MZ19H

REPAIR

MANUAL

87045364 2/04

MZ19H REPAIR MANUAL CONTENTS

SECTION 1 - GENERAL INFORMATION

SECTION 2 - MODEL/SERIAL NUMBER LOCATION

SECTION 3 - GREASING AND LUBRICATION

SECTION 4 - ENGINE

SECTION 5 - TRANSAXLE

SECTION 6 - CHASSIS

SECTION 7 - MOWER DECKS

SECTION 8 - ELECTRICAL SYSTEM

The sections used through out all New Holland product Repair manuals may not be used for each

product. Each Repair manual will be made up of one or several books. Each book will be labeled as

to which sections are in the overall Repair manual and which sections are in the each book.

The sections listed above are the sections utilized for the MZ19H series tractors.

SECTION 1 - GENERAL INFORMATION

SECTION 1 - GENERAL INFORMATION

CONTENTS

Section Description Page

General Information ................................................................................................... 1-2

Think Safety First....................................................................................................... 1-2

Engine Specifications - (MZ19H)............................................................................... 1-3

Bolt Torques............................................................................................................... 1-7

Maintenance Schedule - (MZ19H)............................................................................. 1-8

1-1

SECTION 1 - GENERAL INFORMATION

This symbol means WARNING or PERSONAL SAFETY INSTRUCTION - read the

instruction because it has to do with your safety. Failure to comply with the instruction may

result in personal injury or even death

This manual is intended as a service and repair manual only. The safety instructions provided herein are for

troubleshooting, service, and repair of the MZ19H zero radius tractor. The MZ19H zero radius

attachment operator's manuals contain safety information and operating tips for safe operating practices.

Operator's manuals are available through your New Holland dealer

.

tractor and

THINK SAFETY FIRST

AVOID UNEXPECTED STARTING OF ENGINE...

Always turn off the engine and disconnect the spark

plug wire(s) before cleaning, adjusting, or repair.

AVOID LACERATIONS AND AMPUTATIONS...

Stay clear of all moving parts whenever the engine

is running. Treat all normally moving parts as if they

were moving whenever the engine is running or

has the potential to start.

AVOID BURNS...

Do not touch the engine, muffler, or other

components which may increase in temperature

during operation, while the unit is running or shortly

after it has been running.

AVOID FIRES AND EXPLOSIONS...

AVOID INJURY FROM BATTERIES...

Battery acid is poisonous and can cause burns.

Avoid contact with skin, eyes, and clothing. Battery

gases can explode. Keep cigarettes, sparks, and

flames away from the battery.

AVOID INJURY DUE TO INFERIOR PARTS...

Use only original equipment parts to ensure that

important safety criteria are met.

AVOID INJURY TO BYSTANDERS...

Always clear the area of bystanders before starting

or testing powered equipment.

AVOID INJURY DUE TO PROJECTILES...

Always clear the area of sticks, rocks, or any other

debris that could be picked up and thrown by the

powered equipment.

Avoid spilling fuel and never smoke while working

with any type of fuel or lubricant. Wipe up any

spilled fuel or oil immediately. Never remove the fuel

cap or add fuel when the engine is running. Always

use approved, labeled containers for storing or

transporting fuel and lubricants.

AVOID ASPHYXIATION...

Never operate an engine in a confined area without

proper ventilation.

AVOID MODIFICATIONS...

Never alter or modify any part unless it is a factory

approved procedure.

AVOID UNSAFE OPERATION...

Always test the safety interlock system after

making adjustments or repairs on the machine.

Refer to the Electrical section in this manual for

more information.

1-2

SECTION 1 - GENERAL INFORMATION

SPECIFICATIONS

MZ19H

ENGINE

Type............................................................... Kawasaki

Model............................................................. FH580V

Horsepower ................................................... 14.2 kw (19)@3600 RPM

Cylinders........................................................ V-Twin

Displacement................................................. 585CC (35.7 cu. in.)

Low Idle Speed.............................................. 1400 RPM

Maximum Speed:

High Idle .................................................... 3400 RPM

Oil Capacity ................................................... 1.9 qt. (1.8L)

Spec Number................................................. AS13

Fuel Unleaded Gasoline ................................ 87 octane min.

Vertical Shaft ................................................. 1 in. (2.54 cm) Dia

Charge coil .................................................... 12v - 13 amp

Other.............................................................. Air cooled, Dual element air cleaner, Fuel pump,

Overhead valve, Four cycle, Electronic ignition, Full

pressure lubricated with oil filter

CONSTRUCTION

Front Frame................................................... Welded 1 x 2 x .120 structural steel tube

Rear Frame ................................................... Welded, 7 and 10 ga. high strength steel

Frame Assembly............................................ Front and rear frames bolted together

FUEL SYSTEM

Capacity......................................................... 5 Gallon (18.9 L)

Type............................................................... Single fuel tank fender mounting on left side

Other.............................................................. Fuel tank shut-off, Fuel filter (replaceable in-line type),

Large diameter vented fuel cap, Tank includes molded

beverage holder

TRACTION SYSTEM

Transaxles ..................................................... Twin Hydro-Gear Hydrostatic Transaxles

Transaxle Drive ............................................. Belt drive with self-tensioning system

Ground speed................................................ Infinite, 0 to 7-MPH (10.5-km/hr) forward, 0 to 3.4-MPH

(5.5-km/hr) reverse

Transport Rods.............................................. Allow unit to be moved without engine running

ATTACHMENT DRIVE

Clutch ............................................................ Electric Clutch

Type............................................................... Vertical drive with single deep B-groove Pulley

1-3

SECTION 1 - GENERAL INFORMATION

MZ19H

TIRES

Rear Drive Tires ............................................ 18 x 10.5-10 4 ply with “Multitrac CS” tread

Front Castor Tires.......................................... 410/350 x 4 with “sawtooth” tread

Tire Pressure ................................................. 13 psi (90 kPa), rear, 35 psi (241 kPa) front

OPERATORS SEAT

Type............................................................... High back foam padded with arm rests

Mounting........................................................ Hinged mounting for easy access to battery and controls;

spring suspension

Adjustment..................................................... Fore and aft 3 in. (76 mm) by loosening 2 knobs and

sliding seat

STEERING

Levers............................................................ Dual wrap-around levers control hydraulic pumps

Dampening .................................................... Dual hydraulic dampers

Turning Radius .............................................. Zero radius turn (ZRT)

CONTROLS

Steering Lever ............................................... Dual wrap-around with cushioned grips

Parking Brake ................................................ Left hand operated lever with cushioned grip

Attachment Lift............................................... Right hand operated lever with cushioned grip

Cutting Height................................................ Rightside incorporated with attachment lift

Engine Throttle .............................................. Rightside console mounted lever

Ignition Switch ............................................... Rightside console mounted electric with key

Power Take Off .............................................. Rightside console mounted electric

INTERLOCKS

Seat ............................................................... Operator presence switch

Control Lever ................................................. Dual neutral sensing switch

Power Take Off .............................................. Position switch

Brake ............................................................. Position switch

ELECTRICAL SYSTEM

Battery Voltage .............................................. 12 volt negative ground

Battery Type .................................................. BCI Group U1

Fused............................................................. (1) 30 amp blade type, main

(1) 25 amp blade type, charge system

(1) 10 amp (blade type) included with optional light kit

1-4

SECTION 1 - GENERAL INFORMATION

MZ19H

LUBRICATION FITTINGS

Front Castor Pivots........................................ 2 Fittings

Front Castor Wheels...................................... 2 Fittings

Lift Assembly ................................................. 3 Fittings

Deck Idler Pivot ............................................. 1 Fitting

Transaxle Idler Pivot...................................... 1 Fitting

Control Linkage Pivot .................................... 2 Fittings

DIMENSIONS

Wheel Base ................................................... 52.1 in. (132.3 cm) center of castor to center of drive tires

Width ............................................................. 47.6 in. (120.9 cm) outside rear tires

Overall Width ................................................. 65 in. (165.1 cm) with deck deflector down

58 in. (147.3 cm) Gate width with deck deflector up.

Overall Length ............................................... 77.5 in. (196.9 cm)

Overall Height................................................ 41 in. (104.1 cm)

Track Width ................................................... 37.5 in. (95.3 cm) center to center of rear tires

30.4 in. (77.2 cm) center to center of castor tires

Deck Width .................................................... 65 in. (165.1 cm) w/deflector down

WEIGHT

Net Weight 680 lbs. (309 kg) (estimated)

DECK Right side discharge. 52 in. (132 cm) cut, three blade

mid-mounted rotary. Drawn 12 gauge steel deck with

welded mounting brackets and gauge wheel brackets.

Frame supported.

DECK BELT COVERS Removable 16 gauge formed sheet metal, fastened to

deck with thread forming screws. Access holes in top for

greasing spindles.

DEFLECTOR 12 gauge formed, held down by torsion springs at pivot

bracket.

ANTI-SCALP ROLLERS One front mounted

DECK OFFSET None. Deck centerline on machine centerline.

1-5

SECTION 1 - GENERAL INFORMATION

MZ19H

GAUGE WHEELS One on each front corner, one on each rear corner to

reduce scalping. Gauge wheels have four height position

adjustments.

HEIGHT OF CUT Adjusts from 1.5” to 4.5” (38 to 114 mm) (7 positions)

UNCUT CIRCLE 0” uncut circle

ENGINE TO DECK DRIVE HB-section Kevlar cord “V” belt from engine clutch

sheave to deck spindle sheaves. Spring loaded idler for

belt tension and take-up

SPINDLE ASSEMBLIES Three 17-mm diameter spindles turning in permanently

lubed ball bearings. Die cast aluminum spindle housings.

BLADES Three 18” x 2.5” x .187” heat treated steel blades

TIP SPEED 17,500 ft/min (5334 m/min) @ 3400 RPM nominal

18,070 ft/min (5507 m/min) @ 3500 RPM max

DECK MOUNTING Deck suspended from front frame by four trunnion rods

and attached to lift mechanism by two multi-position links

(“pork chops”).

OPTIONAL EQUIPMENT

Recycler Kit

Light Kit

Snow Plow Attachment

Tire Chains

Smooth Castor Wheel Kit

Striping Kit

Decal Kit - Canada

CERTIFICATION Conforms to California CARB and EPA Certification.

Conforms to ANSI B71.1-2001

1-6

SECTION 1 - GENERAL INFORMATION

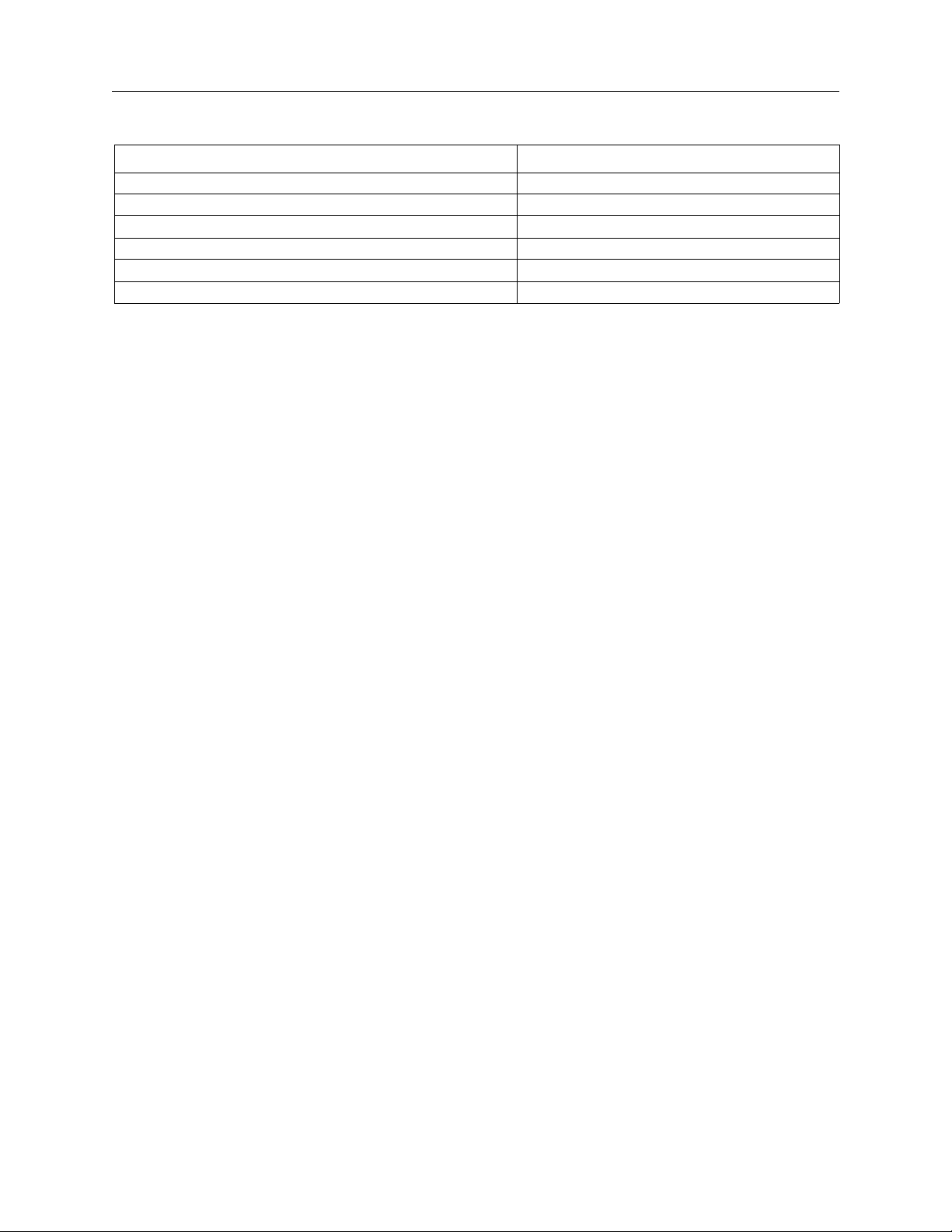

BOLT TORQUES

DESCRIPTION TORQUE

Blade to Spindle 80 - 100 ft lb (109 - 136 N·m)

Caster Bolts 77 - 95 ft lb (105 - 130 N·m)

Clutch Bolt 50 - 60 ft lb (68 - 82 N·m)

Engine Mounting Bolts 120 - 180 ft lb (164 - 246 N·m)

Spindle Pulley Nuts 80 - 100 ft lb (109 - 136 N·m)

Wheel Lug Nuts 70 - 90 ft lb (95.5 - 123 N·m)

1-7

SECTION 1 - GENERAL INFORMATION

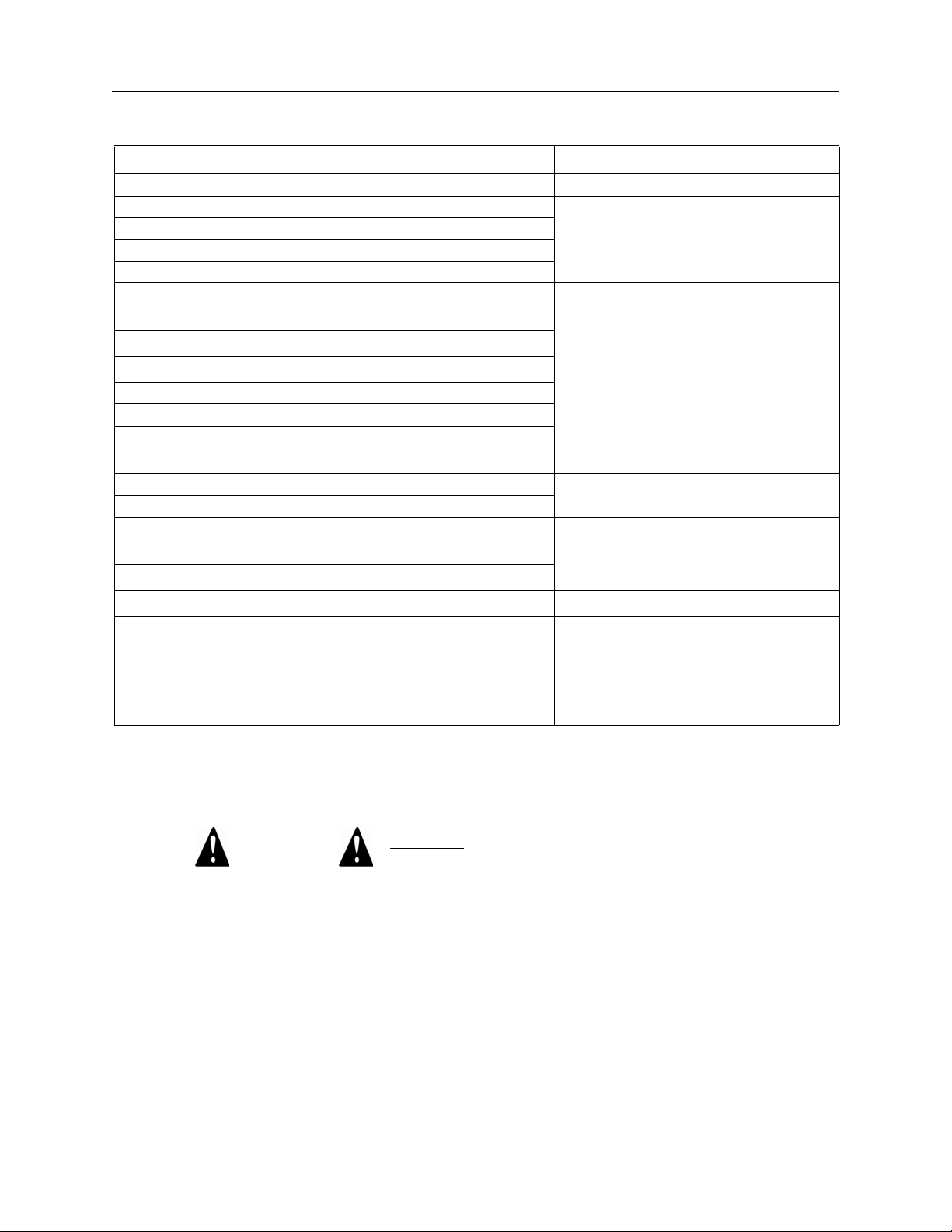

MAINTENANCE SECHUDLE (MZ19H)

MAINTENANCE PROCEDURE SERVICE INTERVAL

Check the engine oil After first use

Check the engine oil level

Check the safety system

Clean the air intake screen

Clean the mower housing

Check the cutting blades Every 5 hours

Grease all lubrication points

Oil the linkage bushings

Service the foam air cleaner

1

1

1

Check the belts for wear/cracks

Check the battery electrolyte

Check the tire pressure

Service the paper air cleaner

1

Change the engine oil

Check the spark plug(s)

Change the oil filter

1

Replace the fuel filter

Replace the paper air cleaner

Clean the engine shrouds and cooling fins

1

1

Before Storage:

• Perform all maintenance procedures listed above.

• Drain the fuel tank.

• Charge the battery and disconnect the battery cables.

• Paint any chipped surfaces.

Each use

Every 25 hours

Every 50 hours

Every 100 hours

Every 200 hours

Every 300 hours

1

More often in dusty, dirty conditions

IMPORTANT: Refer to your engine operator’s manual for additional maintenance procedures.

CAUTION

If you leave the key in the ignition switch,

someone could accidently start the engine and

seriously injury you or other bystanders.

Remove the key from the ignition and

disconnect the wire from the spark plug(s)

before you do any maintenance. Set the wire

aside so that it does not accidentally contact

the spark plug.

1-8

SECTION 2 - MODEL/SERIAL NUMBER LOCATION

SECTION 2 - MODEL/SERIAL NUMBER LOCATION

CONTENTS

Section Description Page

Model/Serial Number Location .................................................................................. 2-2

2-1

SECTION 2 - MODEL/SERIAL NUMBER LOCATION

MODEL/SERIAL NUMBER LOCATION

The unit model and serial number plates is on the

frame under the seat as shown in the illustration.

The engine has its own model and serial number

identification. Consult the appropriate engine

manufacture’s service literature for the location and

translation of the engine model and serial number

information.

Transaxles also have their own model/serial

number.

2-2

SECTION 3 - GREASING AND LUBRICATION

SECTION 3 - GREASING AND LUBRICATION

CONTENTS

Section Description Page

Service Interval/Specification .................................................................................... 3-2

Lubrication Points ...................................................................................................... 3-3

3-1

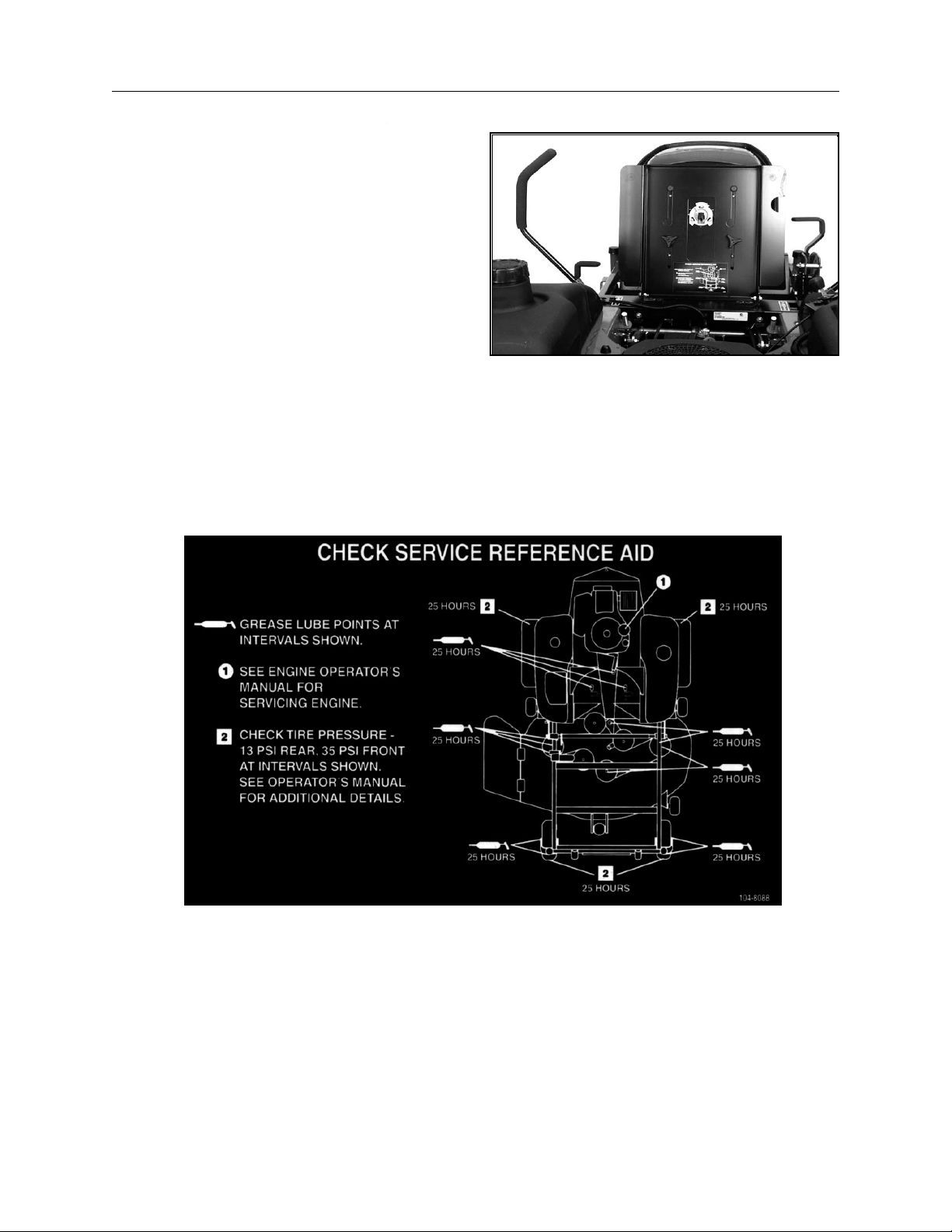

SECTION 3 - GREASING AND LUBRICATION

SERVICE INTERVAL/SPECIFICATION

The unit should be greased every 25 hours; more

often when operating in dirty, dusty, or sandy

conditions.

A decal located under the seat shows the location

of all the grease zerks.

Grease Type: New Holland Ambra GR-9 multipurpose grease (General-purpose lithium base

grease).

3-2

SECTION 3 - GREASING AND LUBRICATION

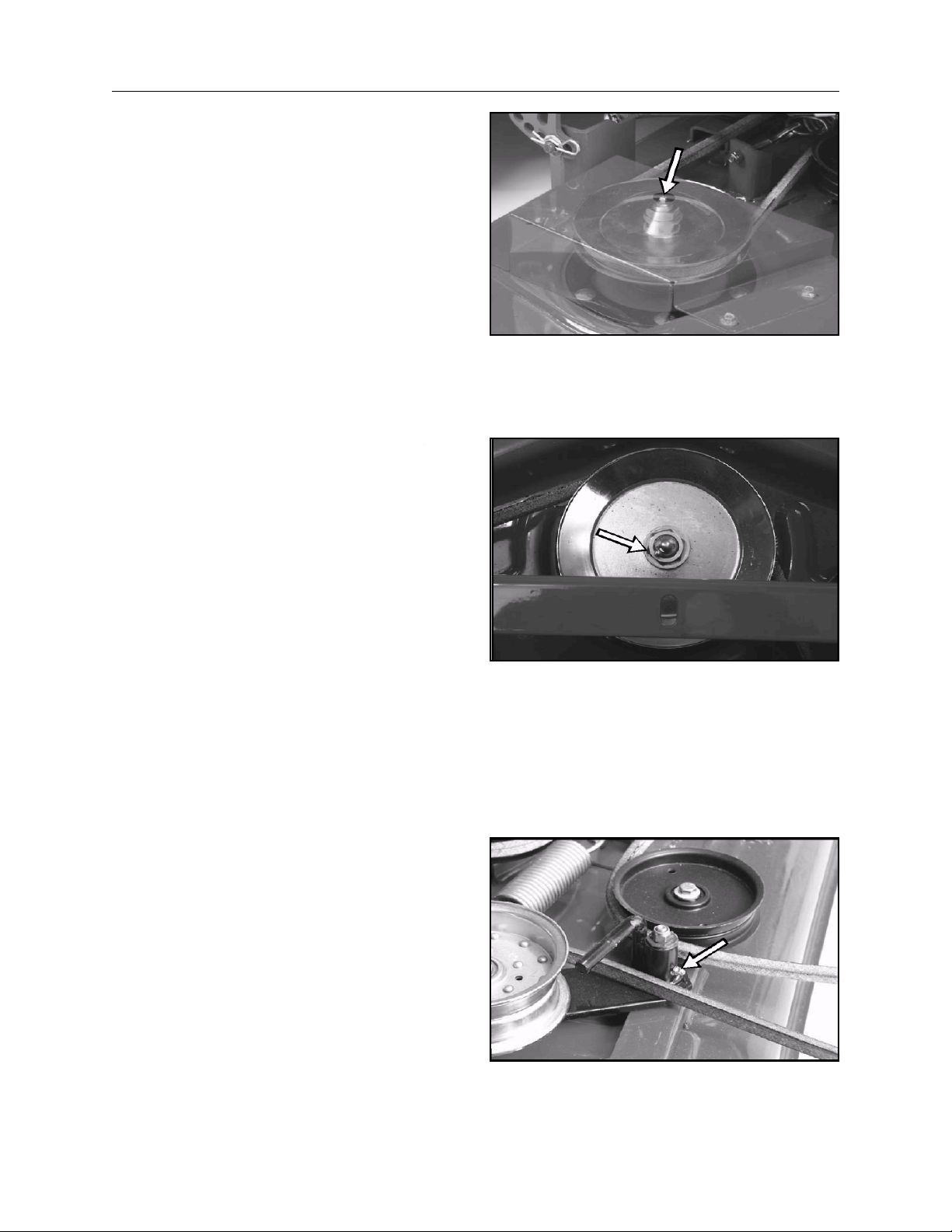

LUBRICATION POINTS

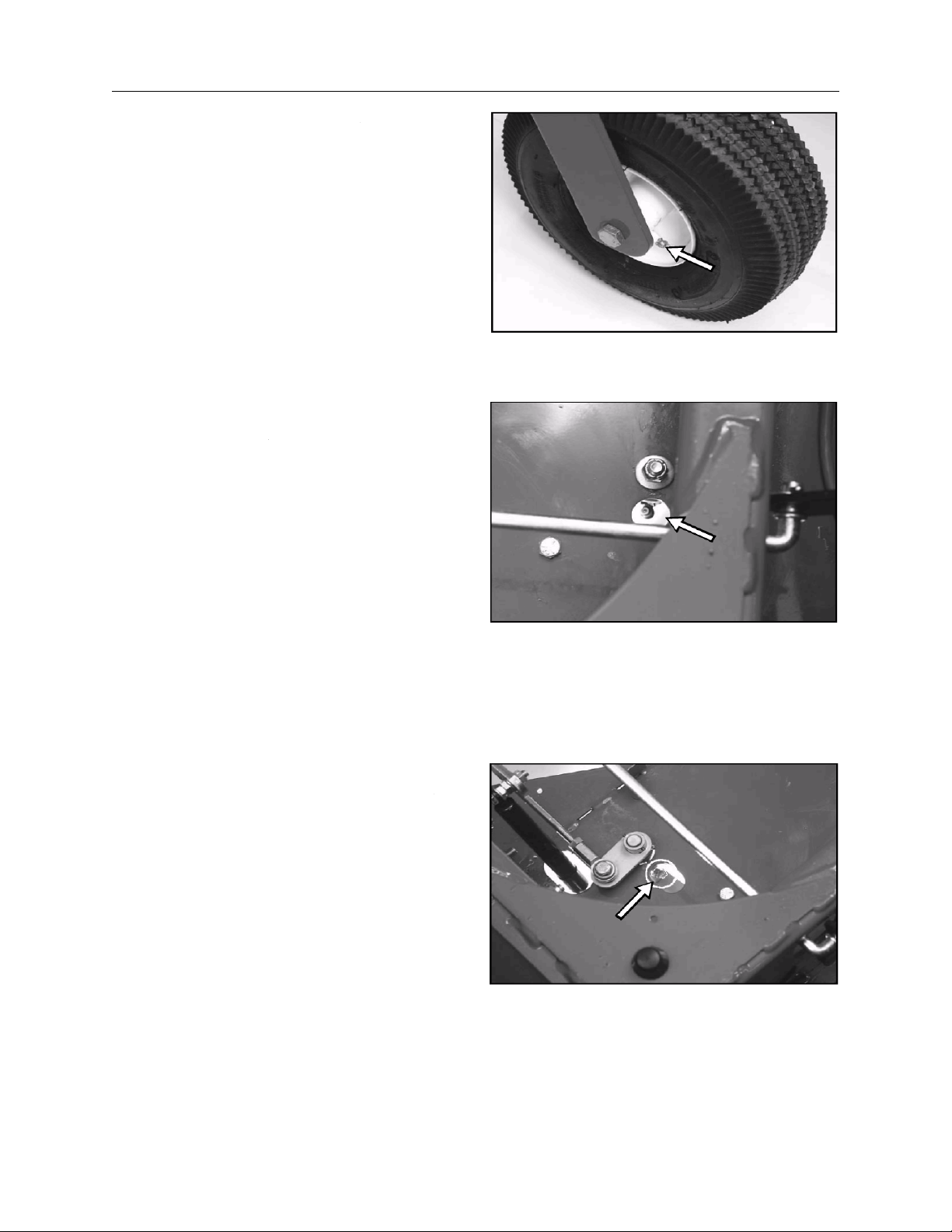

There is a grease fitting on the mower for right and

left outer spindle.

The grease zerk for the center mower spindle.

There is a grease fitting for the deck idler arm

bushing.

3-3

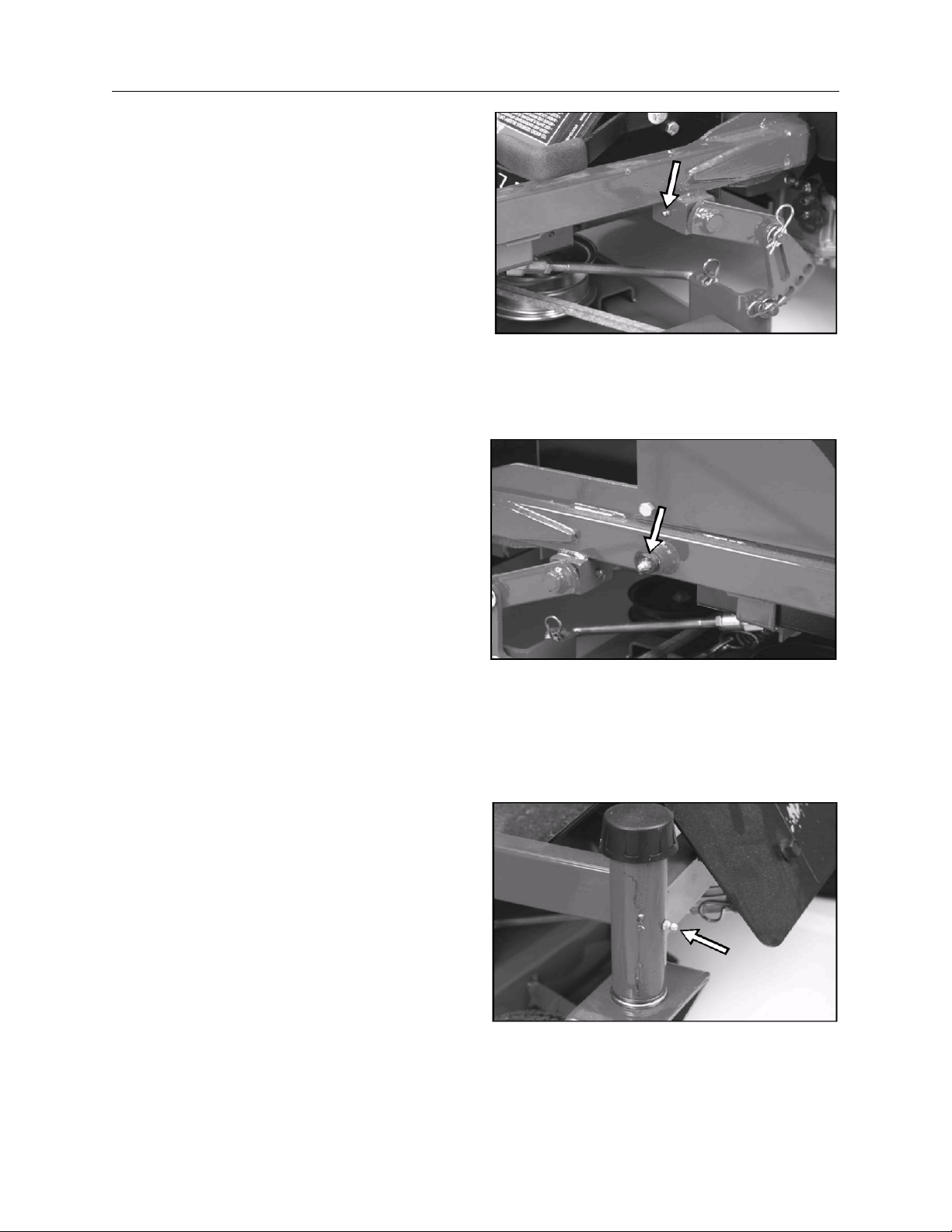

SECTION 3 - GREASING AND LUBRICATION

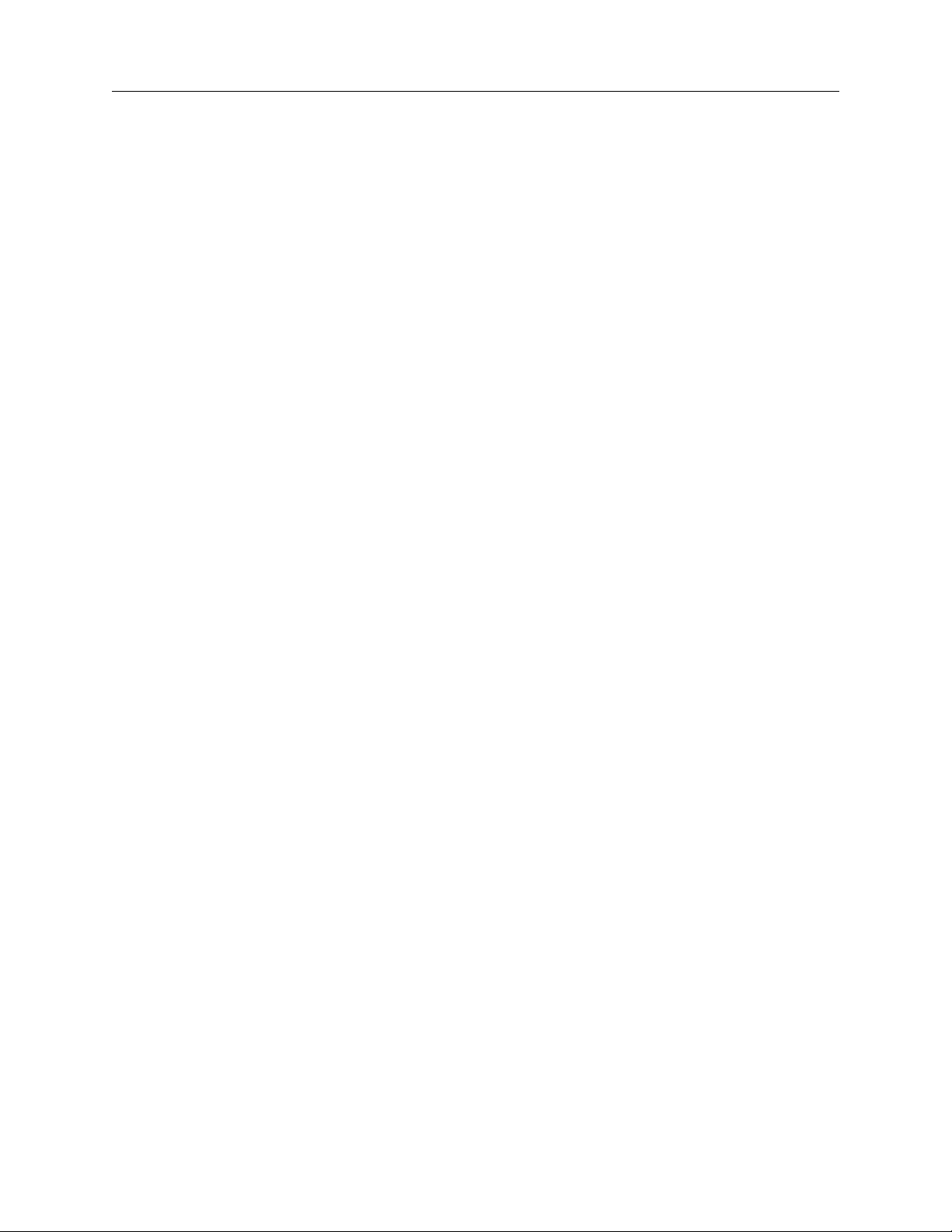

There are two grease fittings for the deck raising

pivot bushings - one on each side of the unit.

The grease zerk for the deck height adjustment

lever is on the right side of the machine.

There are grease fittings for each front castor

bushing,

3-4

SECTION 3 - GREASING AND LUBRICATION

as well as the castor wheel bearings.

The zerk fitting for the traction belt idler bushing is

located under the seat.

Also under the seat are the fittings for the motion

control lever pivot bushings - one for each lever.

3-5

SECTION 3 - GREASING AND LUBRICATION

3-6

SECTION 4 - ENGINE

SECTION 4 - ENGINE

CONTENTS

Section Description Page

Kawasaki Engine ....................................................................................................... 4-2

Kawasaki Air Cleaner ................................................................................................ 4-2

Spark Plug ................................................................................................................. 4-3

Engine Remove and Replace .................................................................................... 4-4

4-1

SECTION 4 - ENGINE

KAWASAKI ENGINE

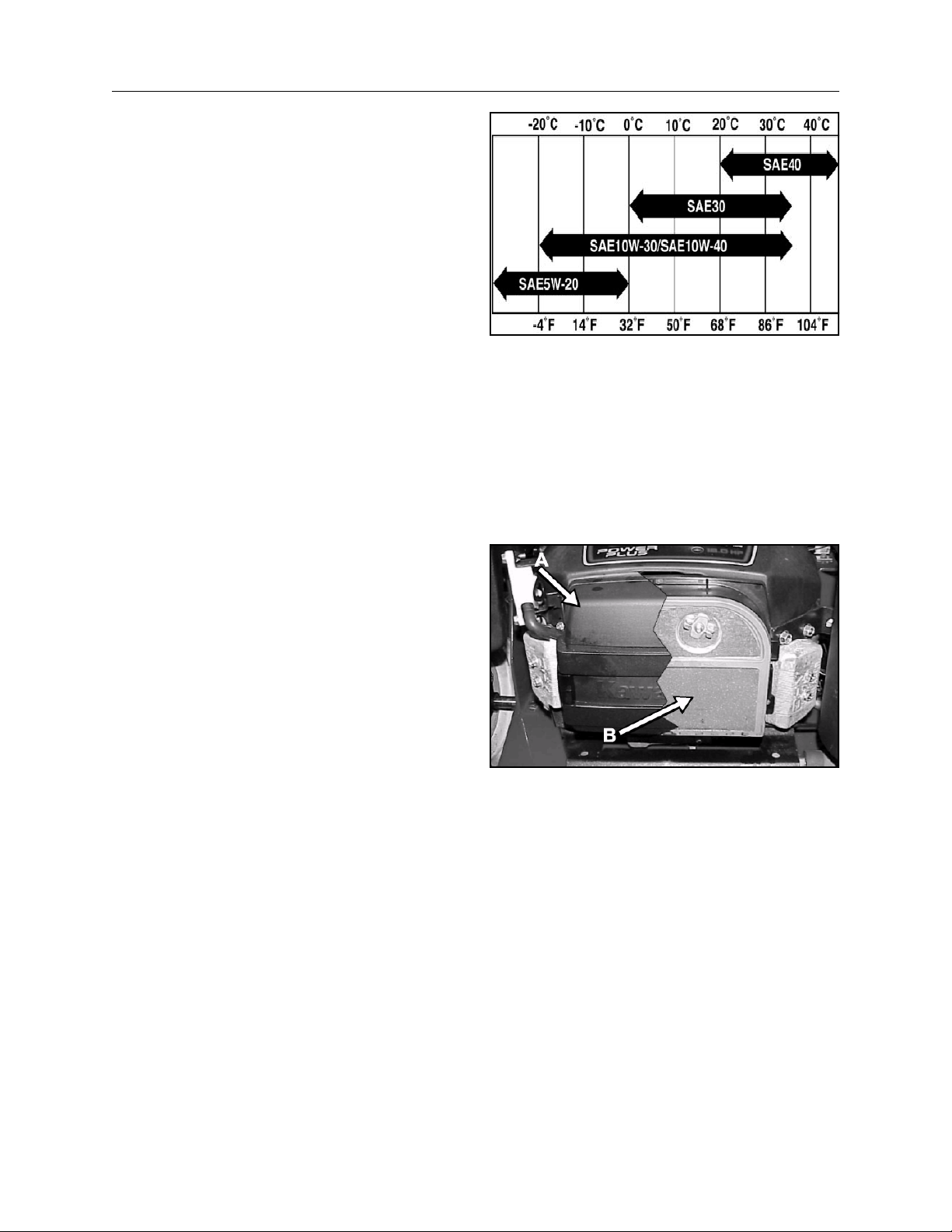

Oil Type: New Holland Ambra Super Gold

detergent oil (API service SC, SD, SE, SF, SG, or

SH).

Crankcase Capacity (with filter): 1.6 qt. (1.5 l).

Viscosity: See table.

Change Oil:

• After the first use.

• Every 100 hours.

Change oil filter every 200 hours.

KAWASAKI AIR CLEANER

The air cleaner assembly consists of a paper filter

element and a foam precleaner.

To clean the paper element, tap lightly on a flat

surface to remove dust and dirt. Inspect the

element for tears, oil contamination, and damage

to the rubber seal.

NOTE: Never clean the paper element with

compressed air or solvents. If the element is dirty

or damaged, replace it immediately.

(A) COVER

(B) AIR FILTER

4-2

SECTION 4 - ENGINE

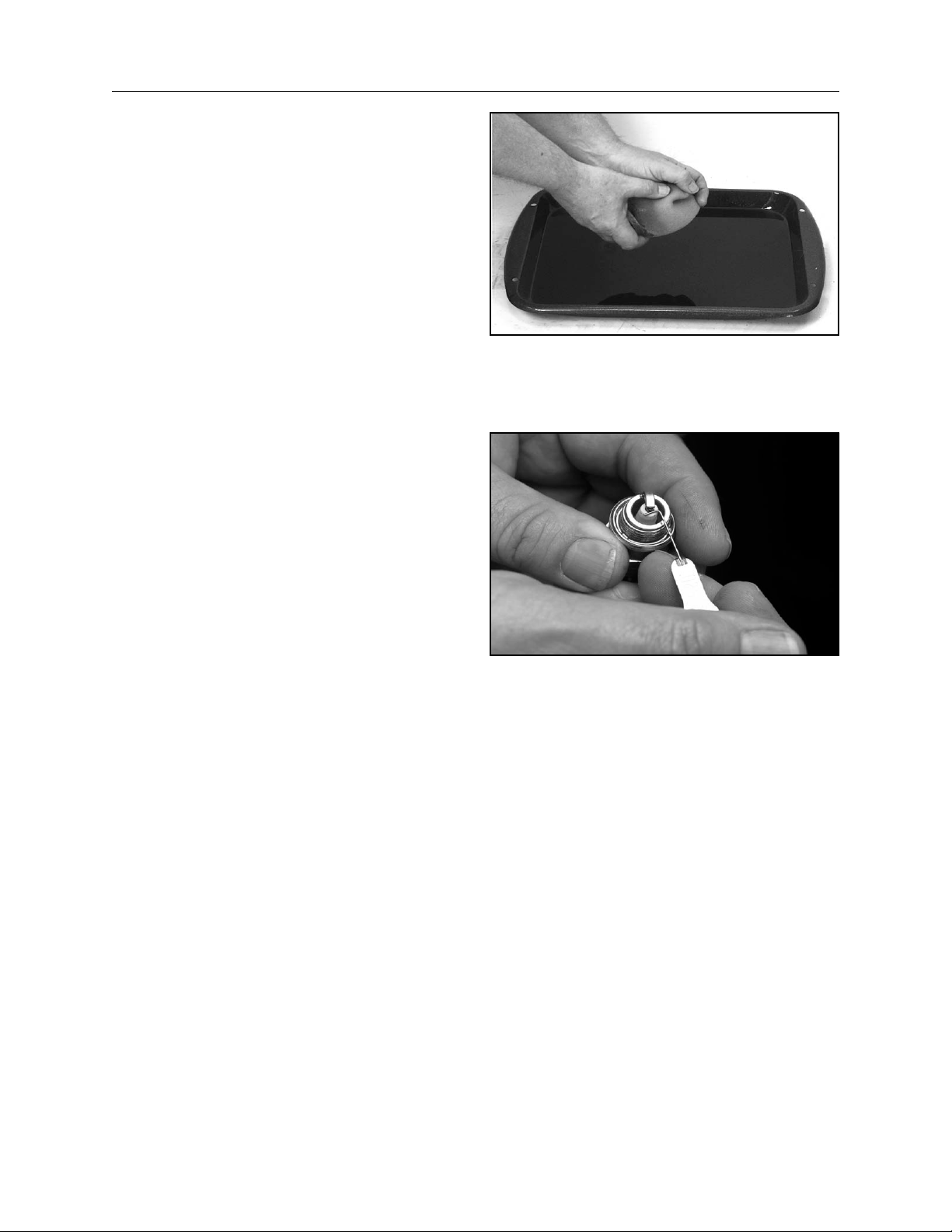

Every 25 hours (more often in dusty, dirty

conditions), wash the foam element in liquid soap

and warm water. When the element is clean, rinse

it thoroughly.

Dry the element by squeezing it in a clean cloth (do

not wring). Allow the element to air dry.

Follow engine manufacturer’s recommendation for

treatment of precleaner prior to installation.

SPARK PLUG

On Kawasaki engines, replace the spark plug(s)

every 100 operating hours.

If the insulator on the spark plug(s) is light brown or

gray, the engine is running properly. A black

coating on the insulator indicates the air cleaner

may be dirty.

IMPORTANT: Never clean the spark plug(s).

Always replace the spark plug(s) when it has a

black coating, worn electrodes, an oily film, or

cracks.

Gap: .030” (0.76 mm)

Type: Champion RCJ86 (or equivalent)

4-3

ENGINE REMOVE AND REPLACE

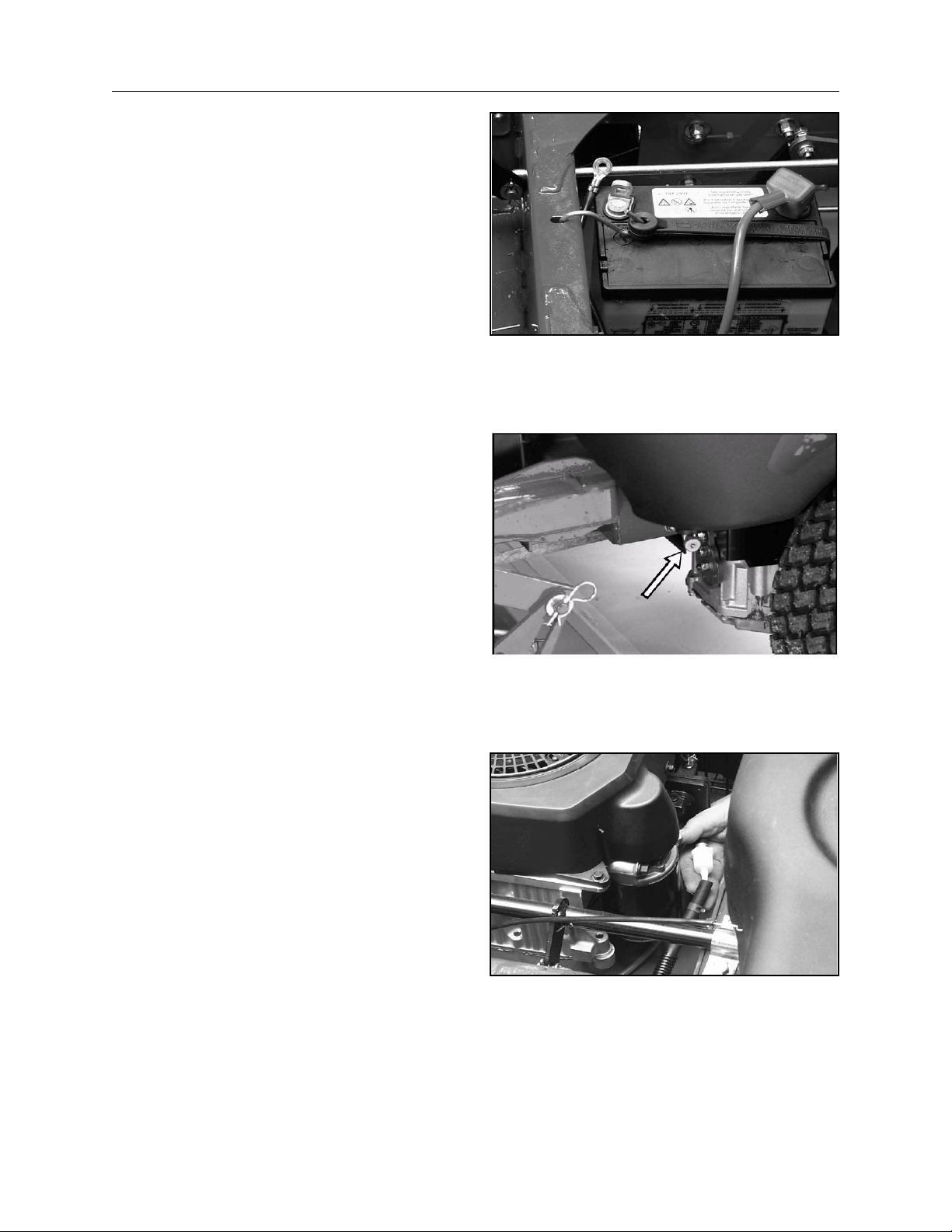

Disconnect the negative battery cable.

Close the fuel shut-off.

SECTION 4 - ENGINE

Remove the fuel line from the fuel filter.

4-4

SECTION 4 - ENGINE

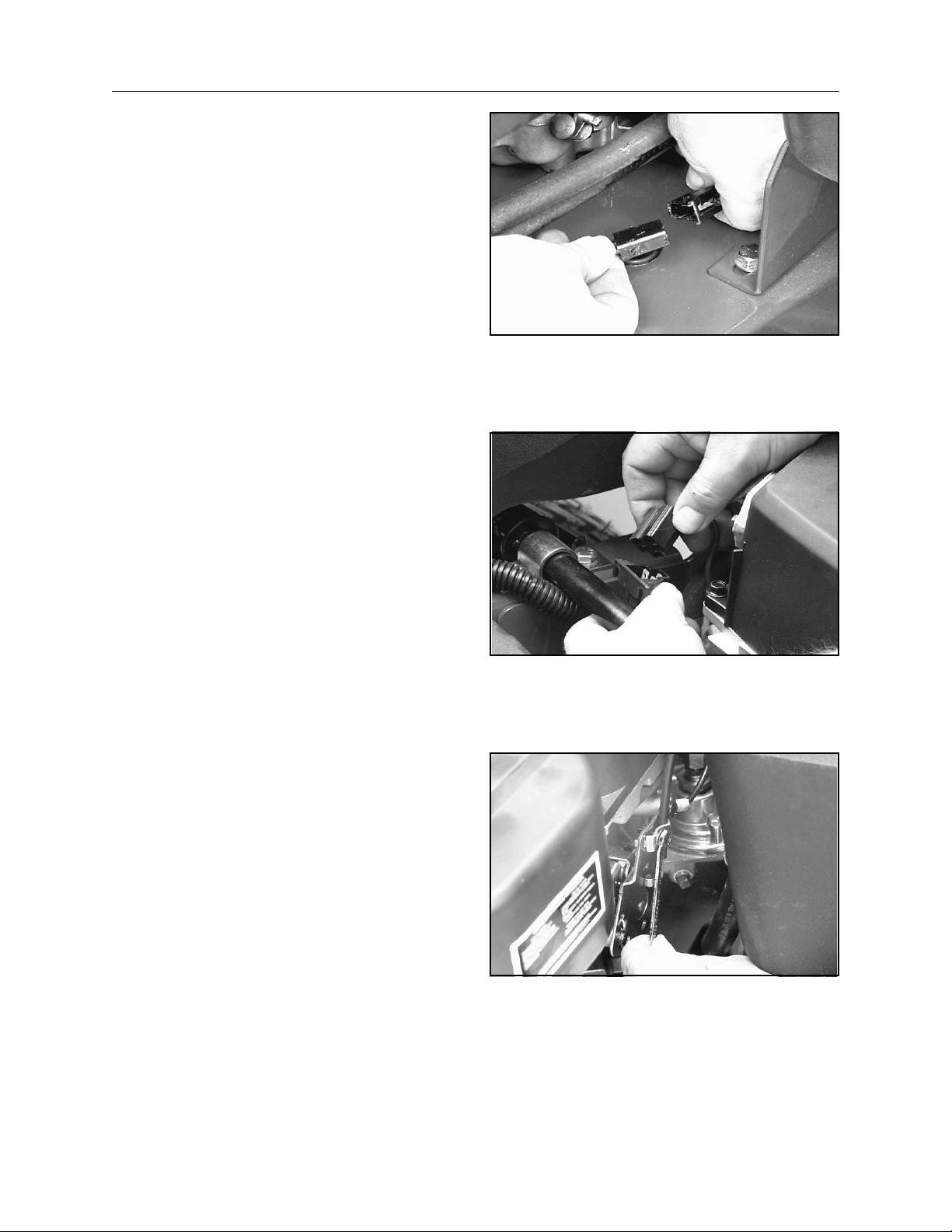

Disconnect the clutch PTO wiring.

Disconnect the engine wiring harness plug.

Loosen the throttle/choke clamp and remove the

cable from the governor linkage.

4-5

SECTION 4 - ENGINE

Remove the ground cable from the engine block.

Remove the starter cable.

Remove mower drive belt. See complete

procedure in Section 7, Mower Decks.

4-6

SECTION 4 - ENGINE

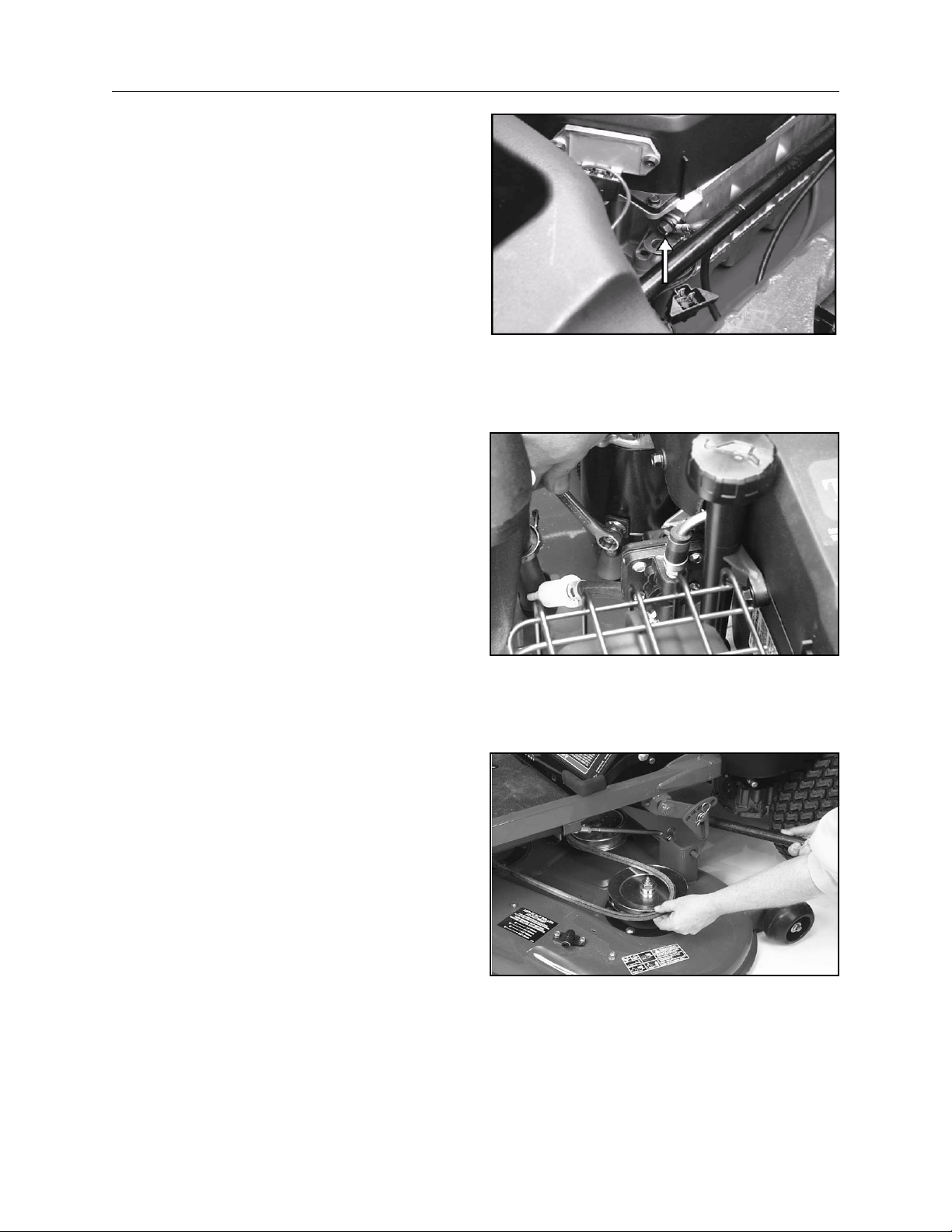

Remove the clutch bolt and lower the clutch

assembly.

Remove traction drive belt.

Move the idler pulley to lessen the tension on the

traction drive belt and slip the belt up off the engine

drive pulley. Then remove the clutch and drive

pulley from the crankshaft.

Remove the 4 engine mounting bolts.

4-7

Lift the engine from the chassis.

Reverse the above steps to replace.

SECTION 4 - ENGINE

4-8

SECTION 5 - TRANSAXLE

SECTION 5 - TRANSAXLE

CONTENTS

Section Description Page

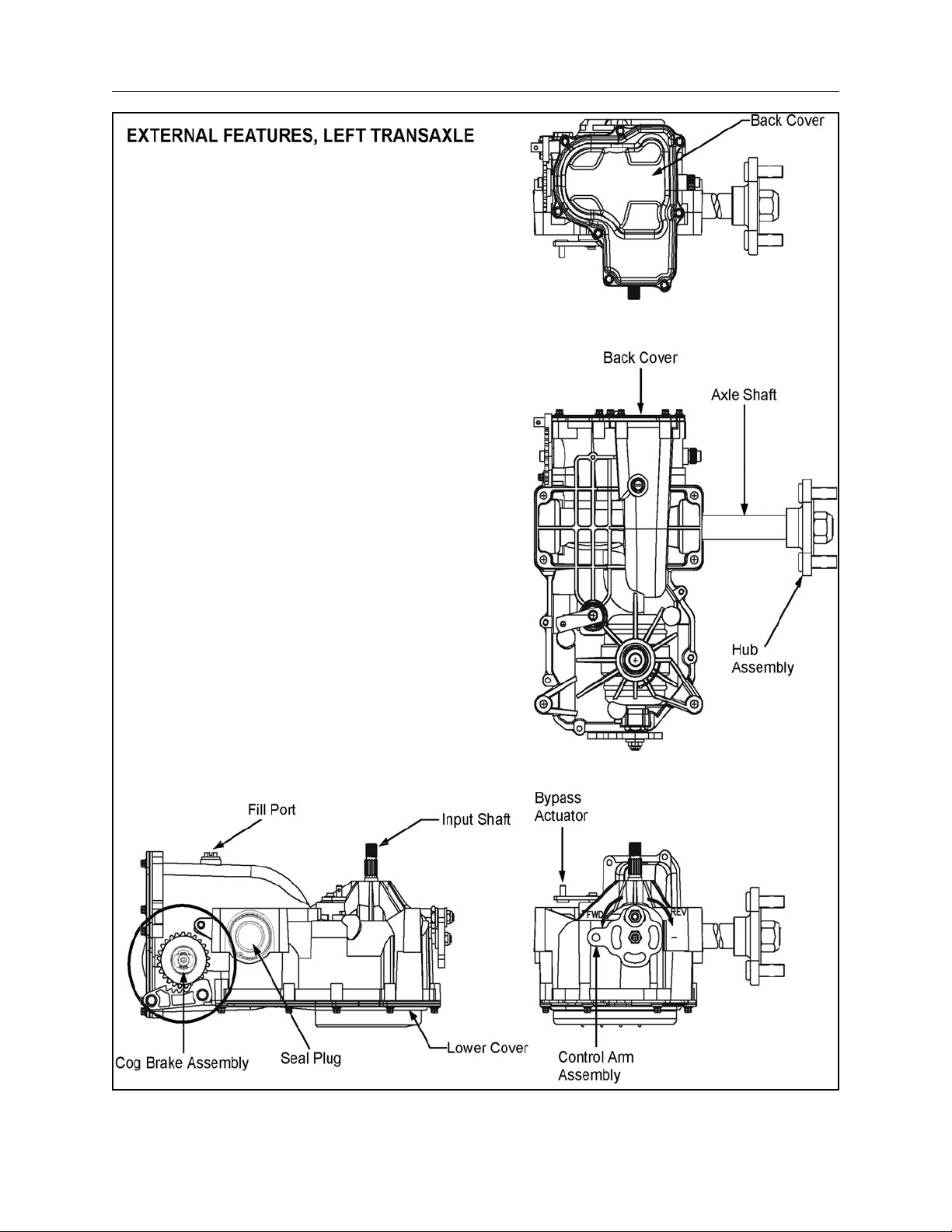

Description and Operation ......................................................................................... 5-2

General Description ................................................................................................... 5-2

Hydraulic Schematic .................................................................................................. 5-3

Technical Specifications ............................................................................................ 5-6

Product Identification ................................................................................................. 5-6

Troubleshooting Checklist ......................................................................................... 5-7

Fluids ......................................................................................................................... 5-9

Fluid Change ............................................................................................................. 5-9

Control Handle-Return To Neutral Adjustment ........................................................ 5-10

Purging the System ................................................................................................. 5-12

Neutral Adjustment .................................................................................................. 5-14

Tracking Adjustment................................................................................................ 5-18

Control Handle Adjustment...................................................................................... 5-20

Remove and Replace Transaxle ............................................................................. 5-21

Reassembly............................................................................................................. 5-26

Repair ...................................................................................................................... 5-30

General Instructions ................................................................................................ 5-30

Limited Disassembly................................................................................................ 5-30

Back Cover .............................................................................................................. 5-32

Brakes ..................................................................................................................... 5-33

Brake Shaft and Bevel Gear.................................................................................... 5-34

Axle Shaft and Spur Gear........................................................................................ 5-35

Lower Housing and Filter......................................................................................... 5-37

Motor Shaft and Bevel Gear .................................................................................... 5-38

Center Section, Cylinder Blocks and Bypass .......................................................... 5-39

Input Shaft and Trunnion Arm.................................................................................. 5-41

Sealant Application .................................................................................................. 5-43

5-1

SECTION 5 - TRANSAXLE

DESCRIPTION AND OPERATION

This manual includes the transaxle general

description, hydraulic schematic, technical

specifications, servicing and troubleshooting

procedures.

The transaxle normally will not require servicing

during the life of the vehicle in which it is installed.

Should other servicing be required, the exterior of

the transaxle will need to be thoroughly cleaned

before beginning most procedures.

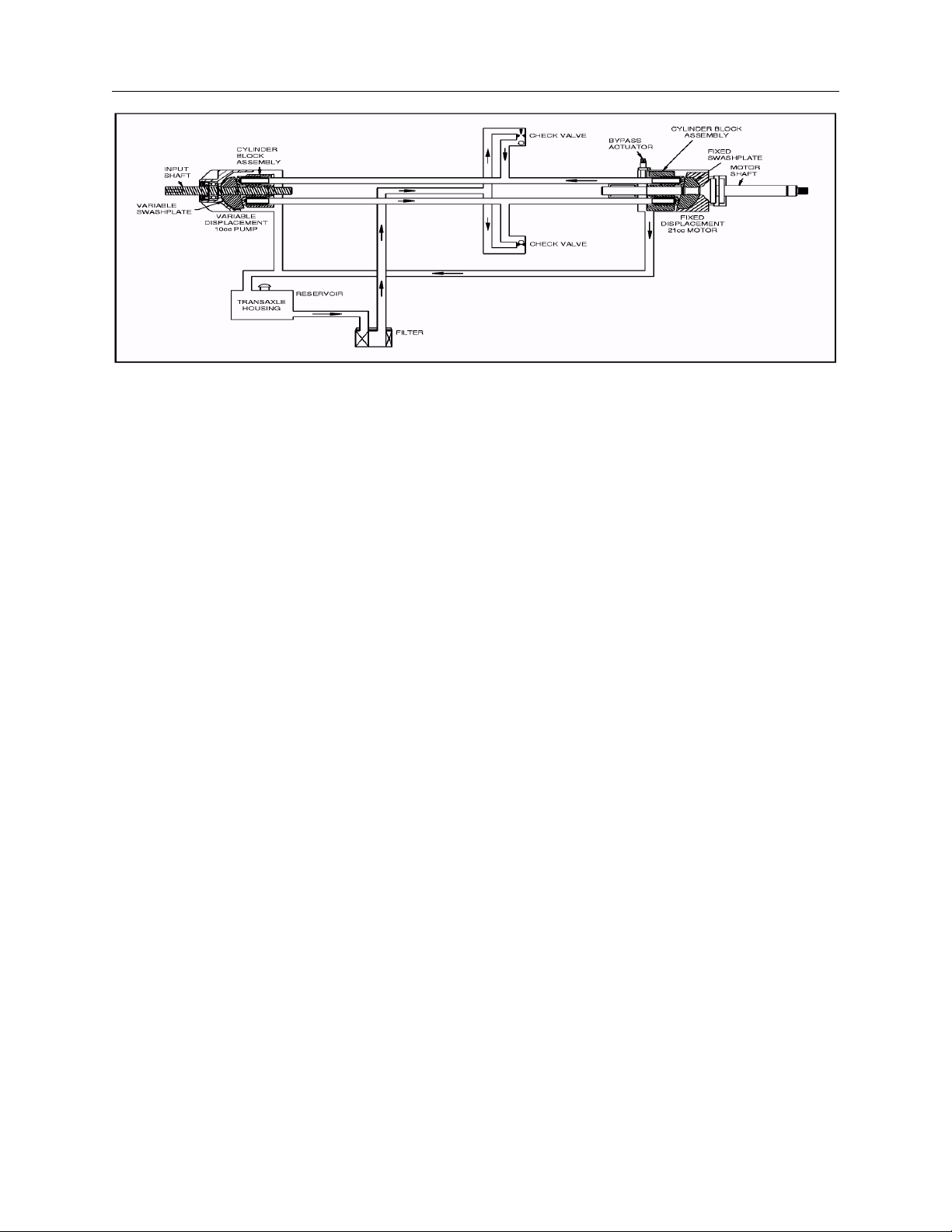

GENERAL DESCRIPTION

The transaxle is a self contained unit designed for

the transfer and control of power. It provides an

infinitely variable speed range between zero and

maximum in both forward and reverse modes of

operation.

This transaxle uses a variable displacement pump

with a maximum displacement of 10cc per

revolution, and motor with a fixed displacement of

21cc per revolution. The variable displacement

pump features a cradle mounted swashplate with a

direct-proportional displacement control. Reversing

the direction of the swashplate reverses the flow of

oil from the pump an thus reverses the direction of

the motor output rotation. The pump and motor are

of the axial piston design and utilize spherical

nosed pistons which are held against a thrust race

by internal compression springs.

The transaxle has a self contained fluid supply and

an internal filter. The fluid is forced through the filter

by a positive “head” on the fluid in the housing/

expansion tank with an assist by the negative

pressure created in the pump pistons as they

operate.

The check valves in the center section are used to

control the makeup flow of the fluid to the low

pressure side of the loop.

A bypass is utilized in this unit to permit moving the

vehicle for a short distance at a maximum of 2

m.p.h. (3.2 Km/h) without starting the engine.

WARNING

WARNING

Actuating the bypass will result in the loss of

hydrostatic braking capacity. The machine

must be stationary on a level surface and in

neutral when actuating the bypass.

5-2

SECTION 5 - TRANSAXLE

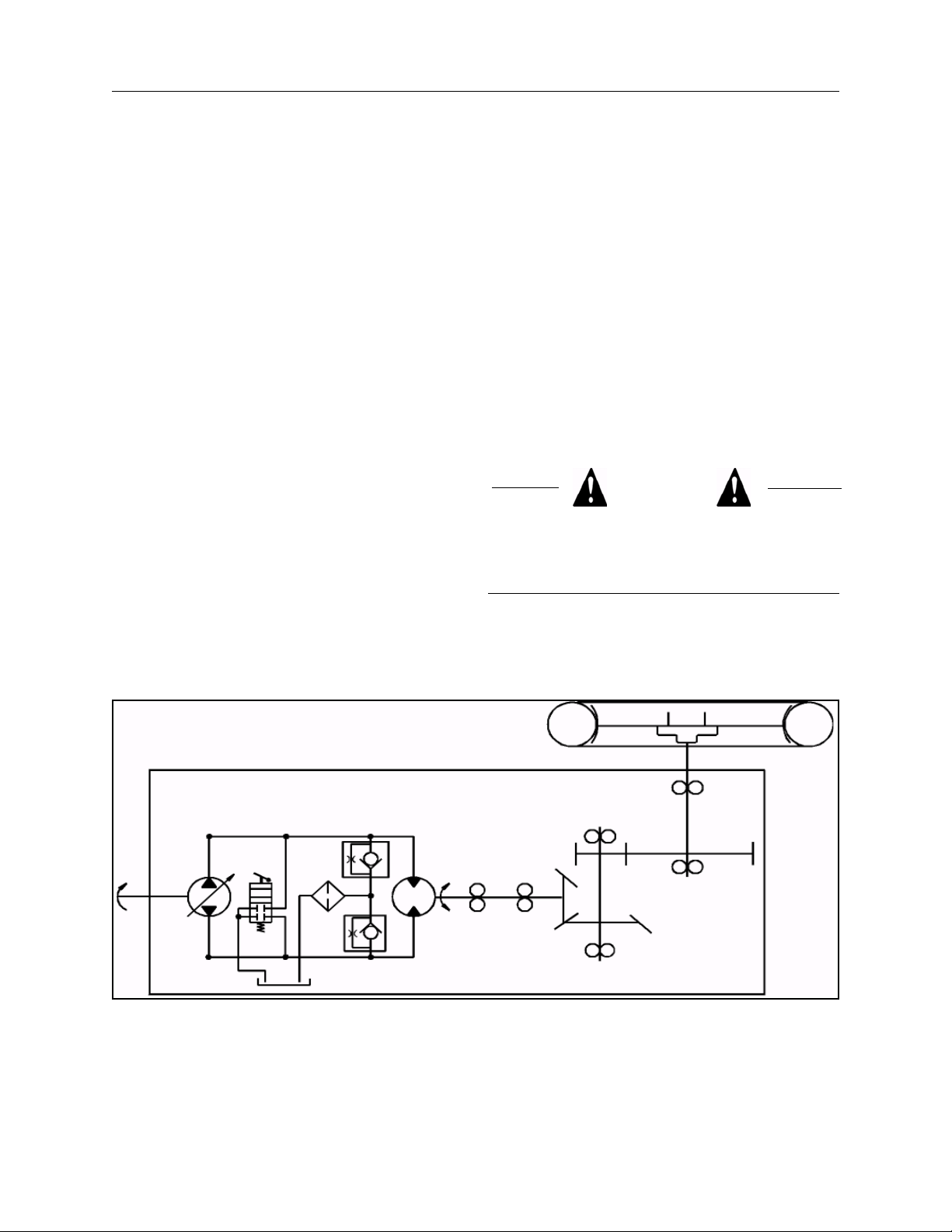

HYDRAULIC SCHEMATIC

The illustration above provides a flow diagram of

the hydraulic oil circuit. The oil supply for the

hydraulic system of the transaxle is also utilized for

lubricating the components of the final drive

assembly.

The input shaft and pump cylinder block are turned

in one direction only by the engine/drive belt/pulley

combination. Output of the oil flow is controlled by

the direction and amount that the variable

swashplate is angled. As the pump pistons

compress they force the oil to flow through one of

two passageways (forward or reverse) in the

center section to the motor cylinder block and

motor shaft. Since the motor has fixed

displacement angle it is forced to turn with the flow

of oil. As the angle of the pump swashplate is

increased the amount of oil being pumped will

increase and cause a higher speed output of the

motor. Reversing the angle of the swashplate will

reverse the direction of oil flow.

The motor cylinder block mounts onto a splined

motor shaft which drives the gear train.

The bypass feature in the transaxle has a

mechanical lever which lifts the motor block off of

the center section running surface, allowing any oil

flowing from the pump block to be discharged into

the housing without turning the motor.

During the operation of the transaxle, fluid is “lost”

from the hydraulic loop through leak paths

designed into the product for lubrication purposes

(around pistons, under the rotating cylinder blocks,

etc.). This “lost” fluid returns to the transaxle

housing, then is pulled back into one of the check

valves depending upon the direction of vehicle

operation. All of this oil must pass through an

internal filter.

5-3

SECTION 5 - TRANSAXLE

5-4

SECTION 5 - TRANSAXLE

5-5

SECTION 5 - TRANSAXLE

TECHNICAL SPECIFICATIONS

Overall Transaxle Reduction ......... 19.2:1

Input Speeds

Maximum...................................

Minimum....................................

Tire Diameter................................. 18 in; (45.7 cm) with 325 lbs; (147.4 kg) maximum weight on tires

Axle Shaft Options

Type...........................................

Diameter....................................

Type...........................................

Diameter....................................

Brake Type .................................... Cog, Parking

Weight of Unit................................ 30 lb; (14 kg)

PRODUCT IDENTIFICATION

3000 RPM

1800 RPM

Keyed/Double “D”

0.984 inch; (25.0 cm)

Flanged

Hub

The model and configuration of the transaxle can

be determined from the label shown below.

5-6

SECTION 5 - TRANSAXLE

WARNING

WARNING

Do not attempt any servicing or adjustments

with the engine running. Use extreme caution

while inspecting the drive belt assembly, and

all vehicle linkage!

Follow all safety procedures outlined in the

vehicle owner’s manual!

TROUBLESHOOTING CHECKLIST

PROBLEM Possible Cause Corrective Action

Unit operates in one

direction only

Vehicle does not drive/

track straight

Control linkage bent or out of adjustment

Drive belt slipping or pulley damaged

Vehicle tires improperly inflated

In many cases problems with the drive system are

not related to a defective transaxle, but are caused

by slipping drive belts, partially engaged bypass

valves, and loose or damaged control linkages. Be

sure to perform all operational checks and

adjustments before assuming the unit is

malfunctioning. The table below provides a

troubleshooting check list to help determine the

cause of operational problems.

Repair or replace linkage

Repair or replace drive belt or pulley

Inflate to recommended pressure.

Check tire diameters are approximately equal, side-to-side

Control linkage bent, loose, or out of

adjustment

Bypass partially engaged.

Unit is noisy Oil level low or contaminated oil

Excessive loading

Brake setting incorrect

Loose parts

Bypass assembly sticking

Air trapped in hydraulic system

Repair, adjust, or replace vehicle

linkage

Adjust bypass linkage

Fill to proper level or change oil

Reduce vehicle loading

Adjust brake to proper setting

Repair or replace loose parts

Repair or replace valve or linkage

Purge hydraulic system

5-7

SECTION 5 - TRANSAXLE

PROBLEM Possible Cause Corrective Action

Unit has no/low power Engine speed low

Control linkage bent or out of adjustment

Brake setting incorrect

Drive belt slipping or pulley damage

Oil level low or contaminated oil

Excessive loading

Bypass assembly sticking

Air trapped in hydraulic system

Unit operating hot Debris buildup around transaxle

Brake setting incorrect

Cooling fan damaged

Oil level low or contaminated oil

Adjust to correct setting

Repair or replace linkage

Adjust brake to proper setting

Repair or replace drive belt or pulley

Fill to proper level or change oil

Reduce vehicle loading

Repair or replace valve or linkage

Purge hydraulic system

Clean off debris

Adjust brake to proper setting

Repair or replace cooling fan

Fill to proper level or change oil

Excessive loading

Air trapped in hydraulic system

Transaxle leaks oil Damaged seals, housing, or gaskets

Air trapped in hydraulic system

Reduce vehicle loading

Purge hydraulic system

Replace damaged components

Purge hydraulic system

5-8

SECTION 5 - TRANSAXLE

FLUIDS

Engine oil with a minimum rating of 55 SUS at 212

F° and an API classification of SH/CD is

recommended. A 20W-50 engine oil has been

selected for use by the factory and is

recommended for normal operating temperatures.

Check oil level when cold. To check the transaxle

fluid level, remove the vent. Oil level should be

1-7/8” - 2-3/16” (4.8 cm - 5.56 cm) from the top of

the vent port.

The oil level can only be checked when the

transaxle is removed from the machine.

FLUID CHANGE

This transaxle is factory filled, sealed and does not

require oil maintenance. However, in the event of

oil contamination or degradation, oil addition or

change may alleviate certain performance

problems.

It is essential that the unit exterior be free of debris

prior to fluid maintenance. The transaxle must be

removed from the vehicle for oil drainage from the

top.

5-9

SECTION 5 - TRANSAXLE

CONTROL HANDLE-RETURN TO

NEUTRAL ADJUSTMENT

1. With the engine off, move the directional

control handles to the reverse position.

2. Let the handles go. They should return to the

neutral position, which means the handle

should line up with the neutral slot (neutral

lockout position).

3. If adjustment is needed:

A. Lift the seat and locate the adjusters.

Loosen the jam nut on the yoke.

5-10

SECTION 5 - TRANSAXLE

B. Turn the top bolt head until the directional

control handle is lined up with the neutral

slot (Neutral Lockout Position).

C. Tighten the jam nut and then test the

directional control handle by pulling the

handle in reverse and then let the handle

go. It should return to the neutral slot.

D. Before starting the unit, follow the

procedures on Purging the System.

5-11

SECTION 5 - TRANSAXLE

PURGING THE SYSTEM

Due to the effect air has on efficiency in hydrostatic

drive applications, it is critical that it be purged from

the system.

These purge procedures should be implemented

any time a hydrostatic system has been opened to

facilitate maintenance or any additional oil has

been added to the system.

Air creates inefficiency because its compression

and expansion rate is higher than that of the oil

normally approved for use in hydrostatic drive

systems.

The following procedures should be performed with

the vehicle drive wheels off the ground, the seat

switch temporarily bypassed, and the brake arm

completely disengaged from the brake cog, (see

Parking Brake Adjustment, Section 6). The

procedure may need to be repeated under normal

operating conditions.

1. With the bypass valves open (hand push

mode) and the engine running, slowly move

the directional control handles in both forward

and reverse directions 5 to 6 times, to purge

trapped air from the unit.

5-12

SECTION 5 - TRANSAXLE

2. Place the bypass valves in the closed position

(operating). With the engine running, slowly

move the directional control handles through

the forward and reverse directions (5 to 6

times).

3. It may be necessary to repeat steps 1 and 2

until all the air is completely purged from the

system. When the transaxle moves forward

and reverse at normal speed, purging is

complete.

5-13

SECTION 5 - TRANSAXLE

NEUTRAL ADJUSTMENT

1. If the unit creeps in neutral, it will be necessary

to make an adjustment to the transaxle.

2. Operate the unit to determine which transaxle

needs adjustment.

3. Raise the unit and place it on jack stands.

4. Warm the transaxle fluid by running for at least

10 minutes.

5. Unplug the seat switch and temporarily

connect a jumper wire across the plug

connector.

5-14

SECTION 5 - TRANSAXLE

6. Place the directional control handles in the

neutral lockout position. Start the engine and

run at half throttle.

7. The rear traction wheels should remain

stationary or creep slightly in reverse.

8. If necessary, loosen the jam nuts (A) and turn

the control rod until the wheel stops between

forward and reverse. In some cases, you may

have a slight creep in reverse. When you lower

the unit to the ground, it should stop.

5-15

SECTION 5 - TRANSAXLE

9. After you have a adjusted the rods, move the

directional control handle in reverse position,

then let go of the handles. The handles should

move to the neutral position and the drive

wheels should remain stationary, or have a

very slight amount of creep in reverse. The

wheels should not creep in the forward

direction when the control handles are in the

neutral lock out position.

10. Run the engine at full throttle. Check neutral

again by moving the directional control handles

in reverse, then let go of the handles. The

handles should move to the neutral position

and the dive wheels should not move. A slight

creep could be observed when the machine is

elevated. However, when lowering the unit to

the ground, the weight of the unit should stop

the creep.

11. When the adjustment is complete, hold the

control rod stationary with pliers and tighten

the jam nuts. Always test again to make sure

the unit is still neutralized.

5-16

SECTION 5 - TRANSAXLE

12. Remove the jumper wire on the seat switch

and plug the switch into the harness. Lower the

unit to the ground.

5-17

SECTION 5 - TRANSAXLE

TRACKING ADJUSTMENT

When operating the unit in forward, it is not

unusual for the unit to track slightly right or left

when going for a distance. This is because of the

different tolerances between two different

hydrostatic pumps. If the tracking deviation is

large, check the following.

NOTE: Ground surface should be level when

checking the tracking.

1. Check the tire pressure in each tire. 13 psi (90

kPa) rear, 35 psi (241 kPa) front. Tire pressure

has a great influence on the tracking of these

units.

It is advisable to check for a large deviation in

outside diameter of the tires, side-to-side, if the

tracking error is severe. Also, check that the

front casters rotate freely, and the front wheel

bearings are in good condition.

2. You may be able to make a slight tracking

adjustment by turning the neutral control rods

without affecting the neutral position.

IMPORTANT: Be sure to recheck the neutral

adjustment to be sure the machine does not creep

after correcting the tracking.

5-18

SECTION 5 - TRANSAXLE

NOTE: All of the control linkage is set up for

forward motion. It is not unusual to have a large

tracking error when going a distance in reverse. Do

not try to adjust reverse tracking. If you do, it will

misadjust the forward linkage.

3. After attempting any tracking change with the

unit, make sure it is still neutralized.

5-19

SECTION 5 - TRANSAXLE

CONTROL HANDLE ADJUSTMENT

If the directional control handles do not line up with

each other, they require adjustment.

1. Loosen the bolts attaching the handles to the

control linkage.

2. Adjust the position of the handles so that they

are aligned. Tighten the bolts after adjustment.

5-20

SECTION 5 - TRANSAXLE

REMOVE AND REPLACE TRANSAXLE

Disconnect the battery.

Close the fuel shut-off.

Raise the rear of the unit and support it with jack

stands.

5-21

SECTION 5 - TRANSAXLE

Remove the clip that secures the vent hose to the

chassis.

If necessary, engage the parking brake to facilitate

wheel removal.

Remove the wheel assembly.

5-22

SECTION 5 - TRANSAXLE

Remove the parking brake link from the brake arm.

Disconnect the motion control link from the

transaxle.

Remove the hairpin cotter and washer from the

bypass valve lever. Leave the rod in place.

5-23

SECTION 5 - TRANSAXLE

Move the idler pulley to lessen the tension on the

traction drive belt and slip the belt up off the engine

drive pulley.

Remove the belt from the transaxle being

removed.

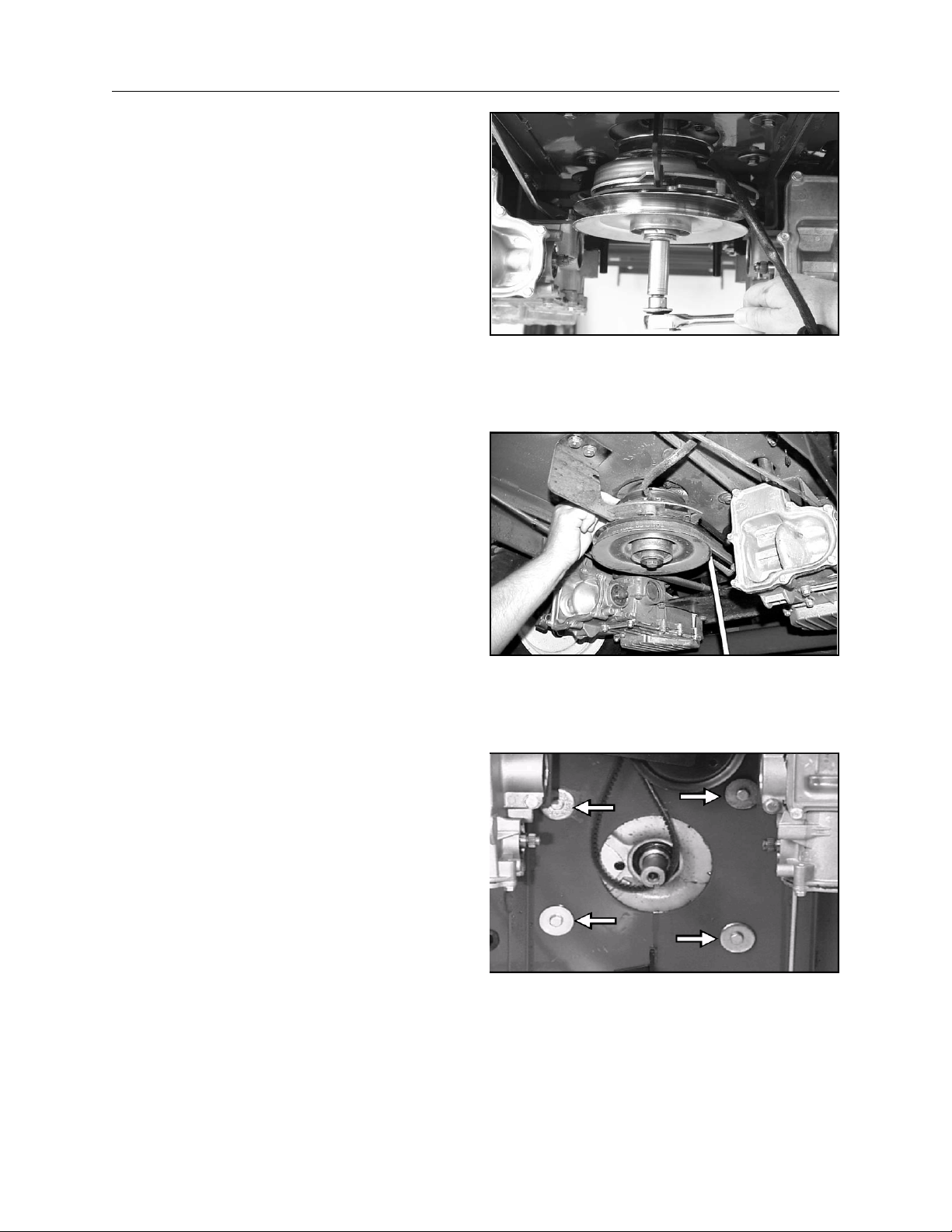

Loosen and remove the six bolts and washer

between both transaxles. Remove the hydro lower

plate. Note the orientation of the hydro lower plate.

It must be reinstalled with the lip facing down,

toward the front.

5-24

SECTION 5 - TRANSAXLE

Support the transaxle with a jack while removing

the last bolts.

Guide the transaxle as it is lowered. Make sure the

cooling fan and vent hose clear the chassis.

5-25

SECTION 5 - TRANSAXLE

REASSEMBLY

IMPORTANT: Before installing a new transaxle,

check the oil level and check the torque on the nut

retaining the input pulley. Torque to 30 - 35 ft. lbs.

(40.7 N·m - 47.5 N·m).

Use a jack to lift the transaxle into the chassis.

Carefully guide it into position so that the cooling

fan does not catch on the chassis and the bypass

rod is properly positioned in the lever. Insert the

vent hose through the slot provided for it in the

frame.

Install the two axle bolts, washers, and nuts to the

frame. Do not tighten the bolts. Reinstall the rest of

the bolts, washers, and nuts in the lower hydro

plate. If the plate was completely removed, make

sure the lip of the plate is pointing to the front and

down. Tighten the transaxle bolts and nuts

following the sequence shown in the photo. Torque

the bolts and nuts to 200 in. lbs. (22.6 N·m).

5-26

SECTION 5 - TRANSAXLE

Place the traction belt on the pulley. Check for

correct belt routing.

(A) Engine Pulley

(B) Idler Pulley

(C) Right Hydro

(D) Left Hydro

Install the hairpin cotter pin and washer on the

bypass valve lever.

Reinstall the motion control link.

5-27

SECTION 5 - TRANSAXLE

NOTE: The length of the link is set at the factory

and should not normally require adjustment in the

field.

If the link has been tampered with, the distance

between bolt centers is:

• Left side 3.6” (9.14 cm)

• Right side 3.1” (7.9 cm)

Install the parking brake linkage.

Replace the wheel assembly.

5-28

SECTION 5 - TRANSAXLE

Secure the vent hose to the chassis.

Recheck to make sure the brake arm clears the

teeth of the brake cog when the park brake is

disengaged.

5-29

SECTION 5 - TRANSAXLE

REPAIR

Each subassembly illustrated in this section is

illustrated by an exploded view showing the parts

involved. The item reference numbers in each

illustration are for assembly instructions only. A

complete exploded view and item list of the

transaxle is provided at the end of this section.

Many of the parts and subassemblies of this

transaxle can be removed and serviced

independently of other components. Where some

components and assemblies must be removed

before a given assembly can be serviced, that

information is given at the beginning of the

disassembly instructions.

GENERAL INSTRUCTIONS

Cleanliness is a primary means of assuring

satisfactory life on repaired units. Thoroughly clean

all exposed surfaces prior to any type of

maintenance. Cleaning of all parts by using a

solvent wash and air drying is usually adequate. As

with any precision equipment, all parts must be

kept free of foreign material and chemicals.

Upon removal, it is recommended that all seals, Orings, and gaskets be replaced. During installation

lightly lubricate all seals, O-rings, gaskets with a

clean petroleum jelly prior to assembly. Also

protect the inner diameter of seals by covering the

shaft with a cellophane (plastic wrap, etc.) material.

Parts requiring replacement must be replaced

using only original New Holland parts.

LIMITED DISASSEMBLY

The following procedures are presented in the

order in which they must be performed to

completely disassemble the unit. Do not

disassemble the unit any further than is necessary

to accomplish the required repairs. Each

disassembly procedure is followed by a

corresponding assembly procedure.

Reassembly is accomplished by performing the

“Assembly” portions of the procedures. If the unit

has been completely disassembled, a summary of

the assembly procedures, in the order in which

they should occur.

Protect all exposed sealing surfaces and open

cavities from damage and foreign material. The

external surfaces should be cleaned before

beginning any repairs.

5-30

SECTION 5 - TRANSAXLE

REQUIRED TOOLS

Miscellaneous Sockets

MZ19H Service & Repair Manual 3/8”

Flat Blade Screw Driver 1/2”

Torque Wrench 7/16”

Air Impact Wrench 9/16”

Rubber Mallet E-8 Torx Head

Pliers Wrenches

Needle Nose 1/2”

Large External Snap Ring

Small External Snap Ring

Large Internal Snap Ring

REQUIRED TORQUE VALUES

Operation U.S. Torque Metric Torque Item Description

Wheel Hub Nut 200-295 ft-lbs 271-400 Nm 108 Nut, hex 3/4-16

Fan/Pulley Nut 360-520 in-lbs 41-59 Nm 49 Nut, hex lock 1/2-20

Back Cover Screws 110-150 in-lbs 12-17 Nm 50 Screw, 1/4-20

Friction Pack Stud 50-120 in-lbs 6-14 Nm 36 Stud, 5/16-24

Control Arm Nut 180-240 in-lbs 20-27 Nm 35 Nut, 5/16-24

Control Bolt 192-252 in-lbs 22-28 Nm 76/121 Nut/Bolt, 5/16-18

Brake Yolk Screw 80-120 in-lbs 9-14 Nm 123/211 Screw, 1/4-28

Cog Brake Arm Screw 110-150 in-lbs 12-17 Nm 123 Screw, hex 1/4-20

Check Plug Assembly 200-360 in-lbs 23-41 Nm 45 Check plug assembly

Lower Housing Screw 110-150 in-lbs 12-17 Nm 50 Screw, 1/4-20

Center Section Screw 525-700 in-lbs 59-79 Nm 44 Screw, 3/8-24

Lock Down Screw 210-270 in-lbs 24-30 Nm 208 Screw, 5/16-24 (Lock Down

5-31

SECTION 5 - TRANSAXLE

BACK COVER

DISASSEMBLY

1. Remove the eight screws, 50, from the back

cover, 13, and discard.

2. Remove the back cover, 13. Take care not to

damage the casting surfaces.

3. Clean off the sealant from the mating surfaces

of the back cover, 13, and the main housing

assembly, 1.

INSPECTION

1. Inspect the back cover, 13, for excessive wear

or damage.

ASSEMBLY

1. Apply sealant to the back cover, 1. Refer to

Sealant Application.

2. Place the back cover, 13, onto the main

housing assembly, 1.

3. Install the eight replacement screws, 50, to

secure the back cover, 13, to the main housing

assembly, 1. Tighten the eight screws, 50, to

the torque value listed in the table above.

5-32

SECTION 5 - TRANSAXLE

BRAKES

DISASSEMBLY

1. Remove the external retaining ring, 63.

2. Remove the brake bolt, 123, brake arm, 70,

and brake disc, 73.

NOTE: The orientation of the hub on the brake

disc.

INSPECTION

1. Inspect the brake disc, 73, for damaged

splines or gear teeth.

2. Inspect the brake arm, 70, for damaged teeth.

ASSEMBLY

1. Insert the brake shaft, 55, into the main

housing, 1. Slide the brake disc, 73, onto the

brake shaft, 55.

NOTE: The orientation of the brake disc. The

hub on the brake disc should face inward on

right hand units and outward on left hand units.

2. Install the brake arm, 70, and brake bolt, 123,

onto the main housing, 1. Tighten the brake

bolt, 123, to the torque value listed in the

above table.

3. Install an external retaining ring, 63, onto the

brake shaft, 55.

5-33

SECTION 5 - TRANSAXLE

BRAKE SHAFT & BEVEL GEAR

DISASSEMBLY

1. Remove the back cover. See Back Cover.

2. Remove the brake. See Brakes.

3. Remove the brake shaft lip seals, 58, and

retaining rings, 126. Discard the lip seals, 58.

4. Remove the retaining ring, 67, from the outside

of the ball bearing, 26.

5. Remove the brake shaft, 55, and ball bearing,

26, from the 19 tooth bevel gear, 53. It may be

necessary to tap lightly on the brake shaft, 55,

to remove the bearing, 26.

6. Remove the 19 tooth bevel gear, 52.

INSPECTION

1. Inspect the brake shaft, 55, ball bearing, 26,

and bevel gear, 52, for wear or damage.

ASSEMBLY

1. Insert the brake shaft, 55, and ball bearing, 26,

into the main housing, 1, allowing the brake

shaft, 55, to pass through the 19 tooth bevel

gear, 52.

2. Install the retaining ring, 67.

3. Install the brake shaft lip seals, 58, and

retaining rings, 126.

4. Install the brake. See Brakes.

5. Install the back cover. See Back Cover.

5-34

SECTION 5 - TRANSAXLE

AXLE SHAFT & SPUR GEAR

DISASSEMBLY

1. Remove the back cover. See Back Cover.

2. Remove the brake. See Brakes.

3. Remove the brake shaft and bevel gears. See

Brake Shaft & Bevel Gears.

4. Remove the hub assembly, 107, if not already

removed.

NOTE: The orientation of the hub and axle to

the main housing is critical in reassembly.

5. Remove the retaining ring, 68, from the outside

of the axle shaft seal.

6. Remove the axle shaft seal, 66, and discard.

7. Remove the retaining ring, 68, from the outside

of the side seal plug, 60.

8. Remove the side seal plug, 60, by lightly

tapping on the end of the axle shaft, 56, with a

plastic or rubber mallet. Discard the side seal

plug, 60.

9. Remove the axle shaft retaining ring, 62, from

the axle shaft, 56.

ASSEMBLY

1. Place the spur gear, 53, and axle bushings, 81

& 82, per noted orientation, into the main

housing, 1.

2. Insert the axle shaft bearings, 64, and axle

shaft, 56, into the main housing, 1. (A clean

screwdriver may be used to help align the gear

and bushings during installation).

3. Place the axle retaining ring, 62, onto the end

of the axle shaft, 56.

4. Using a rubber or plastic mallet, lightly tap a

new side seal plug, 60, into the main housing,

1. Install the seal plug retaining ring, 68.

5. Slide the axle shaft bearing, 65, onto the hub

end of the axle shaft, 56.

6. Slide the axle seal, 66, onto the axle shaft, 56.

Remember to protect the seal, 66, during

installation by covering the axle shaft, 56, with

cellophane. Remove the cellophane once the

seal, 66, is installed.

7. Install the retaining ring, 68.

8. Install the hub assembly, 107, and nut, 108,

with the bolt threads facing away from the

transaxle.

10. Remove the axle shaft, 56, from the main

housing assembly, 1. Remove the ball

bearings, 64 & 65, from the axle shaft, 56.

Remove the two axle shaft bushings, 81 & 82,

and spur gear, 53, from the inside of the main

housing, 1.

NOTE: The orientation of the axle shaft

busings, 81 & 82. This is important for

reassembly.

INSPECTION

1. Inspect the ball bearings, 64 & 65, and axle

shaft, 56, for wear or damage.

2. Inspect the spur gear, 53, for wear or damage.

9. Install the brake shaft and bevel gear. See

Brake Shaft and Bevel Gear.

10. Install the brake. See Brakes.

11. Install the back cover. See Back Cover.

5-35

SECTION 5 - TRANSAXLE

5-36

SECTION 5 - TRANSAXLE

LOWER HOUSING & FILTER

DISASSEMBLY

1. Remove the ten screws, 50, holding the lower

housing, 2, to the main housing, 1, and

discard.

2. Remove the lower housing, 2, and old sealant.

Take care not to damage the casting surfaces.

3. Remove and discard the internal filter, 46.

INSPECTION

1. Inspect the lower housing, 2, for excessive

wear or damage.

ASSEMBLY

1. Install a new filter, 46.

2. Apply sealant to the lower housing, 2, where

the lower housing, 2, mates with the main

housing, 1. Refer to Sealant Application.

3. Place the lower housing, 2, on the main

housing, 1.

4. Install the ten replacement screws, 50, that

hold the lower housing, 2, to the main housing,

1.

5. Torque the ten screws, 50, to the value listed in

the table.

5-37

SECTION 5 - TRANSAXLE

MOTOR SHAFT & BEVEL GEAR

DISASSEMBLY

1. Remove the back cover. See Back Cover.

2. Remove the brake. See Brakes.

3. Remove the brake shaft and bevel gear. See

Brake Shaft & Bevel Gear.

4. Remove the axle shaft and spur gear. See Axle

Shaft & Spur Gear.

5. Remove the 14 tooth bevel gear, 51, from the

motor shaft, 54.

6. Remove the motor shaft, 54, wire retaining

ring, 27, and bearing assembly, 26, from the

main housing, 1.

NOTE: The bearing, 26, does not fit flush with

the housing. This is important for reassembly.

ASSEMBLY

1. Install the motor shaft, 54, bearing assembly,

26, and wire retaining ring, 27.

NOTE: The splines must be aligned when

inserting the motor shaft, 54.

2. Install the 14 tooth bevel gear, 51, on the end

of the motor shaft, 54.

3. Install the axle shaft and spur gear. See Axle

Shaft & Spur Gear.

4. Install the brake shaft and bevel gear. See

Brake Shaft & Bevel Gear.

5. Install the brake. See Brakes.

6. Install the back cover. See Back Cover.

INSPECTION

1. Inspect the gear, 51, shaft, 54, and bearing,

26, for wear or damage.

5-38

SECTION 5 - TRANSAXLE

CENTER SECTION, CYLINDER BLOCKS

AND BYPASS

DISASSEMBLY

1. Remove the back cover. See Back Cover.

2. Remove the brake assembly. See Brakes.

3. Remove the brake shaft and bevel gear. See

Brake Shaft & Bevel Gear.

4. Remove the axle shaft and spur gear. See Axle

Shaft & Spur Gear.

5. Remove the lower housing and filter. See

Lower Housing & Filter.

6. Remove the motor shaft and bevel gear. See

Motor Shaft & Bevel Gear.

7. Remove the three screws, 44, holding the

center section, 3, to the upper housing, 1. Lift

to remove the center section, 3, and motor

cylinder block assembly, 21. Remove the two

pins, 43.

INSPECTION

1. Check the pistons in the motor and pump

blocks for free movement.

2. Remove and inspect the pistons, springs and

seats for wear or damage.

3. Inspect the piston bores in the cylinder blocks

for wear or damage.

4. Check the running surface of the motor and

pump cylinder blocks for damage. This surface

must be smooth in the three sealing areas.

Reassemble the motor and pump cylinder

block assemblies and set aside.

5. Inspect the bushing in the center section and

the bypass plate, 38.

6. Check the motor and pump cylinder block

running surfaces on the center section, 3. This

surface should be smooth. Drag a fingernail

across it to detect scratches or smearing.

7. Inspect the thrust bearing assemblies, 11 & 25,

for wear or damage.

8. Remove the motor cylinder block assembly,

21.

9. Remove the motor block thrust bearings

assembly, 25.

NOTE: The thick race is located nearest to the

pistons when assembled properly.

10. Remove the pump block assembly, 15.

11. Remove the pump block spring, 14, washer,

24, and swashplate assembly, 10.

12. Remove the thrust bearing assembly, 11.

NOTE: The thick race is located nearest to the

pistons when assembled properly.

13. Remove the slot guide, 30. See Input Shaft &

Trunnion Arm.

14. Remove the bypass arm retaining ring, 42,

bypass arm, 41, and bypass lip seal, 40.

Discard the lip seal.

ASSEMBLY

1. Install a new bypass lip seal, 40. Install the

bypass arm, 41, and retaining ring, 42, onto

the bypass actuator, 39.

2. Install the slot guide, 30. See Input Shaft &

Trunnion Arm.

3. Install the swashplate assembly, 10, (including

the thrust bearing assembly).

NOTE: Install the thrust bearing assembly, 11,

with the thick race towards the pistons.

4. Actuate the trunnion arm, 31, and swashplate,

10, to verify free movement.

5. Install the pump block washer, 24, and spring,

14.

6. Install the pump block assembly, 15.

7. Center the bypass actuator, 39, in the housing

pocket.

5-39

SECTION 5 - TRANSAXLE

8. Install the two pins, 43.

9. Install the bypass plate, 38, into the center

section, 3. Install the center section, 3, and

motor cylinder block assembly, 21.

10. Install the three screws, 44, that hold the

center section, 3, in place.

11. Install the thrust bearing assembly, 25.

NOTE: Install the thrust bearing assembly with

the thick race towards the pistons.

12. Install the motor shaft and bevel gear. See

Motor Shaft & Bevel Gear.

13. Install the filter and lower housing. See Lower

Housing & Filter.

14. Install the axle shaft and spur gear. See Axle

Shaft & Spur Gear.

15. Install the brake shaft and bevel gear. See

Brake Shaft & Bevel Gear.

16. Install the brake. See Brakes.

17. Install the back cover. See Back Cover.

5-40

SECTION 5 - TRANSAXLE

INPUT SHAFT & TRUNNION ARM

DISASSEMBLY

1. Remove the back cover. See Back Cover.

2. Remove the brakes. See Brakes.

3. Remove the brake shaft and bevel gear. See

Brake Shaft & Bevel Gear.

4. Remove the axle shaft and spur gear. See Axle

Shaft & Spur Gear.

5. Remove the lower housing and filter. See

Lower Housing & Filter.

6. Remove the motor shaft and bevel gear. See

Motor Shaft & Bevel Gear.

7. Remove the center section and cylinder block

assemblies. See Center Section, Cylinder

Blocks and Bypass.

8. Remove the input shaft retaining ring, 7.

9. Remove and discard the lip seal, 4.

ASSEMBLY

1. Install the trunnion arm, 31, if removed and

install a new trunnion seal, 33.

2. Install the slot guide, 30.

3. Install the input shaft, 12, bearing assembly, 8,

and wire retaining ring, 6, if removed.

4. Install the spacer, 5.

5. Install a new input shaft lip seal, 4. Remember

to protect the seal during installation by

covering the shaft with cellophane.

6. Install the input shaft retaining ring, 7.

7. Install the center section and cylinder block

assemblies. See Center Section, Cylinder

Blocks and Bypass.

8. Install the motor shaft and bevel gear. See

Motor Shaft & Bevel Gear.

9. Install the lower housing and filter. See Lower

Housing & Filter.

10. Remove the spacer, 5.

11. Remove the input shaft, 12, and bearing, 8.

12. Remove the slot guide, 30.

13. Rotate the trunnion arm, 31, to check for free

movement.

14. Remove the trunnion shaft seal, 33, if

necessary and remove the trunnion arm, 31.

INSPECTION

1. Inspect the input shaft, 12, and bearing, 8, for

wear or damage.

2. Inspect the slot guide, 30.

3. Inspect the trunnion arm, 31, for wear or

damage.

4. Inspect the non-removable cradle bearings, 9,

in the main housing, 1, for excessive wear.

10. Install the axle shaft and spur gear. See Axle

Shaft & Spur Gear.

11. Install the brake shaft and bevel gear. See

Brake Shaft & Bevel Gear.

12. Install the brakes. See Brakes.

13. Install the back cover. See Back Cover.

5-41

SECTION 5 - TRANSAXLE

5-42

SECTION 5 - TRANSAXLE

SEALANT APPLICATION

NOTE: Prior to applying the new sealant, the old

sealant must be removed from all surfaces.

A small bead of the sealant around the outer part

of the housing face will be sufficient. Use sparingly.

The illustrations below indicate the correct areas.

5-43

SECTION 5 - TRANSAXLE

5-44

SECTION 6 - CHASSIS

SECTION 6 - CHASSIS

CONTENTS

Section Description Page

Remove and Replace Dampers ................................................................................ 6-2

Remove and Replace Control Linkage ...................................................................... 6-3

Replace Control Linkage ........................................................................................... 6-7

Remove and Replace Brake Linkage ...................................................................... 6-10

Replace Brake Linkage ........................................................................................... 6-14

Parking Brake Adjustment ....................................................................................... 6-17

Replace Traction Belt .............................................................................................. 6-19

6-1

SECTION 6 - CHASSIS

REMOVE AND REPLACE DAMPERS

Remove the E-clip and washer at the bottom of the

damper.

Remove the bolt at the top of the damper and

remove the damper.

6-2

SECTION 6 - CHASSIS

REMOVE AND REPLACE CONTROL

LINKAGE

Remove the control arm.

Remove the electrical connector from the motion

control switch.

Remove the pin from the return to neutral yoke.

6-3

SECTION 6 - CHASSIS

Remove the link between the front and rear

bellcranks.

NOTE: All the ball joint assemblies are installed

with a flat washer between the ball joint and lever.

Disconnect the steering damper.

6-4

SECTION 6 - CHASSIS

Remove the bolts securing the bushings at each

end of the control shaft.

Remove the control shaft.

Disconnect the link between the transaxle and the

bellcrank.

NOTE: Do not change the length of the link.

6-5

SECTION 6 - CHASSIS

Use a small punch to drive the roll pin out of the

upper bellcrank lever, then remove the lever and

thrust washer.

Pull the lower lever and shaft from the bushing.

6-6

SECTION 6 - CHASSIS

REPLACE CONTROL LINKAGE

Lubricate the bellcrank shaft and install the

bushing. The lever welded to the shaft goes on the

underside of the chassis.

Carefully position the top lever on the shaft and

secure with roll pin.

Install the link between the transaxle and bellcrank

lever.

6-7

SECTION 6 - CHASSIS

Place the motion control shaft in position in the

console and secure with nuts and bolts.

NOTE: Make sure shaft is rotating freely after

installation.

Reconnect the steering damper.

Replace the link connecting the control shaft and

bellcrank.

6-8

SECTION 6 - CHASSIS

Attach the return to neutral adjustment yoke to the

control shaft lever.

Connect the wiring to the neutral switch.

Position the motion control handle and secure with

two bolts.

6-9

SECTION 6 - CHASSIS

REMOVE AND REPLACE BRAKE LINKAGE

Remove the brake link from the brake arm.

Remove the clip and yoke from the brake shaft

lever.

Remove the cotter pin and washer from the

actuator rod.

NOTE: The actuator rod cannot be removed from

the lever at this time.

6-10

SECTION 6 - CHASSIS

Remove the two clamps securing the brake shaft.

NOTE: During reassembly, the wiring harness is

routed below the brake shaft, throttle cable is

routed above.

Remove the brake shaft from the chassis and

actuator rod.

To remove the front brake shaft, first remove the

brake handle.

6-11

SECTION 6 - CHASSIS

Remove the brake switch.

Remove the cotter pin and washer from the brake

rod, and remove the rod.

Remove the two bolts and nuts securing the

bushing.

6-12

SECTION 6 - CHASSIS

Remove the E-clip from the brake shaft.

To remove the bellcrank, first slide it to the

(operator’s) left then down.

6-13

SECTION 6 - CHASSIS

REPLACE BRAKE LINKAGE

Place bearings, E Ring, and washer on the forward

brake shaft.

Position the brake shaft in the console. Secure with

nuts and bolts. Install bolts from the outside.

NOTE: Make sure shaft rotates freely after

installation.

Connect the brake rod to the brake shaft lever.

Secure with the cotter pin and washer.

6-14

SECTION 6 - CHASSIS

Replace the brake switch and install wiring.

Install the brake handle on the brake shaft.

Position the rear brake shaft on the chassis with

the upper brake rod through the hole in the lever

and secure with a washer and cotter pin.

6-15

SECTION 6 - CHASSIS

Make sure that the wiring harness is routed below

the brake shaft and the throttle cable above. Then

secure the brake shaft with the two clamps.

Install the brake links to the brake arms with a

washer and cotter pin.

Install the adjustment yokes to the brake shaft

levers with clevis pins and hairpins.

6-16

SECTION 6 - CHASSIS

PARKING BRAKE ADJUSTMENT

The MZ Series is equipped with a cog type parking

brake. When the lever is moved to the “on”

position, the brake linkage pivots the brake arm

engaging the parking brake cog and locking the

brake shaft.

IMPORTANT: Never attempt to engage the

parking brake when the unit is moving. When the

parking brake is disengaged, there must be

clearance between the brake arm and the brake

cog, or severe damage could occur to the

transaxle.

(A) Brake Linkage

(B) Brake Cog

(C) Brake Arm

When the parking brake is released, the brake arm

pivots away from the brake cog allowing the brake

shaft to turn.

The brake arm is held in place by spring tension.

The nut at the bottom of the spring should have

approximately two threads showing.

NOTE: Do not attempt to adjust the parking brake

by turning this nut.

6-17

SECTION 6 - CHASSIS

To adjust the parking brake:

1. Loosen the jam nut at the clevis yoke.

2. Remove the clevis pin and turn the yoke to

adjust length of the rod until the brake arm

engages and disengages the cog completely.

3. Reconnect the brake rod clevis and tighten the

jam nut. Recheck to make sure the brake arm

clears the teeth of the brake cog when the

parking brake is disengaged.

6-18

SECTION 6 - CHASSIS

REPLACE TRACTION BELT

Disconnect the electrical connection for the PTO

clutch.

Remove the mower deck drive belt from the left

side pulley and clutch pulley.

Place the rear of the unit on jack stands.

Remove the PTO clutch bolt and the electric clutch

assembly.

6-19

SECTION 6 - CHASSIS

Remove traction drive belt.

Move the idler pulley to lessen the tension on the

traction drive belt and slip the belt up off the engine

drive pulley.

Remove the traction belt from the transaxle

pulleys.

Install the traction belt following the belt routing.

Reconnect the idler bracket spring and tighten the

eye bolt.

(A) Engine Pulley

(B) Idler Pulley

(C) Right Hydro

(D) Left Hydro

6-20

SECTION 6 - CHASSIS

Reinstall the electric PTO clutch; apply Loctite 271

to the bolt.

Torque the clutch bolt to 50 - 60 ft. lbs. (68.3 - 81.8

N·m).

It will be necessary to remove the flywheel screen

and hold the flywheel nut to achieve proper torque.

6-21

SECTION 6 - CHASSIS

6-22

SECTION 7 - MOWER DECKS

SECTION 7 - MOWER DECKS

CONTENTS

Section Description Page

Belt Removal and Replacement ................................................................................ 7-2

Mower Deck Remove and Replace ........................................................................... 7-4

Mower Deck Side to Side Adjustment ....................................................................... 7-7

Mower Deck Front to Rear Adjustment...................................................................... 7-8

Spindle Bearing Replacement ................................................................................. 7-10

7-1

SECTION 7 - MOWER DECKS

BELT REMOVAL AND REPLACEMENT

Place the deck height lever in its lowest position.

Remove the pulley covers.

Remove the hairpin and washers on left and rear

mower (pork chop) bracket.

7-2

SECTION 7 - MOWER DECKS

Place a length of 3/4” pipe over the idler pulley rod

and remove the belt tension. Remove the belt from

the pulley.

Reverse the steps above to reassemble. Route the

drive belt as shown.

7-3

SECTION 7 - MOWER DECKS

MOWER DECK REMOVE AND REPLACE

Place the mower deck in its lowest position.

Remove the pulley covers.

Remove the belt as described in this section.

7-4

SECTION 7 - MOWER DECKS

Remove the mower (pork chop) brackets.

Remove the rear trunnion rods.

Remove the front trunnion rods.

7-5

SECTION 7 - MOWER DECKS

Tie the rear trunnion rods to the frame.

Slide the deck out from under the right side of the

unit.

7-6

SECTION 7 - MOWER DECKS

MOWER DECK SIDE TO SIDE

ADJUSTMENT

Place the unit on a level surface. Check and adjust

the tire pressure, if necessary.

Raise the deck to the 3” (7.6 cm) position. Use a

blade height gauge to measure the distance

between the blade tips and the surface on both

sides of the deck.

If the difference is greater than 3/16” (4.72 mm),

adjustment is required.

1. Remove the spring clip and washers from the

pork chop bracket.

2. Rotate the bracket toward the front to lower, or

toward the rear to raise that side of the deck.

3. Replace the spring clip.

NOTE: Each adjustment hole changes the

dimension by 1/8 inch (3 mm).

7-7

SECTION 7 - MOWER DECKS

MOWER DECK FRONT TO REAR

ADJUSTMENT

Place the unit on a level surface. Check and adjust

the tire pressure, if necessary.

Measure the length of the rear trunnion rods. The

distance between centers should be 11.5” (29.3

cm).

If necessary, loosen the jam nut. Remove the

spring clip and washer, and turn the rod to achieve

the correct length.

Reinstall the trunnion rods and raise the deck to

the 3” (7.6 cm) position. Rotate the blades until the

ends face forward and backward.

7-8

Loading...

Loading...