Nematron OptiLogic User Manual

OptiLogic Series

Opti

Logic

Optimal Automation for Industry

Input/Output Modules

Optimation, Inc.

(256)883-3050 1

www.optimate.com

OptiLogic Series

WARNING

Thank you for purchasing industrial control products from Optimation, Inc. We want your new

system to operate safely. Anyone who installs or uses this equipment should read this manual

(and any other relevant publication) before installing or operating the system.

To minimize the risk of potential safety problems, you should follow all applicable local and

national codes that regulate the installation and operation of your system. These include the

National Fire Code, National Electric Code, and other codes of the National Electrical

Manufacturer’s Association (NEMA). There may be local regulatory or governmental offices

that can help determine which codes and standards apply to your situation. It is your

responsibility to determine which codes and should be followed, and to verify that the

equipment, installation, and operation is in compliance with the latest revision of these codes. If

you have any questions concerning the installation and operation of Optimation products, please

call us at (256)883-3050.

All Optimation products are warranted against defects in materials and workmanship for a period

of one year from the date of shipment. Warranty applies to unmodified product under normal

and proper use and service. Optimation’s sole obligation under this warranty shall be limited to

either, at Optimation’s option, repairing or replacing defective product. The cost of freight to

and from Optimation will be borne by the customer. No other warranty is given or implied.

This publication is based on information that was available at the time it was printed. We

constantly strive to improve our products and services, so we reserve the right to make changes

to the products and/or publications at any time without notice and without any obligation. This

publication may also discuss features that may not be available in certain revisions of the

product.

Trademarks

This publication may contain references to products produced and/or offered by other

companies. These products and company names may be trademarked and are the sole property

of the respective owners. Optimation disclaims any proprietary interest in the marks and names

of others.

Copyright 1999, Optimation, Inc.

All rights reserved

No part of this document shall be copied, reproduced or transmitted in any way without the prior,

written consent of Optimation, Inc. Optimation retains the exclusive rights to all information

included in this document.

Optimation, Inc.

(256)883-3050

www.optimate.com

2

OptiLogic Series

Table of Contents

Introduction . . . . . . . . 6

Digital Inputs . . . . . . . . 7

Input Isolation . . . . . . . 7

DC Inputs . . . . . . . . 7

AC Inputs . . . . . . . . 8

Digital Input Voltage . . . . . . 8

I/O “Common” Terminals . . . . . 8

Digital Outputs . . . . . . . 9

Relay Outputs . . . . . . . 9

Transistor Outputs . . . . . . . 10

NPN Transistor Sinking Outputs . . . . 10

Solid State Relay Outputs . . . . . . 10

Analog Inputs . . . . . . . . 11

Isolation . . . . . . . . 11

Resolution . . . . . . . . 12

Accuracy . . . . . . . . 12

Range . . . . . . . . . 12

Multiplexing . . . . . . . . 12

Single Ended Inputs . . . . . . 13

Differential Inputs . . . . . . . 13

OL2104 Isolated Relay Output Module . . . 14

OL2108 Relay Output Module . . . . . 15

OL2109 DC Sinking Output Module . . . 16

OL2111 AC Solid State Relay Module . . . 17

OL2201 Digital Input Simulator Module . . . 18

OL2205 Isolated AC/DC Input Module . . . 19

OL2208 DC Digital Input Module . . . . 20

OL2211 AC Digital Input Module . . . . 21

OL2252 Dual High Speed Pulse Counter . . . 22

OL2258 High Speed Pulse Counter . . . . 25

OL2304 4 Channel Analog Voltage Output . . 28

OL2408 Analog Voltage Input Module . . . 29

OL2418 Analog Current Input Module . . . 30

Optimation, Inc.

(256)883-3050 3

www.optimate.com

OptiLogic Series

OL2602 Dual RS232 Module . . . . . 31

Optimation, Inc.

(256)883-3050

www.optimate.com

4

www.optimate.com

R

evision History

Issue

Date

Pages

Description

Original 8/99

1.1

1.2

1.3

1.4

1.5

Optimation, Inc. (256)883-3050 5

1-24

1/00

9/00

04/01

09/02

13, 18, 25

25-28

various

15

10/2012 14, 15

Original release

Added OL2104, OL2205, OL2418

Added OL2258, OL2304

Added specs requested by UL

Changed wording of OL2108 voltage rating spec

Changed voltage ratings of OL2104 and OL2108

to match UL ratings

OptiLogic Series

OptiLogic Input/Output Modules

Introduction

Optimation’s OptiLogic series is a

flexible, modular system, designed to allow you

the ability to configure an optimal solution for

your exact needs. To accomplish this goal,

Optimation has developed a series of I/O

modules, communications modules, specialty

modules and operator panels that can be plugged

together in nearly any combination. This

manual covers the currently available modules

that plug into the card cage.

Additional I/O modules are under

development. Please check our web site at

optimate.com for a complete list of available

modules.

Most OptiLogic modules can be installed

in any card cage slot and used in any

combination and quantity that will fit in the card

cage. This applies to all general purpose digital

and analog I/O. If you need all digital inputs plug in digital input modules only. If you need a

mixture of analog and digital inputs and output select the mixture that fits your needs. Snap

together modularity gives you the ability to

optimize your system for your needs.

OptiLogic I/O modules are designed to

meet your needs in real world application. They

are all small circuit boards with a few available

points to minimize your system cost. Most

module connectors are pluggable terminal strips

for easy connection, and easy maintainability.

The snap-together design means low labor costs

- or costs on your time. Visual status indicators

on digital I/O and communications modules

provide a convenient means for monitoring

operation. All together, the result is a cost

effective, easy to use and maintain set of

industrial control hardware.

This manual covers general I/O

characteristics and applications first. Specific

I/O boards are covered in the latter pages. The

general pages should serve as a guide to

selecting and installing I/O boards in your

application.

Communications and specialty modules

are covered in the latter pages of this manual.

It is Optimation’s desire for this manual

to serve as a guide in your selection of the

modules appropriate for your application, as

well as to provide complete information for their

use.

Optimation, Inc.

(256)883-3050

www.optimate.com

6

OptiLogic Series

processor

Sourcing DC input

Digital Inputs

Digital I/O modules are used to either

monitor (input) or control (output) the “state” of

something. “State” being on or off, active or

inactive, open or closed - etc. In the “real world”

digital I/O requirements come in a variety of

shapes and sizes. Therefore, there are a variety

of available modules designed to meet the

variety of needs.

Typical digital inputs are connected to

switches, buttons, digital outputs from other

equipment, discrete level sensors, thermostats

and other on/off sensing devices.

Digital status is sensed by a controller,

such as an OptiLogic system, by passing current

through an input sensor. When the current is on,

the input state is active. When it is not there, the

input state is inactive.

Input Isolation

In most cases, it is important to “isolate”

the real world inputs from the internal

electronics of the controller. You want to

prevent some external situation from “zapping”

the controller’s electronics.

figure shown, when the digital input contact

closes, the circuit path is complete and current

will flow. On the input module this circuit path

passes through a device which emits light when

current flows through it. The light emitter is in

very close physical proximity to (actually in the

same chip) a photo sensor, which will turn on

when it senses light. In this way, a digital input

module can sense whether the input device is

closed (current flow) or open (no current flow)

without a direct electrical connection between

the external sensor and the internal electronics.

DC Inputs

DC digital inputs are typically supplied

by a DC power supply. The most common DC

supplies used in industry are 12VDC and

24VDC.

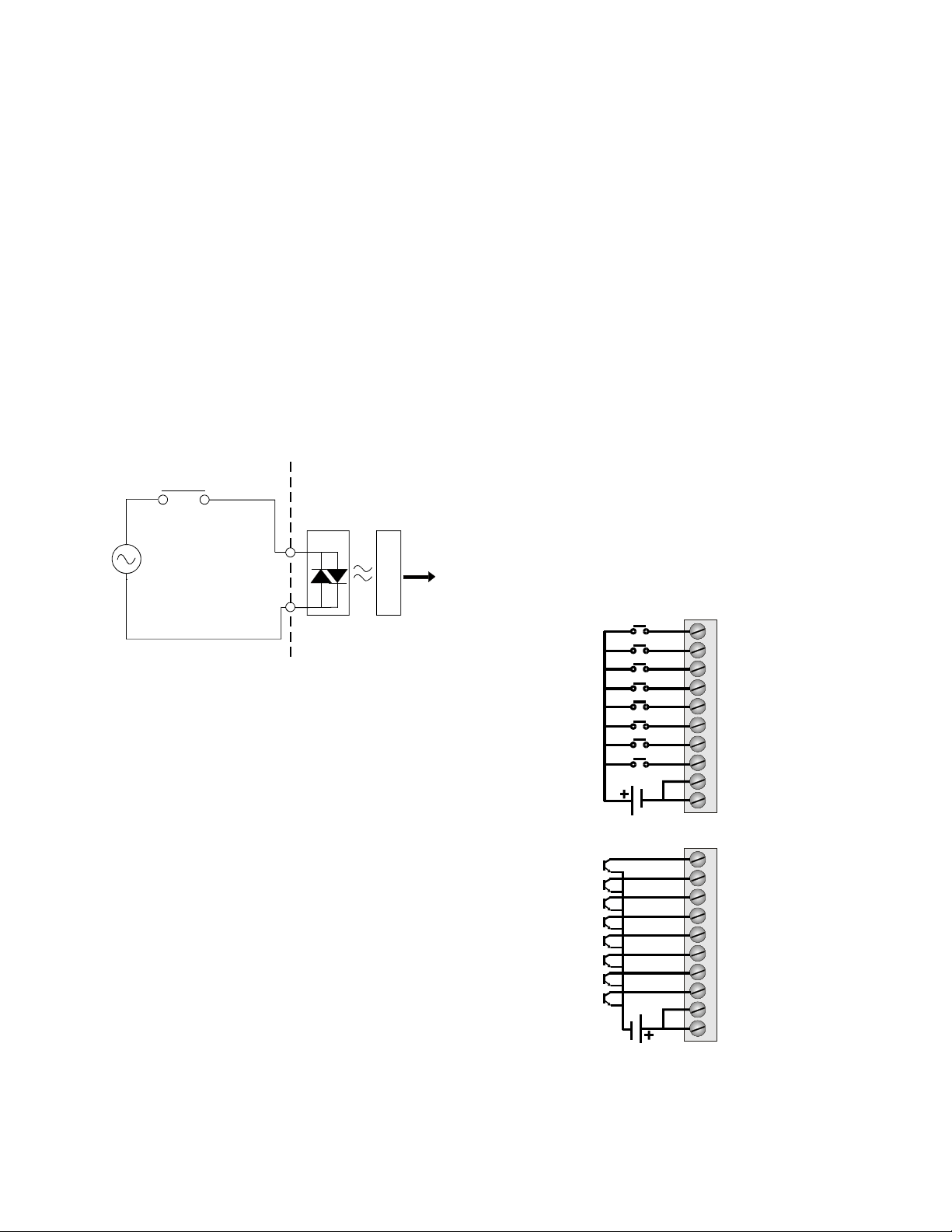

Typical DC digital input circuits are

shown below. As shown, the physical optical

emitter on the input module is an LED (light

emitting diode). OptiLogic DC inputs use

bidirectional LEDs - i.e. Your inputs may either

source or sink current. The top figure shows a

sourcing input. The figure below it shows a

sinking input. When inputs are connected to a

“common” (most instances), inputs must be

either all sourcing or all sinking.

electrical isolation is optical isolation. The

figure below illustrates the basic concepts of

optical isolation of a digital input circuit. In the

Power

source

Optimation, Inc.

An effective means of providing such

sensor

optical

isolation

To

OptiLogic

Input module

(256)883-3050 7

www.optimate.com

sensor

common

Sinking DC input

common

optical

isolation

OptiLogic

processor

Input module

optical

isolation

OptiLogic

processor

Input module

To

To

OptiLogic Series

Sourcing

10-30VDC

processor

AC Inputs

AC digital inputs are typically supplied

either directly from line voltage or transformed

down from line voltage. The most common AC

inputs are 120VAC and 24VAC, although any

voltage range is possible.

A typical AC input circuit is shown

below. As shown, the physical optical emitter

on the input module consists of two LEDs of

opposite polarity. An AC (alternating current)

connection flows current one way, then the

other. Light is emitted in both cases.

sensor

optical

isolation

To

OptiLogic

maximum voltage corresponds to the maximum

current the optocoupler can handle without

being damaged.

I/O “Common” Terminals

For a digital input circuit, one input

terminal and one output terminal is necessary for

operation. For practical application, one of these

two terminals may be “common” to several

circuits.

In most systems, the power source for all

digital inputs is from the same supply. In such

cases, connecting all of the circuit return lines

together results in reduced equipment costs as

well as simpler system wiring.

The example below illustrates a digital

input board that has eight inputs and two

commons. This can be accomplished with a 10

terminal connector block.

Input module

There is a short period when voltage, and

therefore current flow, switches from one

direction to the other when no current flows.

This is called zero crossover. During zero

crossover, the digital input circuit must

“debounce” the signal to ensure that the system

does not provide a false indication that the input

contact is not closed when it is, in fact, closed.

OptiLogic AC digital inputs handle such zero

crossover conditions.

Digital Input Voltage

Any digital input module, AC or DC, is

designed to operate within an input voltage

range. The input voltage directly controls the

amount of current flowing through the circuit.

The minimum voltage corresponds to a voltage

that creates enough current to produce LED light

sufficient to be sensed by the optical sensor. The

IN7

IN6

IN5

IN4

IN3

IN2

IN1

IN0

10-30VDC

Sinking

IN7

IN6

IN5

IN4

IN3

IN2

IN1

IN0

10

9

8

7

6

5

4

3

2

1

10

9

8

7

6

5

4

3

2

1

Optimation, Inc.

(256)883-3050

www.optimate.com

8

OptiLogic Series

Digital Outputs

Digital outputs are used to turn “loads”

on and off. “Loads” may be lights, motors,

solenoids, or any type of on/off device found in

the “real world”.

Digital outputs in the OptiLogic series

come in three types - relay, transistor and solid

state relay. Each type has applications it is best

suited for. The following is a general list of

application characteristics for each output type.

Relay

•

Low contact loss

•

AC or DC

•

Moderate to high current rating

•

Low cost

Should not be used for

•

Ultra low current switching (less than 10mA)

•

Switching loads at high frequency

Transistor

•

DC application only

•

Low current rating

High frequency switching

•

•

Low cost

Relay Loads

Relays are affected by the type of load

that is switched. Inductive loads (solenoids,

motors, etc.) tend to wear the relay much more

than resistive loads (lights, heaters, etc.).

Inductive load wear is due to the fact that

inductive loads will continue to conduct current

for a period, even after the circuit is broken. This

current flow builds up opposing polarity charges

between the contact segments that just

separated. This makes the two segments attract

each other - making opening the contact more

difficult. It also can result in arcing while the

contact is being opened. Arcing, in turn, builds

up carbon deposits, i.e. wear.

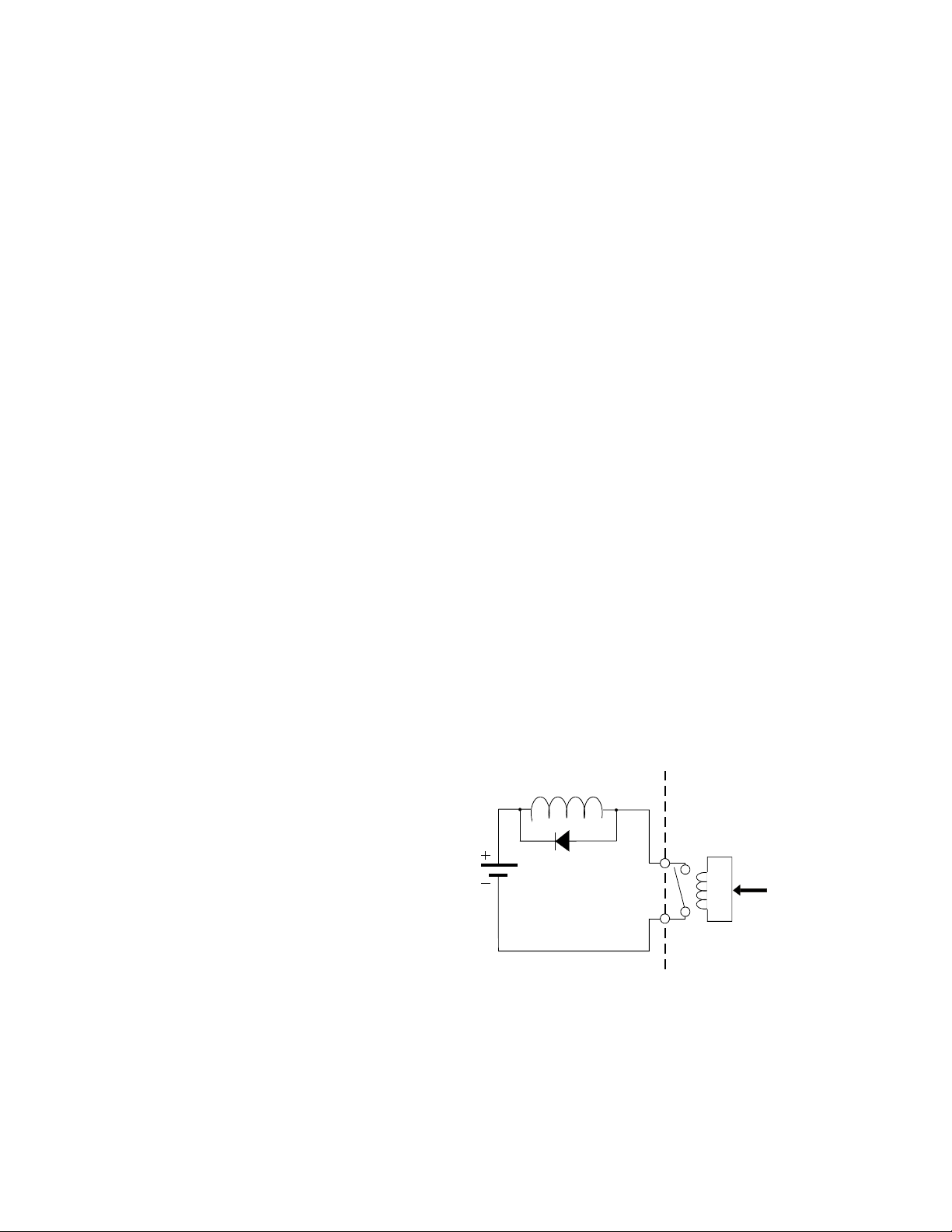

This situation can be improved for DC

inductive circuit loads by the addition of

external diode protection of the circuit. The

figure below illustrates diode protection. When

the contact is closed, the diode is reverse biased

and no current flows through it. When the

contact opens, current will continue to flow

through the inductive load. The diode provides a

path for current flow. The result that is the

energy is dissipated in the inductive coil and not

the relay contact.

Inductive load

Solid State Relay

•

AC application

•

Any switching frequency

•

Moderate current

•

Moderate cost

Relay Outputs

Relays are basically electrically

controlled mechanical switches. All current

OptiLogic Relay output boards utilize form A

relays - i.e. the contact is either open or closed.

Optimation, Inc.

(256)883-3050 9

www.optimate.com

Diode protection

isolation

From

OptiLogic

processor

Output module

Note : Do not use this circuit for AC loads.

OptiLogic Series

processor

processor

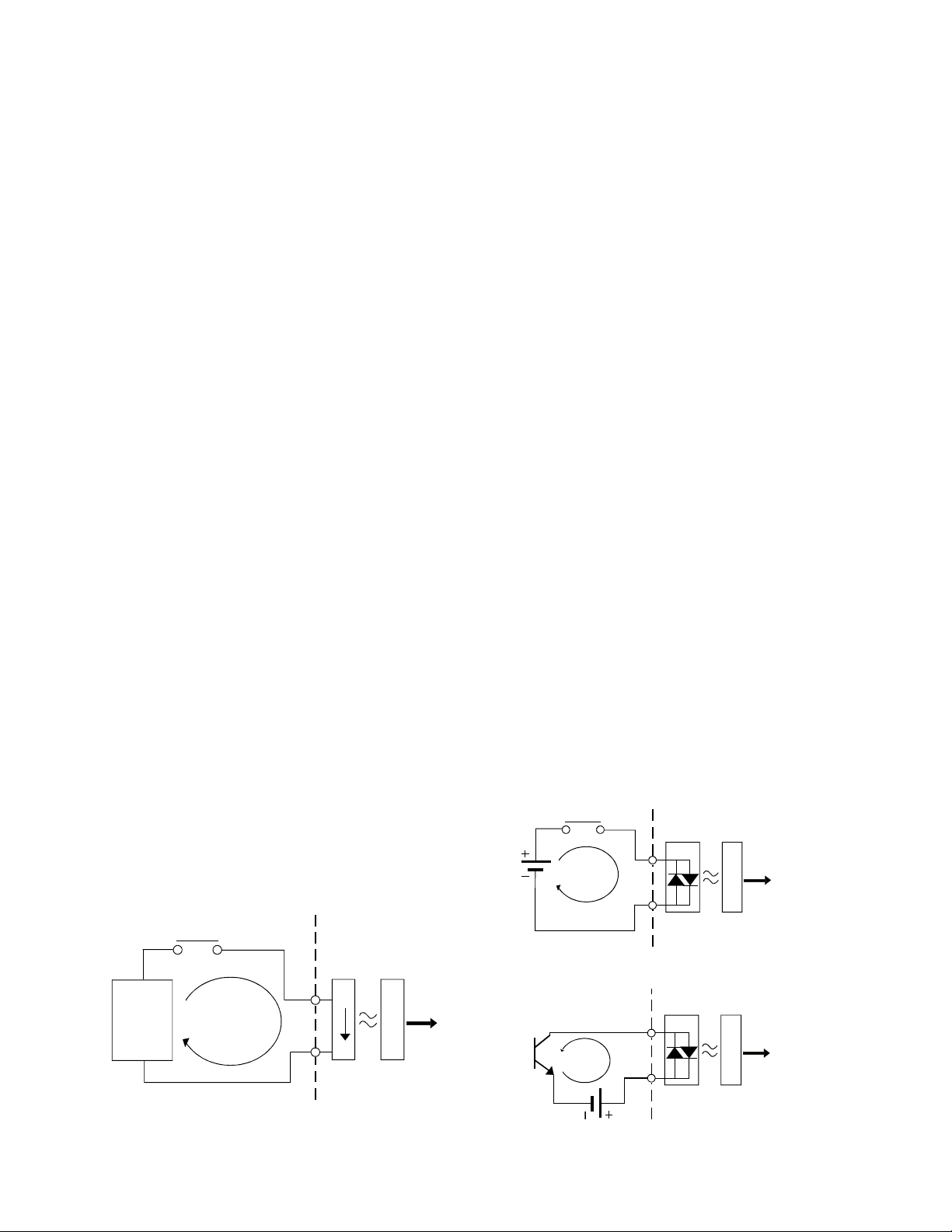

Transistor Outputs

NPN Transistor Sinking Outputs

An NPN transistor sinking output

provides a path to ground. A typical circuit is

shown below.

Inductive load

optical

Diode protection

There is a small voltage drop across the

transistor in such a circuit. The voltage drop will

generate heat in the transistor. Therefore NPN

transistor outputs are generally limited to lower

current applications.

isolation

From

OptiLogic

Output module

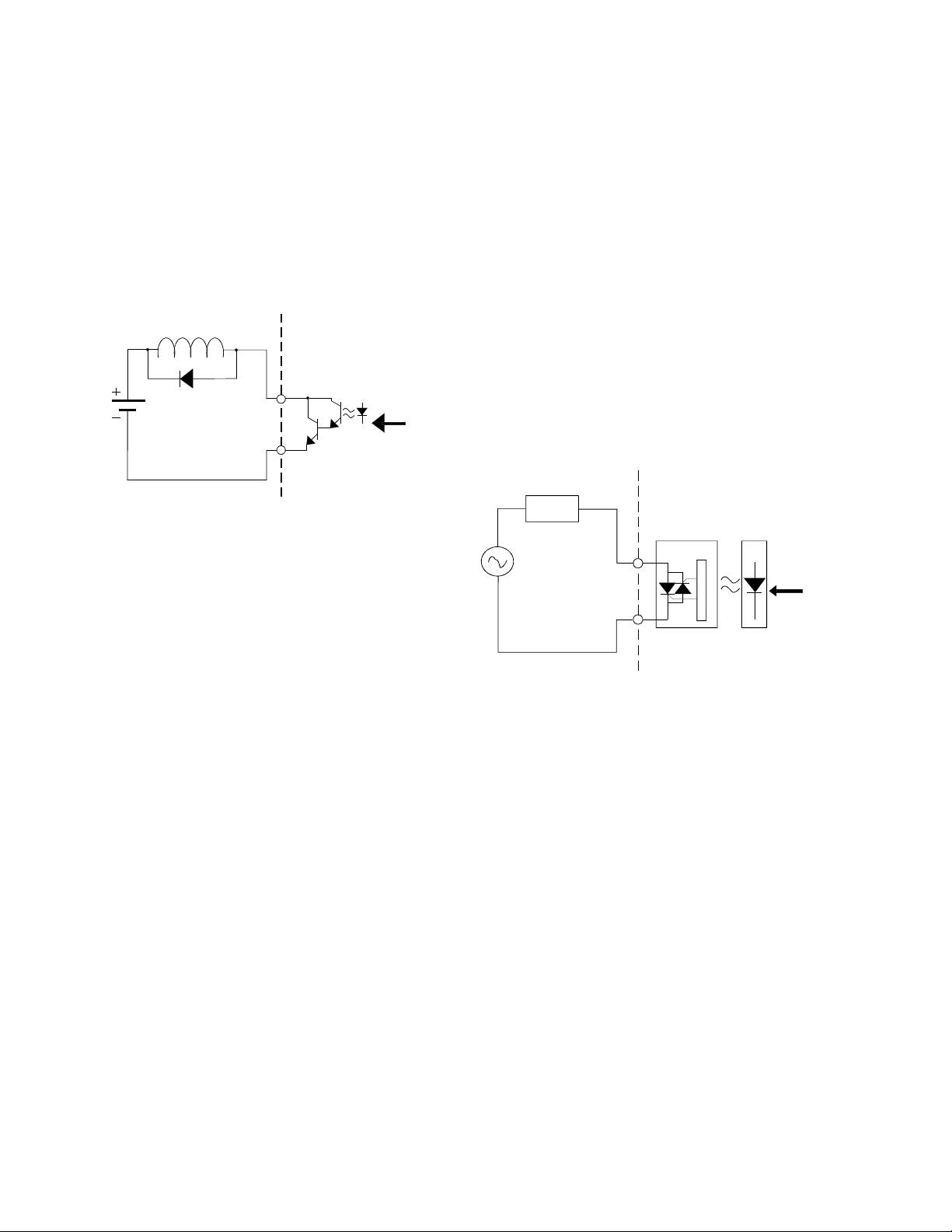

Solid State Relay Outputs

Solid state relays are semiconductor

switches that operate very much like mechanical

relays. They have an advantage over mechanical

relays by virtue of the fact that they are

semiconductors. Solid state relays can be

switched at relatively high frequencies and they

do not wear out. However they are more

expensive and there is a small voltage drop

across the contact.

The figure below illustrates a typical

solid state relay output. OptiLogic Solid state

relays are designed for AC load operation.

load

optical

isolation

From

OptiLogic

Transistor outputs can be operated at

high frequency. There is no effective wear on a

transistor output from switching, as there is in a

mechanical relay.

Diode protection applied to inductive

loads is recommended in cases where the load

current approaches the rated current limit of the

output. In most cases OptiLogic outputs are

designed to withstand voltages of at least twice

the rated output voltage. However, diode

protection like that shown above will ensure that

turn off voltage spikes will never get to that

level.

Output module

Optimation, Inc.

(256)883-3050

www.optimate.com

10

Loading...

Loading...