Nemox gelato 12k Instruction Book

Gelato 12K

EN

FR

ES

D

INSTRUCTION BOOK

MODE D’EMPLOI

INSTRUCCIONES PARA EL USO

ISTRUZIONI PER L’USO

IT

GEBRAUCHSANWEISUNG

Pag.

Pag.

Pag.

Pag.

Seite

4

10

16

22

28

www.nemox.com

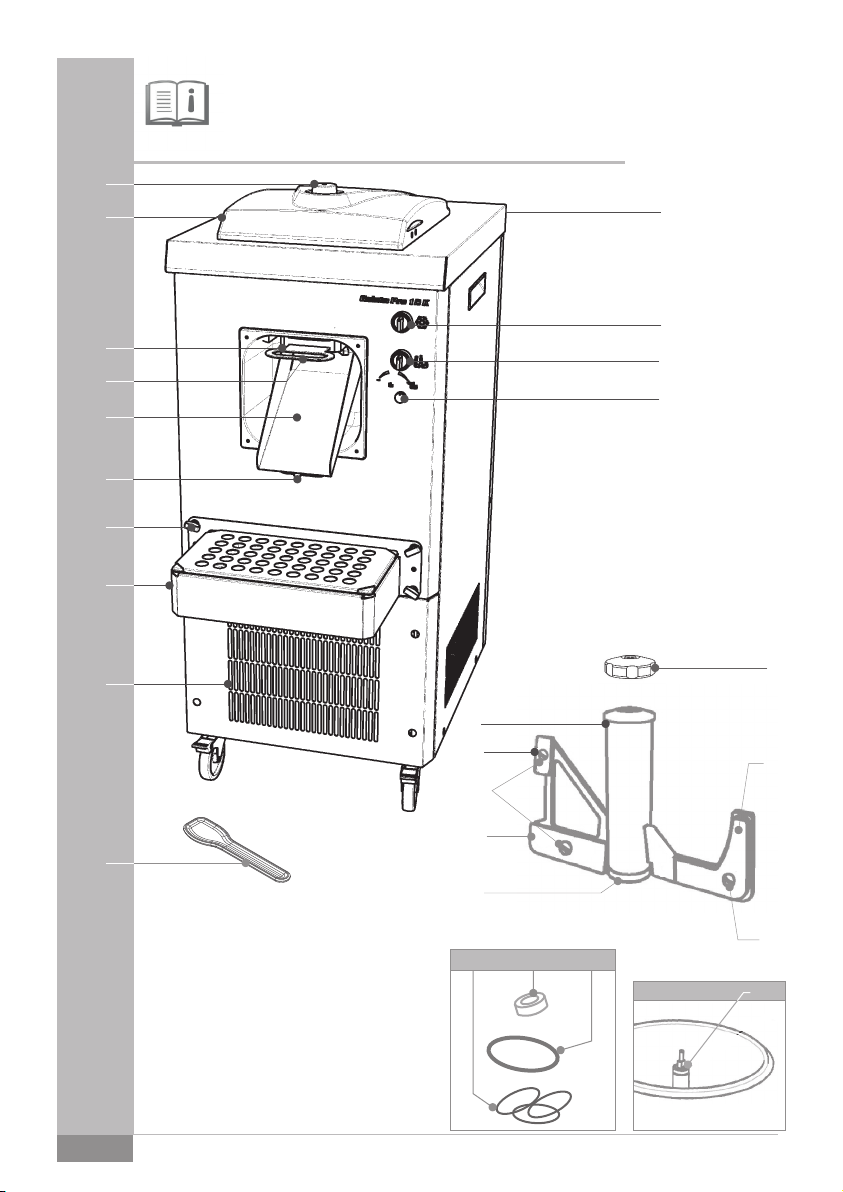

3A

3

13

9

11

14

12

8

6

Gelato 12K

10

1

2

7

4

23

2

5

21

20

19

17

22

18

20

1615

22

2

ATTENTION:

Pls keep the packaging boxes. They will be necessary in case you should return the machine for

repair or you should return it for any other reason. If the machine will be sent back with a

packaging box not suitable for transportation all repairing charges will be at charge of the sender,

even if the machine is under warranty . If the machines doesn't need to be repaired and the

package will not be suitable the machine will be returned to the sender too.

ATTENTION:

Veuillez conserver les emballages. Ils seront necessaires au cas où la machine sera retournée

pour réparation ou pour n'import quelle raison. Si les machines seront retournées dans un

emballage pas conforme au transport toutes les frais de réparation seront à charge de

l'expéditeur même si la machine sera sous garantie. Aussi s'il ne s'agit pas de réparation et si

l'emballage ne sera pas conforme la machine ne sera pas acceptée et elle sera retournée à

l'expéditeur.

CUIDADO:

Guardar los emballajes en el caso el aparato sea devuelto para reparacion o devoluciòn. En el

caso los aparatos seran entrgados en cajas no bien protegidas los gastos de la reparaciòn seran

cargados al cliente a pesar de la garancia, mientras las devoluciones no seran aceptadas.

ATTENZIONE:

Conservare gli imballi in caso la macchina debba essere restituita per riparazioni o resa. In caso

di macchine spedite in imballo non adatto alle modalità di trasporto gli interventi di riparazione

saranno interamente a carico del mittente a prescindere dalla garanzia, mentre i resi non saranno

accettati.

ACHTUNG:

Bewahren Sie bitte immer die Originalverpackung. Falls das Gerät nicht in seiner

Originalverpackung zum Kundendienst zugeschickt wird, gehen die Kosten für die Reparatur

auch während der Garantiezeit zu Lasten des Kunden. Retouren ohne Originalverpackung

werden verweigert.

Made in Italy by

Nemox International s.r.l. reserves the right to carry out all modifications which might be considered necessary.

Nemox International s.r.l. se réserve le droit d'apporter toute modification qui se rend nécessaire.

Nemox International s.r.l. se reserva el derecho de hacer toda modificaciòn que cree necesaria.

Nemox International s.r.l. si riserva il diritto di apportare tutte le modifiche ritenute necessarie.

Nemox International s.r.l. hält das Recht alle notwendingen Aenderungen durchzufuehren.

|

3

English English

IMPORTANT SAFEGUARDS

When using electrical appliances, basic safety precautions should always be observed, including the

following:

•Read all instructions carefully.

•To protect against risk of electric shock, do not put the main body of appliance in water or any other liquid.

•This appliance has not been designed to be used by persons (including children) with physical, sensory

or mental impairments or who are lacking in experience or knowledge, unless they have been given the

necessary supervision and prior instructions about how to use this appliance by a person responsible for

their safety. Young children should be supervised to ensure that they do not play with the appliance.

•Unplug from outlet when not in use, before putting on or taking off parts, and before cleaning.

•Avoid contact with moving parts.

•Do not operate any appliance with a damaged cord or plug, or after the appliance malfunctions, or is

dropped or damaged in any manner. Return the appliance to an authorised Service Center for

examination, repair or electrical or mechanical adjustment.

•The use of attachments not recommended or sold by the appliance manufacturer may result in fire,

electric shock or injury.

•Do not use outdoors.

•Do not let cord hang over edge of table or counter, or touch hot surfaces.

SAVE THESE INSTRUCTIONS

CAUTION

•An authorised service representative should perform any servicing other than cleaning and user

maintenance. Authorised service personnel only should do repair.

•After removing the appliance from the packaging, check it for damage. If in doubt, do not use the

appliance and contact an authorised service centre.

•Plastic bags, polystyrene, nails, etc. must not be left within reach of children as they are potentially

dangerous.

•The appliance's manufacturer and vendor reject any responsibility for failure to comply with the

instructions provided in this user manual.

•Check that the voltage shown on the rating plate corresponds to the voltage of the mains.

•Do not use sharp utensils inside the bowl! Sharp objects will scratch and damage the inside of the bowl.

A rubber spatula or metal spoon may be used, when the appliance is in the “OFF”or “0” position.

•Never clean with scouring powders or hard implements.

•Do not place or use the appliance on or near hot surfaces, such as stoves, hotplates, or near open gas

flames.

•Do not unplug the unit by pulling on the cord.

•The appliance must be connected to an electrical system and power supply socket with a minimum

capacity of 16A, equiped with an efficient earth contact. The manufacturer is not responsible for

damages to things or people in the event that the prescribed safety norms have not been respected.

•Before carrying out any maintenance or cleaning operations, make sure that the appliance has been

disconnected from the electrical mains by removing the plug from the power supply socket.

•Never wash the appliance using water jets or place it in water!

•This appliance is suitable for use with 43°C max. ambient temperature (climatic class “T”).

IMPORTANT:

This Ice Cream Machine contains its own refrigerant which must be allowed to settle after transport. Leave

the Ice Cream Machine on a horizontal surface for at least 12 hours after purchase or after any move which

might have stored the machine the wrong way up.

Leave at least 20 cm on each side of the machine to allow free air circulation. Make sure the vent slots are

free and unobstructed.

4

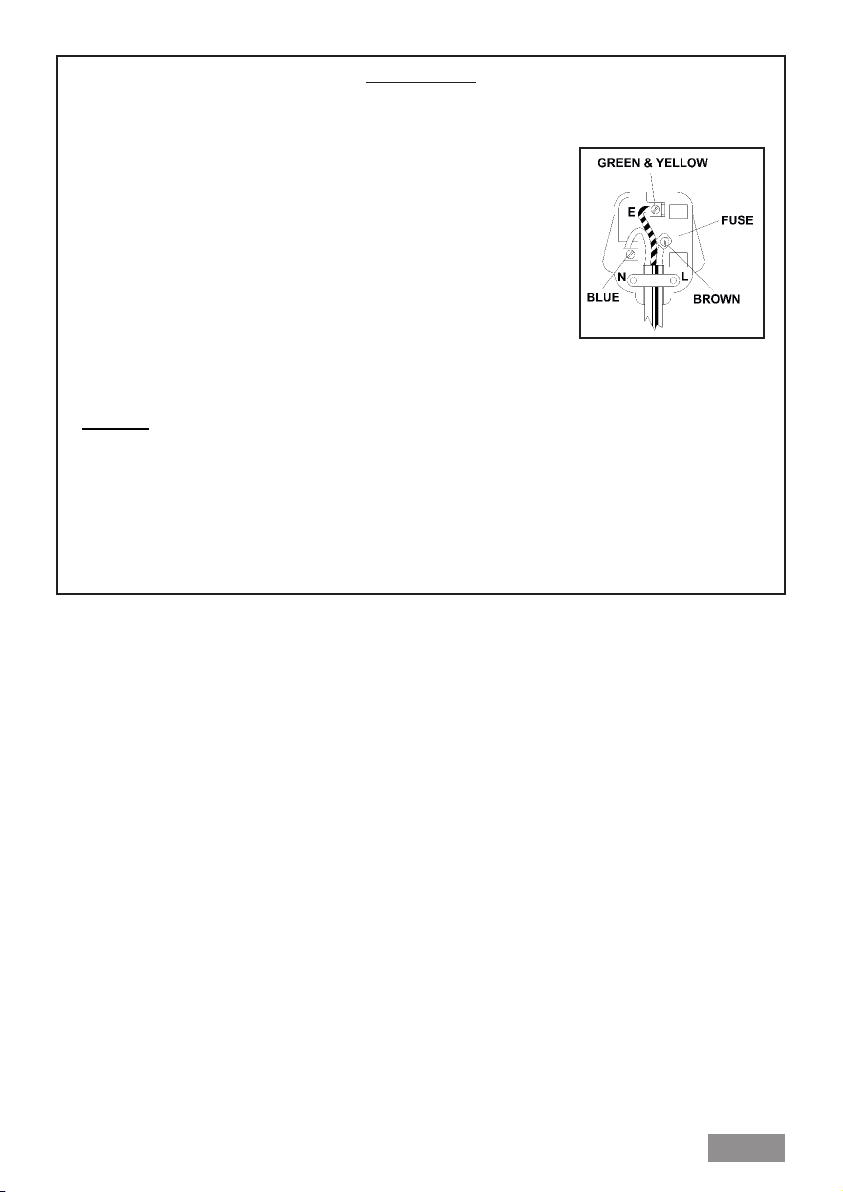

UK USERS ONLY

HOW TO CONNECT THE CORD TO A U.K. PLUG: IMPORTANT

The wires in the mains lead are coloured in accordance with the following code:

•Green and yellow: Earth

•Blue: Neutral

•Brown: Live

Please, read the instructions given below before connecting the cord to a plug.

If in doubt, please, consult a qualified electrician. As the colours of the wires in

the mains lead of this appliance may not correspond with the coloured

markings identifyng the terminals in your plug, proceed as follows: the wire

that is coloured Green and Yellow must be connected to the terminal in the

plug which is marked with the letter E or the Earth symbol (G), or coloured

Green or Green and Yellow.

The wire that is coloured Brown must be connected to the terminal which is

marked with the letter L or coloured Red. The wire that is coloured Blue must be

connected to the terminal which is marked with the letter N or coloured Black.

SAFETY POINTS FOR REWIRABLE OR MOULDED PLUG

The mains lead of this appliance may be already fitted with a BS1363 13A plug.

•If your socket outlet is not suitable for the plug, then the plug must be removed (cut off if it is a moulded on plug),

the flexible cord insulation should be stripped back as appropriate and a suitable 3 pin plug fitted.

•WARNING: Dispose of a plug that has been cut from the power supply cord, as such a plug is hazardous if

inserted in a live 13A socket outlet elsewhere in the house.

•Should the fuse need to be replaced an ASTA marked fuse, approved to BS 1362, of the same rating must be

used.

•Always replace the fuse cover after fitting a fuse. The plug must NOT be used if the cover is omitted or lost until a

replacement is obtained. Make certain that only the correct fuse cover is used and fitted.

•For plugs with detachable fuse cover, the replacement must be the same as the colour insert in the base of the

plug, or as directed by the embossed wording on the base of the plug.

•If the detachable fuse cover is lost a replacement may be purchased from a Service Centre.

•Information for supply may also be obtained from the plug manufacturer.

1). Refrigeration system knob.

2). Mixing paddle and rotation sense knob.

3). Transparent lid.

3a). Ingredients adding hole.

4). Paddle locking nut.

5). Mixing paddle with inserts.

6). Ventilation slot.

7). Speed adjusting knob.

8). Support frame for tray.

9). Extrusion flat gate handle.

10). Power switch.

11). Ice cream chute.

12). Support frame fixation screws.

Congratulations!

You have purchased a latest generation

NEMOX ice cream machine.

The operation of the compressor and

paddle are independent so as to make the

most of your experience.

An electronic device stops the paddle when

the consistency of the preparation is

excessive, thus preventing compromising

the mechanical functions of the machine.

13). Flat gate fixation screws.

14). Chute fixation screw.

15). Paddle plastic sleeve gasket set.

16). Extrusion gate gasket set.

17). Paddle plastic sleeve.

18). Vertical scraper.

19). Horizontal scraper.

20). Interlocking buffer.

21). Small vertical scraper.

22). Oil seal.

23). Spatula.

The cooling system will continue to run until

it is manually stopped.

FIRST USE

•Place on a flat surface, make GELATO 12K

sure that the ventilation grids (6) are not

obstructed. Leave a minimum clearance

of 10 cm. around the ventilation grids.

•During use, the appliance must be kept

clear of walls or furniture so as to not

obstruct the inflow and outflow of cooling

5

air. The leakage of warm or hot air is an

integral part of the operation of the device,

that exchanges heat with the outside for

refrigeration.

•Hygiene is extremely important when

dealing with food. Carefully follow the

provi s i ons of hygi e ne standa r d s

applicable in your country (HACCP or

equivalent). Wash thoroughly all parts

coming in contact with ice cream (bowl,

paddle, lid, chute and flat gate).

•Mount the chute (11) and fix it in position by

the appropriate screws (14).

•Mount the metal frame and fix it in position

by the appropriate screws (12). Place in

position the tray and the cover grid.

•Insert the flat gate in the appropriate seat

and verify that there is no leaking when in

closed position.

PREPARING THE MIXTURE

Select the recipe and prepare the mixture,

paying attention to the following:

•Handle the ingredients as required by the

hygiene standards applicable in your

country (HACCP or equivalent).

•For the preparation of ice creams and

sorbets, do not introduce more than 5kg 2.

of mixture, in order to allow for proper

volume increase while mixing.

•It is recommended to pour the mixture at a

temperature between +10°C and +20°C.

H i g her t em p e rat u r es m ay a l so

considerably increase the processing

time.

METHOD OF OPERATION

•Check that voltage on the rating plate

corresponds to the voltage of the mains.

Connect the plug to an electrical socket.

•Power on the machine by rotating the

general power switch (10).

•Insert the mixing paddle (5) in the

container, turning it clockwise until it is

correctly positioned on the bottom.

•Fit the retainer (4) to ensure that the mixing

paddle is locked in position.

•Verify that the flat gate (9) is in closed

position.

•Pour the ice-cream mixture previously

prepared intothe bowl.

•Turn on the knob (1) to start cooling.

IMPORTANT: if the appliance switches off,

due to a temporary power blackout, or

because the refrigeration switch was

accidentally turned off, wait five minutes

before restarting. The refrigeration circuit

has a special safety device preventing the

compressor to restart until cool, as to avoid

damages to the unit.

•Close the transparent lid (3) over the bowl.

•To start the paddle movement, rotate the

knob (2) clockwise. Set the rotating speed

near the half of maximum by rotating the

kno b (7) . Prepar ation time varies

according to quantity, temperature of the

mix, type of ice cream (cream-style or

sherbet), and room temperature.

IMPORTANT: Movement of the mixing

paddle is completely independent from the

freezing system. A safety device stops

automatically the paddle when the lid is not

in closed position.

•Depending on the quantity of ingredients

and recipe used you will have a delicious

fresh ice cream in 10/15 minutes.

•By the opening (3a) on the cover, you can

add s ome ingredi ents d uring the

preparation of the ice cream.

•When the ice cream has reached the

desired consistency, is now possible to

proceed with the extrusion operation.

EXTRUSION OF THE ICE CREAM

Proceed as described:

•Prepare the ice cream tray on the bracket

(8).

•Turn off the freezing plant by rotating the

knob (1).

•Open the extrusion system by pull out the

flat gate (9).

•Rotate counterclockwise the knob (2). The

paddle will turn clockwise starting the

extrusion process.

•When the quantity of the ice cream in the

6

EnglishEnglish

bowl decrease, you can increase the

rotating speed of the paddle by turnig the

knob (7).

•In order to extrude the last portion of ice

cream, stop the paddle by operating the

knob (2), lift the cover (3) and patch the

residual ice cream on the bottom of the

bowl. Proceed again with the extrusion

procedure.

•Once the extrusion process is terminated,

close the extrusion gate with the handle

(9).

ATTENTION! The extrusion time strictly

depends from the ice cream hardness. An

hard ice cream will thake longer time to

extrude. Under certain circumstances, the

power required to start the extrusion

process may cause the motor thermal

protection trip. In this case, power off the

motor, wait a few

minutes in order to allow to the ice cream

becoming softer and power on the motor

again: the extrusion process will restart.

HELPFUL HINTS

•Ingredients should preferably be prechilled to refrigerator temperature; this will

shorten ice-cream making times.

•For better results, start refrigeration by

turning the knob (1) 5 minutes before

pouring in the ingredients.

•To allow volume to increase of the mixture,

do not fill the container to more than half its

capacity (use max. 2,5 Kg of ingredients).

•The ice-cream maker has a GELATO 12K

powerful refrigeration system. Do not

leave the ice cream in the container for too

long with the refrigeration on, you might

find it frozen!

CLEANING THE BOWL

Cleaning the bowl of is very GELATO 12K

easy. Proceed as follows:

•Once the paddle is removed, turn off the

freezing plant and simply put inside the

bowl 2 litres of warm water.

•Wash out the bowl with a sponge. Do not

use sharp utensils inside the bowl!

•Pout an empty container of at least 3 litres

capacity under the chute (11).

•Open the extrusion system by pulling

theFlat gate (9); the water will flow on the

container below.

•If necessary, repeat the cleaning cycle until

the bowl will be clean. Clean the bottom of

the bowl with a sponge. Proceed with the

sanitization (see the SANITIZATION

chapter) in order to avoid any bacteria

growth.

•Dry the carefully the ice cream maker bowl

with a cloth in order to avoid any dirty deposit.

APPLIANCE CLEANING AND MAINTENANCE

•Before starting to clean make sure that the

machine is switched off (power switch (10)

in OFF position) and unplugged.

•Remove the steel pin and remove the

transparent lid (3) from the machine.

•Wash the paddle (5), the transparent lid (3)

and the locking nut (4), in a soapy warm

water.

•To better clean the paddle, remove the

plastic inserts (18), (19) and (21) by pulling

it from his site.

•If the inserts are worn out, they must be

replaced to prevent the mixing action from

becoming less effective. These parts are

available from all authorised service

centres.

•Clean the chute (11) and the frame (8).

Leave it out from his site by unscrewing the

aprropriate screws (12) and (14). Clean

carefully the surrounding area.

ATTENTION: when mounting the pieces,

the screws must be tightened by hands.

•Clean carefully the extrusion system by

leaving out the flat gate support (9).

Unscrew the appropriate screws (13).

Clean carefully the gasket and the

surrounding zone. Check the integrity of

the gasket: an excessive wear can cause a

mixture leakage during ice cream making

operations.

ATTENTION: when mounting the pieces,

the screws must be tightened by hands.

7

•Clean the body of the appliance and nonremovable parts with a specific product

given in the SANITIZATION paragraph.

IMPORTANT: never wash the appliance

with jets of water! - it contains electrical

parts.

•Before storing the appliance, clean it with

an absorbent cloth.

•Clean the ventilation grids (6) also on the

rear part of the machine at least once a

year.

•Regularly (at least once every 3 months)

check the oil seal (22) on top of the

transmission shaft: if necessary replace or

lubricate with H1 category grease or

higher. A specially designed grease can

be purchased at any Authorized Service

Centre. An oil seal replacement (22) is

supplied with the machine.

SANITIZATION

Sanitizing operations, if properly carried out,

allow for the removal of a significant

proportion of micro-organisms whose cells

and spores find, thanks to processing

residues, favourable conditions for survival

and proliferation. Must be carried out at the

end of daily production cycle or more often,

if necessary.

WARNING: standby mode should not be

used in lieu of proper cleaning and

sanitization proceduces at the frequencies

required by the federal, state, or local

regulatory agency.

Sanitizing involves two phases:

• Remove dirt (coa rse CLE ANSING

residues) and rinse with lukewarm water

immediately after work; cleaning action is

provided by manual friction and water

pressure. The use of a chemical detergent

reduces, but does not cancel, the manual

cleaning requested above. CAUTION:

cleansing only, even if accurate, does not

ensure complete removal of micro-biotic

contaminants. Proceed as follows:

•Remove the coarse dirt mechanically.

•Rinse with hot water first, at 45°C, to

8

dissolve grease and facilitate its removal,

but below 60°C to avoid "cooking"

proteins, sugar or fat and make them

stick even firml y to the surfaces

subjected to cleaning. The tools and

removable parts of the equipment can be

cleaned simply, in about 15 minutes.

•Apply detergent: due to the fact that most

of food residues (proteins and fat) cannot

be dissolved in water, their complete

removal requires the use of a detergent

that detaches dirt form the surface and

enables its further removal by rinsing.

•Carefully clean the recessed zones like

the extrusion opening and the bottom of

the bowl. Use a cleaner or an hard bristle

brush, if required.

•Final rinsi n g w i t h w a t er a t t ap

temperature for at least 5 minutes if

immersed.

• . D i sinfecti o n o r D ISINFEC T I O N

decontamination involves the verified

des tru ction of n on sp ore f orming

pathogenic bacteria and significant

reduction of non pathogenic and non

spore forming bacteria. Cleansing and

disinfec t i n g o p erations must be

performed separately.

After cleansing, proceed with disinfection.

Proceed as follows:

•Use a specific disinfecting agent suitable

for food industry sector. For the best

result in the disinfection operations we

suggest to use a product with ethanol

(concentration between 20 and 30%),

iso propyl alcohol ( concent ration

between 1 and 5%) and a quaternary

ammonium compound (concentration

under 200ppm). Anyway, check that on

the package are properly marked the

following features:

•Disinfecting agent, Medical Device or

similar.

•Registration number at Healthcare

Agency.

•The message "for food industry use“.

•Dosage and use times.

EnglishEnglish

•Ingredients, manufacturer, batch and

production date.

•Warnings on safe use.

•Dilute the disinfecting product following

th e i n structions g i v e n by th e

manufacturer. Attention: using less

d i s i n f e c t i n g p r o d u c t t h a n

recommended may promote bacteria

proliferation at dangerous levels, as well

as using excess active principle does

not improve efficiency.

•Leave the disinfecting agent to act for the

contact time required. If left less time than

required, disinfection may be ineffective.

•In order to carry out the various operations

correctly, you must proceed from up

downwards, finishing with the floor.

•After applying disinfecting agent, remove

residues with a final rinse.

•Pay utmost care to clean the extrusion

opening, the bottom of the bowl and all the

recessed zones which can to be in contact

with food. Use a cleaner or an hard bristle

brush, if required.

•Dry thoroughly the surfaces to avoid

bacteria proliferation due to moisture;

•We recommend you alternate every 6

months the type of disinfecting agent to

avoid developing resistant forms of

bacteria. Bacteria spores are the most

resistant biological forms and, therefore, it

is recommended you use chloride-based

products.

TROUBLESHOOTING

•Machine does not cool:

•Check that the power plug is properly

inserted and the appliance has electrical

energy.

•The safety device of the compressor

comes into action: wait 5-10 minutes

before restarting the machine. Rapid and

continued start-up attempts do nothing

but prolong the period of inactivity of the

machine.

•Check that the machine is correctly

positioned with the ventilation grids (6)

free of any obstructions.

•The paddle does not turn:

•Check that the paddle (5) is properly

attached to the tube and locked with a

special locking ring (4).

•Make sure it is free from obstacles that

prevent it from rotating.

•Make sure the lid is closed in the correct

position: a safety device stops the

paddle when the lid is opened.

•The ice cream was too hard and the

motor has stalled. A safety system has

stopped the motor in order to prevent any

damage. Turn off the paddle motor by

turning the knob (2), let the mixture

become softer (turn off the freezing plant)

and restart.

•The machine is noisy:

•Some noise is part of the normal

operating specification s, but if it

becomes excessive contact the Service

Centre to avoid further and more serious

problems.

•Extrusion procedure is very slow:

•The ice cream is too hard. Turn off the

freezing plant, wait a few minutes and try

again.

•The extrusion discharge gate leaks:

•Replace the gasket. Two additional

gaskets sets (16) are provided with the

machine.

•The plastic sleeve (17) on the lower part of

the paddle is too easy to separate.

•Replace the gasket with the new one.

Four additional gasket (15) are provided

with the machine.

•The paddle does not scrape properly the

sides of the bowl.

•Check that the scrapers (18), (19) and

(21) are not damaged or worn.

•Check that the resilient pads (20) are not

distorted. If they are distorted replace

them with new parts. One set is included.

9

Français

INSTRUCTIONS GENERALES DE SECURITE

Pendant l'utilisation des appareils électriques, il est indispensable de respecter scrupuleusement quelques

règles de sécurité fondamentales, en particulier:

•Lire attentivement le mode d'emploi avant d'installer et utiliser l'appareil.

•Ne pas plonger le corps principal de l'appareil dans l'eau ou autres liquides: danger de chocs électriques.

•Cet appareil n'est pas prévu pour être utilisé par des personnes (y compris les enfants) dont les capacités

physiques, sensorielles ou mentales sont réduites, ou des personnes dénuées d'expérience ou de

connaissance, sauf si elles ont pu bénéficier, par l'intermédiaire d'une personne responsable de leur

sécurité, d'une surveillance ou d'instructions préalables concernant l'utilisation de l'appareil. Il convient de

surveiller les enfants pour s'assurer qu'ils ne jouent pas avec l'appareil.

•Débrancher l'appareil de la prise de courant quand il n'est pas utilisé et avant de le démonter ou de le

nettoyer.

•Ne pas toucher les parties en mouvement.

•Ne pas utiliser l'appareil si le cordon d'alimentation ou la fiche sont abîmés, ou après un fonctionnement

anormal de l'appareil, ou si l'appareil est tombé par terre ou s'il a été endommagé de quelque façon que ce

soit. Dans ces cas, il est recommandé de s'adresser au Service Après-vente agrée pour les réparations.

•Emploi d'accessoires qui n'ont pas été recomandés ou vendus par le constructeur de cet appareil pourrait

entraîner des risques d'incendie ou des chocs électriques ou des lésions à l’utilisateur.

•Ne pas utiliser l'appareil à l'extérieur.

•Eviter que le cordon d'alimentation puisse pendre le long du bord de la table ou du plan de travail ou

touches des surfaces chaudes.

CONSERVER CES INSTRUCTIONS

•Toute réparation ne devra être exécutée que par des centres d'assistance technique ou de personnel agrées.

•Après avoir sorti l'appareil de l'emballage, s'assurer qu'il soit intact. En cas de doute, ne pas utiliser l'appareil

et s'adresser à un centre d'assistance technique agrée.

•Les sachets en plastique, le polystyrène, les clous etc., étant des sources potentielles de danger, ne doivent

pas être laissés à la portée des enfants.

•Cet appareil est destiné exclusivement à l'emploi pour lequel il a été conçu. Le constructeur et le vendeur de

l'appareil déclinent toute responsabilité en cas de non-respect des indications contenues dans ce manuel

d'utilisation.

•S'assurer que la tension de réseau correspond à celle qui est indiquée sur l'appareil avant d'insérer la fiche

dans la prise de courant.

•Ne pas utiliser d’objets ou d'outiles coupants à l’intérieur du bol. Ceux-ci risquent en effet de griffer ou abîmer

la cuve. Une spatule en caoutchouc ou une cuillère plastique peuvent être utilisées lorsque l'appareil est

éteint en position “0” ou “OFF”.

•Ne jamais nettoyer l’appareil avec des utensiles abrasives.

•Ne pas utiliser l’appareil sur surfaces chaudes ou près de flammes.

•N’arrêter jamais la machine en retirant la fiche de la prise de courant.

•L'appareil doit obligatoirement être relié au secteur et avoir une prise de courant avec une portée minimum de

16A, avec contact de mise à la terre efficace. Le constructeur n'est pas responsable des dommages

éventuels causés par l'absence de la mise à terre dans l'installation.

•Avant d'effectuer n'importe quelle opération d'entretien ou de nettoyage, vérifier que l'appareil ait été

débranché du secteur en retirant la fiche de la prise de courant.

•Ne jamais laver l'appareil avec des jets d'eau, ne jamais l'immerger dans l'eau!

•Cet appareil appartient à la classe climatique “T” pour l’utilisation avec une témperature ambiante de 43°C.

IMPORTANT:

Laisser la machine reposer sur un plan horizontal pendant au moins 12 h avant de l'utiliser pour la première

fois. Les agents réfrigérants pourraient en effet être dispersés, au cas où la machine aurait été renversée

pendant le transport et ils doivent avoir le temps de revenir dans la bonne position. Suivre la même procédure

par la suite aussi, toutes les fois que la machine aura été mise en position non horizontale pour quelque motif

que ce soit. Placer la machine de façon à ce qu'il y ait suffisamment d'espace autour (au moins 20 cm), pour ne

pas obstruer les prises d'air latérales.

ATTENTION

10

Français

1). Interrupteur de refroidissement.

2). Interrupteur pale mélangeuse et

rotation.

3). Couvercle transparent.

3a). Trou pour ingrédients supplémentaires.

4). Ecrou de fixage pale.

5). Pale mélangeuse.

6). Grille d'aération.

7). Poignée pour régler la vitesse de la

pale.

8). Plateau.

9). Poignée de la vanne.

10). Interrupteur général.

11). Goulotte.

Félicitations!

Vous avez acheté une turbine à glace

NEMOX de dernière génération.

Le fonctionnement du compresseur et de la

pelle sont indépendants pour exploiter au

mieux votre expérience.

Un dispositif électrique intervient pour

arrêter la pelle au cas où la consistance de la

préparation soit excessive, afin d'éviter de

compromettre les fonctionnalités

mécaniques de la machine. L'installation

réfrigérante continue de fonctionner jusqu'à

son arrêt manuel.

MISE EN PLACE DE L'APPAREIL

•Placez votre sur une surface GELATO 12K

plate vérifiez que rien ne puisse obstruer

les grilles d'aération (6) situées sur les

côtés et qu'il y ait autour de l'appareil un

espace suffisant pour assurer une

circulation correcte de l'air.

•Pendant l'utilisation l'appareil doit être

conservé loin de murs ou meubles afin de

ne pas créer d'obstacle à la circulation de

l'air de refroidissement. La sortie d'air tiède

ou cha ud fait pa rtie intégrante du

fonctionnement de l'appareil qui échange

la chaleur avec l'extérieur pour la

réfrigération.

•Pour la préparation de la glace, le

nettoyage et l'hygiène ont une importance

primordial. Avant d'employer l'appareil

laver soigneusement toutes les parties qui

entrent en contact avec la glace, tels que:

12). Vis fixage du plateau.

13). Vis fixage de la vanne d'extrusion.

14). Vis fixage de la goulotte.

15). Set joints pour douille pale

mélangeuse.

16). Set joints système extrusion.

17). Douille pale mélangeuse.

18). Insert vertical.

Insert horizontal.19).

Tampon de verrouillage.20).

21). Insert supérieur.

22). Joint.

23). Spatule.

le bol, la pale et le couvercle, la goulotte et

la vanne. Suivre scrupuleusement les

prescriptions de la réglementation

hygiénique applicable dans votre Pays

(HACCP ou correspondant).

•Monter la goulotte (11) et la fixer avec sa vis

(14).

•Monter la corniche de support, la fixer avec

les vis (12) et y positionner le plateau (8) et

la grille. Positionner la vanne jusqu'au fond

de sa siège et contrôler qu'elle fais une

tenue hermétique..

PRÉPARATION DU MÉLANGE

Choisir la recette et préparer le mélange, en

faisant attention à ce qui suit :

•Manipuler les ingrédients selon ce qui est

prescrit par les normes hygiéniques

applicables dans votre Pays (HACCP ou

correspondant).

•Pour la préparation de gelati et sorbets ne

pas introduire plus de 2.5kg de mélange,

afin de permettre une augmentation

correcte de volume pendant le mélange.

•Il est conseillé de verser le mélange à une

température comprise entre +10°C et

+20°C. Avec des températures plus

élevées les temps de pr oduct ion

p o u r r a i e n t a u g m e n t e r m ê m e

considérablement .

FONCTIONNEMENT

•Contrôler que le voltage indiqué sur la

plaque des caractéristiques techniques

11

Loading...

Loading...