NEC QX-S5500G, QX-S5524GT-4X1C, QX-S5524GP-4X1C, QX-S5524GT-4X2Q, QX-S5548GT-4X2Q Installation Manual

...Page 1

GVT-048974-001-00 1.1

QX-S5500G Series Ethernet Switches

Installation Guide

Page 2

Revision History

Revision Date Reason for Change

1.0 2017/10

1.1 2017/10/31

First Revision

・A writing error of the weight of "Chapter 9 Appendix A Technical specifications" was

corrected.

・Writing error correction

Page 3

Copyright © NEC Corporation 2017

All Rights Reserved

No part of this manual may be reproduced or transmitted in any form or by any

means without prior written consent of NEC Corporation.

Trademarks

All other trademarks that may be mentioned in this manual are the property of their

respective owners.

Notice

The information in this document is subject to change without notice. Every effort

has been made in the preparation of this document to ensure accuracy of the

contents, but all statements, information, and recommendations in this document do

not constitute the warranty of any kind, express or implied.

Page 4

Preface

Version

This command reference corresponds after software version 7.1.X.

Documentation Set

The Documentation Set of QX-S5500G Series Ethernet Switches includes the

following documentations.

Documentation Set Description

Sections

QX-S5500G Series Ethernet Switches

Installation Guide

QX-S5500G Series Ethernet Switches

Configuration Guides

QX-S5500G Series Ethernet Switches

Command References

This documentation describes installation.

This documentation describes configuration.

This documentation describes commands.

This installation guide includes the following sections.

Product overview

The Product overview describes commands for QX-S5500G Series panel views.

Preparing for installation

The Preparing for installation describes commands for Safety recommendations,

Examining the installation site, Temperature/humidity, etc.

Installing the switch

The Installing the switch describes commands for Installing, Mounting, Grounding,

etc.

Accessing the switch for the first time

The Accessing the switch for the first time describes commands for Setting up the

configuration environment, Connecting, etc.

Setting up an IRF fabric

The Setting up an IRF fabric describes commands for IRF fabric setup flowchart,

Planning and Connecting IRF fabric, etc.

Page 5

Upgrading software

The Upgrading software describes the type of the software used by the switch,

during movement or upgrade method when normally not starting.

Maintenance and troubleshooting

The Maintenance and troubleshooting describes commands for Power module

failure, Fan failure, etc.

Appendix A Technical specifications

The Appendix A Technical specification describes commands for Technical

specifications.

Appendix B FRUs and compatibility matrixes

The Appendix B FRUs and compatibility matrixes describe commands for Hot

swappable power modules, Hot swappable fan trays.

Appendix C Ports and LEDs

The Appendix C Ports and LEDs describe commands for Ports, UTP cables, LEDs,

etc.

Appendix D Cooling system

Conventions

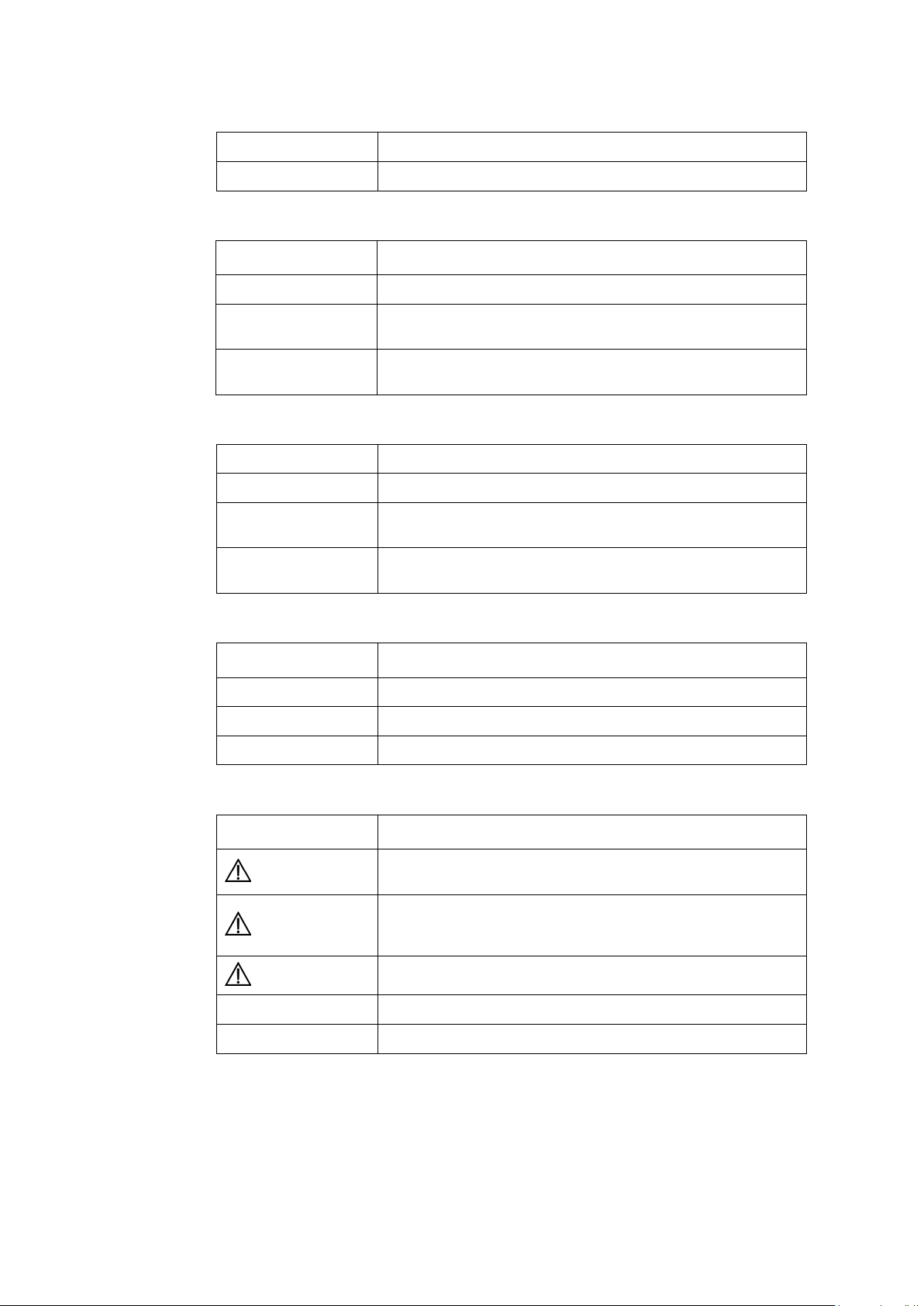

I. Command conventions

The Appendix D Cooling system describes commands for QX-S5500G Series

cooling system.

This section describes the conventions used in this documentation set.

Convention Description

Boldface Bold text represents commands and keywords that you enter literally as shown.

Italic Italic text represents arguments that you replace with actual values.

[ ]

{ x | y | ... }

[ x | y | ... ]

Square brackets enclose syntax choices (keywords or arguments) that are

optional.

Braces enclose a set of required syntax choices separated by vertical bars, from

which you select one.

Square brackets enclose a set of optional syntax choices separated by vertical

bars, from which you select one or none.

{ x | y | ... } *

[ x | y | ... ] *

&<1-n>

Asterisk marked braces enclose a set of required syntax choices separated by

vertical bars, from which you select at least one.

Asterisk marked square brackets enclose optional syntax choices separated by

vertical bars, from which you select one choice, multiple choices, or none.

The argument or keyword and argument combination before the ampersand (&)

sign can be entered 1 to n times.

Page 6

Convention Description

# A line that starts with a pound (#) sign is comments.

II. GUI conventions

Convention Description

< > Button names are inside angle brackets. For example, click <OK>.

[ ]

/

Window names, menu items, data table and field names are inside square

brackets. For example, pop up the [New User] window.

Multi-level menus are separated by forward slashes. For example,

[File/Create/Folder].

III. Keyboard Operations

Convention Description

<KEY> Push the KEY of keyboard. For example, <Enter> is push the Enter key.

<KEY1 + KEY2>

<KEY1, KEY2>

Push some KEYs of keyboard. For example, <Ctrl+Alt+A> is push the Ctrl key, the

Alt key and the A key at the same time.

Push in turn some KEYs of keyboard. For example, <Alt,A> is push the Alt key

then push the A key.

IV. Mouse Operations

Convention Description

Click Push the button of the mouse one time quickly. Usually, push the left button.

Double Click Push the left button of the mouse two times quickly.

Drag Move the mouse while holding down the left button of the mouse.

V. Symbols

Convention Description

WARNING

CAUTION

IMPORTANT

NOTE An alert that contains additional or supplementary information.

TIP An alert that provides helpful information.

An alert that calls attention to important information that if not understood or

followed can result in personal injury.

An alert that calls attention to important information that if not understood or

followed can result in data loss, data corruption, or damage to hardware or

software.

An alert that calls attention to essential information.

VI. Configuration Example

The configuration example of the command reference is an example. Interface

Number or the information of the display command, etc. may differ from your device.

Page 7

This installation guide includes 11 sections.

01 - Product overview

02 - Preparing for installation

03 - Installing the switch

04 - Accessing the switch for the first time

05 - Setting up an IRF fabric

06 - Upgrading software

07 - Maintenance and troubleshooting

08 - Appendix A Technical specifications

09 - Appendix B FRUs and compatibility matrixes

10 - Appendix C Ports and LEDs

11 - Appendix D Cooling system

Page 8

Installation Guide

QX-S5500G Series Ethernet Switches

Contents

Contents

1. Product overview ....................................................................................................................... 1-1

1.1 QX-S5524GT-4X2Q panel views ....................................................................................... 1-1

1.2 QX-S5548GT-4X2Q panel views ....................................................................................... 1-2

1.3 QX-S5524GT-4X1C panel views ....................................................................................... 1-3

1.4 QX-S5548GT-4X1C panel views ....................................................................................... 1-4

1.5 QX-S5524GP-4X1C panel views ....................................................................................... 1-5

i

Page 9

Installation Guide

QX-S5500G Series Ethernet Switches

1. Product overview

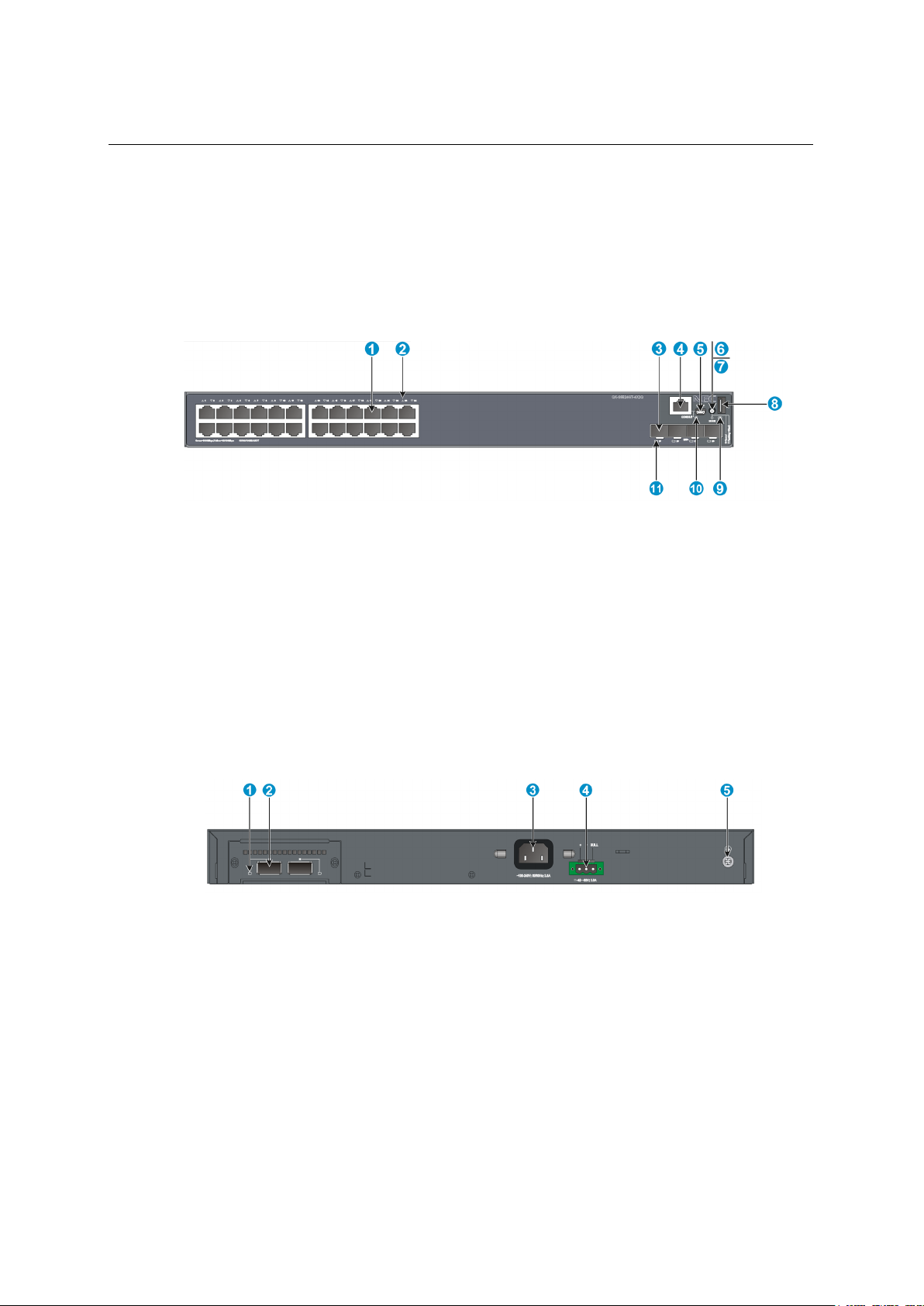

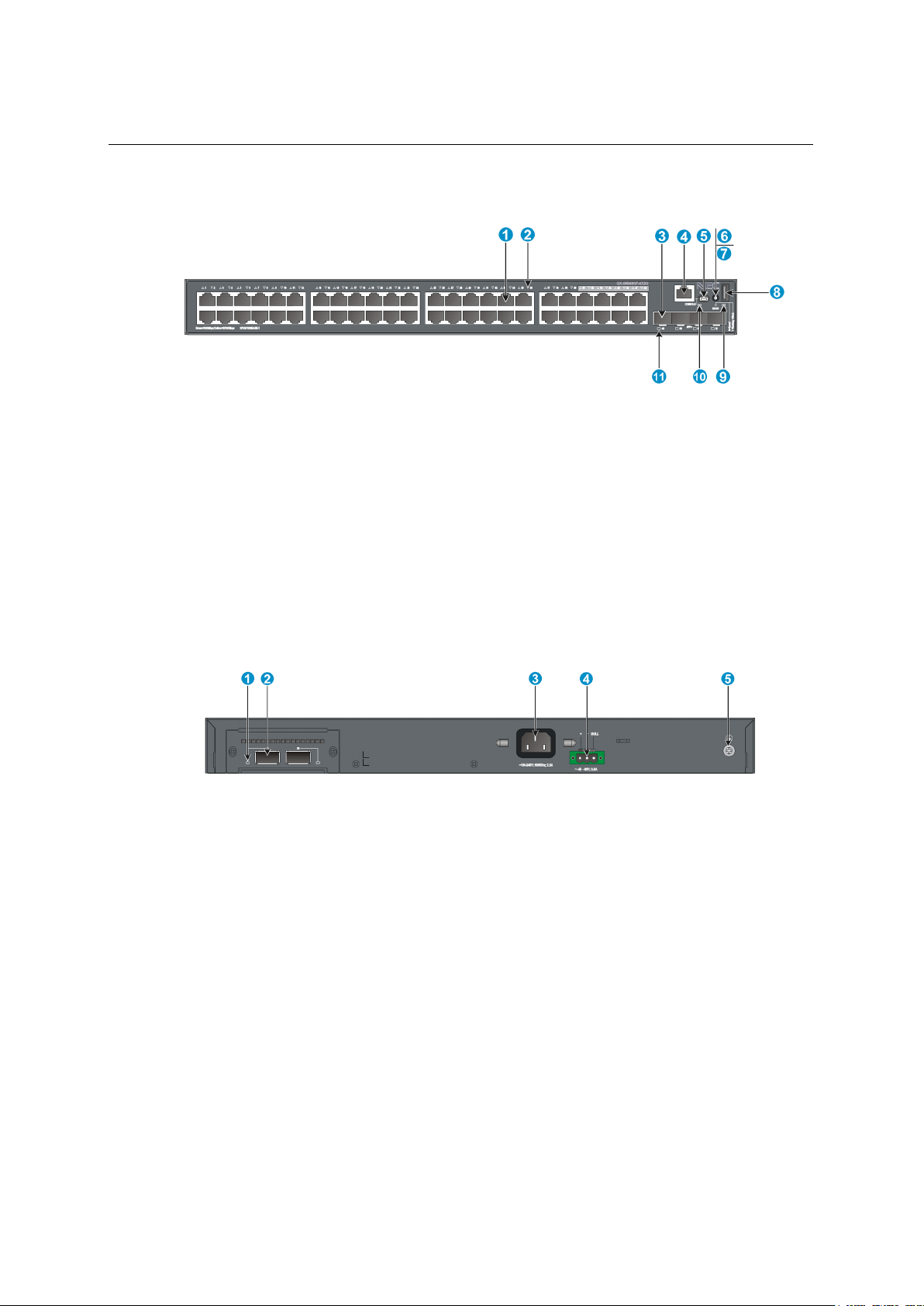

(1) 10/100/1000 BASE-T autosensing Ethernet port

(2) 10/100/1000 BASE-T autosensing Ethernet port LED

(3) SFP+ port

(4) Console port

(5) USB mini Console port

(6) Port LED mode switching button

(7) Port mode LED

(8) USB port

(9) System status LED (SYS)

(10) RPS status LED (RPS)

(11) SFP+ port LED

(1) QSFP+ port LED

(2) QSFP+ port

(3) AC-input power receptacle

(4) RPS receptacle

(5) Grounding screw

1. Product overview

1.1 QX-S5524GT-4X2Q panel views

Figure 1-1 QX-S5524GT-4X2Q front panel

Figure 1-2 QX-S5524GT-4X2Q rear panel

1-1

Page 10

Installation Guide

QX-S5500G Series Ethernet Switches

1. Product overview

(1) 10/100/1000 BASE-T autosensing Ethernet port

(2) 10/100/1000 BASE-T autosensing Ethernet port LED

(3) SFP+ port

(4) Console port

(5) USB mini Console port

(6) Port LED mode switching button

(7) Port mode LED

(8) USB port

(9) System status LED (SYS)

(10) RPS status LED (RPS)

(11) SFP+ port LED

(1) QSFP+ port LED

(2) QSFP+ port

(3) AC-input power receptacle

(4) RPS receptacle

(5) Grounding screw

1.2 QX-S5548GT-4X2Q panel views

Figure 1-3 QX-S5548GT-4X2Q front panel

Figure 1-4 QX-S5548GT-4X2Q rear panel

1-2

Page 11

Installation Guide

QX-S5500G Series Ethernet Switches

1. Product overview

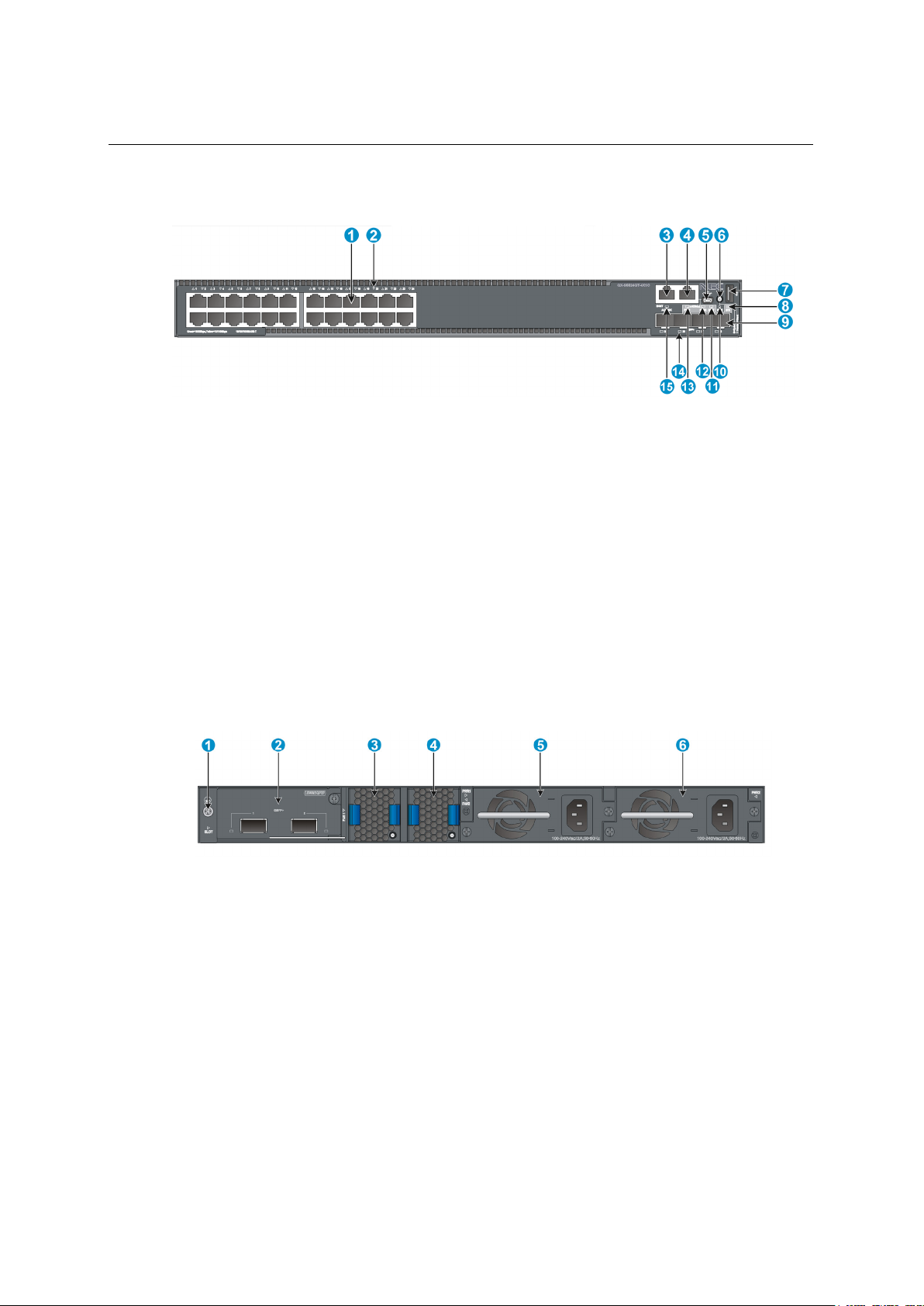

(1) 10/100/1000 BASE-T autosensing Ethernet port

(2) 10/100/1000 BASE-T autosensing Ethernet port LED

(3) Management Ethernet port

(4) Console port

(5) USB mini Console port

(6) Port LED mode switching button

(7) USB port

(8) System status LED (SYS)

(9) SFP+ port

(10) Port mode LED

(11) Interface card status LED (SLOT)

(12) Power module 2 status LED (PWR2)

(13) Power module 1 status LED (PWR1)

(14) SFP+ port LED

(15) Management Ethernet port LED

(1) Grounding screw

(2) Interface card slot

(3) Fan tray slot1

(4) Fan tray slot2

(5) Power module slot1

(6)Power module slot2

1.3 QX-S5524GT-4X1C panel views

Figure 1-5 QX-S5524GT-4X1C front panel

Figure 1-6 QX-S5524GT-4X1C rear panel

The QX-S5524GT-4X1C switch comes with power module slot 1 empty and power module

slot 2 installed with a filler panel. You can install one or two power modules for the switch as

required. In this figure, two PSR150-A1 AC power modules are installed in the power

module slots. For more information about installing and removing a power module, see

1-3

Page 12

Installation Guide

QX-S5500G Series Ethernet Switches

1. Product overview

(1) 10/100/1000 BASE-T autosensing Ethernet port

(2) 10/100/1000 BASE-T autosensing Ethernet port LED

(3) Management Ethernet port

(4) Console port

(5) USB mini Console port

(6) Port LED mode switching button

(7) USB port

(8) System status LED (SYS)

(9) SFP+ port

(10) Port mode LED

(11) Interface card status LED (SLOT)

(12) Power module 2 status LED (PWR2)

(13) Power module 1 status LED (PWR1)

(14) SFP+ port LED

(15) Management Ethernet port LED

"Installing/removing a power module."

The QX-S5524GT-4X1C switch comes with the two fan tray slots empty. You must install

two fan trays of the same model for the switch. In this figure, two LSPM5FANSA fan trays

are installed in the fan tray slots. For more information about installing and removing a fan

tray, see "Installing/removing a fan tray."

The QX-S5524GT-4X1C switch comes with a filler panel in the interface card slot. You can

select an interface card for the switch as required. In this figure, an LSWM5QP2P interface

card is installed in the interface card slot. For more information about installing and

removing an interface card, see "Installing/removing an interface card."

1.4 QX-S5548GT-4X1C panel views

Figure 1-7 QX-S5548GT-4X1C front panel

1-4

Page 13

Installation Guide

QX-S5500G Series Ethernet Switches

1. Product overview

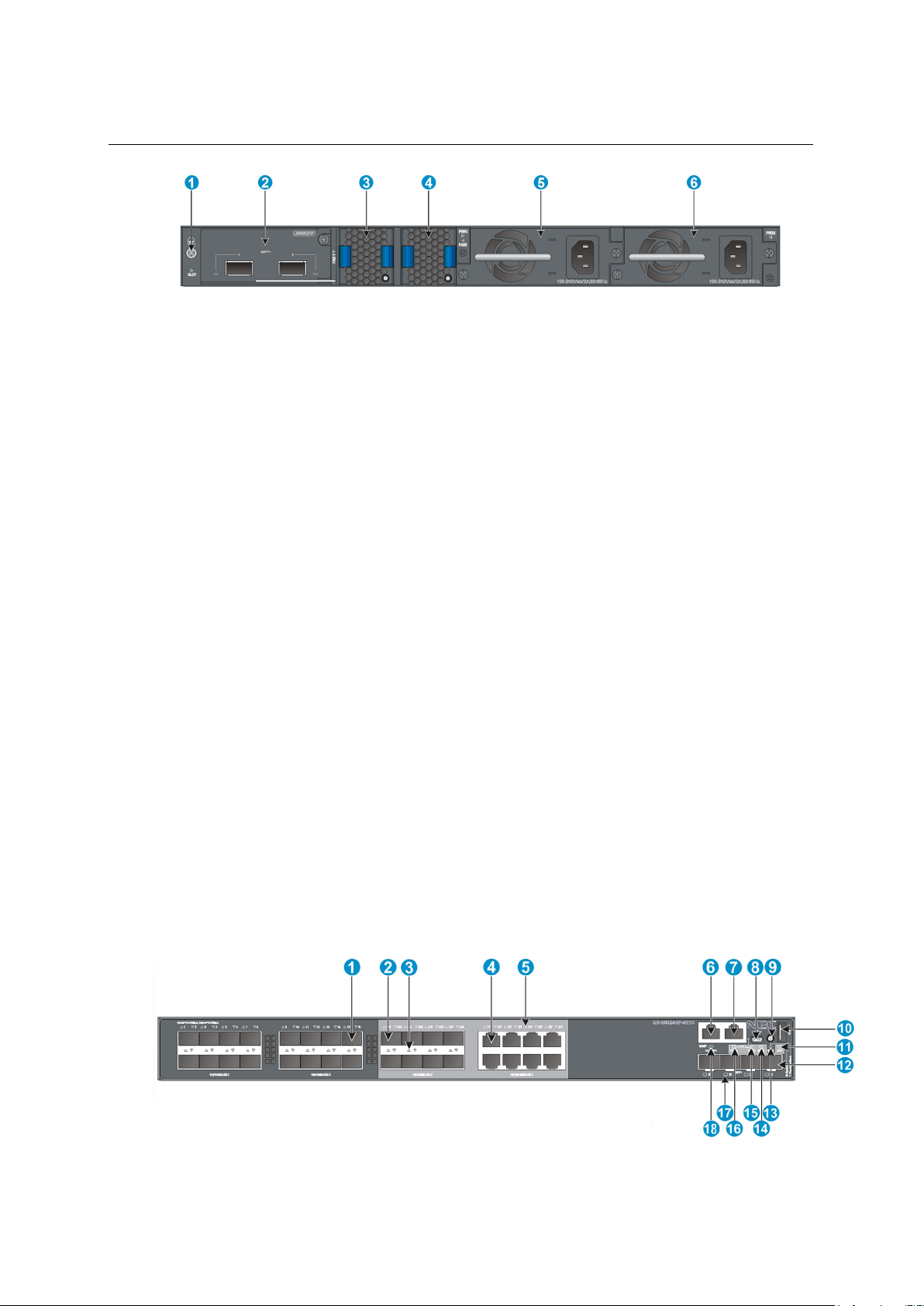

(1) Grounding screw

(2) Interface card slot

(3) Fan tray slot1

(4) Fan tray slot2

(5) Power module slot1

(6) Power module slot2

The QX-S5548GT-4X1C switch comes with power module slot 1 empty and power module

slot 2 installed with a filler panel. You can install one or two power modules for the switch as

required. In this figure, two PSR150-A1 AC power modules are installed in the power

module slots. For more information about installing and removing a power module, see

Figure 1-8 QX-S5548GT-4X1C rear panel

"Installing/removing a power module."

The QX-S5548GT-4X1C switch comes with the two fan tray slots empty. You must install

two fan trays of the same model for the switch. In this figure, two LSPM5FANSA fan trays

are installed in the fan tray slots. For more information about installing and removing a fan

tray, see "Installing/removing a fan tray."

The QX-S5548GT-4X1C switch comes with a filler panel in the interface card slot. You can

select an interface card for the switch as required. In this figure, an LSWM5QP2P interface

card is installed in the interface card slot. For more information about installing and

removing an interface card, see "Installing/removing an interface card."

1.5 QX-S5524GP-4X1C panel views

Figure 1-9 QX-S5524GP-4X1C front panel

1-5

Page 14

Installation Guide

QX-S5500G Series Ethernet Switches

1. Product overview

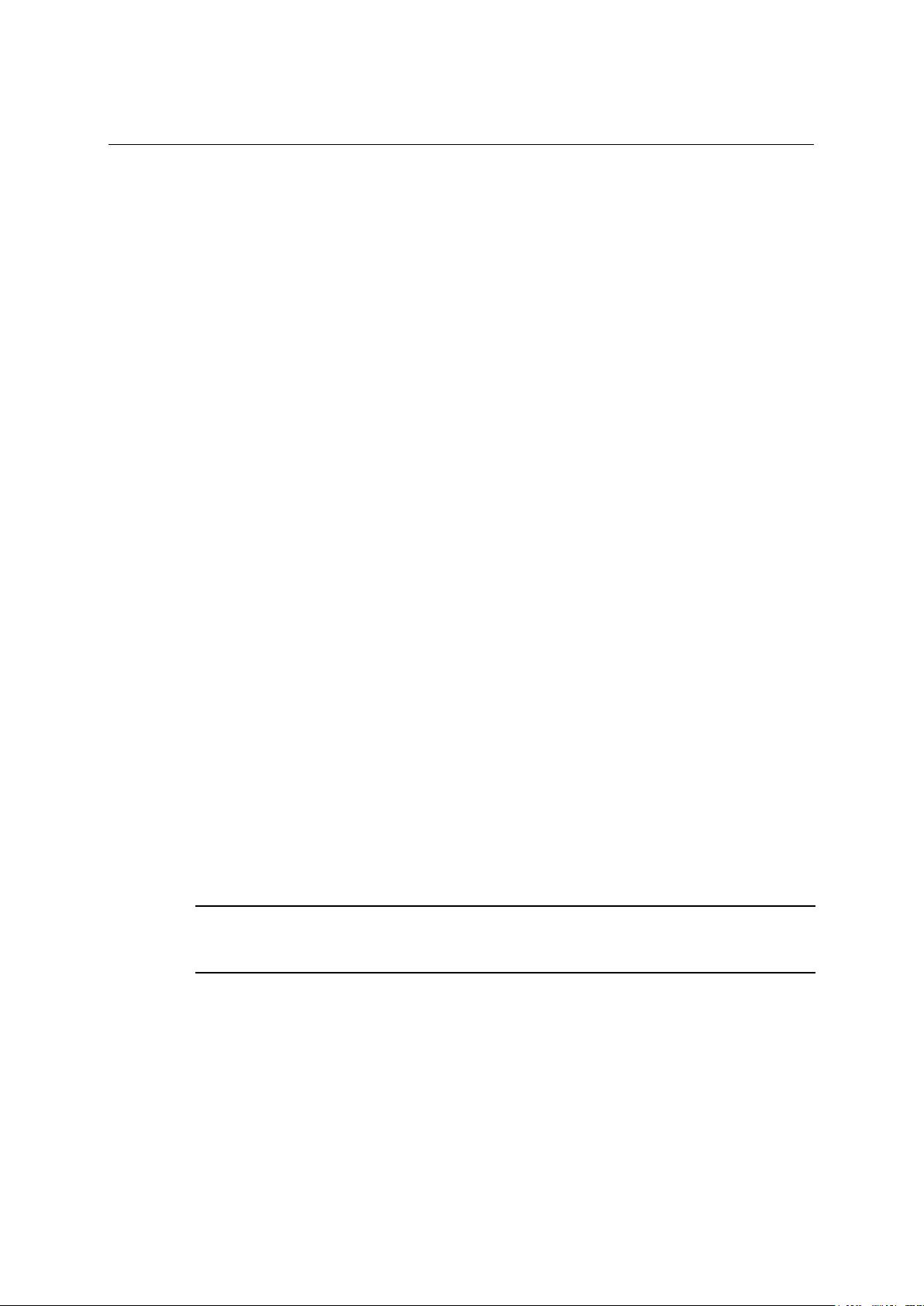

(1) SFP port

(2) SFP port (Combo port, port 17S to 24S)

(Combo port, port 17T to 24T)

(5) 10/100/1000 BASE-T autosensing Ethernet port LED

(6) Management Ethernet port

(7) Console port

(8) USB mini Console port

(9) Port LED mode switching button

(10) USB port

(11) System status LED (SYS)

(12) SFP+ port

(13) Port mode LED

(14) Interface card status LED (SLOT)

(15) Power module 2 status LED (PWR2)

(16) Power module 1 status LED (PWR1)

(17) SFP+ port LED

(18) Management Ethernet port LED

(1) Grounding screw

(2) Interface card slot

(3) Fan tray slot1

(4) Fan tray slot2

(5) Power module slot1

(6) Power module slot2

(3) SFP port LED (4) 10/100/1000 BASE-T autosensing Ethernet port

Figure 1-10 QX-S5524GP-4X1C rear panel

The QX-S5524GP-4X1C switch comes with power module slot 1 empty and power module

slot 2 installed with a filler panel. You can install one or two power modules for the switch as

required. In this figure, two PSR150-A1 AC power modules are installed in the power

module slots. For more information about installing and removing a power module, see

"Installing/removing a power module."

The QX-S5524GP-4X1C switch comes with the two fan tray slots empty. You must install

two fan trays of the same model for the switch. In this figure, two LSPM5FANSA fan trays

are installed in the fan tray slots. For more information about installing and removing a fan

tray, see "Installing/removing a fan tray."

The QX-S5524GP-4X1C switch comes with a filler panel in the interface card slot. You can

select an interface card for the switch as required. In this figure, an LSWM5QP2P interface

card is installed in the interface card slot. For more information about installing and

1-6

Page 15

Installation Guide

QX-S5500G Series Ethernet Switches

1. Product overview

removing an interface card, see "Installing/removing an interface card."

1-7

Page 16

Installation Guide

QX-S5500G Series Ethernet Switches

Contents

Contents

2. Preparing for installation .......................................................................................................... 2-1

2.1 Safety recommendations ................................................................................................... 2-1

2.2 Connecting the RJ45 connector ........................................................................................ 2-1

2.3 Examining the installation site ........................................................................................... 2-2

2.3.1 Temperature/humidity ............................................................................................. 2-2

2.3.2 Cleanness ............................................................................................................... 2-3

2.3.3 EMI .......................................................................................................................... 2-3

2.3.4 Laser safety ............................................................................................................. 2-3

2.4 Installation tools ................................................................................................................. 2-4

i

Page 17

Installation Guide

QX-S5500G Series Ethernet Switches

Preparing for installation

2. Preparing for installation

2.1 Safety recommendations

To avoid any equipment damage or bodily injury caused by improper use, read the

following safety recommendations before installation. Note that the recommendations do

not cover every possible hazardous condition.

Regarding with installation and maintenance of this product, please make the engineer who

acquired a right operating method to do that.

Remove dust on and around the Switch regularly.

Before cleaning the switch, unplug all power cords from the switch. Do not clean the

switch with wet cloth or liquid.

Before moving the Switch, unplug all power cords from the switch.

Do not place the switch near water or in a damp environment. Prevent water or

moisture from entering the switch chassis.

Do not place the switch on an unstable case or desk. The switch might be severely

damaged in case of a fall.

Ensure proper ventilation of the equipment room and keep the air inlet and outlet vents

of the switch free of obstruction.

Connect the yellow-green protection grounding cable before power-on.

Make sure the operating voltage is in the required range.

Please don't open equipment. Breakdowns when opening, will be applying of the

guarantee.

When replacing FRUs, including power modules and fan trays, wear an

ESD-preventive wrist strap to avoid damaging the units.

Please be sure to do service operation of the equipment which is being used after a

power supply is off.

Please put dustproof cover on the port where SFP/SFP+/QSFP+ transceiver module

isn't mounted.

2.

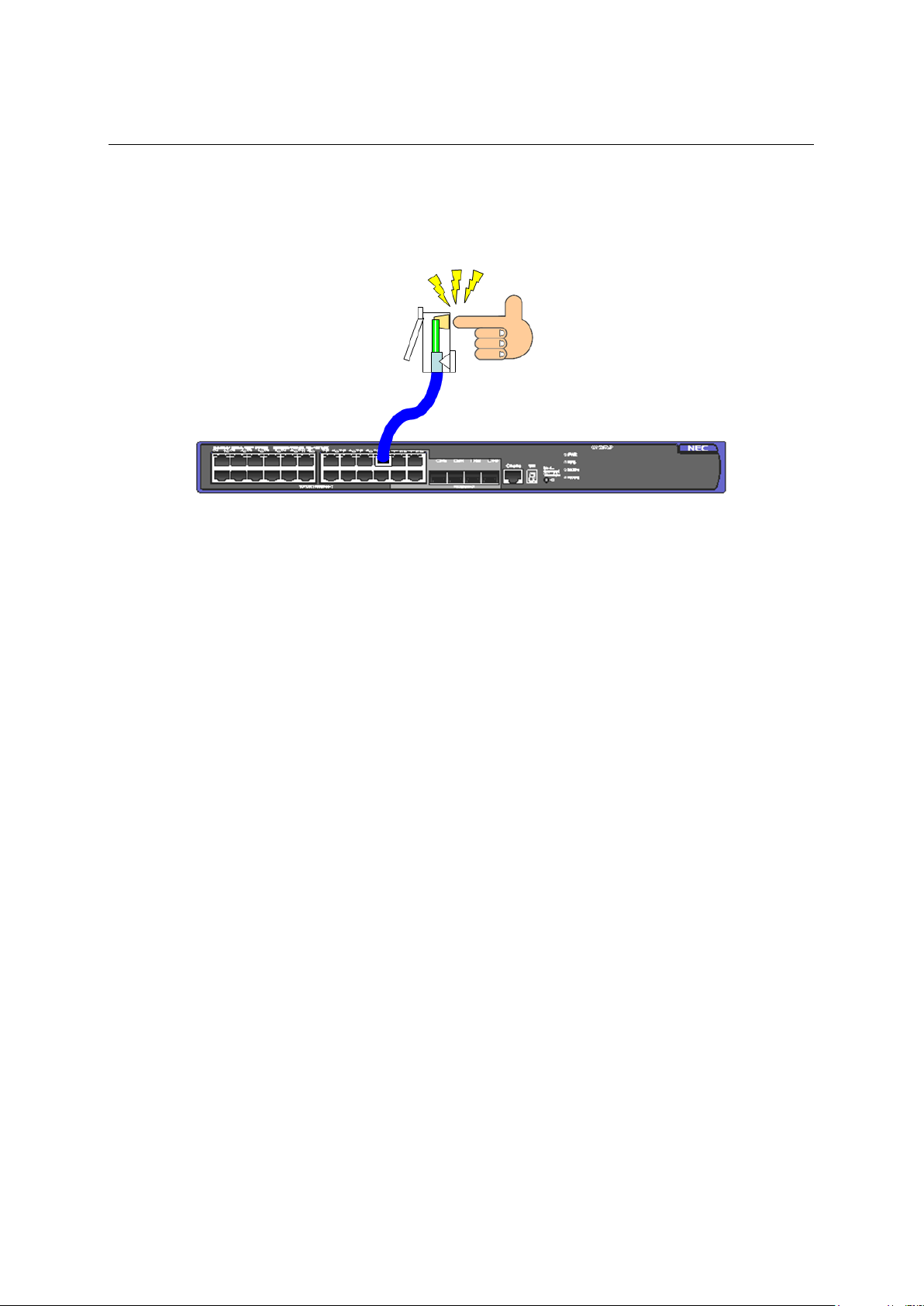

2.2 Connecting the RJ45 connector

NOTE:

When connecting the RJ45 cable, wear a wrist strap to protect against static electricity.

Do not touch the RJ45 Ethernet cable terminal. If you touch the RJ45 Ethernet cable

terminal which is connecting to the Switch, the interface circuit may be broken by the static

electricity. When you connect the Console cable, you need also a same care.

2-1

Page 18

Installation Guide

QX-S5500G Series Ethernet Switches

Preparing for installation

Figure 2-1 Connecting the RJ45 connector

2.3 Examining the installation site

2.

The QX-S5500G Series switches must be used indoors.

You can mount your switch in a rack, or on a workbench, and make sure:

Adequate clearance is reserved at the air inlet and exhaust vents for ventilation.

The rack, or on the workbench have a good ventilation system.

Identify the hot aisle and cold aisle at the installation site, and make sure ambient air

flows into the switch from the cold aisle and exhausts to the hot aisle.

Identify the airflow designs of neighboring devices, and prevent hot air flowing out of

the bottom device from entering the top device.

The rack, or the workbench are sturdy enough to support the switch and its

accessories.

The rack is well earthed.

To ensure normal operation and long service life of your switch, install it in an environment

that meets the requirements described in the following subsections.

2.3.1 Temperature/humidity

Maintain appropriate temperature and humidity in the equipment room.

Lasting high relative humidity can cause poor insulation, electricity creepage,

mechanical property change of materials, and metal corrosion.

Lasting low relative humidity can cause washer contraction and ESD and bring

problems including loose captive screws and circuit failure.

High temperature can accelerate the aging of insulation materials and significantly

lower the reliability and lifespan of the switch.

For the temperature and humidity requirements of different switch models, see "Technical

specifications" of “Chapter 1 Product overview”.

2-2

Page 19

Installation Guide

QX-S5500G Series Ethernet Switches

Preparing for installation

Dust ≤ 3 x 104 (no visible dust on the tabletop over three days)

Note:

Dust diameter ≥ 5 μm

SO

2

0.2

H2S

0.006

NH3

0.05

Cl2

0.01

2.3.2 Cleanness

Dust buildup on the chassis may result in electrostatic adsorption, which causes poor

contact of metal components and contact points, especially when indoor relative humidity is

low. In the worst case, electrostatic adsorption can cause communication failure.

The equipment room must also meet strict limits on salts, acids, and sulfides to eliminate

corrosion and premature aging of components, as shown in Table 2-2

2.

Table 2-1 Dust concentration limit in the equipment room

Substance Concentration limit (particles/m³)

Table 2-2 Harmful gas limits in the equipment room

Gas Maximum concentration (mg/m3)

2.3.3 EMI

All electromagnetic interference (EMI) sources, from outside or inside of the switch and

application system, adversely affect the switch in a conduction pattern of capacitance

coupling, inductance coupling, electromagnetic wave radiation, or common impedance

(including the grounding system) coupling. To prevent EMI, take the following actions:

Please take the effective measures to reduce the intervention the power supply

system exerts on the switch.

Keep the switch far away from high-power radio launchers, radars, and equipment

with high frequency or high current.

If AC power is used, use a single-phase three-wire power receptacle with protection

earth (PE) to filter interference from the power grid.

Keep the switch far away from radio transmitting stations, radar stations, and

high-frequency devices.

Use electromagnetic shielding, for example, shielded interface cables, when

necessary.

Route interface cables only indoors to prevent signal ports from getting damaged by

overvoltage or overcurrent caused by lightning strikes.

2.3.4 Laser safety

The QX-S5500G Series switches are Class 1 laser devices.

2-3

Page 20

Installation Guide

QX-S5500G Series Ethernet Switches

Preparing for installation

WARNING:

Do not stare into any fiber port when the switch has power. The laser light emitted from the optical fiber may

hurt your eyes.

2.4 Installation tools

Phillips screwdriver

Flat-blade screwdriver

ESD-preventive wrist strap

NOTE:

All these installation tools have to be prepared by a user.

2.

2-4

Page 21

Installation Guide

QX-S5500G Series Ethernet Switches

Contents

Contents

3. Installing the switch .................................................................................................................. 3-1

3.1 Installation flow .................................................................................................................. 3-1

3.2 Installing the switch in a 19-inch rack ................................................................................ 3-3

3.2.1 Mounting bracket kits .............................................................................................. 3-3

3.2.2 Rack-mounting by using front mounting brackets ................................................... 3-3

3.2.3 Mount the chassis in the rack .................................................................................. 3-5

3.3 Mounting the switch on a workbench ................................................................................. 3-7

3.4 Grounding the switch ......................................................................................................... 3-7

3.4.1 Grounding the switch with a grounding strip ........................................................... 3-8

3.4.2 Connecting the rear grounding point to a grounding strip ....................................... 3-9

3.4.3 Grounding the switch with a grounding conductor buried in the earth ground...... 3-10

3.4.4 Grounding the switch by using the AC power cord ............................................... 3-11

3.5 Installing/removing a fan tray ........................................................................................... 3-13

3.5.1 Installing a fan tray ................................................................................................ 3-13

3.5.2 Removing a fan tray .............................................................................................. 3-14

3.6 Installing/removing a power module ................................................................................ 3-15

3.6.1 Installing a power module ..................................................................................... 3-16

3.6.2 Removing a power module ................................................................................... 3-18

3.7 Connecting the power cord .............................................................................................. 3-18

3.7.1 Connecting a AC power cord to the switch ........................................................... 3-19

3.7.2 Connecting a DC power cord to the switch ........................................................... 3-20

3.7.3 Connecting a AC power cord to the PSR150-A1 .................................................. 3-21

3.7.4 Connecting a DC power cord to the PSR150-D1 .................................................. 3-22

3.7.5 Making of DC power cord ...................................................................................... 3-23

3.8 Installing/removing an interface card ............................................................................... 3-26

3.8.1 Installing an interface card .................................................................................... 3-26

3.8.2 Removing an interface card .................................................................................. 3-29

3.9 Installing/Removing a SFP/SFP+/QSFP+ transceiver module ........................................ 3-29

3.9.1 Installing a SFP/SFP+/QSFP+ transceiver module .............................................. 3-30

3.9.2 Removing a SFP/SFP+/QSFP+ transceiver module ............................................ 3-30

3.10 Connecting an interface cable ....................................................................................... 3-31

3.10.1 Connecting a UTP cable ..................................................................................... 3-31

i

Page 22

Installation Guide

QX-S5500G Series Ethernet Switches

Contents

3.10.2 Connecting a fiber optic-cable ............................................................................. 3-31

3.11 Verifying the installation ................................................................................................. 3-32

ii

Page 23

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

3. Installing the switch

CAUTION:

Keep the tamper-proof seal on a mounting screw on the chassis cover intact. If you tear off the tamper-proof

seal, switch shall not be guarantee applying. If you tear off the tamper-proof seal and open the chassis, NEC

shall not be liable for any consequence caused thereby.

NOTE:

The description of an installation procedure of device is indicated on this chapter , but please refer to a product

for the outward appearance of the actual equipment .

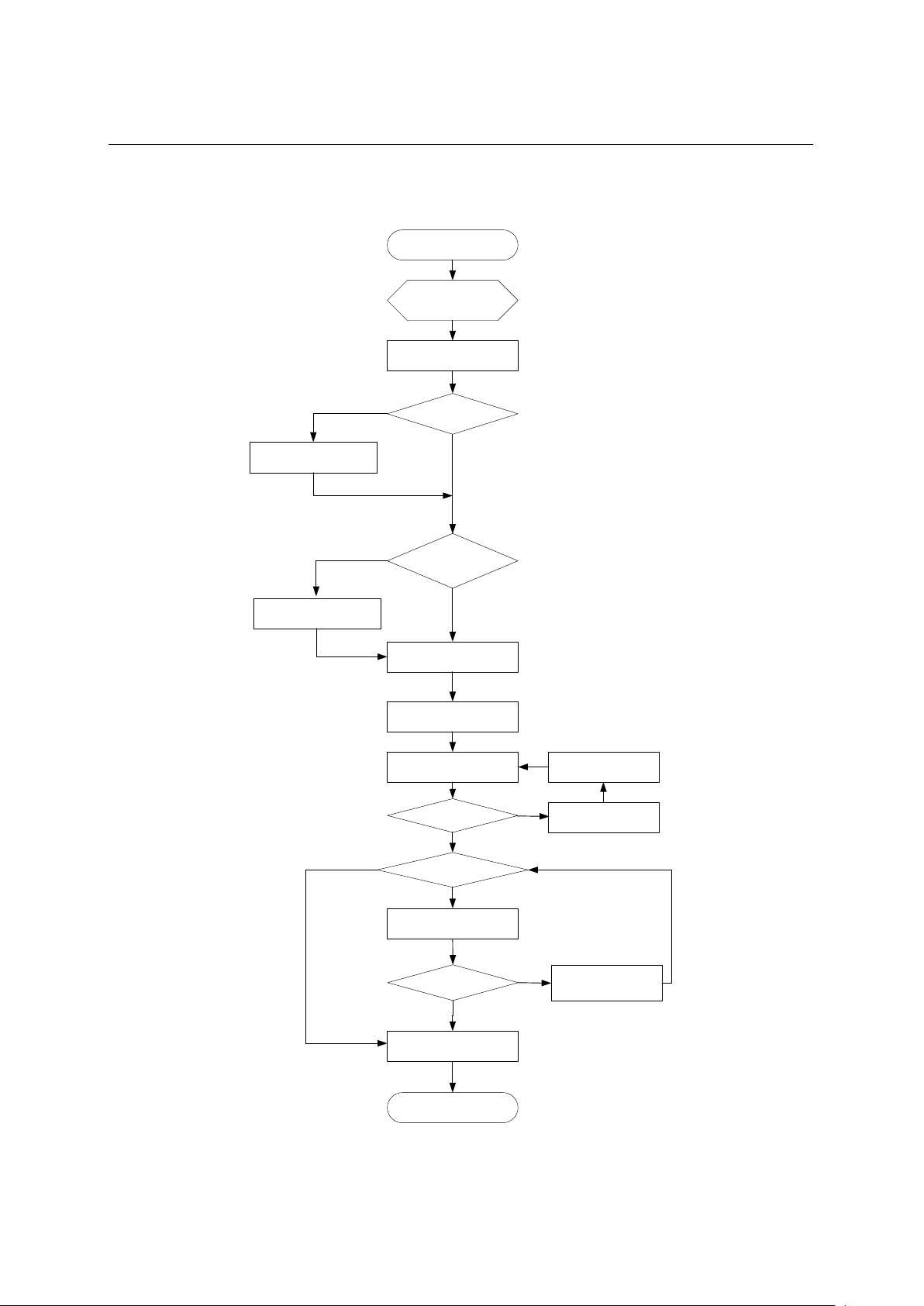

3.1 Installation flow

3-1

Page 24

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

Ground the switch

Install the switch

Start

Connect power cords

Verify the installation

Power on the switch

Select and install power

modules

Hot-swap power

modules?

Yes

No

Operating correctly?

Power off the switch

Troubleshoot the switch

No

Yes

Hot-swap cards?

Install interface cards

Yes

Troubleshoot the switch

Yes

No

End

No

Hot-swap

fan trays?

Select and install fan trays

Yes

No

Operating correctly?

Install transceiver modules

and cables

Figure 3-1 Hardware installation flow

3-2

Page 25

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

L1

L2

1

2

(1) Hole for attaching the bracket to a

rack

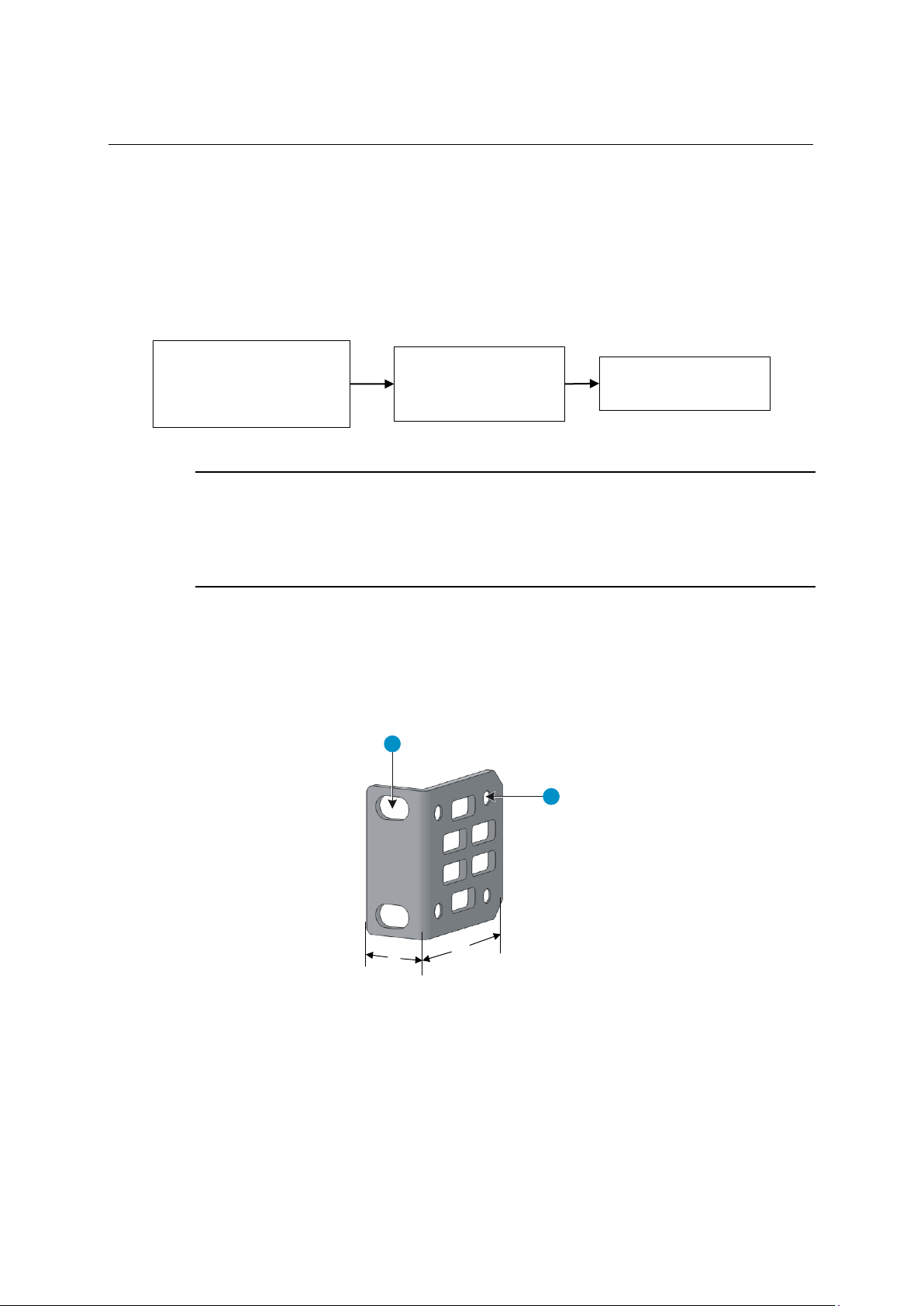

(2) Hole for attaching the bracket to the

switch chassis

Attach the front

Mount the switch in the

Identify the mounting

3.2 Installing the switch in a 19-inch rack

The mounting bracket kit can be installed on the port side, power module side, or the

middle bracket installation position. Attach on the appropriate location with an actual

necessary condition .

Figure 3-2 Rack-mounting procedure

position ( port side, the

power side, or middle

position ) for the mounting

brackets

NOTE:

If a rack shelf is available, you can put the switch on the rack shelf, slide the switch to an appropriate location,

and attach the switch to the rack by using the mounting brackets.

3.2.1 Mounting bracket kits

mounting brackets to the

two sides of the switch

Figure 3-3 Front mounting bracket kit

rack

3.2.2 Rack-mounting by using front mounting brackets

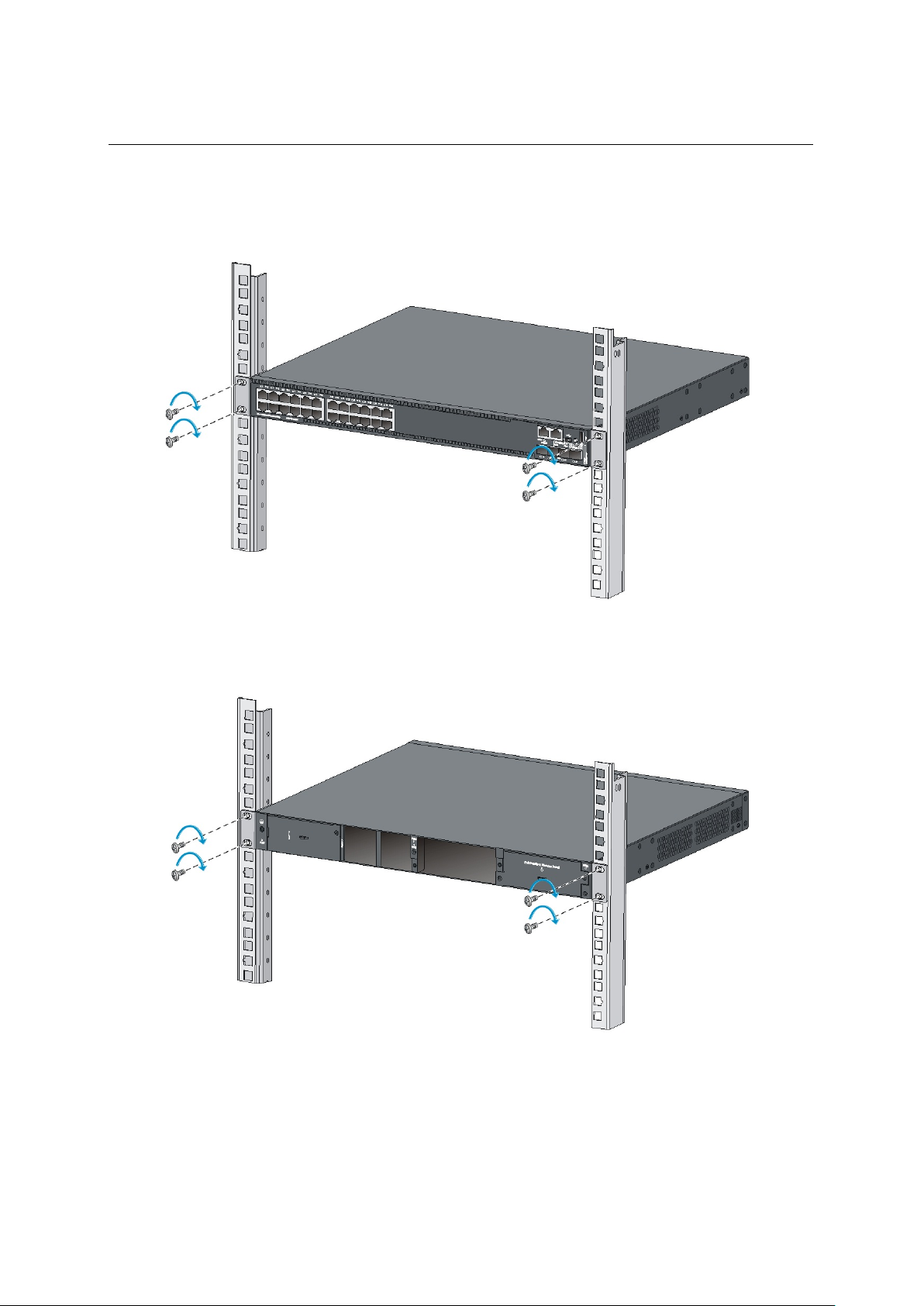

To install the switch in a 19-inch rack by using the front mounting brackets:

3-3

Page 26

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

Identify the mounting positions.

1) Wear an ESD wrist strap and make sure it makes good skin contact and is correctly

2) Attach the front mounting brackets to the chassis:

3) Unpack the front mounting brackets and the M4 screws (supplied with the switch) for

4) Align the round holes in the wide flange of one front mounting bracket with the screw

5) Use M4 screws to attach the mounting bracket to the chassis.

6) Repeat the proceeding two steps to attach the other mounting bracket to the chassis.

grounded.

attaching the brackets to the switch chassis.

holes in the chassis. The bracket mounting positions is Port side, power module side,

or middle installation position.

Figure 3-4 Attaching the front mounting bracket to the port side

3-4

Page 27

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

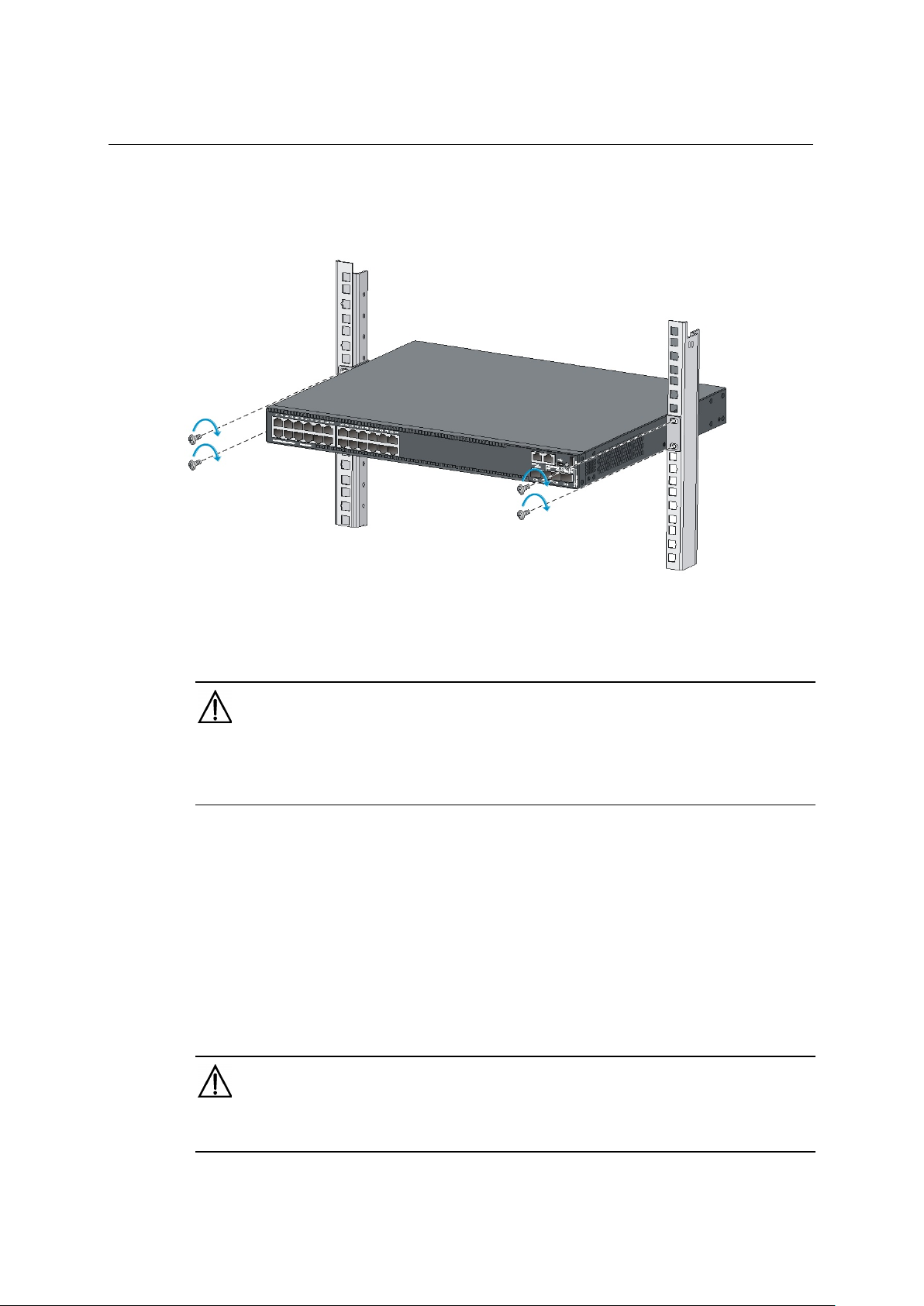

Figure 3-5 Attaching the front mounting bracket to the middle installation position

Figure 3-6 Attaching the front mounting bracket to the power module side

3.2.3 Mount the chassis in the rack

This task requires two people.

1) One person supports the chassis bottom with one hand, holds the front part of the

chassis with the other hand, and pushes the chassis into the rack gently

2) The other person uses M6 screws and cage nuts (user supplied) to attach the switch

to the rack. Prepare the cage nuts and the screws yourself.

3-5

Page 28

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

Figure 3-7 け Mounting the switch in the rack (front mounting brackets at the port side)

Figure 3-8 Mounting the switch in the rack (front mounting brackets at the power module side)

3-6

Page 29

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

Figure 3-9 Mounting the switch in the rack (front mounting brackets at the middle installation position)

3.3 Mounting the switch on a workbench

IMPORTANT:

Ensure good ventilation and 10 cm (3.9 in) of clearance around the chassis for heat dissipation.

Avoid placing heavy objects on the switch.

To mount the switch on a workbench:

1) Verify that the workbench is sturdy and correctly grounded.

2) Place the switch with bottom up, and clean the round holes in the chassis bottom with

dry cloth.

3) Attach the rubber feet to the four round holes in the chassis bottom.

4) Place the switch with upside up on the workbench.

3.4 Grounding the switch

WARNING:

Correctly connecting the switch grounding cable is crucial to lightning protection and EMI protection.

3-7

Page 30

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

The power input end of the switch has a noise filter, whose central ground is directly

connected to the chassis to form the chassis ground (commonly known as PGND). You

must securely connect this chassis ground to the earth so the faradism and leakage

electricity can be safely released to the earth to minimize EMI susceptibility of the switch.

You can ground the switch in one of the following ways, depending on the grounding

conditions available at the installation site:

Grounding the switch with a grounding strip

Grounding the switch with a grounding conductor buried in the earth ground

Grounding the switch by using the AC power cord

NOTE:

The power and grounding terminals in this section are for illustration only.

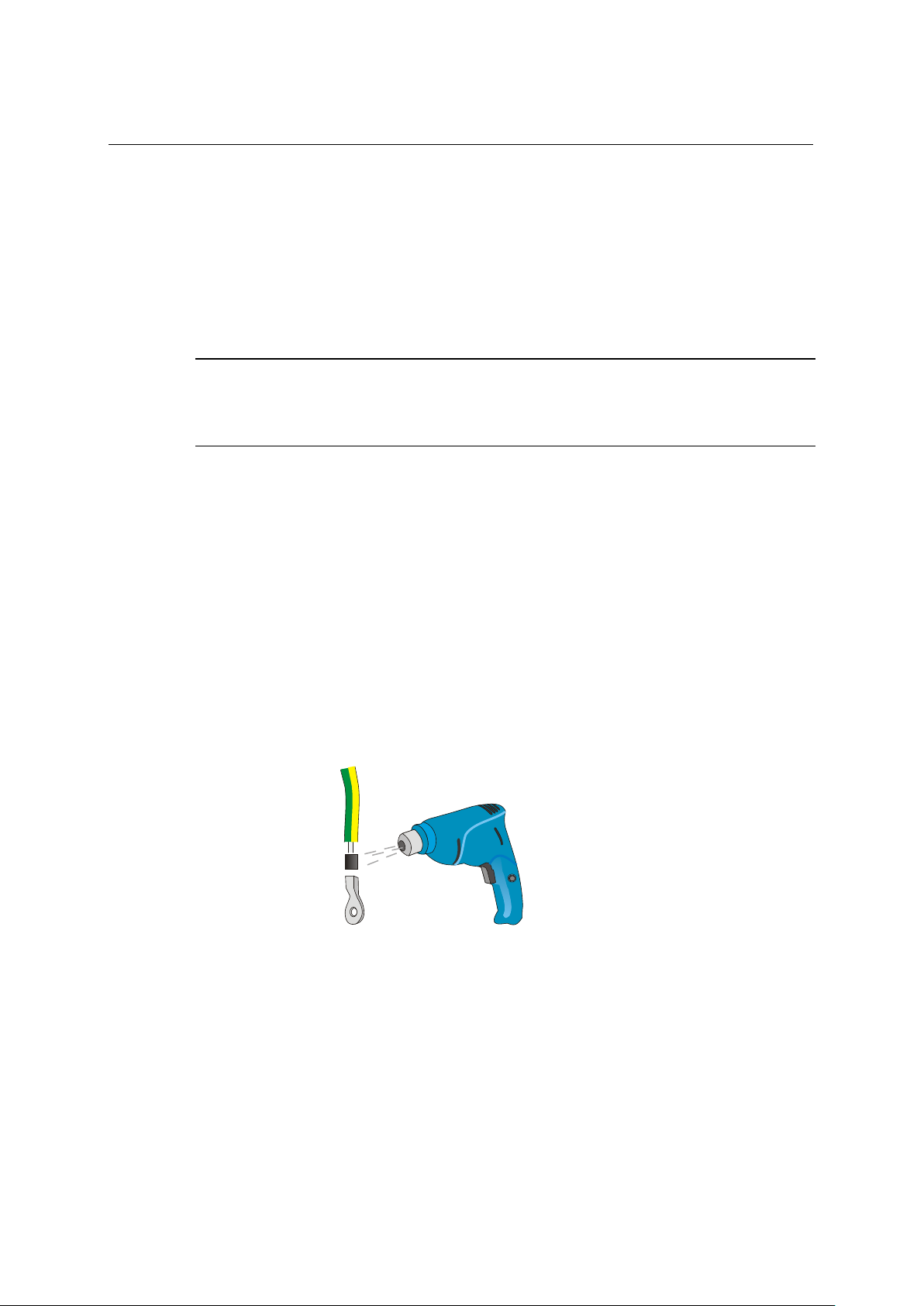

3.4.1 Grounding the switch with a grounding strip

If a grounding strip is available at the installation site, connect the grounding cable to the

grounding strip.

1) Cut the grounding cable as appropriate for connecting to the grounding strip.

2) Peel 5 mm (0.20 in) of insulation sheath by using a wire stripper, and insert the bare

metal part through the black insulation covering into the end of the ring terminal

supplied with the switch.

3) Secure the metal part of the cable to the ring terminal with a crimper, cover the joint

with the insulation covering, and heat the insulation covering with a blow dryer to

completely cover the metal part.

Figure 3-10 Attaching a ring terminal to the grounding cable

3-8

Page 31

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

(1) Grounding cable

(2) Grounding sign

(3) Grounding hole

(4) Ring terminal

(5) Grounding screw

3.4.2 Connecting the rear grounding point to a grounding strip

WARNING:

Connect the grounding cable to the grounding system in the equipment room. Do not connect it to a fire main or

lightning rod.

Connecting the rear grounding point to a grounding strip:

1) Remove the grounding screw from the rear panel of the switch chassis.

2) Use the grounding screw to attach the ring terminal of the grounding cable to the

grounding screw hole.

Figure 3-11 Connecting the grounding cable to the chassis

IMPORTANT:

Orient the grounding cable as shown in Figure 3-11 so you can easily install or remove interface card.

3) Verify that the grounding cable has been securely connected to the rear grounding

point.

4) Remove the hex nut of a grounding post on the grounding strip.

5) Cut the grounding cable as appropriate for connecting to the grounding strip.

3-9

Page 32

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

1

4

3

2

(1) Grounding post

(2) Grounding strip

(3) Grounding cable

(4) Hex nut

Figure 3-12 Connecting the grounding cable to a grounding strip

3.4.3 Grounding the switch with a grounding conductor buried in the earth ground

If the installation site has no grounding strips, but earth ground is available, hammer a 0.5

m (1.64 ft.) or longer angle iron or steel tube into the earth ground to serve as a grounding

conductor.

The dimensions of the angle iron must be a minimum of 50 × 50 × 5 mm (1.97 × 1.97 × 0.20

in). The steel tube must be zinc-coated and its wall thickness must be a minimum of 3.5 mm

(0.14 in).

Weld the yellow-green grounding cable to the angel iron or steel tube and treat the joint for

corrosion protection.

3-10

Page 33

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

1

2

3

4

5

6

(1) Grounding screw

(2) Chassis rear panel

(3) Grounding cable

(4) Earth

(5) Joint

(6) Grounding conductor

Figure 3-13 Grounding the switch by burying the grounding conductor into the earth ground

3.4.4 Grounding the switch by using the AC power cord

If the installation site has no grounding strips or earth ground, you ground an AC-powered

switch through the PE wire of the power cord. Make sure:

The power cord has a PE terminal.

The ground contact in the power outlet is securely connected to the ground in the

power distribution room or on the AC transformer side.

The power cord is securely connected to the power outlet.

NOTE:

If the ground contact in the power outlet is not connected to the ground, report the problem and reconstruct the

grounding system.

3-11

Page 34

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

(1) Three-wire AC power cord

(2) Chassis rear panel

Figure 3-14 Grounding through the PE wire of the AC power cord

NOTE:

To guarantee the grounding effect, use the grounding cable provided with the switch to connect to the

grounding strip in the equipment room as long as possible.

3-12

Page 35

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

3.5 Installing/removing a fan tray

CAUTION:

Install two fan trays of the same model on the switch. Do not power on the switch when it does not have fan

trays or has only one fan tray installed.

Make sure slots are installed with fan trays or blank filler panels for the device to operate.

At the first login to the QX-S5524GT-4X1C, QX-S5548GT-4X1C or QX-S5524GP-4X1C, use the fan

prefer-direction command to set the airflow direction of the switch to be the same as the airflow direction

of the fan tray. If the fan tray has a different airflow direction than the switch, the system outputs traps and

logs to notify you to replace the fan tray.

By default, the switch uses the same airflow direction (power-to-port) as the LSPM5FANSA fan tray.

If both fan trays fail during operation, replace them immediately. One fan trays don't make switch move,

please while breaking down.

Please don't remove a broken fan module until exchange preparations of a fan trays can be done.

If fan trays fail during operation, replace them within 2 minutes while the switch is operating. Please don't

make switch move in the state which has no fan trays for more than 2 minutes.

Failure to comply with these operating requirements may void the warranty.

The QX-S5524GT-4X1C, QX-S5548GT-4X1C or QX-S5524GP-4X1C switches support

hot-swappable fan trays.

The switch comes with empty fan tray slots. Choose the fan tray models based on the

ventilation requirement of the site. The air flow direction varies by fan tray model.

The LSPM5FANSA has a blue handle and provides power-to-port air flow.

The LSPM5FANSB has a red handle and provides port-to-power air flow.

3.5.1 Installing a fan tray

CAUTION:

To prevent damage to the fan tray or the connectors on the backplane, insert the fan tray gently. If you

encounter a hard resistance while inserting the fan tray, pull out the fan tray and insert it again.

To install a fan tray:

1) Wear an ESD wrist strap and make sure it makes good skin contact and is correctly

grounded.

2) Unpack the fan tray and verify that the fan tray model is correct.

3-13

Page 36

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

3) Grasp the two handles of the fan tray with the side marked TOP facing up, and slide

the fan tray along the guide rails into the slot until the fan tray seats in the slot and has

a firm contact with the backplane.

Figure 3-15 Installing a fan tray

3.5.2 Removing a fan tray

WARNING:

Do not touch conductors or terminals on the fan trays.

Do not place the fan tray in moist place. Prevent liquid from entering the fan tray.

Fan trays with faulty internal wiring and conductors require maintenance from maintenance engineers. Do

not disassemble the faulty fan trays.

To remove a fan tray:

1) Wear an ESD wrist strap and make sure it makes good skin contact and is correctly

grounded.

2) Grasp the two handles of the fan tray, as shown by callout 1 in Figure 3-16, and pull

out the fan tray slowly along the guide rails.

3) Put the removed fan tray in an antistatic bag.

3-14

Page 37

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

Install the power

module

Connect the power

cord

Turn on the circuit

breaker

Figure 3-16 Removing a fan tray

3.6 Installing/removing a power module

CAUTION:

Provide a circuit breaker for each power module.

There is power supply module slot 2 on which power supply module slot 1 in the empty and

a blank panel were mounted with two power supply module slots for the

QX-S5524GT-4X1C, QX-S5548GT-4X1C or QX-S5524GP-4X1C. You can install one or

two power modules for the switch as needed. For more information about effective power

supply module, see "Appendix B FRUs and compatibility matrixes”

In power redundancy mode, you can replace a power module without powering off the

switch but you must strictly follow the installation and procedures in Figure 3-17 and Figure

3-18 to avoid any bodily injury or damage to the switch.

Figure 3-17 Installation procedure

3-15

Page 38

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

Turn off the circuit

breaker

Disconnect the power

cord

Remove the power

module

These procedures are common by PSR150-A1 and PSR150-D1. It's explained taking

PSR150-A1 for instance at this chapter.

3.6.1 Installing a power module

To install a power module:

1) Wear an ESD wrist strap and make sure it makes good skin contact and is correctly

grounded.

2) Unpack the power module and verify that the power module model is correct.

3) Correctly orient the power module with the power module slot (use the letters on the

power module faceplate for orientation), grasp the handle of the power module with

one hand and support its bottom with the other, and slide the power module slowly

along the guide rails into the slot (see callout 1 in Figure 3-19).

To prevent damage to the power module or the connectors on the backplane, insert the

power module gently. If you encounter a hard resistance while inserting the power

module, pull out the power module and insert it again.

4) Fasten the captive screws on the power module with a Phillips screwdriver to secure

the power module in the chassis (see callout 2 in Figure 3-19).

If the captive screw cannot be tightly fastened, verify the installation of the power

module.

Figure 3-18 Removal procedure

3-16

Page 39

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

1

2

1

Figure 3-19 Installing a power module

NOTE:

If the power module slot where you want to install a power module is covered by a filler

panel, remove the filler panel first.

When necessary power supply module is one, please insert power supply module in

power supply module slot 1. Then insert a filler panel in power supply module slot 2.

Removing the filler panel:

Loosen the captive screws of the power module with a Phillips screwdriver until they

are completely disengaged.

Put a flat screwdriver in central prominence of a filler panel, please so as not to

damage. And remove a filler panel. Please keep a filler panel in the purpose when

using it next time.

Figure 3-20 Removing the filler panel

3-17

Page 40

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

QX-S5524GT-4X2Q

QX-S5548GT-4X2Q

AC power

Connecting an AC power cord to the switch

DC power

Connecting an DC power cord to the switch

QX-S5524GT-4X1C

QX-S5524GP-4X1C

PSR150-A1

AC power

Connecting an AC power cord to the PSR150-A1

3.6.2 Removing a power module

CAUTION:

When two of power supply module is mounted on switch, even if one of power supply module is removed, it

doesn't influence movement of switch. When only one of power supply module is mounted on equipment, when

power supply module is removed, a power supply of equipment becomes off.

To remove a power module:

1) Wear an ESD wrist strap and make sure it makes good skin contact and is correctly

grounded.

2) Disconnect the power cord.

3) Loosen the captive screws of the power module with a Phillips screwdriver until they

are completely disengaged.

4) Grasp the handle of the power module with one hand and pull it out a little, support the

bottom with the other hand, and pull the power module slowly along the guide rails out

of the slot.

5) Put away the removed power module in an antistatic bag or the power module

package bag for future use.

3.7 Connecting the power cord

Warning:

When fixing power cord on switch, please can cut a power supply of switch anytime in the state which reaches

a plug of power cord and an outlet right now.

Table 3-1 Tasks list

Switch

QX-S5548GT-4X1C

Power

module

-

PSR150-D1 DC power Connecting an DC power cord to the PSR150-D1

CAUTION:

The AC power cord isn't attached to switch. The AC power cord has to be prepared by

a user.

The socket-outlet shall be installed near the switch and shall be easily accessible.

Power

type

Connection procedure reference

3-18

Page 41

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

IEC-320-C13

IEC-320-C13

Connector(on the Device Side) Cable Ratings Cable Length Plug(Power Facility)

Figure 3-21 Power cord Specifications

125V, 10A

250V, 10A

Comply the standard of

each country

Comply the standard of

each country

Comply the standard of

each country

Comply the standard of

each country

The DC power cord isn't attached to switch. The DC power cord has to be prepared by a user. see “Making

of DC power cord”.

When using QX-PS800-T2, please prepare connected DC power cord to QX-PS800-T2. supplied DC

power cord is attached to QX-PS800-T2.

NOTE:

The power cord isn't attached to switch. The power cord has to be prepared by a user.

There is a possibility that a Power Cable Holder can't be used for a power cord, depending on the kind of

power cord.

3.7.1 Connecting a AC power cord to the switch

To connect an AC power cord to the QX-S5524GT-4X2Q or QX-S5548GT-4X2Q that uses

fixed power modules:

1) Wear an ESD wrist strap and make sure it makes good skin contact and is correctly

grounded.

2) Attach the hooks of the bail latch into the holes on the two sides of the AC-input power

receptacle, and pull the bail latch upwards (see Figure 3-22).

3) Connect one end of the AC power cord to the AC-input power receptacle on the switch

(see callout 1 in Figure 3-23).

4) Pull the bail latch down to secure the plug to the power receptacle (see callout 2 in

Figure 3-23).

5) Connect the other end of the power cord to the AC power outlet.

3-19

Page 42

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

1

2

Figure 3-22 Connecting an AC power cord to the switch (1)

Figure 3-23 Connecting an AC power cord to the switch (2)

3.7.2 Connecting a DC power cord to the switch

To connect a DC power cord to the switch:

1) Wear an ESD wrist strap and make sure it makes good skin contact and is correctly

grounded.

2) Correctly orient the plug at one end of the cable with the power receptacle on the

power module, and insert the plug into the power receptacle. See callout 1 in Figure

3-24.

3) If you cannot insert the plug into the receptacle, re-orient the plug rather than use

excessive force to push it in.

4) Tighten the screws on the plug with a flat-blade screwdriver to secure the plug in the

power receptacle. See callout 2 in Figure 3-24.

3-20

Page 43

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

2

1

5) Connect the two wires at the other end of the power cord to a –48 VDC power source

or QX-PS800-T2. Please classify two cord by a mark of (+) and (-) to stop a connection

mistake.

Figure 3-24 Connecting a DC power cord to the switch

3.7.3 Connecting a AC power cord to the PSR150-A1

To connect an AC power cord to the QX-S5524GT-4X1C, QX-S5548GT-4X1C, or

QX-S5524GP-4X1C use PSR150-A1 power supply module.

1) Wear an ESD wrist strap and make sure it makes good skin contact and is correctly

grounded.

2) Attach the hooks of the bail latch (supplied with the power module) into the two holes

next to the power receptacle on the power module, and pull the bail latch leftwards

(see Figure 3-25).

3) Connect one end of the AC power cord supplied with the power module to the power

receptacle (see callout 1 in Figure 3-26).

4) Pull the bail latch rightwards to secure the plug to the power receptacle (see callout 2

in Figure 3-26).

5) Connect the other end of the power cord to an AC power outlet.

3-21

Page 44

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

Figure 3-25 Connecting the PSR150-A1 (1)

Figure 3-26 Connecting the PSR150-A1 (2)

3.7.4 Connecting a DC power cord to the PSR150-D1

To connect an AC power cord to the QX-S5524GT-4X1C, QX-S5548GT-4X1C, or

QX-S5524GP-4X1C use PSR150-D1 power supply module.

1) Wear an ESD wrist strap and make sure it makes good skin contact and is correctly

grounded.

2) Unpack the DC power cord, correctly orient the plug at one end of the cable with the

power receptacle on the power module, and insert the plug into the power receptacle

(see callout 1 in Figure 3-27).

The power receptacle is foolproof. If you cannot insert the plug into the receptacle,

re-orient the plug rather than use excessive force to push it in.

3) Tighten the screws on the plug with a flat-blade screwdriver to secure the plug in the

power receptacle (see callout 2 in Figure 3-27).

4) Connect the two wires at the other end of the power cord to a –48 VDC power source.

3-22

Page 45

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

3.7.5 Making of DC power cord

Figure 3-27 Connecting the PSR150-D1

NOTE:

Please prepare the single line type for DC power cord.

The procedure which makes DC power cord is indicated below.

The DC power cord connector attached to switch consists of the following two parts. The

direction of the B of parts needs attention in particular.

After referring to Figure 3-28 and confirming the direction of the connector, please work so

that there are no connection mistakes.

3-23

Page 46

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

Figure 3-28 DC power cord connector supplied

Figure 3-29 Connectors B of parts

1) Please pass the DC power cord prepared into A of parts as shown in Figure 3-30.

3-24

Page 47

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

Figure 3-30 A of parts through DC power cord

2) A terminal for DC power cord is connected to B of parts. When connecting, please

connect so that it may correspond to a connector on the switch side. Please fix by the

screw which sticks to the upper part after connecting, so that a terminal doesn't come

off.

Figure 3-31 B of parts and connection of DC power cord

3) You combine B of parts with A of parts, tighten a screw and fix. There is a part where a

cable is fixed in A of parts. Please fix by tie-wrap (wire band) etc.

3-25

Page 48

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

Figure 3-32 DC power cord completion figure

3.8 Installing/removing an interface card

The QX-S5524GT-4X1C, QX-S5548GT-4X1C, or QX-S5524GP-4X1C each have one

expansion interface slot. It's possible to mount at most 1 expansion interface card as

needed. For the interface cards available for the switches, see "Appendix B FRUs and

compatibility matrixes."

CAUTION:

When an expansion interface card is inserted or it’s removed, don't touch joining terminal of a connector,

and please have a side.

To stop damage of an expansion interface card slot or a connector of a backplane, insert an expansion

interface card gently. If you encounter a hard resistance while inserting an expansion interface card, pull

out an expansion interface card and insert it again..

If no new card is to be installed, install the filler panel to prevent dust and ensure good ventilation in the

switch.

3.8.1 Installing an interface card

To connect an expansion interface card to switch:

3-26

Page 49

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

2

1

1) Wear an ESD wrist strap and make sure it makes good skin contact and is correctly

2) Remove the mounting screws on the filler panel over the interface card slot with a

grounded.

Phillips screwdriver and remove the filler panel. Keep the filler panel for future use.

Put a flat screwdriver in central prominence of a filler panel, please so as not to

damage. And remove a filler panel. Please keep a filler panel in the purpose when

using it next time.

Figure 3-33 Removing the filler panel over an interface card slot

3) Unpack the interface card.

4) (Optional.) If the interface card has an ejector lever, rotate out the ejector lever. Skip

this step if the interface card does not have an ejector lever.

5) Gently push the interface card in along the guide rails until the interface card has good

contact with the switch chassis

6) (Optional.) If the interface card has an ejector lever, rotate in the ejector lever. Skip this

step if the interface card does not have an ejector lever.

7) Tighten the captive screws with a Phillips screwdriver to secure the interface card in

the slot.

3-27

Page 50

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

Figure 3-34 Installing an interface card with an ejector lever

Figure 3-35 Installing an interface card without an ejector lever

3-28

Page 51

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

When LSWM5SP8PM was inserted, the chassis depth increases by 55 mm (2.17 in).

NOTE:

Figure 3-36 The LSWM2XGT8PM interface card installed in the switch

3.8.2 Removing an interface card

To remove an interface card:

1) Wear an ESD wrist strap and make sure it makes good skin contact and is correctly

grounded.

2) Use a Phillips screwdriver to completely loosen the captive screw on the interface

card.

3) (Optional.) If the interface card has an ejector lever, rotate out the ejector lever. Skip

this step if the interface card does not have an ejector lever.

4) Gently pull the interface card along the guide rails until it completely comes out of the

switch chassis.

3.9 Installing/Removing a SFP/SFP+/QSFP+ transceiver module

WARNING:

Do not touch the connector terminal when you insert and remove the SFP/SFP+/QSFP+ transceiver module.

You can install some SFP/SFP+/QSFP+ transceiver modules as needed. When using

QSFP+ by the QX-S5524GT-4X1C, QX-S5548GT-4X1C or QX-S5524GP-4X1C, mounting

of LSWM5QP2P is needed.

For more information about a SFP/SFP+/QSFP+ transceiver module available for the

switches, see “Appendix C Ports and LEDs".

3-29

Page 52

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

3.9.1 Installing a SFP/SFP+/QSFP+ transceiver module

CAUTION:

To prevent damage to the connectors inside the switch chassis, insert a SFP/SFP+/QSFP+ transceiver module

gently. If you encounter a hard resistance while inserting a SFP/SFP+/QSFP+ transceiver module, pull out a

SFP/SFP+/QSFP+ transceiver module and insert it again.

WARNING:

Do not remove the dust-proof cover before connecting a fiber optic-cable.

Do not connect a fiber optic-cable before inserting a SFP/SFP+/QSFP+ transceiver module.

Don't touch joining terminal of a SFP/SFP+/QSFP+ transceiver module.

To install a SFP/SFP+/QSFP+ transceiver module into the switch:

1) Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is

well grounded.

2) Raise up to the module part until a latch of SFP/SFP+/QSFP+ transceiver module is

fixed.

3) Put in the slot and be crowded with both sides of the SFP/SFP+/QSFP+ transceiver

module.

4) Force by a thumb until SFP/SFP+/QSFP+ transceiver module is fixed.

5) Confirm that a latch of SFP/SFP+/QSFP+ transceiver module is fixed.

3.9.2 Removing a SFP/SFP+/QSFP+ transceiver module

To remove a SFP/SFP+/QSFP+ transceiver module into the switch:

1) Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is

well grounded.

2) Pull down the lever on the SFP/SFP+/QSFP+ transceiver module.

3) Hold the lever and pull out the module.

3-30

Page 53

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

3.10 Connecting an interface cable

CAUTION:

After the interface cable connects to the switch, disconnect the interface cable if the port LED is green blinking.

Switch sends a great deal of broadcast packets or, there is a possibility which is being received. In this case, cut

off the network connection of equipment, and check the network and the configuration of the switch.

3.10.1 Connecting a UTP cable

To connecting an interface cable:

1) Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is

well grounded.

2) Insert a UTP cable until you hear a click.

NOTE:

You must use Category5 cable or better (including Cat5e and Cat6).

The UTP cable is used for the connecting to 10/100/1000BASE-T autosensing Ethernet port, 1000BASE-T

SFP/SFP+ port, and management Ethernet port.

3.10.2 Connecting a fiber optic-cable

CAUTION:

Do not look in the port of each SFP/SFP+/QSFP+ transceiver module.

Please check the RX/TX position of SFP/SFP+/QSFP+ transceiver module by the direction of RX/TX which

is ▲ or ↑.

1) Wear an ESD-preventive wrist strap and make sure it makes good skin contact and is

well grounded.

2) Do clean a LC connector with a dedicated optical connector cleaner.

3) Insert a fiber optic-cable as shown in Figure 3-37 until you hear a click.

3-31

Page 54

Installation Guide

QX-S5500G Series Ethernet Switches

3. Installing the switch

(1) TX

(2) RX

LC

(2)

(1)

Figure 3-37 SFP/SFP+/QSFP+ transceiver module

connector

NOTE:

Please check the RX/TX position of SFP transceiver module is connected correctly. If the LED of the

SFP/SFP+/QSFP+ port does not turn on, the connected port(RX/TX) may be wrong.

3.11 Verifying the installation

After you complete the installation, verify that:

There is enough space for heat dissipation around the switch, and the rack is stable.

The grounding cable is securely connected.

The correct power source is used.

The power cords are properly connected.

All the interface cables are cabled indoors. If any cable is routed outdoors, verify that

the socket strip with lightning protection and lightning arresters for network ports have

been properly connected.

3-32

Page 55

Installation Guide

QX-S5500G Series Ethernet Switches

Contents

Contents

4. Accessing the switch for the first time ................................................................................... 4-1

4.1 Setting up the configuration environment .......................................................................... 4-1

4.2 Connecting the console cable ............................................................................................ 4-1

4.2.1 Serial console cable ................................................................................................ 4-1

4.2.2 Connecting the USB mini console cable ................................................................. 4-3

4.3 Setting terminal parameters ............................................................................................... 4-4

4.4 Powering on the switch ...................................................................................................... 4-5

i

Page 56

Installation Guide

QX-S5500G Series Ethernet Switches

4. Accessing the switch for the first time

4. Accessing the switch for the first time

4.1 Setting up the configuration environment

You can access Swich through the serial port or the mini USB port. NEC recommends that

you access the switch through the serial port by using the provided console cable.

To access the switch through the mini USB port, you need to prepare the mini USB console

cable.

Figure 4-1 Connecting the console port to a terminal

4.2 Connecting the console cable

4.2.1 Serial console cable

A console cable is an 8-core shielded cable, with a crimped RJ-45 connector at one end for

connecting to the console port of the switch, and a DB-9 female connector at the other end

for connecting to the serial port on the console terminal.

4-1

Page 57

Installation Guide

QX-S5500G Series Ethernet Switches

4. Accessing the switch for the first time

Main label

1

8

B side

B

Pos.9

Pos.1

A side

A

1

RTS 8 CTS 2 DTR 6 DSR 3 TXD 2 RXD 4 SG 5 SG 5 SG 5 SG 6 RXD 3 TXD 7 DSR 4 DTR 8 CTS 7 RTS

Figure 4-2 Console cable

Table 4-1 Console port signaling and pinout

RJ-45 Signal DB-9 Signal

To connect a terminal (for example, a PC) to the switch:

1) Plug the DB-9 female connector of the console cable to the serial port of the PC.

2) Connect the RJ-45 connector to the console port of the switch.

NOTE:

Identify the mark on the console port and make sure you are connecting to the correct port.

The serial ports on PCs do not support hot swapping. If the switch has been powered on, connect the

console cable to the PC before connecting to the switch, and when you disconnect the cable, first

disconnect from the switch.

4-2

Page 58

Installation Guide

QX-S5500G Series Ethernet Switches

4. Accessing the switch for the first time

4.2.2 Connecting the USB mini console cable

A USB mini console cable isn't attached to switch. The A USB mini console cable has to be

prepared by a user.

A USB mini console cable has a USB mini-Type B connector at one end to connect to the

USB mini console port of the switch, and a standard USB Type A connector at the other end

to connect to the USB port on the configuration terminal.

To connect to the configuration terminal through the USB mini console cable:

1) Connect the standard USB Type A connector to the USB port of the configuration

terminal.

2) Connect the USB mini Type B connector to the USB mini console port of the switch.

3) Install a USB console driver. (When it's necessary.)

Click the following link, or copy it to the address bar on the browser to log in to

download page of the USB console driver, and download the driver.

http://qx.zpf.nec.co.jp/

4) Select a driver program according to the operating system you use:

OS: Windows 2000/XP/Vista/7/8

32bit Windows: XR21V1410_XR21B1411_Windows_Ver1840_x86_Installer.EXE

64Bit windows: XR21V1410_XR21B1411_Windows_Ver1840_x64_Installer.EXE

5) Click Next on the installation wizard.

Figure 4-3 Device Driver Installation Wizard

4-3

Page 59

Installation Guide

QX-S5500G Series Ethernet Switches

4. Accessing the switch for the first time

6) Click Continue Anyway if the following dialog box appears.

Figure 4-4 Software Installation

7) Click Finish.

4.3 Setting terminal parameters

To configure and manage the switch, you must run a terminal emulator program on the

console terminal.

4-4

Page 60

Installation Guide

QX-S5500G Series Ethernet Switches

4. Accessing the switch for the first time

The following are the required terminal settings:

Bits per second :9,600

Data bits :8

Parity :None

Stop bits :1

Flow control :None

Emulation :VT100

To set terminal parameters, for example, on a Windows HyperTerminal:

1) Select Start > All Programs > Accessories > Communications > HyperTerminal. The

2) Enter the name of the new connection in the Name field and click OK.

A cereal console and USB mini console are similar setting together.

Connection Description dialog box appears.

NOTE:

4.4 Powering on the switch

Before powering on the switch, verify that the following conditions are met:

The power cord and ground earthing wire are correctly connected.

The input power voltage meets the requirement of the switch.

The console cable is correctly connected. The configuration terminal (a PC, for

example) has started, and its serial port settings are consistent with the console port

settings on the switch.

Power on the switch. During the startup process, you can access Boot ROM menus to

perform tasks such as software upgrade and file management. The Boot ROM interface

and menu options differ with software versions. For more information about Boot ROM

menu options, see the software-matching release notes for the device.

After the startup completes, you can access the CLI to configure the switch.

For more information about the configuration commands and CLI, see “QX-S5500G Series

Ethernet Switch Configuration Guides” and “QX-S5500G Series Ethernet Switch

Command References”.

4-5

Page 61

Installation Guide

QX-S5500G Series Ethernet Switches

Contents

Contents

5. Setting up an IRF fabric ............................................................................................................ 5-1

5.1 IRF fabric setup flowchart .................................................................................................. 5-1

5.2 Planning IRF fabric setup .................................................................................................. 5-2

5.2.1 Planning IRF fabric size and the installation site .................................................... 5-2

5.2.2 Identifying the master switch and planning IRF member IDs.................................. 5-3

5.2.3 Planning IRF topology and connections ................................................................. 5-3

5.2.4 Identifying physical IRF ports on the member switches .......................................... 5-5

5.2.5 Planning the cabling scheme .................................................................................. 5-6

5.3 Configuring basic IRF settings ........................................................................................... 5-8

5.4 Connecting the physical IRF ports ..................................................................................... 5-8

5.5 Verifying the IRF fabric setup ............................................................................................ 5-9

i

Page 62

Installation Guide

QX-S5500G Series Ethernet Switches

5. Setting up an IRF fabric

Start

Plan IRF fabric setup

Install IRF member switches

Connect the grounding cable

and power cords

Power on the switches

Configure basic IRF settings

Connect the physical IRF ports

Standby switches reboot and

the IRF fabric is automatically

established

End

5. Setting up an IRF fabric

You can use IRF technology to connect and virtualize QX-S5500G Series Ethernet

Switches into a large virtual switch called an "IRF fabric" for flattened network topology, and

high availability, scalability, and manageability.

5.1 IRF fabric setup flowchart

Figure 5-1 IRF fabric setup flowchart

To set up an IRF fabric:

5-1

Page 63

Installation Guide

QX-S5500G Series Ethernet Switches

5. Setting up an IRF fabric

switches.

cords.

Installing the switch”.

switches.

Guides.

established.

1. Plan IRF fabric

2. Install IRF

Step Description

Plan the installation site and IRF fabric setup parameters:

Planning IRF fabric size and the installation site

Identifying the master switch and planning IRF member IDs

setup.

member

Planning IRF topology and connections

Identifying physical IRF ports on the member switches

Planning the cabling scheme

See "Installing the switch in a 19-inch rack" of “Chapter 3 Installing the switch”.

3. Connect ground

wires and power

See "Grounding the switch" and "Connecting the power cord" of “Chapter 3

4. Power on the

N/A

5. Configure basic

See “Chapter 2 IRF” of QX-S5500G Series Ethernet Switches Configuration

IRF settings.

Connect physical IRF ports on switches.

Use SFP+/QSFP+ transceiver modules and fibers to connect 10-Gigabit SFP+

6. Connect the

physical IRF

ports/40-Gigabit QSFP+ ports over a long distance, or use SFP+/QSFP+ DAC

cables to connect 10-Gigabit SFP+ ports/40-Gigabit QSFP+ ports over a short

ports.

distance.

All switches except the master switch automatically reboot, and the IRF fabric is

5.2 Planning IRF fabric setup

This section describes issues that an IRF fabric setup plan must cover.

5.2.1 Planning IRF fabric size and the installation site

Choose switch models and identify the number of required IRF member switches,

depending on the user density and upstream bandwidth requirements. The switching

capacity of an IRF fabric equals the total switching capacities of all member switches.

Plan the installation site depending on your network solution as follows:

Place all IRF member switches in one rack for centralized high-density access.

5-2

Page 64

Installation Guide

QX-S5500G Series Ethernet Switches

5. Setting up an IRF fabric

Distribute the IRF member switches in different racks to implement the top-of-rack

(ToR) access solution for a data center.

As your business grows, you can plug QX-S5500G Series Ethernet Switches into the IRF

fabric to increase the switching capacity without any topology change or replacement.

NOTE:

An IRF fabric of QX-S5500G Series can compose at most 9.

5.2.2 Identifying the master switch and planning IRF member IDs

Determine which switch you want to use as the master for managing all member switches

in the IRF fabric.

An IRF fabric has only one master switch. You configure and manage all member switches

in the IRF fabric at the CLI of the master switch. IRF member switches automatically elect a

master.

You can affect the election result by assigning a high member priority to the intended

master switch. For more information about master election, see QX-S5500G Series

Ethernet Switches Configuration Guides.

Prepare an IRF member ID assignment scheme. An IRF fabric uses member IDs to

uniquely identify and manage its members, and you must assign each IRF member switch

a unique member ID.

5.2.3 Planning IRF topology and connections

You can create an IRF fabric in daisy chain topology or more reliable ring topology. In ring

topology, the failure of one IRF link does not cause the IRF fabric to split as in daisy chain

topology. Instead, the IRF fabric changes to a daisy chain topology without interrupting

network services.

You co nnect the IRF member switches through IRF ports, the logical interfaces for the

connections between IRF member switches. Each IRF member switch has two IRF ports:

5-3

Page 65

Installation Guide

QX-S5500G Series Ethernet Switches

5. Setting up an IRF fabric

1

2

3

IRF-port1

IRF-port2

IRF-port1

IRF-port2

1

2

3

IRF-port 1 and IRF-port 2. To use an IRF port, you must bind a minimum of one physical

port to it.

When connecting two neighboring IRF member switches, you must connect the physical

ports of IRF-port 1 on one switch to the physical ports of IRF-port 2 on the other switch.

The QX-S5500G Series switches can provide 10-GE IRF connections through SFP+ ports

and 40-GE IRF connections through QSFP+ ports, and you can bind several SFP+/QSFP+

ports to an IRF port for increased bandwidth and availability.

Figure 5-2 and Figure 5-3 show the topologies of an IRF fabric made up of three

QX-S5524GT-4X1C switches. The IRF port connections in the two figures are for

illustration only, and more connection methods are available.

Figure 5-2 IRF fabric in daisy chain topology

5-4

Page 66

Installation Guide

QX-S5500G Series Ethernet Switches

5. Setting up an IRF fabric

IRF-port1

IRF-port2

IRF-

port1

IRF-port1

IRF-port2

IRF-port2

1

2

3

1

2 3

QX-S5524GP-4X1C

Figure 5-3 IRF fabric in ring topology

5.2.4 Identifying physical IRF ports on the member switches

Identify the physical IRF ports on the member switches according to your topology and

connection scheme.

Table 5-1 shows the physical ports that can be used for IRF connection and the port use

restrictions.

Table 5-1 Physical IRF port requirements

Chassis Candidate physical IRF ports Requirements

Four fixed SFP+ ports on the

QX-S5524GT-4X2Q

QX-S5548GT-4X2Q

QX-S5524GT-4X1C

QX-S5548GT-4X1C

front panel

Two fixed QSFP+ ports on the

rear panel

Four fixed SFP+ ports on the

front panel

Ports on the expansion

interface card on the rear panel

All physical ports to be bound to an IRF port

must be the same type.

For other models, physical ports on

different interface cards can be bound to

the same IRF port.

If a QSFP+ port is split into four SFP+ ports,