New Holland Boomer 47, Boomer 41 Owner's Manual

OPERATOR’S MANUAL

Boomer™ 41

™

Boomer

Compact Tractor

47

Part number 47578243

st

edition English

1

January 2014

Contents

1GENERALINFORMATION

NotetotheOwner..........................................................................1-1

Biodieselfuel...............................................................................1-2

Tractorintendeduse........................................................................1-3

Electro-magneticcompatibility(EMC)......................................................1-4

Productidentication.......................................................................1-5

Operator'smanualstorage.................................................................1-6

Machineorientation.........................................................................1-7

Proposition65..............................................................................1-8

ExhaustGasRecirculation(EGR)-DieselParticulateFilter(DPF)exhausttreatment-Product

overview....................................................................................1-9

2SAFETYINFORMATION

Precautionarystatements..................................................................2-1

Safetyrules.................................................................................2-2

Donotoperatetag.........................................................................2-11

RollOverProtectiveStructure(ROPS)....................................................2-12

Ecologyandtheenvironment.............................................................2-13

Safetysigns...............................................................................2-14

Instructionalsigns.........................................................................2-27

Internationalsymbols......................................................................2-34

3CONTROLSANDINSTRUMENTS

OPERATOR'SSEAT

Seatbelt................................................................................3-1

Seatcontrols...........................................................................3-2

RollOverProtectiveStructure(ROPS)................................................3-3

FORWARDCONTROLS

Instrumentpanel........................................................................3-5

Enginefaultcodesdisplay..............................................................3-7

Cruisecontrol..........................................................................3-10

Transmissionshuttleshiftlever........................................................3-11

Clutchpedal...........................................................................3-12

Brakepedals..........................................................................3-13

Footthrottlepedal.....................................................................3-14

Handthrottlelever.....................................................................3-15

Hornswitch............................................................................3-16

Hazardlightswitch....................................................................3-17

PowerT ake-Off(PTO)switch..........................................................3-18

Keyswitch.............................................................................3-19

Differentiallockpedal..................................................................3-20

Hydrostatictransmision(HST)footpedals............................................3-21

Tiltsteeringlever......................................................................3-22

Multifunctionlightswitch...............................................................3-23

DPFswitch............................................................................3-24

LEFT-HANDSIDECONTROLS

RIGHT-HANDSIDECONTROLS

EXTERIORCONTROLS

4OPERATINGINSTRUCTIONS

Transmissionrangelever..............................................................3-25

Parkbrake.............................................................................3-26

Front-wheeldrivelever................................................................3-27

MidPowerTakeOff(PTO)lever-optional............................................3-28

Hydraulicpowerlift(HPL).............................................................3-29

Draftcontrol-optional.................................................................3-30

Rearremotecontrolvalve(s)-optional...............................................3-31

Midmounttwospoolcontrolvalve....................................................3-32

Transmissionmainshiftlever..........................................................3-34

Transmissionrangelever..............................................................3-35

Hoodreleaselatch....................................................................3-36

COMMISSIONINGTHEUNIT

Enginebreak-inprocedure.............................................................4-1

DieselParticulateFilter(DPF)regeneration............................................4-2

PowerT ake-Off(PTO)operation.......................................................4-8

Three-pointlinkage....................................................................4-10

Attachingthree-pointequipment......................................................4-11

Extendibledrawbar....................................................................4-14

Hydraulicliftrocker....................................................................4-15

HydraulicPowerLift(HPL)dropratecontrolvalve....................................4-15

STARTINGTHEUNIT

Keyswitch.............................................................................4-16

Coldstartingaids......................................................................4-17

Startingtheengine....................................................................4-18

Startingthetractorwithjumpercables................................................4-23

STOPPINGTHEUNIT

Stoppingtheengine...................................................................4-24

Emergencystopping...................................................................4-25

Brakes.................................................................................4-26

MOVINGTHEUNIT

Steeringwheeladjustment............................................................4-28

Steeringoperation.....................................................................4-29

Transmissionoperationatlowambienttemperatures.................................4-30

HydrostaticTransmission(HST)operation............................................4-31

16x16Synchronizedtransmissionoperation.........................................4-33

PARKINGTHEUNIT

Brakesandcontrols-Park............................................................4-35

5TRANSPORTOPERATIONS

ROADTRANSPORT

Externallighting-Identication.........................................................5-1

Hazardwarninglightoperation.........................................................5-2

Turnsignaloperation...................................................................5-3

Roadlightsoperation...................................................................5-4

Worklightsoperation..................................................................5-5

Rearworklight(optional)...............................................................5-6

Drivingthevehicle......................................................................5-7

SHIPPINGTRANSPORT

Carryingthetractoronatransporter...................................................5-8

RECOVERYTRANSPORT

Towing..................................................................................5-8

6WORKINGOPERATIONS

GENERALINFORMATION

Tractorballasting.......................................................................6-1

Tractorballastingweights..............................................................6-2

Liquidballast...........................................................................6-4

7MAINTENANCE

GENERALINFORMATION

Generalinformation....................................................................7-1

Safetyrulesdieselfuel.................................................................7-3

Biodieselfuel...........................................................................7-3

Refuelingthetractor....................................................................7-4

Consumables...........................................................................7-5

MAINTENANCECHART

MaintenanceChart.....................................................................7-6

Every10hoursordaily

Engineoillevel.........................................................................7-7

Enginecoolingsystem.................................................................7-9

Afterrst50hours

Engineoilandlter....................................................................7-10

Pre-fuellter...........................................................................7-12

Fuellter...............................................................................7-13

Hydraulicoillter-Hydraulicsystem.................................................7-14

Hydrostatic(HST)oillter.............................................................7-15

RollOverProtectiveStructure(ROPS)...............................................7-16

Wheelsbolt/nut........................................................................7-17

Every50hours

Greasettings.........................................................................7-18

Transmissionuidlevel................................................................7-19

Clutchpedalfreeplay.................................................................7-19

Brakepedalfreeplay..................................................................7-20

Hydrostatictransmission(HST)neutraladjustment..................................7-20

Enginebelts...........................................................................7-21

Tiresandwheels......................................................................7-22

Frontaxledifferentialoillevel.........................................................7-23

Aircleaner-Primaryelement.........................................................7-24

Every100hours

Fuellter...............................................................................7-25

Every300hours

Engineoilandlter....................................................................7-26

Hydrauliclter.........................................................................7-26

Hydrostatic(HST)oillter-HSTsystem.............................................7-26

Pre-fuellter...........................................................................7-26

Enginebelts...........................................................................7-26

Wheelsbolt/nut........................................................................7-26

Aircleanerprimaryelement...........................................................7-27

Every500hours

Fuellter...............................................................................7-28

Every600hours

Frontaxledifferentialuid.............................................................7-29

Transmissionuid.....................................................................7-30

Every1000hours

Aircleanerinnerelement..............................................................7-31

Enginecoolant.........................................................................7-32

Generalmaintenance

Fuelinjectionsystem-Bleed..........................................................7-33

Hydrostatictransmission(HST)neutraladjustment..................................7-35

Enginebelts...........................................................................7-36

RollOverProtectiveStructure(ROPS)frame-Replace-Possibledamage.........7-37

Battery.................................................................................7-37

Alternator..............................................................................7-38

Fuses..................................................................................7-39

Maxi-fuse..............................................................................7-40

Headlightbulb.........................................................................7-40

Tail/brakelightbulb....................................................................7-41

Turnsignal/hazardlightbulb..........................................................7-41

Wheelsbolt/nut........................................................................7-43

Frontwheelstoe-in....................................................................7-43

Brakepedalfreeplay..................................................................7-44

Clutchpedalfreeplay.................................................................7-45

STORAGE

Storingthetractor.................................................................7-46

Removaloftractorfromstorage..................................................7-47

8TROUBLESHOOTING

SYMPTOM(S)

Engine-Troubleshooting.......................................................8-1

Clutch-Troubleshooting.......................................................8-2

Hydraulicservicebrakes-Troubleshooting....................................8-2

HydraulicLiftSystem-Troubleshooting........................................8-2

Steering-Troubleshooting.....................................................8-3

Hydrostatictransmission-Troubleshooting....................................8-4

Electricalsystem-Troubleshooting............................................8-4

9SPECIFICATIONS

Wheeltreadsettings........................................................................9-1

Tireinationpressures.....................................................................9-2

Liquidballast...............................................................................9-3

Generalspecications......................................................................9-4

Tractordimensions.........................................................................9-9

10ACCESSORIES

Optionalequipment........................................................................10-1

11FORMSANDDECLARATIONS

Deliveryreport-ownercopy..............................................................1 1-3

Deliveryreport-dealercopy..............................................................1 1-5

1-GENERALINFORMATION

1-GENERALINFORMATION###_1_###

NotetotheOwner

Thismanualcontainsinformationconcerningtheadjustmentandmaintenanceofyournewequipment.Youhave

purchasedadependablemachine,butonlybypropercareandoperationcanyouexpecttoreceivetheperformance

andlongservicebuiltintothisequipment.Pleasehavealloperatorsreadthismanualcarefullyandkeepitavailable

forreadyreference.

YourNEWHOLLANDdealerwillinstructyouinthegeneraloperationofyournewequipment.(Refertothe'Delivery

Report'atthebackofthismanual.)Y ourdealer'sstaffoffactory-trainedservicetechnicianswillbegladtoanswer

anyquestionsthatmayariseregardingtheoperationofyourmachine.

YourNEWHOLLANDdealercarriesacompletelineofgenuineNEWHOLLANDserviceparts.Thesepartsare

manufacturedandcarefullyinspectedtoinsurehighqualityandaccuratettingofanynecessaryreplacementparts.

Bepreparedtogiveyourdealerthemodelandproductidenticationnumberofyournewequipmentwhenordering

parts.Locatethesenumbersnowandrecordthembelow.Refertothe'GeneralInformation'sectionofthismanual

forthelocationofthemodelandproductidenticationnumbersofyourmachine.

PLEASERECORDTHEFOLLOWINGINFORMATION

Model

ProductIdenticationNumber(PIN)

DatePurchased

EngineModel

EnginePIN

Thisisthesafetyalertsymbol.Itisusedwithandwithoutsignalwordstoalertyoutopotential

personalinjuryhazards.Obeyallsafetymessagesthatfollowthissymboltoavoidpossible

deathorinjury.

WARNING

Illustrationsinthismanualmayshowprotectiveshieldingopenorremovedtobetterillustrateaparticularfeatureoradjustment.

Replaceallshieldsbeforeoperatingthemachine.

Failuretocomplycouldresultindeathorseriousinjury.

IMPROVEMENTS

W0012A

CNHAmericaLLCiscontinuallystrivingtoimproveitsproducts.Wereservetherighttomakeimprovementsor

changeswhenitbecomespracticalandpossibletodoso,withoutincurringanyobligationtomakechangesoradditionstotheequipmentsoldpreviously.

1-1

Biodieselfuel

1-GENERALINFORMATION

FattyAcidMethylEsterBiodiesel(BiodieselFuel)consistsofafamilyoffuelsderivedfromvegetableoils

treatedwithmethylesters.

NOTICE:BiodieselFuelblendsareapprovedforyourengineonlyiftheycomplywithEN14214SpecicationStan-

dardsorASTMD6751.

NOTICE:ItisimperativethatyoucheckwhichblendisapprovedforyourenginewithyourNEWHOLLANDdealer.

BeawarethattheuseofBiodieselFuelthatdoesnot

complywiththeStandardsmentionedabovecouldlead

toseveredamagetotheengineandfuelsystemofyour

machine.Theuseoffuelsthatarenotapprovedmayvoid

NEWHOLLANDWarrantycoverage.

BiodieselFuelUsageConditions

NOTICE:TheBiodieselFuelmustmeetthefuelSpecicationmentionedabove.

BiodieselFuelmustbepurchasedfromatrustedsupplierthatunderstandstheproductandmaintainsgood

fuelquality.BiodieselFuelmustbepre-blendedbythe

supplier.MixingBiodieselFuelson-sitecanresultincorrectmixturethatcanleadtoproblemswithbothengine

andfuelsystem.

EngineperformanceisaffectedbytheuseofBiodiesel

Fuel.Theremaybeupto12 %reductioninpoweror

torquedependingontheblendused.

NOTICE:DONOTmodifytheengineand/orinjection

pumpsettingstorecoverthereducedperformance.

Thereducedpowermustbeacceptedifusingany

BiodieselFuelblend.

WithBiodieselFuels,itmaybenecessarytochangethe

engineoil,engineoillterandfuellterelementsmore

frequentlythanwithDieselFuels.BiodieselFuelcanremoverustandparticlesfromtheinsideofon-sitefuel

storagetanksthatwouldnormallyadheretothesides

ofthetank.Likeparticledepositsthatcommonlyoccur

withDieselFuel,theseparticlescanbecometrappedby

themachinefuellters,causingblockageandshortening

lterlife.Incoldweather,thisismorelikelytohappen.

ConsultyourNEWHOLLANDdealerforinformationon

coldweatheroperationandpropermaintenanceintervals

whenusinganyBiodieselFuelblend.

WhenhandlingBiodieselFuel,caremustbetakennotto

allowwaterintothefuelsupply.BiodieselFuelwillactuallyattractmoisturefromtheatmosphere.

Fueltanksmustbekeptasfullaspossibletolimitthe

amountofairandwatervaporsinthem.Itmaybenecessarytodrainthefuellterwatertapmorefrequently.

Potentialoxidationandstabilitycouldbeaproblemwith

thefuelstoredinthemachine.

NOTICE:Machinesmustnotbestoredformorethan

threemonthswithBiodieselFuelblendsinthefuelsystem.

Iflongstorageperiodsarenecessary ,theenginemust

runonDieselFuelfor20hourstoushtheBiodieselFuel

outoftheenginefuelsystempriortostorage.

NOTICE:BiodieselFuelmustnotbestoredinon-sitestoragetanksformorethanthreemonths.

AnyspillageofBiodieselFuelmustbecleanedupimmediatelybeforeitcancausedamagetotheenvironment

andthepaintnishofthemachine.

Somemodicationmayberequiredtoallowyourengine

torunBiodieselFuel.Consultyoudealerforcomplete

informationonthesemodications.

BiodieselFuelhasahighercloudpointthanDieselFuel.

NOTICE:TheuseofhighBiodieselFuelblendsarenot

recommendedincoldweatherconditions.

BeforeusingBiodieselFuelblendsyoushouldconsult

withyourdealertoreceivefullinformationabouttheapprovedblendforyourmachineandanydetailedconditionsofitsusage.

NOTICE:Beawarethatnotfulllingtherequirements

andconditionsofBiodieselFuelusagewillvoidyourmachine’sNEWHOLLANDWarrantycoverage.

1-2

1-GENERALINFORMATION

Tractorintendeduse

Thismachinewasdesignedtopowerandpropelitself.Itisintendedforagriculturalusetopullorcarrytractorattachmentsorloadandmovematerialswhenequippedwithafrontendloaderwithavarietyofbuckets.

PROHIBITEDUSAGE

Nopartsorattachmentsshouldbettedtothismachine,whichhavenotbeenreleasedbyNEWHOLLAND.They

mightaffectmachineoperation,safetyoftheuserorotherpeople,stabilityorwearcharacteristicsofthemachine.

NOTICE:Useonlyapprovedaccessoriesandattachmentsdesignedforyourmachine.Consultyourdealer

onchanges,additionsormodicationsthatmayberequiredforyourmachine.Donotmakeanyunauthorized

modicationstoyourmachine.

NOTICE:DONOTusethismachineforanypurposeorinanymannerotherthanasdescribedinthemanual,decals,

orotherproductsafetyinformationprovidedwiththemachine.Thesematerialsdenethemachine'sintendeduse.

NOTICE:Theengineandfuelsystemonyourmachineisdesignedandbuilttogovernmentemissionsstandards.

Tamperingbydealer,customers,operatorsandusersisstrictlyprohibitedbylaw.Failuretocomplycouldresultin

governmentnes,reworkcharges,invalidwarranty,legalactionandpossibleconscationofthemachineuntilrework

tooriginalconditioniscompleted.Engineserviceand/orrepairsmustbedonebyacertiedtechnicianonly!

NOTE:Allpersonswhowillbeoperatingthismachineshallpossessavalidlocalvehicleoperatingpermitand/orother

applicablelocalageworkpermits.

1-3

1-GENERALINFORMATION

Electro-magneticcompatibility(EMC)

Interferencemayariseasaresultofadd‐onequipmentthatmaynotnecessarilymeettherequiredstandards.As

suchinterferencecanresultinseriousmalfunctionoftheunitand/orcreateunsafesituations,youmustobserve

thefollowing:

Themaximumpowerofemissionequipment(radio,telephones,etc.)mustnotexceedthelimitsimposedbythe

•

nationalauthoritiesofthecountrywhereyouusethemachine

Theelectro‐magneticeldgeneratedbytheadd‐onsystemshouldnotexceed24 V/matanytimeandatanylo-

•

cationintheproximityofelectroniccomponents

Theadd‐onequipmentmustnotinterferewiththefunctioningoftheonboardelectronics

•

FailuretocomplywiththeseruleswillrendertheNEWHOLLANDwarrantynullandvoid.

1-4

1-GENERALINFORMATION

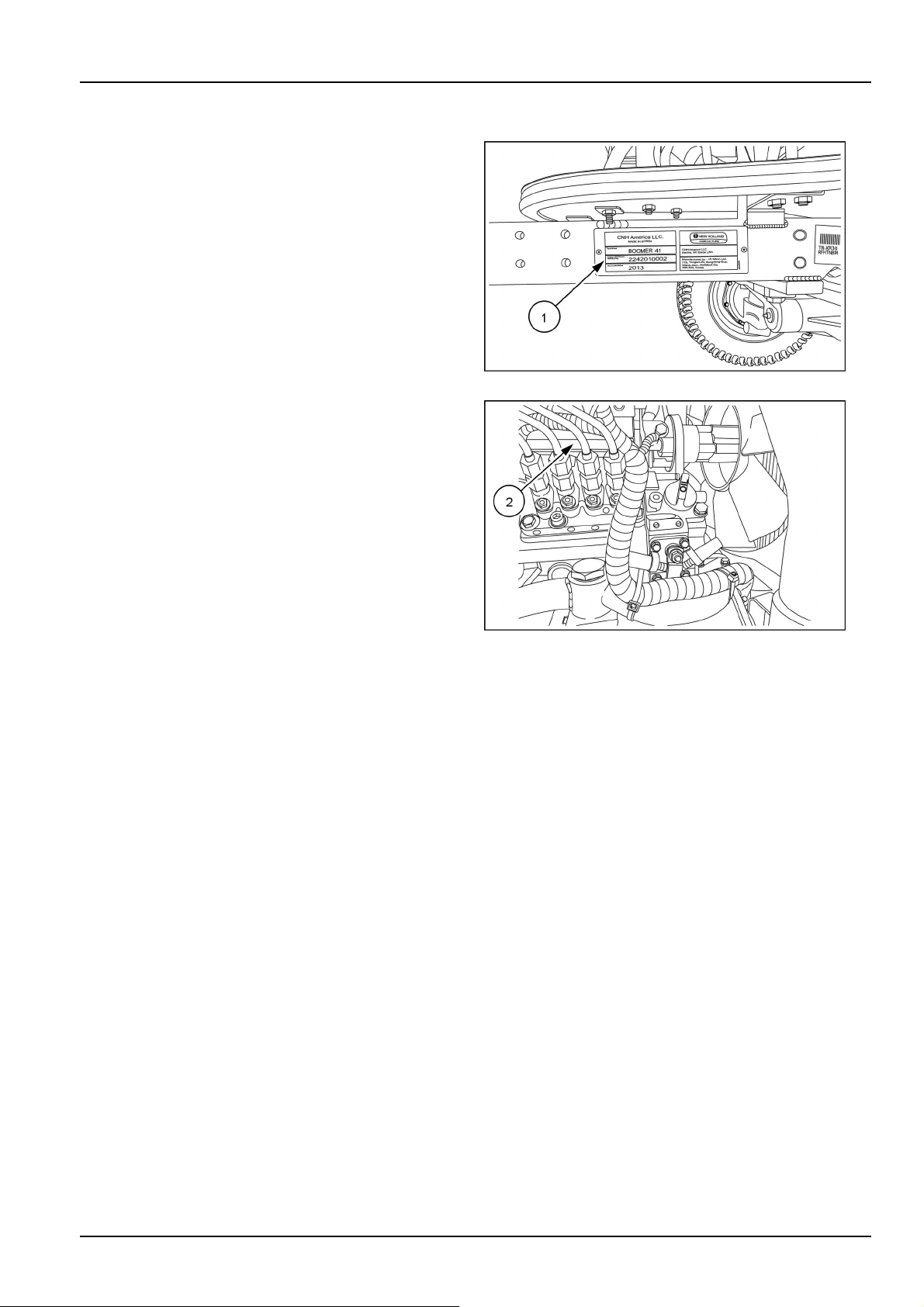

Productidentication

TheProductIdenticationPlate(1)islocatedontheleft-

handsideofthefrontframe..

Thenumbersontheplateareimportantintheeventyour

tractorshouldrequirefutureservice.

Theengineidenticationinformationplate(2)islocated

ontheright-handsideoftheengineblock,behindthefuel

injectionpump.

NHIL13CT01348AA1

NHIL13CT011 18AA2

1-5

1-GENERALINFORMATION

Operator'smanualstorage

Theoperator’smanualmustbestoredinacompartment

(1)locatedintherearoftheoperator’sseatbackandbe

keptavailableforusebyalloperators.

NHIL13CT01163AA1

1-6

1-GENERALINFORMATION

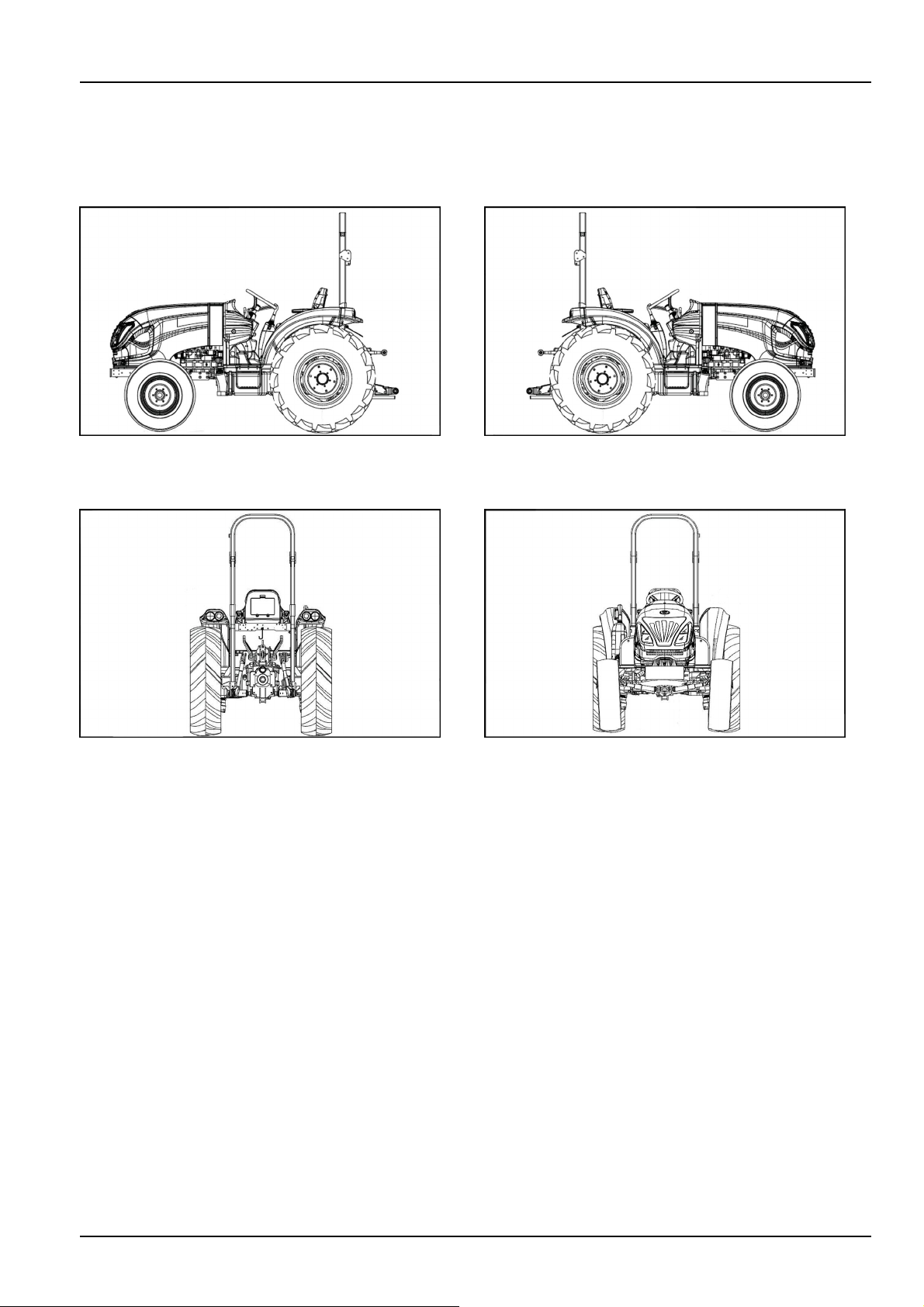

Machineorientation

NOTE:Onthisequipment,left–handandright-handare

determinedbystandingbehindtheunit,lookinginthedirectionoftravel.

Left-handview

Rearview

NHIL13CT01187AA1

NHIL13CT01186AA3

NHIL13CT01188AA2

Right-handview

NHIL13CT01345AA4

Frontview

1-7

Proposition65

1-GENERALINFORMATION

BT09A2131

1-8

1-GENERALINFORMATION

ExhaustGasRecirculation(EGR)-DieselParticulateFilter(DPF)

exhausttreatment-Productoverview

WhatisExhaustGasRecirculation(EGR)?

YourNEWHOLLANDmachineisequippedwithadditionalcomponentstocomplywithnationalandlocalexhaust

emissionsrequirements.EGRworksbyrecirculatingaportionoftheengineexhaustgassesbackintotheengine

combustionchambertolowercombustiontemperatures.

ThemaincomponentsoftheEGRsysteminclude:

EGRvalve

•

DieselParticulateFilter(DPF)

•

DieselOxidationCatalyst(DOC)

•

Exhaustgastemperaturesensors

•

Differentialpressuresensor

•

Throttlevalveactuator

•

WhatisaDieselParticulateFilter(DPF)?

ADieselParticulateFilter(DPF)isaltermountedintheexhauststream.Duringnormaloperatingconditions,the

exhaustgassespassthroughtheporouswallsoftheDPFandtrapParticulateMatter(PM)generatedbythecombustionprocessoftheengine.Whenchannelsinsidethe(DPF)llupwith(PM),thesystemmustbecleaned.The

cleaningprocessiscalledregeneration.

Howdoestheregenerationprocesswork?

Whenthe(DPF)becomesrestricted,thesystemwillneedtobecleanedorregeneratedbyraisingexhausttemperaturestoburnoffthetrappedParticulateMatter(PM).Thisprocessisusuallydoneautomatically.BurnedPMwill

leavebehindtracesofashwithinthe(DPF).TheashmustbecleanedoutbyaNEWHOLLANDdealeroutttedwith

machinesspecicallydesignedtoclean(DPF)systems.Seethe[**Linktomaintenancechart**]forserviceintervals.

Automaticregeneration

WhentheDPFentersautomaticregenerationmode,thedisplaywillindicate“DPFON”.Severalconditionsneedto

befollowedtoproperlyletthemachineperformthisfunction.

Duringthismodedonotidleorshutthemachinedown.

•

Hotexhaustgasseswillbegenerated.Useinawellventilatedareaawayfromcombustiblematerials.

•

Usethemachineundernormalworkscenariosuntiltheautomaticregenerationprocesshascompleted.

•

FindingaDieselParticulateFilter(DPF)cleaningfacility

TondaNEWHOLLANDdealerthatisfullyequippedtoserviceyourDPFsystem,pleasecallthenumberbelow.

NewHollandT opService:1-866-639-4563

na.topservice@newholland.com

1-9

1-GENERALINFORMATION

FEDERALEMISSIONSWARRANTY

WARRANTYSTATEMENT

ISMwarrantsthatyour2013andlateroff-roaddieselenginewasdesigned,builtandequippedtoconformto

applicableU.S.EnvironmentalProtectionAgency(EPA)regulationsandisfreefromdefectsinmaterialsand

workmanshipwhichcauseittofailtoconformwithsuchregulations,forthefollowingperiodofoperation:

Foraperiodoftwo(2)yearsor1,500hoursofoperation,whicheveroccursrst,afterthedateofdeliverytotheinitial

•

retailownerofanyvariablespeedoff-roaddieselengineratedatlessthan19 kW(25 Hp)andanyconstant-speed

off-roaddieselengineratedatlessthan37 kW(50 Hp)withratedspeedgreaterthanorequalto3,000 RPM.

Foraperiodofve(5)yearsor3,000hoursofoperation,whicheveroccursrst,afterthedateofdeliverytothe

•

initialretailownerforallotheroff-roaddieselengines.

WARRANTYINFORMATION

Themodelyear,classofdieselengine,andemissionapplicationforyourengineareidentiedontheemissioncontrol

informationlabelafxedtotherighthandsideofyourengine’sfrontsideoftiminggearcaseorheadcover.

Anyemissioncontrolsystempartsthatareprovendefectiveduringnormalusewillberepairedorreplacedduring

thewarrantyperiod.ThewarrantyrepairsandservicewillbeperformedbyanyauthorizedISMdealeratthedealer’s

placeofbusiness,withnochargeforpartsorlabor(includingdiagnosis).

Astheengineowner,youareresponsibletoperformalltherequiredmaintenancelistedinyourowner’smanual.ISM

willnotdenyanemissionwarrantyclaimsolelybecauseyouhavenorecordofmaintenance;however,aclaimmay

bedeniedifyourfailuretoperformmaintenanceresultedinthefailureofawarrantedpart.Receiptscoveringregular

maintenanceshouldberetainedintheeventofquestionsandthesereceiptsshouldbepassedontoeachsubsequent

owneroftheengine.

ItisrecommendedthatreplacementpartsusedformaintenanceorrepairsbeISMServicePartstomaintainthequality

originallydesignedintoyouremissioncertiedengine.Theuseofnon-ISMpartsdoesnotinvalidatethewarrantyon

othercomponentsunlesstheuseofsuchpartscausesdamagetowarrantedparts.

ISMwishestoassurethattheemissioncontrolsystemswarrantyisbeingproperlyadministered.Ifyoubelieveyou

havenotreceivedtheservicetowhichyouareentitledtounderthiswarranty,youshouldcontactthenearestISM

BranchOfceforassistance.TheaddressandphonenumberofeachBranchOfceisinyourowner’smanual.

EXCEPTIONS

PleasenotethatEmissionWarrantydoesnotcover:

1.Systemsandpartsthatwerenotrstinstalledonthe

newequipmentorengineasoriginalequipmentby

ISM

2.Partmalfunctionscausedbyabuse,misuse,im-

properadjustment,modication,alteration,tampering,disconnection,improperorinadequate

maintenance,oruseofnonrecommendedfuelsand

lubricatingoils.

3.Damagecausedbyaccident,actsofnature,orother

eventsbeyondISM’scontrol.

4.Replacementofexpendableitemsmadeinconnec-

tionwithscheduledmaintenance.

5.Partsrequiringreplacementorinspectionoradjustmentduringscheduledmaintenanceintervalswhere

thepartisnotdefective.

6.PartswhicharenotISMServiceParts.

7.Lossoftime,inconvenience,lossofuseofequipment/engineorcommercialloss.

8.Equipmentwithanalteredordisconnectedhourmeterwherethehourscannotbedetermined.

9.EquipmentnormallyoperatedoutsidetheUnited

States

10.Non-defectivepartsreplacedbyotherthanISMdealers.

PARTSCOVERED

Thisemissioncontrolsystemwarrantyappliestothe

followingemissioncontrolparts:

FuelInjectionPump

•

FuelInjectors

•

IntakeManifold

•

ExhaustManifold

•

PositiveCrankcaseVentilationsystemparts(including

•

PCVValveandOilFillerCap)

1-10

1-GENERALINFORMATION

Turbocharger(ifequipped)

•

Chargeaircoolingsystem(ifequipped)

•

Smokepufflimiter(ifequipped)

•

EGRsystem(includingEGRValve,EGRPipeandEGR

•

cooler)(ifequipped)

Intakethrottlevalve(ifequipped)

•

ExhaustAftertreatmentsystem(ifequipped)

•

AftertreatmentRegenerationdevice(ifequipped)

•

Miscellaneoushoses,clamps,connectorsandsealing

•

gasketsordevicesusedintheabovesystems.

CALIFORNIAEMISSIONCONTROLWARRANTYSTATEMENT

CaliforniaAirResourcesBoard(CARB)

YOURWARRANTYRIGHTSANDOBLIGATIONS

TheCaliforniaAirResourcesBoardandISM(ISM)arepleasedtoexplaintheemissioncontrolsystemwarrantyon

your2013andlaterengine.InCalifornia,newenginesmustbedesigned,builtandequippedtomeettheState’s

stringentanti-smogstandards.ISMmustwarranttheemissioncontrolsystemonyourenginefortheperiodsoftime

listedbelowprovidedtherehasbeennoabuse,neglectorimpropermaintenanceofyourengine.Additionalconditions

andresponsibilitiesarefurtheroutlinedbelow.Whereawarrantableconditionexists,ISMwillrepairyourengineat

nocosttoyouincludingdiagnosis,partsandlabor.

MANUFACTURER’SWARRANTYCOVERAGE:

ISMwarrantstotheoriginalowner,andtoeachsubsequentowner,ofanew,dieselenginethattheemission

controlsystemofyourengine:

1.Wasdesigned,builtandequippedsoastoconformatthetimeofsalewithallapplicableregulationsoftheCaliforniaAirResourcesBoard(CARB).

2.Isfreefromdefectsinmaterialandworkmanshipthatwillcausesuchenginetofailtoconformwithapplicable

regulationsforthefollowingwarrantyperiod:

forvariablespeedenginesratedunder19 kW(25 Hp):two(2)yearsor1,500hoursofoperation,whichever

•

occursrst.Intheabsenceofadevicetomeasurehoursofuse,theengineshallbewarrantedforaperiodof

twoyears.

forconstantspeedenginesratedunder37 kW(50 Hp)withpeakpowerratedat3,000 RPMorgreater:two(2)

•

yearsor1,500hoursofoperation,whicheveroccursrst.Intheabsenceofadevicetomeasurehoursofuse,

theengineshallbewarrantedforaperiodoftwoyears.

forenginesratedatorabove19 kW(25 Hp):ve(5)yearsor3,000hoursofoperation,whicheveroccursrst.

•

Intheabsenceofadevicetomeasurehoursofuse,theengineshallbewarrantedforaperiodofveyears.

forenginesratedatorabove37 kW(50 Hp):ve(5)yearsor3,000hoursofoperation,whicheveroccursrst.

•

Intheabsenceofadevicetomeasurehoursofuse,theengineshallbewarrantedforaperiodofveyears.

Thewarrantyperiodshallbegin:

onthedatetheequipmentisrstdeliveredtotherstretailpurchaser,or;

•

iftheequipmentisplacedinservicefordemonstrationpurposespriortosaleatretail,onthedatetheengineisrst

•

placedinservice.

TheemissioncontrolsystemsofyournewISMengineweredesigned,builtandtestedusinggenuineISMparts,and

theengineiscertiedasbeinginconformitywithCARBemissioncontrolregulations.

Accordingly,itisrecommendedthatanyreplacementpartsusedformaintenance,repairorreplacementofemission

controlsystemsbeISMparts.Anyreplacementpartmaybeusedintheperformanceofanymaintenanceorrepairs,

althoughISMrecommendsthattheownerobtainassurancethatsuchpartsarewarrantedbytheirmanufacturerto

beequivalenttogenuineISMparts.Suchuseshallnotreducethewarrantyobligationsoftheenginemanufacturer,

providedtheyarewarrantedtobeequivalenttogenuineISMparts.

Anywarrantedpartthatisnotscheduledforreplacement,asrequiredmaintenanceshallbewarrantedforthewarranty

perioddenedabove.Ifanysuchpartfailsduringtheperiodofwarrantycoverage,itwillberepairedorreplacedunder

warranty.Anysuchpartrepairedorreplacedunderthewarrantyshallbewarrantedfortheremainingwarrantyperiod.

1-11

1-GENERALINFORMATION

Anywarrantedpartthatisscheduledonlyforregularinspectioninthewritteninstructionsshallbewarrantedforthe

warrantyperioddenedabove.Astatementinthewritteninstructionstotheeffectof"repairorreplaceasnecessary"shallnotreducetheperiodofwarrantycoverage.Anysuchpartrepairedorreplacedunderwarrantyshallbe

warrantedfortheremainingwarrantyperiod.

Anywarrantedpartthatisscheduledforreplacement,asrequiredmaintenanceshallbewarrantedfortheperiodof

timepriortotherstscheduledreplacementpointforthatpart.Ifthepartfailspriortotherstscheduledreplacement,

thepartshallberepairedorreplacedbytheenginemanufacturerunderwarranty.Anysuchpartrepairedorreplaced

underwarrantyshallbewarrantedfortheremainderoftheperiodpriortotherstscheduledreplacementpointfor

thepart.

Repairorreplacementofanywarrantedpartunderwarrantyshallbeperformedatnochargetotheowneratawarrantystation.

ISMprovideswarrantyservicesorrepairsatallmanufacturerdistributioncenters(warrantystations)thatarefranchisedtoservicethesubjectengines.PleaseseetheCustomerAssistancesectionofthisstatementforhelpin

locatingsuchservicecenters.

Theownerwillnotbechargedfordiagnosticlaborthatleadstothedeterminationthatawarrantedpartisinfact

defective,providedthatsuchdiagnosticworkisperformedatawarrantystation.

ISMisliablefordamagestootherenginecomponentsproximatelycausedbyafailureunderwarrantyofanywarrantedpart.

ISMisrequiredbyCaliforniaregulationstomaintainasupplyofwarrantedpartssufcienttomeettheexpecteddemandforsuchpartsduringthewarrantyperiodfortheenginescoveredbythiswarranty.

OWNER’SWARRANTYRESPONSIBILITIES:

Thisengineisdesignedtooperateonultra-lowsulfurdieselfuelonlyifrated>19kW,andonlowsulfurorultra-low

sulfurdieselfuelonlyifrated<19kW.Useofanyotherfuelmayresultinthisenginenolongeroperatingincompliance

withCalifornia’semissionsrequirements.

Thepurchaserisresponsibleforinitiatingthewarrantyprocess.TheCaliforniaAirResourcesBoardsuggeststhat

theenginebepresentedtoanISMdealerassoonasaproblemexists.Thewarrantyrepairsshouldbecompletedby

thedealerasexpeditiouslyaspossible.

Add-onormodiedparts,asdenedinSection1900(b)(1)and(b)(10),Title13,thatarenotexemptedbytheAir

ResourcesBoardmaynotbeused.Theuseofanynon-exemptedadd-onormodiedpartsshallbegroundsfor

disallowingawarrantyclaimmadeinaccordancewiththisarticle.Theenginemanufacturershallnotbeliableunder

thisarticletowarrantfailuresofwarrantedpartscausedbytheuseofanon-exemptedadd-onormodiedpart.

TheemissionscontrolpartscoveredbythisEmissionControlSystemWarrantyarelistedunder“WhatisCovered

BytheEmissionWarranty .”Astheoff-roadengineowner,youareresponsiblefortheperformanceoftherequired

maintenancelistedinyourowner'smanual.ISMrecommendsthatyouretainallreceiptscoveringmaintenanceon

youroff-roadengine,butISMcannotdenywarrantysolelyforthelackofreceiptsorforyourfailuretoensurethe

performanceofallscheduledmaintenance.

Astheoff-roadengineowner,youshouldhoweverbeawarethatISMmaydenyyouwarrantycoverageifyouroff-road

engineoraparthasfailedduetoabuse,neglect,impropermaintenanceorunapprovedmodications.

CustomerAssistance

IntheeventthatyoudonotreceivethewarrantyservicetowhichyoubelieveyouareentitledundertheEmission

ControlSystem’sWarranty,youshouldcontactISMattheaddressbelowforassistance.Ifyouneedadditional

assistanceorinformationconcerningtheEmissionControlSystemWarranty,contact:

IHIShibauraMachineryCorporation

Qualitydepartment

1-1-1Ishishiba,Matsumoto,Nagano,

390-8714,Japan

Telephone:+81-263-25-4589

1-12

WhatisNotCoveredbytheEmissionWarranty

1-GENERALINFORMATION

PleasenotethatEmissionWarrantydoesnotcover:

1.Systemsandpartsthatwerenotrstinstalledonthe

newequipmentorengineasoriginalequipmentby

ISM

2.Partmalfunctionscausedbyabuse,misuse,im-

properadjustment,modication,alteration,tampering,disconnection,improperorinadequate

maintenance,oruseofnonrecommendedfuelsand

lubricatingoils.

3.Damagecausedbyaccident,actsofnature,orother

eventsbeyondISM’scontrol.

4.Replacementofexpendableitemsmadeinconnec-

tionwithscheduledmaintenance.

5.Partsrequiringreplacement,inspectionoradjustmentduringscheduledmaintenanceintervalswhere

thepartisnotdefective.

6.PartsthatarenotISMServiceParts.

7.Lossoftime,inconvenience,lossofuseofequipment/engineorcommercialloss.

8.Equipmentwithanalteredordisconnectedhourmeterwherethehourscannotbedetermined.EquipmentnormallyoperatedoutsidetheUnitedStates.

9.Non-defectivepartsreplacedbyotherthanISMdealers.

WhatisCoveredbytheEmissionWarranty

ThefollowingisalistofsystemsandpartsthatareconsideredapartoftheEmissionControlSystemandarecovered

bytheEmissionWarrantyforenginesthatwerebuilttoconformtoCARBregulations:

IMPORTANT!Thismaynotincludeexpendablemaintenanceitems.Emissionrelatedpartsrequiringscheduledmaintenancearewarranteduntiltheirrstscheduledreplacementpointonly.

PARTSCOVERED

Thisemissioncontrolsystemwarrantyappliestothe

followingemissioncontrolparts.

Fuelinjectionsystem

•

Intakemanifold

•

Exhaustmanifold

•

Positivecrankcaseventilationsystemparts(including

•

PCVValveandOilFillerCap)

Turbocharger(ifequipped)

•

Chargeaircoolingsystem(ifequipped)

•

Smokepufflimiter(ifequipped)

•

EGRsystem(includingEGRValve,EGRPipeandEGR

•

cooler)(ifequipped)

Intakethrottlevalve(ifequipped)

•

Exhaustaftertreatmentsystem(ifequipped)

•

AftertreatmentRegenerationDevice(ifequipped)

•

Miscellaneoushoses,clamps,connectersandsealing

•

gasketsordevicesusedintheabovesystems.

1-13

1-GENERALINFORMATION

1-14

2-SAFETYINFORMATION

2-SAFETYINFORMATION###_2_###

Precautionarystatements

Personalsafety

Thisisthesafetyalertsymbol.Itisusedtoalertyoutopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoidpossibledeathorinjury.

Throughoutthismanualandonmachinesafetysigns,youwillndthesignalwordsDANGER,WARNING,andCAUTIONfollowedbyspecialinstructions.Theseprecautionsareintendedforthepersonalsafetyofyouandthose

workingwithyou.

Readandunderstandallthesafetymessagesinthismanualbeforeyouoperateorservicethemachine.

DANGERindicatesahazardoussituationthat,ifnotavoided,willresultindeathorseriousinjury.Thecolor

associatedwithDANGERisRED.

WARNINGindicatesahazardoussituationthat,ifnotavoided,couldresultindeathorseriousinjury.Thecolor

associatedwithWARNINGisORANGE.

CAUTIONindicatesahazardoussituationthat,ifnotavoided,couldresultinminorormoderateinjury.The

colorassociatedwithCAUTIONisYELLOW.

FAILURETOFOLLOWDANGER,WARNING,ANDCAUTIONMESSAGESCOULDRESULT

INDEATHORSERIOUSINJURY.

Machinesafety

NOTICE:Noticeindicatesasituationthat,ifnotavoided,couldresultinmachinedamageorpropertydamage.The

colorassociatedwithNoticeisBLUE.

ThroughoutthismanualyouwillndthesignalwordNoticefollowedbyspecialinstructionstopreventmachinedamageorpropertydamage.ThewordNoticeisusedtoaddresspracticesnotrelatedtopersonalsafety.

Information

NOTE:Noteindicatesadditionalinformationthatclariessteps,procedures,orotherinformationinthismanual.

ThroughoutthismanualyouwillndthewordNotefollowedbyadditionalinformationaboutastep,procedure,or

otherinformationinthemanual.ThewordNoteisnotintendedtoaddresspersonalsafetyorpropertydamage.

2-1

Safetyrules

Generalsafetyrules

2-SAFETYINFORMATION

Readthismanualcarefullybeforestarting,usingcarrying

outmaintenance,refuelingorperforminganyothertype

ofoperationonthetractor.

Readallthesafetydecalsonthetractorandfollowtheinstructionsthereonbeforestarting,operating,refuelingor

carryingoutmaintenanceonthetractor.Promptlyreplace

anydecalsthataredamaged,lostorillegible.Cleanthe

decalsiftheyarecoveredbymudordebris.

Thetractormustonlybeusedbyresponsiblepersonnel,

trainedintractoruseandauthorizedtooperatethetractor .

Usecautionwhenoperatingthetractoronslopes.Raised

equipment,fulltanksandotherloadswillchangethecenterofgravityofthetractor.Thetractorcantiporroll

overwhennearditchesandembankmentsorunevensurfaces.

Avoidusingthetractorinunsuitablephysicalconditions,

stopworkinstead.

Neverpermitanyoneotherthantheoperatortorideon

thetractor.

Neveroperatethetractorundertheinuenceofalcohol,

drugs,orwhileotherwiseimpaired.

Donotalterthecalibrationofthepressurereliefvalves

inthevarioushydrauliccircuits(steering,hydrauliclift,

auxiliarydistributors,etc.).

Keepclearofmovingparts.Looseclothing,jewelry,

watches,longhair,andotherlooseorhangingitemscan

becomeentangledinmovingparts.

Wearprotectiveequipmentwhenappropriate.

DONOTattempttoremovematerialfromanypartofthe

tractorwhileitisbeingoperatedorcomponentsarein

motion.

Makesureallguardsandshieldsareingoodcondition

andproperlyinstalledbeforeoperatingthetractor.Never

operatethetractorwithshieldsremoved.Alwaysclose

accessdoorsorpanelsbeforeoperatingthetractor.

Enterandleavethetractorusingthestepsandhandles

provided.Dirtyorslipperysteps,ladders,walkways,and

platformscancausefalls.Makesurethesesurfacesremaincleanandclearofdebris.

Apersonorpetwithintheoperatingareaofatractorcan

bestruckorcrushedbythetractororitsequipment.DO

NOTallowanyonetoentertheworkarea.

Whendiggingorusinggroundengagingattachmentsbe

awareofburiedcables.Contactlocalutilitiestodetermine

thelocationsofservices.

Payattentiontooverheadpowerlinesandhangingobstacles.Highvoltagelinesmayrequiresignicantclearance

forsafety.

Hydraulicoilordieselfuelleakingunderpressurecan

penetratetheskin,causingseriousinjuryorinfection.

DONOTuseyourhandtocheckforleaks.Useapiece

•

ofcardboardorpaper.

Stopengine,removekeyandrelievethepressurebe-

•

foreconnectingordisconnectinguidlines.

Makesureallcomponentsareingoodconditionand

•

tightenallconnectionsbeforestartingtheengineor

pressurizingthesystem.

Ifhydraulicuidordieselfuelpenetratestheskin,seek

•

medicalattentionimmediately .

Continuouslongtermcontactwithhydraulicuidmay

•

causeskincancer.Avoidlongtermcontactandwash

theskinpromptlywithsoapandwater.

Beforeremovinganyhydraulictubing,checkthatthe

•

systemisnotpressurized.

Raisedequipmentand/orloadscanfallunexpectedlyand

crushpersonsunderneath.Neverallowanyonetoenter

theareaunderneathraisedequipmentduringoperation.

Neveroperateengineinenclosedspacesasharmfulexhaustgasesmaybuildup.

Beforestartingthetractor,besurethatallcontrolsarein

neutralorparklockposition.

Beforestartingtheengine,makesurethatallattached

implementsareloweredtotheground.

Starttheengineonlyfromtheoperator’sseat.Ifthe

safetystartswitchisbypassed,theenginecanstartwith

thetransmissioningear.Donotconnectorshortacross

terminalsonthestartersolenoid.Attachjumpercables

asdescribedinthemanual.Startingingearmaycause

deathorseriousinjury.

Alwayskeepwindows,mirrors,alllighting,andSlowMovingVehicle(SMV)emblemcleantoprovidethebestpossiblevisibilitywhileoperatingthetractor.

Operatecontrolsonlywhenseatedintheoperator’sseat,

exceptforthosecontrolsexpresslyintendedforusefrom

otherlocations.

2-2

2-SAFETYINFORMATION

Beforeleavingthetractor:

1.Parktractoronarmlevelsurface.

2.Putallcontrolsinneutralorparklockposition.

3.Engageparkbrake.Usewheelchocksifrequired.

4.Lowerallhydraulicequipment—Implements,header,

etc.

5.Turnoffengineandremovekey.

When,duetoexceptionalcircumstances,youwould

decidetokeeptheenginerunningafterleavingthe

operator’sstation,thenthefollowingprecautionsmust

befollowed:

1.Bringtheenginetolowidlespeed.

Usingthetractor

1.Selectthemostsuitablewheelsettingfortheworkin

hand,i.e.:thesettingthatprovidesthebeststability.

2.Depressthespeedcontrolpedalslowly:ifengaged

tooquickly,especiallywhenthetractorisgettingout

ofahole,ditchoroperatingonmuddygroundor

steepslopes,thetractormayoverturn.

Releasethespeedcontrolpedalimmediatelyiffront

wheelsbegintolift.

3.Whentravelingdownhill,keepthetractoringear.

Neverplaceshuttleshiftleverintheneutralposition.

4.Whenthetractorismoving,theoperatormustremain

correctlyseatedinthedrivingposition.

5.Nevergetonoroffthetractorwhileinmovement.

2.Disengagealldrivesystems.

3.

4.Applytheparkingbrake.

6.Whenusingthebrakes,pressthepedaldownslowly.

7.Avoidtakingturnsathighspeeds.

8.Alwaysusethetractorataspeedthatwillguarantee

9.Ifyouhavetoworkwiththetractoronagradient,

10.Proceedwithmaximumcautionwhenworkingwith

11.Whendrivingonpublichighways,observetheHigh-

WARNING

Somecomponentsmaycontinuetorun

downafterdisengagingdrivesystems.

Makesurealldrivesystemsarefullydisengaged.

Failuretocomplycouldresultindeathor

seriousinjury .

Shiftthetransmissionintoneutral.

safeoperationonthetypeoflandbeingworked.

Whenworkingonunevenground,usemaximum

caretoensureproperstability.

forexampleonhillsides,driveatmoderatespeed

especiallywhentakingturns.

thewheelsneartheedgeofditchesorslopes.

wayCode.

W0113A

Generalmaintenancesafety

Keepareausedforservicingthetractorcleananddry.

Cleanupspilleduids.

Servicetractoronarmlevelsurface.

Installguardsandshieldsafterservicingthetractor.

Closeallaccessdoorsandinstallallpanelsafterservicing

thetractor.

Donotattempttoclean,lubricate,clearobstructionsor

makeadjustmentstothetractorwhileitisinmotionor

whiletheengineisrunning.

Alwaysmakesureworkingareaisclearoftools,parts,

otherpersonsandpetsbeforeyoustartoperatingthe

tractor.

Unsupportedhydrauliccylinderscanlosepressureand

droptheequipmentcausingacrushinghazard.Donot

leaveequipmentinaraisedpositionwhileparkedorduringservice,unlesssecurelysupported.

Jackorliftthetractoronlyatjackorliftpointsindicatedin

thismanual.

Incorrecttowingprocedurescancauseaccidents.When

towingadisabledtractorfollowtheprocedureinthismanual.Useonlyrigidtowbars.

Stoptheengine,removekeyandrelievepressurebefore

disconnectingorconnectinguidlines.

Stoptheengineandremovekeybeforedisconnectingor

connectingelectricalconnections.

Scaldingcanresultfromincorrectremovalofcoolant

caps.Coolingsystemoperatesunderpressure.Hot

coolantcansprayoutifacapisremovedwhilethe

systemishot.Allowsystemtocoolbeforeremovingcap.

Whenremovingacapturnitslowlytoallowpressureto

escapebeforecompletelyremovingthecap.

2-3

2-SAFETYINFORMATION

Replacedamagedorworntubes,hoses,electricalwiring,

etc.

Engine,transmission,exhaustcomponents,andhydrauliclinesmaybecomehotduringoperation.Take

carewhenservicingsuchcomponents.Allowsurfacesto

coolbeforehandlingordisconnectinghotcomponents.

Wearprotectiveequipmentwhenappropriate.

Whenwelding,followtheinstructionsinthemanual.Alwaysdisconnectthebatterybeforeweldingonthetractor.

Wheelsandtires

Uponreceivingyourtractor,checktheairpressureinthe

tiresandcheckevery50hoursorweekly.Refertothe

tablebelowfortirepressurefornormaloperation.

Makesuretiresarecorrectlyinated.Donotexceedrecommendedloadorpressure.Followinstructionsinthe

manualforpropertireination.

Tiresareheavy.Handlingtireswithoutproperequipment

couldcausedeathorseriousinjury.

Neverweldonawheelwithatireinstalled.Alwaysremovetirecompletelyfromwheelpriortowelding.

Alwayshaveaqualiedtiretechnicianservicethetires

andwheels.Ifatirehaslostallpressure,takethetireand

wheeltoatireshoporyourdealerforservice.Explosive

separationofthetirecancauseseriousinjury.

DONOTweldtoawheelorrimuntilthetireiscompletely

removed.Ensuretherimiscleanandfreeofrustordamage.Donotweld,braze,otherwiserepairoruseadamagedrim.Inatedtirescangenerateagasmixturewith

theairthatcanbeignitedbyhightemperaturesfromweldingproceduresperformedonthewheelorrim.Removing

theairorlooseningthetireontherim(breakingthebead)

willNOTeliminatethehazard.Thisconditioncanexist

whethertiresareinatedordeated.ThetireMUSTbe

completelyremovedfromthewheelorrimpriortoweldingthewheelorrim.

Alwayswashyourhandsafterhandlingbatterycomponents.

Beforetouchinganyelectricalcomponents,disconnect

thegroundleadfromthebattery.

Onlyremovetheradiatorcapaftertheenginehasbeen

allowedtocool.Withtheengineswitchedoff,useacloth

toslowlyunscrewthecapandreleasethepressurebeforecompletelyremovingthecap.

Whenchangingorstoringtires,makesuretheyare

stackedcorrectlyandcannotrollortoppleovercausing

personalinjury .

Whencheckingtirepressures,inspectthetiresfordamagedtreadandsidewalls.Incorrectpressurewillleadto

earlytirefailure.

Donotinateatirethathasbeenrunatorseriously

under-inateduntilithasbeeninspectedfordamageby

aqualiedperson.

Torquewheelboltstospecicationafterinstallingthe

wheel.Checknuttightnessdailyuntiltorquestabilizes.

Referto'TRACTORBALLASTING'section,Front

wheels-Ballastbeforeaddingballasttothetires.

Usejackstandsorothersuitableblockingtosupportthe

tractorwhilerepairingtires.Ensurethejackisplacedona

rm,levelsurface.Ensurethejackhasadequatecapacity

forliftingyourtractor.Donotputanypartofyourbody

underthetractororstarttheenginewhilethetractorison

thejack.

Neverhitatireorrimwithahammer.

Donotinateatireunlesstherimismountedonthetractororissecuredsothatitwillnotmoveifthetireorrim

shouldsuddenlyfail.

Drivingonpublicroadsandgeneraltransportationsafety

Complywithlocallawsandregulations.

Useappropriatelightingtomeetlocalregulations.

MakesureSMVemblemisvisible.

Makesurebrakepedallatchisengaged.Brakepedals

mustbelockedtogetherforroadtravel.

Usesafetychainsfortrailedequipmentwhenprovided

withtractororequipment.

Liftimplementsandattachmentshighenoughabove

groundtopreventaccidentalcontactwithroad.

Whentransportingequipmentortractoronatransport

trailer,makesureitisproperlysecured.BesuretheSMV

ontheequipmentortractoriscoveredwhilebeingtransportedonatrailer.

Beawareofoverheadstructuresorpowerlinesandmake

surethetractorand/orattachmentscanpasssafelyunder.

Travelspeedshouldbesuchthatcompletecontroland

tractorstabilityismaintainedatalltimes.

Slowdownandsignalbeforeturning.

Pullovertoallowfastertrafctopass.

2-4

2-SAFETYINFORMATION

Followcorrecttowingprocedureforequipmentwithor

withoutbrakes.

Towing

1.T oguaranteetractorstabilitywhenmoving,adjustthe

hitchingdeviceaccordingtothetrailerorimplementto

beused.

2.Driveslowlywhentowingextremelyheavyloads.

3.Donottowtrailersthatarenotttedwithanindependentbrakingsystem.

4.Ifthetractorisusedtotowheavyloads,alwaysuse

thehitchingdeviceandneverhitchloadsontothe

Whendriving,donotrestyourfeetonthebrakepedals.

lowerarmsorthetoplinkofthethree-pointlinkage.

Thismayresultintippingoroverturning

5.Whentowing,donotnegotiateturnswiththedifferentiallockengagedasthismaypreventyoufromsteeringthetractor.

2-5

Usingimplementsandagriculturalmachinery

2-SAFETYINFORMATION

1.Donotconnectimplementsormachinerythatrequire

morepowerthancanbegeneratedbyyourtractor

model.

2.Nevernegotiatesharpturnswiththepowertake-off

underaheavyload;thismaydamagetheuniversaljointsonthetransmissionshaftconnectedtothe

powertake-off.

3.Neverstandbetweenthereversingtractorandtheimplementwhenhitching.

4.Whenusingimplementsthatrequirethetractortobe

stationarywiththeenginerunning,keeptheshuttle

Fireandexplosionprevention

Fueloroilleakedorspilledonhotsurfacesorelectrical

componentscancauseare.

Cropmaterials,trash,debris,birdnests,orammable

materialcanigniteonhotsurfaces.

Alwayshaveareextinguisheronornearthetractor.

Makesurethereextinguisher(s)ismaintainedandservicedaccordingtothemanufacturer’sinstructions.

leverintheneutralposition,applythehandbrakeand

usesuitablewheelchocks.

5.Donotoperatetractorsconnectedtothepowertakeoffwithoutrstensuringthattheoperatingrangeof

thetractorisfreeofbystanders.Alsocheckthatall

rotatingpartsconnectedtothepowertake-offshaft

arecorrectlyprotected.

6.Addsometypeofrearballastwhenusingliftingequipmentttedtothefrontofthetractor.Rearballast,such

as,rearwheelweights,uidinreartiresorthree-point

weightbox.

belts,gears,cleaningfan,etc.Morefrequentcleaning

ofyourtractormaybenecessarydependingonthe

operatingenvironmentandconditions.

Inspecttheelectricalsystemforlooseconnectionsor

frayedinsulation.Repairorreplacelooseordamaged

parts.

Donotstoreoilyragsorotherammablematerialonthe

tractor.

Atleastonceeachdayandattheendofthedayremove

alltrashanddebrisfromthetractorespeciallyaroundhot

componentssuchasengine,transmission,exhaust,battery,etc.Morefrequentcleaningofyourtractormaybe

necessarydependingontheoperatingenvironmentand

conditions.

Atleastonceeachday,removedebrisaccumulation

aroundmovingcomponentssuchasbearings,pulleys,

Generalbatterysafety

Alwaysweareyeprotectionwhenworkingwithbatteries.

Donotcreatesparksorhaveopenamenearbattery.

Ventilatewhenchargingorusinginanenclosedarea.

Disconnectnegative(-)rstandreconnectnegative(-)

last.

Whenweldingonthetractor,disconnectbothterminalsof

thebattery .

Donotweld,grind,orsmokenearabattery .

Whenusingauxiliarybatteriesorconnectingjumpercablestostarttheengine,usetheprocedureshowninthe

operator’smanual.Donotshortacrossterminals.

Donotweldoramecutanyitemsthatcontainammable

material.Cleanitemsthoroughlywithnon-ammablesolventsbeforeweldingorame-cutting.

Donotexposethetractortoames,burningbrush,or

explosives.

Promptlyinvestigateanyunusualsmellsorodorsthat

mayoccurduringoperationofthetractor.

Followmanufacturer’sinstructionswhenstoringandhandlingbatteries.

Batterypost,terminals,andrelatedaccessoriescontain

leadandleadcompounds.Washhandsafterhandling.

ThisisaCaliforniaProposition65warning.

Batteryacidcausesburns.Batteriescontainsulfuricacid.

Avoidcontactwithskin,eyes,orclothing.Antidote(external):Flushwithwater.Antidote(eyes):ushwithwater

for15minutesandseekmedicalattentionimmediately.

Antidote(internal):Drinklargequantitiesofwaterormilk.

Donotinducevomiting.Seekmedicalattentionimmediately.

Keepoutofreachofchildrenandotherunauthorizedpersons.

Operatorpresencesystem

Yourtractorisequippedwithanoperatorpresencesystemtopreventtheuseofsomefeatureswhiletheoperator

isnotintheoperator’sseat.

Theoperatorpresencesystemshouldneverbedisconnectedorbypassed.

2-6

Ifthesystemisinoperable,thesystemmustberepaired.

PowerTake-Off(PTO)

2-SAFETYINFORMATION

PTO-drivenmachinerycancausedeathorseriousinjury.

BeforeworkingonornearthePTOshaftorservicingor

clearingthedriventractor,putthePTOleverinthedisengageposition,stoptheengine,andremovethekey.

WheneveraPTOisinoperation,aguardmustbeinplace

topreventdeathorinjurytotheoperatororbystanders.

WhendoingstationaryPTOwork,keepclearofallmoving

partsandmakesureappropriateguardsareinplace.

Neveruseasplineadapter:

Reectorsandwarninglights

Flashingamberwarninglightsmustbeusedwhenoperatingonpublicroads.Locationanduseofashingamber

warninglightsisshownonCabcontrols-Control.

Seatbelts

Seatbeltsmustbewornatalltimes.

Seatbeltinspectionandmaintenance:

Keepseatbeltsingoodcondition.

•

Keepsharpedgesanditemsthancancausedamage

•

awayfromthebelts.

Periodicallycheckbelts,buckles,retractors,tethers,

•

slacktake-upsystem,andmountingboltsfordamage

andwear.

Replaceallpartsthathavedamageorwear.

•

Replacebeltsthathavecutsthatcanmakethebelt

•

weak.

MatchtherighttractorPTOsplineandspeedwiththe

•

PTOdriveshaftprovidedwithanimplement.Thiswill

assurepropergeometryandoperatingspeed.

Neveroperate540 RPMimplementsat1000 RPM.

•

Neveroperate1000 RPMimplementsat540 RPM.

•

UseofPTOadapterswillvoidthewarrantyofthedrive

•

shaft,andthePTOdrivetrainofthemachineandim-

plement.

Forcorrecthitchgeometry,seetheimplementopera-

•

tor’smanual.

Checkthatboltsaretightontheseatbracketormount-

•

ing.

Ifbeltisattachedtoseat,makesureseatorseatbrack-

•

etsaremountedsecurely.

Keepseatbeltscleananddry.

•

Cleanbeltsonlywithsoapsolutionandwarmwater.

•

Donotusebleachordyeonthebeltsbecausethiscan

•

makethebeltsweak.

Forproperseatbeltuse,seeSeatrestraints-Oper-

•

ating.

2-7

Operatorprotectivestructure

2-SAFETYINFORMATION

Yourtractorisequippedwithanoperatorprotectivestructure,suchas:aRollOverProtectiveStructure(ROPS),

FallingObjectProtectiveStructure(FOPS),oracabwith

ROPS.AROPSmaybeacanframeoratwo-postedor

four-postedstructureusedfortheprotectionoftheoperatortominimizethepossibilityofseriousinjury.The

mountingstructureandfastenersformingthemounting

connectionwiththetractorarepartoftheROPS.

Theprotectivestructureisaspecialsafetycomponentof

yourtractor.

DONOTattachanydevicetotheprotectivestructurefor

pullingpurposes.DONOTdrillholestotheprotective

structure.

Theprotectivestructureandinterconnectingcomponents

areacertiedsystem.Anydamage,re,corrosion,or

modicationwillweakenthestructureandreduceyour

protection.Ifthisoccurs,THEPROTECTIVESTRUCTUREMUSTBEREPLACEDsothatitwillprovidethe

sameprotectionasanewprotectivestructure.Contact

yourdealerforprotectivestructureinspectionandreplacement.

Afteranaccident,re,tiporrollover,thefollowingMUST

beperformedbyaqualiedtechnicianbeforereturning

thetractortoeldorjob-siteoperations:

TheprotectivestructureMUSTBEREPLACED.

•

Themountingorsuspensionfortheprotectivestruc-

•

ture,operatorseatandsuspension,seatbeltsand

mountingcomponents,andwiringwithintheoperator’s

protectivesystemMUSTbecarefullyinspectedfor

damage.

AlldamagedpartsMUSTBEREPLACED.

•

DONOTWELD,DRILLHOLES,ATTEMPTTO

STRAIGHTEN,ORREPAIRTHEPROTECTIVESTRUCTURE.MODIFICATIONINANYWAYCANREDUCE

THESTRUCTURALINTEGRITYOFTHESTRUCTURE,

WHICHCOULDCAUSEDEATHORSERIOUSINJURY

INTHEEVENTOFFIRE,TIP,ROLLOVER,COLLISION,

ORACCIDENT .

Seatbeltsarepartofyourprotectivesystemandmustbe

wornatalltimes.Theoperatormustbeheldtotheseat

insidetheframeinorderfortheprotectivesystemtowork.

2-8

2-SAFETYINFORMATION

PersonalProtectiveEquipment(PPE)

WearPersonalProtectiveEquipment(PPE)suchashard

hat,eyeprotection,heavygloves,hearingprotection,protectiveclothing,etc.

DoNotOperatetag

Beforeyoustartservicingthetractor,attacha‘DoNot

Operate’warningtagtothetractorinanareathatwillbe

visible.

Hazardouschemicals

Ifyouareexposedtoorcomeincontactwithhazardous

chemicalsyoucanbeseriouslyinjured.Theuids,lubricants,paints,adhesives,coolant,etc.requiredforthe

functionofyourtractorcanbehazardous.Theymaybe

attractiveandharmfultodomesticanimalsaswellashumans.

MaterialSafetyDataSheets(MSDS)provideinformation

aboutthechemicalsubstanceswithinaproduct,safe

handlingandstorageprocedures,rstaidmeasuresand

procedurestobetakenintheeventofaspilloraccidental

release.MSDSareavailablefromyourdealer.

BeforeyouserviceyourtractorchecktheMSDSforeach

lubricant,uid,etc.usedinthistractor.Thisinformation

indicatestheassociatedrisksandwillhelpyouservice

thetractorsafely.FollowtheinformationintheMSDS,on

manufacturercontainers,aswellastheinformationinthis

manualwhenservicingthetractor.

Utilitysafety

Whendiggingorusingground-engagingequipment,be

awareofburiedcablesandotherservices.Contactyour

localutilitiesorauthorities,asappropriatetodetermine

thelocationsofservices.

Makesurethetractorhassufcientclearancetopassin

alldirections.Payspecialattentiontooverheadpower

linesandhangingobstacles.Highvoltagelinesmayrequiresignicantclearanceforsafety.Contactlocalauthoritiesorutilitiestoobtainsafeclearancedistancesfrom

highvoltagepowerlines.

Retractraisedorextendedcomponents,ifnecessary.

Removeorlowerradioantennasorotheraccessories.

Shouldacontactbetweenthetractorandanelectric

Disposeofalluids,lters,andcontainersinanenvironmentallysafemanneraccordingtolocallawsandregulations.Checkwithlocalenvironmentalandrecyclingcentersoryourdealerforcorrectdisposalinformation.

Storeuidsandltersinaccordancewithlocallawsand

regulations.Useonlyappropriatecontainersforthestorageofchemicalsorpetrochemicalsubstances.

Keepoutofreachorchildrenorotherunauthorizedpersons.

Additionalprecautionsarerequiredforappliedchemicals.Obtaincompleteinformationfromthemanufacturer

ordistributorofthechemicalsbeforeusingthem.

powersourceoccur,thefollowingprecautionsmustbe

taken:

Stopthetractormovementimmediately .

•

Applytheparkbrake,stoptheengine,andremovethe

•

key.

Checkifyoucansafelyleavethecaboryouractual

•

positionwithoutcontactwithelectricalwires.Ifnot,stay

inyourpositionandcallforhelp.Ifyoucanleaveyour

positionwithouttouchinglines,jumpclearofthetractor

tomakesureyoudonotmakecontactwiththeground

andthetractoratthesametime.

Donotpermitanyonetotouchthetractoruntilpower

•

hasbeenshutofftothepowerlines.

2-9

Electricalstormsafety

2-SAFETYINFORMATION

Donotoperatetractorduringanelectricalstorm.

Ifyouareonthegroundduringanelectricalstorm,stay

awayfrommachineryandequipment.Seekshelterina

permanent,protectedstructure.

Mountinganddismounting

Mountanddismountthetractoronlyatdesignatedlocationsthathavehandholds,steps,orladders.

Donotjumpoffthetractor.

Makesuresteps,ladders,andplatformsremainclean

andclearofdebrisandforeignsubstances.Injurymay

resultfromslipperysurfaces.

Facethetractorwhenmountinganddismounting.

Workingatheights

Whenthenormaluseandmaintenanceofthetractor

requiresworkingatheights:

Correctlyuseinstalledsteps,ladders,andrailings.

•

Neveruseladders,steps,orrailingswhilethetractoris

•

moving.

Ifanelectricalstormshouldstrikeduringoperation,remaininthecab.Donotleavethecaboroperator’splatform.Donotmakecontactwiththegroundorobjects

outsidethetractor.

Maintainathree-pointcontactwithsteps,ladders,and

handholds.

Nevermountordismountfromamovingtractor.

Donotusethesteeringwheelorothercontrolsoraccessoriesashandholdswhenenteringorexitingthecabor

operator’splatform.

Donotstandonsurfaceswhicharenotdesignatedas

•

stepsorplatforms.

Donotusethetractorasalift,ladder,orplatformforworkingatheights.

Liftingandoverheadloads

Neveruseloaderbuckets,forks,etc.orotherlifting,handling,ordiggingequipmenttoliftpersons.

Donotuseraisedequipmentasaworkplatform.

Knowthefullareaofmovementofthetractorandequipmentanddonotenterorpermitanyonetoenterthearea

ofmovementwhilethetractorisinoperation.

Neverenterorpermitanyonetoentertheareaunderneathraisedequipment.Equipmentand/orloadscanfall

unexpectedlyandcrushpersonsunderneathit.

Donotleaveequipmentinraisedpositionwhileparked

orduringservice,unlesssecurelysupported.Hydraulic

cylindersmustbemechanicallylockedorsupportedif

theyareleftinaraisedpositionforserviceoraccess.

Loaderbuckets,forks,etc.orotherlifting,handling,or

diggingequipmentanditsloadwillchangethecenterof

gravityofthetractor.Thiscancausethetractortotipon

slopesorunevenground.

Loaditemscanfallofftheloaderbucketorliftingequipmentandcrushtheoperator.Caremustbetakenwhen

liftingaload.Useproperliftingequipment.

Donotliftloadhigherthannecessary.Lowerloadsto

transport.Remembertoleaveappropriateclearanceto

thegroundandotherobstacles.

Equipmentandassociatedloadscanblockvisibilityand

causeanaccident.Donotoperatewithinsufcientvisibility.

2-10

Loading...

Loading...