Page 1

PlasmaSync™ Multimedia Monitor

MODEL PX-42M2A

PX-42M2G

SERVICE MANUAL

Better Service

PART No. 399910943

Better Reputation

Better Profit

SAFETY CAUTION:

Before servicing this chassis, it is important that the service

technician read and follow the “Safety Precautions” and “Product

Safety Notice” in this Service Manual.

WARNING:

SHOCK HAZARD - Use an isolation transformer when servicing.

Page 2

CONTENTS

SAFETY PRECAUTIONS .................................................................................................................................. 2-1

USERS MANUAL............................................................................................................................................... 3-1

TROUBLE SHOOTING ...................................................................................................................................... 4-1

METHOD OF ADJUSTMENTS .......................................................................................................................... 5-1

CIRCUIT DESCRIPTION ................................................................................................................................... 6-1

METHOD OF DISASSEMBLY ........................................................................................................................... 7-1

DISASSEMBLY.................................................................................................................................................. 8-1

METHOD OF WIRING ....................................................................................................................................... 9-1

PACKAGING.................................................................................................................................................... 10-1

REPLACEMENT PART LIST ........................................................................................................................... 11-1

CONNECTION DIAGRAMS............................................................................................................................. 12-1

BLOCK DIAGRAM ........................................................................................................................................... 13-1

SCHEMATIC DIAGRAMS................................................................................................................................ 14-1

VI/O PWB (PWC-4213B) ............................................................................................................................ 14-1

ANALOG PWB (PWC-4214)....................................................................................................................... 14-3

VIDEO PWB (PWC-4213A) ...................................................................................................................... 14-15

AUDIO PWB (PWC-4216A) ...................................................................................................................... 14-20

SOUND PWB (PWC-4216B) .................................................................................................................... 14-23

POWER PWB (PWC-4216G) ................................................................................................................... 14-25

CTL PWB (PWC-4216F)........................................................................................................................... 14-26

VOL PWB (PWC-4216C) .......................................................................................................................... 14-27

R TERMINAL PWB (PWC-4216E)............................................................................................................ 14-28

L TERMINAL PWB (PWC-4216D) ............................................................................................................ 14-29

CAUTION

In transporting the product, be sure to use the specified box. If the product does not

have the specified stand, attach the stand, then pack the project. Packing the product

without the specified stand and transporting it could cause a product failure.

1-1

Page 3

SAFETY PRECAUTIONS

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT OPEN TOP COVER. NO USER-SERVICEABLE

PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

This symbol warns the user that uninsulated voltage within the unit may have

sufficient magnitude to cause electric

shock. Therefore, it is dangerous to make

any kind of contact with any part inside of

this unit.

This symbol alerts the user that important

literature concerning the operation and

maintenance of this unit has been

included.

Therefore, it should be read carefully in

order to avoid any problems.

ATTENTION

RISQUE D'ELECTROCUTION

NE PAS OUVRIR

ATTENTION: POUR EVITER LES RISQUES D' ELECTROCUTION, NE PAS ENLEVER LE CONVERCLE SUPERIEUR. AUCUN

DES ELEMENTS INTERNES NE DOIT ETRE REPARE PAR L'UTILISATEUR. NE CONFIER L' ENTRETIEN QU'A UN

PERSONNEL QUALIFIE.

L'éclair fléché dans un triangle équilatéral est

destiné à avertir l'utilisateur de la présence,

dans l'appareil, d'une zone non-isolée soumise

à une haute tension dont l'intensité est suffisante pour constituer un risque d'électrocution.

Le point d'exclamation dans un triangle équilatéral est destiné à attirer l' attention de l'utilisateur sur la présence d'informations de

founctionnement et d'entretien importantes dans

la brochure accompagnant l'appareil.

WARNING

HEATSINK MAY BE ENERGIZED.

TEST BEFORE TOUCHING.

2-1

Page 4

SAFETY PRECAUTIONS

1. Before returning an instrument to the customer, al-

ways make a safety check of the entire instrument, in-

cluding, but not limited to, the following items.

a. Be sure that no built-in protective devices are

defective and/or have been defeated during

servicing. (1) Protective shields are provided on

this chassis to protect both the technician and

the customer. Correctly replace all missing protective shields, including any removed for servicing convenience. (2) When reinstalling the

chassis and/or other assembly in the cabinet, be

sure to put back in place all protective devices,

including,but not limited to, nonmetallic control

knobs,insulating fishpapers,adjustment and

compartment covers/shields, and isolation resistor/capacitor networks. Do not operate this

instrument or permit it to be operated without all protective devices correctly installed

and functioning.

b. Be sure that there are no cabinet openings

through which an adult or child might be able to

insert their fingers and contact a hazardous voltage. Such opening include,but are not limited to,

(1) spacing between the picture tube and the

cabinet mask, (2) excessively wide cabinet ventilation slots, and (3) an improperly fitted and/or

incorrectly secured cabinet back cover.

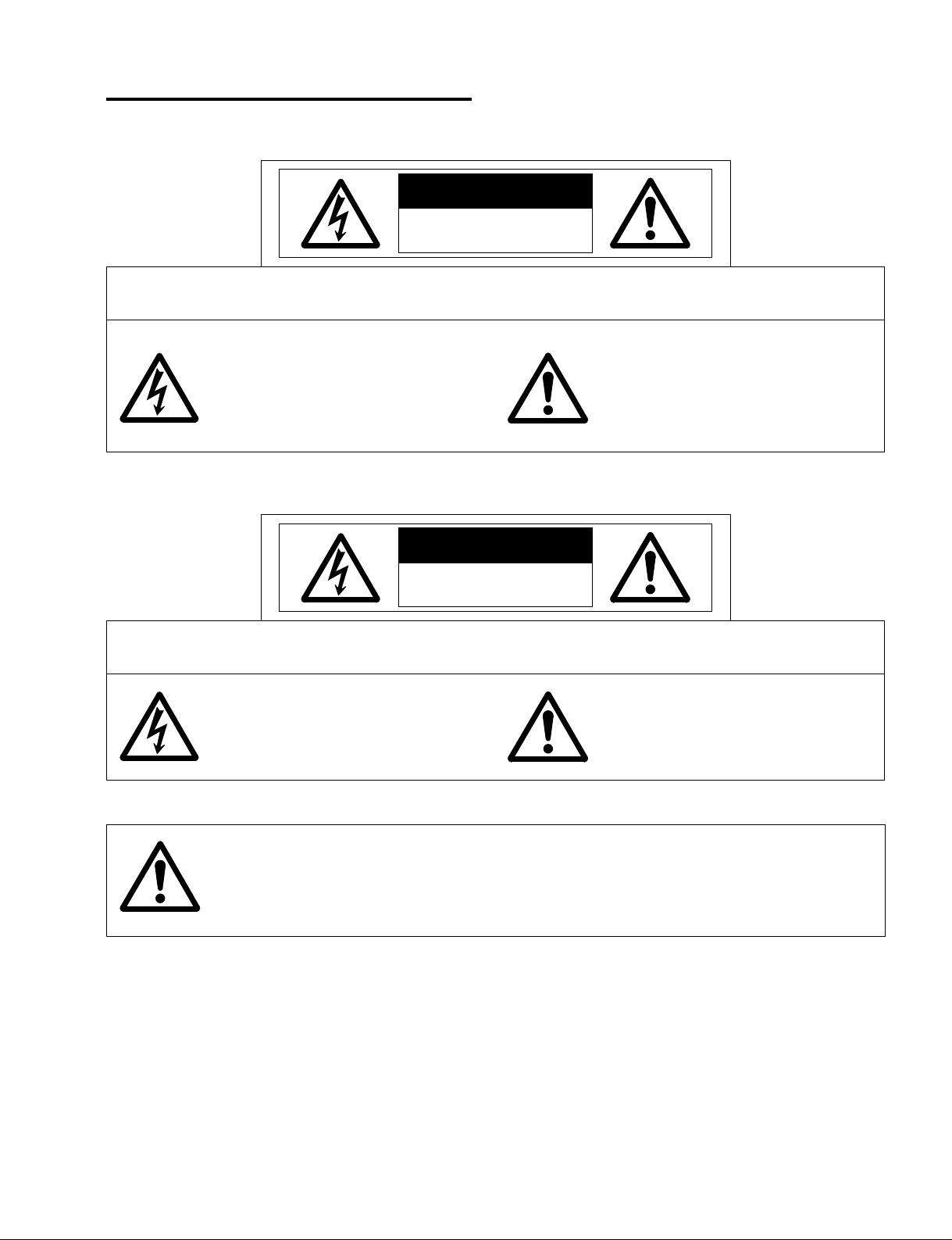

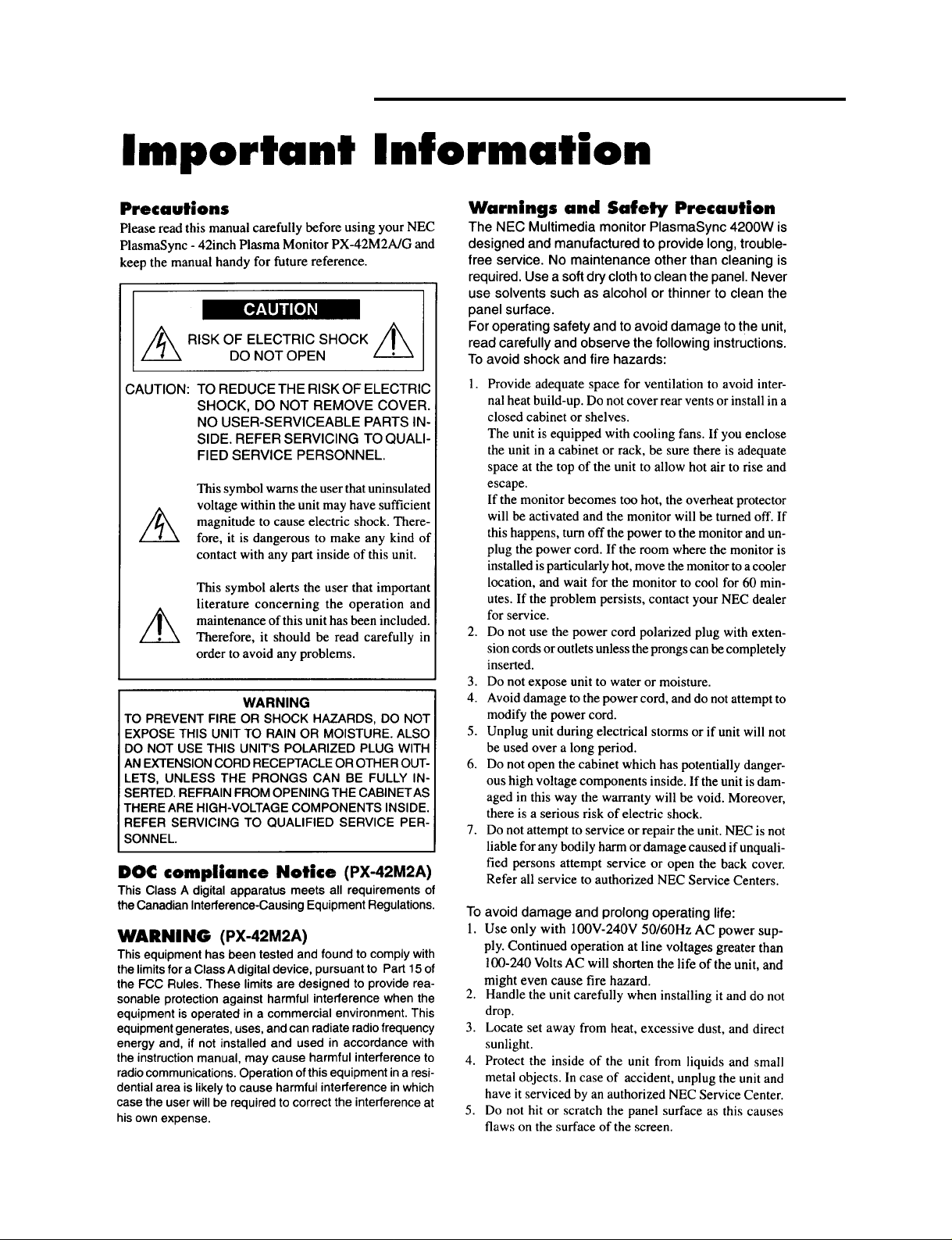

c. Leakage Current Hot Check — With the instru-

ment completely reassembled,plug the AC line

cord directly into a 120V AC outlet (PX-42M2G :

240V AC outlet). (Do not use an isolation transformer during this test.) Use a leakage current

tester or a metering system that complies with

American National Standards Institutes (ANSI)

C101.1 Leakage Current for Appliances and Underwriters Laboratories(UL) 1950. With the instrument AC switch first in the ON position and

then in the OFF position, measure from a

known earth ground (metal waterpipe,

conduit,etc.) to all exposed metal parts of the

instrument(antennas, handle bracket, metal

cabinet, screwheads, metallic overlays, control

shafts,etc.), especially any exposed metal parts

that offer an electrical return path to the chassis.

Any current measured must not exceed 3.5

milliamp. Reverse the instrument power cord

plug in the outlet and repeat test.ANY MEA-

SUREMENTS NOT WITHIN THE LIMITS

SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE

ELIMINATED BEFORE RETURNING THE INSTRUMENT TO THE CUSTOMER.

AC Leakage Test

(READING SHOULD

NOT BE ABOVE

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

3-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

LEAKAGE

CURRENT

TESTER

+–

3.5 mA)

EARTH

GROUND

2. Read and comply with all caution and safety-related

notes on or inside the Monitor cabinet, on the Projection Monitor chassis, or on the picture tube.

3. Design Alteration Warning — Do not alter or add

to the mechanical or electrical design of this unit.

Design alterations and additions, including, but not

limited to, circuit modifications and the addition of

the items such as auxiliary audio and/or video output connections might alter the safety characteristics of this Monitor and create a hazard to the user.

Any design alterations or additions will void the

manufacturer's warranty and will make you,the

servicer,responsible for personal injury or property

damage resulting therefrom.

4. Hot Chassis Warning — a. Some MultiSync Monitor

chassis are electrically connected directly to one

conductor of the AC power cord and may be safely

serviced without an isolation transformer only if the

AC power plug is inserted so that the chassis is

connected to the ground side of the AC power

source. To confirm that the AC power plug is inserted correctly, with an AC voltmeter measure between the chassis and a known earth ground. If a

voltage reading in excess of 1.0V is obtained, remove and reinsert the AC power plug in the opposite polarity and again measure the voltage potential between the chassis and a known earth ground.

b. Some Projection Monitor chassis normally have

85V AC (RMS), between chassis and earth ground

regardless of the AC plug polarity. These chassis

can be safely serviced only with an isolation transformer inserted in the power line between the receiver and the AC power source, for both personnel

and test equipment protection. c. Some Projection

Monitor chassis have a secondary ground systems

in addition to the main chassis ground. This secondary ground system is not isolated from the AC

power line. The two ground system are electrically

separated by insulating material that must not be

defeated or altered.

2-2

Page 5

5. Observe original lead dress. Take extra care to

assure correct lead dress in the following areas:

a. near sharp edges, b. near thermally hot parts—

be sure that leads and components do not touch

thermally hot parts, c. the AC supply, d. high voltage, and e. antenna wiring. Always inspect in all

areas for pinched, out-of-place, or frayed wiring. Do

not change spacing between components, and between components and the printed-circuit board.

Check AC power cord for damage.

6. Components,parts, and/or wiring that appear to

have overheated or are otherwise damaged should

be replaced with components, parts, or wiring that

meet original specifications. Additionally,determine

the cause of overheating and/or damage and, if

necessary, take corrective action to remove any

potential safety hazard.

7. PRODUCT SAFETY NOTICE —Many MultiSync

Monitor electrical and mechanical parts have spe-

cial safety-related characteristics some of which

are often not evident from visual inspection, nor

can the protection they give necessarily be obtained by replacing them with components rated

for higher voltage, wattage, etc. Parts that have

special safety characteristics are identified in this

service data by shading with a mark on schematics and by shading or a mark in the parts list. Use

of a substitute replacement part that does not have

the same safety characteristics as the recommended replacement part in this service data parts

list might create shock, fire, and/or other hazards.

SAFETY PRECAUTIONS

2-3

Page 6

PRECAUTIONS DE SECURITE

1. Avant de remettre un appareil à un client, faire

toujours d'abord un examen de sécurité de

l'appareil en entier comprenant, mais ne s'y limitant

pas les points cités ci-dessous:

a. Vérifier qu' aucun des dispositifs de protection ne

soit défectueux ou n' ait été endommagé pendant

les travaux.

(1) Les volets protecteurs sur ce châssis ont été

montés pour protéger aussi bien le technicien

que le client. Remplacer correctement tous les

volets protecteurs manquants, aussi bien que

ceux qui ont pu être enlevés pour la commodité

des travaux.

(2) Quand vous remettez le châssis ou d'autres

assemblages ensemble dans le coffret, vérifier

qu' ont été remis à leur place tous les dispositifs

de protection, comprenant mais ne s' y limitant

point, les boutons de contrôle non-métalliques,

les feuilles d'isolation, les couverture/volets de

l'ajustement et du compartiment, et l'isolation des

réseaux résistance/condensateur. Ne pas

travailler sur cet appareil ni permettre qu'y

soit effectué un travail sans que tous les

dispositifs de protection n' y soient

correctement installés fonctionnants.

b. Bien vérifier qu'il n'y ait aucune ouverture sur le

coffret qui ne puisse permettre à un adulte ou à

un enfant d'y faire pénétrer ses doigts et attraper

une décharge électrique.

De telles ouvertures comprendraient sans pour

autant s'y limiter (1) l'espace entre le tube à images et le coffret de l'eppareil, (2) les espaces

excessivement ouverts pour la ventilation et (3) la

couverture arrière du coffret improprement fixée

ou incorrectement protegée.

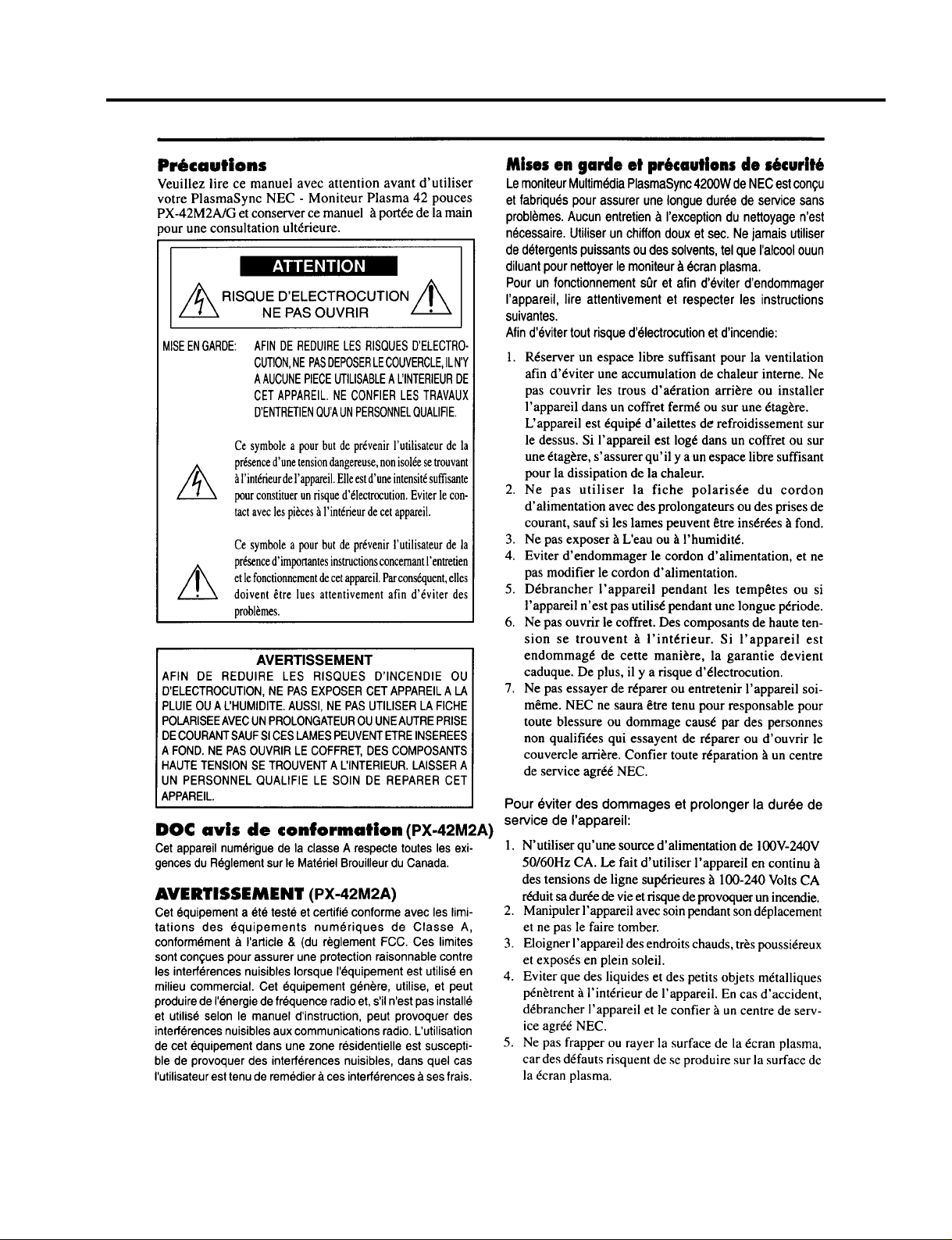

c. Vérification de courant de fuite

L'appareil ayant été complètement réassemblé,

brancher-le à une prise de courant de 120V (PX-42M2G

: 240V). (Ne pas se servir d'un transformateur

d'isolation pendant ce test). Se servir d'un

vérificateur de courant d'excitation ou d'un

système de mesure conforme aux normes ANSI

(American National Standards Institute) C101.1

Leakage Current for Appliances et U. L (Underwriters Laboratories) 1950. Le bouton de

l'appareil en position "Marche" et ensuite en position "Arrêt", mesurer à partir d'une prise de terre

(métallique tuyauterie, conduite, etc...) à toutes

les pièces métalliques de l'appareil exposées

(antennes, poignet métalliques, coffren

métallique, tête des vis, surfaces métalliques,

traits de contrôle, etc.) surtout à toutes les pièces

métalliques exposées qui peuvent reconduire le

courant au châssis. En aucun cas, la mesure du

2-4

courant ne doit dépasser 3.5 milliamp. Inverser la

fiche de courant de l'appareil dans la prise et

répéter le test. Tout mesurage ne s'arrêtant

pas aux limites spécifiées icicomporte un risque de décharge électrique dangereux, qui

doit être éliminé, avant que l'appareil ne soit

remis au client.

EXAMEN DE COURANT

D'EXCITATION

(LA MESURE DU COURANT

NE DOIT PAS DEPASSER

3.5 MILLIAMP)

DISPOSIT IF

SOUS

L ' EXAMEN

EXAMINER TOUTES

LES PIECES METALLIQUES

DEL' APPAREIL EXPOSEE

3-CORDES DE FIL

EXAMINER AVEC

LA FICHE DE COURANT

INVERSEE

(SE SERVIR DE LA FICHE DE COURANT

DE L' A DAPTATEUR COMME DEMANDEE)

+–

VERIFICATEUR

DE CORANT

DE FUITE

PRISE DE TERRE

2. Lire et respecter toutes les mises en garde et notes

de sécurité à l'intérieur ou à l'extérieur du coffret du

rétro-projecteur, sur le châssis du rétro-projecteur

ou sur le tube à images.

3. Mise en garde contre la modification du dessin

Ne pas modifier ni ajouter à la pièce mécanique ou

électrique du modèle. Des modifications ou additions, comportant, mais ne s'y limitant pas, des

modifications des circuits et l'addition d'éléments

tels que des auxilliairs audio et/ou des

branchements pour la prise de vidéo, pourrait

éprouver la sécurité de ce rétro-projecteur et créer

un risque pour l'utilisateur. Tout changement ou ad-

dition accomplie annulera la garantie du fabricant et

va rendre votre service d'entretien, responsable des

dommages corporels ou de biens en résultant.

4. Mise en garde contre le châssis sous tension

a. Certains châssis de rétro-projecteur sont

électriquement reliés à un conducteur du fil de

courant et ainsi peuvent ne comporter aucun risque sans un transformateur d'isolation seulement

si la prise de courant est branchée, de manière

que le châssis est relié à la prise de terre de la

source de courant. Pour s'assurer que la prise de

courant est correctement insérée, relever les

mesures avec un voltmètre de courant entre le

châssis et un point de prise de terre bien connu.

Si le voltage indiqué est supérieur à 1,0V,

débrancher et reinsérer la prise de courant dans

la polarité contraire et une fois de plus remesurer

le voltage potentiel entre le câssis et la prise de

terre.

Page 7

PRECAUTIONS DE SECURITE

b. Certains châssis de moniteur ont habituellement

85V (RMS) entre le châssis et la prise de terre, en

fonction de la polarité de la prise de courant. Ces

châssis peuvent ne comporter aucun risque

seulement avec un transformateur d'isolation

inséré dans la ligne de puissance située entre de

rétro-projecteur et la source d'électricité, cela

pour la protection aussi bien du personnel que du

matériel de vérfication.

c. Certains châssis de rétro-projecteur ont un

système secondaire de masse en addition avec

le système principal de masse du châssis. Ce

système secondaire de masse n'est pas isolé du

courant électrique. Les deux systèmes sont

électriquement séparés par du matériel

d'isolation qu' on vérifiera bien qu'il ne soit ni

altéré ni défectueux.

5. Vérifier la couverture originale en plomb. Accorder

la plus grande attention à la couverture de plomb

notamment aux endroits ci-dessous indiqués.

a. Près des bords aigus

b. près des parties très chaudes

Vérifier que les composants et les plombs ne

touchent pas les parties très chaudes telles que:

c. l'alimentation du courant

d. la haute tension

e. Ies fils de l'antenne

Pousser l'inspection, à tous les endroits, à la recherche des cordes pincées, déplacées ou effilochées.

Ne pas changer l'écartement entre composants, et

entre composants et le tableau de circuit imprimé.

Vérifier que le fil de conduite électrique est en bon

état.

6. Les composants, parts (pièces) et/ou fils qui ont été

trouvés surchauffés devraient être remplacés avec

les composants, pièces et fils s'y reliant avec d'autre

qui ont les mêmes spécifications que les originales.

De plus, rechercher la cause du surchauffement et/

ou des dommages et si nécessaire, prendre les

mesures propres pour prévenir tout risque potentiel.

7. Note sur sûreté de l'appareil

Beaucoup de pièce de rétro-projecteur, qu'elles

soient électriques ou mécaniques, ont des dispositions de sécurité qui ne sont pas toujours évidentes

d'une simple inspection visuelle et la protection

qu'elles donnent nécessairement ne pourront être

pas obtenues par les remplaçants avec des

composants aux voltages ou watts plus élevés.

Les pièces qui ont des caractéristiques particulières

de sécurité sont identifiées avec un trait marqué

sur les schémas et sont ombragés ou comportent

un trait sur la liste des pièces. L'utilisation d'un

produit substitutif qui n'aurait pas les mêmes

caractéristiques comme il est recommandé dans

ces données d'entretien pourrait provoquer une

décharge électrique, un feu, et/ou d'autres dangers.

2-5

Page 8

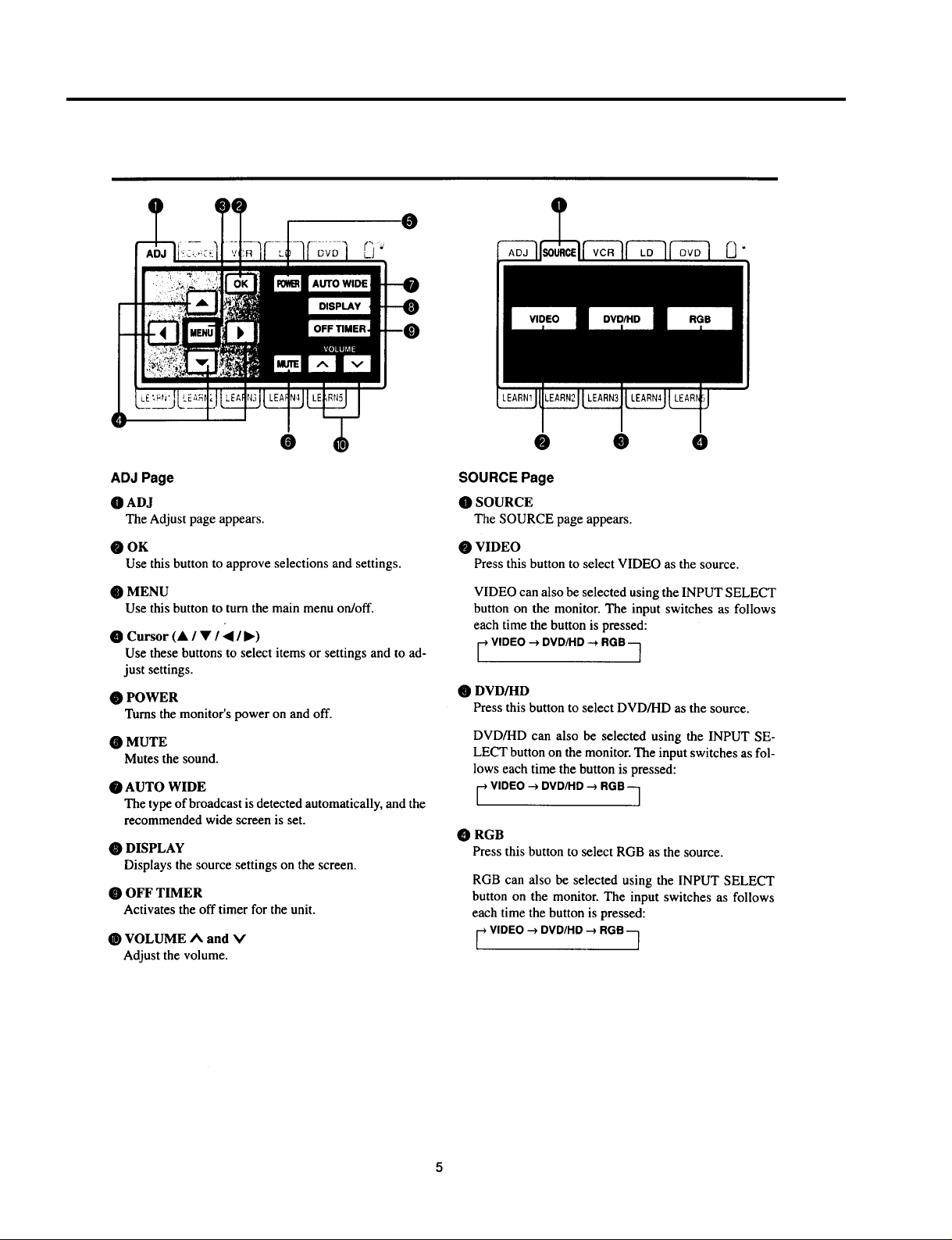

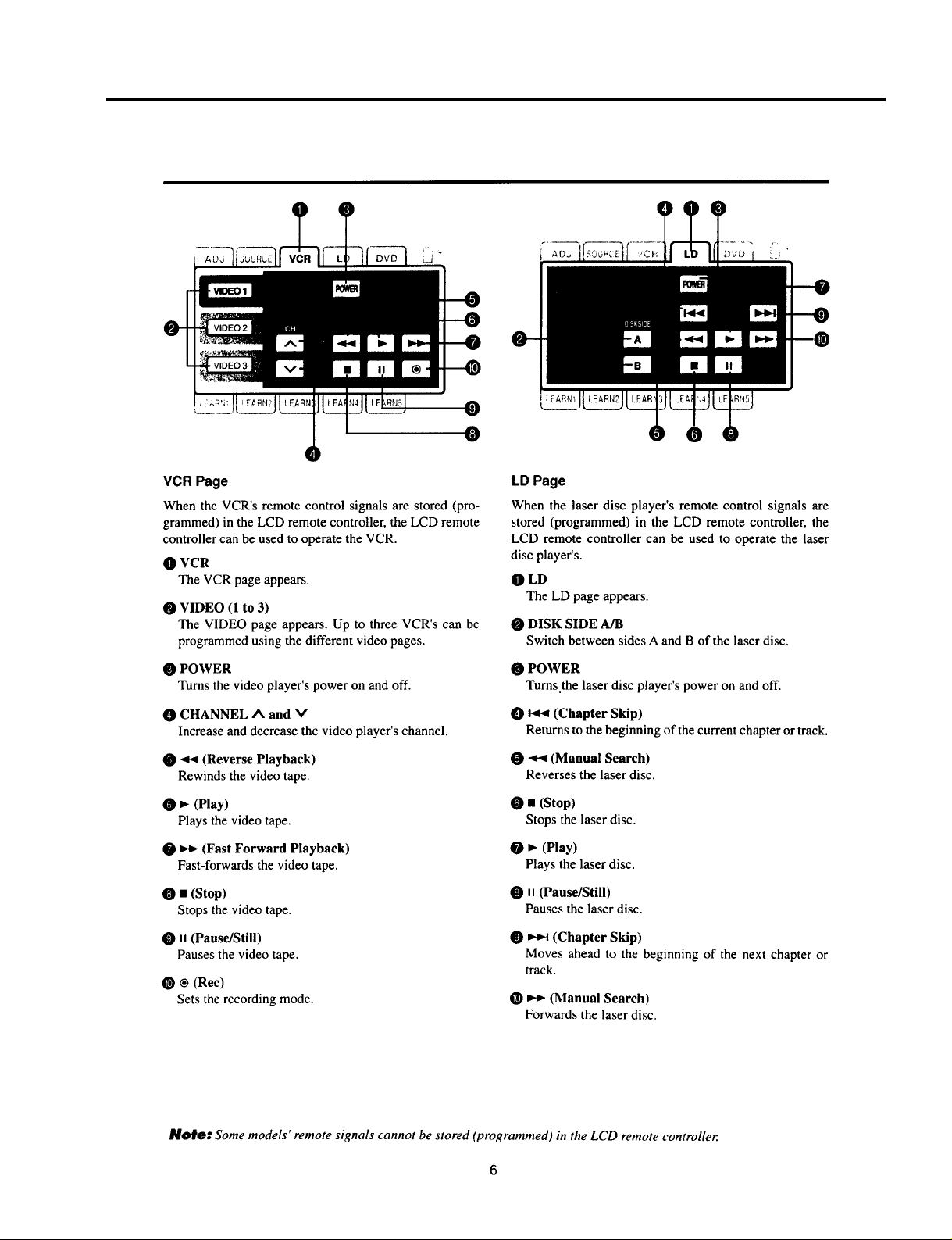

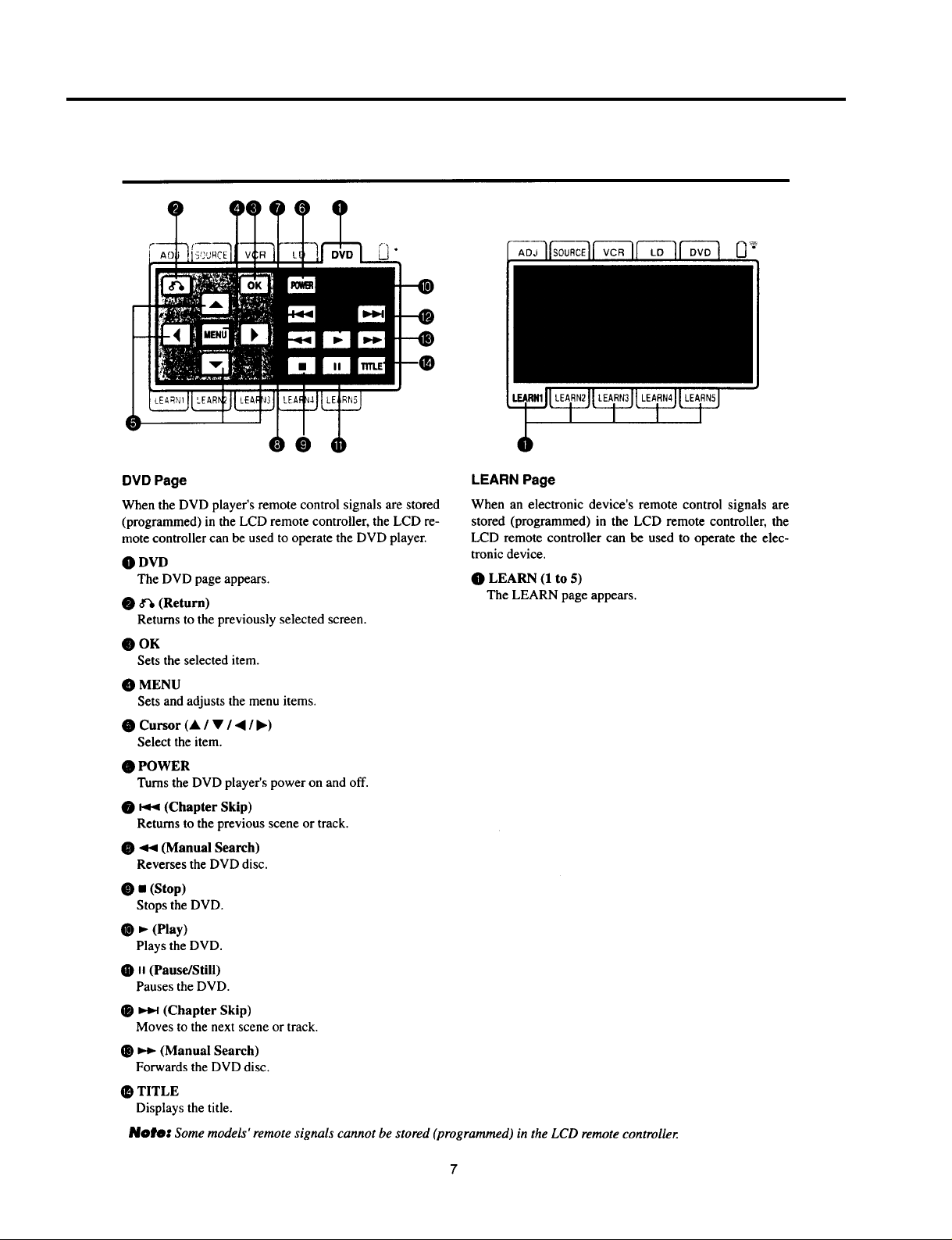

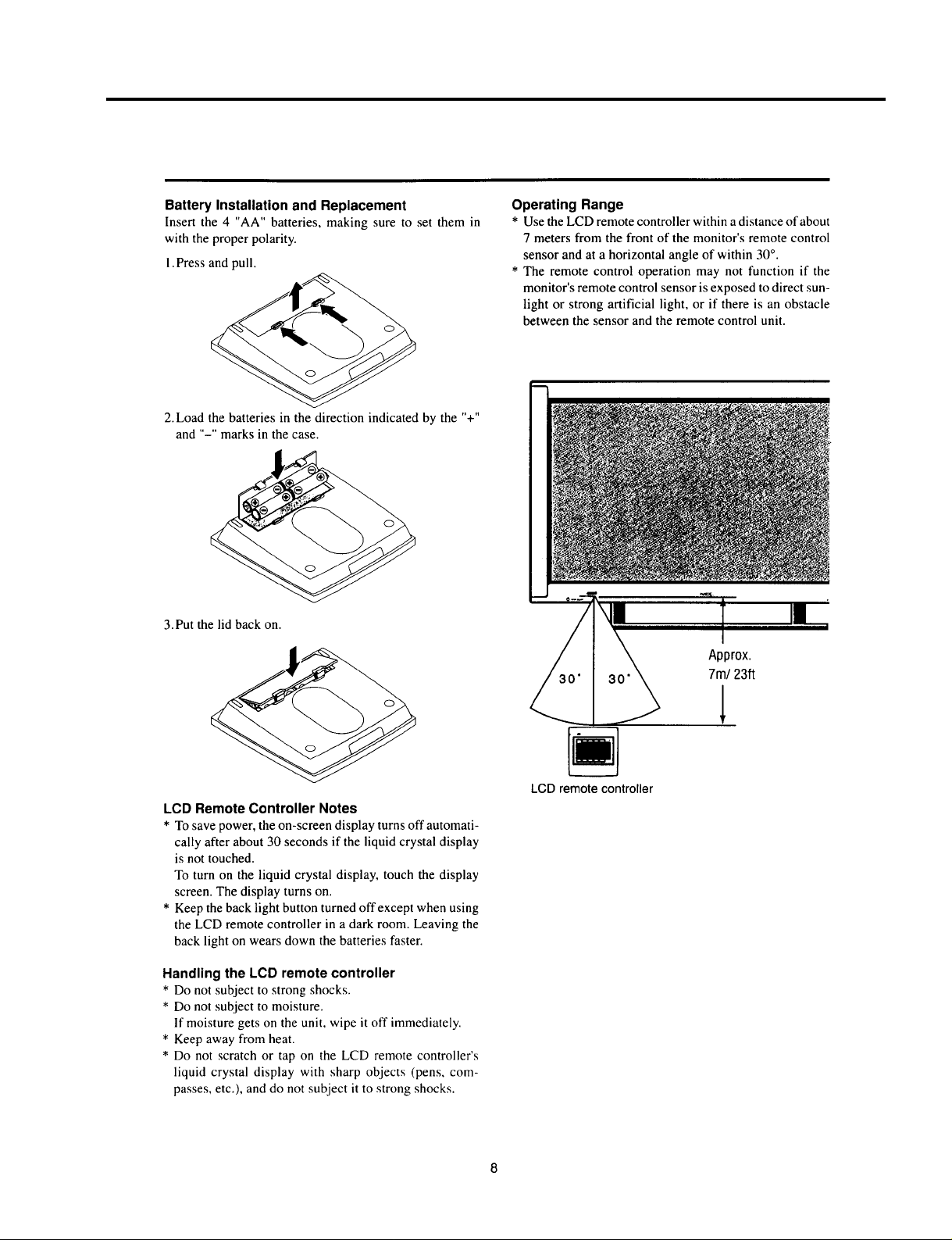

USERS MANUAL

3-1

Page 9

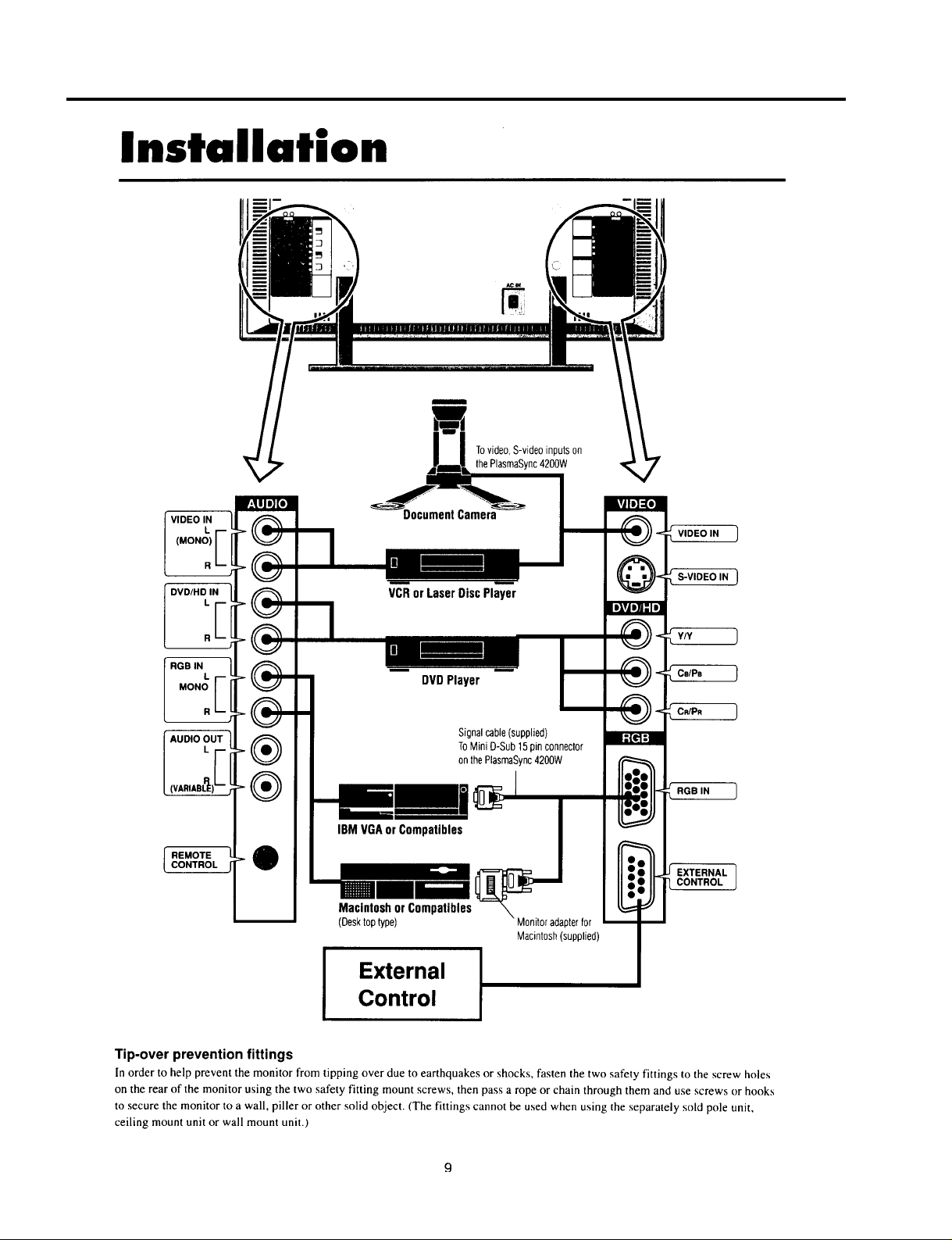

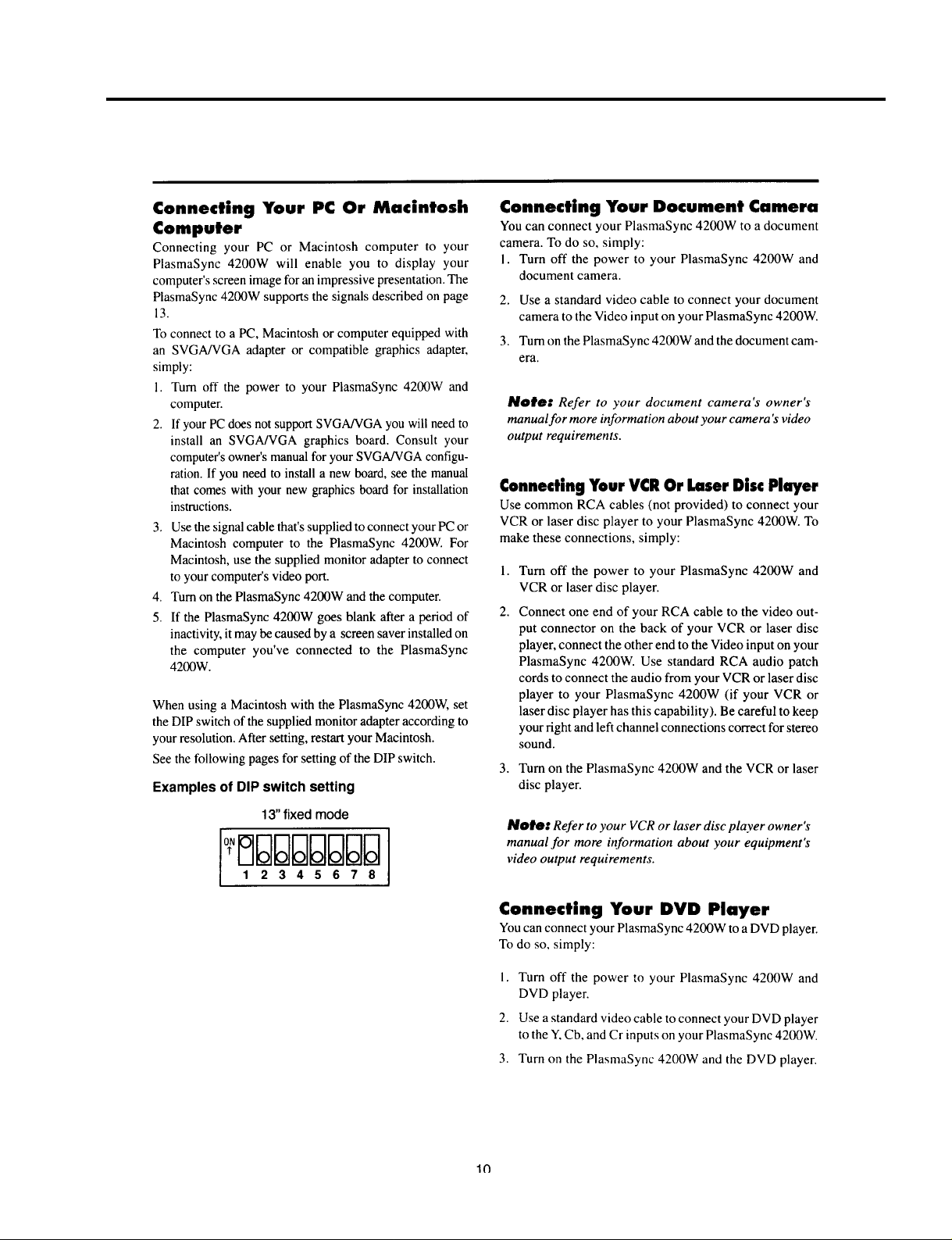

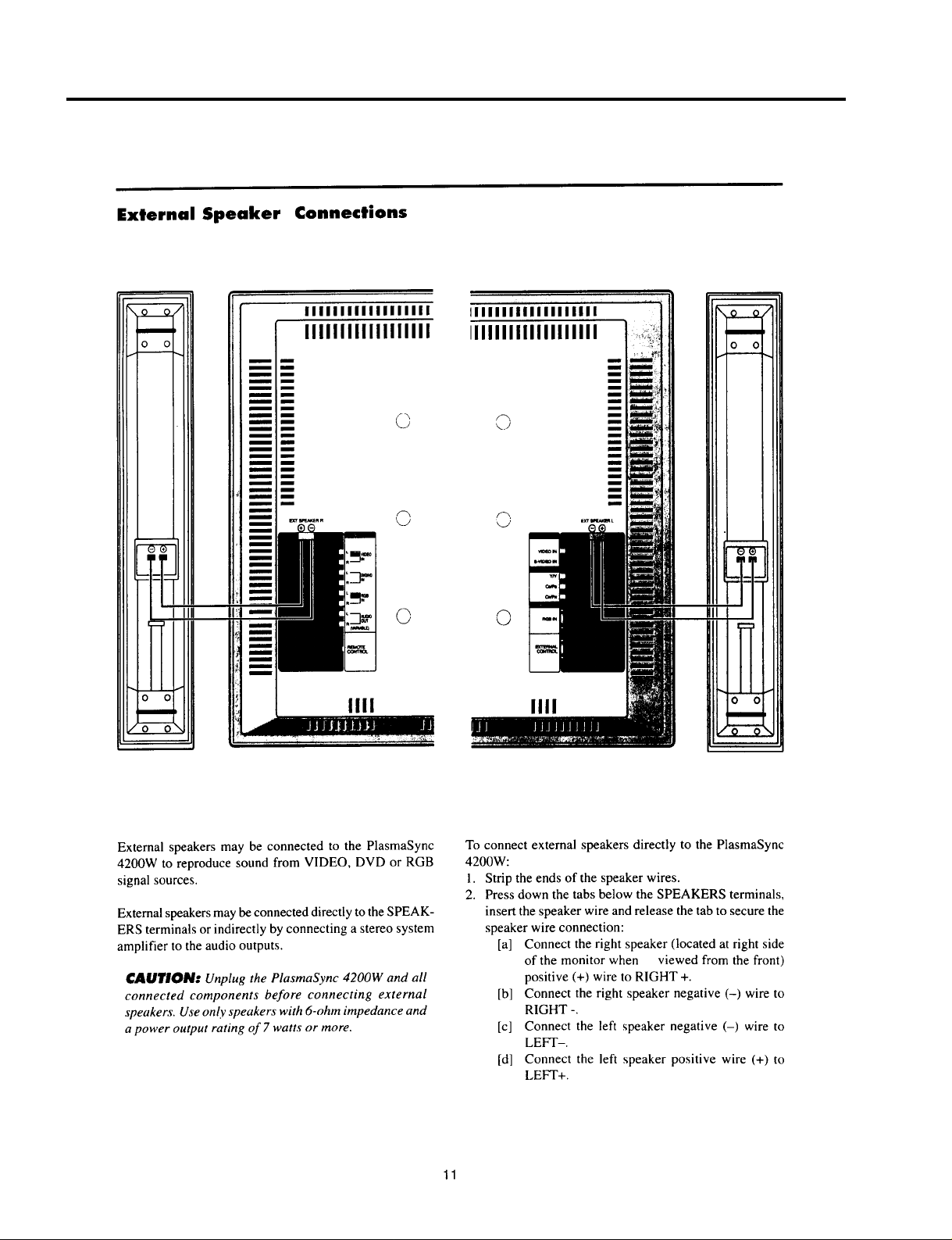

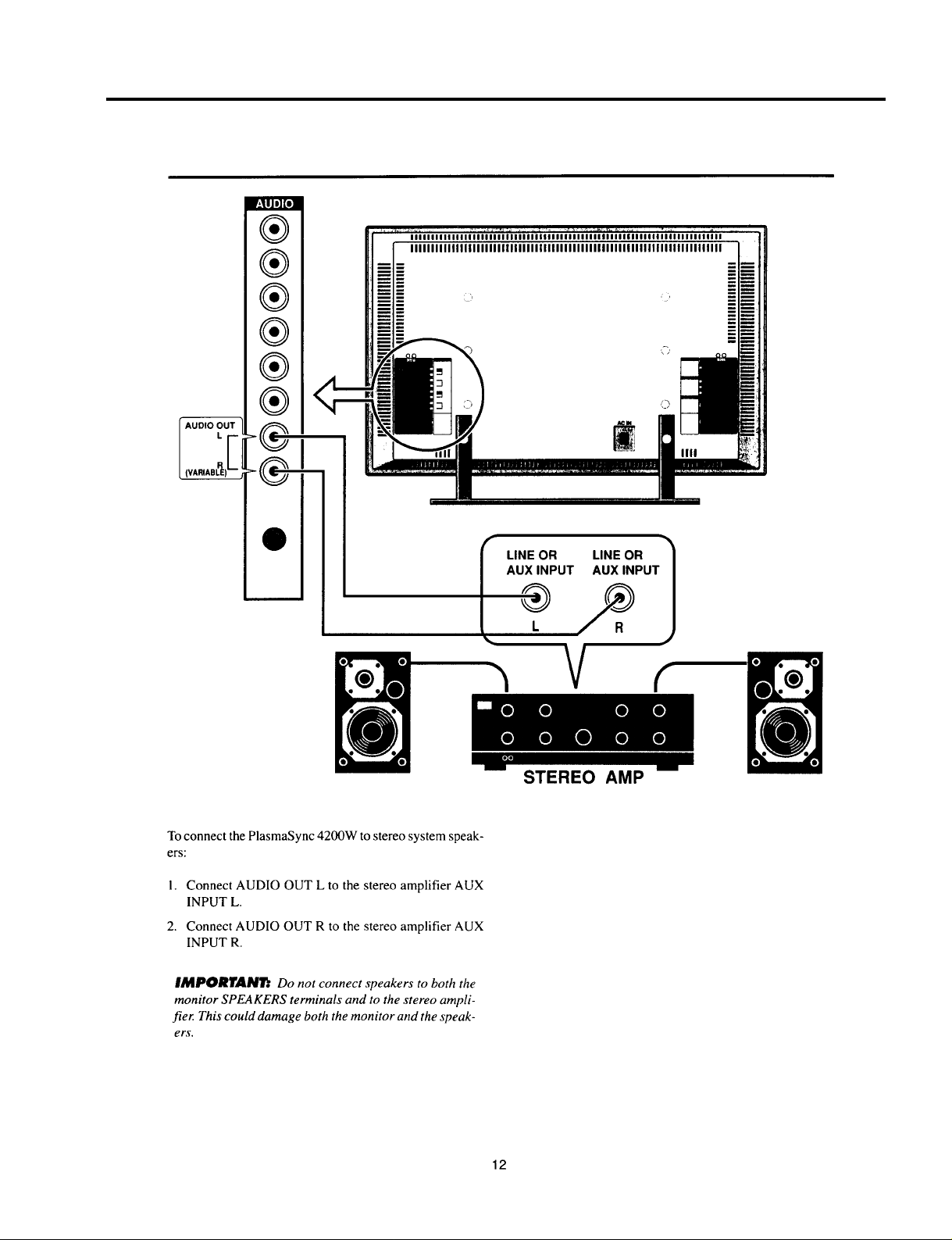

USERS MANUAL

3-2

Page 10

USERS MANUAL

3-3

Page 11

USERS MANUAL

3-4

Page 12

USERS MANUAL

3-5

Page 13

USERS MANUAL

3-6

Page 14

USERS MANUAL

3-7

Page 15

USERS MANUAL

3-8

Page 16

USERS MANUAL

3-9

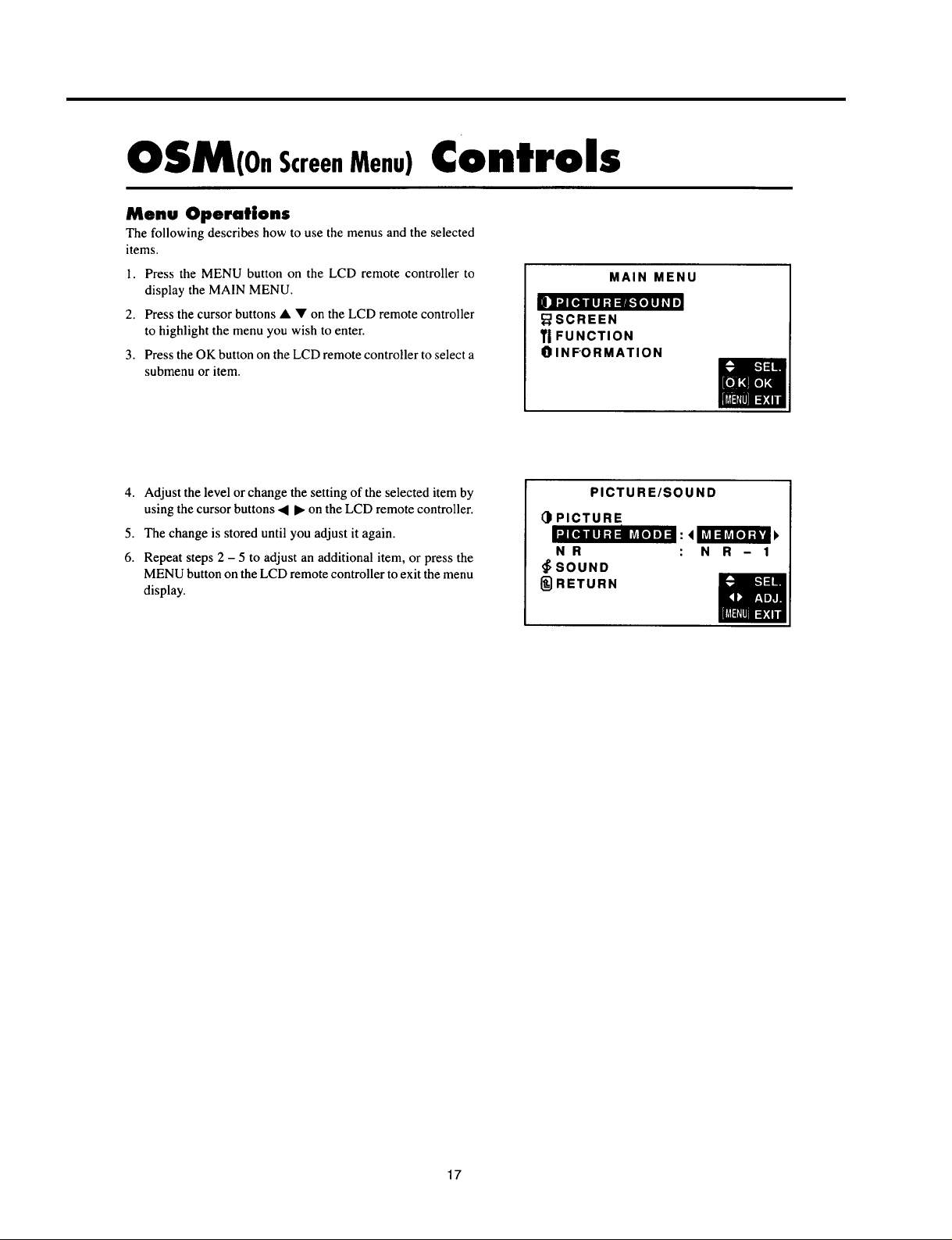

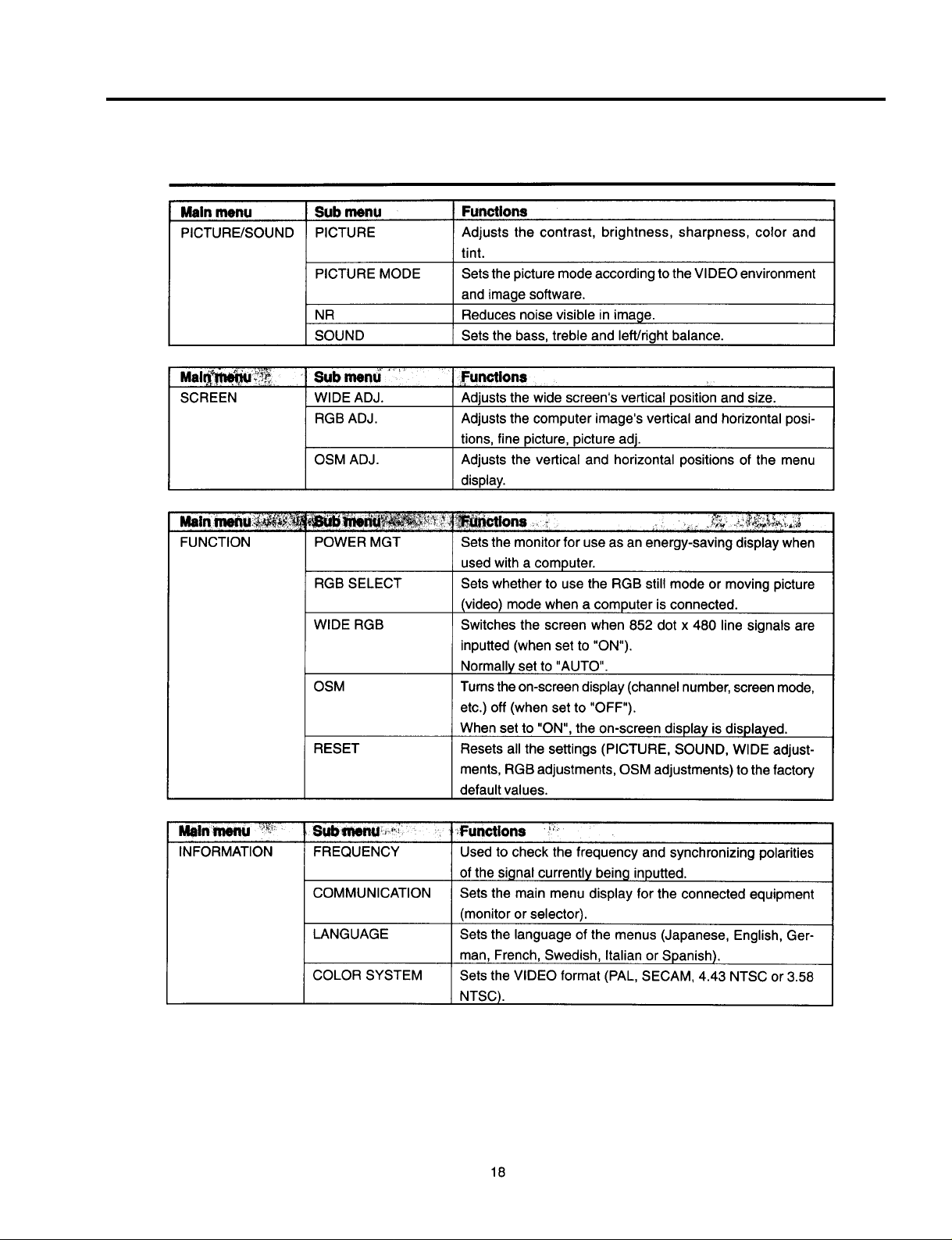

Page 17

USERS MANUAL

3-10

Page 18

USERS MANUAL

3-11

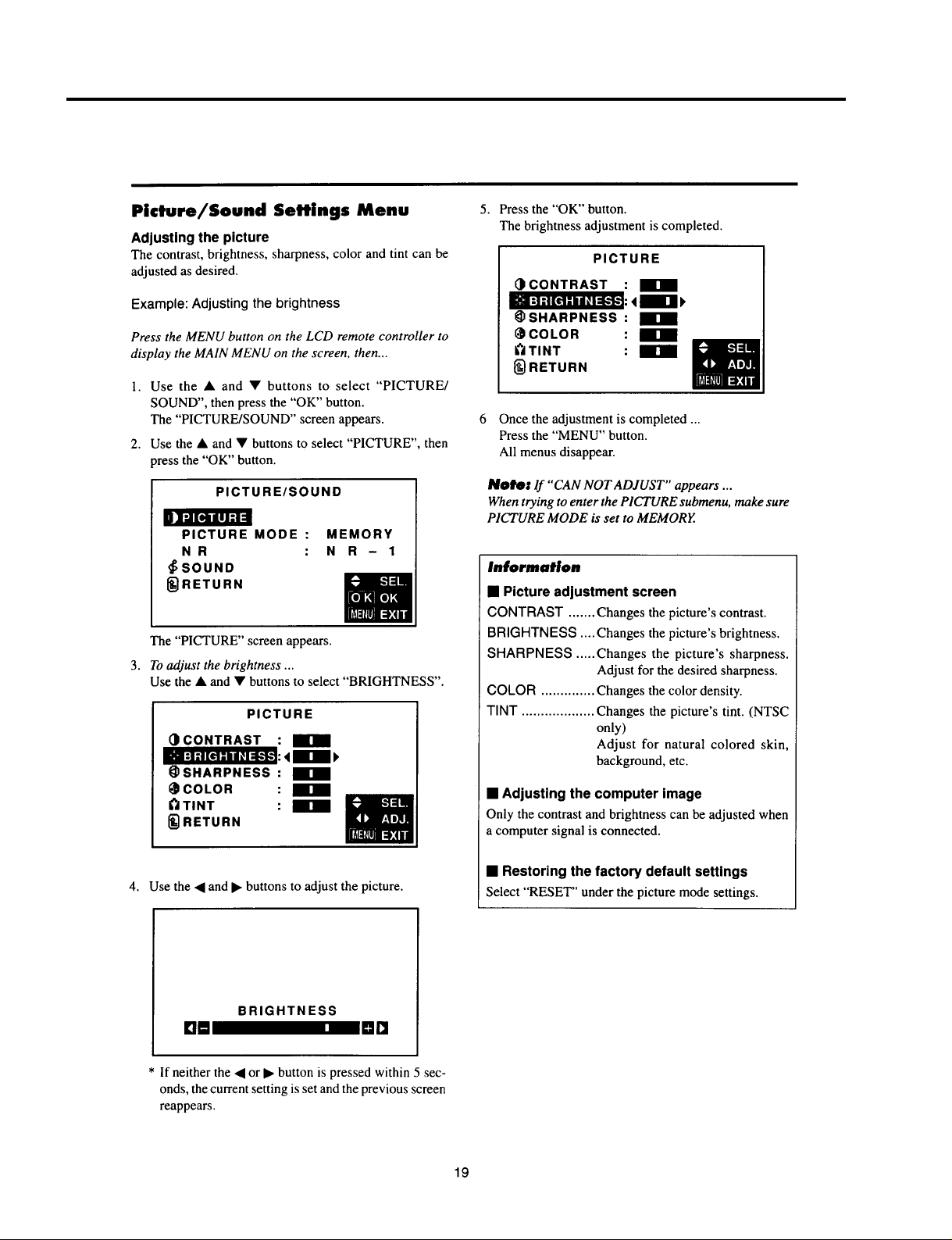

Page 19

USERS MANUAL

3-12

Page 20

USERS MANUAL

3-13

Page 21

USERS MANUAL

3-14

Page 22

USERS MANUAL

3-15

Page 23

USERS MANUAL

3-16

Page 24

USERS MANUAL

3-17

Page 25

USERS MANUAL

3-18

Page 26

USERS MANUAL

3-19

Page 27

USERS MANUAL

3-20

Page 28

USERS MANUAL

3-21

Page 29

USERS MANUAL

3-22

Page 30

USERS MANUAL

3-23

Page 31

USERS MANUAL

3-24

Page 32

USERS MANUAL

3-25

Page 33

USERS MANUAL

3-26

Page 34

USERS MANUAL

3-27

Page 35

USERS MANUAL

3-28

Page 36

USERS MANUAL

3-29

Page 37

USERS MANUAL

3-30

Page 38

USERS MANUAL

3-31

Page 39

USERS MANUAL

3-32

Page 40

USERS MANUAL

3-33

Page 41

USERS MANUAL

3-34

Page 42

USERS MANUAL

3-35

Page 43

USERS MANUAL

3-36

Page 44

USERS MANUAL

3-37

Page 45

USERS MANUAL

3-38

Page 46

USERS MANUAL

3-39

Page 47

USERS MANUAL

3-40

Page 48

USERS MANUAL

3-41

Page 49

USERS MANUAL

3-42

Page 50

USERS MANUAL

3-43

Page 51

USERS MANUAL

3-44

Page 52

USERS MANUAL

3-45

Page 53

USERS MANUAL

3-46

Page 54

USERS MANUAL

3-47

Page 55

USERS MANUAL

3-48

Page 56

USERS MANUAL

3-49

Page 57

USERS MANUAL

3-50

Page 58

USERS MANUAL

3-51

Page 59

USERS MANUAL

3-52

Page 60

USERS MANUAL

3-53

Page 61

USERS MANUAL

3-54

Page 62

USERS MANUAL

3-55

Page 63

USERS MANUAL

3-56

Page 64

USERS MANUAL

3-57

Page 65

USERS MANUAL

3-58

Page 66

USERS MANUAL

3-59

Page 67

USERS MANUAL

3-60

Page 68

USERS MANUAL

3-61

Page 69

USERS MANUAL

3-62

Page 70

USERS MANUAL

3-63

Page 71

USERS MANUAL

3-64

Page 72

USERS MANUAL

3-65

Page 73

USERS MANUAL

3-66

Page 74

USERS MANUAL

3-67

Page 75

USERS MANUAL

3-68

Page 76

USERS MANUAL

3-69

Page 77

USERS MANUAL

3-70

Page 78

USERS MANUAL

3-71

Page 79

USERS MANUAL

3-72

Page 80

USERS MANUAL

3-73

Page 81

USERS MANUAL

3-74

Page 82

USERS MANUAL

3-75

Page 83

TROUBLE SHOOTING

No energization of POWER circuit

Is POWER LED NO Is the power plug correctly NO Rearrange the power plug

lit? connected to the wall outlet? connection correctly.

YES YES

Is there AC 100V behind the NO Fuses F1 and F2 have blown

fuses F1 and F2? out.

Green flashing: To 1 (Page 4-2) If the fuses blow out again after

Red flashing: To 2 (Page 4-2) replacement, the POWER unit

Green and red flashing: To 3 (Page 4-3) is out of order.

Green lighting: To 4 (Page 4-3)

YES

Is there M+15V output at NO Disconnect the PM and PQ

Pin 1 of the PM connector? connectors from one after an-

other. If there is M+14V output,

the circuit beyond the connectors is out of order. If there is no

output, the POWER unit is out

of order.

YES

Is there +5V output at Pin

of IC6805 (ANALOG PWB)? and related circuits.

YES

Is there +5V output at Pin

of the PW connector? POWER PWB

YES

Is there +5V output at Pin

of the PW connector? IC6800 (ANALOG PWB).

YES

Failure in POWER PWB

2

NO Failure in SW2001 (CTL PWB)

5

NO Failure in +5V line as far as

3

NO Failure in peripheral area of

4-1

Page 84

TROUBLE SHOOTING

1

Is 0V observed at Pin 4 of Failure in peripheral area of IC6800

IC6800 (ANALOG PWB)?

YES

Is 0V observed at Pin 1 or

of IC6553 (ANALOG PWB)?

YES

1

0V at Pin 1: Failure in fan’s peripheral area of the set

2

0V at Pin 2: Failure in fan’s peripheral area in the POWER unit

2

Is 0V observed at Pin 57 of Failure in peripheral area of IC6800

IC6800 (ANALOG PWB)?

2

NO

NO

NO

Failure peripheral area of IC6553

YES

Is 0V observed at Pin 5 of Failure in peripheral area of IC6808

IC6808 (ANALOG PWB)?

YES

Failure in TH1 of the POWER

unit and peripheral circuits

NO

4-2

Page 85

TROUBLE SHOOTING

3

Is 0V observed at Pin $ of Failure in peripheral area of IC6800

IC6800 (ANALOG PWB)?

YES

Failure in peripheral area of

MODULE circuit

4

Is “H” maintained at Pins 2 and Failure in peripheral area of IC6800

3

of the PM connector?

YES

Is “H” maintained at Pin 7 of Failure in peripheral area of MODULE

the PH connector?

YES

Is power supply available when Confirm that the power supply is a vailable by disconnecting

SW1 (POWER unit: HV system the connectors of PV, PQ, PN, PA from one after another

is OFF) is turned OFF? (others keptconnected). If available, circuit of the disconn-

YES

NO

NO

NO

NO

ected connector is out of order. If not available, the POWER

unit is out of order.

Failure in peripheral area of the

HV system in MODULE and

POWER unit.

4-3

Page 86

TROUBLE SHOOTING

No display (no video screen display)

Enter a color bar signal input.

Is there on-screen display NO Refer to Fault Analysis for

of VIDEO? ANALOG PWB and thereafter.

YES

Is there a video signal at NO

TP1001? is there a video signal at the source.

YES YES

With the YC connector NO Failure in peripheral area of

disconnected, is there a IC1001

video signal at TP1025?

YES

Is there a video signal at NO Is there a rectangular waveform NO Failure in peripheral

Pin 2 of the VD connector signal of 5Vp-p at pins 2 and 3 area of IC6800

in VIDEO PWB? of the JC connector?

YES YES

Refer to Fault Analysis for

ANALOG PWB and thereafter.

With the signal line disconnected,

signal line terminal?

Failure in peripheral area of

IC1001

To 5 (Page 4-5)

NO Failure in signal

4-4

Page 87

5

Signal Y input is available NO Failure in peripheral area of

at Pin 53 of IC5008. IC5008.

YES

Signal Y output is available NO Failure in peripheral area of

from Pin 4 of IC5008. IC5012 ~ IC5017.

YES

Signal Y (or VIDEO) input NO Failure in peripheral area of

is available at Pin 15 of IC5008.

IC5008.

YES

Signal Y (or VIDEO) output NO Failure in Q5011 and Q5037~

is available at Pin 6 of Q5039.

IC5005.

TROUBLE SHOOTING

YES

There is a signal input at IC5006: NO Failure in peripheral area of

Signal Y at Pin 14 for NTSC, Signal Y at IC5005.

Pin 16 for PAL, Signal VIDEO at Pin 1 for

SECAM, and Signal Y at Pin 9 for S-input.

YES

Abnormality occurring with SECAM/S input

is due to failure in V-I/O board. Abnormality

occurring with NTSC/PAL is due to failure in

YC separator circuit.

4-5

Page 88

TROUBLE SHOOTING

No display (no HD/DVD screen display)

Enter a color bar signal

input.

Is there on-screen display NO Refer to Fault Analysis for

of “HD” or “DVD”? ANALOG PWB and thereafter.

YES

Is there a video signal at NO With the signal line disconnec- NO Failure in signal

TP1004? ted is there a video signal at source.

the signal line terminal?

YES YES

Failure in the signal line of

IC6110 or before it.

Refer to Fault Analysis

for ANALOG PWB and

thereafter.

4-6

Page 89

TROUBLE SHOOTING

No display (no RGB/PC screen display)

Enter a VGA or SVGA

color bar signal input.

Is there on-screen display NO Refer to Fault Analysis for

of “PC”? ANALOG PWB and thereafter.

YES

Is LED lit in green ? NO Is there horizontal sync at NO Failure in the signal

(Not in power management) Pin 13 of M1006, or vertical line.

sync at Pin 14?

YES YES

Is there horizontal sync at NO Failure in the VI/O

Pin 8 of ANALOG PWB “PC” sync system (Q1050

connector, or vertical sync at and peripheral area

Pin 10? of IC1006).

YES

Is there horizontal sync at Pin Failure in the ANALOG

89 of IC6800, or vertical sync PWB sync system.

at Pin 19?

YES

Failure in the peripheral area

of IC6800.

Is there a video signal at NO With the signal line disconnected, NO Failure in the signal

TP1007, TP1008, and is there a video signal at the line.

TP1009? signal line terminal?

YES YES

Failure in the signal line of

IC6110 or before it.

Refer to Fault Analysis for

ANALOG PWB and

thereafter.

NO

4-7

Page 90

TROUBLE SHOOTING

No display (fault analysis for ANALOG PWB and thereafter)

Is there a video signal at TP6139, NO Failure in ANALOG PWB (peripheral area of the signal line

TP6140, and TP6141? before AD converter)

YES

Is there a signal of 5Vp-p at Pins 1 NO Failure in ANALOG PWB (signal circuit or sync system circuit

~ 47 of the AD connector of AD converter and thereafter, or peripheral area of IC6800).

(odd-numbers only)?

YES

Is there a clock signal at Pin 49 NO Failuure in ANALOG PWB (sync system circuit or peripheral

of the AD connector? area of IC6800).

YES

Is there a signal of 5Vp-p at NO Failure in ANALOG PWB (sync system circuit or peripheral

Pin 52 of the AD connector area of IC6800).

(H-SYNC), Pin 53 (V-SYNC),

or Pin 76 (V period)?

YES

NO

Is normal display available after Failure in the AD cable.

replacement of AD cable?

YES

NO

Is normal display available after Failure in ANALOG PWB

replacement of ANALOG PWB?

YES

NO

Are the PD and PH connectors Make correct connections.

correctly connected?

YES

NO

Are there normal outputs of 180V , Refer to No energization of POWER circuit.

80V , and D+5V in the POWER unit?

YES

Failure in the plasma display

module.

4-8

Page 91

TROUBLE SHOOTING

No video in NTSC Mode

YES

Signal Y is available at Failure in Q9001 ~ Q9003.

TP9003.

NO

There is a VIDEO signal YES There is an FSC signal NO Failure in Q9010/

at TP9007. (3.5MHz sine wave) at TP9008. Q9015/Q9016/Q9023.

NO YES

6

There is a VIDEO Failure in There is an 8FSC signal NO There is a vertical

signal at Pin 1 of Q9009/9011/ (28.63MHz sine wave) at TP9013. sync signal at Pin 1 of

the POYC connector.

NO YES

Failure in the V-I/O board. There is a horizontal sync signal NO

YES

Q9012/ Q901. IC9004, and also a

composite sync signal

at Oin 2.

at TP901 1.

YES

There is a vertical sync signal NO

at TP9012.

YES YES

Failure in the peripheral area Failure in IC9004.

of IC9086.

NO

Failure in Q9013/

Q9017/ Q9018 or in

the pre-stage.

4-9

Page 92

TROUBLE SHOOTING

No PAL Reproduction

YES

Signal Y is available at Failure in Q5007/Q5046/IC5015.

TP5004.

NO

There is a VIDEO signal YES There in an FSC signal (3.58MHz NO Failure in the peripheral

at TP5030. sine wave) at Pin 19 of IC5007. area of Q5023.

NO YES

7

There is a VIDEO Failure in Pin 10 of IC5007 is led to LO.

signal at Pin 1 of Q5036/Q5004

the POYC connector.

NO YES NO

Failure in the V-I/O board. Failure in the peripheral area Failure in the peripheral

YES

~Q5006.

of IC5007 areaof Q5035.

4-10

Page 93

No color Reproduction

TROUBLE SHOOTING

RGB signal is available at Failure in ANALOG PWB

Pins 1, 3, 5 of the POVD

connector.

NO

R-Y/B-Y signal is available Failure in the peripheral area of IC5008.

at Pins 51 and 52 of IC5008.

NO

R-Y/B-Y signal is available Failure in the peripheral area of IC5012.

at Pins 7 and 8 of IC5012.

NO

R-Y/B-Y signal is available Failure in the peripheral area of IC5009.

at Pins 26 and 27 of IC5009.

NO

Failure in the SECAM demodulation system for SECAM.

Failure in the peripheral area of IC5010 (SECAM demodulation system)

if there is R-Y/B-Y signal is available at Pins 12/13 of IC5010. If there is no

such signal, it is then a failure in the Y/C separator circuit (or IC5008).

YES

YES

YES

YES

4-11

Page 94

TROUBLE SHOOTING

No NTSC color generation

Signal C is available at Pin 13 of IC5008. Failure in the peripheral area of IC5008.

NO

Signal C is available at Pin 14 of IC5006. Failure in the peripheral area of IC5006.

NO

Signal C is available at TP9004. Failure in Q9005 ~ Q9008.

NO

To Step 6 (Page 4-9)

YES

YES

YES

No PAL color generation

Signal C is available at Pin 13 of IC5008. Failure in the peripheral area of IC5008.

NO

YES

Signal C is available at Pin 16 of IC5006. Failure in the peripheral area of IC5006.

NO

Signal C is available at TP9005. Failure in Q5009/ Q5047/ IC5016.

NO

To Step 7 (Page 4-10)

YES

YES

No SECAM color generation

Signal C is available at TP5017. Failure in the peripheral area of IC5006.

NO

Failure in the peripheral area of IC5017.

YES

4-12

Page 95

Abnormality in the sync system

Enter a color bar signal

input.

TROUBLE SHOOTING

Is it a VIDEO input? Is it an HD/DVD input?

YES YES

Is there a video signal at NO Is there a video signal NO Is threr a sync signal

TP1025? at Pin 2 of the “HD” at Pin 8 and 10 of

YES YES YES

Is there a sync signal at VIDEO PWB defective.

Pins 6 and 8 of the “VD”

connector?

Are there a clock signal

synchronized with the input NO ANALOG PWB

signal, a horizontal sync defective.

signal, and a vertical sync

signal respectively at Pins

49, 51, and 53 of the “AD”

connector?

NO NO

connector? the “PC” connector?

NO

NO

VI/O PWB

defective.

YES

NO

Is normal display available Failure in the AD cable.

after replacement of AD

cable?

NO

Is normal display available NO Failure in ANALOG

after replacement of PWB

ANALOG PWB?

NO

Failure in the plasma

display module.

4-13

Page 96

TROUBLE SHOOTING

No audio signal from speaker output

Audio signal is available Voltage is 3V or about TP3003. Failure in IC3003.

at POSR/POSL.

NO

Audio signal is available YES

at TP3004/3005.

NO 8 NO

Audio signal is available Failure in Q3003 and Q3004.

at Pins 10/21 of IC3001.

NO YES

Audio signal is available Failure in the peripheral area

at TP3001/3002 of IC3002.

NO YES

Audio signal is available Failure in the peripheral area

at TP4002/4003. of IC3001.

NO YES

YES YES

Audio signal is available Failure in the peripheral area

at Pins 1/3/4/6/8/10 of of IC4002.

IC4001.

NO YES

Check each PHONO Failure in the peripheral area

pin input. of IC4001.

4-14

Page 97

No audio output from AUDIO OUT

TROUBLE SHOOTING

Audio signal is available at TP4006/4007. Check the Super-woofer side.

NO

Audio signal is available at Pins 1/3 of the Faiurte in IC4003

POMS connector.

NO

To Step 8 (Page 4-14)

YES

YES

4-15

Page 98

METHOD OF ADJUSTMENTS

I. Application

This specification covers the method of adjustments for the color plasma display “PX-42M2A/G” for domestic users.

II. Adjustment items

<Analog Block>

1. Setting and confirmation before adjustments

2. Adjustment of µPC1885

3. Adjustment of image level (M52327SP)

3-0. Lowpass Filter Level Adjustment

3-1. Adjustment of HD/DVD level

3-2. Adjustment of video level

3-3. Adjustment of PC/RGB level

3-4. Adjustment of sub-brightness

3-5. Adjustment of sub-contrast

4. Setting for APL control

5. Unit inspection for ANALOG PWB and VIDEO PWB

5-1. Setting of inverse gamma

5-2. Confirmation of video siganls

5-3. Confirmation of video control siganls

5-4. Confirmation of HD/DVD signal processing

5-5. Confirmation of HD/DVD signal mode

5-6. Confirmation of PC 400-line mode

5-7. Confirmation of PC VGA mode

5-8. Confirmation of PC SVGA mode

5-9. Confirmation of PC MAC signal mode

5-10. Confirmation of APL correction data

5-11. Detection of fan stop

5-12. Confirmation of short-circuit test panel crack detection signal

6 . Data writing for plug and play

7 . Setting and confirmation before shutdown

<Audio Block>

1. Confirmation before adjustments

2. Adjustment of audio output level

3. Adjustment of audio balance

<Set Adjustment>

1. Adjustment of screen position and phase

1-1. Adjustment of video screen position

1-2. Adjustment of HD/DVD screen position

1-3. Adjustment of PC/RGB screen position

1-4. Tuner Selector Adjustment

2. Adjustment of -180V and +80V

3. Adjustment of +5V

5-1

Page 99

<Protector Operation>

1. Confirmation of overcurrent protector

2. Confirmation of reduced-voltage protector

<Printed Wiring Board Layout>

1. ANALOG board (PWC-4214)

2. VIDEO board (PWC-4213)

3. AUDIO board (PWC-4216)

4. Top view of power unit

<Signal Waveforms for Adjustment>

1. Video input

2. HD/DVD input

3. RGB input

METHOD OF ADJUSTMENTS

<Contents of Adjustment after changing PWB>

1. After changing ANALOG PWB (PWC-4214):

Perform the steps as described in the “Adjustment of video level”, item 3-2 (P5-6~P5-7) of <ANALOG PWB>

and the “Adjustment of screen and phase”, item 1 (P5-14~P5-16) of <Set Adjustment>.

2. After changing VIDEO PWB (PWC-4213A):

Perform the steps described in “Adjustment of video level”, item 3-2 (P5-6~P5-7) of <ANALOG PWB)> and the

“Adjustment of video screen position”, item 1-1 (P5-14) of <Set Adjustment>.

3. After changing the Power Unit:

Perform the steps described in the “Adjustment of –180V and +180V”, item 2 (P5-16) of <Set Adjustment>. The

appropriate voltage is indicated in the label on the Module.

Also perform the steps described in the “Adjustment of +5V”, item 3 (P5-16) of <Set Adjustment>.

Replacing another PWB does not require further adjustment unless abnormal conditions are encountered.

5-2

Page 100

METHOD OF ADJUSTMENTS

<ANALOG PWB>

Adjustment for the ANALOG PWB, PWC-4214, should be performed in a pair with the VIDEO PWB, PWC-4213A.

The ANALOG PWB shall be adjusted if the ANALOG PWB or VIDEO PWB has been replaced.

1. Setting and confirmation before adjustments

1-1 Insert a short-plug on the opposite side of “▲ silk” in JP6550. However, this should be done only for unit

operation of the board only. After adjustment of the board, return the short-plug to the side of “▲ silk.”

Confirm that a short-plug is inserted on the opposite side of Pin 3 “▲ silk” in JP6600. (Selection of microcomputer side)

Confirm that a short-plug is inserted on the side of Pin 1 “▲ silk” in JP6551. (Selection of microcomputer

side)

1-2 Confirm that the 5ns delay line (A T -10) is set in DL6501 and another 5ns delay line (AT-05) is set in DL6502,

and that short-pins are inserted in DL6500, DL6503, and DL6506.

1-3 Move the dip switches SW6500 and SW6501 to the “OFF” side. Confirm that the dip switches SW6550 and

SW6603 are set on the “ON” side.

1-4 Set the rotary switch W6602 in the “F” position. (Set at inverse gamma correction OFF)

1-5 Confirm that each terminal voltage specified below is kept within the standard range at an ordinary tem-

perature.

Board name Terminal No Signal name Standard voltage value

ANALOG PWC-4214 PM

VIDEO PWC-4213A PV

VI/O PWC-4213B PQ

1

PM

5

PM

!

PN

1

PN

6

IC6073

IC6072

IC6000

IC6301

IC6001

IC6300

IC6003

IC6805

PV

TP5001 VIDEO + 9V 9 ± 0.27V

TP5002 SW + 9V 9 ± 0.27V

TP5003 VIDEO + 5V 5 ± 0.15V

TP5011 VIDEO + 12V 12± 0.15V

PQ

IC1008

IC1009

3

1

3

3

3

3

3

2

1

3

1

4

4

3

M + 14V 14V ± 5%

D + 12V 5 ± 5%

F + 12V 12 ± 10%

A + 14V 14V ± 5%

A + 7V 6.5~9.0V

VDD3 3.14~3.46V

CDDVCO 5 ± 0.15V

A1 + 12V 12 ± 0.15V

A0 + 12V 12 ± 0.15V

A1 + 5V 5 ± 0.15V

A1 + 5V 5 ± 0.15V

M1 + 12V 12 ± 0.35V

M + 5V 5 ± 0.15V

A + 14V 14 ± 5%

A + 7V 6.5~9.0V

M + 14V 14 ± 5%

MA + 7V 6.5~9.0V

AMP + 5V 5 ± 0.15V

RGB + 5V 5 ± 0.12V

5-3

Loading...

Loading...