Page 1

User’s Manual

V850ES/Fx3 - CAN it!

Demonstration Kit for the V850ES/Fx3

32-bit RISC microcontroller

Document No. U18560EE1V0UM00

Date Published January 2007

© NEC Electronics (Europe) GmbH

Page 2

V850ES/Fx3 – CAN it!

・ The information in this document is current as of date of its publication. The information is subject to

change without notice. For actual design-in, refer to the latest publications of NEC Electronics data

sheets or data books, etc., for the most up-to-date specifications of NEC Electronics products. Not all

products and/or types are available in every country. Please check with an NEC sales representative

for availability and additional information.

・ No part of this document may be copied or reproduced in any form or by any means without prior

written consent of NEC Electronics. NEC Electronics assumes no responsibility for any errors that may

appear in this document.

・ NEC Electronics does not assume any liability for infringement of patents, copyrights or other

intellectual property rights of third parties by or arising from the use of NEC Electronics products listed

in this document or any other liability arising from the use of such NEC Electronics products. No

license, express, implied or otherwise, is granted under any patents, copyrights or other intellectual

property rights of NEC Electronics or others.

・ Descriptions of circuits, software and other related information in this document are provided for

illustrative purposes in semiconductor product operation and application examples. The incorporation

of these circuits, software and information in the design of customer's equipment shall be done under

the full responsibility of customer. NEC Electronics no responsibility for any losses incurred by

customers or third parties arising from the use of these circuits, software and information.

・ While NEC Electronics endeavors to enhance the quality, reliability and safety of NEC Electronics

products, customers agree and acknowledge that the possibility of defects thereof cannot be

eliminated entirely. To minimize risks of damage to property or injury (including death) to persons

arising from defects in NEC Electronics products, customers must incorporate sufficient safety

measures in their design, such as redundancy, fire-containment and anti-failure features.

・ NEC Electronics products are classified into the following three quality grades: “Standard”, “Special”

and “Specific”.

The "Specific" quality grade applies only to NEC Electronics products developed based on a customerdesignated “quality assurance program” for a specific application. The recommended applications of NEC

Electronics product depend on its quality grade, as indicated below. Customers must check the quality

grade of each NEC Electronics product before using it in a particular application.

"Standard": Computers, office equipment, communications equipment, test and measurement

equipment, audio and visual equipment, home electronic appliances, machine tools,

personal electronic equipment and industrial robots.

"Special": Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti disaster systems, anti-crime systems, safety equipment and medical equipment (not

specifically designed for life support).

"Specific": Aircraft, aerospace equipment, submersible repeaters, nuclear reactor control systems,

life support systems and medical equipment for life support, etc.

The quality grade of NEC Electronics products is “Standard” unless otherwise expressly specified in NEC

Electronics data sheets or data books, etc. If customers wish to use NEC Electronics products in

applications not intended by NEC Electronics, they must contact NEC Electronics sales representative in

advance to determine NEC Electronics 's willingness to support a given application.

Notes: 1." NEC Electronics" as used in this statement means NEC Electronics Corporation and also

includes its majority-owned subsidiaries.

2. " NEC Electronics products" means any product developed or manufactured by or for NEC

Electronics (as defined above).

User’s Manual U18560EE1V0UM00 2

Page 3

V850ES/Fx3 – CAN it!

CAUTION

This is a Test- and Measurement equipment with possibility to be significantly

altered by user through hardware enhancements/modifications and/or test or

application software. Thus, with respect to Council Directive 89/336/EEC

(Directive on compliance with the EMC protection requirements), this equipment

has no autonomous function. Consequently this equipment is not marked by the

CE-symbol.

EEDT-ST-005-10

CAUTION

This equipment should be handled like a CMOS semiconductor device. The

user must take all precautions to avoid build-up of static electricity while

working with this equipment. All test and measurement tool including the

workbench must be grounded. The user/operator must be grounded using

the wrist strap. The connectors and/or device pins should not be touched

with bare hands.

EEDT-ST-004-10

Redemption of Waste Electrical and Electronic Equipment

(WEEE) in accordance with legal regulations applicable in the

European Union only: This equipment (including all

accessories) is not intended for household use. After use the

equipment cannot be disposed of as household waste. NEC

Electronics (Europe) GmbH offers to take back the equipment.

All you need to do is register at www.eu.necel.com/weee.

User’s Manual U18560EE1V0UM00 3

Page 4

V850ES/Fx3 – CAN it!

Regional Information

Some information contained in this document may vary from country to country. Before using any NEC

product in your application, please contact the NEC office in your country to obtain a list of authorized

representatives and distributors. They will verify:

• Device availability

• Ordering information

• Product release schedule

• Availability of related technical literature

• Development environment specifications (for example, specifications for

third-party tools and components, host computers, power plugs, AC supply

voltages, and so forth)

• Network requirements

In addition, trademarks, registered trademarks, export restrictions, and otherlegal issues may also vary

from country to country.

NEC Electronics Inc. (U.S.)

Santa Clara, California

Tel: 408-588-6000

800-366-9782

Fax: 408-588-6130

800-729-9288

NEC Electronics (Europe) GmbH

Duesseldorf, Germany

Tel: 0211-65 03 0

Fax: 0211-65 03 1327

Sucursal en España

Madrid, Spain

Tel: 091- 504 27 87

Fax: 091- 504 28 60

Succursale Française

Vélizy-Villacoublay, France

Tel: 01-30-67 58 00

Fax: 01-30-67 58 99

Filiale Italiana

Milano, Italy

Tel: 02-66 75 41

Fax: 02-66 75 42 99

Branch The Netherlands

Eindhoven, The Netherlands

Tel: 040-244 58 45

Fax: 040-244 45 80

Branch Sweden

Taeby, Sweden

Tel: 08-63 80 820

Fax: 08-63 80 388

United Kingdom Branch

Milton Keynes, UK

Tel: 01908-691-133

Fax: 01908-670-290

NEC Electronics Hong Kong Ltd.

Hong Kong

Tel: 2886-9318

Fax: 2886-9022/9044

NEC Electronics Hong Kong Ltd.

Seoul Branch

Seoul, Korea

Tel: 02-528-0303

Fax: 02-528-4411

NEC Electronics Singapore Pte. Ltd.

Singapore

Tel: 65-6253-8311

Fax: 65-6250-3583

NEC Electronics Taiwan Ltd.

Taipei, Taiwan

Tel: 02-2719-2377

Fax: 02-2719-5951

NEC do Brasil S.A.

Electron Devices Division

Guarulhos, Brasil

Tel: 55-11-6465-6810

Fax: 55-11-6465-6829

User’s Manual U18560EE1V0UM00 4

Page 5

V850ES/Fx3 – CAN it!

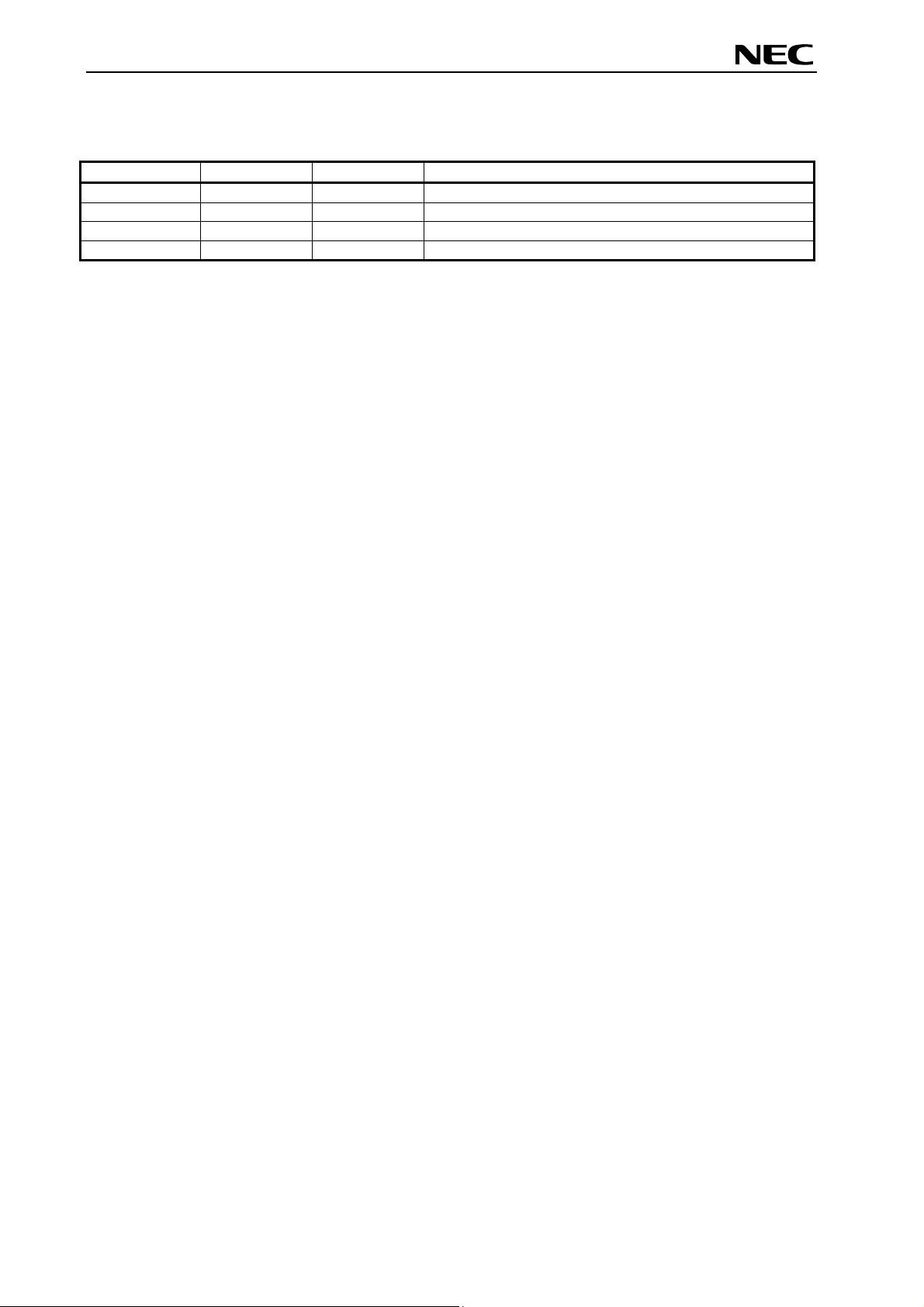

Revision History

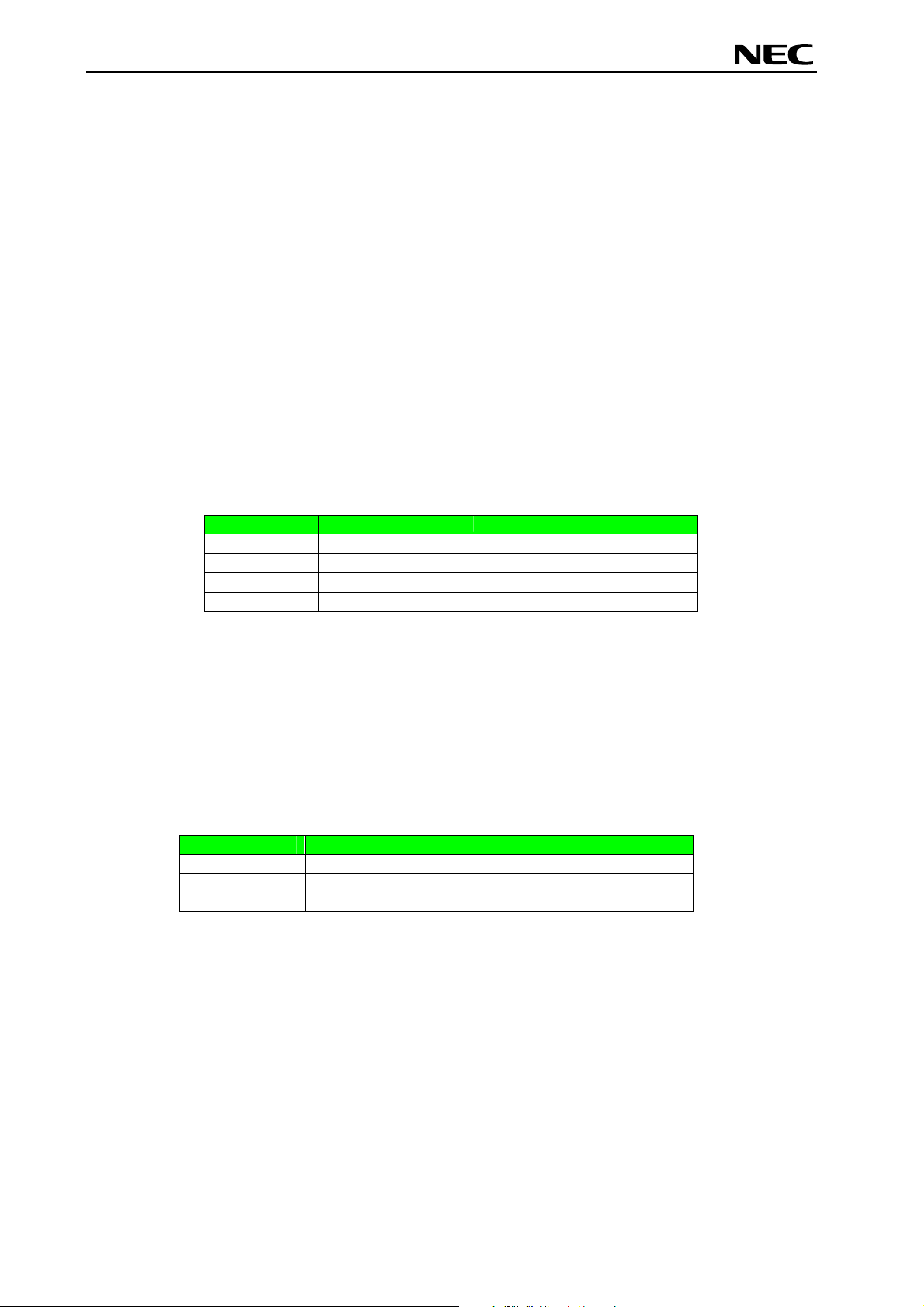

Date Revision Chapter Description

12-01-2007 V1.00 --- First release

User’s Manual U18560EE1V0UM00 5

Page 6

V850ES/Fx3 – CAN it!

Table of Contents

1. Introduction ........................................................................................................................11

1.1 Main features of V850ES/Fx3 – CAN it! ......................................................................................... 11

1.2 System requirements ...................................................................................................................... 13

1.3 Package contents ............................................................................................................................ 13

1.4 Trademarks ...................................................................................................................................... 13

2. V850ES/Fx3 – CAN it! system configuration....................................................................14

2.1 V850ES/Fx3 – CAN it! ...................................................................................................................... 14

2.2 Host computer ................................................................................................................................. 14

2.3 Power supply via USB interface..................................................................................................... 14

3. V850ES/Fx3 – CAN it! baseboard components ...............................................................15

3.1 RESET button SW1.......................................................................................................................... 16

3.2 User button SW2.............................................................................................................................. 16

3.3 User button SW3.............................................................................................................................. 16

3.4 Configuration switch SW4 .............................................................................................................. 16

3.4.1 Operation mode selection SW4/S1 ................................................................................................ 16

3.4.2 TK-V850 / FPL mode selection switch SW4/S2 ............................................................................. 17

3.4.3 UART/ LIN mode selection SW4/S3............................................................................................... 17

3.4.4 User switch SW4/S4 ....................................................................................................................... 17

3.5 LIN plug JP1 ..................................................................................................................................... 17

3.6 USB interface connector CN6 ........................................................................................................ 18

3.7 Connector CN4................................................................................................................................. 19

3.8 External Potentiometer R7.............................................................................................................. 19

3.9 Display D1, 12*2 character LC display .......................................................................................... 20

3.10 External Potentiometer R14.......................................................................................................... 20

3.11 AD converter reference voltage input ......................................................................................... 20

3.12 Temperature sensor ...................................................................................................................... 21

3.13 External LED’s D1–D4 ................................................................................................................... 22

4. V850ES/Fx3 – CAN it! CPU module components ............................................................23

4.1 V850ES/Fx3 – CAN it! CPU module................................................................................................ 23

4.1.1 External connector CN7 and CN8 .................................................................................................. 24

4.2 High Speed CAN connector CN6 ................................................................................................... 24

4.3 CAN connectors, CN3 and CN4...................................................................................................... 25

4.4 External power supply input, CN5 ................................................................................................. 25

4.4.1 N-Wire connector CN9 ................................................................................................................... 26

5. On-Chip debugging............................................................................................................27

5.1 OCD via TK-V850 debugging.......................................................................................................... 27

5.2 OCD via N-Wire debugging............................................................................................................. 28

6. V850ES/Fx3 – CAN it! installation and operation ............................................................29

6.1 Getting started ................................................................................................................................. 29

6.1.1 CD-ROM contents .......................................................................................................................... 29

User’s Manual U18560EE1V0UM00 6

Page 7

V850ES/Fx3 – CAN it!

7. Hardware installation .........................................................................................................30

8. Software installation ..........................................................................................................30

8.1 IAR Systems Embedded Workbench for V850 installation ......................................................... 30

8.2 TK-V850 driver installation ............................................................................................................. 30

8.3 FPL FLASH programming GUI installation ................................................................................... 30

8.4 Sample program installation .......................................................................................................... 30

8.5 USB Driver Installation.................................................................................................................... 31

8.5.1 Installation on Windows 98SE/Me.................................................................................................. 31

8.5.2 Installation on Windows 2000......................................................................................................... 33

8.5.3 Installation on Windows XP ............................................................................................................ 39

8.6 Confirmation of USB Driver Installation........................................................................................ 44

8.7 Driver Uninstallation........................................................................................................................ 45

9. FPL FLASH programming software..................................................................................47

9.1 Introduction...................................................................................................................................... 47

9.2 Starting up the GUI Software ......................................................................................................... 47

9.3 Toolbar.............................................................................................................................................. 48

9.4 Menu Bar .......................................................................................................................................... 49

9.4.1 [File] menu ...................................................................................................................................... 49

9.4.2 [Device] menu................................................................................................................................. 50

9.4.3 [View] menu .................................................................................................................................... 57

9.4.4 [Help] menu .................................................................................................................................... 58

9.5 Programmer Parameter Window.................................................................................................... 59

10. How to use FPL FLASH programming software............................................................60

10.1 Installing the FPL GUI software ................................................................................................... 60

10.2 Installing the driver........................................................................................................................ 60

10.3 Installing the parameter file.......................................................................................................... 60

10.4 Connecting and starting ............................................................................................................... 61

10.5 Setting the programming environment ....................................................................................... 62

10.6 Selecting a user program ............................................................................................................. 65

10.7 [Autoprocedure(EPV)] command execution............................................................................... 66

10.8 Terminating the GUI ...................................................................................................................... 66

10.9 Execute “ADC_DEMO” application ............................................................................................. 66

10.10 Restarting the GUI ....................................................................................................................... 66

11. TROUBLESHOOTING .......................................................................................................67

12. TK-V850 debugging.......................................................................................................... 69

12.1 Monitor resources ......................................................................................................................... 70

12.1.1 UARTD0 ....................................................................................................................................... 70

12.1.2 Interrupt vectors............................................................................................................................ 70

12.1.3 Reset vector.................................................................................................................................. 71

12.1.4 Memory area................................................................................................................................. 71

12.1.5 Clock operation............................................................................................................................. 71

12.1.6 Other limitations............................................................................................................................ 71

12.2 IAR sample session....................................................................................................................... 72

User’s Manual U18560EE1V0UM00 7

Page 8

V850ES/Fx3 – CAN it!

13. Sample programs .............................................................................................................78

13.1 General Introduction ..................................................................................................................... 78

13.2 ADC demo ...................................................................................................................................... 79

13.3 CAN demo ...................................................................................................................................... 79

13.4 ReacTime demo ............................................................................................................................. 79

13.5 Timer demo .................................................................................................................................... 80

13.6 UART demo .................................................................................................................................... 80

14. USB interface cable (Mini-B type) ...................................................................................81

15. Schematics .......................................................................................................................82

User’s Manual U18560EE1V0UM00 8

Page 9

V850ES/Fx3 – CAN it!

List of Figures

Figure 1: V850ES/Fx3 – CAN it! system configuration ...............................................................................

Figure 2: V850ES/Fx3 – CAN it! baseboard connectors, switches and LED’s ...........................................15

Figure 3: Connector CN6, USB Mini-B Type Host Connector Pin Configuration........................................18

Figure 4: V850ES/Fx3 – CAN it! CPU module components .......................................................................23

Figure 5: CAN transceivers .........................................................................................................................25

Figure 6: Configuration for On-Chip debugging ..........................................................................................27

Figure 7: Add New Hardware Wizard (Windows 98SE).............................................................................31

Figure 8: Search Method (Windows 98SE).................................................................................................31

Figure 9: Search Location Specification (Windows 98SE)..........................................................................32

Figure 10: Checking Driver to Be Installed (Windows 98SE)......................................................................32

Figure 11: Installation Completion (Windows 98SE)...................................................................................33

Figure 12: Found New Hardware Wizard 1 (Windows 2000)......................................................................33

Figure 13: Search Method 1 (Windows 2000).............................................................................................34

Figure 14: Driver File Location 1 (Windows 2000)......................................................................................34

Figure 15: Address Specification 1 (Windows 2000) ..................................................................................35

Figure 16: Driver File Search 1 (Windows 2000) ........................................................................................35

Figure 17: USB Driver Installation Completion 1 (Windows 2000) .............................................................36

Figure 18: Found New Hardware Wizard 2 (Windows 2000)......................................................................36

Figure 19: Search Method 2 (Windows 2000).............................................................................................37

Figure 20: Driver File Location 2 (Windows 2000)......................................................................................37

Figure 21: Address Specification 2 (Windows 2000) ..................................................................................38

Figure 22: Driver File Search 2 (Windows 2000) ........................................................................................38

Figure 23: USB Driver Installation Completion 2 (Windows 2000) .............................................................39

Figure 24: Found New Hardware Wizard 1 (Windows XP).........................................................................39

Figure 25: Search Location Specification 3 (Windows XP).........................................................................40

Figure 26: Windows XP Logo Testing 3 (Windows XP)..............................................................................40

Figure 27: USB Driver Installation Completion 1 (Windows XP).................................................................41

Figure 28: Found New Hardware Wizard 2 (Windows XP).........................................................................41

Figure 29: Search Location Specification 2 (Windows XP).........................................................................42

Figure 30: Windows XP Logo Testing 2 (Windows XP)..............................................................................42

Figure 31: USB Serial Port2 Driver Installation Completion (Windows XP)................................................43

Figure 32: Device Manager .........................................................................................................................44

Figure 33: Driver Uninstallation ...................................................................................................................45

Figure 34: Driver Uninstaller........................................................................................................................45

Figure 35: Completion of Driver Uninstallation............................................................................................46

Figure 36: GUI Software Main Window .......................................................................................................47

Figure 37: Toolbar Buttons..........................................................................................................................48

Figure 38: [File] Menu..................................................................................................................................49

Figure 39: HEX File Selection Window .......................................................................................................49

Figure 40: [Device] Menu ............................................................................................................................50

Figure 41: Device Setup Window - Standard ..............................................................................................52

Figure 42: Setup Window - Parameter File Selection .................................................................................53

Figure 43: Parameter File Selection Window..............................................................................................53

Figure 44: Setup Window - Communication interface to device .................................................................54

Figure 45: Setup Window - Supply Oscillator Selection..............................................................................54

Figure 46: Setup Window - Operation Mode...............................................................................................55

Figure 47: Device Setup Window - Advance...............................................................................................56

Figure 48: Setup Window - Command options ...........................................................................................56

Figure 49: [View] Menu................................................................................................................................57

Figure 50: [Help] Menu ................................................................................................................................58

Figure 51: About FPL Window ....................................................................................................................58

Figure 52: Programmer Parameter Window ...............................................................................................59

Figure 53: GUI Software Startup Screen.....................................................................................................62

Figure 54: <Standard Device Setup> Dialog Box .......................................................................................62

Figure 55: Parameter File Selection............................................................................................................63

Figure 56: Port Selection .............................................................................................................................63

Figure 57: <Standard Device Setup> Dialog Box after Setting...................................................................64

14

User’s Manual U18560EE1V0UM00 9

Page 10

V850ES/Fx3 – CAN it!

Figure 58: <Advance Device Setup> Dialog Box ........................................................................................

Figure 59: Completion of Parameter Setting...............................................................................................65

Figure 60: After Downloading......................................................................................................................65

Figure 61: After EPV Execution...................................................................................................................66

Figure 62: IAR Embedded Workbench .......................................................................................................72

Figure 63: IAR project workspace ...............................................................................................................73

Figure 64: IAR debugger options 1/2 ..........................................................................................................73

Figure 65: IAR debugger options 2/2 ..........................................................................................................74

Figure 66: IAR Linker options......................................................................................................................74

Figure 67: TK-V850 hardware setup menu .................................................................................................75

Figure 68: IAR project download .................................................................................................................76

Figure 69: IAR C-SPY debugger .................................................................................................................77

Figure 70: USB interface cable (Mini-B type)..............................................................................................81

Figure 71: V850ES/Fx3 – CAN it! baseboard schematics ..........................................................................82

Figure 72: V850ES/Fx3 – CAN it! CPU module schematics.......................................................................83

64

List of Tables

Table 1: Configuration switch SW4, factory settings...................................................................................

Table 2: Operation mode selection SW4/S1 ...............................................................................................16

Table 3: TK-V850 / FPL mode selection switch SW4/S2 ............................................................................17

Table 4: UART/ LIN mode selection SW4/S3 .............................................................................................17

Table 5: User switch SW4/S4......................................................................................................................17

Table 6: LIN plug JP1 ..................................................................................................................................17

Table 7: Pin Configuration of USB Connector CN6 ....................................................................................18

Table 8: CN4, PG-FP4 connector ...............................................................................................................19

Table 9: SW4 configuration when using PG-FP4........................................................................................19

Table 10: Display connections ....................................................................................................................20

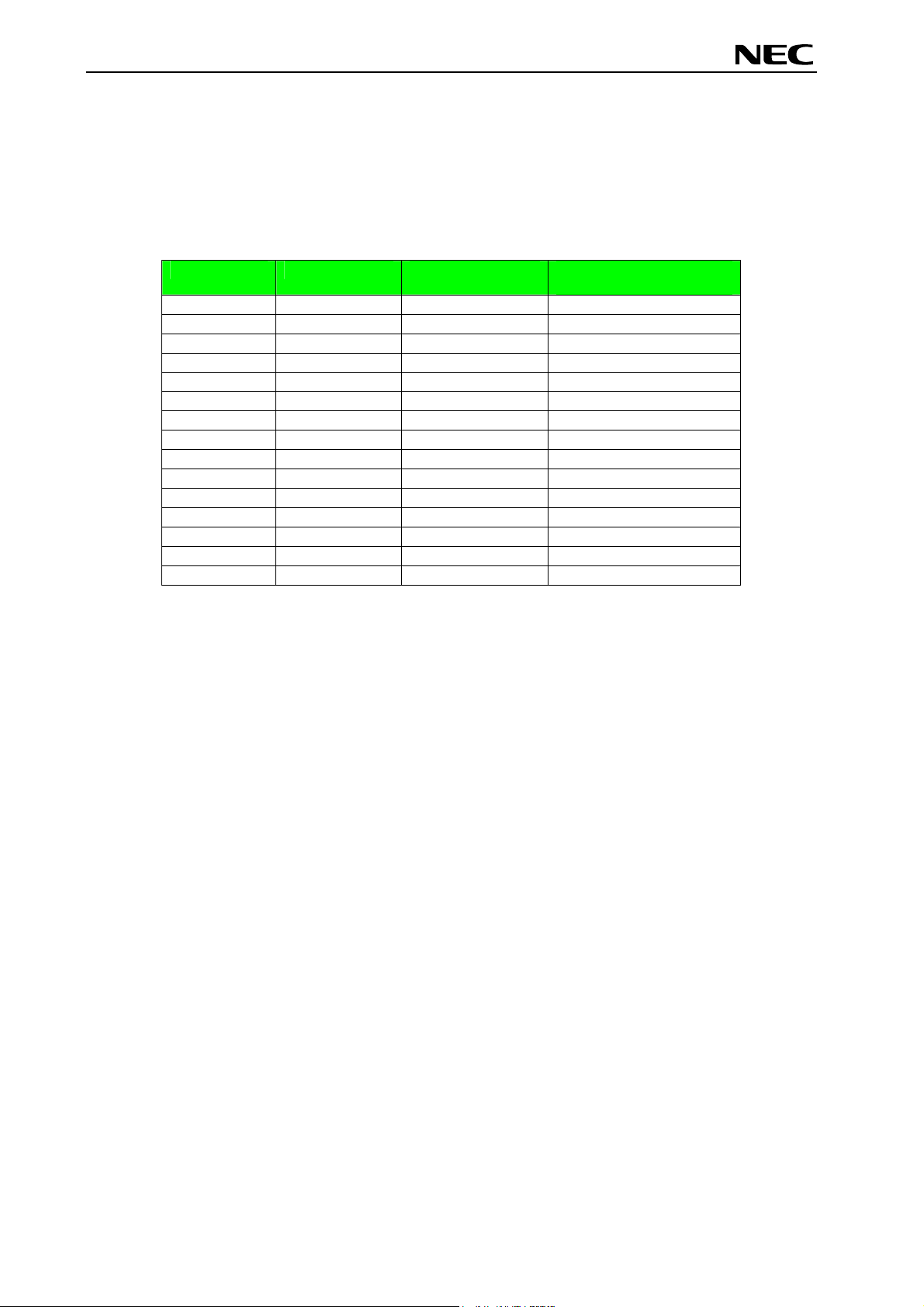

Table 11: Distribution of temperature factor kT............................................................................................21

Table 12: LED D1–D4 connection...............................................................................................................22

Table 13: Connector CN7............................................................................................................................24

Table 14: Connector CN8............................................................................................................................24

Table 15: CAN connector CN6....................................................................................................................24

Table 16: External power supply input, CN5...............................................................................................25

Table 17: N-Wire connector CN9 ................................................................................................................26

Table 18: SW4 configuration for OCD via QB-V850MINI-EE .....................................................................26

Table 19: SW4 configuration for TK-V850 debugging.................................................................................27

Table 20: SW4 configuration for N-Wire debugging....................................................................................28

Table 21: V850ESFx3 – CAN it! CD-ROM directory structure....................................................................29

Table 22: Example directory structure ........................................................................................................78

16

User’s Manual U18560EE1V0UM00 10

Page 11

V850ES/Fx3 – CAN it!

1. Introduction

V850ES/Fx3 – CAN it! is a demonstration kit for the V850ES/Fx3 32-bit RISC microcontroller. It supports

On-Board debugging via the TK-V850 interface (monitor debugging) or via N-Wire. Additional FLASH

programming and real time execution of application programs based on the V850ES/FG3 32-bit RISC

microcontroller is supported by the V850ES/Fx3 – CAN it! demonstration kit. The board is prepared to be

connected to user hardware parts such as digital I/O or analogue signals.

1.1 Main features of V850ES/Fx3 – CAN it!

• Easy to use device demonstration capabilities

V850ES/Fx3 – CAN it! contains elements to easily demonstrate simple I/O-functions, i.e. push

buttons, 12*2 character LC display, LED output, AD reference voltage, I/O lines, UART serial

interface, LIN and CAN serial interfaces.

• TK-V850 debugging

The V850ES/Fx3 – CAN it! supports an On-Board debug function by using the IAR C-SPY debugger

and the UART / USB interface without a need of additional debug hardware. It allows FLASH

programming and supports standard debug functions i.e. code execution, single stepping, software

breakpoints, memory manipulation etc.

• N-Wire debugging

The V850ES/Fx3 – CAN it! is prepared to be equipped with a 20-pin connector in order to connect

the QB-V850MINI-EE On-Chip debug emulator to use On-Chip debug function of the V850ES/FG3

device. Please note, the QB-V850MINI-EE is separate product from NEC and it is not included in this

starterkit package.

• Power supply via USB interface

V850ES/Fx3 – CAN it! is powered via USB interface, no separate power supply is needed.

• Character LCD module

V850ES/Fx3 – CAN it! provides a 12*2 character LC display, allowing the implementation of human /

machine interfaces, comfortable input / output functions, output of measurement values, output of

status information etc.

• FPL, FLASH programming software

A windows based FLASH programming software allows to select and download application programs

to the V850ES/Fx3 – CAN it! board for evaluation purposes.

• Analogue to digital signal conversion is supported

• Various input / output signals available, such as

° I/O ports prepared to be connected to user hardware

° Timer input / output signals

° Two or three wire serial I/O

° UART interface, via USB UART chip FT232

° High Speed CAN bus interfaces with transceiver PCA82C250

LIN bus support, via TJA 1020 transceiver

°

° 16 analogue input lines

° Temperature sensor KTY13-5

° 4 I/O ports connected to LED

° 2 push buttons prepared for external interrupt generation

• The IAR Embedded Workbench for V850 and the IAR C-SPY debugger / simulator are included. This

package is restricted in such that maximum program code size is limited to 16 kByte.

• Full documentation is included for the NEC V850ES/FG3 microcontroller, IAR Systems Embedded

Workbench, IAR Systems C-SPY debugger / simulator and the NEC FPL FLASH programming

software.

User’s Manual U18560EE1V0UM00 11

Page 12

V850ES/Fx3 – CAN it!

V850ES/Fx3 – CAN it! is not intended for code development. NEC does not allow and does not

support in any way any attempt to use V850ES/Fx3 – CAN it! in a commercial or technical product.

User’s Manual U18560EE1V0UM00 12

Page 13

V850ES/Fx3 – CAN it!

1.2 System requirements

HOST PC

Host interface

1.3 Package contents

Please verify that you have received all parts listed in the package contents list attached to the

V850ES/Fx3 – CAN it! package. If any part is missing or seems to be damaged, please contact the dealer

from whom you received your V850ES/Fx3 – CAN it! starterkit.

Note:

Updates of the IAR Embedded Workbench for V850, FP3 FLASH programming software,

documentation and/or utilities for V850ES/Fx3 – CAN it!, if available, may be downloaded from

the NEC WEB page(s) at

A PC supporting Windows 98SE, Windows ME, Windows 2000 or

Windows XP is required for the IAR Systems Embedded Workbench

demo-version and the FPL FLASH programming software.

Pentium 166 MHz (at least), 128 MB of RAM, 256-color display (1024 *

768), mouse, CD-ROM drive and 200 Mbytes of free hard disk space are

required to install the tool packages.

Above listed requirements are valid for the IAR Systems Embedded

Workbench and the FPL FLASH programming software.

USB interface that enables communication based on USB (Ver1.1 or

later)

http://www.eu.necel.com/updates

1.4 Trademarks

IAR Embedded Workbench, visualSTATE, IAR MakeApp and C-SPY are registered trademarks of IAR

Systems AB. Microsoft and Windows are registered trademarks of Microsoft Corporation. Adobe and

Acrobat Reader are registered trademarks of Adobe Systems Incorporated.

All other product names are trademarks or registered trademarks of their respective owners.

User’s Manual U18560EE1V0UM00 13

Page 14

V850ES/Fx3 – CAN it!

2. V850ES/Fx3 – CAN it! system configuration

The V850ES/Fx3 – CAN it! system configuration is given in the diagram below:

Figure 1: V850ES/Fx3 – CAN it! system configuration

2.1 V850ES/Fx3 – CAN it!

V850ES/Fx3 – CAN it! is a demonstration kit for the V850ES/FG3 32-Bit RISC microcontroller. The

V850ES/Fx3 – CAN it! board is connected to the host system via a USB interface cable. The host system

may be used for On-Board debugging of application software by using the IAR C-SPY debugger or the

programming of the V850ES/FG3 internal FLASH memory by using the FPL programming GUI, to allow

execution of application programs on the V850ES/Fx3 – CAN it! starterkit hardware.

The V850ES/Fx3 – CAN it! is equipped within an 4.0000 MHz crystal oscillator. This allows running the

V850ES/FG3 device at a speed of 32 MHz by using the internal PLL of the microcontroller.

2.2 Host computer

The USB host interface enables communication to the V850ES/Fx3 – CAN it! board. The USB UART chip

FT232 allows application software to access the USB device in the same way as it would access a

standard RS232 interface. The FTDI's Virtual COM Port (VCP) driver appears to the windows system as

an extra Com Port, in addition to any existing hardware Com Ports.

2.3 Power supply via USB interface

V850ES/Fx3 – CAN it! is powered by USB interface, no separate power supply is needed. The USB

interface provides the V850ES/Fx3 – CAN it! board with 5V supply voltage.

User’s Manual U18560EE1V0UM00 14

Page 15

V850ES/Fx3 – CAN it!

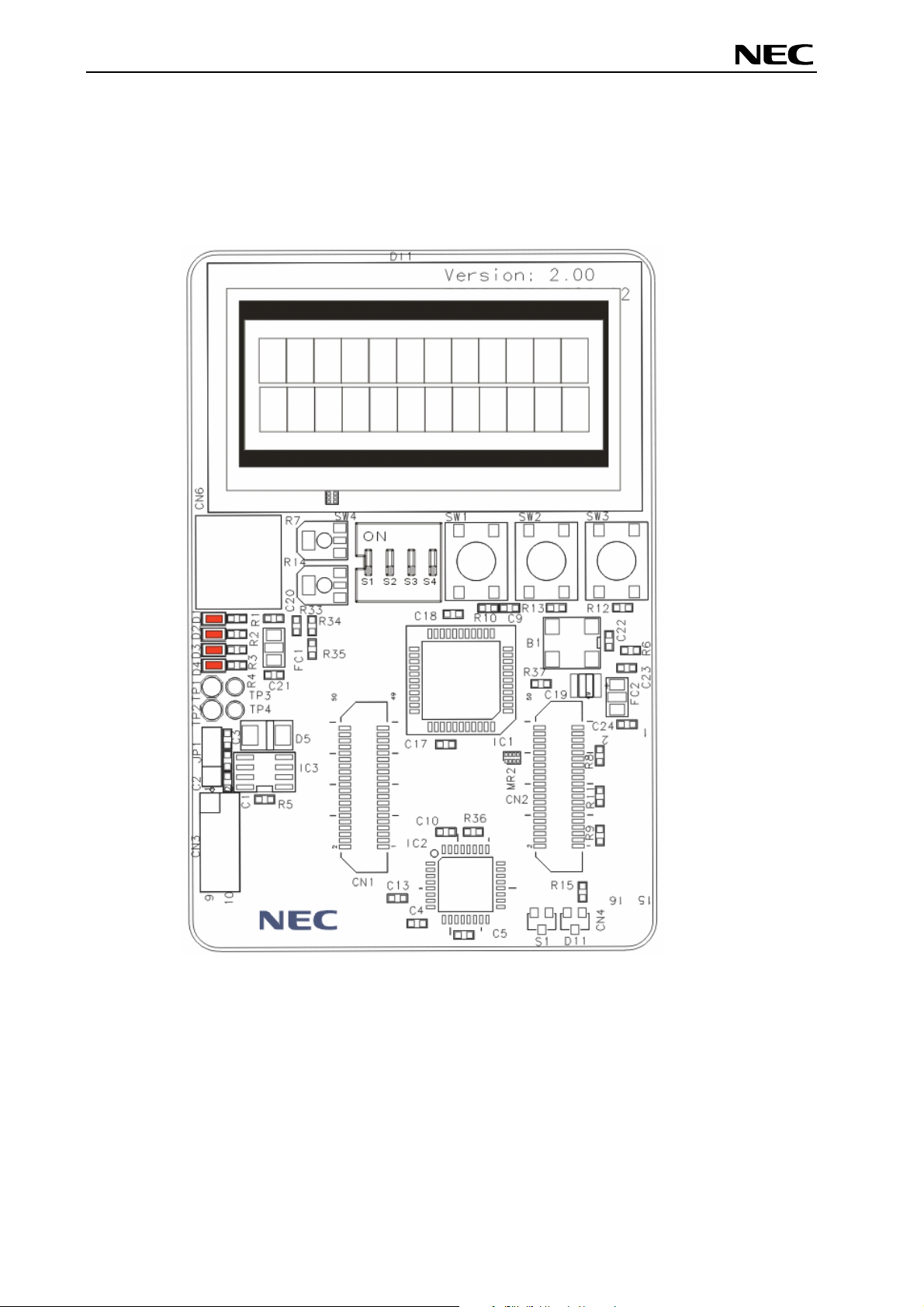

3. V850ES/Fx3 – CAN it! baseboard components

The V850ES/Fx3 – CAN it! baseboard is equipped with push buttons, a 12*2 character LC display, LED’s

and with several connectors in order to be connected to host computers, FLASH programmer and LIN

busses.

Figure 2: V850ES/Fx3 – CAN it! baseboard connectors, switches and LED’s

Some of the V850ES/Fx3 – CAN it! components are free for user application hardware and software.

Please read the user’s manual of the V850ES/FG3 device carefully to get information about the electrical

specification of the available I/O ports before you connect any external signal to the V850ES/Fx3 – CAN

it! board.

User’s Manual U18560EE1V0UM00 15

Page 16

V850ES/Fx3 – CAN it!

3.1 RESET button SW1

SW1 is a reset button. It activates the power on reset. It is connected to the reset input of the

V850ES/FG3 CPU module.

3.2 User button SW2

SW2 is a push button connecting V

to port P913 of the V850ES/FG3 device. The port may be programmed to generate interrupt INTP4. The

necessary initialisation for this purpose is described in the user’s manual of the V850ES/FG3 device. The

port is connected to a 4.7K pull down resistor.

3.3 User button SW3

SW3 is a push button connecting V

to port P914 of the V850ES/FG3 device. The port may be programmed to generate interrupt INTP5. The

necessary initialisation for this purpose is described in the user’s manual of the V850ES/FG3 device. The

port is connected to a 4.7K pull down resistor.

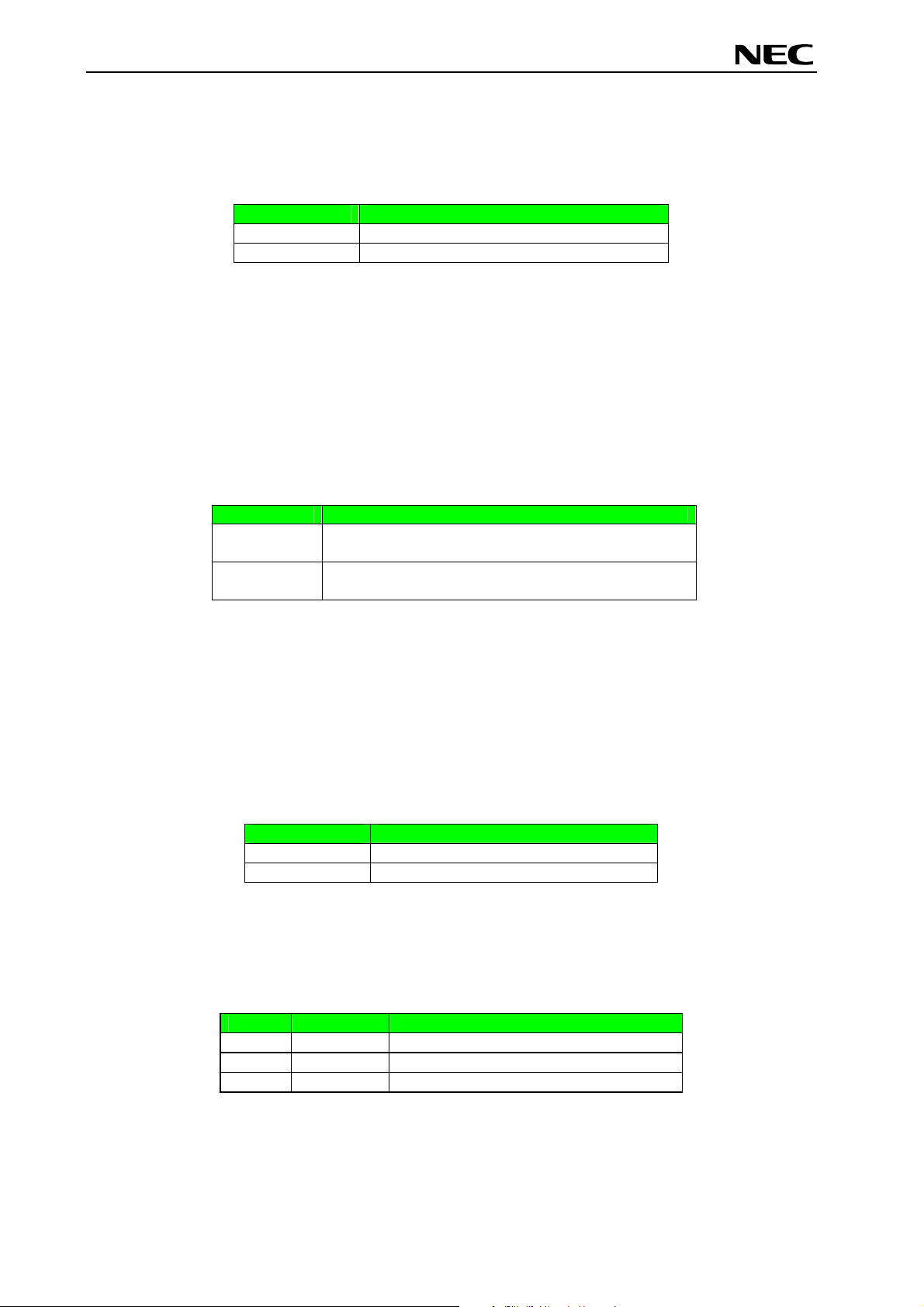

3.4 Configuration switch SW4

The different operation modes of the V850ES/Fx3 – CAN it! board can be set by SW4 switches S1-S4.

SW4 Factory settings

S1 OFF Operation mode select

S2 OFF TK-V850 / FPL mode select

S3 OFF UART/ LIN mode selection

S4 OFF User switch

Table 1: Configuration switch SW4, factory settings

to external interrupt input INTP4 of the microcontroller. This is equal

CC

to external interrupt input INTP5 of the microcontroller. This is equal

CC

Functionality

3.4.1 Operation mode selection SW4/S1

SW4 switch S1 controls the operation mode of the V850ES/Fx3 – CAN it! board. Setting SW4/S1 to ON

enables the TK-V850 On-Board debug function. Additional On-Board FLASH programming by using the

FPL software is supported in this mode.

Within normal operation mode (setting SW4/S1 to OFF) the user program stored in the internal FLASH

memory of V850ES/FG3 device is executed. Additional debugging via N-Wire interface and FLASH

programming via the PG-FP4 FLASH programmer is supported in this mode.

SW4, S1 Operation mode

OFF Normal operation mode

ON TK-V850 debugging / FPL FLASH programming

mode

Table 2: Operation mode selection SW4/S1

For more details on how to configure V850ES/Fx3 – CAN it! in order to use On-Chip debugging please

refer to CHAPTER 5, ON-CHIP DEBUGGING.

User’s Manual U18560EE1V0UM00 16

Page 17

V850ES/Fx3 – CAN it!

3.4.2 TK-V850 / FPL mode selection switch SW4/S2

SW4 switch S2 selects the TK-V850 On-Board debugging or FPL FLASH programming mode. Setting

SW4/S2 to OFF enables the TK-V850 On-Board debug function. Switching SW4/S2 to ON allows OnBoard FLASH programming by using the FPL FLASH programmer software.

SW4, S2 Operation mode

OFF TK-V850 debugging mode

ON FPL FLASH programming mode

Table 3: TK-V850 / FPL mode selection switch SW4/S2

For more details on how to configure V850ES/Fx3 – CAN it! in order to use On-Chip debugging please

refer to CHAPTER 5, ON-CHIP DEBUGGING.

3.4.3 UART/ LIN mode selection SW4/S3

SW4 switch S3 controls the serial communication mode of V850ES/Fx3 – CAN it! board. Setting SW4/S3

to OFF connects the UARTD0 receive and transmit signals to the FT232 interface lines and the UARTD2

receive and transmit signals to the TJA1020 LIN transceiver. Switching SW4/S3 to ON connects the

UARTD0 and UARTD2 signals vice versa.

SW4, S3

OFF UARTD0 connected to FT232 UART chip

UARTD2 connected to TJA1020 LIN transceiver

ON UARTD0 connected to TJA1020 LIN transceiver

UARTD2 connected to FT232 UART chip

Table 4: UART/ LIN mode selection SW4/S3

Operation Mode

By using the TK-V850 debugging / FPL FLASH programming mode set switch SW4/S3 to OFF. UARTD0

is reserved as communication channel for On-Board debugging or FLASH programming and can not be

used by a user program.

3.4.4 User switch SW4/S4

SW4 switch S4 is connected to port P911 of the V850ES/FG3 device. This switch can be freely used by

the user software. Switching SW4/S4 to ON applies V

to port P911.

SS

SW4, S4

V850ES/FG3

OFF VCC applied to P911

ON VSS applied to P911

Table 5: User switch SW4/S4

3.5 LIN plug JP1

JP1 is a 3 pin connector for the LIN bus, connected to the transceiver TJA1020.

JP1 Signal Description

1 BAT Reference voltage for the LIN bus level

2 LIN LIN bus line

3 GND Ground

Table 6: LIN plug JP1

User’s Manual U18560EE1V0UM00 17

Page 18

V850ES/Fx3 – CAN it!

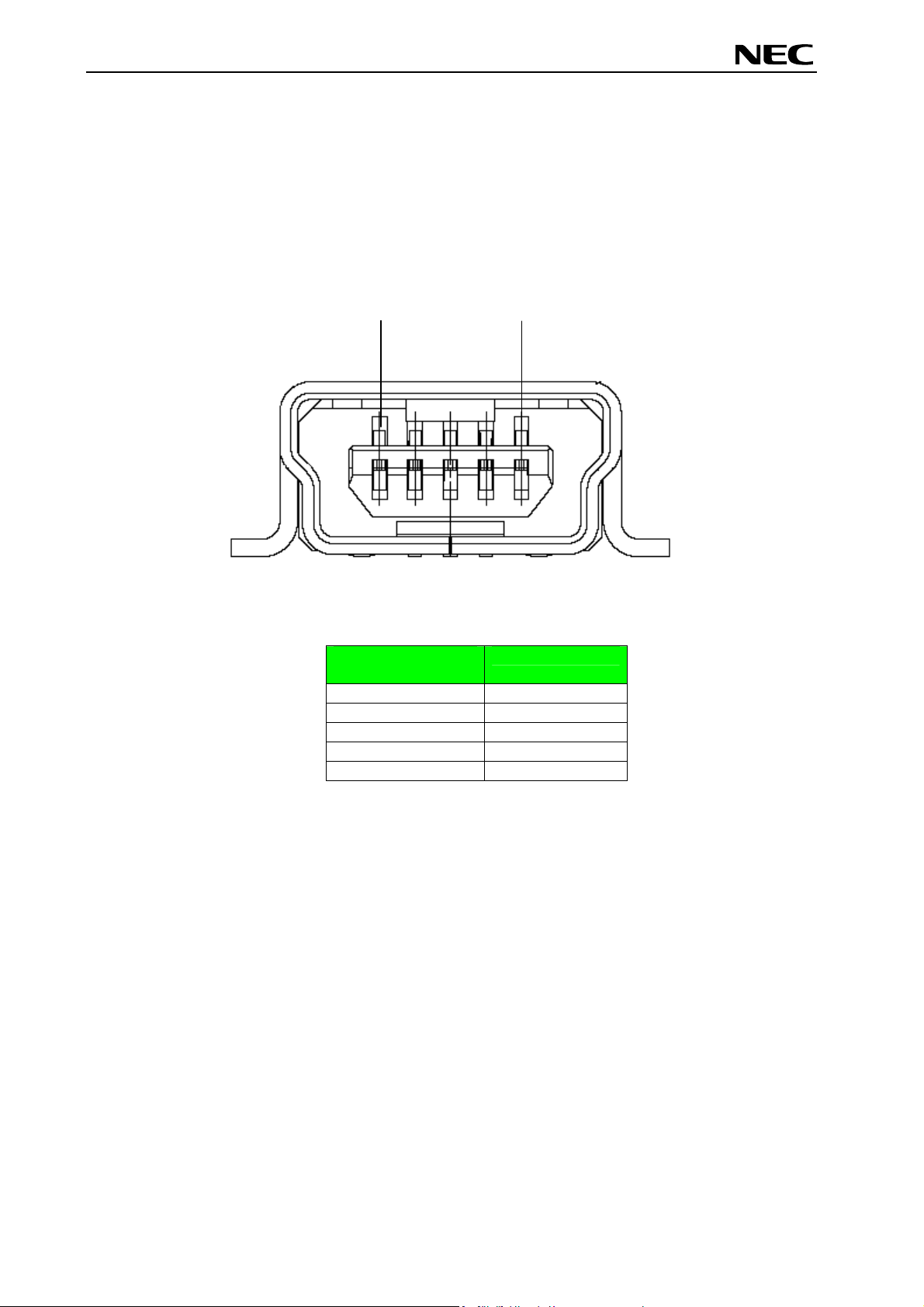

3.6 USB interface connector CN6

The CN6 connector allows connecting the IAR C-SPY debugger or FPL FLASH programming software to

the V850ES/Fx3 – CAN it! board in order to debug application software or program the V850ES/FG3

internal FLASH memory. The board power supply of 5V is also provided by connector CN6.

For standard communication to a host system, i.e. by using a terminal program, the input/output signals

of UARTD0 respectively UARTD2 of the V850ES/FG3 device are connected to CN6. Please configure

switch SW4 accordingly to use this mode.

1

Figure 3: Connector CN6, USB Mini-B Type Host Connector Pin Configuration

USB Connector

CN6

1 VBUS

2 DM

3 DP

4 N.C.

5 GNDBUS

Table 7: Pin Configuration of USB Connector CN6

5

Signal

For connection with the host machine, use a USB cable (Mini-B type). For confirmation,

NEC Electronics used only the USB cable delivered with the V850ES/Fx3

User’s Manual U18560EE1V0UM00 18

– CAN it! board.

Page 19

V850ES/Fx3 – CAN it!

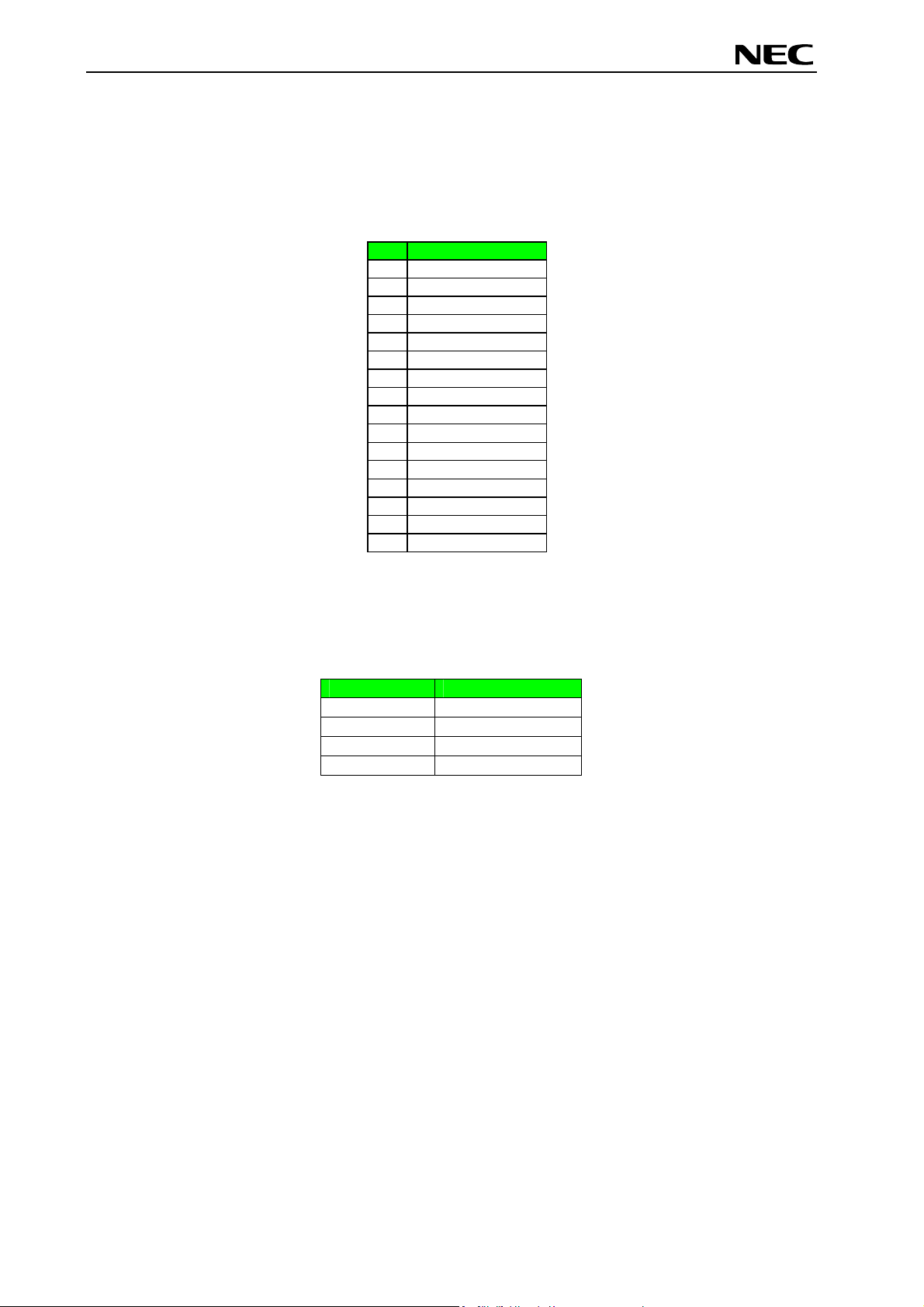

3.7 Connector CN4

CN4 connector (not assembled) allows connecting the PG-FP4 flash programmer to V850ES/Fx3 – CAN

it! board in order to program application software into the FLASH memory of the V850ES/FG3 device.

Please note, PG-FP4 is a separate product from NEC and it is not included in this package.

CN4 Signal

1 GND

2 RESET

3 SI

4 VCC

5 SO

6 N.C.

7 SCK

8 N.C.

9 N.C.

10 N.C.

11 N.C.

12 FLMD1

13 N.C.

14 FLMD0

15 N.C.

16 N.C.

Table 8: CN4, PG-FP4 connector

When using PG-FP4, the programming interface to the V850ES/FG3 device must be set to clock serial

interface, CSI. Set configuration of switch SW4 of the V850ES/Fx3 – CAN it! board to the following:

SW4 Setting

S1 OFF

S2 OFF

S3 Don’t care

S4 Don’t care

Table 9: SW4 configuration when using PG-FP4

3.8 External Potentiometer R7

A 47K potentiometer R7 is connected between Vcc and ground. The potentiometer arm is connected to

the V0 signal of the LCD module. It controls the operating voltage - contrast adjustment - of the display.

User’s Manual U18560EE1V0UM00 19

Page 20

V850ES/Fx3 – CAN it!

3.9 Display D1, 12*2 character LC display

The V850ES/Fx3 – CAN it! board is equipped with a character LC display. The display font is equal to 12

character words at 2 lines. The LCD module contains about a character generator ROM - including

predefined standard characters - and a character RAM where the user can define its own characters. The

display is connected to the V850ES/FG3 device via three control lines and eight data lines.

Display Pin Display Signal

V850ES/FG3 Signal

1 Vss - GND

2 Vcc - Vcc

3 V0 - R7 potentiometer arm

4 RS PDL12 5 R/W PDL13 6 E PDL7 7 DB0 PDL0 8 DB1 PDL1 -

9 DB2 PDL2 10 DB3 PDL3 11 DB4 PDL8 12 DB5 PDL9 13 DB6 PDL10 14 DB7 PDL11 15 A - Vcc via diode

Table 10: Display connections

V850ES/Fx3 - CAN it!

baseboard

For more details about the LC display specification, commands and character table, please refer to the

corresponding User’s Manual “WH1202A-NFA-ET.pdf” located in the /doc folder of the V850ES/Fx3 –

CAN it!.

3.10 External Potentiometer R14

A 47K potentiometer R14 is connected between Vcc and ground. The potentiometer arm is connected to

port P713 of V850ES/FG3 device. This is equal to the ANI13 analogue input.

3.11 AD converter reference voltage input

A 1.2V reference voltage is supplied to the ANI14 analogue input, equal to port P714 of V850ES/FG3

device.

User’s Manual U18560EE1V0UM00 20

Page 21

V850ES/Fx3 – CAN it!

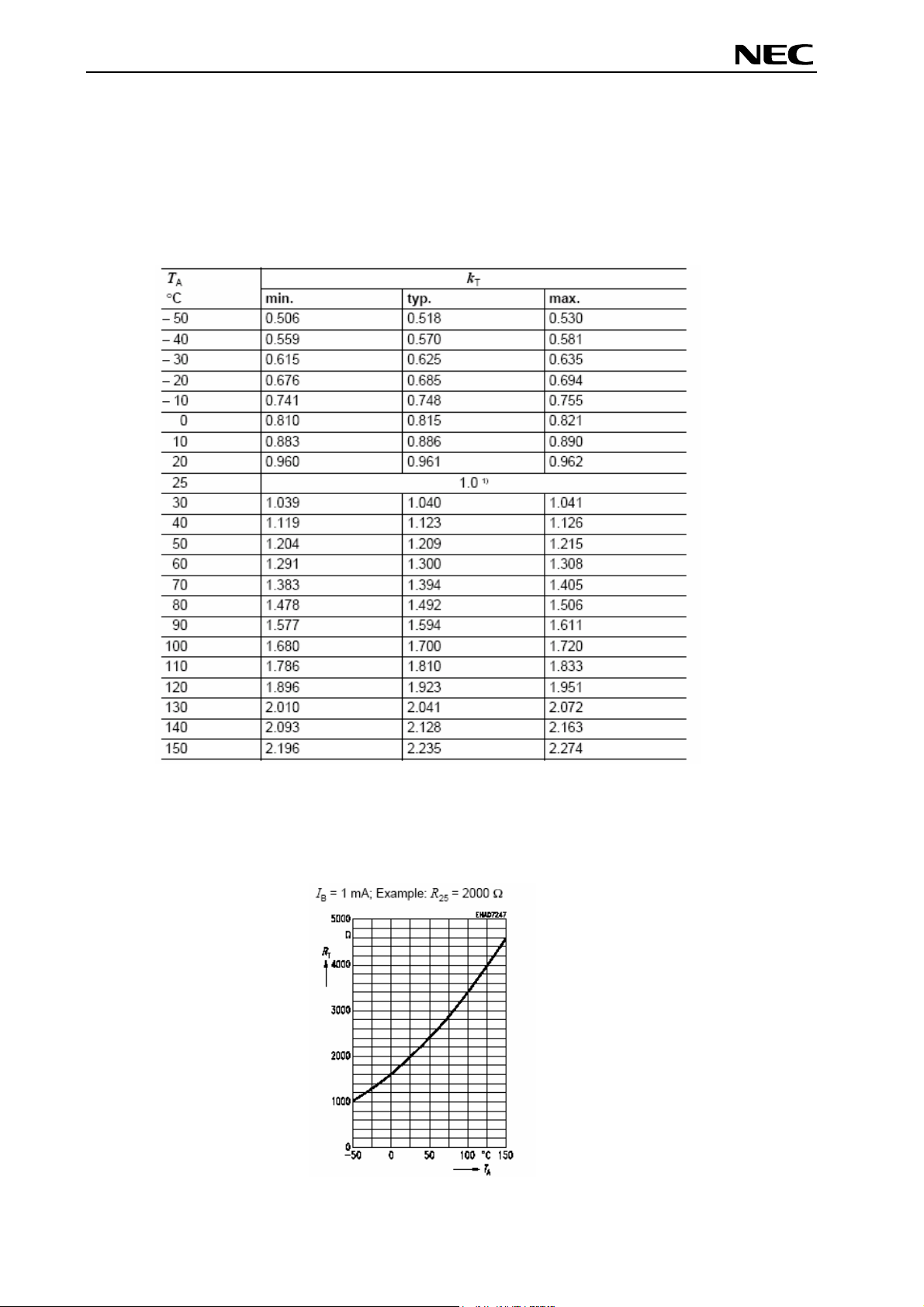

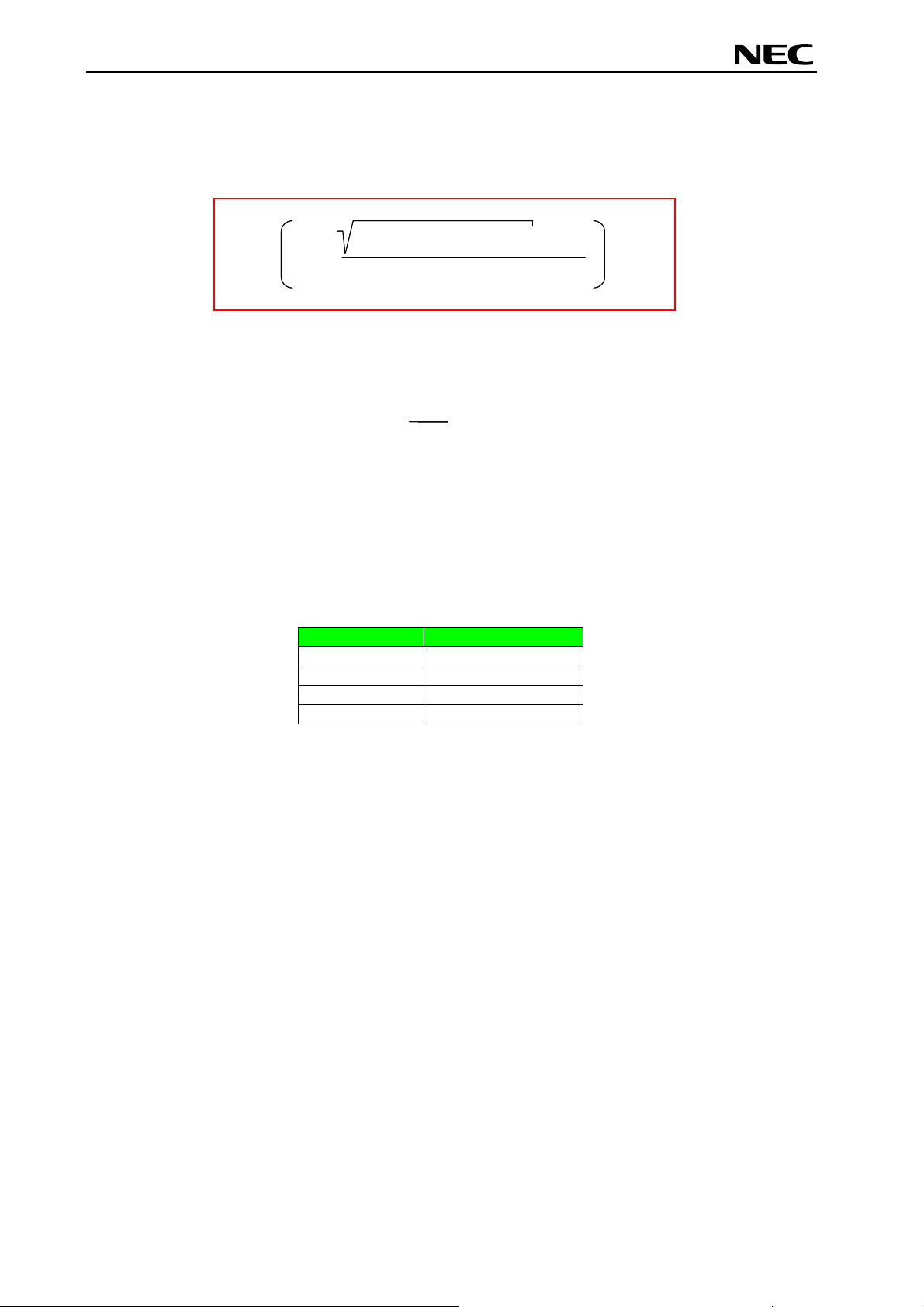

3.12 Temperature sensor

For temperature measurement and primarily as an application example a silicon temperature sensor

KTY13-5 is connected to the ANI15 analogue input, equal to port P715 of V850ES/FG3 device.

The temperature sensor has a resistor range of R

centigrade, with I

= 1mA. The distribution of the temperature factor kT is shown in the table below:

OP

= 1950 • and R

25 min

= 1990 • at 25 degrees

25 max

1) Normalising point

Table 11: Distribution of temperature factor kT

The sensor resistance can be calculated as following:

RT = kT * R

25 =

•(TA)

User’s Manual U18560EE1V0UM00 21

Page 22

V850ES/Fx3 – CAN it!

The temperature at the sensor can be calculated from the change in the sensors resistance from the

following equation, which approximates the characteristic curve:

α²-4 x β + 4 x β x k

α²-4 x β + 4 x β x kT- α

T = 25 + ° C

T = 25 + ° C

2 x β

2 x β

-3

-3

25

25

25

-3

T

T

T

with:

with:

α = 7,88 x 10 x K

α = 7,88 x 10 x K

α = 7,88 x 10 x K

β = 1,937 x 10 x K

β = 1,937 x 10 x K

β = 1,937 x 10 x K

R

R

R

T

=

T

=

T

=

k

k

k

R

R

R

T

-1

-1

-1

-5 -2

-5 -2

-5 -2

- α

3.13 External LED’s D1–D4

LED’s D1 to D4 are connected to port PCT of the V850ES/FG3 device. A low signal output at each port

switches the corresponding LED on.

LED

V850ES/FG3 Signal

D1 PCT0

D2 PCT1

D3 PCT4

D4 PCT6

Table 12: LED D1–D4 connection

User’s Manual U18560EE1V0UM00 22

Page 23

V850ES/Fx3 – CAN it!

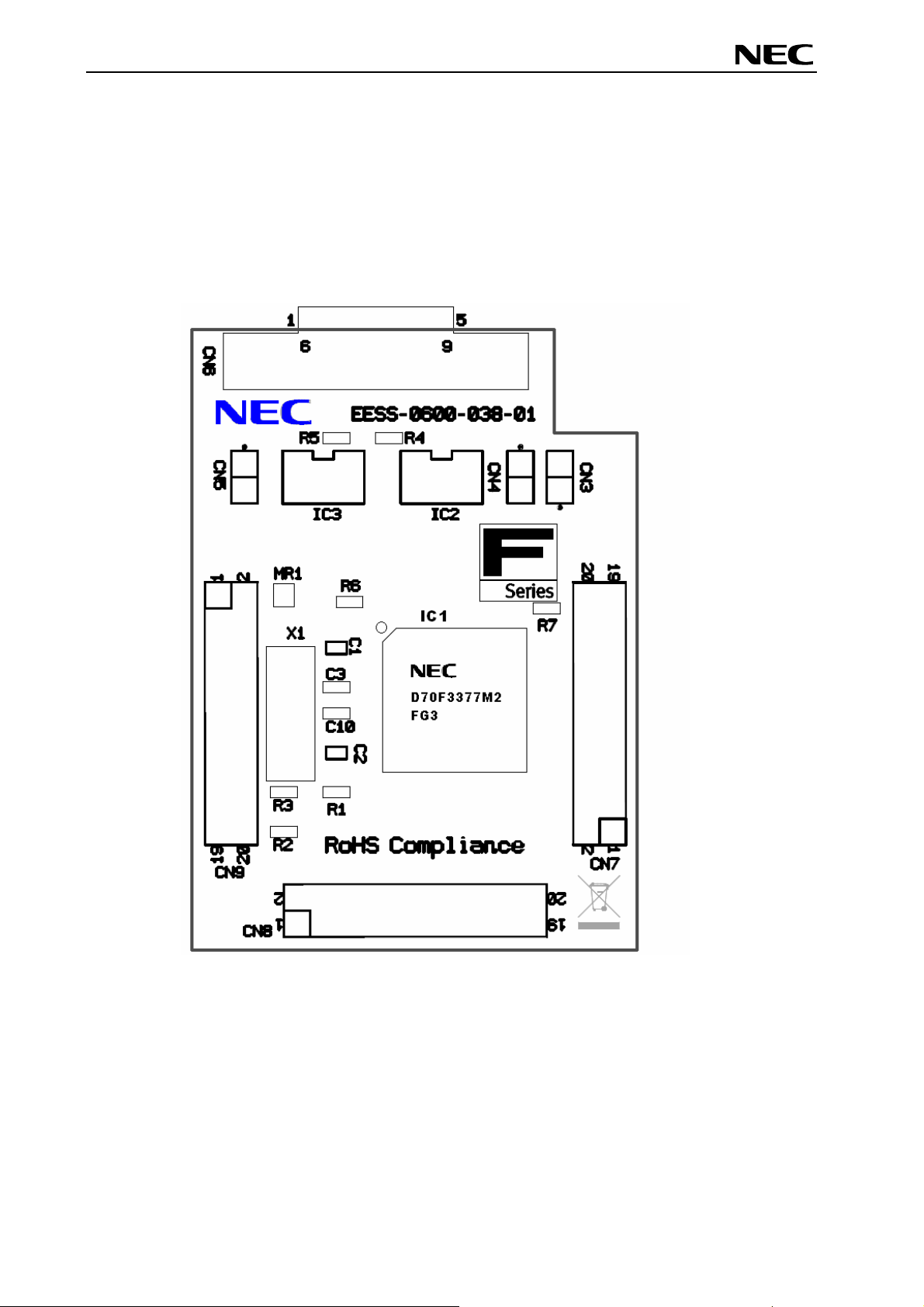

4. V850ES/Fx3 – CAN it! CPU module components

The V850ES/FG3 CPU module is equipped with 2 connectors CN7 and CN8 in order to be connected to

user defined hardware. Additionally the V850ES/FG3 CPU module contains about connector CN9 (not

assembled) for N-Wire debugging and connectors CN3, CN4 and CN6 for CAN communication purpose.

4.1 V850ES/Fx3 – CAN it! CPU module

Figure 4: V850ES/Fx3 – CAN it! CPU module components

User’s Manual U18560EE1V0UM00 23

Page 24

V850ES/Fx3 – CAN it!

4.1.1 External connector CN7 and CN8

CN7 and CN8 are connectors for external user hardware. The following signals of the V850ES/FG3

microcontroller are connected to CN7 and CN8:

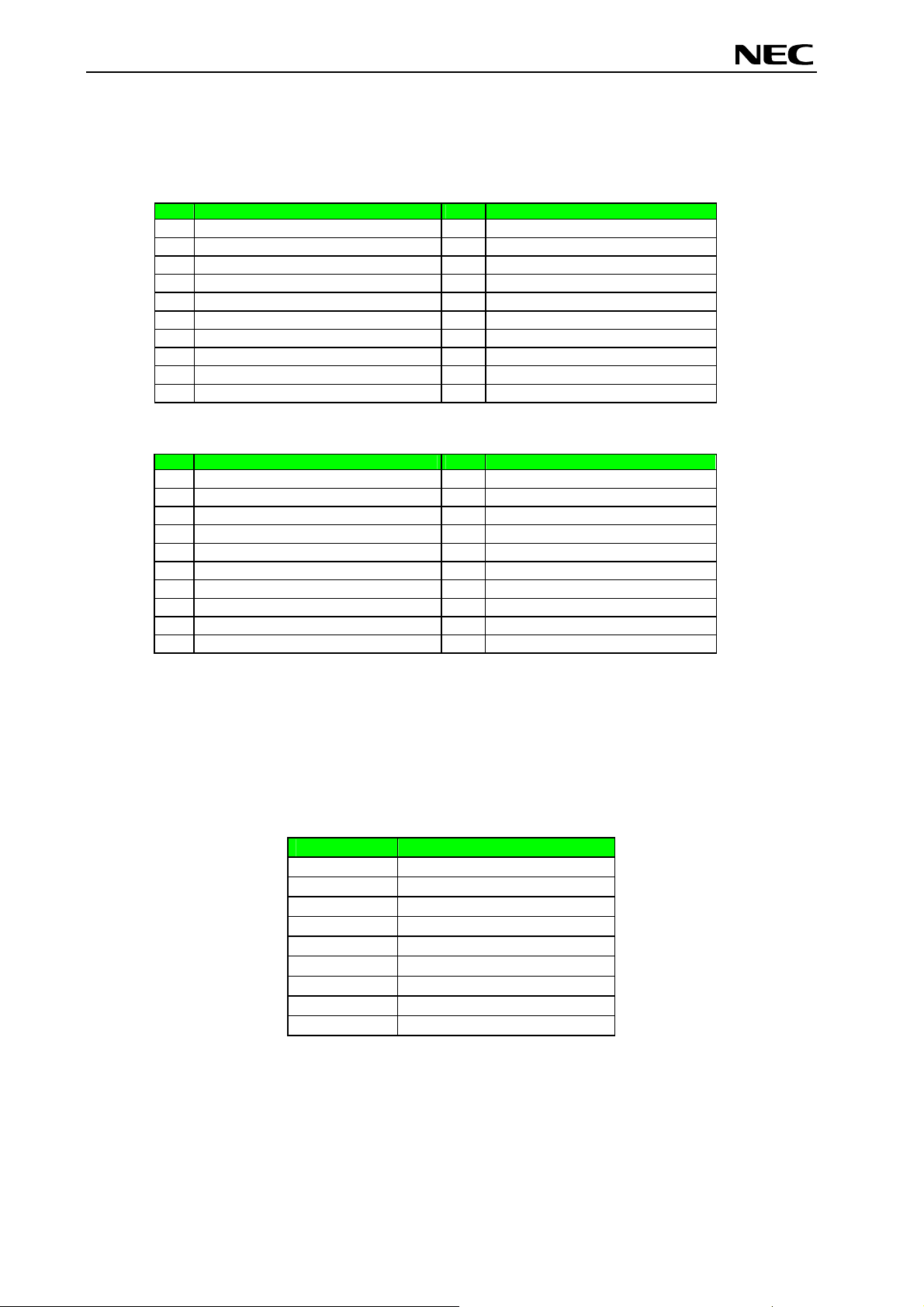

CN7 V850ES/FG3 Signal CN7 V850ES/FG3 Signal

P99, SCKB1, TIAB00, TOAB00

1

PCS0

3

PCS1

5

PCM0

7

PCM1, CLKOUT

9

PCM2

11

PCM3

13

P712, ANI12

15

P711, ANI11

17

P710, ANI10

19

Table 13: Connector CN7

CN8 V850ES/FG3 Signal CN8 V850ES/FG3 Signal

P10, INTP9

1

P11, INTP10

3

P00, TIAA31, TOAA31

5

P01, TIAA30, TOAA30

7

P02, NMI, TIAA40, TOAA40

9

P03, INTP0, ADTRG, TIAA41, TOAA41

11

P04, INTP1, CRXD0

13

P32, ASCKD0, TOAA01, TIAA00, TOAA00

15

P35, TIAA11, TOAA11

17

P50, KR0, TIAB01, TOAB01, TOAB0T1

19

Table 14: Connector CN8

P79, ANI9

2

P78, ANI8

4

P77, ANI7

6

P76, ANI6

8

P75, ANI5

10

P74, ANI4

12

P73, ANI3

14

P72, ANI2

16

P71, ANI1

18

P70, ANI0

20

P51, KR1, TIAB02, TOAB02, TOAB0B1

2

P90, KR6, TXDD1

4

P91, KR7, RXDD1

6

P92, TIAB11, TOAB11

8

P93, TIAB12, TOAB12

10

P94, TIAB13, TOAB13

12

P95, TIAB10, TOAB10

14

P96, TIAA21, TOAA21

16

P97, SIB1, TIAA20, TOAA20

18

P98, SOB1, TIAB03, TOAB03

20

4.2 High Speed CAN connector CN6

CN6 is a D-SUB 9 connector for High Speed CAN with CiA standard pin assignment. The used CAN

transceiver is the PCA82C250 with bus termination. The transceiver is connected to the CAN0 interface

of the V850ES/FG3 device per default, whereby the standby mode control is selected by port P915.

CN6 Signal

1 N.C.

2 CANL

3 GND

4 N.C.

5 N.C.

6 N.C.

7 CANH

8 N.C.

9 N.C.

Table 15: CAN connector CN6

User’s Manual U18560EE1V0UM00 24

Page 25

V850ES/Fx3 – CAN it!

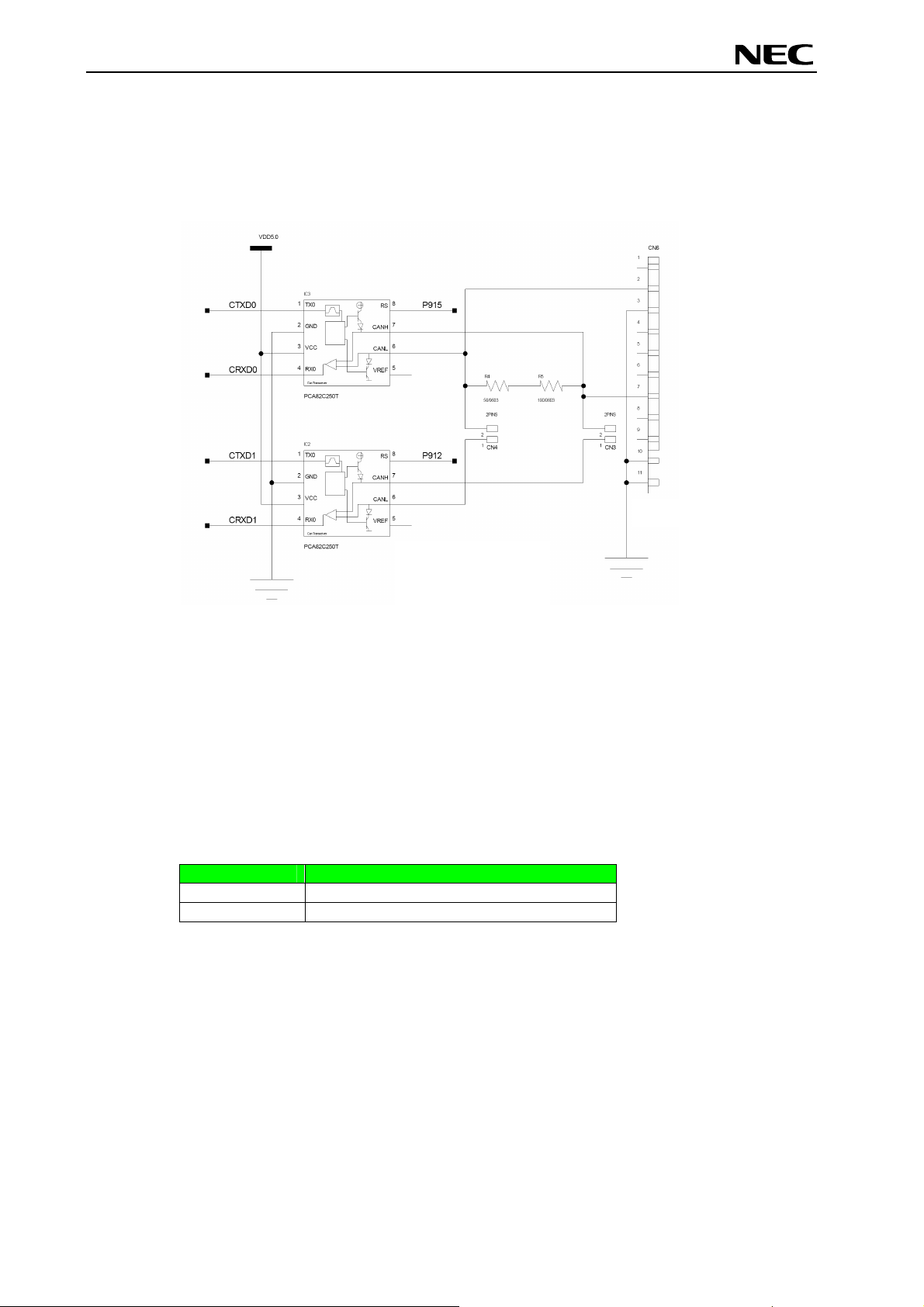

4.3 CAN connectors, CN3 and CN4

By closing the connectors CN3 and CN4 (not assembled) both CAN macros of the V850ES/FG3 device

are connected via a PCA82C250 CAN transceiver each. Within this mode a simple CAN network with two

CAN nodes can be simulated.

Figure 5: CAN transceivers

The CAN0 interface of the V850ES/FG3 device is connected to transceiver IC3, whereby the standby

mode control of the CAN transceiver is selec

ted by port P915.

The CAN1 interface of the V850ES/FG3 device is connected to transceiver IC2, whereby the standby

mode control of the CAN transceiver is selec

ted by port P912.

4.4 External power supply input, CN5

By using connector CN5 (not assembled) external power supply can be applied to the V850ES/Fx3 –

CAN it! board without a need of an active USB connection.

CN5 Input

1 GND

2 VDD (+5V)

Table 16: External power supply input, CN5

Note: Be sure to unplug the USB connection before applying external power supply to input CN5.

User’s Manual U18560EE1V0UM00 25

Page 26

V850ES/Fx3 – CAN it!

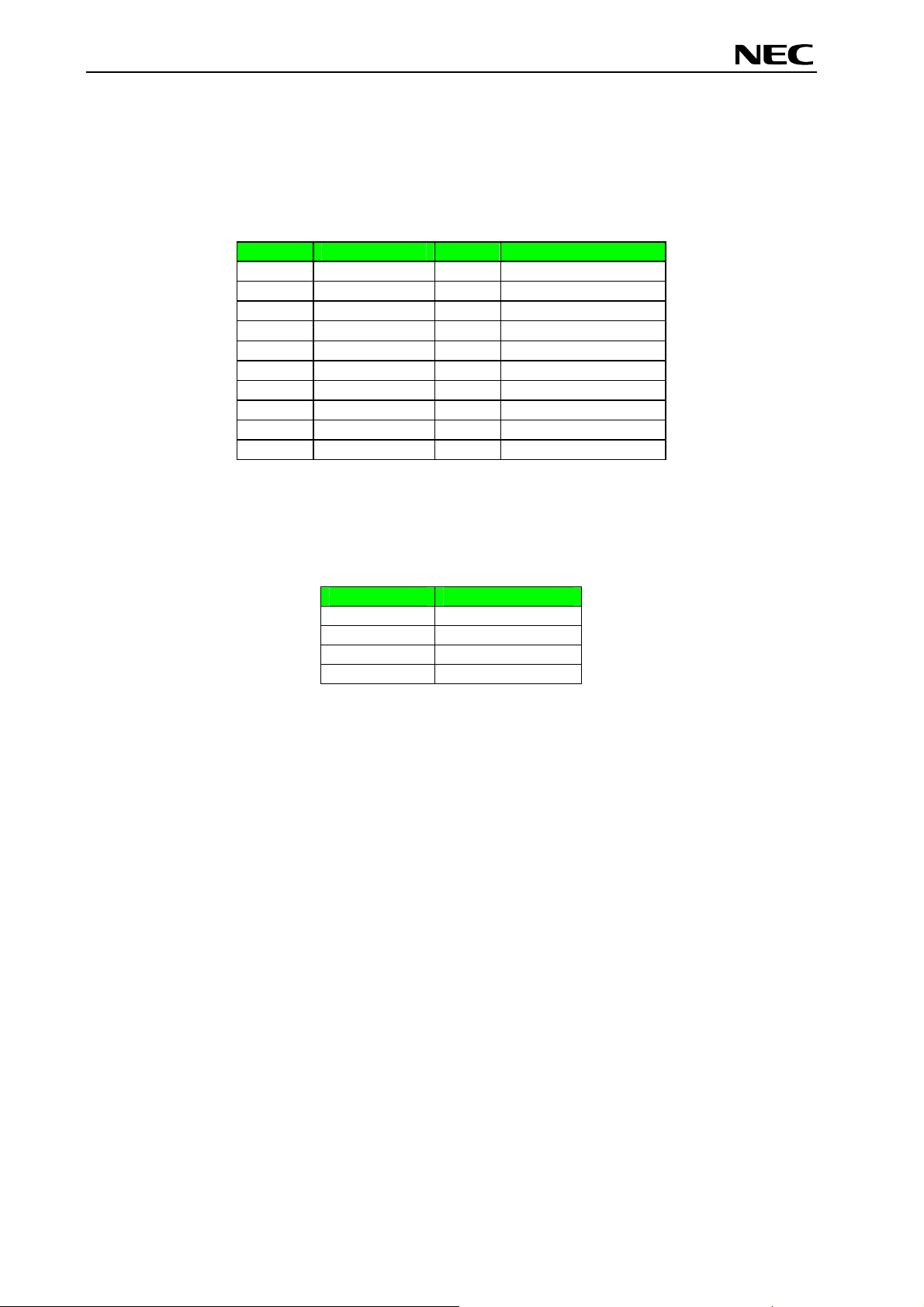

4.4.1 N-Wire connector CN9

Connector CN9 (not assembled) allows connecting the QB-V850MINI-EE On-Chip debug emulator to the

V850ES/Fx3 – CAN it! board in order to use the N-Wire debug function of the V850ES/FG3 device.

QB-V850MINI-EE is a separate product from NEC and it is not included in this starterkit package.

CN9 Signal CN9 Signal

1 GND 2 DCK

3 GND 4 DMS

5 GND 6 DDI

7 GND 8 DRST

9 GND 10 N.C.

11 GND 12 RESET

13 GND 14 FLMD0

15 GND 16 N.C.

17 GND 18 DDO

19 GND 20 VCC

Table 17: N-Wire connector CN9

To enable N-Wire debugging by using the QB-V850MINI-EE, please set switch SW4 to the following

configuration:

SW4 Setting

S1 OFF

S2 OFF

S3 Don’t care

S4 Don’t care

Table 18: SW4 configuration for OCD via QB-V850MINI-EE

For more details on how to configure V850ES/Fx3 – CAN it! in order to use On-Chip debugging please

refer to CHAPTER 5, ON-CHIP DEBUGGING.

User’s Manual U18560EE1V0UM00 26

Page 27

V850ES/Fx3 – CAN it!

5. On-Chip debugging

The V850ES/Fx3 – CAN it! board offers two possibilities to use On-Chip debugging. The TK-V850 debug

function of V850ES/Fx3 – CAN it! allows On-Chip debugging without a need of external debug hardware.

Within this mode the default USB / UART connection to the Host computer is used as debug interface. All

standard debug functions are available in the On-Board debugging mode like FLASH programming /

downloading, code execution, single stepping, breakpoints, memory manipulation etc.

Additionally V850ES/Fx3 – CAN it! supports N-Wire debugging by using the QB-V850MINI-EE On-Chip

debug emulator in order to use On-Chip debug function of the V850ES/FG3 device. The system

configuration for On-Chip debugging is shown in the figure below.

Figure 6: Configuration for On-Chip debugging

5.1 OCD via TK-V850 debugging

To operate the V850ES/Fx3 – CAN it! board within the On-Board debug mode configure switch SW4 as

following:

SW4 Setting

S1 ON

S2 OFF

S3 OFF

S4 Don’t care

Table 19: SW4 configuration for TK-V850 debugging

User’s Manual U18560EE1V0UM00 27

Page 28

V850ES/Fx3 – CAN it!

5.2 OCD via N-Wire debugging

To operate the V850ES/Fx3 – CAN it! board together with the QB-V850MINI-EE On-Chip debug emulator,

configure switch SW4 as following:

SW4 Setting

S1 OFF

S2 OFF

S3 Don’t care

S4 Don’t care

Table 20: SW4 configuration for N-Wire debugging

User’s Manual U18560EE1V0UM00 28

Page 29

V850ES/Fx3 – CAN it!

6. V850ES/Fx3 – CAN it! installation and operation

6.1 Getting started

The IAR C-SPY debugger allows to download and debug application software on the V850ES/Fx3 – CAN

it! starterkit hardware. Additionally the FPL FLASH programming software can be used for simple FLASH

programming of the V850ES/FG3 internal FLASH memory. As communication interface between the host

computer and the V850ES/Fx3 – CAN it! board a USB interface line is needed. Before you can download,

debug or execute an application program, hardware and software must be installed properly.

6.1.1 CD-ROM contents

The CD-ROM shows following directory structure:

V850ES/Fx3 – CAN it! (F:)

Acrobat

Doc

FPL

Drivers

FPL

PRM

IAR Embedded Workbench V850

SamplePrograms

TK-V850 Driver

DDF

DEVICES

NEC

Table 21: V850ESFx3 – CAN it! CD-ROM directory structure

CD-ROM ROOT

- Acrobat Reader for 32Bit Windows OS

- Documentation

- FPL FLASH programming software

… USB driver

… FPL setup directory

… PRM parameter files

- IAR Embedded Workbench for V850

- Sample programs for V850ES/Fx3 – CAN it!

- TK-V850 Driver for V850ES/Fx3 – CAN it!

… Device Description File and

… SFR Description File for IAR C-SPY

… Menu File for IAR Embedded Workbench

… TK-V850 driver for IAR C-SPY

… Device File

User’s Manual U18560EE1V0UM00 29

Page 30

V850ES/Fx3 – CAN it!

7. Hardware installation

After unpacking V850ES/Fx3 – CAN it!, connect the board to your host computer using the provided USB

interface cable. When V850ES/Fx3 – CAN it! is connected, the USB driver needs to be installed on the host

machine. Please refer to the following CHAPTER 8 SOFTWARE INSTALLATION.

8. Software installation

The V850ES/Fx3 – CAN it! package comes with several software demo packages:

• IAR Systems Embedded Workbench for V850, including C compiler, assembler, linker, librarian and IAR

C-SPY debugger

• TK-V850 Driver for V850ES/Fx3 – CAN it!

• FPL FLASH programming software

• Sample programs

The IAR Systems Embedded Workbench and the FPL FLASH programming GUI must be installed on your

PC. For detailed installation hints, refer to the following chapters and to the corresponding documentation of

the IAR Embedded Workbench.

8.1 IAR Systems Embedded Workbench for V850 installation

To install the IAR Systems Embedded Workbench for V850 including C-SPY debugger, select the SETUP

program in the directory \IAR Embedded Workbench V850\ewv850\ of the CDROM. The setup

dialogues will guide you through the installation process.

8.2 TK-V850 driver installation

To install the TK-V850 driver for the V850ES/Fx3 – CAN it! in order to use the IAR C-SPY debugger and OnBoard debugging, select the SETUP program in the directory \TK-V850 driver\ of the CDROM. The

setup dialogues will guide you through the installation process.

8.3 FPL FLASH programming GUI installation

To install the FPL FLASH programming GUI select the SETUP program in the directory \FPL\ of the

CDROM. The setup dialogues will guide you through the installation process.

8.4 Sample program installation

To install the sample programs for the V850ES/Fx3 – CAN it! board select the SETUP program in the

directory \SamplePrograms\ of the CDROM. The setup dialogues will guide you through the installation

process.

User’s Manual U18560EE1V0UM00 30

Page 31

V850ES/Fx3 – CAN it!

8.5 USB Driver Installation

When the V850ES/Fx3 – CAN it! board and FPL is used, the driver needs to be installed on the

host machine. Install the driver according to the following procedure:

Installation on Windows 98SE/Me ......... Page 31

Installation on Windows 2000 ................ Page 33

Installation on Windows XP ................... Page 39

8.5.1 Installation on Windows 98SE/Me

1. When the V850ES/Fx3 – CAN it! board is connected with the host machine, the board is

recognized by Plug and Play, and the wizard for adding new hardware is started. Click

Next>.

Figure 7: Add New Hardware Wizard (Windows 98SE)

Click.

2. The window below is displayed. So, check that "Search for a suitable driver ..." is selected,

then click Next>.

Figure 8: Search Method (Windows 98SE)

Check that "Search for a

suitable driver ..." is selected.

Click.

User’s Manual U18560EE1V0UM00 31

Page 32

V850ES/Fx3 – CAN it!

3. Check the "Specify a location" check box only and enter "C:\Program

Files\NECTools32\FPL\DRIVER" in the address bar, then click Next>.

Figure 9: Search Location Specification (Windows 98SE)

<1> Check "Specify

a l

ocation" only.

備考 3.1 ソフトウエアのインストール先のフォルダを変更した場合は,

<2> Enter "C:\Program Files\NECTools32\FPL\DRIVER".

<3> Click.

Remark If the installation destination folder is changed at the time of GUI software installation,

enter "new-folder\DRIVER".

4. The window below is displayed. Click Next>.

Figure 10: Checking Driver to Be Installed (Windows 98SE)

Click.

User’s Manual U18560EE1V0UM00 32

Page 33

V850ES/Fx3 – CAN it!

5. When the window below is displayed, the installation of the USB driver is completed. Click

Finish. The installation of the USB Serial Port driver is then automatically performed.

Figure 11: Installation Completion (Windows 98SE)

Click.

8.5.2 Installation on Windows 2000

1. When the V850ES/Fx3 – CAN it! board is connected with the host machine, the board is

recognized by Plug and Play, and the wizard for finding new hardware is started. Click

Next>.

Figure 12: Found New Hardware Wizard 1 (Windows 2000)

Click.

User’s Manual U18560EE1V0UM00 33

Page 34

V850ES/Fx3 – CAN it!

2. The window below is displayed. So, check that "Search for a suitable driver ..." is selected,

then click Next>.

Figure 13: Search Method 1 (Windows 2000)

Check that "Search for a

suitable driver ..." is selected.

Click.

3. Check the "Specify a location" check box only, then click Next>.

Check that "Specify a

location" only is checked.

ed.hed.

Figure 14: Driver File Location 1 (Windows 2000)

Click.

User’s Manual U18560EE1V0UM00 34

Page 35

V850ES/Fx3 – CAN it!

4. Enter "C:\Program Files\NECTools32\FPL\DRIVER" in the address bar, then click OK.

Figure 15: Address Specification 1 (Windows 2000)

Click.

Enter "C:\Program Files\NECTools32\FPL\DRIVER".

Remark If the installation destination folder is changed at the time of GUI software installation,

enter "new-folder\FPL\DRIVER".

5. Click Next>.

Figure 16: Driver File Search 1 (Windows 2000)

Click.

User’s Manual U18560EE1V0UM00 35

Page 36

V850ES/Fx3 – CAN it!

6. Click Finish to complete the installation of the USB driver.

Figure 17: USB Driver Installation Completion 1 (Windows 2000)

Click.

7. Proceed to the installation of the USB Serial Port driver. Click Next>.

Figure 18: Found New Hardware Wizard 2 (Windows 2000)

Click.

User’s Manual U18560EE1V0UM00 36

Page 37

V850ES/Fx3 – CAN it!

8. The window below is displayed. So, check that "Search for a suitable driver ..." is selected,

then click Next>.

Figure 19: Search Method 2 (Windows 2000)

Check that "Search for a

suitable driver ..." is selected.

Click.

9. Check the "Specify a location" check box only, then click Next>.

Check that "Specify a

location" only is checked.

Figure 20: Driver File Location 2 (Windows 2000)

Click.

User’s Manual U18560EE1V0UM00 37

Page 38

V850ES/Fx3 – CAN it!

10. Enter "C:\Program Files\NECTools32\FPL\DRIVER" in the address bar, then click OK.

Figure 21: Address Specification 2 (Windows 2000)

Click.

Enter "C:\Program Files\NECTools32\FPL\DRIVER".

Remark If the installation destination folder is changed at the time of GUI software installation,

enter "new-folder\DRIVER".

11. Click Next>.

Figure 22: Driver File Search 2 (Windows 2000)

Click.

User’s Manual U18560EE1V0UM00 38

Page 39

V850ES/Fx3 – CAN it!

12. Click Finish to complete the installation of the USB driver.

Figure 23: USB Driver Installation Completion 2 (Windows 2000)

Click.

8.5.3 Installation on Windows XP

1. When the V850ES/Fx3 – CAN it! board is connected with the host machine, the board is

recognized by Plug and Play, and the wizard for finding new hardware is started. Check

that "Install from a list or specific ..." is selected, then click Next>.

Figure 24: Found New Hardware Wizard 1 (Windows XP)

Check that "Install from a list or

specific ..." is selected.

Click.

User’s Manual U18560EE1V0UM00 39

Page 40

V850ES/Fx3 – CAN it!

2. Check that "Search for the best driver in these locations." is selected. Check the "Include

this location in the search:" check box and enter "C:\Program

Files\NECTools32\FPL\DRIVER" in the address bar, then click Next>.

Figure 25: Search Location Specification 3 (Windows XP)

<1> Check that "Search for the

best driver in these locations."

is selected.

<2> Check "Include this

location in the search:"

only.

<4> Click.<3> Enter "C:\Program Files\NECTools32\FPL\DRIVER".

3. As shown below, "has not passed Windows Logo testing to verify its compatibility with

Windows XP." is displayed. Click Continue Anyway.

Figure 26: Windows XP Logo Testing 3 (Windows XP)

Click.

User’s Manual U18560EE1V0UM00 40

Page 41

V850ES/Fx3 – CAN it!

4. When the window below is displayed, the installation of the USB driver is completed. Click

Finish.

Figure 27: USB Driver Installation Completion 1 (Windows XP)

Click.

5. Proceed to the installation of the USB Serial Port driver. Click Next>.

Figure 28: Found New Hardware Wizard 2 (Windows XP)

Check that "Install from a list

or specific ..." is selected.

Click.

User’s Manual U18560EE1V0UM00 41

Page 42

V850ES/Fx3 – CAN it!

6. Check that "Search for the best driver in these locations." is selected. Check the "Include

this location in the search:" check box and enter "C:\Program

Files\NECTools32\FPL\DRIVER", then click Next>.

Figure 29: Search Location Specification 2 (Windows XP)

<1> Check that "Search for the best

driver in these locations." is

selected.

<2> Check "Include this location in

the search:" only.

<3> Enter "C:\Program Files\NECTools32\FPL\DRIVER".

<4> Click.

7. As shown below, "has not passed Windows Logo testing to verify its compatibility with

Windows XP." is displayed. Click Continue Anyway.

Figure 30: Windows XP Logo Testing 2 (Windows XP)

Click.

User’s Manual U18560EE1V0UM00 42

Page 43

V850ES/Fx3 – CAN it!

8. When the window below is displayed, the installation of the USB driver is completed. Click

Finish.

Figure 31: USB Serial Port2 Driver Installation Completion (Windows XP)

Click.

User’s Manual U18560EE1V0UM00 43

Page 44

V850ES/Fx3 – CAN it!

8.6 Confirmation of USB Driver Installation

After installing the two types of drivers, check that the drivers have been installed normally,

according to the procedure below. When using the V850ES/Fx3 – CAN it! board in combination

with FPL GUI, the information to be checked here is needed.

By clicking the "Device Manager" tab, check that the drivers are installed normally.

Figure 32: Device Manager

Check that "USB Serial Port

(COM?)" is present.

Check that "USB High Speed

Serial Converter" is present.

For Windows 98SE/Me

Caution Do not select Update and Erase when communicating with the target

device.

For Windows 2000/XP

Caution Do not perform "Hardware Modification Scan" when communicating with the target

device.

Remark In the GUI port list box, the same communication port as COM? of USB Serial Port

(COM?) needs to be selected.

If the drivers above are not displayed, or the mark "×" or "!" is prefixed, refer to

CHAPTER 11 TROUBLESHOOTING.

User’s Manual U18560EE1V0UM00 44

Page 45

V850ES/Fx3 – CAN it!

8.7 Driver Uninstallation

The driver uninstallation program is installed on the host machine when the FPL software is

installed. Use the procedure below for driver uninstallation.

1. When using Windows XP, log on as the computer administrator. When using Windows

2000, log on as the Administrator.

2. Double-click in the order from "My Computer" to "(C:)" to "Program Files" to "NECTools32"

to "FPL" to "DRIVER". "Ftdiunin.exe" is displayed. Double-click "Ftdiunin.exe".

Figure 33: Driver Uninstallation

Double-click.

3. Click Continue.

Figure 34: Driver Uninstaller

Click.

User’s Manual U18560EE1V0UM00 45

Page 46

V850ES/Fx3 – CAN it!

4. Click Finish to complete driver uninstallation.

Figure 35: Completion of Driver Uninstallation

Click.

Caution If the GUI software is uninstalled earlier, "Ftdiunin.exe" is also deleted. At this time, delete

"USB Serial Port (COM?)" and "USB High Speed Serial Converter" from Device Manager

manually.

User’s Manual U18560EE1V0UM00 46

Page 47

V850ES/Fx3 – CAN it!

9. FPL FLASH programming software

9.1 Introduction

The parameter file of the V850ES/FG3 device is installed automatically during installation of FPL

GUI, folder <FPL install-path>\PRM. Nevertheless, newest version of parameter file for the

µPD70F3377 device can by download from the NEC Electronics Web site.

Download the parameter file for the PG-FP4 from the following NEC Electronics Web site:

http://www.eu.necel.com/updates

Copy the parameter file downloaded from the NEC Electronics Web site into sub-directory

<FPL.EXE-install-path>\PRM created during GUI software setup (refer to CHAPTER 6

SOFTWARE INSTALLATION).

9.2 Starting up the GUI Software

• GUI software startup

Select FPL.EXE from the start menu to start the FPL GUI software.

When the GUI software is started normally, the following screen appears.

Figure 36: GUI Software Main Window

Menu bar

Toolbar

Status bar

Programmer

parameter

window

Action log window

User’s Manual U18560EE1V0UM00 47

Page 48

V850ES/Fx3 – CAN it!

This window consists of the following items:

Name Display Information

Menu bar

(displayed at the top)

Toolbar

(displayed under the menu bar)

Action log window

(displayed under the toolbar)

Programmer parameter window

(displayed to the right of the action log

window)

Status bar Displays status.

9.3 Toolbar

The toolbar contains buttons for starting the important procedures of the FPL.

Figure 37: Toolbar Buttons

Displays menu items executable by the

FPL.

Displays frequently used commands as

icons.

Displays an FPL action log.

Displays programming parameter

settings.

[D

evice] → [Setup] button

[File] → [Load] button

[Device] → [Blank Check] button

evice] → [Erase] button

[D

evice] → [Program] button

[D

[D

evice] → [Verify] button

evice] → [Autoprocedure(EPV)] button

[D

User’s Manual U18560EE1V0UM00 48

Page 49

V850ES/Fx3 – CAN it!

9.4 Menu Bar

Depending on the actual device status and device type, some menu items may be enabled or

disabled.

9.4.1 [File] menu

Clicking the [F

This menu mainly contains commands related to file operation.

ile] menu displays the pull-down menu as shown below.

Figure 38: [File] Menu

(1) [L

oad] command

oad] command allows you to select a program file.

The [L

The selected program file is programmed into the flash memory of the device by

executing the [P

rogram] command or [Autoprocedure(EPV)] command.

Figure 39: HEX File Selection Window

The file selection window for program loading displays the most recently used directory to

which a user program has been loaded. After a user program is loaded, a checksum

calculation is made and the result is displayed in the programmer parameter window.

[ O

pen button]

Selects a user program as a program to be written to the target device.

[ Cancel button]

Closes the window without selecting a program.

User’s Manual U18560EE1V0UM00 49

Page 50

V850ES/Fx3 – CAN it!

(2) [Q

The [Q

User settings are saved in the FPL.INI

uit] command

uit] menu is the command for terminating the FPL GUI software. Clicking × on the

right side of the task bar also terminates the FPL GUI software.

Note

file, so that the GUI software starts up next time

with the same settings.

Note FPL.INI is created in the Windows folder when Windows 98SE, Windows Me, or

Windows XP is used.

When Windows 2000 is used, FPL.INI is created in the Winnt folder.

9.4.2 [D

evice] menu

Clicking the [D

evice] menu displays the pull-down menu as shown below.

This menu mainly contains commands for programming operations such as deletion,

programming, and verification on the target device.

(1) [B

lank Check] command

The [Blank Check] command allows you to make a blank check on the target device

connected to the FPL. If the flash memory of the target device is erased, a blank

check is terminated normally. If the flash memory is not completely erased, the

indication "not blank" is provided. Before starting programming, erase the flash

memory of the target device.

(2) [E

rase] command

The [E

rase] command erases the flash memory of the target device connected to the

FPL. While the flash memory is being erased, the progress status is displayed in the

action log window to indicate programmer operation.

The execution on the [B