DATA SHEET

MOS Integrated Circuit

µ

PD75P036

4-BIT SINGLE-CHIP MICROCONTROLLER

DESCRIPTION

The µPD75P036 is a 4-bit signgle-chip microcontroller that replaced the µPD75028's on-chip ROM with

one-time PROM or EPROM. Because this device can operate at the same supply voltage as its mask

version, it is suited for preproduction in development stage or small-scale production.

The one-time PROM version is programmable only once and is useful for small-scale production of many

different products and time-to-market of a new product. The EPROM version is programmable, erasable,

and reprogrammable, and is suited for the evaluation of application systems.

Detailed functions are described in the followig user's manual. Be sure to read it for designing.

µ

PD75028 User's Manual: IEU-1280

★

FEATURES

•

µ

PD75028 compatible

µ

• At full production, the

PD75P036 can be replaced with the µPD75028 which incorporates mask ROM

• Memory capacity

• Program memory (PROM): 16256 x 8 bits

• Data memory (RAM): 1024 x 4 bits

• Internal pull-up resistors can be specified by software: Ports 0-3, 6-8

• Internal pull-down resistors can be specified by software: Port 9

• Open-drain input/output: Ports 4, 5, 10

• Can operate at low voltage: VDD = 2.7 to 6.0 V

ORDERING INFORMATION

Part Number Package Internal ROM Quality Grade

µ

PD75P036CW 64-pin plastic shrink DIP (750 mils) One-time PROM Standard

µ

PD75P036GC-AB8 64-pin plastic QFP (14 x 14 mm) One-time PROM Standard

µ

PD75P036KG 64-pin ceramic WQFN EPROM Not applicable

Caution Internal pull-up/pull-down resistors cannot be specified by mask option as for this device.

Please refer to "Quality grade on NEC Semiconductor Devices" (Document number IEI-1209) published by NEC Corporation

to know the specification of quality grade on e devices and its recommended applications.

★

The reliability of the EPROM version, µPD75P036KG, is not guaranteed when used in mass-produced application

sets. Please use this device only experimentally or for evaluation during trial manufacture.

The function common to the one-time PROM and EPROM versions is referred to as PROM throughout this document.

Document No. U10051EJ3V0DS00 (3rd edition)

(Previous No. IC-2967

Date Published September 1995 P

Printed in Japan

The information in this document is subject to change without notice.

The mark ★ shows revised points.

NEC Corporation

1991

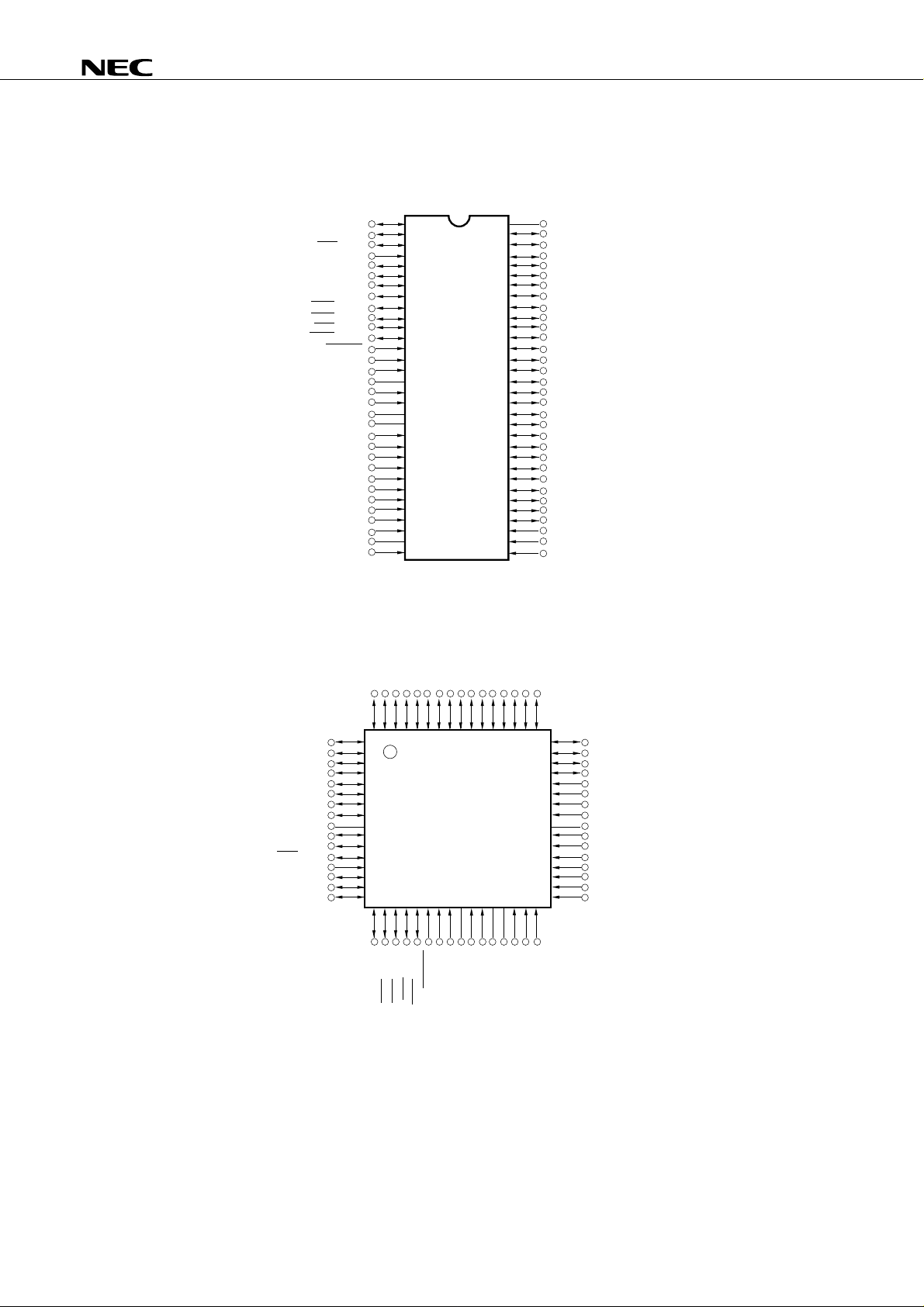

PIN CONFIGURATIONS (Top View)

• 64-pin plastic shrink DIP (750 mils)

µ

PD75P036

SB1/SI/P03

SB0/SO/P02

SCK/P01

INT4/P00

BUZ/P23

PCL/P22

PPO/P21

PTO0/P20

MAT/P103

MAZ/P102

MAI/P101

MAR/P100

RESET

X1

X2

V

XT1

XT2

V

AV

AV

REF+

AV

REF-

AN7

AN6

AN5

AN4

AN3/P113

AN2/P112

AN1/P111

AN0/P110

AV

TIO/P13

PP

DD

DD

SS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

µ

PD75P036CW

• 64-pin plastic QFP (14 x 14 mm)

• 64-pin ceramic WQFN

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

V

SS

P30/MD0

P31/MD1

P32/MD2

P33/MD3

P40

P41

P42

P43

P50

P51

P52

P53

P60/KR0

P61/KR1

P62/KR2

P63/KR3

P70/KR4

P71/KR5

P72/KR6

P73/KR7

P80

P81

P82

P83

P90

P91

P92

P93

P10/INT0

P11/INT1

P12/INT2

P43

P42

P41

P40

MD3/P33

MD2/P32

MD1/P31

MD0/P30

V

SB1/SI/P03

SB0/SO/P02

SCK/P01

INT4/P00

BUZ/P23

PCL/P22

PPO/P21

P50

P51

P52

P53

P60/KR0

P61/KR1

P62/KR2

1

2

3

4

5

6

7

8

SS

9

10

11

12

13

14

15

16

171819

µ

PD75P036KG

X1

RESET

MAI/P101

PTO0/P20

MAT/P103

MAZ/P102

MAR/P100

P73/KR7

P80

P81

P72/KR6

52535455565758596061626364

51 50 49

DDAVDD

V

XT2

REF+

AV

P82

32313029282726252423222120

REF-

AV

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

P70/KR4

P63/KR3

P71/KR5

µ

PD75P036GC-AB8

PP

X2

V

XT1

P83

AN7

P90

P91

P92

P93

P10/INT0

P11/INT1

P12/INT2

TI0/P13

SS

AV

AN0/P110

AN1/P111

AN2/P112

AN3/P113

AN4

AN5

AN6

2

µ

PD75P036

PIN IDENTIFICATION

P00-P03 : Port 0 INT0, INT1, INT4: External Vectored Interrupt

P10-P13 : Port 1 INT2 : External Test Input

P20-P23 : Port 2 X1, X2 : Main System Clock Oscillation

P30-P33 : Port 3 XT1, XT2 : Subsystem Clock Oscillation

P40-P43 : Port 4 MAR : Reference Integration

P50-P53 : Port 5 Control

P60-P63 : Port 6 MAI : Integration Control

P70-P73 : Port 7 MAZ : Autozero Control

P80-P83 : Port 8 MAT : External Comparate

P90-P93 : Port 9 Timing Input

P100-P103 : Port 10 PPO : Programmable Pulse Output

P110-P113 : Port 11 ··· MFT timer mode

KR0-KR7 : Key Return AN0-AN7 : Analog Input

SCK : Serial Clock AV

SI : Serial Input AB

SO : Serial Output AV

REF+ : Analog Reference (+)

REF– : Analog Reference (–)

DD : Analog VDD

SB0, SB1 : Serial Bus AVSS : Analog VSS

RESET : Reset Input VDD : Positive Power Supply

TI0 : Timer Input V

SS : Ground

PTO0 : Programmable Timer Output MD0-MD3 : Mode Selection

BUZ : Buzzer Clock VPP : Programming/Verifying Power Supply

PCL : Programmable Clock

MFT A/D mode

★

Remark MFT: Multifunction Timer

3

4

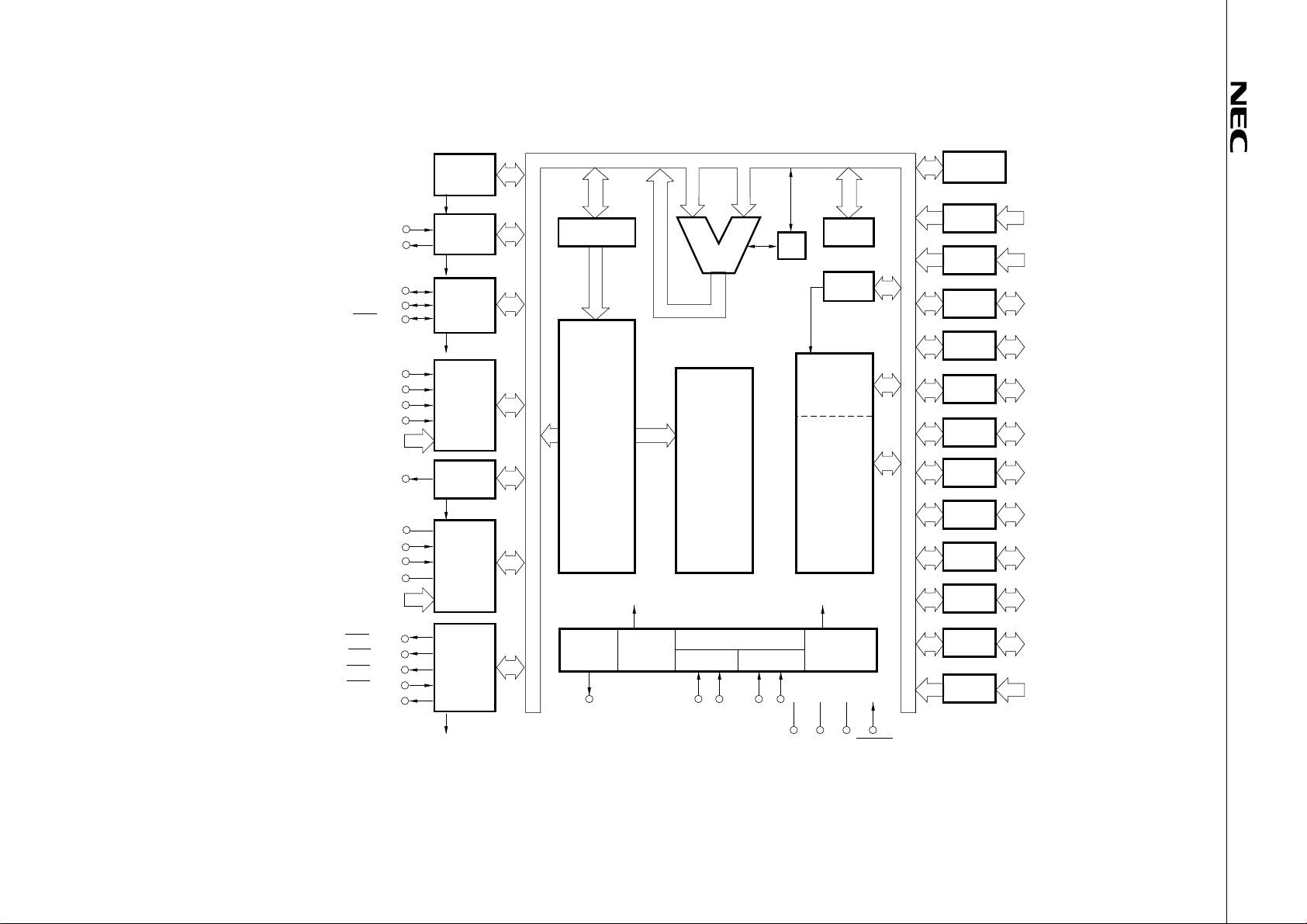

BLOCK DIAGRAM

TI0/P13

PTO0/P20

SI/SB1/P03

SO/SB0/P02

SCK/P01

INT0/P10

INT1/P11

INT2/P12

INT4/P00

KR0-KR3/P60-P63

KR4-KR7/P70-P73

BUZ/P23

AV

AV

REF+

AV

REF–

AV

AN0-AN3/P110-P113

AN4-AN7

MAR/P100

MAI/P101

MAZ/P102

MAT/P103

PPO/P21

BASIC

INTERVAL

TIMER

INTBT

TIMER

/COUNTER

#0

INTT0

SERIAL

INTERFACE

INTCSI

INTERRUPT

CONTROL

WATCH

TIMER

INTW

DD

A/D

CON-

SS

VERTER

MULTIFUNCTION

TIMER

INTMFT

PROGRAM

COUNTER

PROM

PROGRAM

MEMORY

16256 x 4 BITS

CLOCK

OUTPUT

CONTROL

PCL/P22

fx/2

CLOCK

DIVIDER

ALU

DECODE

AND

CONTROL

N

CLOCK GENERATOR

SUB

XT1 XT2 X1 X2

MAIN

CY

GENERAL

REG.

RAM

DATA

MEMORY

1024 x 4 BITS

STAND BY

CONTROL

V

PPVDDVSS

SP

BANK

CPU CLOCK

Φ

RESET

BIT SEQ.

BUFFER

PORT 0

PORT 1

PORT 2

PORT 3

PORT 4

PORT 5

PORT 6

PORT 7

PORT 8

PORT 9

PORT 10

PORT 11

P00–P03

P10–P13

P20–P23

P30/MD0-P33/MD3

P40–P43

P50–P53

P60–P63

P70–P73

P80–P83

P90–P93

P100–P103

P110–P113

µ

PD75P036

CONTENTS

1. PIN FUNCTIONS ... 6

1.1 Port Pins ... 6

1.2 Non-Port Pins ... 8

1.3 Pin Input/Output Circuits ... 10

1.4 Recommended Connection of Unused Pins ... 13

2. MEMORY ... 14

2.1 Differences between µPD75P036 and µPD75028/75036 ... 14

2.2 Program Memory (ROM) ... 15

2.3 Data Memory (RAM) ... 17

3. WRITING AND VERIFYING PROM (PROGRAM MEMORY) ... 19

3.1 Operation Modes For Writing/Verifying Program Memory ... 19

3.2 Program Memory Write Procedure ... 20

3.3 Program Memory Read Procedure ... 21

3.4 Erasure (µPD75P036KG only) ... 22

µ

PD75P036

★

★

4. ELECTRICAL SPECIFICATIONS ... 23

5. CHARACTERISTIC CURVES ... 38

6. PACKAGE DRAWINGS ... 44

7. RECOMMENDED SOLDERING CONDITIONS ... 47

APPENDIX A. DEVELOPMENT TOOLS ... 48

APPENDIX B. RELATED DOCUMENTS ... 49

★

★

5

µ

PD75P036

1. PIN FUNCTIONS

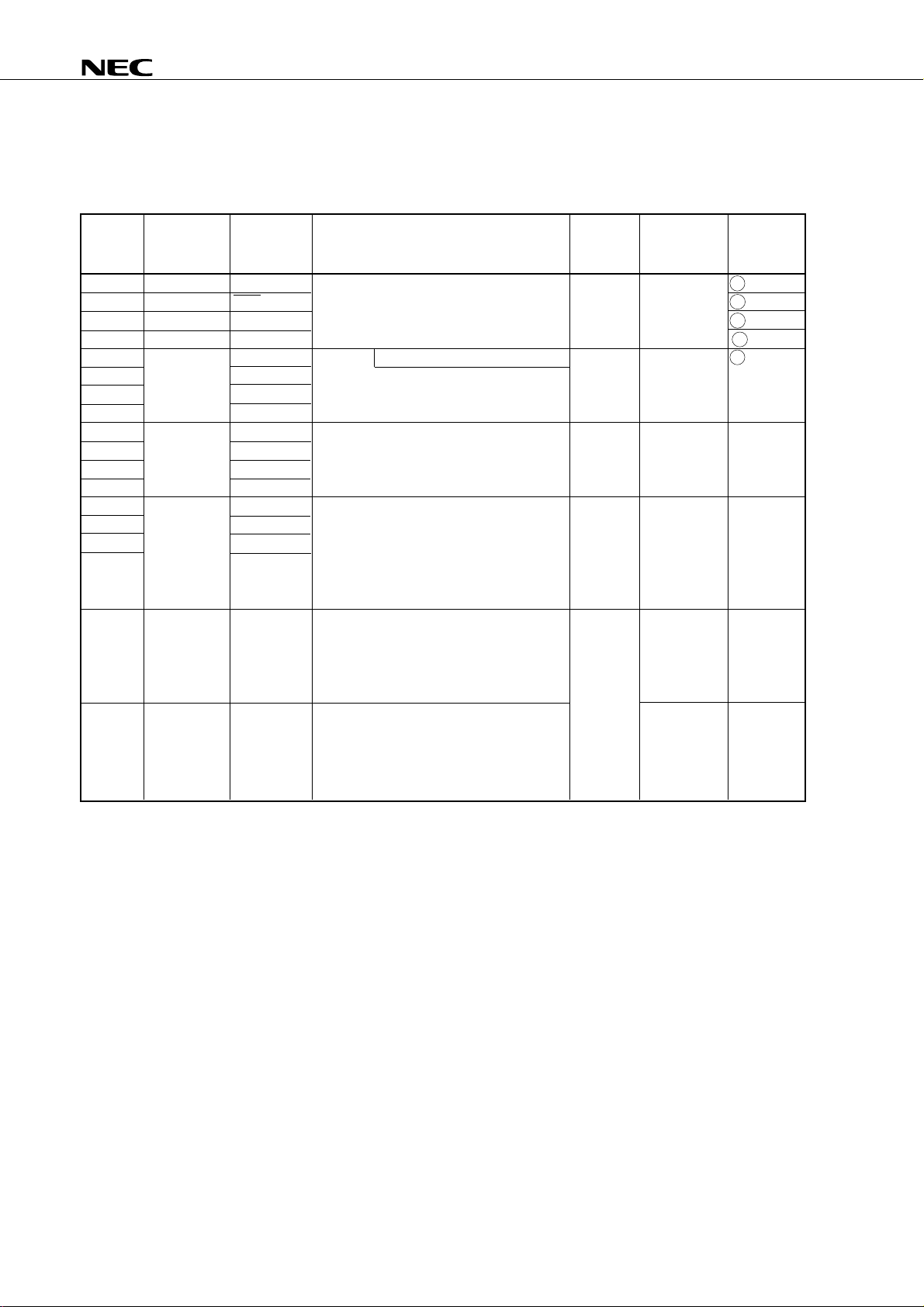

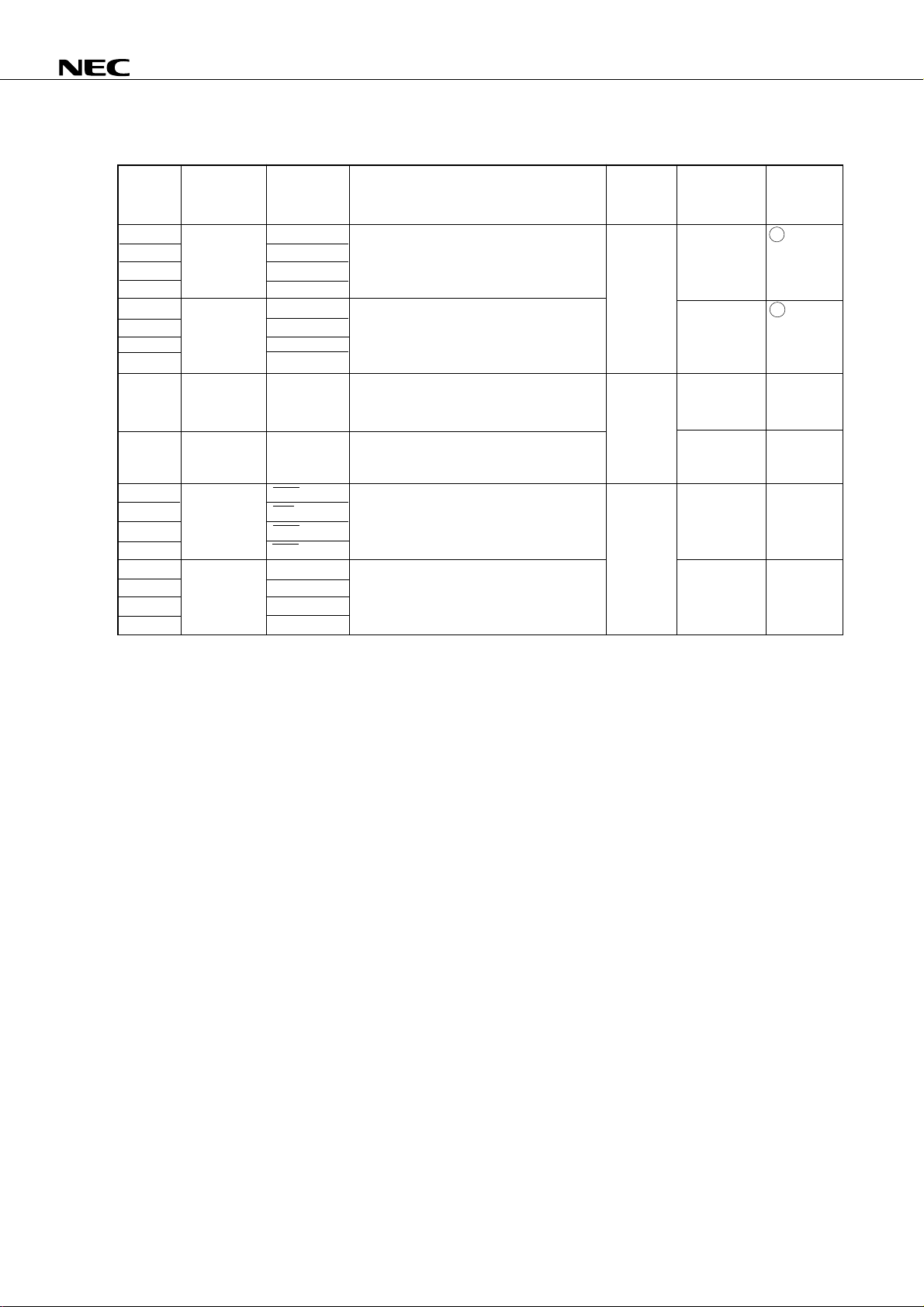

1.1 Port Pins (1/2)

Pin Name Input/Output Alternate Function 8-Bit I/O When Reset Input/Output

Function Circuit

P00 Input INT4 4-bit input port (PORT0). No Input B

P01 Input/Output SCK Internal pull-up resistors can be specified in F - A

P02 Input/Output SO/SB0 3-bit units for the P01 to P03 pins by F - B

P03 Input/Output SI/SBI software. M - C

P10 Input INT0 With noise elimination function No Input B - C

P11 INT1 4-bit input port (PORT1).

P12 INT2 Internal pull-up resistors can be specified in

P13 TI0 4-bit units by software.

P20 Input/Output PTO0 4-bit input/output port (PORT2). No Input E - B

P21 PPO Internal pull-up resistors can be specified in

P22 PCL 4-bit units by software.

P23 BUZ

Note 2

P30

P31

P32

P33

Input/Output MD0 Programmable 4-bit input/output port No Input E - B

Note 2

Note 2

Note 2

MD1 (PORT3).

MD2 This port can be specified for input/output

MD3 in bit units.

Internal pull-up resistors can be specified in

4-bit units by software.

Note 2

N-ch open-drain 4-bit input/output port Yes Input M - A

P40-P43 Input/Output (PORT4).

Withstands up to 10 V.

Data input/output pin for writing and verifying

of program memory (PROM) (lower 4 bits).

Note 2

Input/Output N-ch open-drain 4-bit input/output port Input M - A

P50-P53 (PORT5).

Withstands up to 10 V.

Data input/output pin for writing and verifying

of program memory (PROM) (upper 4 bits).

Type

Note 1

Notes 1. Circles indicate Schmitt-triggerred inputs.

2. Can directly drive LEDs.

6

µ

PD75P036

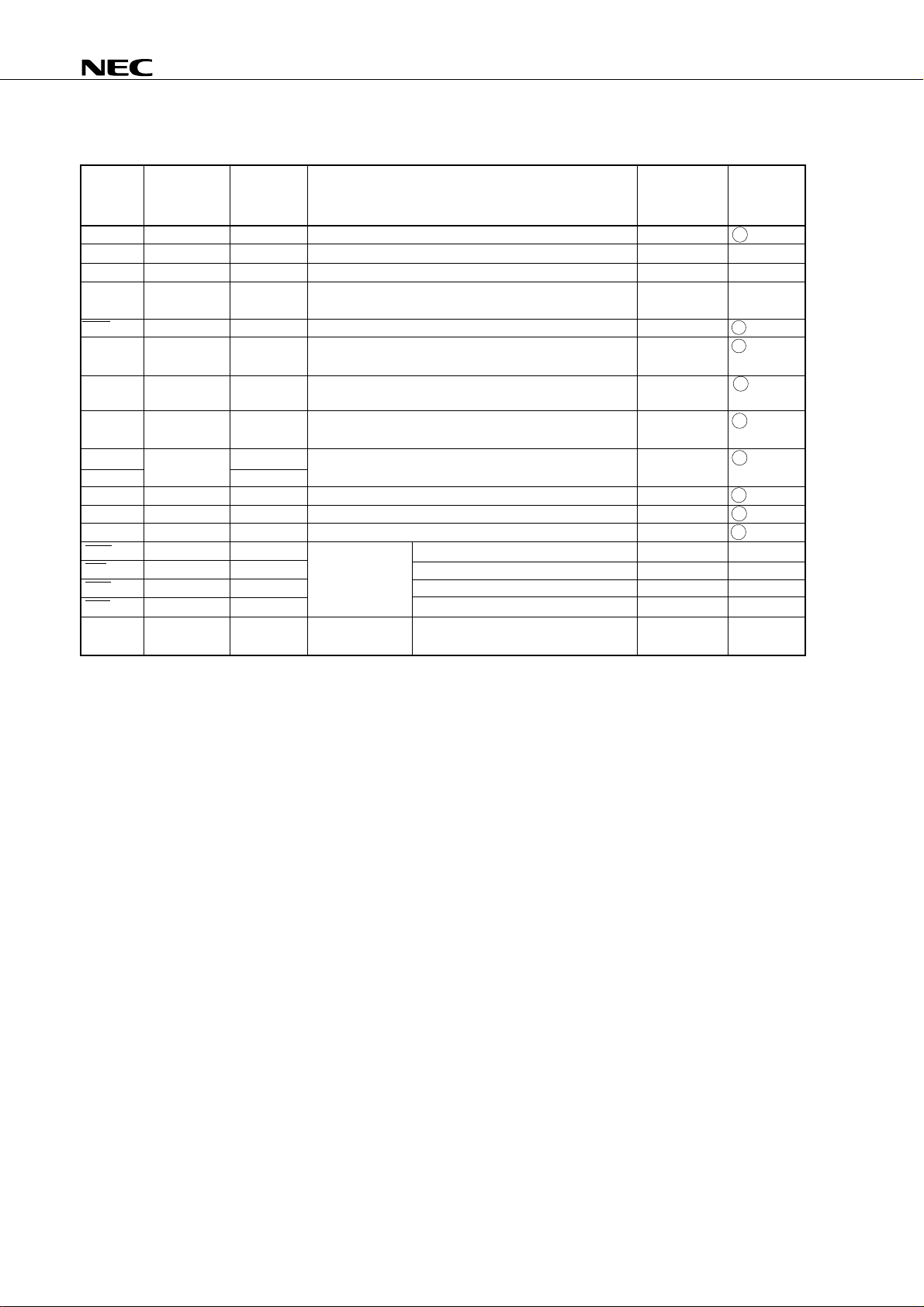

1.1 Port Pins (2/2)

Pin Name Input/Output Alternate Function 8-Bit I/O When Reset Input/Output

Function Circuit

P60 Input/Output KR0 Programmable 4-bit input/output port Yes Input F - A

P61 KR1 (PORT6).

P62 KR2 Internal pull-up resistors can be specified in

P63 KR3 4-bit units by software.

P70 Input/Output KR4 4-bit input/output port (PORT7). Input F - A

P71 KR5 Internal pull-up resistors can be specified in

P72 KR6 4-bit units by software.

P73 KR7

P80-P83 Input/Output — 4-bit input/output port (PORT8). No Input E - B

Internal pull-up resistors can be specified in

4-bit units by software.

P90-P93 Input/Output — 4-bit input/output port (PORT9). Input E - D

Internal pull-up resistors can be specified in

4-bit units by software.

P100 Input/Output MAR N-ch open-drain 4-bit input/output port No Input M -A

P101 MAI (PORT10).

P102 MAZ Withstands up to 10 V in open-drain mode.

P103 MAT

P110 Input AN0 4-bit input/output port (PORT11). Input Y

P111 AN1

P112 AN2

P113 AN3

Type

Note 1

Note Circles indicate schmitt-triggerred inputs.

7

µ

PD75P036

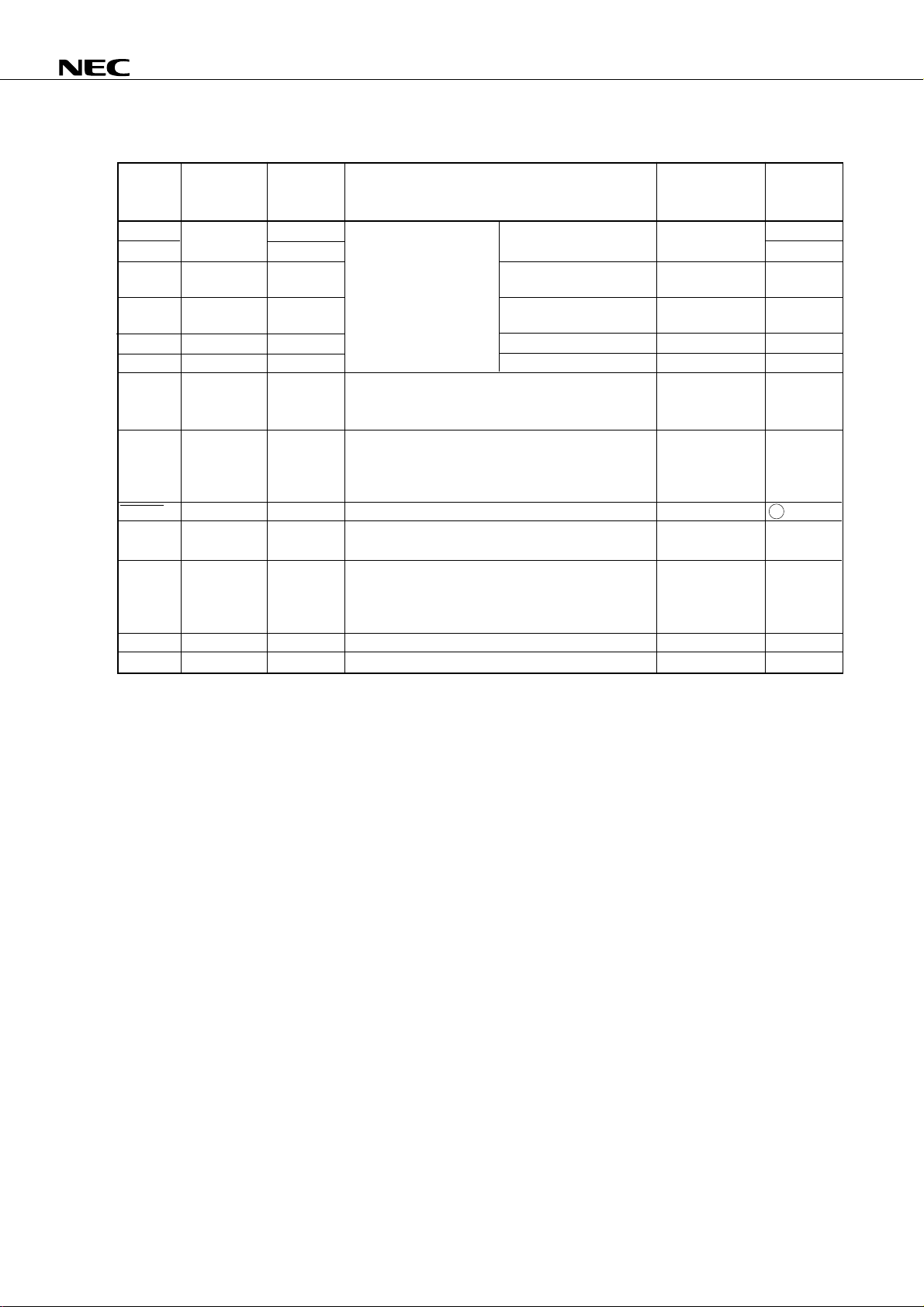

1.2 Non-Port Pins (1/2)

Pin Name Input/Output Alternate Function 8-Bit I/O When Reset Input/Output

Function Circuit

TI0 Input P13 External event pulse input pin to timer/event counter Input B - C

PTO0 Input/Output P20 Timer/event counter output pin Input E - B

PCL Input/Output P22 Clock output pin Input E - B

BUZ Input/Output P23 Fixed frequency output pin (for buzzer or for trimming Input E - B

the system clock)

SCK Input/Output P01 Serial clock input/output pin Input F - A

SO/SB0 Input/Output P02 Serial data output pin Input F - B

Serial bus input/output pin

SI/SB1 Input/Output P03 Serial data output pin Input M - C

Serial bus input/output pin

INT4 Input P00 Edge detection vectored interrupt input pin (Either Input B

rising or falling edge detection is effective)

INT0 Input P10 Edge detection vectored interrupt input pin (Detection Input B - C

INT1 P11 edge can be selected)

INT2 Input P12 Edge detection testable input pin (rising edge detection) Input B - C

KR0-KR3 Input/Output P60-P63 Testable input/output pin (parallel falling edge detection) Input F - A

KR4-KR7 Input/Output P70-P73 Testable input/output pin (parallel falling edge detection) Input F - A

MAR Input/Output P100 In integral A/D Reverse integration signal output pin Input M - A

MAI Input/Output P101 converter mode Integration signal output pin Input M - A

MAZ Input/Output P102 of MFT Auto zero signal output pin Input M - A

MAT Input/Output P103 Comparator input pin Input M - A

PPO Input/Output P21 In timer mode Timer pulse output pin Input E - B

of MFT

Type

Note 1

Note Circles indicate Schmitt-triggerred inputs.

Remark MFT: Multifunction timer

8

µ

PD75P036

1.2 Non-Port Pins (2/2)

Pin Name Input/Output Alternate Function When Reset Input/Output

Function Circuit

AN0-AN3 Input P110-P113 Pins only for A/D 8-bit analog input pin. — Y

AN4-AN7 — converter Y - A

AVREF+ Input — Reference voltage input — Z - A

pin (AVDD side).

AVREF– Input — Reference voltage input — Z - A

pin (AVSS side).

AVDD — — Positive power supply pin. — —

AVSS — — GND potential pin. — —

X1, X2 Input — Crystal or ceramic resonator connection for main — —

system clock generation. To use external clock, input

the external clock to X1 and its reverse phase to X2.

XT1, XT2 Input — Crystal or ceramic resonator connection for subsystem — —

clock generation. To use external clock, input the

external clock to XT1 and its reverse phase to XT2.

XT1 can be used as a 1-bit input (test) pin.

RESET Input — System reset input pin. — B

MD0/MD3 Input/Output P30-P33 Mode selection pins in program memory (PROM) Input E - B

Note 2

VPP

VDD — — Positive power supply pin. — —

VSS — — GND potential pin. — —

— — Program voltage application pin in program memory — —

write/verify mode.

(PROM) write/verify mode.

At normal operation, connect the pin to VDD directly.

In the PROM write/verify mode, apply +12.5 V.

Type

Note 1

Notes 1. Circles indicate schmitt trigger inputs.

2. If the V

PP pin is not connected directly to the VDD pin at normal operation, the

normally.

µ

PD75P036 does not operate

9

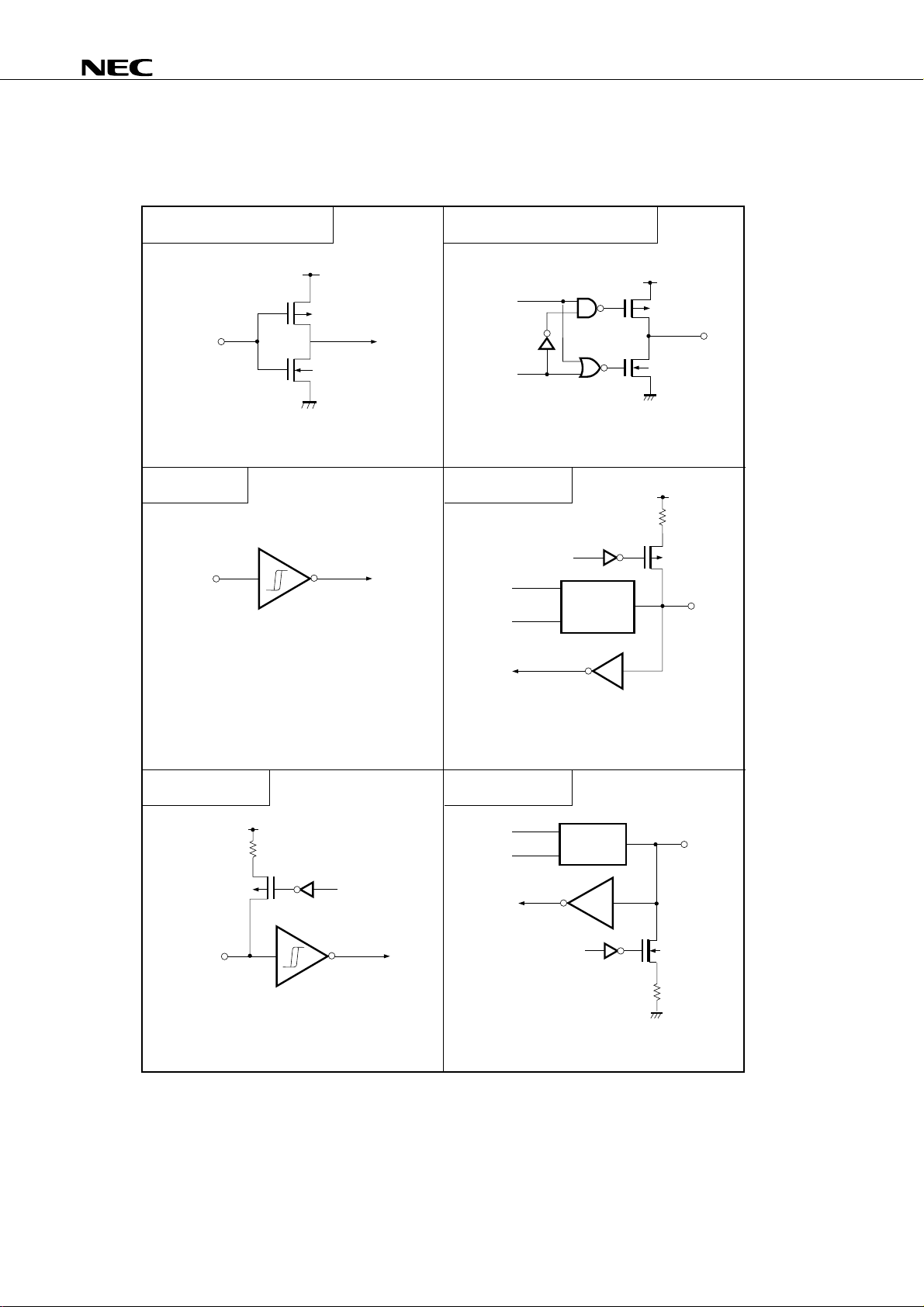

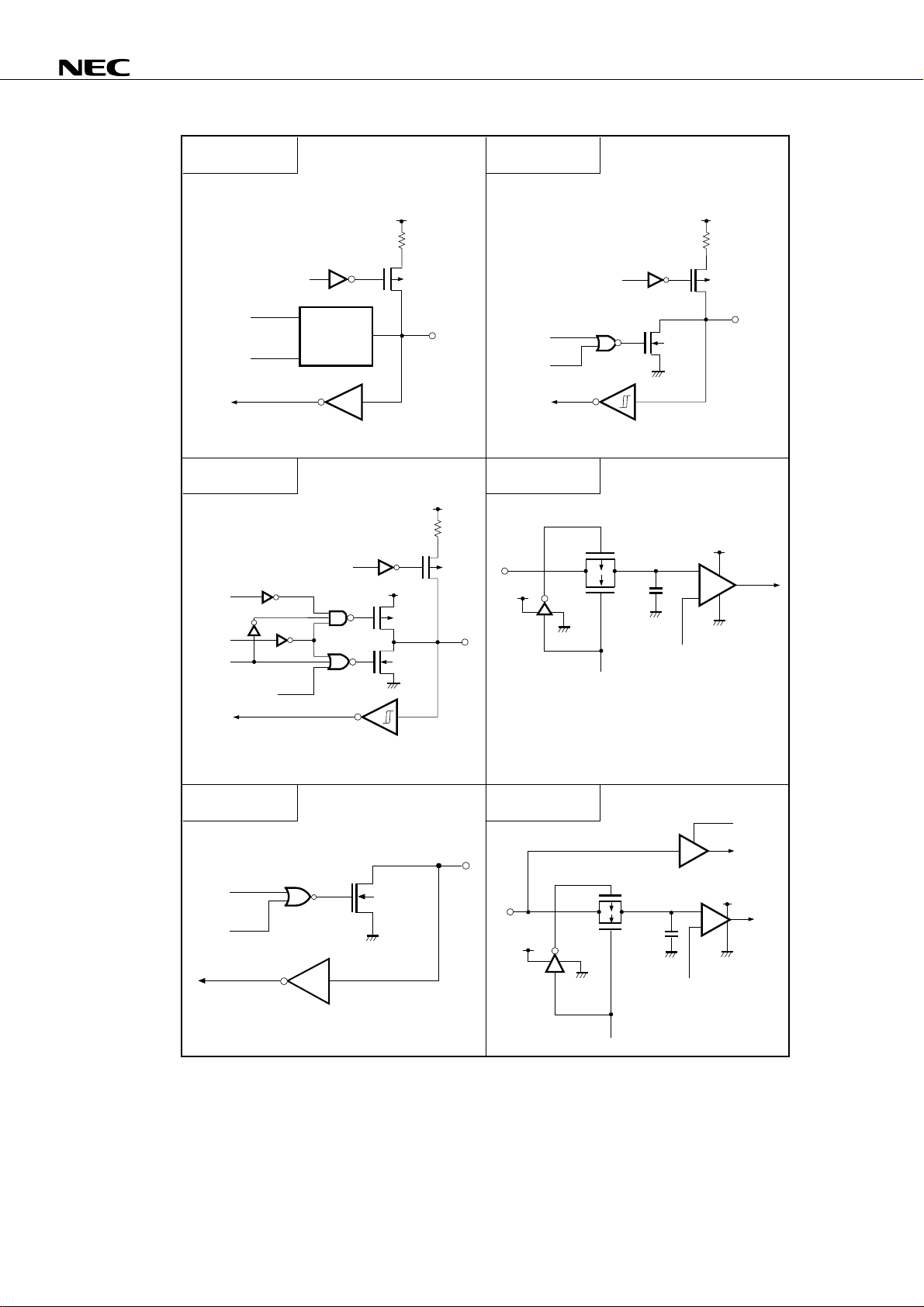

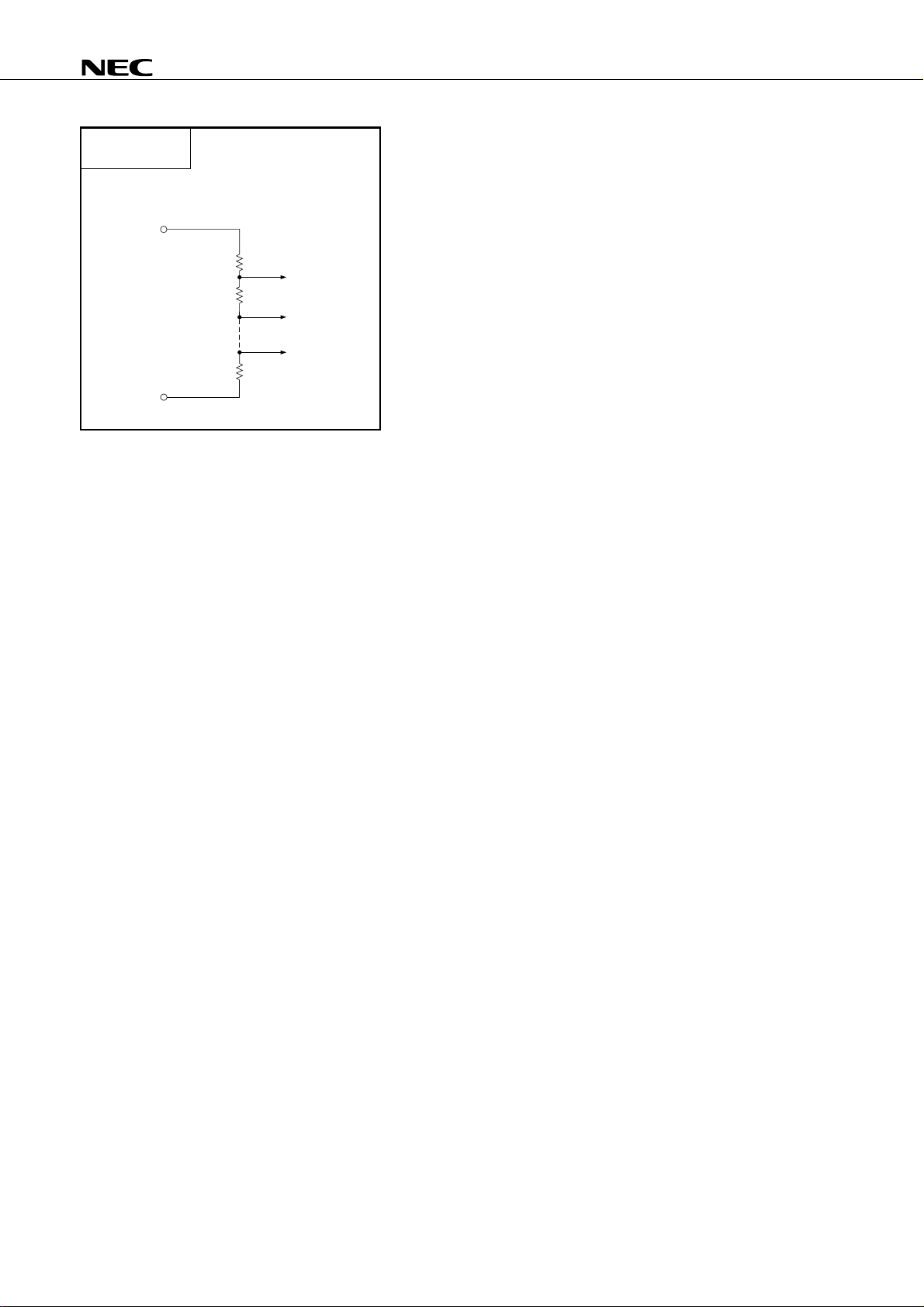

1.3 Pin Input/Output Circuits

The following shows a simplified input/output circuit diagram for each pin of the

µ

PD75P036.

µ

PD75P036

TYPE A (for TYPE E - B)

V

DD

P-ch

IN

N-ch

CMOS-level input buffer

TYPE B

IN

Schmitt-triggerred input with hysteresis characteristics

TYPE D (for TYPE E - B, F - A)

V

DD

data

output

disable

Push-pull output that can be set in an output

high-impedance state (both P-ch and N-ch are off)

TYPE E - B

P.U.R.

enable

data

output

disable

P.U.R. : Pull-Up Resistor

Type D

Type A

P-ch

N-ch

V

DD

OUT

P.U.R.

P-ch

IN/OUT

10

TYPE B - C

P-ch

IN

V

DD

P.U.R.

P.U.R.

enable

P.U.R. : Pull-Up Resistor

TYPE E - D

data

output

disable

P.D.R. : Pull-Down Resistor

Type D

Type A

P.D.R.

enable

IN/OUT

N-ch

P.D.R.

µ

PD75P036

TYPE F - A

output

disable

TYPE F - B

output

disable

(P)

data

output

disable

P.U.R.

enable

data

P.U.R. : Pull-Up Resistor

output

disable

(N)

Type D

P.U.R.

enable

Type B

TYPE M - C

V

DD

P.U.R. P.U.R.

P-ch P-ch

IN/OUT

data

P.U.R.

enable

N-ch

output

disable

P.U.R. : PullUp Resistor

TYPE Y

V

DD

P.U.R.

V

DD

P-ch

N-ch

P-ch

IN/OUT

IN

AV

P-ch

N-ch

DD

Sam-

pling

C

AV

SS

Reference voltage

(from serial resistor

input

string voltage tap)

enable

V

+

–

DD

AV

AV

IN/OUT

DD

SS

TYPE M - A

data

output

disable

P.U.R. : Pull-Up Resistor

N-ch

(+10-V

voltage)

Middle-voltage input buffer

(withstands up to + 10 V)

P.U.R. : Pull-Up Resistor

IN/OUT

TYPE Y - A

IN

AV

DD

P-ch

N-ch

AV

IN instruction

Input buffer

AV

DD

+

Sam-

pling

–

C

AV

SS

SS

Reference voltage

(from serial resistor

string voltage tap)

11

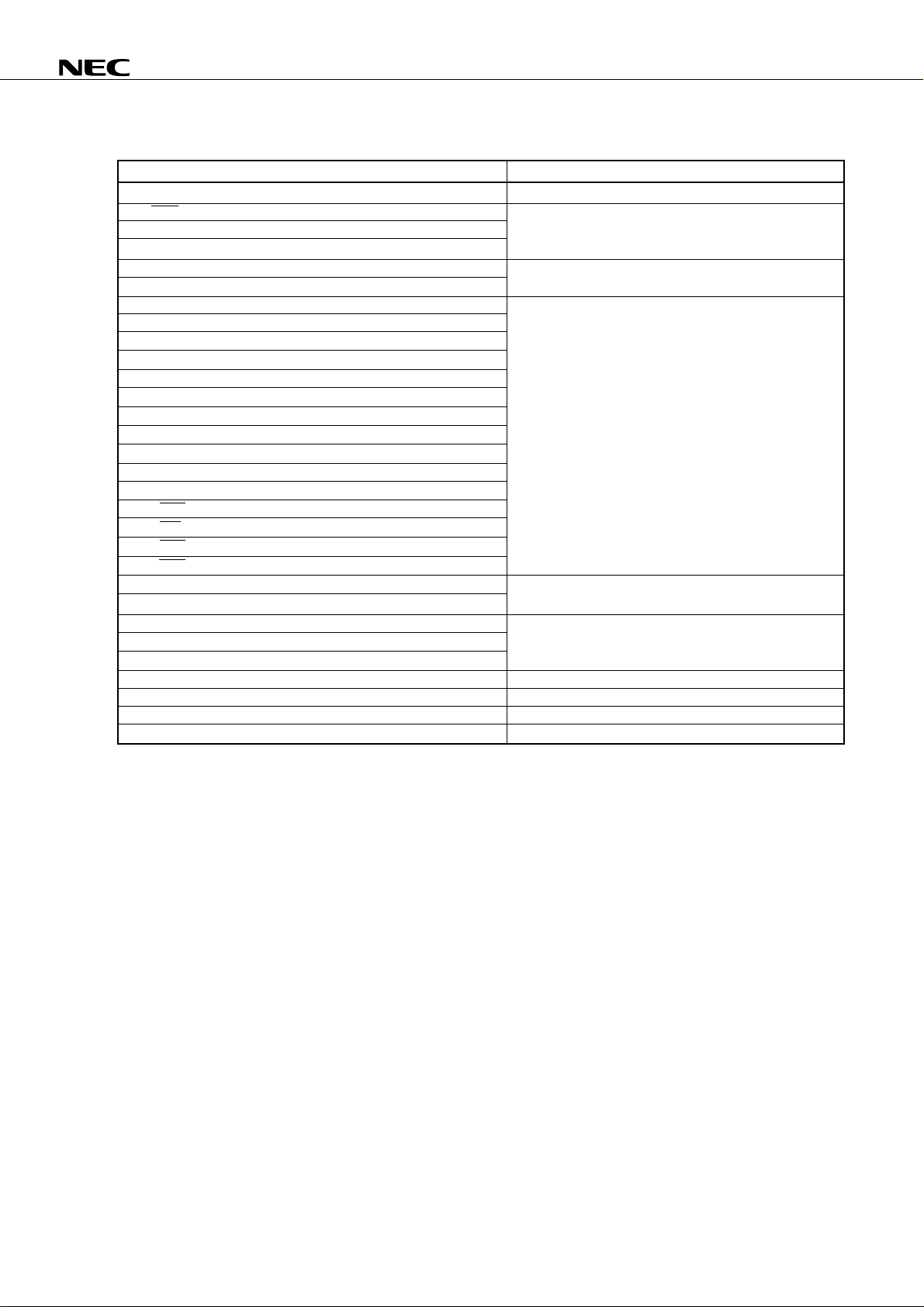

TYPE Z - A

AVREF+

AVREF-

Reference voltage

µ

PD75P036

12

µ

PD75P036

1.4 Recommended Connection of Unused Pins

Pin Name Recomended Connecting Method

P00/INT4 Connect to VSS.

P01/SCK Connect to VSS or VDD.

P02/SO/SB0

P03/SI/SB1

P10/INT0-P12/INT2 Connect to VSS.

P13/TI0

P20/PTO0 Input state: Independently connect to VSS or VDD via a

P21/PPO resistor.

P22/PCL Output state: Leave Open.

P23/BUZ

P30/MD0-P33/MD3

P40-P43

P50-P53

P60/KR0-P63/KR3

P70/KR4-P73/KR7

P80-P83

P90-P93

P100/MAR

P101/MAI

P102/MAZ

P103/MAT

P110/AN0-P113/AN3 Connect to VSS or VDD.

AN4-AN7

AVREF+ Connect to VSS.

AVREF–

AVSS

AVDD Connect to VDD.

XT1 Connect to VSS or VDD.

XT2 Leave Open.

VPP Connect directly to VDD.

★

13

µ

PD75P036

2. MEMORY

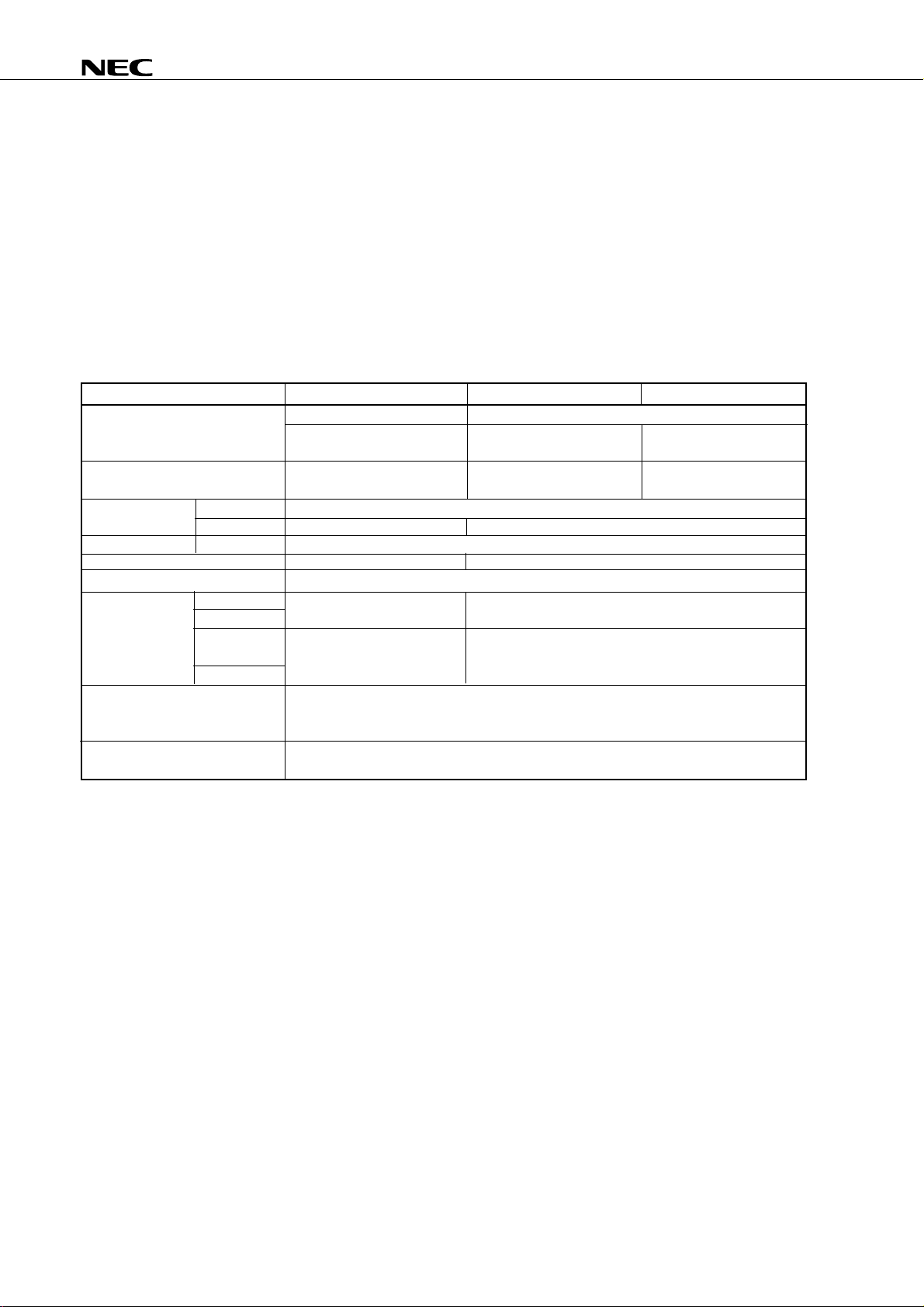

2.1 Differences between µPD75P036 and µPD75028/75036

µ

PD75P036 is a microcontroller provided by replacing the µPD75028's on-chip mask ROM with one-time

The

PROM or EPROM. Capacity of program memory and data memory are different, but CPU function and internal

hardware are identical. Table 2-1 shows the differences between the µPD75P036 and µPD75028/75036. Users

should fully consider these differences especially when debugging or producing an application system on an

experimental basis by using the PROM version and then mass-producing the system using the mask ROM version.

µ

For details about the CPU function and the internal hardware, refer to

PD75028 User's Manual (IEM-1280).

★

Item

Program memory One-time PROM/EPROM Mask ROM

Data memory 000H-3FFH 000H-1FFH 000H-3FFH

Pull-up resistor Ports 0-3, 6-8 Can be specified by software.

Pull-down resistor Port 9 Can be specified by software.

XT1 feedback resistor Provided on-chip Can be disconnected by mask option

Supply voltage VDD = 2.7 to 6.0 V

Pin connection Pin 16 (SDIP) VPP Internally connected

Electrical specifications Supply current and operating temperature ranges differ between µPD75P036 and

Others Noise immunity and noise radiation differ because circuit complexity and mask layout are

Table 2-1. Differences between µPD75P036 and µPD75028/75036

µ

PD75P036

0000H-3F7FH 0000H-1F7FH 0000H-3F7FH

(16256 x 8 bits) (8064 x 8 bits) (16256 x 8 bits)

(1024 x 4 bits) (512 x 4 bits) (1024 x 4 bits)

Ports 4, 5, 10 Not provided Can be connected by mask option

Pin 25 (QFP)

Pins 60-63 P33/MD3-P30/MD0 P33-P30

(SDIP)

Pins 5-8 (QFP)

µ

PD75028/75036. For details, refer to the electrical specifications described in Data Sheet

of each model.

different.

µ

PD75028

µ

PD75036

Caution The noise immunity and noise radiation differ between the PROM and mask ROM versions. To

replace the PROM version with the mask ROM version in the course of experimental production

to mass production, evaluate your system by using the CS version (not ES) of the mask ROM

version.

14

µ

PD75P036

2.2 Program Memory (ROM) ··· 16256 words x 8 bits

The program memory is a 16256-word x 8-bit PROM and stores programs, table data, etc.

The program memory is accessed by referencing the program counter contents. Table data can be referenced

by executing a table look-up instruction (MOVT).

Figure 2-1 shows the address range in which a branch can be taken by branch instructions and subroutine call

instructions. A relative branch instruction (BR $addr) enables a branch to addresses [PC value –15 to –1, +2 to

+16] regardless of block boundaries.

Program memory addresses are 0000H-3F7FH and the following addresses are assigned to special purposes:

(All areas except 0000H or 0001H can be used as normal program memory.)

• Addresses 0000H-0001H

Vector table into which the program start address and MBE setting value when the RESET signal is generated

are written.

Processing at reset is started at any desired address.

• Addresses 0002H-000DH

Vector table into which the program start address and MBE setting value when each vectored interrupt is

generated are written.

Interrupt servicing can be started at any desired address.

• Addresses 0020H-007FH

Table area referenced by the GETI instruction

Note

.

Note The GETI instruction is provided to execute any 2-byte or 3-byte instruction or two 1-byte instructions as a 1-

byte instruction; it is used to reduce the number of program steps.

15

µ

PD75P036

Address

0000H

0002H

0004H

0006H

0008H

000AH

000CH

7

MBE

MBE

MBE

MBE

MBE

MBE

MBE

Figure 2-1. Program Memory Map

6

0

Internal reset start address (high-order six bits)

Internal reset start address (low-order eight bits)

INTBT/INT4 start address (high-order six bits)

0

INTBT/INT4 start address (low-order eight bits)

INT0 start address (high-order six bits)

0

INT0 start address (low-order eight bits)

INT1 start address (high-order six bits)

0

INT1 start address (low-order eight bits)

INTCSI start address (high-order six bits)

0

INTCSI start address (low-order eight bits)

INT0 start address (high-order six bits)

0

INT0 start address (low-order eight bits)

INTMFT start address (high-order six bits)

0

INTMFT start address (low-order eight bits)

0

CALLF

! faddr

instruction

address

entry

BRCB

! caddr

instruction

branch

address

CALL ! addr

instruction

subroutine

entry addres

BR ! addr

Instruction

branch

address

BR $ addr

instruction

relative

branch Address

(–15 to –1 and

+2 to +16)

0020H

007FH

0080H

07FFH

0800H

0FFFH

1000H

1FFFH

2000H

2FFFH

3000H

3F7FH

GETI instruction reference table

BRCB ! caddr

instruction

branch addresses

BRCB ! caddr

instruction

branch addresses

BRCB ! caddr

instruction

branch addresses

Branch destination

address and

subroutine entry

address to be set

by GETI instruction

16

µ

PD75P036

2.3 Data Memory (RAM)

The data memory consists of a data area and a peripheral hardware area as shown in Figure 2-2.

The data memory consists of banks, each consisting of 256 words x 4 bits, and the following memory banks can

be used:

• Memory banks 0-3 (data area)

• Memory bank 15 (peripheral hardware area)

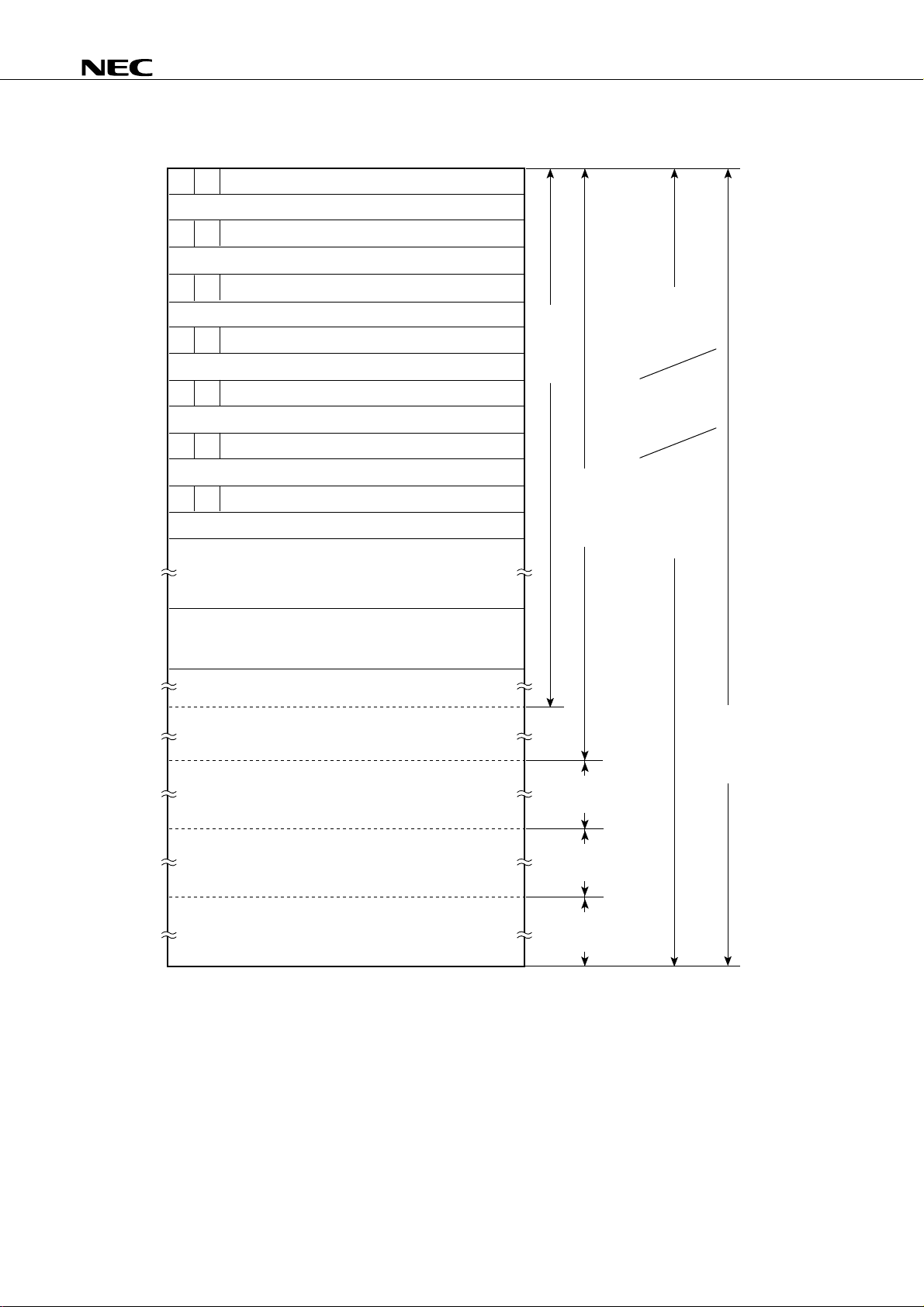

Figure 2-2. Data Memory Map

Data Memory Memory Bank

General purpose

register area

Stack area

000H

007H

008H

0FFH

100H

(8 x 4)

256 x 4

256 x 4

0

1

Data area

Static RAM

(1024 x 4)

Peripheral

hardware area

1FFH

200H

2FFH

300H

3FFH

F80H

FFFH

256 x 4

256 x 4

Not implemented

128 x 4

2

3

15

17

µ

(1) Data area

The data area consists of static RAM and is used to store process data and as stack memory when a

(subroutine) or an interrupt is executed. Even when CPU operation is stopped in the standby mode, the memory

contents can be retained for hours with battery backup, etc. The data area is manipulated by executing memory

manipulation instructions.

The static RAM is mapped each 256 x 4 bits in memory banks 0-3. Bank 0 is mapped as a data area; it can

also be used as a general purpose register area (000H-007H) and a stack area (000H-0FFH).

One address of the static RAM consists of four bits; however it can be manipulated in 8-bit units by executing

8-bit memory manipulation instructions and bit-wise by executing bit manipulation instructions. To execute an

8-bit memory manipulation instruction, specify an even address.

(a) General purpose register area

Can be handled by executing general purpose register and memory manipulation instructions. A maximum

of eight 4-bit registers can be used. The portions of the eight general purpose registers not used by a

program can be used as a data area or stack area.

(b) Stack area

Is set by an instruction and can be used as a save area when a subroutine is executed or interrupt servicing

is performed.

PD75P036

(2) Peripheral hardware area

The peripheral hardware area is mapped in addresses F80H-FFFH of memory bank 15.

Like the static memory, the peripheral hardware area is handled by executing memory manipulation instructions.

However, the bit units in which the peripheral hardware can be manipulated vary depending on the address.

Addresses in which the peripheral hardware is not mapped do not contain data memory and cannot be

accessed.

18

µ

PD75P036

3. WRITING AND VERIFYING PROM (PROGRAM MEMORY)

The program memory incorporated in the µPD75P036 is a 16256 x 8-bit electrically writable PROM. The pins

as listed in the table given below are used for write and verification of the PROM. No address is input; instead, an

address is updated by inputting a clock from the X1 pin.

Pin Name Function

VPP Applies voltage when program memory is written/verified (normally, at VDD potential)

X1, X2 These pins input clock that updates address when program memory is written/verified. To X2 pin,

input X1's signal reverse phase.

MD0-MD3 (P30-P33) These pins select operation mode when program memory is written/verified.

P40-P43 (Lower 4) These pins input/output 8-bit data when program memory is written/verified.

P50-P53 (Upper 4)

VDD Power supply voltage application pin.

Apply 2.7 to 6.0 V to this pin during normal operation and 6 V when program memory is written/verified.

Cautions 1. Always cover the erasure window of the µPD75P036KG with an opaque film except when the

contents of the EPROM are erased.

2. The one-time PROM version µPD75P036CW/GC is not equipped with a window, and therefore,

the contents of the program memory of this model cannot be erased by exposing it to ultraviolet

rays.

3.1 Operation Modes For Writing/Verifying Program Memory

When +6V is applied to the V

DD pin of the

µ

PD75P036 with +12.5V applied to the VPP pin, the µPD75P036 is set

in the program memory write/verify mode. In this mode, the following operation modes can be set by using the MD0-

SS

MD3 pins. At this time, all remaining pins are set to the V

Operating Mode Specification Operating Mode

VPP VDD MD0 MD1 MD2 MD3

+12.5 V +6 V H L H L Program memory address 0 clear mode

L H H H Write mode

L L H H Verify mode

H X H H Program inhibit mode

potential with pull-down resistors.

x: L or H

★

19

3.2 Program Memory Write Procedure

The program memory write procedure is as follows. High-speed program memory write is possible.

µ

PD75P036

(1) Connect the unused pins to V

(2) Supply 5 V to the V

(3) Wait for 10

µ

DD and VPP pins.

s.

SS via pull-down resistors. The X1 pin must be low.

(4) Set program memory address 0 clear mode.

(5) Supply 6 V to the VDD pin and 12.5 V to the VPP pin.

(6) Set program inhibit mode.

(7) Write data in 1 ms write mode.

(8) Set program inhibit mode.

(9) Set verify mode. If data has been written connectly, proceed to step (10). If data has not yet been written,

repeat steps (7) to (9).

(10) Write additional data for (the number of times data was written (X) in steps (7) to (9)) times

1 ms.

(11) Set program inhibit mode.

(12) Supply a pulse to the X1 pin four times to update the program memory address by 1.

(13) Repeat steps (7) to (12) to the last address.

(14) Set program memory address 0 clear mode.

(15) Change the voltages of V

DD and VPP pins to 5 V.

(16) Turn off the power supply.

Steps (2) to (12) are illustrated below.

V

V

PP

V

VDD+1

V

DD

V

X1

P40-P43

P50-P53

MD0

(P30)

MD1

(P31)

MD2

(P32)

MD3

(P33)

X-time repetition

Write Verify

PP

DD

DD

Data input

Data

output

Additional

data write

Data input

Address

increment

20

3.3 Program Memory Read Procedure

µ

PD 75P036 program memory contents can be read in the following procedure. Read operation should be

The

performed in the verify mode.

µ

PD75P036

(1) Connect the unused pins to V

(2) Supply 5 V to the V

(3) Wait for 10

µ

DD and VPP pins.

s.

SS via pull-down resistors. The X1 pin must be low.

(4) Set program memory address 0 clear mode.

(5) Supply 6 V to the V

DD pin and 12.5 V to the VPP pin.

(6) Set program inhibit mode.

(7) Set verify mode. Data of each address is sequentially output each time a clock pulse is input to the X1 pin

four times.

(8) Set program inhibit mode.

(9) Set program memory address 0 clear mode.

(10) Change the voltages of V

DD and VPP pins to 5 V.

(11) Turn off the power supply.

Steps (2) to (9) are illustrated below.

V

PP

V

PP

V

DD

VDD+1

V

DD

V

DD

X1

P40-P43

P50-P53

MD0

(P30)

MD1

(P31)

MD2

(P32)

MD3

(P33)

"L"

Data output

Data output

21

★

3.4 Erasure (µPD75P036KG only)

The contents of the data programmed to the

rays.

The wavelength of the ultraviolet rays used to erase the contents is about 250 nm, and the quantity of the

ultraviolet rays necessary for complete erasure is 15 W•s/cm

When a commercially available ultraviolet ray lamp (wavelength: 254 nm, intensity: 12 mW/cm

15 to 20 minutes is required.

Cautions 1. The contents of the program memory may be erased if the

time to direct sunlight or a fluorescent light. To protect the contents from being erased, mask

the window with the opaque film. NEC attaches quality-tested opaque film to the UV EPROM

products for shipping.

2. To erase the memory contents, the distance between the ultraviolet ray lamp and the

should be 2.5 cm or less.

Remark The time required for erasure changes depending on the degradation of the ultraviolet ray lamp and the

surface condition (dirt) of the window.

µ

PD75P036 can be erased by exposing the window to ultraviolet

2

(= ultraviolet ray intensity x erasure time).

2

) is used, about

µ

PD75P036 is exposed for a long

µ

PD75P036

µ

PD75P036

22

µ

PD75P036

4. ELECTRICAL SPECIFICATIONS

Absolute Maximum Ratings (TA = 25 °C)

Parameter Symbol Test Conditions Ratings Unit

Supply voltage VDD –0.3 to +7.0 V

VPP –0.3 to +13.5 V

Input voltage VI1 Other than ports 4, 5, or 10 –0.3 to VDD+0.3 V

VI2 Ports 4, 5 and 10 Open-drain –0.3 to +11 V

Output voltage VO –0.3 to VDD+0.3 V

Output current, high IOH Per pin –10 mA

All pins –30 mA

Output current, low IOL

Operating ambient temperature TA –40 to +70 °C

Storage temperature Tstg –65 to +150 °C

Note

Ports 0, 3, 4 and 5 peak value 30 mA

Per pin r.m.s. value 15 mA

Other than ports peak value 20 mA

0, 3, 4 and 5 r.m.s. value 5 mA

Per pin

Total for ports 0, 3-9, 11 peak value 170 mA

r.m.s. value 120 mA

Total for 0, 2, 10 peak value 30 mA

r.m.s. value 20 mA

★

Note r.m.s. values should be calculated as follows: [r.m.s. value] = [peak value] x Duty

Caution Product quality may suffer if the absolute maximum rating is exceeded for even a single parameter,

or even momentarily. In other words, the absolute maximum ratings are rated values at which the

product is on the verge of suffering physical damage, and therefore the product must be used under

conditions which ensure that the absolute maximum ratings are not exceeded.

Capacitance (TA = 25 °C, VDD = 0 V)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Input capacitance C I f = 1 MHz 15 pF

Output capacitance CO Unmeasured pins returned to 0 V 15 pF

I/O capacitance CIO 15 pF

★

23

µ

PD75P036

Main System Clock Oscillator Characteristics (TA = –40 to +70 °C, VDD = 2.7 to 6.0 V)

Resonator Recommended Parameter Test Conditions MIN. TYP. MAX. Unit

Constants

Ceramic Oscillation frequency VDD = Oscillation voltage 2.0 5.0

resonator (fX)

X1 X2

Note 1

range

Oscillation stabilization After VDD came to MIN. 4 ms

C1 C2

V

DD

time

of oscillation voltage range

Note 2

Crystal Oscilaltion frequency 2.0 4.19 5.0

resonator (fX)

X1 X2

Note 1

Oscillation stabilization VDD = 4.5 to 6.0 V 10 ms

Note 2

C1 C2

V

time

DD

External clock X1 input frequency 2.0 5.0

X1 X2

(fX)

Note 1

X1 input high- and 100 250 ns

PD74HCU04

µ

low-level widths (tXH, tXL)

Note 3

Note 3

30 ms

Note 3

MHz

MHz

MHz

Notes 1. The oscillation frequency and X1 input frequency are indicated only to express the characteristics of the

oscillator. For instruction execution time, refer to AC Characteristics.

2. Time required for oscillation to stabilize after V

reaches the minimum value of the oscillation voltage

DD

range or the STOP mode has been released.

3. When the oscillation frequency is 4.19 MHz < fx ≤ 5.0 MHz, do not select PCC = 0011 as the instruction

µ

execution time: otherwise, one machine cycle is set to less than 0.95

value of 0.95

★

Caution When using the oscillation circuit of the main system clock, wire the portion enclosed in dotted

µ

s.

s, falling short of the rated minimum

line in the figures as follows to avoid adverse influences on the wiring capacity:

• Keep the wiring length as short as possible.

• Do not cross the wiring over the other signal lines. Do not route the wiring in the vicinity of

lines through which a high alternating current flows.

• Always keep the ground point of the capacitor of the oscillator circuit at the same potential as

DD. Do not connect the power source pattern through which a high current flows.

V

• Do not extract signals from the oscillation circuit.

24

µ

PD75P036

Subsystem Clock Oscillator Characteristics (TA = –40 to +70 °C, VDD = 2.7 to 6.0 V)

Resonator Recommended Parameter Test Conditions MIN. TYP. MAX. Unit

Constants

Crystal Oscillation frequency 32 32.768 35 kHz

resonator (fX)

External clock X1 input frequency 32 100 kHz

XT1 XT2

R

C3 C4

V

DD

X1 X2

Notes 1. The oscillation frequency and XT1 input frequency are indicated only to express the characteristics of

the oscillator. For instruction execution time, refer to AC Characteristics.

2. Time required for oscillation to stabilize after VDD reaches the minimum value of the oscillation voltage

range.

Note 1

Oscillation stabilization VDD = 4.5 to 6.0 V 1.0 2 s

Note 2

time

10 s

Note 1

(fX)

X1 input high-, low-level 5 15

widths (tXH, tXL)

µ

s

Cautions When using the oscillation circuit of the main system clock, wire the portion enclosed in dotted

line in the figures as follows to avoid adverse influences on the wiring capacity:

• Keep the wiring length as short as possible.

• Do not cross the wiring over the other signal lines. Do not route the wiring in the vicinity of lines

through which a high alternating current flows.

• Always keep the ground point of the capacitor of the oscillator circuit at the same potential as

DD. Do not connect the power source pattern through which a high current flows.

V

• Do not extract signals from the oscillation circuit.

The amplification factor of the subsystem clock oscillation circuit is designed to be low to reduce the current

dissipation and therefore, the subsystem clock circuit is influenced by noise more easily than the main

system clock oscillation circuit. When using th subsystem clock, therefore, exercise utmost care in wiring

the circuit.

★

25

µ

PD75P036

DC Characteristics (TA = –40 to +70 °C, VDD = 2.7 to 6.0 V)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Input voltage, high VIH1 Ports 2, 3, 8, 9, 11 0.7VDD VDD V

VIH2 Ports 0, 1, 6, 7, RESET 0.8VDD VDD V

VIH3 Ports 4, 5, 10 Open-drain 0.7VDD 10 V

VIH4 X1, X2, XT1, XT2 VDD–0.5 VDD V

Input voltage, low VIL1 Ports 2 to 5, 8 to 11 0 0.3VDD V

VIL2 Ports 0, 1, 6, 7, RESET 0 0.2VDD V

VIL3 X1, X2, XT1, XT2 0 0.4 V

Output voltage, high VOH VDD = 4.5 to 6.0 V, IOH = –1 mA VDD–1.0 V

IOH = –100 µAVDD–0.5 V

Output voltage, low VOL Ports 3, 4, 5 VDD = 4.5 to 6.0 V, 0.4 2.0 V

IOL = 15 mA

VDD = 4.5 to 6.0 V, IOL = 1.6 mA 0.4 V

IOL = 400 µA 0.5 V

SB0, 1 Open-drain 0.2VDD V

Pull-up Resistor ≥ 1 kΩ

Input leakage current, high ILIH1 VI = VDD Other than below 3

ILIH2 X1, X2, XT1, XT2 20

ILIH3 VI = 9 V Ports 4, 5, 10 20

(Open-drain)

Input leakage current, low ILIL1 VI = 0 V Other than below –3

ILIL2 X1, X2, XT1, XT2 –20

Input leakage current, high ILOH1 VO = VDD 3

ILOH2 VO = 9 V Ports 4, 5, 10 20

(Open-drain)

Input leakage current, low ILOL VO = 0 V –3

Internal pull-up resistor RUI Ports 0, 1, 2, VDD = 5.0 V ± 10 %154080kΩ

3, 6, 7, 8 VDD = 3.0 V ± 10 % 30 300 kΩ

(except P00)

VI = VDD

Internal pull-down resistor RD Port 9 VDD =5.0 V ± 10 %104070kΩ

VI = VDD VDD = 3.0 V ± 10 % 10 60 kΩ

µ

µ

µ

µ

µ

µ

µ

µ

A

A

A

A

A

A

A

A

26

µ

PD75P036

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Supply current

Note 1

IDD1 4.19 MHz VDD = 5 V ± 10%

Crystal VDD = 3 V ± 10%

IDD2 oscillator

C1 = C2 = 22 pF mode V DD = 3 V ± 10% 300 900

IDD3 32.768 kHz Operating VDD = 3 V ± 10% 100 300

Crystal mode

IDD4 oscillator

IDD5 XT1 = 0 V VDD = 5 V ± 10% 0.5 20

STOP mode V DD = 0.1 10

IDD6 32.768 kHz V DD = 3 V ± 10%

Crystal oscillator

STOP mode

Note 2

Note 5

HALT VDD = 5 V ± 10% 700 2100

HALT VDD = 3 V ± 10% 20 60

mode

3 V ± 10% TA = 25˚C 0.1 5

Note 3

Note 4

Note 6

4.5 14 mA

0.9 3 mA

515

Notes 1. Currents for the internal pull-up resistor are not included.

2. Including when the subsystem clock is operated.

3. High-speed mode operation (when processor clock control register (PCC) is set to 0011).

4. Low-speed mode operation (when PCC is set to 0000).

5. When operated with the subsystem clock by setting the system clock control register (SCC) to SCC3 =

1 and SCC0 = 0 to stop the main system clock operation.

6. When subsystem clock is operated by executing STOP instruction during main system clock operation.

µ

A

µ

A

µ

A

µ

A

µ

A

µ

A

µ

A

µ

A

27

AC CHARACTERISTICS (TA = –40 to +70 °C, VDD = 2.7 to 6.0 V)

µ

PD75P036

Parameter Symbol Conditions MIN. TYP. MAX. Unit

CPU clock cycle time

(minimum instruction execution main system clock 3.8 32

time = 1 machine cycle) Operating on 114 122 125

TI0 input frequency fTI VDD = 4.5 to 6.0 V 0 1 MHz

TI0 input high-, low-level widths tTIH,VDD = 4.5 to 6.0 V 0.48

Interrupt input high-, low-level tINTH, INT0 Note 2

widths tINTL INT1, 2, 4 10

RESET low-level width tRSL 10

Notes 1. The CPU clock (Φ) cycle time is determined

by the oscillation frequency of the connected

oscillator, system clock control register (SCC),

Note 1

tCY Operating on VDD = 4.5 to 6.0 V 0.95 32

subsystem clock

0 275 kHz

tTIL 1.8

KR0 - 7 10

t

CY vs VDD

(During Main System Clock Operation)

32

and processor clock control register (PCC).

The figure on the right is cycle time t

supply voltage V

DD characteristics at the

main system clock.

CY or 128/fx depending on the setting of the

2. 2t

CY vs.

6

5

4

µ

[ s]

3

CY

Operation Guaranteed

Range

interrupt mode register (IM0).

2

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

Cycle Time t

1

0.5

0123456

Power Supply Voltage V

[V]

DD

28

µ

PD75P036

SERIAL TRANSFER OPERATION

Two-Wire and Three-Wire Serial I/O Modes (SCK: internal clock output)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCK cycle time tKCY1 VDD = 4.5 to 6.0 V 1600 ns

3800 ns

SCK high-, low-level widths tKL1 VDD = 4.5 to 6.0 V (tKCY1/2)–50 ns

tKH1 (tKCY1/2)–150 ns

SI setup time (to SCK ↓)tSIK1 150 ns

SI hold time (from SCK ↑)tKSI1 400 ns

SO output delay time tKSO1 RL = 1 kΩ,VDD = 4.5 to 6.0 V 0 250 ns

from SCK ↓ CL = 100 pF

Note

0 1000 ns

Two-Wire and Three-Wire Serial I/O Modes (SCK: external clock input)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCK cycle time tKCY2 VDD = 4.5 to 6.0 V 800 ns

3200 ns

SCK high-, low-level widths tKL2 VDD = 4.5 to 6.0 V 400 ns

tKH2 1600 ns

SI setup time (to SCK ↓)tSIK2 100 ns

SI hold time (from SCK ↑)tKSI2 400 ns

SO output delay time tKSO2 RL = 1 kΩ,VDD = 4.5 to 6.0 V 0 300 ns

from SCK ↓ CL = 100 pF

Note

0 1000 ns

★

★

★

★

Note RL and CL are load resistance and load capacitance of the SO output line.

29

SBI Mode (SCK: internal clock output (master))

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCK cycle time tKCY3 VDD = 4.5 to 6.0 V 1600 ns

3800 ns

SCK high-/low-level widths tKL3 VDD = 4.5 to 6.0 V (tKCY3/2)–50 ns

tKH3 (tKCY3/2)–150 ns

SB0, 1 Setup time (to SCK ↑)tSIK3 150 ns

SB0, 1 hold time (from SCK ↑)tKSI3 tKCY3/2 ns

SB0, 1 output delay time tKSO3 RL = 1 kΩ,VDD = 4.5 to 6.0 V 0 250 ns

from SCK ↓ CL = 100 pF

SB0, 1 ↓ from SCK ↑ tKSB tKCY3 ns

SCK ↓ from SB0, 1 ↓ tSBK tKCY3 ns

SB0, 1 low-level width tSBL tKCY3 ns

SB0, 1 high-level width tSBH tKCY3 ns

Note

0 1000 ns

SBI Mode (SCK: external clock output (master))

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

SCK cycle time tKCY4 VDD = 4.5 to 6.0 V 800 ns

3200 ns

SCK high-/low-level widths tKL4 VDD = 4.5 to 6.0 V 400 ns

tKH4 1600 ns

SB0, 1 setup time (to SCK ↑)tSIK4 100 ns

SB0, 1 hold time (from SCK ↑)tKSI4 tKCY4/2 ns

SB0, 1 output delay time tKSO4 RL = 1 kΩ,VDD = 4.5 to 6.0 V 0 300 ns

from SCK ↓ CL = 100 pF

SB0, 1 ↓ from SCK ↑ tKSB tKCY4 ns

SCK ↓ from SB0, 1 ↓ tSBK tKCY4 ns

SB0, 1 low-level width tSBL tKCY4 ns

SB0, 1 high-level width tSBH tKCY4 ns

Note

0 1000 ns

µ

PD75P036

Note RL and CL are load resistance and load capacitance of the SO output line.

30

µ

PD75P036

A/D Converter (TA = –40 to +70˚C, VDD = 2.7 to 6.0 V, AVSS = VSS = 0 V)

Parameter Symbol Test conditions MIN. TYP. MAX. Unit

Resolution 8 8 8 bit

Absolute accuracy

Conversion time

Sampling time

Analog input voltage VIAN AVREF– AVREF+ V

Analog supply voltage AVDD 2.5 VDD V

Reference input voltage

Reference input voltage

Analog input high impedance RAN 1000 MΩ

AVREF current AIREF 0.35 2.0 mA

Notes 1. Absolute accuracy from which quantization error (±1/2 LSB) is removed.

2. Time until conversion end (EOC = 1) after conversion start instruction execution (40.1

fx = 4.19 MHz).

3. Time until sampling end after conversion start instruction execution (10.5 µs: Operation at fx = 4.19 MHz).

4. (AV

Note 1

Note 2

Note 3

Note 4

Note 4

REF+) – (ABREF–) should be 2.5 V or more.

tCONV 168/fxµs

tSAMP 44/fxµs

AVREF+ 2.5 V ≤ (AVREF+) – (AVREF–) 2.5 AVDD V

AVREF– 2.5 V ≤ (AVREF+) – (AVREF–) 0 1.0 V

2.5 V ≤ AVREF+ ≤ AVDD –10 ≤ TA ≤ 70 ˚C ±1.5 LSB

–40 ≤ TA ≤ –10 ˚C ±2.0 LSB

µ

s: Operation at

31

AC Timing Test Point (excluding X1 and XT1 inputs)

µ

PD75P036

Clock Timing

TI0 Timing

X1 Input

XT1 Input

0.8 V

0.2 V

DD

DD

t

XL

Test Points

1/f

x

0.8 V

DD

0.2 V

DD

t

XH

VDD - 0.5 V

0.4 V

1/f

XT

t

XTL

t

XTH

VDD - 0.5 V

0.4 V

TI0

1/f

TI

t

TIL

t

TIH

32

Serial Transfer Timing

Three-Wire Serial I/O Mode:

t

KCY1

µ

PD75P036

SCK

SI

SO

Two-Wire Serial I/O Mode:

t

KSO1

t

KL1

t

SIK1

Input Data

t

KL2

t

KH1

t

KSI1

Output Data

t

KCY2

t

KH2

SCK

SB0,1

t

KSO2

t

SIK2

t

KSI2

33

Serial Transfer Timing

Bus Release Signal Transfer

SCK

SB0,1

Command Signal Transfer

t

KSB

µ

PD75P036

t

KCY3,4

t

KL3,4

t

SBL

t

SBH

t

SBK

t

KH3,4

t

KSO3,4

t

SIK3,4

t

KSI3,4

SCK

SB0,1

Interrupt Input Timing

INT0,1,2,4

RESET Input Timing

KR0 - 7

t

KCY3,4

t

KL3,4

t

KSB

t

SBK

t

INTL

t

KH3,4

t

INTH

t

KSO3,4

t

SIK3,4

t

KSI3,4

34

RESET

t

RSL

µ

PD75P036

Data Memory STOP Mode: Low-voltage Data Retention Characteristics (TA = –40 to +70 °C)

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Data retention supply voltage VDDDR 2.0 6.0 V

Data retention supply IDDDR VDDDR = 2.0 V 0.1 10

Note 1

current

Release signal set time tSREL 0

Oscillation stabilization wait tWAIT Released by RESET 217/fx ms

Note 2

time

Released by interrupt Note 3 ms

Notes 1. Does not include current in the internal pull-up resistor

2. The oscillation stabilization wait time is the time during which the CPU is stopped to prevent unstable

operation when oscillation is started.

3. Depends on the setting of the basic interval timer mode register (BTM) as follows:

µ

A

µ

s

BTM3 BTM2 BTM1 BTM0 WAIT time ( ): fx = 4.19 MHz

—0 0 0 2

—0 1 1 2

—1 0 1 2

—1 1 1 2

20

/fx (approx. 250 ms)

17

/fx (approx. 31.3 ms)

15

/fx (approx. 7.82 ms)

13

/fx (approx. 1.95 ms)

Data Retention Timing (releasing STOP mode by RESET)

STOP mode

Data retention mode

V

DD

STOP instruction execution

RESET

V

DDDR

Internal reset operation

HALT mode

t

SREL

t

WAIT

Operating

mode

Data Retention Timing (standby release signal: releasing STOP mode by interrupt)

HALT mode

Operating

mode

V

DD

STOP instruction execution

Standby release signal

(interrupt request)

STOP mode

Data retention mode

V

DDDR

t

SREL

t

WAIT

35

DC Programming Characteristics (TA = 25 ± 5 °C, VDD = 6.0 ± 0.25 V, VPP = 12.5 ± 0.3 V, VSS = 0 V)

★

Parameter Symbol Test Conditions MIN. TYP. MAX. Unit

Input voltage, high VIH1 Other than X1 or X2 0.7VDD VDD V

VIH2 X1 and X2 VDD–0.5 VDD V

Input voltage, low VIL1 Other than X1 or X2 0 0.3VDD V

VIL2 X1 and X2 0 0.4 V

Input leakage current ILI VIN = VIL or VIH 10

Output voltage, high VOH IOH = –1 mA VDD–1.0 V

Output voltage, low VOL IOL = 1.6 mA 0.4 V

VDD supply current IDD 30 mA

VPP supply current IPP MD0 = VIL, MD1 = VIH 30 mA

µ

PD75P036

µ

A

Cautions 1. V

★

AC Programming Characteristics (TA = 25 ± 5 °C, VDD = 6.0 ± 0.25 V, VPP = 12.5 ± 0.3 V, VSS = 0 V)

Parameter Symbol Note 1 Test Conditions MIN. TYP. MAX. Unit

Address setup time

MD1 setup time (to MD0 ↓)tM1S tOES 2

Data setup time (to MD0 ↓)tDS tDS 2

Address hold time

Data hold time (from MD0 ↑)tDH tDH 2

Data output float delay time from MD0 ↑ tDF tDF 0 130 ns

VPP setup time (to MD3 ↑)tVPS tVPS 2

VDD setup time (to MD3 ↑)tVDS tVCS 2

Initialized program pulse width tPW tPW 0.95 1.0 1.05 ms

Additional program pulse width tOPW tOPW 0.95 21.0 ms

MD0 setup time (to MD1 ↑)tMOS tCES 2

Data output delay time from MD0 ↓ tDV tDV MD0 = MD1 = VIL 1

MD1 hold time (from MD0 ↑)tM1H tOEH tM1H + tM1R ≥ 50 µs2

MD1 recovery time (from MD0 ↓)tM1R tOR 2

Program counter reset time tPCR —10

X1 input high-/low-level width tXH, tXL — 0.125

X1 input frequency fX — 4.19 MHz

Initial mode set time tI —2

MD3 setup time (to MD1 ↑)tM3S —2

MD3 hold time (from MD1 ↓)tM3H —2

MD3 setup time (from MD0 ↓)tM3SR — When data is read from 2

Address

Address

MD3 hold time (from MD0 ↑)tM3HR — When data is read from 2

Data output float delay time from MD3 ↓ tDFR — When data is read from 2

PP must not exceed +13.5 V, including the overshoot.

2. Apply V

Note 2

to data output delay time tDAD tACC When data is read from 2

Note 2

to data output hold time t HAD tOH When data is read from 0 130 ns

DD before VPP and disconnect it after VPP.

Note 2

(to MD0 ↓)tAS tAS 2

Note 2

(from MD0 ↑)tAH tAH 2

program memory

program memory

program memory

program memory

program memory

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

Notes 1. These symbols are correspond to µPD27C256A symbols.

2. The internal address signal is incremented by 1 at the rising edge of fourth X1 input. The internal address

is not connected to any pin.

36

µ

PD75P036

Program Memory Write Timing

t

t

VPS

VDS

V

PP

V

PP

V

DD

VDD + 1

V

DD

V

DD

X1

P40-P43

P50-P53

t

I

Data input

t

DS

MD0

t

PW

MD1

t

PCR

t

M1StM1H

MD2

t

M3S

MD3

Program Memory Read Timing

★

t

XH

t

Data

output

t

tDVt

OH

t

M1R

DF

t

MOS

Data input

t

DS

t

OPW

XL

t

DH

t

AH

Data input

t

AS

t

M3H

★

V

PP

V

DD

X1

P40-P43

P50-P53

MD0

MD1

MD2

MD3

V

PP

V

DD

VDD + 1

V

DD

t

VPS

t

VDS

t

XH

t

XL

Data output

t

t

M3SR

DV

t

I

t

PCR

t

DAD

t

HAD

Data output

t

t

M3HR

DFR

37

★

5. CHARACTERISTIC CURVES (REFERENCE VALUES)

IDD vs VDD (4.19-MHz Main System Clock, Crystal Resonator)

= 25 °C)

(T

A

µ

PD75P036

5.0

3.0

1.0

0.5

[mA]

DD

0.1

0.05

Supply Current I

PCC = 0011

PCC = 0010

PCC = 0000

Main system clock

HALT mode

+ 32 kHz oscillation

Subsystem clock

HALT mode

Subsystem clock

HALT mode

Main system clock

STOP mode

+ 32 kHz oscillation

38

0.01

0.005

0.001

X1

resonator

4.19 MHz

22 pF

Supply Voltage VDD [V]

Crystal

X2 XT1

V

DD

resonator

32.768 kHz

6

Crystal

18 pF

V

XT2

330 kΩ

18 pF22 pF

DD

8420

IDD vs VDD (2.0-MHz Main System Clock, Crystal Resonator)

5.0

(T

= 25 °C)

A

µ

PD75P036

3.0

1.0

0.5

[mA]

DD

0.1

0.05

Supply Current I

PCC = 0011

PCC = 0010

PCC = 0000

Main system clock

HALT mode

+ 32 kHz oscillation

Subsystem clock

HALT mode

Subsystem clock

HALT mode

Main system clock

STOP mode

+ 32 kHz oscillation

0.01

0.005

0.001

X1

resonator

2.0 MHz

22 pF 18 pF22 pF

Supply Voltage VDD [V]

Crystal

X2 XT1

V

DD

resonator

32.768 kHz

6

Crystal

18 pF

V

XT2

330 kΩ

DD

8420

39

IDD vs VDD (4.19-MHz Main System Clock, Ceramic Resonator)

(T

= 25 °C)

A

µ

PD75P036

5.0

3.0

1.0

0.5

[mA]

DD

0.1

0.05

Supply Current I

PCC = 0011

PCC = 0010

PCC = 0000

Main system clock

HALT mode

+ 32 kHz oscillation

Subsystem clock

HALT mode

Subsystem clock

HALT mode

Main system clock

STOP mode

+ 32 kHz oscillation

0.01

0.005

0.001

X1

resonator

4.19 MHz

30 pF 18 pF30 pF

Supply Voltage VDD [V]

Ceramic

V

X2 XT1

DD

6

Crystal

resonator

32.768 kHz

18 pF

V

DD

XT2

330 kΩ

8420

40

IDD vs VDD (20-MHz Main System Clock, Ceramic Resonator)

5.0

(T

= 25 °C)

A

µ

PD75P036

3.0

1.0

0.5

[mA]

DD

0.1

0.05

Supply Current I

PCC = 0011

PCC = 0010

PCC = 0000

Main system clock

HALT mode

+ 32 kHz oscillation

Subsystem clock

HALT mode

Subsystem clock

HALT mode

Main system clock

STOP mode

+ 32 kHz oscillation

0.01

0.005

0.001

X1

Ceramic

resonator

2.0 MHz

30 pF 18 pF30 pF

Supply Voltage VDD [V]

X2 XT1

V

DD

resonator

32.768 kHz

6

Crystal

18 pF

V

XT2

330 kΩ

DD

8420

41

µ

PD75P036

5

4

3

[mA]

DD

I

2

1

0

X1

IDD vs f

X2

x

= 5 V, TA = 25 °C)

(V

DD

PCC = 0011

PCC = 0010

PCC = 0000

Main system

clock

HALT mode

1023

f

[MHz]

x

4

65

2.0

1.5

1.0

[mA]

DD

I

0.5

0

X1

IDD vs f

X2

x

= 3 V, TA = 25 °C)

(V

DD

PCC = 0010

PCC = 0000

Main system

clock

HALT mode

1023

f

[MHz]

x

4

65

40

30

20

[mA]

OL

I

10

0

IOL vs VOL (Port 0) IOL vs VOL (Ports 2, 6 to 10)

(TA = 25°C)

VDD = 6 V

0

VDD = 5 V

VDD = 4 V

VDD = 3 V

VDD = 2.7 V

12345

V

[V] VOL [V]

OL

= 25°C)

(T

30

A

25

VDD = 6 V

20

15

[mA]

OL

I

10

VDD = 5 V

VDD = 4 V

VDD = 3 V

VDD = 2.7 V

5

0

012345

42

IOL vs VOL (Ports 3 to 5)

µ

PD75P036

40

30

20

[mA]

OL

I

10

0

(TA = 25°C)

VDD = 6 V

VDD = 5 V

VDD = 4 V

VDD = 3 V

VDD = 2.7 V

0

12345

V

[V]

OL

IOH vs VDD–VOH

15

10

[mA]

OH

I

5

0

(TA = 25°C)

VDD = 6 V

VDD = 5 V

VDD = 4 V

VDD = 3 V

VDD = 2.7 V

0

12345

– V

OH

[V]

V

DD

43

6. PACKAGE DRAWINGS

64 PIN PLASTIC SHRINK DIP (750 mil)

64 33

A

µ

PD75P036

321

K

I

J

H

G

NOTE

Each lead centerline is located within 0.17 mm (0.007 inch) of

1)

its true position (T.P.) at maximum material condition.

Item "K" to center of leads when formed parallel.2)

F

M

D

N

L

B

C

ITEM MILLIMETERS INCHES

A

B

C

D

F

G

H

I

J

K

L

M

N

R

M

58.68 MAX.

1.78 MAX.

1.778 (T.P.)

0.50±0.10

0.9 MIN.

3.2±0.3

0.51 MIN.

4.31 MAX.

5.08 MAX.

19.05 (T.P.)

17.0

+0.10

0.25

–0.05

0.17

0~15°

2.311 MAX.

0.070 MAX.

0.070 (T.P.)

0.020

0.035 MIN.

0.126±0.012

0.020 MIN.

0.170 MAX.

0.200 MAX.

0.750 (T.P.)

0.669

0.010

0.007

0~15°

P64C-70-750A,C-1

+0.004

–0.005

+0.004

–0.003

R

44

64 PIN PLASTIC QFP ( 14)

µ

PD75P036

A

B

48

49

64

F

1

G

H

M

I

P

N

NOTE

Each lead centerline is located within 0.15

mm (0.006 inch) of its true position (T.P.) at

maximum material condition.

33

32

detail of lead end

C

D

S

Q

17

16

J

K

M

L

ITEM MILLIMETERS INCHES

A

B

C

D

F

G

H

I

J

K

L

M

N

17.6±0.4

14.0±0.2

14.0±0.2

17.6±0.4

1.0

1.0

0.35±0.10

0.15

0.8 (T.P.)

1.8±0.2

0.8±0.2

+0.10

0.15

–0.05

0.10

P 2.55 0.100

Q

0.1±0.1

S 2.85 MAX. 0.112 MAX.

P64GC-80-AB8-3

0.693±0.016

+0.009

0.551

–0.008

+0.009

0.551

–0.008

0.693±0.016

0.039

0.039

+0.004

0.014

–0.005

0.006

0.031 (T.P.)

0.071±0.008

+0.009

0.031

–0.008

+0.004

0.006

–0.003

0.004

0.004±0.004

5°±5°

45

µ

PD75P036

★

64 PIN CERAMIC WQFN

A

B

R

S

J

M

H

I

Q

T

U

C D

64

U1

W

1

K

E

G

F

Z

NOTE

Each lead centerline is located within 0.08 mm (0.003 inch) of

its true position (T.P.) at maximum material condition.

ITEM MILLIMETERS INCHES

+0.011

A

13.8±0.25

B

13.0

C

12.4

D 13.8±0.25 0.543

E 1.94 0.076

2.14 0.084

F

3.56 MAX. 0.141 MAX.

G

0.51±0.1 0.020±0.004

H

I

0.08 0.003

J

0.8 (T.P.) 0.031 (T.P.)

1.0±0.15 0.039±0.006

K

C 0.3 C 0.012

Q

0.9 0.035

R

0.9 0.035

S

T

R 1.5 R 0.059

U

6.0 0.236

1.0 0.039

U1

W

0.75±0.15 0.030

Z

0.10 0.004

0.543

–0.010

0.512

0.488

+0.011

–0.010

+0.006

–0.007

X64KG-80A-1

46

µ

PD75P036

7. RECOMMENDED SOLDERING CONDITIONS

It is recommended that the µPD75P036 be soldered under the following conditions.

For details on the recommended soldering conditions, refer to Information Document "Semiconductor Devices

Mounting Technology Manual" (IEI-1207).

For soldering methods and conditions other than those recommended, please contact your NEC sales

representative.

Table 7-1. Soldering Conditions for Surface Mount Devices

µ

PD75P036GC-AB8: 64-pin plastic QFP (14 x 14 mm)

Soldering Method Soldering Conditions Recommended Soldering

Code

Wave soldering Soldering bath temperature: 260˚C max., WS60-162-1

Time: 10 seconds max., Number of times: 1,

Maximum number of days: 2 days

prebaking is required at 125˚C),

Preheating temperature: 120°C max. (package surface

temperature).

Infrared reflow Package peak temperature: 230˚C, IR30-162-1

Time: 30 seconds max. (210˚C min.),

Number of times: 1, Maximum number of days: 2 days

(thereafter, 16 hours of prebaking is required at 125˚C)

VPS Package peak temperature: 215˚C, VP15-162-1

Time: 40 seconds max. (200˚C min.),

Number of times: 1, Maximum number of days: 2 days

(thereafter, 16 hours of prebaking is required at 125˚C)

Partial heating Pin temperature: 300˚C max., —

Time: 3 seconds max. (per pin row)

Note

, (thereafter, 16 hours of

Note

Note

Note Number of days after unpacking the dry pack. Storage conditions are 25°C and 65% RH max.

Caution Do not use different soldering methods together (except the partial heating method).

Table 7-2. Soldering Conditions for Through-hole Devices

µ

PD75P036CW: 64-pin Plastic Shrink DIP (750 mils)

Soldering Method Soldering Conditions

Wave soldering (pin only) Soldering bath temperature: 260˚C max., Time: 10 seconds max.

Partial heating Pin temperature: 300˚C max., Time: 3 seconds max. (per pin row)

Caution Apply wave soldering only to the lead part and be careful so as not to bring solder into direct

contact with the device body.

47

APPENDIX A. DEVELOPMENT TOOLS

★

The following development tools are readily available to support development of systems using µPD75P03s:

µ

PD75P036

Hardware IE-75000-R

Note 1

In-circuit emulator for 75K series

IE-75001-R

IE-75000-R-EM

Note 2

Emulation board for IE-75000-R and IE-75001-R

EP-75028CW-R Emulation prove for µPD75P036CW

EP-75028GC-R Emulation prove for µPD75P036GC. Provided with 64-pin conversion socket.

EV-9200GC-64 EV-9200G-80 used for µPD75P036GC/75P036KG

PG-1500 PROM programmer

PA-75P036CW PROM programmer adapter used for µPD75P036CW. It is connected to PG-1500.

PA-75P036GC PROM programmer adapter used for µPD75P036GC. It is connected to PG-1500.

Software IE control program Host machine

PG-1500 controller • PC-9800 series (MS-DOSTM Ver. 3.30 to Ver. 5.00A

Note 3

)

RA75X relocatable • IBM PC/ATTM (Refer to document OS for IBM PC)

assembler

Notes 1. For maintenance purpose only

2. Not provided with IE-75001-R

3. Ver.5.00/5.00A has a task swap function, but this function cannot be used with these software.

Remark Please refer to the 75X SERIES SELECTION GUIDE (IF-1027) for information on third party development

tools.

OS for IBM PC

The following OS are supported for IBM PC.

OS Version

PC DOS

MS-DOS Ver. 5.0 to Ver. 6.2

IBM DOS

TM

TM

Ver. 3.1 to Ver. 6.3

Note

J6.1/V

5.0/V

J5.02/V

to 16.3/V

Note

to J6.2/V

Note

Note

Note

Note Supported only English mode.

Caution Ver. 5.0 or later has a task swap function, but this function cannot be used with these software.

48

µ

PD75P036

APPENDIX B. RELATED DOCUMENTS

Please use this document in conjunction with the following.

Related document may be "Preliminary." However, in this document, "Preliminary" is not indicated.

Device Document

Title Document Number

Japanese English

µ

PD75P036 Data Sheet (This document) IC-7914 IC-2967

µ

PD75028 User's Manual IEU-694 IEU-1280

µ

PD75028 Instruction List IEM-5511 —

µ

PD75028 Application Note — Basics IEA-689 IEA-1277

75X series Selection Guide IF-151 IF-1027

Development Tool Document

Title Document Number

Japanese English

Hardware IE-75000-R/IE-75001-R User's Manual EEU-846 EEU-1416

IE-75000-R-EM User's Manual EEU-673 EEU-1294

EP-75028CW-R User's Manual EEU-697 EEU-1314

IE-75028GC-R User's Manual EEU-692 EEU-1306

PG-1500 User'ss Manual EEU-651 EEU-1335

Software RA75X Assembler Package User's Manual Operation EEU-731 EEU-1346

Language EEU-730 EEU-1363

PG-1500 Controller User's Manual PC-9800 series EEU-704 Scheduled

(MS-DOS) based

IBM PC series EEU-5008 EEU-1291

(PC DOS) based

★

49

µ

PD75P036

Other Document

Title Number

Japanese English

Package Manual IEI-635 IEI-1213

Semiconductor Device Mounting Technology Manual IEI-616 IEI-1207

Quality Grades on NEC Semiconductor Devices IEI-620 IEI-1209

NEC Semiconductor Device Reliability/Quality Control System IEM-5068 —

Electrostatic Discharge (ESD) Test MEM-539 —

Guide to Quality Assurance for Semiconductor Devices MEI-603 MEI-1202

Microcomputer-Related Product Guide — Third Party Products MEI-604 —

Caution The contents of the documents listed above are subject to change without prior notice to user's.

Make sure to use the latest edition when starting design.

50

µ

NOTES FOR CMOS DEVICES

(1) PRECAUTION AGAINST ESD FOR SEMICONDUCTORS

Note: Strong electric field, when exposed to a MOS device, can cause destruction

of the gate oxide and ultimately degrade the device operation. Steps must be

taken to stop generation of static electricity as much as possible, and quickly

dissipate it once, when it has occurred. Environmental control must be

adequate. When it is dry, humidifier should be used. It is recommended to

avoid using insulators that easily build static electricity. Semiconductor

devices must be stored and transported in an anti-static container, static

shielding bag or conductive material. All test and measurement tools including

work bench and floor should be grounded. The operator should be grounded

using wrist strap. Semiconductor devices must not be touched with bare

hands. Similar precautions need to be taken for PW boards with semiconductor

devices on it.

PD75P036

(2) HANDLING OF UNUSED INPUT PINS FOR CMOS

Note: No connection for CMOS device inputs can be cause of malfunction. If no

connection is provided to the input pins, it is possible that an internal input

lelvel may be generated due to noise, etc., hence causing mulfunction. CMOS

device behave differently than Bipolar or NMOS devices. Input levels of CMOS

devices must be fixed high or low by using a pull-up or pull-down circuitry.

Each unused pin should be connected to VDD or GND with a resistor, if it is

considered to have a possibility of being an output pin. All handling related

to the unused pins must be judged device by device and related specifications

governing the devices.

(3) STATUS BEFORE INITIALIZATION OF MOS DEVICES

Note: Power-on does not necessarily define initial status of MOS device. Production

process of MOS does not define the initial operation status of the device.

Immediately after the power source is turned ON, the devices with reset

function have not yet been initialized. Hence, power-on does not guarantee

out-pin levels, I/O settings or contents of registers. Device is not initialized

until the reset signal is received. Reset operation must be executed immediately

after power-on for devices having reset function.

51

µ

PD75P036

MS-DOS is a trademark of Microsoft Corporation.

IBM DOS, PC/AT, and PC DOS are trademarks of IBM Corporation.

The export of these products from Japan is regulated by the Japanese government. The export of some

or all of these products may prohibited without governmental license. To export or re-export some or all

or these products from a country other than Japan may also be prohibited without a license from that

country. Please call an NEC sales representative.

License not needed:

The customer must judge the need for license: µPD75P036CW, 75P036GC-AB8

No part of this document may be copied or reproduced in any form or by any means without the prior written consent

of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in this document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties b y or arising from use of a device described herein or any other liability arising from use of

such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or property

arising from a defect in an NEC semiconductor device, customer must incorporate sufficient safety measures in

its design, such as redundancy, fire-containment, and anti-failure features.

NEC devices are classified into the following three quality grades:

"Standatd", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated "quality assurance program" for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computer, office equipment, communication equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical eqiupment (not specifically designed for

life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nucleare reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices in "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade, they

should contact NEC Sales Representative in advance.

Anti-radioactive design is not implemented in this product.

µ

PD75P036KG

M4 94.11

Loading...

Loading...