NEXCOM International Co., Ltd.

Industrial Computing Solutions

Applied Panel Display

APPD 1200T/1205T/1500T/1700T/1900T

User Manual

NEXCOM International Co., Ltd.

Published May 2014

www.nexcom.com

Content

Contents

Preface

Copyright ............................................................................................. iv

Disclaimer .............................................................................................. iv

Acknowledgements ............................................................................... iv

Regulatory Compliance Statements ........................................................ iv

Declaration of Conformity ...................................................................... iv

RoHS Compliance ................................................................................... v

Warranty and RMA ................................................................................ vi

Safety Information ................................................................................viii

Installation Recommendations ...............................................................viii

Safety Precautions .................................................................................. ix

Technical Support and Assistance ............................................................ x

Conventions Used in this Manual ............................................................ x

Global Service Contact Information ........................................................ xi

Package Contents ................................................................................. xiii

Ordering Information .............................................................................xv

Chapter 1: Product Introduction

Overview - APPD 1200T/1205T ...............................................................1

Key Features ...........................................................................................1

Overview - APPD 1500T .......................................................................... 2

Key Features ...........................................................................................2

Overview - APPD 1700T .......................................................................... 3

Key Features ...........................................................................................3

Overview - APPD 1900T .......................................................................... 4

Key Features ...........................................................................................4

Specifications .......................................................................................... 5

APPD 1200T ........................................................................................ 5

Specifications .......................................................................................... 6

APPD 1205T ........................................................................................ 6

Specifications .......................................................................................... 7

APPD 1500T ........................................................................................ 7

Specifications .......................................................................................... 8

APPD 1700T ........................................................................................ 8

Specifications .......................................................................................... 9

APPD 1900T ........................................................................................ 9

Knowing Your APPD Series ...................................................................10

Front Top View of APPD 1200T/1205T ...............................................10

Front Top View of APPD 1500T ..........................................................10

Front Top View of APPD 1700T ..........................................................10

Front Top View of APPD 1900T ..........................................................10

Front Top View in Detail .....................................................................11

Rear Bottom View of APPD 1200T/1205T ..........................................12

Rear Bottom View of APPD 1500T ..................................................... 12

Rear Bottom View of APPD 1700T ..................................................... 12

Rear Bottom View of APPD 1900T ..................................................... 12

Rear Bottom View in Detail ................................................................ 13

Rear View of APPD 1200T/1205T .......................................................14

Rear View of APPD 1500T .................................................................15

Rear View of APPD 1700T .................................................................16

Rear View of APPD 1900T .................................................................17

Mechanical Dimensions .........................................................................18

APPD 1200T/1205T ...........................................................................18

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

ii

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Content

APPD 1500T ...................................................................................... 19

APPD 1700T ...................................................................................... 20

APPD 1900T ...................................................................................... 21

Chapter 2: Connector Pin Definitions

External I/O Interfaces ........................................................................... 22

USB Port ............................................................................................ 22

COM Port .......................................................................................... 22

DVI Port (DVI-D) .................................................................................23

VGA Port ........................................................................................... 23

12 – 24V DC Input ............................................................................24

Chapter 3: System Setup

Panel Mounting ....................................................................................25

Installing the Power Adapter Bracket ..................................................... 28

Chapter 4: Adjusting the Display

OSD Menu Functions ............................................................................33

Chapter 5: Touch Driver Settings...........................49

Appendix A: Power Consumption.........................50

Appendix B: Extended Display Identification

Data Timing Support..............................................51

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

iii

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Preface

Preface

Copyright

This publication, including all photographs, illustrations and software, is

protected under international copyright laws, with all rights reserved. No

part of this manual may be reproduced, copied, translated or transmitted in

any form or by any means without the prior written consent from NEXCOM

International Co., Ltd.

Disclaimer

The information in this document is subject to change without prior notice and

does not represent commitment from NEXCOM International Co., Ltd. However,

users may update their knowledge of any product in use by constantly checking

its manual posted on our website: http://www.nexcom.com. NEXCOM shall

not be liable for direct, indirect, special, incidental, or consequential damages

arising out of the use of any product, nor for any infringements upon the rights

of third parties, which may result from such use. Any implied warranties of

merchantability or fitness for any particular purpose is also disclaimed.

Acknowledgements

APPD 1200T/1205T/1500T/1700T/1900T is a trademark of NEXCOM

International Co., Ltd. All other product names mentioned herein are

registered trademarks of their respective owners.

Regulatory Compliance Statements

This section provides the FCC compliance statement for Class B devices and

describes how to keep the system CE compliant.

Declaration of Conformity

FCC

This equipment has been tested and verified to comply with the limits for

a Class B digital device, pursuant to Part 15 of FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference

to radio communications. Operation of this equipment in a residential area

(domestic environment) is likely to cause harmful interference, in which

case the user will be required to correct the interference (take adequate

measures) at their own expense.

CE

The product(s) described in this manual complies with all applicable

European Union (CE) directives if it has a CE marking. For computer systems

to remain CE compliant, only CE-compliant parts may be used. Maintaining

CE compliance also requires proper cable and cabling techniques.

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

iv

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Preface

RoHS Compliance

NEXCOM RoHS Environmental Policy and Status

Update

This publication, including all photographs, illustrations

and software, is protected under international copyright

laws, with all rights reserved. No part of this manual

may be reproduced, copied, translated or transmitted in any form or by any

means without the prior written consent from NEXCOM International Co.,

Ltd.

RoHS restricts the use of Lead (Pb) < 0.1% or 1,000ppm, Mercury (Hg) < 0.1%

or 1,000ppm, Cadmium (Cd) < 0.01% or 100ppm, Hexavalent Chromium

(Cr6+) < 0.1% or 1,000ppm, Polybrominated biphenyls (PBB) < 0.1% or

1,000ppm, and Polybrominated diphenyl Ethers (PBDE) < 0.1% or 1,000ppm.

In order to meet the RoHS compliant directives, NEXCOM has established

an engineering and manufacturing task force to implement the introduction

of green products. The task force will ensure that we follow the standard

NEXCOM development procedure and that all the new RoHS components

and new manufacturing processes maintain the highest industry quality

levels for which NEXCOM are renowned.

The model selection criteria will be based on market demand. Vendors and

suppliers will ensure that all designed components will be RoHS compliant.

How to recognize NEXCOM RoHS Products?

For existing products where there are non-RoHS and RoHS versions, the

suffix “(LF)” will be added to the compliant product name.

All new product models launched after January 2006 will be RoHS compliant.

They will use the usual NEXCOM naming convention.

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

v

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Preface

Warranty and RMA

NEXCOM Warranty Period

NEXCOM manufactures products that are new or equivalent to new in

accordance with industry standard. NEXCOM warrants that products will

be free from defect in material and workmanship for 2 years, beginning on

the date of invoice by NEXCOM. HCP series products (Blade Server) which

are manufactured by NEXCOM are covered by a three year warranty period.

NEXCOM Return Merchandise Authorization (RMA)

▪ Customers shall enclose the “NEXCOM RMA Service Form” with the

returned packages.

▪ Customers must collect all the information about the problems

encountered and note anything abnormal or, print out any on-screen

messages, and describe the problems on the “NEXCOM RMA Service

Form” for the RMA number apply process.

▪ Customers can send back the faulty products with or without accessories

(manuals, cable, etc.) and any components from the card, such as CPU

and RAM. If the components were suspected as part of the problems,

please note clearly which components are included. Otherwise, NEXCOM

is not responsible for the devices/parts.

▪ Customers are responsible for the safe packaging of defective products,

making sure it is durable enough to be resistant against further damage

and deterioration during transportation. In case of damages occurred

during transportation, the repair is treated as “Out of Warranty.”

▪ Any products returned by NEXCOM to other locations besides the

customers’ site will bear an extra charge and will be billed to the customer.

Repair Service Charges for Out-of-Warranty Products

NEXCOM will charge for out-of-warranty products in two categories, one is

basic diagnostic fee and another is component (product) fee.

Repair Service Charges for Out-of-Warranty Products

NEXCOM will charge for out-of-warranty products in two categories, one is

basic diagnostic fee and another is component (product) fee.

System Level

▪ Component fee: NEXCOM will only charge for main components such as

SMD chip, BGA chip, etc. Passive components will be repaired for free,

ex: resistor, capacitor.

▪ Items will be replaced with NEXCOM products if the original one cannot

be repaired. Ex: motherboard, power supply, etc.

▪ Replace with 3rd party products if needed.

▪ If RMA goods can not be repaired, NEXCOM will return it to the customer

without any charge.

Board Level

▪ Component fee: NEXCOM will only charge for main components, such

as SMD chip, BGA chip, etc. Passive components will be repaired for free,

ex: resistors, capacitors.

▪ If RMA goods can not be repaired, NEXCOM will return it to the customer

without any charge.

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

vi

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Preface

Warnings

Read and adhere to all warnings, cautions, and notices in this guide and

the documentation supplied with the chassis, power supply, and accessory

modules. If the instructions for the chassis and power supply are inconsistent

with these instructions or the instructions for accessory modules, contact

the supplier to find out how you can ensure that your computer meets

safety and regulatory requirements.

Cautions

Electrostatic discharge (ESD) can damage system components. Do the

described procedures only at an ESD workstation. If no such station is

available, you can provide some ESD protection by wearing an antistatic

wrist strap and attaching it to a metal part of the computer chassis.

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

vii

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Preface

Safety Information

Before installing and using the device, note the following precautions:

▪ Read all instructions carefully.

▪ Do not place the unit on an unstable surface, cart, or stand.

▪ Follow all warnings and cautions in this manual.

▪ When replacing parts, ensure that your service technician uses parts

specified by the manufacturer.

▪ Avoid using the system near water, in direct sunlight, or near a heating

device.

▪ The load of the system unit does not solely rely for support from the

rackmounts located on the sides. Firm support from the bottom is highly

necessary in order to provide balance stability.

Installation Recommendations

Ensure you have a stable, clean working environment. Dust and dirt can get

into components and cause a malfunction. Use containers to keep small

components separated.

Adequate lighting and proper tools can prevent you from accidentally

damaging the internal components. Most of the procedures that follow

require only a few simple tools, including the following:

▪ A Philips screwdriver

▪ A flat-tipped screwdriver

▪ A grounding strap

▪ An anti-static pad

Using your fingers can disconnect most of the connections. It is recommended

that you do not use needle-nose pliers to disconnect connections as these

can damage the soft metal or plastic parts of the connectors.

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

viii

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Preface

Safety Precautions

1. Read these safety instructions carefully.

2. Keep this User Manual for later reference.

3. Disconnect this equipment from any AC outlet before cleaning. Use a

damp cloth. Do not use liquid or spray detergents for cleaning.

4. For plug-in equipment, the power outlet socket must be located near the

equipment and must be easily accessible.

5. Keep this equipment away from humidity.

6. Put this equipment on a stable surface during installation. Dropping it or

letting it fall may cause damage.

7. The openings on the enclosure are for air convection to protect the

equipment from overheating. DO NOT COVER THE OPENINGS.

8. Make sure the voltage of the power source is correct before connecting

the equipment to the power outlet.

9. Place the power cord in a way so that people will not step on it. Do not

place anything on top of the power cord. Use a power cord that has been

approved for use with the product and that it matches the voltage and

current marked on the product’s electrical range label. The voltage and

current rating of the cord must be greater than the voltage and current

rating marked on the product.

10. All cautions and warnings on the equipment should be noted.

11. If the equipment is not used for a long time, disconnect it from the

power source to avoid damage by transient overvoltage.

12. Never pour any liquid into an opening. This may cause fire or electrical

shock.

13. Never open the equipment. For safety reasons, the equipment should be

opened only by qualified service personnel.

14. If one of the following situations arises, get the equipment checked by

service personnel:

a. The power cord or plug is damaged.

b. Liquid has penetrated into the equipment.

c. The equipment has been exposed to moisture.

d. The equipment does not work well, or you cannot get it to work

according to the user’s manual.

e. The equipment has been dropped and damaged.

f. The equipment has obvious signs of breakage.

15. Do not place heavy objects on the equipment.

16. The unit uses a three-wire ground cable which is equipped with a third

pin to ground the unit and prevent electric shock. Do not defeat the

purpose of this pin. If your outlet does not support this kind of plug,

contact your electrician to replace your obsolete outlet.

17. CAUTION: DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY

REPLACED. REPLACE ONLY WITH THE SAME OR EQUIVALENT TYPE

RECOMMENDED BY THE MANUFACTURER. DISCARD USED BATTERIES

ACCORDING TO THE MANUFACTURER’S INSTRUCTIONS.

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

ix

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Preface

CAUTION!

Technical Support and Assistance

1. For the most updated information of NEXCOM products, visit NEXCOM’s

website at www.nexcom.com.

2. For technical issues that require contacting our technical support team or

sales representative, please have the following information ready before

calling:

– Product name and serial number

– Detailed information of the peripheral devices

– Detailed information of the installed software (operating system,

version, application software, etc.)

– A complete description of the problem

– The exact wordings of the error messages

Warning!

1. Handling the unit: carry the unit with both hands and handle it with care.

2. Maintenance: to keep the unit clean, use only approved cleaning products

or clean with a dry cloth.

3. CompactFlash: Turn off the unit’s power before inserting or removing a

CompactFlash storage card.

Conventions Used in this Manual

Warning:

Information about certain situations, which if not observed,

can cause personal injury. This will prevent injury to yourself

when performing a task.

CAUTION!CAUTION!

Caution:

Information to avoid damaging components or losing data.

Note:

Provides additional information to complete a task easily.

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

x

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Preface

Global Service Contact Information

Headquarters

NEXCOM International Co., Ltd.

15F, No. 920, Chung-Cheng Rd.,

ZhongHe District, New Taipei City, 23586,

Taiwan, R.O.C.

Tel: +886-2-8226-7786

Fax: +886-2-8226-7782

www.nexcom.com

America

USA

NEXCOM USA

2883 Bayview Drive,

Fremont CA 94538, USA

Tel: +1-510-656-2248

Fax: +1-510-656-2158

Email: sales@nexcom.com

www.nexcom.com

Asia

Taiwan

Central Taiwan Office

16F, No.250, Sec. 2, Chongde Rd.,

Beitun Dist., Taichung City 406, R.O.C.

Tel: +886-4-2249-1179

Fax: +886-4-2249-1172

Email: sales@nexcom.com.tw

www.nexcom.com.tw

Japan

NEXCOM Japan

9F, Tamachi Hara Bldg., 4-11-5, Shiba Minato-ku,

Tokyo, 108-0014, Japan

Tel: +81-3-5419-7830

Fax: +81-3-5419-7832

Email: sales@nexcom-jp.com

www.nexcom-jp.com

China

NEXCOM China

1F & 2F, Block A, No. 16 Yonyou Software Park,

No. 68 Beiqing Road, Haidian District,

Beijing, 100094, China

Tel: +86-010-5704-2680

Fax: +86-010-5704-2681

Email: sales@nexcom.cn

www.nexcom.cn

Shanghai Office

Room 603/604, Huiyinmingzun Plaza Bldg., 1,

No.609, Yunlin East Rd.,

Shanghai, 200062, China

Tel: +86-21-5278-5868

Fax: +86-21-3251-6358

Email: sales@nexcom.cn

www.nexcom.cn

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

xi

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Preface

Shenzhen Office

Room1707, North Block, Pines Bldg.,

No.7 Tairan Rd., Futian Area,

Shenzhen, 518040, China

Tel: +86-755-8332-7203

Fax: +86-755-8332-7213

Email: sales@nexcom.cn

www.nexcom.cn

Wuhan Office

1-C1804/ 1805, Mingze Liwan,

No. 519 South Luoshi Rd.,

Hongshan District,

Wuhan, 430070, China

Tel: +86-27-8722-7400

Fax: +86-27-8722-7400

Email: sales@nexcom.cn

www.nexcom.cn

Chengdu Office

9F, Shuxiangxie, Xuefu Garden,

No.12 Section 1, South Yihuan Rd.,

Chengdu, 610061, China

Tel: +86-28-8523-0186

Fax: +86-28-8523-0186

Email: sales@nexcom.cn

www.nexcom.cn

Europe

Italy

NEXCOM ITALIA S.r.l

Via Gaudenzio Ferrari 29,

21047 Saronno (VA), Italia

Tel: +39 02 9628 0333

Fax: +39 02 9286 9215

Email: nexcomitalia@nexcom.eu

www.nexcomitalia.it

United Kingdom

NEXCOM EUROPE

10 Vincent Avenue,

Crownhill Business Centre,

Milton Keynes, Buckinghamshire MK8 0AB,

United Kingdom

Tel: +44-1908-267121

Fax: +44-1908-262042

Email: sales.uk@nexcom.eu

www.nexcom.eu

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

xii

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Preface

Package Contents

Before continuing, verify that the package you received is complete. The APPD series package, APPD 1200T/1205T/1500T/1700T/1900T, should have all the

items listed in the table.

APPD 1200T/1205T/1500T/1700T

Item Description Qty

1 Panel Mount Kit 12

2 Driver CD 1

3 Touch Pen 1

4 VGA Cable (1.8m) 1

5 USB Cable (1.8m) 1

6 Serial Cable (1.8m) 1

7 Terminal blocks 3-pin Phoenix Contact Plug 1

8 Panel Mount Hole Block 12

Terminal blocks

3-pin Phoenix

Contact Plug

VGA Cable USB Cable

Panel Mount Kit Driver CD Touch Pen

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

xiii

Serial Cable Panel Mount Hole Block

Note: Package contents may vary depending on your country

region, some items may be optional. Please contact your local

distributor for more information.

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Preface

APPD 1900T

Item Description Qty

1 Panel Mount Kit 14

2 Driver CD 1

3 Touch Pen 1

4 VGA Cable (1.8m) 1

5 USB Cable (1.8m) 1

6 Serial Cable (1.8m) 1

7 Terminal blocks 3-pin Phoenix Contact Plug 1

8 Panel Mount Hole Block 14

Terminal blocks

3-pin Phoenix

Contact Plug

VGA Cable USB Cable

Panel Mount Kit Driver CD Touch Pen

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

xiv

Serial Cable

Panel Mount Hole Block

Note: Package contents may vary depending on your country

region, some items may be optional. Please contact your local

distributor for more information.

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Preface

Ordering Information

The following provides ordering information for the Applied Panel Display series.

• Barebone

APPD 1200T (P/N: 10IAD120000X0)

12.1” SVGA industrial 4:3 LED Backlight flush touch monitor with VGA, and DVI-D input, 12~24VDC input, RS-232 and USB touch screen interfaces

APPD 1205T (P/N: 10IAD120500X0)

12.1” XGA industrial 4:3 LED Backlight flush touch monitor with VGA, and DVI-D input, 12~24VDC input, RS-232 and USB touch screen interfaces

APPD 1500T (P/N: 10IAD150000X0)

15” XGA industrial 4:3 LED Backlight flush touch monitor with VGA, and DVI-D input, 12~24VDC input, RS-232 and USB touch screen interfaces

APPD 1700T (P/N: 10IAD170000X0)

17” SXGA industrial 4:3 LCD flush touch monitor with VGA and DVI-D input, 12~24VDC input, RS-232 and USB touch screen interfaces

APPD 1900T (P/N: 10IAD190000X0)

19” SXGA industrial 4:3 LED Backlight flush touch monitor with VGA, and DVI-D input, 12~24V DC input, RS-232 and USB touch screen interfaces

• Optional

12V, 60W AC/DC power adapter w/o power cord (P/N: 7400060011X00)

US Power Cord (P/N: 60233POW17X00) UK Power Cord (P/N: 60233POW19X00) EU Power Cord (P/N: 60233POW18X00) 1.8m DVI-D Cable (P/N: 60233DVI28X00)

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

xv

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Chapter 1: Product Introduction

Overview - APPD 1200T/1205T

Key Features

▪ IP65 compliant plastic front bezel with flush panel by 5-wire touch screen

▪ Dual display input interface: analog VGA and DVI-D

▪ Shares identical appearance with APPC series

▪ Dual touch screen interface: RS232 and USB

▪ Ultra slim in depth

▪ OSD Multilanguage function

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

1

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Overview - APPD 1500T

Key Features

▪ IP65 compliant plastic front bezel with flush panel by 5-wire touch screen

▪ Dual display input interface: analog VGA and DVI-D

▪ Shares identical appearance with APPC series

▪ Dual touch screen interface: RS232 and USB

▪ Ultra slim in depth

▪ OSD Multilanguage function

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

2

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Overview - APPD 1700T

Key Features

▪ IP65 compliant plastic front bezel with flush panel by 5-wire touch screen

▪ Dual display input interface: analog VGA and DVI-D

▪ Shares identical appearance with APPC series

▪ Dual touch screen interface: RS232 and USB

▪ Ultra slim in depth

▪ OSD Multilanguage function

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

3

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Overview - APPD 1900T

Key Features

▪ IP65 compliant plastic front bezel with flush panel by 5-wire touch screen

▪ Dual display input interface: analog VGA and DVI-D

▪ Shares identical appearance with APPC series

▪ Dual touch screen interface: RS232 and USB

▪ Ultra slim in depth

▪ OSD Multilanguage function

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

4

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Specifications

APPD 1200T

Panel

▪ LED Size: 12.1”, 4:3

▪ Resolution: SVGA 800x600

▪ Luminance: 450cd/m

▪ Contrast ratio: 700

▪ LCD color: 16.2M

▪ Viewing Angle: 65(U), 75(D), 80(L), 80(R)

▪ Backlight: LED

Touch Screen

▪ 5-wire resistive (flush panel type)

▪ Light transmission: 80%

▪ Interface: USB and RS232

Rear I/O

▪ Touch screen interface port: RS-232 (1x DB9) / USB Type A

▪ Video port: VGA (1x DB15) / DVI-D (1x DVI-I connector)

▪ DC power input connector: 3-Pin Phoenix terminal Blocks

OSD Function

▪ OSD keypad

▪ Multilanguage OSD

2

▪ Power input: 12V~24VDC

▪ Power adapter: optional AC to DC power adapter (+12V, 60W)

▪ Vibration:

IEC 68 2-64

2Grms @ sine, 5~500Hz, 1hr/axis (Operating)

2.2Grms @ random condition, 5~500Hz, 0.5hr/axis (Non-operating)

▪ Shock:

IEC 68 2-27

20G@wall mount, half sine, 11ms

Operating temperature: -5°C to 60°C

Storage temperature: -20°C to 75°C

▪ Operating humidity: 10%~90% relative humidity, non-condensing

▪ Dimension: 317 x 243 x 53.5mm

▪ Weight: 2.9Kg

Certifications

▪ CE approval

▪ FCC Class B

Mechanical & Environment

▪ Color: pantone black

▪ IP protection: IP65 front

▪ Mounting: panel/ wall/ stand/ VESA 100mm x 100mm

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

5

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Specifications

APPD 1205T

Panel

▪ LED Size: 12.1”, 4:3

▪ Resolution: XGA 1024x768

▪ Luminance: 500cd/m

▪ Contrast ratio: 700

▪ LCD color: 16.2M

▪ Viewing Angle: 80(U), 80(D), 80(L), 80(R)

▪ Backlight: LED

Touch Screen

▪ 5-wire resistive (flush panel type)

▪ Light transmission: 80%

▪ Interface: USB and RS232

Rear I/O

▪ Touch screen interface port: RS-232 (1x DB9) / USB Type A

▪ Video port: VGA (1x DB15) / DVI-D (1x DVI-I connector)

▪ DC power input connector: 3-Pin Phoenix terminal Blocks

OSD Function

▪ OSD keypad

▪ Multilanguage OSD

2

▪ Power input: 12V~24VDC

▪ Power adapter: optional AC to DC power adapter (+12V, 60W)

▪ Vibration:

IEC 68 2-64

2Grms @ sine, 5~500Hz, 1hr/axis (Operating)

2.2Grms @ random condition, 5~500Hz, 0.5hr/axis (Non-operating)

▪ Shock:

IEC 68 2-27

20G@wall mount, half sine, 11ms

Operating temperature: -5°C to 60°C

Storage temperature: -20°C to 75°C

▪ Operating humidity: 10%~90% relative humidity, non-condensing

▪ Dimension: 317 x 243 x 53.5mm

▪ Weight: 2.9Kg

Certifications

▪ CE approval

▪ FCC Class B

Mechanical & Environment

▪ Color: pantone black

▪ IP protection: IP65 front

▪ Mounting: panel/ wall/ stand/ VESA 100mm x 100mm

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

6

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Specifications

APPD 1500T

Panel

▪ LED Size: 15”, 4:3

▪ Resolution: XGA 1024x768

▪ Luminance: 400cd/m

▪ Contrast ratio: 700

▪ LCD color: 16.2M

▪ Viewing Angle: 60(U), 80(D), 80(L), 80(R)

▪ Backlight: LED

Touch Screen

▪ 5-wire resistive (flush panel type)

▪ Light transmission: 80%

▪ Interface: USB and RS232

Rear I/O

▪ Touch screen interface port: RS-232 (1x DB9) / USB Type A

▪ Video port: VGA (1x DB15) / DVI-D (1x DVI-I connector)

▪ DC power input connector: 3-Pin Phoenix terminal Blocks

OSD Function

▪ OSD keypad

▪ Multilanguage OSD

2

▪ Power input: 12V~24VDC

▪ Power adapter: optional AC to DC power adapter (+12V, 60W)

▪ Vibration:

IEC 68 2-64

2Grms @ sine, 5~500Hz, 1hr/axis (Operating)

2.2Grms @ random condition, 5~500Hz, 0.5hr/axis (Non-operating)

▪ Shock:

IEC 68 2-27

20G@wall mount, half sine, 11ms

Operating temperature: -5°C to 60°C

Storage temperature: -20°C to 75°C

▪ Operating humidity: 10%~90% relative humidity, non-condensing

▪ Dimension: 384.37 x 310 x 51.2 mm

▪ Weight: 3.98Kg

Certifications

▪ CE approval

▪ FCC Class B

Mechanical & Environment

▪ Color: pantone black

▪ IP protection: IP65 front

▪ Mounting: panel/ wall/ stand/ VESA 100mm x 100mm

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

7

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Specifications

APPD 1700T

Panel

▪ LED Size: 17”, 4:3

▪ Resolution: SXGA 1280x1024

▪ Luminance: 380cd/m

▪ Contrast ratio: 1000

▪ LCD color: 16.7M

▪ Viewing Angle: 80(U), 80(D), 85(L), 85(R)

▪ Backlight: CCFL

Touch Screen

▪ 5-wire resistive (flush panel type)

▪ Light transmission: 81%

▪ Interface: USB

Rear I/O

▪ Touch screen interface port: RS-232 (1x DB9) / USB Type A

▪ Video port: VGA (1x DB15) / DVI-D (1x DVI-I connector)

▪ DC power input connector: 3-Pin Phoenix terminal Blocks

OSD Function

▪ OSD keypad

▪ Multilanguage OSD

2

▪ Power input: 12V~24VDC

▪ Power adapter: optional AC to DC power adapter (+12V, 60W)

▪ Vibration:

IEC 68 2-64

2Grms @ sine, 5~500Hz, 1hr/axis (Operating)

2.2Grms @ random condition, 5~500Hz, 0.5hr/axis (Non-operating)

▪ Shock:

IEC 68 2-27

20G@wall mount, half sine, 11ms

Operating temperature: -5°C to 50°C

Storage temperature: -20°C to 75°C

▪ Operating humidity: 10%~90% relative humidity, non-condensing

▪ Dimension: 410.4 x 340.4 x 43.7 mm

▪ Weight: 5.3 Kg

Certifications

▪ CE approval

▪ FCC Class B

Mechanical & Environment

▪ Color: pantone black

▪ IP protection: IP65 front

▪ Mounting: panel/ wall/ stand/ VESA 100mm x 100mm

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

8

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Specifications

APPD 1900T

Panel

▪ LED Size: 19”, 4:3

▪ Resolution: SXGA 1280x1024

▪ Luminance: 350cd/m

▪ Contrast ratio: 1000

▪ LCD color: 16.7M

▪ Viewing Angle: 80(U), 80(D), 85(L), 85(R)

▪ Backlight: LED

Touch Screen

▪ 5-wire resistive (flush panel type)

▪ Light transmission: 81%

▪ Interface: USB

Rear I/O

▪ Touch screen interface port: RS-232 (1x DB9) / USB Type A

▪ Video port: VGA (1x DB15) / DVI-D (1x DVI-I connector)

▪ DC power input connector: 3-Pin Phoenix terminal Blocks

OSD Function

▪ OSD keypad

▪ Multilanguage OSD

2

▪ Power input: 12V~24VDC

▪ Power adapter: optional AC to DC power adapter (+12V, 60W)

▪ Vibration:

IEC 68 2-64

2Grms @ sine, 5~500Hz, 1hr/axis (Operating)

2.2Grms @ random condition, 5~500Hz, 0.5hr/axis (Non-operating)

▪ Shock:

IEC 68 2-27

20G@wall mount, half sine, 11ms

Operating temperature: -5°C to 50°C

Storage temperature: -20°C to 75°C

▪ Operating humidity: 10%~90% relative humidity, non-condensing

▪ Dimension: 457.64 x 379.24 x 49.25 mm

▪ Weight: 5.4 Kg

Certifications

▪ CE approval

▪ FCC Class B

Mechanical & Environment

▪ Color: pantone black

▪ IP protection: IP65 front

▪ Mounting: panel/ wall/ stand/ VESA 100mm x 100mm

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

9

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Knowing Your APPD Series

Front Top View of APPD 1200T/1205T

Power & OSD

Menu Buttons

Front Top View of APPD 1500T

Front Top View of APPD 1700T

Power & OSD

Menu Buttons

Front Top View of APPD 1900T

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

Power & OSD

Menu Buttons

10

Power & OSD

Menu Buttons

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Front Top View in Detail

Power Switch

LED

Increase Brightness/

move down/

increase value

Decrease Brightness/

move up/

decrease value

Menu

LED

Displays the power status of the display. Green LED indicates the display is

switched on, if the display is not connected to a computer, the LED will flash red.

AUTO|EXIT

Power Switch

Press to power-on or power-off the display.

◀|▼

No OSD menu: Press to increase the brightness of the screen.

Inside OSD menu: Press to move the selection down in OSD menu.

Configuring options: Press to increase the value.

▶|▲

No OSD menu: Press to decrease the brightness of the screen.

Inside OSD menu: Press to move the selection up in OSD menu.

Configuring options: Press to decrease the value

OSD Menu

No OSD Menu: Press to load the OSD menu.

Inside OSD Menu: Press to select the highlighted option in OSD menu.

AUTO|EXIT

Press to exit the OSD menu, or return to main menu.

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

11

The OSD will exit automatically if there is no activity in 5

seconds. This timer can be adjusted in OSD menu (Default:

On, 5 seconds).

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Rear Bottom View of APPD 1200T/1205T

Rear Bottom View of APPD 1500T

Rear Bottom View of APPD 1700T

Rear Bottom View of APPD 1900T

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

12

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Rear Bottom View in Detail

USB COM DVI-D VGA DC Input

Touchscreen Connector (USB) (Optional)

This USB connector must be attached to the USB port of the PC. The

touchscreen cable is included in accessory box.

Touchscreen Connector (DB-9) (Optional)

This RS-232 connector must be connected to the RS-232 port of the PC.

RS-232 & USB touchscreen interface does not allow

connection into the system at the same time.

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

DVI Port (DVI-D)

Connected with a standard DVI connector through I/O port of this unit. Only

supports digital signals.

VGA Port (DB-15)

This DB-15 connector can be connected to the system.

12 – 24V DC Input

Terminal block socket used to plug a DC power cord.

13

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Rear View of APPD 1200T/1205T

VESA Mounting Hole

VESA Mounting Hole

VESA Mounting Hole

VESA Mounting Hole

VESA Mounting Holes

These are mounting holes for VESA mount (100x100mm)

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

14

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Rear View of APPD 1500T

VESA Mounting Hole

VESA Mounting Hole

VESA Mounting Hole

VESA Mounting Hole

VESA Mounting Holes

These are mounting holes for VESA mount (100x100mm)

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

15

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Rear View of APPD 1700T

VESA Mounting Hole

VESA Mounting Hole

VESA Mounting Hole

VESA Mounting Hole

VESA Mounting Holes

These are mounting holes for VESA mount (100x100mm)

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

16

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Rear View of APPD 1900T

VESA Mounting Hole

VESA Mounting Hole

VESA Mounting Hole

VESA Mounting Hole

VESA Mounting Holes

These are mounting holes for VESA mount (100x100mm)

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

17

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

Mechanical Dimensions

APPD 1200T/1205T

316.76

53.50 100.00

8.80

28.50

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

242.76

18

100.00

RS-232

DVI-D

APPD 1200T/1205T/1500T/1700T/1900T User Manual

+-

VGA

DCIN 12-24V

GND

Chapter 1: Product Introduction

8.80

APPD 1500T

51.20

384.37

7

19.20

292.20

309.95

RS-232DVI-D VGA+-GND

DCIN 12-24V

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

19

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

APPD 1700T

17.80

22.02

410.31

22.02

17.80

340.20

43.70

17.80

33.39

100.00

100.00

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

20

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 1: Product Introduction

APPD 1900T

457.64

379.24

49.25

24.25

25.00

RS-232

270.50

DVI-D

175.22

+-

VGA

GND

DCIN 12-24V

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

21

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 2: Connector Pin Definitions

Chapter 2: Connector Pin Definitions

External I/O Interfaces

USB Port

Connector type: USB port

Pin Definition

1 VCC5

2 DATA_N

3 DATA_P

4 GND

COM Port

Connector type: DB-9 port

1 5

6 9

Pin Definition Pin Definition

1 NC 2 RXD#: Receive Data

3 TXD: Transmit Data 4 NC

5 GND 6 NC

7 NC 8 NC

9 NC

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

22

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 2: Connector Pin Definitions

DVI Port (DVI-D)

Connector type: 24-pin D-Sub, 2.0mm-M-180 (DVI)

Pin Definition Pin Definition

1 TMDS Data 2- 2 TMDS Data 2+

3 Shield 4 NC

5 NC 6 DDC clock

7 DDC data 8 Reserved

9 TMDS Data 1- 10 TMDS Data 1+

11 Shield 12 NC

13 NC 14 +5V

15 GND 16 Hot plug detect

17 TMDS data 0- 18 TMDS data 0+

19 Shield 20 NC

21 NC 22 Shield

23 TMDS clock+ 24 TMDS clock-

C1 NC C2 NC

C3 NC C4 NC

C5 NC

VGA Port

Connector type: DB-9 port, 9-pin D-Sub (COM1)

5 1

15 11

Pin Definition Pin Definition

1 RED 2 GREEN

3 BLUE 4 ID2

5 GND 6 RGND

7 GGND 8 BGND

9 KEY 10 SGND

11 ID0 12 SDA

13 HSYNC or CSYNC 14 VSYNC

15 SCL

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

23

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 2: Connector Pin Definitions

12 – 24V DC Input

Connector type: 3-pin Terminal Block

1 3

Pin Definition

1 +

2 3 GND

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

24

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 3: System Setup

371.00 3.00mm

Chapter 3: System Setup

Panel Mounting

1. Select a place on the panel where you will mount the Industrial Touch

Monitor.

2. Cut out a shape on the panel that corresponds to the Industrial Touch

Monitor’s rear dimensions.

The thickness of the panel (e.g. steel board, plank, acrylic board, wall,

etc.) where you will mount the Industrial Touch Monitor must not exceed

3mm for APPD 1500T/1900T and 4mm for APPD 1200T/1205T/1700T. If

the distance between the front bezel and panel mount hole is too wide,

it will not fit the panel mount kit.

304.50 4.00mm

230.00

APPD 1200T/1205T

297.00

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

25

APPD 1500T

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 3: System Setup

CAUTION!

436.00

3.00mm

329.00

366.00

399.00 4.00mm

APPD 1700T

3. Slide the Industrial Touch Monitor through the hole until it is properly

fitted against the panel.

4. Position the mounting clamps along the rear edges of the Industrial Touch

Monitor. The first and second clamps must be positioned and secured

diagonally prior to mounting the rest of the clamps. Tighten the clamp’s

screw until it touches the panel.

CAUTION!CAUTION!

Clamp

Do not overtighten the screws to prevent damaging the

Panel PC.

Panel

APPD 1900T

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

26

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 3: System Setup

5. The illustration below shows all clamps properly mounted.

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

27

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 3: System Setup

Installing the Power Adapter Bracket

(Optional accessory for APPD 1900T only)

1. Locate the mounting screws for the bracket on the back side of the

chassis.

2. Remove the mounting screws and store them in a safe place for later

use.

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

28

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 3: System Setup

3. Wire the power adapter cabling into the cable opening on the bracket,

then place the adapter inside the bracket.

Cable opening Power adapter cable

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

29

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 3: System Setup

4. Turn the bracket over to the back side, and place the cable tie into the

two tie mounts.

Tie mount Cable tie

5. Wrap the power adapter cable, then secure the cable firmly by tying the

cable tie.

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

30

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 3: System Setup

6. With the bracket still facing backwards, align the mounting holes on the

bracket to the mounting holes on the back of the chassis, then tighten

screws to secure it.

7. Plug the 3-pin terminal block connector into the DC input.

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

31

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 3: System Setup

CAUTION!

8. Plug the positive, negative and GND wires of the DC power cable into

the corresponding pins on the DC input, then tighten the screws on the

terminal blocks to secure the wires.

9. Plug the AC power cord into the power adapter.

AC power cord

Before plugging the DC power cable wires into the DC input, use

CAUTION!CAUTION!

a multimeter or voltmeter to measure which wire is positive “+”,

negative “-” and GND, and ensure that they are connected to

the correct pins.

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

32

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

Chapter 4: Adjusting the Display

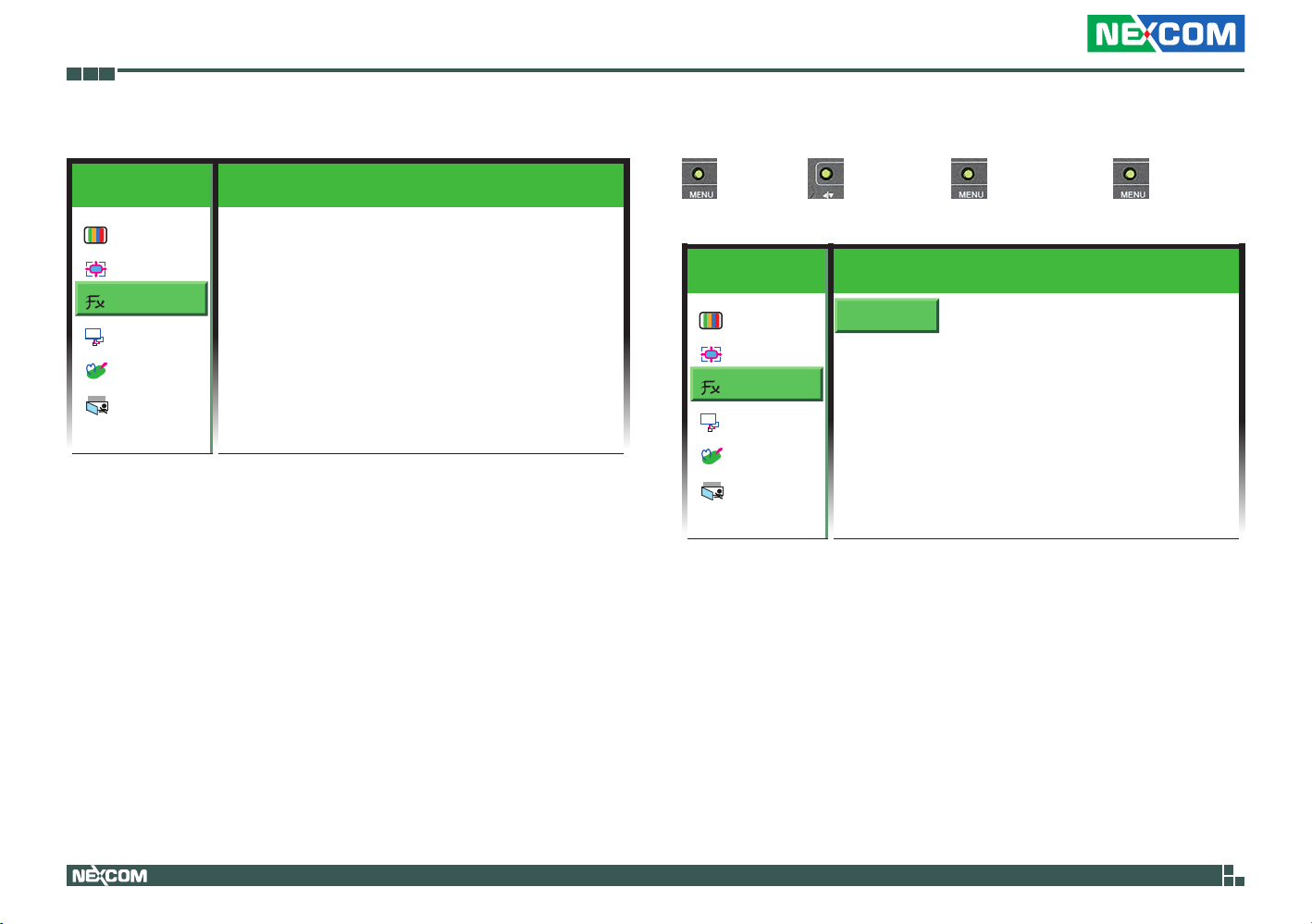

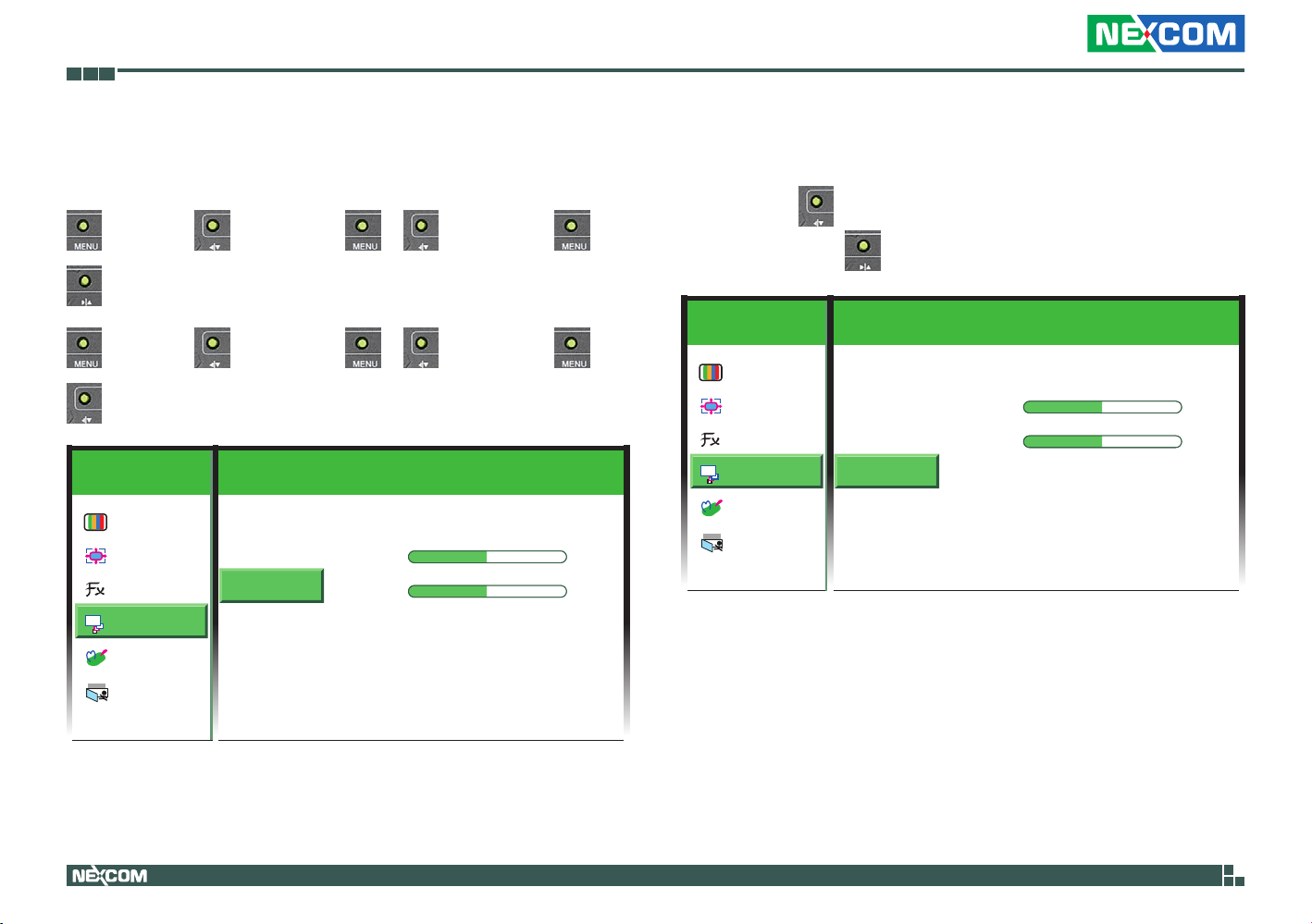

OSD Menu Functions

The On Screen Display (OSD) menu provides options to adjust the display.

Press the MENU button on the back of the display panel to open the OSD

menu. Refer to the images below for each OSD menu options.

1. Colour

1024x768 59 . 9 Hz

Contrast

Brightness

Colour Temp 9300K 6500K User

Colour Adjust

Exit

50 -

100 -

+

+

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Contrast

→ colour → → contrast → → to increase the contrast.

→ colour → → contrast → → to decrease the

1024x768 59 . 9 Hz

Contrast

Brightness

Colour Temp 9300K 6500K User

Colour Adjust

Exit

58 -

100 -

+

+

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

33

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

Brightness

→ colour → → Brightness → → to increase the brightness.

→ colour → → Brightness → → to decrease the brightness.

1024x768 59 . 9 Hz

Contrast

Brightness

50 -

100 -

Colour Temp 9300K 6500K User

Colour Adjust

Exit

+

+

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Colour Temp

→ colour → → contrast → →colour temp → → to

move it towards left.

→ colour → → contrast → →colour temp → → to

move it towards right.

1024x768 59 . 9 Hz

Contrast

Brightness

0 -

100 -

Colour Temp 9300K 6500K User

Colour Adjust

Exit

+

+

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

34

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

Colour Adjust

→ colour → → red → → increase the value.

→ colour → → red → → decrease the value.

1024x768 75 . 4 Hz

Red

Green

Blue

Exit

100 -

100 -

100 -

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Exit

Exits the Colour Adjust sub-menu or press the button to exit.

1024x768 75 . 4 Hz

Colour

Picture

+

+

OSD

ther

EXIT

Function

OSD Menu

Misc

Exit

Red

Green

Blue

Exit

100 -

100 -

100 -

+

+

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

35

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

Exit

Exits the Colour sub-menu and return to main menu, or press the

button continuously till exit.

1024x768 59 . 9 Hz

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Contrast

Brightness

50 -

100 -

Colour Temp 9300K 6500K User

Colour Adjust

Exit

+

+

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

36

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

2. Picture

Colour

Picture

Function

OSD

OSD Menu

ther

Misc

EXIT

Exit

H . Position

V . Position

Clock

Sharpness

Exit

1024x768 59 . 9 Hz

50 -

50 -

50 -

1 2 3 4 5

H. Position

→ colour → → picture → →H.position → → to move

+

+

+

the screen towards right.

→ colour → → picture → →H.position → → to move

the screen towards left.

1024x768 59 . 9 Hz

H . Position

V . Position

Clock

Sharpness

Exit

50 -

50 -

50 -

1 2 3 4 5

+

+

+

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

37

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

V. Position

→ colour → → picture → →V.position → → to move

the screen down.

→ colour → → picture → →V.position → → to move

the screen up.

1024x768 59 . 9 Hz

H . Position

V . Position

Clock

Sharpness

Exit

50 -

50 -

50 -

1 2 3 4 5

+

+

+

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Clock

→ colour → → picture → →Clock → → stretch the

screen towards right.

→ colour → → picture → →Clock → → stretch the

screen towards right.

1024x768 59 . 9 Hz

H . Position

V . Position

Clock

Sharpness

Exit

50 -

50 -

50 -

1 2 3 4 5

+

+

+

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

38

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

Sharpness

→ colour → → picture → → →sharpness → →

to decrease it.

→ colour → → picture → → →sharpness → →

to decrease it.

1024x768 59 . 9 Hz

Colour

Picture

Function

OSD

OSD Menu

ther

Misc

EXIT

Exit

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

H . Position

V . Position

Clock

Sharpness

Exit

50 -

50 -

50 -

1 2 3 4 5

+

+

+

39

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

3. Function

Colour

Picture

Function

OSD

OSD Menu

ther

Misc

EXIT

Exit

1024x768 59 . 9 Hz

Auto Adjust YES NO

Exit

Auto Adjust

→ colour → → function → →auto adjust → → YES to

automatically adjust the screen size, or NO to abort it.

1024x768 59 . 9 Hz

Auto Adjust YES NO

Exit

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

40

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

Exit

Exits the Function Adjust sub-menu or press the button to exit.

→colour→ →function→ →exit.

1024x768 59 . 9 Hz

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Auto Adjust YES NO

Auto Colour YES NO

Exit

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

41

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

4. OSD Menu

Colour

Picture

Function

OSD

OSD Menu

ther

Misc

EXIT

Exit

1024x768 59 . 9 Hz

Language

OSD H.Pos

OSD V.Pos

OSD Timer ON OFF

Exit

0 -

50 -

Language

Press the button to enter the Language sub-menu.

1024x768 59 . 9 Hz

+

+

Colour

Picture

Function

OSD

OSD Menu

ther

Misc

EXIT

Exit

Language

OSD H.Pos

OSD V.Pos

50 -

50 -

OSD Timer ON OFF

Exit

+

+

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

42

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

Select the desired language for the OSD menu and press the button to

apply the language.

1024x768 59 . 9 Hz

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

English

Deutsch

한국의

繁體中文

日本语

Francais

Español

Italiano

简体中文

Português

OSD H. Pos

→ colour → → osd menu → → →osd H.pos → →

→move it towards left.

→ colour → → osd menu → → →osd H.pos → →

→move it towards right.

1024x768 59 . 9 Hz

Language

OSD H.Pos

OSD V.Pos

50 -

50 -

OSD Timer ON OFF

Exit

+

+

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

43

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

OSD V. Pos

Press ◀|▼ on the back of the display panel to move the OSD menu up, or

▶|▲ to move it down.

→ colour → → osd menu → → →osd V.pos → →

→move it down.

→ colour → → osd menu → → →osd V.pos → →

→move it up.

1024x768 59 . 9 Hz

Language

OSD H.Pos

OSD V.Pos

50 -

50 -

OSD Timer ON OFF

Exit

+

+

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

OSD Timer

Select ON to specify the timeout period of the OSD menu, or OFF to

disable it. Press on the back of the display panel to increment the

timer by 1 second, or to decrement the timer by 1 second.

1024x768 59 . 9 Hz

Language

OSD H.Pos

OSD V.Pos

50 -

50 -

OSD Timer ON OFF

Exit

+

+

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

44

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

Exit

Exits the OSD Menu sub-menu or press the button to exit.

1024x768 59 . 9 Hz

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Language

OSD H.Pos

OSD V.Pos

50 -

50 -

OSD Timer ON OFF

Exit

+

+

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

45

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

5. Misc

Colour

Picture

Function

OSD

OSD Menu

ther

Misc

EXIT

Exit

1024x768 59 . 9 Hz

Reset YES NO

Volume

Input VGA DVI

Exit

Reset

→ colour → → Misc → →reset → → YES to restore

factory default settings, or NOT to abort it.

1024x768 59 . 9 Hz

Reset YES NO

Volume

Input VGA DVI

Exit

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

46

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

Input

→ colour → → Misc → → →Input → → Select

VGA or DVI as the video input.

1024x768 59 . 9 Hz

Reset YES NO

Volume

Input VGA DVI

Exit

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Exit

Exits the Misc sub-menu or press the button to exit.

1024x768 59 . 9 Hz

Reset YES NO

Volume

Input VGA DVI

Exit

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

47

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 4: Adjusting the Display

6. Exit

Exits the OSD main menu or press the button to exit.

1024x768 59 . 9 Hz

OSD

ther

EXIT

Colour

Picture

Function

OSD Menu

Misc

Exit

Reset YES NO

Volume

Input VGA DVI

Exit

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

48

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Chapter 5: Touch Driver Settings

Chapter 5: Touch Driver Settings

Before installing the touch drivers, please adjust the Install.ini file. The Install.

ini file is located under the following folder:

\PenMount Windows Universal Driver V2.2.0.283( Win7_32_64bit_WHQL)\

Driver

1. Open the Install.ini file.

2. Confirm if the Install.ini file has the following settings, if not, please

change it.

[Install]

USB = 1 Must set this to “1”

COM = 1 Must set this to “1”

MMonitor = 1

ENUM = 1

[Option]

TouchReport = 2 USB/COM

EdgeOffset = 5

Smoothing = 1

[ENUM]

Total = 4

COM1 = 1 Set “1” to the COM port you intend to use

COM2 = 0

COM3 = 0

COM4 = 0

[COM1]

AlwaysExist

3. Install the touch drivers.

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

49

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Appendix A: Power Consumption

Appendix A: Power Consumption

Purpose

The purpose of the power consumption test is verified the power

dissipation of the system and the load of the power supply.

Test Equipment

PROVA CM-07 AC/DC CLAMP METER

Desktop PC

Device Under Test

DUT: Sys #1

Test Procedure

1. Power up the DUT and then switch on the desktop PC connecting to it.

2. Measure the power consumption and record it.

3. Enter the standby mode (Turn off display).

4. Measure the power consumption and record it.

APPD 1200T

+12V +24V

Full-Loading Mode 0.73A 0.39A

Total 8.76W 9.36W

Standby Mode 0.05A 0.06A

Total 0.6W 1.44W

APPD 1205T

+12V +24V

Full-Loading Mode 0.75A 0.39A

Total 9W 9.36W

Standby Mode 0.05A 0.05A

Total 0.6W 1.2W

APPD 1500T

+12V +24V

Full-Loading Mode 0.97A 0.5A

Total 11.64W 12W

Standby Mode 0.04A 0.05A

Total 0.48W 1.2W

APPD 1700T

+12V +24V

Full-Loading Mode 2.6A 1.21A

Total 31.2W 29.04W

Standby Mode 0.05A 0.05A

Total 0.6W 1.2W

APPD 1900T

+12V +24V

Full-Loading Mode 1.54A 0.77A

Total 18.48W 18.48W

Standby Mode 0.05A 0.05A

Total 0.6W 1.2W

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

50

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Appendix B: Extended Display Identification Data Timing Support

Appendix B: Extended Display Identification Data Timing Support

APPD 1200T

Resolution

APPD 1205T

Resolution

1024x768

640x480

720x400

800x600

640x480

720x400

800x600

60Hz 70Hz 72Hz 75Hz

60Hz 70Hz 72Hz 75Hz

Vertical Frequencies

Vertical Frequencies

APPD 1500T

Resolution

640x480

720x400

800x600

1024x768

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

Vertical Frequencies

60Hz 70Hz 72Hz 75Hz

51

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Appendix B: Extended Display Identification Data Timing Support

APPD 1700T

Resolution

640x480

60Hz 70Hz 72Hz 75Hz

720x400

800x600

1024x768

1280x1024

APPD 1900T

Resolution

640x480

60Hz 70Hz 72Hz 75Hz

720x400

800x600

1024x768

1280x1024

Vertical Frequencies

Vertical Frequencies

Copyright © 2012 NEXCOM International Co., Ltd. All Rights Reserved.

52

APPD 1200T/1205T/1500T/1700T/1900T User Manual

Loading...

Loading...