Nematron M-Series User Manual

M-Series

Document No. DOC-MON-018,

M-Series User Manual, Rev H Rel. 9-2012

Industrial Flat Panel Monitor

User’s Guide

2

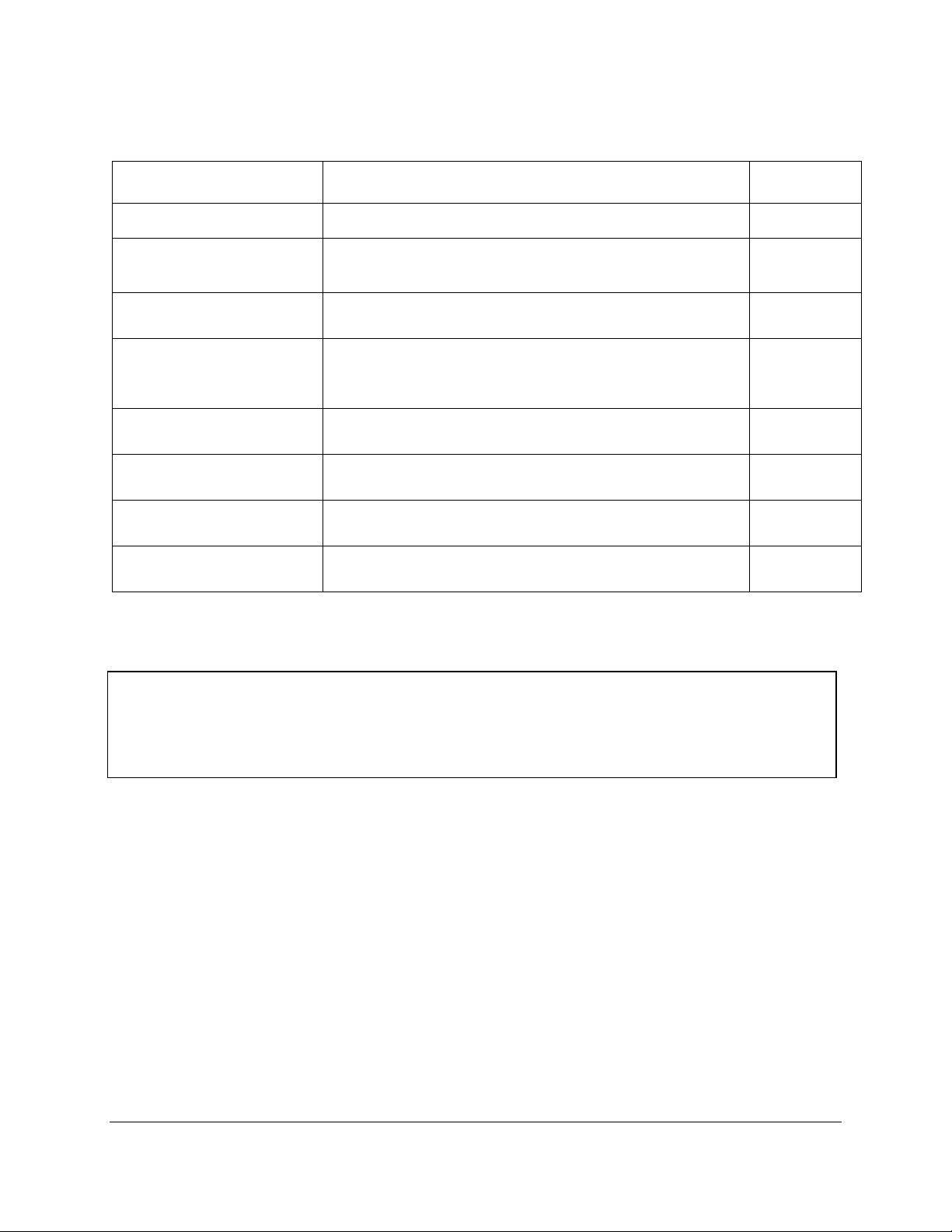

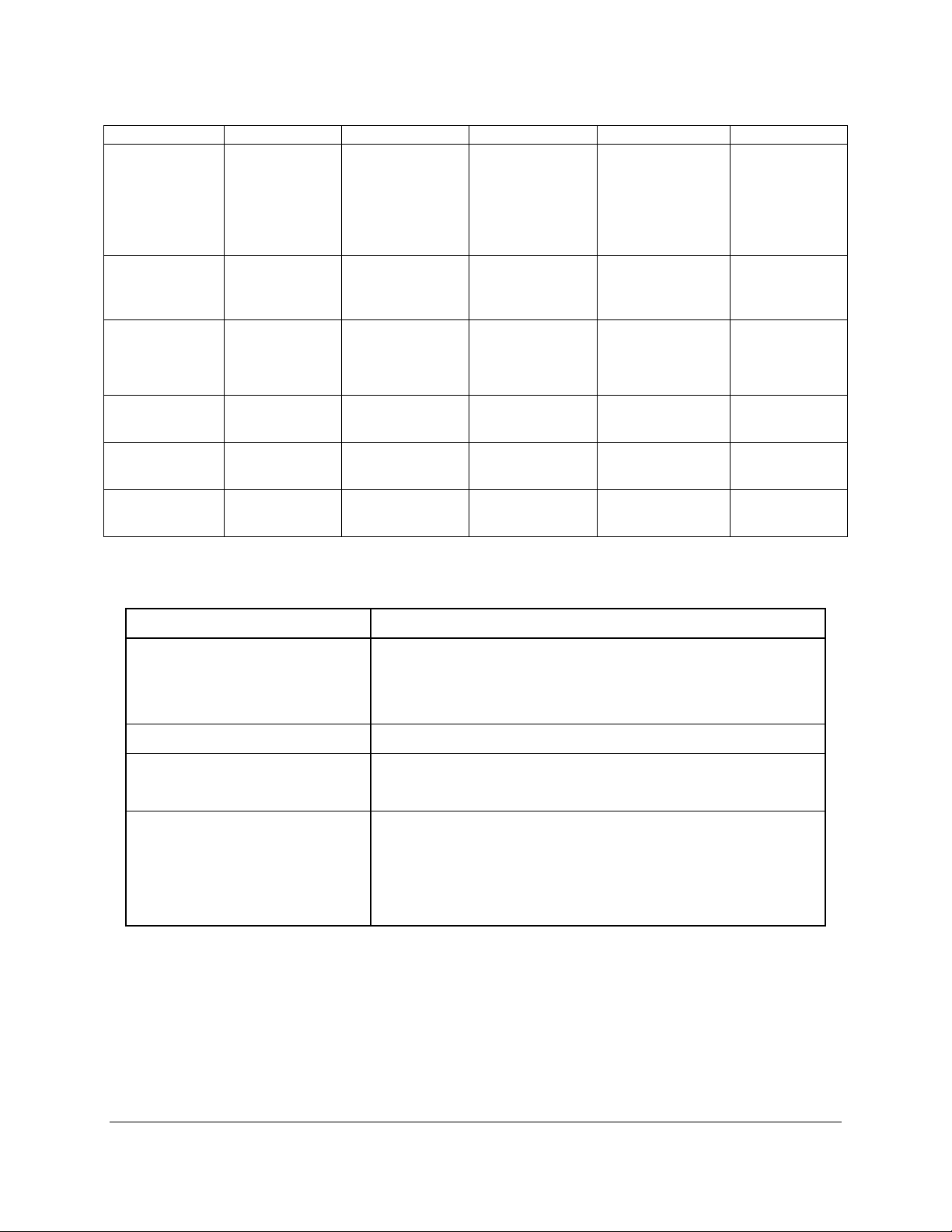

Revision Number

Description of Change

Release Date

B

Added Windows Vista driver to list of supported drivers, Added

4-2007

C

Added DVI functionality, UL Hazardous Locations Notes and

6-2008

E

Revision for Field Wiring Requirements

5-2010

F

Combined all monitors into one, Added –EN options and M1200

9-2010

H

UL Required changes for UL 1604 to ANSI/ISA 12.12.01-2012

9-2012

Nematron reserves the right to make changes in specifications described herein at any time without

responsibility for damage caused by misuse or improper use of its products.

Revision List

A Initial Release 9-2006

notes to driver list, Changed Logo, Corrected H X W Reversals on

page 5

Warnings

D Replaced “Power” with “Display Power” on button description,

added IEC 60950-1& RoHS to Agency Approvals, Added Input

Source Select instructions, Changed input power to 25 Watts and

updated display specifications.

G Added M2200WT 12-2011

Conversion

8-2008

notice in order to improve design and r eliability. Nematron do es not assume any respons ibility for

the use of any circuitry de scribed; no circuit patent licenses ar e implied. Nematron assumes no

WARRANTY

Nematron warrants to Customer that the Products will be free from defects in material and

workmanship under norm al use and service for a period of two years from date of invoice. Custom er’s

exclusive remed y for breac h of this war rant y is th at Nematron will either (i) r epair or re place , at its o ption,

any Product which fails dur ing the warranty period because of s uch def ect (if Cus tom er prom ptly reported

the failure to Nematron in writing) or, (ii) if Nematron is unabl e to repair or rep lace, Nematron will refund

the purchase price of the Product upon its return to Nematron. This warranty does not apply to any

Product which has b een s ubj ected t o m isuse, ab norm al ser vice or han dling, or which has bee n altere d or

modified in design or construction, or which has been serviced by anyone other than Nematron. The

warranty set forth herein is in lieu of, and exclusive of, all other warranties, express or implied.

Document No. DOC-MON-018, M-Series User Manual, Rev H Rel. 9-2012

3

Chapter 1 - Introduction

The M-Series are high performance TFT flat panel monitors specifically designed for harsh

industrial environments including Class I & II, Division 2 Hazardous Locations. The monitors accept

standard analog VGA or Digital DVI inputs. They can display VESA video m odes up to 1680 x 10 50 at

75Hz with 16 million color s. An optional 5-w ire analog touch scr een is available that offers both RS -232

and USB interface cap ability. The m onitor is housed in a heavy dut y steel chassis with a powder coate d

machined aluminum bezel. The monitor is c ertified to NEM A 4/4X/12 standar ds, is UL/CUL list ed, meets

CE requirements and is RoHS com pliant. Panel mounting is sim plified using convenient mount ing clips

instead of conventional studs. Options include: a 5-wire analog resistive touch screen or clear Lexan

window, a 304 stainless steel bezel, rack mount bezel (M1900 only), enclosed versions (M1500 and

M1900 only), and 24 volt DC in put power supply (not available on the enclosed o ptions). A ll monitors are

shipped with a power input wiring receptacle, VGA cable, touch screen cable (if equipped), mounting

hardware, manual and driver software.

Features

• UL 508 and ANSI/ISA 12.1 2.01-2012 listed for Hazardous Locations: Class I, Division 2, Groups

A, B, C, D and Class II, Division 2, Groups F and G, Class III hazardous locations when mounted

in a NEMA Type 1, 4, 4x, or 12 enclosure (does not include –EN options, -EN units only have UL

508 approvals only)

• NEMA 4/4X/12 front bezel (does not include –EN or –RM options)

• 2-Year warranty

• RoHS Compliant

• Integral 100 -240 VAC power supply

• Simplified installation with no studs

• Thin design – Only 2.7” behind bezel

• Accepts Analog Video or Digital Video (DVI) inputs

• VESA compliant – all modes up to WSXGA+, 75Hz

• Optional 5-wire resistive touch screen with both RS-232 and USB interface

• Optional 304 stainless steel front bezel

• Optional 24 VDC input power

• Optional Rack Mount front bezel on the M1900 (19”)

• Optional Rear NEMA 1 Enclosure (-EN)

4

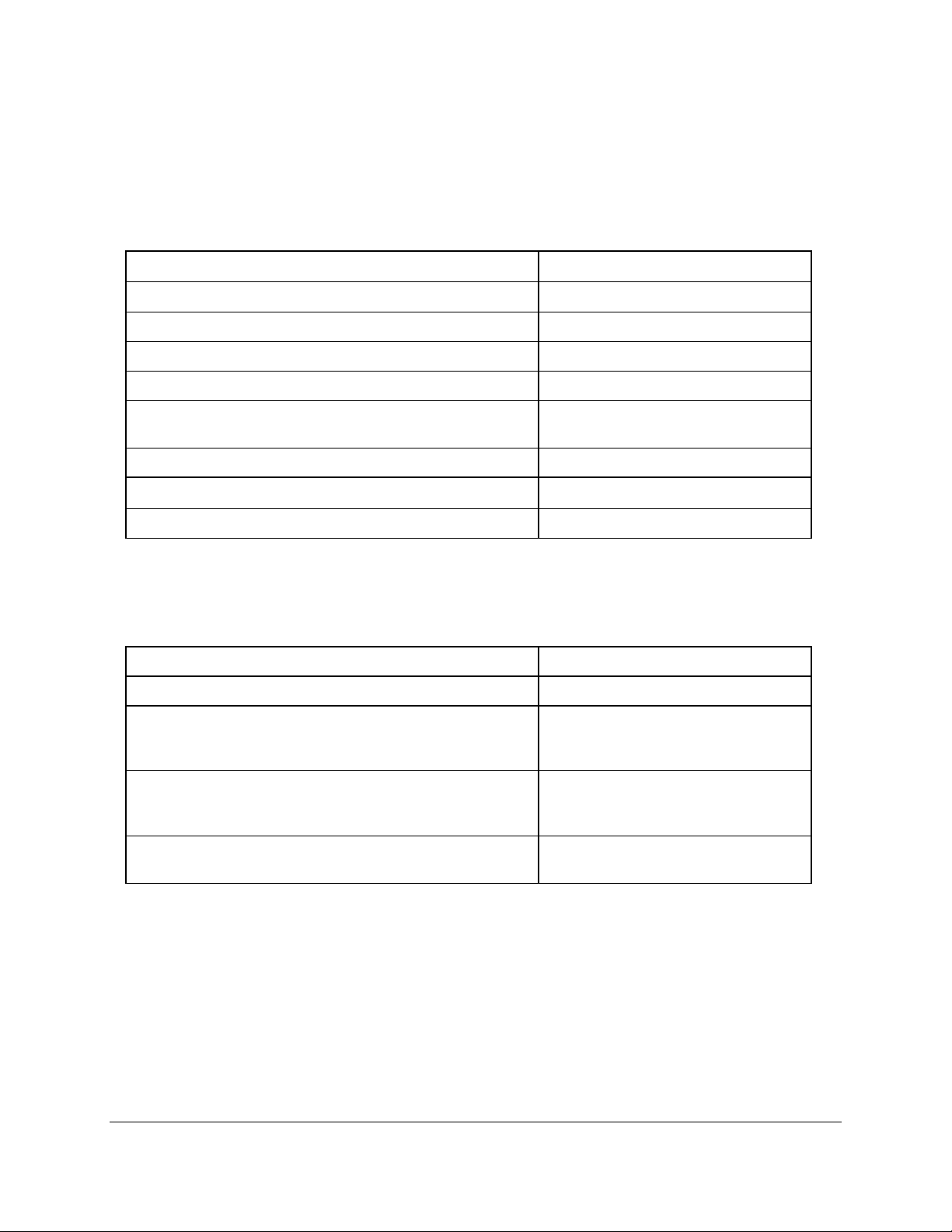

Mode

640 x 350 @ 70Hz

720 x 400 @ 70Hz

640 x 480 @ 60Hz

640 x 480 @ 72Hz

800 x 600 @ 56HZ

800 x 600 @ 60Hz

800 x 600 @ 72Hz

1024 x 768 @ 60Hz

1024 x 768 @ 70Hz

1024 x 768 @ 75Hz

1280 x 1024 @ 75Hz

1600 x 1050 @ 75Hz

Supported PC Video Modes

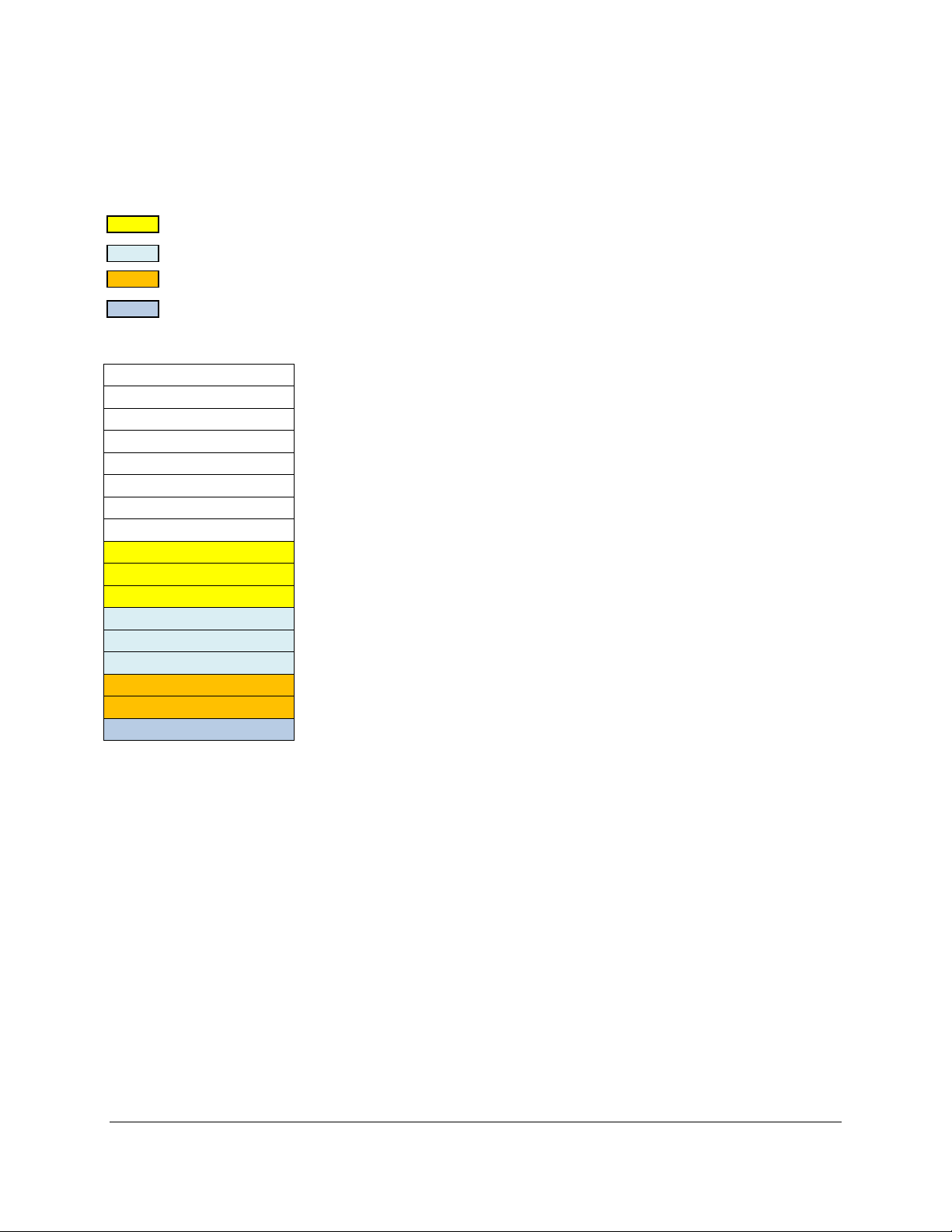

The M-Series monitors support the following video modes:

Note: The highlighted PC display modes produce the best image quality on the size monitors as follows:

- M1200

- M1500

- M1700 & M1900

- M220W

640 x 400 @ 70Hz

640 x 480 @ 75Hz

800 x 600 @ 75Hz

1280 x1024 @ 60Hz

5

Specifications

M1200

M1500

M1700

M1900

M2200W

Front Panels

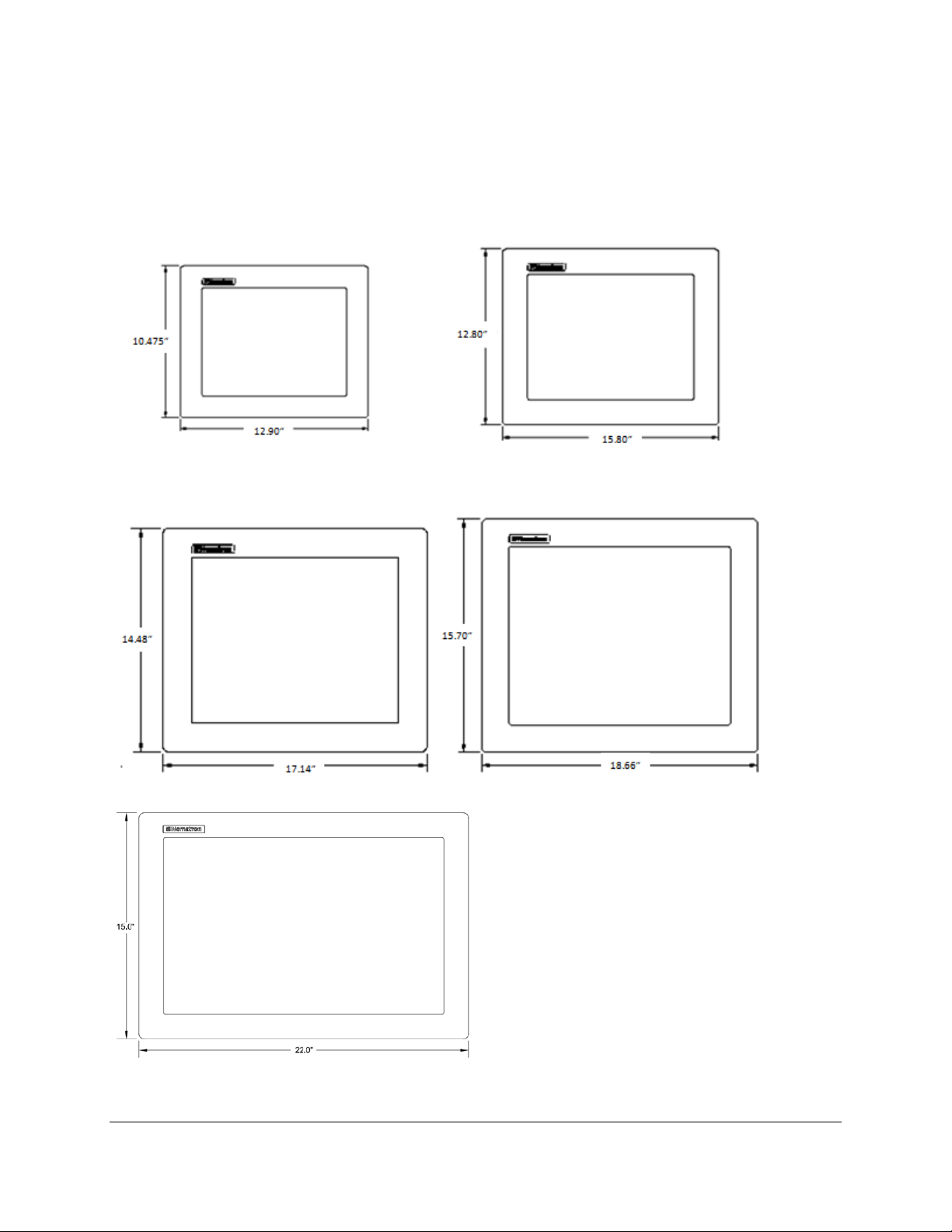

The M-Series monitors have NEMA 4/4X/12 sealed f ront panels when m ounted in an appropr iate

NEMA rated enclosure. See Chapter 2 for more details on installation and selection of an appropriate

enclosure. All five sizes have very similar front panels with different dimensions.

Figure 1.0: M-Series Front Panel Comparison

6

The standard front p anels are p owder coated aluminum . The optiona l Stainless Steel front pa nel is t ype

M1200

M1500

M1700

M1900

M2200W

12.1”

(307.34mm)

15.0”

(381.0mm)

17.0”

(431.8mm)

19.0”

(482.6mm)

22.0”

(558.8mm)

304 and will not contain a logo pock et or logo on the f ront. T he window area is c lear pol ycarbo nate when

ordered without a to uchscreen. The touchsc reen option is chemicall y strengthened glass cover ed by a

polyester overlay. The polyester overlay has better resistance to chemicals than the polycarbonate

window. Depending on the chemicals involved in your application consideration should be given to

choosing the proper win dow m aterial. In add ition ther e is a Rack Mount front p anel opt ion for the M19 00

(19” unit) only. This f ront panel is powder coated alu minum and is 9U high wit h four rack mount s paced

counter-bored mounting holes on each side of the panel. This panel is not NEMA sealed when installed.

DISPLAY

Display Diagonal

Display Size

(Active Area

HxV)

Native

Resolution

Displayable

Colors

Brightness,

Typical

Contrast Ratio,

Typical

Horizon/Vertical

View Angle,

CR>5, Typical

Backlight Life,

Typical

TOUCH SCREEN (Optional)

Touch Screen Technology 5- Wire Analog Resistive

9.69” x 7.26”

(246.0mm x

184.5mm)

SVGA,

800 x 600

262K 16M 16M 16M 16M

400 Nit 300 Nit 380 Nit 300 Nit 300 Nit

500:1 800:1 1000:1 2000:1 1000:1

130°/110° 150°/145° 170°/170° 178°/178° 178°/178°

50,000 hrs 50,000 hrs 50,000 hrs 50,000 hrs 50,000 hrs

11.97” x 8.98”

(304.0mm x

228.1mm)

XGA,

1024 x 768

13.30” x

10.64”

(337.8mm x

270.3mm)

SXGA,

1280 x 1024

14.82” x

11.85”

(376.4mm x

301.0mm)

SXGA,

1280 x 1024

(360.68mm x

18.65” x

11.65”

538.48mm)

WSXGA+

1680 x 1050

Interface RS-232 or USB

Positional Accuracy (Maximum Error) 0.18” (0.19” M1900)

4.57mm (4.83mm M1900)

Positional Accuracy (Standard Deviation of Error) < 0.08” (< 2.0 mm)

Expected Life >35,000,000 Activations

7

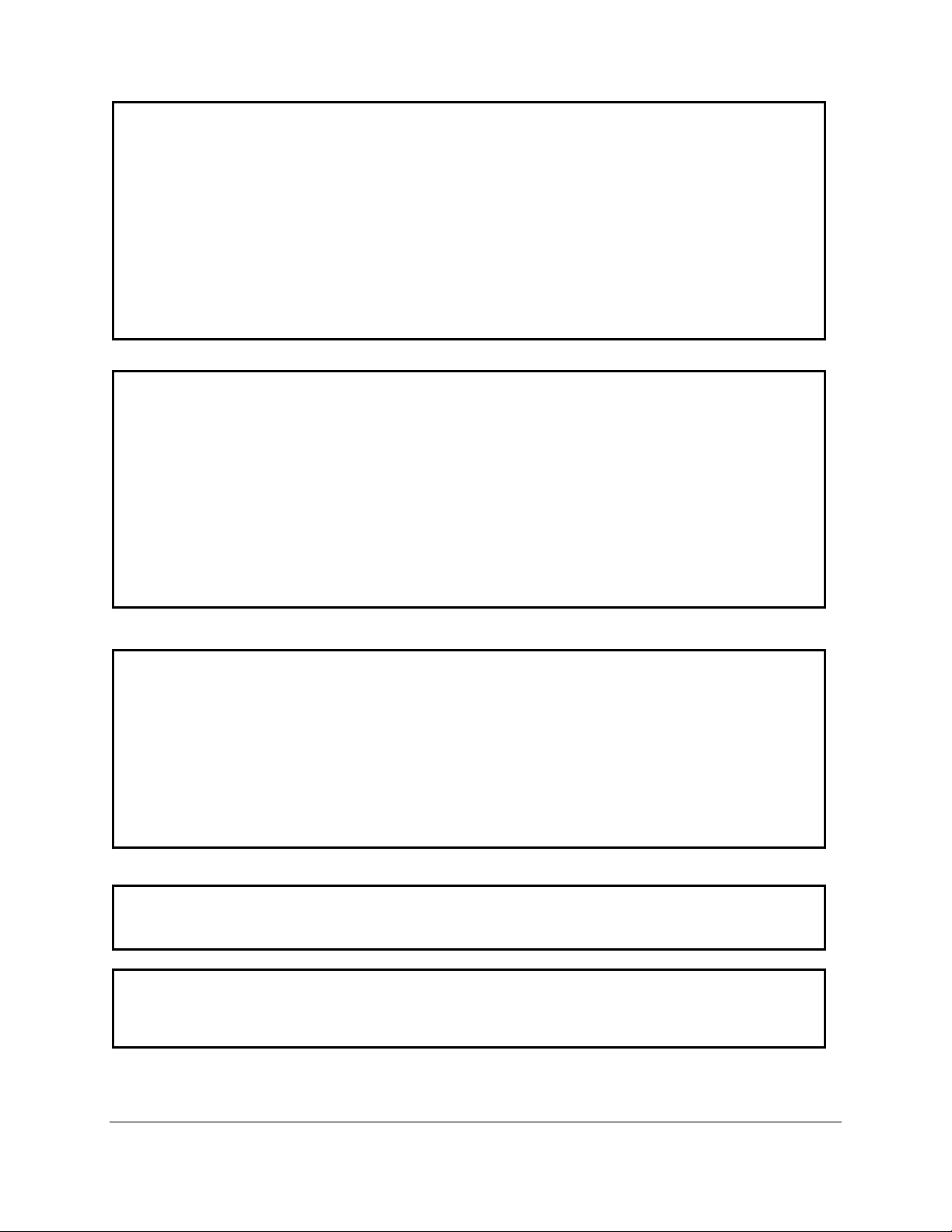

PHYSICAL

M1200

M1500

M1700

M1900

M2200W

10.475” x

Over All

Dimensions

(H x W x D)

Panel

Mounting

Depth

Cutout

Dimensions

(H x W)

Weight

Shipping

Weight

Option Weight

(-SS)

ELECTRICAL

AC Input Voltage 100 – 240 VAC, 50/60 Hz

12.9” x 2.65”

(266.1mm x

327.2mm x

67.3mm)

2.4”

(61.0mm)

9.68” x 12.10”

(245.9mm x

307.3mm)

9.5 lbs

(4.31kg)

14.0 lbs

(5.89kg)

+2.5 lbs

(1.13kg)

12.80” x 15.80”

x 2.65”

(325.1mm x

401.3mm x

67.3mm)

2.4”

(61.0mm)

12.00” x 15.00”

(305mm x

381mm)

14.0 lbs

(6.35kg)

19.0 lbs

(8.62kg)

+3.5 lbs

(1.58kg)

14.48” x 17.14”

x 2.85”

(367.8mm x

442.0mm x

72.4mm)

2.6”

(66.0mm)

13.70” x 16.35”

(348mm x

415.3mm)

18.5 lbs

(8.39kg)

23.5 lbs

(10.66kg)

+3.75 lbs

(1.70kg)

15.70” x 18.66”

(398.8mm x

474.0mm x

75.0mm)

(68.6mm)

14.90” x 17.75”

(378.5mm x

450.9mm)

(10.21kg)

(12.47kg)

+4.0 lbs (1.81kg) N/A

x 2.95”

2.7”

22.5 lbs

27.5 lbs

15.00” x 22.0”

x 2.95

(381mm x

558.8mm x

75.0mm)

2.7”

(68.6mm)

14.2” x 21.2”

9360.68mm x

538.48mm)

23.0 lbs

(10.43kg)

30.0 lbs

(13.60kg)

AC Input Current M1200 & M1500 – 0.5 A Maximum

M1700 & M1900 - 1.0 A M aximum

M2200W – 1.0 A Maximum

DC Input Voltage (Optional) 18 – 36 VDC

DC Input Current (Optional) M1200, M1500, M1700, & M1900 -2.0 A Max

M2200W – 4.5 A Max

Input Power M1200/M1500 - 25 W Typical*

M1700 – 30 W Typical*

M1900 – 35 W Typical*

M2200W – 60 W Typical*

* Typical Power is m easured witho ut an y add itional I/O or exp ansi on opt ions. An y addit ional I/ O ins talled

during application can increase this value.

8

CE, EN 55022: Class A,

2: Class A,

2,

ENVIROMENTAL

Operating Temperature

0°C to 50°C

Non-Operating Temperature

Operating & Non-Operating Humidity 20% to 80% RH, non-condensing

Operating Shock* 15g peak acceleration, 11msec

Non-Operating Shock 30g peak acceleration 11msec

Operating Vibration (5-2000 Hz) 1 0.006” peak to peak displacement,

Non-Operating Vibration (5-2000 Hz) 1

Operating Altitude 2 Sea level – 10,000 feet

Non-Operating Altitude 2 Sea level – 40,000 feet

1 Shock and Vibration specifications are established using Solid State drives and non-rotating media.

2 Altitude Specification is established by using all internal component specifications.

AGENCY

Front Panel NEMA Rating NEMA 4/4X/12, IP65

FCC 47 CFR, Part 15, Class A

EU CE Marking Compliance

EN 61000-3-3, EN 61000-6-

-20°C to 60°C

1g maximum acceleration

EN 61000-3-

Safety Agency Approvals (panel mount versions only) UL 508 Listed, ANSI/ISA 12.12.01-

2012 Listed*, cUL Listed CSA C22.2,

#142, CSA C22.2, #143*

Safety Agency Approvals (enclosed versions only) UL 508 Listed, cUL Listed CSA

C22.2

* See appropriate note below for the applicable unit or option being utilized.

9

WARNING – EXPLOSION HAZARD – DO NOT DISCONNECT EQUIPMENT

OF IGNITABLE CONCENTRATIONS.

NOTE (RACK MOUNT VERSIONS):

UNT INSTALLATION ON A TYPE 1 ENCLOSURE WITH

NOTE: (ENCLOSED M-SERIES VERSIONS):

WARNING – EXPLOSION HAZARD – SUBSTITUTION OF ANY COMPONENTS

NOTE (PANEL MOUNT VERSIONS):

SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C AND D, CLASS

II DIVISION 2, GROUPS F AND G, CLASS III HAZARDOUS LOCATIONS, OR

NONHAZARDOUS LOCATIONS ONLY

FOR USE ON A FLAT SURFACE OF A TYPE 1, 4, 4X, OR 12 ENCLOSURE

WITH PROVISIONS FOR CLASS I DIVISION 2 WIRING METHODS

TEMPERATURE CODE: T5

SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C AND D, CLASS

II DIVISION 2, GROUPS F AND G, CLASS III HAZARDOUS LOCATIONS, OR

NONHAZARDOUS LOCATIONS ONLY

FOR RACK MO

PROVISIONS FOR CLASS I DIVISION 2 WIRING METHODS

TEMPERATURE CODE: T5

A LISTED VESA STYLE MOUNT SUITABLE W ITH A MINIMUM LOAD RATING

OF 35 POUNDS SHALL BE USED IN THE END INSTALLATION

FOR USE IN NONHAZARDOUS LOCATIO NS ONLY

TYPE 1 ENCLOSURE

MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION 2

WHILE THE CIRCUIT IS LIVE OR UNLESS THE AREA IS KNOW TO BE FREE

10

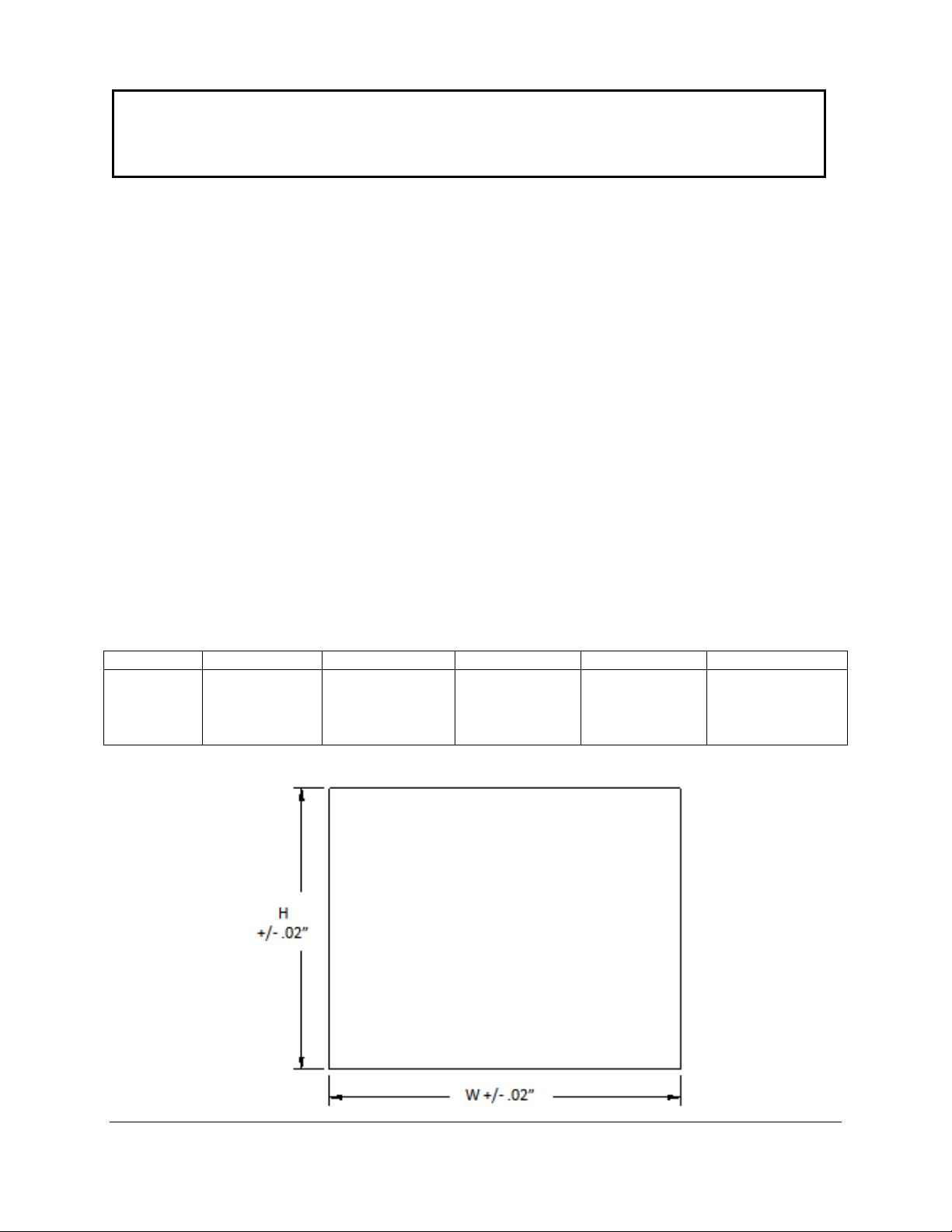

M1200

M1500

M1700

M1900

M2200WT

WARNING – EXPLOSION HAZARD – DO NOT DISCONNECT THE USB PORTS

UNLESS THE POWER HAS BEEN SWITCHED OFF AND THE AREA IS KNOWN

TO BE NON-HAZARDOUS

Chapter 2 - Installation of Computer

Panel Mount M-Series Unit installation

The panel m ount versions of the M-Series are intended to be m ounted in an d used where NEM A

1, NEMA 4/4x and NEM A 12 type enclosures are emplo yed. Enclosures made of heavier gaug e metal

work better because they won’t deform or bend as easily when the monitor’s sealing gasket is

compressed. The monitor meets NEMA 4/12 sealing specifications when properly installed in an

approved NEMA enc losure constructed from 14-gaug e or hea vier ste el. T he com puter uses “U”-shaped

clips and a special gasket to achieve the proper seal.

When selecting an enclos u re r em em ber to allo w ad eq uate s pace ar oun d t h e r ear of the computer

for good air flow. Do not bl oc k air flow from below or a bov e th e monitor. If possibl e mount the computer in

a vertical orientation. T he unit is designed t o work in env ironments up to 5 0 degrees Centigra de ambient

temperature inside the enc losure. Remember to account for heat diss ipated from other equipment that

may be installed inside the same enclosure.

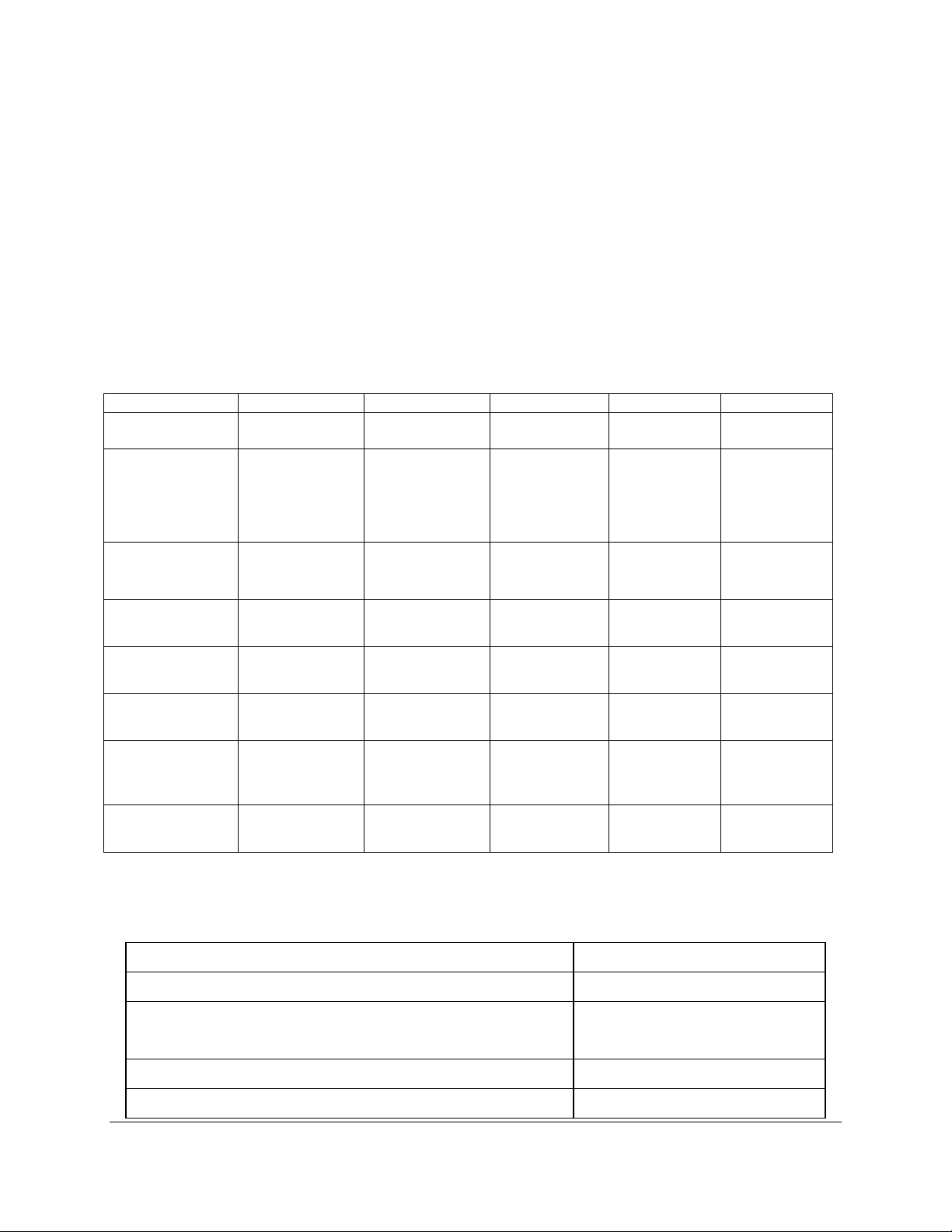

To install the computer , make a cutout accordin g to the diagrams below in one of the walls of

your NEMA enclosure. N ex t hold the u nit in p lace w hile you install t he m ounting clips. T ighten the c lips

to the point where the back of the unit’s front bezel just begins to contact the front of the NEMA

enclosure. The use of an adjustabl e torque driver is recomm ended. The screws s hould b e tightened to 8

inch-pounds. Tighten the clips in a cross pattern. This will help to develop an even pressure on the

sealing gasket. DO NOT OVER TIGHT EN AS DAMAGE CAN RESULT IN THE COM PUTER CAUSING

LOSS OF SEALING INTEGRITY.

Cutout

Dimensions

(H x W)

9.68” x 12.10”

(245.9mm x

307.3mm)

12.00” x 15.00”

(305mm x

381mm)

13.70” x 16.35”

(348mm x

415.3mm)

14.90” x 17.75”

(378.5mm x

450.9mm)

14.20” x 21.2”

(473.8mm x

296.1mm)

Loading...

Loading...