µµµµ

查询UPD16878供应商

MONOLITHIC QUAD H BRIDGE DRIVER CIRCUIT

DESCRIPTION

The µPD16878 is a monolithic quad H bridge driver IC that employs a CMOS control circuit and a MOS FET

output circuit. Because it uses MOS FETs in its output stage, this driver IC consumes less power than conventional

driver ICs that use bipolar transistors.

Because the µPD16878 controls a motor by inputting serial data, its package has been shrunk and the number of

pins reduced. As a result, the performance of the application set can be improved and the size of the set has been

reduced.

The µPD16878 employs a current-controlled 64-step micro step driving method that drives stepper motor with low

vibration.

The µPD16878 is housed in a 38-pin plastic shrink SOP to contribute to the miniaturization of the application set.

The µPD16878 can simultaneously drive two stepper motors and is ideal for the mechanisms of camcorders.

DATA SHEET

MOS INTEGRATED CIRCUIT

PD16878

FEATURES

• Four H bridge circuits employing power MOS FETs

• Current-controlled 64-step micro step driving

• Motor control by serial data (8 bytes x 8 bits) (original oscillation: 4-MHz input)

Data is input with the LSB first.

EVR reference setting voltage: 100 to 250 mV (@VREF

Chopping frequency: 32 to 124 kHz ... 5-bit data input (4-kHz step)

Original oscillation division or internal oscillation selectable

Number of pulses in 1 VD: 0 to 126 pulses ... 6 bits + 2-bit data input (2 pulses/step)

Step cycle: 0.25 to 8191.75 µs ... 15-bit data input (0.25- µs step)

• 3-V power supply. Minimum operating voltage: 2.7 V (MIN.)

• Low current consumption IDD: 3.0 mA (MAX.), IDD

• 38-pin plastic shrink SOP (7.62 mm (300))

ORDERING INFORMATION

Part number Package

PD16878GS-BGG 38-pin plastic shrink SOP (7.62 mm (300))

µ

= 250 mV) ... 4-bit data input (10-mV step)

: 100 µA (MAX.), I

(RESET)

MO(RESET)

: 1.0 µA (MAX.)

The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

Not all devices/types available in every country. Please check with local NEC representative for

availability and additional information.

Document No. S15974EJ1V0DS00 (1st edition)

Date Published February 2002 N CP(K)

Printed in Japan

©

2002

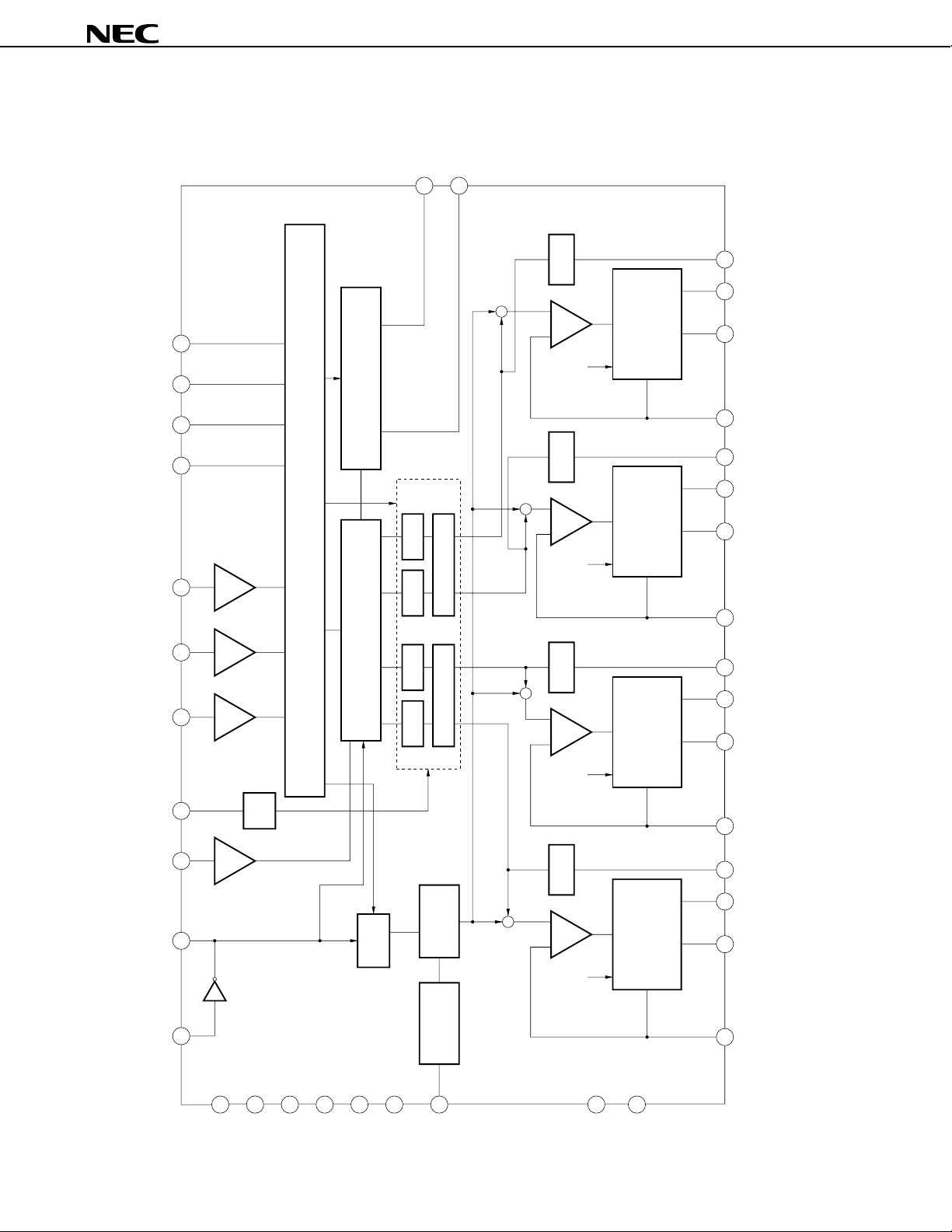

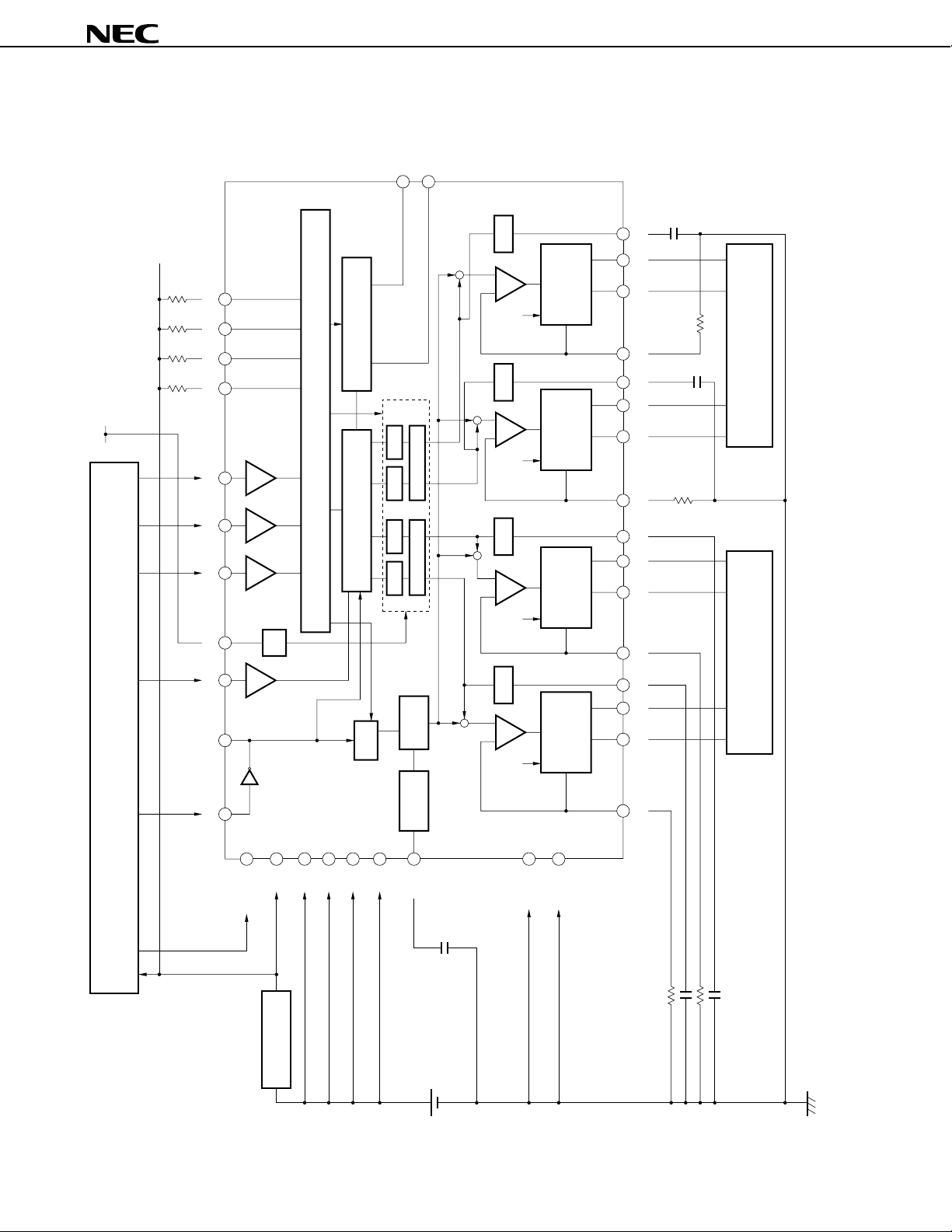

BLOCK DIAGRAM

EXP0 EXP1 EXP2 EXP3

α

β

EXT

EXT

31

22

EXTOUT SELECTOR

β

µµµµ

PD16878

D

FILTERFILTERFILTERFILTER

+

2ch

–+

M

V

β

H BRIDGE

10125141643028326

FIL

2

D

1

D

D

FB

C

FIL

2

+

–+

M

V

1ch

β

H BRIDGE

C

1

C

SCLK SDATA LATCH

REF

V

D

V

OUT

OSC

IN

OSC

SERIAL-PARARELLE DECODER

EVR1 EVR2

CURRENT SET

C

FB

x 2

α

PULSE GENERATER

EVR2

EVR1

CURRENT SET

+

–+

M

V

2ch

α

H BRIDGE

B

FIL

2

B

1

B

B

FB

A

FIL

2

A

OSC

1/N

37 36 32 7 35 34 33 17 18 19 21

SELECTOR

+

–+

M

V

1ch

α

H BRIDGE

1

A

25 24 29 15 11 6

A

FB

38

8

23

27

9

13

2

DD

VM1VM2VM3V

V

M4

OSC

C

RESET

2

Data Sheet S15974EJ1V0DS

1

LGND

20

PGND

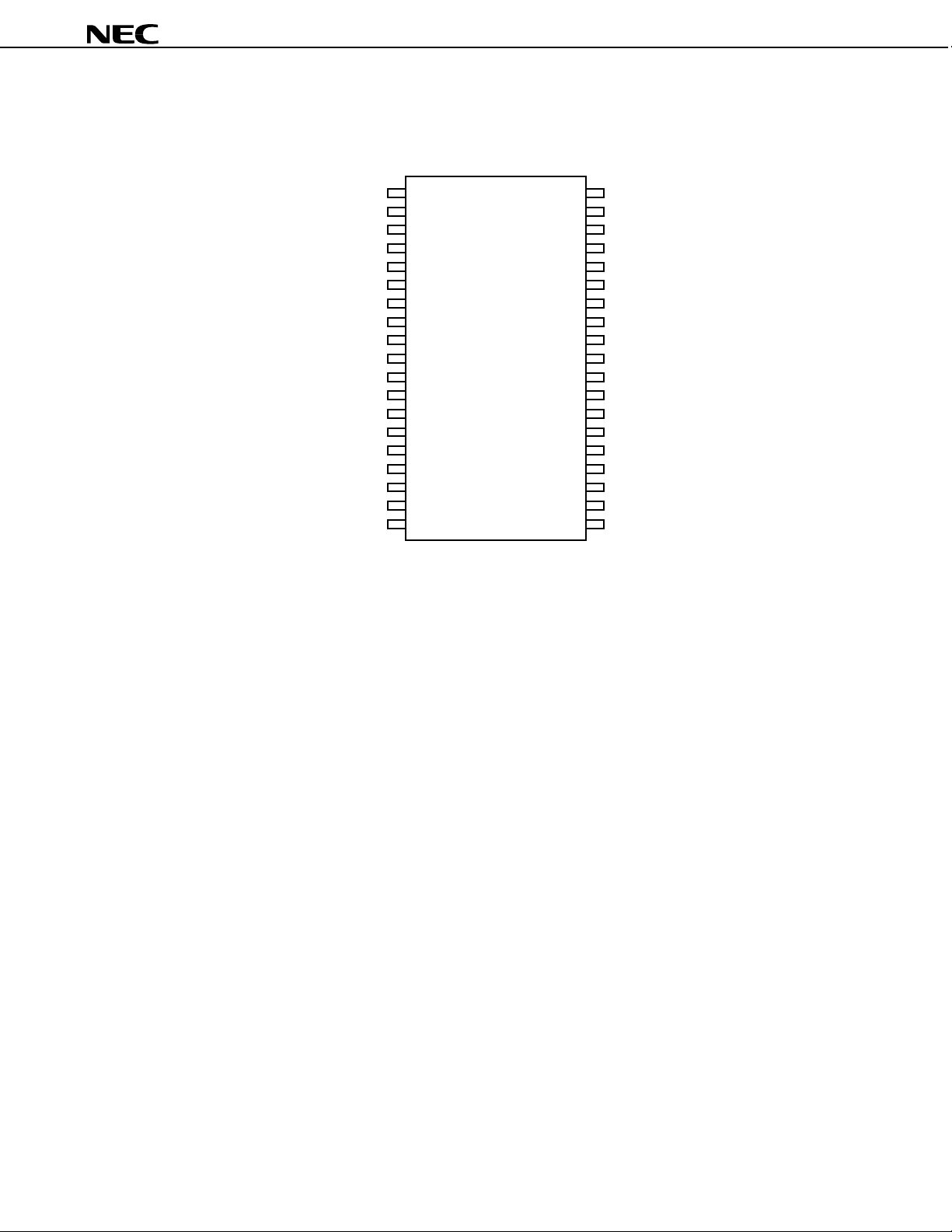

PIN CONFIGURATION

38-pin plastic shrink SOP (7.62 mm (300))

10

11

12

13

14

15

16

17

18

19

µµµµ

PD16878

1

LGND

2

C

OSC

3

FIL

A

4

FIL

B

5

FIL

C

6

FIL

D

7

V

REF

8

V

DD

V

M3

9

D

2

FB

D

D

1

V

M4

C

2

FB

C

C

1

EXP0

EXP1

EXP2

RESET

OSC

OSC

SCLK

SDATA

LATCH

EXT

FB

FB

EXT

EXP3

PGND

V

V

OUT

V

B

B

A

A

38

37

IN

36

35

34

33

D

32

β

31

2

30

B

29

1

28

M2

27

2

26

A

25

1

24

M1

23

α

22

21

20

Data Sheet S15974EJ1V0DS

3

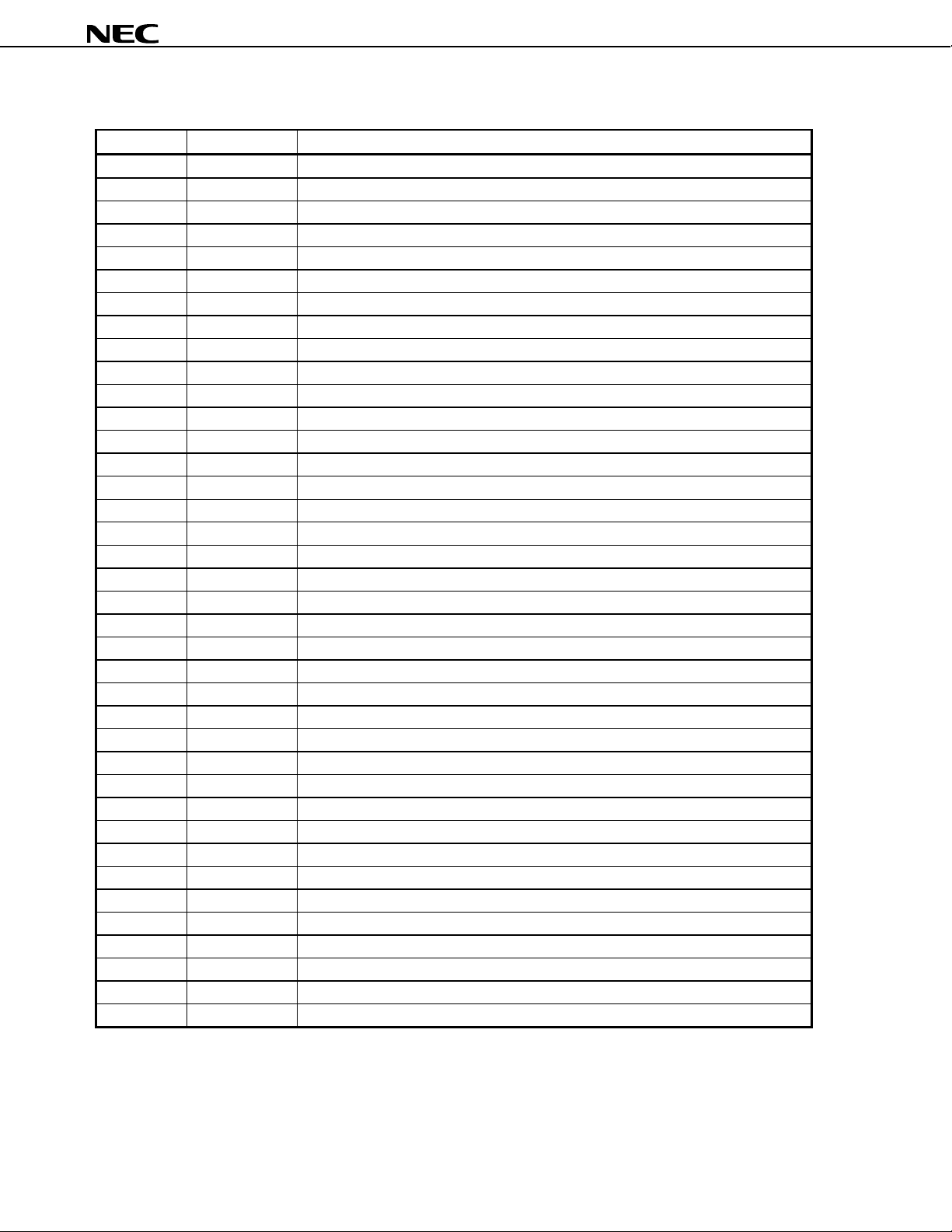

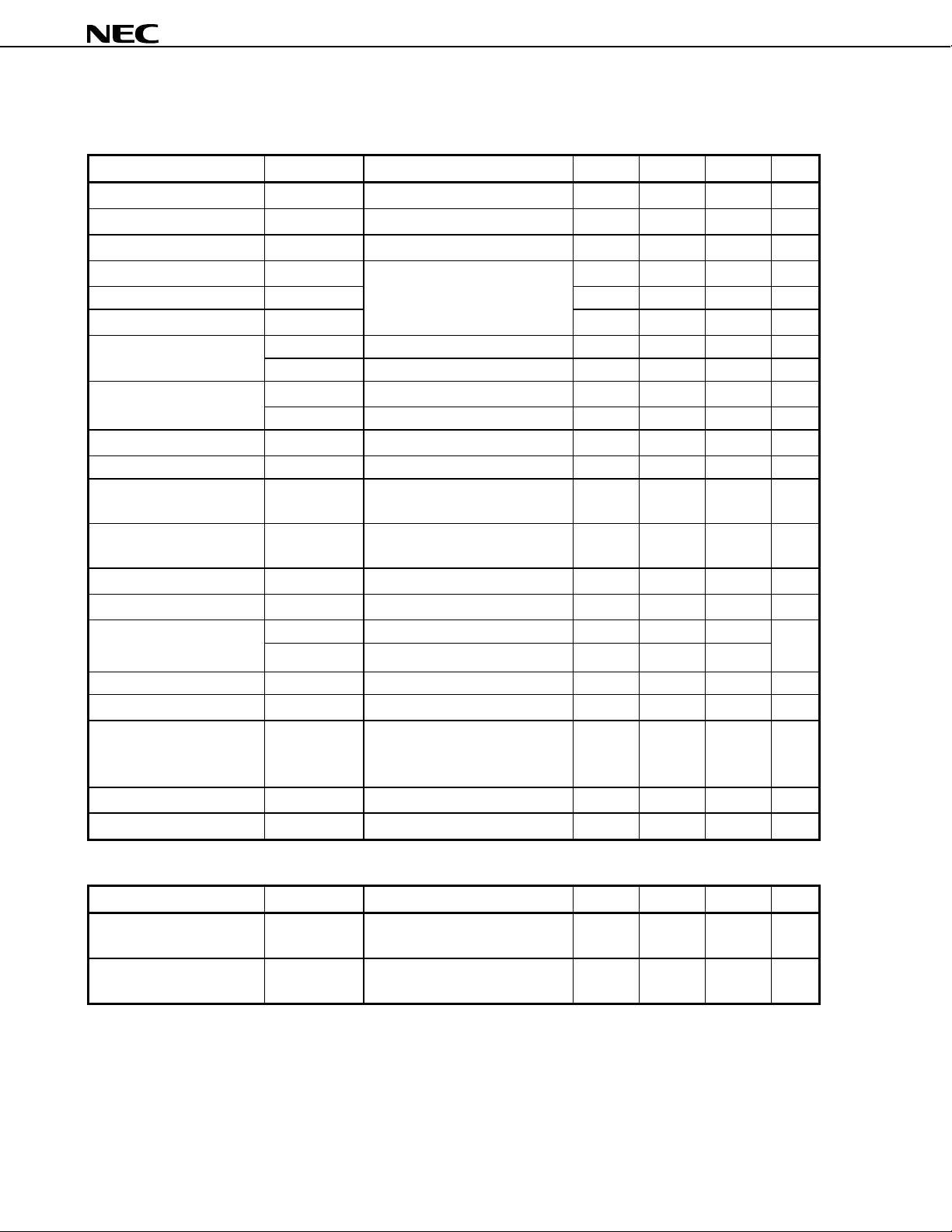

1. PIN FUNCTIONS

Pin No. Symbol Function

1 LGND Control circuit GND pin

2C

3FIL

4FIL

5FIL

6FIL

7V

8V

9V

10 D

11 FB

12 D

13 V

14 C

15 FB

16 C

OSC

A

B

C

D

REF

DD

M3

2

D

1

M4

2

C

1

17 EXP0 Output monitor pin (open drain)

18 EXP1 Output monitor pin (open drain)

19 EXP2 Output monitor pin (open drain)

20 PGND Power circuit GND pin

21 EXP3 Output monitor pin (open drain)

22 EXT

23 V

24 A

25 FB

26 A

27 V

28 B

29 FB

30 B

31 EXT

32 V

α

M1

1

A

2

M2

1

B

2

β

D

33 LATCH Latch signal input pin

34 SDATA Serial data input pin

35 SCLK Serial clock input pin

36 OSC

37 OSC

IN

OUT

38 RESET Reset signal output pin

Chopping capacitor connection pin

α

1-ch filter capacitor connection pin (1000 pF TYP.)

α

2-ch filter capacitor connection pin (1000 pF TYP.)

β

1-ch filter capacitor connection pin (1000 pF TYP.)

β

2-ch filter capacitor connection pin (1000 pF TYP.)

Reference voltage input pin (250 mV TYP.)

Control circuit supply voltage input pin

Output circuit supply voltage input pin

β

2-ch output pin

β

2-ch sense resistor connection pin

β

2-ch output pin

Output circuit supply voltage connection pin

β

1-ch output pin

β

1-ch sense resistor connection pin

β

1-ch output pin

Logic circuit monitor pin

Output circuit supply voltage input pin

α

1-ch output pin

α

1-ch sense resistor connection pin

α

1-ch output pin

Output circuit supply voltage input pin

α

2-ch output pin

α

2-ch sense resistor connection pin

α

2-ch output pin

Logic circuit monitor pin

Video sync signal input pin

Original oscillation input pin (4 MHz TYP.)

Original oscillation output pin

µµµµ

PD16878

4

Data Sheet S15974EJ1V0DS

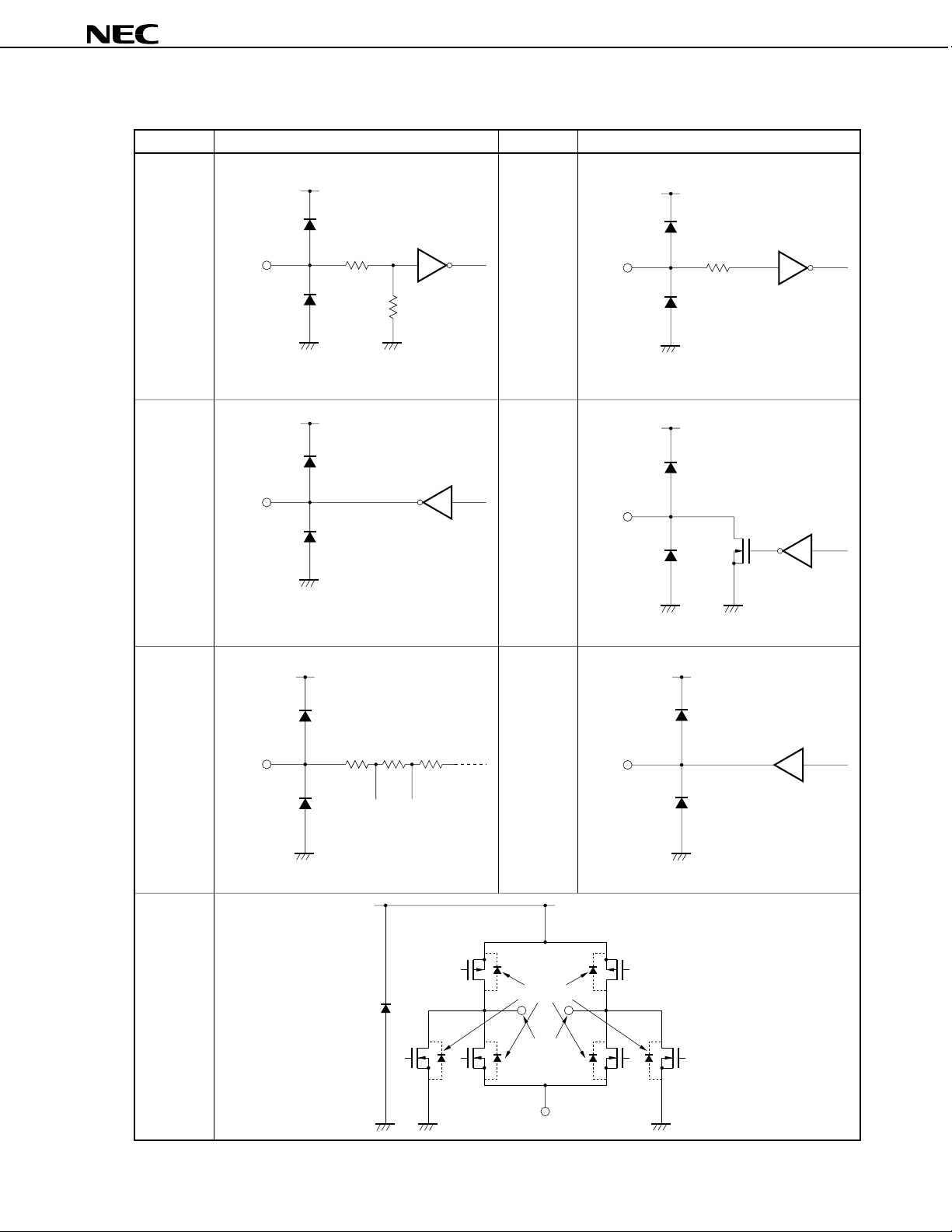

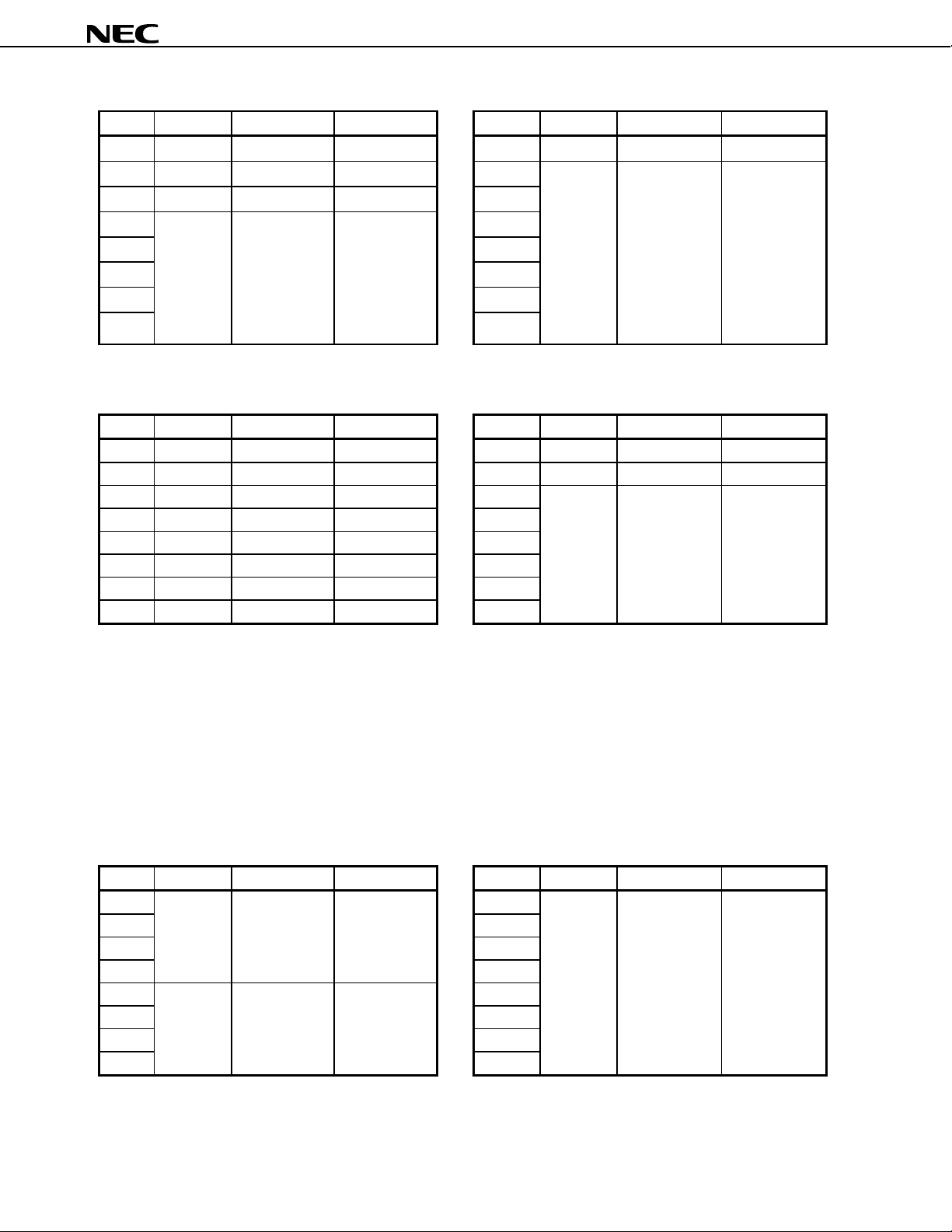

2. I/O PIN EQUIVALENT CIRCUIT

Pin Name Equivalent Circuit Pin Name Equivalent Circuit

DD

V

DD

LATCH

SDATA

SCLK

Pad

V

OSC

IN

Pad

RESET

Pull-down

resistor (125 Ω)

V

DD

V

DD

DD

V

µµµµ

PD16878

OSC

EXT

EXT

V

REF

α

β

OUT

Pad

Pad

EXP0

EXP1

Pad

EXP2

EXP3

V

DD

FIL

A

FIL

FIL

FIL

B

C

D

Pad

V

M

DD

V

Buffer

A1, A

B1, B

C1, C

D1, D

2

2

2

2

Parasitic diodes

Pad

FB

Data Sheet S15974EJ1V0DS

5

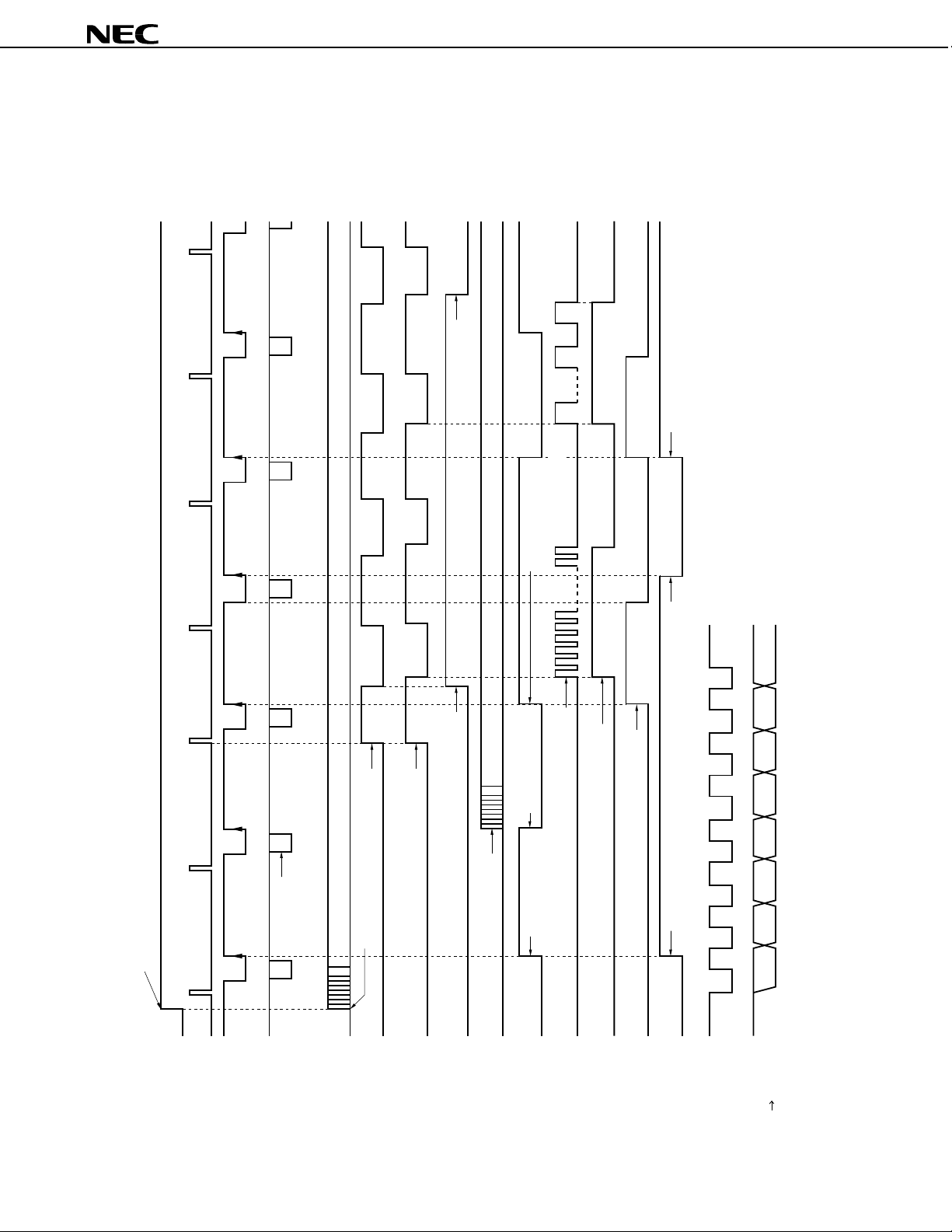

3. EXAMPLE OF STANDARD CONNECTION

α

EXT

100 kΩ x 4

EXTOUT SELECTOR

: 64 kHz

OSC

250 mV

EVR : 1010

f

CPU

EXP0 EXP1EXP2 EXP3

SCLK SDATA LATCH

REF

V

D

V

OUT

OSC

EVR1 EVR2

SERIAL-PARARELLE DECODER

EVR2

PULSE GENERATER

EVR1

x2

1/N

β

EXT

+

+

β

CURRENT SET

α

+

CURRENT SET

OSC

+

FILTERFILTERFILTERFILTER

– +

M

V

– +

M

V

– +

M

V

– +

M

V

2ch

β

H BRIDGE

1ch

β

H BRIDGE

2ch

α

H BRIDGE

1ch

α

H BRIDGE

D

FIL

2

D

1

D

D

FB

C

FIL

2

C

1

C

C

FB

B

FIL

2

B

1

B

B

FB

A

FIL

2

A

1

A

1000 pF

6.8 Ω

6.8 Ω

1000 pF

µµµµ

PD16878

MOTOR 1 MOTOR 2

IN

OSC

SELECTOR

A

FB

4 MHz

M4

OSC

C

LGND

PGND

RESET

DD

VM1VM2VM3V

V

33 pF

3.3 V

6.8 Ω x 2

REGULATOR

6

Data Sheet S15974EJ1V0DS

BATTERY

4.8 to 11 V

1000 pF x 2

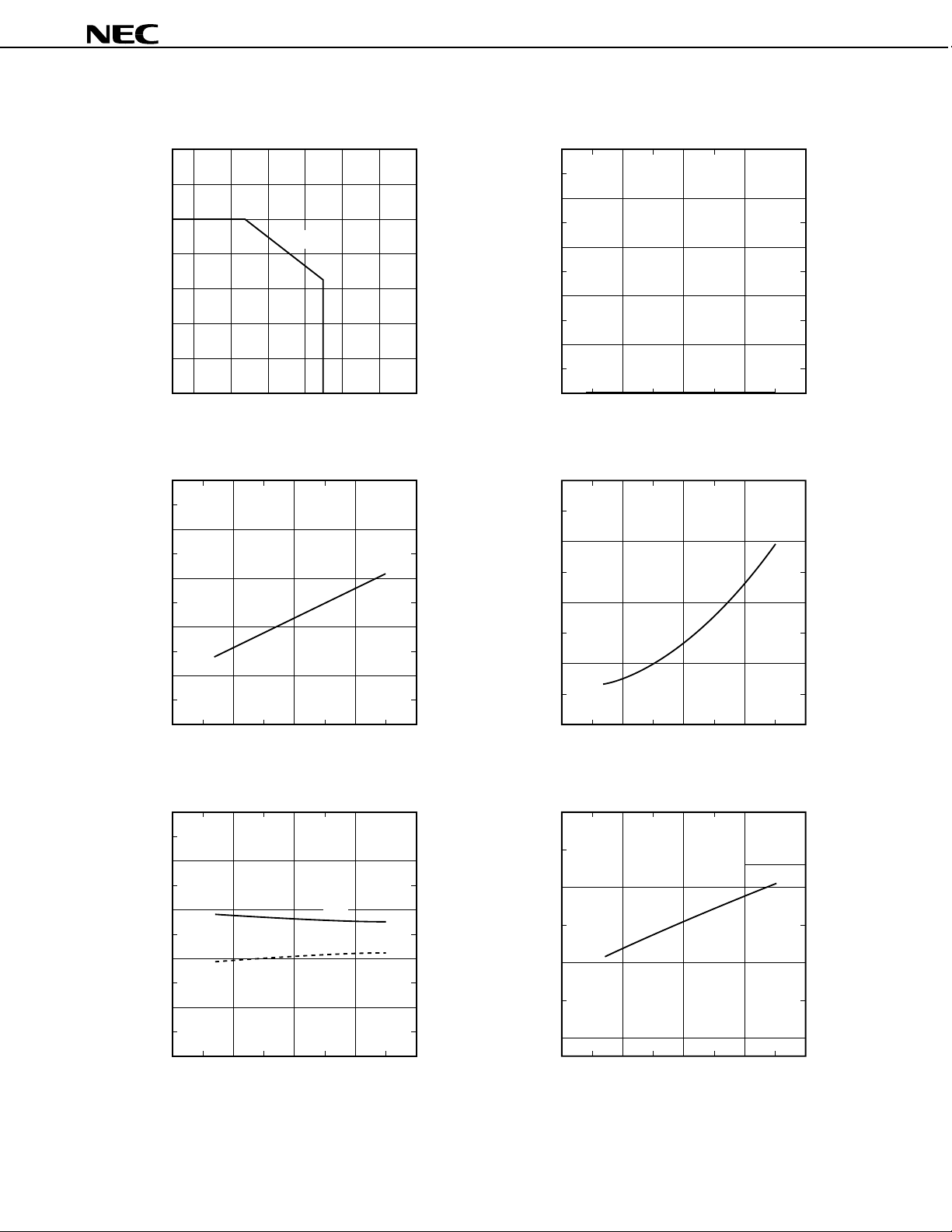

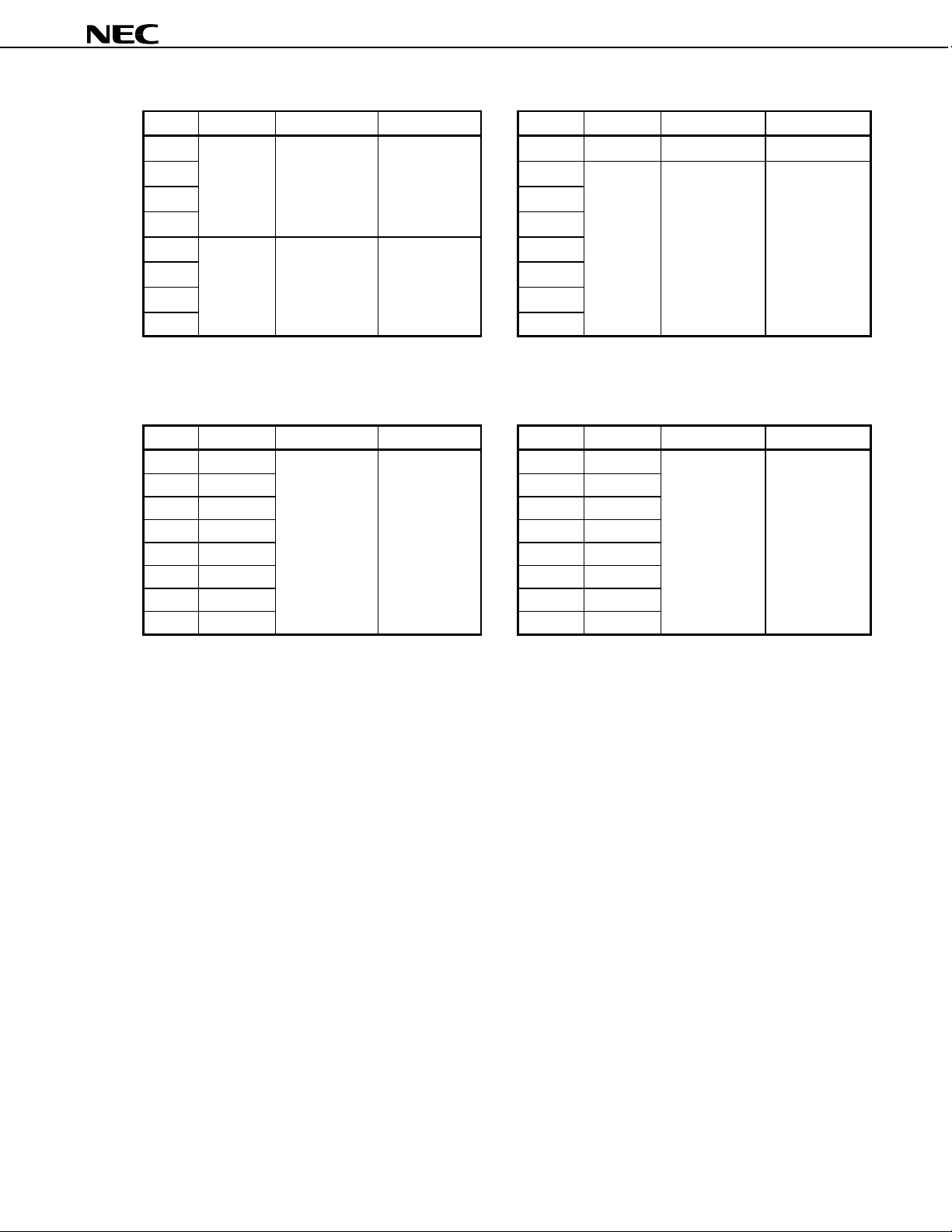

4. STANDARD CHARACTERISTICS CURVES

µµµµ

PD16878

1.4

PT vs. TA Characteristics I

1.2

(W)

T

1.0

125°C/W

0.8

0.6

0.4

Total Power Dissipation P

0.2

0

20 40 60–10 0

Ambient Temperature T

5

IDD vs. VDD Characteristics

4

(mA)

DD

3

2

pin Current I

DD

V

1

0

234

Control Circuit Supply Volage V

80 100 120

A

(°C)

TA = 25°C,

operating,

output open

56

DD

(V)

1

µ

0.8

( A)

MO (RESET)

0.6

MO (RESET)

vs. VM Characteristics

0.4

pin Current I

M

0.2

OFF V

0

468

Output Circuit Supply Voltage V

200

µ

( A)

150

DD (RESET)

DD (RESET)

vs. VDD Characteristics

I

100

50

pin Current at Reset State I

DD

V

0

234

Control Circuit Supply Volage V

TA = 25°C,

no load,

after reset

10 12

M

(V)

TA = 25°C,

after reset

56

DD

(V)

VIH/VDD, VIL/VDD vs. VDD Characteristics

1

(V)

0.8

DD

/V

IL

, V

0.6

DD

/V

IH

0.4

0.2

Input Voltage V

0

234

Control Circuit Supply Volage V

TA = 25°C

V

IH

IL

V

56

DD

(V)

60

µ

( A)

IL

/I

IH

40

20

0

High-level/Low-level Input Current I

Data Sheet S15974EJ1V0DS

IIH/IIL vs. VIN Characteristics

I

IH

I

IL

234

IN

Input Voltage V

(V)

TA = 25°C,

IIH: VIN = VDD,

I

IL

:

VIN = 0 V

56

7

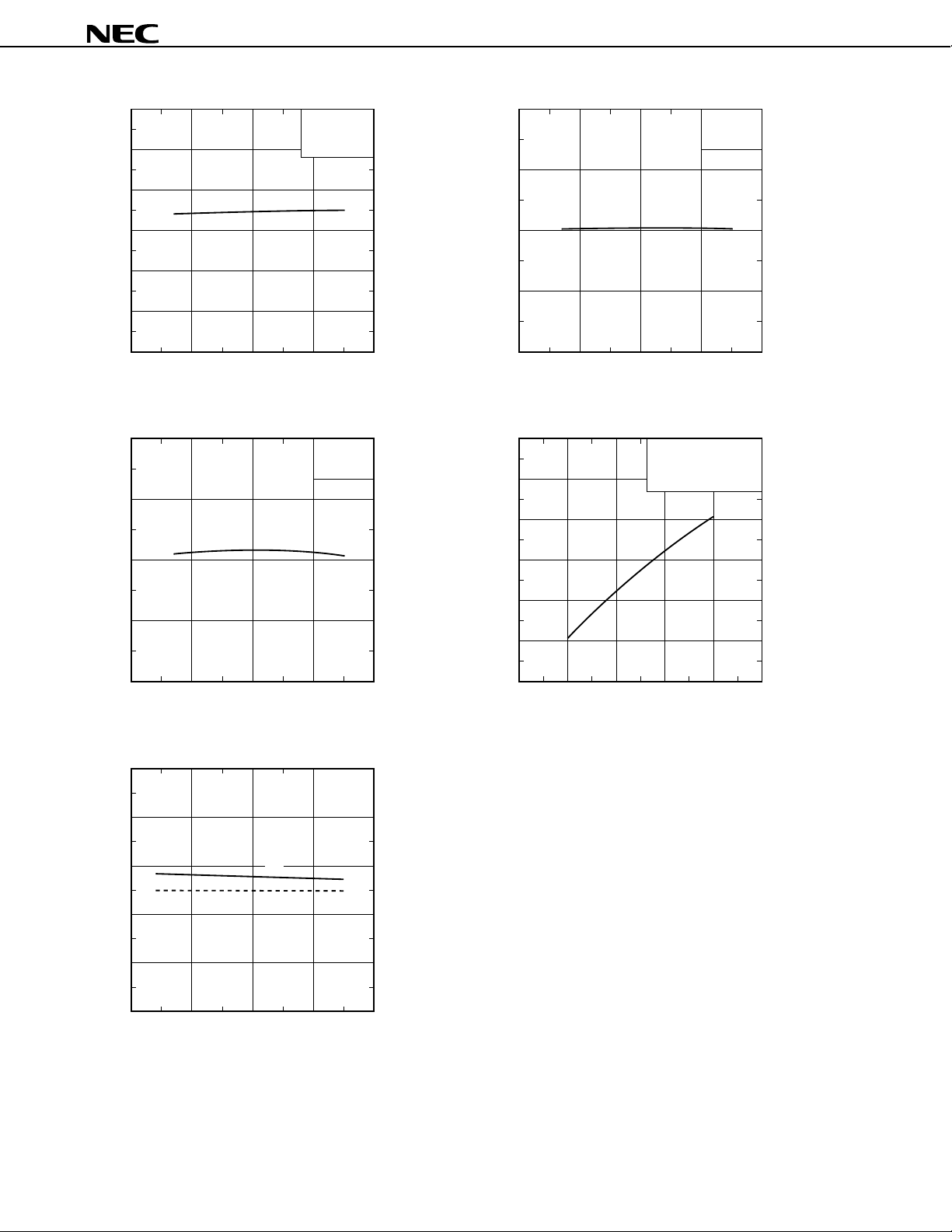

f

OSC

150

vs. VDD Characteristics f

140

(kHz)

130

OSC

120

110

Chopping Frequency f

100

TA = 25°C,

C

OSC

= 100 pF,

DATA: all high

6

STEP vs. VDD Characteristics

5

(kHz)

STEP

4

3

Step Frequency f

TA = 25°C,

C

OSC

= 100 pF

µµµµ

PD16878

90

23456

Control Circuit Supply Voltage V

V

REFVER

40

vs. VDD Characteristics

DD

(V)

TA = 25°C,

V

REF

= 250 mV

(mV)

30

REFVER

20

10

EVR Variable Voltage V

0

234

Control Circuit Supply Voltage V

tON, t

OFF

500

vs. VM Characteristics

56

DD

(V)

TA = 25°C,

IM = 100 mA,

C

FIL

(ns)

400

OFF

/t

ON

300

t

ON

: none

2

234

Control Circuit Supply Voltage V

I

M (MAX)

80

vs. EVR Characteristics

56

DD

(V)

TA = 25°C, VM = 6 V

(mA)

70

M (MAX)

Rs = 6.8 Ω, f

L = 25 mH/R = 100 Ω at 1 kHz

OSC

= 64 kHz,

60

50

40

30

Sine Wave Peak Output Current I

20

50 100 150 200 250 300

Reference Setting Voltage EVR (mV)

200

100

Turn-on Time, Turn-off Time t

0

468

Output Circuit Supply Voltage V

8

t

OFF

10 12

M

(V)

Data Sheet S15974EJ1V0DS

µµµµ

PD16878

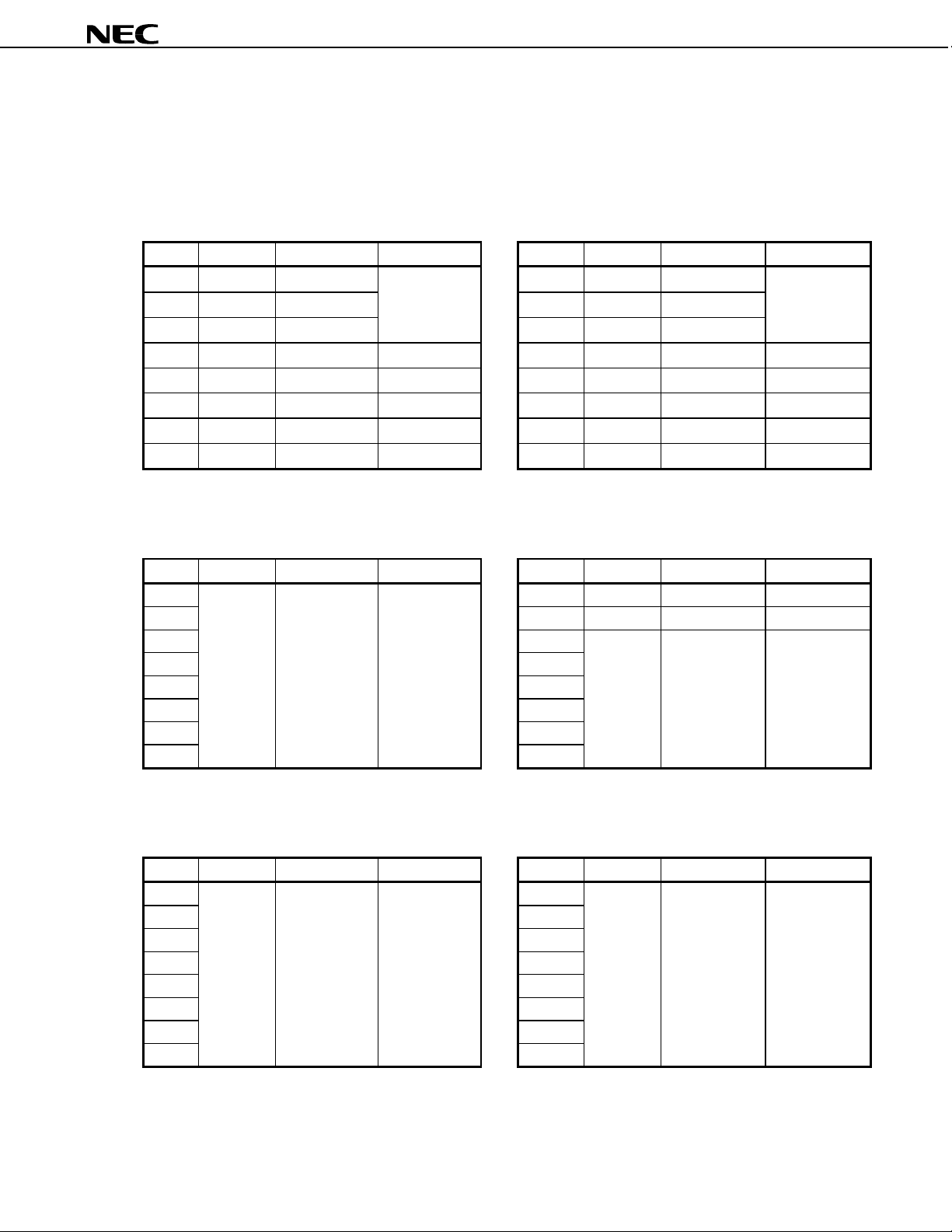

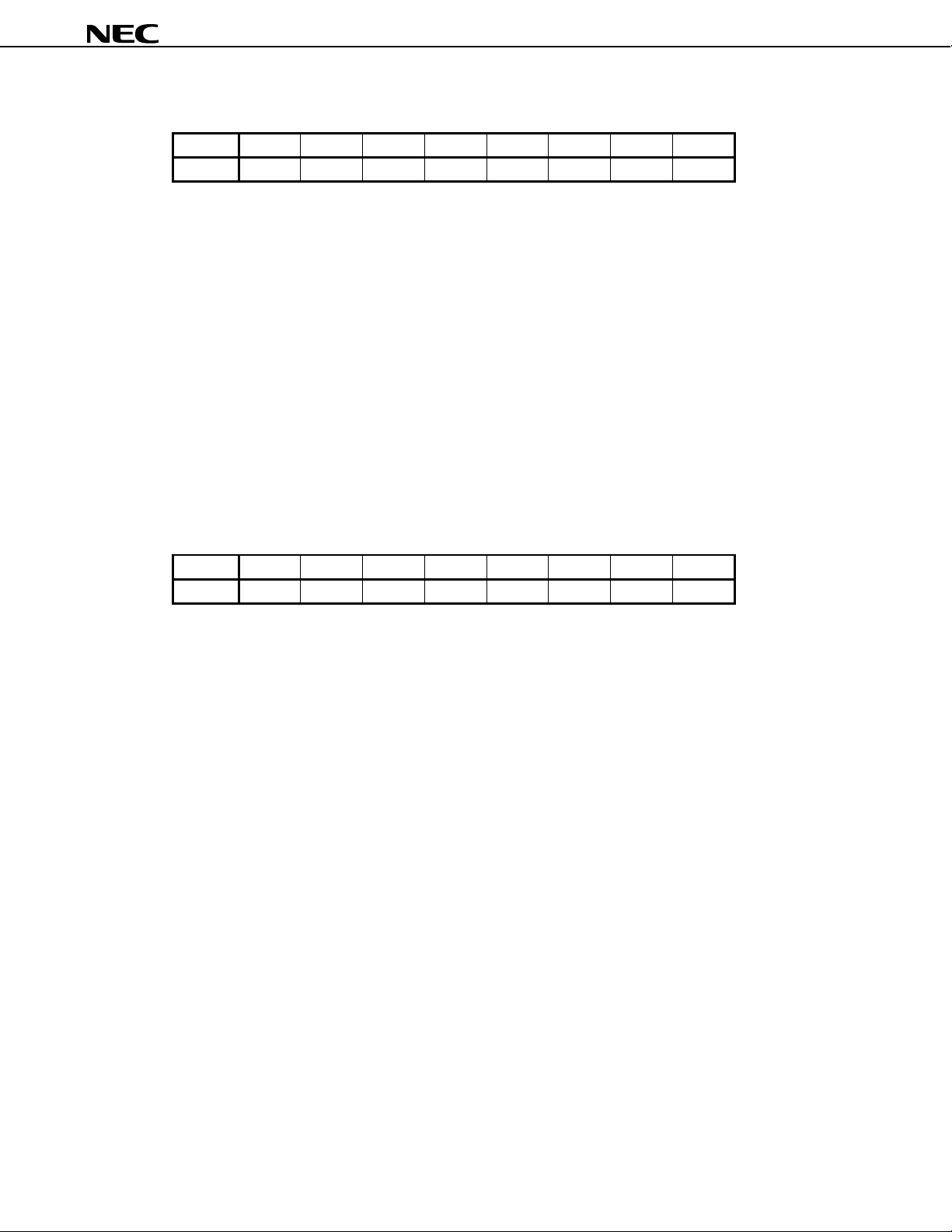

5. INTERFACE (I/F) CIRCUIT DATA CONFIGURATION (f

= 4-MHz EXTERNAL CLOCK INPUT)

CLK

Input data consists of serial data (8 bytes x 8 bits).

Input serial data with the LSB first, from the 1st byte to 8th byte.

(1) Initial data (2) Standard data

<1st byte> <1st byte>

Bit Data Function Setting Bit Data Function Setting

D7 1

D6 1

D5 1

D4 0 −− D4 0 −−

D3 1 or 0 EXP3 Hi-Z or L D3 1 or 0 EXP3 Hi-Z or L

D2 1 or 0 EXP2 Hi-Z or L D2 1 or 0 EXP2 Hi-Z or L

D1 1 or 0 EXP1 Hi-Z or L D1 1 or 0 EXP1 Hi-Z or L

D0 1 or 0 EXP0 Hi-Z or L D0 1 or 0 EXP0 Hi-Z or L

HEADER DATA2

HEADER DATA1

HEADER DATA0

DATA selection

Remark Hi-Z : High impedance,

L : Low level (current sink)

D7 0

D6 0

D5 0

HEADER DATA2

HEADER DATA1

HEADER DATA0

Remark Hi-Z : High impedance,

L : Low level (current sink)

DATA selection

<2nd byte> <2nd byte>

Bit Data Function Setting Bit Data Function Setting

D7 D7 1 or 0

D6 D6 1 or 0

D5 D5

D4 D4

8-bit data

input

D3 D3

D2 D2

D1 D1

D0

Note

First Point Wait

Start point wait

s to 2.04 ms

8

µ

Setting

(1 to 255)

s

µ

∆t = 8

6-bit data

input

D0

ROTATION

α

ENABLE

α

Pulse Number

α

ch CCW/CW

α

ch ON/OFF

α

ch

α

Number of

pulses in 1 VD

Setting (0 to 63)

∆n = 2 pulses

Note Input other than “0”. Note The number of pulses can be varied in 2-pulse

steps.

Note

<3rd byte> <3rd byte>

Bit Data Function Setting Bit Data Function Setting

D7 D7

D6 D6

D5 D5

D4 D4

8-bit data

input

D3 D3

D2 D2

D1 D1

D0

Note

First Point

Magnetize Wait

Start point drive

wait

s to 2.04 ms

µ

8

Setting

(1 to 255)

s

µ

∆t = 8

D0

15-bit data

Low-order

8-bit data

input

Pulse Width

α

ch pulse

α

cycle

0.25 to 8191.75 µs

Setting

(1 to 32767)

∆t = 0.25

Note Input other than “0”.

Data Sheet S15974EJ1V0DS

s

µ

9

<4th byte> <4th byte>

Bit Data Function Setting Bit Data Function Setting

D7 1 or 0 OSCSEL

Internal/external

D6 0 - - D6

D7 1 or 0 Current Set

15-bit data

α

D5 0 - - D5

D4 D4

D3 D3

5-bit data

D2 D2

input

D1 D1

Chopping

Frequency

D0

Chopping

frequency :

32 to 124 kHz

Setting

(8 to 31)

∆f = 4 kHz

Note

D0

High-order

7-bit data

input

Pulse Width

α

Note The frequency is 0 kHz if 0 to 7 is input.

<5th byte> <5th byte>

Bit Data EXT

α

D7 0 - - D7 1 or 0

D6

D5

D4

D3

D2

D1

D0

Note 5

Note 5

Note 5

Note 5

Note 5

Note 5

Note 5

ENABLE

ROTATION

Pulse Out

FF7

FF3

Checksum

Chopping

Note1

α

Note2

α

α

α

α

Note3

Note4

Notes 1. H level : Conducts, L level : Stops

2. H level : Reverse (CCW),

EXT

ENABLE

β

ROTATION

Pulse Out

FF7

β

FF3

β

FF2

β

FF1

β

β

Note1

Bit Data Function Setting

ROTATION

β

D6 1 or 0

Note2

β

β

D5

D4

D3

D2

6-bit data

input

ENABLE

β

Pulse Number

β

D1

D0

Note The number of pulses can be varied in 2-pulse

steps.

L level : Forward (CW)

3. H level : Normal data input,

L level : Abnormal data input

4. Not output in internal oscillation mode.

5. Select one of D0 to D6 and input “1”.

If two or more of D0 to D6 are selected,

they are positively ORed for output.

µµµµ

PD16878

set2/set1

α

ch

pulse cycle :

0.25 to 8191.75 µs

Setting

(1 to 32767)

∆t = 0.25

ch CCW/CW

β

ch ON/OFF

β

β

ch

s

µ

Number of

pulses in 1 VD

Setting (1 to 63)

∆n = 2 pulses

Note

<6th byte> <6th byte>

Bit Data Function Setting Bit Data Function Setting

D7 D7

D6 D6

4-bit data

input

D5 D5

ch

α

Current Set2

D4

D3 D3

D2 D2

4-bit data

input

D1 D1

ch

α

Current Set1

D0

α

ch Output current

setting 2

EVR : 100

to 250 mV

Setting (0 to 15)

α

ch Output current

setting 1

EVR : 100

to 250 mV

Setting (0 to 15)

Note

Note

D4

D0

15-bit data

Low-order

8-bit data

input

Pulse Width

β

Note A voltage of about double EVR is output to

the FIL pin.

10

Data Sheet S15974EJ1V0DS

β

ch pulse

cycle:

0.25 to 8191.75 µs

Setting

(1 to 32767)

∆t = 0.25

s

µ

<7th byte> <7th byte>

Bit Data Function Setting Bit Data Function Setting

D7 D7 1 or 0 Current Set

D6 D6

4-bit data

input

D5 D5

ch

β

Current Set2

D4

D3 D3

D2 D2

4-bit data

input

D1 D1

ch

β

Current Set1

D0

β

ch Output

current setting 2

EVR: 100 to 250 mV

Setting (0 to 15)

ch Output

β

current setting 1

EVR: 100 to 250 mV

Setting (0 to 15)

Note

Note

D4

D0

15-bit data

High-order

7-bit data

input

Pulse Width

β

β

Note A voltage of about double EVR is output to

the FIL pin.

<8th byte> <8th byte>

Bit Data Function Setting Bit Data Function Setting

D7 1 or 0 D7 1 or 0

D6 1 or 0 D6 1 or 0

D5 1 or 0 D5 1 or 0

D4 1 or 0 D4 1 or 0

D3 1 or 0 D3 1 or 0

Checksum Checksum

D2 1 or 0 D2 1 or 0

D1 1 or 0 D1 1 or 0

D0 1 or 0

Note Data is input so that the sum of the 1st

through the 8th bytes is 00H.

Note

Checksum Checksum

D0 1 or 0

Note Data is input so that the sum of the 1st

through the 8th bytes is 00H.

µµµµ

PD16878

set2/set1

β

ch pulse

cycle:

0.25 to 8191.75 µs

Setting

(1 to 32767)

∆t = 0.25

µ

s

Note

Data Sheet S15974EJ1V0DS

11

µµµµ

PD16878

Data Configuration

Data can be input in either of two ways. Initial data can be input when the power is first applied, or standard data

can be input during normal operation. Input serial data with the LSB first, i.e., starting from the D0 bit (LSB) of the 1st

byte. Therefore, the D7 bit of the 8th byte is the most significant bit (MSB).

When inputting initial data, set a start point wait time that specifies the delay from power application to pulse

output, and the start point drive wait time. At the same time, also set a chopping frequency and a reference voltage

(EVR) that determines the output current of each channel. Because the

internal operations, the parameter to be monitored can be selected by initial data.

When inputting standard data, input the rotation direction of each channel, the number of pulses, and the data for

the pulse cycle.

Initial data or standard data is selected by using bits D5 to D7 of the 1st byte (see Table 5-1).

Table 5-1. Data Selection Mode (1st byte)

D7 D6 D5 Data type

1 1 1 Initial data

0 0 0 Standard data

Remark If the high-order three bits are high, the initial data is selected;

if they are low, the standard data is selected.

Data other than (0, 0, 0) and (1, 1, 1) must not be input.

PD16878 has an EXT pin for monitoring the

µ

Input the serial data during start point wait time.

Details of Data Configuration

How to input initial data and standard data is described below.

(1) Initial data input

<1st byte>

The 1st byte specifies the type of data (initial data or standard data) and determines the presence or absence of

the EXP pin output. Bits D5 to D7 of this byte specify the type of data as shown in Table 5-1, while bits D0 to D3

select the EXP output (open drain).

Table 5-2. 1st Byte Data Configuration

Bit D7D6D5D4D3D2D1D0

Data 1 1 1 0 0 or 1 0 or 1 0 or 1 0 or 1

The EXP pin goes low (current sink) when the input data is “0”, and high (high impedance state) when the input

data is “1”. Pull this pin up to V

for use. Input “0” to bit D4.

DD

12

Data Sheet S15974EJ1V0DS

µµµµ

PD16878

<2nd byte>

The 2nd byte specifies the delay between data being read and data being output. This delay is called the start up

wait time, and the motor can be driven from that point at which the start up wait time is “0”. This time is counted at the

rising edge of VD. The start up wait time can be set to 2.04 ms (when a 4-MHz clock is input), and can be fine-tuned

by means of 8-bit division (8-µs step: with 4-MHz clock). The start up wait time is set to 2.04 ms when all the bits of

the 2nd byte are set to “1”.

Caution Always input data other than “0” to this byte because the start up wait time is necessary for

latching data. If “0” is input to this byte, data cannot be updated. Transfer standard data during the

start up wait time.

<3rd byte>

The 3rd byte specifies the delay between the start point wait time being cleared and the output pulse being

generated. This time is called the start up drive wait time, and the output pulse is generated from the point at which

the start up drive wait time reaches “0”. The start up drive wait time is counted at the falling edge of the start up wait

time. The start up drive wait time can be set to 2.04 ms (with 4-MHz clock) and can be fine-tuned by means of 8-bit

division (8 µs step: with 4-MHz clock). The start up drive wait time is set to 2.04 ms when all the bits of the 3rd byte

are “1”.

Caution Always input data other than “0” to this byte because the start up drive wait time is necessary for

latching data. If “0” is input to this byte, data cannot be updated.

<4th byte>

The 4th byte selects a chopping frequency by using 5-bit data. It also selects whether the chopping frequency is

created by dividing the original oscillation (external clock) or whether the internal oscillator is used. The chopping

frequency is selected by bits D0 to D4. Bit D7 specifies the method used to create the chopping frequency. When this

bit is “0”, the original oscillation (external clock input to OSCIN) is used; when it is “1”, the internal oscillator is used.

Bits D5 and D6 are fixed to “0”.

The chopping signal is output after the initial data has been input and the first standard data has been latched

(see Timing Chart).

Table 5-3. 4th Byte Data Configuration (Initial data)

Bit D7D6D5D4D3D2D1D0

Data 0 or 1 0 0 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1

The chopping frequency is set to 0 kHz and to a value in the range of 32 to 124 kHz (in 4-kHz steps), as follows.

Although the chopping frequency is set by 5 bits of data, it is internally configured using 7-bit data (with the low-

order 2 bits fixed to 0).

Data Sheet S15974EJ1V0DS

13

µµµµ

PD16878

BitD7D6D5D4D3D2D1 D0

Data0 or 1000000 0

Bit D7D6D5D4D3D2D1D0

Data0 or 1000011 1

Bit D7D6D5D4D3D2D1D0

Data 0 or 1 0 0 0 1 0 0 0

Bit D7D6D5D4D3D2D1D0

Data0 or 1000100 1

Bit D7D6D5D4D3D2D1D0

Data0 or 1001111 1

f

= 0 kHz

OSC

f

= 0 kHz

OSC

f

= 32 kHz

OSC

f

= 36 kHz

OSC

f

= 124 kHz

OSC

<5th byte>

The 5th byte selects a parameter to be output to the EXT pin (logic operation monitor pin). Input data to bits D0 to

D6 of this byte. Bit D7 is fixed to “0”.

There are two EXT pins. EXT

α

indicates the operating status of α ch, and EXTβ indicates that of β ch. The

relationship between each bit and each EXT pin is as shown in Table 5-4.

Table 5-4. 5th Byte Data Configuration (Initial data)

Bit Data EXT

D7 0 Not used Not used

D6 0 or 1 ENABLE

D5 0 or 1 ROTATION

D4 0 or 1 PULSEOUT

D3 0 or 1 FF7

D2 0 or 1 FF3

D1 0 or 1 CHECKSUM FF2

D0 0 or 1 CHOPPING FF1

α

α

α

α

α

α

ENABLE

ROTATION

PULSEOUT

FF7

β

FF3

β

β

β

The checksum bit is cleared to “0” in the event of an error. Normally, it is “1”.

If two or more signals that output signals to EXT

α

and EXTβ are selected, they are positively ORed for output.

Caution The CHOPPING signal is not output in internal oscillation mode.

EXT

β

β

β

β

14

Data Sheet S15974EJ1V0DS

µµµµ

PD16878

Remark The meanings of the symbols listed in Table 5-4 are as follows:

ENABLE : Output setting (H : Conducts, L : Stops)

ROTATION : Rotation direction (H : Reverse (CCW), L : Forward (CW))

PULSEOUT : Output pulse signal

FF7 : Presence/absence of pulse in LATCH cycle (Outputs H level if output pulse information exists in

standard data.)

FF3 : Pulse gate (output while pulse exists)

FF2 : Outputs H level during start up wait time + start up drive wait time

FF1 : Outputs H level during start up wait time

CHECKSUM : Checksum output (H : when normal data is transmitted,

L : when abnormal data is transmitted)

CHOPPING : Chopping wave output (in original oscillation mode only)

<6th byte>

The 6th byte sets the peak output current value of α ch. The output current is determined by the EVR reference

voltage.

The 250-mV (TYP.) voltage input from an external source to the VREF

pin is internally doubled and input to a 4-bit

D/A converter. By dividing this voltage by 4-bit data, an EVR reference voltage can be set inside the IC within the

range of 200 to 500 mV, in units of 20 mV.

The µPD16878 can set two values of the EVR reference voltage in advance. This is done by using bits D0 to D3

or D4 to D7. Which of the two EVR reference voltage values is to be used is specified by the CURRENT SET bit in

the standard data.

If all the bits of the 6th byte are “0”, the EVR reference voltage of 200 mV is selected; if they are “1”, the EVR

reference voltage of 500 mV is selected.

Table 5-5. 6th Byte Data Configuration (Initial data)

Bit D7D6D5D4D3D2D1D0

Data 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1

Remark Bits D4 to D7 : Reference voltage 2 (EVR

Bits D0 to D3 : Reference voltage 1 (EVR

)

α

2

)

α

1

<7th byte>

The 7th byte specifies the peak output current value of

β

ch. The output current is determined by the EVR

reference voltage.

The 250-mV (TYP.) voltage input from an external source to the VREF

pin is internally doubled and input to a 4-bit

D/A converter. By dividing this voltage by 4-bit data, an EVR reference voltage can be set inside the IC within a range

of 200 to 500 mV, in units of 20 mV.

The µPD16878 can set two values of the EVR reference voltage in advance. This is done using bits D0 to D3 or

D4 to D7. Which of the two EVR reference voltage values is to be used is specified by the CURRENT SET bit in the

standard data.

If all the bits of the 7th byte are “0”, the EVR reference voltage of 200 mV is selected; if they are “1”, the EVR

reference voltage of 500 mV is selected.

Data Sheet S15974EJ1V0DS

15

µµµµ

Table 5-6. 7th Byte Data Configuration (Initial data)

Bit D7D6D5D4D3D2D1D0

Data 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1

Remark Bits D4 to D7 : Reference voltage 2 (EVR

Bits D0 to D3 : Reference voltage 1 (EVR

<8th byte>

The 8th byte is checksum data. Normally, the sum of the 8-byte data is 00H.

If the sum is not 00H because data transmission is abnormal, the stepping operation is inhibited and the

checksum output pin (EXT pin) is kept “L”.

(2) Standard data input

<1st byte>

The 1st byte specifies the type of data and whether the EXP pin output is used, such as when the initial data is

input.

)

β

2

)

β

1

PD16878

Table 5-7. 1st Byte Data Configuration

Bit D7D6D5D4D3D2D1D0

Data 1 1 1 0 0 or 1 0 or 1 0 or 1 0 or 1

The EXP pin goes low (current sink) when the input data is “0”, and high (high impedance state) when the input

data is “1”. Input “0” to bit D4.

<2nd byte>

The 2nd byte specifies the rotation direction of the

pulses (126 pulses MAX.) during the 1VD

period (in 1 cycle of FF2) of the

α

channel, enables output of the α channel, and the number of

α

channel.

Bit D7 is used to specify the rotation direction. The rotation is in the forward direction (CW mode) when this bit is

“0”; it is in the reverse direction (CCW mode) when the bit is “1”.

Bit D6 is used to enable the output of the α channel. The α channel enters the high impedance state when this bit

is “0”; it is in conduction mode when the bit is “1”.

The number of pulses is set by bits D0 to D5. It is set by 6 bits in terms of software. However, the actual circuit

uses an 8-bit counter with the low-order two bits fixed to “0”. Therefore, the number of pulses that is actually

generated during start up wait time + start up drive wait (FF2) cycle is the number of pulses input x 2. The number of

pulses can be set to a value in the range of 0 to 126, in units of 2 pulses.

16

Data Sheet S15974EJ1V0DS

µµµµ

PD16878

Table 5-8. 2nd Byte Data Configuration (Standard data)

Bit D7D6D5D4D3D2D1D0

Data 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1

Rotation direction ENABLE Number of pulses

<3rd and 4th bytes>

The 3rd and 4th bytes select the pulse cycle of the

the initial mode, is to be used (CURRENT SET

α

α

channel and which of the two reference voltages, created in

).

The pulse cycle is specified using 15 bits : bits D0 (least significant bit) to D7 of the 3rd byte, and bits D0 to D6

(most significant bit) of the 4th byte. The pulse cycle can be set to a value in the range of 0.25 to 8191.75 µs in units

of 0.25 µs (with a 4-MHz clock).

CURRENT SET

α

is specified by bit D7 of the 4th byte. When this bit is “0”, reference voltage 1 (EVR

selected; when it is “1”, reference voltage 2 (EVR

) is selected. For further information, refer to the description of the

α

2

) is

α

1

6th byte of the initial data.

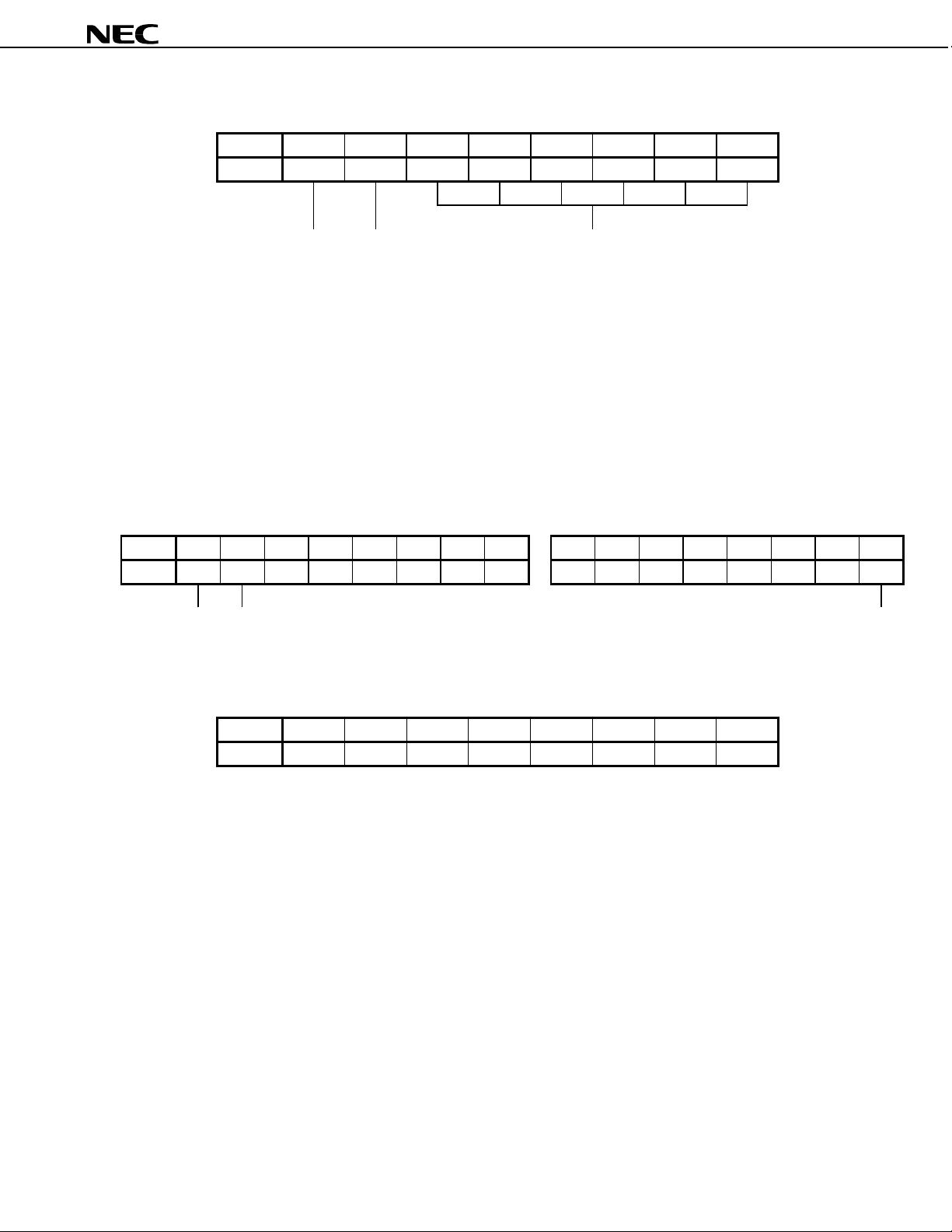

Table 5-9. 4th Byte Data Configuration (Standard data) Table 5-10. 3rd Byte Data Configuration (Standard data)

Bit D7D6D5D4D3D2D1D0 D7D6D5D4D3D2D1D0

Data

CURRENT SET

0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1

α

Most significant

Least significant bit

bit

(Reference) 6th Byte Data Configuration for Initial Data

Bit D7D6D5D4D3D2D1D0

Data 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1

Remark Bits D4 to D7 : Reference voltage 2 (EVR

Bits D0 to D3 : Reference voltage 1 (EVR

)

α

2

)

α

1

<5th byte>

The 5th byte specifies the rotation direction of the

pulses (126 pulses MAX.) during the 1VD

period (in one cycle of FF2) of the

β

channel, enables output of the β channel, and the number of

β

channel.

Bit D7 is used to specify the rotation direction. The rotation is in the forward direction (CW mode) when this bit is

“0”; it is in the reverse direction (CCW mode) when the bit is “1”.

Bit D6 is used to enable the output of the β channel. The β channel goes into a high impedance state when this bit

is “0”; it is in the conduction mode when the bit is “1”.

The number of pulses is set by bits D0 to D5. It is set by six bits in terms of software. However, the actual circuit

uses an 8-bit decoder with the low-order two bits fixed to “0”. Therefore, the number of pulses that is actually

generated during start up wait time + start up drive wait (FF2) cycle is the number of pulses input x 2. The number of

pulses can be set in a range of 0 to 126 and in units of 2 pulses.

Data Sheet S15974EJ1V0DS

17

µµµµ

PD16878

Table 5-11. 5th Byte Data Configuration (Standard data)

Bit D7D6D5D4D3D2D1D0

Data 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1

Rotation direction ENABLE Number of pulses

<6th and 7th bytes>

The 6th and 7th bytes select the pulse cycle of the

the initial mode, is to be used (CURRENT SET

β

β

channel and which of the two reference voltages, created in

).

The pulse cycle is specified using 15 bits : bits D0 (least significant bit) to D7 of the 6th byte, and bits D0 to D6

(most significant bit) of the 7th byte. The pulse cycle can be set to a value in the range of 0.25 to 8191.75 µs in units

of 0.25 µs (with a 4-MHz clock).

CURRENT SET

β

is specified by bit D7 of the 7th byte. When this bit is “0”, reference voltage 1 (EVR

selected; when it is “1”, reference voltage 2 (EVR

) is selected. For further information, refer to the description of the

β

2

) is

β

1

7th byte of the initial data.

Table 5-12. 7th Byte Data Configuration (Standard data) Table 5-13. 6th Byte Data Configuration (Standard data)

Bit D7D6D5D4D3D2D1D0 D7D6D5D4D3D2D1D0

Data

CURRENT SET

0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1

β

Most significant bit Least significant bit

(Reference) 7th Byte Data Configuration for Initial Data

Bit D7D6D5D4D3D2D1D0

Data 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1 0 or 1

Remark Bits D4 to D7 : Reference voltage 2 (EVR

Bits D0 to D3 : Reference voltage 1 (EVR

)

β

2

)

β

1

<8th byte>

The 8th byte is checksum data. Normally, the sum of the 8-byte data is 00H.

If the sum is not 00H because data transmission is abnormal, the stepping operation is inhibited and the

checksum output pin (EXT pin) is held at “L”.

18

Data Sheet S15974EJ1V0DS

µµµµ

PD16878

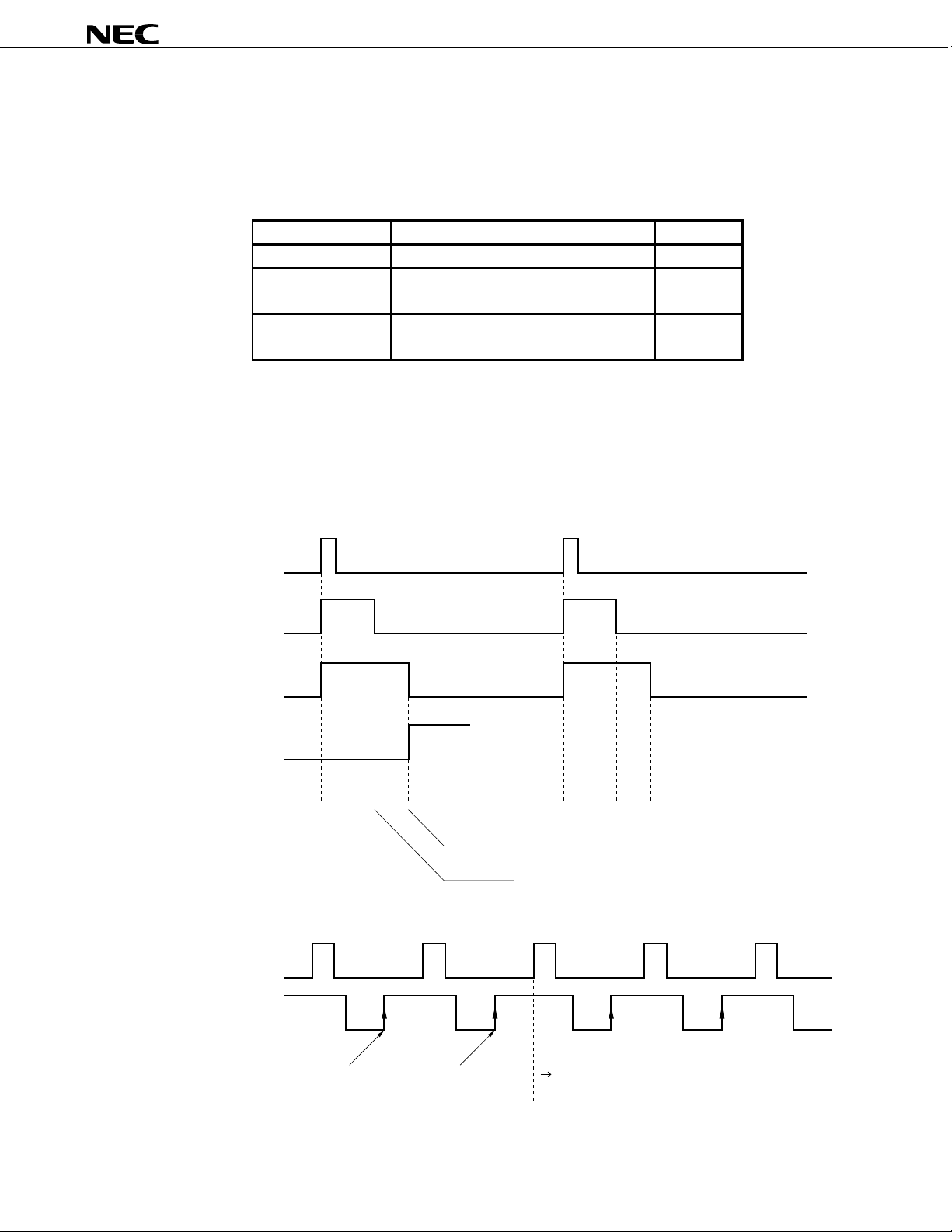

(Data Update Timing)

The standard data (pulse width, number of pulses, rotation direction, current setting, and ENABLE) of this product

are set and updated at the following latch timing.

Table 5-14. Data Update Timing

ENABLE change 1 → 10 → 11 → 00 → 0

Pulse width FF2↓ FF2↓ FF2↓−

Number of pulses FF2↓ FF2↓ FF2↓−

Rotation direction FF2↓ FF2↓ FF2↓−

Current setting FF2↓ FF1↓ FF2↓−

ENABLE FF2↓ FF1↓ FF2↓−

The timing at which data is to be updated differs, as shown in Table 5-14, depending on the enabled status.

For example, suppose the enable signal is currently “0” (output high impedance) and “1” (output conduction) is

input by the next data. In this case, the pulse width, number of pulses, and rotation direction signals are updated at

FF2(upon the completion of start up wait), and the current setting and ENABLE signals are updated at FF1 (upon

completion of start up drive wait).

Start up wait

FF1

FF2

Start up wait +

start up drive wait

Pulse output

V

D

Pulse width, number of pulses, and rotation direction

are updated.

Current setting and ENABLE are updated

(ENABLE change: 0 to 1).

V

D

(1)

(2)

(3)

LATCH I1

Initial data

identification

S1

Standard data

identification

Data Sheet S15974EJ1V0DS

S2

I1 data is output.

FF1, FF2 output

S3

19

(1) (2) (3)

µµµµ

PD16878

Pulse width Internal data retained.

Output reset

Rotation direction Internal output retained Not output

Number of pulses Internal data retained.

Output reset

Current setting Internal output retained Not output

ENABLE Internal output retained Not output

Not output

Not output

The initial mode of this product is as follows.

The IC operation can be initialized as follows:

(1) Turns ON VDD.

(2) Make RESET input “L”.

(3) Input serial initial data.

In initial mode, the operating status of the IC is as shown in Table 5-15.

Table 5-15. Operations in Initial Mode

Updated to S2 data at FF2

Updated to S2 data at either FF1 or FF2

by enable data of (2)

Item Specifications

Current consumption 100 µA

OSC Oscillation stops.

Input of external clock is inhibited.

V

D

FF1 to FF7 “L” level

PULSE OUT “L” level

EXP0 to EXP3 Undefined in the case of (1) above.

Serial operation Can be accessed after initialization in the case of (1) above.

Input inhibited.

Previous value is retained in the case of (2) above.

Can be updated by serial data in the case of (3) above.

Can be accessed after RESET has gone “H” in the case of (2) above.

Can be accessed in the case of (3) above.

Step pulse output is inhibited and FF7 is made “L” if the following conditions are satisfied.

(1) If the set number of pulses (2nd/5th: standard data) is 00H.

(2) If the checksum value is other than 00H.

(3) If the start up wait time is set to 1 VD or longer.

(4) If the start up wait time + start up drive wait time is set to 1 VD or longer.

(5) If start up wait is completed earlier than LATCH (↑).

(6) If VD is not input.

20

Data Sheet S15974EJ1V0DS

µµµµ

PD16878

Cautions on Correct Use

(1) With this product, input the data for start up wait and start up drive wait. Because the standard data are

set or updated by these wait times, if the start up wait time and start up drive wait time are not input, the

data are not updated.

(2) The start up wait time must be longer than LATCH.

(3) If the rising of the start up drive wait time is the same as the falling of the last output pulse, a count error

occurs, and the IC may malfunction.

(4) Input the initial data in a manner that it does not straddle the video sync signal (VD). If it does, the initial

data is not latched.

(5) Transmit the standard data during the start up wait time (FF1). If it is input at any other time, the data

may

not be transmitted correctly.

(6) If the LGND potential is undefined, the data may not be input correctly. Keep the LGND potential to the

minimum level. It is recommended that LGND and PGND be divided for connection (single ground) to

prevent the leakage of noise from the output circuit.

Data Sheet S15974EJ1V0DS

21

µµµµ

PD16878

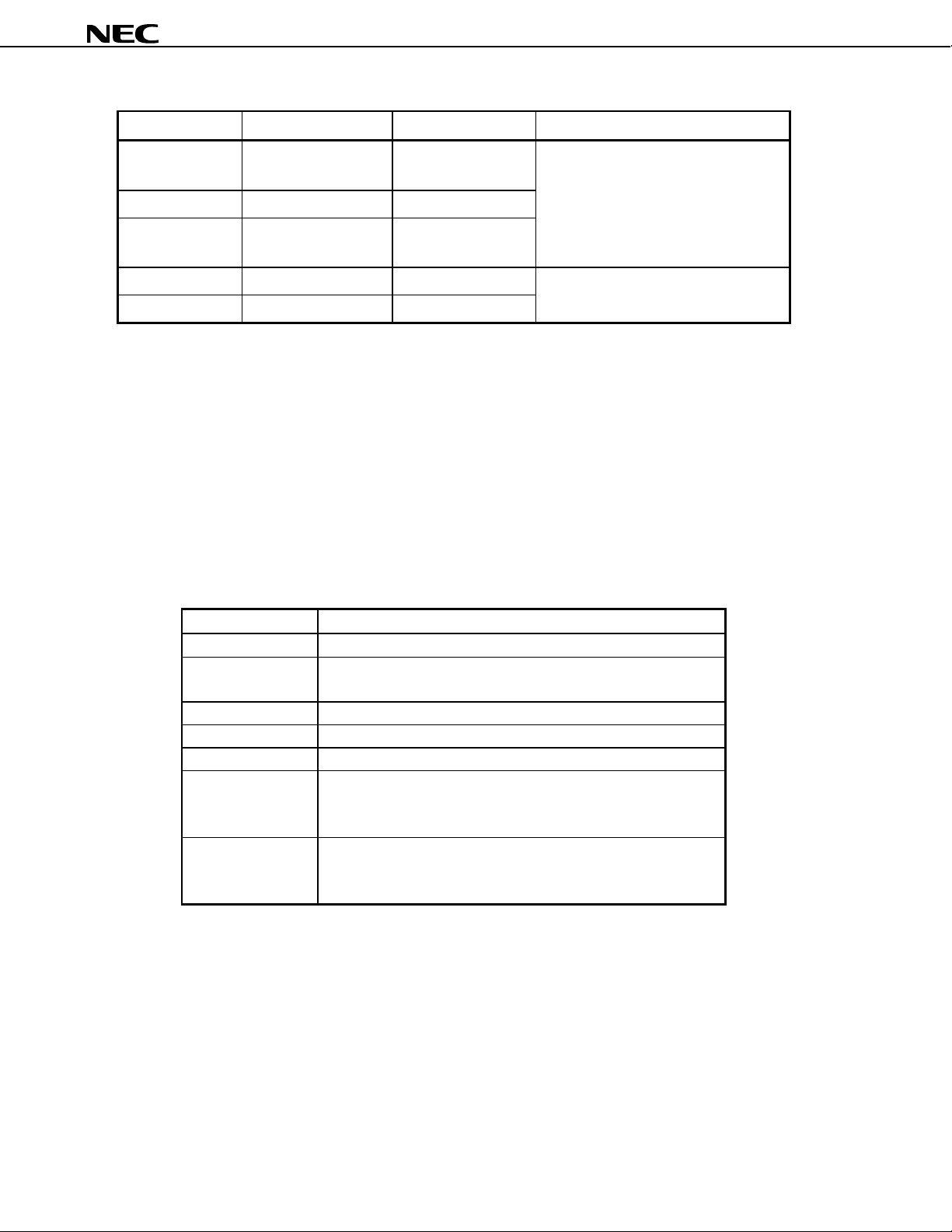

6. ELECTRICAL SPECIFICATIONS

Absolute Maximum Ratings (TA = 25°C)

Parameter Symbol Condition Rating Unit

V

DD

V

M

Input voltage V

Reference voltage V

H bridge drive current

Note 1

Instantaneous H bridge drive

Note 1

current

Power consumption

Note 2

Peak junction temperature T

Storage temperature T

IN

REF

I

M(DC)

I

M(pulse)

P

T

CH(MAX.)

stg

DC ±150 mA/phase

PW ≤ 10 ms, Duty ≤ 5% ±300 mA/phase

Notes 1. Permissible current per phase with the IC mounted on a PCB.

2. When the IC is mounted on a glass epoxy PCB (10 cm x 10 cm x 1 mm).

Caution If the absolute maximum rating of even one of the above parameters is exceeded even

momentarily, the quality of the product may be degraded. Absolute maximum ratings, therefore,

specify the values exceeding which the product may be physically damaged. Be sure to use the

product within the range of the absolute maximum ratings.

–0.5 to +6.0 VSupply voltage

–0.5 to +11.2 V

–0.5 to VDD+ 0.5 V

500 mV

1.0 W

150 °C

–55 to +150 °C

Recommended Operating Range

Parameter Symbol MIN. TYP. MAX. Unit

V

DD

V

M

Input voltage V

Reference voltage V

EXP pin input voltage V

EXP pin input current I

H bridge drive current I

H bridge drive current I

Clock frequency (OSCIN)f

Clock frequency amplitude

Serial clock frequency (SCLK) f

Video sync signal width PW

LATCH signal wait time t

SCLK wait time t

SDATA setup time t

SDATA hold time t

Chopping frequency f

Reset signal pulse width t

Operating temperature T

Peak junction temperature T

IN

REF

EXPIN

EXPIN

M(DC)

Note 1

M(pulse)

Note 2

CLK

Note 2

fCLK

V

SCLK

Note 3

(VD)

(VD-LATCH)

(SCLK-LATCH)

Note 4

setup

Note 4

hold

Note 3

OSC

RST

A

CH(MAX.)

Note 4

Note 4

2.7 5.5 VSupply voltage

4.8 11 V

0V

225 250 275 mV

−100 +100 mA

−200 +200 mA

3.9 4 5.0 MHz

0.7 V

DD

250 ns

400 ns

400 ns

80 ns

80 ns

32 124 kHz

100

−10 +85 °C

Notes 1. PW ≤ 10 ms, duty ≤ 5%

2. COSC

3. f

CLK

= 33 pF, V

= 4 MHz

= 250 mV

REF

4. Serial data delay time(see the figure on the next page.)

+ 0.4 V

DD

V

DD

100

V

DD

5.0 MHz

125 °C

V

A

µ

V

s

µ

22

Data Sheet S15974EJ1V0DS

µµµµ

PD16878

V

D

(VD-LATCH)

t

LATCH

SCLK

t

(SCLK-LATCH)

Ignored because LATCH is at H level. Ignored because LATCH is at H level.

LATCH

SDATA D1 D2 D3

SCLK

50%

50% 50%

t

(SCLK-LATCH)

t

setupthold

64 clocks (8 bits x 8 bytes)

t

(SCLK-LATCH)

Data Sheet S15974EJ1V0DS

23

µµµµ

PD16878

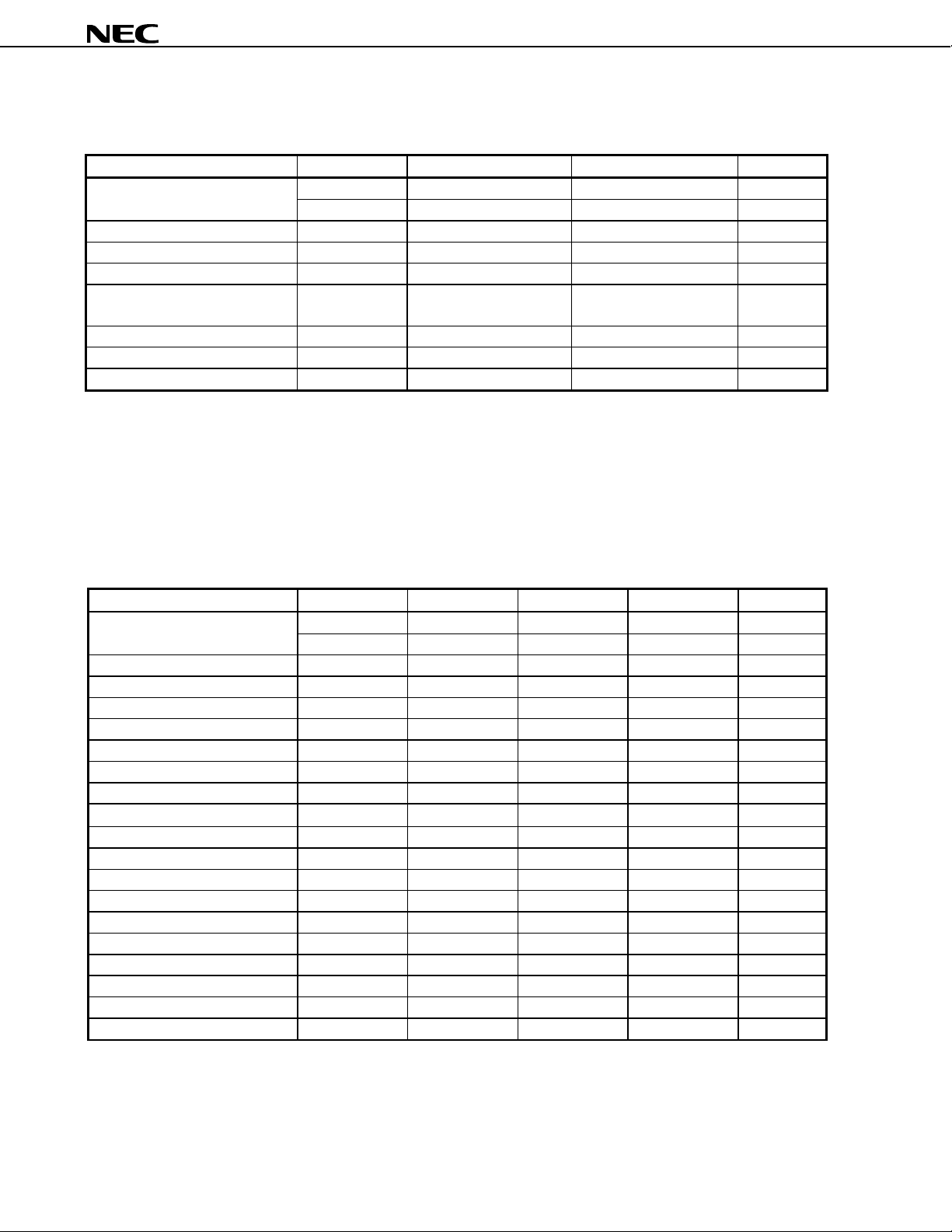

ELECTRICAL CHARACTERISTICS

DC Characteristics (Unless otherwise specified, VDD = 3.3 V, VM = 6.0 V, VREF = 250 mV, TA = 25°C, fCLK = 4 MHz,

COSC = 33 pF, CFIL = 1000 pF, EVR = 100 mV (0000))

Parameter Symbol Condition MIN. TYP. MAX. Unit

Off VM pin current I

V

pin current I

DD

V

pin current I

DD

High level input voltage V

Low level input voltage V

Input hysteresis voltage V

α, β

)

(EXT

(EXP0 to EXP3 : open drain)

High level input current I

Low level input current I

Reset pin high level input

current

Reset pin low level input

current

Input pull down resistor R

H bridge ON resistance

oscillation: C

OSC

Note 1

= 100 pF)

MO(RESET)

DD

DD(RESET)

IH

IL

H

V

OM α (H)

V

OM α (L)

V

OEXP(H)

VOEXP(L)

IH

IL

I

IH(RST)

I

IL(RST)

IND

R

ON

f

OSC(1)

OSC(2)

f

, V

, V

No load, reset period 1.0

Output open

3.0 mA

Reset period 100

LATCH, SCLK, SDATA, VD,

RESET, OSC

IN

0.7 V

DD

0.3 V

DD

A

µ

A

µ

V

V

300 mV

5th byte 0.9 V

OM β (H)

5th byte 0.1 V

OM β (L)

Pull up (VDD)V

I

= 100 µA 0.1 V

OEXP

VIN = V

DD

DD

DD

0.06 mA

VIN = 0 V −1.0

V

= V

RST

DD

V

= 0 −1.0

RST

LATCH, SCLK, SDATA, V

D

50 200 kΩ

1.0

VMonitor output voltage 1

V

DD

VMonitor output voltage 2

V

DD

A

µ

A

µ

A

µ

IM = 100 mA 3.5 5.0 Ω

DATA: 00000 (4th byte) 0Chopping frequency (internal

kHz

DATA: 11111 (4th byte) 100 124 150

Step frequency f

VD delay time

Note 2

Sine wave peak output

Note 3

current

FIL pin voltage

FIL pin step voltage

Note 4

Note 4

STEP

VD

∆t

I

M

V

EVR

V

EVRSTEP

Minimum step 4 kHz

L = 25 mH/R = 100 Ω (1 kHz)

52 mA

EVR = 200 mV (1010)

= 6.8 Ω, f

S

R

OSC

= 64 kHz

EVR = 200 mV (1010) 370 400 430 mV

Minimum step 20 mV

AC Characteristics (Unless otherwise specified, VDD = 3.3 V, VM = 6.0 V, TA = 25°C, fCLK = 4 MHz)

Parameter Symbol Condition MIN. TYP. MAX. Unit

H bridge output circuit turn on

t

ONH

IM = 100 mA

Note 5

1.0 2.0

time

H bridge output circuit turn off

t

OFFH

IM = 100 mA

Note 5

1.0 2.0

time

Notes 1. Total of ON resistance at top and bottom of output H bridge

2. By OSCIN

and VD sync circuit

3. FB pin is monitored.

4. FIL pin is monitored. A voltage about twice that of the EVR value is output to the FIL pin.

5. 10 to 90% of the pulse peak value without filter capacitor (C

FIL

)

250 ns

s

µ

s

µ

24

Data Sheet S15974EJ1V0DS

TIMING CHART (1)

5

S

Standard

EXP : 0

ENABLE: 1

Standard

4

S

EXP : 1

ENABLE: 0

Output by S5

data setting

4DATA output

S

µµµµ

PD16878

Restore to high level because

data is normal.

Initialization

EXP : 1

error DATA

Standard

3

S

EXP : 1

ENABLE: 1

Standard

2

S

1

S

Standard

Dummy data

1

I

Initial

ENABLE: 0

EXP: 1 EXP : 0

Output by

Output by

Input at rising

I1 data

I1 data

edge of RESET

Output by S2

data setting

Output by chopping

setting of I1 data

Pulse error Enable

Output by EXP

setting of S2DATA

2DATA output

S

Output by EXP

setting of S1 data

Output by EXP

setting of I1 data

to high, and at the falling edge of FF2 when the level changes from high

to low.

No pulse output because

data is erroneous

Notes 1. ENABLE is set at the falling edge of FF1 when the level changes from low

Low level because

data is abnormal.

Outputs high level while

pulse is being generated

High level because

data is normal.

Outputs high level for standard data while a

pulse output signal exists (LATCH cycle)

of a pulse in the standard data, is updated at the rising edge of LATCH

and reset once at the falling edge of LATCH. If CHECK SUM is other than

“00H”, FF7 goes low, inhibiting pulse output, even if a pulse is generated.

2. FF7 is an output signal that is used to check for the presence or absence

D0 D7D6D5D4D3D2D1

(LSB)

3. CHECK SUM output is updated at the rising edge of LATCH.

RESET

D

V

LATCH

DATA

OUT

OSC

(FF1)

Start point wait

(original oscillation)

Start point wait +

Note 1

(FF2)

EXP0 to EXP3

Chopping pulse

ENABLE OUT

start point drive wait

Data Sheet S15974EJ1V0DS

(FF3)

PULSE OUT

PULSE GATE

Note 3

Note 2

(FF7)

CHECK SUM

PULSE CHECK

SCLK

Data is held at rising edge of SCLK.

SDATA

1st byte 8th byte

25

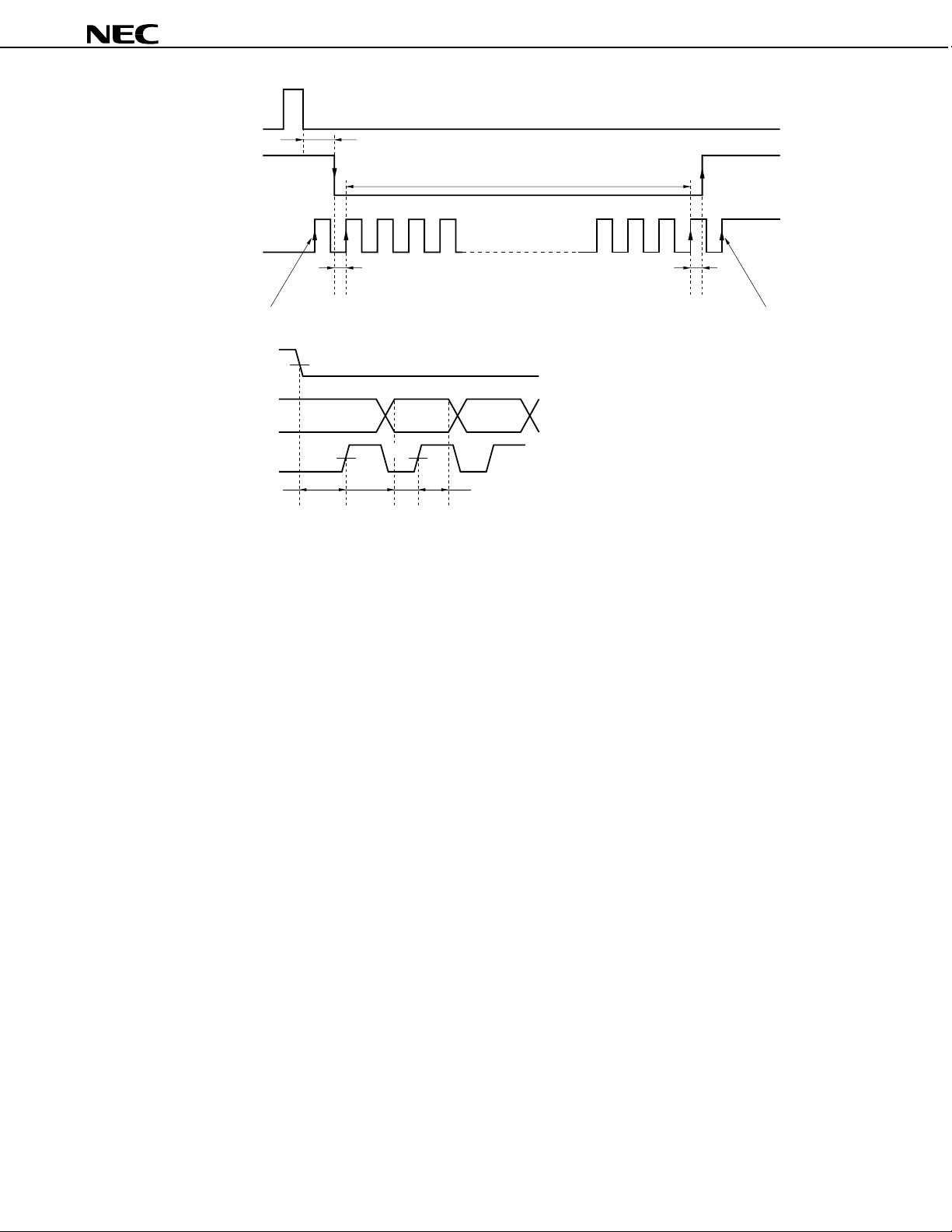

TIMING CHART (2)

CLK

(PULSE OUT)

MOB

(CW mode)

µµµµ

PD16878

H bridge ,

1ch output status

2ch output status

α β

α β

H bridge ,

PULSE OUT

Position No. 1 2 3

H bridge

1ch output status

Current direction: A1 A2

Current direction: B2 B1

(Expanded view)

CW mode CCW mode CW mode

CLK

CW

Note1

4565

CCW

CW

Current direction: B1 B2

4323

4

CCW

CW

Current direction: A2 A1

Current direction: B2 B1

Note1Note2

CW

H bridge

2ch output status

CW

CCW

CW

CCW

Notes1. : Position No. is incremented.

In CW mode

2.

In CCW mode

: Position No. is decremented.

Remarks 1. The current value of the actual wave is approximated to the value shown on the next page.

2. The C1

, C2, D1, and D2 pins of β channel correspond to the A1, A2, B1, and B2 pins of α channel.

3. The CW mode is set if the D7 bit of the 2nd and 5th bytes of the standard data is “0”.

4. The CCW mode is set if the D7 bit of the 2nd and 5th bytes of the standard data is “1”.

26

Data Sheet S15974EJ1V0DS

RELATION BETWEEN ROTATION ANGLE, PHASE CURRENT, AND VECTOR QUANTITY

(64-DIVISION MICRO STEP)

µµµµ

PD16878

(Values of

00− 0 −−100 − 100

θ

1 5.6 2.5 9.8 17.0 − 100 − 100.48

θ

2 11.3 12.4 19.5 26.5 93.2 98.1 103 100

θ

3 16.9 22.1 29.1 36.1 90.7 95.7 100.7 100.02

θ

4 22.5 31.3 38.3 45.3 87.4 92.4 97.4 100.02

θ

5 28.1 40.1 47.1 54.1 83.2 88.2 93.2 99.99

θ

6 33.8 48.6 55.6 62.6 78.1 83.1 88.1 99.98

θ

7 39.4 58.4 63.4 68.4 72.3 77.3 82.3 99.97

θ

8 45 65.7 70.7 75.7 65.7 70.7 75.7 99.98

θ

9 50.6 72.3 77.3 82.3 58.4 63.4 68.4 99.97

θ

10 56.3 78.1 83.1 88.1 48.6 55.6 62.6 99.98

θ

11 61.9 83.2 88.2 93.2 40.1 47.1 54.1 99.99

θ

12 67.5 87.4 92.4 97.4 31.3 38.3 45.3 100.02

θ

13 73.1 90.7 95.7 100.7 22.1 29.1 36.1 100.02

θ

14 78.8 93.2 98.1 103 12.4 19.5 26.5 100

θ

15 84.4 − 100 − 2.5 9.8 17.0 100.48

θ

16 90 − 100 −−0 − 100

θ

µµµµ

PD16878 for reference)

Step Rotation angle (

θ

) A phase current B phase current Vector quantity

MIN. TYP. MAX. MIN. TYP. MAX. TYP.

Remark These data do not indicate guaranteed values.

Data Sheet S15974EJ1V0DS

27

7. PACKAGE DRAWING

38-PIN PLASTIC SSOP (7.62 mm (300))

38 20

detail of lead end

F

G

µµµµ

PD16878

119

A

P

E

H

I

S

C

D

M

M

N

S

NOTE

Each lead centerline is located within 0.10 mm of

its true position (T.P.) at maximum material condition.

B

K

L

ITEM

MILLIMETERS

A

B

C

D

E

F

G

H

I

J

K

L

M

N

P

P38GS-65-BGG-1

J

12.7±0.3

0.65 MAX.

0.65 (T.P.)

+0.05

0.37

−0.1

0.125±0.075

1.675±0.125

1.55

7.7±0.2

5.6±0.2

1.05±0.2

+0.1

0.2

−0.05

0.6±0.2

0.10

0.10

+7°

3°

−3°

28

Data Sheet S15974EJ1V0DS

µµµµ

PD16878

8. RECOMMENDED SOLDERING CONDITIONS

When soldering this product, it is highly recommended to observe the conditions as shown below. If other

soldering processes are used, or if the soldering is performed under different conditions, please make sure to consult

with our sales offices.

For more details, refer to our document “SEMICONDUCTOR DEVICE MOUNTING TECHNOLOGY MANUAL”

(C10535E).

Type of Surface Mount Device

µµµµ

PD16878GS-BGG: 38-pin plastic shrink SOP (7.62 mm (300))

Process Soldering conditions Symbol

Infrared Ray Reflow Peak temperature: 235°C or below (Package surface temperature),

Reflow time: 30 seconds or less (at 210°C or higher),

Maximum number of reflow processes: 3 time or less,

Number of days: None

Flux: Rosin-based flux with low chlorine content (chlorine 0.2 Wt% or below) is

recommended.

Note

,

IR35-00-3

Vapor Phase Soldering Peak temperature: 215°C or below (Package surface temperature),

Reflow time: 40 seconds or less (at 200°C or higher),

Maximum number of reflow processes: 3 time or less,

Number of days: None

Flux: Rosin-based flux with low chlorine content (chlorine 0.2 Wt% or below) is

recommended.

Wave Soldering Solder temperature: 260°C or below, Flow time: 10 seconds or less,

Maximum number of flow processes: 1 time,

Pre-heating temperature: 120°C or below (Package surface temperature),

Flux: Rosin-based flux with low chlorine content (chlorine 0.2 Wt% or below) is

recommended.

Partial Heating Method Pin temperature: 300°C or below,

Heat time: 3 seconds or less (Per each side of the device).

Note

,

VP15-00-3

WS60-00-1

−

Note Number of days the device can be stored after the dry pack has been opened, at conditions of 25°C, 65%RH.

Caution Apply only one kind of soldering condition to a device, except for “partial heating method”, or the

device will be damaged by heat stress.

Data Sheet S15974EJ1V0DS

29

[MEMO]

µµµµ

PD16878

30

Data Sheet S15974EJ1V0DS

NOTES FOR CMOS DEVICES

1 PRECAUTION AGAINST ESD FOR SEMICONDUCTORS

Note:

Strong electric field, when exposed to a MOS device, can cause destruction of the gate oxide and

ultimately degrade the device operation. Steps must be taken to stop generation of static electricity

as much as possible, and quickly dissipate it once, when it has occurred. Environmental control

must be adequate. When it is dry, humidifier should be used. It is recommended to avoid using

insulators that easily build static electricity. Semiconductor devices must be stored and transported

in an anti-static container, static shielding bag or conductive material. All test and measurement

tools including work bench and floor should be grounded. The operator should be grounded using

wrist strap. Semiconductor devices must not be touched with bare hands. Similar precautions need

to be taken for PW boards with semiconductor devices on it.

2 HANDLING OF UNUSED INPUT PINS FOR CMOS

Note:

No connection for CMOS device inputs can be cause of malfunction. If no connection is provided

to the input pins, it is possible that an internal input level may be generated due to noise, etc., hence

causing malfunction. CMOS devices behave differently than Bipolar or NMOS devices. Input levels

of CMOS devices must be fixed high or low by using a pull-up or pull-down circuitry. Each unused

DD

pin should be connected to V

being an output pin. All handling related to the unused pins must be judged device by device and

related specifications governing the devices.

or GND with a resistor, if it is considered to have a possibility of

µµµµ

PD16878

3 STATUS BEFORE INITIALIZATION OF MOS DEVICES

Note:

Power-on does not necessarily define initial status of MOS device. Production process of MOS

does not define the initial operation status of the device. Immediately after the power source is

turned ON, the devices with reset function have not yet been initialized. Hence, power-on does

not guarantee out-pin levels, I/O settings or contents of registers. Device is not initialized until the

reset signal is received. Reset operation must be executed immediately after power-on for devices

having reset function.

Data Sheet S15974EJ1V0DS

31

µµµµ

PD16878

•

The information in this document is current as of January, 2002. The information is subject to

change without notice. For actual design-in, refer to the latest publications of NEC's data sheets or

data books, etc., for the most up-to-date specifications of NEC semiconductor products. Not all

products and/or types are available in every country. Please check with an NEC sales representative

for availability and additional information.

•

No part of this document may be copied or reproduced in any form or by any means without prior

written consent of NEC. NEC assumes no responsibility for any errors that may appear in this document.

•

NEC does not assume any liability for infringement of patents, copyrights or other intellectual property rights of

third parties by or arising from the use of NEC semiconductor products listed in this document or any other

liability arising from the use of such products. No license, express, implied or otherwise, is granted under any

patents, copyrights or other intellectual property rights of NEC or others.

•

Descriptions of circuits, software and other related information in this document are provided for illustrative

purposes in semiconductor product operation and application examples. The incorporation of these

circuits, software and information in the design of customer's equipment shall be done under the full

responsibility of customer. NEC assumes no responsibility for any losses incurred by customers or third

parties arising from the use of these circuits, software and information.

•

While NEC endeavours to enhance the quality, reliability and safety of NEC semiconductor products, customers

agree and acknowledge that the possibility of defects thereof cannot be eliminated entirely. To minimize

risks of damage to property or injury (including death) to persons arising from defects in NEC

semiconductor products, customers must incorporate sufficient safety measures in their design, such as

redundancy, fire-containment, and anti-failure features.

•

NEC semiconductor products are classified into the following three quality grades:

"Standard", "Special" and "Specific". The "Specific" quality grade applies only to semiconductor products

developed based on a customer-designated "quality assurance program" for a specific application. The

recommended applications of a semiconductor product depend on its quality grade, as indicated below.

Customers must check the quality grade of each semiconductor product before using it in a particular

application.

"Standard": Computers, office equipment, communications equipment, test and measurement equipment, audio

and visual equipment, home electronic appliances, machine tools, personal electronic equipment

and industrial robots

"Special": Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

"Specific": Aircraft, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems and medical equipment for life support, etc.

The quality grade of NEC semiconductor products is "Standard" unless otherwise expressly specified in NEC's

data sheets or data books, etc. If customers wish to use NEC semiconductor products in applications not

intended by NEC, they must contact an NEC sales representative in advance to determine NEC's willingness

to support a given application.

(Note)

(1) "NEC" as used in this statement means NEC Corporation and also includes its majority-owned subsidiaries.

(2) "NEC semiconductor products" means any semiconductor product developed or manufactured by or for

NEC (as defined above).

M8E 00. 4

Loading...

Loading...