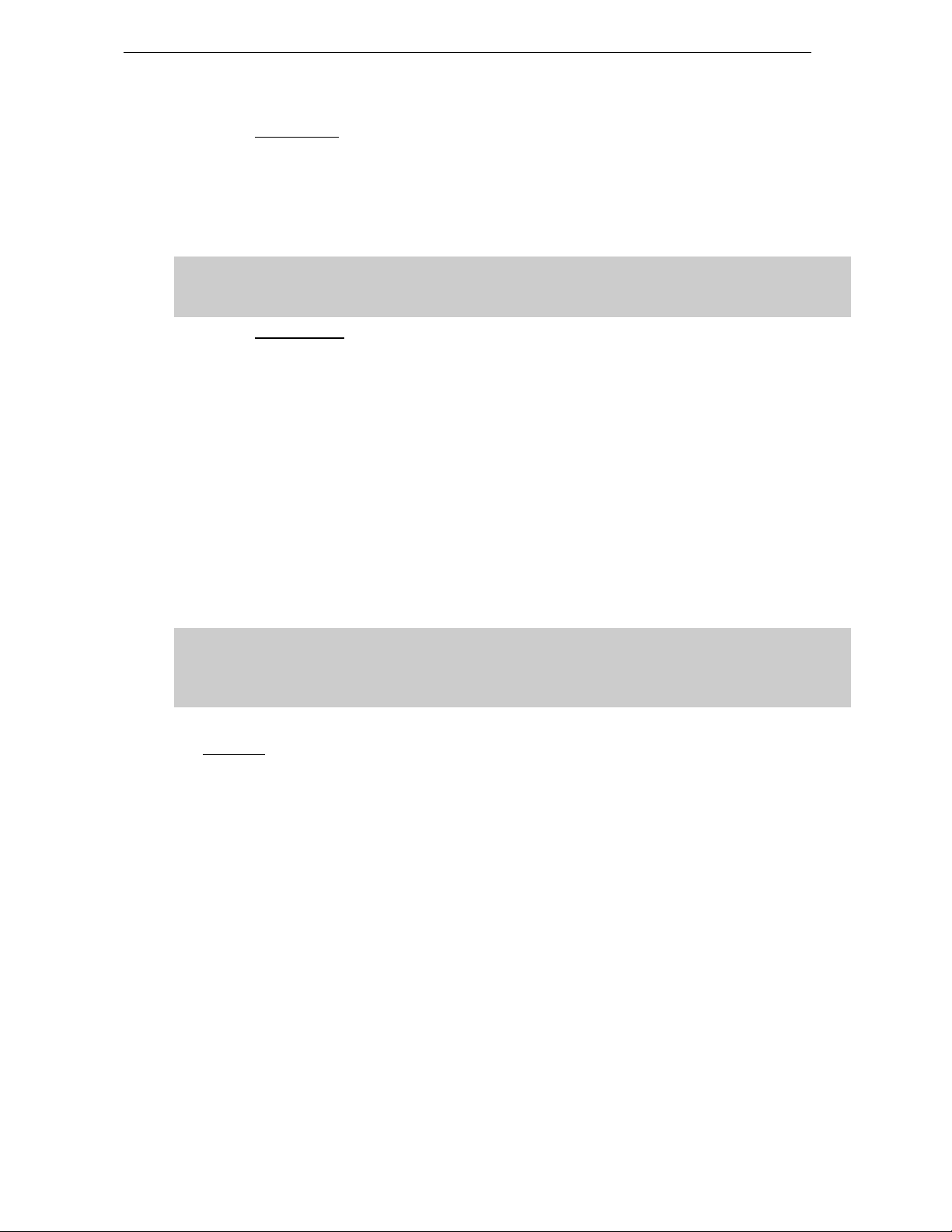

2.2.1 GEO D10 recommended amplification

GEO D10 is rated for very high power handling and has a 16 Ohms nominal impedance per channel

(Passive 2 ways or Active 3 ways).

These high impedance values allow connection of 3 to 6 cabinets in parallel for each amplifier channel.

Nexo recommends amplifiers in agreement with table below:

Recommended

Amplifier#

GEO D10 Passive Mode

3 in parallel (5.3 Ohms load)

GEO D10 Active Mode

3 in parallel (5.3 Ohms load)

GEO D10 Passive Mode

4 in parallel (4 Ohms load)

GEO D10 Active Mode

4 in parallel (4 Ohms load)

GEO D10 Passive Mode

6 in parallel (2.7 Ohms load)

GEO D10 Active Mode

6 in parallel (2.7 Ohms load)

Channel 1

LF Rear

1750 to 3100 W / 4 Ohms 1750 to 3100 W / 4 Ohms

1750 to 3100 W / 4 Ohms 1750 to 3100 W / 4 Ohms 875to 1550 W / 4 Ohms

2000 to 3600 W / 4 Ohms 2000 W to 3600 W / 4 Ohms -

2000 to 3600 W / 4 Ohms 2000 to 3600 W / 4 Ohms 1000 to 1800 W / 4 Ohms

3300 to 6000 W / 2 Ohms 3300 to 6000 W / 2 Ohms

3300 to 6000 W / 2 Ohms 3300 to 6000 W / 2 Ohms 1650 to 3000 W / 2 Ohms

LF/MF Front + HF in Passive Mode

Channel 2

Channel 3

HF in Active Mode

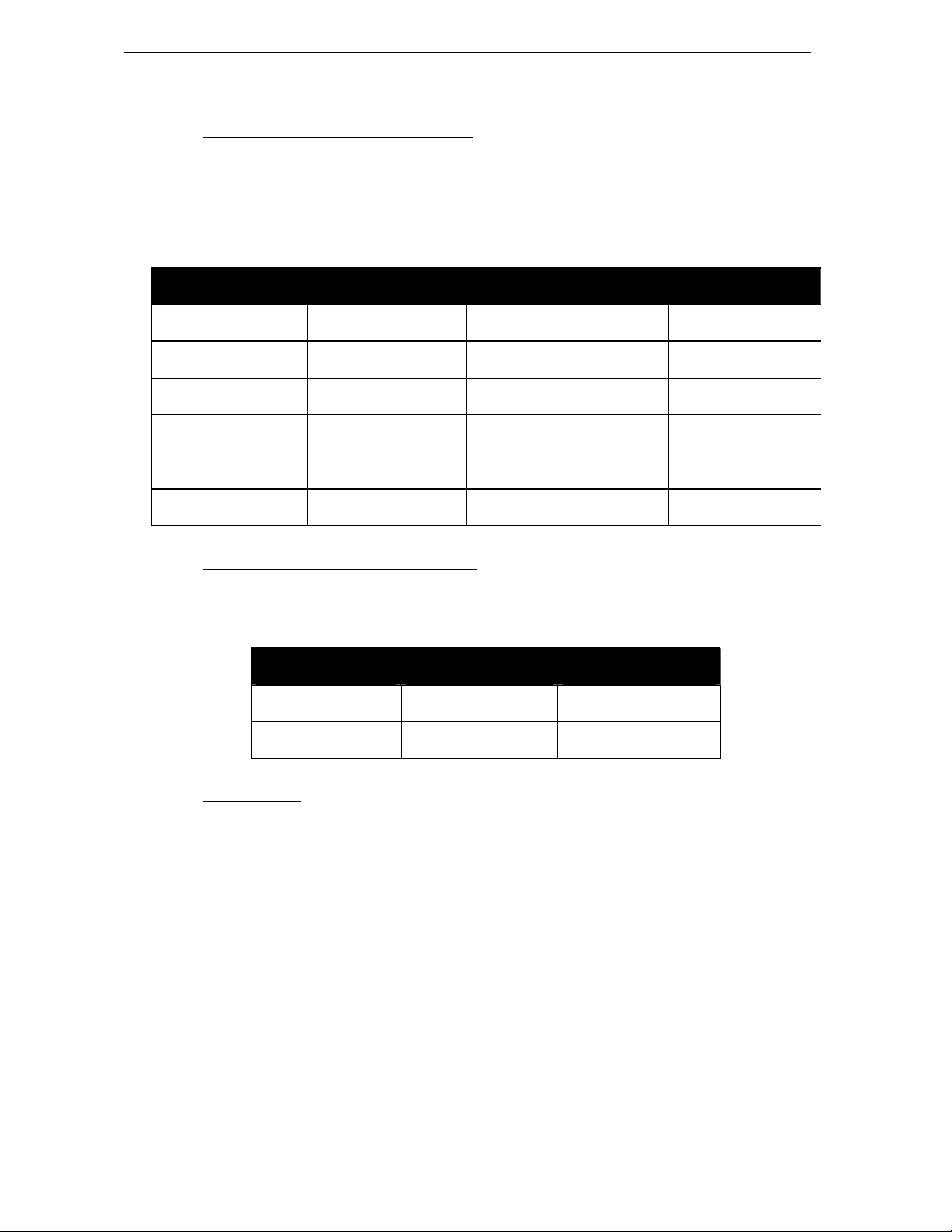

2.2.2 GEO SUB recommended amplification

The GEO SUB requires two amplifier channels delivering separately processed signals to produce its

directional pattern.

Recommended

Amplifier#

GEO SUB

Single (8 Ohms load)

GEO SUB

2 in parallel (4 Ohms load)

Channel 1

VLF Rear

1000 to 2000 W / 8 Ohms 1000 to 2000 W / 8 Ohms

2000 to 4000 W / 4 Ohms 2000 to 4000 W / 4 Ohms

Channel 2

VLF-LF Front

2.2.3 Current rating

It is very important that the amplifier behaves correctly under low load conditions. A speaker system is

reactive by nature: on transient signals like music it will require four to ten times more instantaneous

current than its nominal impedance would indicate. Amplifiers are generally specified by continuous

RMS power into resistive loads, however the only useful information about current capacity is the

specification into a 2 Ohm load. It is possible to perform an amplifier listening test by loading the amps

with twice the number of cabinets considered for the application (2 speakers per channel instead of one,

4 instead of 2) and running the amps up to the onset of clipping. If the signal does not noticeably

deteriorate, the amplifier is well adapted (overheating after approximately ten minutes is normal but

thermal pro tection must not operate too quickly after starting this test).

Page 14/97 GEO D GENERAL SET-UP INSTRUCTIONS

2.2.4 Amplifier settings

Gain valu e

Gain is the key to correct alignment of the system. It is especially important to know the gain of all

amplifiers use d in you r s et- up. The t ol er ance sh ould be about ±0.5 dB. In practice this can be difficult to

achieve because:

• Some amplifier brands have an identical input sensitivity for models of different power rating (this

infers a different voltage gain for each model). For example, a range of amplifiers with different

power outputs, all having a published input sensitivity of 775mV/0dBm or 1.55V/+6dBm, will have

a wide range of actual gains – the higher the power, the greater the gain.

• Various other brands may offer constant gain but only within a given product range, for example

they may fit fixed input sensitivity only on their semi-professional amps.

• Even if a manufacturer applies the constant gain rule to all models, the value selected will not

necessarily be the same as that chosen by other manufacturers.

• Some products can exhibit manufacturing tolerances for the same model of ±1dB or more. Some

amplifiers may have been modified, possibly without any label indicating the new values. Others

may have gain switches fitted internally where it is impossible for the user to v erify the actual

setting without opening the amplifier casing.

• In cases where you don't know the gain of your amplifier (or want to check it) please follow this

procedure:

1) Unplug any loudspeakers from the amplifier outputs

2) With a signal generator, feed a sine wave at 1000Hz at a known voltage (say 0.5V) to

the input of the amplifier under test

3) Measure the voltage at the output of the amplifier

4) Calculate the gain using the formula Gain = 20 * LOG10(Vout/Vin).

Some examples:

Vin / Gain 20dB 26dB 32dB 37dB (1.4V sensitivity / 1350Wrms)

0.1 V 1 V 2 V 4 V 7.1 V

0.5 V 5 V 10 V 20 V 35.4 V

1 V 10 V 20 V 40 V 70.8 V

Remember that constant sensitivity settings will give a different gain value when the amplifier power is

different.

NEXO recommends low gain amplifiers: +26dB is recommended, as it is at the same time adequately

low and quite common amongst amplifier manufacturers. This gain setting improves signal to noise ratio

and allows al l prec ed ing el ec tron ic eq uip ment , inc lud ing th e NX 24 2 TDc ont rol le r, to ope rat e at opt imu m

level. Remember that using a high gain amplifier will raise the noise floor proportionally.

Operating Mode

Most two channel amplifiers available on the pro-audio market have the following operating modes:

• Stereo:

two fully independent channels deliver identical power into identical loads

NEXO recommends Stereo Mode for all amplifier channels feeding GEO D10’s and GEO SUB’s.

GEO D GENERAL SET-UP INSTRUCTIONS Page 15/97

• Bridge-Mono:

reversed phase. The (single) load is connected between the two positive channel outputs using a

suitable connection. While the total output of the amplifier remains the same, the available output

voltage, the minimum impedance that can be connected and the voltage gain are d oubled as

compared with stereo operation. Typically, only channel 1 input is active. Positive and negative

output connections vary depending on amplifier manufacturers.

NEXO does not recommend Bridge Mono Mode unless amplifier power is clearly not sufficient.

the second signal channel processes the same input as the first channel, but with

IMPORTANT

When in Bridge-Mono mode, check your amplifier user manual for proper connection of

outputs 1(+) and (2+) in relation to input phase.

• Parallel-mono: the output terminals of the two channels are configured in parallel using an

internal relay. The (single) load is connected either to the output of channel 1 or to that of channel

2 (as if in stereo). While the total output of the amplifier remains the same the output voltage level

is also the same as in stereo mode. The minimum impedance that can be connected is reduced

by half due to the fact that current capability is doubled. T ypically, only channel 1 input is active.

NEXO does not recommend Parallel-Mono Mode for any GEO D10 or GEO SUB amplification.

Warning on amplifiers signal processing features

Some high-end amplifiers may include signal processing funct ions similar to those found in the NX242

TDcontroller ("loudspeaker offset integration", "limiter", "compressor," etc.). Moreover, when this

processing is digital, computation latency time can introduce a few milliseconds delay from input to

output. These functions are not adapted to specific system requirements and may interfere with the

complex protection algorithms used in the NX242.

NEXO do not advise using other protection systems in conjunct ion with the NX242 and they should be

disabled.

IMPORTANT

For proper system protection, no latency time or non-linear devices should be

introduced between the output of the NX242 TDcontroller and the input of loudspeakers

through use of DSP modules such as internal amplifier signal processing.

2.2.5 Example

For a 6 GEO D10 and 2 GEO SUB cluster, and considering an amplifier model which is capable of

delivering 2 x 3300W into 2 Ohms or 2 x 2300W into 4 Ohms, NEXO recommends the following

quantities and settings:

• GeoD Passive Mode:

2 amplifiers, 3 x GEO D10 per amplifier (1 channel LF rear, 1 channel LF/MF/HF Front), mode

switch in Stereo position, Gain switch in 26 dB gain position, all dynamic or filter processing

switches off.

• GEO SUB :

1 amplifier, 2 x GEO SUB per amplifier (1 channel VLF rear, 1 channel VLF/LF Front), mode

switch in Stereo position, Gain switch in 26 dB gain position, all dynamic or filter processing

switches off.

Which gives a total of 3 identical amplifiers for such a cluster.

Page 16/97 NS-1 SIMULATION SOFTWARE

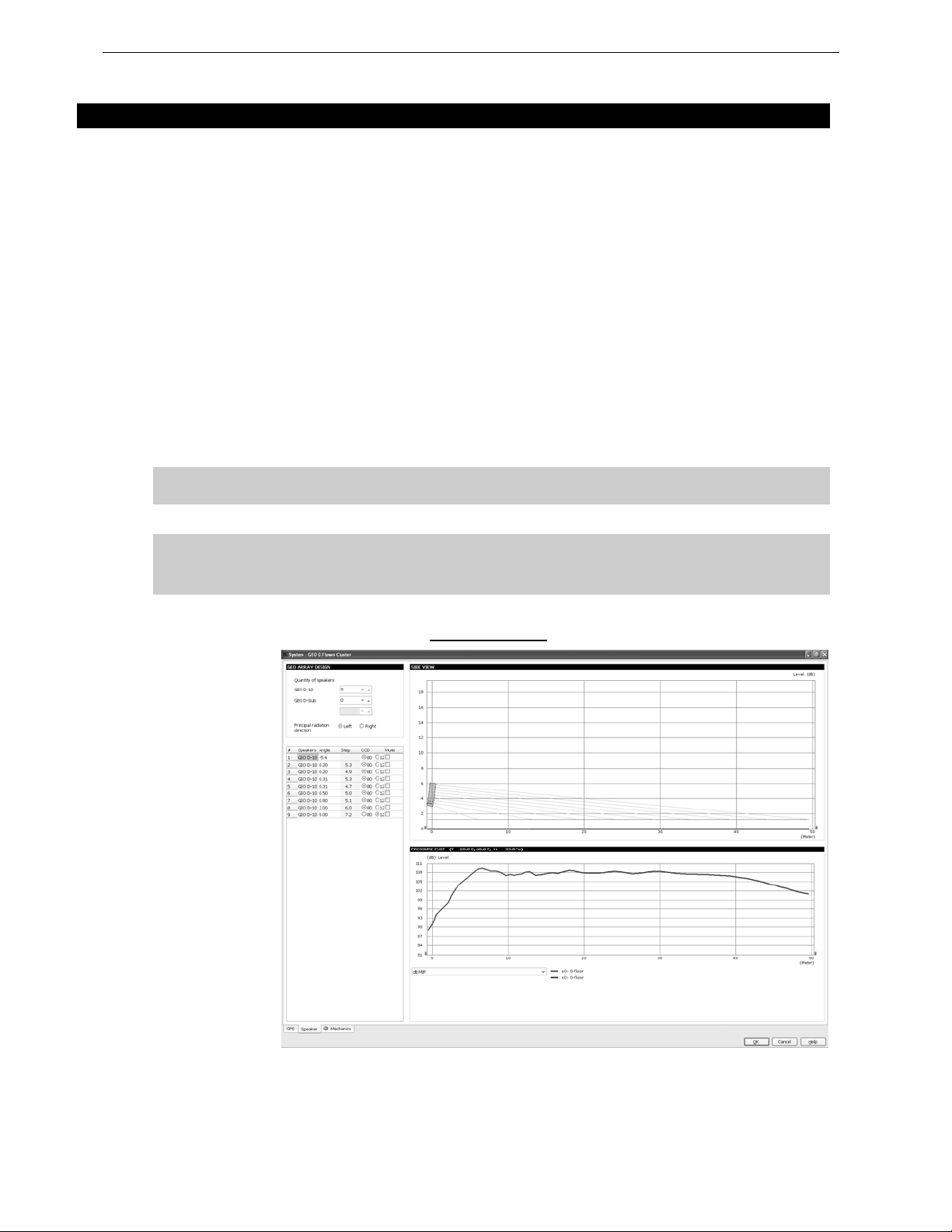

3 NS-1 SIMULATION SOFTWARE

NS-1 software is a R&D simulation tool derived application. It processes measured speaker data with

complex mathem atical algorit hms to ass ist the us er in optimizing system design. Due to the complexity

of the interaction of multiple cabinets, it is simply not possible to reliably design curved vertical arrays

without using the processing power of a computer to predict the optimum array structure for a given

audience geometry. The design logic is far more complex than looking at a section drawing of the

venue, measuring the overall angle needed to cover the audience from the cluster location, and dividin g

by 10 degrees to determine the require d amount number of GEO D10 & GEO SUB cabinet s.

NS-1 is an easy to use tool that allows to shape the energy leaving the cluster to fit the audience. It

predicts pressure levels radiated from the system to ensure enough cabinets are provided for the

application, as well as mechanical constraints for safe flown systems.

In addition, it provides mechanical information for all clusters in agreement with Structural Analysis

Reports (available in the Help section): dimensions, weight, gravity center position, forces, moments,

working load and safety factor.

Geo D10 and GEO SUB Structural Analysis Reports have been validated by German Certification

Organization RWTUV systems GmbH.

NS-1 installation package includes all NEXO User Manuals, Structural Analysis Reports and Certificates

PDF files (which can be found in the last section of User Manuals).

NS-1 is a freeware available for all Nexo users. Please contact your local distributor for

licensing procedure.

IMPORTANT

Never install a GEO D / GEO SUB cluster without checking its acoustical performances

and mechanical safety in NS-1 prior to installation.

Any question or bug report please contact technical@nexo.fr

NS-1 GEO S12 ACOUSTIC PAGE

CONFIGURABLE DIRECTIVITY DEVICE Page 17/97

4 CONFIGURABLE DIRECTIVITY DEVICE

The GEO Wavesource controls dispersion of acoustic energy using an hyperboloid acoustical reflector

in the “coupling plane” (the vertical plane of a curved vertical tangent array) and a dif fraction slot in the

“non-coupling plane” (the horizontal plane of a curved vertical tangent array). The patented

Configurable Directivity Device consists of bolt-on flanges that alter the diffraction slot’s exit flare rate.

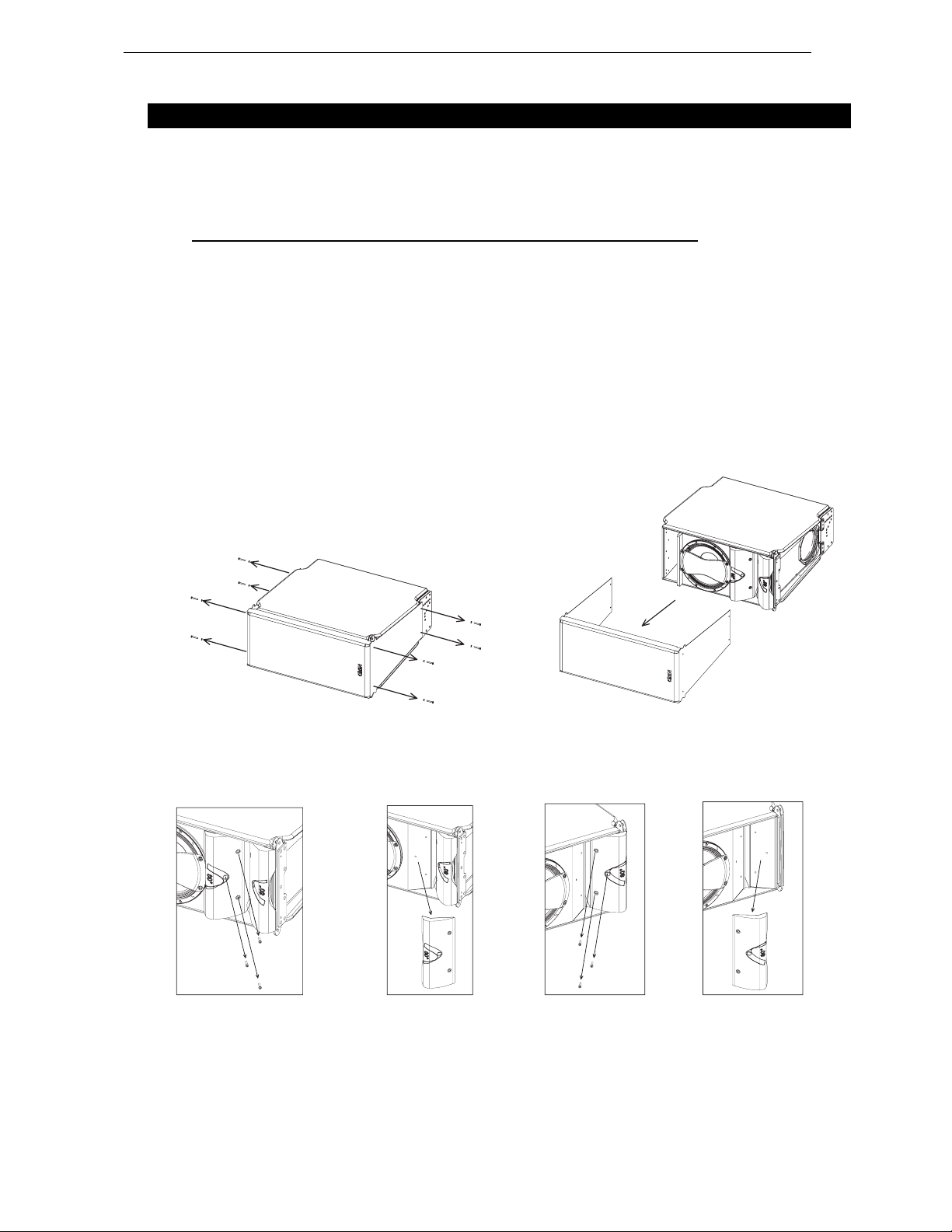

4.1 Installing & removing GEO’s Configurable Directivity flanges

GEO D10 are shipped in the 80° dispersion configuration, with the 120° flanges in a separate bag.

To change dispersion in the non-coupling plane to 120°:

• remove the front grill (drawings below);

• remove the three TORX (head 25) screws per flange on each side of the GEO Waveguide

(drawings below) ;

• install the 120° flanges with the six TORX screws

• re-install the grid, being carefull that the NEXO logo must be on the GEO Waveguide side.

REMOVING THE GRILL

REMOVING THE FLANGES

Page 18/97 CONFIGURABLE DIRECTIVITY DEVICE

4.2 When & where to use Configurable Directivity flanges

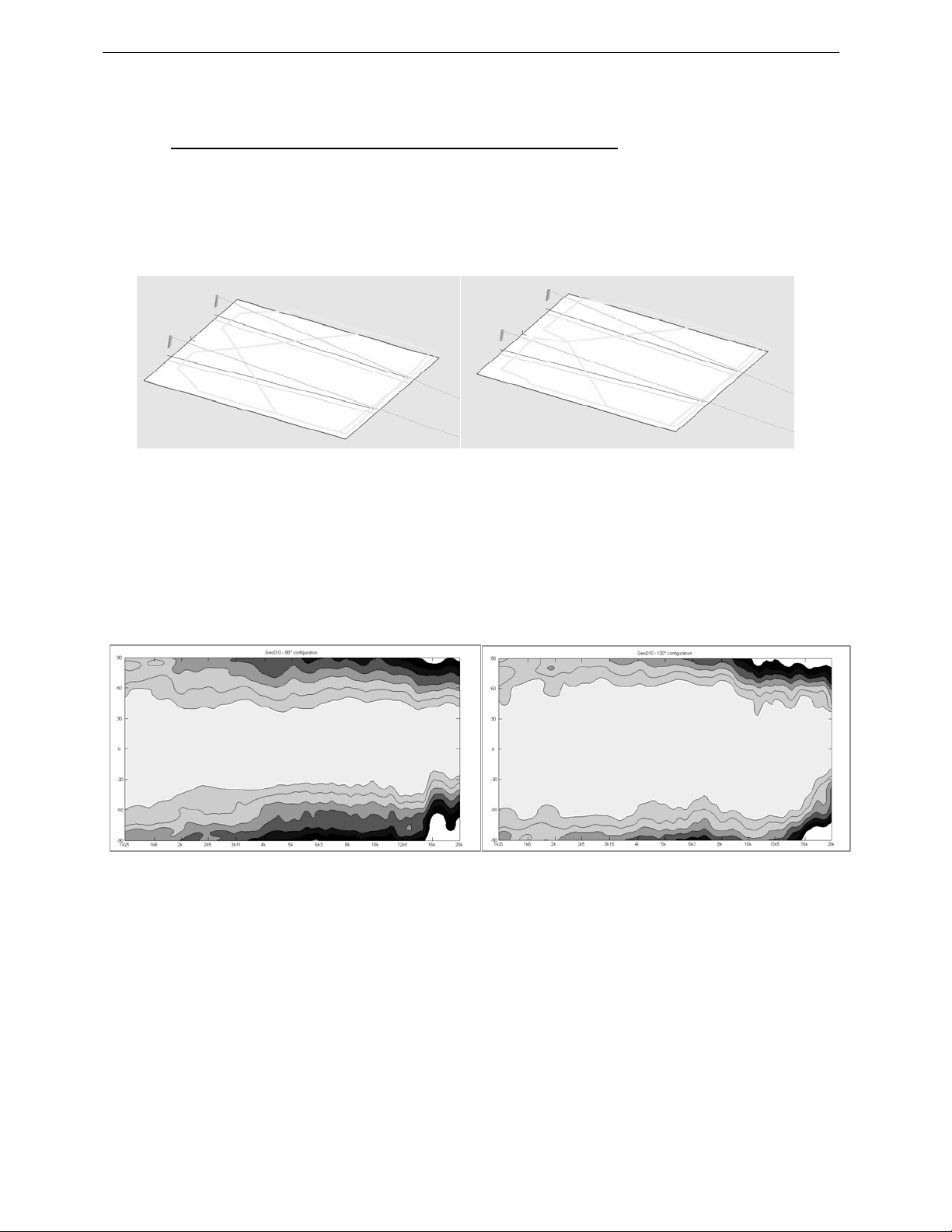

The diagrams show audience area coverage for a stereo system. While the GEO cluster will deliver

even SPL from the front to the rear of this audience area, there are “holes” near the front in the centre

and at the outside edges. We cannot fill the outside coverage gaps without enlarging the centre gap,

and vice versa (left figur e below).

If 120° Configurable Directivity Devices are installed at the bottom cabinet of the clusters, coverage will

look more like the pattern in right figure below.

-6dB coverage, all GEO D10’s in 80° configuration -6dB coverage, bottom GEO D10’s in 120° configuration

In curved vertical arrays, the 120° Configurable Directivity Device can be used:

• On the bottom row of curved vertical arrays, to fill in coverage gaps in the front rows.

• On all rows of curved vertical arrays, in cases where 120° of horizontal coverage is

preferred to 80°.

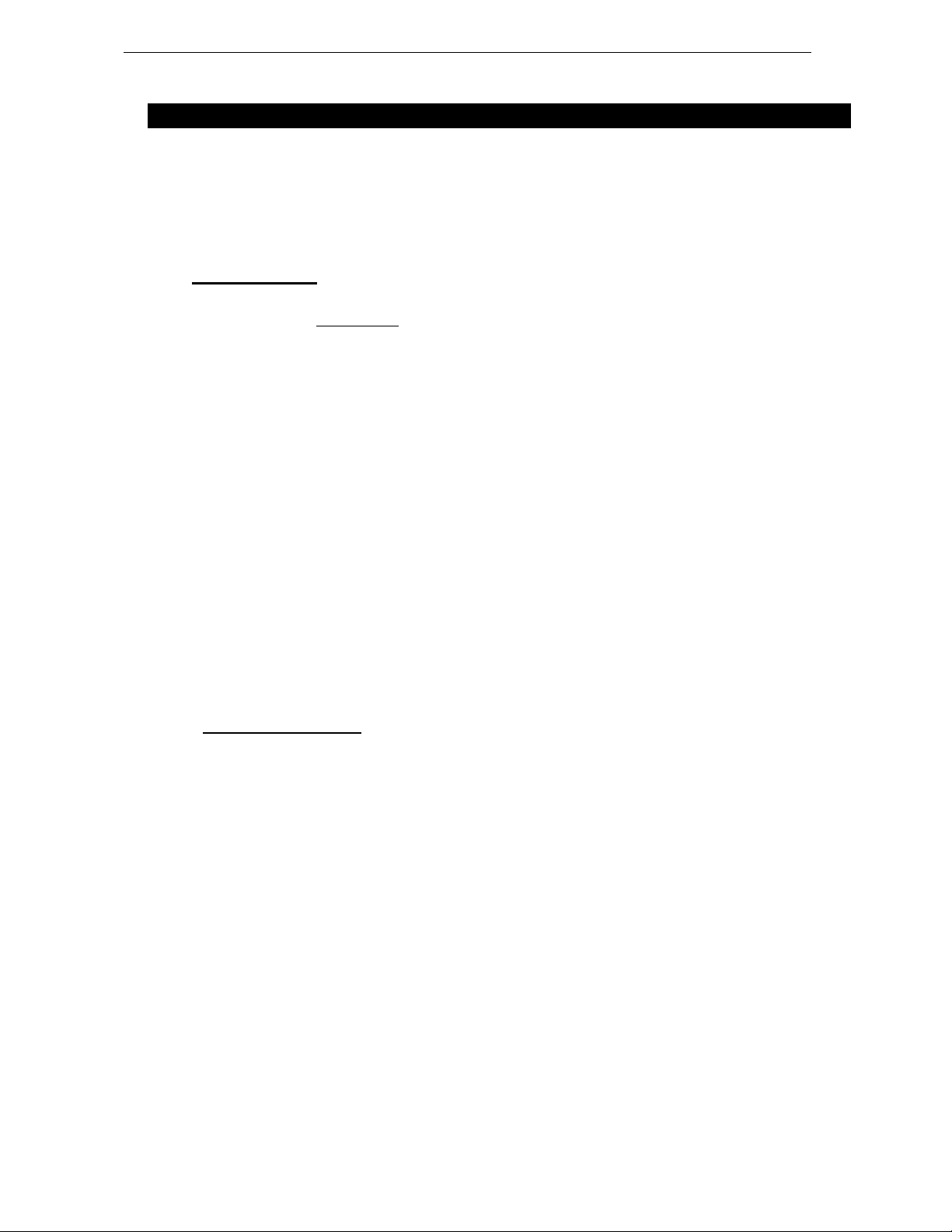

Figure below shows isocontour coverage for 80° and 120° configurations.

FIGURE 3: 80° AND 120° CONFIGURATIONS ISOCONTOUR COVERAGE

GEO D RIGGING PROCEDURE Page 19/97

5 GEO D RIGGING PROCEDURE

Before proceeding with assembly of GEO D arrays, please ensure that the components are present and

undamaged. A component list is appended to this manual. In the event of any shortage, please contact

your supplier.

For maximum efficiency the GEO D rigging system requires three experienced persons for set-up:

typically one motor hoist operator, and one GEO D operator per side of the array. Good synchronisation

and crosscheck between the operators are key elements for a reliable and safe set-up.

5.1 SAFETY FIRST

GEO D / GEO SUB Rigging System structural computations and related documents are available in

Geosoft2 or at Nexo (info@nexo.fr

We include this section to remind you of safe practice when flying the GEO D / GEO SUB system.

Please read it carefully. However, user must always apply his or her knowledge, experience and

common sense. If in any doubt, seek advice from your supplier or NEXO agent.

This manual offers guidance only for GEO D / GEO SUB loudspeaker systems. References in this

manual to other rigging equipment such as motor hoists, steels, shackles etc. are made to clarify the

description of GEO D / GEO SUB procedures. The user must ensure that operators are properly trained

by other agencies in the use of these items.

The GEO D / GEO SUB Rigging System has been optimised for the deployment of curved vertical

tangent arrays of GEO D / GEO SUB loudspeakers. Vertical angle adjustment between cabinets has

been limited to specific settings to ensure correct acoustic coupling.

The GEO D / GEO SUB Rigging System is a professional precision tool set, and should be handled with

extreme care. Only persons who are fully conversant with the operation of the GEO D / GEO SUB

Rigging System and provided with suitable safety equipment should deploy GEO Arrays. Misuse of the

GEO D / GEO SUB Rigging System could lead to dangerous consequences.

Used and maintained correctly, the GEO D / GEO SUB Rigging System will give many years of reliable

service in portable systems. Please take the time to read and understand this manual. Always use

GEOSoft2 to determine the optimum angle settings for a particular venue, hang point and curved

vertical GEO D / GEO SUB. Applied forces and moments are strongly cabinet quantity and angle

configuration dependent. Cluster configuration must be implemented and validated in Geosoft2 prior to

installation.

) upon request.

5.1.1 Flown Systems Safety

• Always inspect all the rigging components and cabinets for damage before assembly. Pay

special attention to the lifting points, and safety clips. If you suspect that any of the components

are damaged or defective, DO NOT USE THE AFFECTED PARTS. Contact your supplier for

replacements.

• Read this manual carefully. Also be familiar with the manuals and safe working procedures for

any ancillary equipment that will be used with the GEO D / GEO SUB Rigging System.

• Appli ed forces and moments are strongly cabinet quantity and angle configuration dependent.

Cluster configuration must be implemented and validated in Geosoft2 prior to installation.

• Ensure that all local and National regulations regarding the safety and operation of flying

equipment are understood and adhered to. Information on these regulations can usually be

obtained from Local Government Offices.

• When deploying a GEO D / GEO S UB system always wear protective headwear, footwear and

eye protection.

• Do not allow inexperienced persons to handle a GEO D / GEO SUB system. Installation

personnel should be trained in loudspeaker flying techniques and should be fully conversant with

this manual.

Page 20/97 GEO D RIGGING PROCEDURE

• E nsure that motor hoists, hoist control systems and ancillary rigging components are currently

certified as safe and that they pass a visual inspection prior to use.

• Ensure that public and personnel are not allowed to pass beneath the system during the

installation process. The work area should be isolated from public access.

• Never leave the system unattended during the installation process.

• Do not place any object, no matter how small or light, on top of the system during the installation

procedure. The object may fall when the system is flown and is likely to cause injury.

• Secondary safety steels must be installed once the system has been flown to the operating

height. Secondary steels must be fitted irrespect ive of requirements of the local s afet y standards

applicable to the territory.

• Ensure that the system is secure and prevented from pivoting around the motor hoist.

• Avoid any form of excessive dynamic loading to the assembly (structural computations on GEO

D / GEO SUB Rigging System are based on a 1/1.2 factor for hoist or motor acceleration).

• NEVER attach any item to the GEO D / GEO SUB system ot her than the GEO D / GEO SUB

accessories.

• When flying outdoor systems ensure that the system is not exposed to excess ive wind or snow

loads and is protected from rainfall.

• T he GEO D / GEO SUB Rigging System requires regular i nspect ion and testing by a competent

test centre. NEXO recommend that the system is load tested and certified annually or more

frequently if local regulations require.

• When de-rigging the system ensure that the same duty of care is given to the proced ure as for

the installation. Pack GEO D / GEO SUB components carefully to prevent damage in transit.

5.1.2 Ground Stacking Safety

Statistically, many more injuries occur due to unstable ground stacked PA systems than those

associated with flown systems. There are several reasons for this fact, however the message is clear:

• Always survey t he supporting structure upon which a ground stack is to be built. Always look

beneath PA wings to inspect the deck support and if necessary ask for the stage scrims and

dressings be removed to allo w access.

• If the stage surface slopes, as it does in some theatres, ensure that the system is prevented from

sliding forwards due to vibration. This may require the fitting of timber battens to the stage floor.

• For outdoor systems ensure that that the system is protected from wind forces which might

cause the ground stack to become unstable. Wind forces can be huge, especially upon l arge

systems, and should never be underestimated. Observe meteorological forec asts, calculate the

“worst case” effect upon the system prior to erection and ensure that the system is secured

appropriately.

• Take care when stacking cabinets. Always employ safe lifting procedures and never attempt to

build stacks without sufficient personnel and equipment.

• Never allow anyone, whether operators, artists or members of the public to climb onto a grou nd

stacked PA system. Anyone who needs to climb over 2m (6 ft) high should be fitted with suitable

safely equipment including a clip-on harness. Please refer to local Health and Safety legislation in

your territory. Your dealer can help with advice on access to this information.

• Apply the same attention to all safety matters when de-stacking systems.

• B e aware that safet y procedures a re as important in the truc k and in the ware house as t hey are

at the venue.

GEO D RIGGING PROCEDURE Page 21/97

5.1.3 Contacts

Correct training is fundamental to safe practise when working with loudspeakers flying systems. NEXO

recommend that users contact local industry associations for information on specialist course.

Information for International training agencies can be obtained by contacting either:

The Production Services Association

(PSA),

School Passage,

Kingston-upon-Thames,

KT1 SDU Surrey,

ENGLAND

Telephone: +44 (0) 181 392 0180

ESTA

Rigstar Training and Testing Center

82 Industrial Dr. Unit 4

Northampton, Massachusetts 01060 U.S.A.

Phone: 413-585-9869 -- Fax: 413-585-9872

school@rigstar.com

Entertainment Services & Technology Association

875 Sixth Avenue, Suite 1005

NEW YORK, NY 10001 USA

Phone: 212-244-1505 – Fax: 212-244-1502

info@esta.org

- www.esta.org

Page 22/97 GEO D RIGGING PROCEDURE

5.2 General Description

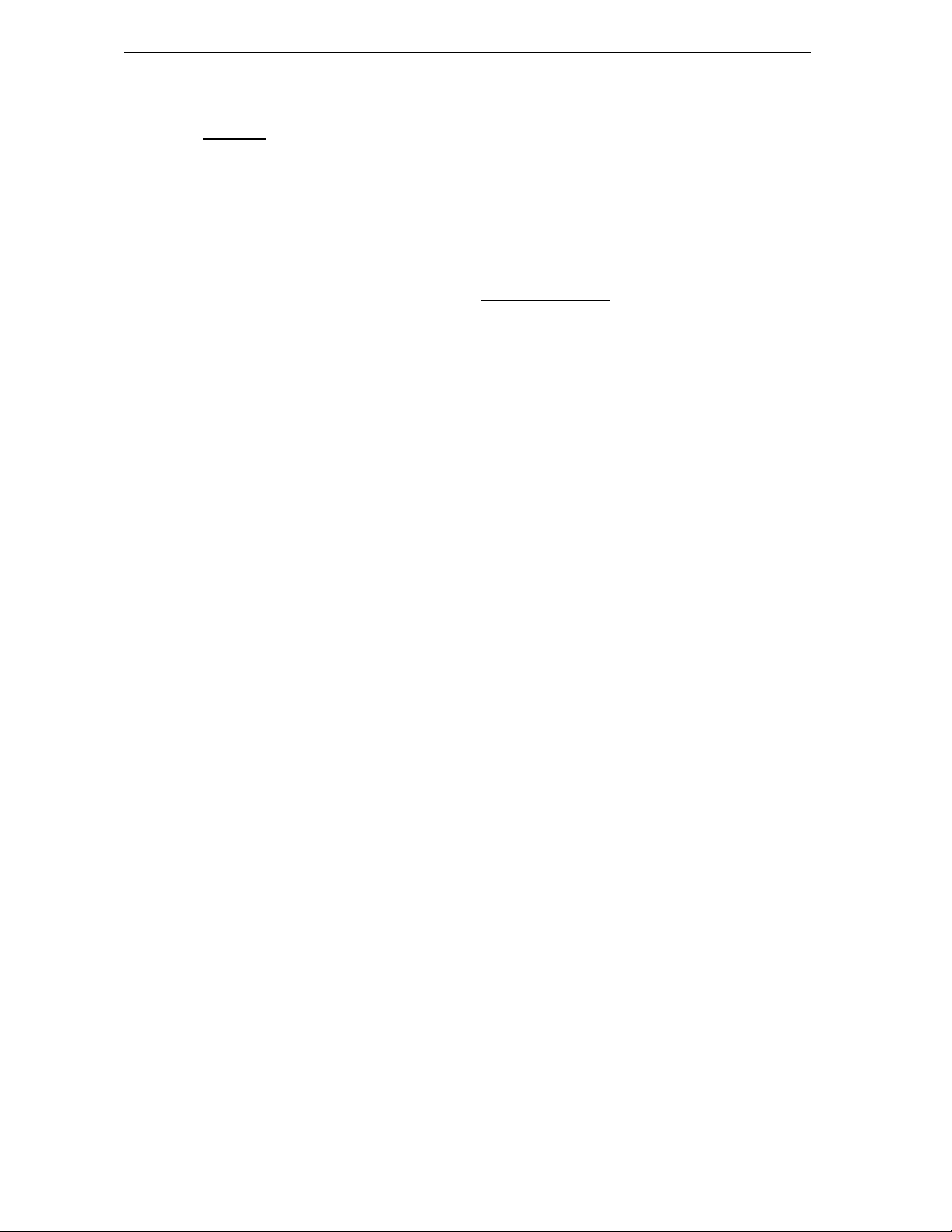

5.2.1 GEO D10 and GEO SUB

Each GEO D and GEO SUB Array Module includes an individual rigging system, which is mounted at

the NEXO factory.

GEOD10 ARRAY MODULE GEO S SUB ARRAY MODULE

GEO D10 and GEO SUB angle sequences are identical and follow logarithmic scales. Angle setting

values are:

• Bumper to first cabinet (GEO D10 or GEO SUB): 0°

• Cabinet t o cabinet (GE OD10 or GEO SUB): 0.20° - 0.315° - 0.50° - 0.80° - 1.25° - 2.0° - 3.15° -

5.0° - 6.3° - 8.0° - 10°

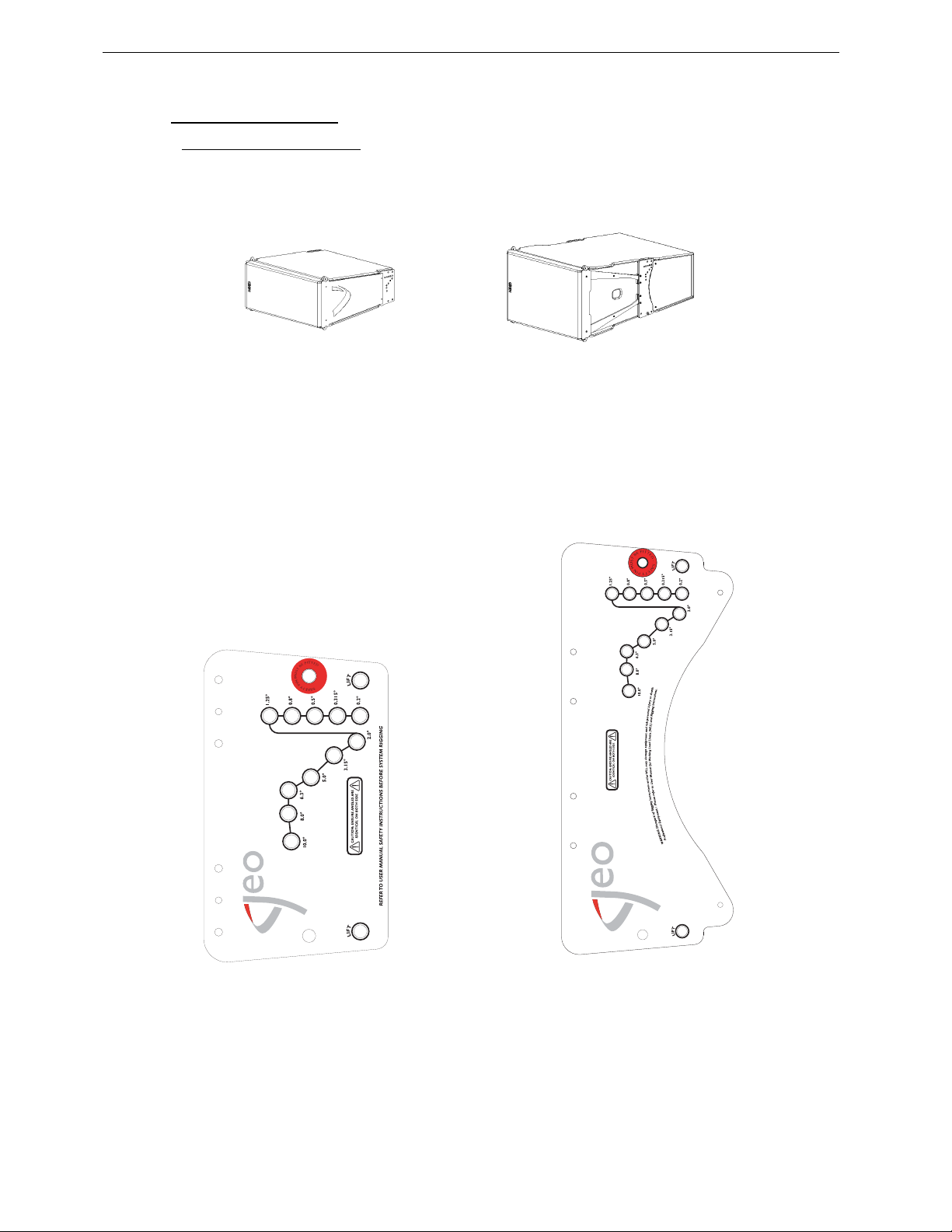

GEO D10 RIGGING PLATE GEO SUB RIGGING PLATE

GEO D RIGGING PROCEDURE Page 23/97

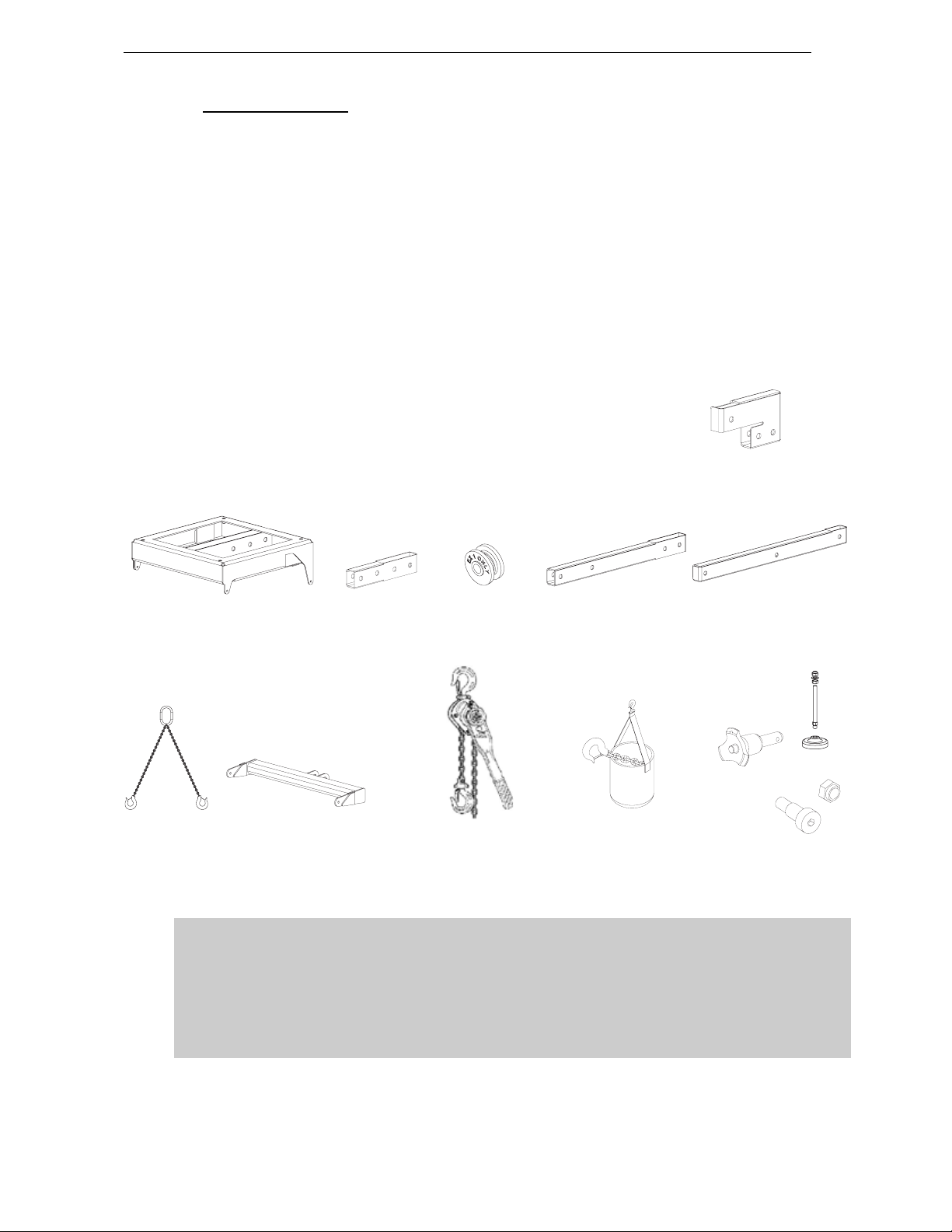

5.2.2 Rigging Accessories

Rigging Ac cessories are:

• Bumper (GEOD-BUMPER)

• Short Extension Bar (GEOD-EXBAR1)

• Compression Wheel for Short Extension Bar EXBAR1 (GEOD-ORP)

• Two legs Bridle (GEO-BRIDLE)

• Long Extension Bar (GEOD-EXBAR2)

• Bottom Extension Bar (GEOD-EXBAR3)

• Front Extension Bar (GEOD-EXBAR4)

• Bottom Bumper (GEOD-BTBUMPER)

• Chain Lever Hoists (LEVA0750 or LEVA1500)

• Chain Bag (CHBAG)

• Push-Pins (BLGEOD)

• Shoulder Bolts an d N ut s (G EOD -BNF IX)

• Bumper Stands stacking kit (GEOD-BUDP)

GEOD-EXBAR4

GEOD-BUMPER GEOD-EXBAR1 GEOD-ORP GEOD-EXBAR2 GEOD-EXBAR3

6 x

GEO BRIDLE GEOD-BTUMPER GEOD-LEVA750 & LEVA150 CHBAG BLGEOD -GEOD-BNFIX

GEOD-BUDP

IMPORTANT

All GEOD / GEO SUB Rigging Components are specifically rated in agreement with

structural co m putations.

Never use other accessories – including push-pins - when assembling GEO D / GEO SUB

clusters than the ones provided by NEXO: NEXO will decline responsability over the

entire GEOD / GEO SUB rigging system if any component is purchased from different

supplier.

x 4

Page 24/97 GEO D RIGGING PROCEDURE

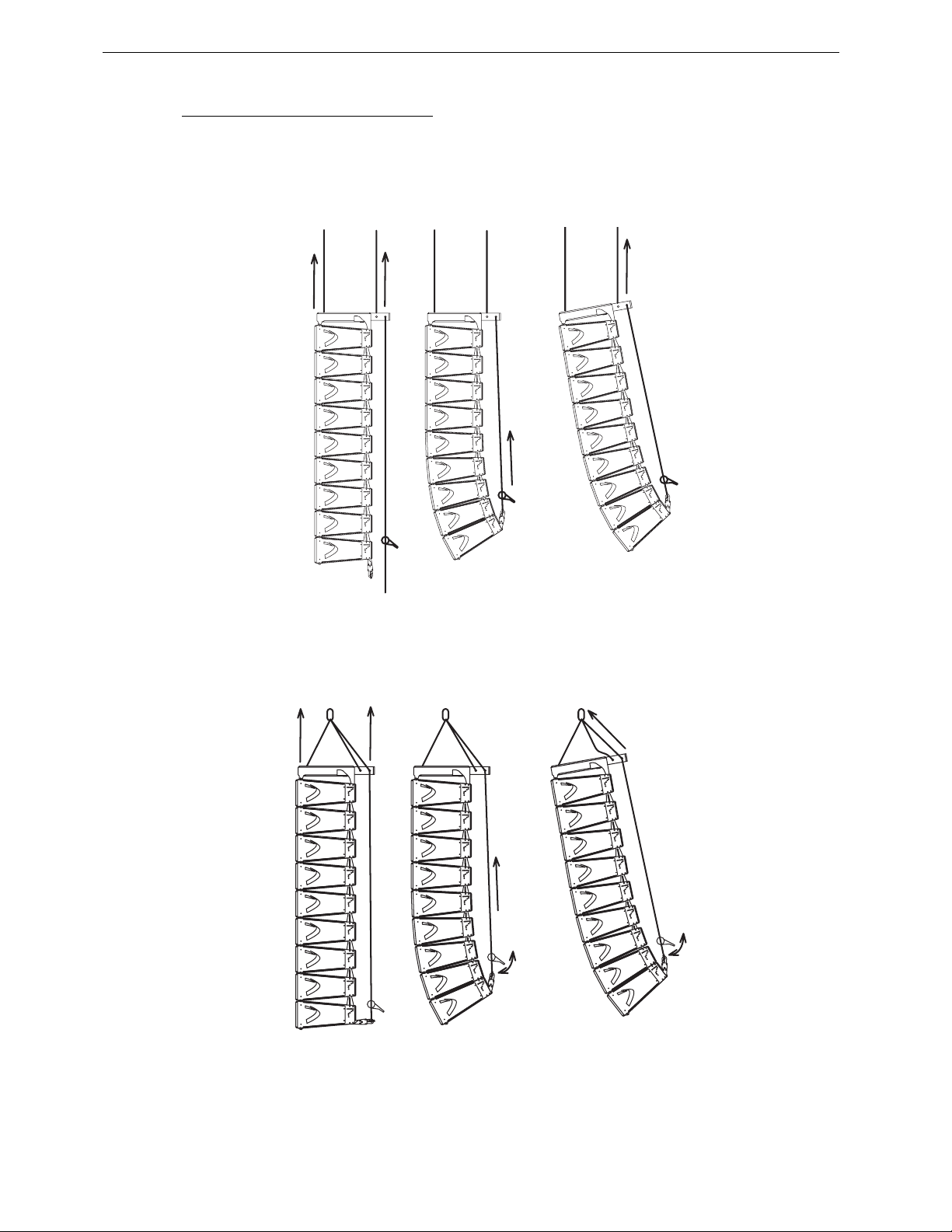

5.2.3 Configurations and operating mode

General Pr inciple

GEO D10 / GEO SUB rigging system operates in compression mode: pull-back force applied between

the extreme bottom cabinet and the top bumper set angles between cabinets. When the array is lifted

into position all cabinets are at 0° (1) and it is only when the pull-up force is applie d that the correct

angles are obtained (2). Bumper angle is then set by adjusting front and rear motors (3).

(1) LIFTING CLUSTER VERTICALLY (2) APPL YING COMPRESSION (3) ADJUSTING BUMPER ANGLE

In case GeoD10 cluster is flown from one rigging point (8 GEO D maximum, no GEO SUB allowed),

array is lifted with all cabinets at 0°. Pull-back force and bumper angle are then set with the Chain Lever

Hoist LEVA750. Please refer to sections below for detailed desc ription.

(1) LIFTING CLUSTER VERTICALLY (2) APPL YING COMPRESSION (3) ADJUSTING BUMPER ANGLE

GEO D RIGGING PROCEDURE Page 25/97

ER

ER

gging

ER

GEOD-BUPDP

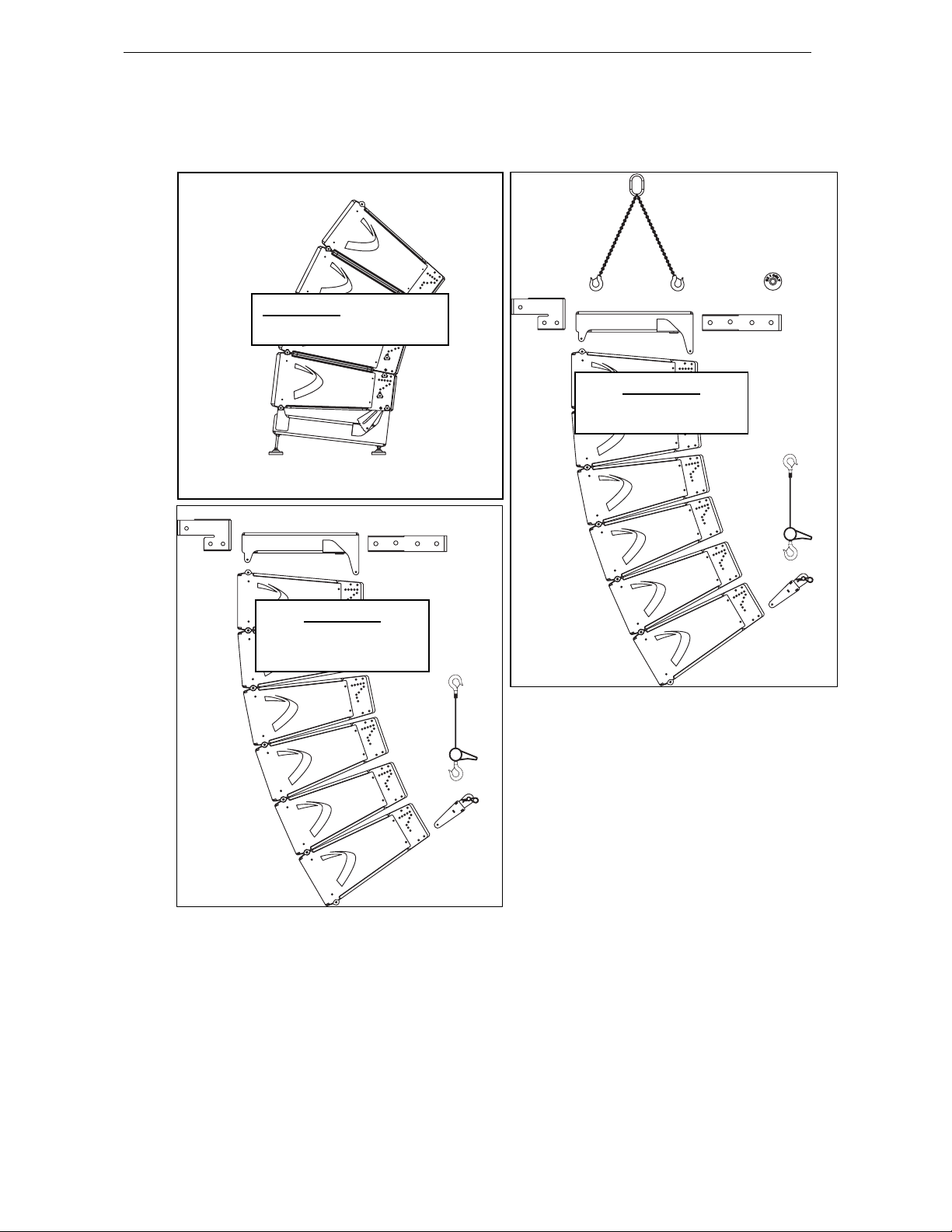

Described Cases

Sections below describe GEO D10 and GEO SUB clusters rigging procedures for the following cases:

GEOD-EXBAR4

Section 5.3

GEOD Ground Stacked

GEOD-BUMP

GEOD-BUMPER

GEOD-EXBAR1

Section 5.5

GEO D Cluster

Two Rigging Points

GEOD-EXBAR4

GEOD-BUMPER

GEO D Cluster

One Ri

LEVA750

GEOD-BTBUMP

GEO-BRIDLE

GEOD-ORP

GEOD-EXBAR1

Section 5.4

Point

LEVA750

GEOD-BTBUMP

R3

GEOD-EXBAR4

GEOD-EXBAR4

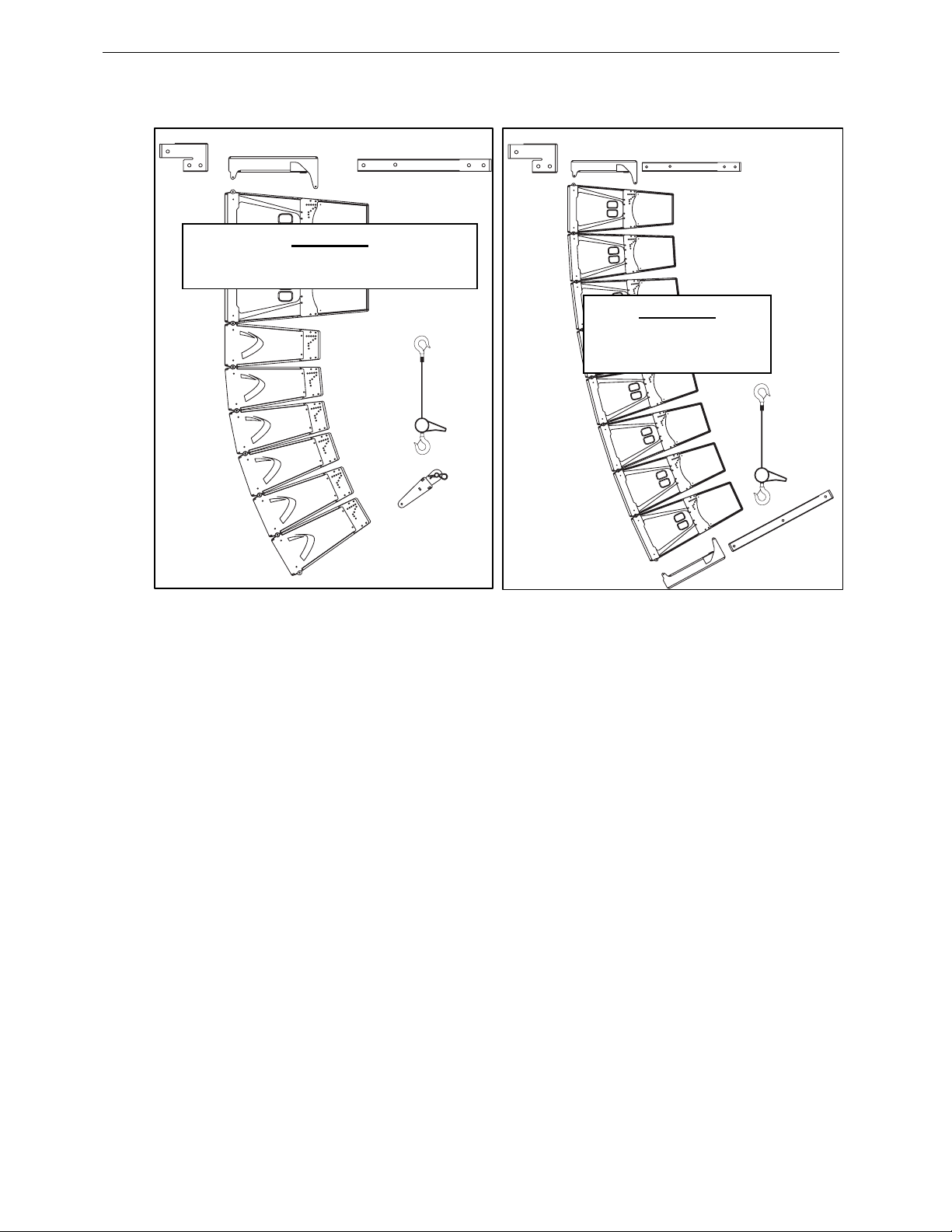

Page 26/97 GEO D RIGGING PROCEDURE

GEOD-BUMPER

GEOD-EXBAR2

GEOD-BUMPER

GEOD-EXBAR2

Combined GEO D – GEO SUB Cluster

Section 5.6

Two Rigging Points

Section 5.7

GEO SUB Cluster

Two Rigging Points

LEVA750

LEVA1500

GEOD-BTBUMPER

GEOD-EXBA

GEOD-BUMPER

GEO D RIGGING PROCEDURE Page 27/97

5.3 GEO D – GEO SUB Ground Stacked

Stacking a GEO D10 cluster requires the following accessories:

• 1 x GEO D Main Bumpe r (G EOD- BU MPER )

• 1 x GEO D Bumper Stands kit (GEOD-BUDP)

• 6 x GEOD push-pins per stacked GEO D10 or GEO SUB (BLGEOD )

• or 1 x GEOD shoulder bolts and nuts kit for fixed installations per stacked GEO D (GEOD-

BNFIX)

IMPORTANT

Ensure platform (ground, riser…) is solid enough to support stacked cluster weight

(distributed on four points), and perfectly horizontal.

5.3.1 Allowed stacked configurations

IMPORTANT

Allowed Stacked Configurations are:

- 4 GEO D maximum

- or 1 GEO SUB max (bottom) + 3 GEOD max (top)

- or 2 GEO SUB

Bumper angle must never exceed +/- 6.5°

5.3.2 Installing Bumper Stands on Bumper

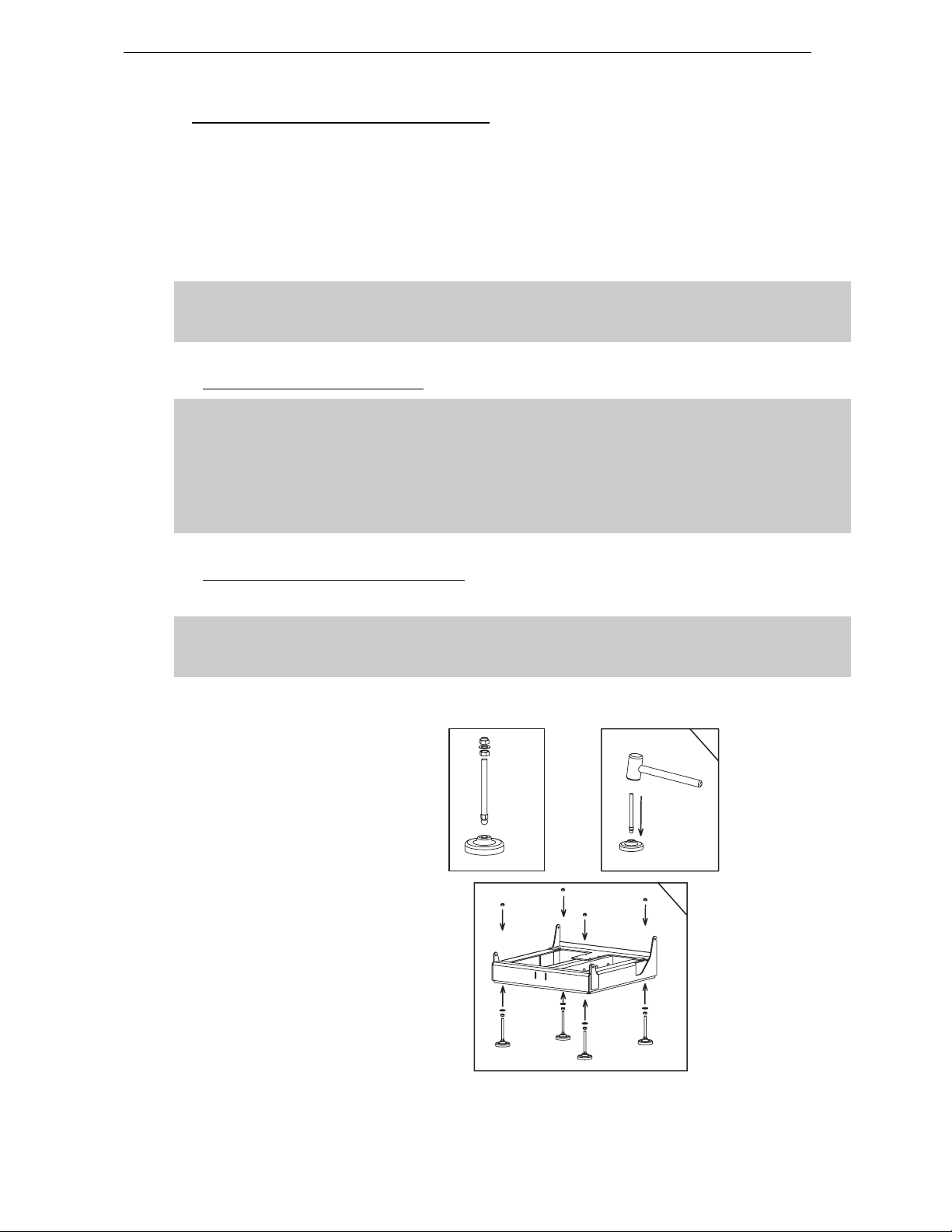

• Install bumper stands and nuts according to drawing below.

IMPORTANT

Make sure nuts are properly positioned on both sides of the bumper. These are

mandatory for system safety

• Adjust length of each stand so that desired bumper angle is achieved (bumper side edge angle in

relation to horizontal); ensure that bumper front edge is perfectly horizontal;

• Secure nuts.

INSTALLING BUMPER STANDS

x 4

1

2

Page 28/97 GEO D RIGGING PROCEDURE

5.3.3 Bumper to first GEO D10 assembly

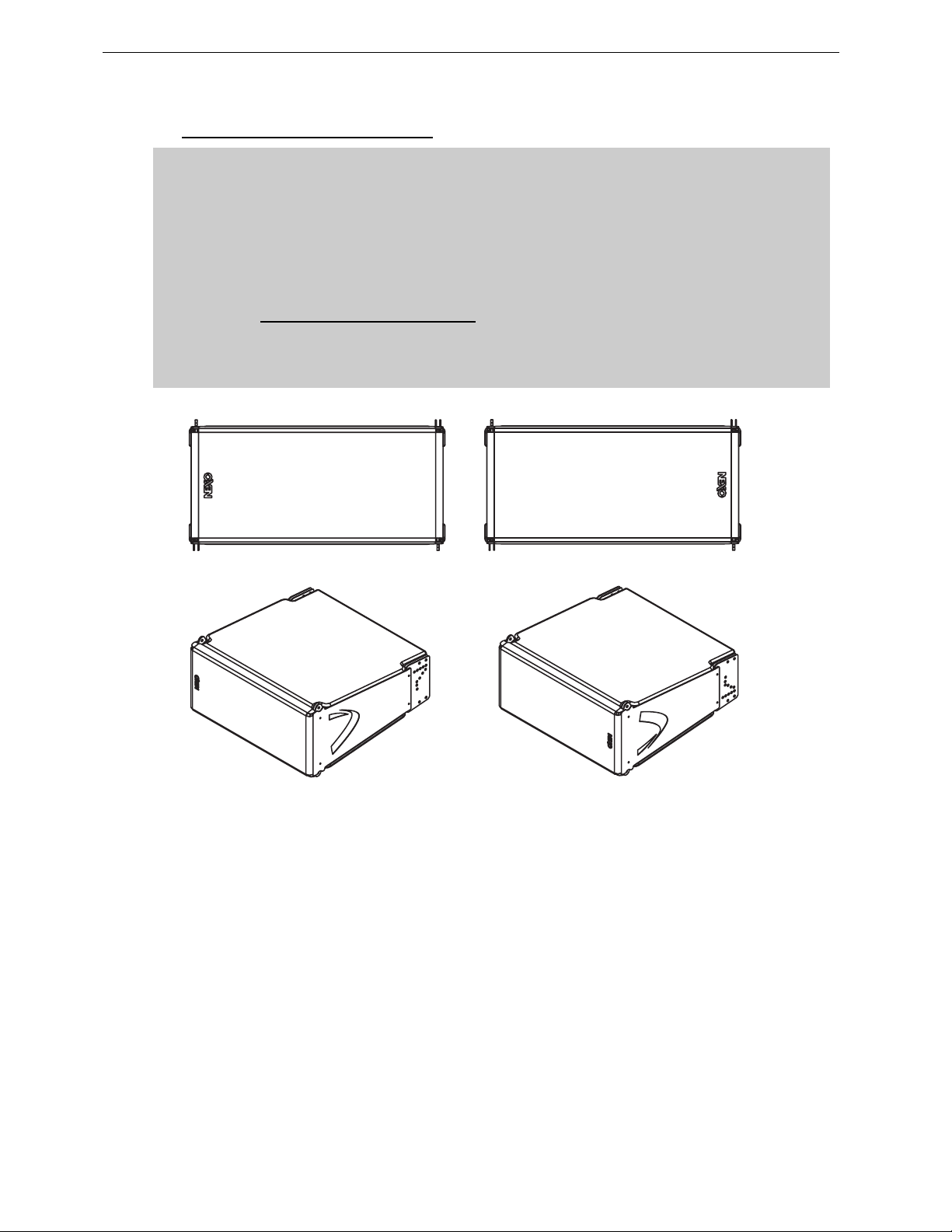

IMPORTANT

GEO D10 can be stacked “Left” or “Right” :

- “Left” means Nexo logo on front grid is left as seen from front;

- “Right” means Nexo logo on front grid is right as seen from front.

GEO D10 can be connected to bumper “Left” or “Right” by simply flippin g the cabinets

upside down: do not reverse rigging plates

Whenever possible, NEXO recommends symmetrical designs (preferably NEXO logo

inwards in stereo configurations)

‘’LEFT’’ CONFIGURATION ’’RIGHT’’ CONFIGURATION

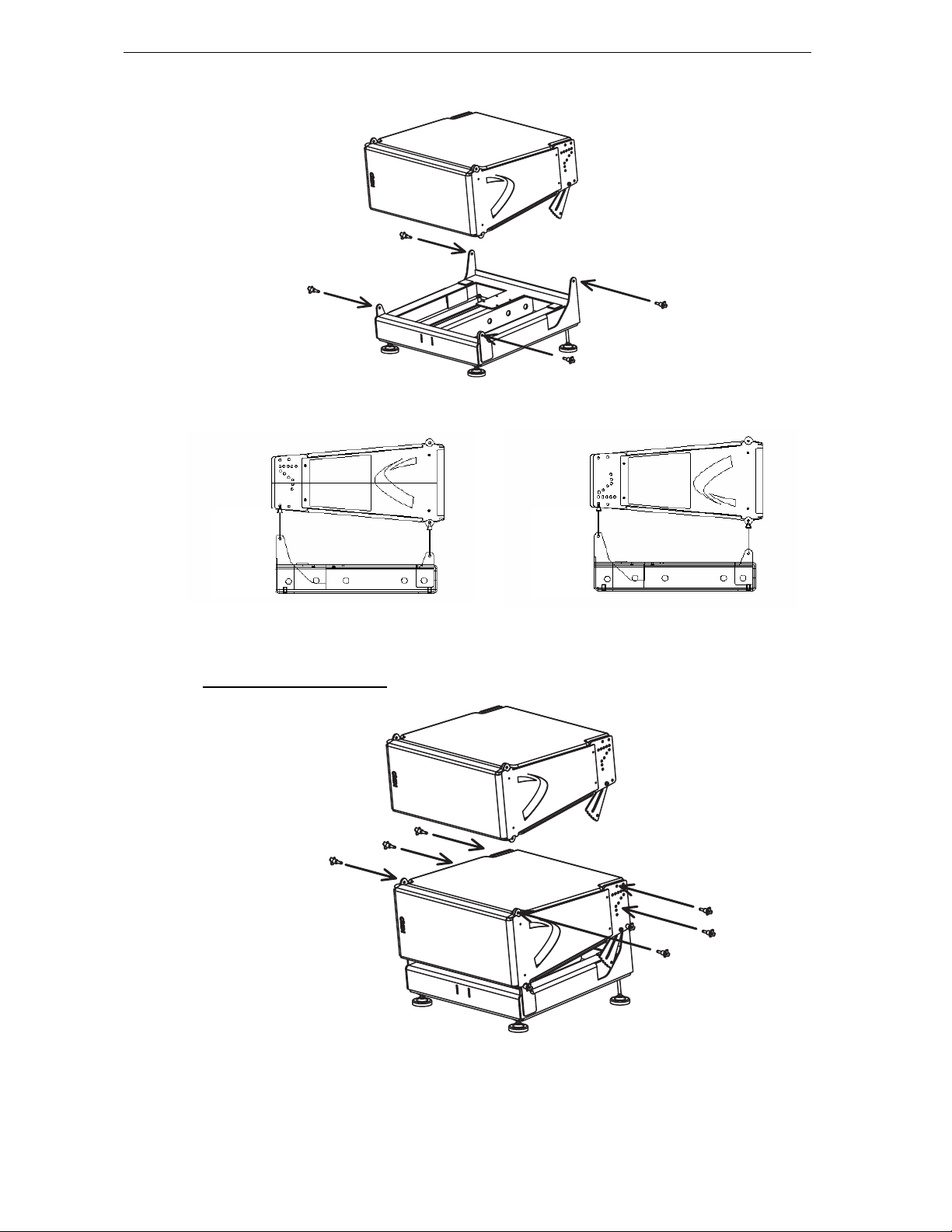

4 push-pins (BLGEOD, 10mm diameter x 20 mm length) connect the bottom GEO D10 to the bumper.

• Position the first GEO D10 on bumper;

• Link the GEO D10 to the bumper assembly using the four 10mm x 20mm push-pins; front

bumper connects at GEO D10 front articulation point, rear bumper connects at “LIFT” GEO D10

rigging plates holes;

• Check that all push-pins are in their locked position.

GEO D RIGGING PROCEDURE Page 29/97

BUMPER TO FIRST GEOD ASSEMBLY

‘’LEFT’’ CONFIGURATION ’’RIGHT’’ CONFIGURATION

5.3.4 First to second GEO D 10

FIRST TO SECOND GEO D10