Page 1

SERVICE MANUAL

PIXIE COFFEE MACHINES

PIXIE C EF 280

PIXIE D EF 281

Version 1.2 en

Page 2

Pixie service manual

2

CONTENTS

1 General Safety Notes ........................................................................................5

2 Main Components..............................................................................................6

2.1 Overview............................................................................................................ 6

2.2 Interior view........................................................................................................ 7

2.3 Fluid System ...................................................................................................... 8

2.3.1 Water circuit diagram................................................................................8

2.3.2 Water circuit..............................................................................................9

3 Technical Data ..................................................................................................10

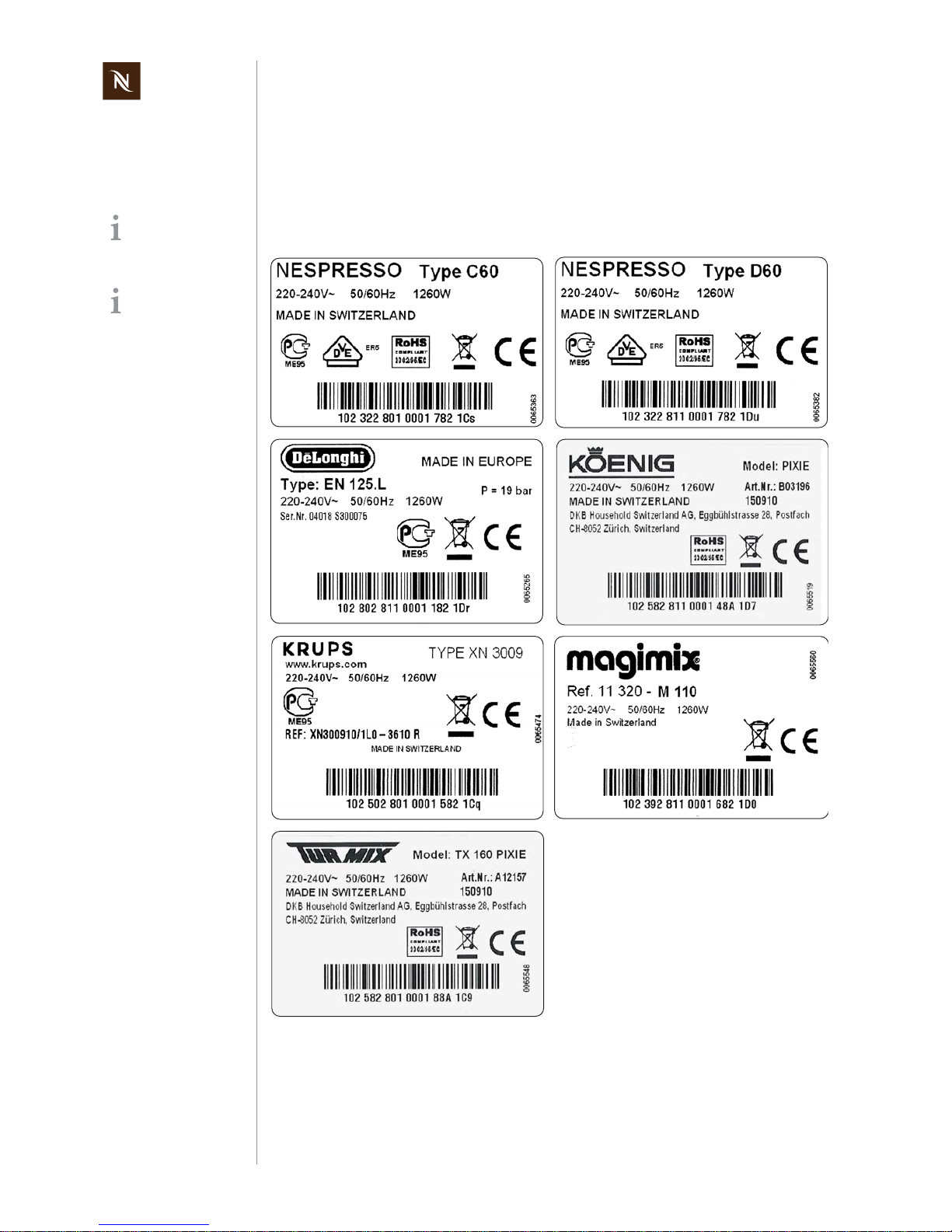

3.1 Rating plates.................................................................................................... 10

3.1.1 Examples of brand specific rating plates ................................................10

3.1.2 Rating plate details (example) ................................................................11

3.2 Technical specifications................................................................................... 12

3.2.1 Dimensions and weight...........................................................................14

4 Operation............................................................................................................15

4.1 General information.......................................................................................... 15

4.2 Status indication............................................................................................... 15

4.3 Machine modes................................................................................................ 16

4.4 Program/reset fill up level................................................................................. 18

4.4.1 Programming the fill up level...................................................................18

4.4.2 Resetting the fill up level and auto shut off.............................................19

4.5 Empty water system......................................................................................... 19

4.6 Program auto shut off time............................................................................... 20

5 Maintenance ......................................................................................................21

5.1 Descaling ......................................................................................................... 21

5.1.1 Descaling procedure...............................................................................21

5.2 Cleaning procedure.......................................................................................... 25

6 Troubleshooting...............................................................................................26

6.1 Check list.......................................................................................................... 26

7 Repairs................................................................................................................28

7.1 Safety instructions............................................................................................ 28

7.2 Repair and mounting tips................................................................................. 28

7.3 Tools and accessories ..................................................................................... 30

7.4 General disassembly........................................................................................ 31

7.4.1 Prepare coffee machine for disassembly................................................31

7.4.2 Remove side panels ...............................................................................32

7.4.3 Remove power cord................................................................................33

7.4.4 Remove water guiding............................................................................35

7.4.5 Remove damper springs.........................................................................36

7.4.6 Remove closing handle...........................................................................37

7.4.7 Remove cable cover...............................................................................37

7.4.8 Remove right light guide.........................................................................38

7.4.9 Remove blind..........................................................................................39

Page 3

Pixie service manual

3

7.4.10Remove housing right.............................................................................39

7.4.11Remove main assembly .........................................................................44

7.4.12Remove front ring ...................................................................................46

7.4.13Remove key caps of push buttons.......................................................... 47

7.5 Replacing pump............................................................................................... 48

7.6 Replacing functional block............................................................................... 50

7.7 Replacing brewing unit..................................................................................... 52

7.8 Replacing flow meter ....................................................................................... 57

7.9 Wiring diagrams............................................................................................... 59

7.9.1 Wiring diagram 220 V - 240 V IEC..........................................................59

7.9.2 Wiring diagram 120 V UL (USA / Canada).............................................60

7.9.3 Wiring diagram 127 V IEC (Brazil).......................................................... 61

7.9.4 Wiring diagram 127 V IEC (Mexico) .......................................................62

7.9.5 Wiring diagram 100 V IEC (Japan).........................................................63

7.9.6 Wiring diagram 110 V IEC (Taiwan).......................................................64

8 Function tests................................................................................................... 65

8.1 Safety instructions............................................................................................ 65

8.2 Required equipment......................................................................................... 65

8.2.1 Overview................................................................................................. 65

8.2.2 Pressure gauge adapter.........................................................................66

8.2.3 Mounting pressure gauge adapter.......................................................... 67

8.3 Measure flow rate ............................................................................................ 68

8.4 Pressure and leakage checks.......................................................................... 69

8.4.1 Preparations ...........................................................................................70

8.4.2 Test run...................................................................................................71

8.5 Measure coffee temperature............................................................................ 72

8.6 Protective earth (PE) continuity test................................................................. 74

8.6.1 What is the protective earth continuity test about?.................................74

8.6.2 General...................................................................................................74

8.6.3 Test sequence........................................................................................75

8.6.4 What to do if the protective earth continuity test fails .............................76

8.7 Protective insulation test.................................................................................. 76

8.7.1 What is the protective insulation test about?..........................................76

8.7.2 General...................................................................................................76

8.7.3 Test sequence........................................................................................77

8.7.4 What to do if the insulation test fails.......................................................78

9 Explosion Drawings........................................................................................79

9.1 EF 280 Explosion drawing............................................................................... 79

9.2 EF 281 Explosion drawing............................................................................... 80

10 Parts List............................................................................................................ 81

10.1 Nespresso EF 280 / C60 and EF 281 / D60 .................................................... 81

10.2 208 Turmix TX160 CH..................................................................................... 83

10.3 281 DeLonghi EN125 EU................................................................................. 84

10.4 280 Krups XN300510 EU................................................................................. 85

10.5 281 Magimix M110 EU/GB .............................................................................. 86

10.6 281 Koenig D60 CH......................................................................................... 87

11 Notes................................................................................................................... 88

Page 4

Pixie service manual

4

PREFACE

The purpose of this service manual is to provide the service personnel with all necessary

information with regards to correct handling, maintenance and repair of the Pixie coffee

machines EF 280 and EF 281.

This manual should be used by the technicians as a valuable aid to guarantee the

permanent readiness for use of the machines. In order to take full advantage of all the

functions, it is absolutely necessary to follow the instructions in this manual.

Visit the Nespresso technical website periodically to check for upgrades, technical

modifications, counter measures etc. for these coffee machines:

https://business.nespresso.com

CONTENT UPDATES

Version 1.2

• Improved general disassembly procedures for cable cover and front ring.

Version 1.1

• Function test corrections in connection with translations of this service manual.

Version 1.0

• First released service manual version, in English only.

Please keep this

manual together with

the corresponding

service documentation.

This way you are assured

to have the necessary

information.

Access is restricted

and can be obtained

by asking your

Nespresso technical

contact person..

The version number

of this service manual

is printed on the lower

right corner of the front

page.

Page 5

Pixie service manual

5

GENERAL SAFETY NOTES

1 GENERAL SAFETY NOTES

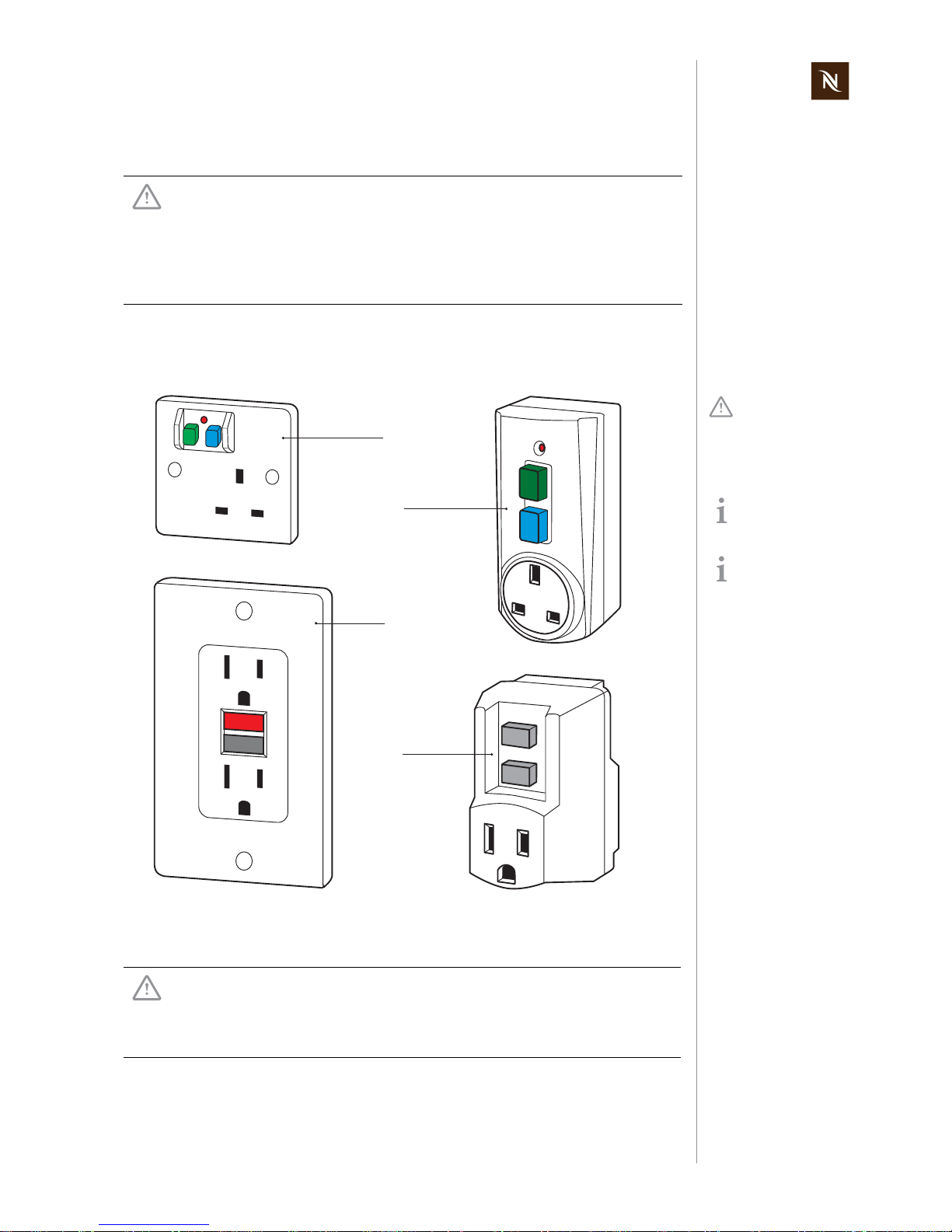

As an additional safety measure, the use of a residual current device (RCD), also called

a ground fault circuit interrupter (GFCI), in the repair centre is highly recommended.

Risk of fatal electrical shock and fire!

Mains voltage inside the coffee machine.

• Unplug appliance before cleaning.

• Never clean wet or immerse plug, cord or appliance in any fluid.

• Disconnect the mains plug before disassembly - the appliance must

be free of voltage.

This device does

not protect against

electrical shock due to

contact with both circuit

conductors.

Example illustrations

of typical devices.

Use a GFCI with a trip

level of 4 - 6 mA (USA)

resp. a RCD with a trip

level of 15 - 30 mA (Europe).

A trip level above 30 mA

provides only very limited

protection against harm

from an electric shock.

1) RCD protected socket-outlet

2) Plug-in RCD unit

3) GFCI socket

4) Plug-in GFCI

Danger of burns!

Hot parts and water under pressure inside the coffee machine

(particularly in the thermoblock).

• Let coffee machine cool down before cleaning or disassembly.

1

2

RESET

TEST

RESET

TEST

3

4

Page 6

Pixie service manual

6

MAIN COMPONENTS

2 MAIN COMPONENTS

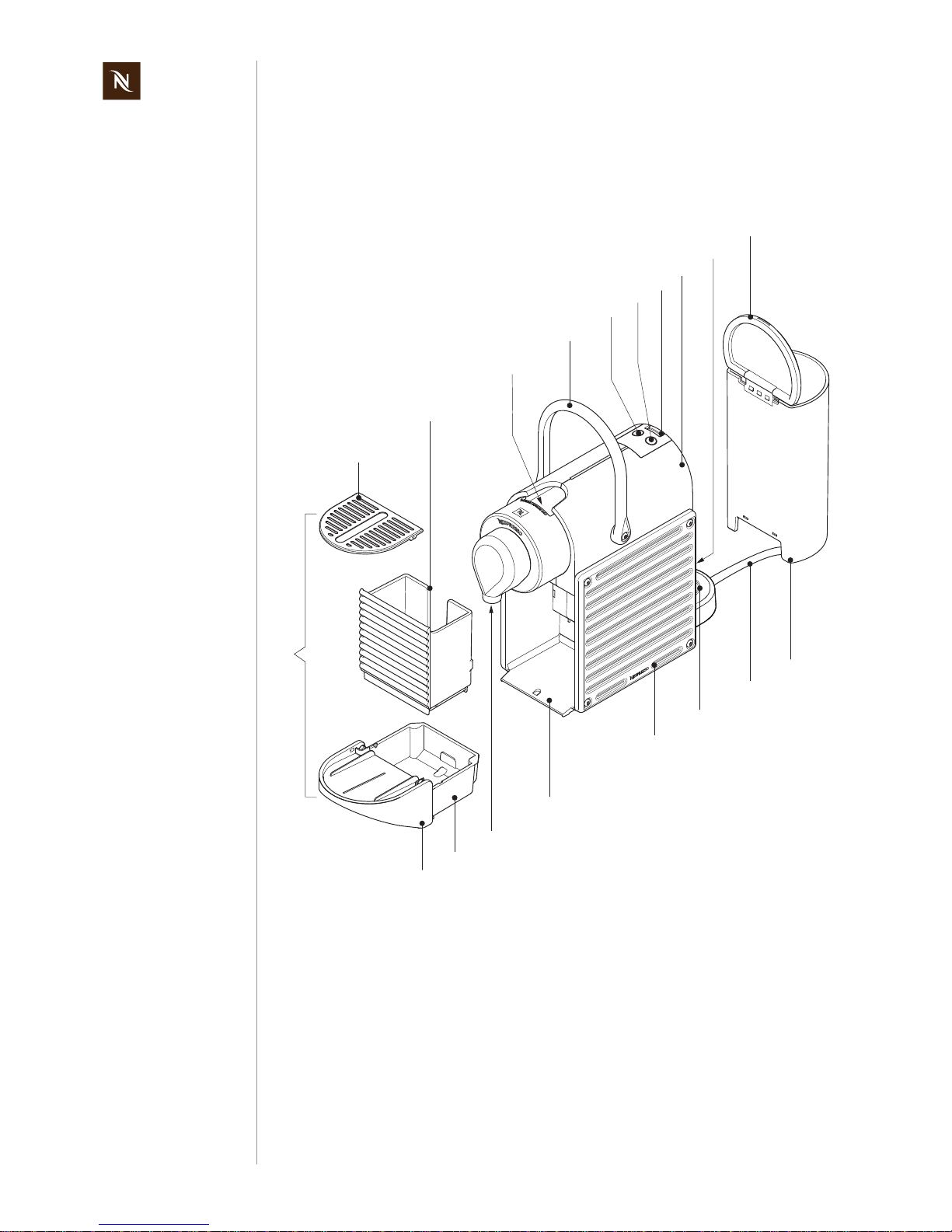

2.1 Overview

1) Drip grid

2) Capsule container for used capsules

(backlighted)

3) Feed opening for capsule

4) Closing handle

5) Coffee button "small cup" / "Espresso"

(backlighted)

6) Coffee button "large cup" / "Lungo"

(backlighted)

7) On/Off switch

8) Housing right

9) Water level detection

10) Water tank lid

11) Water tank

12) Power cord

13) Water tank connector

14) Side panel left/right

15) Housing left

16) Coffee outlet

17) Waste water container

18) Folding cup support

19) Maintenance unit

15

1

2

17

4

3

16

5

7

10

11

12

6

18

14

13

8

9

19

Page 7

Pixie service manual

7

MAIN COMPONENTS

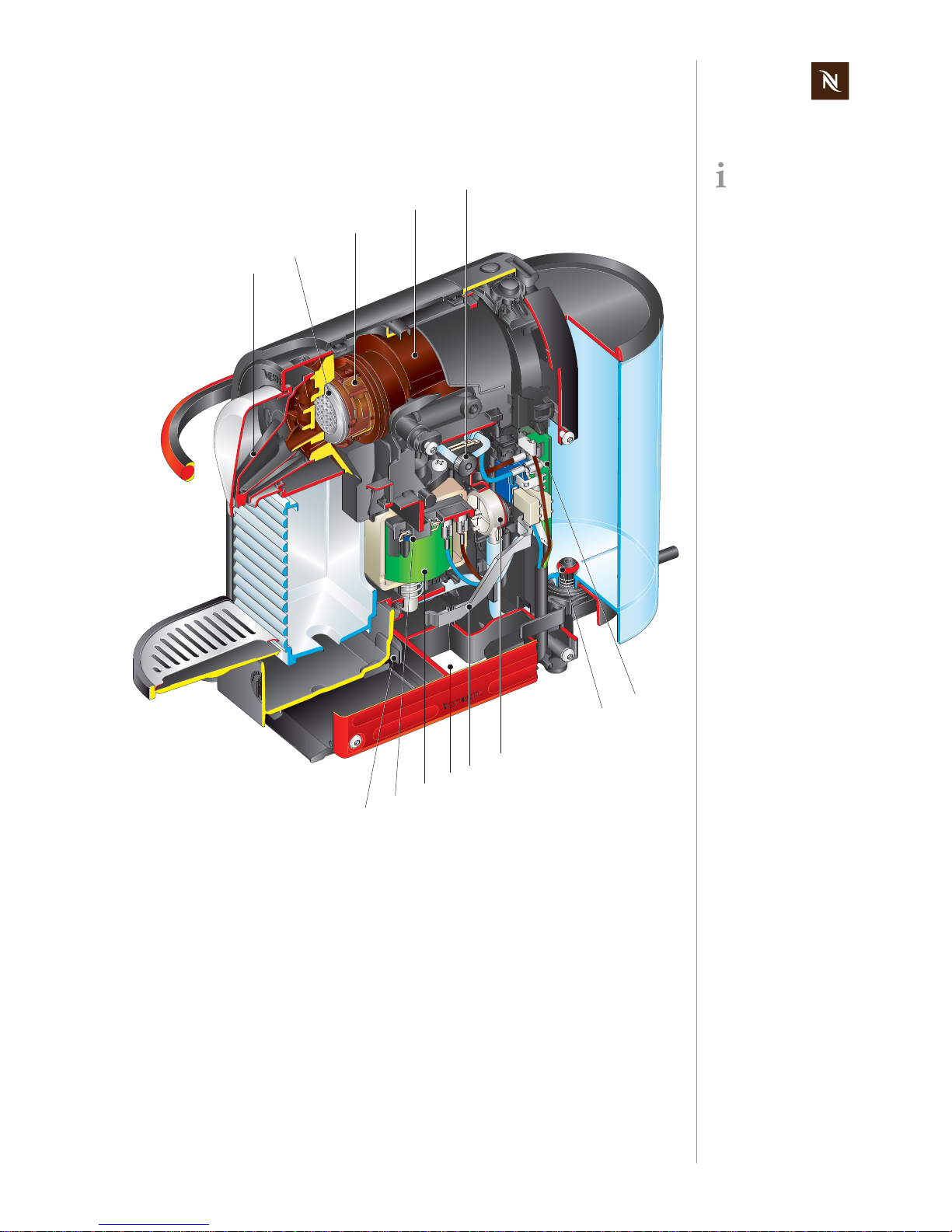

2.2 Interior view

This interior view

shows the wired coffee machine model

Pixie C.

1) Steam cover

2) Pyramid plate

3) Brewing device

4) Thermoblock

5) Sound damper

6) Electronic control board

7) Water tank valve

8) Flow meter

9) Light guide (for capsule container)

10) Opening in the housing to store excess

lenght of power cord

11) Pump

12) Thermal cut off fuse

13) Magnetic mounting

2

3

4

7

8

9

11

12

6

10

13

1

5

Page 8

Pixie service manual

8

MAIN COMPONENTS

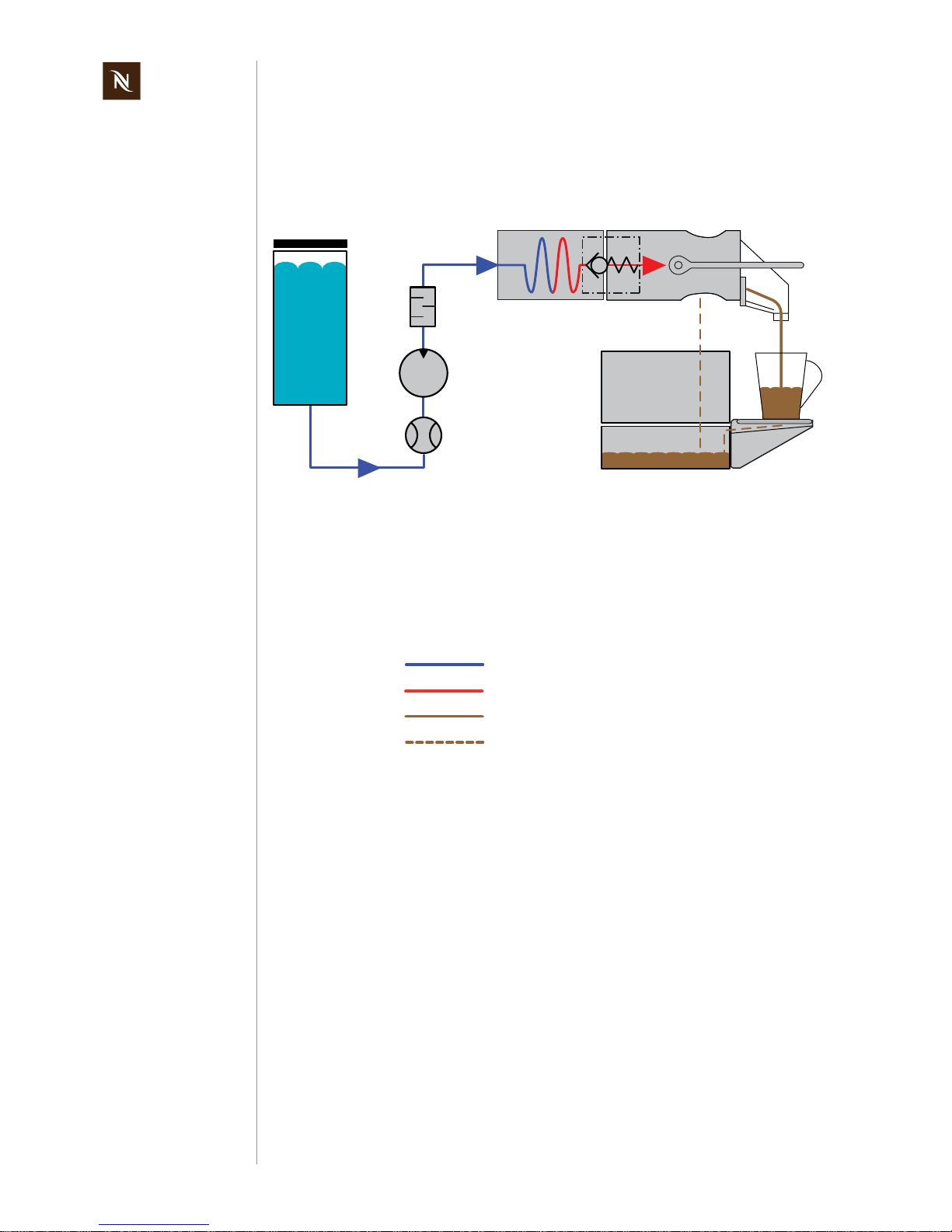

2.3 Fluid System

2.3.1 Water circuit diagram

Legend:

1) Water tank

2) Flow meter

3) Pump

4) Sound damper

5) Thermoblock

6) Check valve

7) Brewing unit

8) Capsule container

9) Waste water container

10) Drip grid

Fresh cold water

Fresh hot water

Coffee

Waste/drip water

BU

TB

1

3

2

5

7

8

9

10

4

6

Page 9

Pixie service manual

9

MAIN COMPONENTS

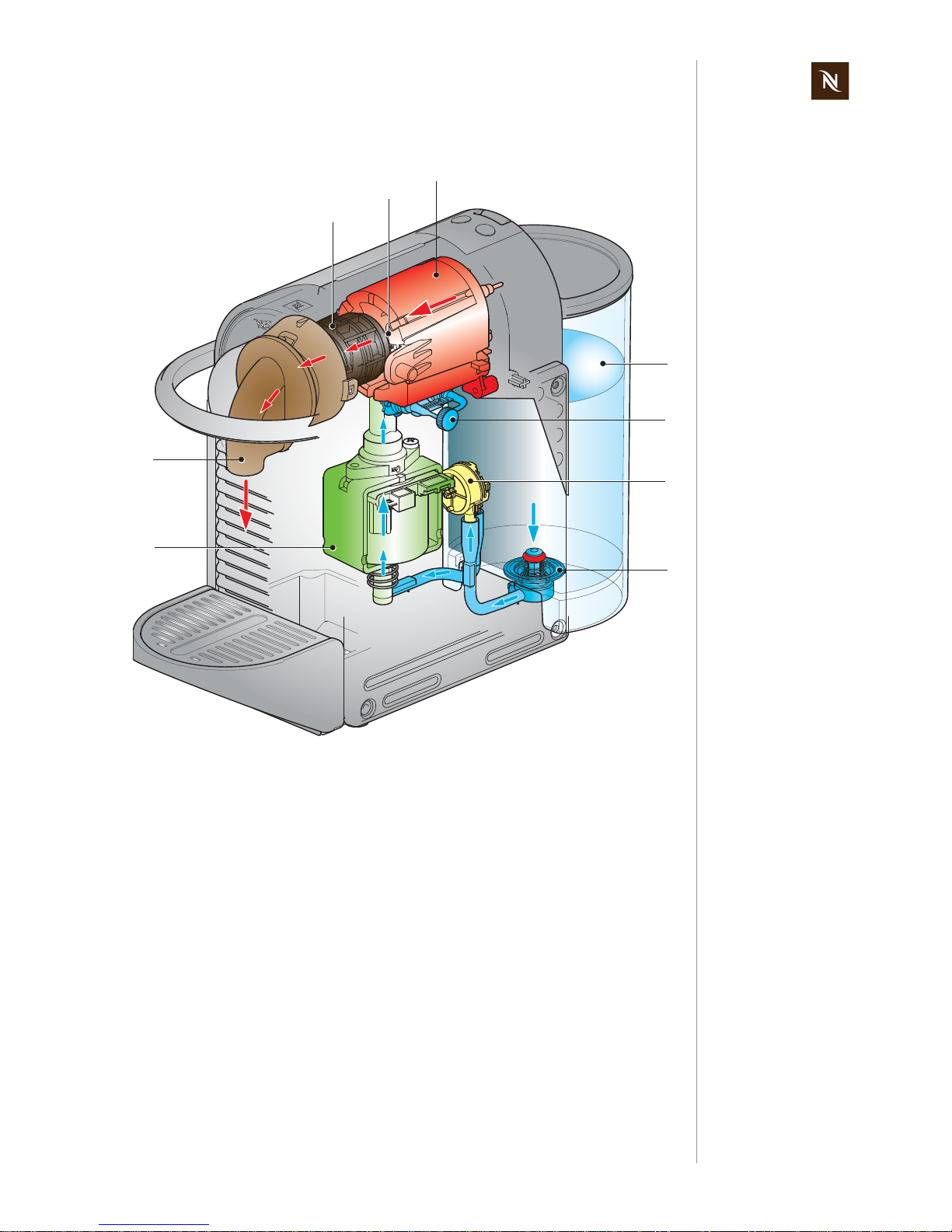

2.3.2 Water circuit

1) Pump

2) Coffee outlet

3) Brewing unit

4) Check valve

5) Thermoblock

6) Water tank

7) Sound damper

8) Flow meter

9) Water tank connector

3

5

4

2

1

6

7

8

9

Page 10

Pixie service manual

10

TECHNICAL DATA

3 TECHNICAL DATA

3.1 Rating plates

3.1.1 Examples of brand specific rating plates

The rating plate can

be found at the bottom of the coffee

machine.

This overview shows

examples of various

brands and is subject

to alterations.

Page 11

Pixie service manual

11

TECHNICAL DATA

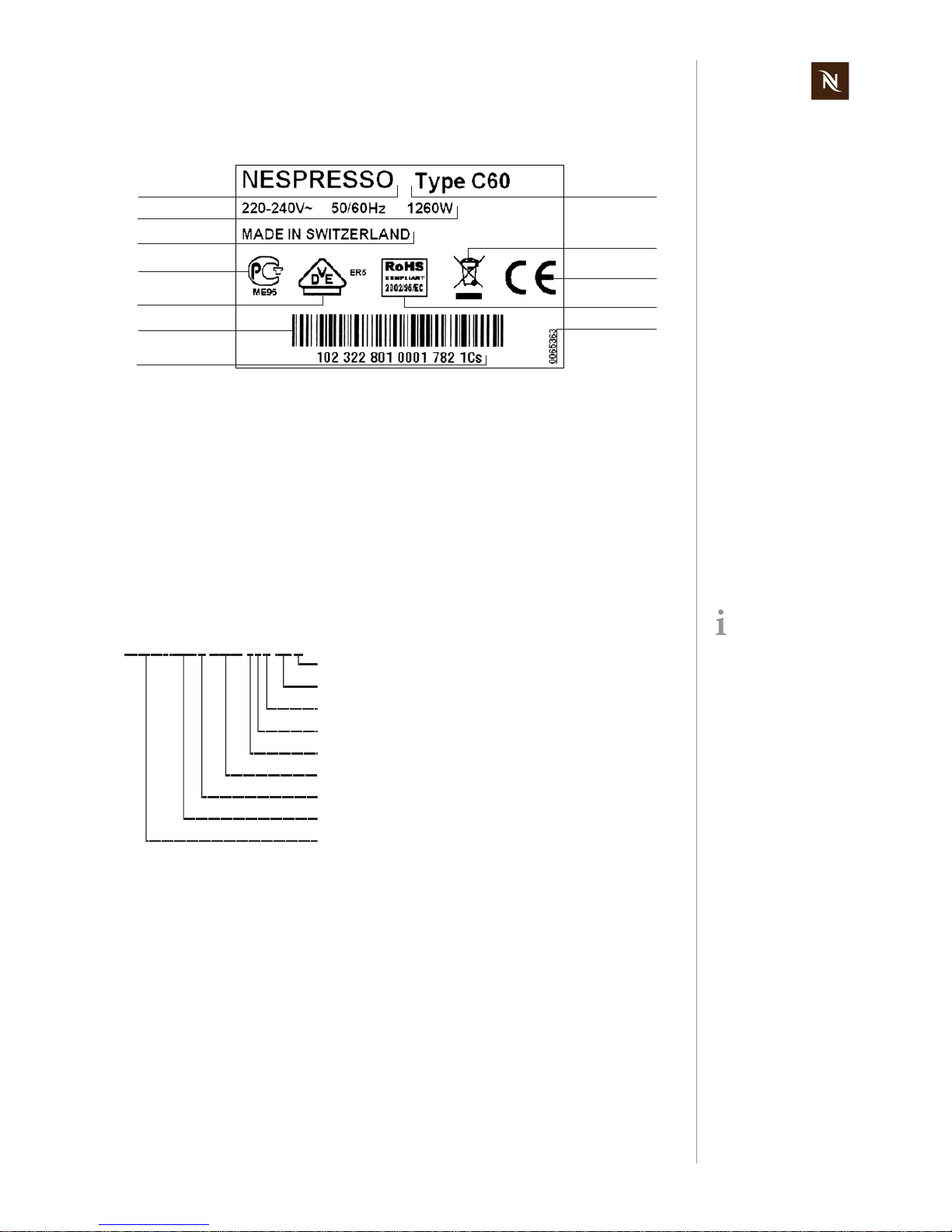

3.1.2 Rating plate details (example)

Decoding the alphanumeric serial number

Example:

1) Brand name

2) Voltage and power rating

3) Place of manufacture

4) National approval sign of Russia

(GOST R)

5) National approval sign of Germany

(VDE)

6) Barcode

7) Serial number

8) Machine type

9) Special disposal icon

(do not dispose with ordinary waste)

10) Sign of conformity (CE)

11) Conformity with RoHS guidelines (lead

free solder, etc.)

12) Article number of the rating plate

1

2

3

6

7

8

9

10

12

4

5

11

By decoding the date

of production and

machine type, the

coffee machine can be

identified exactly.

Checksum

Color version

Type of mains plug

Mains voltage

Distributing partner

Incremental number per production day

Manufacturing plant

Manufacturer designation of the machine type (EF 280)

10232 ... Date of production

(10 = year 2010, 232 = 232nd day of the year)

102 322 801 0001 782 1Cs

Page 12

Pixie service manual

12

TECHNICAL DATA

3.2 Technical specifications

Mains voltage ranges

- Europe, RU, AU, CN, KR, SG, HK, ME, ZA, IL, BR, AR............ 220-240 V, 50/60 Hz

- USA, Canada..................................................................................... 120 V, 50/60 Hz

- BR, MX............................................................................................... 127 V, 50/60 Hz

- Japan ................................................................................................ 100 V, 50/60 Hz

- Taiwan.................................................................................................... 110 V, 60 Hz

Power consumption

220-240 V mains voltage......................................................................approx. 1’260 W

100/110/120/127 V mains voltage.........................................................1’160 - 1’370 W

Power consumption of coffee machine main components

(for all voltages and frequencies)

Thermoblock......................................................................................................1’200 W

Pump......................................................................................................................60 W

Energy consumption (CECED / FEA 2009 method)

Energy efficiency class level ............................................................................. A - 40%

Daily energy consumption....................................................................................72 Wh

Annual energy consumption..........................................................................26.28 kWh

Pump

Pump pressure

- Max. permissible....................................................................................20 bar ± 3 bar

- During coffee preparation (depending on the type of coffee)........................9 - 16 bar

Capacities

Water tank.................................................................................................. approx. 0.7 l

Waste water container......................................................................................... 190 ml

Capsule container .......................................................................... approx. 10 capsules

EuP ... Energy using

Products

See commission regulation no. 1275/2008 of the

European Union.

Approvals CE, UL "for USA and Canada", PSE, Gost R, Ctick,

CCC, KTL, SPRING, SASO, SABS, ISI, IRAM, NOM

EuP standard The coffee machine is EuP 2013 compliant

Advised water tank

capacity to avoid

spilling.

Page 13

Pixie service manual

13

TECHNICAL DATA

Volume of prepared coffee

- factory settings

Small cup "Espresso".................................................................................. 40 ml (±7%)

Large cup "Lungo"..................................................................................... 110 ml (±7%)

- customer settings

Programmable setting range.........................................................................20 - 200 ml

Environmental conditions

Operating temperature............................ + 5 °C up to + 45 °C (+ 41 °F up to + 113 °F)

Storage temperature..................................- 25 °C up to + 65 °C (- 13 °F up to 149 °F)

Altitude............................................................................up to 2’500 m above sea level

Humidity...................................................................................................no restrictions

Various data

Preheating time.......................................................................................approx. 25 sec

Automatic shut off time.................................................................after 9 min of non-use

Safety temperature (electronically controlled)....................................... 120 °C (248 °F)

Safety temperature (thermal cut-off)..................................................... 167 °C (333 °F)

Coffee temperature at outlet ...........................................86 °C ± 3 °C (187 °F ± 5,4 °F)

Page 14

Pixie service manual

14

TECHNICAL DATA

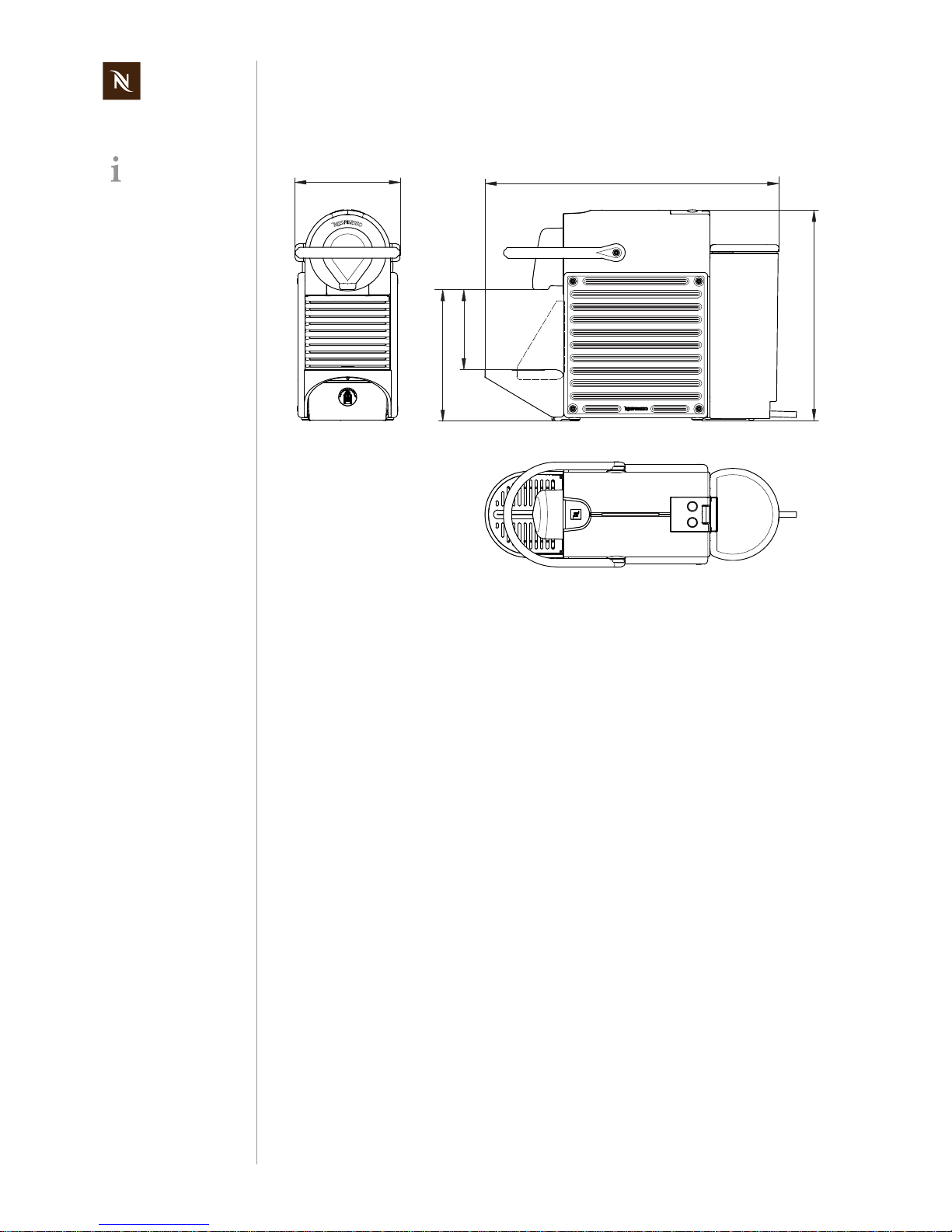

3.2.1 Dimensions and weight

Dimensions ( length x width x height)............................................ 326 x 111 x 235 mm

Power cable length...............................min. 0.8 m (depending on national regulations)

Cup support, folded down ....................... 90 mm, for espresso and lungo cups/glasses

Cup support, tilted up....................................................146 mm, for macchiato glasses

Weight (without water)............................................................................. approx. 2.8 kg

Dimensions in [mm].

235

326

111

90

146

Page 15

Pixie service manual

15

OPERATION

4 OPERATION

4.1 General information

For an overview of operational controls see “Main Components” on page 6.

For basic operation of the machine such as preparing a coffee and other related infor-

mation, refer to the user manual.

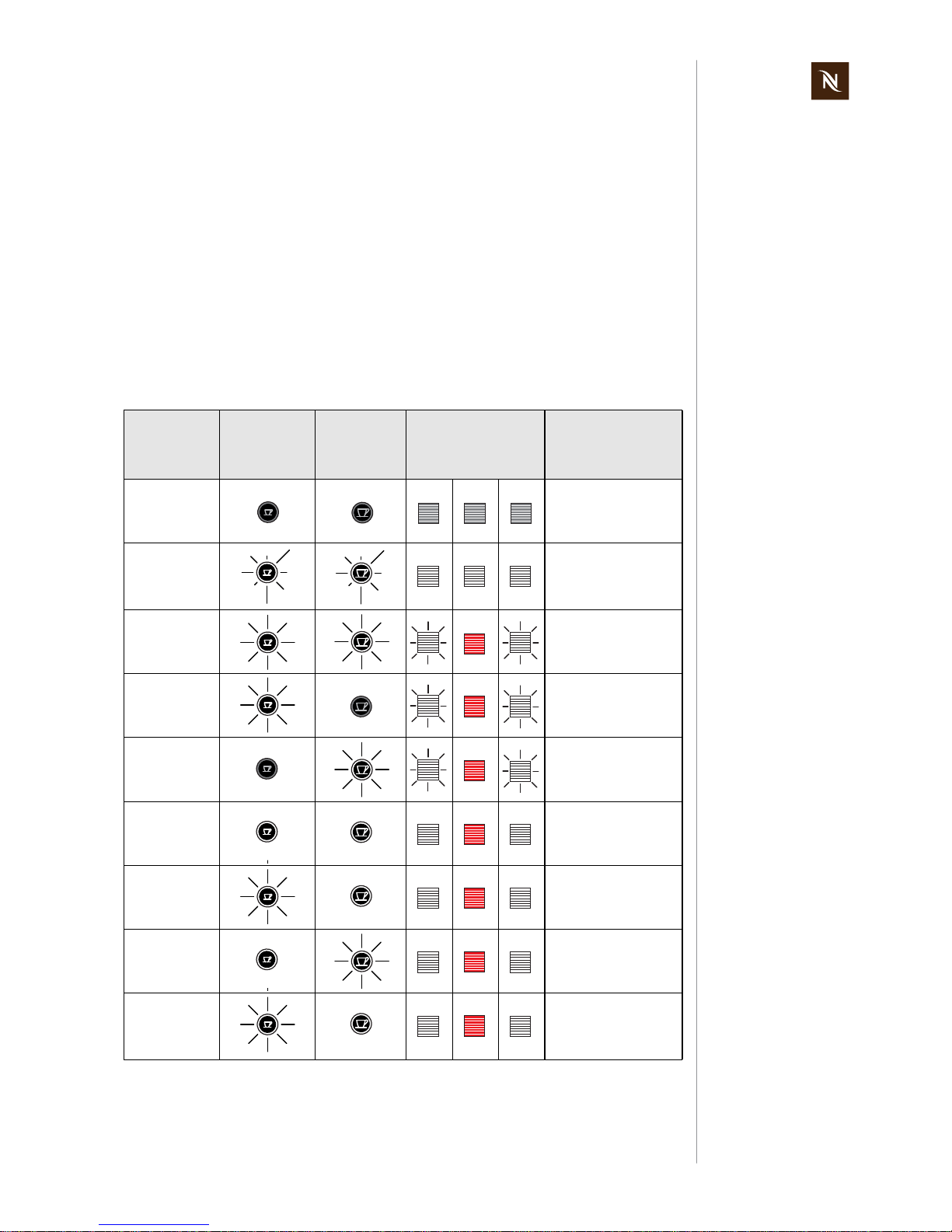

4.2 Status indication

According to the following table the status of the coffee machine is shown by

- the two coffee buttons with white backlight

- the capsule container with white or red backlight.

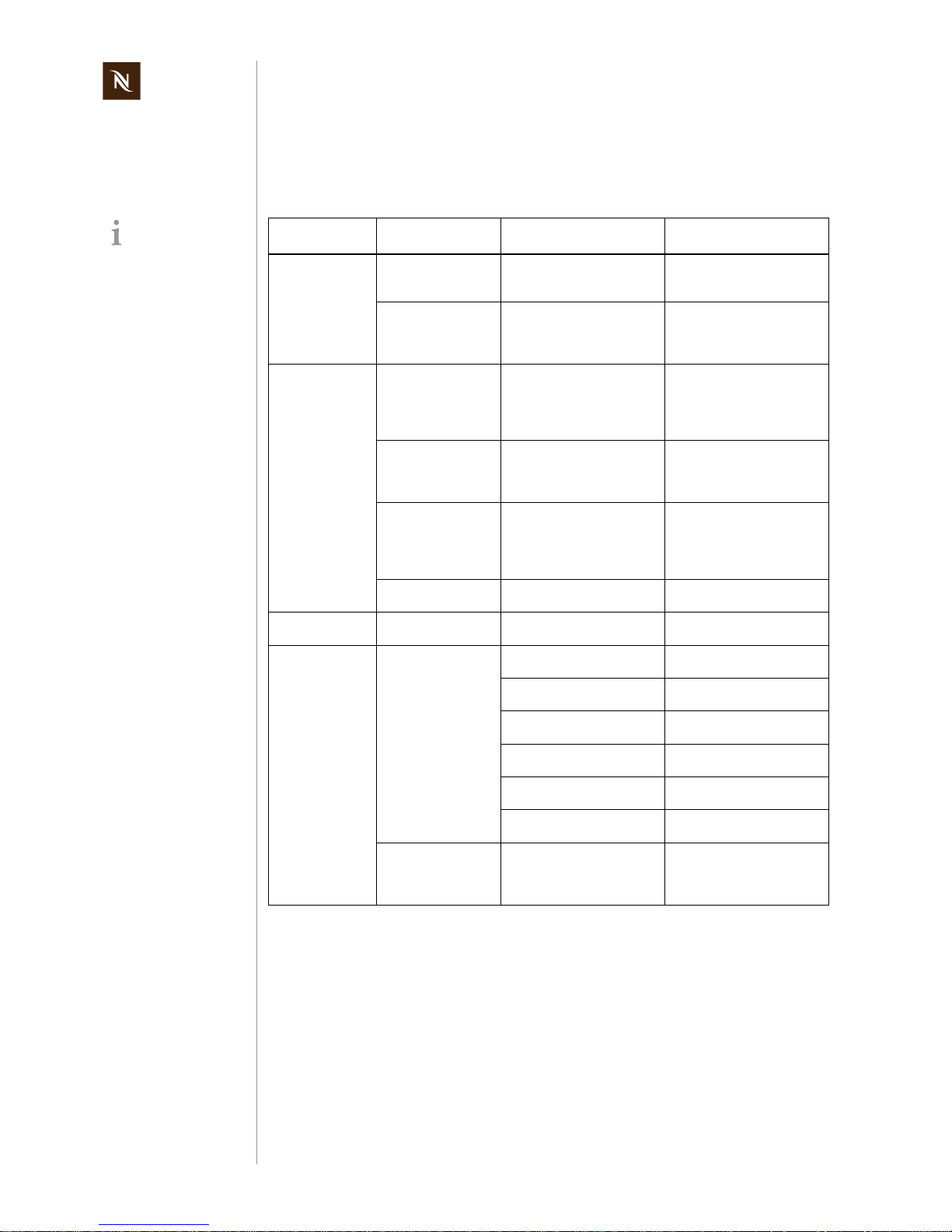

Machine

status etc.

"Small cup"

button

"Large cup"

button

Capsule container

backlight

Water tank level

high / low / missing

LED signal

Off All LED‘s off

Error

Blinking fast (2 Hz,

0.25 s on/0.25 s off)

3 times every 2 seconds, alternating

Heat up

Blinking 1 Hz,

0.5 s on, 0.5 s off

Preselect

small cup

Blinking 1 Hz,

0.5 s on, 0.5 s off

Preselect big

cup

Blinking 1 Hz,

0.5 s on, 0.5 s off

Ready LED‘s on

Brewing small

cup

Blinking 1 Hz,

0.5 s on, 0.5 s off

Brewing big

cup

Blinking 1 Hz,

0.5 s on, 0.5 s off

Rinse small

cup

Blinking 1 Hz,

0.5 s on, 0.5 s off

(same as brewing

small cup)

Page 16

Pixie service manual

16

OPERATION

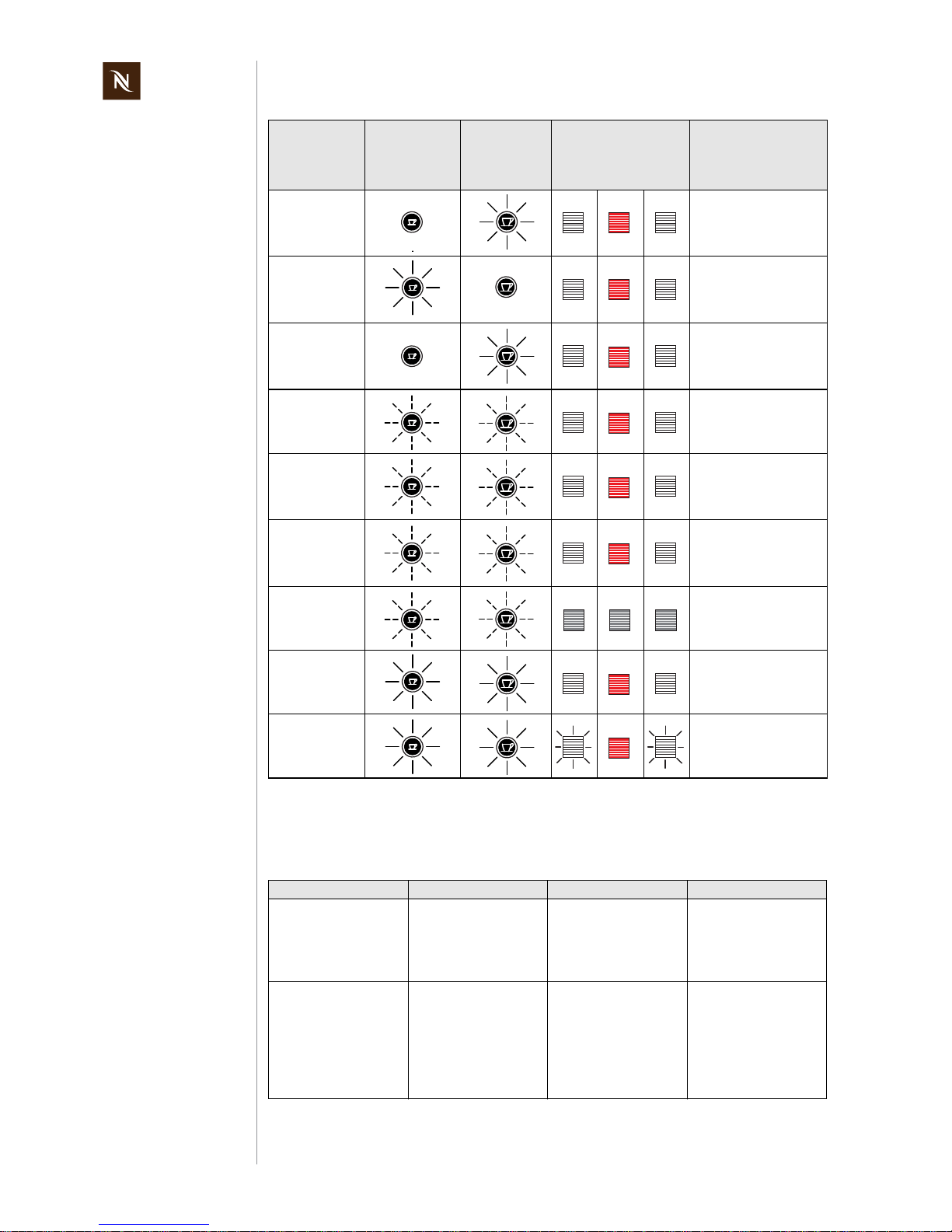

4.3 Machine modes

This table helps to understand the operating modes of the Pixie coffee machines:

Rinse big cup

Blinking 1 Hz,

0.5 s on, 0.5 s off

(same as brewing big

cup)

Volume brewing small cup

Blinking 1 Hz,

0.5 s on, 0.5 s off

(same as brewing

small cup)

Volume brewing big cup

Blinking 1 Hz,

0.5 s on, 0.5 s off

(same as brewing big

cup)

Descaling

ready

Blinking 2 Hz,

0.25 s on, 0.25 s off

Descaling

process pump on

Blinking 2 Hz,

0.25 s on, 0.25 s off

(same as descaling

ready mode)

Descaling

process pump off

Blinking 2 Hz,

0.25 s on, 0.25 s off

(same as descaling

ready mode)

Emptying /

evaporating

Blinking 2 Hz,

0.25 s on, 0.25 s off

Resetting

Blinking 1 Hz,

0.5 s on, 0.5 s off

(same as heat up)

Overheat

Blinking 1 Hz,

0.5 s on, 0.5 s off

(same as heat up)

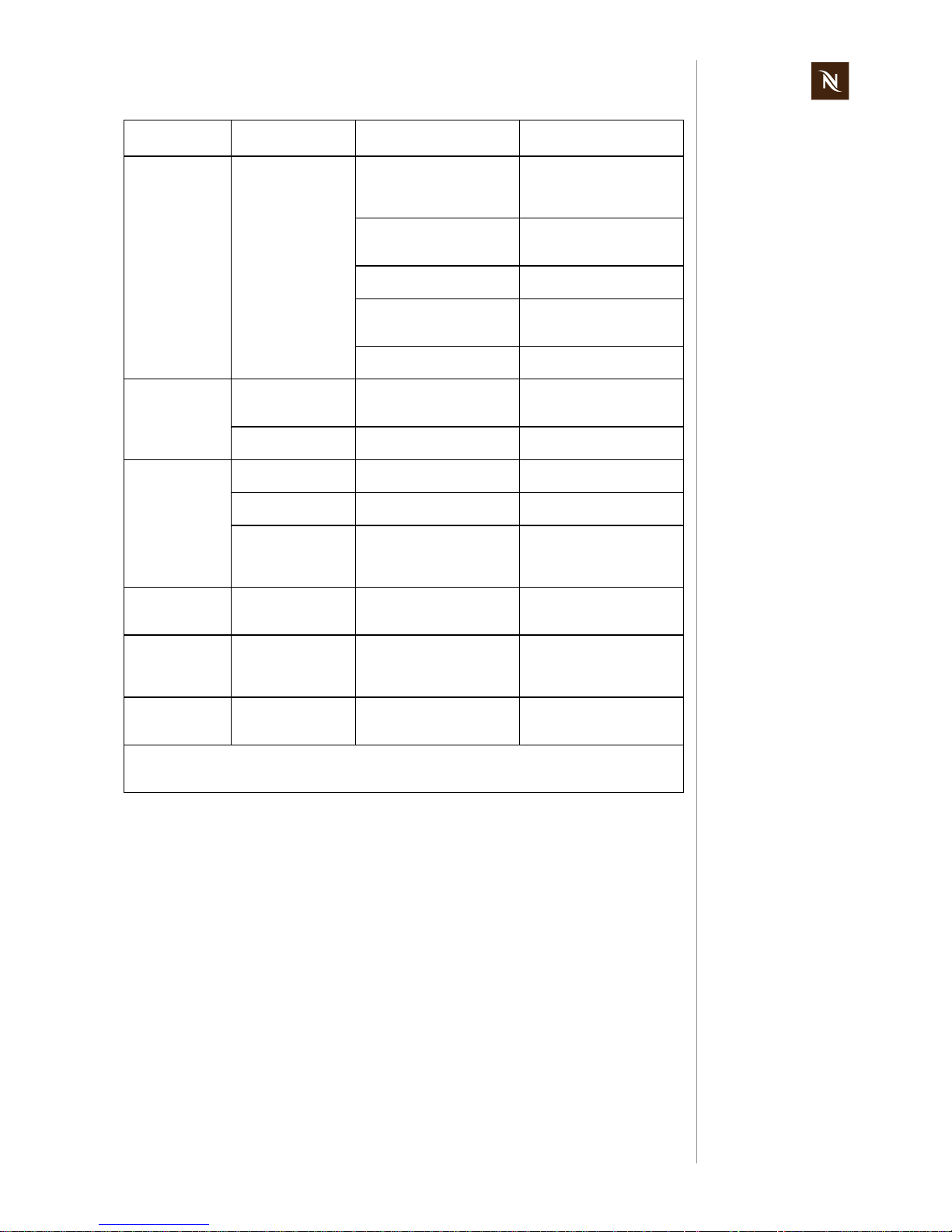

Machine mode Enter mode Actions Exit mode

1 Heat up mode

Every time after switching on machine

Heats up thermoblock

to ready temperature

90 °C within 30 sec

without overshooting

target temperature

e.g. switching off

machine

2 Self test mode

Every time after switching on machine

Tests:

• NTC short circuit

• NTC connected

• Checks if thermoblock reaches ready

temperature within

2 min after switch on

e.g. switching off

machine

Machine

status etc.

"Small cup"

button

"Large cup"

button

Capsule container

backlight

Water tank level

high / low / missing

LED signal

Page 17

Pixie service manual

17

OPERATION

3 Ready mode

• After heat up and self

test mode was ok

• After brewing or

volume brewing

coffee

• After reset mode

• After leaving

descaling mode

Keeps thermoblock

temperature at 90 °C

e.g. switching off

machine

4a Brewing mode

4b Volume brewing

mode (programming cup size)

• Press and release

coffee button "large

cup" or "small cup"

(brewing mode)

• Press and hold

coffee button "large

cup" or "small cup"

for more than 3 s

(programming mode)

• Press and release

coffee button "large

cup" or "small cup"

when machine was

in brewing mode or

automatic exit given

by the flow meter

• Release coffee

button "large cup" or

"small cup" when

machine is in

programming mode

• Switch off machine

5 Descaling mode

• Switch on machine,

wait until ready

• Press and hold both

coffee buttons for at

least 3 sec

• Regulates temperature to 55 °C (after

pump was started)

• Stops and starts

pump with any coffee

button, no volume

brewing in descaling

mode

• Press and hold both

coffee buttons for

1 sec

Note: When machine is

switched off during any

descaling mode, then it

goes to descaling

mode ready state after

next switch on.

6 Emptying mode

(evaporing)

1) Switch off machine

2) Press and hold

coffee button

"small cup"

3) Switch on machine

1) Starts pump

2) Stops pump after

10 sec

3) Heats up thermoblock to 105 °C

(100% power)

4) Switches off thermoblock

5) Switches off

machine

6) Blocks machine for

10 min

Switch off machine

7 Resetting mode

1) Switch off machine

2) Press and hold

coffee button

"large cup"

3) Switch on machine

• Resets programmed

large and small

coffee volumes to

factory setting

• Indicates the resetting mode for 3 sec

Proceeds with self test

mode automatically

8 Auto switch off mode

(factory setting of 9 min

can be changed to

30 min - see page 20)

Automatically after a

certain period of nonuse

• Switch off machine

after 9 min resp.

30 min if no coffee is

brewed or 9 min

resp. 30 min after

last brewed coffee

9 Failure mode

Automatically by following failures:

a) NTC short circuit

b) NTC not connected

c) Heat up too slow

Machine indicates failure with blinking coffee

buttons as long as the

failure is present

When failure is fixed

Machine mode Enter mode Actions Exit mode

Page 18

Pixie service manual

18

OPERATION

4.4 Program/reset fill up level

Each coffee button can be programmed with a coffee volume for an individual cup size.

The procedure for programming/resetting is the same for both coffee buttons.

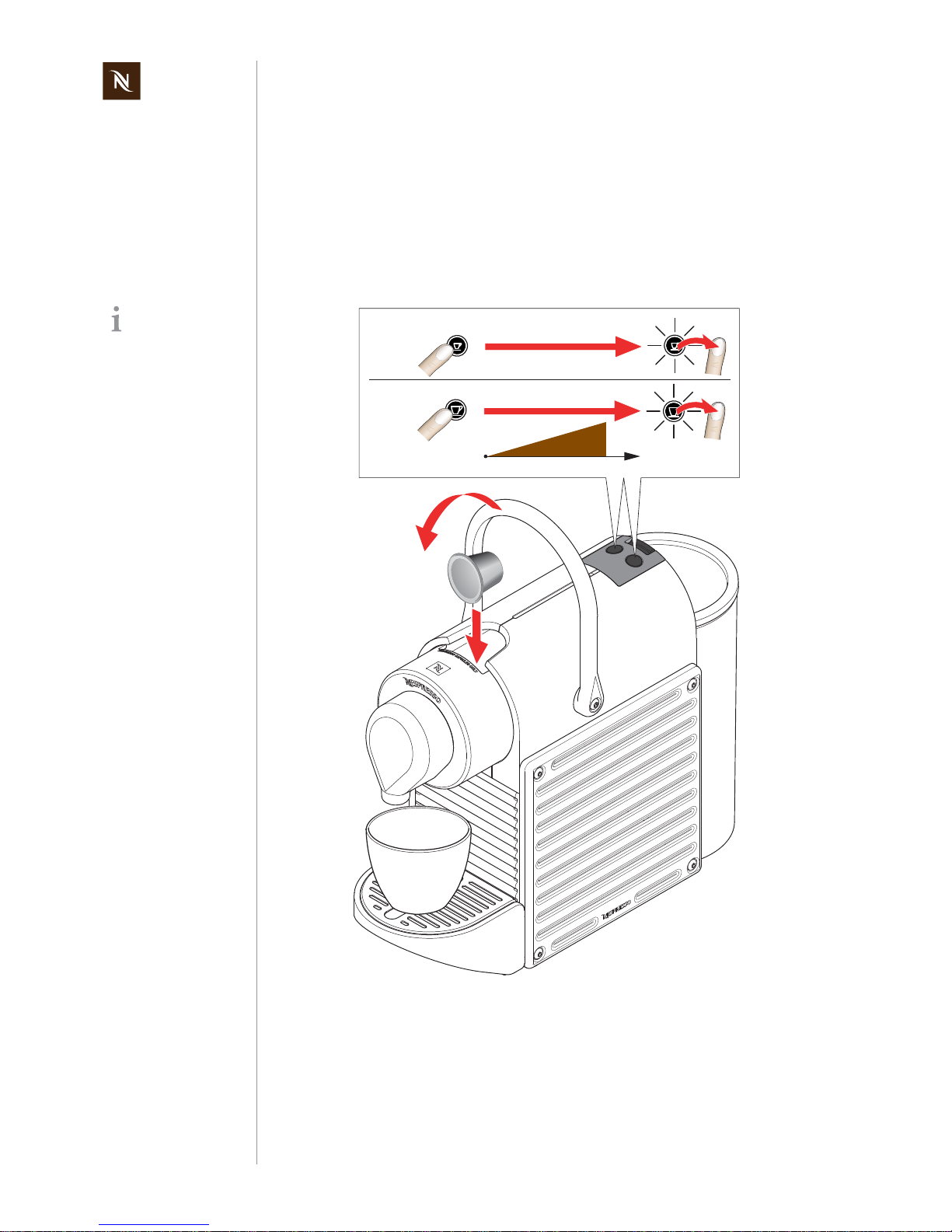

4.4.1 Programming the fill up level

Programmable volume range........................................................................20 - 200 ml

Each new programming cycle starts with

the min. volume

(20 ml after 3 sec), regardless of a preprogrammed

coffee volume.

1) Prepare coffee as usual (see user

manual), but keep the coffee button

pressed for at least 3 seconds in

order to start programming mode.

2) Only release the button when the

desired fill level is reached.

min

3 sec

max 200 ml

20 ml

200 ml

max 200 ml

min

3 sec

Page 19

Pixie service manual

19

OPERATION

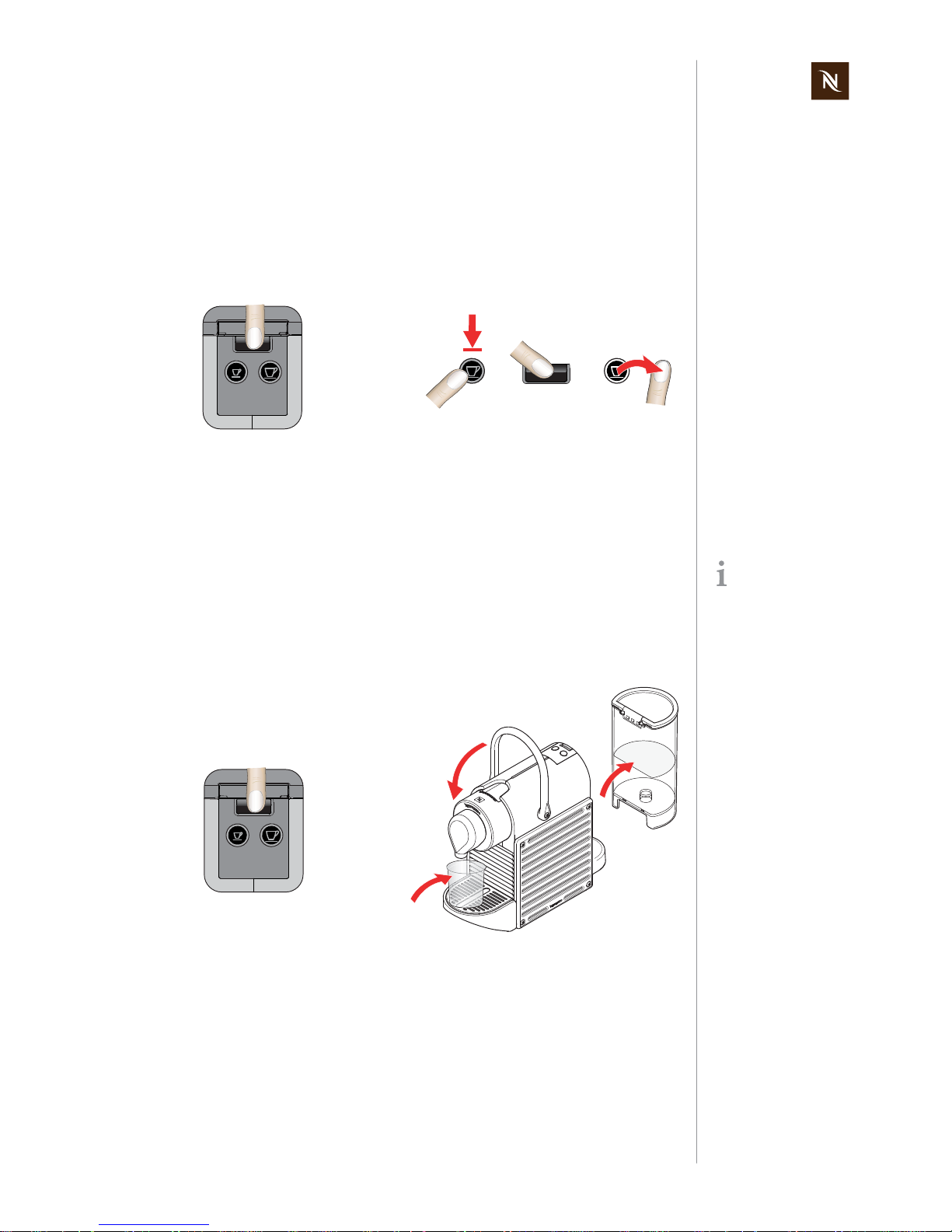

4.4.2 Resetting the fill up level and auto shut off

With the following procedure all programmed fill up levels will be set back to this factory

settings:

Coffee button "small cup" / "Espresso".................................................................. 40 ml

Coffee button "large cup" / "Lungo"...................................................................... 110 ml

Additionally the auto shut off time will be set back to 9 min (factory setting).

4.5 Empty water system

After every operation, some water (max. 25 ml) remains in the coffee machine. Therefore the water system must be emptied

- if the coffee machine will not be used for a long time

- as antifreeze measure

- for repairs and shipment.

1) Switch off the coffee machine. 2) Press and hold the button "large cup".

3) Switch on the coffee machine.

4) Release button "large cup".

1

OFF

2

3

4

ON

After this procedure,

the coffee machine

will not be ready for

approx. 10 min (until the

thermoblock cools to below

100 °C ).

1) Switch off coffee machine. 2) Remove water tank.

3) Place a receptacle under the coffee

outlet.

1

OFF

2

3

Page 20

Pixie service manual

20

OPERATION

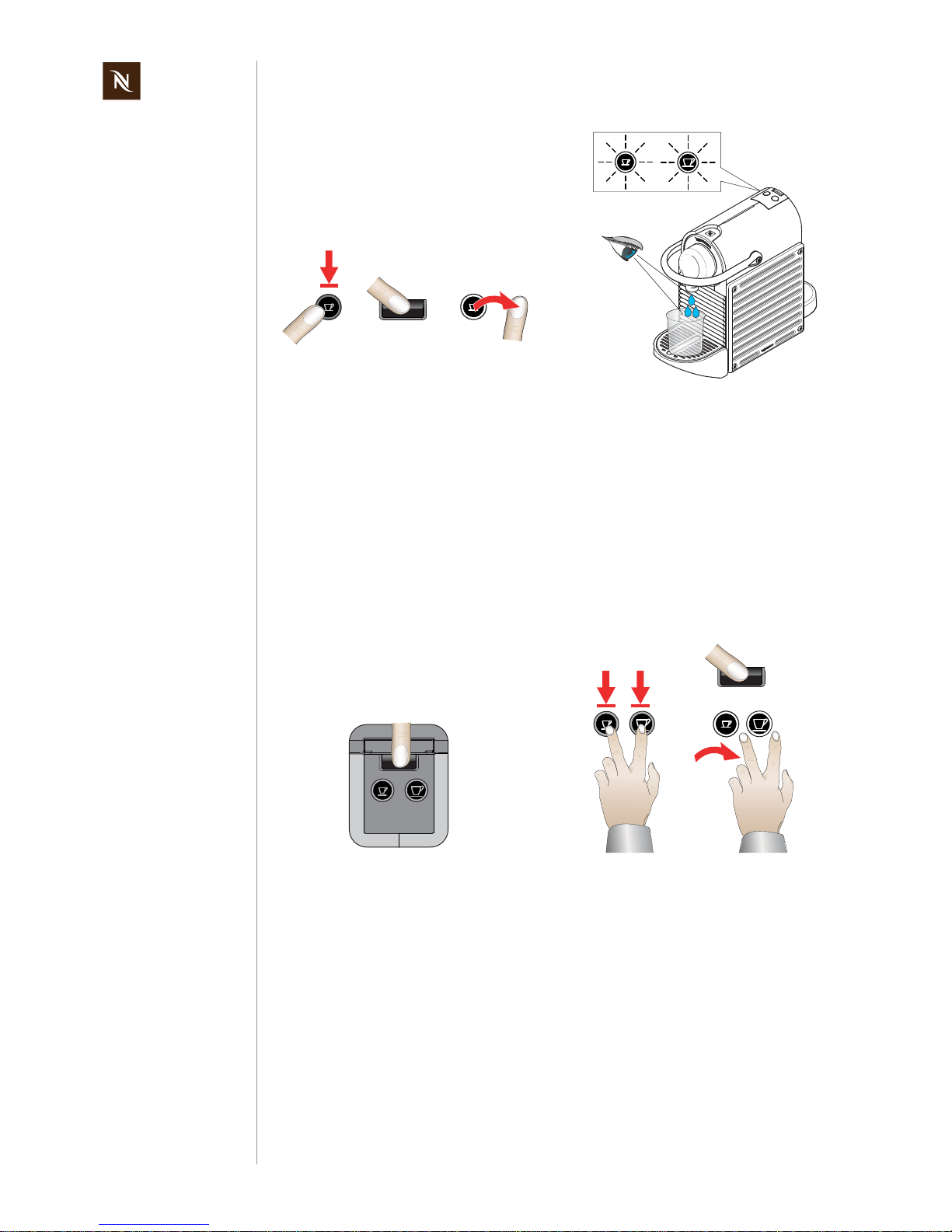

4.6 Program auto shut off time

The auto shut off time of 9 min can be changed to 30 min with the following procedure:

To set the auto shut off time back to the factory default of 9 min, see page 19.

4) Press and hold button "small cup".

5) Switch coffee machine on again.

6) Release button "small cup".

- The coffee buttons blink fast simultaneously.

- The pump starts to drain the water

system and stops automatically.

- After heating up the therrmoblock, the

machine switches itself off automatically and blocks the On/Off switch for

approx. 10 min.

1) Switch off coffee machine. 2) Press and hold both coffee buttons.

3) Switch coffee machine on again.

4) Release both coffee buttons.

4

5

6

ON

Automatic

switch off

1

OFF

2

3

4

ON

Page 21

Pixie service manual

21

MAINTENANCE

5 MAINTENANCE

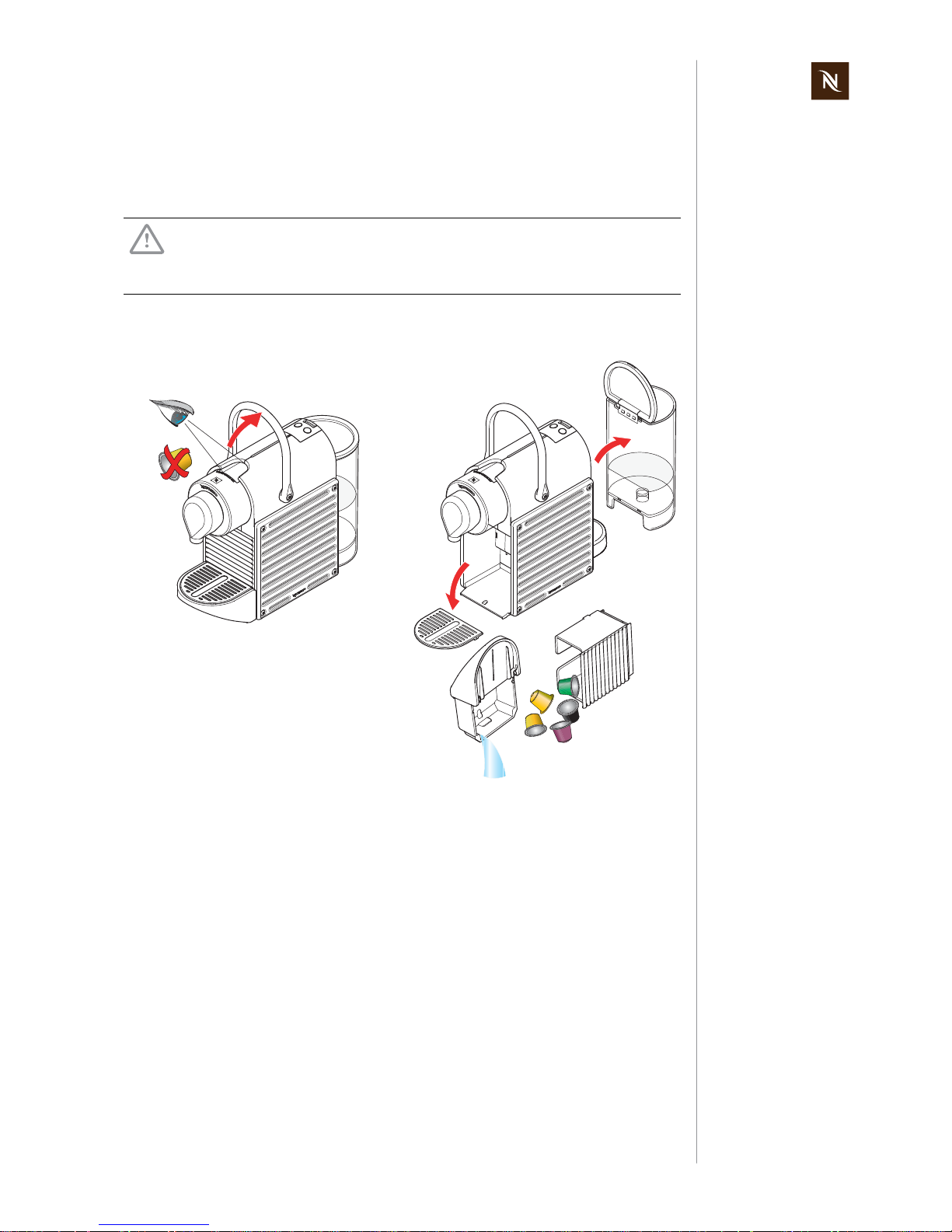

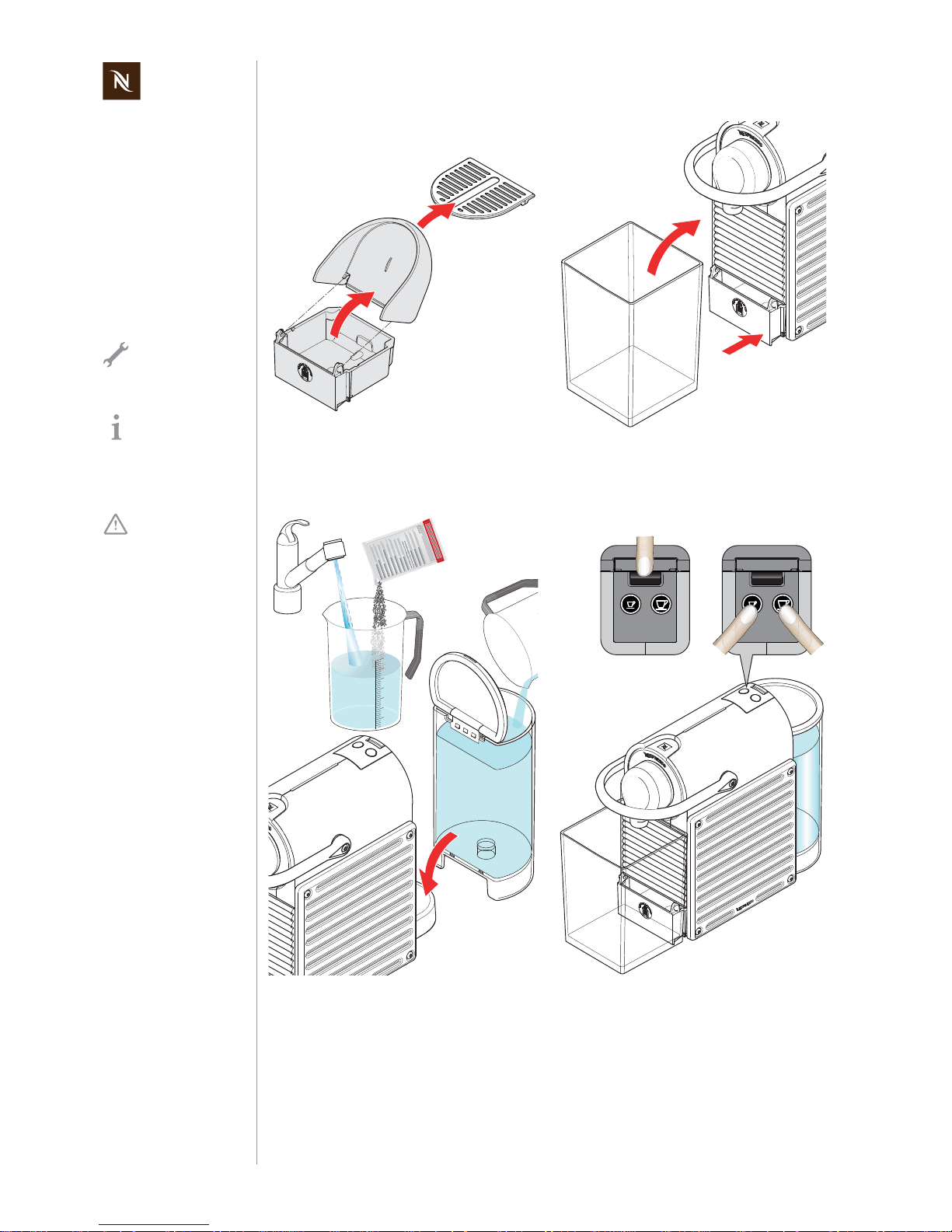

5.1 Descaling

5.1.1 Descaling procedure

Only use Nespresso descaler (5034) or Nespresso descaling kit

(3035/CBU-2) – never use vinegar!

Descaler can damage casing and surfaces.

Immediately clean drops of descaling solution.

1) Eject capsule or check if capsule is

removed.

2) Remove and empty water tank, capsule and waste water container.

1

2

Page 22

Pixie service manual

22

MAINTENANCE

Fold cup support up

to the stop before

pulling it out of the

hinges.

Use a container with a

capacity of min. 1 l.

3) Fold up and release cup support from

waste water container.

4) Re-insert capsule and waste water

container.

5) Place a container under coffee outlet.

3

5

4

Observe the safety

instructions on the

descaler package.

6) Fill measuring jug with 0.1 l (1 bag) of

Nespresso descaling liquid and 0.5 l

fresh, potable water.

7) Fill descaling solution in water tank.

8) Insert water tank into the coffee

machine.

9) Switch machine on and wait till

machine is ready.

10) Press both coffee buttons simultaneously for at least 3 sec.

- The machine is in descaling mode now

(both coffee buttons blinking fast).

6

8

0.5 l

0.1 l

7

9

10

3 sec

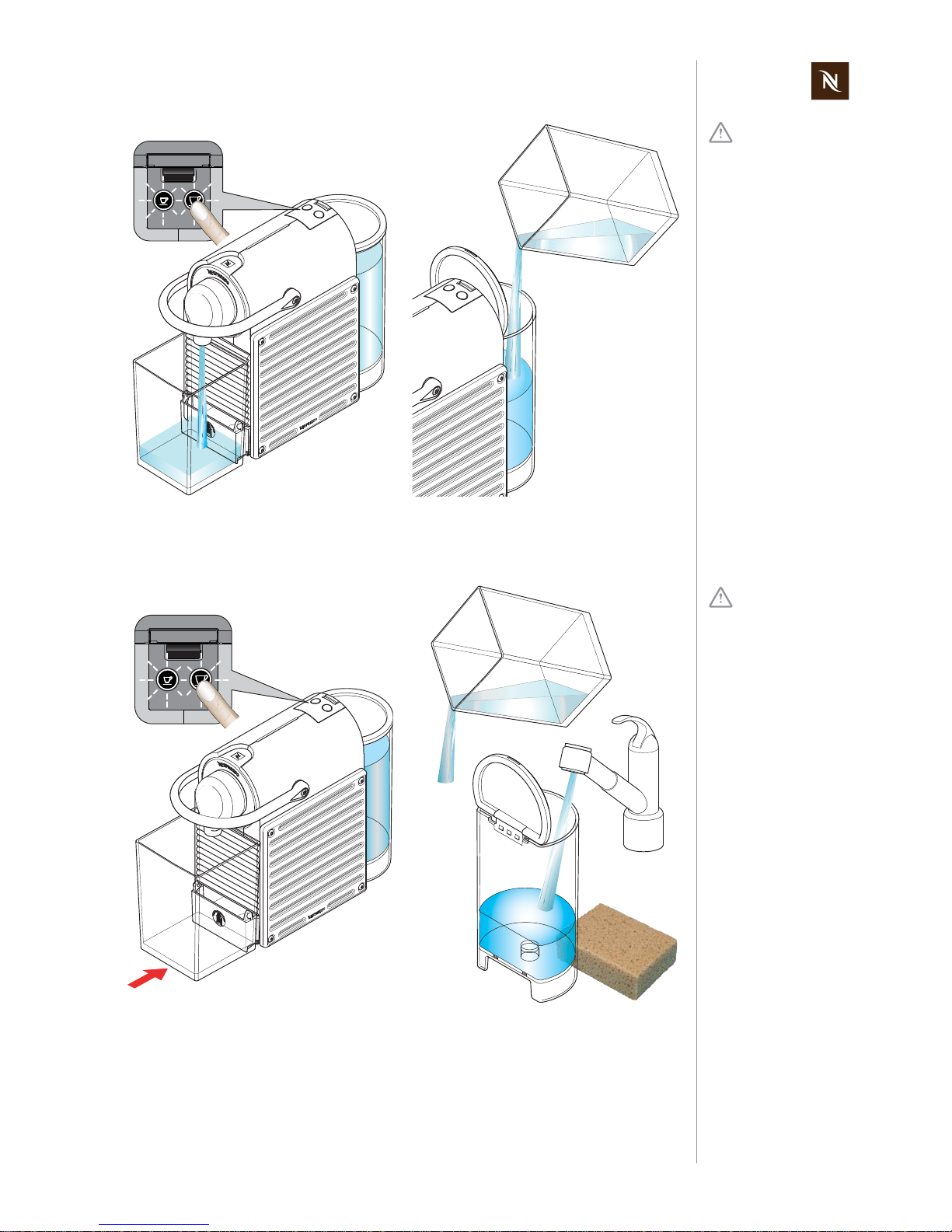

Page 23

Pixie service manual

23

MAINTENANCE

Danger!

Hot splashes of

descaling solution.

Do not open closing handle during descaling

process.

11)

Press any coffee button to start pump.

Let the entire solution in the tank run

through the system.

12) After water tank is empty, pour descaling solution back into water tank.

11

12

Danger of injury!

Residual descaler

may be harmful.

Rinse thoroughly to

remove any residue.

13) Place empty container back under coffee outlet.

14) Descale again: press any coffee

button

and wait until water tank is empty.

15) Empty container and put it back under

coffee outlet.

16) Rinse and clean water tank thoroughly

and fill it with fresh potable water.

13

14

16

15

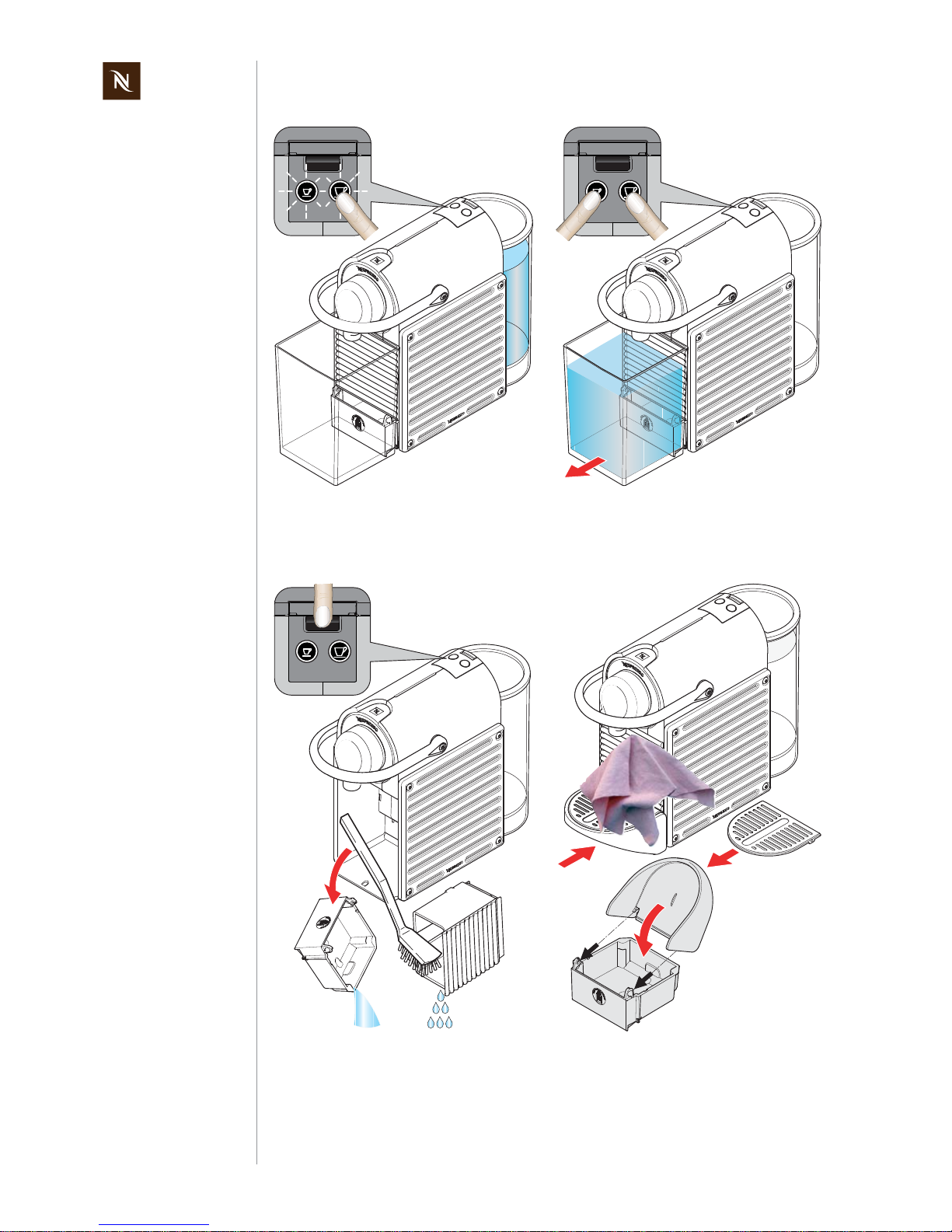

Page 24

Pixie service manual

24

MAINTENANCE

17) Rinse coffee machine by pressing any

coffee button and wait until water tank

is empty.

18) Press both coffee buttons simultaneously for at least 1 sec to end descaling mode.

19) Remove and empty container.

20) Switch off coffee machine.

21) Empty and clean capsule and waste

water container.

22) Clip cup support on waste water container.

23) Clean coffee machine with a damp

cloth if necessary.

17

18

1 sec

19

21

20

22

23

Page 25

Pixie service manual

25

MAINTENANCE

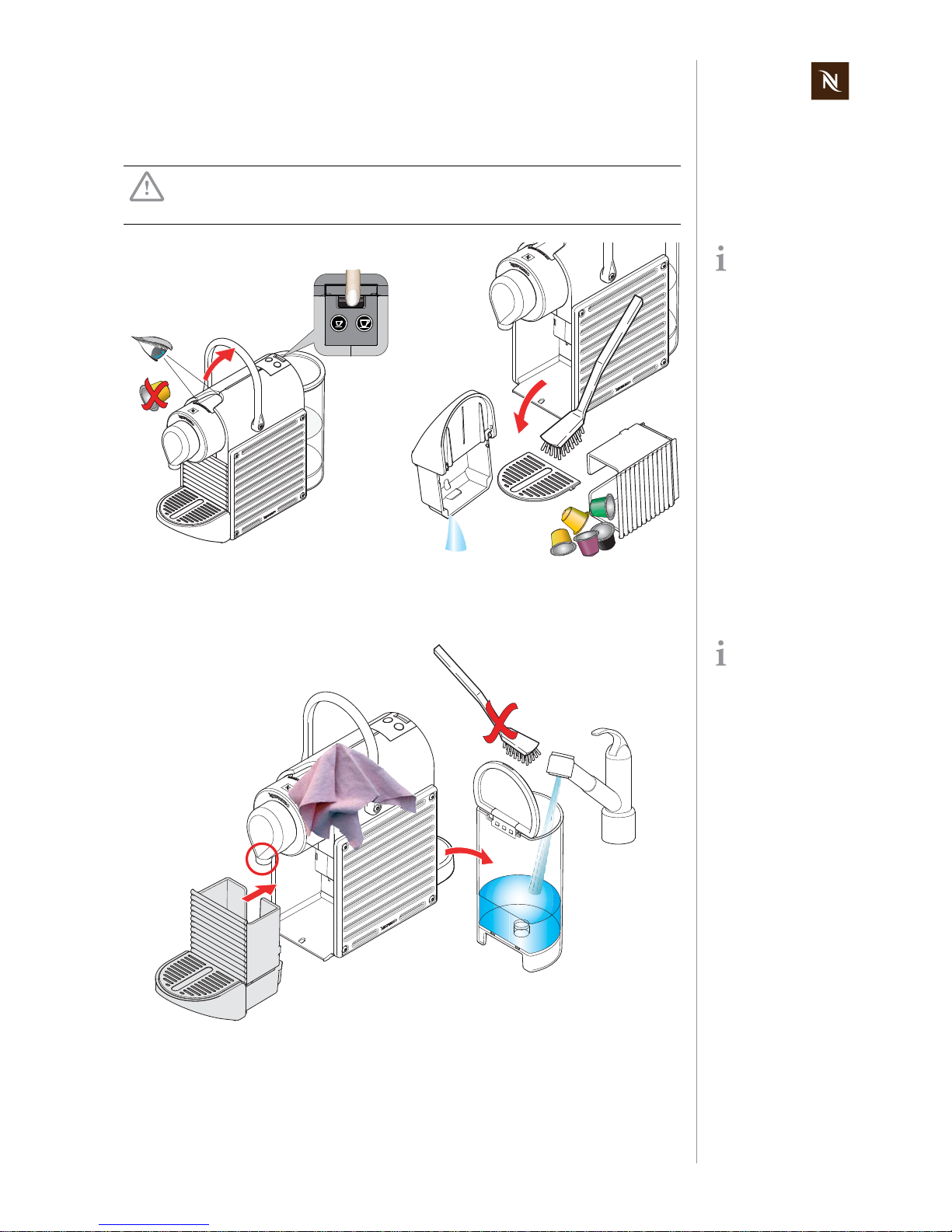

5.2 Cleaning procedure

Risk of fatal electrical shock and fire!

Never clean wet or immerse plug, cord or appliance in any fluid.

Unplug appliance and let it cool down to avoid burns.

Never use brushes

and/or cleaning

agents that contain

aggressive or chemical

components resp. solvents.

Do not put any part in a

dishwasher.

Use only a damp cloth or

sponge and a mild cleaning

agent if necessary

1) Switch machine off.

2) Check if capsule is ejected.

3) Empty and clean

- capsule container (a)

- waste water container (b) with

- cup support (c) and drip grid (d).

2

1

OFF

3

a

b

c

d

Do not use a brush -

the water tank can be

scratched.

4) Empty, rinse and clean water tank.

5) Reassemble coffee machine.

6) Clean coffee outlet with a damp cloth.

7) Clean coffee machine with a damp

cloth if necessary.

5

4

6

7

Page 26

Pixie service manual

26

TROUBLESHOOTING

6 TROUBLESHOOTING

6.1 Check list

After an initial inspection in accordance

with this check list,

errors are quickly found and

corrected with the appropriate measure.

Therefore, adhere to the

sequence of the check list.

Repair every occurring error

and work the check list

through until it is completed.

Check Error symptoms

Measure /

repair work

Further measures /

repair work

1 Check the coffee

machine for visible damage

1.1 Housing parts broken or damaged

YES - replace housing parts if

necessary

NO - continue

1.2 Power cord damaged

YES - replace power cord

NO - connect power cord of

machine to the mains and continue

2 Check mechani-

cal components

2.1 Cup support with

capsule and waste

water container

does not remain in

fitting position

YES - check if waste water

container has its metallic plate

for magnetic mounting

NO - continue

NO - replace waste water container.

2.2 Cup support rattles

when folded down

or during operation

YES - check if 2 rubber stoppers are mounted on waste

water container

NO - continue

NO - replace stoppers

2.3 Closing handle

malfunction

YES - it is very difficult or

almost impossible to close the

handle and to press it all the

way down

NO - continue

YES - replace brewing unit

2.4 Capsule is not

ejected correctly

YES - replace brewing unit

NO - continue

3 Fill water tank 3.1 Water tank leaks

YES - replace water tank

NO - continue

4 Activate On/Off

switch to perform

automatic self test

4.1 Coffee machine is

not working

(does not function)

a) YES - power cord is okay

(loose connection)

YES - continue

NO - replace power cord

b) YES - On/Off switch has typical switching noise

YES - continue

NO - replace functional block

c) YES - pump works (press a

coffee button)

YES - continue with point e)

NO - continue with point d)

d) YES - both coffee buttons

are working

YES - replace pump

NO - replace functional block

e) YES - fine wire fuses or triac

on thermoblock defective

YES - replace thermoblock

NO - continue

f) YES - wiring is okay

NO - continue with point 4.2

YES - replace functional block

NO - replace defective cables

4.2 Both coffee buttons

are blinking 3x fast

YES - thermoblock is hot

NO - self test ok - continue

YES - switch off/on coffee

machine and check again

NO - replace thermoblock or

functional block

Page 27

Pixie service manual

27

TROUBLESHOOTING

5 Rinse coffee

machine

5.1 No water at coffee

outlet

YES - a) water system is empty

YES - open the closing handle

and press a coffee button several times to fill the water system

NO - continue

YES - b) coffee machine is calcified

NO - continue

YES - descale coffee machine

(see page 21)

YES - c) pyramide plate

blocked

YES - replace brewing unit

NO - continue

YES - d) flow meter blocked YES - clean or replace flow

meter

NO - continue

YES - e) pump cannot produce

sufficient water pressure

YES - replace pump

NO - continue

6 Measure coffee

temperature during coffee preparation (see page

72)

6.1 Temperature is too

low (below 83°C)

YES - descale coffee machine

(see page 21)

NO - continue

6.2 Temperature too

high (over 89 °C)

YES - replace thermoblock

NO - continue

7 Check for leakage

(see page 69) and

measure flow rate

(see page 68)

7.1 Hose connections

leak

YES - replace sound damper

NO - continue

7.2 Brewing unit leaks YES - replace brewing unit

NO - continue

7.3 Rate of flow not

within standard

range (60-120ml in

30 sec)

YES - coffee machine is calcified

NO - continue with point 9

YES - descale coffee machine

(see page 21)

NO - replace pump

8

Descale coffee

machine

(if necessary)

8.1 Coffee machine is

calcified

YES - descale coffee machine

(see page 21)

NO - continue with point 9

9 Check water tank

contents after descaling and rinising

9.1 Particles of calcium

and rust visible in

water

YES - descale and rinse coffee

machine again to clean water

circuit

(see page 21)

NO - continue

YES - inform customer to descale coffee machine periodically and to use the specified

descaling product only.

10 Final cleaning

(see page 25)

No errors found according to

check list?

YES - for more information

please contact Nespresso

Service Division

End of check list

Check Error symptoms

Measure /

repair work

Further measures /

repair work

Page 28

Pixie service manual

28

REPAIRS

7 REPAIRS

These repair instructions

- are based on exploded drawings with position numbers combined with repair and

mounting tips,

- presuppose basic knowledge in repairing Nespresso coffee machines.

7.1 Safety instructions

7.2 Repair and mounting tips

These general advices are completed with specific repair tips in this chapter.

Additional information

For components not mentioned in this repair chapter, refer to the chapters "Explosion

Drawings" on page 79 and "Parts List" on page 81.

Snap connections

Parts of the case and components of the coffee machine are connected screwless with

latches.

When loosening these latches, proceed with care and patience to avoid

causing any damage.

Screw connections

Do not overtighten screws of side panels. Plastic threads and inserts are delicate.

Observe max. torque for the screw connections according to the following table:

Risk of fatal electrical shock!

Mains voltage inside the coffee machine.

Disconnect the mains plug before disassembly - the coffee machine

must be free of voltage.

Danger of burns!

Hot parts and water under pressure inside the coffee machine (thermoblock in particular).

Let coffee machine cool down before disassembly.

Page 29

Pixie service manual

29

REPAIRS

Designation of spare parts

The components in the following illustrations are indexed with position numbers.

See separate spare parts list for corresponding spare part numbers.

Electrostatic discharge (ESD) protection

The service technician must must observe basic ESD protection measures when

installing a new functional block.

Wiring arrangement

Random changes in the wiring arrangement of the wired model version during a repair

can cause

- electromagnetic interferences,

- squeezed wires,

- insulation defects due to contact with hot parts,

- insulation problems if low and high voltage wires are not separated,

- damage to the functional block.

Protective measures:

• Do not change the thermoblock wiring (thermo fuses and NTC sensor).

• Refer to wiring diagram when reconnecting cables and wires.

A dynamometric

screwdriver with suitable bits is recom-

mended.

Screw / screw connection Torque Position

TX 15 screw (8 x) /

side panel (2x)

50 - 80 Ncm

0.5 - 0.8 Nm

0.37 - 0.59 ft lb

TX 20 screw (2 x) /

closing handle

200 - 250 Ncm

2 - 2.5 Nm

1.48 - 1.84 ft lb

Page 30

Pixie service manual

30

REPAIRS

Residual water

• If it is necessary to pull off hoses, hold ready a small receptacle and a towel to collect

and wipe away leaking water.

• A special procedure is necessary to empty the fluid system of the coffee machine for

repair or shipment (refer to "Empty water system" on page 19).

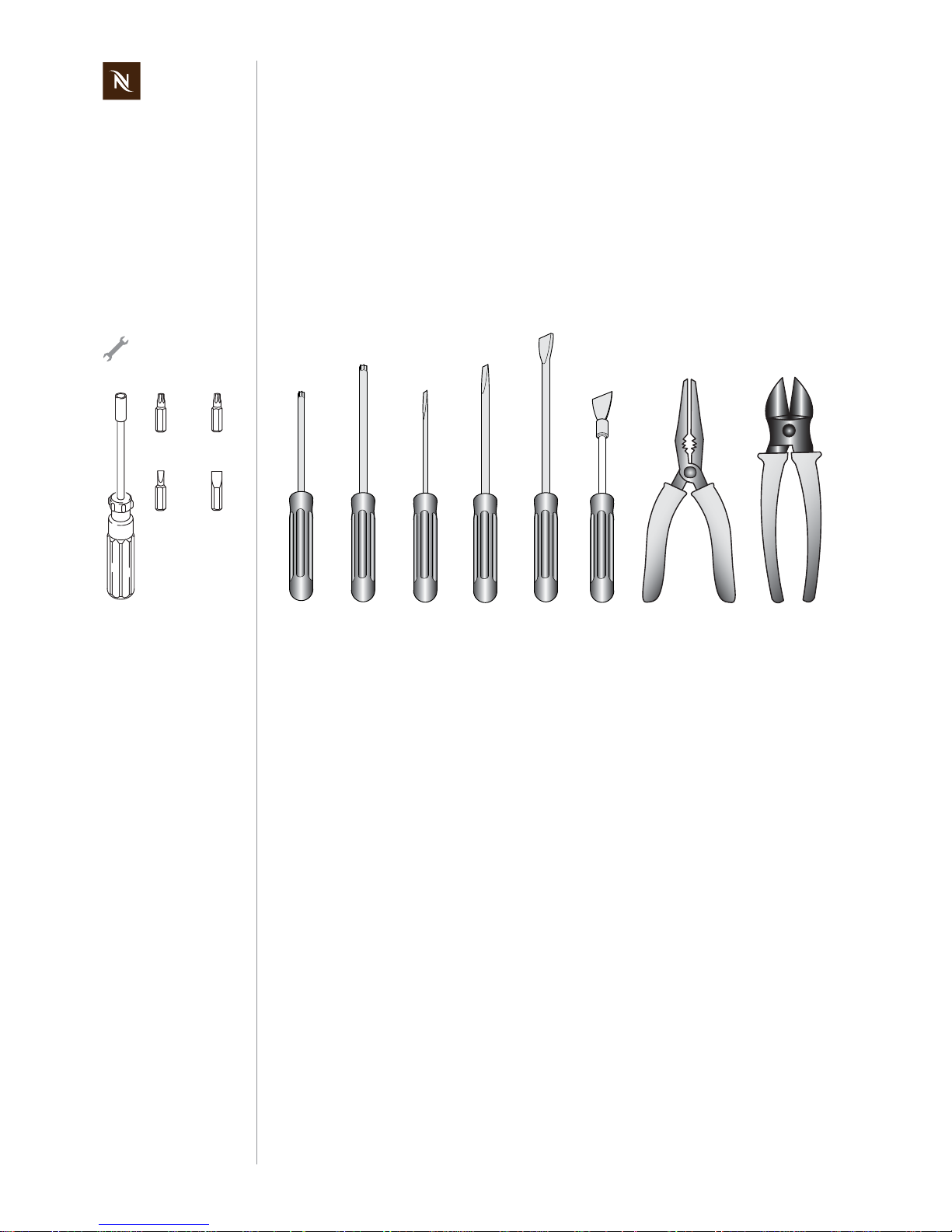

7.3 Tools and accessories

With the following assortment of tools, all repairs described can be made:

A bit holder with

appropriate bits can

also be used:

.

TX 15

TX 20

3.5 mm

8 mm

1) Torx screwdriver TX 15 / TX 20

2) Flat blade screwdrivers:

size blade width

00 2 mm

01 3,5 mm

05 8 mm

3) Disassembly tool (for housing parts,

EFR no. 0060611)

4) Pointed pliers

5) Side cutting pliers

6) Receptacle and towel to catch and

wipe away leaking water

1

2

3

TX 15

TX 20

3.5 mm

8 mm

4

2 mm

5

Page 31

Pixie service manual

31

REPAIRS

7.4 General disassembly

This subchapter shows

- how to replace the power cord,

- all necessary disassembly steps to gain access to the main assembly (brewing unit,

thermoblock, hydraulic unit and functional block.

7.4.1 Prepare coffee machine for disassembly

• Open closing handle to check if a capsule is in the brewing unit.

• Empty water system if hoses have to be detached for repair (see “Empty water

system” on page 19).

• Switch machine off.

• Disconnect power plug (40) and let coffee machine cool down.

• Remove all detachable parts from coffee machine

- waste water container (11) with cup support (12) and drip grid (13)

- capsule container (10)

- water tank with cover (5).

OFF

10

12

11

13

5

40

Page 32

Pixie service manual

32

REPAIRS

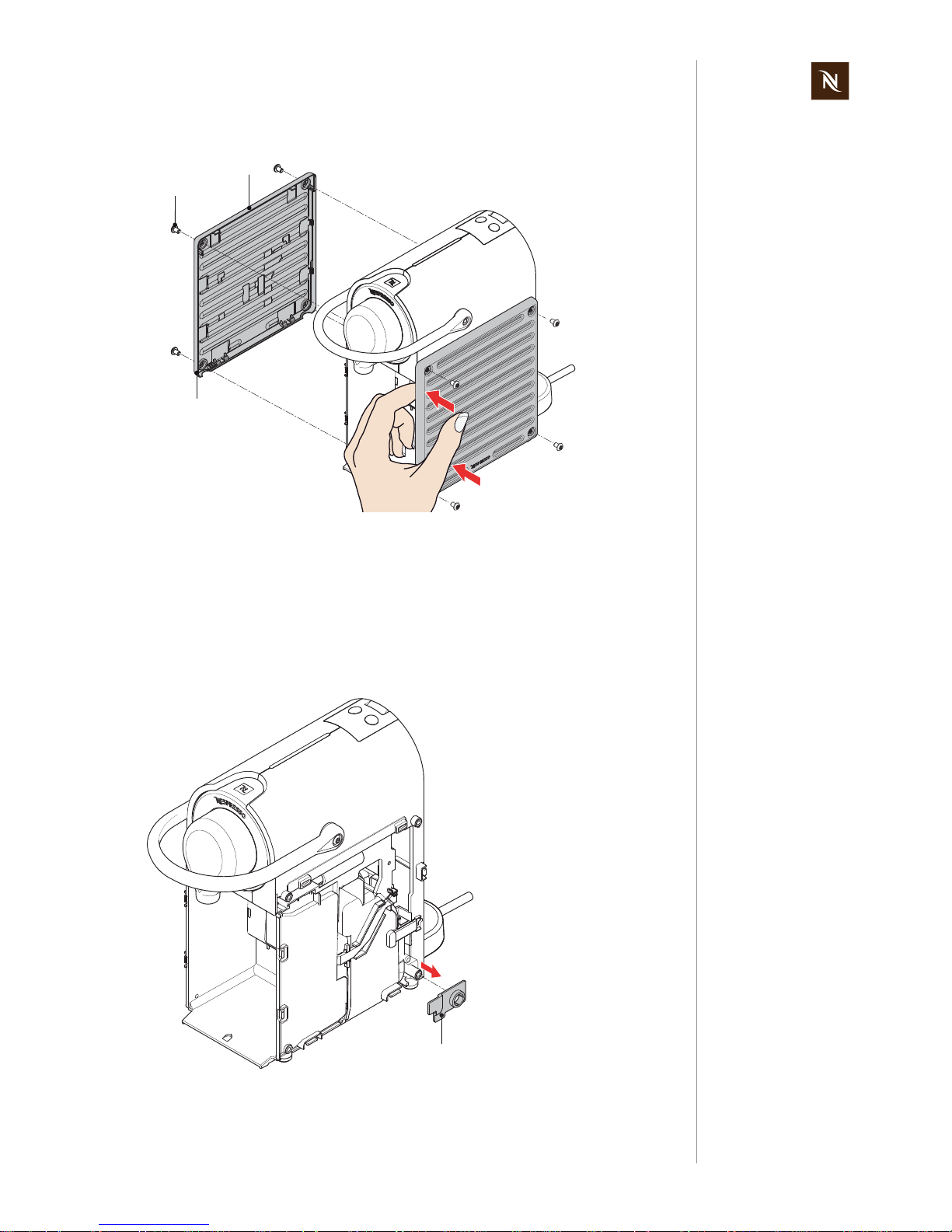

7.4.2 Remove side panels

• Loosen 4 screws (42, torx head TX 15) at each side panel (3).

• Use a screwdriver to release the latches at each side panel (3).

Start by inserting the srewdriver in the 2 semicircular cutouts at the bottom of a side

panel.

• After releasing the 2 latches at the bottom, swing up and remove side panel.

For replacing the

power cord, remove

right side panel only.

42

3

3

Take care not to

scratch the alumin-

ium surface and keep

the side panels at a safe

place.

3

3

Page 33

Pixie service manual

33

REPAIRS

Assembly checkpoints

• Both side panels (3) are identical and interchangeable.

• Position and press down side panel on housing of coffee machine.

• Press down leading edge (see arrows) of side panel additionally till a clicking noise

can be heard.

• Do not overtighten screws (42).

7.4.3 Remove power cord

• Remove cable protection (44).

3

3

42

44

Page 34

Pixie service manual

34

REPAIRS

• Unlatch strain relief clamp (39) with a 2 mm flat blade screwdriver.

• Disconnect ground wire (green/yellow) from thermoblock with pointed pliers.

• Lever out both insulated faston receptacles from electronic control board with a

screwdriver.

• Before removing the power cord (40), check if excessive cable length is retained in

right housing.

39

The strain relief

clamp is under ten-

sion. Therefore, hold

down the strain relief clamp

with your finger when

unlatching it.

40

Page 35

Pixie service manual

35

REPAIRS

Assembly checkpoints

• Only use the original spare part for replacing the country-specific power cord.

• Adjust power cord lenght to customer’s demand.

• Connect the insulated faston receptacles of neutral (N) and live (L) power cord wires

like shown above.

7.4.4 Remove water guiding

• Open brewing unit with closing handle (9).

• At first push up water guiding (8) and simultaneously pull out latch at the bottom with

the help of a screwdriver.

• Then push down again and remove water guiding (see detail).

Live (L)

Neutral (N)

Protective Earth

9

8

Page 36

Pixie service manual

36

REPAIRS

7.4.5 Remove damper springs

The brewing unit must be opened.

• Unhook both damper springs (19) with a screwdriver.

Assembly hint

• Attach damper spring (19) at hook on brewing unit housing.

• With the help of a small screwdriver attach the free eyelet of the spring to the

housing part.

19

19

The damper springs

are under tension.

Therefore, hold a

hand above for protection

when unhooking them.

19

Page 37

Pixie service manual

37

REPAIRS

7.4.6 Remove closing handle

• Close brewing unit.

• Hold closing handle (9) in one hand while loosening both screws (41, torx head

TX 20)

• Pull off closing handle from lever arms.

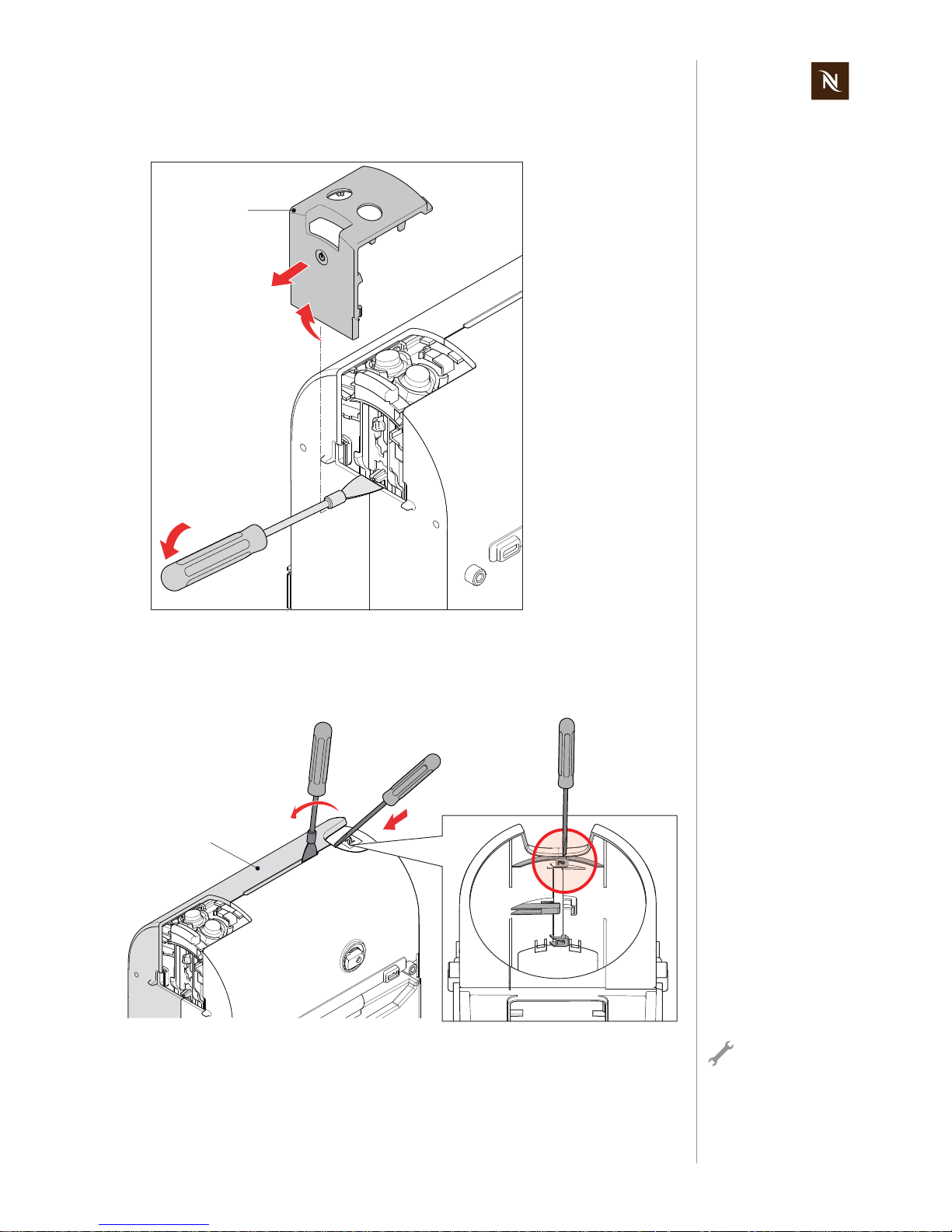

7.4.7 Remove cable cover

• Open 2 latches one after another with disassembly tool.

• Lift cable cover (6) and release remaining 2 latches at the front with a screwdriver if

necessary.

41

9

Take care, that both

lever arms stay in

horizontal position.

Otherwise, disassembling

of housing right is impossible.

Bottom view

6

Latches will break if

not unlocked very

carefully!

Page 38

Pixie service manual

38

REPAIRS

Assembly checkpoints

• Never re-use a damaged cable cover (6) with broken latches.

• Make sure that new cable cover is suitable for the cable diameter of the used power

cord.

7.4.8 Remove right light guide

• Release latch with screwdriver carefully.

• Swing up light guide (35) and remove it out of support.

Assembly checkpoint

• Handle fragile light guide carefully.

This step is necessary for the easy

removal of the right

housing part.

35

Page 39

Pixie service manual

39

REPAIRS

7.4.9 Remove blind

• Open latches with screwdriver and remove blind (7).

7.4.10 Remove housing right

• Position disassembly tool in gap at the front of housing right (2).

• Push down latch with a small screw driver.

• Then turn disassembly tool a bit to unlock the latch.

7

2

Latch will break if not

handled carefully!

Page 40

Pixie service manual

40

REPAIRS

• Position disassembly tool in gap at the rear of housing right (2).

• Push down latch with a small screw driver.

• Then turn disassembly tool a bit to unlock the latch.

• Open latch with screwdriver.

2

Latch will break if not

handled carefully!

Take care not to snap

the latches again by

accident, e.g. by

putting an object into the

gap.

Page 41

Pixie service manual

41

REPAIRS

• Open latch with screwdriver.

• Open latch with screwdriver.

Page 42

Pixie service manual

42

REPAIRS

• Press small screwdriver in opening. Lift housing right (2) simultaneously to release

latch.

• Press in screwdriver to open latch. Lift housing right (2) simultaneously to release

latch.

Detail view is from

above, showing the

latch position inside

of housing.

2

Upper detail view is

through opening into

empty housing.

2

Page 43

Pixie service manual

43

REPAIRS

• Push housings apart forcefully.

• If necessary, use disassembly tool to open remaining latches.

Assembly checkpoint

• Check if housing plate is mounted on housing left (1) before attaching housing right.

Detail view is through

rear opening from

above, showing

remaining closed latches.

1

Page 44

Pixie service manual

44

REPAIRS

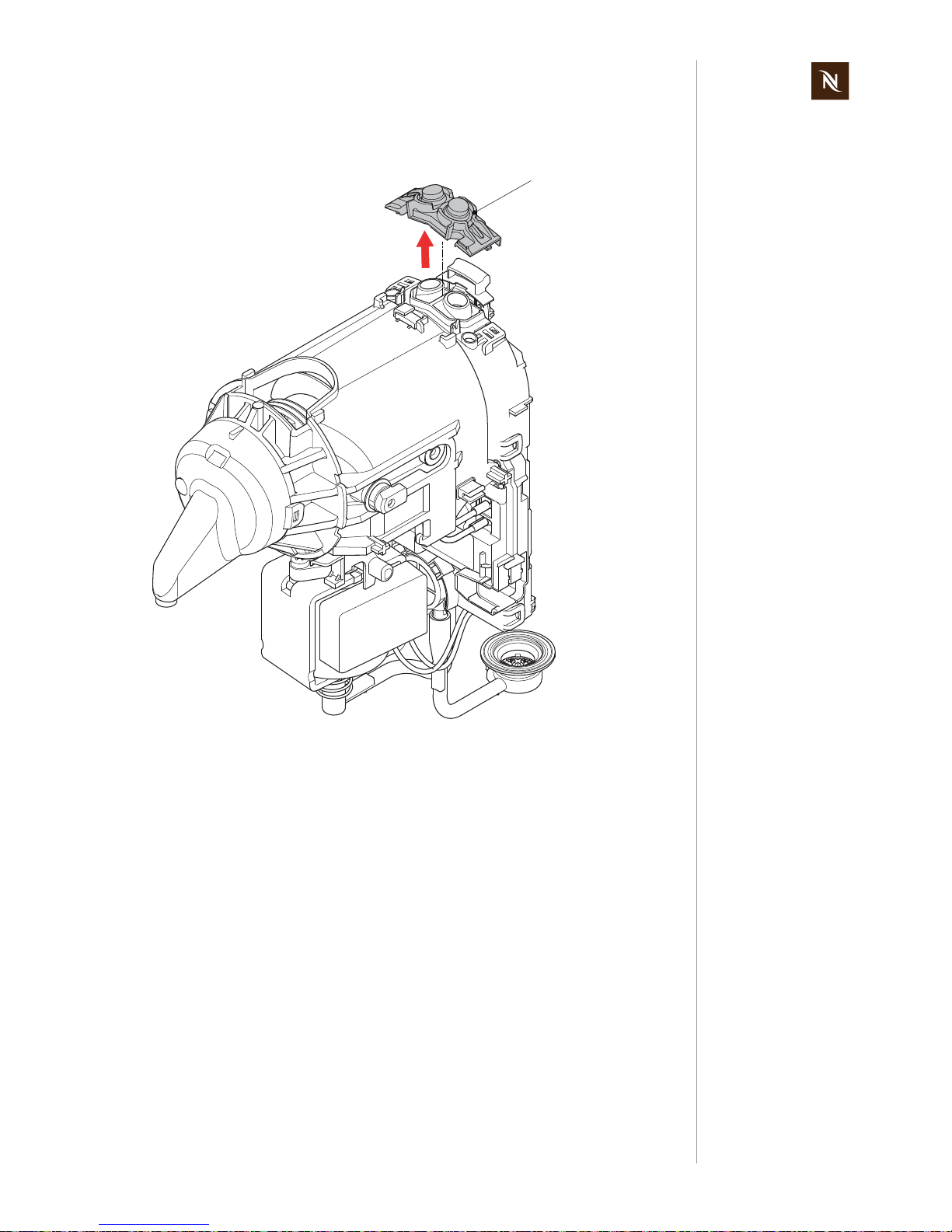

7.4.11 Remove main assembly

• Remove housing plate from top of housing left (1).

The housing plate and a little magnet on the housing of the brewing unit lock the brewing

unit in the open position.

• Release latch of capsule cage with a small screwdriver and lift main assembly

slightly to open the latch.

1

Take care not to lose

this tiny part.

This latch does not

exist in new coffee

machines.

In case of a broken

latch it is not necessary to replace the

capsule cage.

Page 45

Pixie service manual

45

REPAIRS

• Pull water tank connector (33) out of support in housing left (1).

• Open latch with screwdriver and remove main assembly.

The main repair parts like brewing unit, thermoblock, pump and functional block are now

accessible.

33

1

Page 46

Pixie service manual

46

REPAIRS

7.4.12 Remove front ring

The front ring (15)

- is fixed on the brewing unit housing with 4 latches (2 at each side),

- has a detachable front cover (14).

• Press front ring (15) together at right side to release 2 latches.

• Simultaneously swivel front ring to the left to open these latches.

• Repeat same procedure at the left side and remove front ring.

14

15

A screwdriver can be

used instead..

Page 47

Pixie service manual

47

REPAIRS

7.4.13 Remove key caps of push buttons

• Remove key caps of push buttons (26) from main assembly.

Assembly checkpoints and hints

• Make sure that water tank connector (33) fits exactly in support of housing left.

• Press filter element down to bottom of water tank connector.

• Assemble spring (28) on pump support of housing left correctly.

26

Page 48

Pixie service manual

48

REPAIRS

7.5 Replacing pump

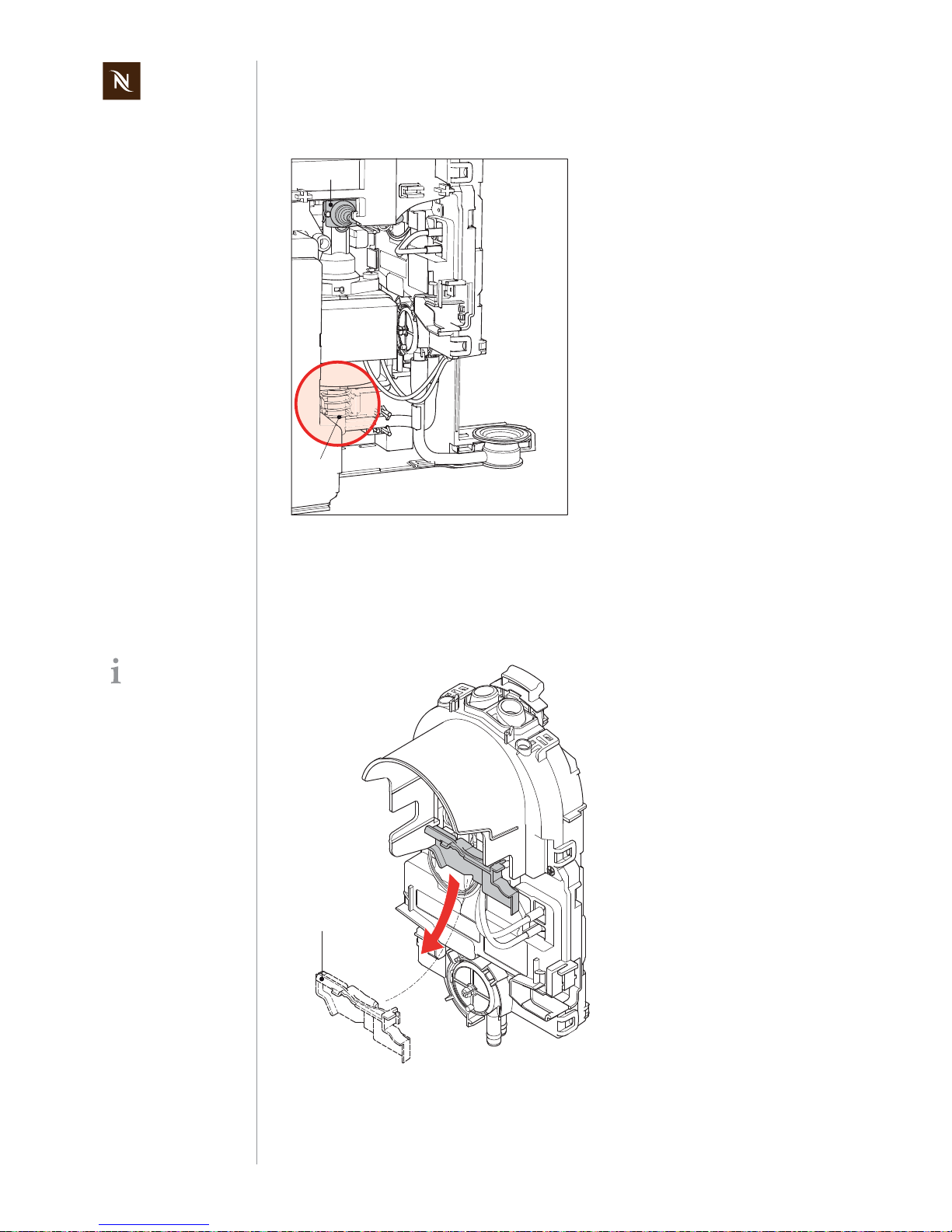

• Remove pump isolation (30) from pump (27).

• Disconnect cables from pump terminal.

30

27

Use pointed pliers or

a screwdriver to

remove receptacles.

Page 49

Pixie service manual

49

REPAIRS

• Remove low pressure hose (32)and pump support spring (28).

• Remove sound damper (29) from pump (27) and thermoblock (22) by cutting

connector clips (43) with side cutting pliers.

32

28

29

43

27

Page 50

Pixie service manual

50

REPAIRS

Assembly checkpoints

• Assemble spring (28) on pump support correctly.

• Sound damper (29) and connector clips (43) must always be replaced to prevent

leakage.

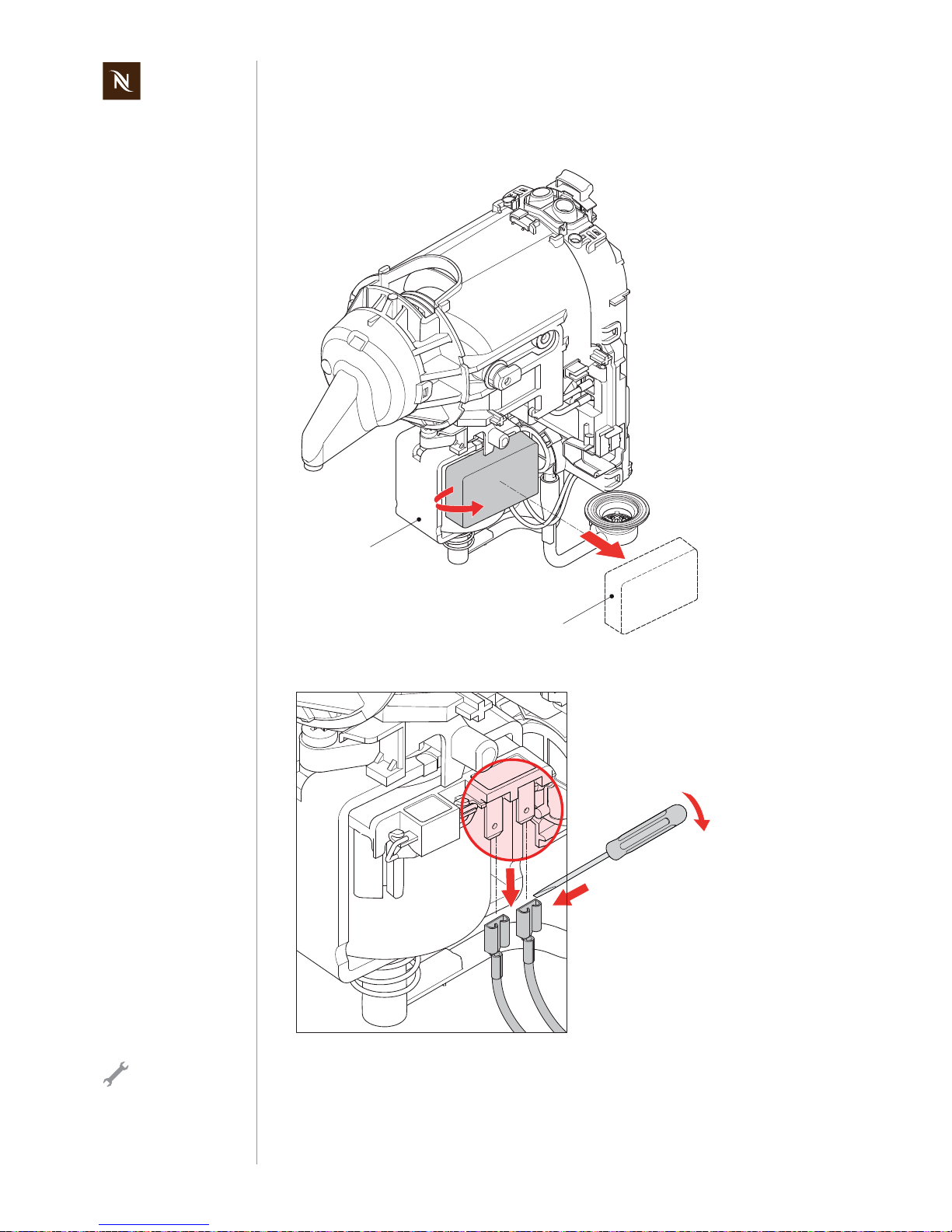

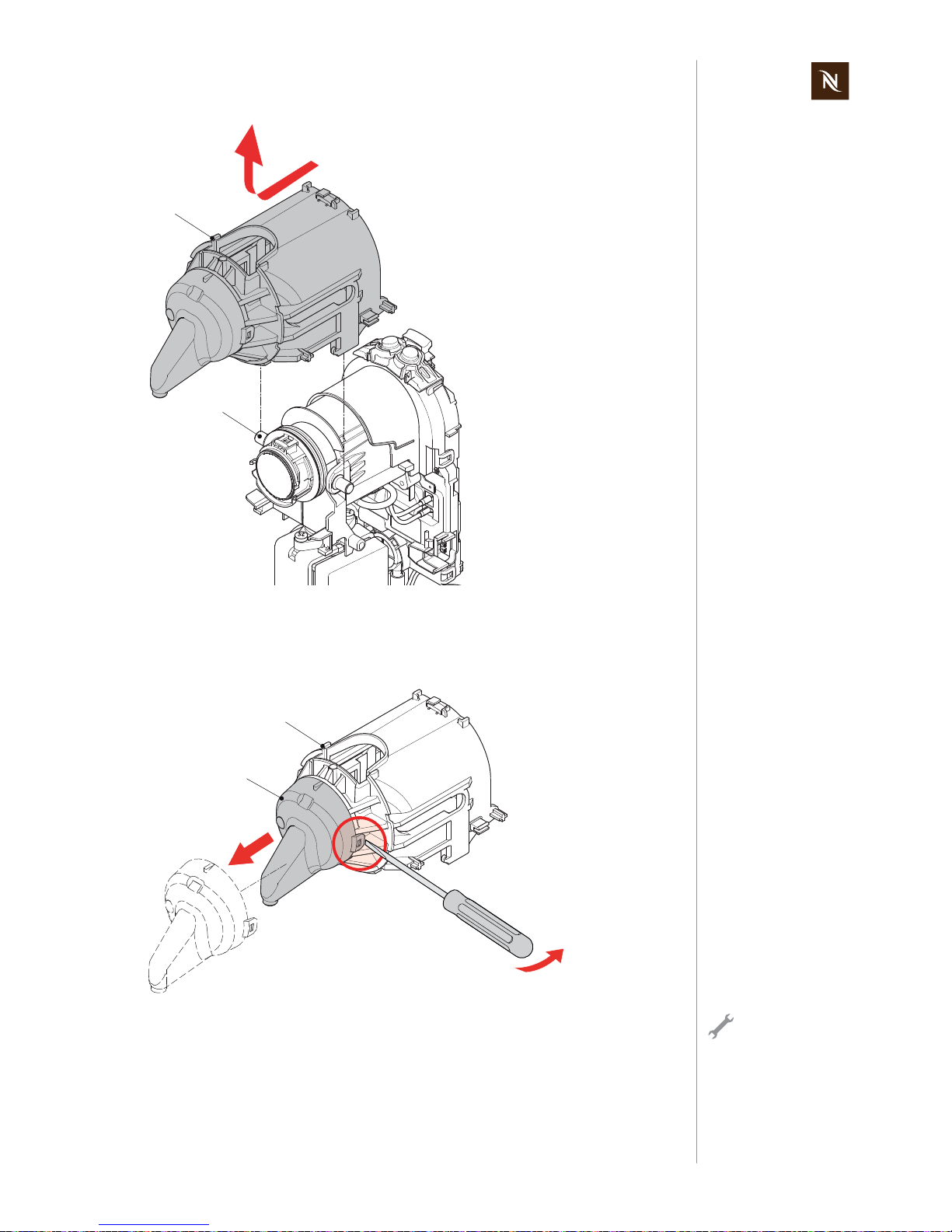

7.6 Replacing functional block

• Remove function block cap (25).

29+43

28

Brewing unit not

shown for better visibility of function block

cap (25).

25

Page 51

Pixie service manual

51

REPAIRS

• Unplug NTC connector and 2 receptacles from thermoblock with pointed pliers.

• Remove brewing unit (22) from functional block (24).

Brewing unit not

shown for better visibility of NTC connec-

tor.

24

22

Page 52

Pixie service manual

52

REPAIRS

Assembly checkpoint

• Connect the 2 receptacles like shown.

7.7 Replacing brewing unit

• To remove lever arms (18), press brewing unit housing (17) down against functional

block (24).

Wrong connection

will damage func-

tional block.

18

24

17

Page 53

Pixie service manual

53

REPAIRS

• Pull away brewing unit housing (17) from thermoblock (22) up to the stop.

• Lift housing from thermoblock at right angels to release axle stubs from guiding

grooves.

• Remove steam cover (16) from brewing unit housing (17).

17

22

17

16

Handle latches carefully.

Page 54

Pixie service manual

54

REPAIRS

• Remove function block cap (25).

• Unplug NTC connector and 2 receptacles from thermoblock with pointed pliers.

Thermoblock not

shown for better visibility of function block

cap (25).

25

Thermoblock not

shown for better visibility of NTC connec-

tor.

Page 55

Pixie service manual

55

REPAIRS

.

• Remove thermoblock (21) from functional block (24).

21

24

Page 56

Pixie service manual

56

REPAIRS

Assembly checkpoints and hints

• Check that magnet is mounted on brewing unit housing (17).

• Connect the 2 faston receptacles like shown.

17

Wrong connection

will damage func-

tional block.

Page 57

Pixie service manual

57

REPAIRS

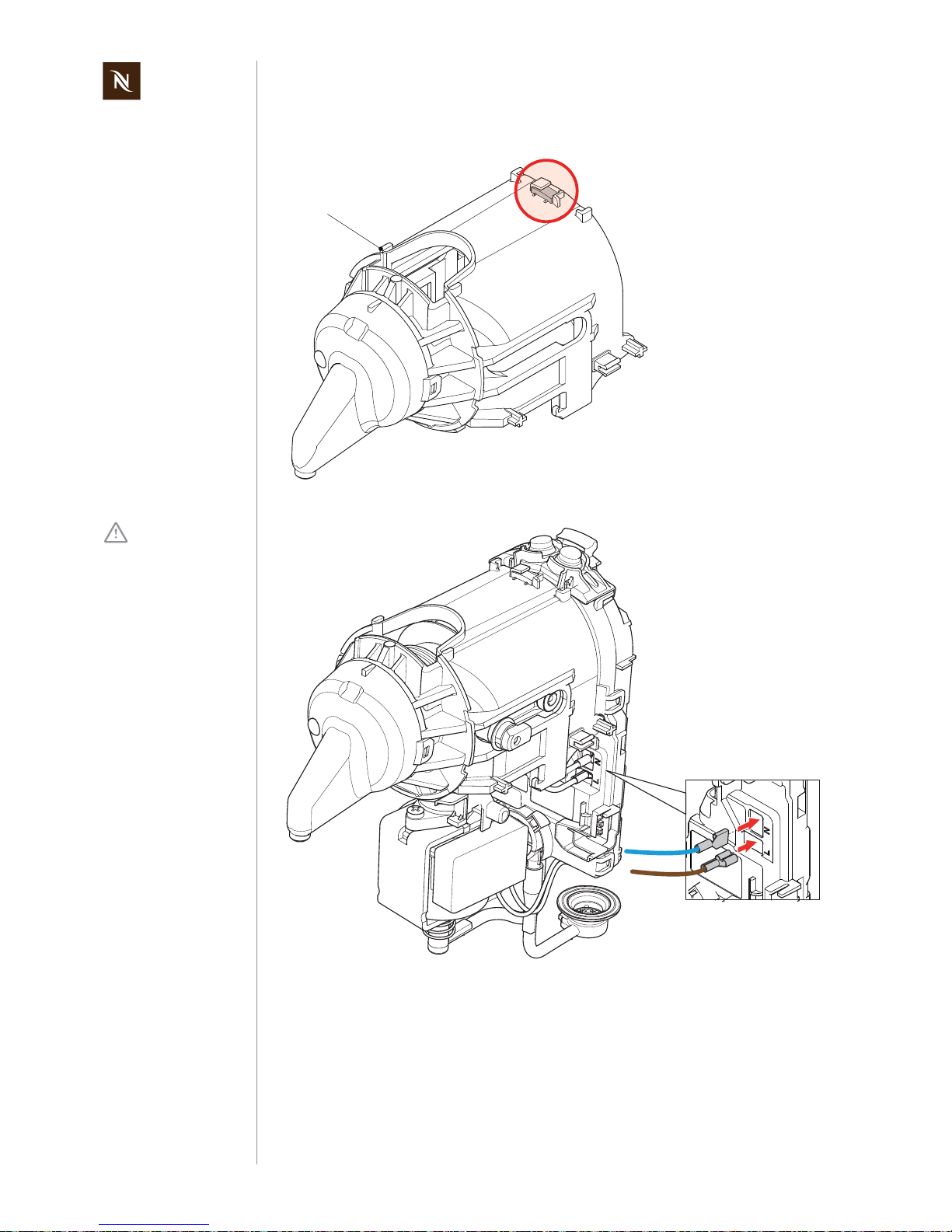

7.8 Replacing flow meter

• Remove hoses from flow meter (31).

• Insert screw driver in openings at the rear side of functional block (24, see detail).

• Unlatch and remove flow meter (31) from electronic main board.

Only functional block

is shown for better

visibility of hose con-

nections.

31

31

24

Page 58

Pixie service manual

58

REPAIRS

Assembly hints

• Always replace a removed flow meter (31) with a new one.

• Check correct mounting position of the hoses (32 and 33) on the flow meter (31).

By removing the flow

meter from the electronic main board its

latches get damaged.

31

32

33

Page 59

Pixie service manual

59

REPAIRS

7.9 Wiring diagrams

7.9.1 Wiring diagram 220 V - 240 V IEC

Depending on

national regulations,

one or two fine wire

fuses are mounted on the

thermoblock.

Small cup

On/Off Switch

Receptacle isolation

Big cup

Flow Meter

Main PCB

MMI PCB

Triac PCB

167°C

167°C

Thermoblock

Neutral

Line

Pump

EN4 220-240V

Overheat

protection

NTC

Triac

Page 60

Pixie service manual

60

REPAIRS

7.9.2 Wiring diagram 120 V UL (USA / Canada)

Small cup

On/Off Switch

Big cup

Flow Meter

Main PCB

MMI PCB

Triac PCB

167°C

Thermoblock

Neutral

Line

Pump

EN4 120-127V UL

Overheat

protection

Receptacle isolation

NTC

Triac

Page 61

Pixie service manual

61

REPAIRS

7.9.3 Wiring diagram 127 V IEC (Brazil)

Small cup

On/Off Switch

Receptacle isolation

Big cup

Flow Meter

Main PCB

MMI PCB

Triac PCB

167°C

167°C

Thermoblock

Neutral

Line

Pump

EN4 120-127V IEC

Overheat

protection

NTC

Triac

Page 62

Pixie service manual

62

REPAIRS

7.9.4 Wiring diagram 127 V IEC (Mexico)

Small cup

On/Off Switch

Receptacle isolation

Big cup

Flow Meter

Main PCB

MMI PCB

Triac PCB

167°C

167°C

Thermoblock

Neutral

Line

Pump

EN4 120-127V IEC

Overheat

protection

NTC

Triac

Page 63

Pixie service manual

63

REPAIRS

7.9.5 Wiring diagram 100 V IEC (Japan)

Small cup

On/Off Switch

Big cup

Flow Meter

Main PCB

MMI PCB

Triac PCB

167°C

Thermoblock

Neutral

Line

Pump

EN4 100-110V

Overheat

protection

167°C

Receptacle isolation

Page 64

Pixie service manual

64

REPAIRS

7.9.6 Wiring diagram 110 V IEC (Taiwan)

Small cup

On/Off Switch

Receptacle isolation

Big cup

Flow Meter

Main PCB

MMI PCB

Triac PCB

167°C

167°C

Thermoblock

Neutral

Line

Pump

EN4 100-110V

Overheat

protection

NTC

Triac

Page 65

Pixie service manual

65

FUNCTION TESTS

8 FUNCTION TESTS

8.1 Safety instructions

Some function tests are performed with an energized, partly opened coffee machine.

8.2 Required equipment

8.2.1 Overview

Danger of electrocution!

Mains voltage inside the coffee machine.

Do not touch any live part while performing tests.

Danger of burns!

Hot parts and water under pressure inside the coffee machine.

Do not touch any hot parts while checking for leakages!

Always wear protective goggles.

Symbolic illustration

of function test equip-

ment.

1) Pressure gauge (EFR no. 42213)

2) Pixie pressure gauge adapter

(EFR no. 66106), spare part seal

(EFR no. 64373)

3) Flashlight

4) Electronic thermometer

5) Timer

6) Measuring cup

7) Test equipment for protective earth continuity test and protective insulation test

T2

T1

RANGE

-200°C - 1370°C

-328°F - 2498°F

1

REL

HOLD

T1 T2

T1

←

T2

°C/°F

MAX MIN

1

2

5

4

6

3

7

MEASURE

LOCK/STOP

COMP

LIGHT

0Ω ADJ

Page 66

Pixie service manual

66

FUNCTION TESTS

8.2.2 Pressure gauge adapter

This pressure gauge adapter is designed for the Pixie coffee machine.

The pressure gauge adapter has 2 parts:

• A hand actuated lifting unit (1) to lock and seal the complete pressure gauge adapter

in the brewing unit.

• A seal carrier assembly (2) with a sealing cone that is inserted in the capsule cage

of the brewing unit.

1) Lifting unit

2) Seal carrier assembly

3) Operating lever

4) Fixation element

5) Quick action coupling for pressure

hose

6) Sealing cone

5

3

4

6

12

Page 67

Pixie service manual

67

FUNCTION TESTS

8.2.3 Mounting pressure gauge adapter

View into feed opening for capsule.

1) Open closing handle.

2) Insert seal carrier assembly.

3) Turn seal carrier assembly towards

capsule cage.

4) Align seal carrier to capsule cage. 5) Push back seal carrier assembly into

capsule cage.

6) Insert lifting unit. 7) Press down operating lever.

1

2

3

4

5

6

7

Page 68

Pixie service manual

68

FUNCTION TESTS

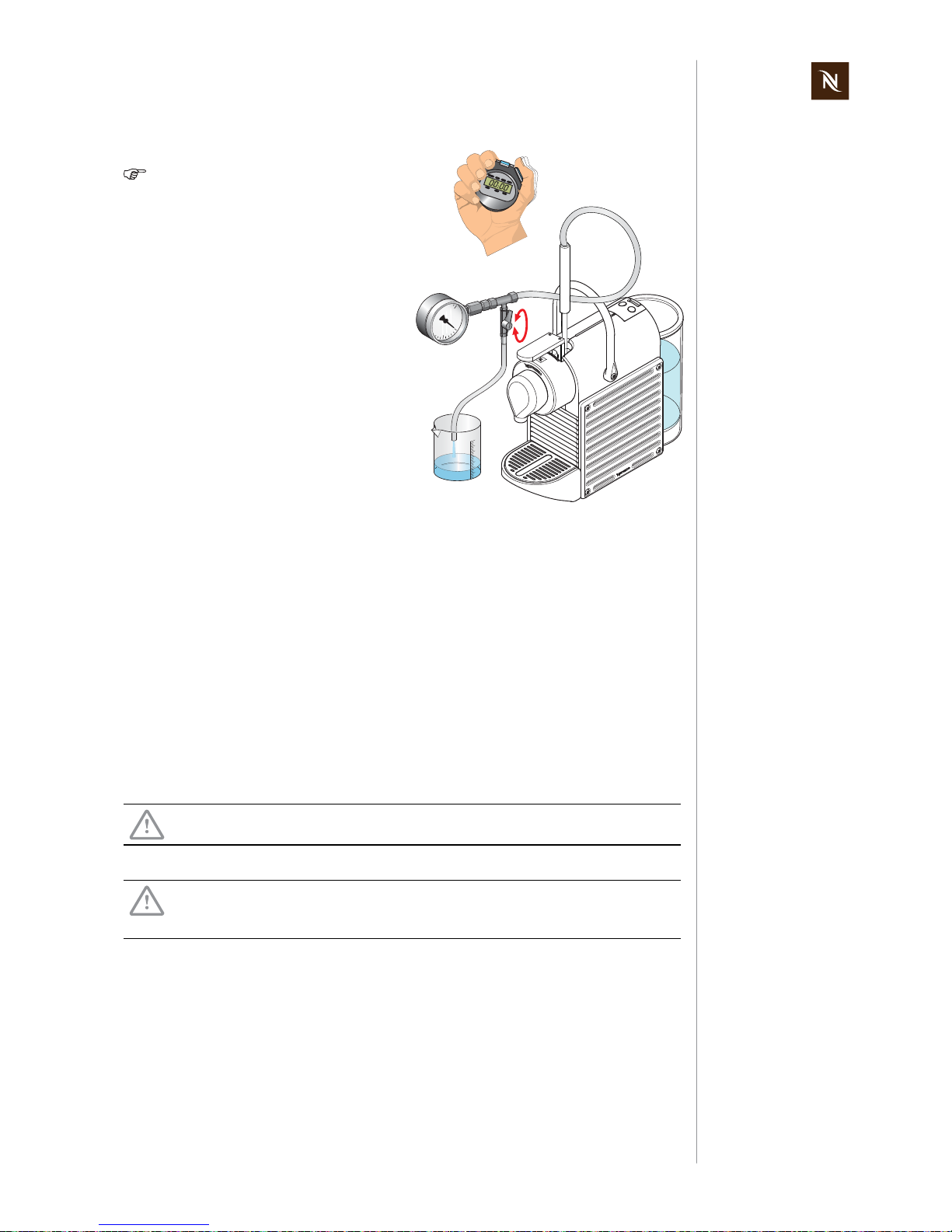

8.3 Measure flow rate

The pressure gauge

adapter must sit

firmly in the capsule

bay.

1) Fill and insert water tank.

2) Open closing handle.

3) Mount pressure gauge adapter (refer

to page 67).

4) Connect pressure hose to pressure

tester.

5) Place a measuring cup under the

drain hose of the pressure tester.

6) Switch on coffee machine.

7) After heating up, press the "large cup"

button.

8) Open the valve until water begins to

flow.

1

2

3

4

5

8

6

7

Page 69

Pixie service manual

69

FUNCTION TESTS

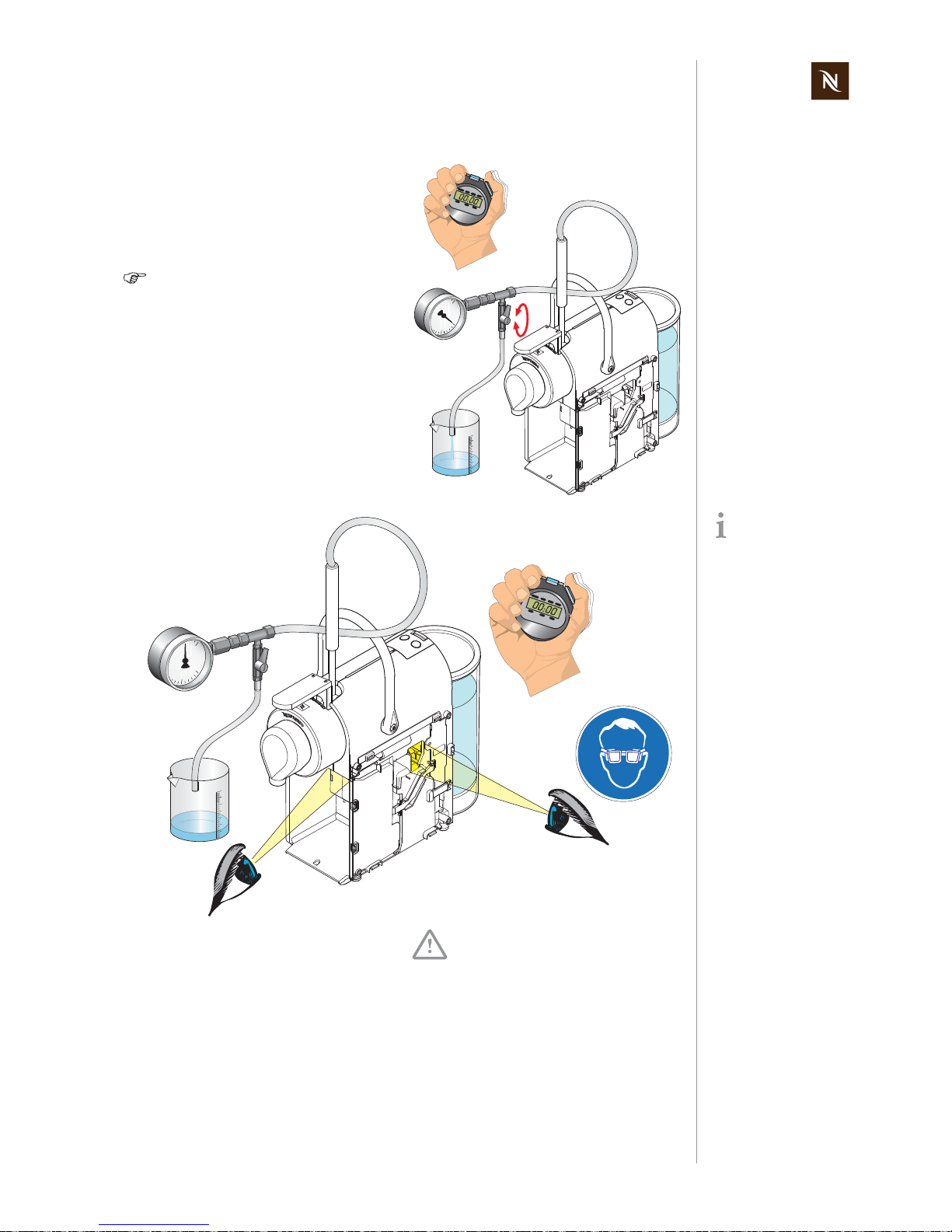

8.4 Pressure and leakage checks

Check the following parts of the coffee machine for leakages:

• Seal between movable part of brewing unit and capsule cage

• Connection between capsule cage and thermoblock (no visual check possible,

water will drop from thermoblock into housing)

• Both connections of sound damper

• Pump

9) Close the valve until the pressure

gauge indicates 12 bar.

Constantly monitor the pressure

gauge and if required readjust the

valve. As the temperature

increases, so does the pressure,

readjust the pressure to 12 bar

when required.

10) Carry out measurement for approx.

30 sec.

11) Control measuring cup: at least 60 120 ml of water must be in the measuring cup.

12) Open the valve and let water flow out

of the pressure tester.

Notices:

• Should < 60 ml leak out, then the pump

is defective or there is a leak in the

water system.

• Large deviations in indicated pressure

while measuring (± 4 bar) means that

the pump is defective.

Dangerous mains voltage inside the coffee machine!

Do not touch any parts under voltage while checking for leakages!

Dangerous hot parts under pressure inside the coffee machine!

Do not touch any hot/pressurized parts while checking for leakages!

Always wear protective goggles.

9 / 12

11

30 sec

> 60 ml

10

Page 70

Pixie service manual

70

FUNCTION TESTS

8.4.1 Preparations

1) Remove maintenace unit.

2) Remove right side panel (see “General

disassembly” on page 31).

3) Fill and insert water tank.

4) Open closing handle.

2

1

3

4

The pressure gauge

adapter must sit

firmly in the capsule

bay.

5) Mount pressure gauge adapter (refer

to page 67).

6) Connect pressure hose to pressure

tester.

7) Place a receptacle under the drain

hose of the pressure tester.

8) Connect mains cable.

9) Switch on coffee machine.

10) After heating up, press the "large cup"

button.

6

7

5

9

10

Page 71

Pixie service manual

71

FUNCTION TESTS

8.4.2 Test run

11) Open the valve and let the water flow

for approximately 10 sec out of the

drain hose.

12) Close the valve completely. The pressure stabilizes after increasing briefly

between 16-19 bar (pressure check).

The pressure increases slowly with

increasing temperature. Should the

pressure exceed 23 bar, switch off

the coffee machine and release the

pressure by opening the valve.

11/ 12

10 sec

For better visibility

use a flashlight.

13) Check connections under pressure for

audible and visible leaks

- through opening in right housing

- through opening for capsule ejection.

Do not run the pump for more

than 50 sec with the valve

closed.

13

max.

50 sec

13

Page 72

Pixie service manual

72

FUNCTION TESTS

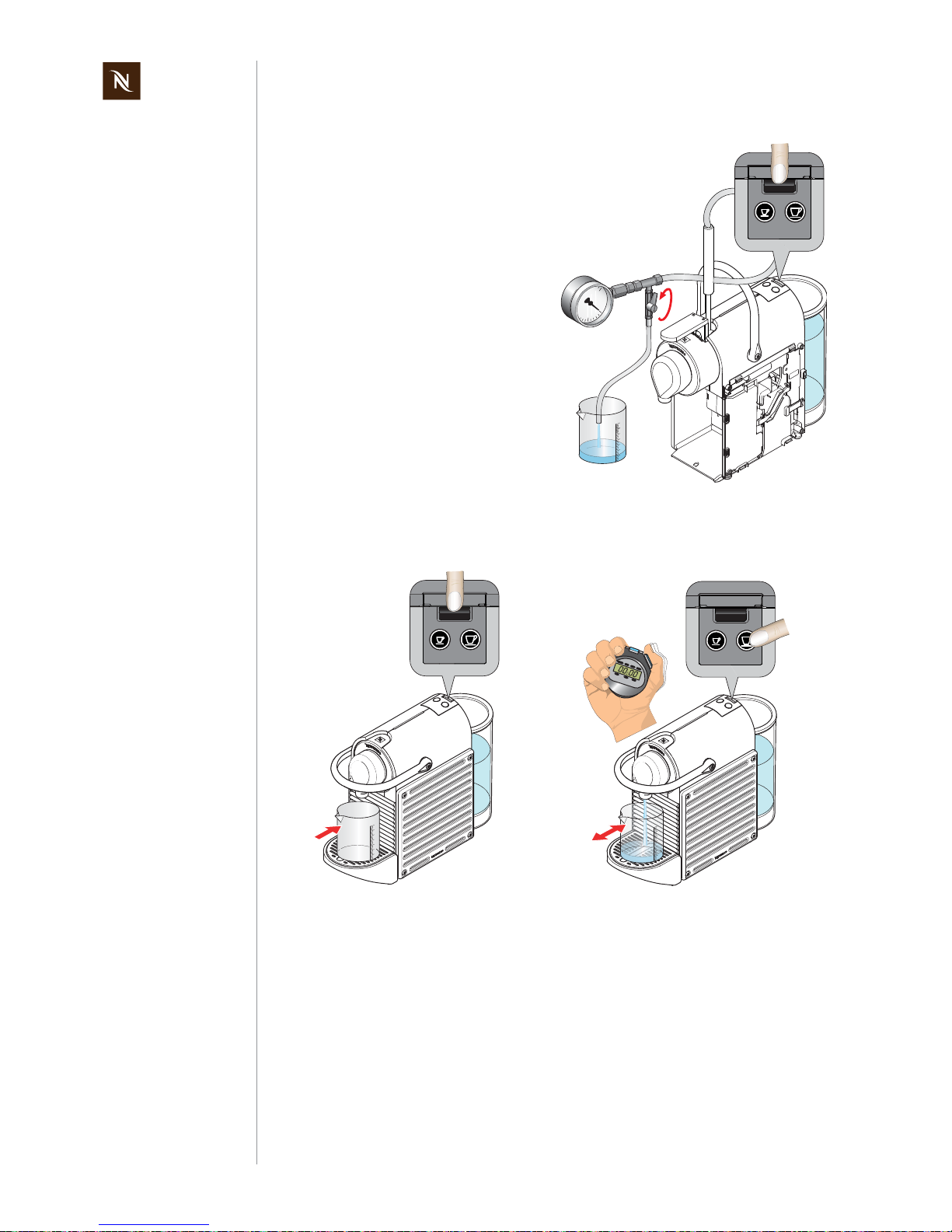

8.5 Measure coffee temperature

14) Switch off the coffee machine.

15) Open the valve and let water flow out

of the pressure tester.

16) Disconnect mains cable.

17) Remove pressure tester and water

tank.

18) Proceed with repair or remount right

side panel

1) Switch on coffee machine.

2) Place a measuring cup on cup support.

3) After heating up, press the "large cup"

button for approximately 10 sec to preheat the coffee outlet with hot water.

4) Empty measuring cup and place it

back on cup support.

15

14

2

1

4

3

10 sec

Page 73

Pixie service manual

73

FUNCTION TESTS

5) Insert capsule (Cosi is best suited).

6) Press the "large cup" button again.

7) Wait until the measuring cup contains

20 ml of coffee.

8) Then measure the coffee temperature

approx. 5-10 mm under the coffee outlet.

The coffee temperature should be

86 °C ± 3 °C (187 °F ± 5.4 °F).

5

6

5 - 10 mm

7

T2 T1

RANGE

-200°C - 1370°C

-328°F - 2498°F

1

REL

HOLD

T1 T2

T1

←

T2

°C/°F

MAX MIN

8

Page 74

Pixie service manual

74

FUNCTION TESTS

8.6 Protective earth (PE) continuity test

8.6.1 What is the protective earth continuity test about?

This test is only necessary

- for class 1 equipment (three-wire power cord with protective earth)

- after a repair whenever a general disassembly was performed.

Therefore all Pixie models have to be tested after general disassembly, except countryspecific models (USA, Canada, Japan) without a protective earth connection (refer to

"Wiring diagrams" on page 59 and following).

8.6.2 General

Legal regulation

In case of a repair/modification of the coffee machine, the repair centre is bound by law

to protect the user/consumer by

- restoring the regular condition of the appliance and

- performing the respective tests according to EN/IEC 60335-1 “Safety of household

and similar electrical appliances” and national regulations (e.g. DIN VDE 0701).

Description

Protective earth continuity measurements are made between the protective earth

terminal of the power plug and the thermoblock casing.

This test assures that

- the ground (earth) connection does not have an interruption between the power plug

and the thermoblock

- the permissible ground resistance is less than 0.3 Ohms (with a test current of

200 mA DC).

Test equipment

Special test equipment is needed that complies with the regulations to perform protective earth continuity measurements. Detailed requirements and tolerances must be verified by your local authorities or measurement supplier in any case.

Test report

For legal reasons a repair or test report should be prepared and filed with following information

- customer (name, address)

- type and serial number of coffee machine

- date of repair/test(s)

- performed test(s)/measuring value(s)

- used test equipment

- signature

Ask Nespresso for

recommendations

about test equipment.

Page 75

Pixie service manual

75

FUNCTION TESTS

8.6.3 Test sequence

This test sequence is

not applicable for cof-

fee machines with

two-wire power cords (without ground pin).

Danger of electrocution!

Do not plug in the coffee machine during the protective earth continuity

test.

Read and observe safety instructions in user manual of test equipment.

Symbolic illustration

of test equipment.

1) Connect black measuring cable to

ground pin of power plug with an alligator clip (example shown: Swiss

power plug).

2) Switch on test equipment and select

protective earth continuity test.

MEASURE

LOCK/STOP

COMP

LIGHT

0Ω ADJ

By looking into the

casule ejection slot

form below, metallic

parts of the thermoblock

are visible on both sides of

the capsule cage.

3) Remove water tank.

4) Remove maintenance unit.

5) Open closing handle.

6) Insert tip of red test probe up into capsule ejection slot and touch thermoblock.

7) Press "measure" button and read off

displayed resistance.

The resistance must be lower than

0.3 Ohm.

8) Fill in measured value in a test report.

5

4

3

7

MEASURE

LOCK/STOP

COMP

LIGHT

0Ω ADJ

0.215 Ohm

Test passed

6

Page 76

Pixie service manual

76

FUNCTION TESTS

8.6.4 What to do if the protective earth continuity test fails

• Check/measure ground wire connection of power cord; replace if necessary.

• Check/measure ground connection terminal on thermoblock. Retighten terminal

screw if necessary.

8.7 Protective insulation test

8.7.1 What is the protective insulation test about?

This test is necessary

- for class 1 and 2 equipment (with/without protective earth)

- after a repair whenever a general disassembly was performed.

8.7.2 General

Legal regulation

In case of a repair/modification of the coffee machine, the repair centre is bound by law

to protect the user/consumer by

- restoring the regular condition of the appliance and

- performing the respective tests according to EN/IEC 60335-1 “Safety of household

and similar electrical appliances” and national regulations (e.g. DIN VDE 0701).

Description

The insulation test

- assures that wiring and insulation of the coffee machine fullfill the normative requirements after a repair,

- rates the insulation capability of the coffee machine,

- is a very dangerous test because of a high test voltage (500 V DC).

For the insulation test, phase and neutral wire are shunted at the power plug. Then a

test voltage is applied between phase/neutral and selected parts of the coffee machine.

Test equipment

Special test equipment is needed that complies with the regulations to perform insulation

and withstanding voltage tests. Detailed requirements and tolerances must be verified

with your local authorities or measurement supplier in any case.

Ideally the test equipment has a national power socket for testing, so that the coffee

machine can plugged in directly. Otherwise a special shunt is necessary to connect the

phase and neutral pin of the coffee machine’s power plug.

Test report

For legal reasons a repair or test report should be prepared and filed with following information

- customer (name, address)

- type and serial number of coffee machine

- date of repair/test(s)

Perform the protective earth (PE) continuity test at first, if it is

mandatory.

Ask Nespresso for

recommendations

about test equipment.

Page 77

Pixie service manual

77

FUNCTION TESTS

- performed test(s)/measuring value(s), test points

- used test equipment

- signature

8.7.3 Test sequence

Danger of electrical shock/short circuit!

Do not plug in the coffee machine during insulation test.

Danger of electrical shock!

Do not touch tip of test probes.

Do not touch metallic parts of coffee machine during test.

Read and observe safety instructions in user manual of test equipment.

A Swiss power plug is

shown here as an

example.

Use a short circuit

plug or special alligator clips etc. as sub-

stitute for this test adapter.

1) Connect the phase and neutral pin of

the power plug together with a test

adapter (procured by the repair

centre).

2) Connect the black measuring cable to

the test adapter (see image).

3) Switch on coffee machine.

Symbolic illustration

of test equipment.

4) Switch on test equipment and select

an insulation test voltage of 500 V DC.

MEASURE

LOCK/STOP

COMP

LIGHT

0Ω ADJ

Some test equipment

displays test passed

or failed instead of

the insulation resistance.

5) Touch right side panel with red test

probe.

6) Press "measure" button.

7) Read off displayed insulation resistance or test result.

8) Test left side panel in the same way.

The insulation resistance must

always be higher than 300 kOhm

(300,000 Ohm).

6

Test passed

5

Page 78

Pixie service manual

78

FUNCTION TESTS

8.7.4 What to do if the insulation test fails

• Assume that the coffee machine is defect after a failed insulation test.

• Check wiring and locate fault. After fault clearance proceed with troubleshooting

check list (see page 26).

By looking into the

capsule ejection slot

form below, metallic

parts of the thermoblock

are visible on both sides of

the capsule cage.

9) Touch closing handle with red test

probe.

10) Press "measure" button.

11) Read off displayed insulation resistance or test result.

12) Insert tip of red test probe up into capsule ejection slot and touch thermoblock.

13) Press "measure" button.

14) Read off displayed insulation resistance or test result.

The insulation resistance must be

always higher than 300 kOhm

(300’000 Ohm).

15) Switch off test equipment.

16) Short red with black test probe to

make sure that test voltage is discharged.

17) Fill in results in a test report.

Risk of damage!

A sparkover can damage the electronic control board etc.

10

Test passed

9

12

Page 79

Pixie service manual

79

EXPLOSION DRAWINGS

9 EXPLOSION DRAWINGS

9.1 EF 280 Explosion drawing

Page 80

Pixie service manual

80

EXPLOSION DRAWINGS

9.2 EF 281 Explosion drawing

Page 81

Pixie service manual

81

PARTS LIST

10 PARTS LIST

10.1 Nespresso EF 280 / C60 and EF 281 / D60

Pos. Part no. Component Remark

1 0067948 Spare holder 280 left mount.

2 0062590 Holder 280 right, black

3 0067953 Spare side wall 281

light blue, packed, 2 pcs. (D60 EU steel

blue, D60 ZA steel blue)

3 0067958 Spare side wall 280

titanium, packed, 2 pcs. (C60 EU titan,

C60 IL titan, C60 SA titan)

3 0067959 Spare side wall 280

red, packed, 2 pcs., (C60 EU red, C60 IL

red, C60 SA red, C60 ZA red)

3 0067960 Spare side wall 280

blue, packed, 2 pcs. (C60 EU indigo,

C60 SA indigo, C60 IL indigo, C60 ZA

idigo)

3 0067961 Spare side wall 281

alu, packed, 2 pcs. (D60 EU alu, D60 ZA

alu)

3 0067962 Spare side wall 281 yellow, packed, 2 pcs. (D60 ZA lime)

4 0000394 Rubber feet 10.0 x 1.6mm black SJ-5816

5 0067944 Spare water tank 280 cpl. packed,6 pcs.

6 0062621 Cover 280 cable EU black

7 0063073 Cover 280 switch black

8 0062821 Guide 280 water black

9 0062787 Lock rod 280 chrom.